LG CH05, General Wall Mounted-Inverter Type, CH53, CH21, CH22 Svc Manual

...

Room Air Conditioner

SVC MANUAL(General)

MODEL : General Wall Mounted-Inverter Type

CAUTION

Before Servicing the unit, read the safety precautions in this SVC manual.

Only for authorized service personnel.

http://biz.lgservice.com

2 Room Air Conditioner

Air Conditioner Service Manual

CONTENTS

Part 1 General Information

1. Safety Precautions........................................................................................................4

2. Nomenclature ...............................................................................................................7

Part 2 Functions & Controls

1. List of Functions & Controls........................................................................................9

2. Basic Mode Controls .................................................................................................10

3. Special Mode Controls ...............................................................................................12

4. Utility Functions .........................................................................................................13

5. Protection Functions & Controls...............................................................................16

Part 3 Test Run

1. Check before Test Run ...............................................................................................31

2. Test Run Flow chart ....................................................................................................32

3. Test Run Detail ............................................................................................................33

Part 4 Trouble Shooting Guide

1. 2-Way, 3-Way Valve ....................................................................................................35

2. Pumping Down ...........................................................................................................36

3. Evacuation (All amount of refrigerant leaked) ........................................................37

4. Gas Charging (After Evacuation) ..............................................................................38

5. Cycle Troubleshooting Guide ....................................................................................39

6. Electric Parts Troubleshooting Guide.......................................................................41

7. Self-diagnosis Function .............................................................................................46

Service Manual 3

1. Safety Precautions ............................................................................................................4

2. Nomenclature......................................................................................................................7

Part 1 General Information

4 Room Air Conditioner

Part 1 General Information

1. Safety Precautions

1.1 Cautions in Repair

To prevent injury to the user or other people and property damage, the following instructions must be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is classified by the following indications.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

■ Meanings of symbols used in this manual are as shown below.

Be sure not to do.

Be sure to follow the instruction.

Dangerous Voltage

Be sure to disconnect the power cable plug from the plug socket before disassembling the equipment for a repair.Internal components and circuit boards are at

main potential when the equipment is connected to the power cables. This high

voltage is extremely dangerous and may cause death or severe injury if come in

contact with it.

Do not touch the discharging refrigerant gas during the repair work.

The discharging refrigerant gas.The refrigerant gas can cause frostbite.

Release the refrigerant gas completely at a well-ventilated place first.

Otherwise, when the pipe is disconnected, refrigerant gas or refrigerating

machine oil discharges and it Can cause injury.

When the refrigerant gas leaks during work, perform ventilation. If the refrigerant

gas comes in contact with a fire, poisonous gas generates. A case of leakage of

the refrigerant and the closed room full with gas is dangerous because a shortage of oxygen occurs. Be sure to perform ventilation.

When removing the front panel or cabinet, execute short-circuit and discharge

between high voltage capacitor terminals. If discharge is not executed, an electric

shock is caused by high voltage resulting in a death or injury.

Do not turn the air-conditioner ON or OFF by plugging or unplugging the power

plug. There is risk of fire or electrical shock.

Service Manual 5

Part 1 General Information

Do not turn on the breaker when the front panel and cabinet are removed.

Be sure to ground the air conditioner with an earthing conductor connected to

the earthing terminal.

Conduct repair works after checking that the refrigerating cycle section has

cooled down sufficiently. Otherwise, working on the unit, the hot refrigerating

cycle section can cause burns.

Do not tilt the unit while removing panels. Otherwise, the water inside the unit

can spill and wet floor.

Do not use the welder in a well-ventilated place. Using the welder in an enclosed

room can cause oxygen deficiency.

Be sure to turn off power switch before connecting or disconnecting connector,

or parts damage may be occur.

Do not use a defective or underrated circuit breaker. Use the correctly rated

breaker and fuse. Otherwise there is a risk of fire or electric shock.

Install the panel and the cover of control box securely. Otherwise there is risk of

fire or electric shock due to dust, water etc.

Indoor/outdoor wiring connections must be secured tightly and the cable should

be routed properly so that there is no force pulling the cable from the connection

terminals. Improper or loose connections can cause heat generation or fire.

Do not touch, operate, or repaire the product with wet hands. Holding the plug by

hand when taking out. Otherwise there is risk of electric shock or fire.

6 Room Air Conditioner

Part 1 General Information

Check to see if the parts are mounted correctly and wires are connected.

Improper installation and connections can cause an electric shock or an injury.

Check whether the installation platform or frame has corroded. Corroded installation platform or frame can cause the unit to fall, resulting in injury.

Be sure to check whether the earth wire is correctly connected.

After the work has finished, be sure to do an insulation test to check whether the

resistance is 2[Mohm] or more between the charge section and the non-charge

metal section (Earth position). If the resistance value is low, a disaster such as a

leak or electric shock is caused at user’s side.

Check the drainage of the indoor unit after the repair. If drainage is faulty the

water may enter the room and wet floor.

1.2 Inspections after Repair

Check to see if the power cable plug is not dirty or loose. If the plug is dusty or

loose it can cause an electrical shock or fire.

Do not use a joined power cable or extension cable, or share the same power

outlet with other electrical appliances. otherwise, it can cause an electrical shock,

excessive heat generation or fire.

Do not insert hands or other objects through the air inlet or outlet while the product is operating. There are sharp and moving parts that could cause personal

injury.

Do not block the inlet or outlet of air flow. It may cause product failure

Service Manual 7

Part 1 General Information

2. Nomenclature

2.1 Global Model Name

Code Type Code of Model Meaning

1 Production Center, A~Z L: Chang-won R22

Refrigerant A: Chang-won R410A

2 Product Type A~Z S: Split Type Air Conditioner

3 Cooling/Heating/Inverter A~Z C: Cooling Only

H: Heat Pump

X: C/O + E/Heater

Z: H/P + E/Heater

V: AC Inverter C/O

N: AC Inverter H/P

Q: DC Inverter C/O

W: DC Inverter H/P

4, 5 Capacity 0~9 Cooling/Heating Capacity

Ex. "09" → 9,000 Btu/h

6 Electric Range 1~9 1: 115V/60Hz

A~Z 2: 220V/60Hz

3: 208-230V/60Hz

5: 200-220V/50Hz

6: 220-240V/50Hz

7: 110V, 50/60Hz

7 Chassis A~Z Name of Chassis

8 Look A~Z Look,

Color (Artcool Model)

9, 10 Function A~Z

11 Serial No. 1~9 LG Model Development Serial No.

12 - 345678910

A Basic

B Basic+4Way

C Plasma Filter

D Plasma Filter+4 Way

E Tele+LCD

F Tele+LCD+Nano plasma+4Way

G NBF F+(A/changeove)+A/clean+Low A

H NBF F+(A/changeove)+A/clean+4way+Low A

I Tele+LED+4way

J Internet

K Plasma F+4Way+Oxygen generator

L NBF F+(A/changeove)+A/clean

M NBF F+(A/changeove)+A/clean+4way

N NBF F+(A/changeove)+A/clean+PTC

P NBF F+(A/changeove)+Autoclean+4way+PTC

Q NBF F+(A/changeove)+A/clean+4way+Low A+PTC

R Negative ion+A/Clean

S (Nano)Plasma+Negative ion+A/Clean

T 4way+(Nano)Plasma F+Negative ion+A/Clean

U

Nano Plasma F+4Way+(A/changeove)+A/clean+Oxygen generator

V

4way+(Nano)Plasma F+Negative ion+A/Clean+Oxygen generator

W Dry contact

Y Basic + Low A

AS W1264GG1

8 Room Air Conditioner

Part 2 Functions & Controls

1. List of Controls & Functions ..........................................................................................9

2. Basic Mode Controls......................................................................................................10

3. Special Mode Controls...................................................................................................12

4. Utility Functions .............................................................................................................13

5. Protection Functions & Controls .................................................................................16

Service Manual 9

Part 2 Functions & Controls

1. List of Functions & Controls

Cooling Mode

Heating Mode

Healthy Dehumidification

Automatic operation

Auto Changeover

Jet Cool

Jet Heat

Energy saving

Forced operation

Auto Clean

Air volume control

Natural Air control

Chaos Swing

Sleep mode Auto control

Auto Restart Function

Five Second Delay (Fan)

Two Minutes Stand-by

(Comp.)

Hot Start

Freeze prevention

Automatic Defrost

Power Relay Control

Inverter (with inverter

power control)

Overheating Protection

(Power Module)

Total Current Control

(Over Current Protection)

DC Peak Control

Discharge Pipe Temp Control

Low Ambient Function

Oil Return Control

Oil Equalizing Control

Category Function Description Remark

Cooling operation

Heating operation

Dry operation

Automatic operation

Cooling mode is automatically changed to heating mode and

vice verse

Powerful cooling mode

Powerful heating mode

Air volume & set temp. are automatically selected for saving

energy in cooling mode

Operation without remote controller

After cooling operation, this function makes the evaporator

dry

Indoor Fan speed Control

Air volume control Program

Vertical Airflow Direction control

Air volume & set temp. are automatically changed for com-

fortable sleep

When power returns after a power failure, Unit restarts in the

previous operating mode

For noise prevention

For overload prevention

To prevent cold wind blow on heating mode start

Evaporator frost prevention

Condenser frost prevention

Over current prevention

Modulation of voltage & frequency

To protect power module

To protect power device

To protect power module

For overheating protection

For operation at low temp.

To protect compressor

To protect compressor

Basic mode

controls

Special Mode

controls

Utility Functions

Protection

Controls &

Functions

Cooling Mode Only

NOTE: The Exploded View SVC Manual has the particular Function table for each model.

10 Room Air Conditioner

Part 2 Functions & Controls

2. Basic Mode Controls

2.1 Cooling Mode

Setting

Temp.

-0.5°C(-1°F)

+0.5°C(1°F)

Comp. OFF

Thermo ON

Thermo OFF

INV. Comp.

Frequency

Low

High LowHigh

• Operating frequency of compressor depends on the load condition, like the difference between the room temp. and

the set temp., frequency restrictions.

• If the compressor operates at some frequency, the operating frequency of compressor cannot be changed within 30

seconds. ( not emergency conditions)

• Compressor turned off when

- intake air temperature is in between ±0.5°C(±1°F) of the setting temp. limit for three minutes continuously.

- intake air temperature reaches below 1.0°C(2°F) of the temperature of setting temp..

• Compressors two minutes time delay.

- After compressor off, the compressor can restart minimum 2 minutes later.

2.2 Heating Mode

T1°C(T2°F).

T2°C(T4°F).

Comp. OFF

INV. Comp.

Frequency

Low

High LowHigh Comp. OFF

Setting

Temp.

Thermo ON

Thermo OFF

• Operating frequency of compressor depend on the load condition, The difference between the room temp. and set

temp., frequency restrictions.

• If compressor operates at some frequency, the operating frequency of compressor cannot be changed within 30 seconds.

• Condition of compressor turned off

- When intake air temperature reaches +T2°C(T4°F) above the setting temperature.

• Condition of compressor turned on

- When intake air temperature reaches +T1°C(T2°F) above the setting temperature.

* Condition of indoor fan turned off

- While in compressor on : indoor pipe temp. < 20°C(68°F)

- While in compressor off : indoor pipe temp. < 30°C(86°F)

• While in defrost control, the indoor and outdoor fans are turned off.

• Compressor 2minutes delay

- After compressor off, the compressor can restart minimum 2 minutes later.

• T1 and T2 may be changed by models

Service Manual 11

Part 2 Functions & Controls

2.3 Healthy Dehumidification operation

• When the dehumidification operation is set by the remote controller, the intake air temperature is detected and the set-

ting temp. is automatically set according to the intake air temperature.

•

When intake air temp. is 1 C(2 F) above the setting temp., condition of compressor is same as in cooling mode operation.

• When intake air temperature reaches 1 C(2 F) below the setting temp., compressor operates in step1~step3 and the

indoor fan speed again operates at low speed or comes to a stop.

2.4 Automatic operation

• When the Auto operation is set by the remote controller, the intake air temperature is detected and the setting temp. is

automatically set according to the intake air temperature and operation mode.

• The air volume is automatically set according to the intake air temperature.

2.5 Auto changeover operation

• The air conditioner changes the operation mode automatically to keep indoor temperature steady.

• When room temperature vary over ±2°C(±4°F) with respect to setting temperature, air conditioner keeps the room tem-

perature in ±2°C(±4°F) with respect to setting temperature by changing the mode from cooling to heating and vice

versa.

Intake air Temp. Setting Temp.

26°C(78.8

°F)

≤ intake air temp. 25°C(77

°F)

24°C(75.2

°F)

≤ intake air temp.< 26°C(78.8

°F)

intake air temp. -1°C(-2

°F)

22°C(71.6

°F)

≤ intake air temp. < 24°C(75.2

°F)

intake air temp. -0.5°C(-1

°F)

18°C(64.4°F) ≤ intake air temp. < 22°C(71.6

°F)

intake air temp.

intake air temp. < 18°C(64.4

°F)

18°C(64.4

°F)

+0.5°C(+1°F)

-0.5°C(-1°F)

-2°C(-4°F)

+4°C(+8°F)

+2°C(+4°F)

Cooling thermo off

Heating thermo off

Switching point

Switching point

Setting

Temp.

Cooling

operation

Heating operation

Cooling

operation

Mode

12 Room Air Conditioner

Part 2 Functions & Controls

3. Special Mode Controls

3.1 Jet Cool operation

• In the heating mode or Fuzzy operation, the Jet cool function does not work.

When it is input while in other mode of operation (cooling, dehumidification, ventilation), the Jet cool operation takes

place.

• In the Jet cool mode, the indoor fan is operated at super-high speed for 30 min. at cooling mode operation.

• In the Jet cool mode, the room temperature is maintained at a setting temperature of 18°C(64.4°F).

• When the sleep timer mode is input during the Jet cool operation, the Jet cool mode has the priority.

• When the Jet cool button is pressed, the upper/lower vane of the unit is reset to those of the initial cooling mode and

then operate so that the air outflow could reach further.

3.2 Jet Heat operation

• While in cooling mode or Fuzzy operation, the Jet Heat function does not work.

When it is input while in the Heating mode operation (dehumidification), the Jet Heat mode operation takes place

• In the Jet Heat mode, the indoor fan operated at super-high speed for 60 min. at Heating mode operation.

• In the Jet Heat mode, the room temperature is maintained at a temperature of 30°C(86°F).

• When the sleep timer mode is input during the Jet Heat mode operation, the Jet Heat mode has the priority.

• When the Jet Heat button is pressed, the upper/lower vane of the unit is the unit reset to those of the initial Jet heating

mode and then operates so that the air outflow could reach under flow.

3.3 Energy saving operation in cooling mode

• During cooling and dehumidification mode of operation, the Energy saving button can be input.

• In this operation, before we feel cold the set temperature and air volume is set automatically to save energy.

• The operation time and the other thing was decided by experiment.

Service Manual 13

Part 2 Functions & Controls

4. Utility Functions

4.1 Forced operation

• To operate the appliance manually in case when the remote control is lost, the forced operation selection switch is on

the main unit of the appliance, and operate the appliance in the standard conditions.

• The operating condition is set according to the outdoor temp. and intake air temperature as follows.

• The unit select the last operation mode in 3 hours.

• Operating procedures when the remote control can't be used is as follows :

- The operation will be started if the ON/OFF button is pressed.

- If you want to stop operation, re-press the button.

- The ON/OFF switch is on the display PCB or side of indoor unit

4.2 Auto cleaning operation

• Function used to perform Self Cleaning to prevent the Unit from Fungus and bad odor.

• Used after the Cooling Operation before turning the unit off, clean the Evaporator and keep it dry for the next opera-

tion.

• The function is easy to operate as it is accessed through the Remote controller.

Indoor temp.

over 24°C(75.2°F)

21~24°C(69.8~75.2°F)

below 21°C(69.8°F)

Setting temp.

22°C(71.6°F)

23°C(73.4°F)

24°C(75.2°F)

Setting speed of

indoor fan

High speed

Operating Mode

Cooling

Healthy Dehumidification

Heating

Unit

Operation

13~14 minutes 1 minute 2~3 minutes

ON

OFF

Comp.

Time

Indoor

Fan

ON

OFF

ON

OFF

Setting step

OFFL Low

14 Room Air Conditioner

Mode2

Mode3

Mode4

Mode5

Mode6

Mode7

Mode8

Mode9

OPEN

CLOSED

8°

Cooling Operation

120°

Mode2

Mode3

Mode4

Mode5

Mode6

Mode7

Mode8

Mode9

OPEN

CLOSED

8°

Heating Operation

120°

Mode1

Mode1

Mode2

Mode3

Mode4

Mode5

Mode6

Mode7

Mode8

OPEN

CLOSED

8°

Cooling Operation

Mode1

Mode2

Mode3

Mode4

Mode5

Mode6

Mode7

Mode8

OPEN

CLOSED

8°

Heating Operation

110°110°

Start

(S4, SE) 9,12kBtu/h Model

Start

Start

Start

(S5) 18, 24kBtu/h Model

(SD) 30kBtu/h Model

Mode

1

Mode

2

Mode

3

Mode

4

Mode

5

Mode

6

Mode

7

Mode

8

OPEN

CLOSED

8¡

Heating Operation

110¡

Start

Mode

7

Mode

1

Mode

2

Mode

3

Mode

4

Mode

5

Mode

6

Mode

8

OPEN

CLOSED

8¡

Cooling Operation

110¡

Start

Part 2 Functions & Controls

4.3 Air volume control

• Indoor fan motor control have 6 steps.

• Air volume is controlled "SH", "H", "Med", "Low" by the remote con-

troller.

• "LL" step is selected automatically in Hot start operation.

4.4 Natural Air Control(Auto Wind)

• When the Auto Step is selected and then operated, the high, medi-

um, or low speed of the airflow mode is operated for 2~15 sec. randomly by the Chaos Simulation.

4.5 Chaos Swing

• By the Chaos swing key input, the upper/lower vane automatically operates with the Chaos swing or it is fixed to the

desired direction.

LL Very low, In heating mode

L Low

M Med

H High

SH Super high

Auto Natural wind

Step Description

NOTE: Some Models are different by swing width and swing pattern.

Service Manual 15

Part 2 Functions & Controls

4.6 Sleep mode Auto control

• When the set sleep time is reached set time of [1,2,3,4,5,6,7hour] input by the remote control during the operation, the

operation of the appliance stops.

• When the appliance is on pause, the sleep timer mode cannot be input.

4.6.1 Sleep timer operation for cooling cycle

• While in cooling mode , 30 min. after the start of the sleep timer, the setting temperature increases by 1 C(2 .

After another 30minutes lapse, it increases again by 1°C(2 .

4.6.2 Sleep timer operation for heating cycle

• While in heating mode, 60 min. after the start of the sleep timer, the setting temperature decreases by 1 C(2 .

After another 60minutes lapse, it decreases again by 1°C(2 .

4.7 Auto restart

• When the power comes back after a sudden power failure during operation, the mode before the power failure is kept

on the memory of the appliance and it automatically operates in the saved mode on the memory.

• Operation mode that is kept on the memory

- State of operation ON/OFF

- Operation mode/setting temp./selected airflow speed

- Sleep timer mode/remaining time of sleep timer

- Chaos Swing

Setting temp. (˚C)

1.0˚C(2˚F) up

1.0˚C(2˚F) up

Cooling ON temp.

(Setting temp. +0.5˚C(+1˚F))

Cooling OFF temp.

(Setting temp. -0.5˚C(-1˚F))

0.5 1 Sleep time (hour

)

Setting temp. (°C)

Heating ON temp.

(Setting temp)

Heating OFF temp.

(Setting temp. +4.0°C(+8°F))

1 2 Sleep time (hr

)

1.0°C(2°F) down

1.0°C(2°F) down

16 Room Air Conditioner

Part 2 Functions & Controls

5.1 Five Seconds Stand-by (fan)

• The indoor unit fan rotates after 5 seconds when unit is turned on.

5.2 Two Minutes Stand-by (comp.)

• Compressor starts two minutes later, after it is turned off

5.3 Hot start

• When unit starts in the heating mode to prevent cold wind blowing, the indoor fan does not rotate until the temp. of

heat exchanger reaches 30°C(86°F)(model by model)

5.4 Freeze prevention (Protection of the evaporator pipe from frosting)

• If the indoor pipe temperaure is below 0°C(32°F) in 7 min. after the compressor operates without pause while in cool-

ing cycle operation mode, ➔ compressor, outdoor fan are turned off.

• When indoor pipe temp. is 7°C(44.6°F) or higher after 2 min pause of compressor ➔ compressor, outdoor fan is turned

on according to the condition of the room temperature.

5. Protection Functions & Controls

Comp. free

Comp. Step 4

Comp. Step 2

Comp. off

T1

3˚C(37.4˚F)

6˚C(42.8˚F)

7˚C(44.6˚F)

Indoor pipe

temp.

T1: 0 ~ 2°C(32~35.6°F)

NOTE: Some Models are different by T1.

Service Manual 17

Part 2 Functions & Controls

5.5 Automatic defrost

5.5.1 9,12kBtu/h Model

• While in heating mode operation in order to protect the evaporator pipe of the outdoor unit from freezing,

reversed to cooling cycle to defrost the evaporator pipe of the outdoor unit.

• Defrosting control is available 40 minutes later since heating cycle started and the difference of the pipe temperature of outdoor unit reaches above option 1.

• The defrosting control is available without reference to heating operation time only if the pipe temperature of

outdoor unit reaches below option 2.

Setting Freq.

Operating

Freq. Of

Comp

(Comp off

Inapplicable.)

4-Way

Indoor

FAN

Indoor

FAN

Pre-Heat

LED

5sec

5sec

Minimum Time

Of Heating

Main Deice time

30 sec

10 sec

1min

ON

OFF

Hi Speed

ON

Setting

Speed

Hot

Start

OFF

Super low speed

° low speed

ON

OFF

OFF

Deice STEP 0123456

EEV

Open step

The Degree

of Superheat

Control

Starting Step

off

Min (Option)_(12)

Step 3 (Option)_(15)

300

(Option)_(14)

off

Step 5 (Option)_(13)

Min (Option)_(12)

off

15 sec

Min (Option)_(12)

Min (Option)_(12)

Operating

Freq. Of

Comp

(Comp off

Applicable.)

Step 3 (Option)_(15)

Step 5 (Option)_(13)

Setting

Speed

Setting

Speed

Setting Freq.

Setting

Freq.

>5>5>5

-25-25-30-30Option 2

Expected heating operating time

And Heating operating time 40 minutes

The minimum Time of

Heating(sec)

>4Option 1

-10˚C(14˚F) less than

0˚C(32˚F) more than-10~-5˚C(14~23˚F) between

-5~0˚C(23~32˚F) between

The mean outdoor

temperature

18 Room Air Conditioner

Part 2 Functions & Controls

5.5.2 18,24,30kBtu/h Model

• Starting to the defrosting operation

1) Defrost operation will be start when the conditions below are matched

a) Accumulation time of operation and the period after completion of defrost = 35 min.

b) After 10 minutes from re-starting the compressor .In case of being over 35 minutes of accumulated operating

time, defrosting operation starts after 10 minutes.

c) Piping temperature of the outdoor heat exchanger maintain below defrost starting temperature for 4 minutes

after 35 minutes continuous operation.

d)In case of passing 10 minutes after oil recovery operation

2) Outdoor piping temperature is below than –6°C (21.2°F, Option) for starting defrosting operation.

Service Manual 19

Part 2 Functions & Controls

• Defrosting Control Algorithm

1) Lowering the compressor frequency when starts the defrosting operation.

Constant speed compressor is ON after 10 seconds from the arrival time of 30 Hz (Option) frequency and is

speed up its revolution till 100 Hz (Option)

2) Every EEV have 350 pulse (Option) of opening when starts defrosting operation.

3) Reversing valve is OFF after 5 seconds from arriving the compressor operating frequency of 30 Hz and then

fans of indoor units turn OFF.(including the indoor unit with being OFF except the remote controller is being

OFF)

4) After 5 seconds from the time arriving 30 Hz, fans of outdoor unit turn OFF and Hot Gas bypass/Oil separator

valve turn ON.

NOTE: Comp.frequency and EEV pulse is different each models.

• Control algorithm of defrost completion

1) Frequency of compressor lowering to 30 Hz and maintain constant speed operation with 30 Hz for 75 seconds

and then stating operation. If the constant speed compressor is OFF, it will be receive OFF signal after 5 seconds from the arrival time of 30 Hz.

2) The EEV will open with the standard previous pulse after 5 seconds from the time of 30 Hz.

3) Reversing valve is ON after 15 seconds from the time of 30 Hz of compressor frequency.

4) Fan of outdoor unit is ON with high speed and maintain it after 5 seconds from the time of 30Hz.

5) Hot Gas bypass valve/Oil separator bypass valve make OFF after 75 seconds from the time of 30Hz.

NOTE: Comp.frequency and EEV pulse is different each models.

20 Room Air Conditioner

Part 2 Functions & Controls

5.6 Power Relay Control

• Power relay turns on 1 second later after the power is supplied to the outdoor unit.

• Control sequence : power on → PTC operating → power relay on

5.7 Inverter

1. The single phase power AC is converted into DC.

2. The single phase power DC is converted into a three phase chopped DC voltage with a variable frequency.

3. When the frequency changes, the rotation speed of the compressor changes resulting in an changed refrigerant circulation. This leads to changeable amount of the heat exchange per unit.

3Ø

Comp.

Motor

U

UV W

V

W

+

Service Manual 21

Part 2 Functions & Controls

5.8 Overheating Protection (Power Module)

5.8.1 9,12kBtu/h Model

• If the temperature of the heat sink thermistor. reaches over Toff, the Compressor stop instantly.

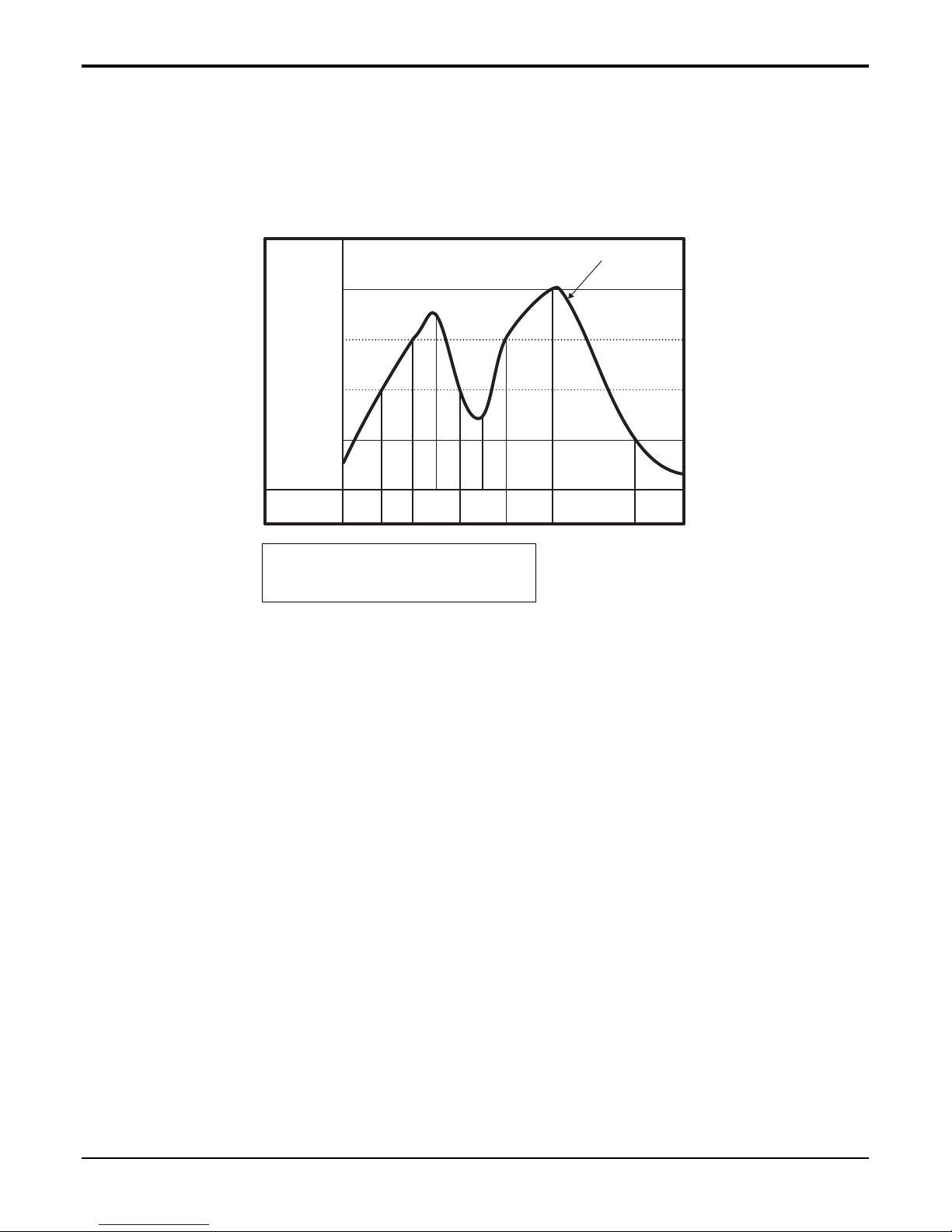

• The compressor operating frequency is limited according to the heat sink thermistor. (refer to below FIG.)

• It will blink 4 times, when the thermistor is open or short, also when the temperature is over T off.

T off °C

T2 °C

Heat Sink Temp.

T1 °C

T on °C

COMP

Freq.

Free OFF FreeFc-1 Fc-1Fc-2 Fc-2

∆T = (T off - T on)/3

T1 = T on + ∆T

T2 = T on + 2 * ∆T

T on : 85°C(185°F) (Model by Model)

T off : 95°C(203°F) (Model by Model)

NOTE: Some Models are different by Ton, and Toff.

Loading...

Loading...