Page 1

M1170

Windrower

Unloading and Assembly Instructions (North America)

214735 Revision A

Original Instruction

The harvesting specialists.

Page 2

M1170 Windrower, featuring Dual Direction®and CrossFlex™rear suspension

1016391

Published: July 2018

Page 3

Introduction

This manual contains unloading, assembly, and predelivery information for the MacDon M1170 Windrower, which

when coupled with one of MacDon’s A40DX, R1 SP Series, D1X Series, or D1XL Series Headers provides a

package designed to cut and lay a variety of grain, hay, and specialty crops in windrows.

The M1170 Windrower is Dual Direction

engine-forward mode. Right and left designations are determined by the operator’s position facing the direction of

travel. This manual uses the terms right cab-forward, left cab-forward, right engine-forward, and left engine-forward

when referencing specific locations on the machine.

The ignition keys were shipped with the shipping documents and are used to lock the cab doors and tool box

compartment.

NOTE:

Keep your MacDon publications up-to-date. The most current version can be downloaded from our website

(www.macdon.com) or from our Dealer-only site (https://portal.macdon.com) (login required).

®

, meaning that the windrower can be driven in the cab-forward or the

214735 i Revision A

Page 4

List of Revisions

The following list provides an account of major changes from the previous version of this document.

Summary of Change

Added caution statement: “Engine exhaust gases

become very hot during operation and can burn people

and common materials. Stay clear of the rear machine

and avoid exhaust gases when engine is running.”

Added caution statement: “Before disconnecting fuel

lines or any other components under high-pressure

between the fuel pump and high-pressure common rail

fuel system, confirm that the fuel pressure is relieved.”

Added topic.

Updated R113 and A40DX tire pressures. Added R116

and A40DX Grass Seed.

Added Warning and Caution statements to beginning of

procedure to ensure engine is off and park brakes are

engaged.

• Added reference to R1 hydraulic drive bundle

(B6621).

• Added step to connect knife pressure hose if

switching from a rotary header.

• Added illustration showing both rotary configuration

and auger/draper configuration.

Location

1.6 Engine Safety, page 11

1.6.1 High-Pressure Rail, page 11

3.10 Replacing Speed Identification Symbol (SIS)

Decal (US Only), page 34

4.1.10 Checking Tire Pressures, page 52

4.1.12 Checking and Adding Wheel Drive Lubricant,

page 59

• Connecting A40DX Hydraulics, page 82

• Connecting D1X or D1XL Series Hydraulics, page

92

• Added step to disconnect knife pressure hose.

• Added illustration showing both rotary configuration

and auger/draper configuration.

• Added steps for closing the left platform.

• Added swath compressor to list of sensors that may

require calibration.

• Revised note to say a sensor requires calibration if

header or attachment is connected for the first time.

• Revised note to say the header must be attached

and engaged to calibrate the knife drive.

Updated system capacities:

• DEF – 28 liters (7.5 US gallons)

• Diesel fuel – 518 liters (137 US gallons)

• Hydraulic oil – 60 liters (15.8 US gallons)

• AC refrigerant – 2.38 kg (5.25 lb.)

214735 ii Revision A

Connecting R1 Series Hydraulics, page 100

4.7 Calibrating the Windrower and Header, page 108

5.1 Lubricants, Fluids, and System Capacities, page

113

Page 5

Summary of Change

Location

Moved Starting the Engine and Checking and Adding

Wheel Drive Lubricant to the end of the Predelivery

Checks chapter.

Added metric equivalents for header sizes throughout

manual.

• 4.1.11 Starting the Engine, page 55

• 4.1.12 Checking and Adding Wheel Drive Lubricant,

page 59

—

214735 iii Revision A

Page 6

Page 7

TABLE OF CONTENTS

Introduction................................................................................................................................................i

List of Revisions ........................................................................................................................................ii

Chapter 1: Safety ....................... ............................................................................................................. 1

1.1 Signal Words .......................................................................................................................................1

1.2 General Safety.....................................................................................................................................2

1.3 Tire Safety...........................................................................................................................................4

1.4 Battery Safety......................................................................................................................................5

1.5 Welding Precaution ..............................................................................................................................6

1.6 Engine Safety .. .................................................................................................................................. 11

1.6.1 High-Pressure Rail .................................................................................................................... 11

1.6.2 Engine Electronics ....................................................................................................................12

1.7 Safety Signs ......................................................................................................................................13

Chapter 2: Unloading the Windrower .............................................................................................. 15

2.1 Using One Forklift to Unload Windrower ..............................................................................................15

Chapter 3: Assembling the Windrower ............................................................................. .............. 17

3.1 Lowering Steps..................................................................................................................................17

3.2 Installing Caster Wheels .....................................................................................................................19

3.3 Installing Drive Wheels .......................................................................................................................21

3.4 Repositioning Right Leg .....................................................................................................................23

3.5 Repositioning Caster Wheels ..............................................................................................................26

3.6 Installing Caster Anti-Shimmy Dampeners ...........................................................................................29

3.7 Installing Windshield Access Step .......................................................................................................31

3.8 Positioning Mirror Arms ......................................................................................................................32

3.9 Installing Slow Moving Vehicle (SMV) Signs .........................................................................................33

3.10 Replacing Speed Identification Symbol (SIS) Decal (US Only) .............................................................34

3.11 Installing Rear Ballast Package .........................................................................................................35

3.12 Lubricating the Windrower ................................................................................................................41

3.12.1 Lubrication Procedure..............................................................................................................41

3.12.2 Lubrication Points....................................................................................................................41

3.13 Connecting Batteries ........................................................................................................................42

Chapter 4: Performing Predelivery Checks ............................................ ....................................... 45

4.1 Completing Predelivery Checklist ........................................................................................................45

4.1.1 Recording Serial Numbers .........................................................................................................45

4.1.2 Checking Engine Air Intake ........................................................................................................46

4.1.3 Checking and Adding Engine Oil ................................................................................................46

4.1.4 Checking and Adding Hydraulic Oil.............................................................................................48

4.1.5 Checking Fuel Separator ........................................................................................................... 49

214735 v Revision A

Page 8

TABLE OF CONTENTS

4.1.6 Checking Engine Coolant Level..................................................................................................49

4.1.7 Checking Engine Gearbox Lubricant Level and Adding Lubricant..................................................50

4.1.8 Checking Air Conditioning (A/C) Compressor Belts ......................................................................50

4.1.9 Checking Operating Safety System ............................................................................................51

4.1.10 Checking Tire Pressures..........................................................................................................52

4.1.11 Starting the Engine .................................................................................................................. 55

Engine Start Troubleshooting Tips .............................................................................................58

4.1.12 Checking and Adding Wheel Drive Lubricant .............................................................................59

4.2 Performing Operational Checks ..........................................................................................................60

4.2.1 Checking Auto Lights.................................................................................................................60

4.2.2 Checking Harvest Performance Display (HPT) ............................................................................61

Navigating the Harvest Performance Tracker..............................................................................62

Setting Language and Units of Measure .....................................................................................64

Setting Time and Date ..............................................................................................................64

Setting Windrower Tire Size ......................................................................................................65

4.2.3 Checking Engine Speed ............................................................................................................66

4.2.4 Checking Exterior Lights ............................................................................................................67

4.2.5 Checking Horn ..........................................................................................................................70

4.2.6 Checking Interior Lights .............................................................................................................71

4.2.7 Checking Air Conditioning and Heater.........................................................................................71

4.2.8 Checking the Radio and Activating the Bluetooth

®

Feature ...........................................................72

4.3 Checking Manuals .............................................................................................................................74

4.4 Performing Final Steps .......................................................................................................................75

4.5 Attaching Headers to M1 Series Windrower .........................................................................................76

4.5.1 A40DX Auger Header................................................................................................................76

Attaching an A40DX Auger Header ............................................................................................76

Connecting A40DX Hydraulics...................................................................................................82

4.5.2 D1X or D1XL Series Draper Header ...........................................................................................85

Attaching Draper Header Supports ............................................................................................85

Attaching a D1X or D1XL Series Header ....................................................................................86

Connecting D1X or D1XL Series Hydraulics ...............................................................................92

4.5.3 R1 Series Disc Header ..............................................................................................................95

Attaching R1 Series Disc Header ............................................................................................... 95

Connecting R1 Series Hydraulics.............................................................................................100

4.6 Checking Header Settings ................................................................................................................107

4.7 Calibrating the Windrower and Header ..............................................................................................108

4.8 Calibrating Windrower Knife Drive on Harvest Performance Tracker (HPT) Display............................... 111

Chapter 5: Reference ............................................. ............................................................................113

5.1 Lubricants, Fluids, and System Capacities ......................................................................................... 113

5.2 Fuel Specifications........................................................................................................................... 115

5.3 Torque Specifications ....................................................................................................................... 116

5.3.1 Metric Bolt Specifications .........................................................................................................116

5.3.2 Metric Bolt Specifications Bolting into Cast Aluminum ................................................................ 118

214735 vi Revision A

Page 9

TABLE OF CONTENTS

5.3.3 O-Ring Boss (ORB) Hydraulic Fittings (Adjustable) .................................................................... 119

5.3.4 O-Ring Boss (ORB) Hydraulic Fittings (Non-Adjustable).............................................................121

5.3.5 O-Ring Face Seal (ORFS) Hydraulic Fittings ............................................................................. 122

5.3.6 Tapered Pipe Thread Fittings ................................................................................................... 123

5.4 Conversion Chart.............................................................................................................................124

5.5 Definitions .......................................................................................................................................125

Predelivery Checklist.........................................................................................................................129

214735 vii Revision A

Page 10

Page 11

1 Safety

1.1 Signal Words

Three signal words, DANGER, WARNING, and CAUTION, are used to alert you to hazardous situations. Signal

words are selected using the following guidelines:

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury. It

may also be used to alert against unsafe practices.

CAUTION

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury. It

may be used to alert against unsafe practices.

214735 1 Revision A

Page 12

1000004

1000005

1010391

SAFETY

1.2 General Safety

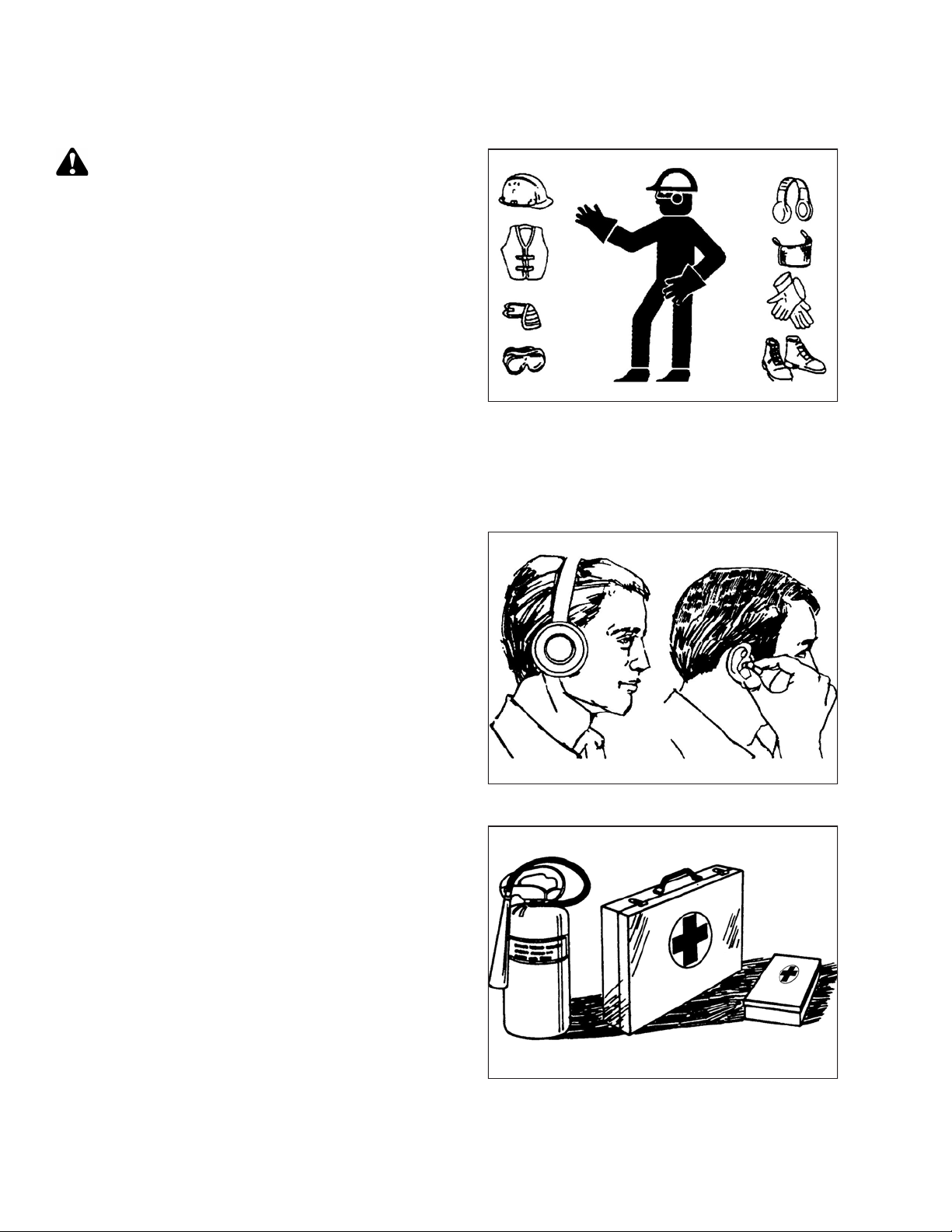

CAUTION

The following are general farm safety precautions that

should be part of your operating procedure for all types

of machinery.

Protect yourself.

• When assembling, operating, and servicing machinery,

wear all protective clothing and personal safety devices

that could be necessary for job at hand. Do NOT take

chances. You may need the following:

• Hard hat

• Protective footwear with slip-resistant soles

• Protective glasses or goggles

• Heavy gloves

• Wet weather gear

• Respirator or filter mask

• Be aware that exposure to loud noises can cause hearing

impairment or loss. Wear suitable hearing protection

devices such as earmuffs or earplugs to help protect

against loud noises.

Figure 1.1: Safety Equipment

Figure 1.2: Safety Equipment

• Provide a first aid kit for use in case of emergencies.

• Keep a fire extinguisher on the machine. Be sure fire

extinguisher is properly maintained. Be familiar with its

proper use.

• Keep young children away from machinery at all times.

• Be aware that accidents often happen when Operator is

tired or in a hurry. Take time to consider safest way.

Never ignore warning signs of fatigue.

Figure 1.3: Safety Equipment

214735 2 Revision A

Page 13

1000007

1000008

1000009

SAFETY

• Wear close-fitting clothing and cover long hair. Never

wear dangling items such as scarves or bracelets.

• Keep all shields in place. NEVER alter or remove safety

equipment. Make sure driveline guards can rotate

independently of shaft and can telescope freely.

• Use only service and repair parts made or approved by

equipment manufacturer. Substituted parts may not meet

strength, design, or safety requirements.

• Keep hands, feet, clothing, and hair away from moving

parts. NEVER attempt to clear obstructions or objects

from a machine while engine is running.

• Do NOT modify machine. Unauthorized modifications

may impair machine function and/or safety. It may also

shorten machine’s life.

Figure 1.4: Safety around Equipment

• To avoid bodily injury or death from unexpected startup of

machine, ALWAYS stop the engine and remove the key

from the ignition before leaving the operator’s seat for

any reason.

• Keep service area clean and dry. Wet or oily floors are

slippery. Wet spots can be dangerous when working with

electrical equipment. Be sure all electrical outlets and

tools are properly grounded.

• Keep work area well lit.

• Keep machinery clean. Straw and chaff on a hot engine is

a fire hazard. Do NOT allow oil or grease to accumulate

on service platforms, ladders, or controls. Clean

machines before storage.

• NEVER use gasoline, naphtha, or any volatile material for

cleaning purposes. These materials may be toxic and/or

flammable.

• When storing machinery, cover sharp or extending

components to prevent injury from accidental contact.

Figure 1.5: Safety around Equipment

Figure 1.6: Safety around Equipment

214735 3 Revision A

Page 14

1000020

1000019

SAFETY

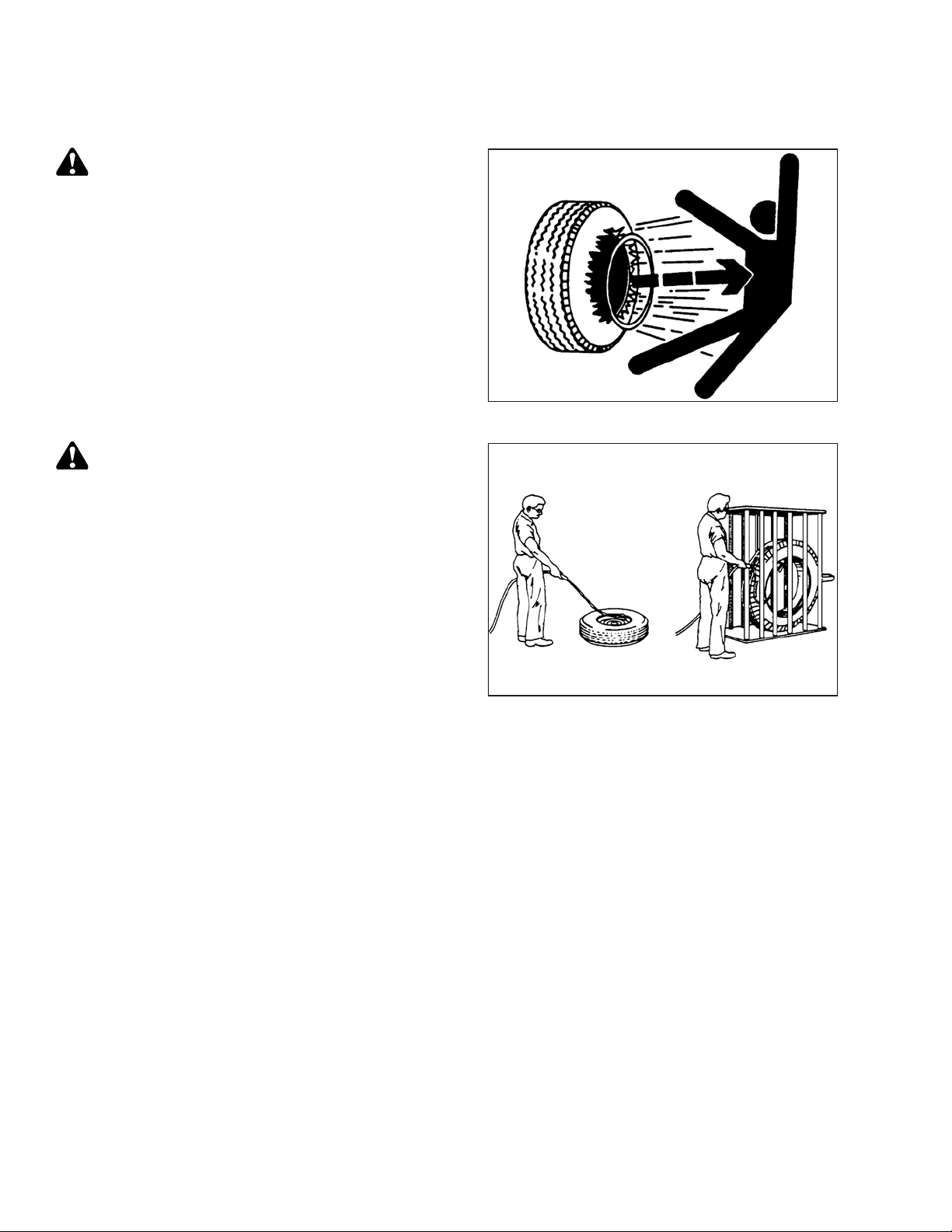

1.3 Tire Safety

WARNING

• Service tires safely.

• A tire can explode during inflation which could cause

serious injury or death.

• Follow proper procedures when mounting a tire on a

wheel or rim. Failure to do so can produce an

explosion that may result in serious injury or death.

WARNING

• Do NOT stand over tire. Use a clip-on chuck and

extension hose.

Figure 1.7: Overinflated Tire

• Do NOT exceed maximum inflation pressure indicated

on tire label.

• Replace tires that have defects.

• Replace wheel rims that are cracked, worn, or

severely rusted.

• Never weld a wheel rim.

• Never use force on an inflated or partially inflated tire.

• Make sure tire is correctly seated before inflating to

operating pressure.

• If tire is not correctly positioned on rim or is overinflated, tire bead can loosen on one side causing air

to escape at high speed and with great force. An air leak of this nature can thrust tire in any direction

endangering anyone in area.

• Make sure all air is removed from tire before removing tire from rim.

• Do NOT remove, install, or repair a tire on a rim unless you have proper equipment and experience to

perform job.

• Take tire and rim to a qualified tire repair shop.

Figure 1.8: Safely Inflating Tire

214735 4 Revision A

Page 15

1000015

1000016

1000017

SAFETY

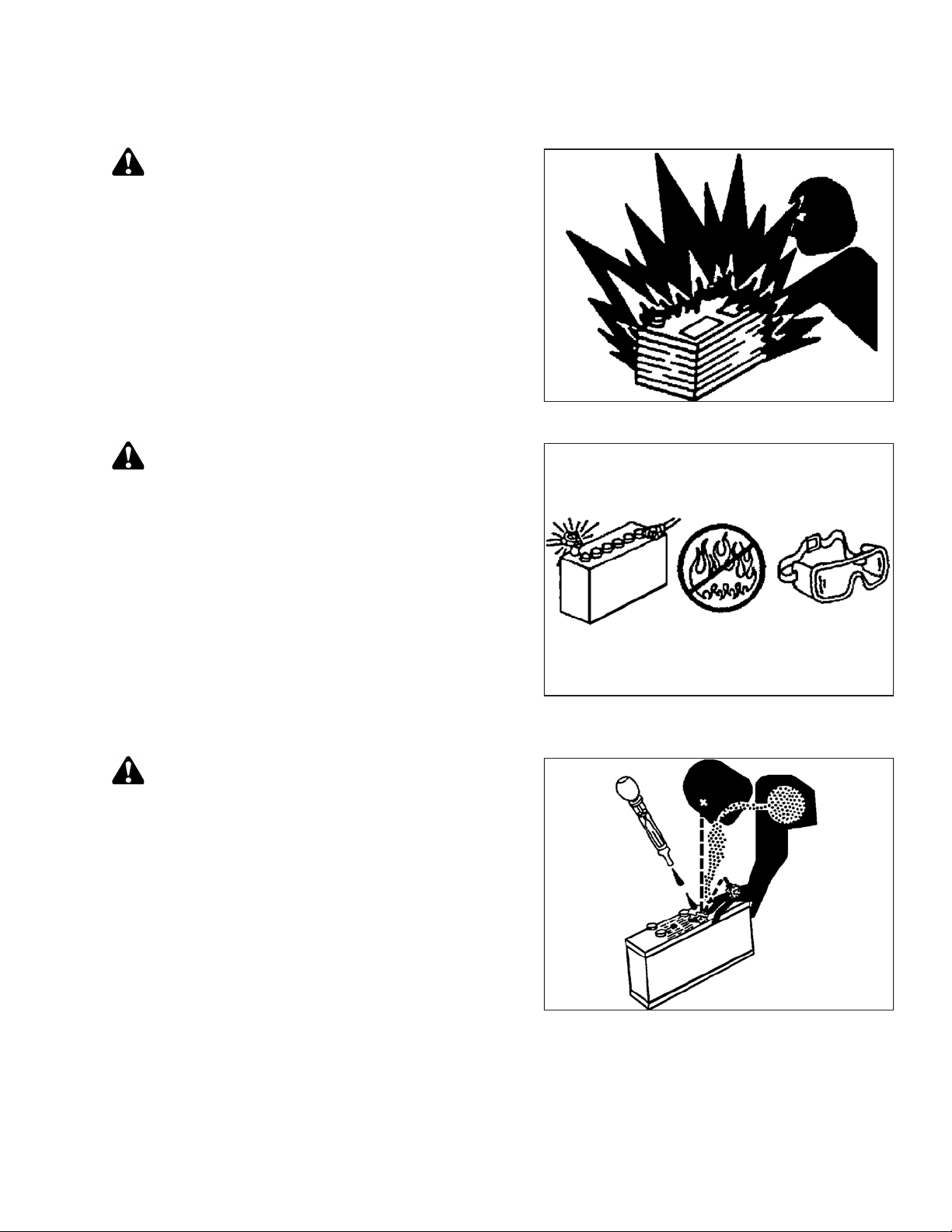

1.4 Battery Safety

WARNING

• Keep all sparks and flames away from batteries, as a

gas given off by electrolyte is explosive.

• Ventilate when charging in enclosed space.

WARNING

• Wear safety glasses when working near batteries.

• Do NOT tip batteries more than 45° to avoid

electrolyte loss.

Figure 1.9: Safety around Batteries

• Battery electrolyte causes severe burns. Avoid

contact with skin, eyes, or clothing.

• Electrolyte splashed into eyes is extremely

dangerous. Should this occur, force eye open, and

flood with cool, clean water for 5 minutes. Call a

doctor immediately.

• If electrolyte is spilled or splashed on clothing or

body, neutralize it immediately with a solution of

baking soda and water, then rinse with clear water.

WARNING

• To avoid injury from spark or short circuit, disconnect

battery ground cable before servicing any part of

electrical system.

• Do NOT operate engine with alternator or battery

disconnected. With battery cables disconnected and

engine running, a high voltage can be built up if

terminals touch frame. Anyone touching frame under

these conditions would be severely shocked.

• When working around storage batteries, remember

that all of the exposed metal parts are live. Never lay a

metal object across terminals because a spark or

short circuit will result.

Figure 1.10: Safety around Batteries

Figure 1.11: Safety around Batteries

• Keep batteries out of reach of children.

214735 5 Revision A

Page 16

10176211017621

A

1017622

A

SAFETY

1.5 Welding Precaution

WARNING

It is very important that correct procedures be followed when welding anything connected to the

windrower. If procedures are not followed, it could result in severe damage to sensitive, expensive

electronics. Even if complete failure of a module doesn’t happen immediately, it is impossible to know

what effect high current could have with regard to future malfunctions or shorter lifespan.

Due to the number of connectors, components to be welded should be removed from the windrower whenever

possible rather than welded in place. When work needs to be completed on a header, disconnect the header

completely from the windrower before welding. These same guidelines apply to plasma cutting, or any other high

current electrical operation performed on the machine.

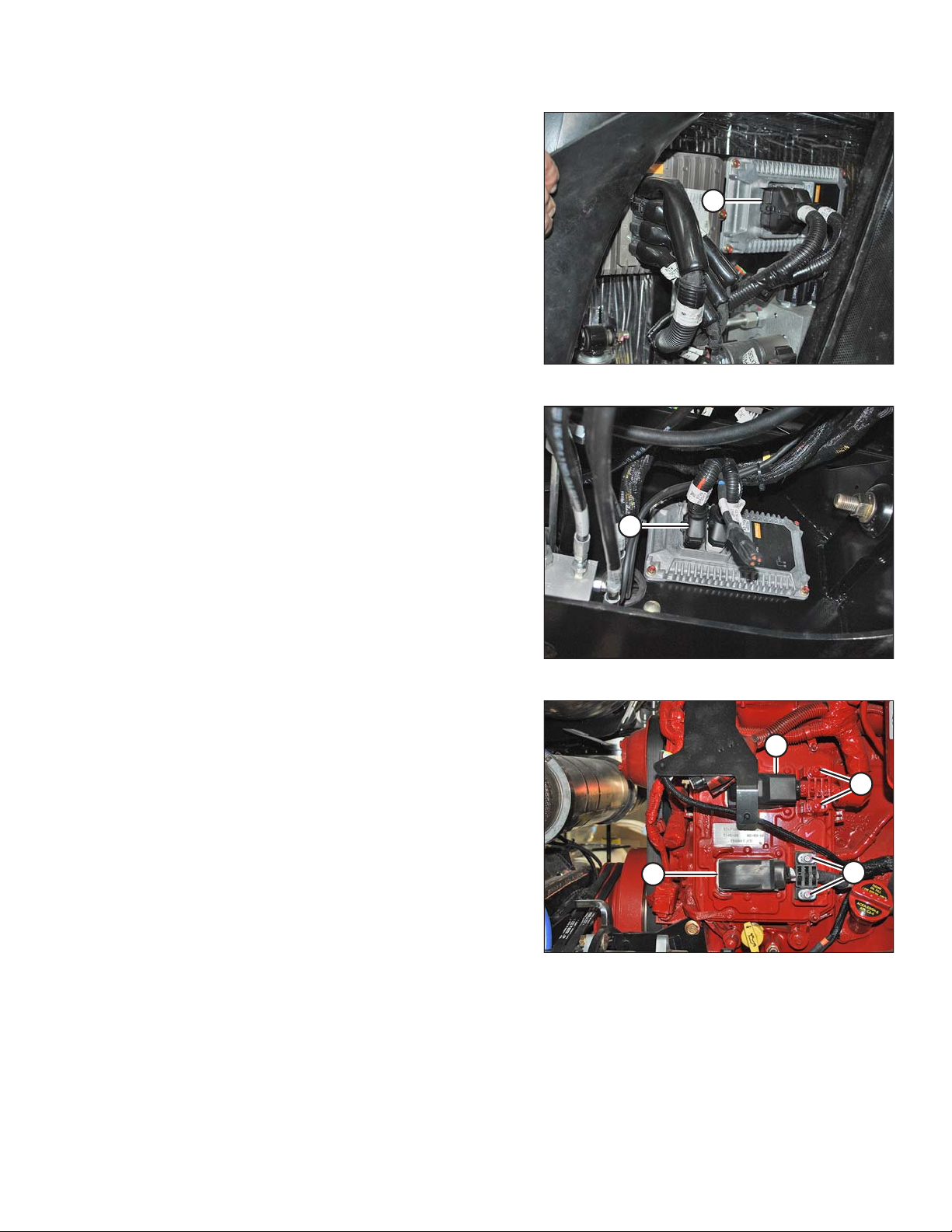

The following items need to be disconnected:

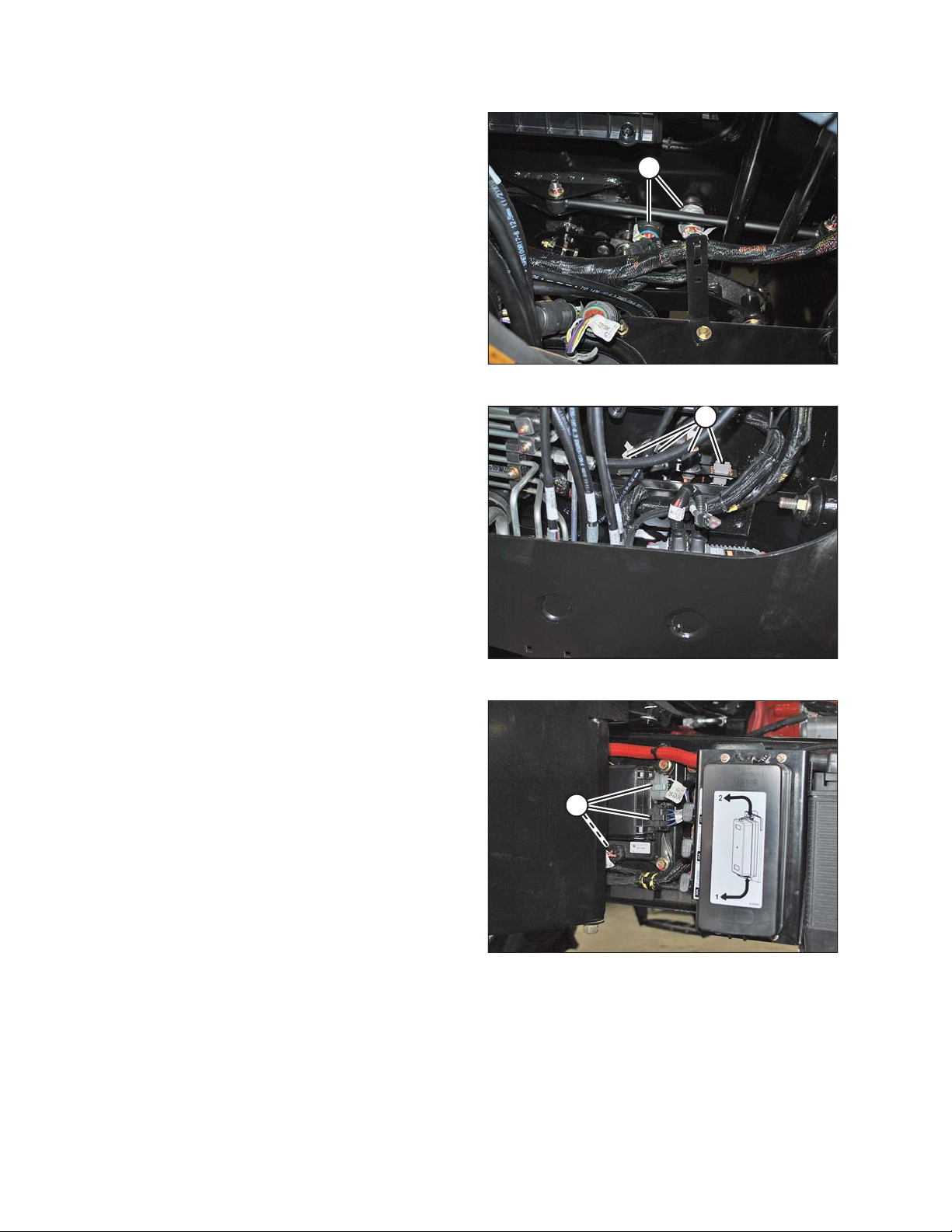

• Negative battery terminals (A) (two connections)

IMPORTANT:

Always disconnect the battery terminals first, and

reconnect them last.

• Master controller (A)

Four connectors: P231, P232, P233, and P234

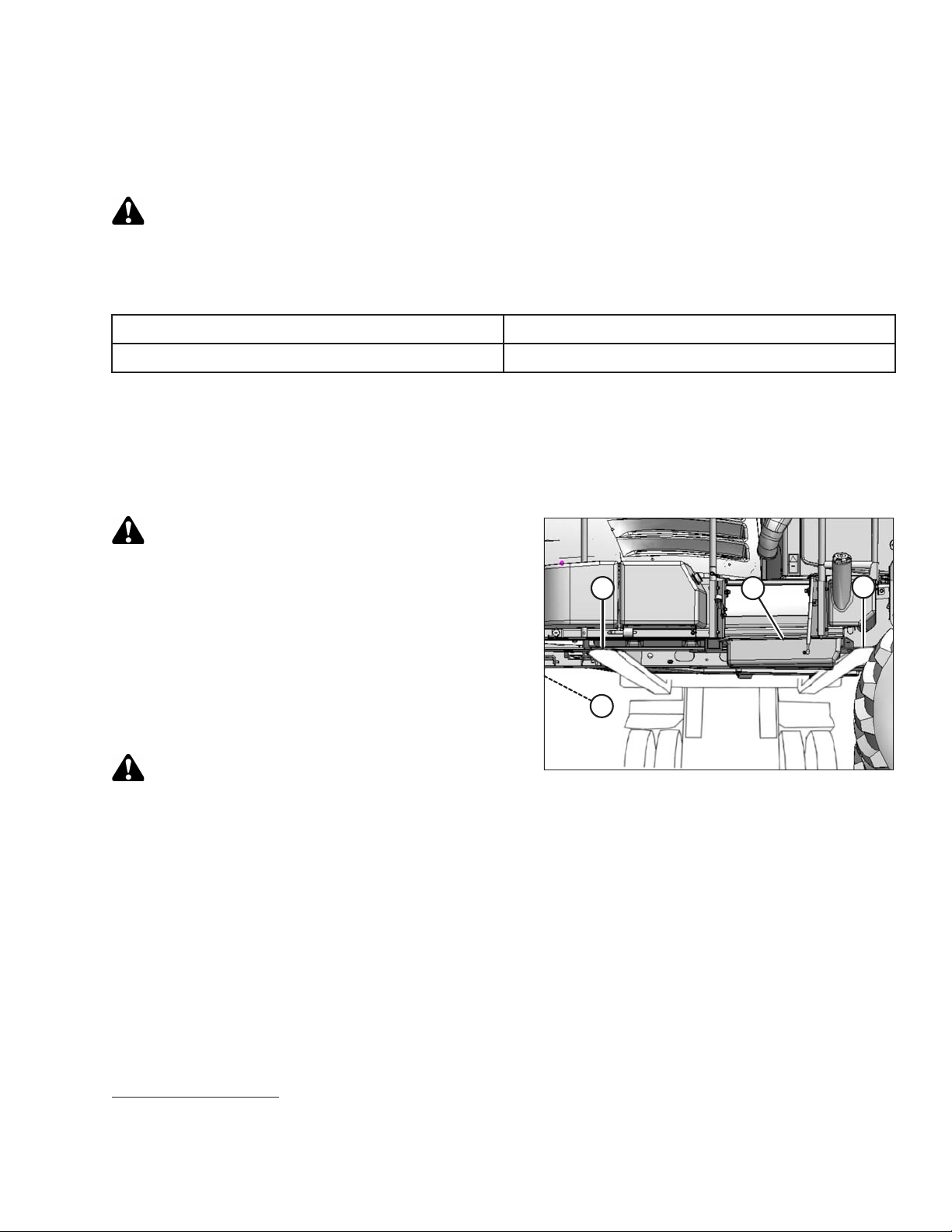

Location: Behind cab, near header lift/fan manifold

To disconnect the connectors, press the two outer tabs,

and pull the connector away from master controller.

IMPORTANT:

When reconnecting these connectors, double-check that

the connectors are fully seated into the master controller,

and that the two locking tabs on each end of all four

connectors have popped outward. If the tabs are not

popped outward, the connector is not fully seated.

IMPORTANT:

Do NOT power up or operate the windrower until these

connectors are locked into place.

Figure 1.12: Negative Terminals

Figure 1.13: Master Controller

214735 6 Revision A

Page 17

1017623

A

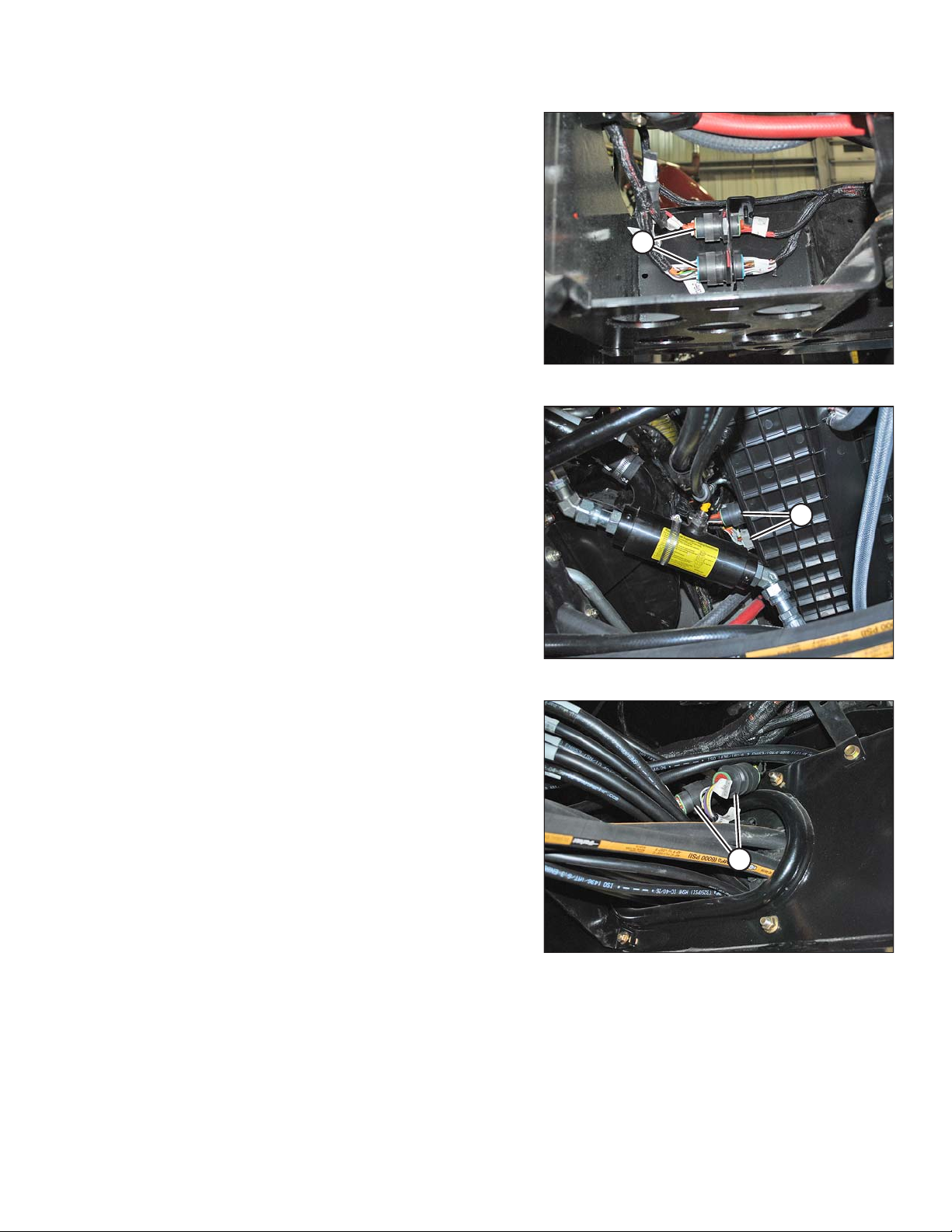

• Firewall extension module (A)

1017624

A

1019753

A

B

C

C

Two connectors: P235 and P236

Location: Behind cab, near header lift/fan manifold.

To disconnect, use a small 3–6 mm (1/8–1/4 in.) blade

screwdriver to insert into the connector’s locking tab.

Gently pry upward (no more than 6 mm [1/4 in.]) to unlock

the connector tab, and then pull the connector away from

the module.

• Chassis extension module (A)

Two connectors: P247 and P248

Location: Under cab, inside left frame rail

To disconnect, use a small 3–6 mm (1/8–1/4 in.) blade

screwdriver to insert into the connector’s locking tab.

Gently pry upward (no more than 6 mm [1/4 in.]) to unlock

the connector tab, and then pull the connector away from

the module.

SAFETY

Figure 1.14: Firewall Extension Module

• Engine Control Module (ECM)

Two connectors for Cummins: P100 (A) and J1 Cummins

Proprietary ECM Connector (B)

Location: On engine

To disconnect, pull the rubber boot off the cover, unlock

the latch, and undo the main over-center latch. Remove

strain relief bolts (C) so the connectors can be pulled

away from the ECM.

IMPORTANT:

Be sure to disconnect both connectors. Note connector

locations.

IMPORTANT:

Be sure to reconnect connectors in the proper locations.

Do NOT cross connect.

Figure 1.15: Chassis Extension Module

Figure 1.16: Engine Control Module

214735 7 Revision A

Page 18

1017626

A

NOTE:

1017627

A

1017628

A

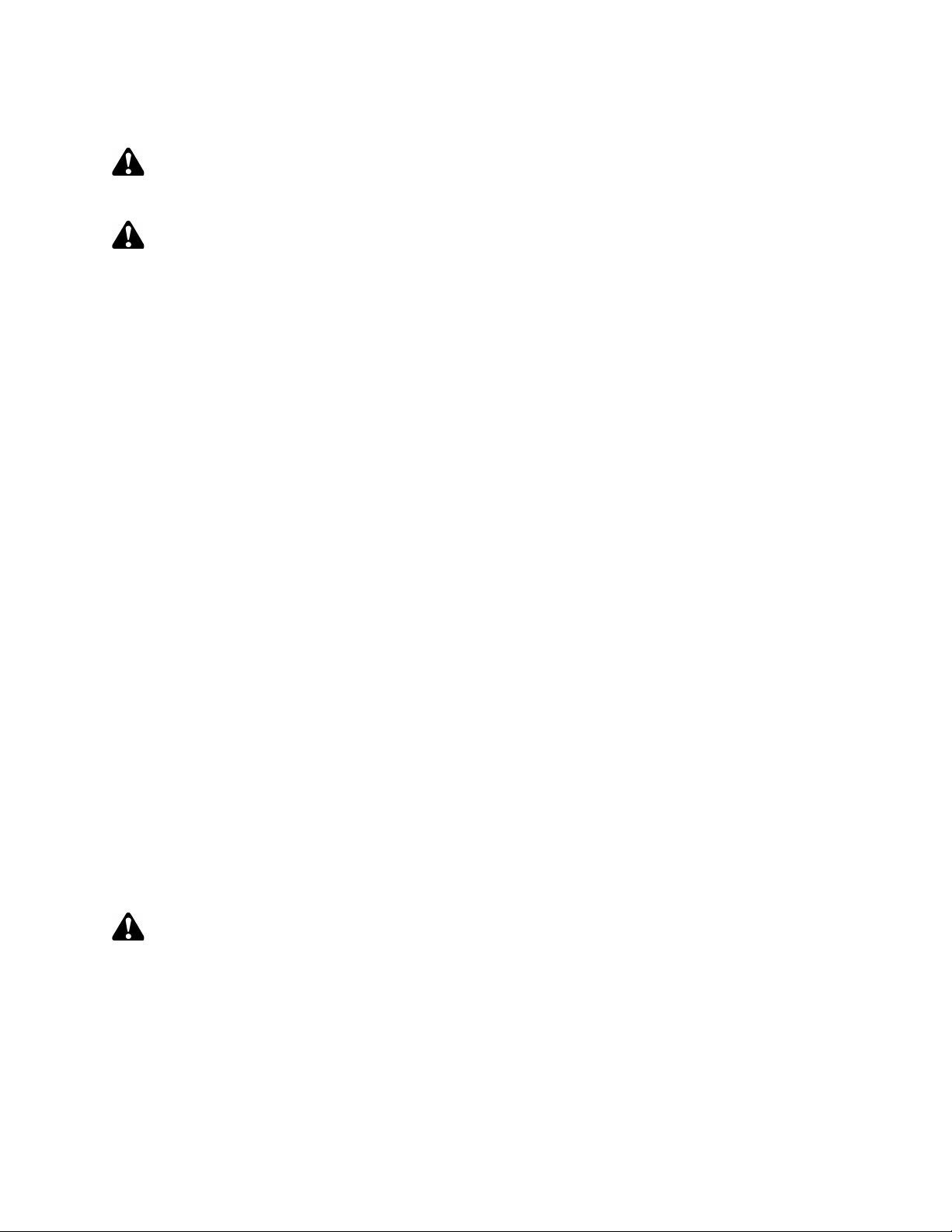

To disconnect the remaining circular Deutsch

connectors, rotate outer collar counterclockwise.

• Cab connectors (A)

Two round connectors: C1 and C2

Location: Under cab

• Roof connectors (A)

Four connectors: C10, C12, C13, and C14

Location: Under cab at base of left cab post

SAFETY

Figure 1.17: Cab Connectors

• Chassis relay module (A)

Three connectors: P240, P241, and P242

Location: Outside left frame rail near batteries

Figure 1.18: Roof Connectors

Figure 1.19: Chassis Relay Module

214735 8 Revision A

Page 19

1017657

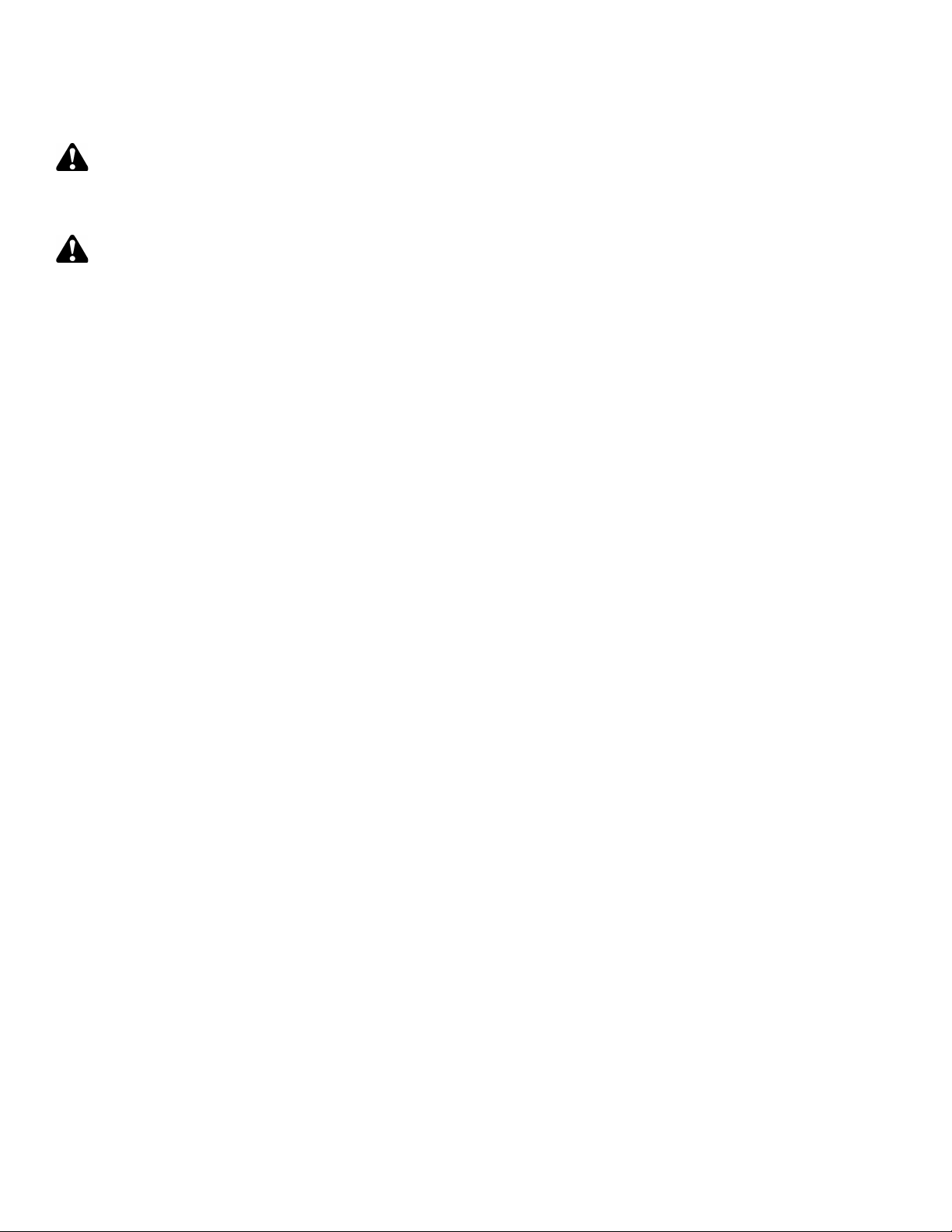

A

• Engine harness (A)

1017630

A

1017631

A

Two round connectors: C30 and C31

Location: Inside left frame rail, at rear of windrower

• Air conditioning (A/C) box connectors (A)

Two connectors: C15 and C16

Location: Rear of A/C box

SAFETY

Figure 1.20: Engine Harness

• Wheel motor connectors (A)

Two round connectors: C25 and C26

Location: Under center of frame, just behind front

cross member

Figure 1.21: A/C Box Connectors

Figure 1.22: Wheel Motor Connectors

214735 9 Revision A

Page 20

SAFETY

IMPORTANT:

To connect circular Deutsch connectors without bending the pins, align connector with receptacle before attempting

to reconnect.

To align the connectors:

1. Observe the channel cuts and mating channel protrusions on the inner part of the circular walls of the

connectors.

2. Face the mating connectors to each other, and rotate connectors so that channels are aligned.

3. Press connectors together while turning the outer connector clockwise until collar locks.

214735 10 Revision A

Page 21

SAFETY

1.6 Engine Safety

WARNING

Do NOT use aerosol starting aids such as ether. Such use could result in an explosion and personal injury.

CAUTION

• On initial start-up of a new, serviced, or repaired engine, always be ready to stop the engine in order to

stop an overspeed. This may be accomplished by shutting off the air and/or fuel supply to the engine.

• Do NOT bypass or disable automatic shutoff circuits. The circuits are provided in order to help prevent

personal injury. The circuits are also provided in order to help prevent engine damage. Refer to the

technical manual for repairs and adjustments.

• Inspect the engine for potential hazards.

• Before starting the engine, ensure that no one is on, underneath, or close to the engine. Ensure that

people clear the area.

• All protective guards and all protective covers must be installed if the engine must be started in order

to perform service procedures.

• To help prevent an accident that is caused by parts in rotation, work around parts carefully.

• If a warning tag is attached to engine start switch or to controls, do NOT start engine or move controls.

Consult with person who attached warning tag before engine is started.

• Start engine from operator’s compartment. Always start engine according to procedure that is

described in Starting Engine section of operator’s manual. Knowing correct procedure will help to

prevent major damage to engine components and prevent personal injury.

• To ensure that the jacket water heater (if equipped) and/or lubricant oil heater (if equipped) is working

correctly, check the water temperature gauge and/or oil temperature gauge during heater operation.

• Engine exhaust contains products of combustion, which can be harmful to your health. Always start

the engine and operate the engine in a well-ventilated area. If the engine is started in an enclosed area,

vent the engine exhaust to the outside.

• Engine exhaust gases become very hot during operation and can burn people and common materials.

Stay clear of the rear of machine and avoid exhaust gases when engine is running.

NOTE:

The engine may be equipped with a device for cold starting. If the engine will be operated in very cold conditions,

then an additional cold starting aid may be required.

1.6.1 High-Pressure Rail

CAUTION

• Contact with high-pressure fuel may cause fluid penetration and burn hazards. High-pressure fuel

spray may cause a fire hazard. Failure to follow these instructions may cause personal injury or death.

• Before disconnecting fuel lines or any other components under high-pressure between the fuel pump

and high-pressure common rail fuel system, confirm that the fuel pressure is relieved.

214735 11 Revision A

Page 22

SAFETY

1.6.2 Engine Electronics

WARNING

Tampering with electronic system installation or original equipment manufacturer (OEM) wiring

installation can be dangerous and could result in personal injury or death and/or engine damage.

WARNING

Electrical Shock Hazard. The electronic unit injectors use DC voltage. The engine control module (ECM)

sends this voltage to the electronic unit injectors. Do NOT come in contact with the harness connector for

the electronic unit injectors while engine is operating. Failure to follow this instruction could result in

personal injury or death.

This engine has a comprehensive, programmable engine monitoring system. The ECM has the ability to monitor

engine operating conditions. If conditions exceed the allowable range, the ECM will initiate immediate action.

The following actions are available for engine monitoring control:

• Warning

• Derate

• Shut down

The following monitored engine operating conditions have the ability to limit engine speed and/or engine power:

• Engine coolant temperature

• Engine oil pressure

• Engine speed

• Intake manifold air temperature

• Diesel exhaust fluid (DEF) system performance

• Aftertreatment system performance

214735 12 Revision A

Page 23

1000694

SAFETY

1.7 Safety Signs

• Keep safety signs clean and legible at all times.

• Replace safety signs that are missing or illegible.

• If original part on which a safety sign was installed is

replaced, be sure repair part also bears current

safety sign.

• Safety signs are available from your MacDon Dealer.

Figure 1.23: Operator’s Manual Decal

214735 13 Revision A

Page 24

Page 25

2 Unloading the Windrower

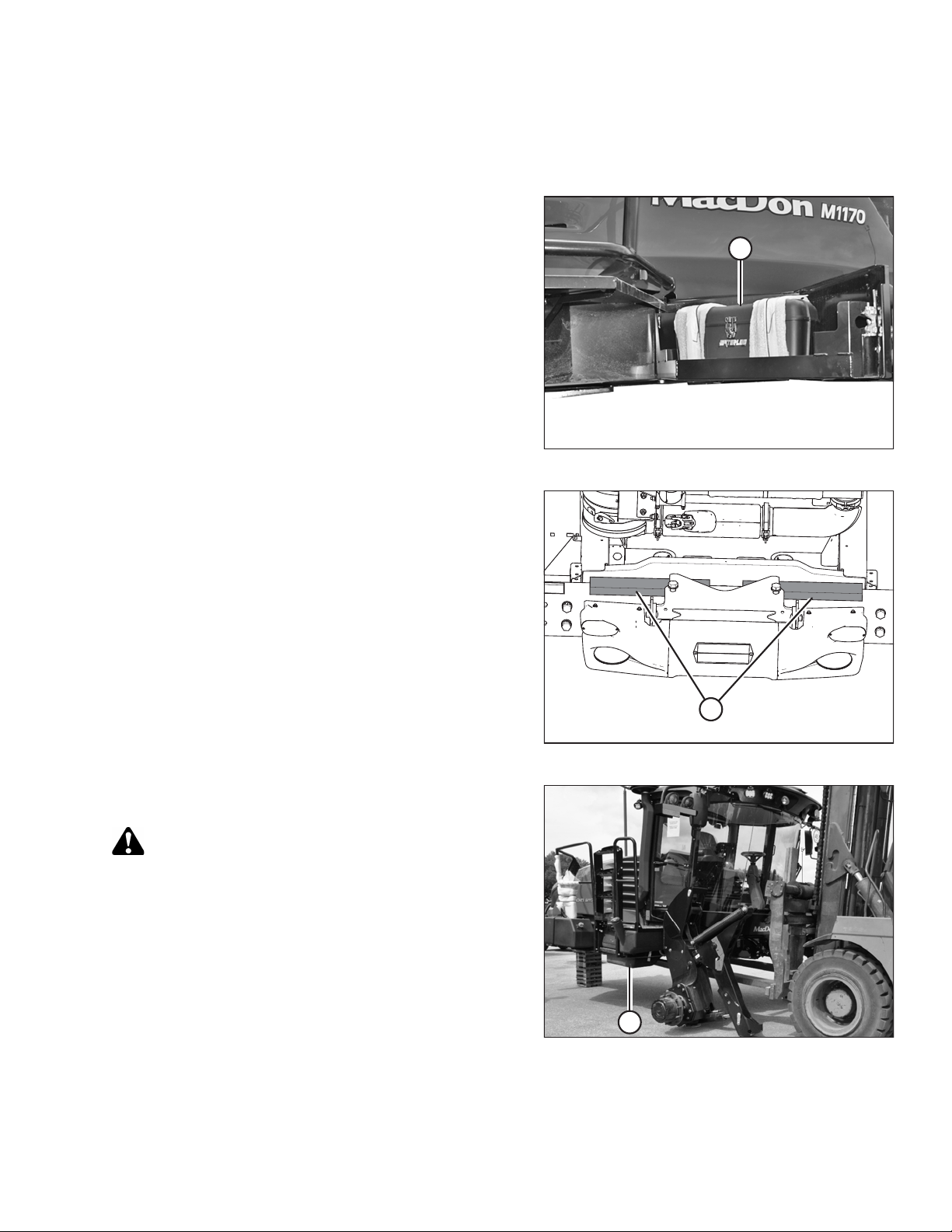

1016187

A

B

C

C

2.1 Using One Forklift to Unload Windrower

CAUTION

Equipment used for unloading must meet or exceed the specified requirements. Using inadequate

equipment may result in chain breakage, vehicle tipping, or machine damage.

Table 2.1 Lifting Vehicle Requirements

Minimum Capacity

Minimum Fork Length

IMPORTANT:

Forklifts are normally rated for a load located 610 mm (24 in.) ahead of the back end of the forks. To obtain forklift

capacity at 122.2 cm (48 in.), check with your forklift distributor.

1. Move the trailer onto level ground and block the trailer wheels.

2. Set forklift tines to the widest possible setting.

1

7037 kg (15,500 lb.)

198.1 cm (78 in.)

CAUTION

Ensure forks do NOT contact or lift on fuel tank (A) or

engine oil pan (B) (not shown).

3. Position forklift from opposite side of fuel tank, and

position forks (C) under windrower frame with the fuel

tank (A) between the forks.

NOTE:

The windrower’s center of gravity is approximately

157.5 cm (62 in.) rearwards from the center of the

drive wheel.

WARNING

Ensure the forks extend beyond the far side of

the frame.

Figure 2.1: Windrower on Trailer

4. Lift until windrower is clear of the trailer deck.

5. Back forklift slowly away from trailer until the windrower is clear of the trailer deck.

6. Lower unit slowly to the ground. If the ground is soft, place wooden blocks under the front shipping stands.

7. Carefully back forklift away from windrower.

8. Check windrower for shipping damage, and check shipment for missing parts.

9. In case of shipping damage or missing parts, confirm that serial number matches shipping manifest, then

contact MacDon immediately with any damage or shortage claims.

1. At 122.2 cm (48 in.) from back end of forks.

214735 15 Revision A

Page 26

Page 27

3 Assembling the Windrower

1014559

A

C

B

1014555

A

B

C

1014555

A

B

C

1014555

A

B

C

Perform all procedures in this chapter in the order in which they are listed.

3.1 Lowering Steps

Lowering the steps allows safe and easy access to the cab where some assembly hardware was stored for

shipping purposes.

Lower steps from shipping position to working position as follows:

NOTE:

Left side shown, right side opposite.

1. Remove stop bolt (A) and discard.

2. Loosen pivot bolts (B) at both sides of step (C).

3. Lower step (A) to working position.

4. Ensure clips (B) are engaged in step.

5. Tighten pivot bolts (C) to 90–100 Nm (66–73 lbf·ft).

Figure 3.1: Left Step – Shipping Position

Figure 3.2: Left Step – Working Position

214735 17 Revision A

Page 28

1022861

A

ASSEMBLING THE WINDROWER

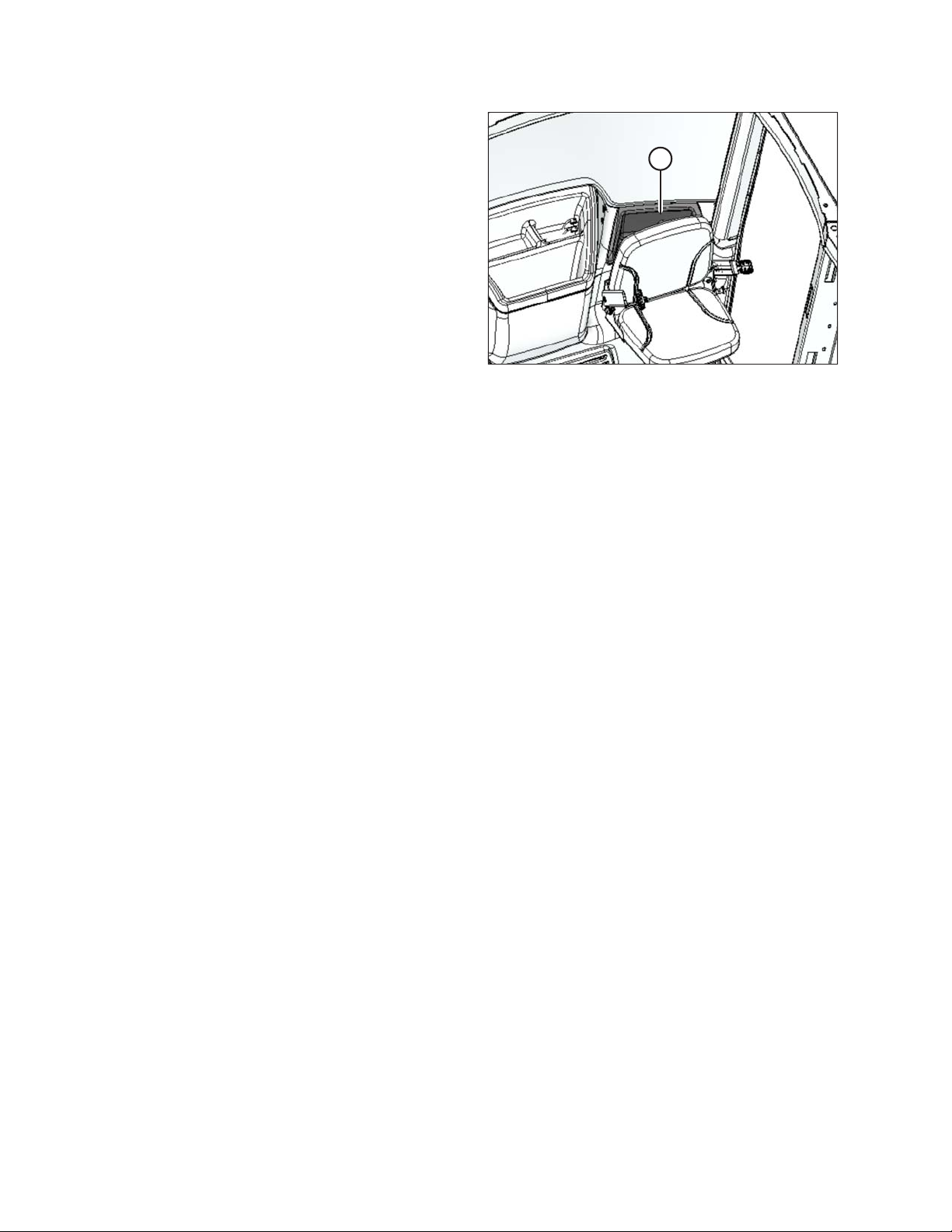

6. Retrieve bag containing drive wheel nuts from the

storage compartment (A) behind the training seat.

Figure 3.3: Storage Compartment

214735 18 Revision A

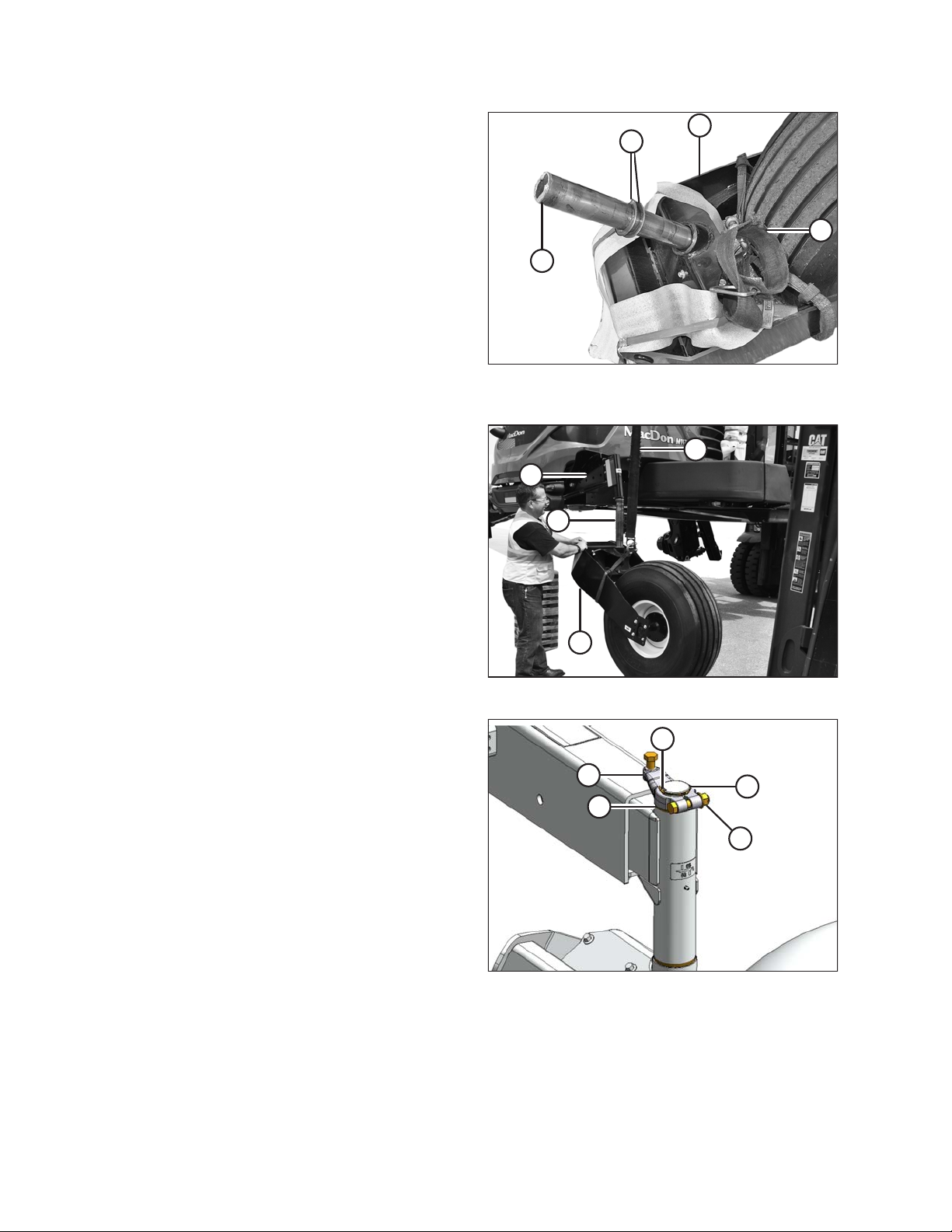

Page 29

1022761

A

1018731

A

1022864

A

ASSEMBLING THE WINDROWER

3.2 Installing Caster Wheels

Some shipping configurations come with caster wheels removed. Follow this procedure to install caster wheels if

required.

1. Retrieve toolbox (A) from the storage compartment, and

remove banding.

NOTE:

Use ignition key to unlock storage compartment.

2. Retrieve hardware from the toolbox (A).

Figure 3.4: Toolbox

3. Remove banding and blocking (A) securing walking

beam to frame.

4. Retrieve caster wheel assemblies from shipment.

5. Using a forklift, approach windrower from the front and

slide forks under frame.

CAUTION

Ensure forks do NOT contact fuel tank (A) and that forks

lift on windrower frame.

6. Raise windrower approximately 152 cm (60 in.) off the

ground. Place suitable stands under the drive wheel

legs and rear frame, and lower windrower onto stands

to partially unload the forks.

Figure 3.5: Windrower Rear

Figure 3.6: Lifting Windrower

214735 19 Revision A

Page 30

1022767

A

B

C

D

1022865

A

B

C

D

1022863

A

B

C

D

E

ASSEMBLING THE WINDROWER

7. Attach a sling (B) to caster assembly (A).

8. Retrieve two washers (C) from the toolbox and place

them on the caster wheel spindle (D).

9. If caster assembly is on a pallet, remove banding and

shipping material securing the assembly (A) to pallet.

10. Attach the sling (A) on the caster assembly (B) to a

suitable lifting device.

11. Tilt walking beam (C) and maneuver caster

assembly (B) so that spindle (D) can be installed onto

walking beam (C).

Figure 3.7: Caster Wheel Assembly in Shipping

Configuration

12. Install the flat washer (A) onto the spindle.

13. Install key (B) and arm (C) onto spindle, ensuring that

arm is positioned so there is no clearance at the top and

bottom of the walking beam extension.

14. Install retaining ring (D).

15. Tighten nut (E) and torque to 190–200 Nm

(140–147 lbf·ft).

16. Remove sling from caster assembly.

17. Repeat Steps 7, page 20 to 16, page 20 for second

caster assembly.

Figure 3.8: Installing Caster Assembly

Figure 3.9: Caster Arm

214735 20 Revision A

Page 31

1022781

A

B

C

1022892

A

C

B

ASSEMBLING THE WINDROWER

3.3 Installing Drive Wheels

IMPORTANT:

Windrower must be supported off the ground with stands.

1. Using a forklift, lift cab-end of windrower to

approximately 130 cm (51 in.) (B) off the ground,

enough to position the drive wheel assembly (A). Place

a stand (C) under windrower frame.

2. Clean mounting surface on wheel drive and rim.

CAUTION

Figure 3.10: Supporting Windrower

Use a lifting device capable of supporting a minimum of

907 kg (2000 lb.) to lift the wheel assembly.

3. Position pallet jack (A) or equivalent under tire and raise

slightly.

4. Locate drive wheel against the wheel drive hub so

air valve (B) is on the outside and the tire tread (C)

points forward with the windrower in cab-forward

orientation.

NOTE:

For turf tires (diamond tread pattern), be sure arrow on

sidewall points in forward rotation with windrower in

cab-forward.

Figure 3.11: Drive Wheel

214735 21 Revision A

Page 32

1011218

A

1

3

4

5

6

7

8

9

10

2

ASSEMBLING THE WINDROWER

5. Position wheel to line up holes in rim with studs on hub

and push wheel onto hub.

6. Install wheel nuts (A).

IMPORTANT:

To avoid damage to wheel rims and studs, do NOT use

an impact wrench. Threads must be clean and dry. Do

NOT apply lubricant or anti-seize compound. Do NOT

overtighten the wheel nuts.

7. Torque drive wheel nuts to 510 Nm (375 lbf·ft) using the

tightening sequence shown.

IMPORTANT:

Use only manufacturer-specified nuts (MD #205397).

8. Repeat tightening sequence two additional times,

ensuring the specified torque is achieved each time.

Figure 3.12: Tightening Sequence

9. Lower jack and move away from work area.

10. Raise windrower, remove stand, and lower windrower to ground.

11. Repeat Steps 2, page 21 to 8, page 22 for the other drive wheel.

12. Repeat torque procedure every hour of operation until two consecutive checks confirm that there is no

movement of the nuts.

214735 22 Revision A

Page 33

1022868

B

A

C

1022788

A

ASSEMBLING THE WINDROWER

3.4 Repositioning Right Leg

The right (cab-forward) leg requires repositioning from shipping to field configuration.

CAUTION

Do NOT open the right cab-forward door when the right leg is in shipping configuration. If glass door

contacts the leg, it may result in broken glass and/or damaged door seal.

1. Using a forklift, lift front of windrower. Place a stand (A)

(or equivalent) to support front of windrower and to

keep right wheel (B) off the ground.

2. Slowly lower windrower onto a stand (A).

3. Place a pallet jack (C) (or equivalent) under the right

wheel (B), and raise pallet jack enough to take the

weight off the right wheel.

4. Remove shipping tag and wire (A) from traction drive

hoses under the cab.

Figure 3.13: Supporting Right Leg of Windrower

Figure 3.14: Under Windrower Cab

214735 23 Revision A

Page 34

1022807

A

1022808

A

B

1022871

A

ASSEMBLING THE WINDROWER

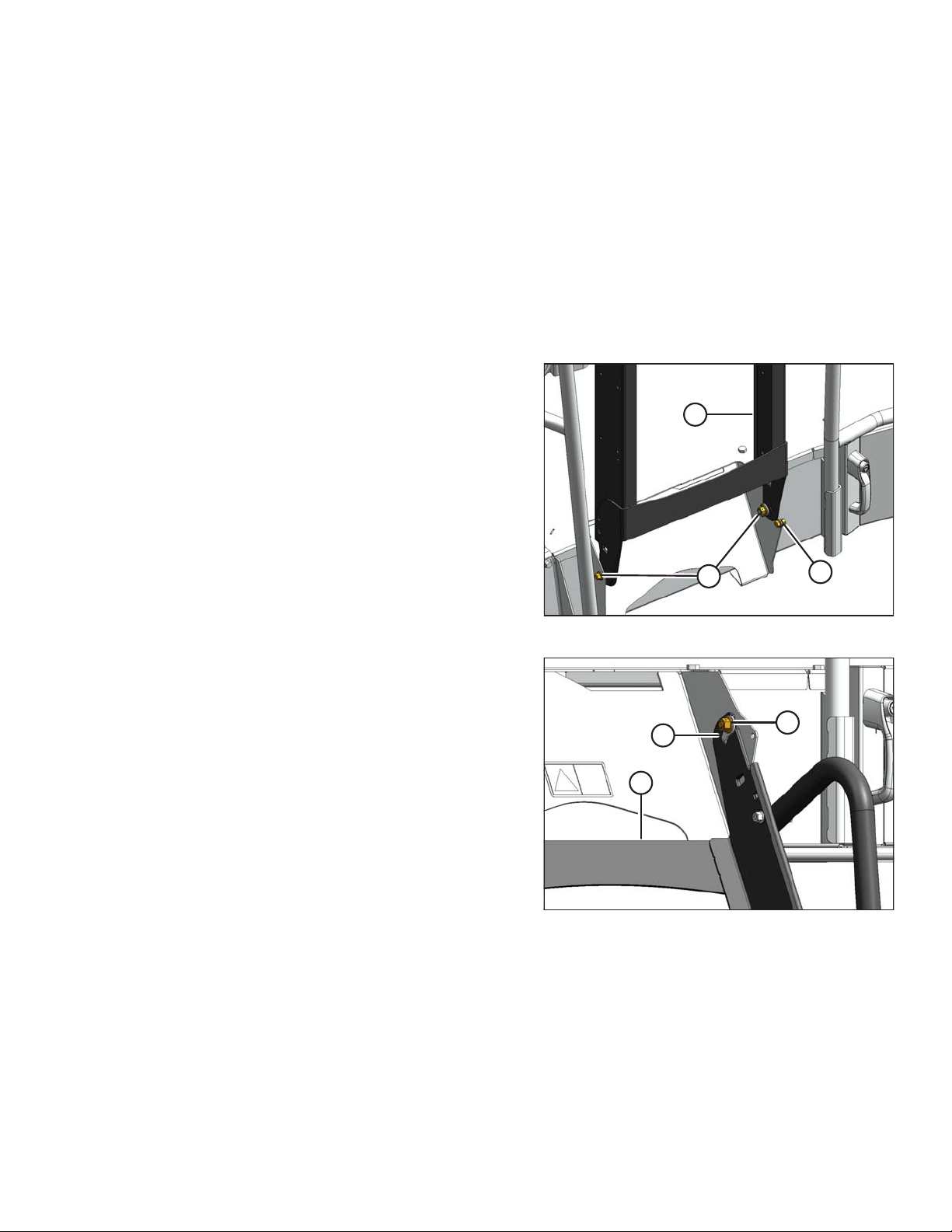

5. Remove two bolts (A), washers, and nuts from frame.

6. Adjust lift height until pin (A) is loose. Extract pin from

front of frame with a slide hammer (B) (MD #209816)

(tool required due to limited space in front of fuel tank).

Instructions are included with the tool.

NOTE:

Removing the pins will be difficult if weight is still on

the leg.

Figure 3.15: Windrower Right Leg

7. Repeat for second pin.

8. Move leg outwards to expose one hole (A) in frame.

Figure 3.16: Slide Hammer

Figure 3.17: Repositioning Right Leg

214735 24 Revision A

Page 35

1022811

A

B

1022807

A

ASSEMBLING THE WINDROWER

9. Align holes at pin locations and use the slide

hammer (B) to reinstall pins (A). If necessary, adjust

jack to prevent damage to the outer edges of the pins.

10. Secure pins with bolts (A), washers, and nuts. Torque

nuts to 136 Nm (100 lbf·ft).

11. Lower pallet jack and move it from work area.

12. Support the windrower with forklift, remove stand, and

lower windrower to ground.

Figure 3.18: Leg Pin

Figure 3.19: Right Leg

214735 25 Revision A

Page 36

1022900

1018697

A

A

B

C

1018731

A

ASSEMBLING THE WINDROWER

3.5 Repositioning Caster Wheels

A narrow caster tread width is better suited for smaller headers because it allows more space for the uncut crop

and provides more maneuverability around poles, irrigation inlets, and other obstacles. A wider caster tread width

reduces runover in heavy crops that produce large windrows.

1. Lift windrower with forklift to take most of the weight off

casters.

Figure 3.20: Supporting Windrower

2. Remove four bolts and washers (A), shock support

brackets (B), and slow moving vehicle (SMV) sign

support bracket (C) from walking beam.

3. Retain hardware and support brackets (B) and (C) for

installation later.

NOTE:

There is one SMV support bracket (C) preinstalled on

shock support brackets (B) at the left cab-forward

walking beam.

4. If not done yet, remove banding and blocking (A)

securing walking beam to frame.

Figure 3.21: Walking Beam

Figure 3.22: Windrower Rear

214735 26 Revision A

Page 37

1022816

B

A

C

1022817

A

B

C

1022821

A

B

ASSEMBLING THE WINDROWER

5. Rotate the caster so the wheel (A) is parallel to the

walking beam to assist with moving the extensions. Pull

walking beam extension (B) out to desired position and

line up bolt holes.

NOTE:

The walking beam extension (B) can be adjusted into

three working positions.

6. Install two M24 x 60 bolts and washers (C) on bottom of

beam. Do NOT tighten.

7. Install two M24 x 60 bolts coated with anti-seize

compound and M24 flat washers (A) from the toolbox in

the outboard side of the walking beam. Do NOT fully

tighten.

NOTE:

Depending on the extent of walking beam position,

outboard bolts may need to be installed first.

Figure 3.23: Walking Beam Extension

8. Place support brackets (B) onto walking beam as

shown and secure with two M24 x 60 bolts coated with

anti-seize compound and M24 flat washers (C).

Do NOT fully tighten.

IMPORTANT:

Ensure support bracket plate (B) is parallel or is

installed straight.

9. Tighten bolts as follows:

a. Snug bottom bolts (A), then snug back bolts (B).

b. Torque back bolts (B) to 745–770 Nm

(550–570 lbf·ft).

c. Torque bottom bolts (A) to 745–770 Nm

(550–570 lbf·ft).

IMPORTANT:

Torque bolts after first 5 hours of operation, and then

again after 10 hours.

Figure 3.24: Anti-Shimmy Brackets

Figure 3.25: Walking Beam Bolts

214735 27 Revision A

Page 38

1013124

=

=

ASSEMBLING THE WINDROWER

10. Repeat Steps 2, page 26 to 9, page 27 at opposite end

of walking beam, ensuring that casters are spaced

equally from center of windrower.

11. Lower windrower to ground.

Figure 3.26: Walking Beam Adjustment

214735 28 Revision A

Page 39

1022660

B

A

C

D

E

1020058

A

B

C

D

1020059

A

B

C

D

ASSEMBLING THE WINDROWER

3.6 Installing Caster Anti-Shimmy Dampeners

1. Retrieve anti-shimmy dampeners and hardware from

bag in toolbox.

2. If unit was shipped with casters installed, then complete

the following procedure. Otherwise, proceed to step 3,

page 29.

a. Remove retaining ring (A).

b. Remove and discard yellow spacer (B).

c. Retrieve key and arm from the toolbox.

d. Install key and arm (D), and secure with retaining

ring (E) on the caster shaft as shown.

e. Tighten nut (C), and torque to 190–200 Nm

(140–147 lbf·ft).

Figure 3.27: Anti-Shimmy Arm – Left Side

3. Attach barrel end of anti-shimmy dampener (A) to

forward hole in support (B) with one M16 x 75 flange

head bolt (C) and one M16 tech loc nut (D). Install bolt

from under support. Do NOT fully tighten.

Figure 3.28: Anti-Shimmy System – Left Side

4. Attach barrel end of second anti-shimmy dampener (A)

to support (B) at aft hole location with one M16 x 90

flange head bolt and M16 tech loc nut (C). Install bolt

from under support. Do NOT fully tighten.

5. Rotate caster so that arm (D) is aligned with

walking beam.

Figure 3.29: Anti-Shimmy System – Left Side

214735 29 Revision A

Page 40

1016210

A

C

B

D

ASSEMBLING THE WINDROWER

6. Attach rod ends of anti-shimmy dampeners to arm with

M16 x 90 flange head bolt (A) and three hardened

washers (B).

NOTE:

These washers (B) are stamped with L9 for

identification.

7. Torque bolt (A) to 244 Nm (180 lbf·ft).

8. Install jam nut (C) and torque to 136–140 Nm

(100–103 lbf·ft).

9. Tighten bolts (D) at barrel end of anti-shimmy

dampeners, and torque to 136–140 Nm

(100–103 lbf·ft).

IMPORTANT:

Maintain arm parallel to walking beam while tightening.

Do NOT overtighten.

10. Repeat Steps 2, page 29 to 9, page 30 for opposite end

of walking beam.

Figure 3.30: Anti-Shimmy System – Left Side

IMPORTANT:

Torque bolts after first 5 hours of operation, and then

again after 10 hours.

214735 30 Revision A

Page 41

1018596

A

B

1016246

A

C

B

ASSEMBLING THE WINDROWER

3.7 Installing Windshield Access Step

The windshield access step is secured on the railing of the right side platform (cab-forward).

1. Remove windshield access step (A) from shipping

location on right platform, and remove packing

materials (B) from step and railing.

2. Retrieve the three self-tapping bolts from a bag in the

toolbox.

NOTE:

Use ignition key to unlock toolbox compartment.

Figure 3.31: Step in Shipping Position

3. Position step (A) on right leg at forward end of platform

as shown.

4. Install two M10 x 20 hex head screws (B) through top of

step, but do NOT tighten.

5. Install one M10 x 20 hex head screw (C) through step

support.

6. Tighten and torque screws to 54–61 Nm (40–45 lbf·ft).

Figure 3.32: Windshield Access Step

214735 31 Revision A

Page 42

1014676

A

B

1014676

A

B

C

1014676

A

B

C

1014676

A

B

C

1014674

A

B

ASSEMBLING THE WINDROWER

3.8 Positioning Mirror Arms

The mirror/light support arms require repositioning from shipping position to working position.

1. Loosen retaining nut (A) and pivot nut (B) on support

arm (C).

2. Swivel support arm (C) forward 90 degrees from

shipping position to working position.

Figure 3.33: Mirror Arm in Shipping Position

3. Tighten retaining nut (A) to 37–41 Nm (28–30 lbf·ft).

4. Tighten pivot nut (B) to 24–27 Nm (18–20 lbf·ft).

5. Repeat above steps for opposite mirror.

Figure 3.34: Mirror Arm in Working Position

214735 32 Revision A

Page 43

1014590

A

B

C

1018716

A

B

C

ASSEMBLING THE WINDROWER

3.9 Installing Slow Moving Vehicle (SMV) Signs

To install the SMV sign onto the mirror/light support and walking beam, proceed as follows:

1. Retrieve SMV signs from inside cab and hardware from toolbox.

NOTE:

Use ignition key to unlock cab door and toolbox compartment.

2. Position sign (A) on existing bracket (B) as shown on

right cab-forward side mirror/light support, and secure

with two M6 x 20 hex head bolts (C) and M6 lock nuts.

IMPORTANT:

Ensure SMV sign does NOT cover brake light.

3. Locate support (A) on left cab-forward side of

walking beam.

4. Position sign (B) on support (A) as shown, and secure

with two M6 x 20 hex head bolts (C) and M6 lock nuts.

Figure 3.35: Right Side Mirror/Light Support

Figure 3.36: Walking Beam Left Side

214735 33 Revision A

Page 44

1019824

A

ASSEMBLING THE WINDROWER

3.10 Replacing Speed Identification Symbol (SIS) Decal (US Only)

This topic applies to windrowers used in the United States only.

1. Locate the existing SIS decal bracket on the left

mirror/lighting arm.

2. Wipe the existing decal with a clean cloth to remove dirt

and grease.

3. Apply the 30 mile/h SIS decal (A) (MD #208900) over

the existing 45 km/h decal.

Figure 3.37: SIS Decal (US Only)

214735 34 Revision A

Page 45

ASSEMBLING THE WINDROWER

3.11 Installing Rear Ballast Package

When windrower operates with a heavy header, ballast needs to be added to the aft end. Use the following table to

determine the amount of ballast required.

Refer to 4.1.10 Checking Tire Pressures, page 52 for proper tire pressures when operating with the applicable

header.

Table 3.1 Ballast Specifications

Header

Type

D125X

D130XL

D130XL

D130XL

D135XL

D135XL

D135XL

D135XL

D135XL

Description

7.6 m (25 ft.), single reel,

double knife, timed

9.1 m (30 ft.), single reel,

double knife, timed

9.1 m (30 ft.), single reel,

double knife, timed

9.1 m (30 ft.), single reel,

double knife, timed

10.6 m (35 ft.), single reel,

double knife, untimed

10.6 m (35 ft.), single reel,

double knife, untimed

10.6 m (35 ft.), single reel,

double knife, untimed

10.6 m (35 ft.), double reel,

double knife, untimed

10.6 m (35 ft.), double reel,

double knife, untimed

Installed Options

—

Base 0 0 0

Transport 1 0 0

Transport + upper cross

auger + vertical knives

Base 1 1 0

Transport 1 1 B6047

Transport + upper cross

auger + vertical knives

Base 1 1 0

Transport 1 1 B6047

Base Kit

00 0

1 0 B6047

1 2 B6047

Additional

Kits

Additional

Float

Springs

D135XL

D140XL

D140XL

D140XL

D145XL

214735 35 Revision A

10.6 m (35 ft.), double reel,

double knife, untimed

12.2 m (40 ft.), double reel,

double knife, untimed

12.2 m (40 ft.), double reel,

double knife, untimed

12.2 m (40 ft.), double reel,

double knife, untimed

13.7 m (45 ft.), double reel,

double knife, untimed

Transport + upper cross

auger + vertical knives

Base 1 1 0

Transport 1 1 B6047

Transport + upper cross

auger + vertical knives

Base 1 1 B6047

1 2 B6047

1 2 B6047

Page 46

1019838

A

B

ASSEMBLING THE WINDROWER

Table 3.1 Ballast Specifications (continued)

Header

Type

D145XL

D145XL

Description

13.7 m (45 ft.), double reel,

double knife, untimed

13.7 m (45 ft.), double reel,

double knife, untimed

Installed Options

Transport 1 2 B6047

Transport + upper cross

auger + vertical knives

Base Kit

Additional

Kits

1 2 B6106

Additional

Float

Springs

NOTE:

• Each kit consists of eight weights and weighs 163 kg (360 lb.).

• Ballast not required for A Series Auger Headers and R1 Series Disc Headers.

To install rear ballast, follow these steps:

WARNING

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and

remove the key from the ignition before leaving the operator’s seat for any reason.

1. Refer to Table 3.1, page 35 to determine ballast to add to windrower.

2. Stop engine, and remove key.

3. Move latch (A) towards right cab-forward side of

windrower.

4. Grasp louver (B), and lift hood to open.

Figure 3.38: Engine Compartment Hood

214735 36 Revision A

Page 47

1022925

A

A

A

A

B

D

C

1022910

B

A

1022911

B

A

B

ASSEMBLING THE WINDROWER

5. Remove eight hex flange bolts (A).

6. Slightly pull light bezel assembly (B), and disconnect

plugs P215 (C) and P210 (D) from back of red tail/brake

lights inside bezel.

7. Remove light bezel assembly (B).

8. Separate light bezel assembly (A) by removing six hex

screws (B).

Figure 3.39: Rear Light Bezel

Figure 3.40: Bezel Assembly

NOTE:

• Retain center portion (A) of light bezel assembly for

reinstallation when rear ballast are removed.

• Install six hex screws (B) on side bezels for

safekeeping. These hex screws will be used when

reinstalling center portion of light bezel.

Figure 3.41: Bezel Assembly

214735 37 Revision A

Page 48

1013204

A

1022921

A

E

B

C

D

E

E

F

F

1018705

A

B

C

D

E

ASSEMBLING THE WINDROWER

9. Grasp hood by louver (A) and lower until hood

engages latch.

CAUTION

To avoid injury, keep fingers clear of weight bracket

when installing weights.

10. Install weights (A) from outboard side and slide to

middle of bracket on walking beam.

Figure 3.42: Engine Compartment

11. Install retaining bracket (B) on each side of weight

bundle.

IMPORTANT:

Ensure retaining bracket (B) engage slot (C) in bracket.

12. Install rod (D) through retaining bracket and weights

with spacers (E) as required.

13. Secure with nuts (F) and tighten.

IMPORTANT:

Ensure nuts (F) are flush with rod.

Figure 3.43: Weights Installed

Figure 3.44: Base Kit – 163 kg (360 lb.)

214735 38 Revision A

Page 49

1018706

A

B

C

D

E

1018707

A

B

C

D

1019838

A

B

ASSEMBLING THE WINDROWER

Figure 3.45: Two Sets – 326 kg (720 lb.)

Figure 3.46: Three Sets – 489 kg (1080 lb.)

14. Move latch (A) towards right cab-forward side of

windrower.

15. Grasp louver (B), and lift hood to open.

Figure 3.47: Engine Compartment Hood

214735 39 Revision A

Page 50

1022915

A

C

B

E

D

1013204

A

ASSEMBLING THE WINDROWER

16. Bring left side bezel (A) close to frame and connect plug

P215 to back of red tail/brake light.

17. Loosely attach left side bezel (A) to frame with four hex

flange bolt (B).

18. Repeat Steps 16, page 40 to 17, page 40 attaching

plug P210 at right side bezel (C).

19. Turn IGNITION key to RUN position, and ensure that

rear swath lights (D) and red tail/brake lights (E) are

working.

20. If lights are working, tighten hex flange bolts (B) to

secure left and right light bezel.

IMPORTANT:

Ensure rear swath lights (D) are centered in light bezel.

21. Grasp hood by louver (A) and lower until hood

engages latch.

NOTE:

Check that latch lever is not tilted to ensure hood is

latched.

Figure 3.48: Rear Light Bezel with Ballast

Figure 3.49: Engine Compartment

214735 40 Revision A

Page 51

10149861014986

B

C

A

ASSEMBLING THE WINDROWER

3.12 Lubricating the Windrower

For grease specification, refer to 5.1 Lubricants, Fluids, and System Capacities, page 113.

3.12.1 Lubrication Procedure

WARNING

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and

remove the key from the ignition before leaving the operator’s seat for any reason.

1. Wipe grease fitting with a clean cloth before greasing to avoid injecting dirt and grit.

2. Inject grease through fitting with grease gun until grease overflows fitting. Do NOT overgrease wheel bearings.

3. Leave excess grease on fitting to keep out dirt.

4. Replace any loose or broken fittings immediately.

5. Remove and thoroughly clean any fittings (including the lubricant passageway) that will not take grease.

Replace fitting, if necessary.

3.12.2 Lubrication Points

Figure 3.50: Lubrication Points

A - Top Link (Two Places) (Both Sides) B - Caster Pivot (Both Sides)

C - Forked Caster Wheel Bearing (Two Places) (Both Wheels)

214735 41 Revision A

Page 52

1019838

A

B

1018879

A

B

1012747

B

A

ASSEMBLING THE WINDROWER

3.13 Connecting Batteries

1. Move latch (A) towards right cab-forward side of the

windrower.

2. Grasp louver (B), and lift the hood to open.

3. Lift up on the cab-end of the cover (A) to disengage it

from the retaining tab (B), and swing cover away from

the frame.

Figure 3.51: Engine Compartment Hood

IMPORTANT:

Batteries are negative grounded. Always connect

starter cable to the positive (+) terminal of battery and

battery ground cable to negative (–) terminal of battery.

Reversed polarity in battery or alternator may result in

permanent damage to electrical system.

NOTE:

Before connecting the harness to the batteries, ensure

that positive terminal is positioned on the right side of

the battery when installed on the battery support.

4. Attach red positive (+) cable terminals to positive

posts (B) on batteries and tighten clamps. Reposition

plastic covers onto clamps.

5. Attach black negative (–) cable terminals to negative

posts (A) on batteries and tighten clamps. Reposition

plastic covers onto clamps.

Figure 3.52: Battery Location

Figure 3.53: Batteries

214735 42 Revision A

Page 53

1018916

A

B

C

ASSEMBLING THE WINDROWER

6. Swing the cover (A) towards the windrower frame. Lift

up on the cab end of the cover until it is secured by the

retaining tab (B) on the frame.

7. Grasp the hood by the louver (C) and lower until hood

engages latch.

NOTE:

Check that the latch lever is not tilted to ensure hood is

latched.

Figure 3.54: Battery Cover

214735 43 Revision A

Page 54

Page 55

4 Performing Predelivery Checks

1022835

A

1022836

A

Perform all procedures in this chapter in the order in which they are listed.

IMPORTANT:

The machine should not require further adjustments; however, perform the following checks and complete the

yellow predelivery checklist at the end of this book to ensure your machine operates at maximum performance.

Make adjustments only if absolutely necessary and in accordance with the instructions in this manual.

4.1 Completing Predelivery Checklist

1. Lower header so that lift cylinders are fully retracted.

2. Shut down engine, and remove key.

3. Perform the final checks and adjustments listed on the following pages and the Predelivery Checklist, page 129

(yellow sheet attached to this instruction) to ensure the machine is field-ready.

IMPORTANT:

Ensure the Operator or the Dealer retains the completed Predelivery Checklist.

4.1.1 Recording Serial Numbers

1. Record the windrower and engine serial numbers on

the Predelivery Checklist, page 129.

The windrower serial number plate (A) is located on the

left side of the main frame near the walking beam

as shown.

2. Confirm serial number with manifest or work order.

The engine serial number plate (A) is located on top of

the engine cylinder head cover as shown.

Figure 4.1: Windrower Serial Number Location

Figure 4.2: Engine Serial Number Location

214735 45 Revision A

Page 56

1015818

A

A

B

1023020

B

C

D

A

1022834

A

PERFORMING PREDELIVERY CHECKS

4.1.2 Checking Engine Air Intake

1. Check all engine air intake ducting (A) and joints for

looseness. Tighten hose clamps as required.

2. Check that end cap (B) is secure and locked.

3. Check the three constant torque hose clamps (A) and

spring clamp (B) on turbocharger intake duct. Clamp (B)

is properly tightened when screw tip (C) extends

beyond housing and Belleville washers (D) are

almost flat.

Figure 4.3: Engine Air Intake

4.1.3 Checking and Adding Engine Oil

NOTE:

Oil can be checked without opening the hood.

1. Remove the dipstick (A) by turning it counterclockwise

to unlock.

2. Wipe the dipstick clean and reinsert it into the engine.

Figure 4.4: Constant Torque Clamps

Figure 4.5: Dipstick Location

214735 46 Revision A

Page 57

1000074

1019838

A

B

1012638

A

PERFORMING PREDELIVERY CHECKS

3. Remove the dipstick again and check the oil level. Oil

level should be between LOW (L) and HIGH (H). If

below the LOW mark, add oil.

NOTE:

Adding 1.9 liters (2 US quarts) will raise the level from

LOW to HIGH.

4. Replace dipstick and turn it clockwise to lock.

If oil level is too low, follow these steps to add oil:

1. Move latch (A) towards right cab-forward side of the

windrower.

2. Grasp louver (B), and lift hood to open.

Figure 4.6: Engine Oil Level

Figure 4.7: Hood

3. Clean around filler cap (A) and remove by turning it

counterclockwise.

4. Carefully add oil to achieve the desired level. A funnel is

recommended to avoid spillage. For oil specifications,

refer to 5.1 Lubricants, Fluids, and System Capacities,

page 113.

CAUTION

Do NOT fill above the HIGH mark.

5. Replace oil filler cap (A) and turn it clockwise until snug.

Figure 4.8: Oil Filler Cap

214735 47 Revision A

Page 58

1013204

A

1012665

A

PERFORMING PREDELIVERY CHECKS

6. Grasp the hood by louver (A) and lower until hood

engages latch.

NOTE:

Check that latch lever is not tilted to ensure hood is

latched.

Figure 4.9: Engine Compartment

4.1.4 Checking and Adding Hydraulic Oil

WARNING

Avoid high-pressure fluids. Escaping fluid can penetrate the skin causing serious injury.

1. Park windrower on level ground, and lower header so that lift cylinders are fully retracted.

2. Stop the engine and remove the key.

3. Locate the sight glass (A) on the right side of the tank. It

indicates the oil level and any signs of contamination.

NOTE:

No oil in the sight glass indicates that the oil level is

below the add mark on the dipstick. The sight glass is

viewable with the hood open or closed.

4. Ensure the hydraulic oil level is between the low and full

indicator marks.

5. Add oil if necessary. For specifications, refer to 5.1

Lubricants, Fluids, and System Capacities, page 113.

NOTE:

After running up a header, the oil level should be

Figure 4.10: Hydraulic Oil Sight Glass

checked again.

214735 48 Revision A

Page 59

1018886

A

1019838

A

B

1018836

A

PERFORMING PREDELIVERY CHECKS

4.1.5 Checking Fuel Separator

1. Place a container under the filter drain valve (A).

2. Turn drain valve (A) by hand 1-1/2 to 2 turns

counterclockwise until fuel begins draining.

3. Drain the filter sump of water and sediment until clear

fuel is visible. Clean as necessary.

4. Turn the drain valve (A) by hand 1-1/2 to 2 turns

clockwise until tight.

5. Dispose of fluid in container in a safe manner.

4.1.6 Checking Engine Coolant Level

NOTE:

Ensure the engine has cooled down prior to checking.

Figure 4.11: Fuel Filter

1. Move latch (A) towards right cab-forward side of the

windrower.

2. Grasp louver (B), and lift hood to open.

3. The tank has a MAX and MIN COLD line marker.

Coolant level should be kept at the MAX COLD line (A).

NOTE:

When checking coolant level, use the MAX COLD line

on the side of tank that faces cab for an accurate

measurement.

NOTE:

For specifications, refer to 5.1 Lubricants, Fluids, and

System Capacities, page 113.

Figure 4.12: Hood

214735 49 Revision A

Figure 4.13: Coolant Tank

Page 60

1013204

A

1023744

A

1016163

A

PERFORMING PREDELIVERY CHECKS

4. Grasp the hood by louver (A) and lower until hood

engages latch.

NOTE:

Check that latch lever is not tilted to ensure hood is

latched.

Figure 4.14: Engine Compartment

4.1.7 Checking Engine Gearbox Lubricant Level and Adding Lubricant

1. Remove hex head check plug (A) on underside of

windrower beneath the main pumps. The lubricant

should be visible through the hole or slightly

running out.

2. Add lubricant, if required, through the check plug

hole (A) using a squeeze bottle, or by removing the

breather at the top right side of the gearbox. For

specification, refer to 5.1 Lubricants, Fluids, and

System Capacities, page 113.

Figure 4.15: Gearbox Lubricant Check Plug

4.1.8 Checking Air Conditioning (A/C) Compressor Belts

1. Ensure A/C compressor belts (A) are tensioned so that

a force of 35–55 N (8–12 lbf) on each belt deflects belt

5 mm (3/16 in.) at midspan.

214735 50 Revision A

Figure 4.16: A/C Compressor Belts

Page 61

1005867

A

B

PERFORMING PREDELIVERY CHECKS

4.1.9 Checking Operating Safety System

Perform the following checks to ensure the windrower operating safety systems are functioning properly:

WARNING

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and

remove the key from the ignition before leaving the operator’s seat for any reason.

CAUTION

Check to be sure all bystanders have cleared the area.

1. With the engine running and the seat base in engine-forward mode, engage the HEADER ENGAGE switch.

Confirm the header drive does NOT engage and the Harvest Performance Tracker (HPT) displays LOCK SEAT

BASE IN CAB-FORWARD.

2. With the engine running and the seat base in cab-forward mode, stand up and engage the HEADER DRIVE

switch. The header drive should NOT engage and the HPT displays OPERATOR MUST BE SEATED.

3. With the engine running and the seat base is between locked positions, move the GSL out of PARK. Confirm

the engine immediately shuts down and the HPT displays LOCK SEAT BASE and sounds a tone.

4. Shut down the engine and engage HEADER ENGAGE switch. Try starting the engine and confirm the HPT

displays DISENGAGE HEADER. If the engine turns over, the safety system requires adjustment. Refer to the

technical manual for adjustment procedures.

5. Shut down the engine and open the cooler box door. Try starting the engine and confirm the HPT displays

CLOSE COOLER BOX DOOR. If the engine turns over, the safety system requires adjustment. Refer to the

technical manual for adjustment procedures.

6. Shut down the engine and perform the following safety

system checks:

a. Open engine compartment hood.

b. Pry the steering interlock away from pintle arms (A)

by inserting a wedge or pry bar between one of the

interlock channels (B) and pintle arm.

c. Insert a wooden block approximately 19 mm

(3/4 in.) thick between the opposite channel and

the pintle arm so the interlock channel is clear of

the pintle arm.

d. Turn the steering wheel off-center and move the

GSL to PARK.

e. Try starting the engine and confirm the HPT

displays LOCK STEERING WHEEL IN CENTER

POSITION. The engine should NOT turn over. If

the engine turns over, the safety system requires

adjustment. Refer to the technical manual for

adjustment procedures.

f. Remove key from ignition.

Figure 4.17: Pintle Arms

g. Remove wooden block and close hood.

214735 51 Revision A

Page 62

1014974

A

B

PERFORMING PREDELIVERY CHECKS

7. Shut down the engine and center the steering wheel. Place the GSL in NEUTRAL but not in PARK. Try starting

the engine and confirm the HPT displays MOVE GSL INTO PARK. The engine should NOT turn over. If the

engine turns over, the safety system requires adjustment. Refer to the technical manual for adjustment

procedures.

8. Shut down the engine and center the steering wheel. Place the GSL in PARK and ensure the operator’s station

is NOT locked. Try starting the engine and confirm that the engine does NOT crank, and the HPT displays

LOCK SEAT BASE. If the engine starts, the safety system requires adjustment. Refer to the technical manual

for adjustment procedures.

4.1.10 Checking Tire Pressures

Check tire pressures with a gauge.

Caster Wheel Tires: Inflate all caster wheel tires (B) to

110 kPa (16 psi).

Drive Wheel Tires: For optimal performance, drive

wheel (A) tire pressures are determined by tire type, header

size, and additional options. Refer to the following table:

Table 4.1 Drive Tire Inflation Specifications

Header Type Description

Installed Options

Draper Header

D115X

single reel

D115X

single reel

D120X

single reel

D120X

single reel

D125X

single reel

D125X

single reel

D130XL

single reel

4.6 m (15 ft.), double

knife, timed

4.6 m (15 ft.), double

knife, timed

6.1 m (20 ft.), double

knife, timed

6.1 m (20 ft.), double

knife, timed

7.6 m (25 ft.), double

knife, timed

7.6 m (25 ft.), double

knife, timed

9.1 m (30 ft.), double

knife, timed

Figure 4.18: Windrower Tires

Weight Kit Tire Type

——

——

——

——

——

——

Bar

Turf 138 (20)

Bar

Turf 138 (20)

Bar

Turf 159 (23)

Transport 1 Bar

Pressure

kPa (psi)

138 (20)

138 (20)

159 (23)

200 (29)

214735 52 Revision A

Page 63

PERFORMING PREDELIVERY CHECKS

Table 4.1 Drive Tire Inflation Specifications (continued)

Header Type Description

D130XL

single reel

D130XL

single reel

D130XL

single reel

D135XL

single reel

D135XL

single reel

D135XL

single reel

D135XL

single reel

D135XL

single reel

D135XL

single reel

9.1 m (30 ft.), double

knife, timed

9.1 m (30 ft.), double

knife, timed

9.1 m (30 ft.), double

knife, timed

10.7 m (35 ft.), double

knife, untimed

10.7 m (35 ft.), double

knife, untimed

10.7 m (35 ft.), double

knife, untimed

10.7 m (35 ft.), double

knife, untimed

10.7 m (35 ft.), double

knife, untimed

10.7 m (35 ft.), double

knife, untimed

Installed Options

Weight Kit Tire Type

Transport 1

Transport + upper

cross auger + vertical

1 Bar

knives

Transport + upper

cross auger + vertical

1 Turf 241 (35)

knives

Base 2 Bar

Base 2

Transport 2 Bar

Transport

2 Turf 241 (35)

Transport + upper

cross auger + vertical

3 Bar

knives

Transport + upper

cross auger + vertical

3

knives

Pressure

kPa (psi)

Turf 241 (35)

241 (35)

200 (29)

Turf 241 (35)

241 (35)

241 (35)

Turf 241 (35)

D135XL

double reel

D135XL

double reel

D135XL

double reel

D135XL

double reel

D135XL

double reel

D135XL

double reel

D140XL

double reel

D140XL

double reel

D140XL

double reel

10.7 m (35 ft.), double

knife, untimed

10.7 m (35 ft.), double

knife, untimed

10.7 m (35 ft.), double

knife, untimed

10.7 m (35 ft.), double

knife, untimed

10.7 m (35 ft.), double

knife, untimed

10.7 m (35 ft.), double

knife, untimed

12.2 m (40 ft.), double

knife, untimed

12.2 m (40 ft.), double

knife, untimed

12.2 m (40 ft.), double

knife, untimed

Base

2

Base 2

Transport 2 Bar

Transport 2

Transport + upper

cross auger + vertical

3 Bar

knives

Transport + upper

cross auger + vertical

3

knives

Base

2

Base 2

Transport 2 Bar

Bar