Page 1

HC10

Hay Conditioner for D-Series

Draper Headers

Setup

, Operation, and Parts Manual

169254 Rev. D

Original Instruction

The harvesting specialists worldwide.

Page 2

MacDon Model HC10 Hay Conditioner

Published on January, 2014.

Page 3

Introduction

This manual contains safety information, set-up instructions, operating and maintenance procedures, and parts

informationforthe Model HC10 HayConditioner. Thishayconditioner,whenteamedwith an M-SeriesSelf-Propelled

Windrowerpower unitand a D-Series Draper Header,will cut and lay crop into uniform, fluffy windrows. Conditioning

or crimping the cut hay allows moisture release for quicker drying and earlier processing.

CAREFULLY READ ALL THE MATERIALPROVIDEDBEFORE ATTEMPTINGTOUNLOAD, ASSEMBLE, OR USE

THE MACHINE.

Use this manual as your first source of information about the machine. If you follow the instructions given in this

manual, your hay conditioner will work well for many years. Use this manual in conjunction with your M-Series

Self-Propelled Windrower and D-Series Draper Header manuals.

Use the Table of Contents to guide you to specific topics. Review the Table of Contents to familiarize yourself with

how the material is organized.

Keep this manual handy for frequent reference and to pass on to new Operators or Owners. Call your Dealer if you

need assistance, information, or additional copies of this manual.

169254

i

Rev. D

Page 4

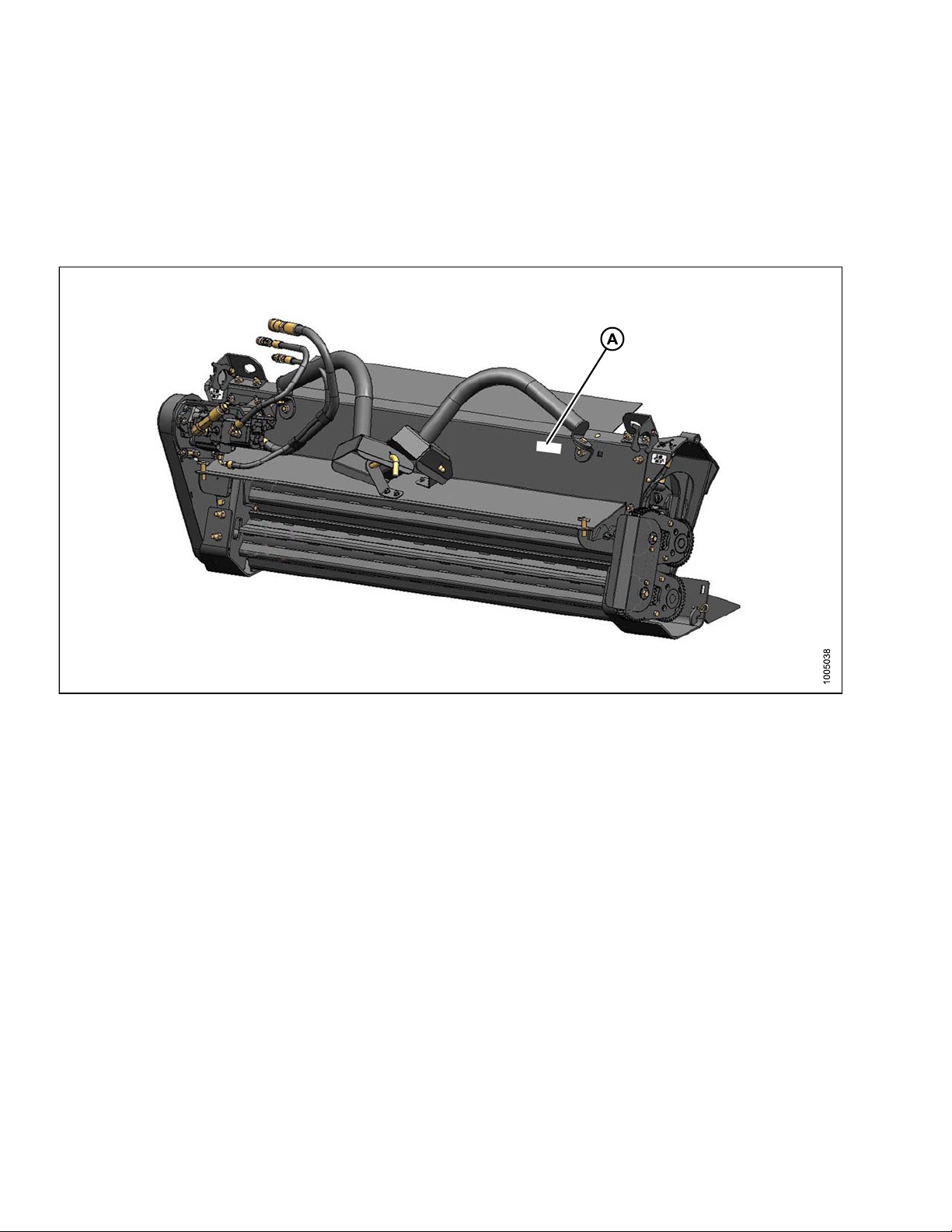

Serial Number

Record the serial number of the hay conditioner in the space below.

HAY CONDITIONER SERIAL NO: ____________

Serial Number Plate (A) is located on the rear cover of the conditioner frame as shown below.

s

Figure 1: Serial Number Plate

169254

i

i

Rev. D

Page 5

TABL E OF CONTENTS

Introduction...................................................................................................................................... i

Serial Numbers.................................................................................................................................ii

1 Safety.................................................................................................................................................... 1

1.1 Safety Alert Symbols........................................................................................................................1

1.2 Signal Words................................................................................................................................... 2

1.3 General Safety................................................................................................................................ 3

1.4 MaintenanceSafety.........................................................................................................................5

1.5 Hydraulic Safety.............................................................................................................................. 6

1.6 Tire Safety.......................................................................................................................................7

1.7 Battery Safety..................................................................................................................................8

1.8 Welding Precaution........................................................................................................................ 10

1.9 Engine Safety.................................................................................................................................11

1.9.1 HighPressure Rails.................................................................................................................11

1.9.2 Engine Electronics ................................................................................................................. 12

1.10 Safety Signs.................................................................................................................................. 13

1.10.1 Installing Safety Decals .......................................................................................................... 13

2 General Information ............................................................................................................................ 15

2.1 Torque Specifications ..................................................................................................................... 15

2.1.1 SAE Bolt Torque Specifications............................................................................................... 15

2.1.2 Metric Bolt Specifications........................................................................................................ 17

2.1.3 Metric Bolt Specifications Bolting intoCast Aluminum............................................................... 20

2.1.4 Flare-Type Hydraulic Fittings................................................................................................... 20

2.1.5 O-Ring Boss (ORB)HydraulicFittings ..................................................................................... 21

2.1.6 O-Ring Face Seal (ORFS)Hydraulic Fittings............................................................................ 22

2.2 Specifications................................................................................................................................ 24

2.3 Conversion Chart........................................................................................................................... 25

2.4 Component Identification................................................................................................................ 26

3 Unloading and Assembly .................................................................................................................... 29

3.1 Unloading the Hay Conditioner....................................................................................................... 29

3.2 Preparing the Header..................................................................................................................... 31

3.3 Installin g the Rock Grate ................................................................................................................ 32

3.4 Insta lling Deck Brackets................................................................................................................. 33

3.5 Installing the Feed Deck................................................................................................................. 35

3.6 Insta lling the Conditioner................................................................................................................ 37

3.6.1 Installing Conditioner: Lifting Method....................................................................................... 37

3.6.2 Installing Conditioner: Windrower Method................................................................................ 39

3.7 Attaching Hydraulics...................................................................................................................... 45

3.7.1 Attaching Hydraulics: 15-FootHeaders.................................................................................... 45

3.7.2 Attaching Hydraulics: All Headers Except 15-Foot.................................................................... 47

3.8 Assembling the Forming Shield ...................................................................................................... 50

3.9 Installing the Forming Sh ie ld........................................................................................................... 53

3.10 Attaching to a Windrower ............................................................................................................... 55

3.11 Lubricating the Conditioner............................................................................................................. 56

3.11.1 Greasing Procedure............................................................................................................... 56

3.11.2 LubricationPoints ................................................................................................................... 57

3.12 Performing Predelivery Checks ....................................................................................................... 59

3.12.1 Checking Roll Drive Belt Tension............................................................................................. 59

3.12.2 Checking Roll Gap ................................................................................................................. 60

3.12.3 Checking Roll Timing.............................................................................................................. 60

3.12.4 Running Up the Conditioner .................................................................................................... 61

3.12.5 StoringManuals..................................................................................................................... 62

4 Operation ............................................................................................................................................ 63

4.1 Owner/Operator Responsibilities ..................................................................................................... 63

169254

ii

i

Rev. D

Page 6

TABLE OF CONTENTS

4.2 OperationalSafety......................................................................................................................... 64

4.2.1 Shutting Down the Machine .................................................................................................... 64

4.3 Attaching Hay Conditioner to Header..............................................................................................65

4.4 Detaching Hay Conditioner fromHeader......................................................................................... 66

4.4.1 Detaching Hay Conditioner: Windrower Method....................................................................... 66

4.4.2 Detaching Hay Conditioner: Lifting Method.............................................................................. 70

4.5 Detaching Feed Deck and Rock Grate............................................................................................ 74

4.6 Break-in Period.............................................................................................................................. 77

4.7 Preseason Check.......................................................................................................................... 78

4.8 Daily StartupCheck....................................................................................................................... 79

4.9 ConditionerOperation.................................................................................................................... 80

4.9.1 Rolland Feed Draper Speed................................................................................................... 80

4.9.2 Adjusting RollGap ................................................................................................................. 80

4.9.3 Checkingand Adjusting Roll Timing......................................................................................... 81

4.9.4 Adjusting ConditionerRoll Tension ......................................................................................... 83

4.9.5 Forming Shields..................................................................................................................... 83

Adjusting Forming ShieldHeight...................................................................................... 84

Adjusting Side Deflectors................................................................................................ 84

Adjusting Rear Deflector (Fluffer Shield)........................................................................... 85

Adjusting Deflector Fins .................................................................................................. 85

4.9.6 Unplugging the Conditioner..................................................................................................... 85

4.10 Storage......................................................................................................................................... 86

5 Maintenance........................................................................................................................................ 87

5.1 Preparation for Servicing ................................................................................................................ 87

5.2 Recommended SafetyProcedures ..................................................................................................88

5.3 Drive Shields................................................................................................................................. 89

5.4 Lubrication .................................................................................................................................... 90

5.4.1 Lubricants.............................................................................................................................. 90

5.4.2 Greasing Procedure............................................................................................................... 90

5.4.3 LubricationPoints................................................................................................................... 91

5.5 Hydraulics ..................................................................................................................................... 94

5.5.1 Hydraulic Hoses and Lines .....................................................................................................94

5.6 FeedDraper.................................................................................................................................. 95

5.6.1 Adjusting FeedDraper Tension............................................................................................... 95

5.7 Drive Belt...................................................................................................................................... 96

5.7.1 Adjusting Drive BeltTension.................................................................................................... 96

5.7.2 Adjusting Drive BeltPulley Alignment ...................................................................................... 97

5.7.3 Checkingand Adjusting Drive Belt Tracking............................................................................. 98

5.7.4 RemovingDriveBelt .............................................................................................................100

5.7.5 Installing Drive Belt ...............................................................................................................100

5.8 MaintenanceSchedule..................................................................................................................102

5.9 Troubleshooting............................................................................................................................104

6Repa

6.1 Abbr

6.2 Ser

6.3 Low

6.4 Upp

6.5 Cov

6.6 Hyd

6.

6.

6.

6.

ir Parts .......................................................................................................................................107

eviations ...............................................................................................................................107

ial NumberBreaks...................................................................................................................108

er Rolland Frame Assembly...................................................................................................109

er RollAssembly ....................................................................................................................111

er and Supports ......................................................................................................................113

raulic Motor, Mounts, and Tensioner.........................................................................................117

7

8

9

10

lt Drive and Shield....................................................................................................................121

Be

draulicCompletion Package......................................................................................................123

Hy

ars and Roll Coupling Assembly................................................................................................127

Ge

rming Shields ...........................................................................................................................129

Fo

169254

v

i

Rev. D

Page 7

TABL E OF CONTENTS

6.11 Feed Deck and Pan......................................................................................................................131

6.12 MountingBrackets ........................................................................................................................135

Index ..................................................................................................................................................137

Model HC10 Hay Conditioner Predelivery Checklist........................................................................143

169254

v

Rev. D

Page 8

Page 9

1 Safety

1.1 Safety Alert Symbols

This safety alert symbol indicates important safety

messages in this manual and on safety signs on

the hay conditioner.

This symbol means:

• ATTENTION!

• BECOME ALERT!

• YOUR SAFETY IS INVOLVED!

Carefully read and follow the safety message

accompanying this symbol.

Why is safety important to you?

• Accidents disable and kill.

• Accidents cost.

• Accidents can be avoided.

Figure 1.1: Read Operator’s Manual Before

Operating

169254

1

Rev. D

Page 10

SAFETY

1.2 Signal Wor

Three signal w

appropriate s

ords, DANGER, WARNING, and CAUTION, are used to alert you to hazardous situations. The

ignal word for each situation has been selected using the following guidelines:

ds

DANGER

Indicates an i

mminently hazardous situation that, if not avoided, will result in death, or serious injury.

WARNING

Indicates a potentially hazardous situation that, if not avoided, could result in death, or serious injury.

It may also be used to alert against unsafe practices.

CAUTION

Indicates a potentially hazardous situation that, if not avoided, may result in minor, or moderate injury.

It may be used to alert against unsafe practices.

169254

2

Rev. D

Page 11

SAFETY

1.3 General Sa

fety

CAUTION

The following are general farm safety precautions

that should be part of your operating procedure

for all types of machinery.

Protect yourself

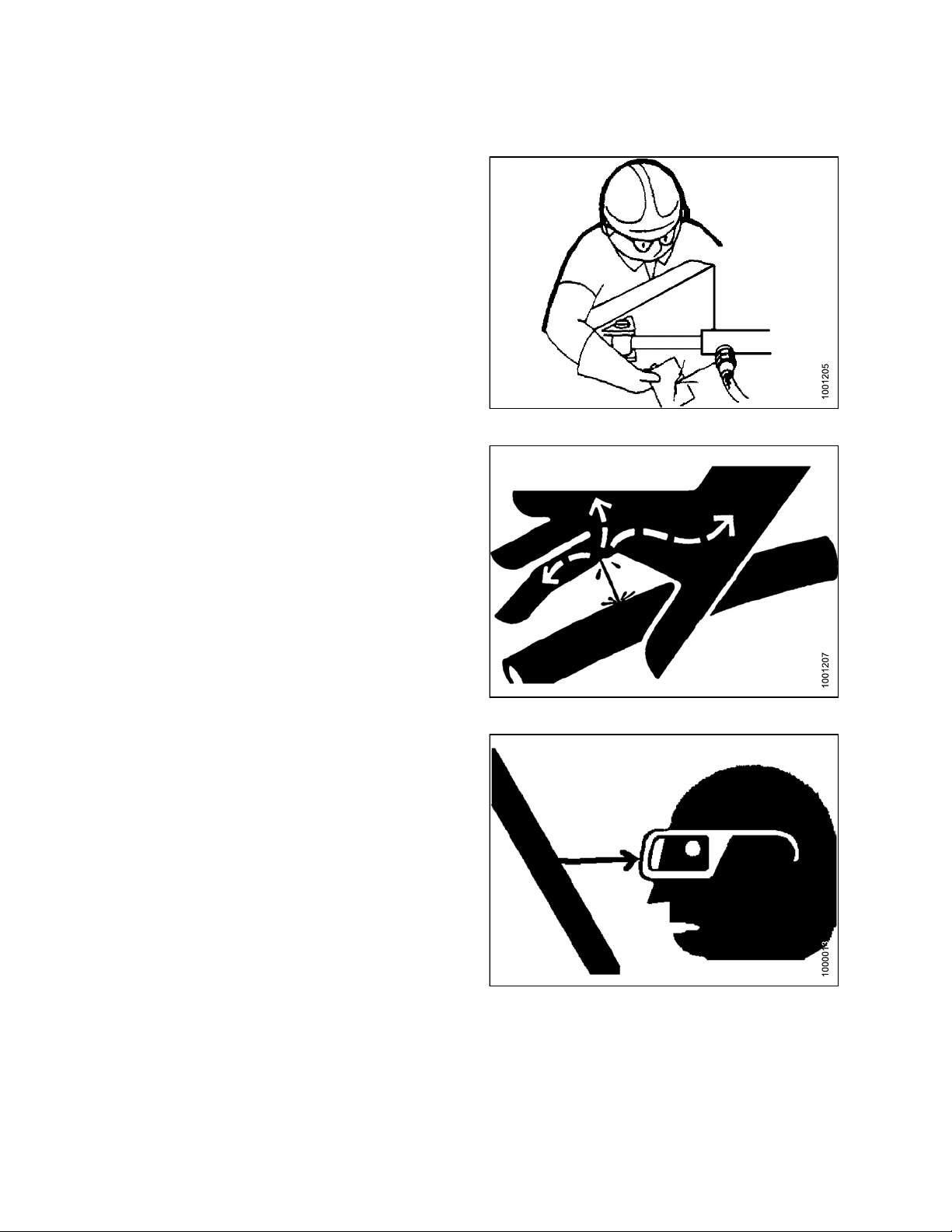

• When assembling, operating, and servicing machinery,

wear all the protective clothing and personal safety

devices that COULD be necessary for the job at hand.

Don’t take chances.

• You may need:

– A hard hat

– Protective footwear with slip resistant soles

– Protective glasses or goggles

– Heavy gloves

Figure 1.2

– Wet weather gear

– A respirator or filter mask

– Hearing protection

Be aware that exposure to loud noise can cause

impairment or loss of hearing. Wearing suitable

hearing protection devices such as ear muffs or ear

plugs. These will help protect against objectionable

or loud noises.

•Provideafirst aid kit for use in case of emergencies.

•Keepafire extinguisher on the machine. Be sure the fire

extinguisher is properly maintained. Be familiar with its

proper use.

• Keep young c hildren away from the machinery at

all times.

• Beaware that accidents often happen when theOperator

istiredorinahurrytogetfinished. Takethetimeto

consider the safest way. Never ignore warning signs

of fatigue.

Figure 1.3

Figure 1.

4

169254 3 Rev. D

Page 12

SAFETY

•Wearclosefitting clothing and cover long hair. Never

wear dangling items such as scarves or bracelets.

• Keep all shields in place. Never alter or remove safety

equipment. Make sure driveline guards can rotate

independently of the shaft and can telescope freely.

• Use only service and repair parts, made, or approved by

the equipment manufacturer. Substituted parts may not

meet strength, design, or safety requirements.

• Keep hands, feet, clothing, and hair away from moving

parts. Never attempt to clear obstructions or objects,

from a machine while the engine is running.

•Do NOT modify the machine. Non-authorized

modificationsmayimpair machine functionand/orsafety.

It may also shorten the machine’s life.

Figure 1.5

• Stop e ngine and remove key from ignition before leaving

operator’s seat for any reason. A child or even a pet

could engage an idling machine.

• Keep the area used for servicing machinery clean

and dry. Wet or oily floors are slippery. Wet spots

can be dangerous when working w ith electrical

equipment. Be sure all electrical outlets and tools are

properly grounded.

• Keep work area well lit.

• Keep machinery clean. Straw and chaff, on a hot

engine, are a fire hazard. Do NOT allow oil or grease to

accumulate on service platforms, ladders, or controls.

Clean machines before storage.

• Never use gasoline, naphtha, or any volatile material

for cleaning purposes. These materials may be toxic

and/or flammable.

• When storing machinery, cover sharp or extending

components to prevent injury from accidental contact.

Figure 1.6

Figure 1.7

169254

4

Rev. D

Page 13

SAFETY

1.4 Maintenan

To ensure your

• Review the ope

operation and

•Placeallcon

brake, remov

partsto stop

• Follow good

– Keep servic

–Besureele

grounded.

– Use adequa

• Relieve pr

and/or dis

• Before ap

sure all c

and coupl

• Keephand

and/or r

safety while maintaining the machine:

rator’smanual and all safety itemsbefore

/or maintenance of the machine.

trolsin Neutral, stop the engine, set the park

e the ignition key, and wait for all moving

beforeservicing,adjusting,and/orrepairing.

shop practices:

e area clean and dry.

ctrical outlets and tools are properly

te light for the job at hand.

essure from hydraulic circuits before servicing

connecting the machine.

plying pressure to a hydraulic system, make

omponents are tight and that steel lines, hoses,

ings are in good condition.

s,feet, clothing, andhair away from all moving

otating parts.

ce Safety

Figure 1.8: Slip on Puddle

•Clearth

carryin

making a

•Instal

frame b

•Ifmore

same ti

mecha

acces

other

of dri

• Wear protective gear when working on the machine.

• Wear heavy gloves when working on knife components.

e area of bystanders especially children when

g out any maintenance and repairs or when

ny adjustments.

l transport lock or place safety stands under the

efore working under the hay conditioner.

than one person is servicing the machine at the

me,beawarethatrotatingadrivelineorother

nically driven component by hand (for example,

sing a lube fitting) will cause drive components in

areas(belts,pulleys, and knife)tomove. Stay clear

ven components at all times.

Figure 1.9: Keep Away

Figure 1.10: Safety Gear

169254 5 Rev. D

Page 14

SAFETY

1.5 Hydraulic

• Always place a

dismounting.

• Makesurethat

are kept in go

•Replaceanyw

hoses and ste

• Do not attem

lines, fitti

or welding.

extremely

suddenly a

• Wearprope

a high-pre

as a backs

aleak.

• If injure

hydrauli

Serious

hydraul

ngs, or hoses by using tapes, clamps, cements,

d by a concentrated high-pressure stream of

c fluid, seek medical attention immediately.

infection or toxic reaction can develop from

ic fluid piercing the skin.

ll hydraulic controls in Neutral before

all components in the hydraulic system

od condition and clean.

orn, cut, abraded, flattened, or crimped

el lines.

pt any makeshift repairs to the hydraulic

The hydraulic system operates under

high pressure. Such makeshift repairs will fail

nd create a hazardous and unsafe condition.

rhand and eyeprotectionwhen searching for

ssurehydraulic leak. Usea piece of cardboard

top instead of hands to isolate and identify

Safety

Figure 1.11: Checking Hydraulic Leaks

• Before

sure al

and co

Figure 1.12: Hydraulic Pressure Hazard

applying pressure to a hydraulic system, make

l components are tight and that steel lines, hoses,

uplings are in good condition.

Figure 1.13: Wear Safety Glasses

169254 6 Rev. D

Page 15

SAFETY

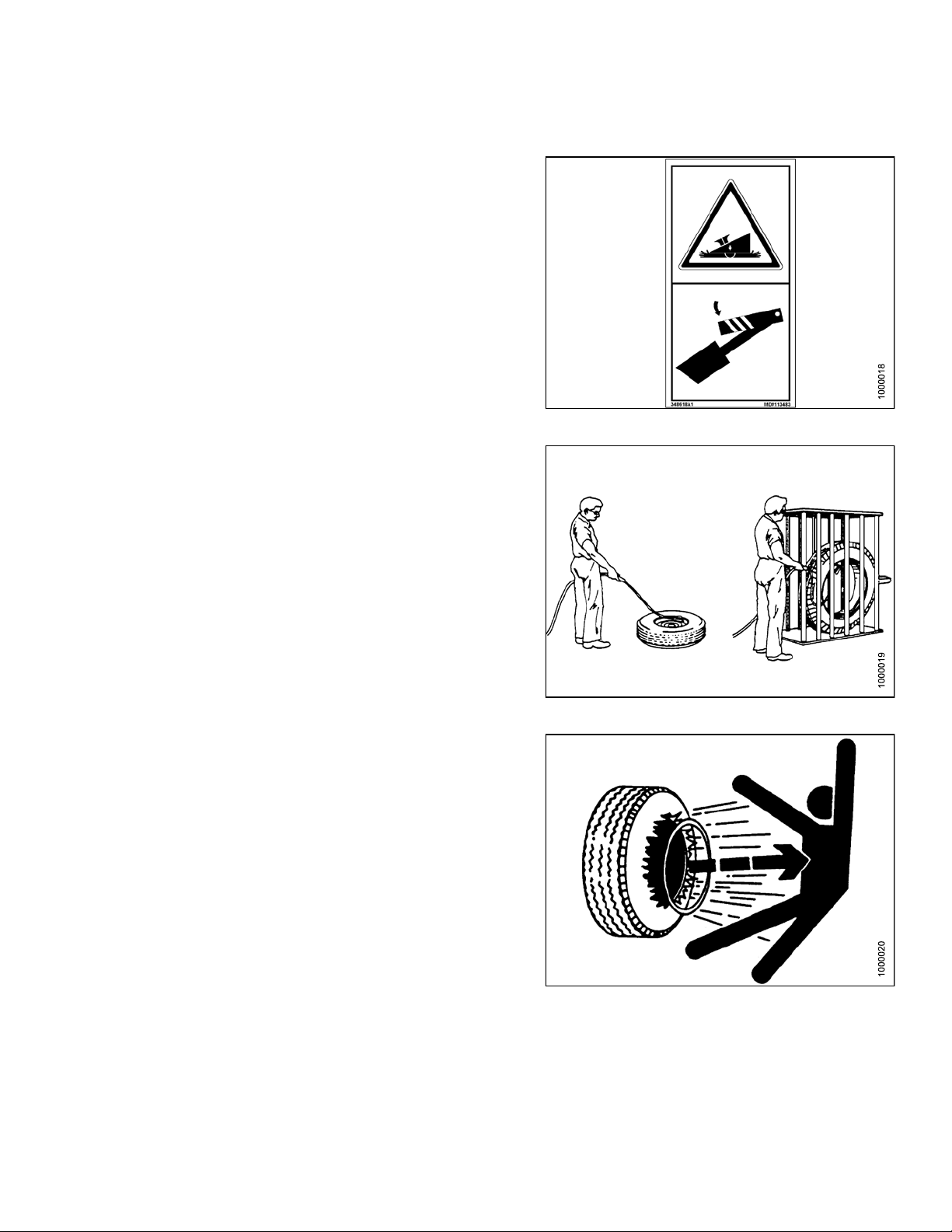

1.6 Tire Safet

• Failure to fol

on a wheel or ri

result in seri

•DoNOT atte

proper tra

low proper procedures when mounting a tire

m can produce an explosion that may

ous injury or death.

mpt to mount a tire unless you have the

ining and equipment.

y

Figure 1.14: Lower All Safety Stops

•Haveaq

ed tire maintenance.

requir

Figure 1.15: Safely Filling a Tire with Air

ualified tire dealer or repair service perform

Figure 1.16: Over-Inflation of Tire

169254

7

Rev. D

Page 16

SAFETY

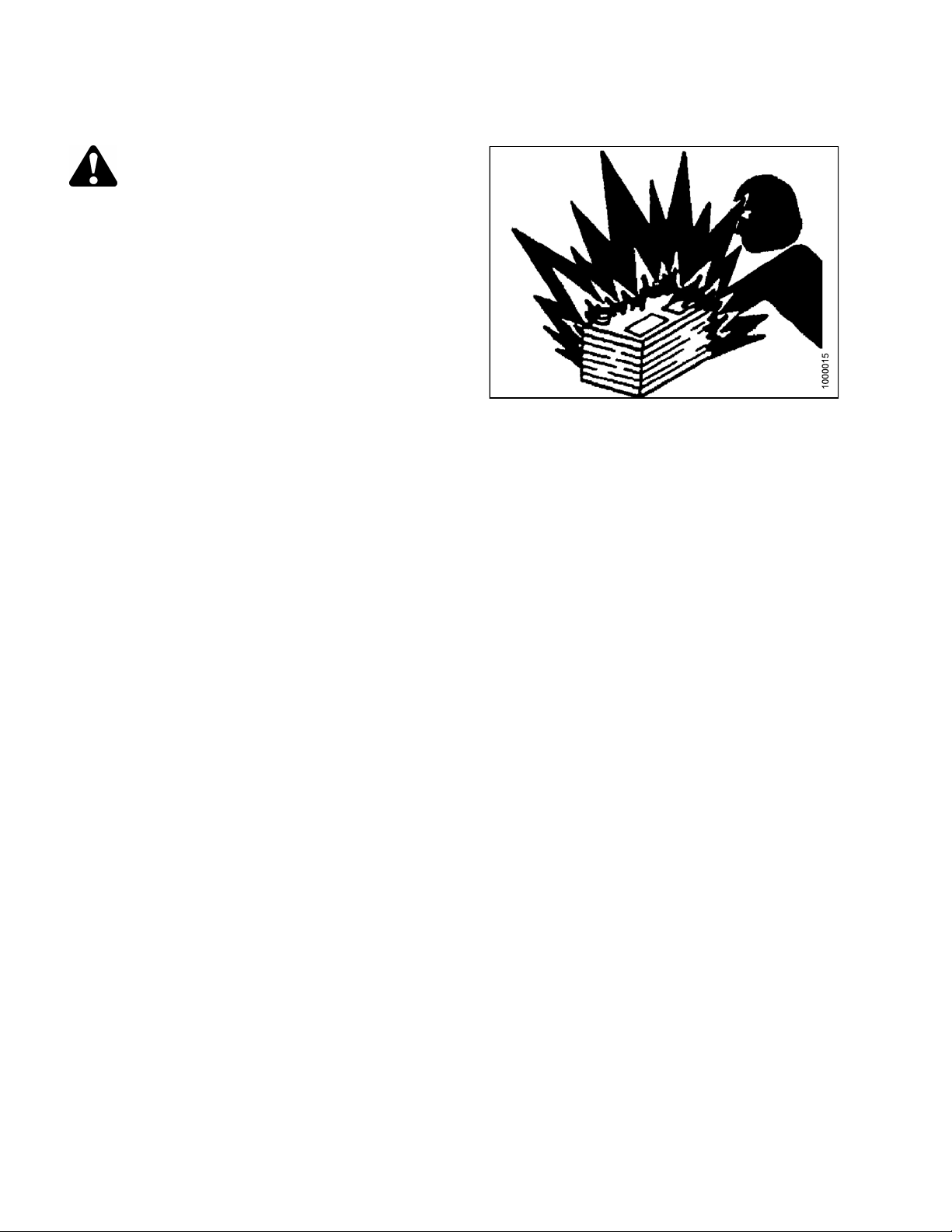

1.7 Battery Sa

WARNING

• Keep all spark

batteries, as

explosive.

•Ventilatewh

a gas given off by electrolyte is

en charging in enclosed space.

fety

sandflames away from the

Figure 1.17

169254 8 Rev. D

Page 17

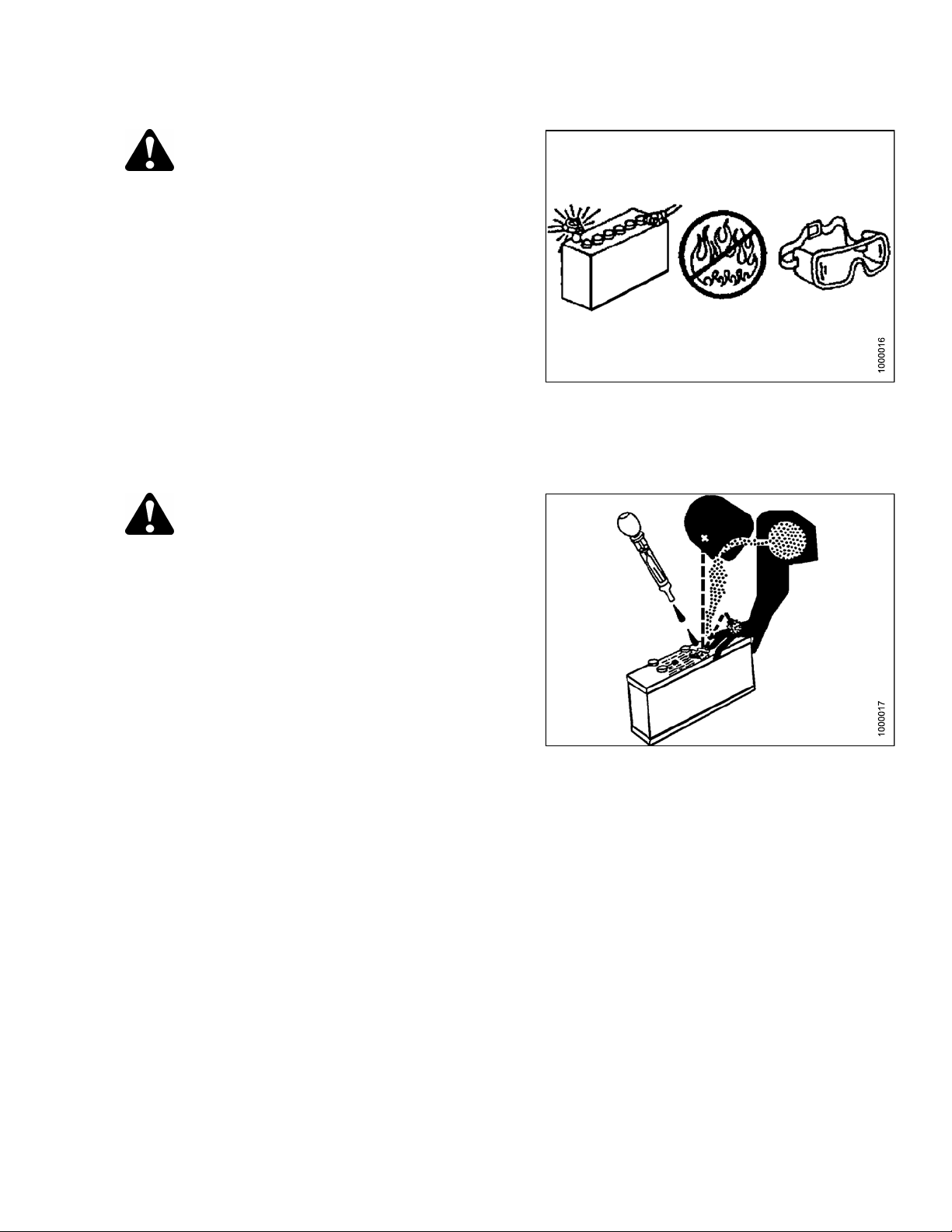

SAFETY

WARNING

• Wear safety glasses when working near

batteries.

• Do not tip batteries more than 45° to avoid

electrolyte loss.

• Battery electrolyte causes severe burns. Avoid

contact with skin, eyes, or clothing.

• Electrolyte splashed into the eyes is extremely

dangerous. Should this occur, force the eye

open, and floodwithcool,cleanwaterforfive

minutes. Call a doctor immediately.

• If electrolyte is spilled or splashed on clothing

or the body, neutralize it immediately with a

solution of baking soda and water, then rinse

with clear water.

Figure 1.18

WARNING

• To avoid injury from spark or short circuit,

disconnect battery ground cable before

servicing and part of electrical system.

• Do not operate the engine with alternator or

battery disconnected. With battery cables

disconnected and engine running, a high

voltage can be built up if terminals t ouch the

frame. Anyone touching the frame under these

conditions would be severely shocked.

• When working around storage batteries,

remember that all of the exposed metal parts

are live. Never lay a metal object across the

terminals because a spark or short circuit will

result.

• Keep batteries out of reach of children.

Figure 1.19

169254 9 Rev. D

Page 18

SAFETY

1.8 Welding Precautio n

High currents and voltage spikes associated with welding can cause damage to electronic components. Before

welding on any part of the windrower or an attached header, disconnect all electronic module harness connections

as well as the battery cables. Refer to your technical manual or MacDon Dealer for proper procedures.

169254 1

0

Rev. D

Page 19

SAFETY

1.9 Engine Saf

ety

WARNING

Do not use aerosol types of starting aids such as ether. Such use could result in an explosion and

personal injury.

CAUTION

• In the initial start-up of a new, serviced, or repaired engine always make provision to shut the

engine off, in order to stop an over-speed. This may be accomplished by shutting off the air and/or

fuel supply to the engine. Over-speed shut down should occur automatically for engines that are

controlled electronically.

• Do not bypass or disable the automatic shutoff circuits. The circuits are provided in order to help

prevent personal injury. The circuits are also provided in order to help prevent engine damage. See

the technical manual for repairs and adjustments.

• Inspect the engine for potential hazards.

• Before starting the engine, ensure that no one is on, underneath, or close to the engine. Ensure that

theareaisfreeofpersonnel.

• Allprotective guards and all protective covers m ust be installed if the engine must be started in order

to perform service procedures.

• To help prevent an accident that is caused by parts in rotation, work around the parts carefully.

• If a warning tag is attached to the engine start switch or to the controls, do NOT start the engine

or move the controls. Consult with the person who attached the warning tag before the engine is

started.

• Start the engine from the operator’s compartment. Always start the engine according to the

procedure that is described in the Engine Starting section of the operator’s manual. Knowing

the correct procedure will help to prevent major damage to the engine components and prevent

personal injury.

• To ensure that the jacket water heater (if equipped) and/or the lube oil heater (if equipped) is working

correctly, check the water temperature gauge and/or the oil temperature gauge during the heater

operation. Engine exhaust contains products of combustion which can be harmful to your health.

Always start the engine and operate the engine in a well ventilated area. If the engine is started in an

enclosed area, vent the engine exhaust to the outside.

NOTE: The engi

cold con

equipp

ne may be equipped with a device for cold starting. If the engine will be operated in very

ditions, then an additional cold starting aid may be required. Normally, the engine will be

ed with the correct type of starting aid for your region of operation.

1.9.1 High Pressure Rails

CAUTION

Contact with high pressure fuel may cause fluid penetration and burn hazards. High pressure fuel spray

may cause a fire hazard. Failure to follow these inspection, maintenance and service instructions may

cause personal injury or death.

169254

1

1

Rev. D

Page 20

SAFETY

1.9.2 Engine Electronics

WARNING

Tampering with the electronic system installation or the Original Equipment Manufacturer (OEM) wiring

installation can be dangerous and could result in personal injury or death and/or engine damage.

WARNING

Electrical Shock Hazard. The electronic unit injectors use DC voltage. The Electronic Control Module

(ECM) sends this voltage to the electronic unit injectors. Do not come in contact with the harness

connectorfor the electronic unit injectorswhilethe engine is operating. Failure to follow this instruction

could result in personal injury or death.

This engine has

the engine oper

initiate an im

The following

• Warning

• Derate

• Shutdown

The followin

• Engine Cool

• Engine Oil P

• Engine Spee

• Intake Man

The engine

the monito

will provi

mediate action.

actions are available for engine monitoring control:

g monitored en gine operating conditions have the ability to limit engine speed and/or the engine power:

ifold Air Temperature

monitoring package can vary for different engine models and different engine applications. However,

ring system and the engine monitoring control will be similar for all engines. Together, the two controls

de the engine monitoring function for the specific engine application.

a comprehensive, programmable engine monitoring system. The ECM has the ability to monitor

ating conditions. If any of the engine parameters extend outside an allowable range, the ECM will

ant Temperature

ressure

d

169254

2

1

Rev. D

Page 21

SAFETY

1.10 Safety Si

• Keep safety si

• Replace safet

become illegi

•Iforiginalp

replaced, be

safety sign.

• Safety sign

Parts Depar

ble.

arts on which a safety sign was installed are

sure the repair part also bears the current

s are available from your Dealer

tment.

gns

gns clean and legible at all times.

y signs that are missing or

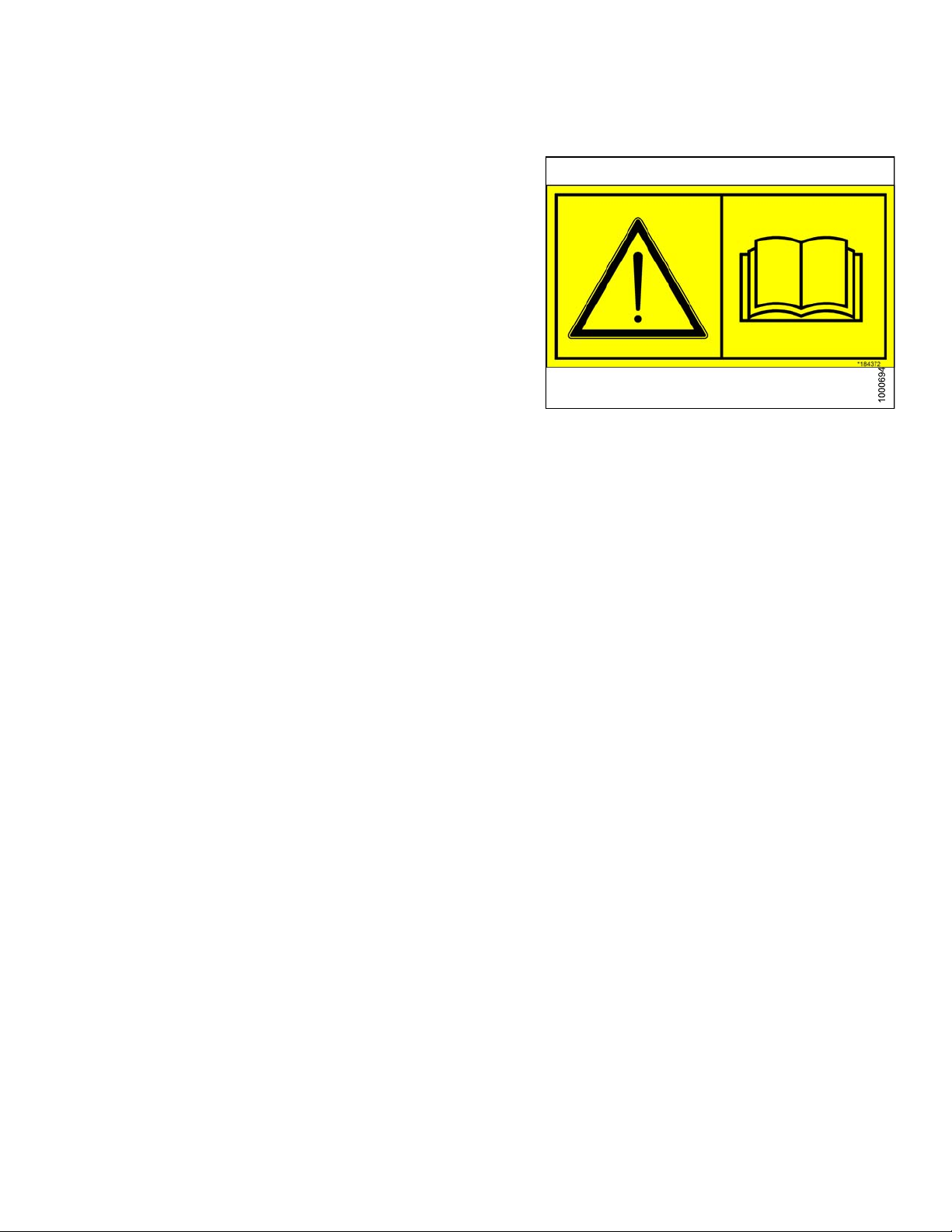

1.10.1 Installing Safety Decals

To install a safety decal, follow these steps:

1. Be sure the installation area is clean and dry.

Figure 1.20: Read Operator’s Manual before

Operating

2. Decide on the exact location before you remove the decal backing paper.

3. Remove the smaller portion of the split backing paper.

4. Place the sign in position and slowly peel back the remaining paper, smoothing the sign as it is applied.

5. Small air pockets can be smoothed out or pricked with a pin.

169254 1

3

Rev. D

Page 22

Page 23

2 General Information

2.1 Torque Specifications

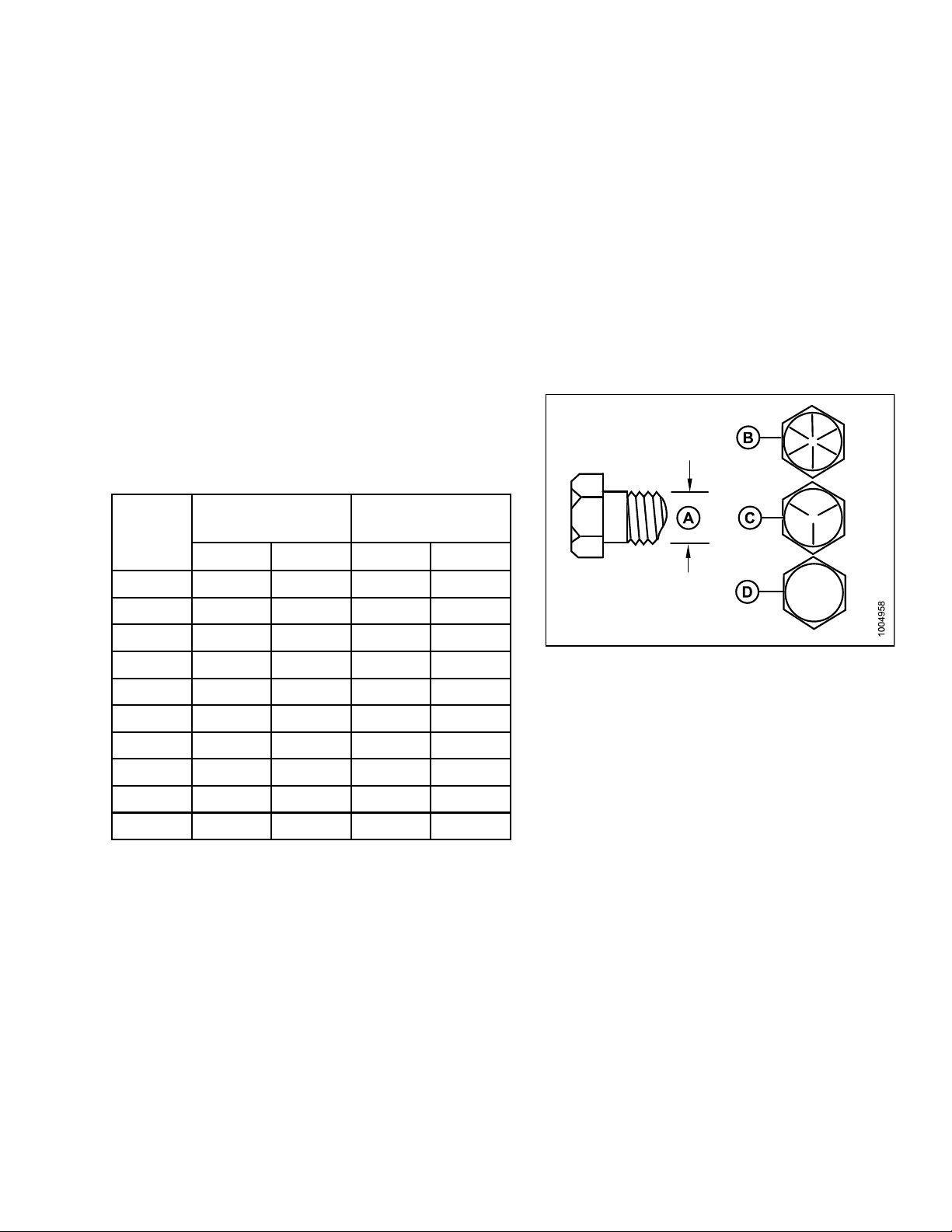

The following tables give correct torque values for various bolts, cap screws, and hydraulic fittings.

• Tighten all bolts to the torques specified in chart (unless otherwise noted throughout this manual).

• Replace hardware with the same strength and grade bolt.

• Check tightness of bolts periodically, using the tables below as a guide.

• Torque categories for bolts and cap screws are identified by their head markings.

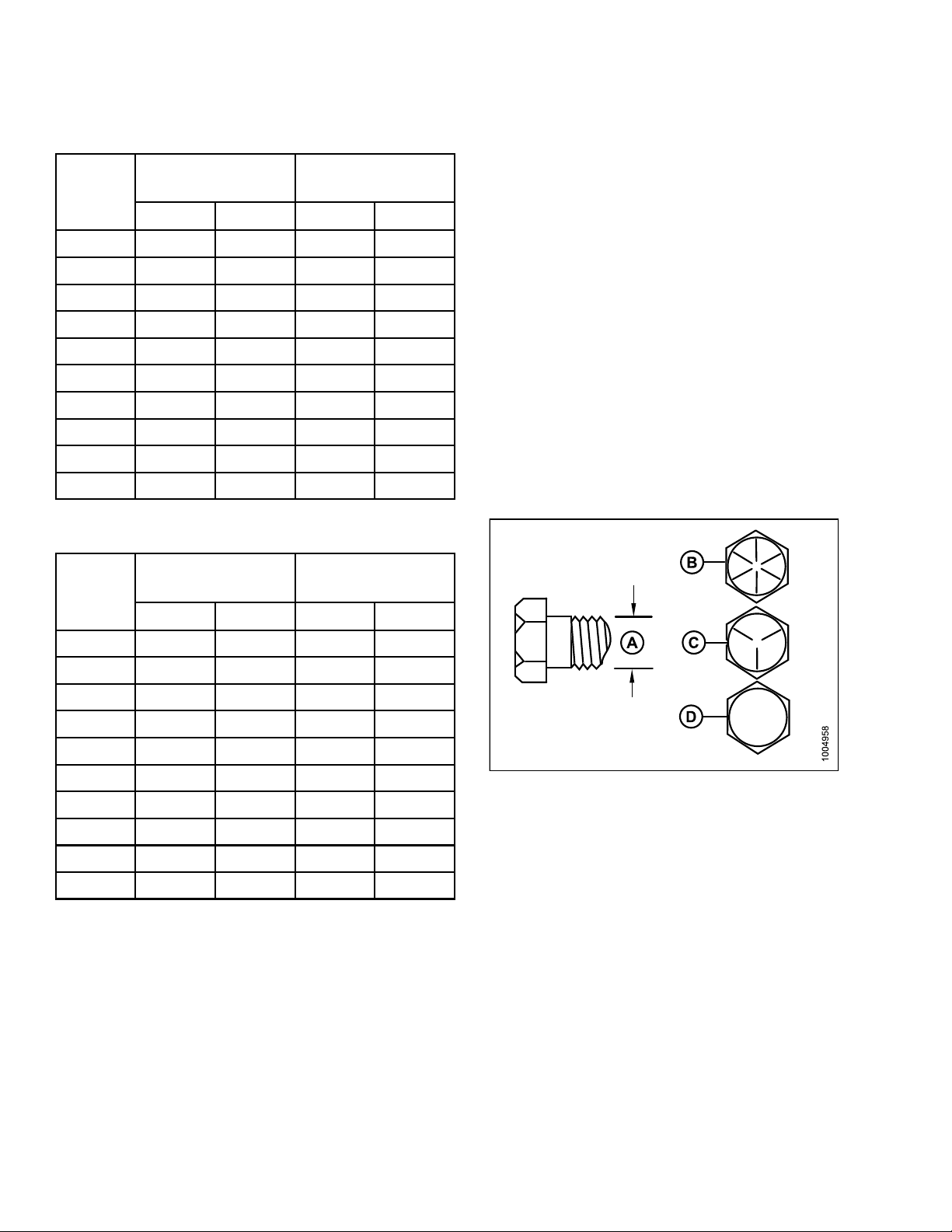

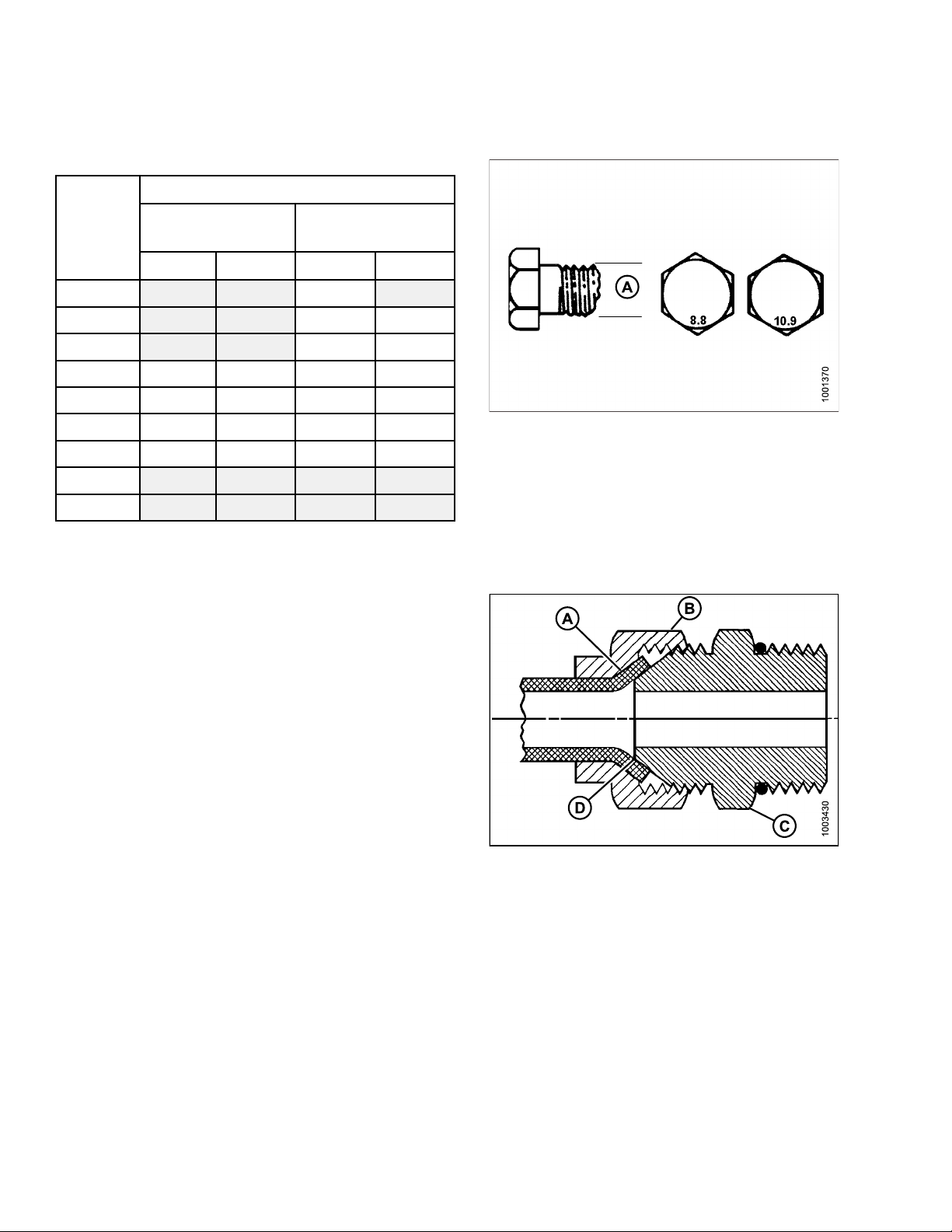

2.1.1 SAE Bolt Torque Specifications

Torque values shown inthistableare valid for non-greased,

ornon-oiledthreadsand heads. Therefore,doNOT grease

or oil bolts or cap screws unless otherwise specified in

this manual.

Table 2.1 SAE Grade 5 Bolt and Grade 5 Free Spinning

Nominal

Torque (ft·lbf)

(*in·lbf)

Torque (N·m)

Size (A)

Min. Max. Min. Max.

1/4-20 *106 *117

5/16-18 *218 *241

3/8-16

7/16-14

1/2-13

9/16-12

5/8-11

3/4-10

7/8-9

1-8 611 676 825 912

32 36 44 48

52

79 87 106 118

114 126 153 170

157 173 212 234

281 311 380 420

449 496 606 669

57

11.9 13.2

24.6 27.1

70

77

Figure 2.1

A-NominalSize B-SAE-8

5

C - SAE-

D - SAE-

2

169254 1

5

Rev. D

Page 24

GENERAL INFORMATION

Table 2.2 SAE Grade 5 Bolt and Grade 5 Distorted Thread Nut

Nominal

Torque (ft·lbf)

(*in·lbf)

Torque (N·m)

Size (A)

Min. Max. Min. Max.

1/4-20 *72 *80

5/16-18 *149 *164

3/8-16

7/16-14

1/2-13

9/16-12

5/8-11

3/4-10

7/8-9

1-8 459 507 619 684

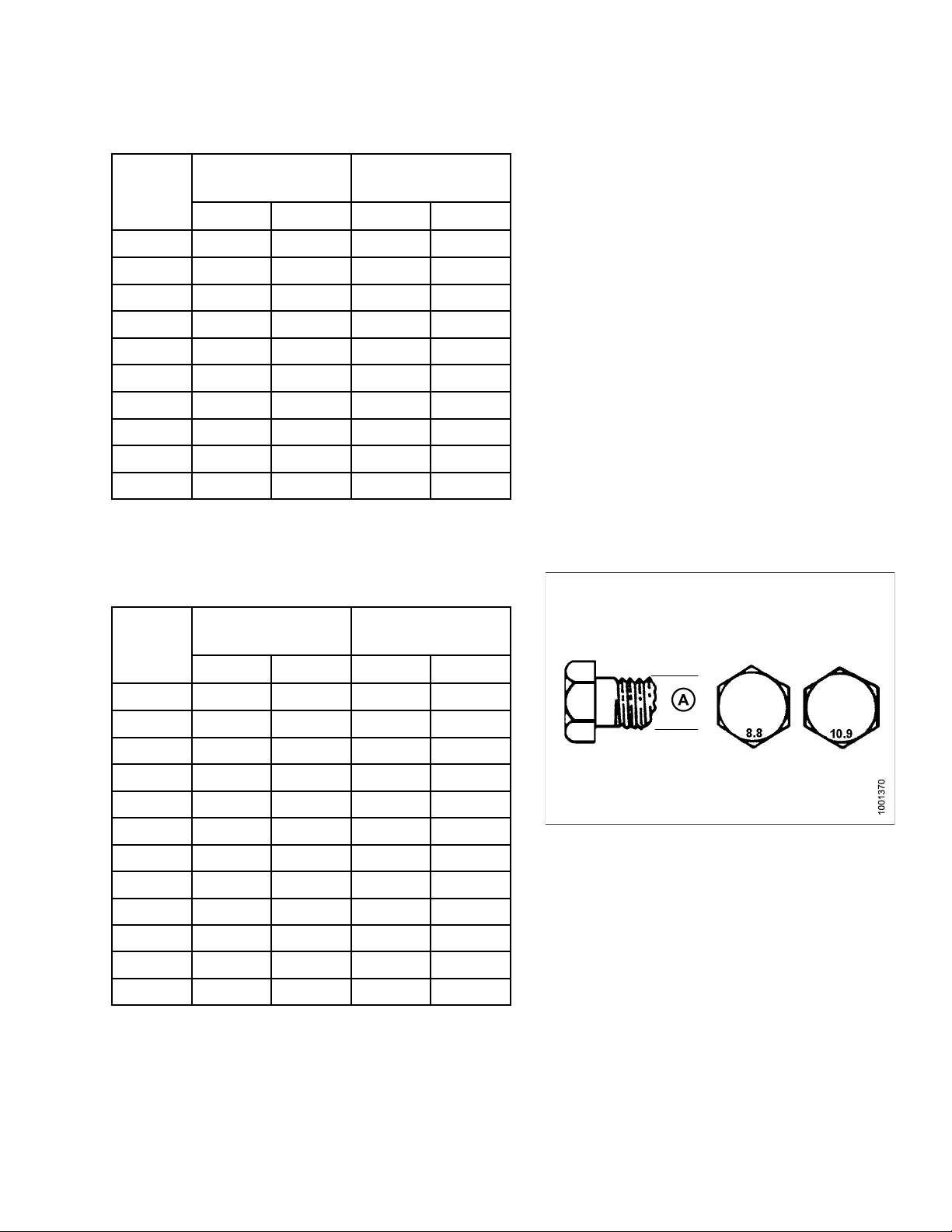

Table 2.3 SAE Grade 8 Bolt and Grade 8 Distorted Thread Nut

22 24 30 33

35 39 48 53

54 59 73 80

77

107 118 144 160

192 212 259 286

306 338 413 456

86 105 116

Torque (ft·lbf)

Nominal

(*in·lbf)

8.1 9

16.7 18.5

Torque (N·m)

Size (A)

Min. Max. Min. Max.

1/4-20 *150 *165

5/16-18

3/8-16

7/16-14

1/2-13

9/16-12

1

5/8-1

3/4-10

7/8-9

1-8 647 716 874 966

18 19 24 26

31 34 42 46

50

76 84 102 113

109 121 148 163

151 167 204 225

268 296 362 400

432 477 583 644

55

16.8 18.6

67 74

Figure 2.2

A-Nomina

C - SAE-5 D - SAE-2

lSize

B - SAE-8

169254 1

6

Rev. D

Page 25

GENERAL INFORMATION

Table 2.4 SAE Grade 8 Bolt and Grade 8 Free Spinning Nut

Nominal

Torque (ft·lbf)

(*in·lbf)

Torque (N·m)

Size (A)

Min. Max. Min. Max.

1/4-20 *150 *165

5/16-18

3/8-16

7/16-14

1/2-13

9/16-12

5/8-11

3/4-10

7/8-9

1-8 863 954 1165 1288

26 28 35 38

46 50 61 68

73 81 98 109

111 123 150 166

160 177 217 239

221 345 299 330

393 435 531 587

633 700 855 945

16.8 18.6

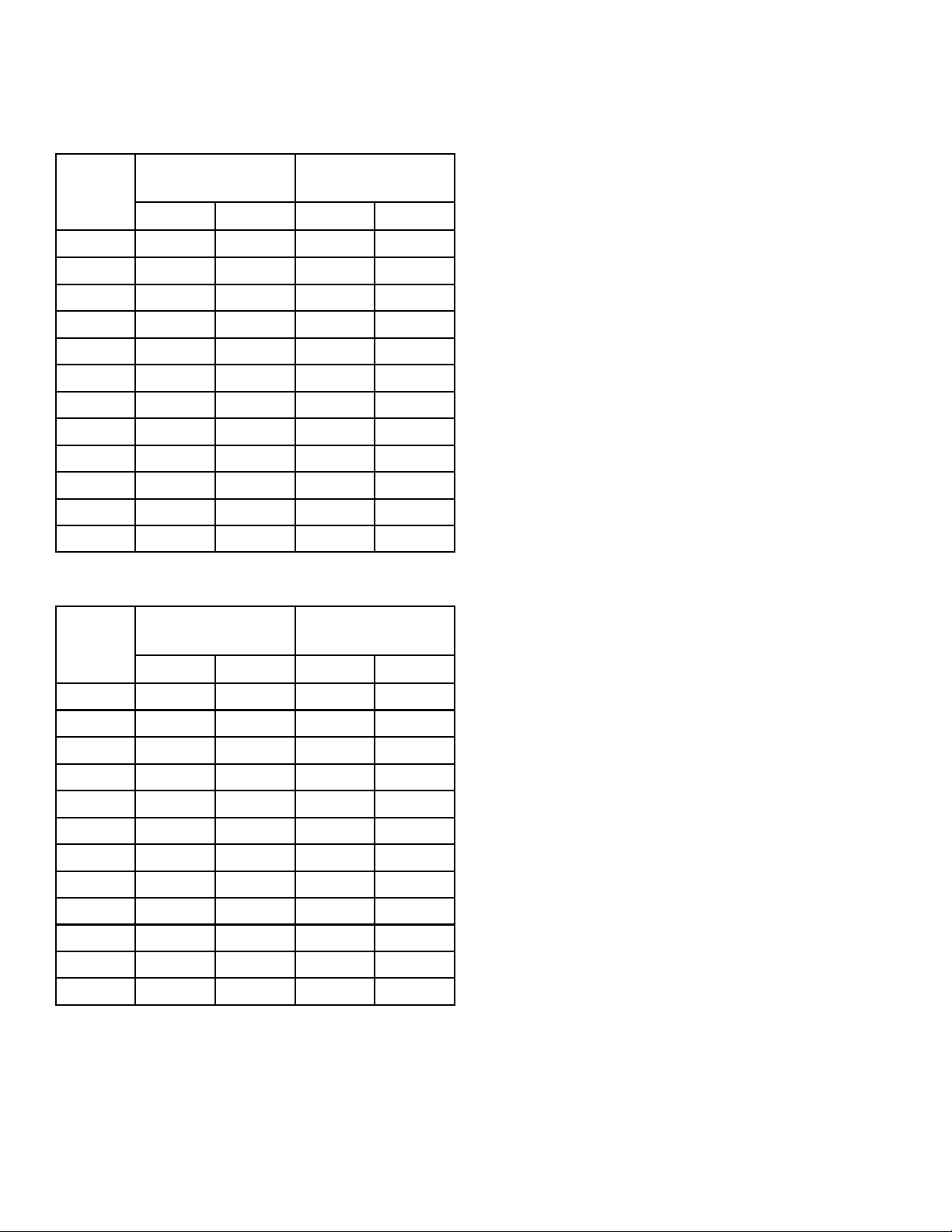

2.1.2 Metric Bolt Specifications

Table2.5MetricClass8.8BoltsandClass9Free Spinning Nut

Nominal

Size

Torque (ft·

(*in·lbf)

Min. Max. Min. Max.

lbf)

Torque (N·

m)

3-0.5

3.5-0.6

4-0.7

5-0.8

6-1.0

8-1.25 20 23 28 30

5

10-1.

12-1.75 70 78 95 105

14-2.0 113 124 152 168

.0

16-2

20-2.5 341 377 460 509

24-3.0 589 651 796 879

*13 *14

*20 *22

*29 *32

*59 *66

*101 *112

40 45

175 193 236 261

1.4 1.6

2.2 2.5

3.3 3.7

6.7 7.4

11.4 12.6

55

60

Figure 2.3

A-NominalSize

169254

7

1

Rev. D

Page 26

GENERAL INFORMATION

Table2.6MetricClass8.8BoltsandClass9Distorted Thread Nut

Nominal

Torque (ft·lbf)

(*in·lbf)

Torque (N·m)

Size

Min. Max. Min. Max.

3-0.5

3.5-0.6

4-0.7

5-0.8

6-1.0

8-1.25

10-1.5 28 30 37 41

12-1.7548536572

14-2.0

16-2.0 119 132 161 178

20-2.5 233 257 314 347

24-3.0 402 444 543 600

Table 2.7 Metric Class 10.9 Bolts and Class 10 Free Spinning Nut

Nominal

*9 *10

*14 *15

*20 *22

*40 *45

*69 *76

*167 *185

77

Torque (ft·

85 104 115

lbf)

(*in·lbf)

11.1

1.5 1.7

2.3 2.5

4.5

7.7

18.8 20.8

Torque (N·m

5

8.6

)

Size

Min. Max. Min. Max.

3-0.5

3.5-0.6

4-0.7

5-0.8

6-1.0

8-1.25 28 31 38 42

5

10-1.

12-1.75 97 108 132 145

14-2.0 156 172 210 232

.0

16-2

20-2.5 472 521 637 704

24-3.0 815 901 1101 1217

*18 *19

*27 *30

*41 *45

*82 *91

*140 *154

56 62

242 267 326 360

1.8 2

2.8 3.1

4.2 4.6

8.4 9.3

14.3 15.8

75

83

169254 1

8

Rev. D

Page 27

GENERAL INFORMATION

Table 2.8 Metric Class 10.9 Bolts and Class 10 Distorted Thread Nut

Nominal

Size

Torque

(ft·lbf)(*in·lbf)

Min. Max. Min. Max.

Torque (N·m)

3-0.5

3.5-0.6

4-0.7

5-0.8

6-1.0

8-1.25 19 21 26 29

10-1.5 38 42 51

12-1.7566739099

14-2.0 106 117 143 158

16-2.0 165 182 222 246

20-2.5 322 356 434 480

0

24-3.

*12 *13

*19 *21

*28 *31

*56 *62

*95 *105

556 614 750 829

1.3 1.5

2.1 2.3

3.1 3.4

6.3

10.7 11.8

7

57

169254 1

9

Rev. D

Page 28

GENERAL INFORMATION

2.1.3 Metric Bolt Specifications Bolting into Cast Aluminum

Table 2.9 Metric Bolt Bolting into Cast Alu minum

Bolt Torque

Nominal

Size

8.8

(Cast Alumin

um)

(Cast Alumin

10.9

um)

ft·lbf N·m ft·lbf N·m

M3 1

M4 2.6 4

M5

M6 6 9 9 12

M8 14 20 20 28

M10 28 40 40

M12 52 70 73 100

M14

M16

5.5

8

55

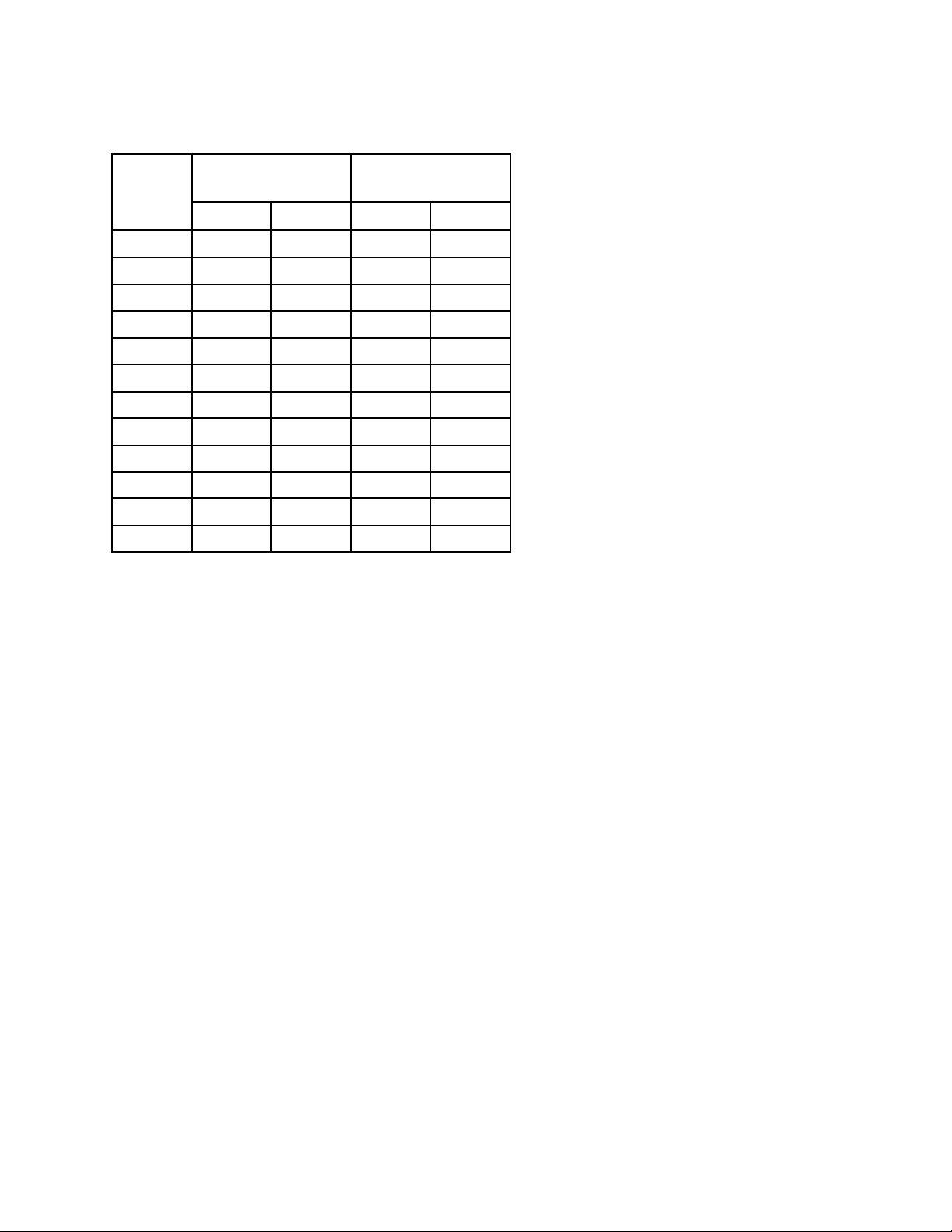

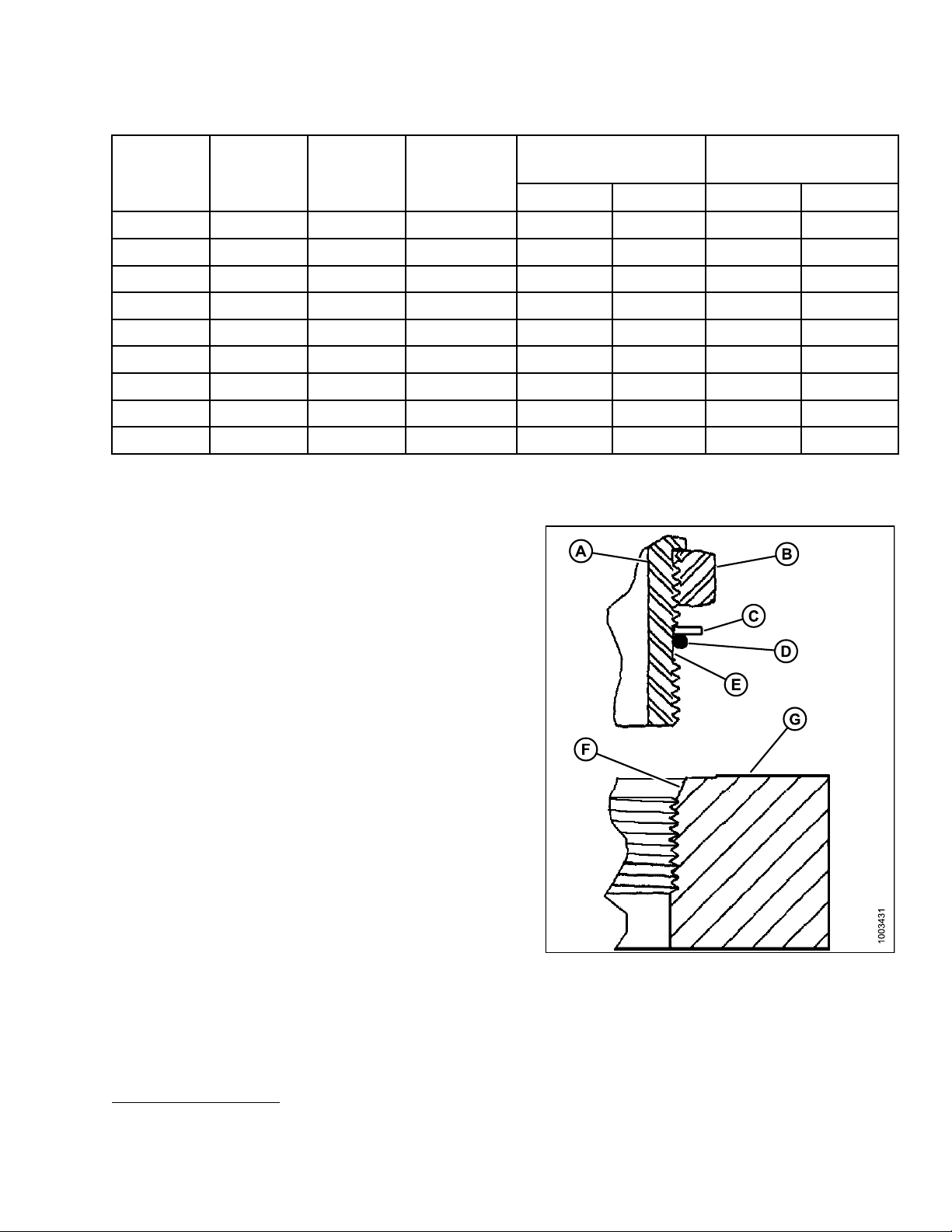

2.1.4 Flare-Type Hydraulic Fittings

1. Check flare and flare seat for defects that might

cause leakage.

2. Align tube with fitting before tightening.

Figure 2.4

A-NominalSize

3. Lubricate connection and hand-tighten swivel nut

until snug.

4. To prevent twisting the tube(s), use two wrenches.

Place one wrench on the connector body and with the

second, tighten the swivel nut to the torque shown.

Figure 2.5

A - Flare B - Nut

C - Flareseat

D - Body

169254 2

0

Rev. D

Page 29

GENERAL INFORMATION

Table 2.10 Flare-Type Hydraulic Tube Fittings

Nut Size

Across

Flats (in.)

SAE No.

Tube Size

O.D. (in.)

Thread

Size (in.)

Torque Value

ft·lbf

1

Flats From Finger

Tight (FFFT)

N·m Flats Turns

3

4 1/4 7/16 9/16 9 12 1 1/6

5

6

8 1/2 3/4 7/8 34 46 1 1/6

10

12

14 7/8 1-3/8 1-3/8 90 122 3/4 1/8

16 1

3/16 3/8 7/16

5/16 1/2 5/8

3/8 9/16 11/16

5/8 7/8

3/41-1/161-1/4

1-5/16 1-1/2

146621

681

12 16 1

18 24 1

75

105 142

102

3/4 1/8

3/4 1/8

2.1.5 O-Ring Boss (ORB) Hydraulic Fittings

1. Inspect O-ring (D) and seat (F)for dirt or obvious

defects.

2. On angle fittings, back off the lock nut (B) until washer

(C) bottoms out at top of groove (E) in fitting (A).

3. Hand-tighten fitting until back up washer (C) or washer

face (if straight fitting) bottoms on part face (G) and

O-ring is seated.

1/6

1/6

1/6

1/6

4. Position angle fittingsby unscrewing NO MORE THAN

one turn.

5. Tighten straight fittings to torque shown.

6. Tighten angle fittings to torque shown in table 2.11

O-Ring Boss (ORB) Hydraulic Fittings (Adjustable),

page 22, while hold ing body of fitting with a wrench.

Figure 2.6

A - Fitting B - Lock Nut

D - O-Ring E - Groove F - Seat

1. Torque values shown are based on lubricated connections as in reassembly.

C - Washer

169254

1

2

Rev. D

Page 30

GENERAL INFORMATION

Table 2.11 O-Ring Boss (ORB) Hydraulic Fittings (Adjustable )

SAE No.

Thread

Size (in.)

Nut Size Across

Flats (in.)

Torque Value

ft·lbf N·m Flats Turns

2

Flats From Finger Tight (FFFT)

3

3

4

5

6

8

10

12

16

20

24

3/8 1/2

7/16 9/16

1/2 5/8

9/16 11/16

3/4 7/8

7/8

1-1/16 1-1/4

1-5/16 1-1/2

1-5/8 1-7/8

1-7/8 2-1/8

14662

68 2

912 2

12 16 2

18 24 2

34 46 2

75

105 142

140 190

160 217

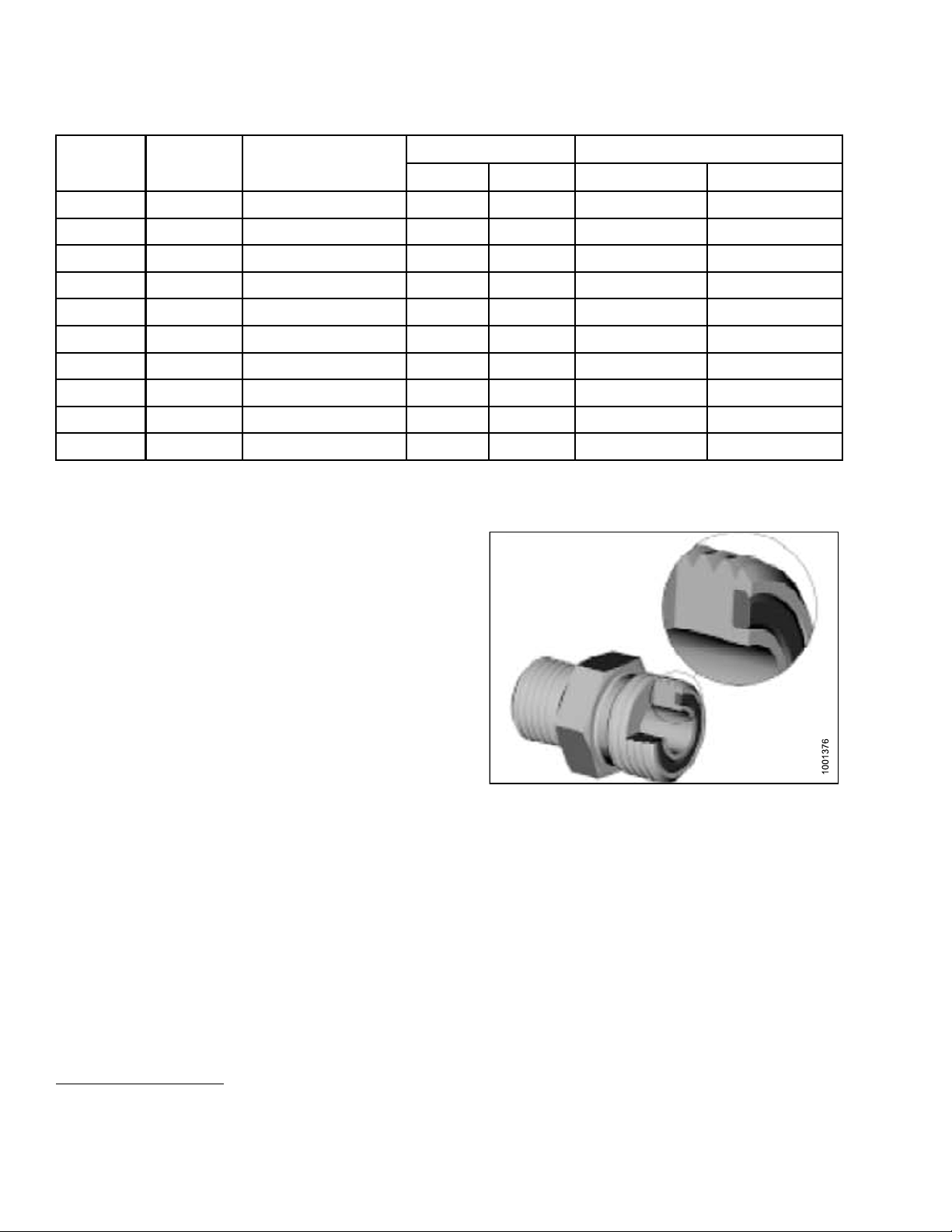

2.1.6 O-Ring Face Seal (ORFS) Hydraulic Fittings

1. Check components to ensure that the sealing surfaces

and fitting threads are free of burrs, nicks, and

scratches or any foreign material.

1-1/2 1/4

102 1

3/4 1/8

3/4 1/8

1/2 1/12

1/3

1/3

1/3

1/3

1/3

1/6

gure 2.7

Fi

2. Torque values shown are based on lubricated connections as in reassembly.

3. Always default to the torque value for evaluation of adequate torque.

169254

2

2

Rev. D

Page 31

GENERAL INFORMATION

2. Apply hydraulic system oil to the O-ring.

3. Align the tube or hose assembly. Ensure that flat face

of the mating flange comes in full contact with O-ring.

4. Thread tube or hose nut until hand-tight. The nut

should turn freely until it is bottomed out.

5. Torque fittingfurthertoagiventorquevalueintable

2.12 O-Ring Face Seal (ORFS) Hydraulic Fittings,

page 23.

NOTE: If applicable, always hold the hex on the

fitting body to prevent unwanted rotation

of fitting body and hose when tightening

the fitting nut.

6. When assembling unions or two hoses together, three

wrenches will be required.

7. Check the final condition of the fitting.

Table 2.12 O-Ring Face Seal (ORFS) Hydraulic Fittings

SAE

No.

3

Thread

Size (in.)

6

Tube O.D.

(in.)

3/16

Torque Value

ft·lbf

––––

Figure 2.8

A - Brazed Sleeve B - O-Ring

C-TwoPiec

E - Fitting Body

e Sleeve

4

D-Nut

Flats From Finger Tight

(FFFT)

N·m Tube Nuts

5

Swivel &

Hose

4 9/16 1/4 11–12 14–16 1/4–1/2 1/2–3/4

5

6

6

5/16

11/16 3/8

8 13/16 1/2 32–35 43–47

10 1

12

1-3/16 3/4

5/8

––––

18–20 24–27

1/2–3/4

45–51 60–68

67–71 90–95

1/4–1/2

14 1-3/16 7/8 67–71 90–95

16

20

1-7/16

1-11/16 1-1/4

24 2 1-1/2 148–16

32

2-1/2

1 93–100 125–135

126–141 170–190

7

2

––––

200–22

1/3–1/2

5

4. Torquevaluesandanglesshownarebasedonlubricated connection, as in reassembly.

5. Always default to the torque value fo r evaluation of adequate torque.

6. O-ring face seal type end not defined for this tube size.

169254 2

3

Rev. D

Page 32

GENERAL INFORMATION

2.2 Specificat

NOTE: Specifications and design are subject to change without notice or obligation to revise previously

sold units.

ions

Item Specification

Frame & Structure

Total Weight (estimated) 1700 lb (770 kg)

Carrier MacDon M150, M155, and M200 Self-Propelled Windrowers

Manual Storage In Windrower Cab

Drives

Main Conditioner 3.16 cu in. (51.83 cc) Hydraulic Motor with 1.29 cu in. (21.14 cc) Flow

Divider

Feed Deck

Connections Flat Faced Quick Attach Couplers – Connect Under Pressure

Normal

Operating

Pressure

Conditioner

Drive

Conditioner 2500-3000 psi (17.0–20.7 MPa)

Feed Deck

4.0 c u in. (65 cc) Hydraulic Motor with 921 psi Relief

600 psi (4.1 MPa)

Hydraulic Motor To Belt Driven Roll To Open Timing Gear System

Roll Type

Roll Diameter

Roll Length

Header Size 15 ft 20 ft & 25 ft 30 ft 35 ft

Roll Speed

Feed Draper Speed 437–553 fpm 407–495 fpm 393–525 fpm 393–491 fpm

Swath Width 36-102 in. (915-2,540 mm)

Forming Shields Header Mounted Tractor Supported Adjustable Forming Shield System

NOTE: To avoid excessive vibration and poor performance, the HC10 Hay Conditioner should not be

attached to single-knife drive headers.

Intermeshing Steel Bars

9.17 in. (233 mm)/6.63 in. (168.4 mm) OD Tube

72 in. (1830 mm)

772–977 rpm 720–874 rpm 695–927 rpm 695–868 rpm

169254

4

2

Rev. D

Page 33

GENERAL INFORMATION

2.3 Conversio

Quantity

Area

Flow

Force

Length

Power horsepower hp x 0.7457 = kilowatts kW

Pressure

Torque

nChart

Inch-Pound Units

Unit Name Abbreviation

acres acres

US gallons per

minute

pounds force lbf

inch in. x 25.4 = millimeters

foot ft.

pounds per

square inch

pound feet or

foot pounds

pound inches or

inch pounds

gpm

psi

ft·lbf

in·lbf

Factor

x 0.4047 = hectares ha

x 3.7854 = liters per minute

x 4.4482 = Newtons N

x0.305=

x 6.8948 = kilopascals kPa

x .00689 = megapascals MPa

÷ 14.50

x 1.3558 =

x 0.1129 =

38 =

SI Units (Metric)

Unit Name Abbreviation

meters

bar (non-SI) bar

newton meters

newton meters

L/min

mm

m

N·m

N·m

Temperature

Velocity

olume

V

Weight pounds lbs x 0.4536 = kilograms kg

degrees

fahrenheit

feet per minute ft/min

feet per second ft/s

miles per hour mph x 1.6063 =

US gallons US gal

ounces oz.

cubic inches in.

˚F(˚F-32) x 0.56 =

x 0.3048 =

x 0.3048 =

x 3.7854 = liters L

x 29.5735 = milliliters ml

3

x 16.3871 =

Celsius

meters per

minute

meters per

second

kilometres per

hour

cubic

centimetres

m/min

km/h

cm

˚C

m/s

3

or cc

169254 2

5

Rev. D

Page 34

GENERAL INFORMATION

2.4 Component

Identification

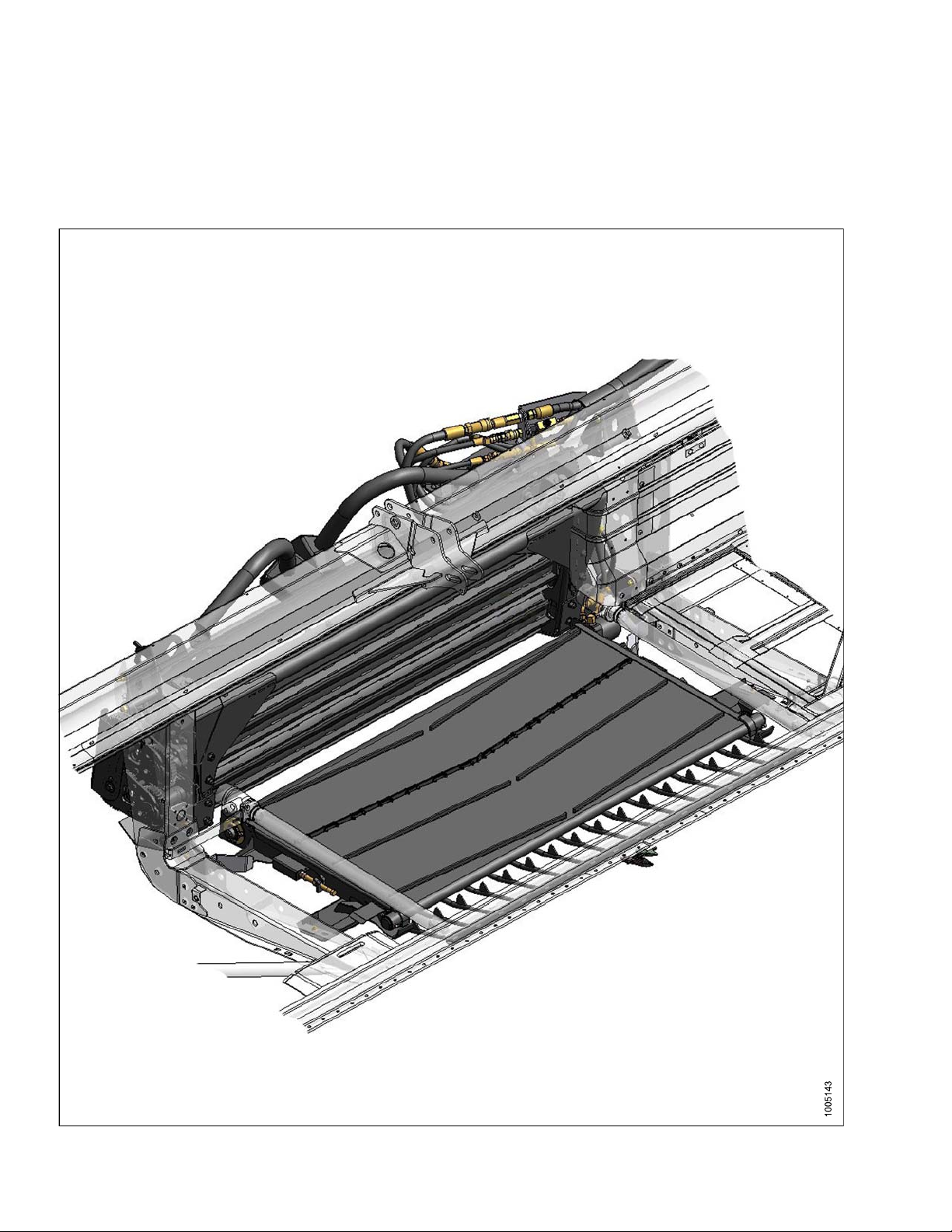

Figure 2.9: Back View of Hay Conditioner Installed in Header

A - Hydraulics To Header

g Gears

E-Timin

B - Lift Arms C - Roll Timing Tool D - Stand

F - L-Pins

G-Hydra

ulic Motor

169254 2

6

Rev. D

Page 35

GENERAL INFORMATION

Figure 2.10: Back View of Hay Conditioner Installed in Header

A - Spacer

E - Spacer

B - Mounti

F-Rolls

ng Bracket

C-LiftingLugs

G - Drive Belt Shield

D - Mounti

ng Bracket

re 2.11: Front View of Hay Conditioner Installed in Header

Figu

A - Mounting Bracket

E - Rock Grate

169254

B - Roll Gap Adjusters C - Feed Deck Motor

F - Feed Deck

G - Draper Tension Adjusters (2)

7

2

D - Mounting Bracket

Rev. D

Page 36

GENERAL INFORMATION

Figure 2.12: Swath Forming Shield

A-SideDeflector Adjusters B - Side Deflectors C - Height Adjust Strap D - Fluffer Shield

E-Deflector Fins

169254 2

8

Rev. D

Page 37

3 Unloading and Assembly

To unload and assemble an HC10 Hay Conditioner, follow each of the procedures in this chapter in order.

3.1 Unloading the Hay Conditioner

CAUTION

To avoid injury to bystanders from being struck

by machinery, do not allow people to stand in

unloading area.

CAUTION

Equipment used for unloading must meet or

exceed the requirements specifie d below. Using

inadequate equipment may result in vehicle

tipping or machine damage.

Lifting Vehicle

Minimum Lifting

Capacity

Minimum Fork Length

7

2000 lb (908 kg)

60 inches (1524 mm)

IMPORTANT

Forklifts are normally rated for a load located 24

inches (610 mm) ahead of back end of the forks.

To obtain the forklift capacity at 48 inches (1220

mm), check with your forklift distributor.

WARNING

Be sure forks are secure before moving away from

load. Stand clear when lifting.

Figure 3.1: Hay Conditioner Bundle #4798

Figure 3.2: Feed Deck Bundle #4799

7. At 48 inches (1220 mm) from back end of forks.

169254 2

9

Rev. D

Page 38

UNLOADING AND ASSEMBLY

To unload the hay conditioner, follow these steps:

1. Remove hauler's tie down straps and chains.

2. Use forklift to lift each of the three pallets of hay

conditioner components off of the trailer deck.

3. Back up until unit clears trailer and slowly lower to 6

inches (150 mm) from ground.

4. Take to storage or set-up area.

5. Set pallet down securely on level ground.

6. Check for shipping damage and missing parts.

Figure 3.3: Forming Shield Bundle #4800

169254 3

0

Rev. D

Page 39

UNLOADING AND ASSEMBLY

3.2 Preparing the Header

To prepare the draper header for installation of the hay

conditioner, follow these steps:

1. Adjust the header stand (A) to mid-position.

2. Trim poly deflector along creased line (A) on back of

poly for proper fit up to conditioner.

Figure 3.4

Figure 3

.5

169254 3

1

Rev. D

Page 40

UNLOADING AND ASSEMBLY

3.3 Installin

To install the

1. Unpa ck feed de

2. Pos ition roc

3. Lift rock grate(A), and position the rear tabs (C) so they

slide over the header leg flanges.

4. Position the front lip (B) of rock grate (A) in front of the

bottom edge of the cutterbar, and slide forward so it

engages the cutterbar.

5. If the header is equipped with cutterbar poly, set the

rock grate on top of the poly in front of the cutterbar,

then push down, and forward to seat the rock grate

onto the cutte rbar.

6. Ensure ro ck grate is p ushed fully forward, and secure

with two bolts installed from underside. Tighten bolts.

g the Rock Grate

rock grate, follow these steps:

ck / rock grate bundle.

k grate into center area of header.

Figure 3.6

169254 3

2

Figure 3.7

Rev. D

Page 41

UNLOADING AND ASSEMBLY

3.4 Installing Deck Brackets

To install the deck brackets onto the header, follow

these steps:

1. Install thetwo lower brackets(A) onto the inside ofboth

center header legs with two bolts and nuts (B) in each

bracket.

2. Install right-hand upper bracket (A) and spacer (B) on

the right-hand center leg as shown and install nut (C).

Figure 3.8

NOTE:

3. Install t

and secur

4. Tighten b

5. Install the left-hand upper bracket (A) and spacer (B)

onto the inboard side of left-hand center leg as shown.

For header

cover,ins

he other bolt through the bracket and spacer

ewithanut(D).

oth bolts.

s with a sheet metal hose

tallbolts from theoutboard side.

Figure 3

.9: 15 ft Header Shown

169254 3

re 3.10

Figu

3

Rev. D

Page 42

UNLOADING AND ASSEMBLY

6. Remove the hose guide (A) located near the left-hand

center leg. (For 20 ft. and larger headers, remove this

support from its mounting position on sheet metal hose

cover.)

7. Attach hose assembly (A) onto the left-hand center leg

and install nut on lower bolt (C). Ensure correct hole is

used when attaching hose assembly (use hole (D) for

15-foot headers).

NOTE:

8. Instal

assemb

9. Tighte

For head

cover, i

l other bolt (B) through bracket, spacer, and hose

ly and secure with a nut.

n both bolts.

ers with a sheet metal hose

nstallbolts from the outboard side.

Figure 3.

Figur

A - Hose Assembly B - Bolt

C - Mounting Position for 20–35-Foot Headers

D - Mounting Position for 15-Foot Headers

11: 15 ft Header Shown

e 3.12: 20–35 ft Header Shown

169254 3

4

Rev. D

Page 43

UNLOADING AND ASSEMBLY

3.5 Installing the Feed Deck

To install the feed deck, follow these steps:

1. Slide feed deck (A) under header opening from the

rear. Deck drive motor faces aft.

2. Set front of deck (A) onto the rock grate and slide the

feed deck forward until the locating pins (B) reach the

pockets on the rock grate.

3. Lift the rear of the feed deck so the mounts on the

deck clear the brackets on the leg and slide deck

forward until mounting pins are fully positioned inside

the pockets.

Figure 3.13

4. Install two 1/2 x 1.25 in. long carriage bolts at rear

mounting brackets.

Figure 3

Figu

.14

re 3.15: LH Side Shown

169254 3

5

Rev. D

Page 44

UNLOADING AND ASSEMBLY

Figure 3.16: RH Side Shown

5. Attach the

with two 3/

6. Adjust hea

2-1/2 to 3

manual fo

hose bracket (A) to the mounting bracket

8 x 1.0 in. long carriage bolts (B).

der side drapers to overlap feed deck by

inches(65 to 75 mm). See header operator’s

rprocedure.

Figure 3.17

169254 3

6

Rev. D

Page 45

UNLOADING AND ASSEMBLY

3.6 Installin

Therearetwom

• The lifting me

• The tractor m

3.6.1 Instal

g the Conditioner

ethods for installing th e conditioner:

thod

ethod

ling Conditioner: Lifting Method

CAUTION

Equipment used for unloading must meet or

exceed the requirements specifie d below. Using

inadequate equipment may result in vehicle

tipping or machine damage.

Lifting Vehicle

Minimum Lifting

Capacity

Minimum Fork Length

8

2000 lb (908 kg)

60 inches (1524 mm)

IMPORTANT

Forklifts are normally rated for a load located 24

inches (610 mm) ahead of back end of the forks.

To obtain the forklift capacity at 48 inches (1220

mm), check with your forklift distributor.

Chain Type Overhead L

Quality (

Minimum Working Load

To install the conditioner using the lifting method, follow

these steps:

1. Attach chain to lifting brackets (A) on conditioner, and

secure chain to lifting device (B).

2. Lift conditioner to upright position.

3. Remove shipping blocks if present.

4. Position conditioner into header opening from the rear.

5000 lb (2270 kg)

ifting

1/2 inch)

Figure 3.18

8. At 48 inches (1220 mm) from back end of forks.

169254 3

7

Rev. D

Page 46

UNLOADING AND ASSEMBLY

5. Carefully lower the windrower lift legs until lugs (A) on

conditioner are seated in the U-shaped brackets (B)

on header.

6. Ensure the conditioner is seated properly in the

brackets, and then remove the chains.

7. Install 5/8 in. x 1-1/2 in. carriage bolt (A) in th e

right-hand lower attachment location.

Figure 3.19

8. Install 5/8 in. x 1-1/2 in. carriage bolt (A) in th e

left-hand lower attachment location.

Figure 3.20: RH Side Shown

Figure 3.21: LH Side Shown

169254 3

8

Rev. D

Page 47

UNLOADING AND ASSEMBLY

9. Reconnect the five hydraulic hoses between the

conditioner and the header as follows:

• Small male quick-disconnect from motor to

header (A)

• Large female quick-disconnect from motor to

header (B)

• Small female quick-disconnect from deck to

header (C)

• Small female quick-disconnect from motor to

deck (D)

• Large female quick-disconnect from header to

motor (E)

3.6.2 Installing Conditioner: Windrower Method

Figure 3.22

A - Case Drain B - Cond itioner Motor Pressure

C - Deck Moto

E - Conditioner Motor Return

rReturn

D - Deck Motor Pressure

To install the conditioner using the windrower method,

follow these steps:

1. Lower header stand to mid-position (A).

2. Attach chain (A) to li

and secure chain to l

3. Lift off of shipping

in upright position

fting brackets (B) on conditioner

ifting device.

pallet and set conditioner on ground

.

Figure 3.23

169254 3

9

Figure 3.24

Rev. D

Page 48

UNLOADING AND ASSEMBLY

4. Retrieve stand (A) and hairpin (B) from conditioner

bundle #4798 and install stand in slot in base at lower

right-hand end of conditioner. Secure stand with

hairpin.

5. Remove shipping blocks if present.

6. Hardware at lifting arms has been tightened for

shipping. Loosen two bolts (A) per side just enough to

allow arms (B) to swing out.

Figure 3.25

Figure 3.26: LH Shown

Figure 3.27: RH Shown

169254 4

0

Rev. D

Page 49

UNLOADING AND ASSEMBLY

7. Remove L-pins securing lifting arms to conditioner.

(Rotatepinstoalignkey-holeslot.)

8. Swing out lift arms and secure latches.

Figure 3.28

9. Position the tractor arms in the lift arm pockets, and

insert the L-pins (A) for safety.

Figure 3.29

Figure 3.30

169254

1

4

Rev. D

Page 50

UNLOADING AND ASSEMBLY

10. Remove the stand (A), and store with hairpin (B)

in toolbox.

11. Lift the conditioner, and position into the header

opening from the rear.

12. Carefully lower the windrower lift legs until lugs (A) on

conditioner are seated in the U-shaped brackets (B)

on header.

13. Ensure the conditioner is seated pro perly in the

brackets before you disconnect from windrower.

Figure 3.31

14. Lift latch (B) to release conditioner lift arm (A), and fold

up to storage position on conditioner.

Figure 3.32

Figure 3.33

169254

2

4

Rev. D

Page 51

UNLOADING AND ASSEMBLY

15. InstallL-pin (A) through armand bracket onconditioner

and lock into place. (Rotate pins to align key-hole slot).

Repeat for other arm.

16. Install 5/8 in. x 1 -1/2 in. carriage bolt (A) in the

right-hand lower attachment location.

Figure 3.34

17. Install 5/8 in. x 1 -1/2 in. carriage bolt (A) in the

left-hand lower attachment location.

Figure 3.35: RH Side Shown

Figure 3.36: LH Side Shown

169254 4

3

Rev. D

Page 52

UNLOADING AND ASSEMBLY

18. Connect the five hydraulic hoses between the

conditioner and the header as follows:

• Small male quick-disconnect from motor to

header (A)

• Large female quick-disconnect from motor to

header (B)

• Small female quick-disconnect from deck to

header (C)

• Small female quick-disconnect from motor to

deck (D)

• Large female quick-disconnect from header to

motor (E)

Figure 3.37

A - Case Drain B - Conditioner Motor Pressure

C - Deck Moto

E - Conditioner Motor Return

rReturn

D - Deck Motor Pressure

169254

4

4

Rev. D

Page 53

UNLOADING AND ASSEMBLY

3.7 Attaching Hydraulics

The procedure for attaching hydraulics is different for 15-ft Draper Headers.

• If attaching a 15-ft. header, refer to section 3.7.1 Attaching Hydraulics: 15-Foot Headers, page 45

• When attaching any other size header, refer to section 3.7.2 Attaching Hydraulics: All Headers Except 15-Foot,

page 47

3.7.1 Attaching Hydraulics: 15-Foot Headers

To attach hydraulics to a 15-foot draper header, follow

these steps:

1. Disconnect return hose (A) at elbow on motor.

2. Install check valve tee (A) on elbow and reconnect

return hose (B) to tee (A).

3. Connect feed draper return line (C) from the

conditioner hose package onto the check valve.

Figure 3.

e3.39

Figur

38

169254 4

5

Rev. D

Page 54

UNLOADING AND ASSEMBLY

4. Remove the knife drive coupler (A), draper drive

coupler (B), the case drain coupler (C) and its

extension tube (D).

5. Retrieve coupler bracket (A) from bundle and position

the coupler bracket (A) o nt o hous ing.

6. Reinstallthe draper drive coupler (B) in original location

and install the knife drive coupler (C) onto the end of

the new bracket (A).

Figure 3.40

7. Install the tee-fitting (A) and union (B) onto motor

case drain.

8. Reinstall the case drain coupler (C).

9. Route the conditioner case drain hose (D) (45°

bent tube) behind the motor and connect to the tee

fitting (A).

Figure 3.41

Figure 3.42

169254 4

6

Rev. D

Page 55

UNLOADING AND ASSEMBLY

10. Route the conditioner pressure hose (A) (orange cable

tie) behind the motor and attach it to the coupler (B).

11. Loop the conditioner return line (A) up over top of the

couplers and connect to the pressure port (B) on the

motor. Ensure all hoses will be clear of tractor tires.

Figure 3.43

Figure 3.44

3.7.2 Attaching Hydraulics: All Hea ders Except 15-Foot

To attach hydraulics to all headers (not including 15-foot),

follow these steps:

1. Identify the hydraulic coupler components shown in

illustration at right.

2. Remove hose cover (A) from left-hand coupler mount.

3. Disconnect the side draper return hose (C).at the main

return te e (see item [E] in illustration at right).

re 3.45

Figu

A -Hose Cover B - Coupler Mount

C -Side Draper Return D - LH Draper Case Drain

E - To Side Drapers (Pressure) F - Case Drain Coupler

G - Knife/Conditioner Pressure

H - Header Return

169254

7

4

Rev. D

Page 56

UNLOADING AND ASSEMBLY

4. Detach knife motor case drain line (D) from bulk head

fitting at coupler mount (A).

5. Install conditioner case Tee fitting (B) and conditioner

case drain line (C).

6. Remove knife drive hose (G).

7. Install check valve tee (A) on the main return tee (E).

NOTE: Arrow on check valve tee fitting should

face up.

Figure 3.46

A - Coupler M ount B - Conditioner Case Tee

C-Conditi

E - Header Return Tee

G-KnifeDr

oner Case Drain

ive Hose

D-KnifeMo

F-KnifeReturn

tor Case Return

8. Install the feed draper return hose (C) with the blue tie

to the check valve tee (A).

9. Reinstall the side draper return hose (B) that was

removedinstep3., Attaching Hydraulics: All Headers

Except 15-Foot, page 47 to the new check valve

tee (A).

10. Connect conditioner return hose (D) with union to

Knifedrivehose(F)removedinstep6., Attaching

Hydraulics: All Headers Except 15-Foot, page 48.

11. AttachConditioner drive hose (G) with orange tie to the

couplerwhereknifedrivehosewasremovedinstep

6., Attaching Hydraulics: All Headers Except 15-Foot,

page 48.

12. Bundle the hoses with cable ties as required. Ensure

hoses do not contact sharp edges.

13. Replace hose cover.

Figure 3.47

A - Check Valve Tee B - Side Draper Motor Return

C - Feed Draper Return D - Conditioner Return

E - Header Return Tee

G - Conditioner Drive

F - Knife Drive Hose

169254 4

8

Rev. D

Page 57

UNLOADING AND ASSEMBLY

Figure 3.48

Shields removed to expose the feed draper return hose connection

A - Check Valve Tee

B - Pressure Reducing Valve

C - Feed Draper Return Hose

169254 4

9

Rev. D

Page 58

UNLOADING AND ASSEMBLY

3.8 Assemblin

To assemble fo

1. Unpack the for

and fins bundle

rming shield, follow these steps:

ming shield cover (A), and deflectors

(B).

g the Forming Shield

2. Lay cover (A) upside down (flanges of side supports

facing up) on a flat surface.

Figure 3.49

Figure 3.50

169254 5

0

Rev. D

Page 59

UNLOADING AND ASSEMBLY

3. Assemble fins (A) to bottom of shield as shown using

hardware provided. The two long fins (B) are handed

and should be installed with bolts on outboard side

of the fin. Bolts should be installed with nuts against

the fins.

NOTE: Fins are only effective for windrows

greater than 70 inches (1778 mm) or if

satisfactory formation is not achieved.

Store for future use if not installed.

4. Position fins approximately as shown and tighten

hardware.

Figure 3.51

5. Remove hardware (A) from side deflectors (B).

Figure 3.52

Figure 3.53

169254 5

1

Rev. D

Page 60

UNLOADING AND ASSEMBLY

6. Position deflector (A) on cover as shown and

install with hex bolt (B) and flange nut removed in

previous step.

7. Tighten flange nut enough to hold deflector (A) in

position, but still allow deflector to move.

8. Install b olt, washers, and handle nut (A) as shown.

Rubber washer (B) must be positioned between metal

washers (C).

9. Tighten handle nut (A) against cover to lock deflector

in desired position.

Figure 3.54

A-SideDeflector

C-Bolt(ref

erred to in next step)

B-HexBolt

10. Repeat for the other deflector.

11. Invert forming shield to installation position as shown.

Figure 3.55

Figure 3.56

169254 5

2

Rev. D

Page 61

UNLOADING AND ASSEMBLY

3.9 Installin

To install the

1. Position the f

onto the two pi

conditioner

2. Insert lyn

condition

forming shield, follow these steps:

.

ch pins (A) to secure forming shield to

er.

g the Forming Shield

orward end of the forming shield (A)

ns (B) located on the rear cover of the

Figure 3.57

3. Set for

loosen

handl

ion.

posit

4. Loose

middl

Figure 3.58

ming shield side deflectors to desired width b y

ing handle (A) and moving deflector (B). Tighten

e. Set both deflectors to approximately the same

n handles (C) and adjust fluffer shield (D) to

e position. Tighten handles (C).

Figure 3.59

169254 5

3

Rev. D

Page 62

UNLOADING AND ASSEMBLY

5. Install shield transport support (A) on windrower frame

with two 3/8 x 1.0 carriage bolts and nuts (B).

Figure 3.60

169254 5

4

Rev. D

Page 63

UNLOADING AND ASSEMBLY

3.10 Attaching to a Windrower

Refer to the windrower unloading and assembly

instructions or operator’s manual for instructions on

attaching the header to an M-Series Self-Propelled

Windrower.

Once the header and windrower are attached, follow

these steps:

1. Lift the aft end of the forming shield and attach straps

(B) to pins (A) on windrower frame.

2. Retrieve washers and hairpins from shipping bundle

and install to secure strap. Use the middle hole and

adjust height to suit the crop.

Figure 3.61

169254 5

5

Rev. D

Page 64

UNLOADING AND ASSEMBLY

3.11 Lubricat

3.11.1 Greasi

ing the Conditioner

ng Procedure

CAUTION

To avoid personal injury, before servicing header

or opening drive covers, follow procedures in 5.1

Preparation for Servicing, page 87.

1. To avoid injecting dirt and grit, wipe grease fitting with

a clean cloth before greasing.

2. Inject grease through fitting with grease gun until

grease overflows fitting, except where noted.

3. Leave excess g rease on fittingtokeepoutdirt.

4. Replace any loose or broken fittings immediately.

5. If fitting w ill not take grease, remove and clean

thoroughly. Also clean lubricant passageway. Replace

fitting if necessa ry.

169254 5

6

Rev. D

Page 65

3.11.2 Lubrication Points

UNLOADING AND ASSEMBLY

Figure 3.62: Every 50 Hours - Use High Temperature Extreme Pressure (EP2) Performance With 1% Max

Molybdenum Disulphide (NLGI Grade 2) Lithium Base

A - Drive Roller Bearing Lubrication Point B - Idler Roller Bearing Lubrication Point

169254 5

7

C - Idler Roller Bearing Lubrication Point

Rev. D

Page 66

UNLOADING AND ASSEMBLY

Figure 3.63: Every 50 Hours - Use High Temperature Extreme Pressure (EP2) Performance With 1% Max

Molybdenum Disulphide (NLGI Grade 2) Lithium Base

A - Roll Shaft Bearing Lubrication Points (Four Places)

169254 5

8

Rev. D

Page 67

UNLOADING AND ASSEMBLY

3.12 Performi

ng Predelivery Checks

WARNING

Stopengine, and remove keybefore making adjustments to machine. A child or evena pet could engage

the drive.

Perform the final checks and adjustments as listed on the "Pre-Delivery Checklist" (yellow sheet) along with the

header final checks and adjustments to ensure the machine is field ready. Refer to the following pages for detailed

instructions as indicated on the check list.

The completed checklists should be retained either by the Operator or the Dealer.

3.12.1 Checking Roll Drive Belt Tension

To check the roll drive belt tension, follow these steps:

1. Remove wing-nut and washer and remove drive cover.

2. Belt should deflect 1/4 inch (7 mm) when a force of

8–16 lbf (36–72 N) is applied at the center of the span.

If belt tension requires adjusting, see section 5.7.1

Adjusting Drive Belt Tension, page 96.

3. Replace cover and secure with washer and wing-nut.

Figure 3.

e3.65

Figur

64

169254 5

9

Rev. D

Page 68

UNLOADING AND ASSEMBLY

3.12.2 Checking Roll Gap

Factory setting should be 0.75 in. (20 mm) or at 1.5 line

on gauge (A). Gauge readings should be the same at both

ends of the roll. If roll gap requires adjusting, refer to

section 4.9.2 Adjusting Roll Gap, page 80.

Figure 3.66

A - Crop direction

B-Rollgap

3.12.3 Checking Roll Timing

CAUTION

Stop engine, and remove key from ignition before

leaving Operator's seat for any reason. A child or

even a pet could engage an idling machine.

To check the roll timing, follow these steps:

1. Lower header to ground, shut down windrower, and

remove key.

2. Remove wing-nut and remove tool from panel at

right-hand end of conditioner.

169254 6

0

Figure 3.67

Figure 3.68

Rev. D

Page 69

UNLOADING AND ASSEMBLY

3. From the rear of the conditioner, locate tool at centre of

rolls as shown and manually turn rolls to limits of tool.

Rolls will engage the tool if timing is correct.

4. Manu ally turn rolls to release tool.

WARNING

Remove tool fr

location befo

5. Replace tool on conditioner with washer and wing nut.

6. If roll timing requires adjusting, refer to section 4.9.3

Checking and Adjusting Roll Timing, page 81.

om rolls and return it to storage

re startin g mach i ne .

Figure 3.69

A - Start position B - Gauge position

3.12.4 Running Up the Conditioner

CAUTION

Never start or move the machine until you are sure all bystanders have cleared the area.

CAUTION

Clearthe area of other persons, pets etc. Keepchildren away from machinery. Walk around the machine

to be sure no one is under, on or close to it.

CAUTION

Before investigating an unusual sound or attempting to correct a problem, shut off engine, engage

parking brake and remove key.

Refer to the windrower unloading and assembly instructions or operator’s manual for windrower operating

instructions.

To run up the conditioner, follow these steps:

1. Start windrower and run the machine. Operate the conditioner slowly for 5 minutes, watching and listening

FROM THE OPERATOR'S SEAT for binding or interfering parts.

2. Run machine for 15 minutes.

3. Perform the run-up check as listed on the "Predelivery Checklist", (yellow sheet attached to this instruction), and

the header run-up check to ensure the machine is field-ready.

169254 6

1

Rev. D

Page 70

UNLOADING AND ASSEMBLY

3.12.5 Storing Manuals

Place this manual (MD #169524) in the storage case (A) in

the windrower. The yellow checklist should be retained by

either the Dealer or the Operator.

Figure 3.70: Manual Storage Case on an M155

Self-Propelled Windrower

169254 6

2

Rev. D

Page 71

4Operation

4.1 Owner/Operator Responsibilities

CAUTION

• It is your responsibility to read and understand this manual completely before operating the header.

Contact your MacDon Dealer if an instruction is not clear to you.

• Follow all safety messages in the manual and on safety decals on the machine.

• Remember that YOU are the key to safety. Good safety practices protect you and the people

around you.

• Before allowing anyone to operate the header, for however short a time or distance, make sure they

have been instructed in its safe and proper use.

• Review the manual and all safety related items with all Operators annually.

• Be alert for other Operators not using recommended procedures or not following safety precautions.

Correct these mistakes immediately, before an accident occurs.

• Do NOT modify the machine. Unauthorized modifications may impair the function and/or safety and

affect machine life.