Page 1

2008 ACCESSORIES & BODY, CAB

Body (Interior & Exterior) - General - Sedona

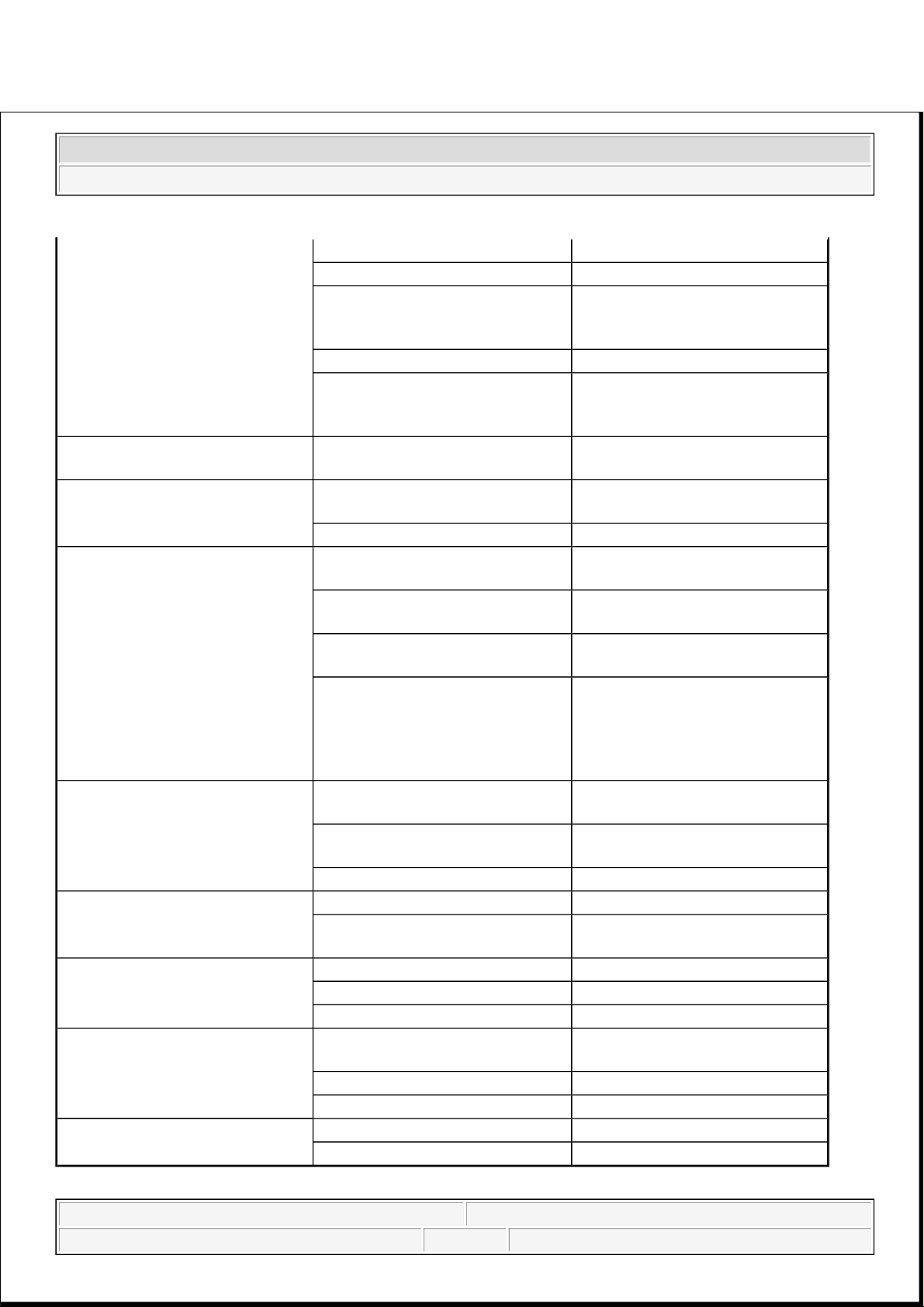

SPECIFICATIONS

GENERAL SPECIFICATIONS

TIGHTENING TORQUE

TIGHTENING TORQUE SPECIFICATIONS

HOOD Type Rear hinged, gas lifter type

FRONT DOOR Construction Front hinged, full door

construction

Regulator system X-ARM type

Locking system Pin-fork system

REAR DOOR Construction Sliding door construction

Regulator system Wire drum type

Locking system Pin-fork system

TAILGATE Type Inner hinged, gas lifter type

GLASS THICKNESS Windshield glass 5 mm

Front door glass 4 mm

Rear door glass 4 mm

Rear window glass 3.5 mm

SEAT BELTS Front 3 point type with Emergency

Locking Retractor (ELR)

Rear 3 point type with Emergency

Locking Retractor (ELR)

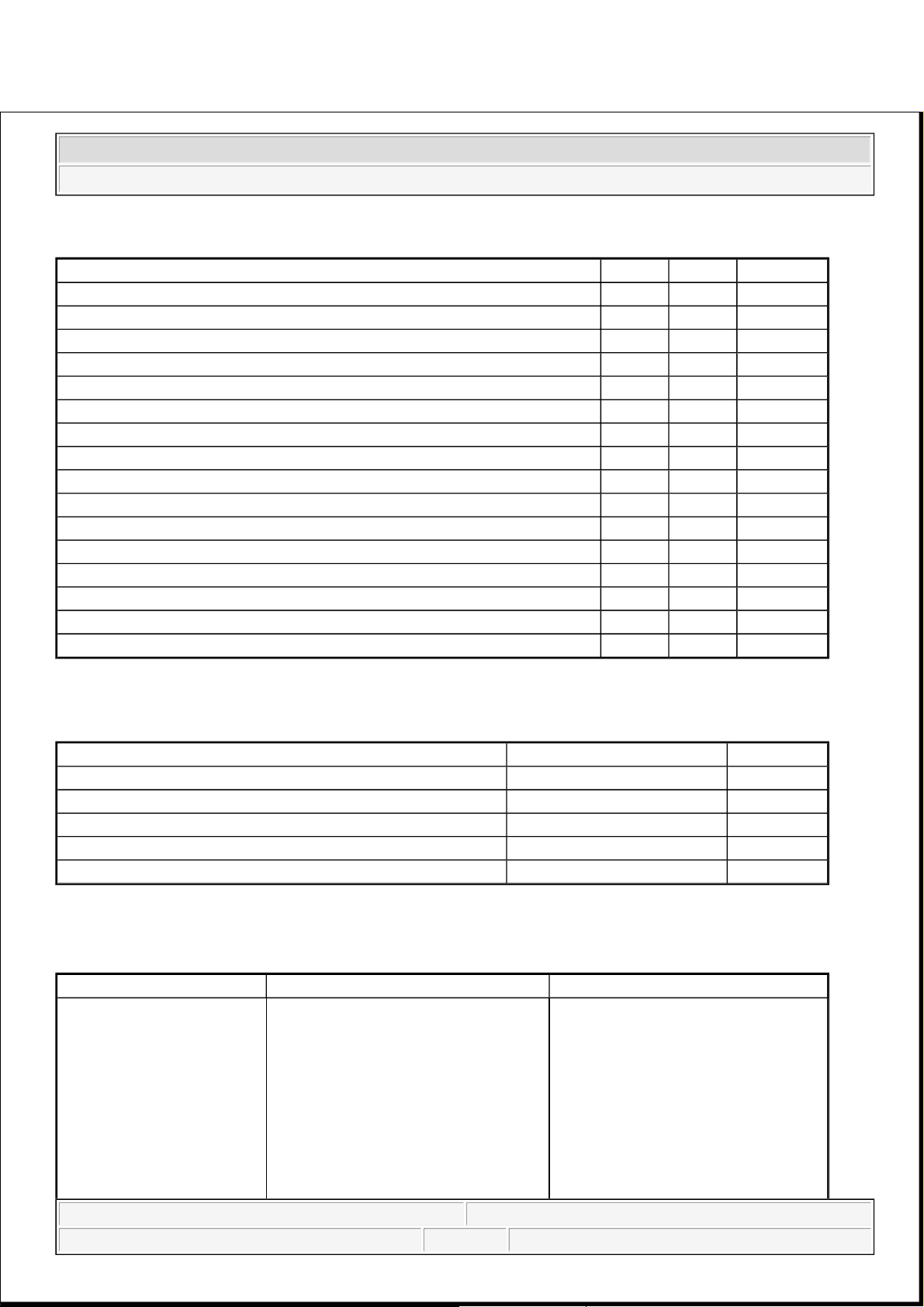

Items N.m Kgf. m Lbf. ft

Front and rear doors Door hinge to body 33.3-41.2 3.4-4.2 24.6-30.4

Door hinge to door 21.6-26.5 2.2-2.7 15.9-19.5

Striker 6.9-10.8 0.7-1.1 5.1-8.0

Glass mounting bolt 7.8-11.8 0.8-1.2 5.8-8.7

Outside handle

mounting bolt

6.9-10.8 0.7-1.1 5.1-8.0

Rear channel

mounting nut

7.8-11.8 0.8-1.2 5.8-8.7

Tailgate Tailgate hinge to

body

6.9-8.8 0.7-0.9 5.1-6.5

Tailgate hinge to

tailgate

6.9-8.8 0.7-0.9 5.1-6.5

Tailgate lift

mounting bolt

6.9-8.8 0.7-0.9 5.1-6.5

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Body (Interior & Exterior) - General - Sedona

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Body (Interior & Exterior) - General - Sedona

Microsoft

Monday, May 24, 2010 4:05:08 PM Page 1 © 2006 Mitchell Repair Information Company, LLC.

Microsoft

Monday, May 24, 2010 4:05:11 PM Page 1 © 2006 Mitchell Repair Information Company, LLC.

Page 2

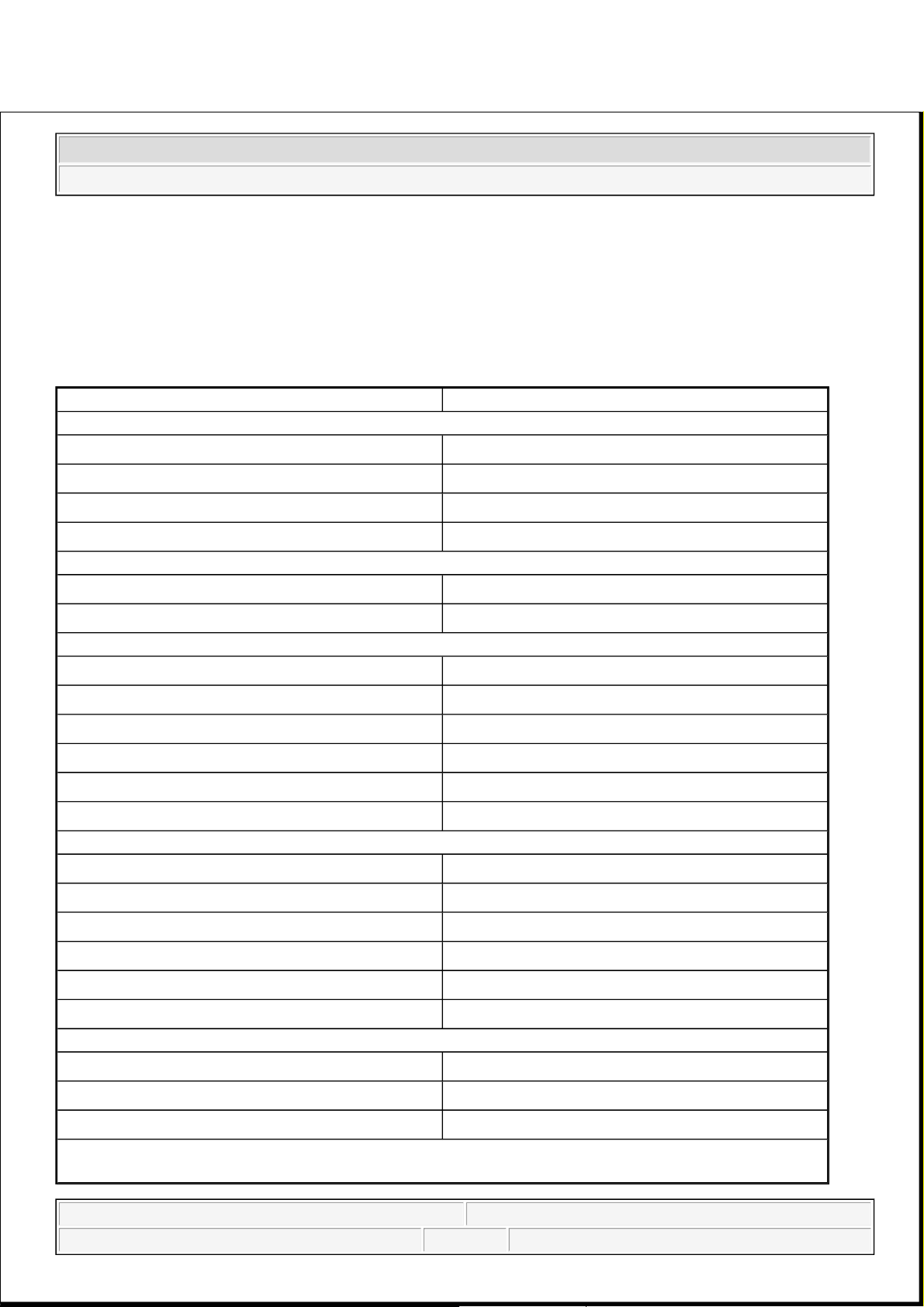

SPECIAL TOOLS

SPECIAL TOOLS REFERENCE CHART

Key cylinder

mounting nut

6.9-10.8 0.7-1.1 5.1-8.0

Hood Hood hinge to body 21.6-26.5 2.2-2.7 15.9-19.5

Hood hinge to hood 21.6-26.5 2.2-2.7 15.9-19.5

Hood latch to body 6.9-10.8 0.7-1.1 5.1-8.0

Seat Front seat mounting

bolts

43.1-64.7 4.4-6.6 31.8-47.7

Rear seat mounting

bolts

43.1-64.7 4.4-6.6 31.8-47.7

Seat belt Front seat belt

height adjuster

39.2-53.9 4.0-5.5 28.9-39.8

Front seat belt

buckle mounting

bolt

39.2-53.9 4.0-5.5 28.9-39.8

Front seat belt

anchor mounting

bolt

39.2-53.9 4.0-5.5 28.9-39.8

Front seat belt lower

anchor

39.2-53.9 4.0-5.5 28.9-39.8

Front seat belt upper

anchor

39.2-53.9 4.0-5.5 28.9-39.8

Rear seat belt

anchor attaching

bolt

39.2-53.9 4.0-5.5 28.9-39.8

Rear seat belt

retractor mounting

bolt

39.2-53.9 4.0-5.5 28.9-39.8

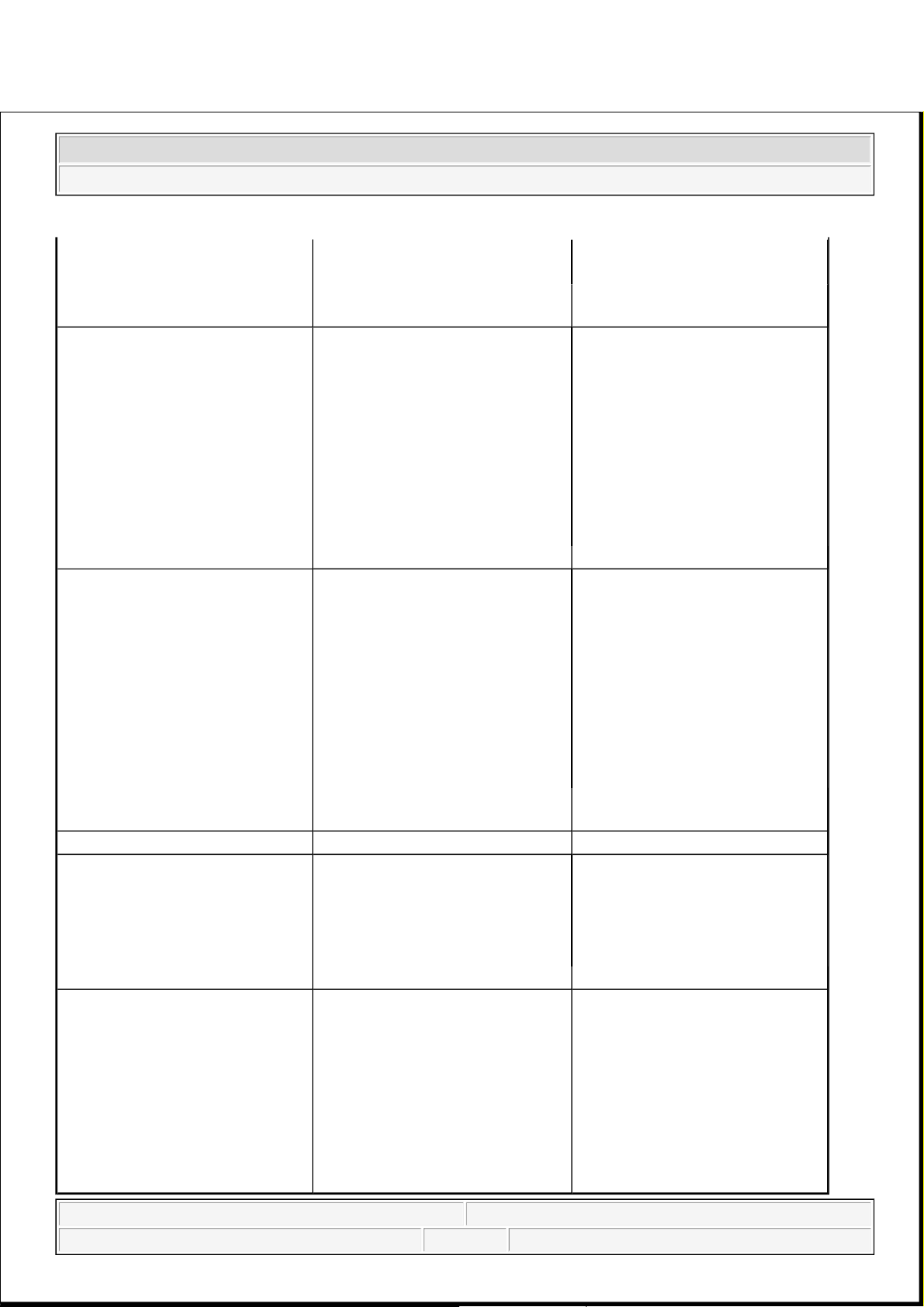

Tool (Number and name) Illustration Use

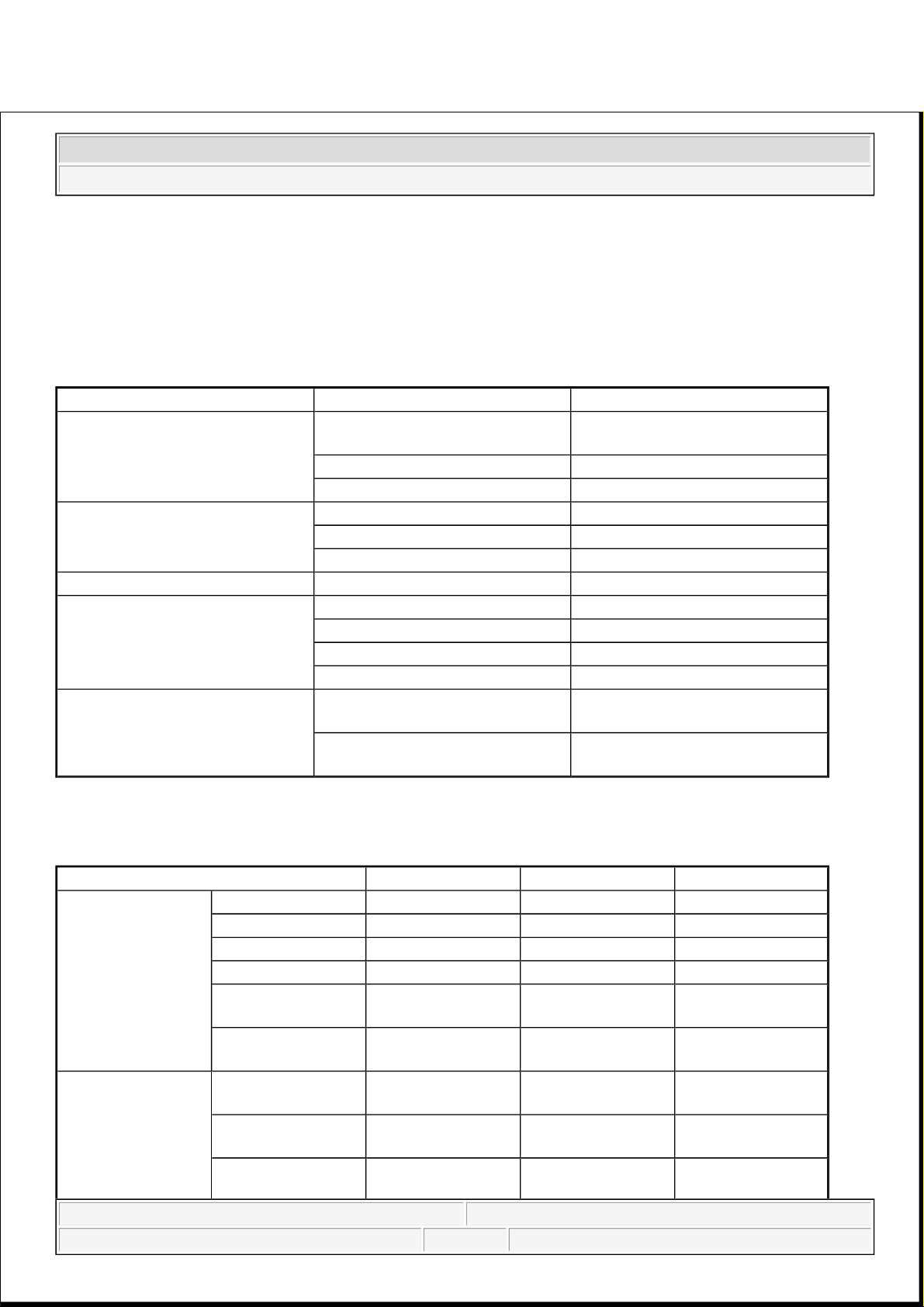

09793-2100

Door hinge adjusting wrench

Adjustment, removal and

installation

Of the door hinge

09800-21000

Ornament remover

Trim removal

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Body (Interior & Exterior) - General - Sedona

Microsoft

Monday, May 24, 2010 4:05:08 PM Page 2 © 2006 Mitchell Repair Information Company, LLC.

Page 3

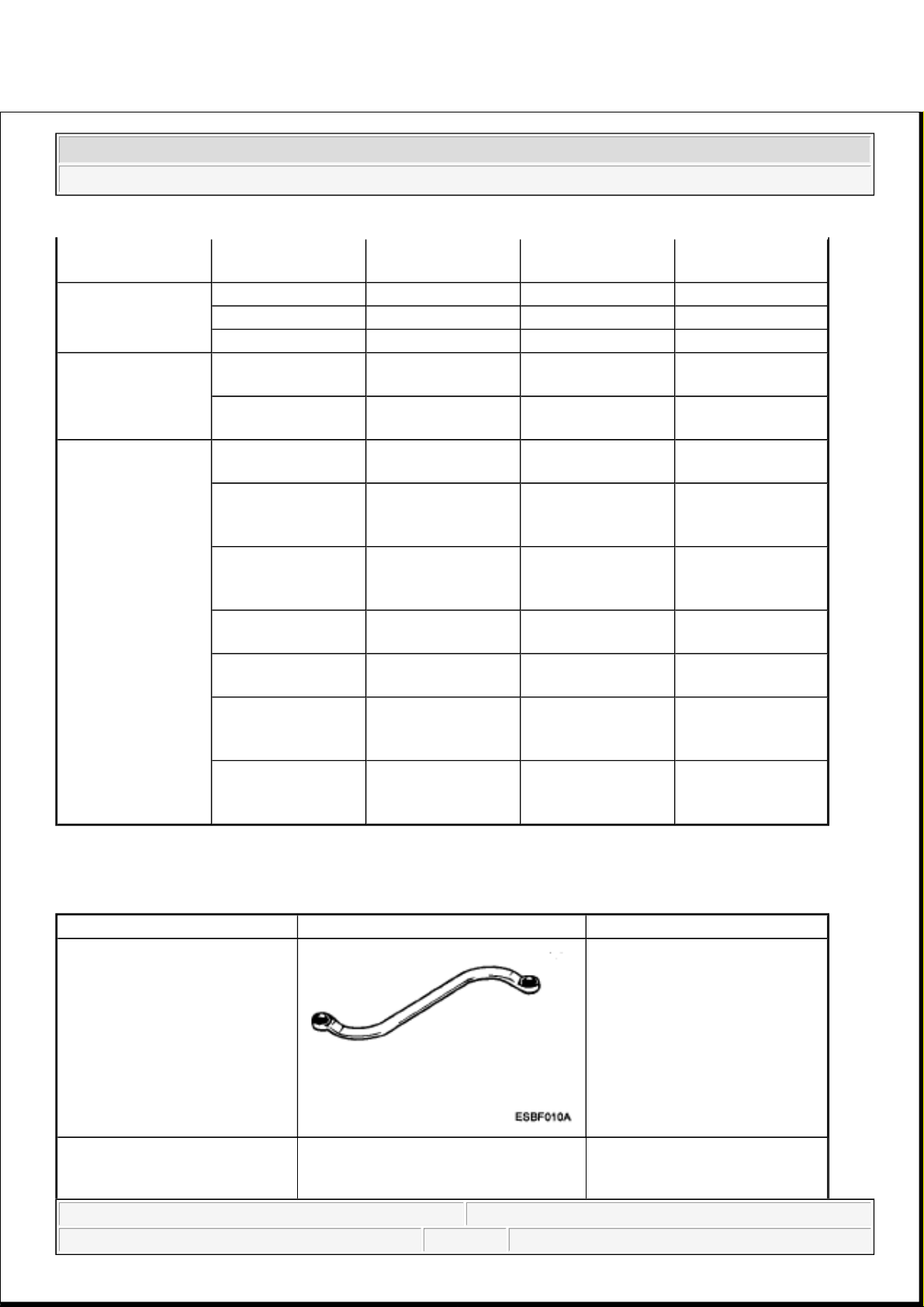

09853-31000

Headliner clip remover

Removal of the headliner clips

09861-31100

Sealant cut-out tool

Cutting the sealant of the

windshield

(Use with 09861-31200)

09861-31200

Sealant cutting blade

Cutting the sealant of the

windshield

(Use with 09861-31100)

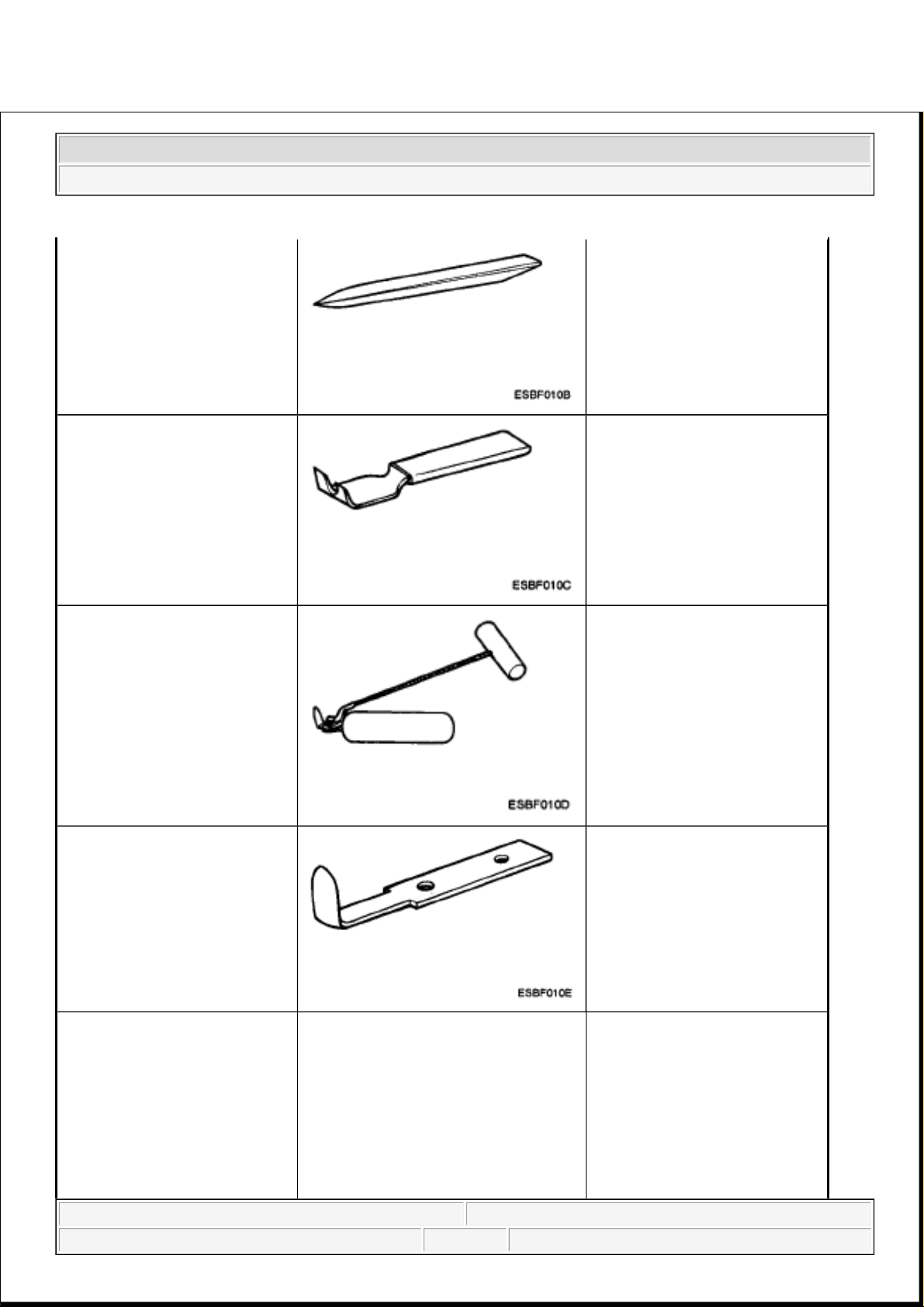

09861-31300

Sealant gun

Application of the sealant to the

windshield

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Body (Interior & Exterior) - General - Sedona

Microsoft

Monday, May 24, 2010 4:05:08 PM Page 3 © 2006 Mitchell Repair Information Company, LLC.

Page 4

TROUBLESHOOTING

TROUBLESHOOTING CHART

09681-31400

Glass holder

Removal and installation of the

windshield

09681-31000

Windshield molding remover

Removal of the windshield

molding

09880-4F000

Hog ring clip installer

Installation of the hog ring clip

Symptom Suspect Area Remedy

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Body (Interior & Exterior) - General - Sedona

Microsoft

Monday, May 24, 2010 4:05:08 PM Page 4 © 2006 Mitchell Repair Information Company, LLC.

Page 5

Water leaks from sunroof Dirt accumulated in drain tube Clear dirt inside of drain

Clogged drain tube Blow air into drain to remove dirt

Broken or dislocated drain tube,

defective

Or cracked clip

Check tube installation and Flange

contact

Deteriorated roof lid weatherstrip Replace

Excessive roof lid-to-body

clearance and Improperly fitted

weatherstrip

Adjust

Wind noise around sunroof Loose or deformed deflector, gaps

In body work

Retighten adjust or replace

Sunroof lid makes a noise when

moving

Foreign particles lodged in guide

rail

Check drive cable and guide Rails

for foreign particles

Loose guide rails and lid Retighten

Motor runs but sunroof does not

move or moves only partially

Foreign particles lodged in guide

rail

Check drive cable and guide Rails

for foreign particles

Incorrect engagement of motor

pinion With drive cable

Check for loose motor installation

And damaged pinion

Decrease in motor's clutch slipping

force

Adjust

Increased sunroof sliding

resistance Or interference of

sunroof with drive cables,

weatherstrip, etc. due to

maladjustment of sunroof

Adjust or replace

Noise in motor (clutch slipping

Noise from motor when sunroof Is

fully opened or closed is not An

unusual noise)

Incorrect engagement of motor

pinion With drive cable

Check pinion installation and

Retighten motor

Worn out or damaged motor

pinion bearing

Replace motor assembly

Worn out or deformed drive cable Replace

Door glass fails to operate Up and

down

Incorrect window glass installation Adjust position

Damaged or faulty regulator arm

or regulator

Correct or replace

Door does not open or close

completely

Incorrect door installation Adjust position

Defective door check assembly Correct or replace

Door hinge requires grease Apply grease

Hood does not open or close

completely

Striker and latch not properly

aligned

Adjust

Incorrectly installed hood Adjust

Incorrect hood bumper height Adjust

Water leak through windshield

end rear window

Defective seal Fill with sealant

Defective flange Correct

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Body (Interior & Exterior) - General - Sedona

Microsoft

Monday, May 24, 2010 4:05:08 PM Page 5 © 2006 Mitchell Repair Information Company, LLC.

Page 6

2008 BRAKES

Brake System - General - Sedona

SPECIFICATIONS

BRAKE SYSTEM SPECIFICATIONS

Item Specification

Master cylinder

Type

Tandem type

I.D. mm (in)

26.99/(1.063)

Piston stroke mm (in)

30 (1.18)

Fluid level warning sensor

Provided

Brake booster

Type

8 + 9 in Tandem

Boosting ratio

9.0: 1

Front brake (Disc)

Type

Floating type with ventilated disc

Disc O.D.

298 mm (11.73 in)

Disc thickness

28 mm (1.10 in)

Pad thickness

10.5 mm (0.41 in)

Cylinder type

Double piston

Cylinder I.D.

Ø48 mm (Ø1.89 in)

Rear Brake (Disc)

Type

Floating type with solid disc

Disc O.D.

302 mm (11.89 in)

Disc thickness

12 mm (0.47 in)

Pad thickness

10 mm (0.39 in)

Cylinder type

Single piston

Cylinder I.D

Ø42.9 mm (Ø1.69 in)

Parking Brake

Type

DIH (Drum in hat)

Actuation

Foot brake

Drum

Ø190 mm (Ø7.48 in)

O.D=Outer Diameter

I.D=Inner Diameter

2008 Kia Sedona

2008 BRAKES Brake System - General - Sedona

2008 Kia Sedona

2008 BRAKES Brake System - General - Sedona

Microsoft

Saturday, May 22, 2010 6:55:01 PM Page 1 © 2006 Mitchell Repair Information Company, LLC.

Microsoft

Saturday, May 22, 2010 6:55:04 PM Page 1 © 2006 Mitchell Repair Information Company, LLC.

Page 7

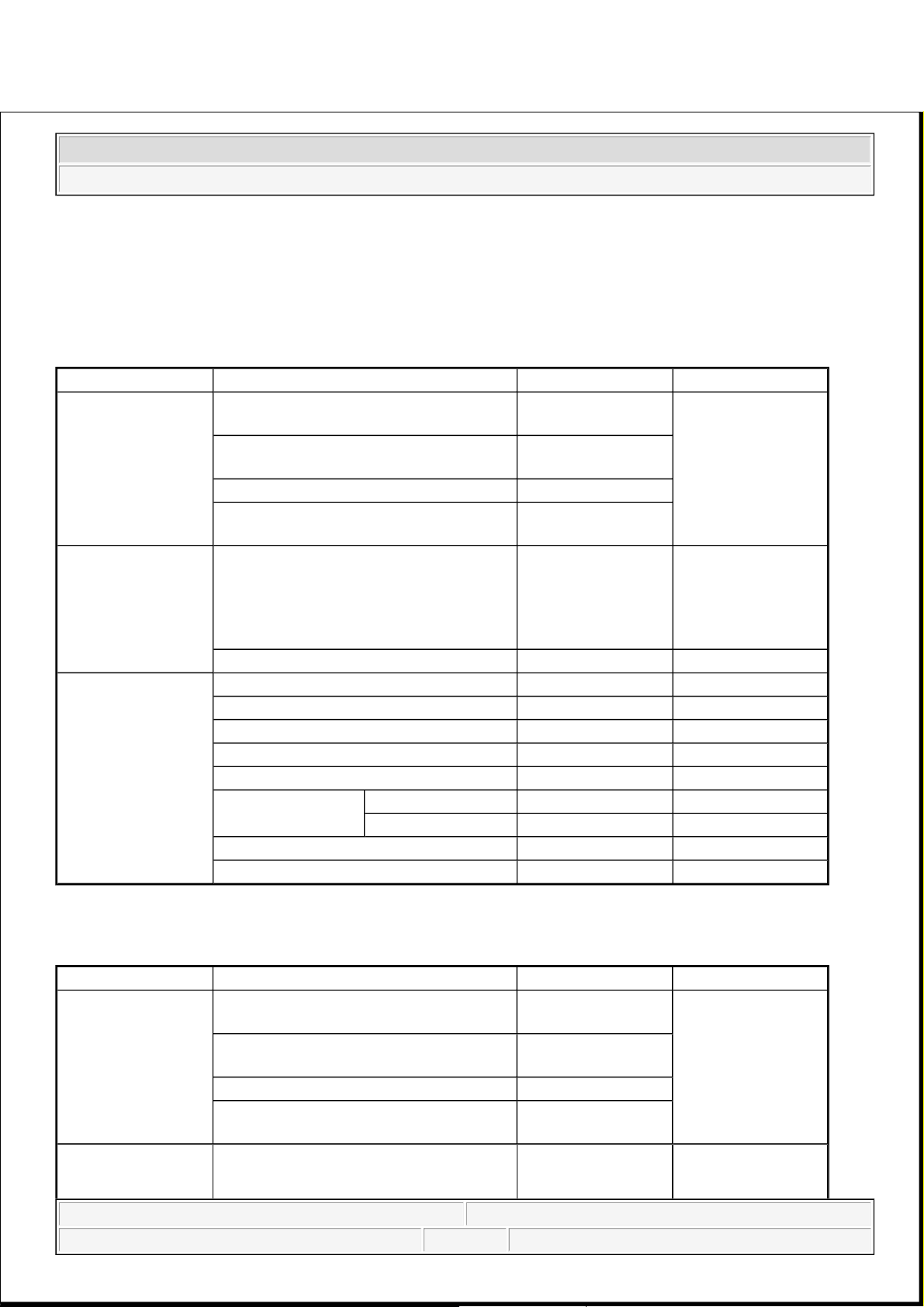

SPECIFICATION (ABS)

ANTI-LOCK BRAKE SYSTEM SPECIFICATIONS

SPECIFICATION (ESC)

ELECTRONIC STABILITY CONTROL SPECIFICATIONS

NOTE: ABS: Anti-Lock Brake System

ESC: Electronic Stability Control

Part Item Standard value Remark

HECU (Hydraulic

and Electronic

Control Unit)

System 4 channel 4 sensor

(Solenoid)

•ABS system: ABS

& EBD control

Type Motor, valve relay

integrated type

Operating voltage 8 V-16 V (DC)

Operating temperature -40 to 120°C (-40 to

248°F)

Warning lamp

Operating voltage 12 V •ABS W/LABS

failure

•Brake W/L:

Parking, brake oil,

EBD failure

Current consumption 80 mA

Active wheel speed

sensor

Supply voltage DC 4.5-2.0 V

Operating temperature -40-150 °C

Output current low 5.9-8.4 mA Typ.7 mA

Output current High 11.8-16.8 mA Typ.14 mA

Frequency range 1-2500 HZ

Air gap

Front 0.15-1.5 mm Typ.0.7 mm

Rear 0.2-1.2 mm Typ.0.7 mm

Tone wheel 48 teeth

Output duty 30-70 %

Part Item Standard Value Remark

HECU (Hydraulic

and Electronic

Control Unit)

System 4 channel 4 sensor

(Solenoid)

•Total control (ABS,

EBD, TCS, ESC)

Type Motor, valve relay

integrated type

Operating voltage 8 V-16 V (DC)

Operating temperature -40 to120°C (-40 to

248°F)

Warning lamp

Operating voltage 12 V •ESC Operating

Lamp

2008 Kia Sedona

2008 BRAKES Brake System - General - Sedona

Microsoft

Saturday, May 22, 2010 6:55:01 PM Page 2 © 2006 Mitchell Repair Information Company, LLC.

Page 8

SERVICE STANDARD

SERVICE STANDARD SPECIFICATIONS

TIGHTENING TORQUE

ESC Warning Lamp

Current consumption 80 mA

Active wheel speed

sensor

Supply voltage DC 4.5-20 V

Operating temperature -40-150 °C

Output current low 5.9-8.4 mA

Output current high 11.8-16.8 mA

Tone wheel 48 teeth

Frequency range 1-2500 HZ

Air gap

Front 0.15-1.5 mm Type. 0.7 mm

Rear 0.2-1.2 mm Type. 0.7 mm

Steering Wheel

Angle Sensor

Operating Voltage 8V-16 V

Current Consumption Max 150 mA

Operating Angular velocity Max ± 780 °/sec

Yaw-rate & Lateral

G sensor

Operating Voltage 8 V-16 V

Current Consumption Max. 120 mA

Output Voltage high 4.35 V-4.65 V Type. 4.5 V

Output Voltage low 0.35-0.65 V Type. 0.5 V

Yaw Sensor Operating Range ±100 ° /s

G Sensor Operating Range ±1.8 G

Reference voltage output 2.464-2.536 V Type. 2.5 V

Items Standard value

Brake pedal height 192.4 mm (7.57 in)

Brake pedal full stroke 122 mm (4.8 in)

Adjust Brake pedal full stroke 60 mm (2.36 in)

Brake pedal free play 3-8 mm (0.11-0.31 in)

Stop lamp switch outer case to pedal stopper

clearance

1.0-1.5 mm (0.04-0.06 in)

Booster push rod to master cylinder piston clearance 0.6-1.7 mm (0.02-0.07 in) (at 500 mm.Hg)

Parking brake pedal stroke when pedal assembly is

depressed with 294N (30kgf, 661b force)

145 mm (5.71 in) above

Front disc brake pad thickness 10.5 mm (0.41 in)

Front disc thickness 28 mm (1.10 in)

Rear disc brake pad thickness 10 mm (0.394 in)

Rear disc brake disc thickness 12 mm (0.47 in)

Rear parking brake liner thickness 4 mm (0.16 in)

2008 Kia Sedona

2008 BRAKES Brake System - General - Sedona

Microsoft

Saturday, May 22, 2010 6:55:01 PM Page 3 © 2006 Mitchell Repair Information Company, LLC.

Page 9

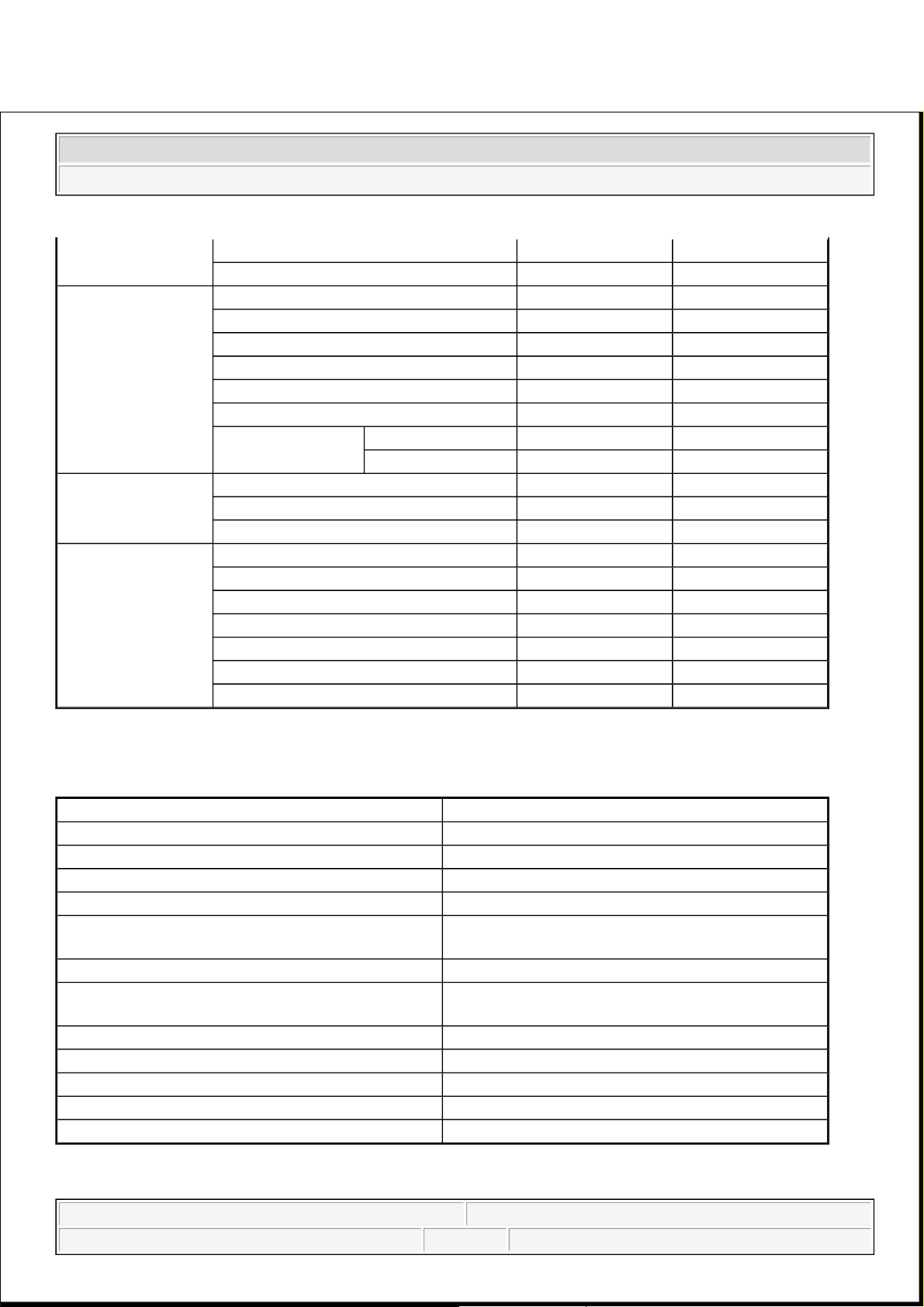

TIGHTENING TORQUE SPECIFICATIONS

LUBRICANT

LUBRICANT SPECIFICATIONS

SPECIAL TOOL

SPECIAL TOOLS DESCRIPTION

Items N.m kgf.m lb-ft

Master cylinder to booster mounting nut 8-12 0.8-1.2 5.8-8.7

Brake booster mounting nut 13-16 1.3-1.6 9.4-11.6

Bleeder screw 7-13 0.7-1.3 5.06-9.4

Brake tube nut, brake hose 13-17 1.3-1.7 9.4-12.3

Caliper guide rod bolt (Front) 22-32 2.2-3.2 15.9-23.1

Caliper guide rod bolt (Rear) 22-32 2.2-3.2 15.9-23.1

Caliper assembly to knuckle (Front) 85-100 8.5-10 61.5-72.3

Caliper assembly to knuckle (Rear) 50-60 5.0-6.0 36.2-43.4

Brake hose to front caliper 25-30 2.5-3.0 18.1-21.7

Brake pedal assembly bracket mounting nut 10-15 1.0-1.5 7.2-10.8

Brake pedal mounting nut 13-16 1.3-1.6 9.4-11.6

Stop lamp switch mounting nut 8-10 0.8-1.0 5.8-7.2

Active wheel speed sensor mounting bolt on the brake plate 7-10 0.7-1.0 5.1-7.2

HECU mounting bracket bolt 17-26 1.7-2.6 12.3-18.8

HECU mounting nut 6-10 0.6-1.0 4.3-7.2

Yaw rate & lateral acceleration sensor bolt 5-8 0.5-0.8 3.6-5.8

Item Recommended lubricant Quantity

Brake fluid DOT 3 or DOT 4 As required

Brake pedal bushing and brake pedal bolt Chassis grease As required

Parking brake shoe and backing plate contact surfaces Bearing grease As required

Caliper guide rod and boot RX - 2 grease 0.8-1.3 g

Rear caliper guide rod and boot Rubber grease 0.8-1.3 g

Tool (Number and Name) Illustration Use

09581-11000

Piston expander

Spreading the front disc brake piston

2008 Kia Sedona

2008 BRAKES Brake System - General - Sedona

Microsoft

Saturday, May 22, 2010 6:55:01 PM Page 4 © 2006 Mitchell Repair Information Company, LLC.

Page 10

TROUBLESHOOTING

PROBLEM SYMPTOMS TABLE

Use the table below to help you find the cause of the problem. The numbers indicate the priority of the like

cause of the problem. Check each part in order. If necessary, replace these parts

TROUBLESHOOTING CHART

Symptom Suspect Area Reference

Lower pedal or spongy pedal 1. Brake system (Fluid leaks) repair

2. Brake system (Air in) air-bleed

3. Piston seals (Worn or damaged) replace

4. Rear brake shoe clearance (Out

of adjustment)

adjust

5. Master cylinder (Inoperative) replace

Brake drag 1. Brake pedal freeplay

(Minimum)

adjust

2. Parking brake lever travel (Out

of adjustment)

adjust

3. Parking brake wire (Sticking) repair

4. Rear brake shoe clearance (Out

of adjustment)

adjust

5. Pad or lining (Cracked or

distorted)

replace

6. Piston (Stuck) replace

7. Piston (Frozen) replace

8. Anchor or Return spring

(Inoperative)

replace

9. Booster system (Vacuum leaks) repair

10. Master cylinder (Inoperative) replace

Brake pull 1. Piston (Sticking) replace

2. Pad or lining (Oily) replace

2008 Kia Sedona

2008 BRAKES Brake System - General - Sedona

Microsoft

Saturday, May 22, 2010 6:55:01 PM Page 5 © 2006 Mitchell Repair Information Company, LLC.

Page 11

3. Piston (Frozen) replace

4. Disc (Scored) replace

5. Pad or lining (Cracked or

distorted)

replace

Hard pedal but brake inefficient 1. Brake system (Fluid leaks) repair

2. Brake system (Air in) air-bleed

3. Pad or lining (Worn) replace

4. Pad or lining (Cracked or

distorted)

replace

5. Rear brake shoe clearance (Out

of adjustment)

adjust

6. Pad or lining (Oily) adjust

7. Pad or lining (Glazed) replace

8. Disc (Scored) replace

9. Booster system (Vacuum leaks) repair

Noise from brake 1. Pad or lining (Cracked or

distorted)

replace

2. Installation bolt (Loosen) adjust

3. Disc (Scored) replace

4. Sliding pin (Worn) replace

5. Pad or lining (Dirty) clean

6. Pad or lining (Glazed) replace

7. Anchor or Return spring

(Inoperative)

replace

8. Brake pad shim (Damage) replace

9. Shoe hold-down spring

(Damage)

replace

Brake fades 1. master cylinder replace

Brake vibration, pulsation

1. brake booster replace

2. pedal free play adjust

3. master cylinder replace

4. caliper replace

5. master cylinder cap seal replace

6. damaged brake lines replace

Brake Chatter

Brake chatter is usually caused by

loose or worn components, or

glazed or burnt linings. Rotors

with hard spots can also contribute

to brake chatter. Additional causes

of chatter are out-of-tolerance

rotors, brake lining not securely

attached to the shoes, loose wheel

bearings and contaminated brake

lining.

2008 Kia Sedona

2008 BRAKES Brake System - General - Sedona

Microsoft

Saturday, May 22, 2010 6:55:01 PM Page 6 © 2006 Mitchell Repair Information Company, LLC.

Page 12

2008 ELECTRICAL

Charging System - Sedona

DESCRIPTION

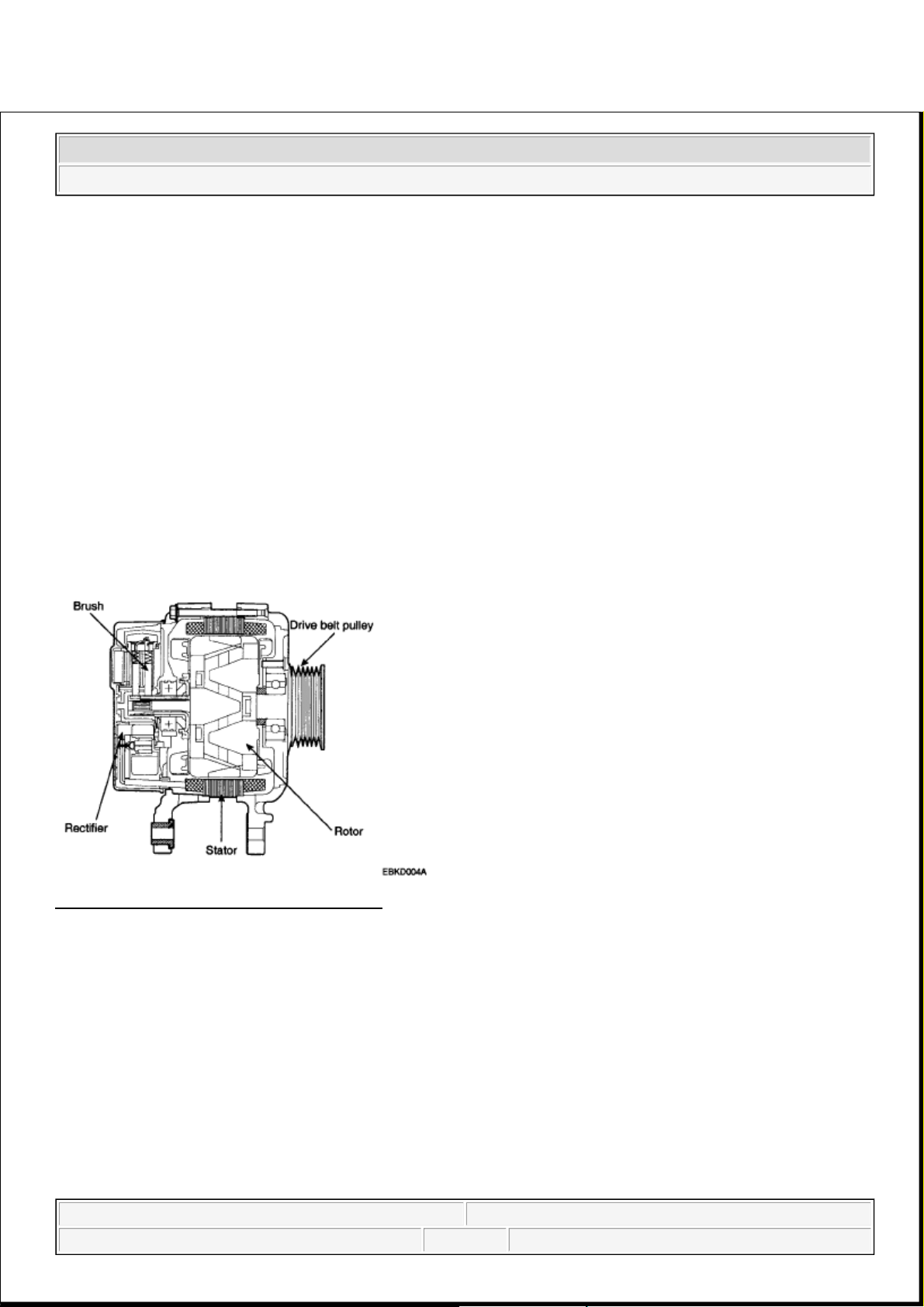

The charging system includes a battery, an generator with a built-in regulator, and the charging indicator light

and wire.

The Generator has built-in diodes, each rectifying AC current to DC current.

Therefore, DC current appears at generator "B" terminal. In addition, the charging voltage of this generator is

regulated by the battery voltage detection system.

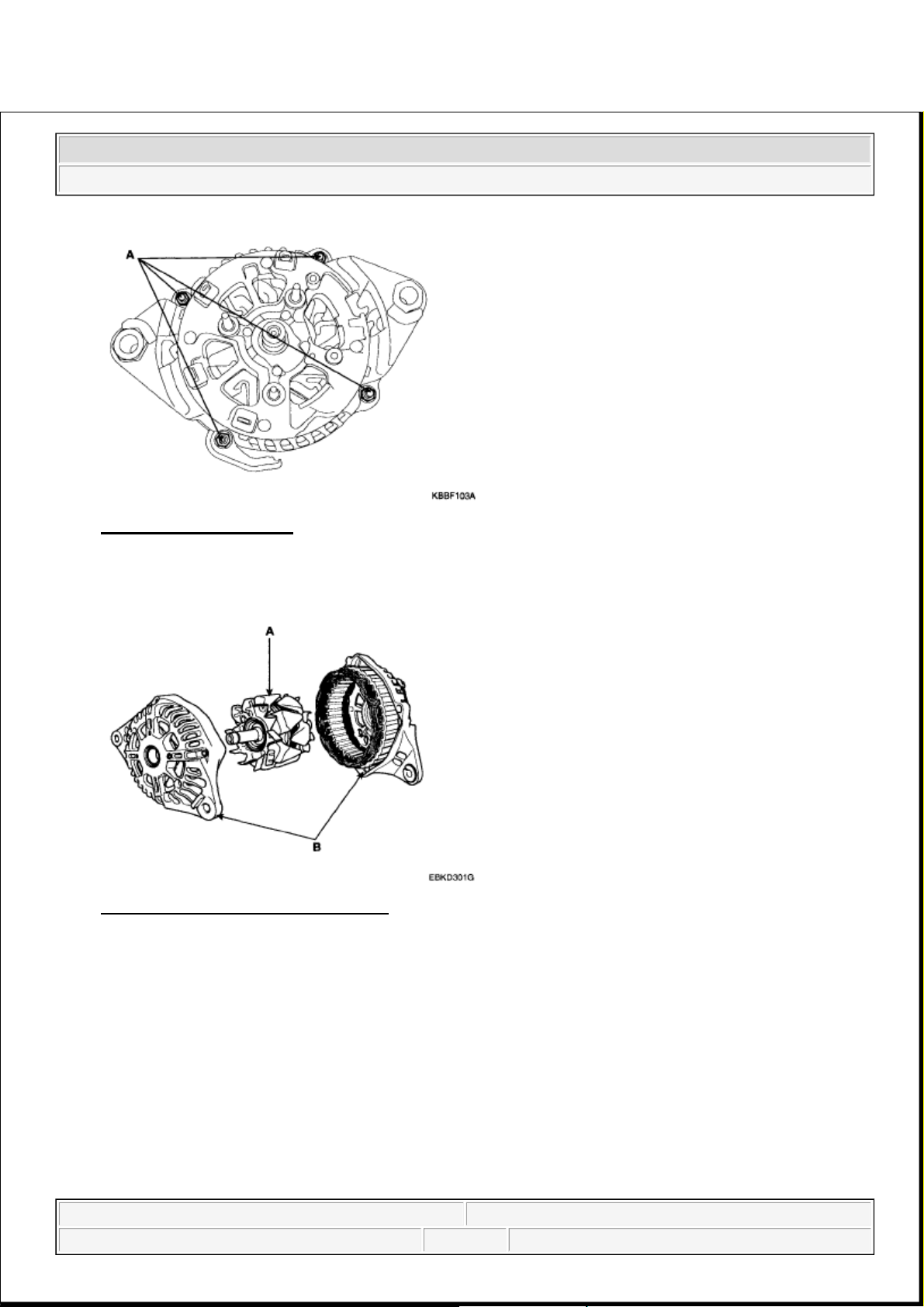

The main components of the generator are the rotor, stator, rectifier, capacitor brushes, bearings and V-ribbed

belt pulley. The brush holder contains a built-in electronic voltage regulator.

Fig. 1: Identifying Generator Components

Courtesy of KIA MOTORS AMERICA, INC.

ON-VEHICLE INSPECTION

CHECK BATTERY VOLTAGE

1. If 20 minutes have not passed since the en

g

ine was stopped, turn the ignition switch ON and turn on the

CAUTION:

Check that the battery cables are connected to the correct terminals.

Disconnect the battery cables when the battery is given a quick

charge.

Never disconnect the battery while the engine is running.

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 1 © 2006 Mitchell Repair Information Company, LLC.

Microsoft

Saturday, May 22, 2010 4:06:14 PM Page 1 © 2006 Mitchell Repair Information Company, LLC.

Page 13

electrical system (headlamp, blower motor, rear defogger etc.) for 60 seconds to remove the surface

charge.

2. Turn the ignition switch OFF and turn off the electrical systems.

3. Measure the battery voltage between the negative (-) and positive (+) terminals of the battery.

Standard voltage: 12.5-12.9V at 20°C (68°F)

If the voltage is less than specification, charge the battery.

CHECK THE BATTERY TERMINALS AND FUSES

1. Check that the battery terminals are not loose or corroded.

2. Check the fuses for continuity.

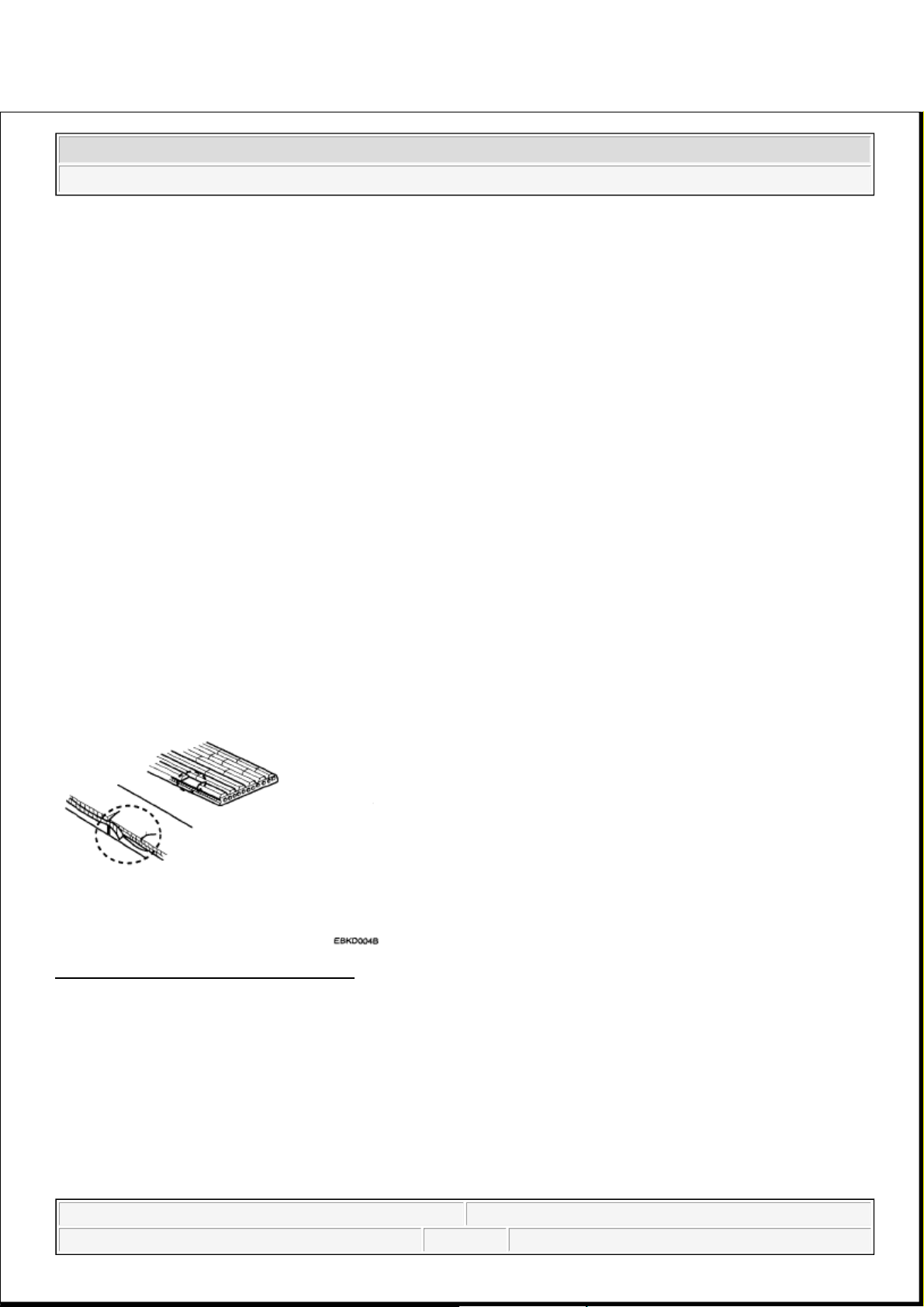

INSPECT DRIVE BELT

Visually check the belt for excessive wear, frayed cords etc.

If any defect has been found, replace the drive belt.

Fig. 2: Identifying Defective Drive Belt

Courtesy of KIA MOTORS AMERICA, INC.

VISUALLY CHECK GENERATOR WIRING AND LISTEN FOR ABNORMAL NOISES

1. Check that the wiring is in good condition.

2. Check that there is no abnormal noise from the alternator while the engine is running.

CHECK BATTERY WARNING LIGHT CIRCUIT

1. Warm up the engine and then turn it off.

NOTE: Cracks on the rib side of a belt are considered acceptable. If the belt has

chunks missing from the ribs, it should be replaced.

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 2 © 2006 Mitchell Repair Information Company, LLC.

Page 14

2. Turn off all accessories.

3. Turn the ignition switch "ON". Check that the battery warning light is lit.

4. Start the engine. Check that the light is lit.

If the light does not go off as specified, troubleshoot the discharge light circuit.

INSPECT CHARGING SYSTEM

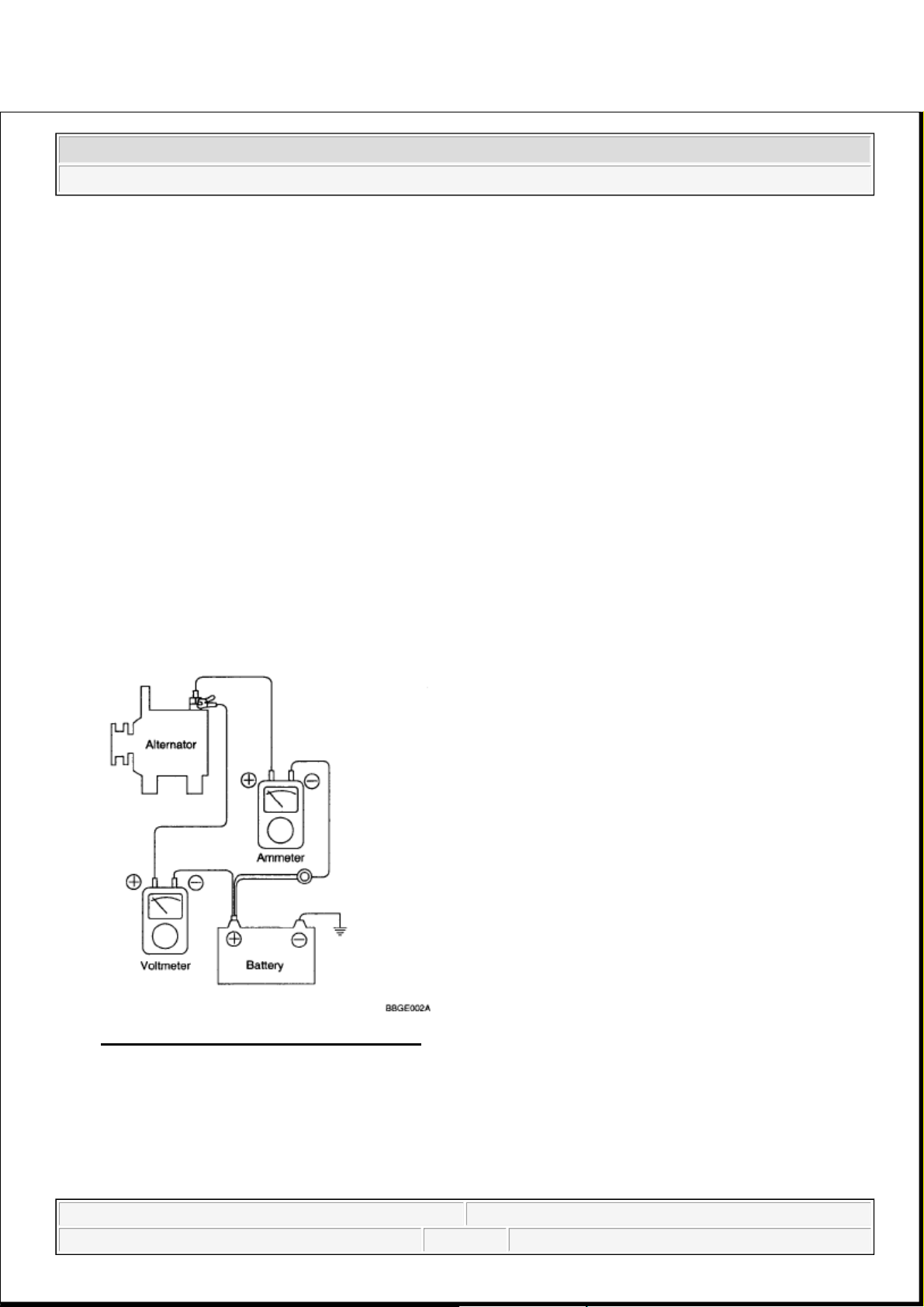

VOLTAGE DROP TEST OF GENERATOR OUTPUT WIRE

This test determines whether or not the wiring between the generator "B" terminal and the battery (+) terminal

is good by the voltage drop method.

PREPARATION

1. Turn the ignition switch to "OFF".

2. Disconnect the output wire from the generator "B" terminal. Connect the (+) lead wire of ammeter to the

"B" terminal of generator and the (-) lead wire of ammeter to the output wire. Connect the (+) lead wire o

f

voltmeter to the "B" terminal of generator and the (-) lead wire of voltmeter to the (+) terminal of battery.

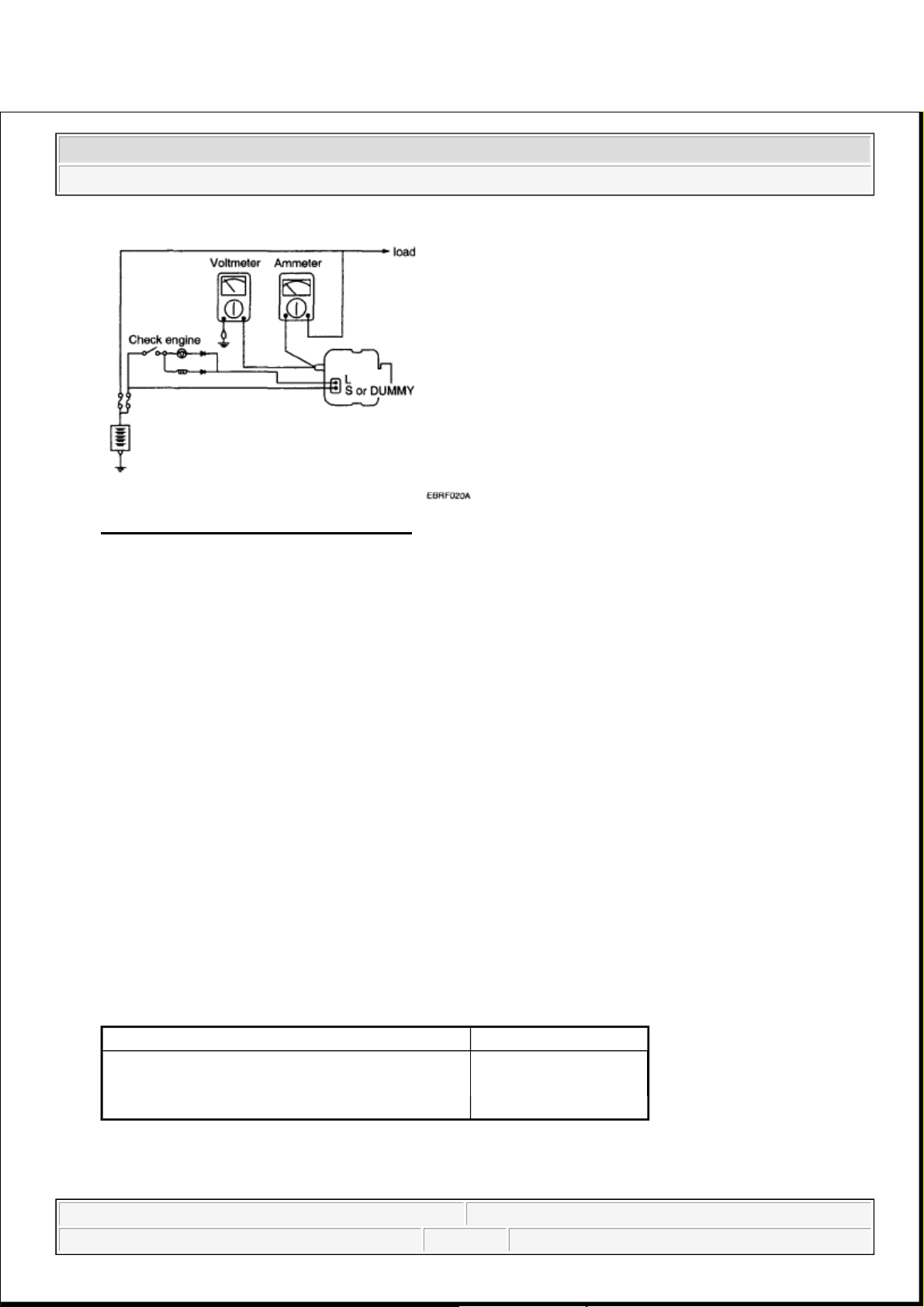

Fig. 3: Charging System Circuit Diagram

Courtesy of KIA MOTORS AMERICA, INC.

TEST

1. Start the engine.

2. Turn on the headlamps and blower motor, and set the engine speed until the ammeter indicates 20A.

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 3 © 2006 Mitchell Repair Information Company, LLC.

Page 15

And then, read the voltmeter at this time.

RESULT

1. The voltmeter may indicate the standard value.

Standard value: 0.2V max

2. If the value of the voltmeter is higher than expected (above 0.2V max.), poor wiring is suspected. In this

case check the wiring from the alternator "B" terminal to the battery (+) terminal. Check for loose

connections, color change due to an overheated harness, etc. Correct them before testing again.

3. Upon completion of the test, set the engine speed at idle.

Turn off the headlamps, blower motor and the ignition switch.

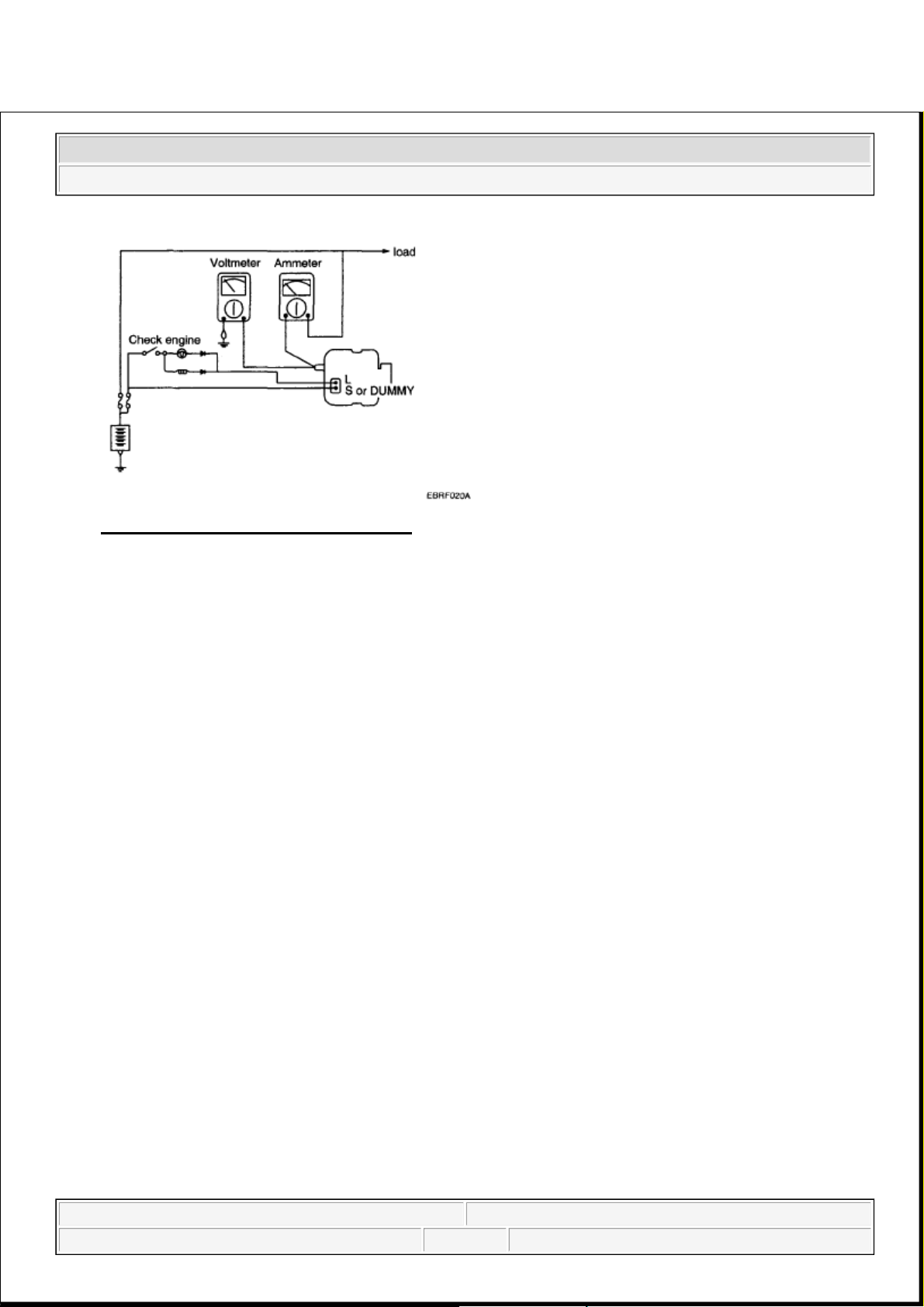

OUTPUT CURRENT TEST

This test determines whether or not the generator gives an output current that is equivalent to the normal output.

PREPARATION

1. Prior to the test, check the following items and correct as necessary.

Check the battery installed in the vehicle to ensure that it is in good condition. The battery checking

method is described in BATTERY.

The battery that is used to test the output current should be one that has been partially discharged. With a

fully charged battery, the test may not be conducted correctly due to an insufficient load.

Check the tension of the generator drive belt. The belt tension check method is described in INSPECT

DRIVE BELT.

2. Turn off the ignition switch.

3. Disconnect the battery ground cable.

4. Disconnect the generator output wire from the alternator "B" terminal.

5. Connect a DC ammeter (0 to 150A) in series between the "B" terminal and the disconnected output wire.

Be sure to connect the (-) lead wire of the ammeter to the disconnected output wire.

6. Connect a voltmeter (0 to 20V) between the "B" terminal and ground. Connect the (+) lead wire to the

alternator "B" terminal and (-) lead wire to a good ground.

7. Attach an engine tachometer and connect the battery ground cable.

8. Leave the engine hood open.

NOTE: Tighten each connection securely, as a heavy current will flow. Do not rely

on clips.

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 4 © 2006 Mitchell Repair Information Company, LLC.

Page 16

Fig. 4: Output Current Circuit Diagram

Courtesy of KIA MOTORS AMERICA, INC.

TEST

1. Check to see that the voltmeter reads as the same value as the battery voltage. If the voltmeter reads 0V,

and the open circuit in the wire between alternator "B" terminal and battery (-) terminal or poor grounding

is suspected.

2. Start the engine and turn on the headlamps.

3. Set the headlamps to high beam and the heater blower switch to HIGH, quickly increase the engine speed

to 2,500 RPM and read the maximum output current value indicated by the ammeter.

RESULT

1. The ammeter reading must be higher than the limit value. If it is lower but the generator output wire is in

good condition, remove the generator from the vehicle and test it.

Limit value: 91A min. (130A alternator)

NOTE: After the engine start up, the charging current quickly drops.

Therefore, the above operation must be done quickly to read the maximum

current value correctly.

NOTE:

The nominal output current value is shown on the nameplate affixed

to the generator body.

The output current value changes with the electrical load and the

temperature of the generator itself.

The nominal output current may not be obtained if the temperature of

the generator itself or ambient temperature is too high.

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 5 © 2006 Mitchell Repair Information Company, LLC.

Page 17

2. Upon completion of the output current test, lower the engine speed to idle and turn off the ignition switch.

3. Disconnect the battery ground cable.

4. Remove the ammeter and voltmeter and the engine tachometer.

5. Connect the generator output wire to the generator "B" terminal.

6. Connect the battery ground cable.

REGULATED VOLTAGE TEST

The purpose of this test is to check that the electronic voltage regulator controls voltage correctly.

PREPARATION

1. Prior to the test, check the following items and correct if necessary.

Check that the battery installed on the vehicle is fully charged. The battery checking method is described

in BATTERY.

Check the alternator drive belt tension. The belt tension check method is described in INSPECT DRIVE

BELT.

2. Turn ignition switch to "OFF".

3. Disconnect the battery ground cable.

4. Connect a digital voltmeter between the "B" terminal of the alternator and ground. Connect the (+) lead of

the voltmeter to the "B" terminal of the alternator. Connect the (-) lead to good ground or the battery (-)

terminal.

5. Disconnect the alternator output wire from the alternator "B" terminal.

6. Connect a DC ammeter (0 to 150A) in series between the "B" terminal and the disconnected output wire.

Connect the (-) lead wire of the ammeter to the disconnected output wire.

7. Attach the engine tachometer and connect the battery ground cable.

In such a case, reduce the temperature before testing again.

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 6 © 2006 Mitchell Repair Information Company, LLC.

Page 18

Fig. 5: Output Current Circuit Diagram

Courtesy of KIA MOTORS AMERICA, INC.

TEST

1. Turn on the ignition switch and check to see that the voltmeter indicates the following value.

Voltage: Battery voltage

If it reads 0V, there is an open circuit in the wire between the generator "B" terminal and the battery and

the battery (-) terminal.

2. Start the engine. Keep all lights and accessories off.

3. Run the engine at a speed of about 2,500 RPM and read the voltmeter when the generator output current

drops to 10A or less

RESULT

1. If the voltmeter reading agrees with the value listed in the regulating voltage table below, the voltage

regulator is functioning correctly. If the reading is other than the standard value, the voltage regulator or

the alternator is faulty.

REGULATING VOLTAGE TABLE

REGULATING VOLTAGE CHART

2. Upon completion of the test, reduce the engine speed to idle, and turn off the ignition switch.

3. Disconnect the battery ground cable.

Voltage regulator ambient temperature °C (°F)Regulating voltage (V)

-30 (-22) 14.2-15.3

25 (77) 14.2-14.8

135 (275) 13.3-14.8

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 7 © 2006 Mitchell Repair Information Company, LLC.

Page 19

4. Remove the voltmeter and ammeter and the engine tachometer.

5. Connect the generator output wire to the generator "B" terminal.

6. Connect the battery ground cable.

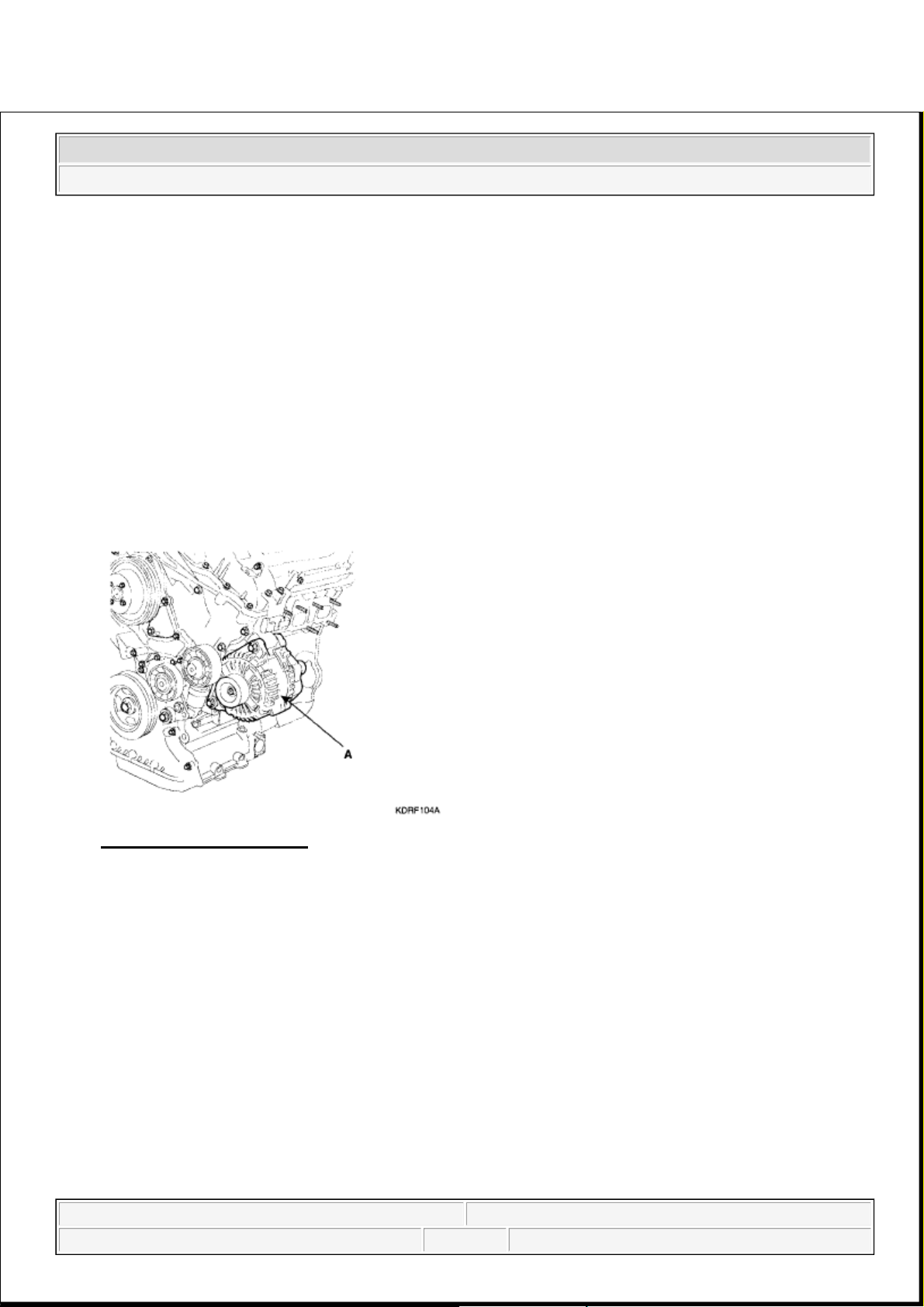

ALTERNATOR

REMOVAL

1. Disconnect the battery negative terminal first, then the positive terminal.

2. Disconnect the alternator connector, and remove the cable from alternator "B" terminal.

3. Remove the drive belt.

4. Pull out the through bolts and then remove the alternator (A).

Fig. 6: Locating Generator

Courtesy of KIA MOTORS AMERICA, INC.

5. Installation is the reverse of removal.

COMPONENT

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 8 © 2006 Mitchell Repair Information Company, LLC.

Page 20

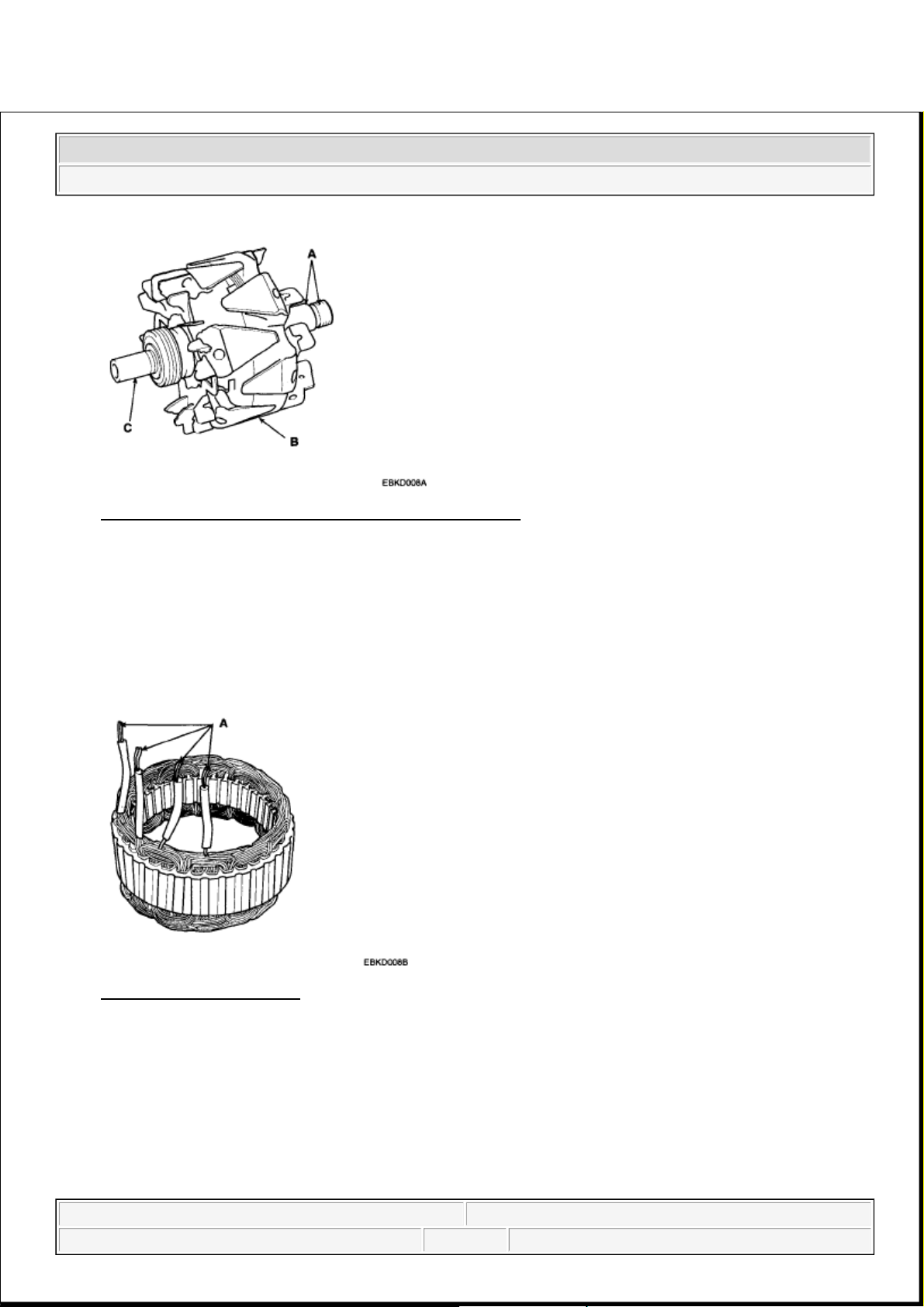

Fig. 7: Exploded View Of Generator

Courtesy of KIA MOTORS AMERICA, INC.

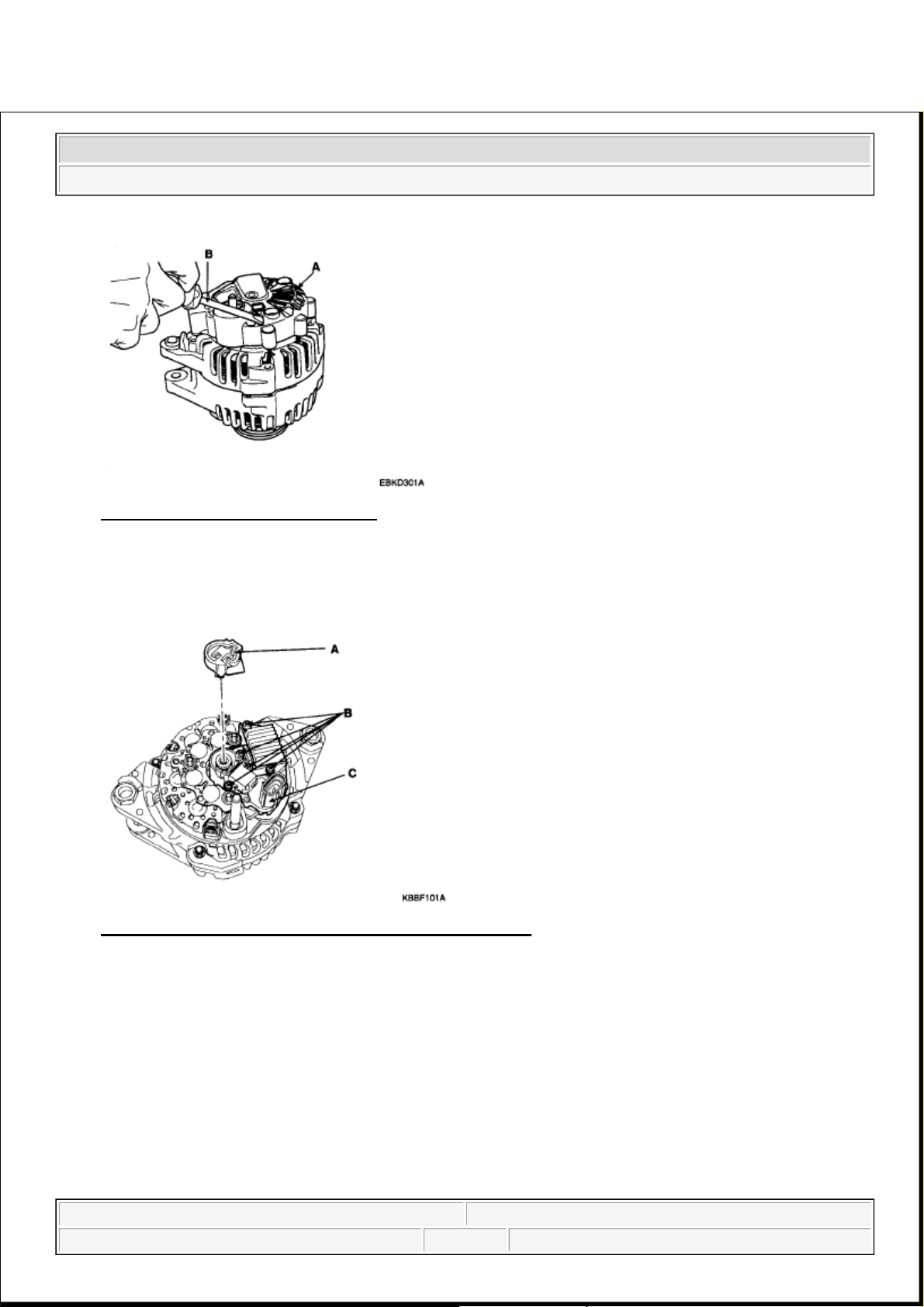

DISASSEMBLY

1. Remove the

g

enerator cover (A) using a screwdriver (B).

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 9 © 2006 Mitchell Repair Information Company, LLC.

Page 21

Fig. 8: Identifying Generator Cover

Courtesy of KIA MOTORS AMERICA, INC.

2. Remove the slip ring guide (A).

3. Loosen the mounting bolts (B) and disconnect the brush holder assembly (C).

Fig. 9: Identifying Slip Ring Guide And Mounting Bolts

Courtesy of KIA MOTORS AMERICA, INC.

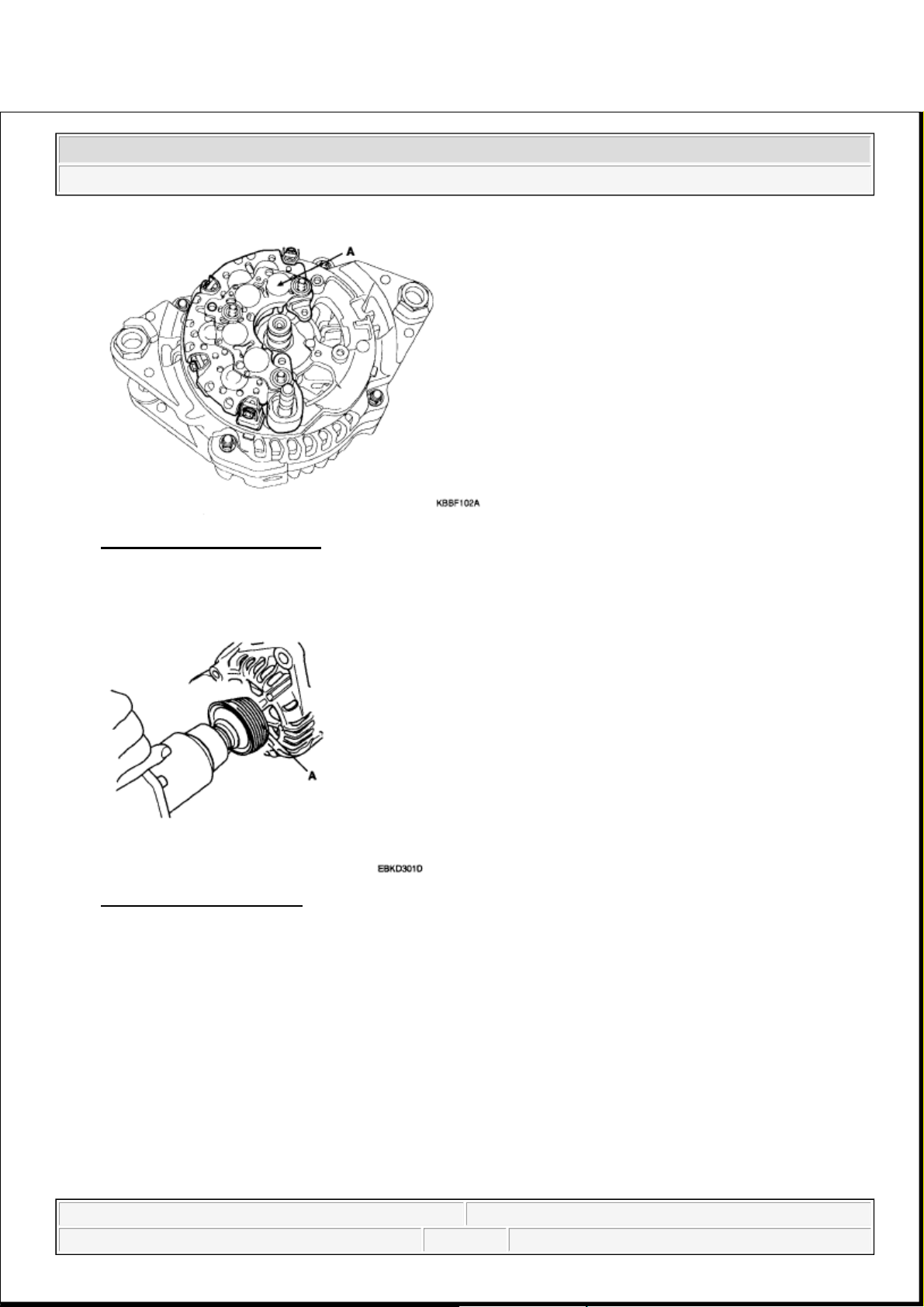

4. Remove the rectifier (A) with 4 screw.

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 10 © 2006 Mitchell Repair Information Company, LLC.

Page 22

Fig. 10: Identifying Rectifier

Courtesy of KIA MOTORS AMERICA, INC.

5. Remove the nut, pulley (A) and spacer.

Fig. 11: Identifying Pulley

Courtesy of KIA MOTORS AMERICA, INC.

6. Loosen the 4 nuts (A).

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 11 © 2006 Mitchell Repair Information Company, LLC.

Page 23

Fig. 12: Identifying Bolts

Courtesy of KIA MOTORS AMERICA, INC.

7. Disconnect the rotor (A) and cover (B).

Fig. 13: Identifying Rotor And Cover

Courtesy of KIA MOTORS AMERICA, INC.

8. Reassembly is the reverse order of disassembly.

INSPECTION

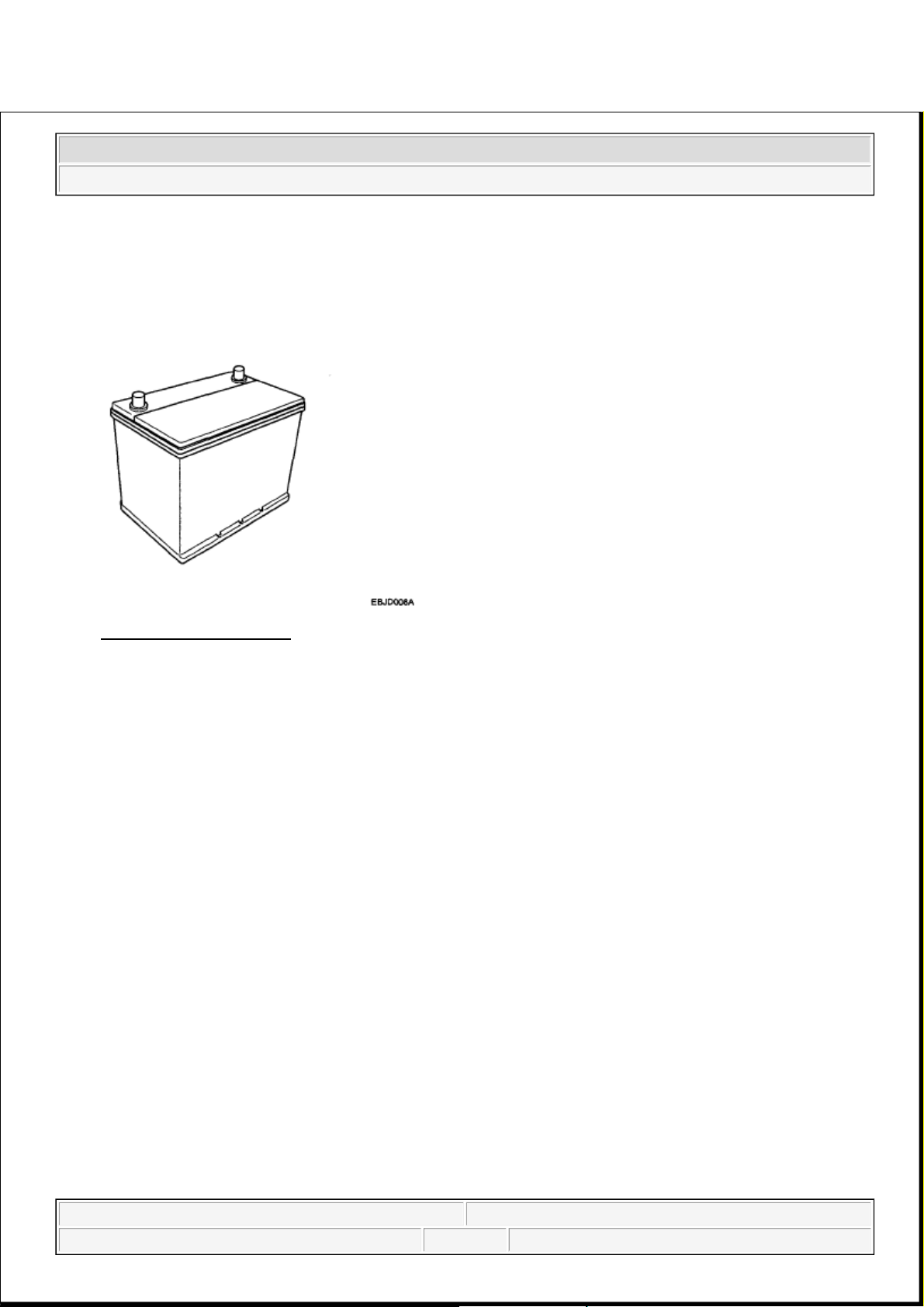

INSPECT ROTOR

1. Check that there is continuity between the slip rings (A).

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 12 © 2006 Mitchell Repair Information Company, LLC.

Page 24

Fig. 14: Identifying Slip Rings, Rotor And Rotor Shaft

Courtesy of KIA MOTORS AMERICA, INC.

2. Check that there is no continuity between the slip rings and the rotor (B) or rotor shaft (C).

3. If the rotor fails either continuity check, replace the generator.

INSPECT STATOR

1. Check that there is continuity between each pair of leads (A).

Fig. 15: Identifying Leads

Courtesy of KIA MOTORS AMERICA, INC.

2. Check that there is no continuity between each lead and the coil core.

3. If the coil fails either continuity check, replace the alternator.

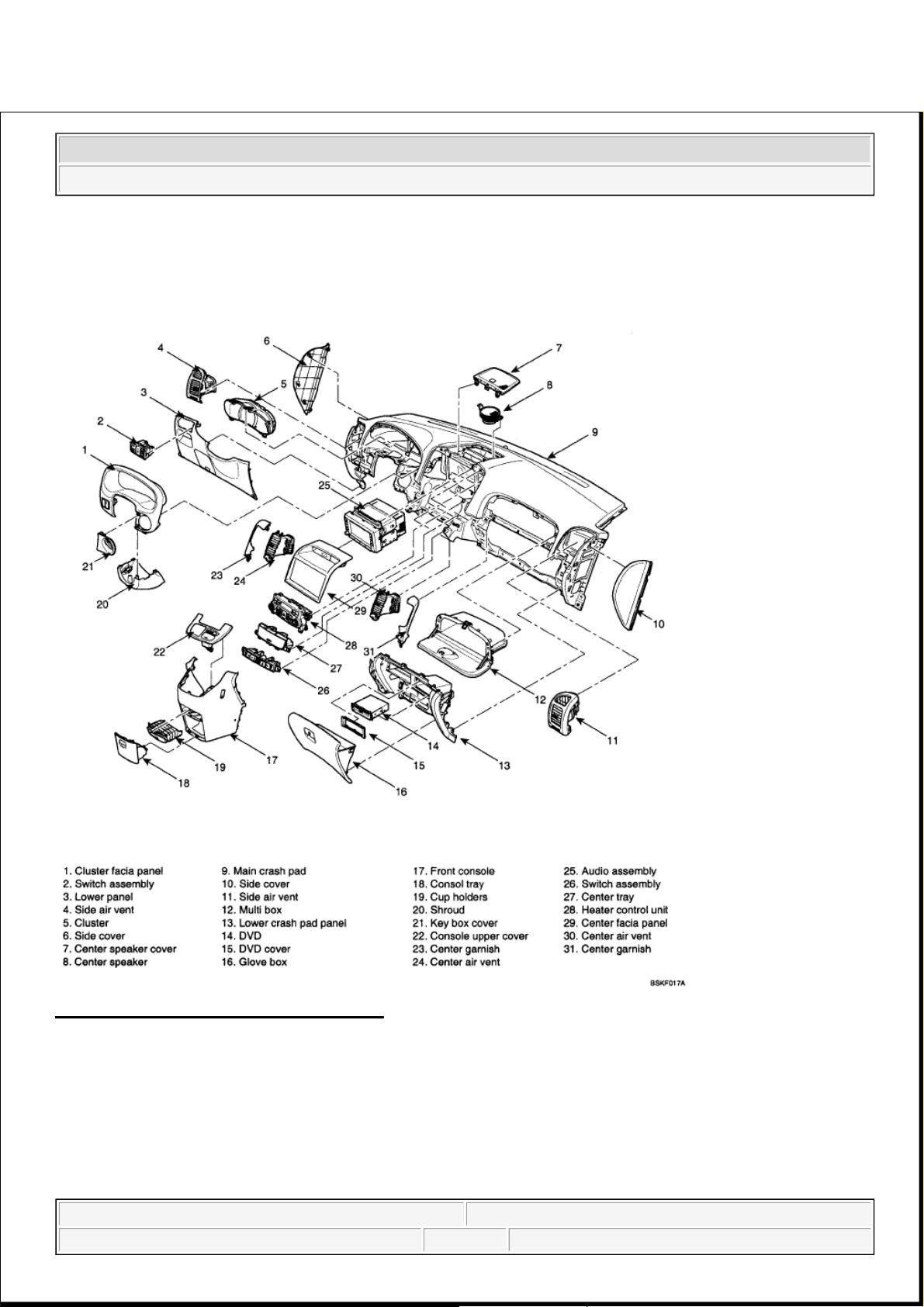

BATTERY

DESCRIPTION

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 13 © 2006 Mitchell Repair Information Company, LLC.

Page 25

1. The maintenance-free battery is, as the name implies, totally maintenance free and has no removable

battery cell caps.

2. Water never needs to be added to the maintenance-free battery.

3. The battery is completely sealed, except for small vent holes in the cover.

Fig. 16: View Of Battery

Courtesy of KIA MOTORS AMERICA, INC.

INSPECTION

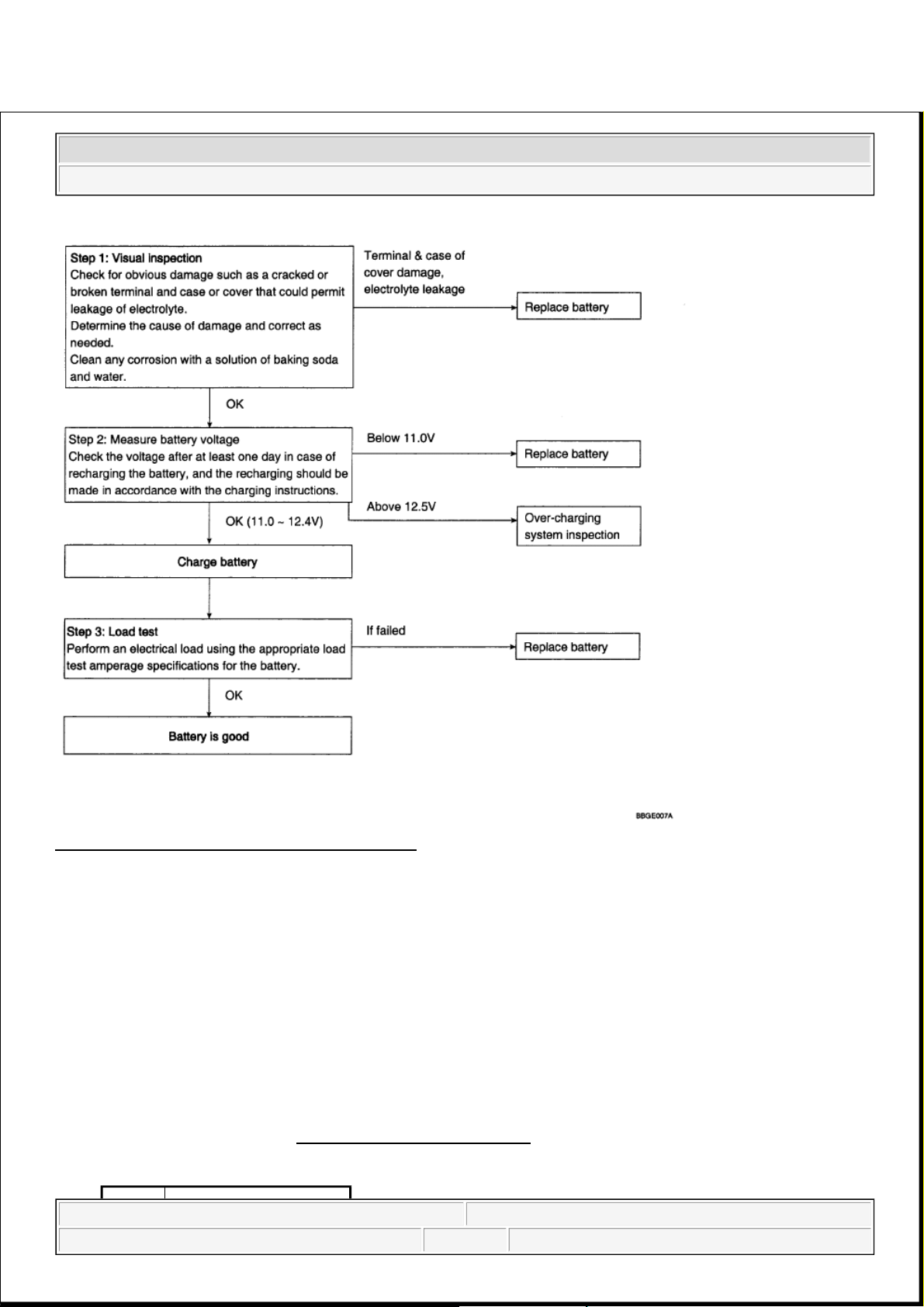

BATTERY DIAGNOSTIC TEST (1)

CHECKING FLOW

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 14 © 2006 Mitchell Repair Information Company, LLC.

Page 26

Fig. 17: Battery Diagnostic Test Flow Diagram

Courtesy of KIA MOTORS AMERICA, INC.

LOAD TEST

1. Perform the following steps to complete the load test procedure for maintenance free batteries.

2. Connect the load tester clamps to the terminals and proceed with the test as follow:

1. If the battery has been on charge, remove the surface charge by connecting a 300 ampere load for

15 seconds.

2. Connect the voltmeter and apply the specified load.

3. Read the voltage after the load has been applied for 15 seconds.

4. Disconnect the load.

5. Compare the voltage reading with the minimum and replace the battery if battery test voltage is

below that shown in BATTERY TEST VOLTAGE

.

BATTERY TEST VOLTAGE

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 15 © 2006 Mitchell Repair Information Company, LLC.

Page 27

BATTERY DIAGNOSTIC TEST (2)

1. Make sure the ignition switch and all accessories are in the OFF position.

2. Disconnect the battery cables (negative first).

3. Remove the battery from the vehicle.

Fig. 18: Disconnecting Negative Battery Cable

Courtesy of KIA MOTORS AMERICA, INC.

4. Inspect the battery tray for damage caused by the loss of electrolyte. If acid damage is present, it will be

necessary to clean the area with a solution of clean warm water and baking soda. Scrub the area with a

stiff brush and wipe off with a cloth moistened with baking soda and water.

Voltage Temperature

9.6V 20°C (68.0°F) and above

9.5V 16°C (60.8°F)

9.4V 10°C (50.0°F)

9.3V 4°C (39.2°F)

9.1V -1°C (30.2°F)

8.9V -7°C (19.4°F)

8.7V -12°C (10.4°F)

8.5V -18°C (-0.4°F)

NOTE:

If the voltage is greater than shown in BATTERY TEST VOLTAGE, the

battery is good.

If the voltage is less than shown in BATTERY TEST VOLTAGE,

replace the battery.

CAUTION: Care should be taken in the event the battery case is cracked or

leaking, to protect your skin from the electrolyte.

Heavy rubber gloves (not the household type) should be wore when

removing the battery.

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 16 © 2006 Mitchell Repair Information Company, LLC.

Page 28

5. Clean the top of the battery with the same solution as described above.

6. Inspect the battery case and cover for cracks. If cracks are present, the battery must be replaced.

7. Clean the battery posts with a suitable battery post tool.

8. Clean the inside surface of the terminal clamps with a suitable battery cleaning tool. Replace damaged or

frayed cables and broken terminal clamps.

9. Install the battery in the vehicle.

10. Connect the cable terminals to the battery post, making sure tops of the terminals are flush with the tops

of the posts.

11. Tighten the terminal nuts securely.

12. Coat all connections with light mineral grease after tightening.

Fig. 19: View Of Battery

Courtesy of KIA MOTORS AMERICA, INC.

CAUTION: When batteries are being charged, an explosive gas forms beneath

the cover of each cell. Do not smoke near batteries being charged or

which have recently been charged. Do not break live circuit at the

terminals of batteries being charged. A spark will occur when the

circuit is broken. Keep open flames away from battery.

2008 Kia Sedona

2008 ELECTRICAL Charging System - Sedona

Microsoft

Saturday, May 22, 2010 4:06:11 PM Page 17 © 2006 Mitchell Repair Information Company, LLC.

Page 29

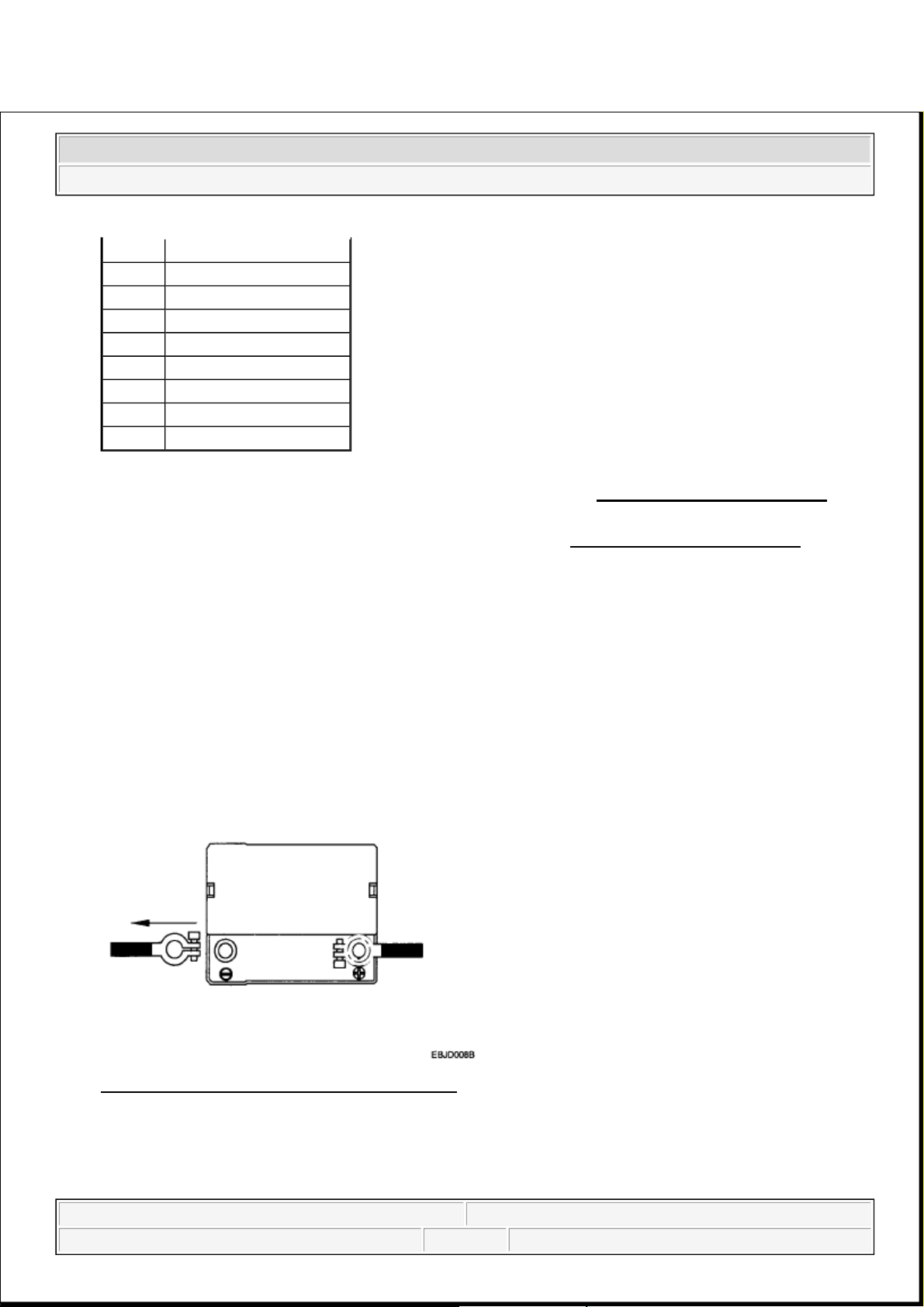

CRASH PAD

COMPONENTS

Fig. 7: Identifying Crash Pad Components

Courtesy of KIA MOTORS AMERICA, INC.

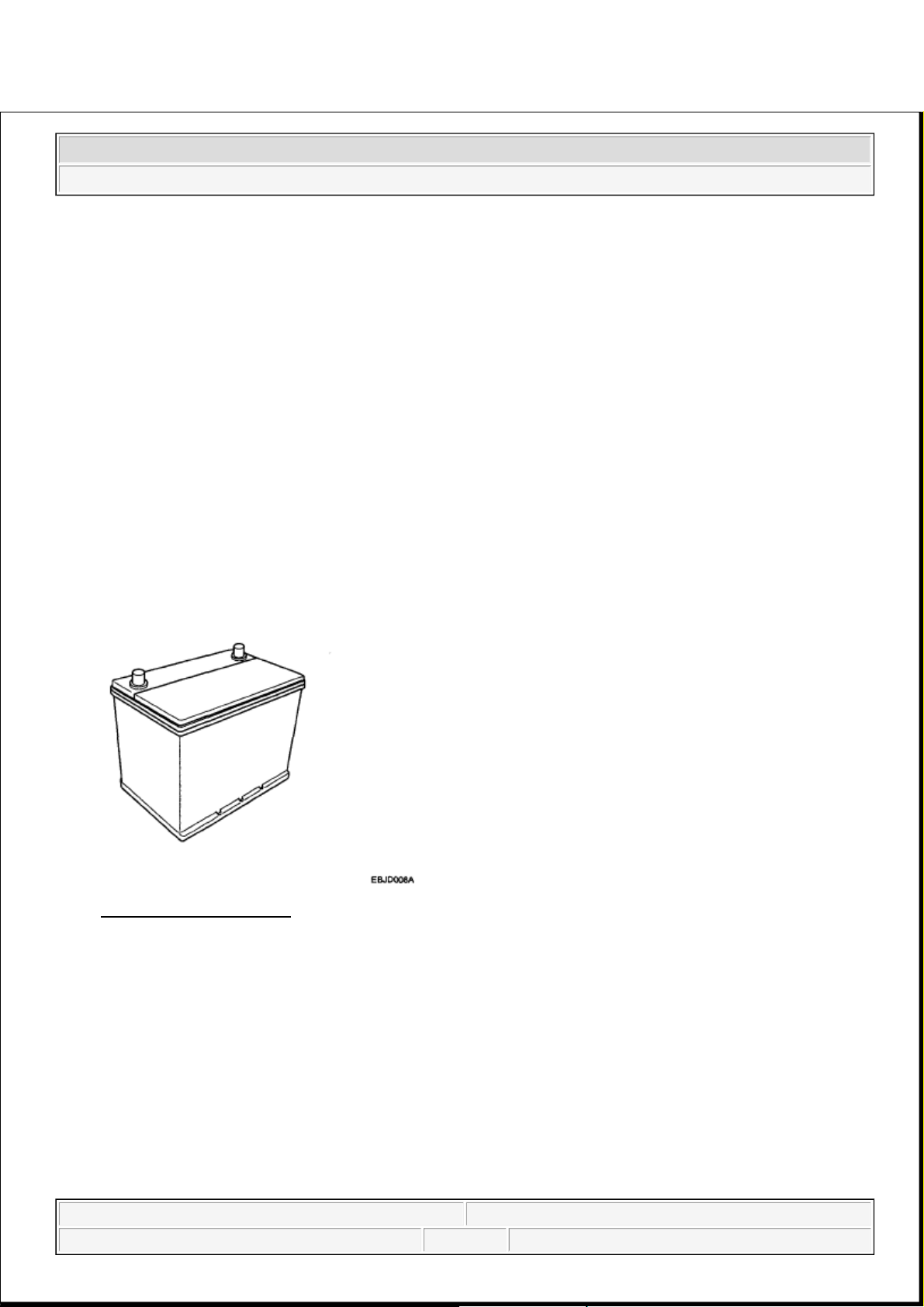

REPLACEMENT

CLUSTER FASCIA PANEL REPLACEMENT

NOTE:

When prying with a flat-tipped screwdriver, wrap it with protective tape,

and apply protective tape around the related parts, to prevent damage.

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:12 PM Page 1 © 2006 Mitchell Repair Information Company, LLC.

Microsoft

Saturday, May 22, 2010 6:56:15 PM Page 1 © 2006 Mitchell Repair Information Company, LLC.

Page 30

1. Tilt the steering column down.

2. Remove the screws, and detach the clips.

3. After disconnecting the connector (A), remove the cluster fascia panel (B).

Fig. 8: Identifying Connector And Cluster Fascia Panel

Courtesy of KIA MOTORS AMERICA, INC.

4. Installation is the reverse of removal.

CENTER FASCIA PANEL REPLACEMENT

1. Detach the clips, then remove the center fascia panel (A).

Put on gloves to protect your hands.

NOTE:

Make sure the connector is plugged in properly.

NOTE:

When prying with a flat-tipped screwdriver, wrap it with protective tape,

and apply protective tape around the related parts, to prevent damage.

Put on gloves to protect your hands.

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:12 PM Page 2 © 2006 Mitchell Repair Information Company, LLC.

Page 31

Fig. 9: Identifying Center Fascia Panel And Clip

Courtesy of KIA MOTORS AMERICA, INC.

2. Installation is the reverse the removal.

LOWER PANEL REPLACEMENT

1. Remove the crash pad side cover. See COVER REPLACEMENT.

2. Remove the fuse box cover (A).

Fig. 10: Identifying Fuse Box Cover

Courtesy of KIA MOTORS AMERICA, INC.

3. After loosenin

g

the crash pad lower panel mounting screws, then remove the lower panel (B).

NOTE:

Make sure the connector is plugged in properly.

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:12 PM Page 3 © 2006 Mitchell Repair Information Company, LLC.

Page 32

4. Remove the parking brake lever (C).

Fig. 11: Identifying Lower Panel, Parking Brake Lever And Fastener Locations

Courtesy of KIA MOTORS AMERICA, INC.

5. Disconnect the connector (A).

Fig. 12: Identifying Connector

Courtesy of KIA MOTORS AMERICA, INC.

6. Installation is the reverse of removal.

HEATER CONTROL UNIT REPLACEMENT

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:12 PM Page 4 © 2006 Mitchell Repair Information Company, LLC.

Page 33

1. Remove the center fascia panel. See REPLACEMENT.

2. Remove the console upper cover (A).

3. Disconnect the connector (B).

Fig. 13: Identifying Center Cover And Connector

Courtesy of KIA MOTORS AMERICA, INC.

4. Loosen the air vent mounting screw, then remove the air vent (A).

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:12 PM Page 5 © 2006 Mitchell Repair Information Company, LLC.

Page 34

Fig. 14: Identifying Air Vent And Fastener Locations

Courtesy of KIA MOTORS AMERICA, INC.

5. After loosening the heater control unit mounting screws, then remove the heater control unit (A).

Fig. 15: Identifying Heater Control Unit And Screw

Courtesy of KIA MOTORS AMERICA, INC.

6. Installation is the reverse of removal.

Fig. 16: Identifying Connector (1 Of 2)

Courtesy of KIA MOTORS AMERICA, INC.

NOTE:

Make sure the connector (A) is plugged in properly.

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:12 PM Page 6 © 2006 Mitchell Repair Information Company, LLC.

Page 35

Fig. 17: Identifying Connector (2 Of 2)

Courtesy of KIA MOTORS AMERICA, INC.

CLUSTER REPLACEMENT

1. Remove the cluster fascia panel. See REPLACEMENT.

2. Loosen the screws.

Fig. 18: Identifying Cluster Panel And Screw

Courtesy of KIA MOTORS AMERICA, INC.

3. Disconnect the cluster connectors (A), then remove the cluster (B).

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:12 PM Page 7 © 2006 Mitchell Repair Information Company, LLC.

Page 36

Fig. 19: Identifying Cluster Connectors And Cluster

Courtesy of KIA MOTORS AMERICA, INC.

4. Installation is the reverse of removal.

AUDIO ASSEMBLY REPLACEMENT

1. Remove the center fascia panel. See REPLACEMENT.

2. Loosen the screws.

Fig. 20: Identifying Center Fascia Panel And Screw

Courtesy of KIA MOTORS AMERICA, INC.

NOTE:

Make sure the connector are plugged in properly.

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:12 PM Page 8 © 2006 Mitchell Repair Information Company, LLC.

Page 37

3. Disconnect the connector (A), then remove the audio assembly (B).

Fig. 21: Identifying Connector And Audio Assembly

Courtesy of KIA MOTORS AMERICA, INC.

4. Installation is the reverse of removal.

AIR VENT REPLACEMENT

1. Remove the side cover. See COVER REPLACEMENT.

2. Loosen the mounting screws, then remove the air vent (A).

NOTE:

Make sure the connector are plugged in properly.

NOTE:

When prying with a flat-tipped screwdriver, wrap it with protective tape,

and apply protective tape around the related parts, to prevent damage.

Put on gloves to protect your hands.

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:12 PM Page 9 © 2006 Mitchell Repair Information Company, LLC.

Page 38

Fig. 22: Identifying Air Vent

Courtesy of KIA MOTORS AMERICA, INC.

3. Installation is the reverse of removal.

GLOVE BOX REPLACEMENT

1. Disconnect the damper (B) from the glove box (A).

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:12 PM Page 10 © 2006 Mitchell Repair Information Company, LLC.

Page 39

Fig. 23: Identifying Damper And Glove Box

Courtesy of KIA MOTORS AMERICA, INC.

2. Remove the glove box (A) from the lift (B).

Fig. 24: Identifying Glove Box And Lift

Courtesy of KIA MOTORS AMERICA, INC.

3. Disconnect the pine (A), then remove the glove box (B).

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:13 PM Page 11 © 2006 Mitchell Repair Information Company, LLC.

Page 40

Fig. 25: Identifying Pine And Glove Box

Courtesy of KIA MOTORS AMERICA, INC.

4. Installation is the reverse of removal.

COVER REPLACEMENT

1. Remove the crash pad side cover (A), crash pad center under cover (B).

1. Crash pad side cover.

NOTE:

When prying with a flat-tipped screwdriver, wrap it with protective tape,

and apply protective tape around the related parts, to prevent damage.

Put on gloves to protect your hands.

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:13 PM Page 12 © 2006 Mitchell Repair Information Company, LLC.

Page 41

Fig. 26: Identifying Crash Pad Side Cover And Clip

Courtesy of KIA MOTORS AMERICA, INC.

2. Front crash pad center under cover, LH.

Fig. 27: Identifying Center Under Cover And Clip

Courtesy of KIA MOTORS AMERICA, INC.

3. Front crash pad center under cover, RH.

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:13 PM Page 13 © 2006 Mitchell Repair Information Company, LLC.

Page 42

Fig. 28: Identifying Front Crash Pad Center Under Cover And Clip

Courtesy of KIA MOTORS AMERICA, INC.

2. Installation is the reverse of removal.

SHROUD REPLACEMENT

1. Loosen the screws.

2. Disconnect the connector, then remove the shroud assembly (A).

Fig. 29: Identifying Shroud Assembly And Screw

Courtesy of KIA MOTORS AMERICA, INC.

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:13 PM Page 14 © 2006 Mitchell Repair Information Company, LLC.

Page 43

3. Installation is the reverse of removal.

LOWER CRASH PAD PANEL REPLACEMENT

1. Remove the glove box. See GLOVE BOX REPLACEMENT.

2. Remove the side air vent. See AUDIO ASSEMBLY REPLACEMENT.

3. Remove the DVD cover (A).

Fig. 30: Identifying DVD Cover

Courtesy of KIA MOTORS AMERICA, INC.

4. Loosen the mounting screws, remove the DVD (A).

Fig. 31: Identifying DVD And Screw

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:13 PM Page 15 © 2006 Mitchell Repair Information Company, LLC.

Page 44

Courtesy of KIA MOTORS AMERICA, INC.

5. Disconnect the connector (A).

Fig. 32: Identifying Connector

Courtesy of KIA MOTORS AMERICA, INC.

6. After loosening the upper glove box mounting screws, then remove the upper glove box (A).

Fig. 33: Identifying Upper Glove Box And Fastener Locations

Courtesy of KIA MOTORS AMERICA, INC.

7. Loosen the panel mounting bolts and screws.

8. After disconnecting the connector, remove the panel (A).

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:13 PM Page 16 © 2006 Mitchell Repair Information Company, LLC.

Page 45

Fig. 34: Identifying Panel And Fastener Locations

Courtesy of KIA MOTORS AMERICA, INC.

9. Installation is the reverse of removal.

CRASH PAD REPLACEMENT

1. Remove the following items.

Front seat. See FRONT SEAT .

Cluster fascia panel, cluster. See CLUSTER REPLACEMENT.

Audio assembly. See AUDIO ASSEMBLY REPLACEMENT.

Glove box. See GLOVE BOX REPLACEMENT.

Side cover, center under cover. See COVER REPLACEMENT.

Front pillar trim. See FRONT PILLAR TRIM.

2. Remove the photo sensor (C), speaker connector (B).

3. Disconnect the passenger's air bag connector (A). Loosen the bolt and nut, then remove the crash pad (D).

4. Installation is the reverse of removal.

NOTE:

When prying with a flat-tipped screwdriver, wrap it with protective tape,

and apply protective tape around the related parts, to prevent damage.

Put on gloves to protect your hands.

NOTE:

Make sure the crash pad fits onto the guide pins correctly.

Before tightening the bolts, make sure the crash pad wire harnesses

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:13 PM Page 17 © 2006 Mitchell Repair Information Company, LLC.

Page 46

Fig. 35: Identifying Crash Pad Fastener Locations

Courtesy of KIA MOTORS AMERICA, INC.

COWL CROSSBAR ASSEMBLY REPLACEMENT

1. Remove the crash pad. See CRASH PAD REPLACEMENT.

2. Remove the connectors.

are not pinched.

Make sure the connectors are plugged in properly, and the antenna

lead is connected properly.

Enter the anti-theft code for the radio, then enter.

NOTE:

When prying with a flat-tipped screwdriver, wrap it with protective tape,

and apply protective tape around the related parts, to prevent damage.

Put on gloves to protect your hands.

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:13 PM Page 18 © 2006 Mitchell Repair Information Company, LLC.

Page 47

3. Loosen the bolts and nuts, then remove cowl crossbar assembly (A).

4. Installation is the reverse of removal.

Fig. 36: Identifying Cowl Crossbar Fastener Locations

Courtesy of KIA MOTORS AMERICA, INC.

NOTE:

Make sure the crash pad fits onto the guide pins correctly.

Before tightening the bolts, make sure the crash pad wire harnesses

are not pinched.

Make sure the connectors are plugged in properly, and the antenna

lead is connected properly.

Enter the anti-theft code for the radio, then enter the customer's radio

station presets.

2008 Kia Sedona

2008 ACCESSORIES & BODY, CAB Interior - Sedona

Microsoft

Saturday, May 22, 2010 6:56:13 PM Page 19 © 2006 Mitchell Repair Information Company, LLC.

Page 48

2008 ACCESSORIES & BODY, CAB

Horns - Sedona

COMPONENT LOCATION

Fig. 1: Horn System Component Locations

Courtesy of KIA MOTORS AMERICA, INC.

HORN

REPLACEMENT

1. Remove the bolt from the high pitch horn and the low pitch horn and disconnect the horn connector, then

remove the horn.

2. Installation is the reverse of removal.

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Horns - Sedona

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Horns - Sedona

Microsoft

Monday, May 24, 2010 4:12:43 PM Page 1 © 2006 Mitchell Repair Information Company, LLC.

Microsoft

Monday, May 24, 2010 4:12:46 PM Page 1 © 2006 Mitchell Repair Information Company, LLC.

Page 49

Fig. 2: Identifying Horn

Courtesy of KIA MOTORS AMERICA, INC.

ADJUSTMENT

Operate the horn, and adjust the tone to a suitable level by turning the adjusting screw.

Fig. 3: Adjusting Horn

Courtesy of KIA MOTORS AMERICA, INC.

INSPECTION

Test the horn by connecting battery voltage to the terminal 1, and ground terminal 2.

The horn should make a sound. If the horn fails to make a sound, replace it.

NOTE: After adjustment, apply a small amount of paint around the screw head to keep

it from loosening.

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Horns - Sedona

Microsoft

Monday, May 24, 2010 4:12:43 PM Page 2 © 2006 Mitchell Repair Information Company, LLC.

Page 50

2008 HVAC

HVAC General - Sedona

SPECIFICATION

AIR CONDITIONER

AIR CONDITIONER SPECIFICATION

BLOWER UNIT

BLOWER UNIT CHART

HEATER AND EVAPORATOR UNIT

HEATER AND EVAPORATOR UNIT CHART

Item

Specification

3.8L

Compressor

Type Fixed type (Swash plate)

Oil type & Capacity FD46XG (PAG), 210 ± 10cc

Pulley type 6PK-TYPE

Displacement 214cc/rev

Condenser Heat rejection 19,500 ± 5% kcal/hr

APT (A/C pressure transducer) The method to measure the

pressure

Vout = 0.00878835* pa +

0.37081095

Expansion valve Type Block (L-TYPE)

Refrigerant

Type R-134a

Capacity [oz. (g)] 31.7 ± 0.88 (900 ± 25)

Item Specification

Fresh and recirculation Operating method Actuator

Blower

Type Sirocco

Speed step Auto + 8 speed (Automatic)

1-8 speed (Manual)

Speed control Power Mosfet

Air filter Type Particle filter

Item Specification

Heater

Type Pin & Tube type

Heating capacity 4,700 ± 5% kcal/hr

Mode operating method Actuator

Temperature operating method Actuator

Evaporator

Temperature control type Evaporator temperature sensor

2008 Kia Sedona EX

2008 HVAC HVAC General - Sedona

2008 Kia Sedona EX

2008 HVAC HVAC General - Sedona

Microsoft

Monday, May 24, 2010 4:02:38 PM Page 1 © 2006 Mitchell Repair Information Company, LLC.

Microsoft

Monday, May 24, 2010 4:02:41 PM Page 1 © 2006 Mitchell Repair Information Company, LLC.

Page 51

TROUBLESHOOTING

PROBLEM SYMPTOMS TABLE

Before replacing or repairing air conditioning components, first determine if the malfunction is due to the

refrigerant charge, air flow or compressor.

Use the Troubleshooting table to help you find the cause of the problem. See TROUBLESHOOTING

CHART. The numbers indicate the priority of the likely cause of the problem. Check each part in order. If

necessary, replace these parts.

After correcting the malfunction, check the complete system to ensure that performance is satisfactory.

STANDARD:

TROUBLESHOOTING CHART

A/C ON/OFF °C (°F)]

ON: 2.6 ± 0.5 (36.7 ± 0.9)

OFF: 1.1 ± 0.5 (34.0 ± 0.9)

Symptom Suspect Area

No blower operation

1. Blower fuse

2. Blower relay

3. Blower motor

4. Power Mosfet

5. Blower speed control switch

6. Wire harness

No air temperature control

1. Engine coolant capacity

2. Heater control assembly

No compressor operation

1. Refrigerant capacity

2. A/C Fuse

3. Magnetic clutch

4. Compressor

5. A/C pressure transducer

6. A/C switch

7. Evaporator temperature sensor

8. Wire harness

No cool air comes out

1. Refrigerant capacity

2. Refrigerant pressure

3. Drive belt

4. Magnetic clutch

5. Compressor

6. A/C pressure transducer

7. Evaporator temperature sensor

8. A/C switch

2008 Kia Sedona EX

2008 HVAC HVAC General - Sedona

Microsoft

Monday, May 24, 2010 4:02:38 PM Page 2 © 2006 Mitchell Repair Information Company, LLC.

Page 52

SPECIAL TOOLS

SPECIAL TOOLS CHART

9. Heater control assembly

10. Wire harness

Insufficient cooling

1.Refrigerant capacity

2. Drive belt

3. Magnetic clutch

4. Compressor

5. Condenser

6. Expansion valve

7. Evaporator

8. Refrigerant lines

9. A/C pressure transducer

10. Heater control assembly

No engine idle-up when A/C switch ON

1. Engine ECM

2. Wire harness

No air inlet control 1. Heater control assembly

No mode control

1. Heater control assembly

2. Mode actuator

No cooling fan operation

1. Cooling fan fuse

2. Fan motor

3. Engine ECM

4. Wire harness

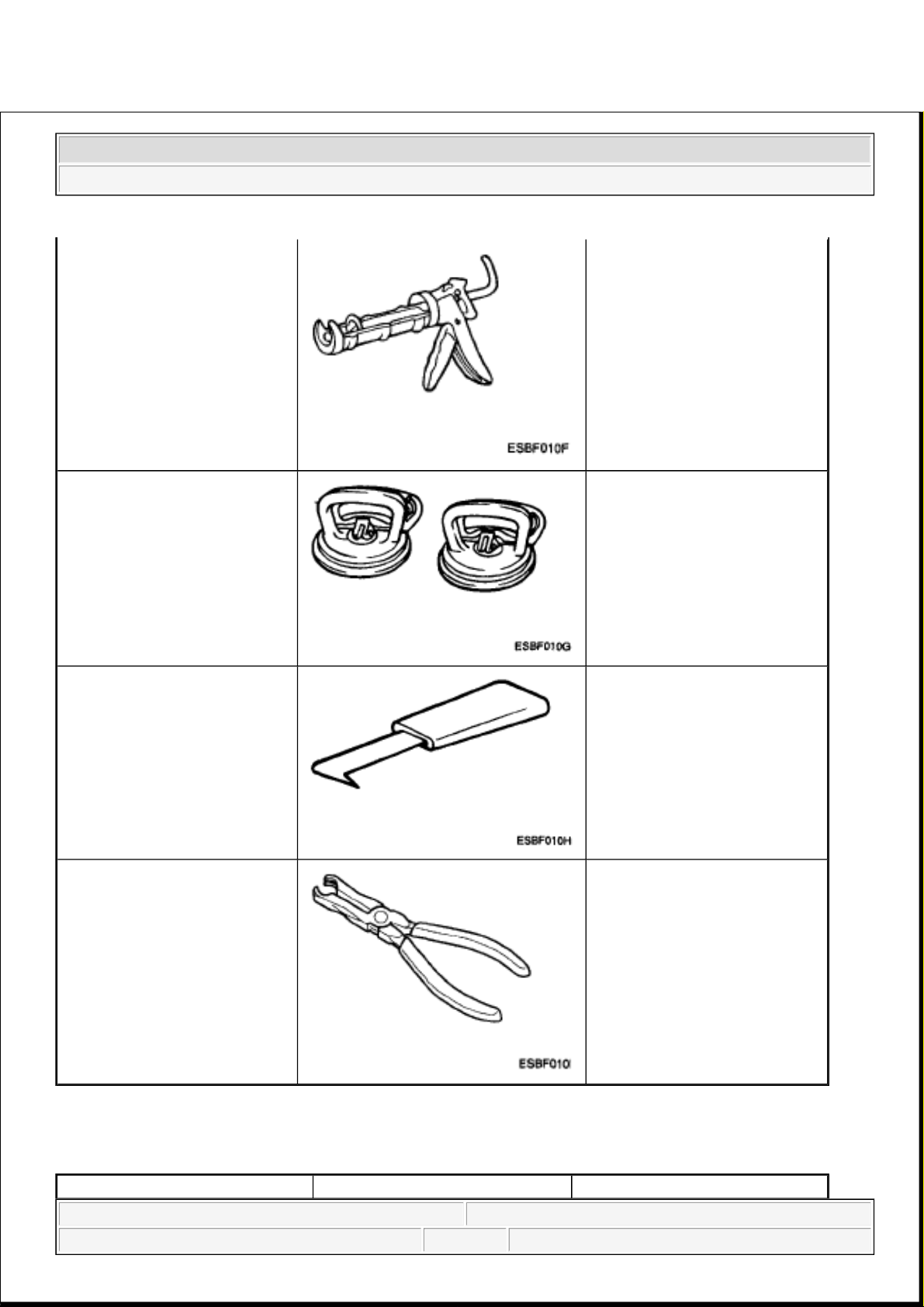

Tool (Number and name) Illustration Use

09977-29000

Disc & hub assembly bolt remover

Removal and installation of the

disc & hub assembly bolt

2008 Kia Sedona EX

2008 HVAC HVAC General - Sedona

Microsoft

Monday, May 24, 2010 4:02:38 PM Page 3 © 2006 Mitchell Repair Information Company, LLC.

Page 53

2008 ACCESSORIES & BODY, CAB

Power Door Mirrors - Sedona

COMPONENT LOCATION

Fig. 1: Power Door Mirror Component Locations

Courtesy of KIA MOTORS AMERICA, INC.

POWER DOOR MIRROR ACTUATOR

INSPECTION

1. Remove the front door quadrant inner cover (A). Take care not to damage fixing clips. Refer to FRONT

DOOR .

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Door Mirrors - Sedona

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Door Mirrors - Sedona

Microsoft

Monday, May 24, 2010 4:12:07 PM Page 1 © 2006 Mitchell Repair Information Company, LLC.

Microsoft

Monday, May 24, 2010 4:12:11 PM Page 1 © 2006 Mitchell Repair Information Company, LLC.

Page 54

Fig. 2: Identifying Front Door Quadrant Inner Cover

Courtesy of KIA MOTORS AMERICA, INC.

2. Disconnect the power door mirror connector from the harness.

3. Verify that the mirror operates properly. See Fig. 4.

Fig. 3: Identifying Power Door Mirror Actuator Connector Terminals

Courtesy of KIA MOTORS AMERICA, INC.

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Door Mirrors - Sedona

Microsoft

Monday, May 24, 2010 4:12:07 PM Page 2 © 2006 Mitchell Repair Information Company, LLC.

Page 55

Fig. 4: Testing Power Mirror Actuator

Courtesy of KIA MOTORS AMERICA, INC.

MIRROR HEATER

Fig. 5: Testing Mirror Heater

Courtesy of KIA MOTORS AMERICA, INC.

FOLDING MIRROR

Fig. 6: Identifying Folding Mirror Position

Courtesy of KIA MOTORS AMERICA, INC.

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Door Mirrors - Sedona

Microsoft

Monday, May 24, 2010 4:12:07 PM Page 3 © 2006 Mitchell Repair Information Company, LLC.

Page 56

Fig. 7: Testing Folding Mirror

Courtesy of KIA MOTORS AMERICA, INC.

OUTSIDE FOLDING MIRROR SWITCH

REPLACEMENT

1. Disconnect the negative (-) battery terminal.

2. Remove the front door trim panel. Refer to FRONT DOOR .

3. Remove the power window main switch mounting screws (3 each) (A) after disconnecting the switch

connector (12-pin) from the switch.

Fig. 8: Identifying Power Window Main Switch And Mounting Screws

Courtesy of KIA MOTORS AMERICA, INC.

4. Remove the switch from the front door trim panel.

5. Installation is the reverse of removal.

INSPECTION

1. Disconnect the 12-pin connector from the switch.

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Door Mirrors - Sedona

Microsoft

Monday, May 24, 2010 4:12:07 PM Page 4 © 2006 Mitchell Repair Information Company, LLC.

Page 57

Fig. 9: Identifying Outside Folding Mirror Switch 12-Pin Connector

Courtesy of KIA MOTORS AMERICA, INC.

2. Check for continuity between the terminals in each switch position. See Fig. 10.

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Door Mirrors - Sedona

Microsoft

Monday, May 24, 2010 4:12:07 PM Page 5 © 2006 Mitchell Repair Information Company, LLC.

Page 58

Fig. 10: Testing Outside Folding Mirror Switch

Courtesy of KIA MOTORS AMERICA, INC.

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Door Mirrors - Sedona

Microsoft

Monday, May 24, 2010 4:12:07 PM Page 6 © 2006 Mitchell Repair Information Company, LLC.

Page 59

2008 ACCESSORIES & BODY, CAB

Power Sliding Door System - Sedona

COMPONENT LOCATION

Fig. 1: Power Sliding Door System Component Locations

Courtesy of KIA MOTORS AMERICA, INC.

DESCRIPTION

Power sliding door is an electro-mechanical system designed to provide power opening and closing of a

vehicle's sliding door through the push of a button of the transmitter key or the main control buttons on the

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Sliding Door System - Sedona

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Sliding Door System - Sedona

Microsoft

Monday, May 24, 2010 4:16:17 PM Page 1 © 2006 Mitchell Repair Information Company, LLC.

Microsoft

Monday, May 24, 2010 4:16:20 PM Page 1 © 2006 Mitchell Repair Information Company, LLC.

Page 60

overhead console or the sub control buttons on the center pillar trim or inside/outside door handle switch.

The power sliding door will reverse direction of travel if resistance to movement is detected while the door is

being closed. If resistance to movement is detected while the power sliding door is being opened, the door will

stop moving.

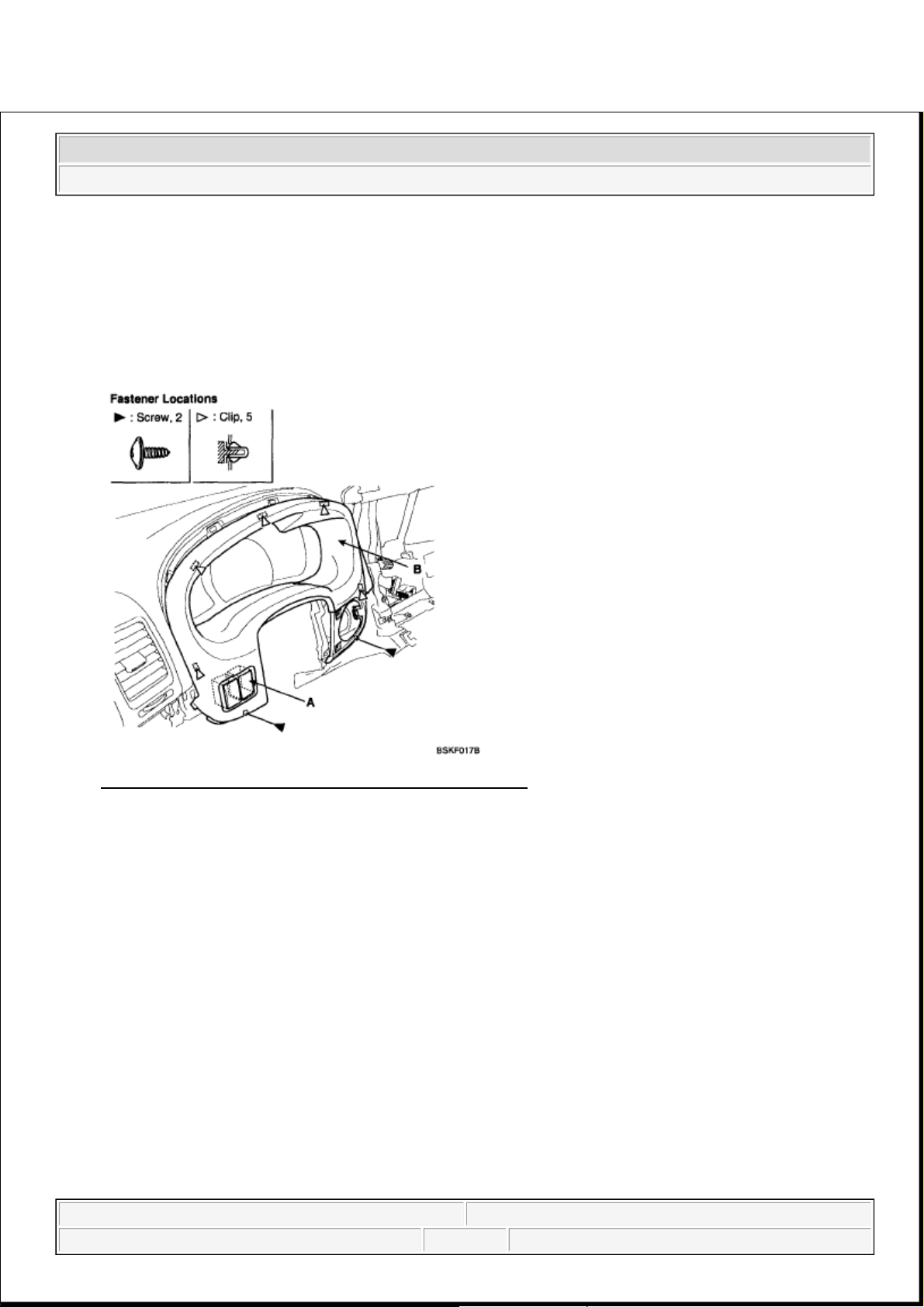

1. DRIVE UNIT

Drive unit (A) consists of a DC motor, optical sensor, clutch, cables and pulleys and wire harness. The

clutch and motor portion of the assembly provides the power and torque required to open or close the

sliding door. The clutch assembly is used to connect or disconnect the motor so that the Sliding Door may

be moved manually, if desired.

Fig. 2: Identifying Drive Unit

Courtesy of KIA MOTORS AMERICA, INC.

2. POWER SLIDING DOOR CONTROL MODULE (PSDM)

The PSD System uses a power sliding door control module (microprocessor controller) to operate the

drive unit. Signals are received from the vehicle and used to start or stop power open or close operations.

The PSDM cannot be ad

j

usted or repaired and if found to be faulty, must be replaced.

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Sliding Door System - Sedona

Microsoft

Monday, May 24, 2010 4:16:17 PM Page 2 © 2006 Mitchell Repair Information Company, LLC.

Page 61

Fig. 3: Identifying Power Sliding Door Control Module

Courtesy of KIA MOTORS AMERICA, INC.

3. SLIDING DOOR CHIME (C)

When the power sliding door detect the resistance or abnormal operation, the chime will sound.

Fig. 4: Identifying Sliding Door Chime

Courtesy of KIA MOTORS AMERICA, INC.

4. ANTI-PINCH STRIP (D)

Secondary Obstacle Detection is provided by means of a contact type strip. Strip is composed of two

conductive zones separated by an air gap. When strip is compressed, conductive zones make contact,

activating the switch signal.

Copper wire is extruded through conductive material to prevent resistive buildup. Terminating resistor is

molded into end of strip to detect failures of strip.

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Sliding Door System - Sedona

Microsoft

Monday, May 24, 2010 4:16:17 PM Page 3 © 2006 Mitchell Repair Information Company, LLC.

Page 62

Fig. 5: Identifying Anti-Pinch Strip

Courtesy of KIA MOTORS AMERICA, INC.

5. OVERHEAD CONSOLE AND REMOTE CONTROL SWITCH (A)

The power sliding doors can be opened and closed automatically with the RKE and the main control

button on the overhead console.

Fig. 6: Identifying Overhead Console And Remote Control Switch

Courtesy of KIA MOTORS AMERICA, INC.

6. DOOR LATCH (B)

The door latch contains a detent switch [C] used to detect the latch state and report the latch state to the

power slidin

g

door module.

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Sliding Door System - Sedona

Microsoft

Monday, May 24, 2010 4:16:17 PM Page 4 © 2006 Mitchell Repair Information Company, LLC.

Page 63

Fig. 7: Identifying Door Latch

Courtesy of KIA MOTORS AMERICA, INC.

7. KEYLESS ENTRY (A)

Power sliding doors can be opened and closed by pressing the button on the RKE more than 0.5 sec.

Open operation shall be reserved when an additional open/close signal is received during power opening.

Fig. 8: Identifying Keyless Entry Transmitter

Courtesy of KIA MOTORS AMERICA, INC.

8. INSIDE/OUTSIDE DOOR HANDLE SWITCH

Power sliding door can be opened and closed manually/automatically from inside or outside vehicle.

Outside door handle switch (A)

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Sliding Door System - Sedona

Microsoft

Monday, May 24, 2010 4:16:17 PM Page 5 © 2006 Mitchell Repair Information Company, LLC.

Page 64

Fig. 9: Identifying Outside Door Handle Switch

Courtesy of KIA MOTORS AMERICA, INC.

Inside door handle switch (B)

Fig. 10: Identifying Inside Door Handle Switch

Courtesy of KIA MOTORS AMERICA, INC.

OPERATION

POWER SLIDING DOOR OPEN/CLOSE

1. The right/left sliding door is opened and closed automatically if the main switch (A) is pressed on the

overhead console.

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Sliding Door System - Sedona

Microsoft

Monday, May 24, 2010 4:16:17 PM Page 6 © 2006 Mitchell Repair Information Company, LLC.

Page 65

Fig. 11: Identifying Main Switch

Courtesy of KIA MOTORS AMERICA, INC.

2. When the power ON/OFF button (PWR) (B) is ON, the power sliding door and power tailgate can be

opened and closed automatically by using trim switch.

3. When the sliding door window is open (more than 3 in/80 mm), the power sliding door will not power

open fully but will open to the 3/4 position and the chime will sound 3 times.

4. General rules for chime functions

Chime shall operate when a power operation cannot be performed as requested except handle pull:

1 Time (Duration 0.5 second on)

Chime shall operate when an obstacle has been detected: 3 Time (0.5 sec on, 0.5 sec off)

Chime shall operate if PSD has not reached primary latch position after a power cinch cycle: 3

Time (0.5 sec on, 0.5 sec off)

POWER SLIDING DOOR OPERATING CONDITION

1. The sliding door will not power open when vehicle is moving above 3 mph (5 km/h) or the gearshift lever

is not in P (Park) for automatic transaxle.

2. The power sliding door will not open with the transmitter or the main control button when all power

sliding doors are locked and closed.

3. The power sliding door will detect the resistance, then stop movement or move to the full open position to

allow the object to be cleared.

4. The left sliding door cannot be opened when the fuel filler lid is open.

5. If the automatic stop and reversal feature operates continuously more than twice during one opening or

closing operation, the power sliding door may stop at that position. At this time, close the doors manually

and operate the door automatically again.

WARNING: Do not leave the power sliding door at half-opened position. Close

the window and then open the door fully. Half-opened door is held

and then released after 10 minutes. The chime sounds 3 times to

indicate the door is released. If the vehicle is stopped on a

downward slope, it may move and cause an injury.

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Sliding Door System - Sedona

Microsoft

Monday, May 24, 2010 4:16:17 PM Page 7 © 2006 Mitchell Repair Information Company, LLC.

Page 66

6. The power sliding door can be opened by pulling the outside door handle while the door is unlocked and

child safety lock is engaged.

CHILD SAFETY LOCKS

To prevent children from opening the power sliding doors from the inside, the child safety locks (A) should be

used whenever children are in the vehicle.

Fig. 12: Identifying Child Safety Locks

Courtesy of KIA MOTORS AMERICA, INC.

NOTE:

If the fuel filler lid is opened when the left sliding door is not closed

completely, the door may be opened. Close the left sliding door

before refueling to prevent possible damage to the door or the fuel

filler lid.

Sudden starting or accelerating the vehicle while the door is closing

could cause it to open the door and result in a serious injury or

damage to cargo.

CAUTION:

The door could suddenly close by itself and cause a serious

injury especially when stopping on a downhill grade.

To prevent the battery from being discharged, do not leave the

power sliding door and power tailgate at open position for a

long time.

WARNING:

Let the rear passengers get on or off the vehicle after the door

is open fully. Sudden closing could cause a serious injury.

To prevent power sliding door system damage, don't use

excessive force to open/close the door during operation.

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Sliding Door System - Sedona

Microsoft

Monday, May 24, 2010 4:16:17 PM Page 8 © 2006 Mitchell Repair Information Company, LLC.

Page 67

POWER OPERATION

The PSD system shall not open the Sliding Door when the vehicle is moving.

The PSD system shall operate through the full range of Sliding Door travel.

The PSD system shall learn the position of each travel extreme: full open and full closed.

PSD SYSTEM OPERATION CHART

WARNING: Be careful, when the child safety lock is used in an accident, that the

passengers are not held in vehicle.

Vehicle

Motion

Door Position

Zone

ON/OFF

Door Lock

Status

Operation

RKE Key

Fob Note 2

PSD main

switch

PSD sub

switch

Door handle

switch

-: No action •: Close O: Open X: Stop

Not

Moving

1 or 2

OFF Any O o - X

ON

Not Locked O O O O

Locked O O

X (Chime 1

T)

X

3 or 4

OFF Any • •

X (Chime 1

T)

X

ON Any • • • •

Closing

OFF Any O O X X

ON Any O O O O

Opening 1 or

2

ON/OFF Any X X X X

Opening 3 or

4

OFF Any • • X X

ON Any • • • •

Moving

1 or 2 ON/OFF Any -

X (Chime 1 T)X (Chime 1

T)

X

3 or 4

OFF Any - •

X (Chime 1

T)

•

ON Any - • • •

Closing ON/OFF Any - X X X

Opening 1 or

2

ON/OFF Any - X X X

Opening 3 or

4

OFF Any - • X X

ON Any - • • •

Any

1 or 2 ON

Any

Manual Move in open/close direction

Any

3 or 4 ON

Any

Manual Move in open/close direction

Any

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Sliding Door System - Sedona

Microsoft

Monday, May 24, 2010 4:16:17 PM Page 9 © 2006 Mitchell Repair Information Company, LLC.

Page 68

1. Vehicle condition

Moving

(IGN=OFF and Vehicle Speed > 5 km/h) or (IGN= ON and (Vehicle Speed > 5 km/h or PIN - not

PIN))

Not moving

(IGN=OFF and Vehicle Speed < 5 km/h) or (IGN= ON and (Vehicle Speed < 5 km/h and TRANS -

P/N))

2. DOOR TRAVEL - ZONES

The door travel is divided into four zones starting at the full closed and latched position.

Dimensions are at the rear edge of the door and are approximate.

Zone 1 - Latching - 0 to 10 mm (primary and secondary latch positions).

Zone 2 - Near latching position including curved track portion -10 to 300 mm.

Zone 3 - Straight track - 300 mm to hold open latch.

Zone 4 - Hold Open - door in hold open latch.

POWER SLIDING DOOR OPERATION

1. Vehicle condition

Stopping condition

When the ignition switch is in the OFF or ACC position, vehicle is stopped or moving below 5

km/h.

When the ignition switch is in the ON position, vehicle is stopped or moving below 5 km/h (the

gearshift lever is in N (Neutral) for manual transaxle, P (Park) for automatic transaxle).

Driving condition

When the ignition switch is in the OFF or ACC position, vehicle is moving above 5 km/h.

When the ignition switch is in the ON position, vehicle is moving above 5 km/h or the gearshift

lever is not in N (Neutral) for manual transaxle, P (Park) for automatic transaxle.

2. Door position

Any OFF Any Manual Move

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Sliding Door System - Sedona

Microsoft

Monday, May 24, 2010 4:16:17 PM Page 10 © 2006 Mitchell Repair Information Company, LLC.

Page 69

If the power sliding door is operated while the door is in slightly-opened position (less than 300mm), the

door is automatically opened fully. If the power sliding door is operated while the door is in slightlyopened position (more than 300mm), the door is automatically closed completely.

3. If the door handle is pulled from inside or outside while the door is locked or child safety lock is engaged,

the power sliding door is not opened.

TROUBLESHOOTING

Check the following items prior to performing Power Sliding Door System service.

1. Manual movement

Make sure the sliding door moves manually. Place the ON/OFF switch on the overhead console in the

OFF position. Move the door manually and check for proper door fit and latch effort. Check for

interference with other body parts such as latch striker, trim, and weather seals.

2. Battery voltage

Make sure the battery is fully charged. The PSD system is an electronic device and requires a minimum

battery voltage to operate. The PSDM (Power sliding door module) monitors the battery voltage present

at the PSDM input battery input and will not permit operation if the battery voltage is out of range.

3. Fuses

Two fuses protect the battery supply to the PSDM (Power sliding door module), one for Power, and one

for logic. Check that the fuses are intact

4. Repeat Operations

Make sure the customer has not been operating the PSD repeatedly while the vehicle is turned off. The

battery will be discharged and the PSDM (Power sliding door module) will not permit operation.

5. Vehicle on Steep Grade

Make sure the customer has not been operating the PSD system when the vehicle is parked on a steep

grade (greater than 30%). The system will operate but the force of gravity and normal flex of the vehicle

body may affect proper operation.

6. Obstacle Detection

The obstacle detection force is not adjustable. Factors that may affect the force are vehicle grade, battery

voltage, or dirt in sliding door tracks.

7. Outside handle response time

When the vehicle has been parked and OFF, there ma

y

be a delay before power operation starts after the

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Sliding Door System - Sedona

Microsoft

Monday, May 24, 2010 4:16:17 PM Page 11 © 2006 Mitchell Repair Information Company, LLC.

Page 70

outside handle is pulled. This is normal because the PSDM (Power sliding door module) must wake up

and check for proper conditions before starting a power open operation.

8. The sliding doors are not identical. Open and close times and obstacle detection efforts may vary when

comparing the two doors. This is normal and is caused by vehicle build conditions such as door fit and

rolling resistance.

9. Scan tool Diagnostic tool

Connect Scan tool to the K-line and check status of system.

POWER SLIDING DOOR SYSTEM DIAGNOSIS

POWER SLIDING DOOR SYSTEM DIAGNOSIS CHART

CONDITION

POSSIBLE

CAUSES

CORRECTION

Sliding Door opens

unexpectedly

Accidental activation

or failure of

open/close command

switch

Check for shorted or defective switch

Failure of latch

assembly

Check wiring connections

Check for diagnostic trouble codes

Failure of Power

Sliding Door or Body

Control module

Disconnect then reconnect battery or fuse to reset

module and function sliding door. If no function exists,

check for loose wire connections. See ENGINE

ELECTRICAL SYSTEM - GENERAL for detailed

procedures

Sliding Door will not

power open or close

Not in Park or false

indication

Check switch status with SCAN tool

Battery voltage at

PSDM is too low

Check for proper voltage at the PSDM. Charge battery

Blown fuse Check for blown fuse

BCM or sliding door

control module

critical fault codes

Check for diagnostic trouble codes

Failure of latch

assembly

Check wire connections and for blown fuse

Check for foreign matter preventing the operation of

latch assembly

Failure of motor

assembly

Test motor assembly

Binding or sticking of

components

Establish location of binding and replace necessary

components

Wiring problems

(system or vehicle)

Troubleshoot using electrical schematics

Refer to appropriate SYSTEM WIRING DIAGRAMS

article.

Troubleshoot using electrical schematics

2008 Kia Sedona EX

2008 ACCESSORIES & BODY, CAB Power Sliding Door System - Sedona

Microsoft

Monday, May 24, 2010 4:16:17 PM Page 12 © 2006 Mitchell Repair Information Company, LLC.

Page 71

Power loss during Sliding

Door operation

Wiring problems

(system or vehicle)

Refer to appropriate SYSTEM WIRING DIAGRAMS

article.

Battery voltage at

PSDM is too low

< 9.5V to start

operation and

< 8.0V to continue

operation

Check for proper voltage at the PSDM.

Charge battery

Failure of Power

Sliding Door or Body

Control Module

Check for diagnostic trouble codes

Failure of motor

assembly

Test motor assembly

Sliding Door does not

close to primary latch

position

Door mis-alignment

Check latch and striker alignment

Check rollers and track alignment

Binding or sticking of

components

Establish location of binding and adjust or replace

necessary components

Failure of Power

Sliding Door or Body

Control Module

Check for diagnostic trouble codes

Sliding Door seal

force too high

Inspect seals for damage, mis-assembly, foreign matter

or other possible obstruction

Failure of motor

assembly

Test motor assembly

Latch will not release

from primary position

Not in Park or false

indication

Check switch status with SCAN tool

Battery voltage at