LG CED-8120B Service Manual

|

TABLE OF CONTENTS |

|

INTRODUCTION.................................................................................................................................................... |

3 |

|

FEATURES............................................................................................................................................................ |

3 |

|

SPECIFICATIONS ............................................................................................................................................. |

4~5 |

|

LOCATION OF CUSTOMER CONTROLS........................................................................................................ |

6~7 |

|

DISASSEMBLY ................................................................................................................................................. |

8~9 |

|

1. CABINET and CIRCUIT BOARD DISASSEMBLY......................................................................................... |

8 |

|

1-1. Bottom Chassis......................................................................................................................................... |

8 |

|

1-2. Front Bezel Assy....................................................................................................................................... |

8 |

|

1-3. Cabinet and Main Circuit Board ................................................................................................................ |

8 |

|

2. MECHANISM ASSY DISASSEMBLY ............................................................................................................ |

8 |

|

2-1. Pick-up Unit............................................................................................................................................... |

8 |

|

2-2. Pick-up ..................................................................................................................................................... |

9 |

|

GLOSSARY ......................................................................................................................................................... |

10 |

|

EXPLODED VIEW ......................................................................................................................................... |

11~12 |

|

MECHANICAL REPLACEMENT PARTS LIST............................................................................................. |

13~17 |

|

THE DIFFERENCES OF CD-R/CD-RW DISCS AND GENERAL CD-ROM ................................................. |

18~24 |

|

1. |

Recording Layer........................................................................................................................................... |

18 |

2. |

Disc Specification......................................................................................................................................... |

18 |

3. |

Disc Materials............................................................................................................................................... |

19 |

4. |

Reading Process of Optical Disc.................................................................................................................. |

20 |

5. |

Writing Process of CD-R Disc ...................................................................................................................... |

21 |

6. |

Writing Process of CD-RW Disc................................................................................................................... |

21 |

7. |

Organization of the PCA, PMA and Lead-in Area ........................................................................................ |

22 |

8. |

Function of PCA and PMA area ................................................................................................................... |

23 |

9. OPC and ROPC ........................................................................................................................................... |

23 |

|

10. Writing Process of DISC ............................................................................................................................ |

24 |

|

INTERNAL STRUCTURE OF THE PICK-UP................................................................................................ |

25~27 |

|

1. |

Block Diagram of the Pick-up....................................................................................................................... |

25 |

2. |

Pin Description ............................................................................................................................................. |

26 |

3. |

Signal detection of the P/U........................................................................................................................... |

27 |

DESCRIPTION OF CIRCUIT ......................................................................................................................... |

28~33 |

|

1. |

ALPC Circuit................................................................................................................................................. |

28 |

2. |

RF Amplifier Circuit ...................................................................................................................................... |

30 |

3. |

Focus/Tracking/Sled Servo Circuit............................................................................................................... |

31 |

4. |

Spindle Servo Circuit.................................................................................................................................... |

33 |

MAJOR IC INTERNAL BLOCK DIAGRAM AND PIN DESCRIPTION ......................................................... |

34~53 |

|

TROUBLESHOOTING GUIDE ...................................................................................................................... |

54~76 |

|

BLOCK DIAGRAM ........................................................................................................................................ |

77~80 |

|

1. |

Overall Block Diagram ................................................................................................................................. |

77 |

2. |

Power Block Diagram................................................................................................................................... |

78 |

3. |

Control Signal Block Diagram ...................................................................................................................... |

79 |

4. |

Read/Write Signal Block Diagram................................................................................................................ |

80 |

CIRCUIT DIAGRAM ...................................................................................................................................... |

81~83 |

|

RINTED CIRCUIT BOARD DIAGRAM.......................................................................................................... |

84~87 |

|

ELECTRICAL REPLACEMENT PARTS LIST ............................................................................................ |

88~109 |

|

CAUTION - INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM.

INTRODUCTION

This service manual provides a variety of service information.

It contains the mechanical structure of the CD- R/RW Drive and the electronic circuits in schematic form. This CD-R/RW Drive was manufactured and assembled under our strict quality control standards and meets or exceeds industry specifications and standards.

This CD-R/RW drive is an internal drive unit designed for use with IBM PC, HP Vectra, or

compatible computer. It can write as much as 650 Mbytes of digital data into CD-R/RW disc, and can read as much as 650 Mbytes of digital data stored in a CD-ROM, CD-R and CD-RW disc.

This CD-R/RW Drive can easily meet the upcoming MPC level 3 specification, and its Enhanced Intelligent Device Electronics (E-IDE) and ATAPI interface allows Plug and play integration in the majority of today’s PCs without the need of an additional interface card.

FEATURES

1.General

1)Enhanced IDE interface.

2)Internal 5.25 inch, halfheight CD-R/RW Drive.

3)8 Mbytes buffer memory.

4)Audio CD like tray loading of a disc without using a caddy.

5)Power loading and power ejecting of a disc. The disc can also be ejected manually.

6)Supports Power saving mode and Sleep mode.

7)Vertical and Horizontal operation.

2.Supported disc formats

1)Reads and writes data in each CD-ROM, CD-ROMXA, CD-I FMV, Video CD, and CD-EXTRA

2)Reads data in Photo CD (Single and Multi session).

3)Reads and writes standard CD-DA.

4)Reads and writes CD-R discs conforming to “Orange Book Part 2”.

5)Reads and writes CD-RW discs conforming to “Orange Book Parts 3”.

3.Supported write method

1)Disc at once (DAO), Session at once (SAO), Track at once (TAO), Variable packet, Fixed packet, and Multi-session.

4.Performance

1)Random 110 ms average access time.

2)Max 4,800 kB/sec (Max 32X) Sustained Transfer rate.

3)Supports real time error correction and real time layered error correction at each speed.

4)CD-R Record speed : 4X, 8X, 12X.

5)CD-RW Record speed : 2X, 4X, 8X.

6)PIO Mode 4 & Multi DMA Mode 2 Support.

7)MPC-3 Spec compliant.

8)Support CD-TEXT read/write.

5.Audio

1)Output 16 bit digital data over ATA interface.

2)4 Times Digital Filter for CD Audio

3)Software Volume Control

4)Equipped with audio line output and headphone jack for audio CD playback.

5)Front panel Volume Control for Headphone Output.

3

SPECIFICATIONS

1. SYSTEM REQUIREMENTS

-CPU: IBM Compatible Pentium 233MHZ (or faster)

(For 12X Write speed, 350MHz or faster recommended.) -32MB Memory or greater

2. SUPPORTING OPERATING SYSTEM

• DOS 3.1 or Higher |

• Solaris Ver 2.4 or higher |

• Windows ‘95/’98/’2000 |

• Linux Slackware Ver 2.3 |

• OS/2 Warp (Ver 3.0) |

• Windows NT 4.0 or later |

3. GENERAL

1) |

Host Interface....................................................................................................................... |

ATAPI compliant |

2) |

Read Function |

|

|

• Acceptable discs ............................................................... |

CD-ROM Mode1 (basic format), CD-ROM XA |

|

|

CD-Audio |

|

|

Mixed Mode (Audio and Data Combined) |

|

|

Photo-CD (Single and Multi-Session) |

|

|

CD-I Ready, Video CD |

|

|

CD-Plus/CD-Extra, |

|

|

CD-R (Conforming to “Orange Book Part2”) |

|

|

CD-RW (Conforming to “Orange Book Part3”) |

3) |

Write function |

|

|

• Applied Format.................................................................. |

CD-ROM Mode-1 |

|

|

CD-ROM XA |

|

|

CD-Audio |

|

|

Mixed Mode (Audio and Data Combined) |

|

|

Video CD |

|

|

CD-Plus/CD-Extra, |

|

• Writing Method.................................................................. |

Disc at once(DAO) |

|

|

Session at once(SAO) |

|

|

Track at once(TAO) |

|

|

Variable packet writing |

|

|

Fixed packet writing |

|

|

Multi-session |

4) |

Cache memory (R/W) ......................................................... |

8 Mbyte |

5) |

Disc diameter ...................................................................... |

12 cm (8 cm Read only) |

6) |

Data capacity (Yellow-Book) |

|

|

• User Data/Block ................................................................ |

2,048 bytes/block (Mode 1 & Mode 2 Form 1) |

|

|

2,336 bytes/block (Mode 2) |

|

|

2,324 bytes/block (Mode 2 Form 2) |

|

|

2,352 bytes/block (CD-DA) |

7) |

Rotational Speed |

|

|

CD-Audio............................................................................. |

8x~20x(CAV) Approx.4000 rpm |

|

CD-RW data ........................................................................ |

10x~24x(CAV) Approx.5000 rpm |

|

CD-ROM/CD-R data............................................................ |

14x~32x(CAV) Approx. 7000 rpm |

8)MTBF

• 125, 000 POH at an operating duty of 10% at room temperature.

4

4. DRIVE PERFORMANCE

1) |

Data Transfer Rate |

|

|

|

* Sustained Data Transfer Rate .......................................... |

150 Kbytes/s (1x) |

|

|

|

300 Kbytes/s (2x) |

|

|

|

600 Kbytes/s (4x) |

|

|

|

1,200 |

Kbytes/s (8x) |

|

|

2,100 to 4,800 Kbytes/s 14 to 32x CAV |

|

|

* Burst Data Transfer Rate (ATAPI) .................................... |

16.67 |

Mbytes/sec (PIO Mode 4) |

|

|

16.67 |

Mbytes/sec (MULTI-DMA Mode 2) |

2) |

Average Access Time |

|

|

|

Random Access .................................................................. |

110 ms Typical (Max.32X) : INCLUDING LATENCY |

|

3) |

Data Buffer Capacity ........................................................... |

8 Mbytes |

|

5.POWER REQUIREMENTS

1)Voltage

+5 V DC with + 5% tolerance, less than 100 mVp-p Ripple voltage +12 V DC with + 5% tolerance, less than 100 mVp-p Ripple voltage

2)Current

|

|

• Hold Track State ............................................................... |

|

|

|

+5V DC 1.1A, +12 V DC 0.6A (Typical) |

|||||||

|

|

• Seeking & Spin up ............................................................ |

|

|

|

+5 V DC 1.3A, +12 V DC 1.7A (Typical) |

|||||||

6. AUDIO PERFORMANCE |

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

Typical |

|

Limit |

|

Test Signal |

|

Test Condition |

Note |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OUT |

|

Output Level |

0.7 Vrms |

|

+ 10 % |

|

1KHz 0 dB |

|

No Filter |

at 47 kΩ |

||

|

|

S/N |

80 dB |

|

75 dB |

|

1KHz 0 dB |

|

with IHF-A + 20KHz LPF |

at 47kΩ |

|||

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AUDIO |

|

THD |

0.1 % |

|

0.15 % |

|

1KHz 0 dB |

|

with IHF-A + 20KHz LPF |

at 47kΩ |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Channel |

70 dB |

|

65 dB |

|

1KHz 0 dB |

|

with IHF-A + 20KHz LPF |

at 47kΩ |

|||

|

|

|

Separation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Frequency |

|

+ |

2dB |

|

+ 3 dB |

|

20Hz~18KHz 0 dB |

|

No Filter |

at 47 kΩ |

|

|

|

Response |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

H/P |

|

0.6Vrms |

|

+ 20 % |

|

1KHz 0dB |

|

No Filter H/P Volume MAX |

at 32 Ω |

|

|

|

|

Output Level |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

* CED-8120B FUNCTION TABLE |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Funtion |

|

|

M O D E L |

|

CED-8120B |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

||||||||||

|

• CD-R Writing speed |

4x/8x/12x Data writing |

|

||||||||||

|

|

|

|

|

|

|

|||||||

|

• CD-RW Writing speed |

|

2x/4x/8x Data writing |

|

|

|

|||||||

|

|

|

|

|

|

|

|||||||

|

• CD-ROM Reading speed |

|

32x Data transfer |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5

LOCATION OF CUSTOMER CONTROLS

Front Panel |

Emergency Eject Hole

READ

Disc Tray

WRITE

|

Stop/Eject Button |

|

Play/Skip Button |

Volume |

|

Control |

Drive Activity Indicators |

Headphone Jack |

|

1.Disc tray

This is the tray for the disc. Place the disc on the ejected disc tray, then lightly push the tray (or push the eject button) and the CD will be loaded.

NOTE: Don’t pull out or push in the disc tray forcibly. This might cause damage to the loading section of the drive.

2.Stop/Eject button

This button is pressed to open the CD tray.

This button works only when power is supplied to the drive.

If an Audio CD is playing, pressing this button will stop it, and pressing it again will open the tray.

3.Play/Skip button

When an Audio CD is in the disc drawer, pressing this button will start playing Audio CDs from the first track. If an Audio CD is playing, pressing this button will skip to the next track.

4.Emergency Eject Hole

Insert a paper clip here to eject the Disc tray manually or when there is no power.

5.Volume control

This is used to adjust the output volume of the headphone jack. It can’t be used to adjust the output volume for the audio output connectors on the rear panel.

NOTE : Turn the volume down before turning on the power. Sudden loud noises can damage your hearing.

6.Headphone jack

This jack is for connecting headphones or minispeakers.

7.Drive activity indicators

Two colored LEDs are used to indicate the operation of CD-R/RW Drive.

(1)Read

The orange color is displayed when the spindle motor begins the Spin up operation: accessing data, reading data, playing Audio, and up loading tray.

(2) Write

The green color is flashed during disc writing sessions.

6

Rear Panel |

Analog Audio Output Connector |

|

|

|

IDE Interface Connector |

||

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Jumper Connector

Power Connector

Digital Audio Output

Connector

1.Power Connector

Connects to the power supply (5-and 12-V DC) of the host computer.

NOTE : Be careful to connect with the proper polarity. Connecting the wrong way may damage the system (and is not guaranteed). Usually this connector can only be attached one-way.

2.IDE Interface Connector

Connect to the IDE (Integrated Device Electronics) Interface using a 40-pin flat IDE cable.

NOTE : Do not connect or disconnect the cable when the power is on, as this could cause a short circuit and damage the system. Always turn the power OFF when connecting or disconnecting the cable.

3.Jumper Connector

This jumper determines whether the drive is configured as a master or slave. Changing the master-slave configuration takes effect after power-on reset.

4.Analog Audio Output Connector

Provides output to a sound card (analog signal). Generally you need this to play a regular audio CD.

5.Digital Audio Output Connector

Provides output to a sound card (digital signal).

7

DISASSEMBLY

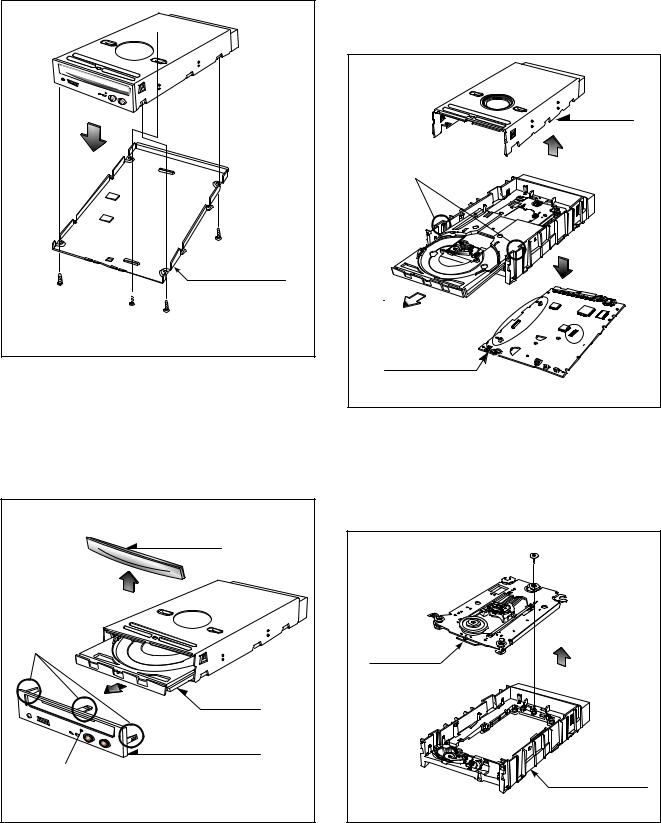

1.CABINET and CIRCUIT BOARD DISASSEMBLY

1-1. Bottom Chassis

A.Release 4 screws (A) and remove the Bottom Chassis in the direction of arrow (1). (See Fig.1-1)

(1)

(A)

Bottom Chassis

(A)

(A)(A)

Fig. 1-1

1-2. Front Bezel Assy

A.Insert and press a rod in the Emergency Eject Hole and then the CD Tray will open in the direction of arrow (2).

B.Remove the Tray Door in the direction of arrow

(3) by pushing the stoppers forward.

C.Release 3 stoppers and remove the Front Bezel Assy.

|

Tray Door |

Stoppers |

|

(2) |

CD Tray |

|

|

|

Front Bezel Assy |

Emergency Eject Hole |

|

Fig. 1-2 |

|

8 |

|

1-3. Cabinet and Main Circuit Board

A.Remove the Cabinet in the direction of arrow (4). (See Fig. 1-3)

B.Release 2 hooks (a) and remove the CD Tray drawing forward.

C.Remove the Main Circuit Board in the direction of arrow (5).

D.At this time, be careful not to damage the 4 connectors, are positioned at left side, of the Main Circuit Board.

|

Cabinet |

Hooks (a) |

(4) |

|

|

|

(5) |

Main |

|

Circuit Board |

|

|

Fig. 1-3 |

2. MECHANISM ASSY DISASSEMBLY

2-1. Pick-up Unit

A.Release screw (B).

B.Separate the Pick-up Unit in the direction of arrow (6).

(B) |

Pick-up Unit |

(6) |

Mechanism Assy |

Fig. 2-1 |

2-2. Pick-up

A. Release 1 screw (C) and remove the Pick-up.

Pick-up Unit

(C)

(C)

Pick-up

Fig. 2-2

9

|

GLOSSARY |

|

|

ATIP |

Absolute Time in Pre-groove. With an additional modulation of the “Wobble”, the “Groove” contains a time |

|

code information. |

|

|

Wobble |

The pre-groove in the Disc is not a perfect spiral but is wobbled. |

|

With : – A typical amplitude of 30 nm |

|

– A spatial peried of 54~64 µm |

|

|

CW |

Continuous Wave. The laser light output is at a constant level. |

|

|

DOW |

Direct Over-Write. The action in which new information is recored over previously recorded information in |

|

CD-RW disc. |

|

|

Overwrite |

The action in which new information is recorded over previously recorded information. |

|

|

(Pre-)Groove |

The guidance track in which clocking and time code information is stored by means of an FM |

|

modulated wobble. |

|

|

Land |

Land is characterized in the following way: |

|

When radial signals are concerned,land is defined as the area between the grooves. |

|

When HF signal are concerned,land is defined as the area between the marks(pits) in tangential |

|

direction. |

|

|

Hybrid Disc |

A Multisession disc of which the first Session is mastered. On a hybrid disc, recorded and |

|

mastered information may co-exist. |

|

|

Mastered |

Information,stored as pits on the disc during the manufacturing process of the disc. |

Information |

(when making the master) |

|

|

OPC |

Optimum Power Control. Procedure is determined optimum recording power according to CD- |

|

R/RW Media in recording start step. |

|

|

ROPC |

Running OPC. The purpose is to continuously adjust the writing power to the optimum power |

|

that is required. |

|

When the optimum power may change because of changed conditions of disc and change in |

|

operating temperature. |

|

|

Jitter |

The 16 value of the time variation between leading and trailing edges of a specific (I3 … I11) pit |

|

or land as measured by Time Interval Analysis. |

|

|

Deviation |

The difference between a fixed value of Pit length and Land length. |

|

|

TOC |

Table Of Contents : in the Lead-in Area the subcode Q-channel contains information about the |

|

Tracks on the disc. |

|

|

Packet |

A method of writing data on a CD in small increments. |

Writing |

Two kinds of packets can be written : Fixed-length and Variable-length. |

Write |

The shape of the HF write signal used to modulate the power of the laser. |

Strategy |

The Write Strategy must be used for recordings necessary for disc measurements. |

|

|

Information |

Wobble, ATIP, Disc Identification, Write Power, Speed Range OPC Parameters, etc are |

Area |

recorded in the Information area of CD-RW Disc |

Finalization |

The action in which (partially) unrecorded or logically erased tracks are finished and the Lead-in |

|

and/or Lead-out areas are recorded or overwritten with the appropriate TOC subcode. |

|

|

Logical Erase |

A method to remove information from a disc area by overwriting it with an EFM signal containing |

|

mode 0 subcode |

|

A logically erased area is equivalent to an unrecorded |

|

|

Physical Erase |

The action in which previously recorded information is erased by overwriting with a CW laser |

|

output. |

|

After a Physical Erase action, the erased area on the CD-RW disc is in the unrecorded state |

|

again. |

|

|

Session |

An area on the disc consisting of a Lead-in area, a Program area, a lead-out area. |

Multi session |

A session that contains or can contain more than one session composed Lead-in and Lead-out |

10

The differences of CD-R/CD-RW discs and General CD-ROM

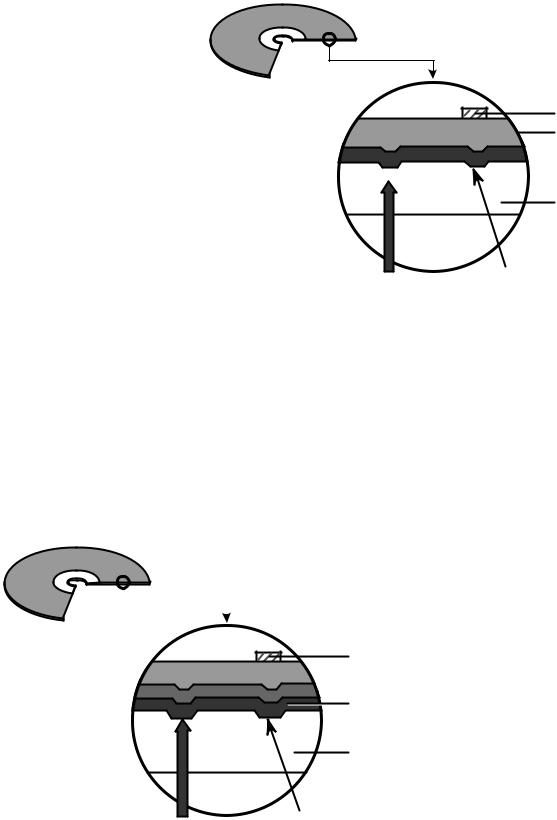

1. Recording Layer

Recordable CD has a wobbled pre-groove on the surface of disc for laser beam to follow track.

Read-only Disc |

CD-ROM (READ-ONLY DISC) |

.6um |

1 |

3~11T |

0.4~0.5 um |

CD-R and CD-RW Disc |

(Pit)Groove |

Land |

|

Track pitch(p) |

a=30nm |

|

A |

|

|

|

|

|

Iw |

|

|

O |

|

|

a |

Radial Direction |

|

|

|

|

|

Radial Error Signal |

Land |

Groove |

|

|

a |

|

|

|

Average center |

|

|

Actual center |

|

|

The Groove wobble |

2. Disc Specification

|

CD-ROM |

CD-R |

CD-RW |

|

Standard |

Yellow Book |

Orange Book II |

Orange Book III |

|

Record |

Not available |

Write once |

Re-writable |

|

I 11/Itop |

> 0.6 |

> 0.6 |

0.55 > M11> 0.70 |

|

(HF Modulation) |

||||

|

|

|

||

Write Laser Power(mW) |

|

10-30 mW |

6-25 mW |

|

Read Laser Power(mW) |

< 0.5 mW |

< 0.7 mW |

< 1.0 mW |

|

Jitter |

< 35 nsec |

< 35 nsec |

< 35 nsec |

|

Reflectivity (Rtop) |

70 % |

65 % |

15 % ~ 25 % |

18

3. Disc Materials

1)CD-ROM disc

•It is composed of Silver _ colored aluminum plate and Reflective layer.

•Groove (Pit) of aluminum plate make a track.

•Laser wavelength : 780 nm, Laser Power (Read): 0.5mW

•Signal is detected by the difference of reflective beam

intensity between “pit” and “Land” on the disc.

Label Printing

Protective Layer

Reflective Layer

Reflective Layer

Substrate (Polycarbonate)

Pit

Laser Beam

2)CD-R disc

•It is so-called WORM (Write Once Read Many) CD.

•It is composed of polycarbonate layer, Organic dye layer, Reflective layer, and Protective layer.Gold/Silver Reflective layer is used to enhance the reflectivity

•According to the kinds of Organic dye layer, it is divided by Green CD, Gold CD, Blue CD.

•Laser Wavelength : 780 nm, Laser Power (read) : 0.7 mW

•Recording Power : 4x(10~15mW), 8x(14~20mW), 12x(15~30mW).

•When some part of dye layer is exposed to laser heat, it’s color changs black.Therefore, writing and reading is enabled by the difference of reflectivity between changed part and unchanged part.

•Polycarbonate layer has Pre_Groove which make a Track.

|

Pigment |

Reflective Layer |

Color |

|

|

|

|

|

Phtalocyanine |

Gold/Silver |

Yellow/White |

|

|

|

|

|

Cyanine |

Gold/Silver |

Dark Green/Bright Green |

|

|

|

|

|

Azo |

Gold/Silver |

Dark Blue |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Label Printing

Protective Layer

Protective Layer

Reflective Layer

Reflective Layer

Organic Dye Layer

Substrate (Polycarbonate)

Laser Beam |

Groove |

19

3) CD-RW Disc

Label Printing

Protective Layer

Protective Layer

Dielectric Layer(TL)

Reflective Layer

Reflective Layer

Dielectric Layer(UL)

Dielectric Layer(UL)

Substrate (Polycarbonate)

Laser Beam |

Groove |

•It is composed of polycarbonate layer, alloy(silver, arsenic) layer, aluminum reflectivity layer, protective layer.

•An crystalized alloy layer is transformed into noncrystalized by the laser heat. Therefore, writing and reading is enabled by the difference of reflectivity.

•It is possible to overwrite about 1000 times.

•Laser Wavelength : 780 nm, Laser Power (Read) : 1.0mW

•Recording Power : Erase (4~12mW), Write (6~25mW)

•When disc rewriting, new data is overwritten previously recorded data.

•Polycarbonate layer has a Pre-Groove which make a track.

4. Reading process of Optical Disc |

|

|

|

Lens |

|

|

H |

|

|

θ |

D |

|

|

|

|

|

Beam |

Focusing |

Numerical aperture: NA=nsinθ, |

Spot |

|

||

Lens |

n: Refractive index |

|

|

Focus depth : H = λ/NA |

|

Laser Spot |

laser spot diameter : D = λ/NA2 |

|

|

|

|

at Constant |

|

|

Read Intensity |

Previously Recorded Marks |

|

|

|

|

|

|

Groove |

Land |

Mirror |

Reflected |

|

|

|

|

Light |

|

|

|

|

Signal |

|

|

|

|

|

I11 |

IG |

IL |

I0 |

I3 |

Itop Laser Spot |

|

|

|

|

Position |

|

|

|

(Time)

20

5. Writing Process of CD-R Disc

Incident |

(Write) |

|

Laser |

|

|

|

|

|

Power |

|

(Read) |

(Read) |

|

|

a |

b c d e f g |

Laser Spot |

Position |

||

|

|

(Time) |

|

a |

|

Laser |

b |

|

Spot |

|

Reflected |

|

c |

|

|

Light |

|

|

|

Signal |

|

d |

|

|

e |

|

|

f |

|

Recorded |

|

g |

Mark |

|

|

|

|

Reflected

Light

Signal

|

|

|

|

|

|

|

|

|

Laser Spot |

|

|

|

|

|

|

|

|

|

|

||

a b c d e f |

g |

|||||||||

Position |

||||||||||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

(Time) |

|

Below "ORP"– Mark Too Short

At Optimum Record Power ("ORP")

Above "ORP" – Mark Too Long

Time

6. Writing process of CD-RW Disc

Crystal phase |

Amorphous |

Write Power |

|

|

|

|

|

|

|

|

|

|

|

||

Melting/ |

|

|

|

|

|

|

|

quenching |

|

Erase Power |

|

|

|

|

|

|

|

|

|

|

|

||

Heating/ |

|

Read Power |

|

|

|

|

|

gradual cooling |

|

|

|

|

|

|

|

Erased state |

Recorded state |

|

|

|

|

|

|

(higher reflectivity) |

(lower reflectivity) |

Groove |

|

|

|

|

|

Crystal Amorphous

21

7. Organization of the PCA, PMA and Lead-in Area

1) Layout of CD-ROM disc

Disc Center |

Diameter 120 mm |

|

Diameter 46 mm

Diameter 15 mm

Center hole |

Clamping and Label Area |

|

Information Area |

|

|

|

|

|

|

|

Read Only Disc |

|

|

|

|

|

|

|

|

Lead-in Area |

Program Area |

|

Lead-out Area |

|

|

|

|

|

|

|

|

|

|

|

2) Layout of CD-R/RW disc

Disc Center |

Diameter 120 mm |

|

|

|

|

Diameter 45 mm

Diameter 15 mm

|

Center hole |

Clamping and Label Area |

|

|

|

Information Area |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Unrecorded Disc |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

PCA |

PMA |

|

Lead-in Area |

|

|

|

Program Area |

Lead-out Area |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Test Area : for performing OPC procedures. |

||

|

Test Area |

|

Count Area |

|

|

|

|

|

|

|

Count Area : to find the usable area immediately in T.A |

|||||

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

Tsl : start time of the Lead-in Area, as encoded in ATIP |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

in |

|

|

|

|

|

|

|

|

|

|

|

|

out |

PMA : Program Memory Area |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tsl-00:35:65 Tsl-00:15:05 Tsl-00:13:25 Tsl |

99:59:74 |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

00:00:00 |

|

|

|

|

||

22

8. Function of PCA and PMA area

1)PCA (Power Calibration Area)

•PCA area is used to determine the correct Laser Power for a disc.

–Method 1 : PCA area is divided by a track.

–Method 2 : The previous Calibration value is referred.

–Method 3 : ROPC is used to determine Laser Power value automatically in data writing.

•CD-R Disc can write maximum 99 Tracks but CD-RW Disc can write unlimited tracks because it has a rewritable function.

2)PMA (Program Memory Area)

•It has a track information (track No, track Start/End time) of every track before writing completed.

–PMA area has the last written point and the next writable point of a disc.

–In case of CD to CD copy, some writer may not write PMA area.

* When Disc is Finalized,

PMA information is transferred to the Lead_In area so that general Driver can read it.

* Because PCA and PMA area exist before Lead-In area, General CD Player or CD-ROM Drive can’t read these areas.

9. OPC and ROPC

1)OPC (Optimum Power Control)

•This is the first step of writing process, because CD writer has its own laser power value and media have different writing characteristics,

–This is determined by the Writing characteristic, speed, temperature, and humidity.

–Laser wavelength is determined by the environmental temperature (775~795nm) and Optical Laser Power is determined by the test and retry.

•Asymmetry and optimum writing Power

–EFM signal Asymmetry is determined by the writing power.

Therefore, Optical Power which has the same value to the preset power value can be estimated by measuring HF signal Asymmetry on the PCA area.

•Measurement of Asymmetry

*Parameter setting (Beta) : Using AC coupled HF signal before equalization Beta = (A1+A2)/(A1-A2)

Signal |

A1 |

|

0 |

|

|

HF |

|

|

|

|

|

|

A2 |

|

|

Time |

P << Po |

P = Po

Time

P >> Po |

Time |

23

Loading...

Loading...