Page 1

NEW LINEUP

I

-

SERIES

Intelligent Sensor

Make Sensing Easy:

FROM SIMPLE DIFFERENTIATION TO HIGH SPEED,

HIGHLY ACCURATE DETECTION

IB S eries

IG S eries

NEW

NEW

Multi-Purpose CCD Laser Micrometer

IG Series

Thrubeam Type Laser Detection Sensor

IB Series

Low-cost

High

Performance

Page 2

2

Detection of presence/absence

Low cost

Thrubeam Type Laser Detection Sensor IB Series

Light volume differentiated with high-accuracy

Light-receiving element PD

Through high-accuracy differentiation of the volume of light received, the photoelectric sensor allows a

multitude of previously impossible applications to be achieved.

A PD (Photo Diode) is used within the light-receiving element. Even very small changes in received light intensity are sensed, making this sensor

incredibly versatile.

High-Accuracy Differentiation Made Easy

without being Influenced by the Target

Detecting cap tightness Differentiation of different films Determining chip gradient Liquid turbidity

❚ Main applications

CHOOSE KEYENCE FOR ALL THRUBEAM TYPES

Photoelectric

sensor

IB S eries

Page 3

3

High-accuracy measurements

High end

Multi-Purpose CCD Laser Micrometer IG Series

High-accuracy differentiation using edge position

Light-receiving element CCD

Achieving high-accuracy differentiation without being influenced by the total light volume

A CCD (Charge Coupled Device) is used in the light-receiving element. High-accuracy differentiation is achieved by capturing the edge of the

thrubeam laser light rather than the volume of received light.

Transparent glass

edge detection

Outer diameter

high-accuracy differentiation

Sheet edge control Roller gap measurement

❚ Main applications

Thrubeam

measuring

instruments

SERIES

Intelligent

To ug h

Easy

I

I

-

SERIES

Intelligent Sensor

IG Series

Page 4

4

❚ Supports everything from simple differentiation to high-accuracy detection

Industrial application examples

IB

Within the various manufacturing processes of liquid crystal, the presence

or absence of a glass plate is detected during transportation. As the light

volume can be differentiated with high-accuracy, stable detection is

possible.

This device definitively detects the chip gradient and/or the presence of a

chip on even minute targets during the mounting process. Fur thermore, as

the sampling occurs at 80 µs, detections on high-speed lines are also

possible.

By sensing two locations simultaneously, the device detects the orientation

of the paper feed and/or the skew angle during transportation. Continuous

measurement is possible with the small type head and high-speed

sampling.

Detects differences in various shafts within metal workings or during the

assembly process. By using the included Hold function, this can be

determined without stopping the target.

By sensing the thrubeam volume of laser light, the device definitively

captures any differences in the transparent film. Fur thermore, by aligning

multiple devices along the width, continuous detection of uneven coating

over multiple points is possible.

By sensing the thrubeam volume of laser light through glass, the turbidity of

factory waste water can be determined. Furthermore, judgment values can

be set between 0 and 100%.

Detects the diameter and cap tightness when adding the caps onto the

bottles. Due to high-speed sampling, detection can be conducted on the

conveyer without stopping the target.

By sensing thrubeam volumes of the laser light, the liquid level can be

detected with high accuracy. Furthermore, by using a compact head the

device can be positioned in even the narrowest of spaces.

IB Series Applications

Liquid Crystal Industry

Detection of presence/absence

of liquid crystal glass

IB

Electronic Industry

Detection of chip components

IB

Metal Industry

Differentiation of different metal

shafts

IB

Electric Industry

Printer paper feed orientation

detection

IB

Plastics Industry

Differentiation of different

films

IB

Food and

Pharmaceutical

Industry

Bottle-neck diameter

judgments and detection

of cap tightness

IB

Food and

Pharmaceutical

Industry

Detecting the liquid level

of test tubes

IB

Factories

Turbidity detection of

factory waste water

IB

Page 5

5

Detect s the notch position of a wafer with high ac curacy. The device

exhibits a repeat accuracy of 5 μm and the differen tial ability that is top of

its cl ass.

Conduc ts high-accuracy trans port position determination of liquid crystal

glass. Inc orporating a new algorithm, stable detection of even transparent

materials is pos sible.

Conduc ts edge control duri ng the winding proces s of electrode sheets,

achieving uniform rolling.

Differentiates the coating line diamete r immediat ely after extrusion. By

calcul ating the roundness d ifferentiati on between X-Y, this can be

conduc ted simulta neously without exter nal softwar e.

Differentiates the positioning of the t arget during pressin g. The device is

IP-67 rated, with the ability to withs tand use i n unfavorable env ironments

over a l ong period of time.

Measur es the internal diameter or ga ps of pressed parts. By using the

various Hold func tions you can also mea sure the m aximum inte rnal

diamet er.

Conduc ts the edge control o f film dur ing windin g processes, and achieves a

uniform roll. The level o f shielded light can be changed at will, allowing for

the hi gh-accuracy determin ation of thin film.

Monito rs the gap of thin pl ate cold rolling. Mounting in narr ow spaces i s

also p ossible thanks to a co mpact head.

X

Y

IG Series Applications

Semi-conductor Industry

Wafer notch detection

IG

Electrical Industry

Edge control of a lithiumion electrode sheet

IG

Metal Industry

Target placement

confirmation

IG

Plastics Industry

Edge control of a

transparent sheet

IG

Electric Cable

Industry

Exter nal diameter

differentiation during

coating extrusion processes

IG

Metal Industry

Inter nal diameter

differentiation of punch

press materials

IG

Iron and Steel

Industry

Roll gap measurement

IG

Liquid Crystal

Industry

Position determination of

liquid crystal glass

IG

Page 6

IG Series

6

Wide Variety of Application Modes

Achieving the Best Stability

Multi-Purpose CCD Laser Micrometer

Reflecting mirror

Parallel light lens

Multi-wavelength

laser

28mm type

IG- 028

10mm type

IG- 010

28 mm

10 mm

Edge Control

Mode

The distance from the end of the measurement range to

the edge of a target is measured.

Outer Diameter

Measurement Mode

The outer diameter or width of a target is measured.

IG Series

Repeatability of 5 μm

Linearity of ± 0.1% (IG-028)

New function: Position Monitor

Page 7

7

Large Distance between the Transmitter and Receiver

L- C CD

I-DSP

Position

monitor

POSITION MONITOR

Measurements are performed

with up to 28,000 optical axes

(IG-028), each of which monitors

the amount of light received.

L-CCD

POSITION

MONITOR

Panel mount type

IG-1500 /1550

DIN-rail mount type

IG-1000/1050

Edge Detection of

Transparent Targets

Measures a transparent edge like glass

Inner Diameter/Gap

Measurement Mode

The inner diameter of a target or a gap between targets is

measured.

IG-028 Max. 1500 mm

IG-010 Max. 1000 mm

Page 8

Linearity of ±0.1%

SPOT IMAGE

Singl e-wavelength las er

(conventional laser sensor)

A patchy pat tern appears.

Due to the mu lti-wavelengt h

laser us ed, the beam pattern

has a more u niform intensi ty

distribution.

Repeatability of 5 µm

Best in its class

Best in its class

STABLE DETECTION OF TRANSPARENT

& MESH TARGETS

The L-CCD makes it possible to detect a target based on its

position. Edge control and positioning of transparent and

mesh targets can be performed stably.

Transparent target Mesh target

Multi-wavelength laser (IG)

SERIES

Intelligent

Tough

Easy

I

Low-cost

High

Performance

THREE CONCEPTS

The intelligent I-Series consists of a high-accuracy sensor lineup that realises low-cost high

performance with only the most advanced functions for on-site operations.

SERIES

Intelligent

Tough

Easy

I

Intelligent

High accuracy was achieved by using the technology and

functions developed for high-accuracy measuring

instruments.

Tough

Developed for use in harsh environments, the I Series was

designed with a strong structure.

Easy

Excellent usability makes it possible to quickly and easily

perform stable measurements without any difficult

adjustments and settings.

I

-

SERIES

Intelligent Sensor

IG Series

8

High stability and measurement accuracy are achieved

with the newly developed optical system

Multi-Wavelength Laser + I-DSP

With conventional lasers, the transmission spot produces a patchy pattern

(as shown in the figure to the right). This is a laser-specific interference

problem caused by the laser having a single wavelength. The IG Series

sensor overcomes this problem by using a multi-wavelength laser. Because

shadows are formed on the CCD more clearly, the sensor remains highly

stable, even with targets that are conventionally

difficult to detect (e.g. transparent objects). With

the I-DSP (a parallel computing chip)

incorporated in the receiver, the sensor can

perform data processing at high speed,

reducing noise to a minimum.

Page 9

9

Extremely easy to use due to the built-in position monitor

Optic al axis alignm ent in

progress

Red: In dicates

the rece ived light

position

Green:

Indic ates the

measurement

position

Optic al axis alignm ent

complete

Easy to maintain thanks to excellent environment resistance

Example

- Prevent dust or oil f rom adhering to the meas urement unit,

which c an cause an abnormal m easurem ent value.

- Dete ct the intru sion of a different typ e of target .

- Check that a measurement t arget fall s within the measurem ent range.

Although dirt reduces the total amo unt of light

received, the me asurement position is th e same.

The shadow of a ta rget is shown.

No break in the cable after

20 million bends (typical)

Load ( W): 250 g

Bendi ng radius: R 50 mm

Rate: 30 bends/minute

(One bend is a cycl e whereby the

cable is bent fro m left to right and

then from right to lef t.)

90°

R

L

SERIES

Intelligent

Tough

Easy

I

L-C CDL-C CD

Received light level

Received light level

Binarization

level

Binarization

level

28 28

00

SERIES

Intelligent

Tough

Easy

I

IP67 Protection

The enclosure satisfies the IP67 rating based on the IEC

standards and remains watertight even after being held at

a depth of one metre for 30 minutes. The enclosure is

resistant to adverse environments and offers long-term

durability.

Flexible Free-Cut Cable

The sensor head cable is a robot cable that withstands

repeated bending. The cable can be used safely in a

position requiring repeated motion.

Edge Check Function

The user can check whether a measurement is performed

correctly by verifying the number of edges in the field of

view.

Key Point: Less Sensitive to Dirt

Because it uses an L-CCD, the IG Series is less sensitive

to materials such as dirt than a sensor that uses a

photodiode (PD) as the light-receiving element.

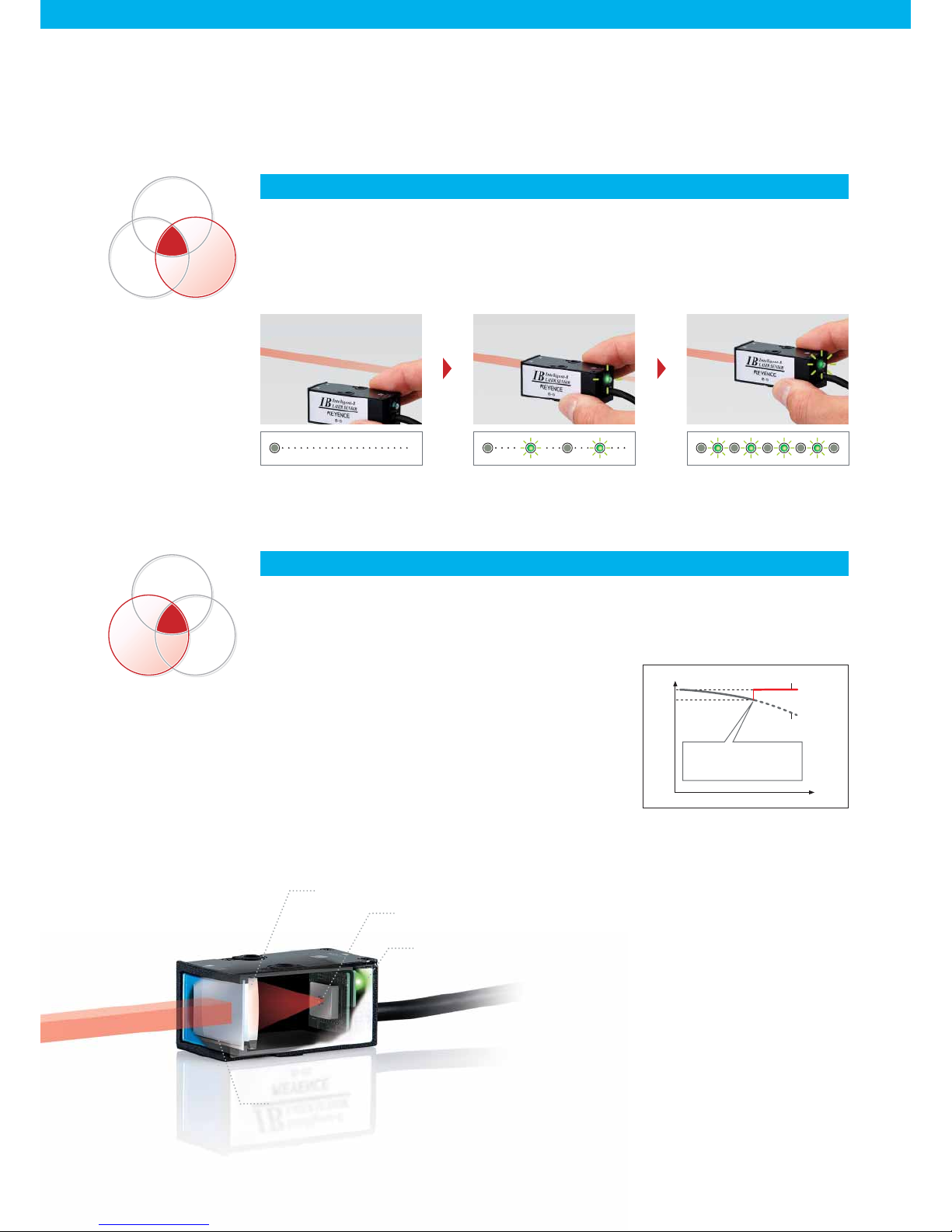

Determining the Part of a Target

to be Measured

The position monitor on the IG Series sensors makes it

possible to visually check how a target is detected. The

user can prevent mounting or setting errors by observing

the red lights that indicate the received light position and

the green lights that indicate the measurement position.

Easier Optical Axis Alignment

The position monitor makes it easier to align the optical

axis. Easily perform optical axis alignment by adjusting

the sensor head so that all of the position monitor lights

turn red.

Free Cut!

If the se nsor

gets d irty...

Page 10

1. The DL-RS1A communication unit is required. 2. The screws for connecting the sensor head and bracket are included. 3. The cable is common to the transmitter and receiver, and can be used with either of them.

4. Two cables are included with a sensor head.

IG Series

Cable length Model Weight Piece

2 m

4.

OP-87056

Approx. 80g

1 cable

included

5 m

OP-87057

Approx. 190g

10 m

OP-87058

Approx. 360g

20 m

OP-87059

Approx. 680g

10

EVEN MORE USEFUL WHEN CONNECTED TO A PC

RS-232C

communication unit

DL-RS1A

Calculation Function

Addition mode

(if a measurement target is large)

SETTING EXAMPLE 1

(length)

SETTING EXAMPLE 2

(width)

Subtraction mode

(to measure the dif ference in level or inclination)

SETTING EXAMPLE 1

(inclination)

SETTING EXAMPLE 2

(difference in thickness)

The confi guration software, IG Confi gurator, allows for a wide range of settings to be made including

the monitoring of the waveforms of received light and the measurement modes.

Sensor head cables

3.

Approx. 50 g Approx. 40 g

PC software

1.

IG-H1

Sensor head mounting

brackets for IG-010

2.

IG-TB01

Sensor head mounting

brackets for IG-028

2.

IG-TB02

Select when a longer cable is required.

Connected connector

with indicator

This connector is required if

the cable is cut.

Connector used to connect to

a display unit (2 pcs.)

OP-84338

Monitoring Function

Measurement conditions such as the waveforms of received

light can be displayed in real time. The mounting and

sensitivity settings can also be adjusted more precisely.

Zero Shift Function

This function shifts an internal measurement value to 0 (to offset

the value). When the target value is changed, this function can be

used to shift an internal measurement value to the new target

value.

Sensitivity Setting

The set value used to judge whether light enters or is blocked,

based on the amount of light received by the CCD, is called the

binarization level. The amount of light received when the reference

waveform is registered is regarded as the 100% level. The light is

judged to be blocked if the

amount of light is less than the

specified binarization level. The

IG Series initially sets a

binarization level of 25% and the

user can change the level

according to the application.

Option

Reading and Writing Settings

The user can enter all settings including the measurement

modes into a PC and then transfer them to the sensor. The

management of setting data is simple and very convenient

when two or more sensors are used.

Received light level

Can be

changed freely

CCD position

100 %

25%

0%

Page 11

11

Specifi cations

Sensor heads

Model IG-010 IG-028

Appearance

Operation principle CCD method

Light source

Visibl e light semic onducto r laser (Wa velengt h:660 n m)

FDA (C DRH) Par t 1040.10

Class 1

1.

IEC60825-1 Class 1

Mounting distance 0 to 1000 m m 0 to 1500 m m

Measu rement ra nge 10 mm 28 mm

Sampling rate 980 µs ( When th e number of ti mes for aver aging is set t o [hsp]: 4 90 µs)

Minimum detectable

object

2.

High sensitivity mode

ø0.1 mm (S etting dis tance : 100 mm)

Standard mode

ø0.2 m m (Setti ng distanc e: 40 mm or less),

ø0.5 mm ( Setting d istance : 500 mm)

ø0.2 m m (Setti ng distanc e: 50mm or less),

ø0.5 mm ( Setting d istance : 500 mm)

Repeatabilit y

3.

5 µm (Se tting dist ance: 10 0 mm)

10 µm (Se tting dist ance: 5 00 mm)

80 µm (Settin g distanc e: 1000 mm )

5 µm (Se tting dist ance: 10 0 mm)

10 µm (Se tting dist ance: 5 00 mm)

80 µm (S etting di stance : 1000 mm)

140 µm (S etting d istance : 1500 mm )

Linearity

4.

±0. 28 % of F.S. (±28 µm ) ±0.1 % of F.S. (± 28 µm)

Temper ature char acteris tics

5.

±0.0 3 % of F.S./° C (±3 µm/ °C) ±0.0 1 % of F.S./° C (±3 µm/ °C)

Operation

indicator

Tran smit ter Optic al axis alig nment indi cator: Gre en LED / Pow er indicat or: Green L ED

Receiver Optic al axis alig nment indi cator: Gre en LED / Posi tion monito r: Dual bar L ED (Red, Gr een)

Environment

resistance

Enclosure rating IP67

Ambient temperature -10 to +45 °C (No free zing)

Ambient humidity 35 to 85 % RH (No cond ensatio n)

Ambient light

6.

Inca ndescen t lamp: 50 00 lux Sunl ight: 50 00 lux

Vibration 10 to 55 Hz D ouble ampli tude 1.5 mm X YZ each ax is: 2 hours

Material

Case Zinc die -cast ( Lower ca se), PBT ( Upper ca se), Poly arylat e (PAR) (Dis play part ), SUS3 04 (Meta llic part)

Lens cover Glass

Cable PVC

Supplied item Transmi tter × 1, Rec eiver × 1, Sens or head ca bles (2 m) × 2

Weigh t (includin g supplied it ems) Appro x. 380 g Approx. 5 00 g

1. The classifi cation for FDA (CDRH) is implemented based on IEC60825-1 in accordance with the requirements of Laser Notice No.50.

2. When the measurement target object is measured at the centre position of the setting distance.

When the measurement mode is set to the glass edge mode, a glass edge of C0.1 mm or more can be detected (Setting distance: 500 mm).

3. When the light is shielded by half at the centre position of the setting distance. Vibration width when the average number of times is set to 16 and sampling is performed for 30 seconds.

(When the analogue output is used, the margin of error of analogue output is added.)

4. When the setting distance is 100 mm and light is shielded at 50 mm position from the receiver. Margin of error to the ideal line.

5. When the setting distance is 100 mm and light is shielded by half at 50 mm position from the receiver.

6. Excluding when the average number of times is set to [hsp].

Display unit (amplifier)

Model IG-1000 IG-1050 IG-1500 IG-1550

Appearance

Amplifier type DIN rail mount Panel mount

Main unit/Ex pansion unit Main unit Expansion unit Main unit Expansion unit

Analogue output Yes No Yes No

Power s upply volt age 10-3 0 VDC, Ripple ( P-P): 10% in cluded, Cl ass 2 or LPS

Power c onsumpt ion

4.

(incl uding analog ue curren t

output)

Normal 2700 mW o r less (at 3 0 V: 90 mA or le ss) 2880 m W or less (a t 30 V: 96 mA or le ss)

Power s aving fun ction (HA LF) 230 0 mW (at 30 V: 77 m A or less)

Power s aving fun ction (AL L) 220 0 mW (at 30 V: 74 mA o r less)

Digital display method Dual 7-seg display / Upper level: Red, 5 digits / Lower level: Green, 5 digits

Dual 7-seg display / Upper level: Red/ Green, 2 colours, 5 digits / Lower level: Green, 5 digits

Displ ay range -99.9 99 to +99 .999, -99 .99 to +99. 99, -99.9 to + 99.9, -9 9 to +99 (se lectabl e)

Display resolution 1 µm, 10 µm, 10 0 µm , 1000 µm (sele ctable )

Output

Judge ment outpu t (select able

bet ween NPN and P NP)

NPN (P NP) open coll ector x3 ch, 30 VDC (P ower suppl y voltage ) or less, re sidual vol tage 1 V (2 V) o r less, N.O. /N.C. sel ectable Ma x. 50 mA /ch

1.

Response time

(judgement output)

1.96 to 40 31.72 ms

2.

Edge ch eck outpu t (select able

bet ween NPN and P NP)

NPN (P NP) open coll ector x1ch , 30 VDC (Pow er supply vo ltage) or l ess, resi dual volta ge 1 V (2 V) or le ss, N.O./ N.C. selec table Max. 50 mA,

1.

respo nse time 20 m s

Analogue output

(sele ctable amo ng ±5V,

1-5 V, 0-5 V, 4- 20 mA)

Input

Gain input Input t ime: 20 ms or m ore, Resp onse dela y time: 120 ms o r less (Non volatile me mory (E EPROM) 1.5 s or l ess)

Rese t input Input t ime: 20 ms or m ore, Resp onse dela y time: 20 ms o r less

Timing input Inpu t time: 2 ms or m ore, Resp onse dela y time: 2 ms or l ess

Zero s hift input Input t ime: 20 ms or m ore, Resp onse dela y time: 20 ms o r less

Bank A in put/B ank B input Input time : 20 ms or more , Respons e delay time : 20 ms or les s

2.

Lase r emission s top input Input t ime: 2 ms or mo re, Respo nse delay ti me: 2 ms or le ss

Environment resistance

Ambient temperature -10 to + 50°C (N o freezin g)

Ambient humidity 35 t o 85%RH (N o condens ation)

Vibration 10 to 55 Hz Do uble ampli tude 1.5 mm XY Z each ax is: 2 hours

Pollution degree 2

Material Cas e/Fron t sheet: P olycarb onate, Ke y top: Polya cetal, Ca ble: PVC

Supplied item Mai n body × 1, Instr uction ma nual × 1 (only f or main unit)

Main bo dy × 1, Panel mou nting bra cket × 1, Front pr otection c over × 1, Power

suppl y and input /output c able (2 m) × 1,

Exp ansion cab le (50 mm) × 1 ( only for exp ansion unit ),

Instr uction ma nual × 1 (only f or main unit)

Weigh t (includin g supplied it ems) Appro x. 150 g Appro x. 140 g Appr ox. 170 g Appr ox. 165 g

1. When expansion units are added: Max. 20 mA/ch

2. For more details, refer to the User’s Manual.

3. Delay time that occurs from the analogue output circuit after the judgment is output.

4. When adding an expansion unit, the consumed electrical power is equal to the total value of the consumed electrical power of all amplifi ers.

Volta ge output Cur rent outp ut

Output range ±5 V (f ull scale 10 V ) 4-20 m A (full sca le 16 mA)

Output resistance 100 Ω

-

Maxi mum load resi stance

-

350 Ω

Repetition accuracy ±1 mV ±1.5 µA

Display accuracy ±0.0 5 % of F.S. ±0. 25 % of F.S.

Temperature characteristics ±0.0 05 % of F.S./ °C ±0.01% of F.S./ °C

Update cycle Sa me as senso r head sam pling cycle

Response time Same as Res ponse tim e (judgem ent outpu t)

Time constant

3.

10 µs (90 % r esponse ) 30 µs (9 0 % respon se)

Page 12

IB Series

12

Achieving an Endless Amount of Applications Unable to be

Detected by Using a Fibre Sensor

IB-10

IB-05

IB-30

DIN-rail mount type

IB-1000/1050

Panel mount type

IB-1500/1550

IB-01

Thrubeam Type Laser Detection Sensor

IB S eries

High-speed sampling of 80 µs

High-accuracy differentiation of 5 µm

New function: Auto adjustment included

Page 13

13

3 devices are required each for

presence/absence, height and timing

detections

All detections conducted using a single device

❚ Photoelectric sensor ❚ Digital laser sensor

As the position changes, the

thrubeam light volume changes

Regardless of position, the thrubeam light volume

remains the same

Detection is not possible when

strayed off the linear optical axis

Definitive detection in a wide detection area

Does not stabilise due to the subtle

difference in thrubeam light volume

Definitive determination of even the most minute

thrubeam light volume difference

Sensitivity changes according to the

influence of dirt, etc

Dirt is eliminated using the Light intensity correction

function

1 device, 3 roles. 3 step output of

presence and size

Upper/lower output-equipped as standard. Not only

presence/absence is detected, but size judgments can also

be conducted using this single device. A timing sensor is also

not required due to the presence of the Auto timing function.

Not influenced by passage position

According to the parallel laser light, no matter where the

target is positioned, the judgment values will remain the

same. This makes high-accuracy differentiation possible

anywhere on the detection area.

No concern of position

misalignment even in wide areas

As the maximum width of the optical axis is 30 mm, stable

detection is possible even if the target is shaking.

Not affected by dirt or temperature

changes

By incorporating a Light intensity correction function, the

numerical margin of error caused by aging variation can be

cancelled. Possible to always achieve stable, high-accuracy

judgments.

High-accuracy detection even in

transparent bodies

In addition to detecting the presence of transparent targets,

detections such as those of single/double transparent films,

density differentiation, and the turbidity of liquids is also

possible. Furthermore, using the percentage display function

the thrubeam rate judgment is also possible.

Page 14

SERIES

Intelligent

Tough

Easy

I

IB Series

Low-cost

High

Performance

THREE CONCEPTS

The intelligent I-Series consists of a high-accuracy sensor lineup that realises low-cost high

performance with only the most advanced functions for on-site operations.

SERIES

Intelligent

Tough

Easy

I

Intelligent

High accuracy was achieved by using the technology and

functions developed for high-accuracy measuring

instruments.

Tough

Developed for use in harsh environments, the I Series was

designed with a strong structure.

Easy

Excellent usability makes it possible to quickly and easily

perform stable measurements without any difficult

adjustments and settings.

14

Mechanism behind stable detection

Light-receiving element (high-sensitivity PD)

Protective glass

Light-receiving lens

Adopting the newly developed optical system used in the IG Series

Multi-Wavelength Laser Beam + High-sensitivity PD

Normal lasers are single wavelength, therefore due to friction, the pattern

becomes patchy, as shown in the diagram on the right. This problem is rectified

in the IB Series by utilising laser light with multiple wavelengths. Targets with a

high level of difficulty can still be detected with a high degree of stability.

Furthermore, by incorporating a high-sensitivity PD within the light receiving

section data can be processed at high speeds, reducing the extraneous

fluctuations to the absolute limit.

SPOT IMAGE

Singl e-wavelength las er

(conventional laser sensor)

A patchy pattern appears.

Due to the mult i-wavelength

laser used, t he beam pattern

has a more unif orm intensity

distribution.

Multi-wavelength laser (IB)

High-accuracy differentiation

of 5 µm

Ultra-long distance

of 2 m

I

-

SERIES

Intelligent Sensor

Page 15

Display value

Time progressed

0

%

100

%

90

%

Auto adjustment function ON

Auto adjustment

function OFF

Automatically adjusts

the received light volume

to the standard value

15

Using the transmission lens, after the laser light

emitted as a parallel beam passes through the light

receiving lens, the light is then converged to the

light-receiving element (high-sensitivity PD). When

the measurement target interrupts this parallel

beam, this beam is in proportion to the volume of

interrupted light and the light entering the received

light element reduces. When this occurs, by

capturing the light volume in the light-receiving

element (high-sensitivity PD), the size and

transparency of the target can be measured.

If the optical axis is not aligned the LED

turns off

When the optical axis begins to align, the

flashing frequency of the LED quickens

High-speed flashing when the optical

axis is aligned

Semi-conductor laser

Alignment LED

Protective glass

Transmission lens

SERIES

Intelligent

Tough

Easy

I

SERIES

Intelligent

Tough

Easy

I

Maintenance-saving according to the Auto adjustment function

Long-term, stable detection even in environments where the

device becomes dirty easily

In the IB Series, should the received light volume decrease

according to such things as dirt on the front of the sensor

head, by using the adjustment input, the received light volume

is adjusted to standard values during input. In addition, the

Auto adjustment function recognises that this adjustment

input has no measurement target, and therefore is executed

regularly automatically. Even when used in environments

where the device becomes dirty easily, stable measurements

and a high degree of maintenance-saving has been achieved

by the device automatically correcting itself.

Simple positioning according to the alignment LED

Easy to align the optical axis

As the optical axis of the laser align, the flash frequency of the laser transmitter indicator quickens. Even

without looking at the amplifier unit, the optimum position can be achieved easily.

Page 16

IB Series

16

Specifi cations

Sensor head

Model IB-01 IB-05 IB-10 IB-30

Appearance

Light source Visibl e semicond uctor las er Wavelen gth: 66 0 nm

Lase r Class Class 1 ( IEC608 25-1, FDA (CD RH) Part 1040.10

1.

)

Mounting distance 0 t o 2000 mm 0 to 300 m m

Measu rement ra nge

Ø1 mm

(Inst allation di stance 0 t o 300 mm)

Ø1 to 2.5 mm ( Install ation dista nce

300 to 2000 m m)

5 mm 10 m m 30 mm

Sampling rate 12,50 0 times/ sec. (8 0 µs)

Minimum

detectable object

2.

Ø8 µm

(Inst allation di stance 0 t o 300 mm)

Ø8 to 50 µm

(Inst allation di stance 3 00 to 200 0 mm)

Ø0.05 mm Ø0.1 mm Ø0. 2 mm

Repeatabilit y

3.

5 µm

(dist ance 0 to 30 0 mm)

5 µm 5 µm 10 µm

Temperature characteristics

4.

±0. 2% of F.S./° C ±0.1% of F.S. /°C (± 5 µm) ±0.1% of F.S. /°C (±10 µm ) ±0.1% of F.S. /°C (± 30 µm)

Operation indicator Lase r emission w arning indi cator: gr een LED

Environmental resistance

Ambient luminance

Inca ndescen t lamp: 50 00 lux

Solar light: 10000 lux

Inca ndescen t lamp: 50 00 lux

Solar li ght: 500 0 lux

Incandescent lamp: 10000 lux

Solar light: 10000 lux

Ambient temperature 0 to +4 0°C (no fre ezing) 0 to +5 0°C (no fre ezing)

Ambient humidity 35 to 85% RH (no con densatio n)

Vibration 10 to 55 Hz Do uble ampli tude 1.5 mm XY Z each ax is: 2 hours

Material

Case PB T Galva nized die c ast

Lens cover Glass

Cable PVC (2 m )

Weight Appro x. 140 g Appro x. 180 g Approx . 220 g Appr ox. 510 g

1. The classification for FDA (CDRH) is implemented based on IEC60825-1 in accordance with the requirements of Laser Notice No.50.

2. Value when measuring the target (white diffuse object) at the middle of the transmitter and receiver position, and at the centre of the measurement range.

3. When distance between transmitter and receiver is set to 300 mm, and light is half-shielded at a position 150 mm from receiver.

Deflection width (±2σ) when sampled for 30 seconds with an average number of times set to 64 times.

4. When distance between transmitter and receiver is set to 100 mm and full light is received.

Amplifi er unit

Model IB-1000 IB-1500 IB-1050 IB-1550

Appearance

Amplifier type DIN rail mount Pan el mount DIN rail mount Panel mount

Main unit/Ex pansion unit Main unit Expansion unit

Head compatibilit y Yes

Display

Display resolution 0.01% , 0.1%, 1% (switc hable)

Displ ay range – 99.999 to 9 9.999, – 99.99 to 99. 99, –99.9 t o 99.9, –9 9 to 99 (swit chable)

Digital display method

Dual 7-s egment dis play

Upper level: 5 red digits

Lower level: 5 green digits

Dual 7-s egment dis play

Upper l evel:2 -colour (g reen/ red) 5

digits

Lower level: 5 green digits

Dual 7-s egment dis play

Upper level: 5 red digits

Lower level: 5 green digits

Dual 7-s egment dis play

Upper level: 2-colour (gr een/red) 5 digits

Lower level: 5 green digits

Operation indicator

Judgm ent indica tor: 2-co lour (gree n/red ) LED (HI, GO, L O),

Bank in dicator: G reen LED x 4,

Lase r emission w arning indic ator: Gre en LED,

Othe rs: Gree n LED x 8, red LE D x 3

Analo gue voltag e output

1.

±5 V, 1 to 5 V, 0 to 5 V Ou tput impe dance 100 Ω

No

Analo gue curren t output

1.

4 to 20 mA M aximum lo ad resist ance 350 Ω

Control

input

2.

Bank s witch inpu t

Non-v oltage inp ut

Zero-shift input

Lase r emission s top input

Timing input

Rese t input

Adjust input

Control

output

3.

Judgment output

Open c ollector ( NPN/P NP switcha ble, N.O./ N.C. swit chable)

Check output

Power supply

Power v oltage 10 to 30 VD C, including r ipple (P-P ) 10% Class 2 or L PS Suppli ed from main u nit

Power c onsumpt ion

4.

1950 mW or l ess

(at 30 V, 6 5 mA max.)

2100 mW or l ess

(at 30 V, 70 m A max.)

1950 mW or l ess

(at 30 V, 6 5 mA max.)

2100 mW or l ess

(at 30 V, 70 m A max.)

Environmental resistance

Ambient temperature -10 to +50 °C (No free zing)

Ambient humidity 35 to 85 % RH (No cond ensatio n)

Vibration 10 to 55 Hz D ouble ampli tude 1.5 mm X YZ each ax is: 2 hours

Pollution degree 2

Material Case /Front p anel: pol ycarbon ate, key top: poly acetal, c able: PV C

Weigh t (includin g supplied it ems) Appro x. 150 g Appr ox. 170 g Appro x. 140 g Appr ox. 165 g

1. ±5 V, 1 to 5 V, 0 to 5 V, or 4 - 20 mA should be selected.

2. The four external input wires are assigned with desired inputs.

Rated no-voltage input: ON voltage 2 V or less, OFF current 0.05 mA or less

Rated voltage input: Max. input rating 30 V or less, ON voltage 7.5 V or more, OFF current 0.05 mA or less

3. Rated NPN open collector output: Max. 50 mA/ch (20 mA/ch when expansion units are connected), 30 V or less, residual voltage 1 V or less

Rated PNP open collector output: Max. 50 mA/ch (20 mA/ch when expansion units are connected), 30 V or less, residual voltage 2 V or less

4. The power consumption with slave units installed is the total of each amplifier unit’s power consumption.

Example: When using one master unit (IB-1000) with two slave units (IB-1050) (1950 mW X 1) + (1950 mW X 2) = 5850 mW

Page 17

IG/IB Series

Models

Communication

method

Connection

device

Read judgment

results

Read

measurement

values

Control

input

Change tolerance

values

Comments

DL-RS1A

RS-232C

PLC PCs of

various

companies

✓✓✓✓

Uses no control sequence

communication. Communicates by

using a communication program.

DL-RB1A

BCD output

PLC PCs of

various

companies

X

✓

XX

Measurement values are updated

by synchronising with the input

terminals. Furthermore, updates

automatically occur using a timer.

Readouts are created by

synchronising with the strobe

output.

17

DATA COMMUNICATION (Common to IG/IB)

The setting can be changed.

Setting value Description

Not output

Analog ue output afte r the judgemen t value is convert ed to the range fro m 0 to 5 V.

Analog ue output afte r the judgemen t value is convert ed to the range of ± 5 V.

Analog ue output afte r the judgemen t value is convert ed to the range fro m 1 to 5 V.

Analog ue output afte r the judgemen t value is convert ed to the range fro m 4 to 20 mA.

Amplifier Function

Communication Unit

NPN/PNP Output Selection (judgment selection)

Both NPN and PNP outputs are supported. The outputs are set

the first time the user turns on the power. These settings can

subsequently be changed. Judgments are output as HIGH, GO,

or LOW.

Analogue Output Selection

The following four types of analogue outputs can be selected.The

output is selected the first time the user turns on the power.

DL-RB1A

BCD output unit

Use this unit when retrieving numerical data

from the IG/ IB Series to an external device as

digital data. A single communication unit can

retrieve data from up to four IG/IB Series display

units in BCD.

DL-RS1A

RS-232C communication unit

Use this unit when outputting digital data to

an external device with RS-232C signals. It

is necessary to connect it to a PC when

using the startup support software, IG

Configurator. A single communication unit

can retrieve data from up to four IG/IB Series

display units.

Bank Function

The bank function can register up to four patterns of specific

settings.* For example, in response to a measurement target

changeover, this function allows the user to easily switch between

the patterns of registered settings.

* HIGH set ting value, LOW setting valu e, binarization level,

shift targ et value, etc.

Page 18

(26)

ø9

2-ø3.4

(Mounting hole)

17

ø4.8

Cable length 170

Edge M8 connector

39.8

54.7

6.7

3.2

25.4

Transmission spot centre

23

11. 2

18.8

31.8

3-M3 Valid screw depth 4

10.4

1.6

50.5

32.7

10.6

4.8

6.7

3.7

* Transmission spot (reference value)

12

15

Base level

2-M4 Valid screw depth 5.2

Measurement

centre

* Light-receiving area

(5 × 14 rectangle)

31.8

18.8±1

11. 2

23

51.5

12.6

23.5

28.5

55

16.2

2-ø3.4

(Mounting hole)

(26)

ø9

3-M3 Valid screw depth 4

3

49.4

4.3

13.5

Base level

2-M4 Valid screw depth 5.2

ø4.8

Cable length 170

Edge M8 connector

* Light-receiving area

(3.6 × 31.2 rectangle)

Measurement

centre

56.2

33.1±0.3

11. 4

23

48.2

4.1

2-ø4.5

(Mounting hole)

7

17.1

11. 4

30.2

29.3

15.5

4.3

2.5

18.5

16.6

0.8

3-M3 Valid screw depth 5.5

Base level

Base level

2-M5 Valid screw

depth 5.2

47.6

16.6

6.4

(26)

ø9

18.8

25.4

11. 5

66.2

4.2

47.5

11. 4

23

33.1

56.2

3-ø4.5

(Mounting hole)

Transmission spot centre

4-M3 Valid screw depth 5.5

63.8

43.8

6.5

4.8

10.4

Base level

10.4

1.8

12

33

* Transmission spot

(reference value)

3-M5 Valid screw depth 5.2

Base level

Edge M8 connector

Edge M8 connector

(26)

ø9

ø4.8

Cable length 170

ø4.8

Cable length 170

50

26

56

(4.2)

(10.2)

(146.4)

11.4

28

6.1

16.4

61.2

61.2

28

38.1±0.3

(17.6)

(45.6)

(24.1)

(52.1)

17

46.7

82.7

11.5

23

11.4(Measurement centre)

Measurement area

Transmitter Receiver

40

151.1

144

23

36.8

36.8

22

23.8±1

10

56.4

(47.6)

11.5

67.9

17

(18.8)

(28.8)

(66.2)

(12.3)

(22.3)

11.4

(Measurement centre)

Measurement area

2-ø4.5 Drilled through hole

ø8.5 Spot facing depth 4

Transmitter Receiver

2-ø4.5 Drilled through hole

ø8.5 Spot facing depth 4

Material: Aluminium Material: Aluminium

IG/IB Series

Unit : mm

Dimensions

IG Series Sensor head

IG Series Sensor head mounting bracket

IG-010

IG-028

IG-TB01 + IG-010 IG-TB02 + IG-028

Transmitter

Transmitter

Receiver

Receiver

18

Page 19

2-ø3.2

(Mounting hole)

7

2.5

16.1

19

12.2

ø4

Cable length 2 m

Slit (1×5)

18

18

7

3.7

ø6

ø4

Cable length 2 m

2.5

37

2-ø3.2

(Mounting hole)

12.2

16

18

* Transmission spot (reference value)

(6×8 ellipse)

2.5

25.2

15.0

15.6

2.6

20.0

2-ø3.2

(Mounting hole)

2.6

ø4

Cable length 2 m

* Light-receiving area (3.5 ×3.5)

2.6

2.6 31.0

2-ø3.2

(Mounting hole)

2.5

36.2

15.0

15.6

ø4

Cable length 2 m

* Transmission spot (reference value)

When distance is 300 mm: approximately ø 1 mm

When distance is 2000 mm: approximately ø 2.5 mm

18

28

7

ø4

Cable length 2 m

2.5

2-ø3.2

(Mounting hole)

13

13.8

Slit (1×10)

20

3.7

7

ø6

2.5

ø4

Cable length 2 m

2-ø3.2

(Mounting hole)

13.8

25

50

20

*Transmission spot (reference value)

(7×13 ellipse)

52

44

4

4

44

3-ø4.5

(Mounting hole)

12

20

28

64

ø4

Cable length 2 m

Slit (1×30)

68

60

3-ø4.5

(Mounting hole)

44

4

4

12

28

20

64

ø4

Cable length 2 m

*Transmission spot (reference value)

(6×36 rectangle)

20

20

28.3

8.9

18.5

Cable diameter ø4.8

Cable diameter ø4.7

Cable length 2 m

18.5

37.4

42.4

17.4

3

20

21.6

35.4

76.3

17.6

Max.135°

When the cover is

open: Max. 109.2

Min.15

Min.15

37.4

42.4

17.4

3

20

21.6

35.4

76.3

17.6

Max.135°

When the cover is

open: Max.109.2

18.5

18.5

1.9

(4.8)

19.2

69.5

8.9

Cable diameter ø4.8 Cable diameter ø4.7

Cable length 2 m

Min.15

Min.15

28.3

44.7

2.3

7.6

1.5

48

73.6

19.1

10.3

19.1

17.6

27.2

44.7

15.3

9.5

35

20.2

4

62.5

12.4

Panel thickness

1 to 6 mm

45mm

+

0.6

-

0

45mm

+

0.6

-

0

Min.85mm

Xmm

45mm

+

0.6

-

0

X = 48 × (number of amplifiers) - 3

Cable diameter ø4.8

Cable diameter ø4.7

Cable length 2 m

76

22.4

10.3

IG/IB Series

Unit : mm

Dimensions

IB Series Sensor head

Sensor amplifi er

(DIN rail mount type)

Sensor amplifi er

(Panel mount type)

IB-01

IB-10

IB-05

IB-30

Receiver

Transmitter

Transmitter

Receiver

Receiver

Transmitter

Transmitter

IG (IB)-1050IG (IB)-1000

Receiver

IG (IB)-1000/IG (IB)-1050

IG (IB)-1500/IG (IB)-1550

19

Page 20

WW1-1010

www.keyence.com

SAFET Y INFORM ATION

Please read the instruction manual carefully in

order to safely operate any KEYENCE product.

Please visit:

SINGAPORE

Phone: +65-6392-1011 Fax: +65-6392-5055

SLOVAKIA

Phone: +421 2 5939 6461 Fax: +421 2 5939 6200

MEXICO

Phone: +52-81-8220-7900 Fax: +52-81-8220-9097

NETHERLANDS

Phone: +31 40 20 66 100 Fax: +31 40 20 66 112

POLAND

Phone: +48 71 36861 60 Fax: +48 71 36861 62

MALAYSIA

Phone: +60-3-2092-2211 Fax: +60-3-2092-2131

CZECH REPUBLIC

Phone: +420 222 191 483 Fax: +420 222 191 505

AUSTRIA

Phone: +43 22 36-3782 66-0 Fax: +43 22 36-3782 66-30

BELGIUM

Phone: +32 27 16 40 63 Fax: +32 27 16 47 27

CHINA

Phone: +86-21-68757500 Fax: +86-21-68757550

CANADA

Phone: +1-905-696-9970 Fax: +1-905-696-8340

FRANCE

Phone: +33 1 56 37 78 00 Fax: +33 1 56 37 78 01

KOREA

Phone: +82-31-642-1270 Fax: +82-31-642-1271

GERMANY

Phone: +49 61 02 36 89-0 Fax: +49 61 02 36 89-100

HUNGARY

Phone: +36 1 802 73 60 Fax: +36 1 802 73 61

HONG KONG

Phone: +852-3104-1010 Fax: +852-3104-1080

ITALY

Phone: +39-02-6688220 Fax: +39-02-66825099

JAPAN

Phone: +81-6-6379-2211 Fax: +81-6-6379-2131

SWITZERLAND

Phone: +41 43-45577 30 Fax: +41 43-45577 40

THAILAND

Phone: +66-2-369-2777 Fax: +66-2-369-2775

TAIWAN

Phone: +886-2-2718-8700 Fax: +886-2-2718-8711

UK & IRELAND

Phone: +44-1908-696900 Fax: +44-1908-696777

USA

Phone: +1-201-930-0100 Fax: +1-201-930-0099

KEYENCE GLOBAL HEADQUA RTERS

1-3-14, Higashi-Nakajima, Higashi-Yodogawa-ku, Osaka, 533-8555, Japan PHONE: +81-6-6379-2211

Copyright (c) 2010 KEYENCE CORPORATION. All rights reserved. IBIG-AS-C-E 1080-1 600863 Printed in Japan

The information in this publication is based on KEYENCE’s internal research/evaluation at the time of release and is subject to change without notice.

*600863*

IG/IB Series

Unit : mm

Dimensions

70

35.4

21.1

43.8

22.5

(48.2)

37.2

70

35.4

21.1

53.4

37.1

22.5

(57.8)

Communication unit

(BCD output type)

DL-RB1A

Communication unit

(RS-232C communication type)

DL-RS1A

34-pin MIL connector

DIN-rail mount DIN-rail mount

Loading...

Loading...