Keithley 6514 User Manual

Model 6514 System Electrometer

Instruction Manual

A G R E A T E R M E A S U R E O F C O N F I D E N C E

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio. You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility. Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Keithley Instruments, Inc.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax:440-248-6168 • 1-888-KEITHLEY (534-8453) • www.keithley.com

Belgium: Sint-Pieters-Leeuw • 02-363 00 40 • Fax: 02-363 00 64 • www.keithley.nl |

Italy: Milano • 02-48 39 16 01 • Fax: 0248 39 16 28 • www.keithley.it |

China: Beijing • 8610-82251886 • Fax: 8610-82251892 • www.keithley.com.cn |

Japan:Tokyo • 81-3-5733-7555 • Fax: 81-3-5733-7556 • www.keithley.jp |

Finland: Helsinki • 09-5306-6560 • Fax: 09-5306-6565 • www.keithley.com |

Korea: Seoul • 82-2-574-7778 • Fax: 82-2-574-7838 • www.keithley.com |

France: Saint-Aubin • 01-64 53 20 20 • Fax: 01-60 11 77 26 • www.keithley.fr |

Netherlands: Gorinchem • 0183-635333 • Fax: 0183-630821 • www.keithley.nl |

Germany: Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34 • www.keithley.de |

Singapore: Singapore • 65-6747-9077 • Fax: 65-6747-2991 • www.keithley.com |

Great Britain:Theale • 0118 929 7500 • Fax: 0118 929 7519 • www.keithley.co.uk |

Sweden: Solna • 08-509 04 600 • Fax: 08-655 26 10 • www.keithley.com |

India: Bangalore • 91-80 2212 8027 • Fax: 91-80 2212 8005 • www.keithley.com |

Taiwan: Hsinchu • 886-3-572-9077 • Fax: 886-3-572-9031 • www.keithley.com.tw |

3/04

Model 6514 System Electrometer

Instruction Manual

©1998, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Fourth Printing, May 2003

Document Number: 6514-901-01 Rev. D

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between Revisions, contain important change information that the user should incorporate immediately into the manual. Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the previous Revision of the manual are incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this print history page.

Revision A (Document Number 6514-901-01) ............................................................ |

October 1998 |

Addendum A (Document Number 6514-901-02)..................................................... |

December 1998 |

Revision B (Document Number 6514-901-01) ........................................................ |

December 1998 |

Revision C (Document Number 6514-901-01) ................................................................. |

June 1999 |

Revision D (Document Number 6514-901-01) ................................................................. |

May 2003 |

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc. Other brand names are trademarks or registered trademarks of their respective holders.

Safety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line voltage or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, and perform safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are rated Measurement Category I and Measurement Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and data I/O signals are Measurement Category I and must not be directly connected to mains voltage or to voltage sources with high transient over-voltages. Measurement Category II connections require protection for high transient over-voltages often associated with local AC mains connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V RMS, 42.4V peak, or 60VDC are present. A good safety practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If the circuit is capable of operating at or above 1000 volts, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance limited sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

5/03

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a lid interlock.

If a  screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

The ! symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The  symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal and common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal and common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The  symbol indicates a connection terminal to the equipment frame.

symbol indicates a connection terminal to the equipment frame.

The WARNING heading in a manual explains dangers that might result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the power transformer, test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals, may be used if the rating and type are the same. Other components that are not safety related may be purchased from other suppliers as long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments to maintain accuracy and functionality of the product.) If you are unsure about the applicability of a replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with no case or chassis (e.g., data acquisition board for installation into a computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper cleaning/servicing.

Table of Contents

1 |

Getting Started |

|

|

General information ................................................................... |

1-2 |

|

Warranty information .......................................................... |

1-2 |

|

Contact information ............................................................ |

1-2 |

|

Safety symbols and terms ................................................... |

1-2 |

|

Inspection ............................................................................ |

1-2 |

|

Options and accessories ...................................................... |

1-3 |

|

System electrometer features ..................................................... |

1-4 |

|

Front and rear panel familiarization ........................................... |

1-5 |

|

Front panel summary .......................................................... |

1-5 |

|

Rear panel summary ........................................................... |

1-8 |

|

Power-up .................................................................................. |

1-10 |

|

Line power connection ...................................................... |

1-10 |

|

Line frequency selection ................................................... |

1-10 |

|

Power-up sequence ........................................................... |

1-11 |

|

Display ..................................................................................... |

1-12 |

|

Status and error messages ................................................. |

1-12 |

|

Default settings ......................................................................... |

1-12 |

|

SCPI programming .................................................................. |

1-15 |

2 |

Measurement Concepts |

|

|

Measurement overview .............................................................. |

2-2 |

|

Performance considerations ....................................................... |

2-2 |

|

Warm-up period .................................................................. |

2-2 |

|

Autozero .............................................................................. |

2-2 |

|

Connection fundamentals ........................................................... |

2-3 |

|

Input connector ................................................................... |

2-3 |

|

Low noise input cables ........................................................ |

2-5 |

|

Basic connections to DUT .................................................. |

2-6 |

|

Test fixture .......................................................................... |

2-9 |

|

Input protection ................................................................. |

2-11 |

|

Floating measurements ..................................................... |

2-11 |

|

Zero check and zero correct ..................................................... |

2-13 |

|

Zero check ......................................................................... |

2-13 |

|

Zero correct ....................................................................... |

2-14 |

|

SCPI programming — zero check and zero correct ......... |

2-15 |

|

Input bias current and offset voltage calibration ...................... |

2-17 |

|

Front panel ........................................................................ |

2-17 |

|

SCPI programming ........................................................... |

2-18 |

|

Measurement considerations .................................................... |

2-19 |

3 |

Volts and Ohms Measurements |

|

|

Measurement overview ............................................................... |

3-2 |

|

Guarding ..................................................................................... |

3-2 |

|

Test circuit leakage .............................................................. |

3-2 |

|

Input cable leakage and capacitance ................................... |

3-3 |

|

Volts and ohms measurement procedure .................................... |

3-4 |

|

V-Drop and I-Source for ohms ............................................ |

3-6 |

|

SCPI programming ..................................................................... |

3-7 |

|

Programming example ........................................................ |

3-8 |

|

Volts and ohms measurement considerations ............................. |

3-9 |

|

Loading effects .................................................................... |

3-9 |

|

Cable leakage resistance ...................................................... |

3-9 |

|

Input capacitance (settling time) ....................................... |

3-10 |

|

Guarding input cable ......................................................... |

3-12 |

|

Application ............................................................................... |

3-14 |

|

Capacitor dielectric absorption .......................................... |

3-14 |

4 |

Amps Measurements |

|

|

Measurement overview ............................................................... |

4-2 |

|

Amps measurement procedure ................................................... |

4-2 |

|

Damping .............................................................................. |

4-4 |

|

High impedance measurement techniques ................................. |

4-5 |

|

SCPI programming ..................................................................... |

4-8 |

|

Programming example ........................................................ |

4-9 |

|

Amps measurement considerations ............................................ |

4-9 |

|

Input bias current ................................................................. |

4-9 |

|

Voltage burden ..................................................................... |

4-9 |

|

Noise .................................................................................. |

4-10 |

|

Applications .............................................................................. |

4-13 |

|

Diode leakage current ........................................................ |

4-13 |

|

Capacitor leakage current .................................................. |

4-14 |

|

Cable insulation resistance ................................................ |

4-14 |

|

Surface insulation resistance (SIR) ................................... |

4-15 |

5 |

Coulombs Measurements |

|

|

Measurement overview ............................................................... |

5-2 |

|

Auto discharge ............................................................................ |

5-2 |

|

Coulombs measurement procedure ............................................ |

5-3 |

|

SCPI programming ..................................................................... |

5-5 |

|

Programming example ........................................................ |

5-6 |

|

Coulombs measurement considerations ..................................... |

5-6 |

|

Input bias current ................................................................. |

5-6 |

|

External voltage source ....................................................... |

5-6 |

|

Zero check hop and auto discharge hop .............................. |

5-7 |

|

Application ................................................................................. |

5-7 |

|

Capacitance measurements ................................................. |

5-7 |

6 |

Range, Units, Digits, Rate, and Filters |

|

|

Range, units, and digits .............................................................. |

6-2 |

|

Range .................................................................................. |

6-2 |

|

Units .................................................................................... |

6-4 |

|

Digits ................................................................................... |

6-4 |

|

SCPI programming - range and digits ................................ |

6-4 |

|

Rate ............................................................................................ |

6-6 |

|

SCPI programming — rate ................................................. |

6-7 |

|

Filters ......................................................................................... |

6-8 |

|

Median filter ........................................................................ |

6-8 |

|

Digital filter ......................................................................... |

6-9 |

|

SCPI programming — filters ............................................ |

6-10 |

7 |

Relative, mX+b and Percent (%) |

|

|

Relative ....................................................................................... |

7-2 |

|

Setting and controlling relative ........................................... |

7-2 |

|

SCPI programming — relative ........................................... |

7-3 |

|

mX+b and percent (%) ............................................................... |

7-4 |

|

mX+b .................................................................................. |

7-4 |

|

Percent (%) .......................................................................... |

7-5 |

|

SCPI programming — mX+b and percent ......................... |

7-6 |

8 |

Buffer |

|

|

Buffer operations ........................................................................ |

8-2 |

|

Store .................................................................................... |

8-2 |

|

Recall .................................................................................. |

8-2 |

|

Buffer statistics ................................................................... |

8-3 |

|

SCPI programming .................................................................... |

8-4 |

|

Programming example ......................................................... |

8-6 |

9 |

Triggering |

|

|

Trigger models ........................................................................... |

9-2 |

|

Idle and initiate ................................................................... |

9-4 |

|

Trigger model operation ...................................................... |

9-4 |

|

Trigger model configuration — front panel ........................ |

9-7 |

|

SCPI programming ..................................................................... |

9-9 |

|

Programming example ...................................................... |

9-10 |

|

External triggering ................................................................... |

9-11 |

|

Input trigger requirements ................................................. |

9-11 |

|

Output trigger specifications ............................................. |

9-12 |

|

External trigger example ................................................... |

9-12 |

10 |

Limit Tests |

|

|

Limit testing .............................................................................. |

10-2 |

|

Binning ..................................................................................... |

10-4 |

|

Component handler interface ............................................ |

10-6 |

|

Component handler types .................................................. |

10-7 |

|

Digital output clear pattern ................................................ |

10-8 |

|

Front panel operation .............................................................. |

10-10 |

|

Limit test configuration ................................................... |

10-10 |

|

Perform limit tests ........................................................... |

10-11 |

|

SCPI programming ................................................................. |

10-12 |

|

Programming example .................................................... |

10-15 |

11 |

Digital I/O, Analog Outputs, and External Feedback |

|

|

Digital I/O port ......................................................................... |

11-2 |

|

Sink mode — controlling external devices ....................... |

11-3 |

|

Source mode — logic control ............................................ |

11-5 |

|

Setting digital output lines ................................................. |

11-5 |

|

SCPI programming — digital output pattern .................... |

11-6 |

|

Analog outputs .......................................................................... |

11-7 |

|

2V analog output ............................................................... |

11-7 |

|

External feedback ................................................................... |

11-11 |

|

Electrometer input circuitry ............................................ |

11-11 |

|

Shielded fixture construction ........................................... |

11-12 |

|

Non-standard coulombs ranges ....................................... |

11-13 |

|

External feedback procedure ........................................... |

11-13 |

|

Logarithmic currents ....................................................... |

11-15 |

|

Non-decade current gains ................................................ |

11-16 |

|

SCPI programming — external feedback ....................... |

11-17 |

12 |

Remote Operation |

|

|

Selecting and configuring an interface ..................................... |

12-2 |

|

Interfaces ........................................................................... |

12-2 |

|

Languages .......................................................................... |

12-2 |

|

Interface selection and configuration procedures .............. |

12-2 |

|

GPIB operation and reference .................................................. |

12-5 |

|

GPIB bus standards ........................................................... |

12-5 |

|

GPIB bus connections ....................................................... |

12-5 |

|

Primary address selection .................................................. |

12-7 |

|

General bus commands ..................................................... |

12-8 |

|

Front panel GPIB operation ............................................ |

12-10 |

|

Programming syntax ....................................................... |

12-11 |

|

RS-232 interface reference ..................................................... |

12-17 |

|

Sending and receiving data .............................................. |

12-17 |

|

RS-232 settings ............................................................... |

12-17 |

|

RS-232 connections ......................................................... |

12-18 |

|

Error messages ................................................................ |

12-19 |

13 |

Status Structure |

|

|

Overview .................................................................................. |

13-2 |

|

Clearing registers and queues ................................................... |

13-4 |

|

Programming and reading registers ......................................... |

13-5 |

|

Programming enable registers ........................................... |

13-5 |

|

Reading registers ............................................................... |

13-6 |

|

Status byte and service request (SRQ) ..................................... |

13-7 |

|

Status byte register ............................................................ |

13-7 |

|

Service request enable register .......................................... |

13-8 |

|

Serial polling and SRQ ..................................................... |

13-9 |

|

Status byte and service request commands ....................... |

13-9 |

|

Status register sets .................................................................. |

13-11 |

|

Register bit descriptions .................................................. |

13-11 |

|

Condition registers .......................................................... |

13-15 |

|

Event registers ................................................................. |

13-16 |

|

Event enable registers ..................................................... |

13-17 |

|

Queues .................................................................................... |

13-18 |

|

Output queue ................................................................... |

13-18 |

|

Error queue ...................................................................... |

13-19 |

14Common Commands

15SCPI Signal Oriented Measurement Commands

16DISPlay, FORMat, and SYSTem

|

DISPlay subsystem .................................................................. |

16-2 |

|

FORMat subsystem .................................................................. |

16-4 |

|

SYSTem subsystem .................................................................. |

16-8 |

17 |

SCPI Reference Tables |

|

|

General notes ............................................................................ |

17-2 |

18 |

Performance Verification |

|

|

Introduction .............................................................................. |

18-2 |

|

Verification test requirements ................................................... |

18-3 |

|

Environmental conditions ................................................. |

18-3 |

|

Warm-up period ................................................................ |

18-3 |

|

Line power ........................................................................ |

18-3 |

|

Recommended test equipment ................................................. |

18-4 |

|

Verification limits ..................................................................... |

18-6 |

|

Example reading limits calculation ................................... |

18-6 |

|

Recalculating resistance reading limits ............................. |

18-6 |

|

Calibrator voltage calculations ................................................. |

18-7 |

|

Current calculations .......................................................... |

18-7 |

|

Charge calculations ........................................................... |

18-7 |

|

Performing the verification test procedures .............................. |

18-8 |

|

Test summary .................................................................... |

18-8 |

|

Test considerations ............................................................ |

18-8 |

|

Restoring factory defaults ......................................................... |

18-9 |

|

Input bias current and offset voltage calibration ...................... |

18-9 |

|

Offset voltage calibration .................................................. |

18-9 |

|

Input bias current calibration ............................................. |

18-9 |

|

Volts measurement accuracy .................................................. |

18-10 |

|

Amps measurement accuracy ................................................. |

18-12 |

|

20µA-20mA range accuracy ........................................... |

18-12 |

|

20pA-2µA range accuracy .............................................. |

18-13 |

|

Ohms measurement accuracy ................................................. |

18-15 |

|

2kΩ-20MΩ range accuracy ............................................. |

18-15 |

|

200MΩ-200GΩ range accuracy ...................................... |

18-17 |

|

Coulombs measurement accuracy .......................................... |

18-18 |

19 |

Calibration |

|

|

Introduction .............................................................................. |

19-2 |

|

Environmental conditions ......................................................... |

19-2 |

|

Temperature and relative humidity..................................... |

19-2 |

|

Warm-up period ................................................................. |

19-2 |

|

Line power ......................................................................... |

19-2 |

|

Calibration considerations ........................................................ |

19-3 |

|

Calibration cycle ................................................................ |

19-3 |

|

Recommended calibration equipment ...................................... |

19-3 |

|

Calibration errors ...................................................................... |

19-5 |

|

Calibration menu ...................................................................... |

19-5 |

|

Aborting calibration .................................................................. |

19-5 |

|

Current and charge calculations ............................................... |

19-6 |

|

Manual calculations............................................................ |

19-6 |

|

Automatic calculations ...................................................... |

19-6 |

|

Calibration procedure ............................................................... |

19-7 |

|

Preparing for calibration .................................................... |

19-7 |

|

Input bias current and offset voltage calibration ............... |

19-7 |

|

Volts calibration ................................................................. |

19-8 |

|

Amps calibration ............................................................. |

19-10 |

|

Coulombs calibration ...................................................... |

19-14 |

|

Ohms calibration ............................................................. |

19-16 |

|

Entering calibration dates and saving calibration ............ |

19-18 |

|

Locking out calibration ................................................... |

19-18 |

|

Changing the calibration code ................................................ |

19-18 |

|

Resetting the calibration code ................................................ |

19-19 |

|

Displaying calibration dates ................................................... |

19-19 |

|

Displaying the calibration count ............................................. |

19-20 |

20 |

Routine Maintenance |

|

|

Introduction .............................................................................. |

20-2 |

|

Setting line voltage and replacing line fuse ............................. |

20-2 |

Front panel tests ................................................................ |

20-4 |

DISP test ........................................................................... |

20-4 |

KEY test ............................................................................ |

20-4 |

ASpecifications

BStatus and Error Messages

CGeneral Measurement Considerations

|

Measurement considerations ..................................................... |

C-2 |

|

Ground loops ...................................................................... |

C-2 |

|

Triboelectric effects ........................................................... |

C-3 |

|

Piezoelectric and stored charge effects .............................. |

C-3 |

|

Electrochemical effects ...................................................... |

C-4 |

|

Humidity ............................................................................ |

C-4 |

|

Light ................................................................................... |

C-4 |

|

Electrostatic interference ................................................... |

C-4 |

|

Magnetic fields ................................................................... |

C-5 |

|

Electromagnetic Interference (EMI) .................................. |

C-5 |

D |

DDC Emulation Commands |

|

|

DDC language ........................................................................... |

D-2 |

E |

Example Programs |

|

|

Programming examples .............................................................. |

E-2 |

|

Changing function and range .............................................. |

E-2 |

|

One-shot triggering ............................................................. |

E-3 |

|

Generating SRQ on buffer full ............................................ |

E-4 |

|

Storing readings in buffer ................................................... |

E-5 |

|

Taking readings using the :READ? command .................... |

E-6 |

|

Controlling the Model 6514 via the RS-232 COM2 port ... |

E-7 |

F |

IEEE-488 Bus Overview |

|

|

Introduction ............................................................................... |

F-2 |

|

Bus description .......................................................................... |

F-3 |

|

Bus lines .................................................................................... |

F-5 |

|

Data lines ............................................................................ |

F-5 |

|

Bus management lines ........................................................ |

F-5 |

|

Handshake lines .................................................................. |

F-6 |

|

Bus commands ........................................................................... |

F-7 |

|

Uniline commands .............................................................. |

F-8 |

|

Universal multiline commands ........................................... |

F-8 |

|

Addressed multiline commands ......................................... |

F-9 |

|

Address commands ............................................................ |

F-9 |

|

Unaddress commands ......................................................... |

F-9 |

|

Common commands ......................................................... |

F-10 |

|

SCPI commands ............................................................... |

F-10 |

|

Command codes ............................................................... |

F-10 |

|

Typical command sequences ............................................ |

F-11 |

|

IEEE command groups ..................................................... |

F-12 |

|

Interface function codes .......................................................... |

F-13 |

G |

IEEE-488 and SCPI Conformance Information |

|

|

Introduction ............................................................................... |

G-2 |

H |

Calibration Options |

|

|

Introduction ............................................................................... |

H-2 |

|

Reading calibration standard values .......................................... |

H-2 |

|

Data transfer connections ................................................... |

H-2 |

|

Reading values ................................................................... |

H-2 |

|

Example program ............................................................... |

H-3 |

|

Remote calibration ..................................................................... |

H-4 |

|

Calibration commands ........................................................ |

H-4 |

|

Remote calibration overview .............................................. |

H-4 |

List of Illustrations

1 |

Getting Started |

|

Figure 1-1 |

Model 6514 front panel .......................................................... |

1-5 |

Figure 1-2 |

Model 6514 rear panel ........................................................... |

1-8 |

2 |

Measurement Concepts |

|

Figure 2-1 |

Input connector configurations .............................................. |

2-4 |

Figure 2-2 |

Maximum input levels ........................................................... |

2-5 |

Figure 2-3 |

Basic connections for unguarded measurements ................... |

2-6 |

Figure 2-4 |

Shielding for unguarded measurements ................................. |

2-7 |

Figure 2-5 |

Basic connections for guarded measurements ....................... |

2-8 |

Figure 2-6 |

General purpose test fixture ................................................... |

2-9 |

Figure 2-7 |

Capacitor test circuit without protection .............................. |

2-11 |

Figure 2-8 |

Capacitor test circuit with protection ................................... |

2-11 |

Figure 2-9 |

Floating measurements ........................................................ |

2-12 |

Figure 2-10 |

Equivalent input impedance with zero check enabled ......... |

2-14 |

3 |

Volts and Ohms Measurements |

|

Figure 3-1 |

High-impedance voltage measurements ................................ |

3-3 |

Figure 3-2 |

Connections for unguarded volts and ohms ........................... |

3-5 |

Figure 3-3 |

Connections for guarded volts and ohms ............................... |

3-6 |

Figure 3-4 |

Meter loading ......................................................................... |

3-9 |

Figure 3-5 |

Effects of input capacitance ................................................. |

3-11 |

Figure 3-6 |

Settling time ......................................................................... |

3-12 |

Figure 3-7 |

Unguarded input cable ......................................................... |

3-12 |

Figure 3-8 |

Guarded input cable ............................................................. |

3-13 |

Figure 3-9 |

Measuring dielectric absorption ........................................... |

3-15 |

4 |

Amps Measurements |

|

Figure 4-1 |

Connections for amps ............................................................ |

4-4 |

Figure 4-2 |

High impedance current measurements ................................. |

4-5 |

Figure 4-3 |

Floating current measurements .............................................. |

4-7 |

Figure 4-4 |

Voltage burden considerations ............................................. |

4-10 |

Figure 4-5 |

Source resistance and capacitance ....................................... |

4-11 |

Figure 4-6 |

Connections; diode leakage current test .............................. |

4-13 |

Figure 4-7 |

Connections; capacitor leakage current test ......................... |

4-14 |

Figure 4-8 |

Connections; cable insulation resistance test ....................... |

4-14 |

Figure 4-9 |

Connections; surface insulation resistance test .................... |

4-15 |

5 |

Coulombs Measurements |

|

Figure 5-1 |

Typical connections for coulombs .......................................... |

5-4 |

Figure 5-2 |

Measuring capacitors ............................................................. |

5-7 |

6 |

Range, Units, Digits, Rate, and Filters |

|

Figure 6-1 |

Speed vs. noise characteristics ............................................... |

6-6 |

Figure 6-2 |

Digital filter types; moving and repeating .............................. |

6-9 |

8 |

Buffer |

|

Figure 8-1 |

Buffer locations ...................................................................... |

8-3 |

9 |

Triggering |

|

Figure 9-1 |

Trigger model — front panel operation ................................. |

9-2 |

Figure 9-2 |

Trigger model — remote operation ........................................ |

9-3 |

Figure 9-3 |

Measure action block of trigger model .................................. |

9-6 |

Figure 9-4 |

Trigger link connection operation ........................................ |

9-11 |

Figure 9-5 |

Trigger link input pulse specifications ................................. |

9-11 |

Figure 9-6 |

Trigger link output pulse specifications ............................... |

9-12 |

Figure 9-7 |

DUT test system ................................................................... |

9-12 |

Figure 9-8 |

Trigger link connections ....................................................... |

9-13 |

Figure 9-9 |

Operation model for triggering example .............................. |

9-14 |

10 |

Limit Tests |

|

Figure 10-1 |

Limit tests ............................................................................. |

10-2 |

Figure 10-2 |

Limit tests example .............................................................. |

10-2 |

Figure 10-3 |

Operation model for limit test .............................................. |

10-3 |

Figure 10-4 |

Binning system ..................................................................... |

10-4 |

Figure 10-5 |

Operation model for limit testing with binning .................... |

10-5 |

Figure 10-6 |

Handler interface connections .............................................. |

10-6 |

Figure 10-7 |

Digital output auto-clear timing example ............................. |

10-9 |

11 |

Digital I/O, Analog Outputs, and External Feedback |

|

Figure 11-1 |

Digital I/O port ..................................................................... |

11-2 |

Figure 11-2 |

Digital I/O port simplified schematic ................................... |

11-3 |

Figure 11-3 |

Controlling externally powered relays ................................. |

11-4 |

Figure 11-4 |

NAND gate control .............................................................. |

11-5 |

Figure 11-5 |

Typical 2V analog output connections ................................. |

11-8 |

Figure 11-6 |

Typical preamp out connections ........................................... |

11-9 |

Figure 11-7 |

Electrometer input circuitry (external feedback mode) ...... |

11-12 |

Figure 11-8 |

Shielded fixture construction .............................................. |

11-14 |

Figure 11-9 |

“Transdiode” logarithmic current configuration ................ |

11-15 |

Figure 11-10 |

Non-decade current gains ................................................... |

11-16 |

12 |

Remote Operation |

|

Figure 12-1 |

IEEE-488 connector ............................................................. |

12-5 |

Figure 12-2 |

IEEE-488 connections ......................................................... |

12-6 |

Figure 12-3 |

IEEE-488 connector location ............................................... |

12-7 |

Figure 12-4 |

RS-232 interface connector ............................................... |

12-18 |

13 |

Status Structure |

|

Figure 13-1 |

6514 status mode structure .................................................. |

13-3 |

Figure 13-2 |

16-bit status register ............................................................. |

13-6 |

Figure 13-3 |

Status byte and service request ............................................ |

13-7 |

Figure 13-4 |

Standard event status .......................................................... |

13-12 |

Figure 13-5 |

Operation event status ........................................................ |

13-13 |

Figure 13-6 |

Measurement event status .................................................. |

13-14 |

Figure 13-7 |

Questionable event status ................................................... |

13-15 |

16 |

DISPlay, FORMat, and SYSTem |

|

Figure 16-1 |

ASCII data format ................................................................ |

16-5 |

Figure 16-2 |

IEEE-754 single precision data format (32 data bits) .......... |

16-5 |

Figure 16-3 |

Key-press codes ................................................................. |

16-10 |

18 |

Performance Verification |

|

Figure 18-1 |

Connections for volts verification ...................................... |

18-10 |

Figure 18-2 |

Connections for 20µA-20mA range verification ............... |

18-12 |

Figure 18-3 |

Connections for 20pA-20µA range verification ................ |

18-13 |

Figure 18-4 |

Connections for ohms verification (2kΩ-20MΩ ranges) ... |

18-15 |

Figure 18-5 |

Connections for ohms verification |

|

|

(200MΩ-200GΩ ranges) .............................................. |

18-17 |

Figure 18-6 |

Connections for coulombs verification .............................. |

18-18 |

19 |

Calibration |

|

Figure 19-1 |

Connections for volts calibration ......................................... |

19-8 |

Figure 19-2 |

Connections for 20µA-20mA range calibration ................ |

19-10 |

Figure 19-3 |

Connections for 20pA-2mA range calibration ................... |

19-11 |

Figure 19-4 |

Connections for coulombs calibration ............................... |

19-14 |

Figure 19-5 |

Connections for ohms calibration |

|

|

(2kΩ and 2MΩ ranges) ................................................ |

19-16 |

Figure 19-6 |

Connections for ohms calibration (2GΩ range) ................ |

19-17 |

20 |

Routine Maintenance |

|

Figure 20-1 |

Power module ...................................................................... |

20-3 |

C |

General Measurement Considerations |

|

Figure C-1 |

Power line ground loops ........................................................ |

C-2 |

Figure C-2 |

Eliminating ground loops ...................................................... |

C-3 |

F |

IEEE-488 Bus Overview |

|

Figure F-1 |

IEEE-488 bus configuration .................................................. |

F-4 |

Figure F-2 |

IEEE-488 handshake sequence ............................................. |

F-6 |

Figure F-3 |

Command codes .................................................................... |

F-8 |

H |

Calibration Options |

|

Figure H-1 |

Data transfer connections ...................................................... |

H-2 |

List of Tables

1 |

Getting Started |

|

Table 1-1 |

SCPI commands - line frequency ........................................ |

1-10 |

Table 1-2 |

Default settings .................................................................... |

1-13 |

2 |

Measurement Concepts |

|

Table 2-1 |

Basic measurement capabilities ............................................. |

2-2 |

Table 2-2 |

SCPI commands — autozero ................................................. |

2-3 |

Table 2-3 |

Display messages for zero check and zero correct .............. |

2-13 |

Table 2-4 |

SCPI commands — zero check and zero correct ................. |

2-15 |

Table 2-5 |

SCPI commands — input bias current and offset |

|

|

voltage calibration .......................................................... |

2-18 |

Table 2-6 |

Summary of measurement considerations ........................... |

2-19 |

3 |

Volts and Ohms Measurements |

|

Table 3-1 |

SCPI commands — volts and ohms function ........................ |

3-7 |

4 |

Amps Measurements |

|

Table 4-1 |

SCPI commands — amps function ........................................ |

4-8 |

Table 4-2 |

Minimum recommended source resistance values .............. |

4-11 |

5 |

Coulombs Measurements |

|

Table 5-1 |

SCPI commands — coulombs function ................................. |

5-5 |

6 |

Range, Units, Digits, Rate, and Filters |

|

Table 6-1 |

Measurement ranges .............................................................. |

6-2 |

Table 6-2 |

SCPI commands — range and digits ..................................... |

6-4 |

Table 6-3 |

SCPI commands — rate ......................................................... |

6-7 |

Table 6-4 |

SCPI commands — filters ................................................... |

6-10 |

7 |

Relative, mX+b and Percent (%) |

|

Table 7-1 |

Range symbols for rel values ................................................. |

7-3 |

Table 7-2 |

SCPI commands — relative (null) ......................................... |

7-3 |

Table 7-3 |

SCPI commands — mX+b and percent ................................. |

7-6 |

8 |

Buffer |

|

Table 8-1 |

SCPI commands — buffer ..................................................... |

8-4 |

9 |

Triggering |

|

Table 9-1 |

Auto delay settings ................................................................. |

9-6 |

Table 9-2 |

SCPI commands — triggering ............................................... |

9-9 |

10 |

Limit Tests |

|

Table 10-1 |

Test limit display messages .................................................. |

10-3 |

Table 10-2 |

SCPI commands — limit tests ........................................... |

10-12 |

11 |

Digital I/O, Analog Outputs, and External Feedback |

|

Table 11-1 |

SCPI commands — digital outputs ...................................... |

11-6 |

Table 11-2 |

Example 2V analog output values ........................................ |

11-7 |

Table 11-3 |

Full-range preamp out values ............................................. |

11-10 |

Table 11-4 |

SCPI commands — external feedback ............................... |

11-17 |

12 |

Remote Operation |

|

Table 12-1 |

General bus commands ........................................................ |

12-8 |

Table 12-2 |

PC serial port pinout ........................................................... |

12-19 |

Table 12-3 |

RS-232 connector pinout .................................................... |

12-19 |

13 |

Status Structure |

|

Table 13-1 |

Common and SCPI commands — reset registers and |

|

|

clear queues .................................................................... |

13-4 |

Table 13-2 |

SCPI command — data formats for reading |

|

|

status registers ................................................................ |

13-6 |

Table 13-3 |

Common commands — status byte and service request |

|

|

enable registers ............................................................... |

13-9 |

Table 13-4 |

Common and SCPI commands — condition registers ....... |

13-16 |

Table 13-5 |

Common and SCPI commands — event registers ............. |

13-16 |

Table 13-6 |

Common and SCPI commands — event enable |

|

|

registers ......................................................................... |

13-17 |

Table 13-7 |

SCPI commands — error queue ......................................... |

13-20 |

14 |

Common Commands |

|

Table 14-1 |

IEEE-488.2 common commands and queries ...................... |

14-2 |

15 |

SCPI Signal Oriented Measurement Commands |

|

Table 15-1 |

Signal oriented measurement command summary .............. |

15-2 |

16 |

DISPlay, FORMat, and SYSTem |

|

Table 16-1 |

SCPI commands — display ................................................. |

16-2 |

Table 16-2 |

SCPI commands — data format ........................................... |

16-4 |

Table 16-3 |

SCPI commands — system .................................................. |

16-8 |

17 |

SCPI Reference Tables |

|

Table 17-1 |

CALCulate command summary |

.......................................... 17-2 |

Table 17-2 |

FORMat command summary ............................................... |

17-5 |

Table 17-3 |

DISPlay command summary ............................................... |

17-5 |

Table 17-4 |

SENSe command summary ................................................. |

17-6 |

Table 17-5 |

STATus command summary ................................................ |

17-9 |

Table 17-6 |

SOURce command summary ............................................... |

17-9 |

Table 17-7 |

SYSTem command summary ............................................ |

17-11 |

Table 17-8 |

TRACe command summary .............................................. |

17-12 |

Table 17-9 |

TRIGger command summary ............................................ |

17-13 |

18 |

Performance Verification |

|

Table 18-1 |

Recommended verification equipment ................................ |

18-4 |

Table 18-2 |

Voltage measurement accuracy reading limits ................... |

18-11 |

Table 18-3 |

20mA-20mA range current measurement accuracy |

|

|

reading limits ................................................................ |

18-13 |

Table 18-4 |

20pA-2µA range current measurement accuracy |

|

|

reading limits ................................................................ |

18-14 |

Table 18-5 |

2kΩ-20MΩ range resistance measurement |

|

|

accuracy limits ............................................................. |

18-16 |

Table 18-6 |

200MΩ-200GΩ resistance measurement |

|

|

accuracy limits ............................................................. |

18-17 |

Table 18-7 |

Coulombs measurement accuracy reading limits .............. |

18-19 |

19 |

Calibration |

|

Table 19-1 |

Recommended calibration equipment ................................. |

19-4 |

Table 19-2 |

Calibration menu ................................................................. |

19-5 |

Table 19-3 |

Volts calibration summary ................................................... |

19-9 |

Table 19-4 |

20mA-20mA range amps calibration summary ................. |

19-11 |

Table 19-5 |

20pA-2µA range amps calibration summary ..................... |

19-13 |

Table 19-6 |

Coulombs calibration summary ......................................... |

19-15 |

Table 19-7 |

Ohms calibration summary ................................................ |

19-17 |

20 |

Routine Maintenance |

|

Table 20-1 |

Power line fuse ..................................................................... |

20-3 |

Table 20-2 |

Front panel tests ................................................................... |

20-4 |

B |

Status and Error Messages |

|

Table B-1 |

Status and error messages ..................................................... |

B-2 |

D |

DDC Emulation Commands |

|

Table D-1 |

Device dependent command summary ................................. |

D-2 |

F |

IEEE-488 Bus Overview |

|

Table F-1 |

IEEE-488 bus command summary ........................................ |

F-7 |

Table F-2 |

Hexadecimal and decimal command codes ........................ |

F-10 |

Table F-3 |

Typical bus sequence ........................................................... |

F-11 |

Table F-4 |

Typical addressed command sequence ................................ |

F-11 |

Table F-5 |

IEEE command groups ....................................................... |

F-12 |

Table F-6 |

Model 6514 interface function codes .................................. |

F-13 |

G |

IEEE-488 and SCPI Conformance Information |

|

Table G-1 |

IEEE-488 documentation requirements ................................ |

G-2 |

Table G-2 |

Coupled commands ............................................................... |

G-4 |

H |

Calibration Options |

|

Table H-1 |

Calibration commands .......................................................... |

H-4 |

1

Getting Started

•General information — Covers general information that includes warranty information, contact information, safety symbols and terms, inspection, and available options and accessories.

•System electrometer features — Summarizes the features of Model 6514.

•Front and rear panel familiarization — Summarizes the controls and connectors of the instrument.

•Power-up — Covers line power connection, line voltage setting, fuse replacement, power line frequency, and the power-up sequence.

•Display — Provides information about the display of Model 6514.

•Default settings — Covers the five instrument setup configurations available to the user; three user defined, GPIB defaults, or factory defaults.

•SCPI programming — Explains how SCPI commands are presented in this manual.

1-2 Getting Started

General information

Warranty information

Warranty information is located at the front of this manual. Should your Model 6514 require warranty service, contact the Keithley representative or authorized repair facility in your area for further information. When returning the instrument for repair, be sure to fill out and include the service form at the back of this manual to provide the repair facility with the necessary information.

Contact information

Worldwide phone numbers are listed at the front of this manual. If you have any questions, please contact your local Keithley representative or call one of our Application Engineers at 1-800-348-3735 (U.S. and Canada only).

Safety symbols and terms

The following symbols and terms may be found on the instrument or used in this manual:

The ! symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The  symbol on the instrument shows that high voltage may be present on the terminal(s). Use standard safety precautions to avoid personal contact with these voltages.

symbol on the instrument shows that high voltage may be present on the terminal(s). Use standard safety precautions to avoid personal contact with these voltages.

The WARNING heading used in this manual explains dangers that might result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading used in this manual explains hazards that could damage the instrument. Such damage may invalidate the warranty.

Inspection

Model 6514 was carefully inspected electrically and mechanically before shipment. After unpacking all items from the shipping carton, check for any obvious signs of physical damage that may have occurred during transit. (There may be a protective film over the display lens, which can be removed). Report any damage to the shipping agent immediately. Save the original packing carton for possible future shipment. The following items are included with every Model 6514 order:

•Model 6514 System Electrometer with line cord.

•Model 237-ALG-2 triax cable.

•Accessories as ordered.

•Certificate of calibration.

•Model 6514 Instruction Manual (P/N 6514-901-01).

•Manual Addenda (pertains to any improvements or changes concerning the instrument or manual).

If an additional manual is required, order the appropriate manual package. The manual packages include a manual and any pertinent addenda.

Getting Started |

1-3 |

|

|

Options and accessories

Input cables, connectors and adapters

Model 237-ALG-2 — This is a 6.6 ft (2-meter) low-noise triax cable terminated with a 3-slot male triax connector on one end and 3 alligator clips on the other. (One Model 237-ALG-2 is included).

Model 237-BNC-TRX adapter — This is a male BNC to 3-lug female triax connector (guard disconnected). It is used to terminate a triax cable with a BNC plug.

Model 237-TRX-T adapter — This is a 3-slot male to dual 3-lug female triax tee adapter for use with 7078-TRX triax cables.

Model 237-TRX-TBC connector — This is a 3-lug female triax bulkhead (internal mount) connector with cap for assembly of custom test fixtures and interface connections.

Model 7078-TRX-TBC connector — This is a 3-lug female triax bulkhead (external mount) connector with cap for assembly of custom test fixtures and interface connections.

Model 7078-TRX-3, 7078-TRX-10 and Models 7078-TRX-20 triax cables — These are low noise triax cables terminated at both ends with 3-slot male triax connectors. The -3 model is 3 ft (0.9m) in length, the -10 model is 10 ft (3m) in length, and the -20 model is 20 ft (6m) in length.

CS-751 barrel adapter — This is a barrel adapter that allows you to connect two triax cables together. Both ends of the adapter are terminated with 3-lug female triax connectors.

GPIB and trigger link cables and adapters

Models 7007-1 and 7007-2 shielded GPIB cables — Connect Model 6514 to the GPIB bus using shielded cables and connectors to reduce electromagnetic interference (EMI). Model 7007-1 is lm long; Model 7007-2 is 2m long.

Models 8501-1 and 8501-2 trigger link cables — Connect Model 6514 to other instruments with Trigger Link connectors (e.g., Model 7001 Switch System). Model 8501-1 is lm long; Model 8501-2 is 2m long.

Model 8502 trigger link adapter — Lets you connect any of the six trigger link lines of

Model 6514 to instruments that use the standard BNC trigger connectors.

Model 8503 DIN to BNC trigger cable — Lets you connect trigger link lines one (Voltmeter Complete) and two (External Trigger) of Model 6514 to instruments that use BNC trigger connectors. Model 8503 is lm long.

1-4 Getting Started

Rack mount kits

Model 4288-1 single fixed rack mount kit — Mounts a single Model 6514 in a standard 19-inch rack.

Model 4288-2 side-by-side rack mount kit — Mounts two instruments (Models 182, 428, 486, 487, 2000, 2001, 2002, 2010, 2400, 2410, 2420, 2430, 6430, 6514, 6517 A, 7001) side-by-side in a standard 19-inch rack.

Model 4288-4 side-by-side rack mount kit — Mounts Model 6514 and a 5.25-inch instrument (Models 195A, 196, 220, 224, 230, 263, 595, 614, 617, 705, 740, 775A, 6512) side-by-side in a standard 19-inch rack.

Carrying case

Model 1050 padded carrying case — A carrying case for Model 6514. Includes handles and shoulder strap.

System electrometer features

Model 6514 is a 6½-digit high-performance system electrometer. It can measure voltage, current, resistance and charge. Details on its measurement capabilities are explained in Section 2 of this manual (see “Measurement Overview”).

Features of Model 6514 System Electrometer include:

•Setup storage — Five instrument setups (three user, GPIB defaults and factory defaults) can be saved and recalled.

•mX+b and percent — These calculations provide mathematical manipulation of readings.

•Relative — Null offsets or establish baseline values.

•Buffer — Store up to 2500 readings in the internal buffer.

•Limits — Set up to two stages of high and low reading limits to test devices.

•Digital I/O port — Four output lines and one input line to control external circuitry. Use as an interface between limit tests and component handler.

•Analog outputs — Provides a 2V analog output for a full range input. Preamp out provides a driven guard for Volts, or can be used for external feedback measurements.

•External feedback — Extends the measurement capabilities of the electrometer; logarithmic currents, non-decade current ranges and non-standard charge ranges.

•Remote interface — Model 6514 can be controlled using the IEEE-488 interface (GPIB) or the RS-232 interface.

•GPIB programming language — When using the GPIB, the instrument can be programmed using the SCPI or DDC programming language.

Getting Started |

1-5 |

|

|

Front and rear panel familiarization

Front panel summary

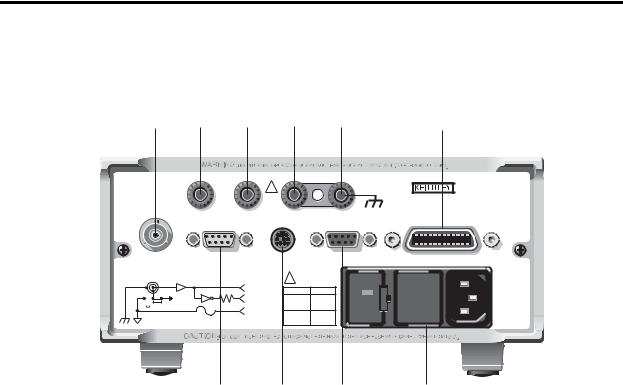

The front panel of Model 6514 is shown in Figure 1-1.

Figure 1-1

Model 6514

front panel 4

1

REM |

STEP SCAN |

CH1 |

CH2 |

CH3 |

CH4 |

CH5 |

CH6 |

CH7 |

CH8 CH9 |

CH10 MATH |

TALK |

|

|

|

|

|

|

|

|

|

REAR |

LSTN |

|

|

|

|

|

|

|

|

|

|

SRQ |

|

|

|

|

|

|

|

|

|

|

SHIFT |

|

|

|

|

|

|

|

|

|

4W |

TIMER |

HOLD TRIG |

FAST |

MED |

SLOW |

REL |

FILT |

AUTO |

ERR |

BUFFER |

STAT |

|

|

|

|

|

|

|

6514 SYSTEM ELECTROMETER |

|

|

|

|

V-DROP AUTO-DIS |

GPIB |

RS-232 |

|

||

SHIFT |

V |

I |

Ω |

Q |

XFBK |

ZCHK |

ZCOR GRD |

|

|

||||||||

|

|

|

|

|

|

|

RANGE |

|

LOCAL |

MX+B |

% |

VAL |

CONF-LIM |

UNITS |

NPLC |

AUTO |

|

AVG |

MEDN |

REL |

LIMIT |

DIGIT |

RATE |

|||

|

|

|||||||

POWER |

TEST |

CAL |

SAVE |

SETUP |

CONF-ARM CONF-TRIG |

RANGE |

||

|

||||||||

STORE |

RCLL |

DELAY |

DAMP |

HALT |

TRIG |

EXIT |

ENTER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

3 |

5 |

|

|

||

NOTE Most keys provide a dual function or operation. The nomenclature on a key indicates its unshifted function/operation, which is selected by pressing the key. Nomenclature

(in blue) above a key indicates its shifted function. A shifted function is selected by pressing the SHIFT key and then the function/operation key.

1 Special keys and power switch

SHIFT |

Use to select a shifted function or operation. |

LOCAL |

Cancels GPIB remote mode. |

POWER |

Power switch. In position turns 6514 on (I), out position turns it off (O). |

2 Function and operation keys

Top Row |

|

Unshifted |

|

V |

Selects voltage measurement function. |

I |

Selects current measurement function. |

ΩSelects resistance measurement function.

Q |

Selects charge measurement function. |

XFBK |