Konica Minolta bizhub 2500P User Manual

User manual

BLM 200 / Bookletmaker 25

Operating information

Copyright

Copyright

2008 Océ

All rights reserved. No part of this work may be reproduced, copied, adapted, or

transmitted in any form or by any means without written permission from Océ.

Océ makes no representation or warranties with respect to the contents hereof and

specifically disclaims any implied warranties of merchantability or fitness for any

particular purpose.

Further, Océ reserves the right to revise this publication and to make changes from

time to time in the content hereof without obligation to notify any person of such

revision or changes.

Note: The contents of this document are subject to copyright

protection by third parties.

Edition 2008-08

US

Table of Contents

Table of Contents

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

What you can do with this machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Guide to components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Booklet maker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Trimmer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Two-side Trimmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SquareFold module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 2

Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Turn on/off the power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Check staples, staple cartridge and stapler head . . . . . . . . . . . . . . . . . . 21

Remove/replace staple cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Remove/replace stapler head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Empty the trim bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 3

Make booklets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Change settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

General procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Set the paper size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Select standard paper sizes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Custom paper size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Staple and Fold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Select stapling mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Adjust staple and fold alignment . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Adjust fold quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Set up narrow width paper sizes . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Select trim on or off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Adjust the cutting margin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SquareFold module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Select the SquareFold module mode . . . . . . . . . . . . . . . . . . . . . . . . . 42

Online/Offline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Rotator module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3

Table of Contents

Basic information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Basic operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Prepare the rotator module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Storage compartment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Problem solving. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

"Not Ready" Status indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Clear paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter 4

System administration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

The Admin screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Size standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Chapter 5

Job control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Store a job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Recall a job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Chapter 6

Clear a paper jam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Booklet maker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Trimmer input area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Trimmer exit area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Two-side Trimmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

SquareFold Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

SquareFold Module exit area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Chapter 7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Fault codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Booklet maker fault codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Booklet quality fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Trimmer fault codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

SquareFold module fault codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Chapter 8

General remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Do’s and don’ts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Place the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

4

Table of Contents

Maintain the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Booklet maker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Two-side Trimmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

SquareFold module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Chapter 9

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Machine Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Booklet maker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Trimmer BLT6289 / BLT6789 (option) . . . . . . . . . . . . . . . . . . . . . . . 104

SquareFold module SFM6204 / SFM6704 (option) . . . . . . . . . . . . . 105

Rotator RTM6240 (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5

Table of Contents

6

Chapter 1 Introduction

7

What you can do with this machine

What you can do with this machine

Introduction

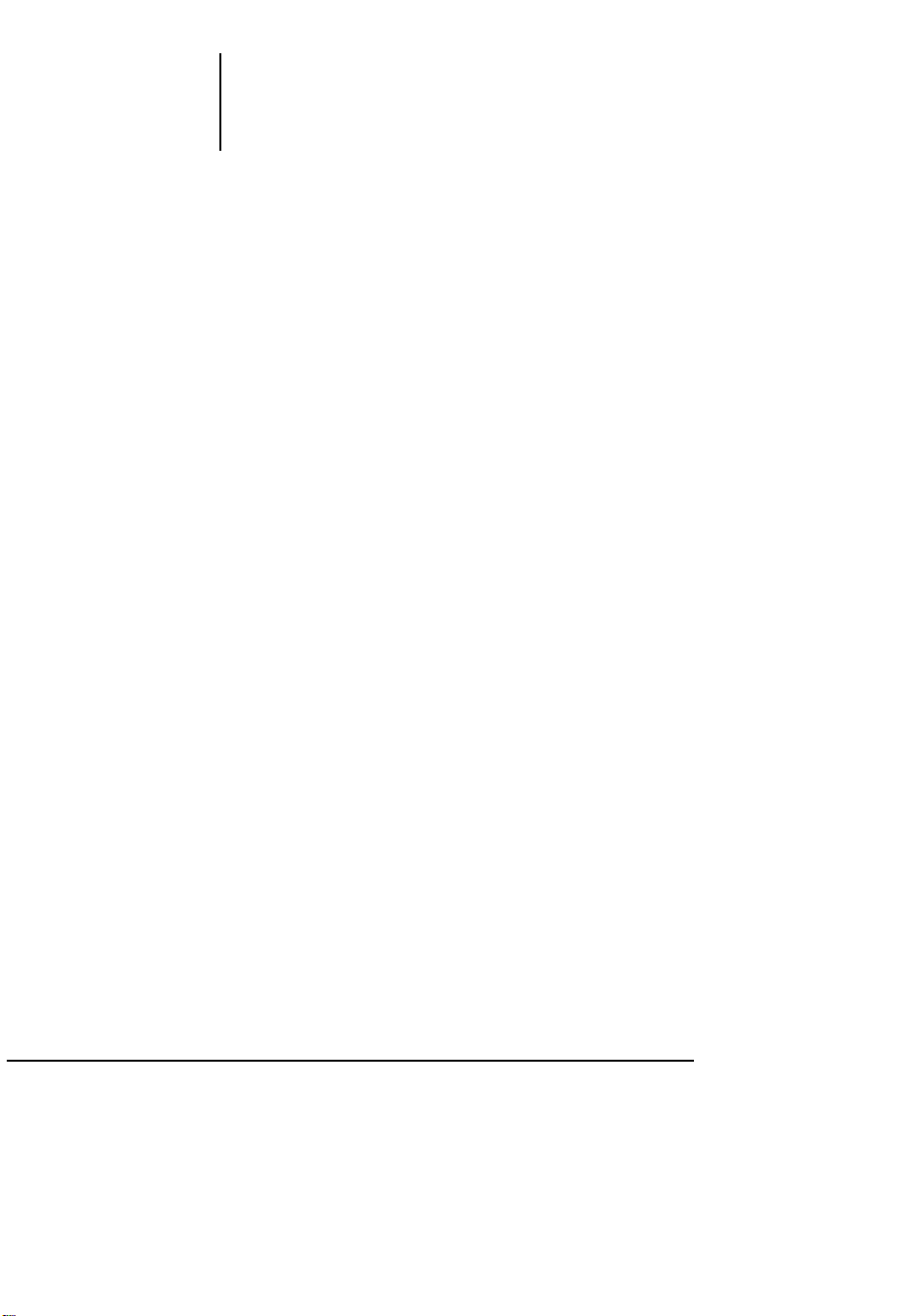

[1]

[1]

Number Description

1 Booklet maker

2Trimmer

3 SquareFold module

4 Belt Stacker

5 Rotator module

The Booklet maker, Trimmer, and SquareFold module form a booklet making

system that works online with copiers or printers.

The printouts from the copier or printer are transported sheet by sheet into the

Booklet maker and collected in the stapler area of the Booklet maker. The Booklet

maker now jogs and then staples the set. The set is then transported further to the

folding area where the set is folded into a booklet and then fed out to the belt stacker.

When a larger number of sheets are folded, an effect called creeping occurs. In order

to rectify creep, the Trimmer can be connected to the Booklet maker. The booklets

are then transported from the Booklet maker into the Trimmer where the front edge

(face) will be cut off. Another option, the SquareFold module, can be installed if a

Trimmer is installed on the Booklet maker. The prints, which have been stapled,

folded and trimmed, will be fed into the SquareFold module. The SquareFold

module will flatten the spine of the booklet into a square shape. The booklets will,

after passing through the SquareFold module, have the look of a perfect bound book.

The booklets are then fed out to the belt stacker.

8 Chapter 1 Introduction

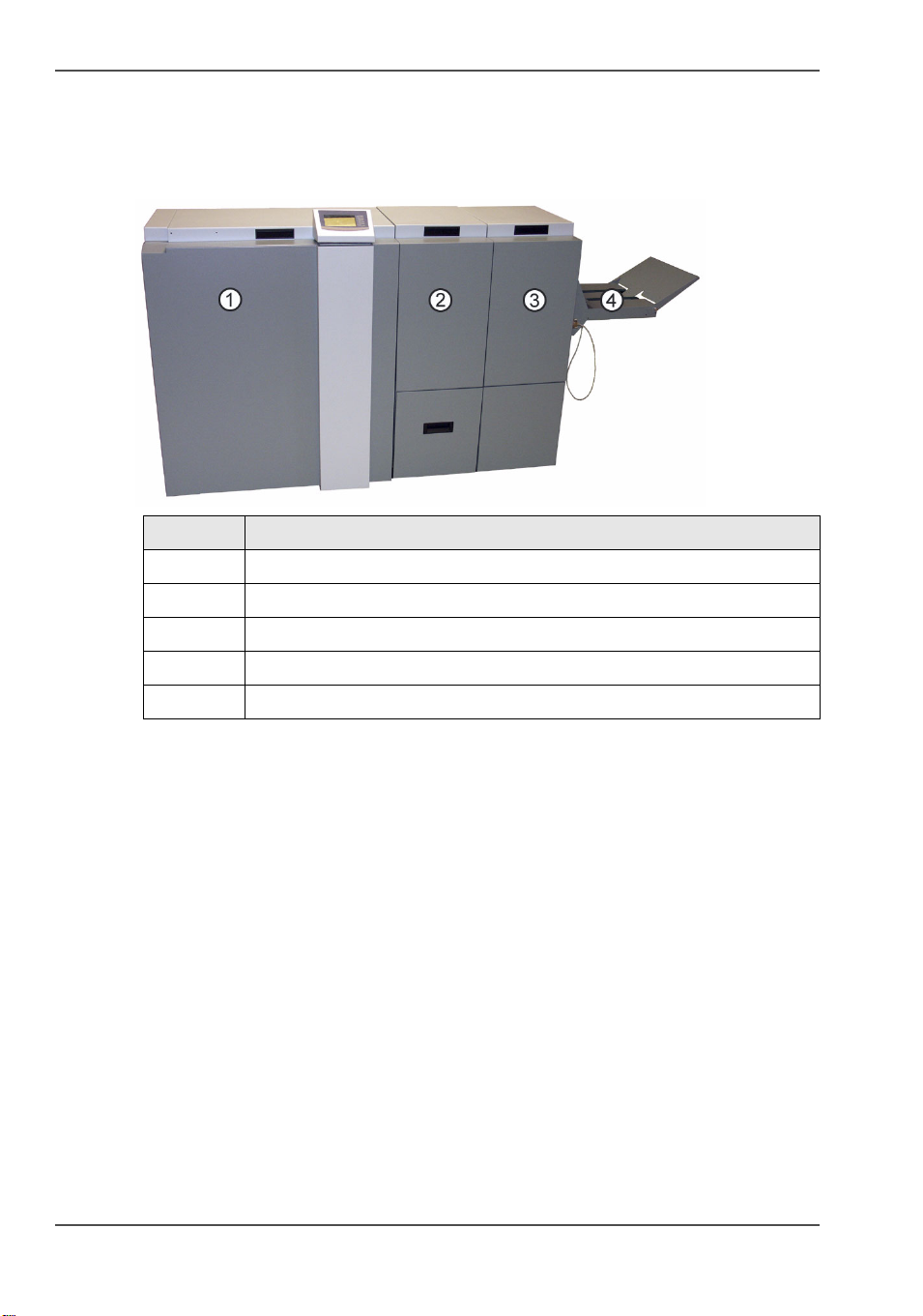

The buttons on the control panel

The entire booklet making system is controlled from a single control panel on the

Booklet maker. The control panel has only six buttons which will allow you to easily

set up, adjust, and operate the complete system.

[2]

[2]

[3]

What you can do with this machine

Description

The buttons are multifunctional, meaning that the

function of each button depends on the information

displayed. For example: In this screen, the icon next

to button 1 indicates you will go up one level in the

menu when the button is pressed.

Example 2: In this screen, button 1 has no function.

[4]

Example 3: Pressing button 1 here will answer “No”

to the question on the screen.

9

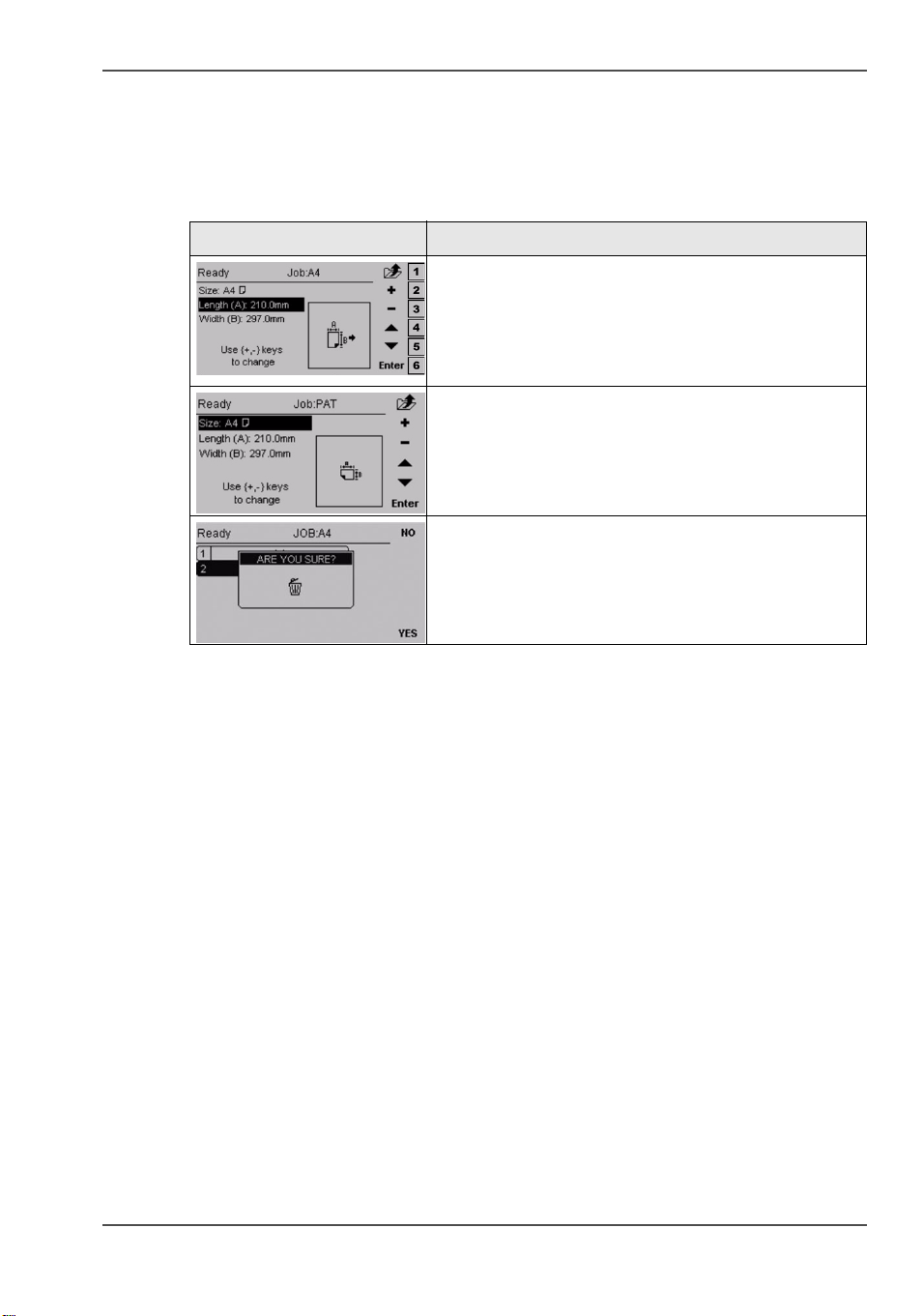

Booklet maker

Guide to components

Booklet maker

Component locator

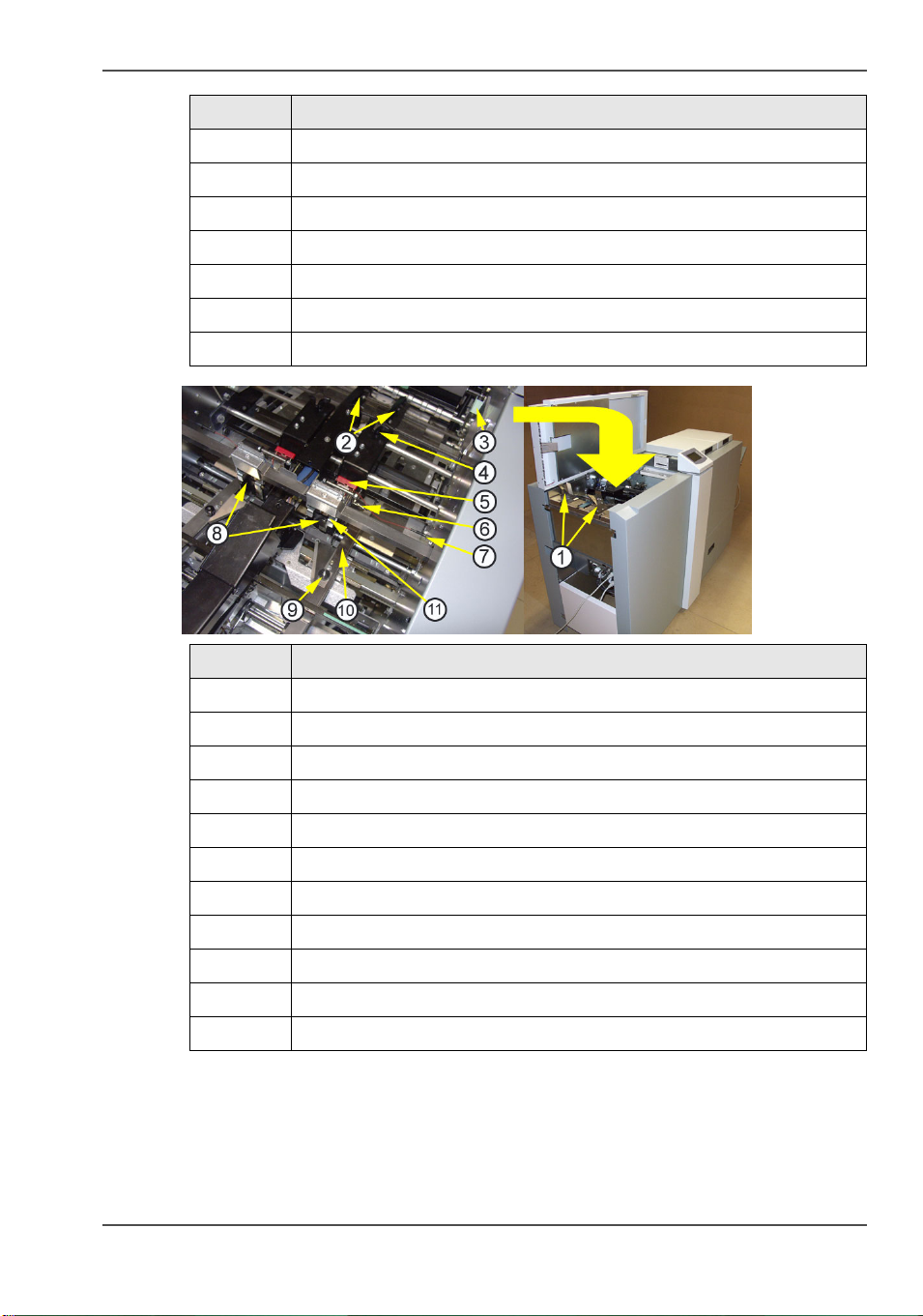

[5]

[3]

Number Component

1 Top cover

2 Infeed assembly

3 Power switch

4 Control panel

5 Belt Stacker Cover

6 Belt Stacker

[6]

10 Chapter 1 Introduction

Booklet maker

[4]

Number Component

1 Communication with Printer/Rotator

2 CAN In: Termination socket

3 CAN Out: Termination socket / Communication with Trimmer

4 Power socket

5 Power out to SquareFold module

6 Interlock jumper

7 Interlock jumper / Power out to Trimmer

[7]

[5]

Number Component

1 Side guides

2Ball cage

3 Fold adjust lever

4 Thumb screw for Stapler assy

5 Cartridge locking levers

6 Locking pin

7 Staple detection leads

8 Stapler heads

9 Side guide extension

10 Thumb screw for Side guide extension

11 Stapler lift bracket

11

Trimmer

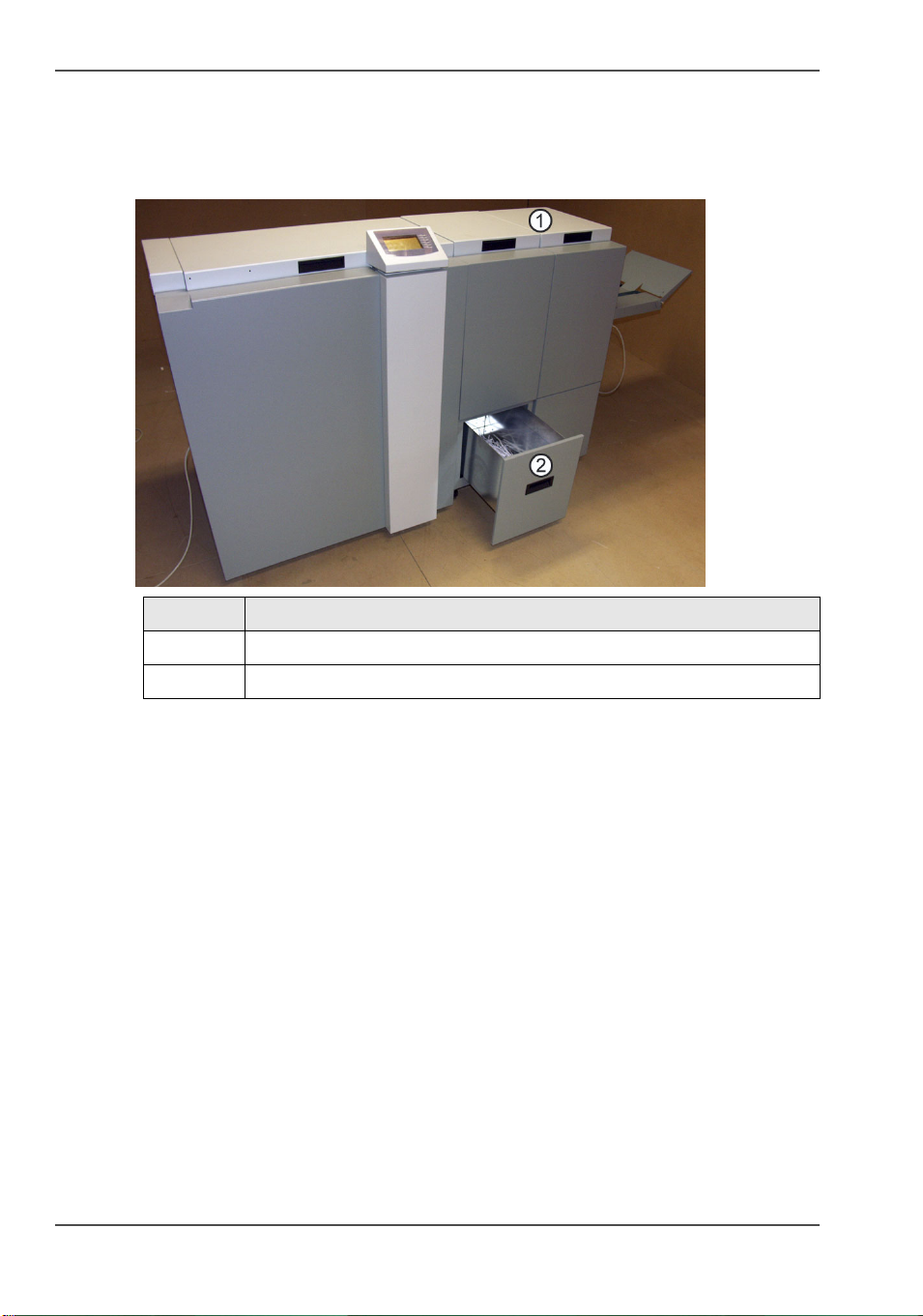

Trimmer

Component locator

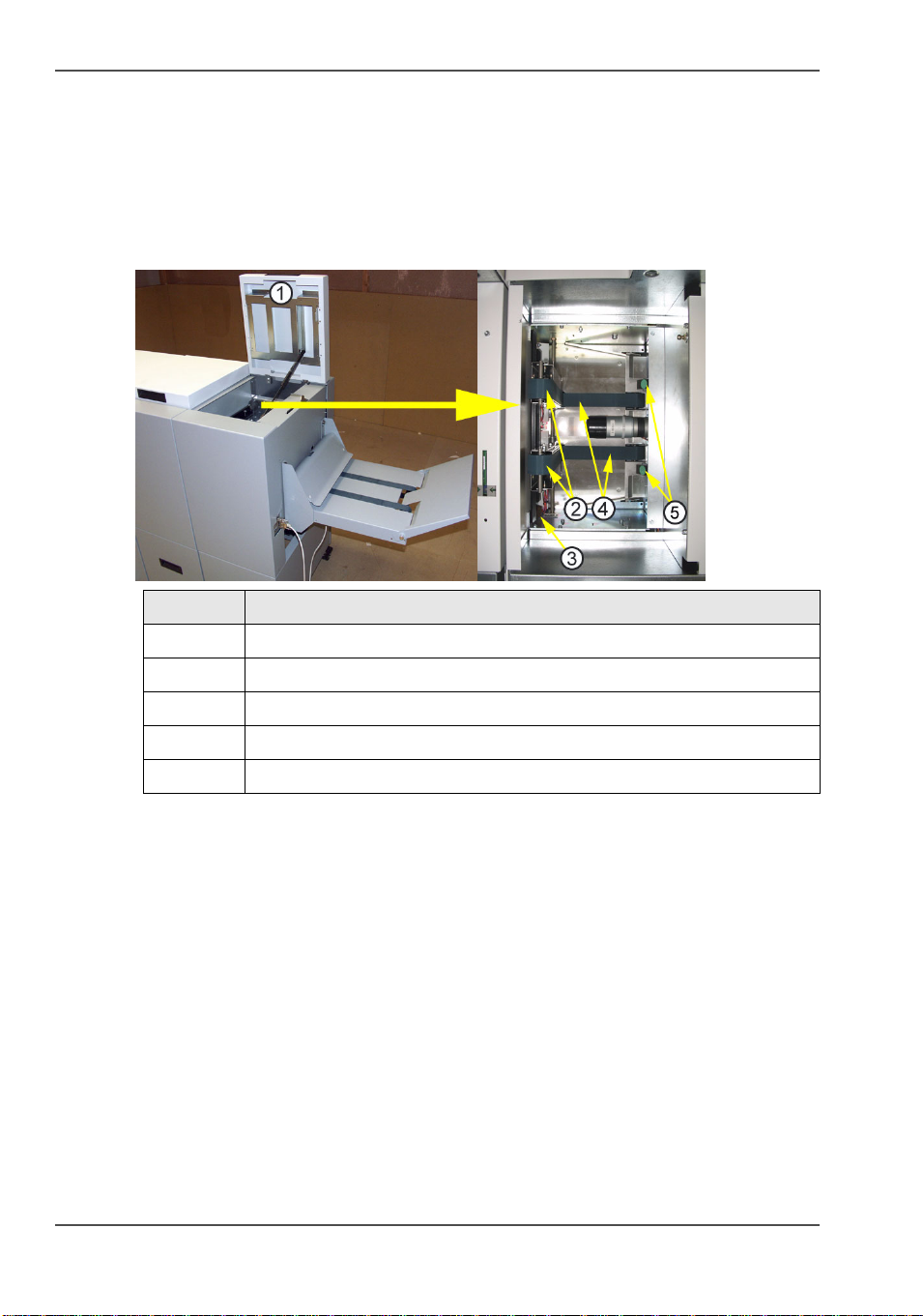

[8]

[6]

Number Component

1 Top cover

2Trim bin

The Trimmer interior has parts that you will come into contact with if a jam occurs.

12 Chapter 1 Introduction

Trimmer

[9]

[7]

Number Component

1 Trimmer fan

2 Infeed latch

3 Docking bracket

4 Infeed roller shaft

5 Knives (not shown in picture)

6 Exit compression brackets

7 Trimmer stop

8Outfeed latch

9 Transport belt

13

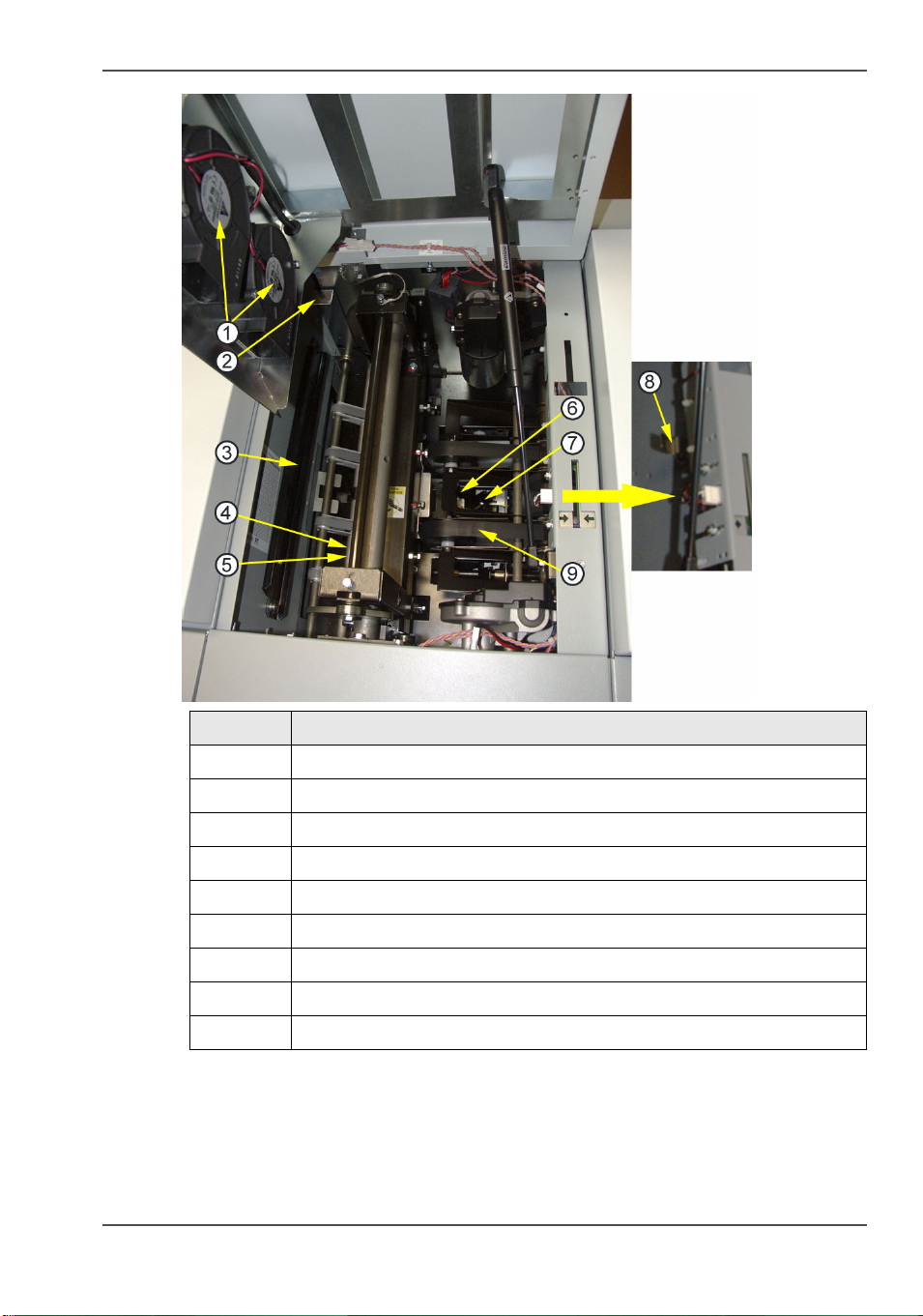

Two-side Trimmer

Two-side Trimmer

Component locator

[10]

1

2

[8]

Number Component

1 Top cover

2 Trim bins

The Two-side Trimmer interior has parts you will come into contact with if a jam

occurs.

[11]

1 2 3 4 5 6

[11] Two-side Trimmer, top view

[9]

Number Component

1 Docking bracket

2Knives

14 Chapter 1 Introduction

Number Component

3 Transport belts

4 Joggers

5 Trimmer stop

6 Power switch

Two-side Trimmer

15

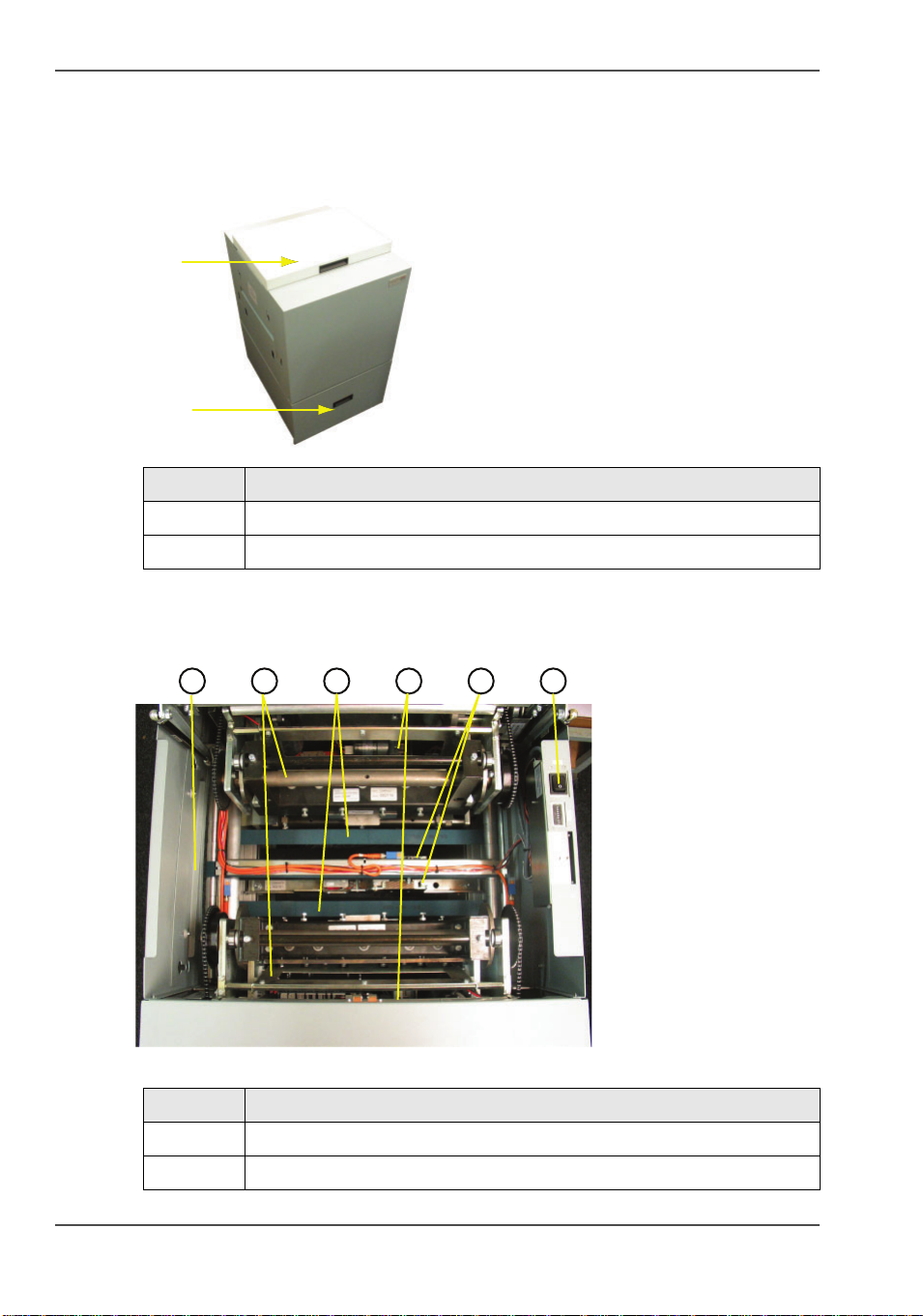

SquareFold module

SquareFold module

Component locator

The SquareFold module interior has parts that you will come into contact with if a

jam occurs.

[12]

[10]

Number Component

1 Top cover

2Upper feed belts

3 Docking bracket

4Lower feed belts

5 Latches

16 Chapter 1 Introduction

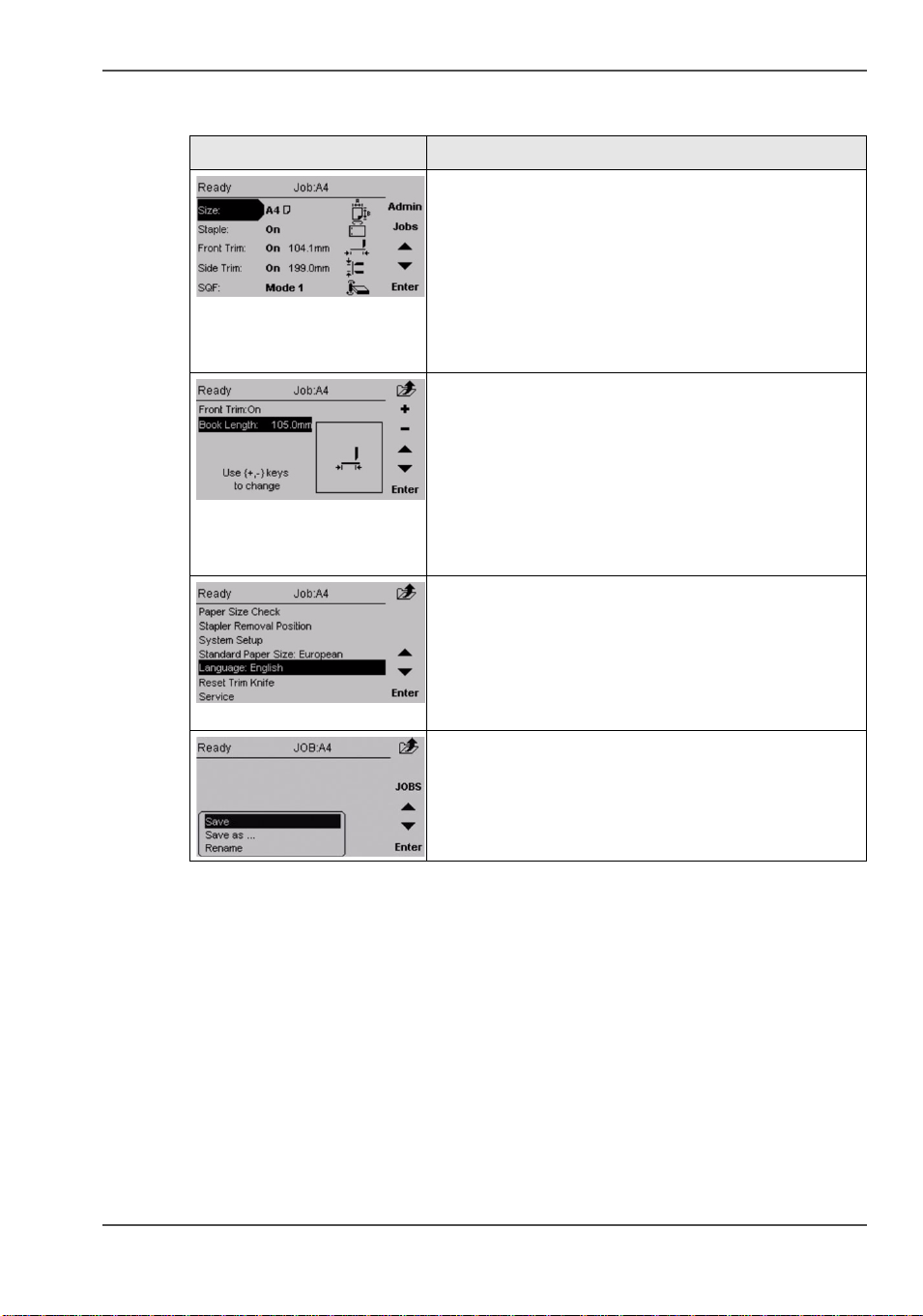

Control panel

[11]

[13]

[14]

[15]

[16]

Control panel

Action

The Main screen.

When the system power is switched on, the Main

screen will be shown. Here you will find information

showing the actual set-up. From this screen you can

also access other screens that will help you operate

the complete Booklet making system. At the top,

throughout the screens, you can see the current state

of the machine and the current job.

Changing settings.

To change or adjust settings: Select an item in the

Main screen with the [arrow] button and press the

[Enter] button. For example you can (finely) adjust

the trimming, change stapling mode, or set the

SquareFold module to the correct mode. Settings are

explored more thoroughly in section 2, Making

Booklets.

The Admin screen.

Pressing the [Admin] button in the Main screen takes

you to the Admin screen. From here you can change

the display language, set paper size standard, and

more. (see ‘Language’ on page 60), for how to

navigate in the Admin screen.

The Jobs screen.

Pressing the [Jobs] button in the Main screen opens

the Jobs screen. From here you customize and save

job settings. Press [Jobs] again and you can load

previously saved jobs. (see ‘Store a job’ on page 64).

17

Control panel

18 Chapter 1 Introduction

Chapter 2 Basics

19

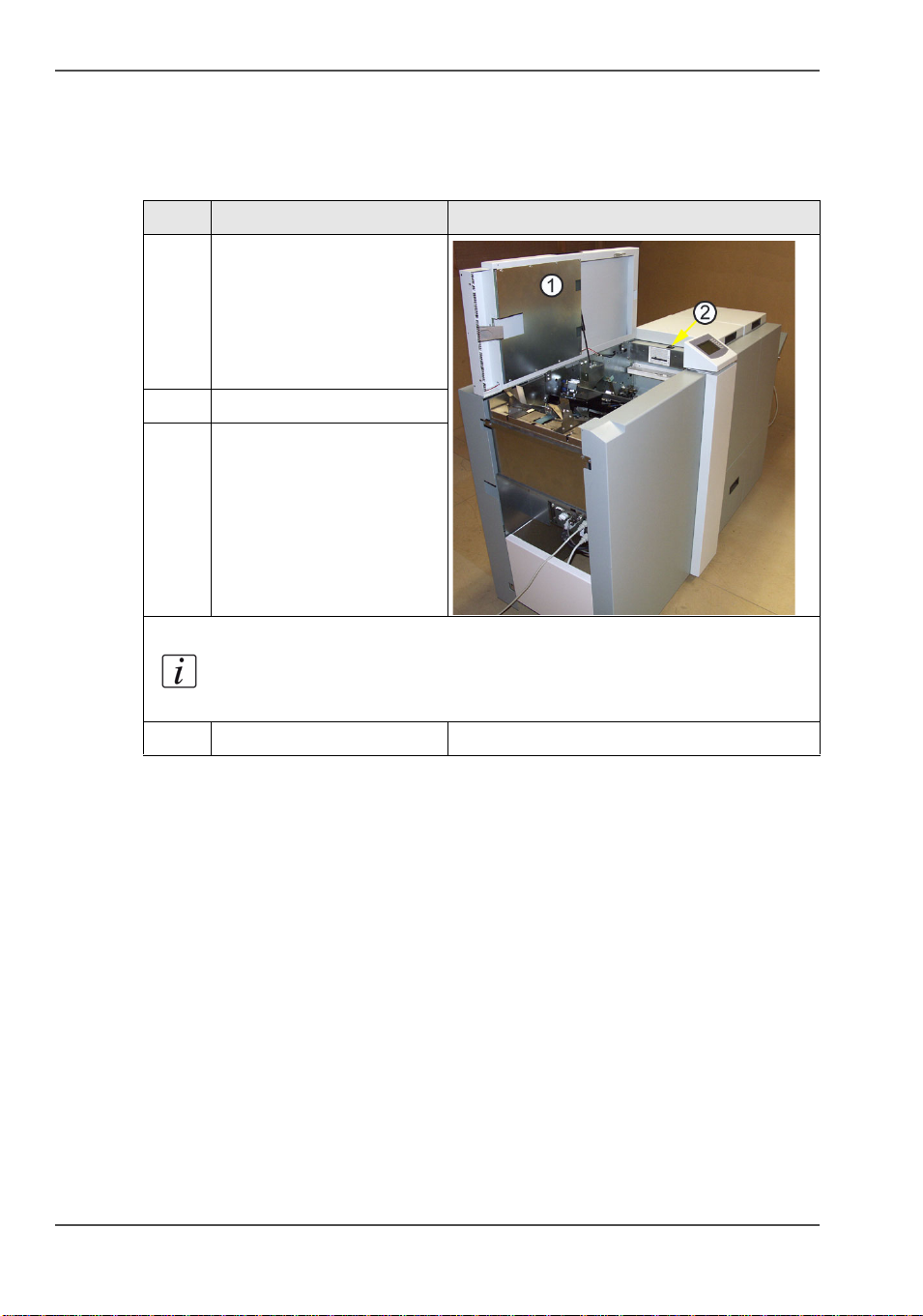

Turn on/off the power

Turn on/off the power

Booklet maker, Trimmer and SquareFold module

[12]

Step Action Description

1 Plug the booklet maker

power cord into the wall

outlet. Trimmer (optional)

and SquareFold module

(optional) are powered

from the booklet maker.

2 Open the Top cover (1).

3 Set power switch (2) on

booklet maker to ON

position.

[17]

Note: The Power switch also controls Trimmer (optional) and

SquareFold module (optional).

4 Close the Top cover (1).

20 Chapter 2 Basics

Remove/replace staple cartridge

Check staples, staple cartridge and stapler head

Remove/replace staple cartridge

Introduction

The first procedure shows you how to remove or replace the staples. (Replacement

staple cartridge S32).

After a staple jam or empty staple cartridge has been detected, the Booklet maker

will automatically advance and feed staples. This feature is called staple recovery.

The second procedure shows you how to replace staples after a staple jam or empty

staple cartridge indication.

21

Remove/replace staple cartridge

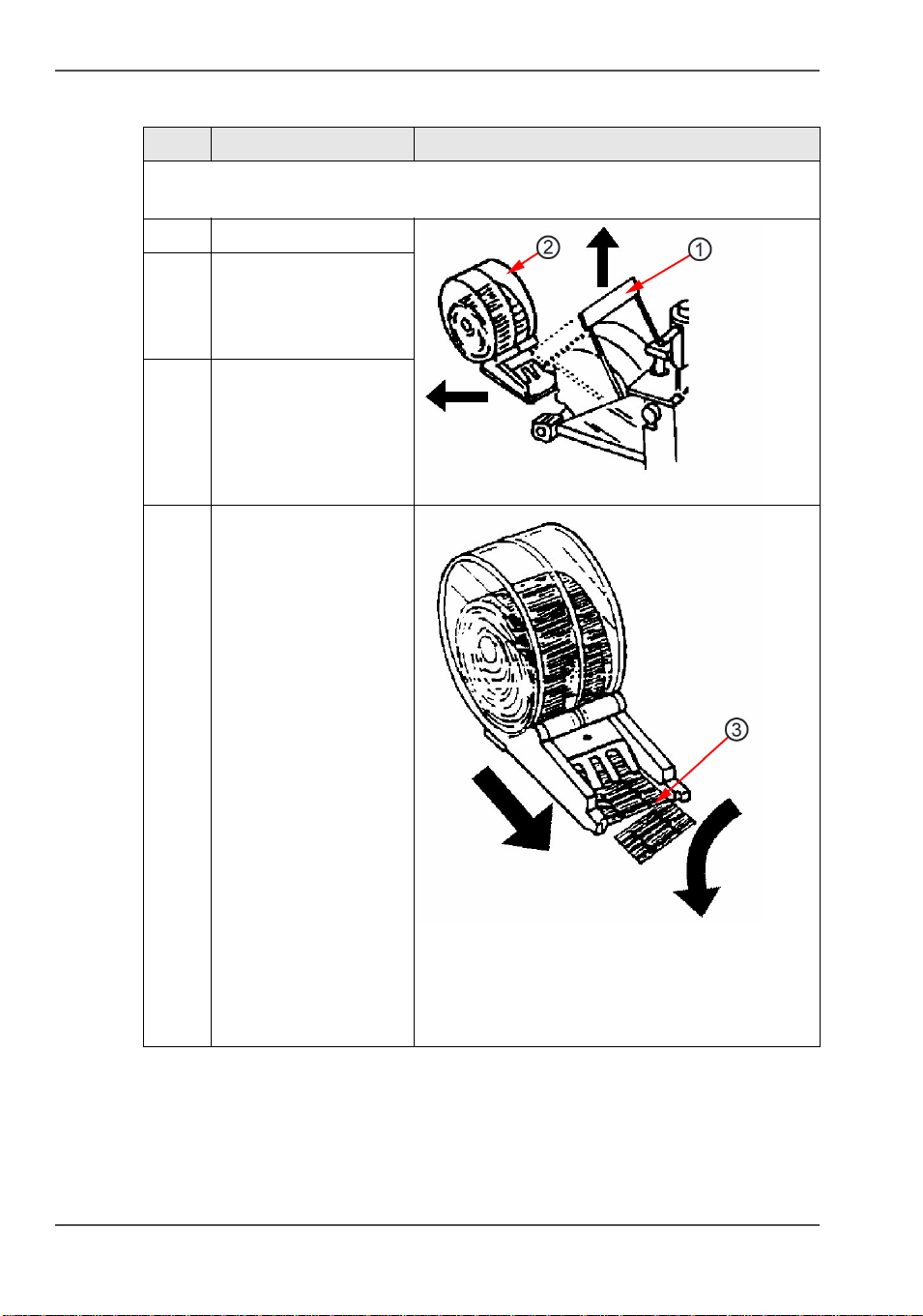

How to remove/replace staples

[13]

Step Action Description

You may remove and replace the staple cartridge while the stapler head assembly

is in place.

1 Open the top cover.

2 Raise the staple

cartridge locking lever

(1) as indicated in the

drawing.

3 Gently twist the staple

cartridge (2) from side

to side, and pull out the

staple cartridge (2)

from the stapler head.

[18]

4 If the staple cartridge is

empty, discard it and

replace it with a new

one. Before replacing

the cartridge, pull at

least 20 mm (approx. 1

inch) of the staples out

and tear off at the

staple tear line (3)

which is marked on the

cartridge. If there has

been a misfeed and the

cartridge still contains

staples, pull 20 mm

(approx. 1 inch) of

staples out of the

cartridge and tear off at

the stapler tear line.

Check that the first

staple is flat. If not, tear

off another 20 mm (1

inch), using less force.

[19]

22 Chapter 2 Basics

Remove/replace staple cartridge

Step Action Description

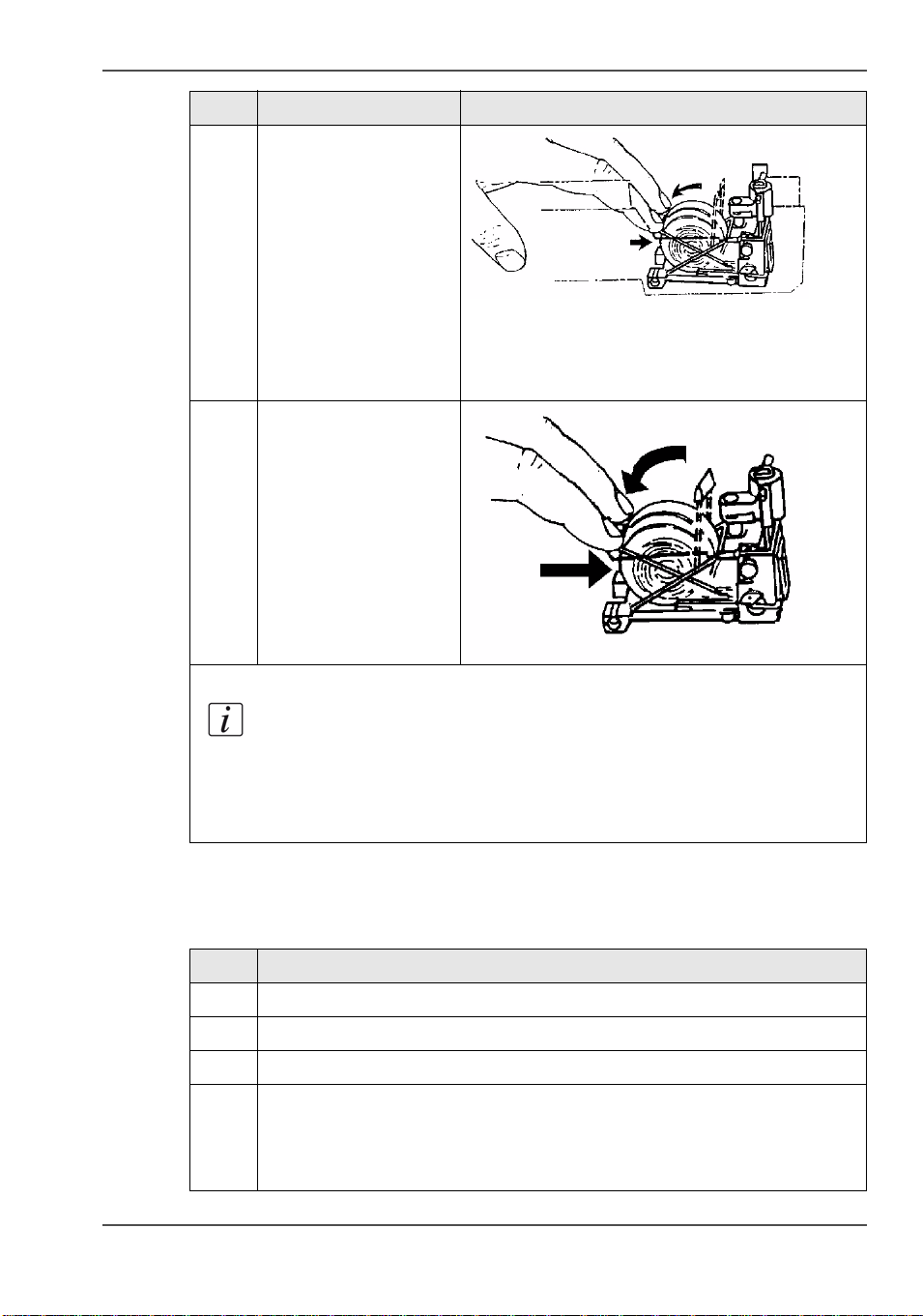

5 Insert the cartridge into

[20]

the stapler head with

the staples facing

towards the head

mechanism. The

cartridge should be

placed flat on the slide

on the bottom of the

stapler head and

pushed firmly into the

stapler head.

6 Hold the staple

[21]

cartridge firmly in

place and push down

the cartridge locking

lever.

Note: It is important that the cartridge is held firmly in position once

it is inserted into the stapler head.

If the cartridge is allowed to move away from the stapler head before

the locking lever is in engaged, remove cartridge and tear off 20 mm

(approx. 1 inch) of staples along the staple tear line.

How to replace the staples after a staple jam or empty staple cartridge

indication.

[14]

Step Action

1 Follow step 1-6 on the previous page.

2 Close the top cover.

3 Feed in a four-page set. Staple recovery will now begin.

4 The Booklet maker has now recovered and production can continue. If the

problem persists and no staples have been fed, the display will indicate

that again. In such a case: repeat this procedure. If the problem still

persists, perform the Removing/replacing Stapler Head procedure.

23

Remove/replace stapler head

Remove/replace stapler head

How to replace the stapler head

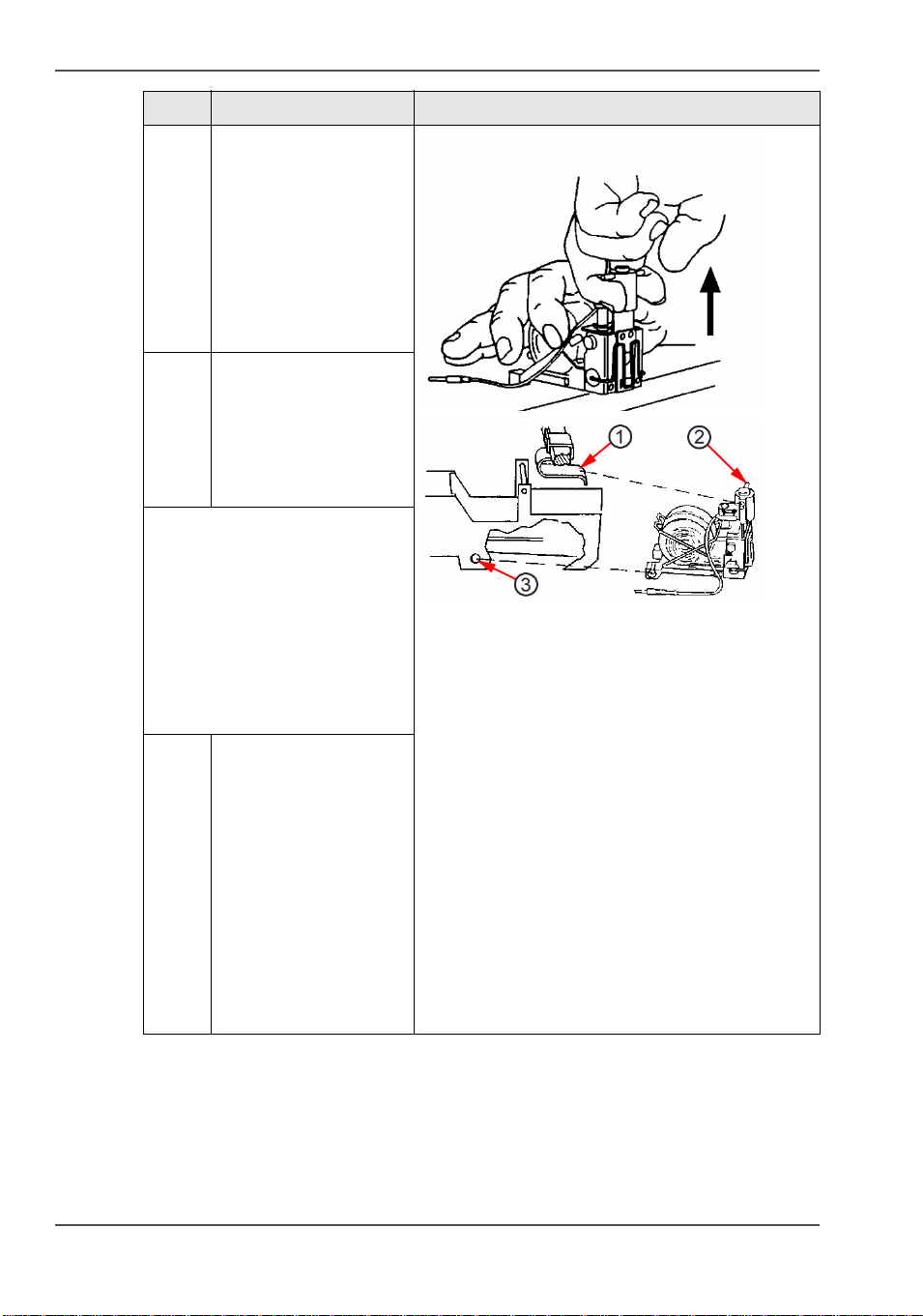

[15]

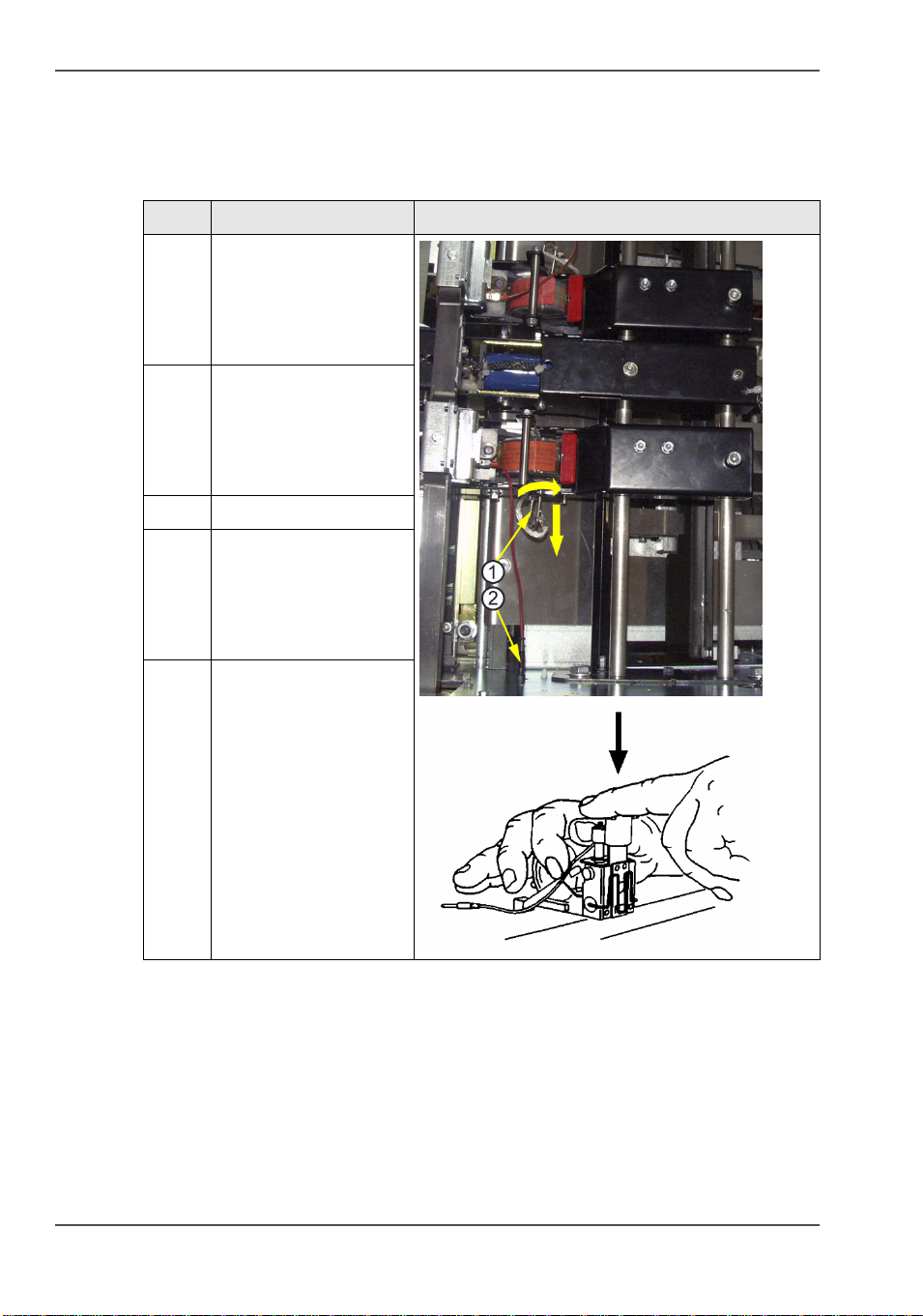

Step Action Description

1 From the main screen,

press [Admin]. Select

stapler removal

position and press

[Enter]

2 Select the A3

(11”x17”) position to

ensure that the side

joggers are away from

the stapler head.

3 Open the top cover.

4 Rotate the locking pin

(1) towards the outfeed

side and pull out the

locking pin from the

stapler head assembly.

[22]

5 Disconnect the staple

detection lead (2).

Push the stapler head

towards the infeed

side, out of the stapler

head assembly.

[23]

24 Chapter 2 Basics

Step Action Description

Note: Whenever you remove a stapler head, be sure to manually eject

some staples before replacing it in the Booklet maker. To do this, rest the

stapler head on a firm surface (for example, the top of a table) and

actuate the staple driver post up/down through full travel. Do this a

number of times to ensure that the staples are ejected on each down

movement. If you need to change the staple cartridge, see (see

‘Remove/replace staple cartridge’ on page 21).

Warnin g:

When manually ejecting the stapler, stay clear of stapler output area.

Remove/replace stapler head

25

Remove/replace stapler head

Step Action Description

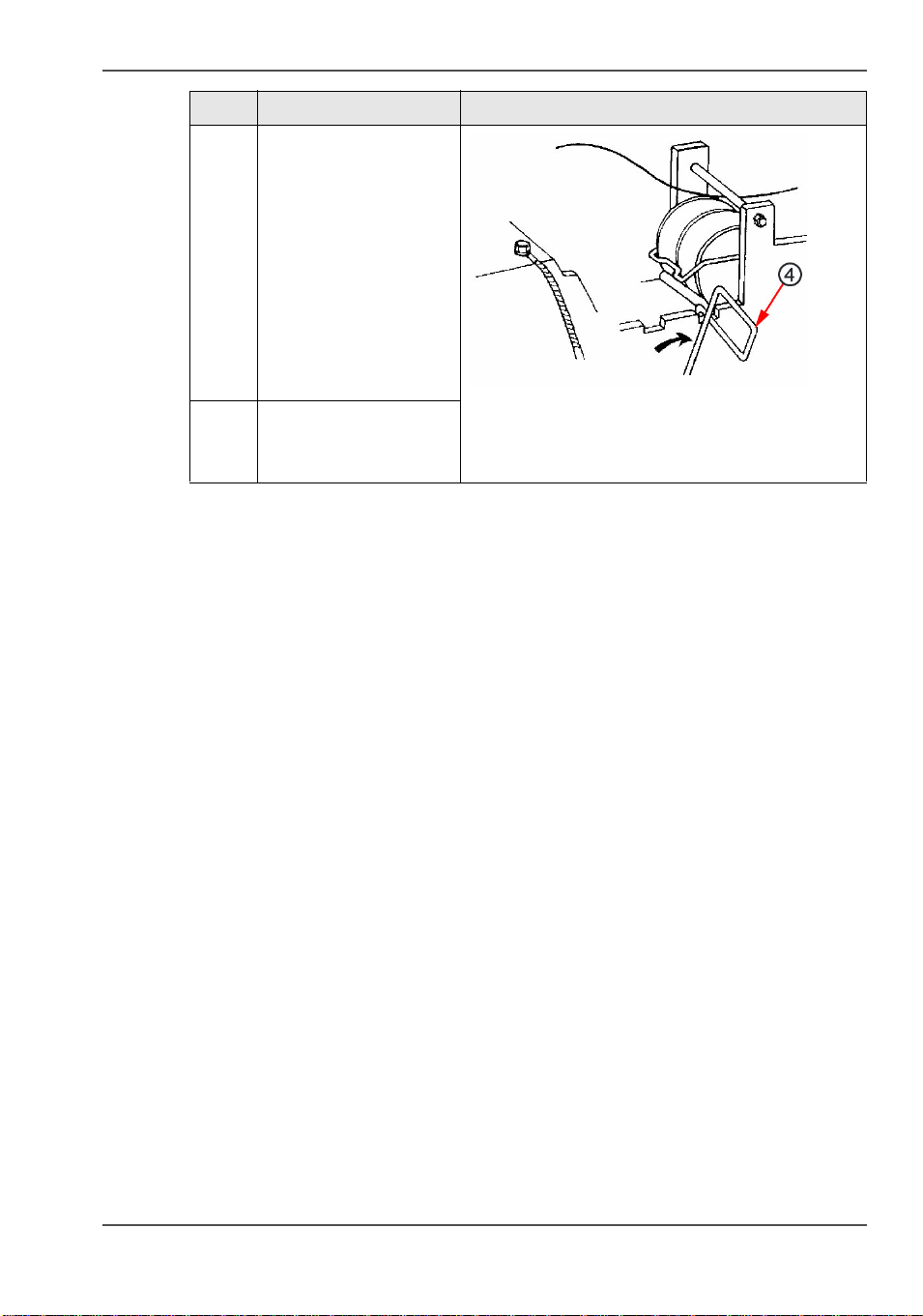

6 Before inserting the

[24]

stapler head, center the

stapler lift bracket (1)

over the area that will

receive the stapler

head. Ensure that the

staple driver post (2) is

in its uppermost

position.

7 Place the stapler head

back into the Booklet

maker. The driver post

[25]

arm (2) must be placed

into the stapler lift

bracket (1).

Caution

If the driver post arm is not

correctly positioned into the

stapler lift bracket (2), it will

cause permanent damage to the

stapler head as well as the

bracket. Subsequently, future

correctly mounted stapler heads

will also be damaged.

8 Press on the lower

front edge of the

stapler head to align

the hole (3) in the

stapler bracket with the

hole in the stapler

head. Insert the locking

pin (4) so that it

engages the stapler

head and the metal

sides of the stapler

assembly.

26 Chapter 2 Basics

Remove/replace stapler head

Step Action Description

9 Lock the pin (4) by

[26]

rotating it towards the

infeed side. Check that

the stapler head is

correctly mounted by

pushing the stapler

head towards the

infeed area. If it is still

loose, it is not correctly

mounted. Tighten

thumbscrews.

10 Insert the staple

detection lead into its

socket.

27

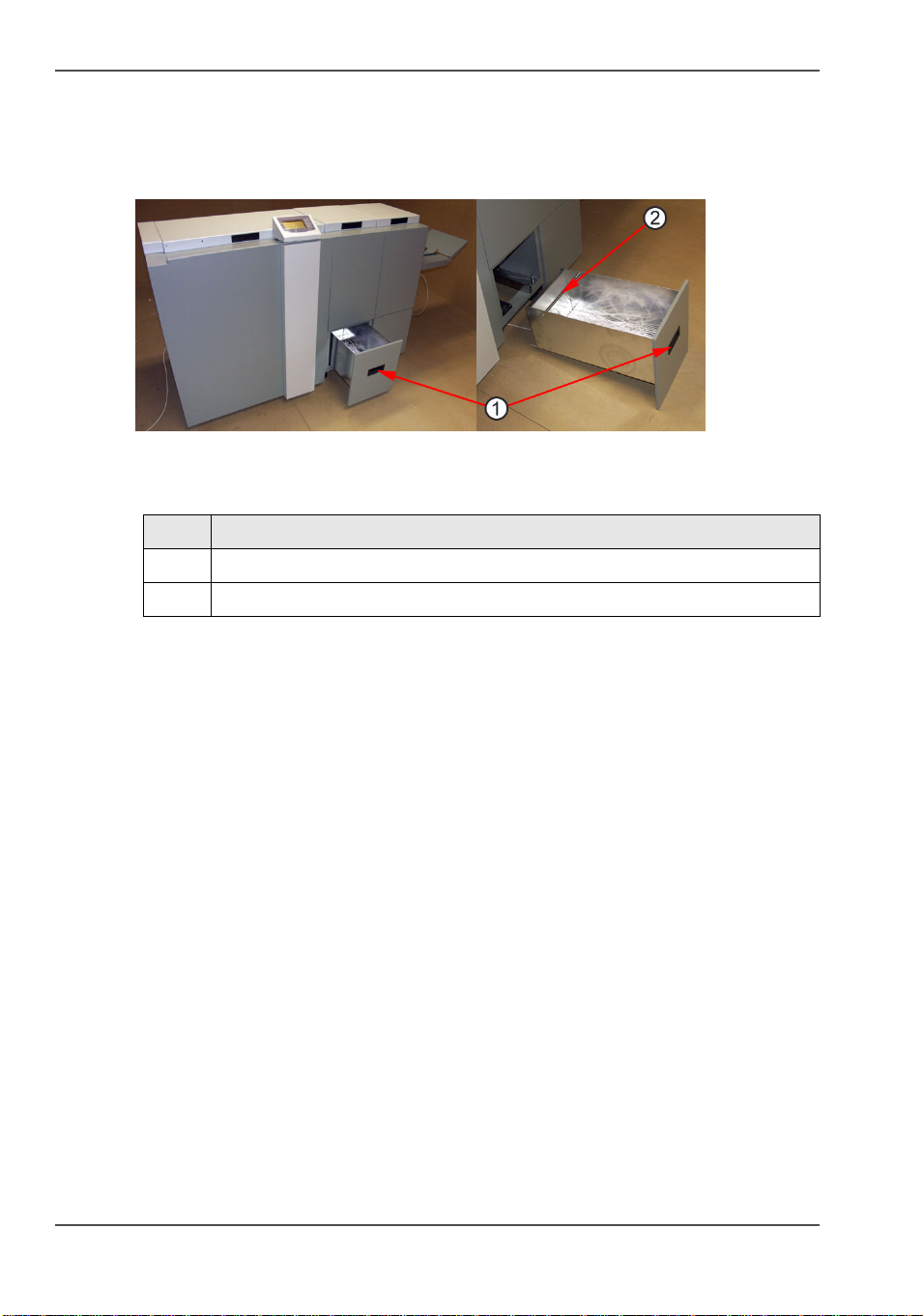

Empty the trim bin

Empty the trim bin

Illustration

[27]

Procedure

[16]

Step Action

1 Remove the trim bin by pulling handle (1)

2 then lift it out by grasping the rod (2) and handle (1).

28 Chapter 2 Basics

Chapter 3 Make booklets

29

General procedure

Change settings

General procedure

Introduction

Changing settings can be performed in two ways. Temporary, which means that the

changes will remain until a new job is loaded or permanent, which means that the

changes will be stored as a job. This job can later be recalled.

Procedure for temporary changes:

From the Main screen, select the option you wish to change and press the [Enter]

button. Confirm changes by pressing the [Enter] button in the next screen.

Procedure for permanent changes:

Same procedure as for temporary changes. But, in addition, from the Main screen,

press the [Jobs] button to reach the Jobs screen. Select Save if you want to

incorporate the change in the current job or Save as... if you want to store the

changed job as a new job.

Note: Choose either of the above mentioned procedures when changing size,

stapling, trimming or Square folding as follows.

30 Chapter 3 Make booklets

Loading...

Loading...