Keithley 2001 User Manual

Model 2001 Multimeter

Quick Reference Guide

Model 2001 Multimeter

Quick Reference Guide

1992, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio 44139

U.S.A.

Document Number: 2001-903-01 Rev. B

Table of Contents |

|

Safety Precautions ....................................................... |

1 |

Introduction ................................................................ |

5 |

Operation Summary.................................................... |

6 |

Multiple Displays ....................................................... |

11 |

Menu Structures ........................................................ |

13 |

Default Conditions .................................................... |

32 |

Error and Status Messages ......................................... |

48 |

IEEE-488.2 Common Commands and Queries........... |

56 |

SCPI Command Subsystems ...................................... |

58 |

Safety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read the operating information carefully before using the product.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating, for example, setting the line voltage or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, and perform safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test fixtures. The American National Standards Institute (ANSI)

1

states that a shock hazard exists when voltage levels greater than 30V RMS, 42.4V peak, or 60VDC are present. A good safety practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

Users of this product must be protected from electric shock at all times. The responsible body must ensure that users are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential human contact. Product users in these circumstances must be trained to protect themselves from the risk of electric shock. If the circuit is capable of operating at or above 1000 volts, no conductive part of the circuit may be exposed.

As described in the International Electrotechnical Commission (IEC) Standard IEC 664, digital multimeter measuring circuits (e.g., Keithley Models 175A, 199, 2000, 2001, 2002, and 2010) are Installation Category II. All other instruments’ signal terminals are Installation Category I and must not be connected to mains.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance limited sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

2

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a lid interlock.

If a  screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

The ! symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The  symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal and common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal and common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The WARNING heading in a manual explains dangers that might result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

3

The CAUTION heading in a manual explains hazards that could damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the power transformer, test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals, may be used if the rating and type are the same. Other components that are not safety related may be purchased from other suppliers as long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments to maintain accuracy and functionality of the product.) If you are unsure about the applicability of a replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with no case or chassis (e.g., data acquisition board for installation into a computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper cleaning/servicing.

2/99

4

Introduction

This quick reference guide includes summary information on front panel and IEEE-488 operation for the Model 2001 Multimeter. For detailed information, consult the Model 2001 Operator’s Manual, the Model 2001 Calibration Manual, and the Model 2001-SCAN Scanner Card Instruction Manual.

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

5

Operation Summary

Default Configuration

The Model 2001 can save from one to ten user setups in memory, depending on the installed memory option. You can select one of the user setups as the power-on default, or have the instrument power up to either of the two factory defaults (optimized for “BENCH” or “GPIB” operation). Reset the instrument to “BENCH” defaults from the front panel by performing the following steps:

1. Press the MENU key to display the main menu:

MAIN MENU

SAVESETUP GPIB CALIBRATION

TEST LIMITS STATUS-MSG GENERAL

TEST LIMITS STATUS-MSG GENERAL

2.If the SAVESETUP option is not blinking, press the

key until it is blinking and then press ENTER to

key until it is blinking and then press ENTER to

view the setup menu:

SETUP MENU

SAVE RESTORE POWERON RESET

3.Select the RESET option and press ENTER to view the reset menu:

RESET ORIGINAL DFLTS

BENCH GPIB

4.Select the BENCH option and press ENTER. The following message is displayed:

RESETTING INSTRUMENT

ENTER to confirm; EXIT to abort

5.Press ENTER to confirm. The display will show DC voltage readings with autorange enabled.

6

Assuming the Model 2001 is set to primary address 16, the instrument can be reset and the reading displayed on the computer CRT from the IEEE-488 bus with the following code fragment:

100 OUTPUT 716;“:syst:pres”

110 OUTPUT 716;“:fetc?”

120 ENTER 716;A$

130 PRINT A$

Instrument Connections

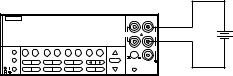

Each measurement function has an appropriate connection scheme. Connections for all functions can be found in Section 3 of the Model 2001 Operator’s Manual. The following steps summarize making DC voltage measurements with the Model 2001:

1.Select the front input jacks with the INPUTS button (outer position for front jacks, inner position for rear).

2.Using the set of supplied test leads, connect the Model 2001 to a DC voltage source (e.g., a battery) as shown in Figure 1.

3.Use the RANGE keys to select autoranging or a manual range. Pressing the AUTO range key toggles autoranging. You can select a different range with the  RANGE and

RANGE and  RANGE keys. The following code statement enables autoranging on the DCV function:

RANGE keys. The following code statement enables autoranging on the DCV function:

100 OUTPUT 716;“:volt:dc:rang:auto on”

7

|

|

|

|

Model 2001 |

|

|

|

||||

|

|

|

|

|

|

|

|

|

SENSE |

INPUT |

|

|

|

|

|

|

|

|

|

|

Ω 4 WIRE |

|

|

|

|

|

|

|

|

|

|

|

HI |

|

|

|

|

|

|

|

|

|

|

350V |

|

1100V |

DC Voltage |

|

|

|

|

|

|

|

|

PEAK |

PEAK |

Source |

|

|

|

|

|

|

|

|

2001 MULTIMETER |

|

|

||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

LO |

500V |

|

|

|

|

|

|

|

|

|

|

INPUTS |

PEAK |

|

PREV |

DCV |

ACV |

DCI |

ACI |

Ω2 |

Ω4 |

FREQ |

TEMP |

|

|

|

DISPLAY |

|

|

|

|

|

|

|

F |

R |

|

|

|

|

|

|

|

|

|

RANGE |

|

|

|

|

NEXT |

REL |

TRIG |

STORE RECALL |

FILTER |

MATH |

|

AUTO |

|

|

|

|

POWER |

|

RANGE |

|

AMPS |

|

||||||

|

|

|

|

|

|

|

CAL |

|

|

||

|

INFO |

LOCAL |

CHAN |

SCAN |

CONFIG MENU |

EXIT |

ENTER |

|

|

|

|

Input Resistance = 10MΩ on 1000V and 200V ranges ;

> 10GΩ on 20V, 2V and 200mV ranges.

= 1MΩ on DCV peak spikes measurement.

Caution : Maximum Input = 1100V peak

Figure 1. Typical DC voltage connections

Changing the Configuration

Each measurement function and operation has the default settings that are listed in Table 18. For example, the default settings for DC voltage are as follows:

•Measurement speed (integration time) Normal, 1 power line cycle.

•Digital filter Advanced, 10 readings, 1% noise tolerance, moving average.

•Display resolution 6.5 digits.

If these settings are not sufficient for your application, they can be changed through configuration menus. For example, to configure the DC voltage function to store high speed measurements, follow these steps:

1. Press CONFIG key and then the DCV key to view

8

the DCV configuration menu:

CONFIGURE DCV

SPEED FILTER RESOLUTION

2.Select SPEED from the menu, then press ENTER. The multimeter displays the following menu:

DCV MEASUREMENT SPEED

NORMAL FAST MEDIUM HIACCURACY

SET-SPEED-EXACTLY SET-BY-RESLN

SET-SPEED-EXACTLY SET-BY-RESLN

3.Using the cursor keys, select the FAST option, then press ENTER. Since the resolution is set to AUTO, where it defaults to a value appropriate for the speed, it will be set to 4.5d automatically.

4.Press EXIT to return to the normal display.

To store readings in the instrument’s data storage buffer, perform the following:

1.Press the STORE key. The following message is displayed:

STORE 00100 READINGS

Use  ,

,  ,

,  ,

,  , ENTER, EXIT, or INFO

, ENTER, EXIT, or INFO

2.Use the cursor and RANGE keys to change the number of readings stored, or just press ENTER to start storing readings.

To recall the stored readings, perform the following:

1.Press RECALL to view the readings. The following message is displayed with the cursor on the least significant digit of the reading number:

9

+000.0000 mVDC

Rdg#+00000 @Time =+000.000000 sec

2.Use the RANGE keys to increment and decrement the reading number and scroll through the buffer.

3.The NEXT and PREV DISPLAY keys can be used while recalling readings to access additional buffer data, such as maximum and minimum readings.

The following code fragment configures the Model 2001 for high speed DC voltage readings, stores 100 readings, and sends the readings over the bus:

100 OUTPUT 716;“:syst:pres”

110 OUTPUT 716;“:volt:dc:nplc 0.01”

120 OUTPUT 716;“:trac:clear”

130 OUTPUT 716;“:trac:feed calc”

140 OUTPUT 716;“:trac:egr full”

150 OUTPUT 716;“:trac:poin 100”

160 OUTPUT 716;“:trac:feed:cont next”

170 OUTPUT 716;“:trac:data?”

180 ENTER 716;A$

190 PRINT A$

10

Multiple Displays

Each measurement function has its own set of “multiple displays” shown on the bottom line of the front panel display. To scroll through the multiple displays available for the present function, repeatedly press and release the NEXT DISPLAY key. The same action with the PREVious DISPLAY key does a reverse scroll through the displays. To return to the default reading display, just press and hold either key.

Table 1. Multiple displays by function

Function |

Next display |

|

|

All |

Bar graph |

|

Zero-centered bar graph |

|

Maximum and minimum values |

|

Relative and actual values |

|

Calculated and actual values (see Note 1) |

|

Limits bar graph (see Note 1) |

|

Adjacent channel readings (see Note 2) |

DC voltage |

DC volts, AC ripple voltage and frequency |

|

Positive peak spikes and highest value |

|

Negative peak spikes and lowest value |

|

Positive and negative peak spikes |

AC voltage |

AC RMS voltage, frequency, and crest factor |

|

AC RMS, average, and peak voltages |

DC current |

(none specific to function) |

AC current |

AC RMS (or average) current and frequency |

|

AC RMS and average current |

2-wire resistance |

Source current |

|

Voltage drop across DUT |

4-wire resistance |

Source current |

|

Voltage drop across DUT |

|

Lead resistance |

Frequency |

Period calculation |

|

Trigger level |

|

|

|

11 |

Table 1. Multiple displays by function (cont.)

Function |

Next display |

|

|

Temperature |

Celsius, Fahrenheit, and Kelvin units |

|

RTD resistance (or thermocouple voltage) |

|

Reference junction (thermocouples only) |

Data storage buffer Maximum and minimum values Average and standard deviation

Notes:

1.Multiple displays for calculated values and limits bar graph are not available for the frequency function.

2.The multiple display for adjacent channel readings is not available for the DC and AC current functions.

12

Menu Structures

The desired menu is displayed by pressing the appropriate key or sequence:

•CONFIG and then DCV (or ACV, DCI, ACI, Ω2, Ω4, FREQ, TEMP) Shows the configuration menu for each measurement function.

•CONFIG and then NEXT DISPLAY (or PREV DIS-

PLAY, REL, TRIG, STORE, FILTER, MATH, CHAN, SCAN) Shows the configuration menu for the multiple displays and each measurement operation.

•MENU The main menu accesses items for which there are not dedicated keys.

Once in a menu structure, place the cursor ( and

and  keys) on the desired selection and press ENTER. Use the cursor keys, RANGE

keys) on the desired selection and press ENTER. Use the cursor keys, RANGE  and RANGE

and RANGE  keys to enter parameters. Use the EXIT key to back out of a menu structure and disable a menu.

keys to enter parameters. Use the EXIT key to back out of a menu structure and disable a menu.

Table 2. CONFIGURE DCV menu structure

Menu item |

Description |

|

|

SPEED |

Measurement speed (integration time) |

|

menu: |

NORMAL |

Select 1 PLC (power line cycle, |

|

16.67msec for 60Hz, 20msec for |

|

50Hz and 400Hz). |

FAST |

Select 0.01 PLC. |

MEDIUM |

Select 0.1 PLC. |

HIACCURACY |

Select 10 PLC. |

SET-SPEED-EXACTLY |

Set integration time in PLC |

|

(0.01-10). |

SET-BY-RSLN |

Default to setting appropriate for |

|

resolution. |

ANALOG-FILTER |

Enable (ON) or disable (OFF) analog |

|

filter. |

|

|

|

13 |

Table 2. CONFIGURE DCV menu structure (cont.)

Menu item |

Description |

|

|

FILTER |

Digital filter menu: |

AUTO |

Default to filter appropriate for |

|

integration time. |

AVERAGING |

Program a simple average filter |

|

(1-100 readings). |

ADVANCED |

Program a simple average filter |

|

(1-100 readings) with a noise tol- |

|

erance window (0-100% of |

|

range). |

AVERAGING-MODE |

Select moving average or repeat- |

|

ing average mode. |

RESOLUTION |

Display resolution menu: |

AUTO |

Default to resolution appropriate |

|

for integration time. |

3.5d, 4.5d, 5.5d, 6.5d, |

Select a specific resolution. |

7.5d |

|

|

|

Table 3. CONFIGURE ACV menu structure

Menu item |

Description |

|

|

SPEED |

Measurement speed (integration time) |

|

menu: |

NORMAL |

Select 1 PLC (power line cycle, |

|

16.67msec for 60Hz, 20msec for |

|

50Hz and 400Hz). |

FAST |

Select 0.01 PLC. |

MEDIUM |

Select 0.1 PLC. |

HIACCURACY |

Select 10 PLC. |

SET-SPEED-EXACTLY |

Set integration time in PLC (0.01-10). |

SET-BY-RSLN |

Default to setting appropriate for res- |

|

olution. |

FILTER |

Digital filter menu: |

AUTO |

Default to filter appropriate for inte- |

|

gration time. |

AVERAGING |

Program a simple average filter |

|

(1-100 readings). |

ADVANCED |

Program a simple average filter |

|

(1-100 readings) with a noise tol- |

|

erance window (0-100% of |

|

range). |

AVERAGING-MODE |

Select moving average or repeating |

|

average mode. |

|

|

14

Table 3. CONFIGURE ACV menu structure (cont.)

Menu item |

Description |

|

|

RESOLUTION |

Display resolution menu: |

AUTO |

Default to resolution appropriate for |

|

integration time. |

3.5d, 4.5d, 5.5d, 6.5d, |

Select a specific resolution. |

7.5d |

|

UNITS |

Display units menu: |

VOLTS |

Select volts. |

dB |

Select dB and set voltage reference |

|

level. |

dBm |

Select dBm and set reference imped- |

|

ance. |

COUPLING |

Coupling menu: |

AC |

Select AC coupled measurements. |

AC+DC |

Select DC coupled measurements. |

AC-TYPE |

Type of ACV measurement menu: |

RMS |

Select true RMS ACV. |

AVERAGE |

Select average ACV. |

PEAK |

Select peak ACV. |

LOW-FREQ-RMS |

Select low frequency (typically |

|

<50Hz) true RMS ACV. |

POSITIVE-PEAK |

Select positive DCV peak spikes |

|

measurements. |

NEGATIVE-PEAK |

Select negative DCV peak spikes |

|

measurements. |

|

|

15

Table 4. CONFIGURE DCI menu structure

Menu item |

Description |

|

|

SPEED |

Measurement speed (integration time) |

|

menu: |

NORMAL |

Select 1 PLC (power line cycle, |

|

16.67msec for 60Hz, 20msec for |

|

50Hz and 400Hz). |

FAST |

Select 0.01 PLC. |

MEDIUM |

Select 0.1 PLC. |

HIACCURACY |

Select 10 PLC. |

SET-SPEED-EXACTLY |

Set integration time in PLC |

|

(0.01-10). |

SET-BY-RSLN |

Default to setting appropriate for |

|

resolution. |

FILTER |

Digital filter menu: |

AUTO |

Default to filter appropriate for inte- |

|

gration time. |

AVERAGING |

Program a simple average filter |

|

(1-100 readings). |

ADVANCED |

Program a simple average filter |

|

(1-100 readings) with a noise tol- |

|

erance window (0-100% of |

|

range). |

AVERAGING-MODE |

Select moving average or repeating |

|

average mode. |

RESOLUTION |

Display resolution menu: |

AUTO |

Default to resolution appropriate for |

|

integration time. |

3.5d, 4.5d, 5.5d, 6.5d, |

Select a specific resolution. |

7.5d |

|

MEASUREMENT-MODE |

Measurement mode menu: |

NORMAL |

Select normal current measurement |

|

(use AMPS terminals). |

IN-CIRCUIT |

Select in-circuit current measure- |

|

ment (use INPUT and SENSE ter- |

|

minals). |

|

|

16

Table 5. CONFIGURE ACI menu structure

Menu item |

Description |

|

|

SPEED |

Measurement speed (integration time) |

|

menu: |

NORMAL |

Select 1 PLC (power line cycle, |

|

16.67msec for 60Hz, 20msec for |

|

50Hz and 400Hz). |

FAST |

Select 0.01 PLC. |

MEDIUM |

Select 0.1 PLC. |

HIACCURACY |

Select 10 PLC. |

SET-SPEED-EXACTLY |

Set integration time in PLC (0.01-10). |

SET-BY-RSLN |

Default to setting appropriate for res- |

|

olution. |

FILTER |

Digital filter menu: |

AUTO |

Default to filter appropriate for inte- |

|

gration time. |

AVERAGING |

Program a simple average filter |

|

(1-100 readings). |

ADVANCED |

Program a simple average filter |

|

(1-100 readings) with a noise toler- |

|

ance window (0-100% of range). |

AVERAGING-MODE |

Select moving average or repeating |

|

average mode. |

RESOLUTION |

Display resolution menu: |

AUTO |

Default to resolution appropriate for |

|

integration time. |

3.5d, 4.5d, 5.5d, 6.5d, |

Select a specific resolution. |

7.5d |

|

COUPLING |

Coupling menu: |

AC |

Select AC coupled measurements. |

AC+DC |

Select DC coupled measurements. |

AC-TYPE |

Type of ACI measurement menu: |

RMS |

Select true RMS ACI. |

AVERAGE |

Select average ACI. |

|

|

17

Table 6. CONFIGURE OHMS-2W menu structure

Menu item |

Description |

|

|

SPEED |

Measurement speed (integration time) |

|

menu: |

NORMAL |

Select 1 PLC (power line cycle, |

|

16.67msec for 60Hz, 20msec for |

|

50Hz and 400Hz). |

FAST |

Select 0.01 PLC. |

MEDIUM |

Select 0.1 PLC. |

HIACCURACY |

Select 10 PLC. |

SET-SPEED-EXACTLY |

Set integration time in PLC |

|

(0.01-10). |

SET-BY-RSLN |

Default to setting appropriate for |

|

resolution. |

FILTER |

Digital filter menu: |

AUTO |

Default to filter appropriate for inte- |

|

gration time. |

AVERAGING |

Program a simple average filter |

|

(1-100 readings). |

ADVANCED |

Program a simple average filter |

|

(1-100 readings) with a noise tol- |

|

erance window (0-100% of |

|

range). |

AVERAGING-MODE |

Select moving average or repeating |

|

average mode. |

RESOLUTION |

Display resolution menu: |

AUTO |

Default to resolution appropriate for |

|

integration time. |

3.5d, 4.5d, 5.5d, 6.5d, |

Select a specific resolution. |

7.5d |

|

OFFSETCOMP |

Enable/disable offset compensation |

|

(20Ω-20kΩ ranges). |

MAXAUTORANGE |

Set upper limit for autoranging of 2- |

1GΩ, 200MΩ, 20MΩ, |

wire resistance. |

Select a specific range. |

|

2MΩ, 200kΩ, 20kΩ |

|

|

|

18

Table 7. CONFIGURE OHMS-4W menu structure

Menu item |

Description |

|

|

SPEED |

Measurement speed (integration time) |

|

menu: |

NORMAL |

Select 1 PLC (power line cycle, |

|

16.67msec for 60Hz, 20msec for |

|

50Hz and 400Hz). |

FAST |

Select 0.01 PLC. |

MEDIUM |

Select 0.1 PLC. |

HIACCURACY |

Select 10 PLC. |

SET-SPEED-EXACTLY |

Set integration time in PLC (0.01-10). |

SET-BY-RSLN |

Default to setting appropriate for res- |

|

olution. |

FILTER |

Digital filter menu: |

AUTO |

Default to filter appropriate for inte- |

|

gration time. |

AVERAGING |

Program a simple average filter |

|

(1-100 readings). |

ADVANCED |

Program a simple average filter |

|

(1-100 readings) with a noise tol- |

|

erance window (0-100% of |

|

range). |

AVERAGING-MODE |

Select moving average or repeating |

|

average mode. |

RESOLUTION |

Display resolution menu: |

AUTO |

Default to resolution appropriate for |

|

integration time. |

3.5d, 4.5d, 5.5d, 6.5d, |

Select a specific resolution. |

7.5d |

|

OFFSETCOMP |

Enable/disable offset compensation |

|

(20Ω-20kΩ ranges). |

MAXAUTORANGE |

Set upper limit for autoranging of 4- |

200kΩ, 20kΩ, 2kΩ |

wire resistance. |

Select a specific range. |

|

|

|

19

Table 8. CONFIGURE FREQUENCY menu structure

Menu item |

Description |

|

|

MAX-SIGNAL-LEVEL |

Display maximum signal level |

|

menu: |

1V, 10V, 100V, 1000V, TTL |

Select maximum voltage level |

|

for voltage inputs. |

1mA, 10mA, 100mA, 1A |

Select maximum current level |

|

for current inputs. |

RESOLUTION |

Display resolution menu: |

4-DIGITS, 5-DIGITS |

Select a specific resolution. |

INPUT-TERMINALS |

Input terminals for frequency |

|

measurements menu: |

VOLTAGE |

Select INPUT HI and INPUT |

|

LO terminals. |

CURRENT |

Select AMPS and INPUT LO |

|

terminals. |

COUPLING |

Coupling menu: |

AC |

Select AC coupled measure- |

|

ments. |

AC+DC |

Select DC coupled measure- |

|

ments. |

|

|

Note: The maximum signal level menu is coupled to the input terminals menu, i.e., voltage levels are shown if voltage is the selected input.

20

Table 9. CONFIG TEMPERATURE menu structure

Menu item |

Description |

|

|

SENSOR |

Sensor type menu: |

4-WIRE-RTD |

4-wire RTD type menu: |

PT385 |

Select a PT385 type. |

PT3916 |

Select a PT3916 type. |

USER-RTD |

Select desired R-zero, alpha, |

|

beta, and delta. |

RTD |

2-wire RTD type menu: |

PT385 |

Select a PT385 type. |

PT3916 |

Select a PT3916 type. |

USER-RTD |

Select desired R-zero, alpha, |

|

beta, and delta. |

SENSOR |

|

THERMOCOUPLE |

Thermocouple setup menu: |

THERMOCOUPLE-TYPE |

Select desired thermocouple |

|

type (J, K, T, E, R, S, B). |

REF-JUNCTIONS |

Configure reference junction |

|

menu (JN1 thru JN5): |

CONFIGURE |

Configure simulated or real |

|

junction. |

ACQUIRE-REF-TEMP |

Acquire reference tempera- |

|

ture. |

UNITS |

Temperature units menu: |

DEG-C, DEG-F, K |

Select desired temperature |

|

units. |

SPEED |

Measurement speed (integration |

|

time) menu: |

NORMAL |

Select 1 PLC (power line cycle, |

|

16.67msec for 60Hz, 20msec |

|

for 50Hz and 400Hz). |

FAST |

Select 0.01 PLC. |

MEDIUM |

Select 0.1 PLC. |

HIACCURACY |

Select 10 PLC. |

SET-SPEED-EXACTLY |

Set integration time in PLC |

|

(0.01-10). |

SET-BY-RSLN |

Default to setting appropriate |

|

for resolution. |

|

|

21

Table 9. CONFIG TEMPERATURE menu structure (cont.)

Menu item |

Description |

|

|

FILTER |

Digital filter menu: |

AUTO |

Default to filter appropriate for |

|

integration time. |

AVERAGING |

Select simple average filter |

|

(1-100 readings). |

AVERAGING-MODE |

Select moving average or |

|

repeating average mode. |

RESLN |

Display resolution menu: |

AUTO |

Default to resolution appropri- |

|

ate for sensor. |

1°, 0.1°, 0.01°, 0.001° |

Select a specific resolution. |

|

|

22

Table 10. CONFIGURE TRIGGER menu structure

Menu item |

Description |

|

|

MEASURE |

Measure layer menu: |

SOURCE |

Select measure source: |

IMMEDIATE |

Use to make measure- |

EXTERNAL |

ments immediately. |

Use external triggers to |

|

|

control measuring. |

MANUAL |

Use TRIG key to control |

|

measuring. |

GPIB |

Use bus triggers to control |

|

measuring. |

TRIGLINK |

Use Trigger Link triggers to |

|

control measuring. Enter |

|

Trigger Link mode and |

|

lines. |

TIMER |

Use a timer to control mea- |

|

suring and enter interval |

|

between triggers (0.001- |

|

999999.999sec). |

HOLD |

Use to hold up the mea- |

|

surement in the measure |

|

layer. |

DELAY |

Use to delay measurement in |

|

the measure layer (0.001- |

|

999999.999sec). |

COUNT |

Define number of measure- |

|

ments to make: |

INFINITE |

Repeat measuring indefi- |

|

nitely. |

ENTER-CHAN-COUNT |

Count = use defined value |

|

(1-99999). |

CONTROL |

Select trigger control mode: |

SOURCE |

Enable Source Bypass. |

ACCEPTOR |

Disable Source Bypass. |

|

|

23

Table 10. CONFIGURE TRIGGER menu structure (cont.)

Menu item |

Description |

|

|

SCAN |

Scan layer menu: |

SOURCE |

Select scan source: |

IMMEDIATE |

Use to pass operation |

|

immediately into the |

EXTERNAL |

measure layer. |

Use external triggers to |

|

|

control scanning. |

MANUAL |

Use TRIG key to control |

|

scanning. |

GPIB |

Use bus triggers to control |

|

scanning. |

TRIGLINK |

Use Trigger Link triggers to |

|

control scanning. Enter |

|

Trigger Link lines. |

TIMER |

Use a timer to control |

|

scanning and enter inter- |

|

val between scans |

|

(0.001-999999.999sec). |

HOLD |

Use to hold up the mea- |

|

surement in the scan |

|

layer. |

DELAY |

Use to delay scan in the scan |

|

layer (0.001- |

|

999999.999sec). |

COUNT |

Define number of scans to be |

|

performed: |

INFINITE |

Repeat scanning indefi- |

|

nitely. |

ENTER-SCAN-COUNT |

Count = user defined value |

|

(1-99999). |

CONTROL |

Select trigger control mode: |

SOURCE |

Enable Source Bypass. |

ACCEPTOR |

Disable Source Bypass. |

|

|

24

Table 10. CONFIGURE TRIGGER menu structure (cont.)

Menu item |

Description |

|

|

ARM |

Arm layer menu: |

SOURCE |

Select arm source: |

IMMEDIATE |

Use to arm meter immedi- |

|

ately and pass operation |

|

into the scan layer. |

EXTERNAL |

Use external triggers to arm |

|

meter. |

MANUAL |

Use TRIG key to arm |

|

meter. |

GPIB |

Use bus triggers to arm |

|

meter. |

TRIGLINK |

Use Trigger Link triggers to |

|

arm meter. Enter Trigger |

|

Link lines. |

HOLD |

Use to hold up the mea- |

|

surement in the arm |

|

layer. |

COUNT |

Define number of times to |

|

arm meter: |

INFINITE |

Continuously re-arm meter. |

ENTER-ARM-COUNT |

User defined count value |

|

(1-99999). |

CONTROL |

Select trigger control mode: |

SOURCE |

Enable Source Bypass. |

ACCEPTOR |

Disable Source Bypass. |

HALT |

Use to halt triggers. Press TRIG |

|

key to resume triggering. |

|

|

25

Table 11. CONFIG DATA STORE menu structure

Menu item |

Description |

|

|

BURST-MODE |

Acquire 4.5-digit readings at 2000 |

|

readings/sec and store in buffer. |

DATA-GROUP |

Select data types to store in buffer. |

FULL |

Store reading, units, channel#, read- |

|

ing#, time-stamp, and status |

|

(overflow). |

COMPACT |

Store reading, units, reading#, and |

|

status (overflow). |

CONTROL |

Select type of buffer control. |

FILL-AND-STOP |

Fill buffer with readings and stop. |

PRETRIGGER |

Wait for pretrigger event; store |

|

before and after readings. |

PERCENTAGE |

Enter percentage of stored read- |

|

ings before trigger. |

READING-COUNT |

Enter count of stored readings |

|

before trigger. |

EVENT |

Select source for pretrigger event. |

CONTINUOUS |

Store readings in buffer continu- |

|

ously. |

NEVER |

Readings are not stored. |

CLEAR-ALL |

Clear all stored readings and buffer |

|

statistics. |

COUNT |

Select buffer size. |

ENTER-COUNT |

Enter number of readings to store. |

USE-TRIGGER-MODEL |

Use (finite) measure count from trig- |

|

ger model. |

FEED |

Select type of reading to store. |

AFTER-CALC |

Store readings after percent or mX+b |

|

calculation. |

BEFORE-CALC |

Store readings before percent or |

|

mX+b calculation. |

|

|

26

Loading...

Loading...