Page 1

Laser Thrubeam Sensor

CAUTION

IB Series

96M11417

Laser emission stop input

Point

When laser emission stop input is set as an external input, laser

emission can be stopped by turning on the external input (2 ms

or more). Laser emission stays stopped while the external input

is on. The laser is emitted within 3 ms after the external input is

turned off. For the conditions of detection outputs and analog

outputs during laser emission stop input, refer to the User's

Manual.

Instruction Manual

Read this manual before using the product in order to achieve maximum performance.

Keep this manual in a safe place after reading it so that it can be used at any time.

For details of functions, refer to the IB Series User's Manual.

• Refer to the “Thrubeam Type Laser Detection Sensor IB Series User’s

Manual” for details on each function.

• The “Laser Thrubeam Sensor IB Series User’s Manual” can be downloaded

from the KEYENCE web site (http://www.keyence.com).

Symbols

The following symbols are used in this manual to alert you to important matters for

preventing personal injury and device damage.

It indicates a hazardous situation which, if not avoided, will result

DANGER

in death or serious injury.

It indicates a hazardous situation which, if not avoided, could

WARNING

result in death or serious injury.

It indicates a hazardous situation which, if not avoided, could

CAUTION

result in minor or moderate injury.

It indicates a situation which, if not avoided, could result in

NOTICE

product damage as well as property damage.

It indicates cautions and limitations that must be followed during operation.

Important

It indicates additional information on proper operation.

Point

It indicates tips for better understanding or useful information.

Reference

Reference pages are indicated.

Safety Information for IB Series

General precautions

• This product is just intended to detect the object(s). Do not

use this product for the purpose to protect a human body or a

part of a human body.

• This product is not intended for use as explosion-proof

WARNING

NOTICE

Safety Precautions on Laser Products

product. Do not use this product in a hazardous location and/

or potentially explosive atmosphere.

• Provide sufficient safety measures to prevent various damage

in the event this product fails.

• When using this product in combination with other devices,

there may be cases when the functions and performance

cannot be achieved because of the working conditions or

environment, etc. Always review the combination carefully

before starting use.

• Do not apply sudden temperature changes on any device

including the peripheral devices. Condensation could cause

device damage.

Troubleshooting

Turn the power OFF immediately in the following cases.

Continuing use in an abnormal state can cause damage.

WARNING

• When water or foreign matter enters the product body.

• When the product has been dropped or the case damaged.

• When smoke or abnormal odors are emitted from the product.

Precautions for Use

• Use this product with the correct power voltage. Failure to do

WARNING

NOTICE

so could result in fire or electric shock.

• Do not disassembly or modify this product. Failure to observe

this could result in fire or electric shock.

• Always turn off the power of the main unit and any device

connected to the main unit before connecting or

disconnecting a cable.

• Do not turn the power off while setting the items. Doing so

could result in the lost of some or all setting data.

Installation Environment

To ensure correct and safe use of this product, do not install it in

the following type of environment. Failure to observe this could

result in faults.

• Location subject to high levels of moisture or dust, or which is

poorly ventilated

• Location subject to high temperatures, such as where product

is subject to direct sunlight

• Location subject to corrosive gases or flammable gases

• Location directly subject to vibration or impact

• Location which may be subject to water, oil or chemical spray

• Location where static electric is easily generated

Effect of Contaminants

• Contaminants such as dirt, dust, water or oil may prevent a

correct measurement from being made.

• Spray any contaminants off the transmitter and receiver

sections with clean air. If heavily contaminated, wipe the

sections off with a soft cloth dampened with alcohol.

• Spray any contaminants off the measurement target with

clean air, or wipe them off.

• If contaminants are suspended in the measurement range,

install a protective cover, or perform air purging, etc.

Measures for Noise

When installing this product near a source of noise such as a

power cable or high voltage cable, it could malfunction or fail

because of the noise. Provide counter measures for noise such

as installing a noise filter, laying the cables in a separate conduit,

or insulating the amplifier unit or sensor head.

Warming Up

Wait at least 30 minutes after turning the power on before

starting use. The circuit will be unstable immediately after the

power is turned on so the display value may gradually fluctuate.

Power On Reset

Once the power is turned on, it will take approx. 2 seconds for the

measurement to start. The judgment output will be output after

the response time (average number of times X sampling rate) has

elapsed.

• This product uses a semiconductor laser for the light source.

• Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

• Follow the instructions mentioned in this manual. Otherwise,

WARNING

FDA (CDRH) Part1040.10

* The classification is implemented based on IEC60825-1 following the requirement

of Laser Notice No.50 of FDA (CDRH).

injury to the human body (eyes and skin) may result.

Precautions on Class 1 laser products

• Do not stare into the beam.

• Do not disassemble this product. Laser emission from this

product is not automatically stopped when it is disassembled.

Model IB-01/IB-05/IB-10/IB-30

Wavelength 660 nm

Output 170 μW

Pulse width 30 μs

IEC 60825-1 Class 1 Laser Product

*

Class 1 Laser Product

Other Precautions

Power Supply

• The product could malfunction by the noise superimposed on

WARNING

1

the power supply. Use a DC stabilized power supply with

insulated transformer for the power supply.

• When using a commercially-available switching regulator,

always ground the frame ground terminal.

Page 2

Precautions on Regulations and Standards

NOTICE

Amplifier x 1

Instruction manual x 1

Amplifier x 1

IB-1000 (main unit) IB-1050 (expansion unit)

Amplifier x 1

IB-1500 (main unit)

Panel mounting bracket x 1 Front protection cover x 1

Instruction manual x 1Power/Input-output cable (2 m) x 1

(Number of cable cores: 12)

Amplifier x 1

IB-1550 (expansion unit)

Panel mounting bracket x 1 Front protection cover x 1

Power/Input-output cable (2 m) x 1

(Number of cable cores: 8)

Expansion cable (50 mm) x 1

R

.oN L

A

IRES

R

ESAL

T

IB-01 (Detecting area I1 to 2.5 mm)

Transmitter x 1 Receiver x 1

Mounting bracket x 2

Flat nut x 2

M3 x L20 screw x 4

RE

S

AL

T

R

.oN LA

I

RES

IB-05 (Detecting area 5 mm)

Transmitter x 1 Receiver x 1

Mounting bracket x 2

Flat nut x 2

M3 x L25 screw x 4

RE

S

AL

T

R

.

oN

L

A

I

RES

IB-10 (Detecting area 10 mm)

Transmitter x 1 Receiver x 1

Mounting bracket x 2

Flat nut x 2

M3 x L25 screw x 4

IB-30 (Detecting area 30 mm)

Mounting

bracket x 2

M4 x L25 screw x 6

Transmitter x 1 Receiver x 1

CE Marking

Keyence corporation has confirmed that this product complies

with the essential requirements of the applicable EC Directives,

based on the following specifications. Be sure to consider the

following specifications when using this product in the Member

States of European Union.

EMC Directive

• Applicable standards EMI: EN60947-5-2, Class A

These specifications do not guarantee that the end-product with

this product incorporated complies with the essential

requirements of the EMC Directives. The manufacturer of the

end-product is solely responsible for ensuring the compliance of

the end-product.

Low-voltage Directive

• Applicable standard: EN60825-1

UL Certification

This product is an UL/cUL Listed product.

• UL File No. E301717

• Category: NRKH, NRKH7

Be sure to consider the following specifications when using this

product as an UL/cUL Listed Product.

• Use the power supply with Class 2 output defined in NFPA70

(NEC: National Electrical Code).

• The UL certificate for the IB series is for the sensor head and

amplifier used incombination. The IB series sensor head must

be used together with the IB series sensor amplifier unit

exclusively.

• Power supply/ Control input/ Control output shall be

connected to a single Class 2 source only.

• Use with the over current protection device which is rated 30 V

or more and not more than 1 A.

• Use this product under pollution degree 2.

EMS: EN60947-5-2

Sensor head

z Sensor head

Checking the Package Contents

Before using the unit, confirm that the parts and equipment listed below are

included in the package of the model you purchased.

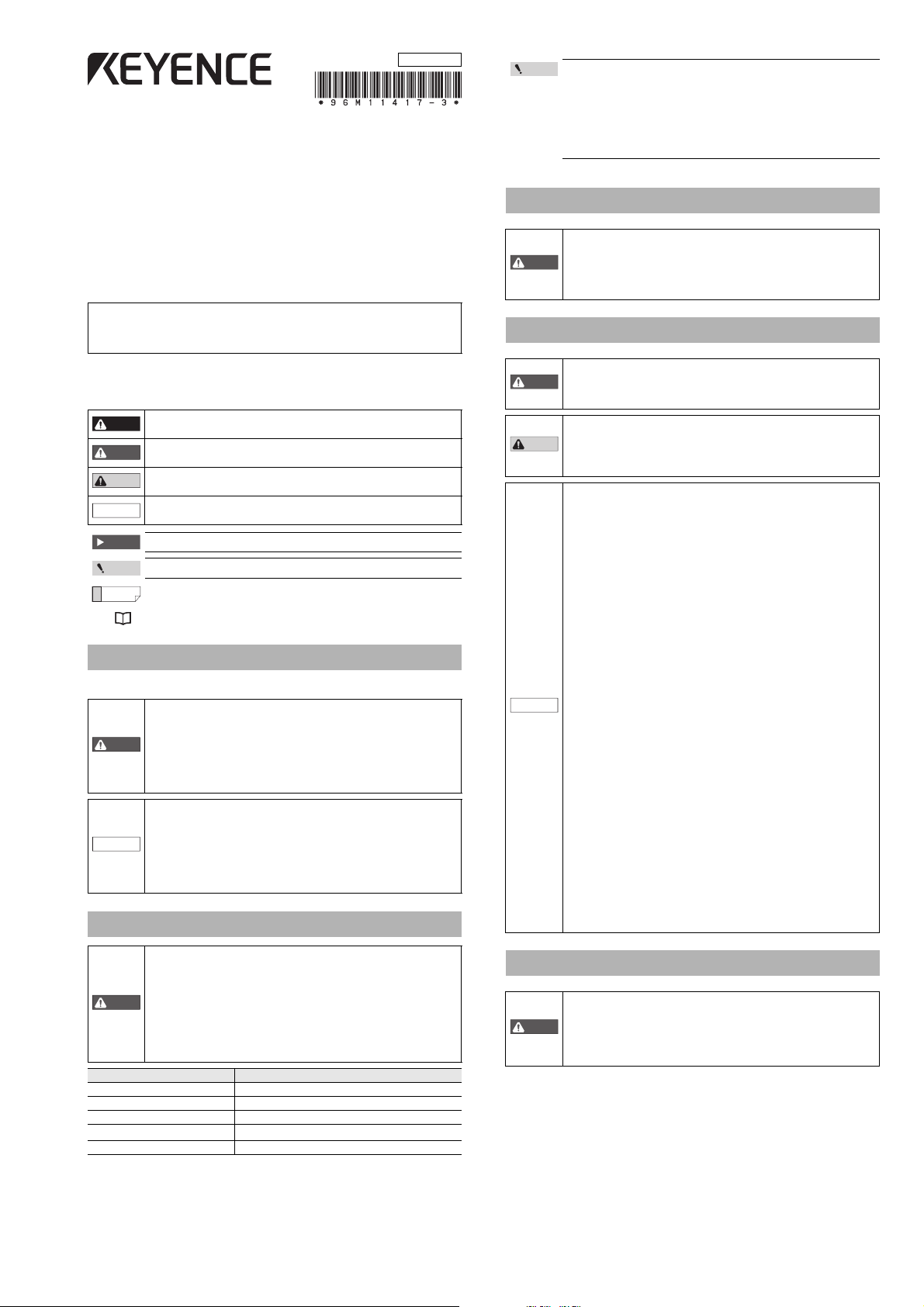

Sensor amplifier unit

z DIN rail mount type

z Panel mount type

LASER

We have thoroughly inspected the package contents before shipment. However, in

the event of defective or broken items, contact your nearest KEYENCE office.

2

Page 3

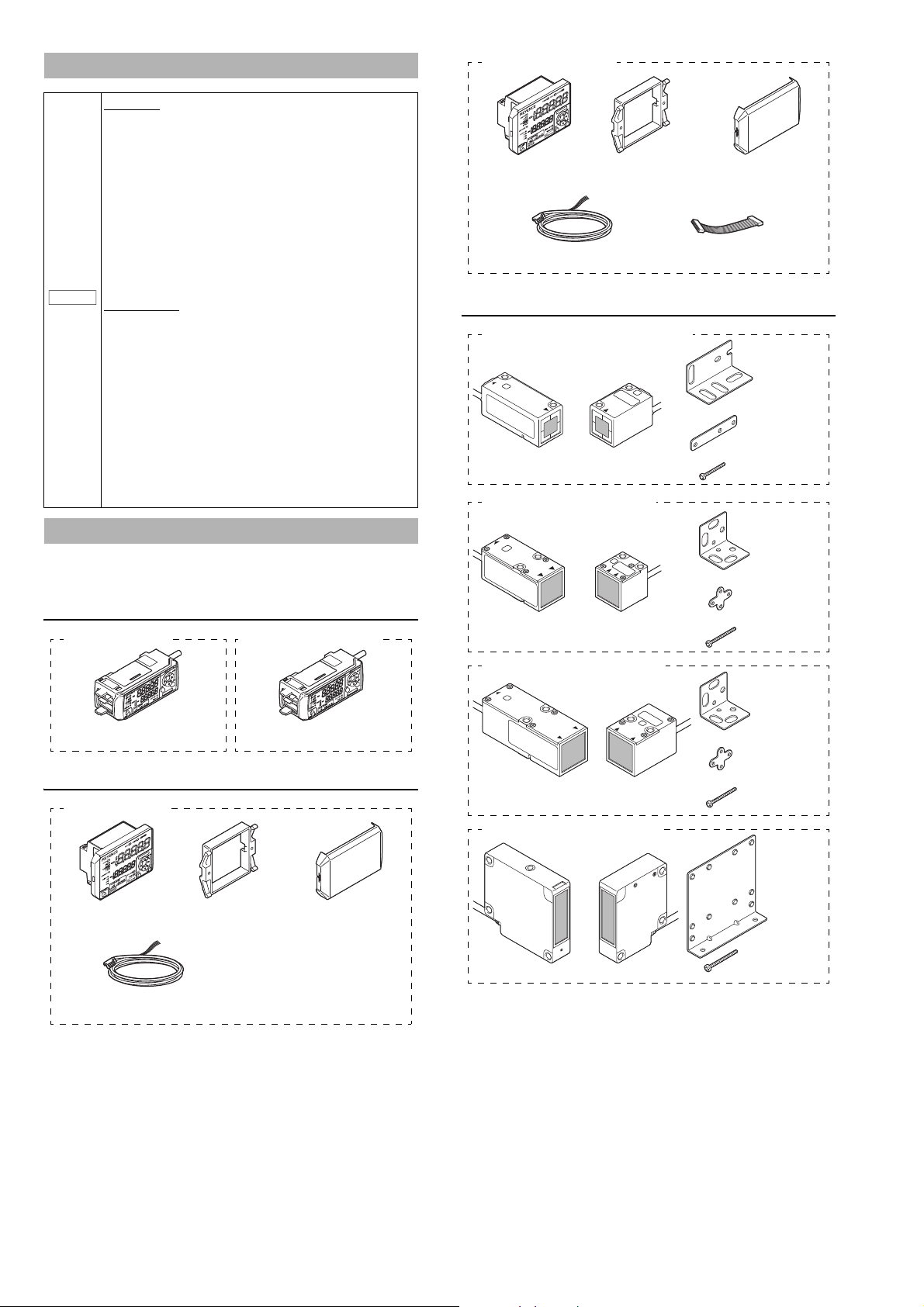

Part Names

IB

(1)

(2)

(3)

(4)

(5)

(6) (7) (8) (9) (10) (11)

(16) (15) (14)

(13

(12)

(1)

(2)

(3)

(4)

(5)

(6) (7) (8) (9) (10) (11) (12)

(16) (15) (14)

(13)

LASER

R

.

o

N LAI

R

ES

RE

S

AL

T

RESAL

T

R

.oN

L

A

IRES

R

.

o

N L

A

IRES

R

ESAL

T

Laser ReceiverLaser transmitter

(1) Laser emission warning indicator

Receiver

Transmitter

Receiver

head

connector

Transmitter

head connector

Point

CAUTION

Point

Connector cover

Main unit

Connecter

Expansion unit

Main unit

Sensor amplifier unit

z DIN rail mount type (IB-1000/IB-1050)

Sensor head

z Panel mount type (IB-1500/IB-1550)

Item Description

(1) Main display

(2) Laser emission warning

indicator

(3) Judgment indicator

(4) Auto adjust indicator Turns on while the auto adjust function is operating.

(5) Bank indicator Indicates the bank in use.

(6) Zero shift button

(7) Sub display identification

indicator

(8) Sub display

(9) Timing input indicator

(10) Zero shift indicator

(11) SET button

(12) MODE button

(13) Arrow buttons

(14) Check indicator Turns on when the check output is on.

(15) Percentage indicator Turns on when the measurement mode is % mode.

(16) Hold indicator

Displays the judgment value (P.V. value) and various

setting items.

Turns on while the laser beam is emitted. Flashes

when laser beam is stopped.

Indicates whether the judgment value (P.V. value) in

respect to the tolerance setting is HIGH (higher than

the upper limit), GO (within tolerance range) or LOW

(lower than the lower limit).

Press this to set the internal measurement value (R.V.

value) to the shift target value.

Turns on according to the type of value displayed on

the sub display.

Displays the internal measurement value (R.V. value),

analog output value and various settings (selections).

If the timing input (external input) is set to level, this

indicator lights while the timing input is on. If the

timing input is set to edge, this indicator turns on for

approx. 0.5 seconds when the timing input is on.

Turns on for approx. 0.5 seconds when zero shift is

executed.

When making various settings, press this button to

automatically set the setting value.

When making various settings, press this button to

start or end the setting or to move the item.

Use this to select the setting item or to change the

details displayed on the sub display.

Turns on when the judgment value (P.V. value) is

held.

Item Description

Always on when the power is supplied to the sensor head. Flashes

(1) Laser emission

warning

indicator

while using the beam axis alignment function. The flashing cycle

quickens as the amount of received light increases and can be uses

as a guide for adjusting the beam axis.

"Beam axis alignment function" (Page 6)

Use a transmitter and receiver with the same serial No.

combination. The operation and accuracy cannot be

guaranteed if units with different serial numbers are used in

combination. The serial No. is attached to the top of the

transmitter and receiver.

SERIAL No.

12345678

Re ceive rTransm itte r

No.

12345678

Mounting the Amplifier

DIN rail mount type, main unit (IB-1000)

Align the claw at the bottom of the main body

with the DIN rail. While pushing the main body in

the direction of the arrow (1), tilt the amplifier in

the direction of the arrow (2).

To remove the amplifier, raise the main body in

the direction of the arrow (3) while pushing it in

the direction of the arrow (1).

(3)

(2)

DIN rail mount type, expansion unit (IB-1050)

Expansion units must be connected to the main unit before they can be used.

Up to 3 expansion units can be connected to one main unit.

• When connecting multiple amplifiers (expansion units), first

check to make sure that the power is turned off to all of the

main and expansion units. Installing an expansion unit with

power on may damage this device.

• Push the amplifiers (expansion units) as far as possible into

the main unit. If they are connected at an angle or not inserted

securely, this device could get damaged.

• When connecting the expansion units, make sure to initialize

the expansion units and set the output polarity.

(1)When turning on the amplifier for the first time after con-

necting the sensor head please reference

"Operation When the Power Is Turned On for the First Time" (Page 6)

(2)When initializing the unit please reference

"Initial Reset (Initialize)" (Page 8)

• Expansion units with different settings for output polarity

(such as an NPN output expansion unit to a PNP output main

unit) cannot be connected together.

• Expansion units using DIN rail mount cannot be connected to

a panel mount style main unit.

1 Remove the expansion protective cover from a IB-1000 (main unit).

(1)

2 Install the amplifiers (expansion units) onto a DIN rail.

Do the same as instructed under "DIN rail mount type, main unit."

3 Push the expansion unit into the main unit connector until a

clicking sound can be heard.

4 Install the end units (OP-26751: 2 units per set) (sold separately)

on both sides of the amplifiers (main or expansion units). Secure

the end units in place with screws on top (2 on each end unit).

The end units are mounted in the same way as the amplifiers.

Mount the amplifiers securely using the end units (OP-26751:

Point

2 units per set) (sold separately) or a commercially available

DIN rail mounting tool to prevent the amplifiers from slipping

and coming off from the DIN rail due to machine vibration.

3

Page 4

Panel mount type, main unit (IB-1500)

· Panel thicknes 1 to 6 mm

· X = 48 × (Number of amplifiers) - 3

+ 0.6

- 0

45 mm

+ 0.6

- 0

45 mm

+ 0.6

- 0

45 mm

X mm

Minimum 85 mm

When stacking

the units vertically.

When stacking

the units horizontally.

Panel mounting bracket

Panel

Amplifier

Front protection cover

CAUTION

Point

Expansion

cable

Point

Unlocked

Lock cover

Click

DIN rail mount type

(IB-1000/IB-1050)

Panel mount type

(IB-1500/IB-1550)

Blue O-ring

Right side is R side

Bottom is R side

Locked

Lock cover

1 Make a hole on the panel as shown in the diagrams below.

2 Insert the back side of amplifier to the hole of the panel.

3 Arrange the panel mounting bracket in the direction below,

mount to the amplifier from the back and attach the front

protection cover to the amplifier.

To remove the panel mounting bracket, widen

the claws at both ends of the panel mounting

tool using a screwdriver, as demonstrated in the

image on the right.

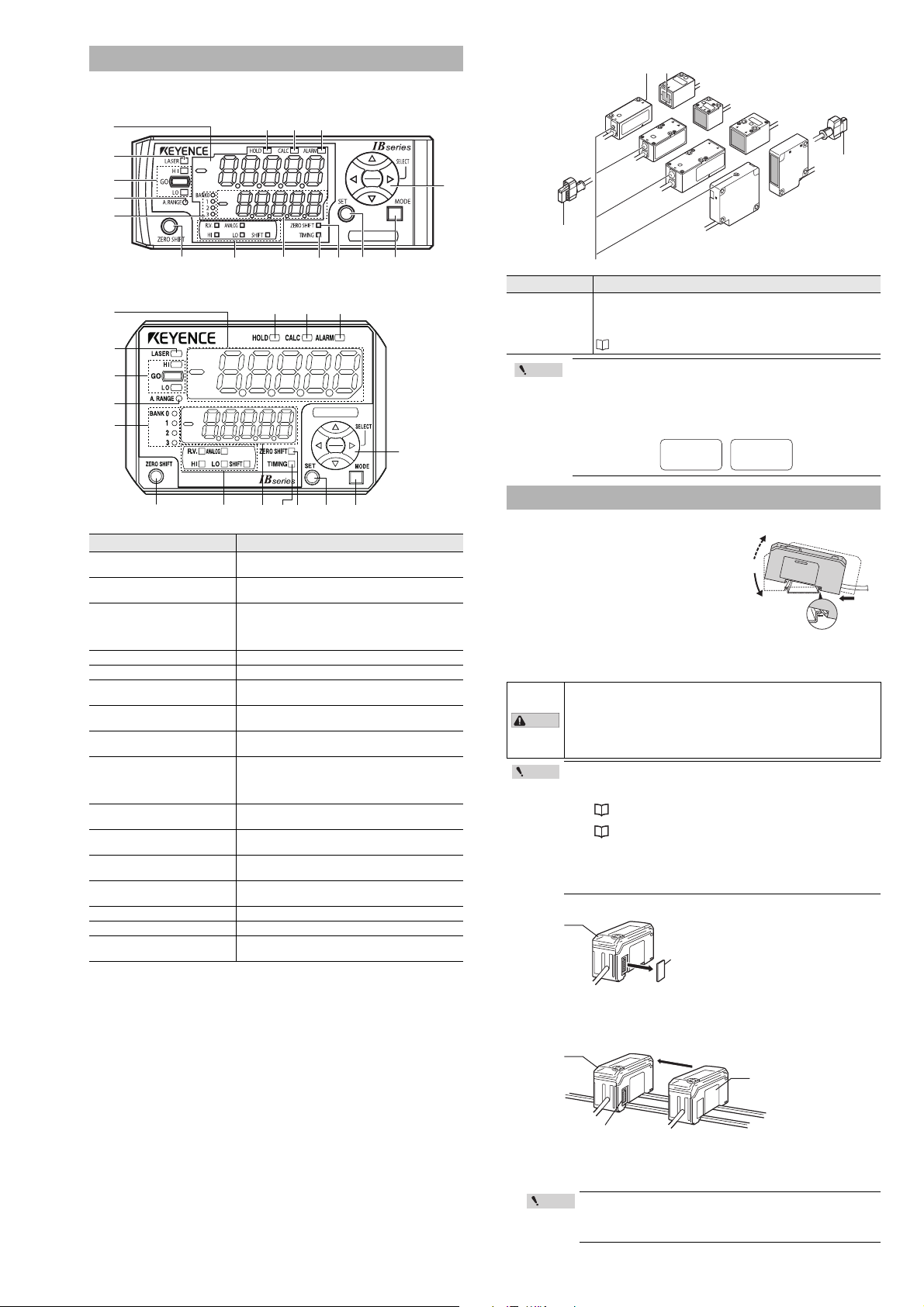

Mounting the Sensor Head

Mounting the sensor head

Mount the sensor head with

the enclosed screws (IB-01/

IB-05/IB-10: M3, IB-30: M4).

Tightening torque: 0.3 N

less

(Tightening torque for IB-01:

0.1N

·m or less)

Important

·m or

• Always use mounting holes facing the same direction for

the sensor head transmitter and receiver. (Excluding IB-01)

• Do not tighten the screws with a torque exceeding 0.3 N.m.

The sensor head could deform, thus preventing beam axis

alignment.

When mounting the sensor, confirm that the transmitter and

receiver faces on which the nameplate label is attached are

facing the same direction. (Only for IB-30)

Panel mount type, expansion unit (IB-1550)

Expansion units must be connected to the main unit before they can be used.

Up to 3 expansion units can be connected to one main unit.

• When connecting the expansion cable, make sure to turn off

the power beforehand. Inserting or removing the cable with

the power turned on may cause damage to the units.

• Push the expansion cable connector securely all the way. Take

care not to insert the connector at an angle and to insert it

securely or the units could get damaged.

• When connecting the expansion units, make sure to initialize

the connected expansion units and set the output polarity.

(1)

When turning on the amplifier for the first time after connecting the sensor head please reference

"Operation When the Power Is Turned On for the First Time" (Page 6)

(2)

When initializing the unit please reference

"Initial Reset (Initialize)" (Page 8)

• Expansion units with different settings for output polarity

(such as an NPN output expansion unit to a PNP output main

unit) cannot be connected together.

• Expansion units using panel mount cannot be connected to a

DIN rail mounted main unit.

1 Make the appropriate number of holes in the panel according to

the number of amplifiers required (expansion units).

For the panel cutting measurement, refer to the "Panel mount type, main unit".

2 Install the amplifiers (expansion units) on the panel.

For the amplifier mounting method, refer to the "Panel mount type, main unit".

3 Connect the amplifiers (main and expansion units) using the

expansion cable (50 mm) supplied with the expansion unit.

When arranging the amplifiers

Reference

side by side, the 300 mm

expansion cable (OP-35361)

is required.

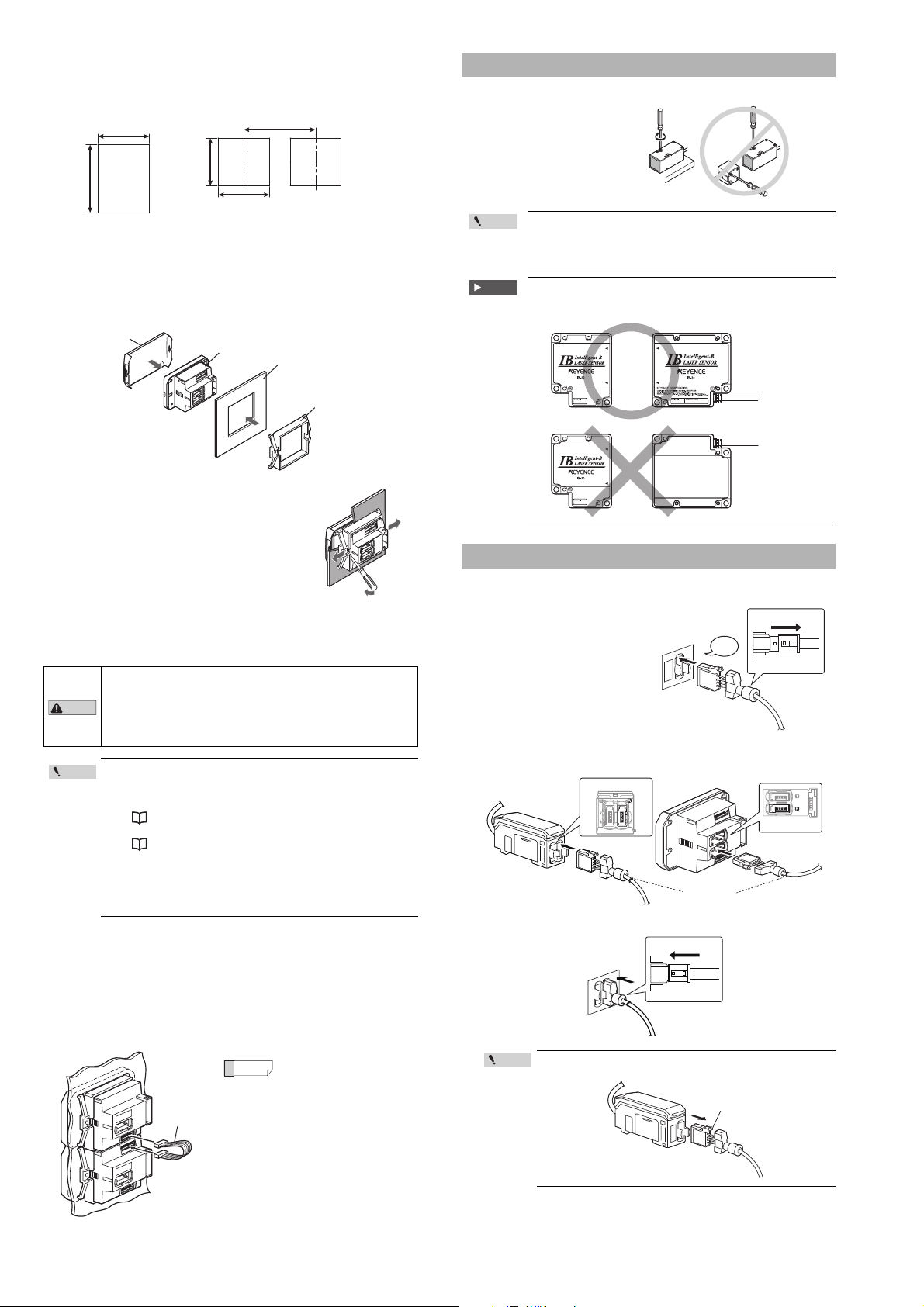

Connection and Wiring

Connecting the sensor head and amplifier

1 Attach the receiver's sensor

head connection cable to the

amplifier’s [R] connector.

Remove the lock cover of the

connector and insert it into the

connectors of amplifier until a

clicking sound can be head.

2 Attach the lock cover to the connector to secure the cable.

When removing the sensor head connection cable, push the

Point

lock lever and pull it back.

Lock lever

4

Page 5

3 Attach the transmitter’s sensor head connection cable to the

Top is T side

Red O-ring

Left is T side

Brown

Black

White

Blue

Power/Input-output cable

To attach To remove

Brown

Blue

Black

White

Gray

Light blue

Orange

Shield

Pink

Yellow

Pink/Purple

Purple

Green

10 to 30 VDC

0 V

HIGH judgment output

LOW judgment output

GO judgment output

Analog output +

Analog output GND

External input 1

(Zero shift input)

External input 2 (Reset input)

External input 3 (Timing input)

External input 4 (Not Used)

Check output

*1 *4

*1

*1

*2

*2

*3

*3

*3

*3

LASER

BANK

0

1

2

3

HI

GO

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

HOLD CALC

CHECK

Press [MODE] and [SET]

for 2 seconds

for 2 seconds

Press [MODE]

press [SET] for 5 times

While pressing [MODE]

press for 2 seconds

or

While pressing [MODE]

for 2 seconds

Press and

Press [MODE] and

for 2 seconds

[MODE] and , or [MODE] and

Press and

[HOLD] ON

amplifier’s [T] connector.

DIN rail mount type

(IB-1000/IB-1050)

Panel mount type

(IB-1500/IB-1550)

z Power/Input-output cable

The following information shows the details of power/Input-output cable. For

information about the input-output circuit, see page 10 of this Instruction Manual.

The connection procedures are the same as the receiver side.

Attaching the sensor head cable connector

(OP-87060: optional)

Cut the sensor head cable to the required length and attach the new connector to

use the sensor. The connection method is the same for the transmitter and receiver.

1 Cut the cable to the required length and strip approx. 15 mm of

insulation from the end.

Point

Do not strip the core wire insulation.

2 Insert each color coded cable into the same colored marked

points on the connector.

Each cable is secured temporarily when it is inserted completely.

3 Confirm that all the cables are inserted properly into the

connector and crimp them using pliers or a similar tool.

Once the connector has been installed, make sure to connect

Point

it to the amplifier and confirm that the sensor operates

normally.

If the sensor head does not function properly, crimp the

connector again using pliers or a similar tool.

Once the connector is crimped, it cannot be reused.

Amplifier wiring

z Connecting power/Input-output cable (IB-1500/IB-1550 panel

mount type)

Connect the power/Input-output cable to the panel mount type main unit and

Input-output cable to the expansion units.

• The number of core wires for the power/Input-output cable

Point

for the main unit is 12, and the number of core wires for

the Input-output cable for the expansion units is 8.

• Power for the expansion units is supplied from the main

unit.

• When not using the I/Os of expansion units, cut the cable

near the connector.

Insert further

than here.

*1 IB-1050/IB-1550 (expansion unit) do not have brown, blue, or light blue wires.

Power is supplied to the expansion units through the IB-1000/IB-1500 (main unit).

*2 The Analog output can be set for the following: Not used (OFF), 0 to 5 V, r5 V, 1

to 5 V and 4 to 20 mA.

"Operation When the Power Is Turned On for the First Time" (Page 6)

"Initial Reset (Initialize)" (Page 8).

*3 In addition to the selections noted on the image above, the external inputs can

also be selected to perform the following: Bank A input, Bank B input, Laser

emission stop input and Not used (OFF).

Amplifier Functions and Displays

Setting method

Main screen

"Reference Light Registration (Gain

Adjustment)" (Page 7)

"Setting procedures (Basic)" (Page 8)

"Initial Reset (Initialize)" (Page 8)

"Adjust function" of the IB Series User's

Manual

"Switching the bank with button

operations" of the IB Series User's

Manual

"4-3 Calibration Function" of the IB

Series User's Manual

"3-9 Key Lock Function" of the IB Series

User's Manual

"Beam axis alignment function"

(Page 6)

Main screen

z P.V. (judgment value) and R.V. (internal measurement value)

R.V. value (internal measurement value) is the measurement value displayed on the

sensor amplifier.

* R.V. = Raw Value

P.V. (judgment value) is the value used for setting the judgment output to ON or OFF

based on the tolerance setting value. Also, the analog output is based on the P.V.

value.

* P.V. = Present Value

"Setting the Tolerance Setting Value" (Page 7)

The P.V. (judgment value) and R.V. (internal measurement value) are basically the

same, however, those values differ when the hold function is used.

z Main display (Upper level)

P.V. (judgment value) is displayed on the main display. Normally, the display differs

as shown below when using the hold function.

5

Normal

The same value as the R.V. (internal measurement value) is

displayed.

When the hold function is being used

The P.V. value (judgment value) is held following the hold function

settings.

For details, refer to the IB Series User's Manual.

Page 6

z Sub display (Lower level)

S/T

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

HOLD CALC

CHECK

GO

GO

HOLD CALC

CHECK

X

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

GO

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

HOLD CALC

CHECK

GO

HOLD CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

GO

HOLD CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI

SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

R.V.

[R.V.]

ON

Analog output

[ANALOG]

ON

HIGH setting value

[HI]

ON

LOW setting value

[LO]

ON

Shift target value

[SHIFT]

ON

QHH

#P.)

Analog output

Reference

1

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

#.K)P

GO

HOLD CALC

CHECK

Received light

Transmitter

ReceiverReceiver

1

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

#.K)P

GO

HOLD CALC

CHECK

Beam axis is misaligned.

Transmitter

1

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

#.K)P

GO

HOLD CALC

CHECK

Beam axis is aligned.

Off

Blink (slow)

Blink (fast)

The sub display switches with each push of the W or X button. According to the

type of displayed value selected, the sub display identification indicator will show

one of the following: [R.V. / ANALOG / HI / LO / SHIFT]

R.V. (internal measurement value)

The R.V. (internal measurement value) is displayed. This

displayed value is not held.

Adjusting the Beam Axis

Adjust the laser beam’s axis.

1 Fix the receiver so that the transmitter and receiver are on the

same line.

2 With no object set in the detection area, move the transmitter

and fix it where the display value is the largest.

Transmitter

Analog output (The analog output will only be displayed for

the main unit and only when it is enabled.)

The voltage value (unit: V) or current value (unit: mA) of the

analog output is displayed.

"Operation When the Power Is Turned On for the First Time" (Page 6)

"Initial Reset (Initialize)" (Page 8)

HIGH setting value

The upper limit of the acceptable range (tolerance setting

value) for the object that is being measured is displayed.

Also, the setting value can be changed. If the P.V. (judgment

value) exceeds the value set here, the HIGH output signal

will be sent.

"Setting the Tolerance Setting Value" (Page 7)

LOW setting value

The lower limit of the acceptable range (tolerance setting

value) for the object that is being measured is displayed.

Also, the setting value can be changed. If the P.V. (judgment

value) falls below the value set here, the LOW output signal

will be sent.

"Setting the Tolerance Setting Value" (Page 7)

Shift target value

When the zero shift button is pressed or the zero shift input is

set to ON, the R.V. (internal measurement value) will be

matched to the value set here.

"Zero Shift Function (Shifting the Internal Measurement

Value)" (Page 7)

Operation When the Power Is Turned On for the First Time

When the amplifier is turned on for the first time after the sensor head is connected,

the initial setting display appears. Make the initial setting according to the following

procedure as this is necessary for both the main unit and the expansion units when

units are added.

1 Select the judgment output and check output

polarity with the S/T button, and press the

[MODE] button.

Setting value Description

PRP NPN output

RPR PNP output

2 Press the

output method and press the [MODE] button.

Setting value Description

QHH Not output

W

W

W

C/RT

After the setting is complete, [GPF] blinks several times on the sub display and

changes to the main screen.

3 Carry out “Adjusting the beam axis” (page 6) and

Make other settings as necessary.

button to select the analog

Analog output after the judgment value is

converted to the range from 0 to 5 V.

"Reference Light Registration (Gain Adjustment)" (Page 7).

Analog output after the judgment value is

converted to ±5 V.

Analog output after the judgment value is

converted to the range from 1 to 5 V.

Analog output after the judgment value is

converted to the range from 4 to 20 mA.

Once the initial setting is completed, the initial setting display

Point

will not appear when the power is turned on the second time or

the after. To change the initial setting, perform the initial reset.

"Initial Reset (Initialize)" (Page 8)

QWV

PRP

Output polarity

Receiver

The beam axis does not need to be adjusted if the base of the

sensor head and the left side of the receiver looking from the

transmitter are installed on the same reference surface.

Beam axis alignment function

The IB series has a beam axis alignment function which makes it easy to adjust the

beam axis.

The beam axis can be adjusted easily with the help of the amplifier unit's display

and sensor head laser emission warning indicator.

1 Press the W/X buttons on the main screen simultaneously for 2

seconds, and display the received light on the sub display (lower

level).

2 With no object in the detection area, move the transmitter and

mount the transmitter and receiver so that the displayed

received light is the largest.

When the beam axis is aligned, the value on

the sub display (lower level) will increase. Fix

the units where the value is the largest when

possible.

At this time, the laser emission warning

indicator on the sensor head will turn off or

blink. The indicator's flashing cycle quickens

as the received light increases.

Adjust the beam axis together with the

incoming light level on the sub display (lower

level).

T

AL

S

Laser emission warning indicator

Laser emission

warning indicator

Off

Blink (slow)*

Blink (fast)*

* The blinking cycle changes in stages. The faster the indicator blinks, the more

accurate the beam axis alignment is.

Description Status drawing

State when laser beam is

not transmitted into receiver.

Axis beam is misaligned.

Axis beam is approximately

aligned.

R

.oN L

AI

RE

S

R

.

oN

L

E

R

AIRES

.

oN

LA

I

R

RE

T

L

A

S

E

R

T

AL

S

RE

S

LASER

3 The main screen will reappear when a random button on the

amplifier unit is pressed.

Reference

All judgment outputs turn off while using the beam axis

alignment function. The analog voltage output is fixed to 5.5 V

and the analog current output is fixed to 3.0 mA.

6

Page 7

W/X

S/T

S/T

W/X

S/T

Reference Light Registration

Point

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

HOLD CALC

CHECK

GO

R.V. value

[

R.V.

]

ON

Tolerance tuning setting width

Measurement upper limit

HIGH side setting value (upper limit)

Master workpiece P.V.

(judgment value)

LOW side setting value (lower limit)

Measurement lower limit

Point

[LO]

ON

LOW setting value

Measurement value of

HIGH limit defective target

Measurement value of

LOW limit defective target

Measurement value of acceptable target

Measurement upper limit

Measurement lower limit

LOW setting value(lower limit )

HIGH setting value(upper limit)

Point

HIGH setting value

[HI]

ON

[LO]

ON

LOW setting value

(Gain Adjustment)

The amount of received light when the sensor head is mounted for the first time is

registered as the reference light amount.

Perform “reference light registration (gain adjustment)” when using the sensor for

the first time or each time the sensor head mounting position has been changed,

etc.

1 Adjust the beam axis.

2 Press the [MODE] and [SET] buttons on the main screen

simultaneously for 2 seconds.

[#.K)P] will display on the main display (upper level), and the reference light

amount will be registered. The main screen will reappear when the registration

is completed.

• Reference light registration (gain adjustment) cannot be

carried out with external inputs. It must be carried out

with the buttons on the main unit.

• If reference light registration (gain adjustment) is

attempted when the received light is low, an error will

appear and the registration will be canceled.

"Displayed Contents and Corrective Actions" (Page 9)

Setting the Tolerance Setting Value

There are two types of tolerance setting values: HIGH (upper limit) and LOW (lower

limit). The value displayed will output its signal as one of the following 3 levels:

When the value exceeds the upper limit (HIGH); when the value is within the

tolerance range (GO); and when the value falls below the lower limit (LOW).

"4. Output mode [QWV]" (Page 8)

Automatic setting (Tolerance tuning)

When a reference workpiece (master workpiece) is available, HIGH tolerance value

(upper limit) and LOW tolerance value (lower limit) can be automatically set

symmetrically with respect to the measured value of the master workpiece.

1 Press the W/X button several times on the

main screen. Display the R.V. (internal

measurement value) on the sub display (lower

level). ([R.V.] will turn on.)

2 Measure the master workpiece, and then press the [SET] button.

The P.V. (judgment value) is imported as the tolerance setting reference value.

[5GV] and the tolerance setting value will alternately display on the sub display

(lower level).

3 Set the tolerance width with the S/T button,

and then press the [SET] button.

Measurement mode Setting range Default value

% mode 0.00 to 999.99 10.00

Dimension mode 0.000 to 99.999 1.000

Master workpiece P.V. value

HOLD CALC

0

1

2

3

ANALOG

R.V.

HI SHIFT

LO

ZERO SHIFT

CHECK

TIMING

LASER

HI

GO

LO

BANK

ALIGNMENT

Setting width of tolerance value

4 Press the X button once, and display the LOW

setting value on the sub display (lower level).

5 Measure the acceptable target again, and press

the [SET] button.

The R.V. (internal measurement value) will be imported.

[.Q5GV] will appear on the main display (upper level).

6 Measure a LOW limit defective target, and press the [SET] button.

The R.V. (internal measurement value) will be imported.

After [5GV] blinks on the main display (upper level), the P.V. (judgment value) will

appear.

The middle value between the measurement value of the acceptable target

measured in Step 5 and the measurement value of the LOW limit defective

target will appear on the sub display (lower level).

This completes setting the LOW setting value (upper limit), and completes

2-point tuning.

Two-point tuning cannot be performed if the internal

measurement value (R.V.) is [], [((((] or [((((]. If

performed, [PQW#.] will blink several times on the main

display.

Manual setting

Set the HIGH setting value (upper limit) and LOW setting value (lower limit) to an

arbitrary value.

1 Press the

main screen. Then display the HIGH setting

value on the sub display (lower level).

2 Press

value.

3

Press the X button once and display the LOW

setting value on the sub display (lower level).

4 Press the

value.

The tolerance settings are complete.

button several times on the

button to set the HIGH setting

Measurement mode Setting range Default value

% mode – 999.99 to 999.99 20.00

Dimension mode – 99.999 to 99.999 2.000

button to set the LOW setting

Measurement mode Setting range Default value

% mode – 999.99 to 999.99 10.00

Dimension mode – 99.999 to 99.999 1.000

When setting the tolerance value with the 2-point tuning or manually,

Point

make sure to set "HIGH tolerance value > LOW tolerance value".

4 Press the [SET] button to complete the tolerance tuning.

[5GV] blinks on the main display (upper level), and the HIGH setting value and

LOW setting value are determined. Then, the display returns to the R.V. screen

automatically.

Automatic setting (2-point tuning)

If there are an acceptable target and a HIGH or LOW limit defective target, the

middle value between the acceptable and the HIGH or LOW limits can be set as the

tolerance value.

1 Press the W/X button several times on the

main screen. Display the HIGH setting value on

the sub display (lower level). ([R.V.] will turn

on.)

2 Measure an acceptable target, and press the [SET] button.

The R.V. (internal measurement value) will be imported.

[*K5'V] will appear on the main display (upper level).

3 Measure a HIGH limit defective target, and press the [SET]

button.

The R.V. (internal measurement value) will be imported.

After [5'V] blinks on the main display (upper level), the P.V. (judgment value) will

appear.

The middle value between the measurement value of the acceptable target

measured in Step 2 and the measurement value of the HIGH limit defective

target will appear on the sub display (lower level).

This completes setting the HIGH setting value (upper limit).

Tolerance tuning cannot be performed when the displayed

P.V. (judgment value) is [], [((((] or [((((]. [PQW#.]

will blink several times on the main display if attempted.

HIGH setting value

[HI]

ON

Zero Shift Function (Shifting the Internal Measurement Value)

When the [ZERO SHIFT] button is pressed or the external zero shift input* has been

activated, the R.V. (internal measurement value) now becomes the newly shifted

target value.

* Zero shift via external input is provided by assigning zero shift input to the

external input 1 (pink wire).

Setting the shift target value

1 Use the

2 Press the

Performing the zero shift

Press the [ZERO SHIFT] button or assign zero shift input to an external input.

The zero shift indicator [ZERO SHIFT] will light up for approx. 0.5 seconds and the

current R.V. (internal measurement value) will now become the shifted target value.

Cancelling the zero shift

Press the zero shift button [ZERO SHIFT] for 2 seconds or more.

The sub display shows [T'5'V], indicating that the zero shift has been cancelled

and set back to the factory setting.

7

button on the main screen to display the shift target

value on the sub display (lower level).

button to change the shift target value.

Measurement mode Setting range Default value

% mode – 999.99 to 999.99 0.00

Dimension mode – 99.999 to 99.999 0.000

The shift target value has now been set.

When using the external zero shift function, any newly shifted

Point

states will be lost when the unit is powered down unless the

status save function is utilized.

For details, refer to the IB Series User's Manual.

Page 8

S/T

[GU

S/T

S/T

(0E

.F

#X'

QWV

Initial Reset (Initialize)

;GU

T'5'V

Performing the initial re set

QHH

#P.)

Analog output

Reference

.K)JV

.F

PQ

QWV

.K)J6 F#T-

2EV .'P 2E V .'P

Normally open [PQ]

Judgment

Judgment output

HIGH GO LOW

HIGH ON OFF OFF

GO OFF ON OFF

LOW OFF OFF ON

Error ON OFF ON

[] OFF OFF OFF

Normally closed [PE]

Judgment

Judgment output

HIGH GO LOW

HIGH OFF ON ON

GO ON OFF ON

LOW ON ON OFF

Error OFF ON OFF

[] ONONON

The initial reset initializes all settings except for the calibration setting.

The initial reset can also be used to change the judgment output and analog output

settings.

1 While holding down the [MODE] button on the main screen,

press the [SET] button 5 times.

[TGUGV] will be displayed on the main display.

2 Press

3 Press

4 Press the

z Calling the setting display

Hold the [MODE] button for approx. 2 seconds on the main screen.

The setting display appears.

Basic operations on the setting display

To change the setting, press the S/T button

To move the next item, press the [MODE] button or X button

To return to the previous item, press the W button

To skip the rest of the settings and finish, press and hold the [MODE] button for

approx. 2 seconds

Setting procedures (Basic)

[MODE] button.

If [PQ] is selected, the settings of output polarity and

analog output can be changed without initial reset.

button to select the output polarity

and press the [MODE] button.

Setting value Description

PRP NPN output

RPR PNP output

button to select the analog

button to select [

] and press the

QWV

Output polarity

output and press [MODE] button.

Setting value Description

QHH Not using the analog output

W Analog output range is from 0 to 5 V.

W Analog output range is ±5 V.

W Analog output range is from 1 to 5 V.

C/RT Analog output range is from 4 to 20 mA.

After the initialization is complete, [GPF] blinks several times on the sub display

and the main screen is restored.

If any button other than the S/T button and [MODE] button are

pressed halfway through the initial reset procedure, the initial

reset is stopped and returned to the screen displayed in step 2.

Setting Method

Press the [MODE] button for 2 seconds.

(PE

2EV

Press the [MODE] or X button.

Press the [MODE] or X button.

#W'

Main screen

"1. Measurement

mode"

"2. Received/

Blocked light

mode"

"3. Averaging/

High-pass filter"

Use S/T to select.

The % mode and dimension mode are set.

Use S/T to select.

The received light mode and blocked light

mode are set.

Use S/T to select.

Set the number of averages. When HPF is

selected, set the high-pass filter.

PRP

Basic setting

1. Measurement mode [

Select whether to display the received light (or blocked light) of the laser beam

emitted to the receiver as a dimension (mm) or a percentage (%) in respect to the

measurement range.

Setting value Description Default value

2EV

.'P Display as a dimension (mm).

Display as a percentage (%) in respect to the

measurement range.

2. Received/Blocked light mode [

Select whether to display according to the light transmitted into the receiver or

according to the amount of light blocked.

Setting value Description Default value

.K)J6

&#T-

Reference

Totally unblocked

Partially blocked

Totally blocked

Display according to the amount of laser beam

transmitted into the receiver.

Display according to the blocked light (amount of

shadow).

Each sensor head’s measurement status and R.V. (internal

measurement value) when set to the "1. Measurement mode" and "2.

Received/Blocked light mode" are as follow.

Received/Blocked

Measurement mode

IB-01 100.00 1.000 0.00 0.000

IB-05 100.00 5.000 0.00 0.000

IB-10 100.00 10.000 0.00 0.000

IB-30 100.00 30.00 0.00 0.00

IB-01 50.00 0.500 50.00 0.500

IB-05 50.00 2.500 50.00 2.500

IB-10 50.00 5.000 50.00 5.000

IB-30 50.00 15.00 50.00 15.00

IB-01 0.00 0.000 100.00 1.000

IB-05 0.00 0.000 100.00 5.000

IB-10 0.00 0.000 100.00 10.000

IB-30 0.00 0.00 100.00 30.00

3. Averaging/High-pass filter [

z Averaging

The average value is moved and averaged. If the measured values fluctuate, stable

measurements can be obtained by increasing the average number of times. When

[*2(] is set, the high-pass filter will be enabled.

Item Setting range Default value

Averaging //////////*2(

z High-pass filter

This function ignores fluctuations which are less than an arbitrary frequency (cut-off

frequency), and displays the results. This is effective to ignore gradual changes

and only capture the sudden changes. When [*2(] is selected on the averaging

setting screen, the cut-off frequency setting screen will open.

Item Setting range Default value

Cut-off frequency /////// //

Reference

The following process takes place when the high-pass filter is set.

Measured

value

Input waveform

light mode

]

]

.

]

Measured

value

Waveform onto

which high-pass

filter was applied

c

c

Press the [MODE] or X button.

Press the [MODE] or X button.

'PF

Press the T or S button.

2TQ

Press the [MODE] or X button.

Advanced setting

"4. Output mode"

"Basic setting

complete"

"Advanced settings"

Use S/T to select.

Set N.O. (Normally Open) or “N.C.

(Normally Closed).

Press the [MODE] button or X button to

return to the main screen.

IB Series User's Manual

Press the W button to return to the main screen.

When Advanced Settings is selected, the

following items can be set. Refer to the IB Series

User’s Manual for details.

“5. Hold function”, “6. Timing input”, “7. Delay

timer”, “8. Hysteresis”, “9. Analog output

scaling”, “10. External input”, “11. Bank

switching method”, “12. Save zero-shift state”,

“13. Save adjust state”, “14. Adjust level”, “15.

Auto adjust function", “16. Check output

function”, “17. Error output mode”, “18. Display

digit”, “19. Power save function”, “20. Judgment

indicator color”, “21. P.V. value display color”

Time

4. Output mode [

Setting the judgment output method

Setting value Description Default value

PQ Output is normally open. c

PE Output is normally closed.

Reference

]

8

Time

Page 9

Displayed Contents and Corrective Actions

Reference

VT

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD CALC

CHECK

TV

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD CALC

CHECK

Alternate display

T

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD CALC

CHECK

.#5'4

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD CALC

CHECK

V

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD CALC

CHECK

T#P)G

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD CALC

CHECK

VK06

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T*

GO

HOLD CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T%

GO

HOLD CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'T'

GO

HOLD CALC

CHECK

Reference

-

LASER

BANK

0

1

2

3

HI

GO

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'4)

HOLD CALC

CHECK

KP(

LASER

BANK

0

1

2

3

HI

GO

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'4)

HOLD CALC

CHECK

-

LASER

BANK

0

1

2

3

HI

GO

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'4#&,

HOLD CALC

CHECK

QW'T

LASER

BANK

0

1

2

3

HI

GO

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'4#&,

HOLD CALC

CHECK

LASER

BANK

0

1

2

3

HI

GO

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

'4EQ/

HOLD CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

HOLD CALC

CHECK

GO

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

HOLD CALC

CHECK

GO

((((

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

((((

HOLD CALC

CHECK

GO

((((

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

((((

HOLD CALC

CHECK

GO

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

.QE

GO

HOLD CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

PQW#.

GO

HOLD CALC

CHECK

'TT

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

5JK(6

GO

HOLD CALC

CHECK

'TT

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

5'6

GO

HOLD CALC

CHECK

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

E/.QE

GO

HOLD CALC

CHECK

When an error is displayed, the judgment output changes to the error state.

"4. Output mode [QWV]" (Page 8)

• The check output functions regardless of the error judgment.

• When [GT% ] is displayed, all the judgment outputs and check

outputs will turn OFF.

• When an error other than ['T%] or ['T'] is displayed, the analog

voltage output is 5.5 V and the analog output current is 3.0 mA.

Error indication Error contents Remedy

Head error

Transmitter/receiver

reverse connection

error

Receiver error

Transmitter laser

error

Transmitter error

Model mismatch

error

The transmitter or receiver is not

connected to the amplifier unit.

The sensor head cable is not

connected correctly.

The transmitter or receiver is defective.

The sensor head cable for the

transmitter or receiver is broken.

The transmitter and receiver are

connected to the amplifier unit in

revers e.

The receiver is not connected to the

sensor amplifier.

The sensor head cable connector is

not connected correctly.

The receiver is broken.

The sensor head cable for the receiver

is broken.

The laser in the transmitter is broken.

The transmitter is not connected to the

sensor amplifier.

The sensor head cable connector is

not connected correctly.

The transmitter is broken.

The sensor head cable for the

transmitter is broken.

The transmitter and receiver model

(measurement range) do not match.

Correctly connect the

transmitter and receiver.

Connect the connector

again.

Replace the transmitter

or receiver.

Replace the sensor head

cable.

Correctly connect the

transmitter and receiver.

Correctly connect the

receiver.

Connect the connector

again.

Replace the transmitter

or receiver.

Replace the sensor head

cable.

Replace the transmitter

or receiver.

Correctly connect the

transmitter.

Connect the connector

again.

Replace the transmitter

or receiver.

Replace the sensor head

cable.

Use a transmitter and

receiver from the same

model (measurement

range).

Error indication Error contents Remedy

• Perform reference light

registration (gain

adjustment).

• Adjust the beam axis.

• Clean the laser

transmitter and

receiver sections on

the sensor head.

• Increase the adjust

level.

• Perform reference light

registration (gain

adjustment).

• Increase the adjust

level.

• Make sure that the

interfering light does

not enter the laser

receiver.

• Connect the transmitter

and receiver in

combination to the

same amplifier unit.

Turn the power OFF and

check the connections

between the amplifiers.

Adjust error 1*

(Light insufficient

error)

Adjust error 2*

(Excess light error)

HOLD CALC

LASER

HI

GO

'4#&,

LO

BANK

0

1

ALIGNMENT

2

KP(

3

ZERO SHIFT

R.V.

ANALOG

LO

HI SHIFT

Adjust error 3*

(Interfering light

error)

TIMING

The adjust function cannot be set

because the amount of received light

is too low.

The adjust function cannot be used

because the amount of received light

is too high.

CHECK

The adjust function cannot be set

because of interfering light or because

the receiver is receiving the laser

beam of a transmitter connected to an

expansion amplifier unit.

Communication between amplifiers is

disabled.

* Press the [MODE] button to remove the error and return to the main screen.

Non-error Related Displays and Countermeasures

When the judgment value (P.V. value) is “

set to normally open), the analog voltage output changes to 5.5 V, and the analog

current output changes to 3.0 mA.

"4. Output mode [QWV]" (Page 8)

Indication Contents Remedy

[-----] displayed for

internal

measurement value

(R.V. value)

[-----] displayed for

judgment value (P.V.

value)

The laser emission stop input is on.

The judgment value (P.V. value) is

being held by the hold function.

”, all judgment outputs turn OFF (when

Turn the laser emission

stop input off.

Check the wiring for the

laser emission stop input.

Check the hold function

setting.

Input a timing input

which matches the

setting.

Transmitter internal

error

Overcurrent error

EEPROM error

Reference light

registration error 1*

(Light insufficient

error)

Reference light

registration error 2*

(Interfering light

error)

The transmitter is broken.

An overcurrent exceeding the

specifications passed to the judgment

output or check output.

Read/write of the non-volatile memory

(EEPROM) save data failed.

The number of writes to the

non-volatile memory (EEPROM)

exceeded 1,000,000 times.

If the adjust function or the zero shift function is

used frequently, do not save settings in the

non-volatile memory (EEPROM).

Refer to the IB Series User's Manual for details.

The reference light registration (gain

adjustment) cannot be completed

because the amount of received light

is too low.

The reference light registration (gain

adjustment) cannot be completed

because of interfering light or because

the receiver is receiving the laser

beam of a transmitter connected to an

expansion amplifier unit.

Replace the transmitter

or receiver.

• Correct the wiring.

• Check the load and

reduce the current to

within the specified

range.

• Check that the output

wire is not touching

another wire or frame.

Turn the power on again.

Perform initial reset.

To save the setting

values when the power is

turned off, replace the

amplifier unit.

• Correctly mount the

transmitter and

receiver.

• Adjust the beam axis.

• Clean the sensor

head’s laser

transmitting and

receiving sections.

• Make sure that the

interfering light does

not enter the laser

receiver.

• Connect the transmitter

and receiver in

combination to the

same amplifier unit.

[((((] is displayed

for the internal

measurement value

(R.V. value)

[((((] is displayed

for the internal

measurement value

(R.V. value)

The internal measurement value (R.V.

value) exceeds the lower limit of the

display range.

The internal measurement value (R.V.

value) exceeds the upper limit of the

display range.

The key lock is enabled and button

operations are prohibited.

Tuning was attempted when [],

[((((] or [((((] was displayed.

The zero shift function was used when

the R.V. is [], [((((] or [((((].

The SET1 or SET2 value is incorrect

and the correction using the

calibration function could not be

performed.

The button operation is disabled.

• Check the shift target

value setting, and shift

the display again.

"Zero Shift

Function (Shifting the

Internal Measurement

Value)" (Page 7)

• Recheck the settings.

• Perform reference light

registration (gain

adjustment) again.

Unlock the key lock state.

Perform tuning when the

target can be measured.

Shift the display when the

internal measurement

value (R.V.) is displayed

(with the object

measured).

Perform the calibration

within the possible

correction range.

The connected

communication unit

<DL-RS1A> read/write

setting switch is set to RW.

Set the read/write setting

switch to R.

9

Page 10

Default Settings (List of Default Values)

Main circuit

Brown

0 V

Blue

*

Load

Overcurrent protection circuit

10 to 30 VDC

*

Black (HIGH judgment output)/

White (LOW judgment output)/

Gray (GO judgment output)/

Green (check output)

10 to 30 VDC

Blue

*

Load

0 V

* Black (HIGH judgment output)/

White (LOW judgment output)/

Gray (GO judgment output)/

Green (check output)

Main circuit

Overcurrent protection circuit

Brown

(Switching number)

Shield

Orange

Analog output GND

Main circuit

Analog current output circuit

Analog voltage output circuit

Analog voltage/

current output

0 to 5 V, 1 to 5 V,

-

5 to 5 V, 4 to 20 mA

NOTICE

10 to 30 VDC

*

Blue

+5V

0V

Brown

Main circuit

* Pink (External input 1)/Yellow (External input 2)/

Pink·Purple (External input 3)/

Purple (External input 4)

(Short-circuit current 2 mA or less)

/

44.7

15.3

4

9.5

1.5

35

20.2

2.3

7.6

73.6

48

19.1

19.1

10.3 10.3

17.6

27.2

22.4

44.7

Cable diameter φ4.7

Cable length 2 m

Cable diameter φ4.8

The default settings (default values) are explained below.

When initial reset (initialization) is preformed, the following values are returned to

the default values, except for the calibration function.

"Initial Reset (Initialize)" (Page 8)

Values set on the main screen

The same values are set in banks 0 to 3.

Setting item

HIGH setting value

LOW setting value

Shift target value

Basic and advanced setting

Setting item

1. Measurement mode 2EV Percentage mode

2. Received/Blocked light

mode

3. Averaging/High-pass filter Average number of times 64 times

4. Output mode PQ Normally open

5. Hold function 5* Sample hold

6. Timing input .'X'. Level

7. Delay timer Q(( Delay timer disabled

8. Hysteresis 0.00

9. Analog output scaling F'(.V Scaling disabled

10. External input F'(.V

11. Bank switching method DVP Button switching

12. Save zero-shift state /Q((

13. Save adjust state /Q((

14. Adjust level 2 Adjust level 20P

15. Auto adjust function Q(( Auto adjust function disabled

16. Check output function Q(( Check output function disabled

17. Error output mode F'(.V Normal mode

18. Display digit F'(.V Default setting

19. Power save function Q(( OFF

20. Judgment indicator color F'(.V HI: Red, GO: green, LO: red

21. P.V. value display color F'(.V

Setting item

Calibration function F'(.V No correction

Default

value

Default

value

Description

.K)J6 Received light mode

External input function not changed from

default settings

Not saved in non-volatile memory

(EEPROM)

Not saved in non-volatile memory

(EEPROM)

HI, LO, error: red

GO: Green

Default

value

Description

z Analog output circuit

Do not short-circuit the shield (analog output GND) and blue (0V).

z Input circuit

When NPN output is selected

When PNP output is selected

Main circuit

(Short-circuit current 2 mA or less)

Dimensions

Brown

10 to 30 VDC

*

Blue

* Pink (External input 1)/Yellow (External input 2)

Pink·Purple (External input 3)/

Purple (External input 4)

0 V

Circuit Diagram

z Output circuit

When NPN output is selected

When PNP output is selected

Sensor amplifier

z IB-1000/IB-1050 (Din Rail Mount Type)

Cable diameter φ4.7/Cable length 2 m

28.3

18.5

42.4

8.9

37.4

17.4

Cable diameter φ4.8

3

20 21.55

35.4

76.25

Max. 135°

18.5

When the cover is open: Max. 109.2

17.6

z IB-1500/IB-1550 (Panel Mount Type)

10

Page 11

Sensor head

16.5

10.0

2.5

36.0

30.0

1.0

19.0

8.0

Less than R1.0

t=1.2

3.5

3.5

19.0

11.5

2.5

36.0

31.0

3-M3

4-R3.5

20.0

7.0

2.5

5.0

10.0 10.0

4-R2.0

3.5

5.0

CBA

* Enclosed screws

M3x20 ... 4 screws

ABC slot

dimensions

φ

4

Cable length 2m

2.5

7

25

13.8

50

3.7

2-φ3.2

(Mounting hole)

φ

4 Cable length 2m

φ

6

20

7

13

20

13.8

28

2.5

2-φ3.2

(Mounting hole)

Installation

reference surface

Installation

reference surface

Installation

reference surface

Installation

reference surface

5.5

φ4

φ4

φ3

φ3

15

13

23

11.5

11.5

5.5

23

13

15

24

t=1.2

4-M3、P=0.5

18.2

12.2

13.8

19.8

t=2

5.4

3

5

4

* Enclosed screws

M3x25 ... 4 screws

(Note) Slot A

dimensions

(Note) Slot B

dimensions

2-Slot A (Note)

2-Slot B (Note)

68

60

44

12

4

64

28

20

3-φ4.5

(Mounting

hole)

3-φ4.5

(Mounting hole)

52

44

44

12

4

64

28

20

Installation

reference surface

Installation

reference

surface

Installation

reference surface

Installation

reference surface

φ

4 Cable length 2m

φ

4 Cable length 2m

2-R3

70 65 49

21

16

10

10

50

2-φ4.5

2-R3

5

70

65

21

9

10-M4

t=1.6

* Enclosed screws

M4x25 ... 6 screws

z IB-01

Transmitter Receiver

(Mounting hole)

20

φ

4 Cable length 2m

25.2

2.5

2-φ3.2

Installation

reference surface

2.6

2.6

15.6

15

2.6

2.6

15.6

Installation

reference surface

15

* The position of each sensor head slit matches the center of the glass on the

front of the receiver.

Mounting bracket (accessory) for IB-01

31

36.2

2-φ3.2

(Mounting hole)

φ

4 Cable length 2m

2.5

z IB-30

Transmitter Receiver

Mounting bracket (accessory) for IB-30

z IB-05

Transmitter Receiver

(Mounting hole)

2-φ3.2

16

37

7

3,7

ø6

φ

4

2.5

Cable length 2m

Installation

reference surface

Installation

reference surface

18

12.2

16.1

19

2-φ3.2

7

2.5

(Mounting hole)

φ

4

Cable length 2m

Installation

reference surface

Installation

reference surface

18

12.2

z IB-10

Transmitter Receiver

Mounting bracket (accessory) for IB-05, IB-10

Specifications

Amplifier unit

Model IB-1000 IB-1500 IB-1050 IB-1550

Amplifier type

Main unit/Expansion unit Main unit Expansion unit

Head compatibility Yes

Display resolution 0.01 %, 0.1 %, 1 % (switchable)

Display range

Display

Digital display

method

Operating indicators

Analog voltage output

Analog current output

*1

*1

Bank switching input

Zero shift input

*2

Laser emission stop

input

Timing input

Control

input

Reset input

Adjust input

*3

Judgment output

Check output

Control

output

Power voltage

Power

supply

Environmental

*4

resistance

Powe r

consumption

(including analog

current output)

Operating ambient

temperature

Operating ambient

humidity

*5

Vibration resistance

Pollution degree 2

Materials

Mass (including accessories)

*1 r5 V, 1 to 5 V, 0 to 5 V, or 4 - 20 mA should be selected.

*2 The four exter nal input wires are assigned with desired inputs.

Rated no-voltage input: ON voltage 2 V or less, OFF current 0.05 mA or less

Rated voltage input: Max. input rating 30 V or less, ON voltage 7.5 V or

11

DIN rail

7-segment

display

Upper level:

5 red digits

Lower level: 5

green digits

Output impedance 100 :

4 to 20 mA Maximum load

Panel mount

mount

–99.999 to 99.999, –99.99 to 99.99

–99.9 to 99.9, –99 to 99 (switchable)

Dual

Judgment indicator: 2-color (green/red) LED (HI, GO, LO)

Laser emission warning indicator: Green LED

r5 V, 1 to 5 V, 0 to 5 V

Dual

7-segment

display

Upper level:

2-color

(green/red)

5 digits

Lower level:

5 green digits

Bank indicator: Green LED x 4

Others: Green LED x 8, red LED x 3

resistance 350 :

DIN rail

mount

7-segment

display

Upper level:

5 red digits

Lower level:

5 green digits

Non-voltage input

(NPN/PNP switchable, N.O./N.C. switchable)

10 to 30 VDC, including

ripple (P-P) 10%

Class 2 or LPS

2400 mW or less

(at 30 V, 80 mA

max.)

Open collector

2550 mW or less

(at 30 V, 85 mA

max.)

Supplied from main unit

2400 mW or less

(at 30 V, 80 mA

-10 to +50 °C (No freezing)

35 to 85 % RH (No condensation)

10 to 55 Hz, compound amplitude 1.5 mm,

2 hours each for X, Y, Z axes

Main unit case/Front panel: polycarbonate,

keytop: polyacetal, cable: PVC

Approx.

150 g

Approx.

170 g

Approx.

140 g

more, OFF current 0.05 mA or less

Dual

max.)

Panel mount

Dual

7-segment

display

Upper level:

2-color

(green/red)

5 digits

Lower level:

5 green digits

No

2550 mW or less

(at 30 V, 85 mA

max.)

Approx.

165 g

Page 12

*3 Rated NPN open collector output: Max. 100 mA/ch (20 mA/ch when expansion

units are connected), 30 V or less, residual voltage 1 V or less

Rated PNP open collector output: Max. 50 mA/ch (20 mA/ch when expansion

units are connected), power voltage or less, residual voltage 2 V or less

*4 Use with the over current protection device which is rated 30 V or more and not

more than 1 A.

*5 Does not include the power consumption of the load. The power consumption

with expansion units installed is the total of each amplifier unit’s power

consumption.

Example: When using one main unit (IB-1000) with two expansion units

(IB-1050)

(2400 mW X 1) + (2400 mW X 2) = 7200 mW

Sensor head

Model IB-01 IB-05 IB-10 IB-30

Light source Visible semiconductor laser Wavelength: 660 nm

Laser

Class

Installation

distance

Measurement

range

Sampling rate 12,500 times/sec. (80 s)

Minimum

detection target

Repeatability

Temperature

characteristics

Operating

indicators

Environmental resistance

Material

Weigh t Approx. 140 g Approx. 180 g Approx. 220 g Approx. 510 g

*1 Classified based on IEC60825-1 following the requirements of FDA (CDRH)

Laser Notice No. 50.

*2 Value when measuring the target (white diffuse object) at the middle of the

transmitter and receiver position, and at the center of the measurement range.

*3 When distance between transmitter and receiver is set to 300 mm, and light is

half-blocked at a position 150 mm from receiver.

Deflection width (±2) when sampled for 30 seconds with an average number

of times set to 64 times.

*4 When distance between transmitter and receiver is set to 100 mm and full light

is received.

*2

*3

*4