Service & Maintenance Manual

Models

3369LE

4069LE

M3369

M4069

3121824

July 23, 2012

INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

SECTION A. INTRODUCTION - MAINTENANCE SAFETY

PRECAUTIONS

AGENERAL

This section contains the general safety precautions

which must be observed during maintenance of the

aerial platform. It is of utmost importance that maintenance personnel pay strict attention to these warnings and precautions to avoid possible injury to

themselves or others, or damage to the equipment.

A maintenance program must be followed to ensure

that the machine is safe to operate.

MODIFICATION OF THE MACHINE WITHOUT CERTIFICATION BY A RESPONSIBLE AUTHORITY THAT THE

MACHINE IS AT LEAST AS SAFE AS ORIGINALLY

MANUFACTURED, IS A SAFETY VIOLATION.

The specific precautions to be observed during

maintenance are inserted at the appropriate point in

the manual. These precautions are, for the most

part, those that apply when servicing electrical,

hydraulic and larger machine component parts.

Your safety, and that of others, is the first consideration when engaging in the maintenance of equipment. Always be conscious of weight. Never attempt

to move heavy parts without the aid of a mechanical

device. Do not allow heavy objects to rest in an

unstable position. When raising a portion of the

equipment, ensure that adequate support is provided.

B HYDRAULIC SYSTEM SAFETY

It should be noted that the machines hydraulic systems operate at extremely high potentially dangerous pressures. Every effort should be made

torelieve any system pressure prior to disconnecting

or removing any portion of the system.

CMAINTENANCE

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS

LISTED IN THIS SECTION MAY RESULT IN MACHINE

DAMAGE, PERSONNEL INJURY OR DEATH AND IS A

SAFETY VIOLATION.

• NO SMOKING IS MANDATORY. NEVER REFUEL DURING ELECTRICAL STORMS. ENSURE THAT FUEL CAP

IS CLOSED AND SECURE AT ALL OTHER TIMES.

• REMOVE ALL RINGS, WATCHES AND JEWELRY WHEN

PERFORMING ANY MAINTENANCE.

• DO NOT WEAR LONG HAIR UNRESTRAINED, OR

LOOSE-FITTING CLOTHING AND NECKTIES WHICH

ARE APT TO BECOME CAUGHT ON OR ENTANGLED

IN EQUIPMENT.

• OBSERVE AND OBEY ALL WARNINGS AND CAUTIONS

ON MACHINE AND IN SERVICE MANUAL.

• KEEP OIL, GREASE, WATER, ETC. WIPED FROM

STANDING SURFACES AND HAND HOLDS.

•USE CAUTION WHEN CHECKING A HOT, PRESSURIZED COOLANT SYSTEM.

SINCE THE MACHINE MANUFACTURER HAS NO

DIRECT CONTROL OVER THE FIELD INSPECTION

AND MAINTENANCE, SAFETY IN THIS AREA IS THERESPONSIBILITY OF THE OWNER/OPERATOR.

• NEVER WORK UNDER AN ELEVATED BOOM UNTIL

BOOM HAS BEEN SAFELY RESTRAINED FROM ANY

MOVEMENT BY BLOCKING OR OVERHEAD SLING, OR

BOOM SAFETY PROP HAS BEEN ENGAGED.

• BEFORE MAKING ADJUSTMENTS, LUBRICATING OR

PERFORMING ANY OTHER MAINTENANCE, SHUT

OFF ALL POWER CONTROLS.

• BATTERY SHOULD ALWAYS BE DISCONNECTED DURING REPLACEMENT OF ELECTRICAL COMPONENTS.

• KEEP ALL SUPPORT EQUIPMENT AND ATTACHMENTS STOWED IN THEIR PROPER PLACE.

• USE ONLY APPROVED, NONFLAMMABLE CLEANING

SOLVENTS.

3121824 – JLG LIft – a

INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

REVISION LOG

Original Issue - January 31, 2001

Revision - April 25, 2001

Revision - June 21, 2002

Revision - October 15, 2002

Revision - May 2, 2003

Revision - December 10, 2003

Revision - May 11, 2004

Revision - January 24, 2005

Revision - February 15, 2005

Revision - February 22, 2007

Revision - April 17, 2007

Revision - October 11, 2007

Revision - November 28, 2007

Revision - March 17, 2008

Revision - January 14, 2011

Revision - July 23, 2012

b – JLG Lift – 3121824

TABLE OF CONTENTS

TABLE OF CONTENTS

SUBJECT - SECTION, PARAGRAPH PAGE NO.

SECTION A - INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

A General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-a

B Hydraulic System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-a

C Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-a

SECTION 1 - SPECIFICATIONS

1.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.3 Pressure Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.4 Component Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.5 Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.6 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.7 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.8 Major Component Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.9 Critical Stability Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.10 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.11 Serial Number Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.12 Torque Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

SECTION 2 - GENERAL

2.1 Machine Preparation, Inspection, and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Service and Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.3 Lubrication and Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.4 Cylinder Drift Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.5 Pins and Composite Bearing Repair Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.6 Preventive Maintenance and Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

SECTION 3 - CHASSIS & SCISSOR ARMS

3.1 Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Tilt Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3 Battery Maintenance and Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3.4 Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.5 Supplementary Fuse For APU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

3.6 Joystick Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

3.7 Torque Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

3.8 Drive Hub. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

3.9 Drive Brake - MICO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

3.10 Torque Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30

SECTION 4 - HYDRAULICS

4.1 Servicing and Maintenance Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2 Lubrication Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.3 Cylinders - Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.4 Valves - Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.5 Component Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.6 Wear Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.7 Motor Controller - Modes of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.8 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.9 Cylinder Checking Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.10 Cylinder Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.11 Cylinder Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.12 Steer Cylinder Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.13 Oscillation Cylinder Bleeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

3121824 – JLG Lift – i

TABLE OF CONTENTS (Continued)

4.14 Cylinder Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

4.15 Pressure Setting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

4.16 Drive Torque Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

4.17 Drive Assist Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

SECTION 5 - JLG CONTROL SYSTEM

5.1 Hand Held Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 PC Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5.3 Flash Codes/DTC’s and Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5.4 Ground Control Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

SECTION 6 - GENERAL ELECTRICAL INFORMATION & SCHEMATICS

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Multimeter Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.3 Applying Silicone Dielectric Compound To Amp Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

6.4 Working With Deutsch Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

LIST OF FIGURES

FIGURE NO. TITLE PAGE NO.

1-1. Lubrication Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-2. Serial Number Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

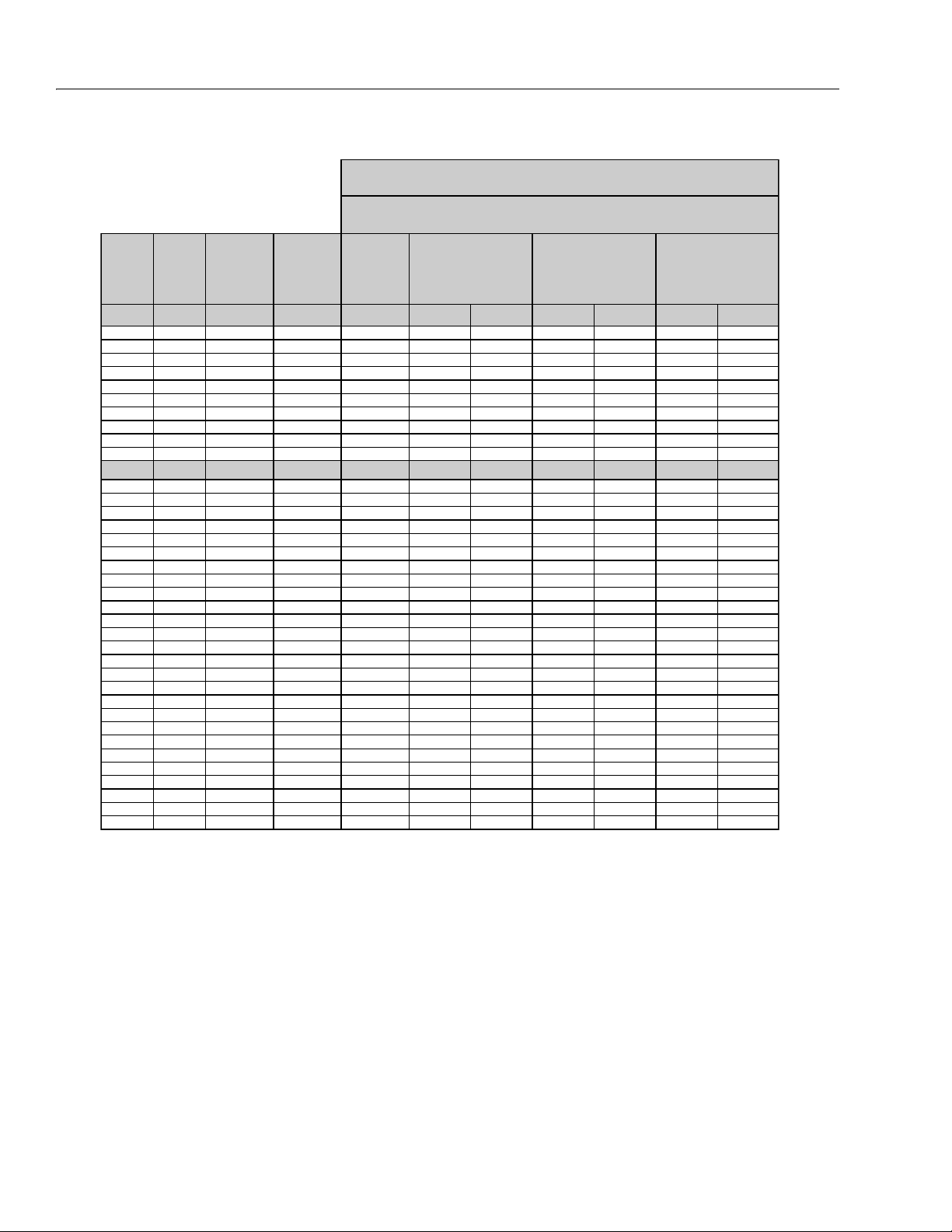

1-3. Torque Chart (SAE Fasteners - Sheet 1 of 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1-4. Torque Chart (SAE Fasteners - Sheet 2 of 7)) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1-5. Torque Chart (SAE Fasteners - Sheet 3 of 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1-6. Torque Chart (SAE Fasteners - Sheet 4 of 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

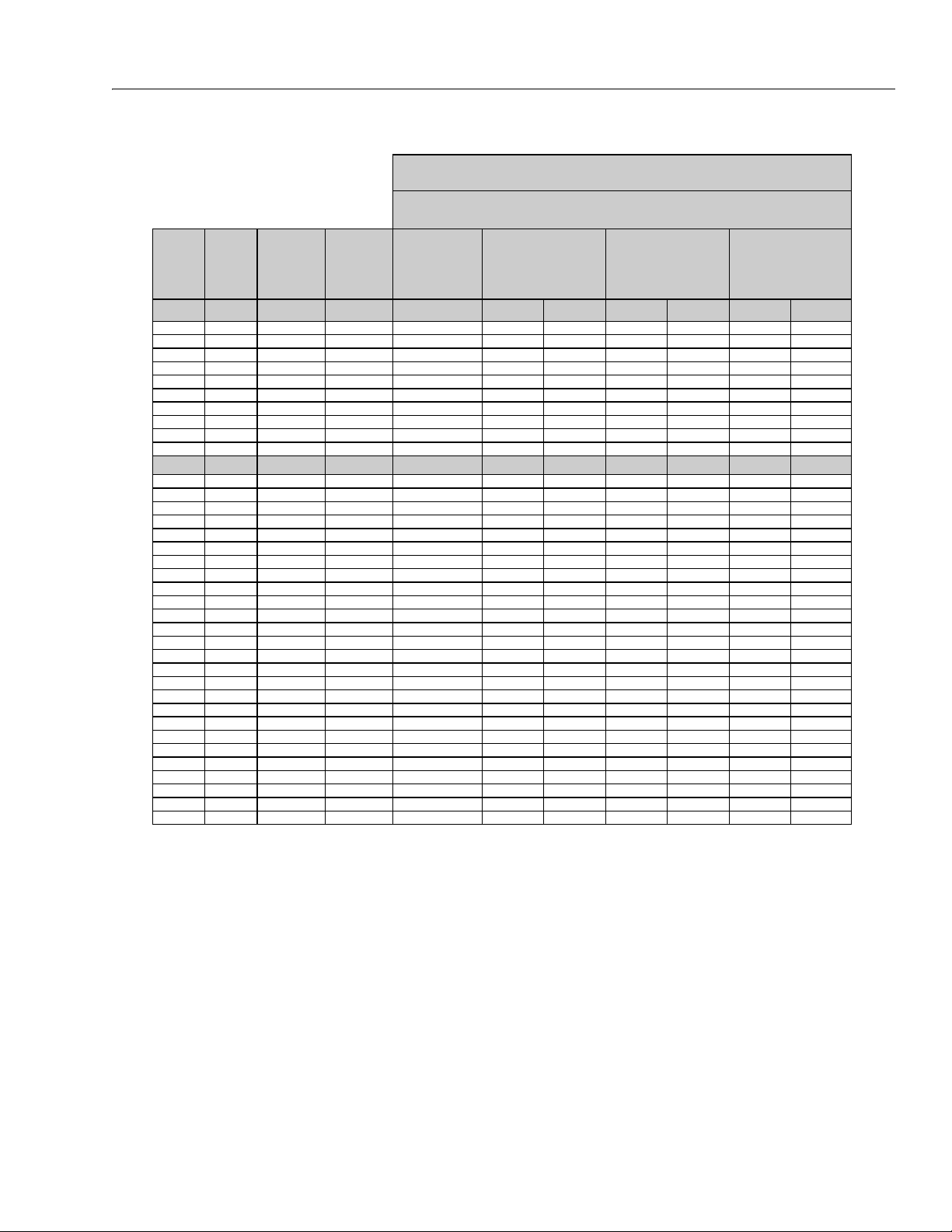

1-7. Torque Chart (METRIC Fasteners - Sheet 5 of 7)) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1-8. Torque Chart (METRIC Fasteners - Sheet 6 of 7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

1-9. Torque Chart (METRIC Fasteners - Sheet 7 of 7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

3-1. Tilt Sensor Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-2. Tilt Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3-3. Tilt Sensor Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-4. Tilt Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3-5. Remote LED Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3-6. Battery Charger Location (M model shown). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3-7. Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3-8. Batteries and Battery Charger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

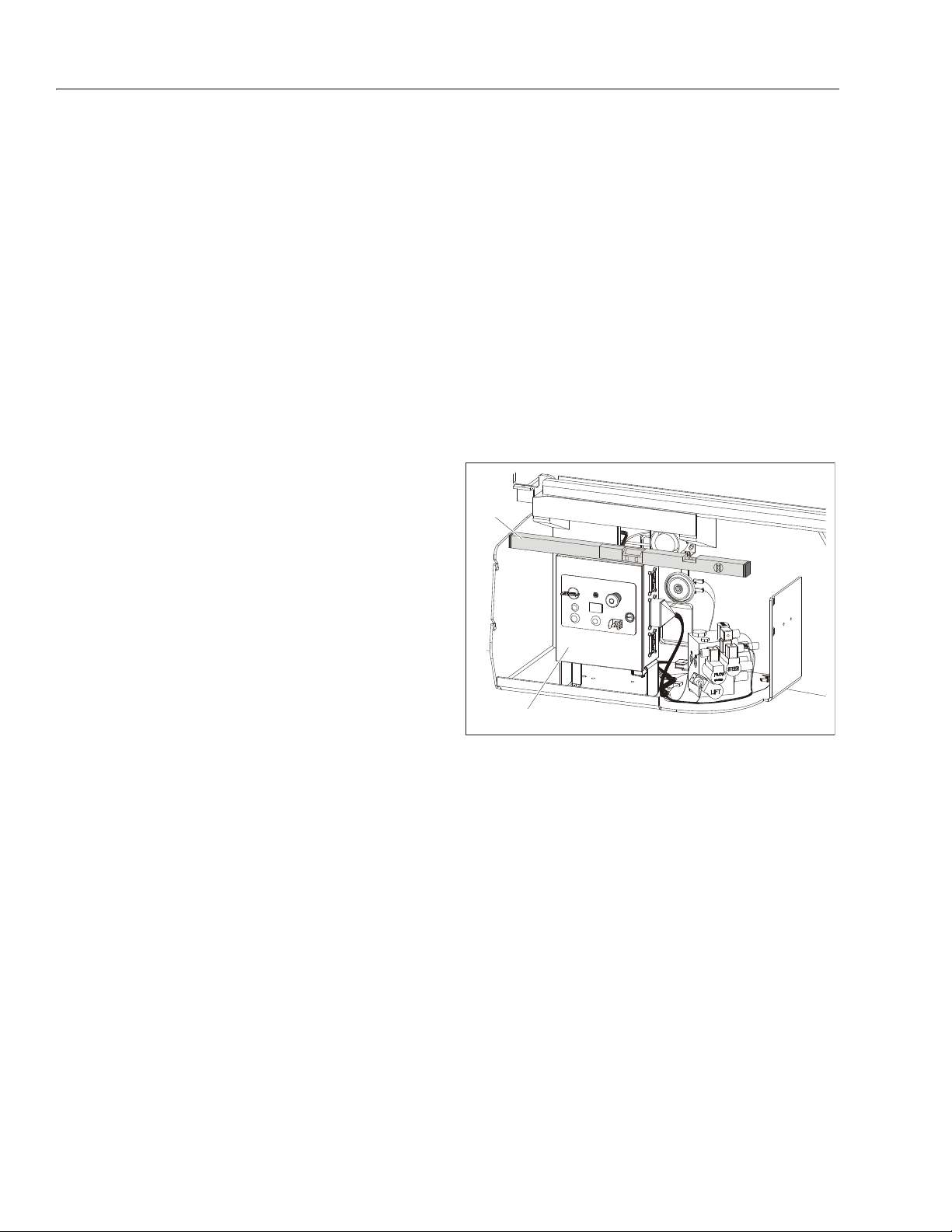

3-9. Generator Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

3-10. Generator System Analyzer Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

3-11. Joystick Controller - (JLG P/N 1600308) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

3-12. Joystick Controller - (JLG P/N 1600403) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3-13. Drive Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

3-14. Power Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3-15. Torque Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

3-16. Brake Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

3-17. Torque Hub Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30

3-18. Bolt Torquing Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

3-19. Hub Main Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

3-20. Output Carrier Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34

3-21. Input Carrier Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35

3-22. Hub-Spindle Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-36

3-23. Cover Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-37

3-24. Input Carrier Sub-Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

3-23. Output Carrier Sub-Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

3-24. Hub-Spindle Sub-Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-40

3-25. Cover Sub-Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

ii – JLG LIft – 3121824

TABLE OF CONTENTS

3-26. Hub Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-42

4-1. Barrel Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4-2. Cap Screw Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4-3. Rod Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4-4. Oil-lite Bearing Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4-5. Rod Seal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4-6. Wiper Seal Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4-7. Installation of Head Seal Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4-8. Piston Seal Kit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4-9. Poly-Pak Piston Seal Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

4-10. Rod Assembly Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

4-11. Lift Cylinder - 3369LE & M3369. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

4-12. Lift Cylinder - 4069LE & M4069. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

4-11. Leveling Jack Cylinder (1001140600). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

4-13. Leveling Jack Cylinder - USA Built Machines S/N 0200112735 to Present) . . . . . . . . . . . . . . . . .4-15

4-14. Leveling Jack Cylinder - USA Built Machines S/N 0200104829 to S/N 0200112735 &

All Belgium Built Machines). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

4-15. Leveling Jack Cylinder - USA Built Machines Prior to S/N 0200104829 . . . . . . . . . . . . . . . . . . . .4-17

4-16. Steer Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

4-17. Axle Lockout Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

4-18. Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

4-19. Drive Assist Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

5-1. Hand Held Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5-2. PC Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5-2. Analyzer Flow Chart - SW V13.X - Sheet 1 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

5-3. Analyzer Flow Chart - SW V13.X - Sheet 2 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

5-4. Analyzer Flow Chart - SW V13.X - Sheet 3 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

5-5. Analyzer Flow Chart - Software P1.X - Sheet 1 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

5-6. Analyzer Flow Chart - Software P1.X - Sheet 2 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

5-7. Analyzer Flow Chart - Software P1.X - Sheet 3 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

6-1. Voltage Measurement (DC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-2. Resistance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6-3. Continuity Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6-4. Current Measurement (DC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6-5. AMP Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

6-6. Connector Assembly (1 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

6-7. Connector Assembly (2 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

6-8. Connector Assembly (3 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

6-9. Connector Assembly (4 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

6-10. Connector Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-11. Connector Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

6-12. DT/DTP Contact Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6-13. DT/DTP Contact Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6-14. HD/HDP Contact Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6-15. HD/HDP Locking Contacts Into Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

6-16. HD/HDP Contact Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

6-17. HD/HDP Unlocking Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

6-18. Electrical Components Installation - (Sheet 1 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

6-19. Electrical Components Installation - (Sheet 2 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

6-20. Electrical Components Installation - (Sheet 3 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

6-21. Electrical Components Installation - (Sheet 4 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-22. Electrical Schematic - Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

6-23. Electrical Schematic - Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

6-24. Electrical Schematic - Kubota Generaltor - Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

6-25. Electrical Schematic - Kubota Generator - Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

6-26. Electrical Schematic - (Sheet 1 of 2) (4069LE AUS Full Drive Height Only) . . . . . . . . . . . . . . . . .6-20

6-27. Electrical Schematic - (Sheet 2 of 2) (4069LE AUS Full Drive Height Only) . . . . . . . . . . . . . . . . .6-21

6-28. Electrical Schematic - Yanmar Engine (M3369 & 3369LE only). . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

.6-15

3121824 – JLG Lift – iii

TABLE OF CONTENTS (Continued)

6-29. Hydraulic Diagram - 3369LE and M3369 (Fixed Axle) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-24

6-30. Hydraulic Diagram - 3369LE and M3369 (Oscillating Axle) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

6-31. Hydraulic Diagram - 4069LE and M4069 (Fixed Axle) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

6-32. Hydraulic Diagram - 4069LE and M4069 (Oscillating Axle) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

6-33. Hydraulic Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-28

LIST OF TABLES

TABLE NO. TITLE PAGE NO.

1-1 Operating Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1-2 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-3 Pressure Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-4 Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-5 Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-6 Lubrication Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-7 Mobil DTE 11M Specs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-8 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-9 Major Component Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-10 Critical Stability Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-11 Lubrication Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

2-1 Inspection and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2-2 Cylinder Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-3 Preventive Maintenance and Inspection Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

3-1 Tilt Sensor Harness Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-2 Tilt Sensor Harness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3-3 Delta-Q - Battery Charger Specs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3-4 Battery Algorithms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3-5 RBS Pre start Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

3-6 RBS Startup Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

3-7 RBS Shutdown Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

3-8 Generator System Flash Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3-9 Joystick Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

3-10 Joystick Plug Loading Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

3-11 Joystick Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3-12 Joystick Plug Loading Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3-13 Power Controller Cable Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

4-1 Cutout Heights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4-2 Cylinder Piston Nut Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

4-3 Holding Valve Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

4-4 Valve Component Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

5-1 Flash Codes/DTC’s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5-2 Power Module Diagnostic LED Flash Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5-3 Machine Model Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

5-4 Machine Configuration Programming Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5-5 J1 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

5-6 J2 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-20

5-7 J3 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-21

5-8 J4 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-22

5-9 J5 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-22

5-10 J6 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-22

5-11 J1 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-23

5-12 J2 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-24

5-13 J3 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-25

5-14 J4 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

5-15 J5 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

5-16 J6 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

iv – JLG LIft – 3121824

SECTION 1 - SPECIFICATIONS

SECTION 1. SPECIFICATIONS

1.1 SPECIFICATIONS

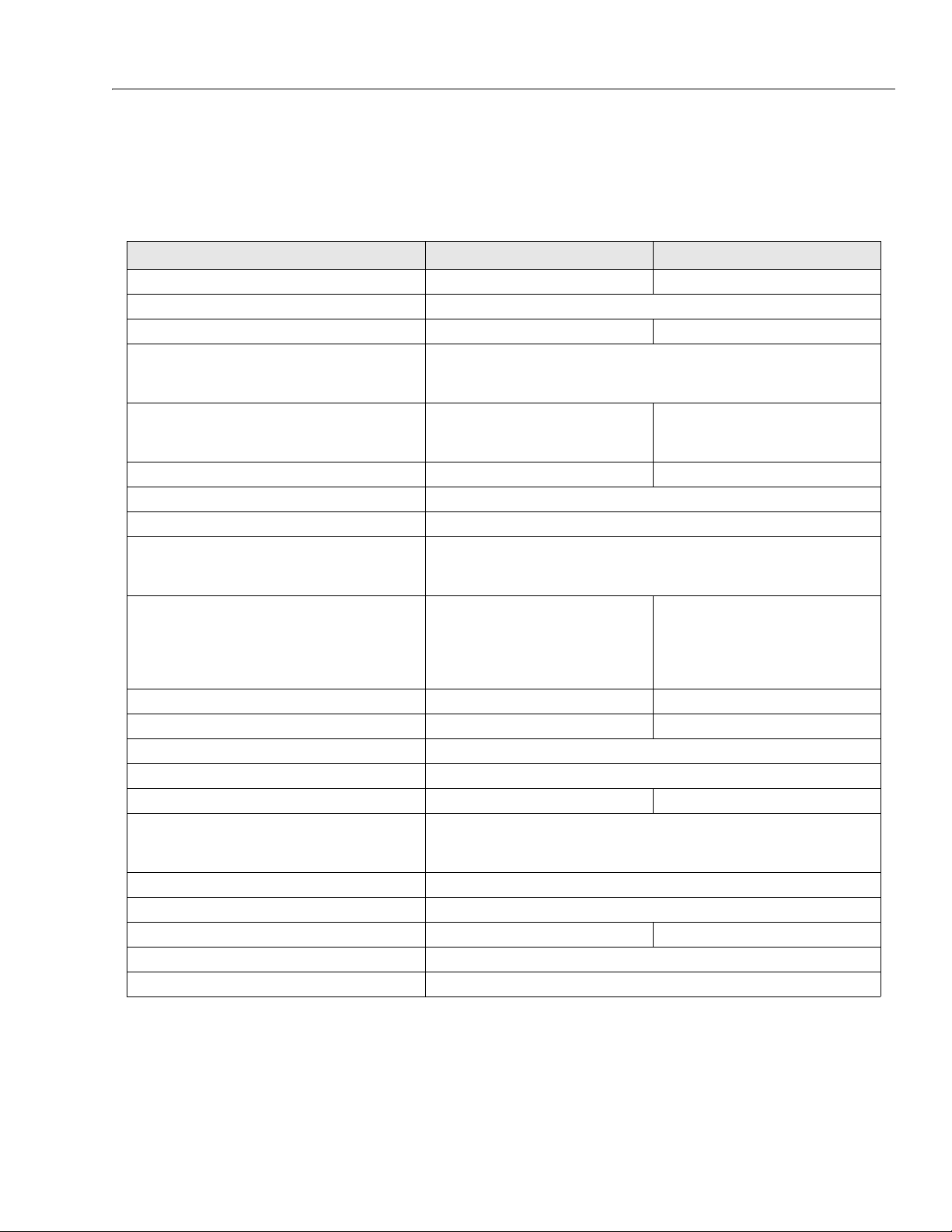

Table 1-1. Operating Specifications

Description 3369LE/M3369 4069LE/M4069

Maximum Platform Height 10.1 m (33 ft) 12.2 m (40 ft)

Maximum Occupants 2

Gross Machine Weight (minimum) 4427 kg (9760 lbs) 4790 kg (10,560 lbs)

Travel Speed:

High Drive Fwd/Rev (sec/50 ft)

Elevated Drive Fwd/Rev (sec/50 ft)

Lifting Speed:

N o L o a d

R at e d L o a d

Lowering Speed (no load) 43 - 48 sec 49 - 51 sec

Gradeability (platform stowed) 35%

Maximum Operating Windspeed 12.5 m/sec (28 mph)

Tu rn in g R ad iu s:

I ns i d e

O ut s id e

Maximum Platform Capacity

- Pl a t fo r m

-Platform Extension

Maximum Ground Bearing Pressure 4 bar (57 psi) 4.3 bar (61 psi)

Maximum Tire Load 1452 kg (3200 lbs) 1680 kg (3700 lbs)

Maximum Hydraulic System Pressure 207 bar (3000 psi)

Electrical System Voltage 48Vdc

Maximum Horizontal Manual Side Force 667 N (150 lb force) 534 N (120 lb force)

Tilt Sensor Setting:

Side to Side

Fo r e a n d A f t

Ground Clearance 20 cm (8 in)

Wheelbase 2.3 m (91.5 in)

Machine Height (w/ rails folded) 1.9 m (76.5 in) 2.01 m (79 in)

Machine Length (stowed) 3.1 m (121 in)

Machine Width 1.75 m (69 in)

ANSI/CSA/Brazil: 1000 lbs (454kg)

CE/AUS: 1000 lbs (450kg)

ANSI/CSA/Brazil: 250 lbs (113kg)

CE/AUS: 250 lbs (120kg)

36 - 40 sec

38 - 44 sec

10.6 - 12 sec

40 - 44 sec

52 - 60 sec

54 - 62 sec

2.3 m (7.5 ft)

4.9 m (16 ft)

ANSI/CSA/Brazil: 800 lbs (363kg)

CE/AUS: 800 lbs (360kg)

ANSI/CSA/Brazil: 250 lbs (113kg)

CE/AUS: 250 lbs (120kg)

3°

5°

3121824 – JLG Lift – 1-1

SECTION 1 - SPECIFICATIONS

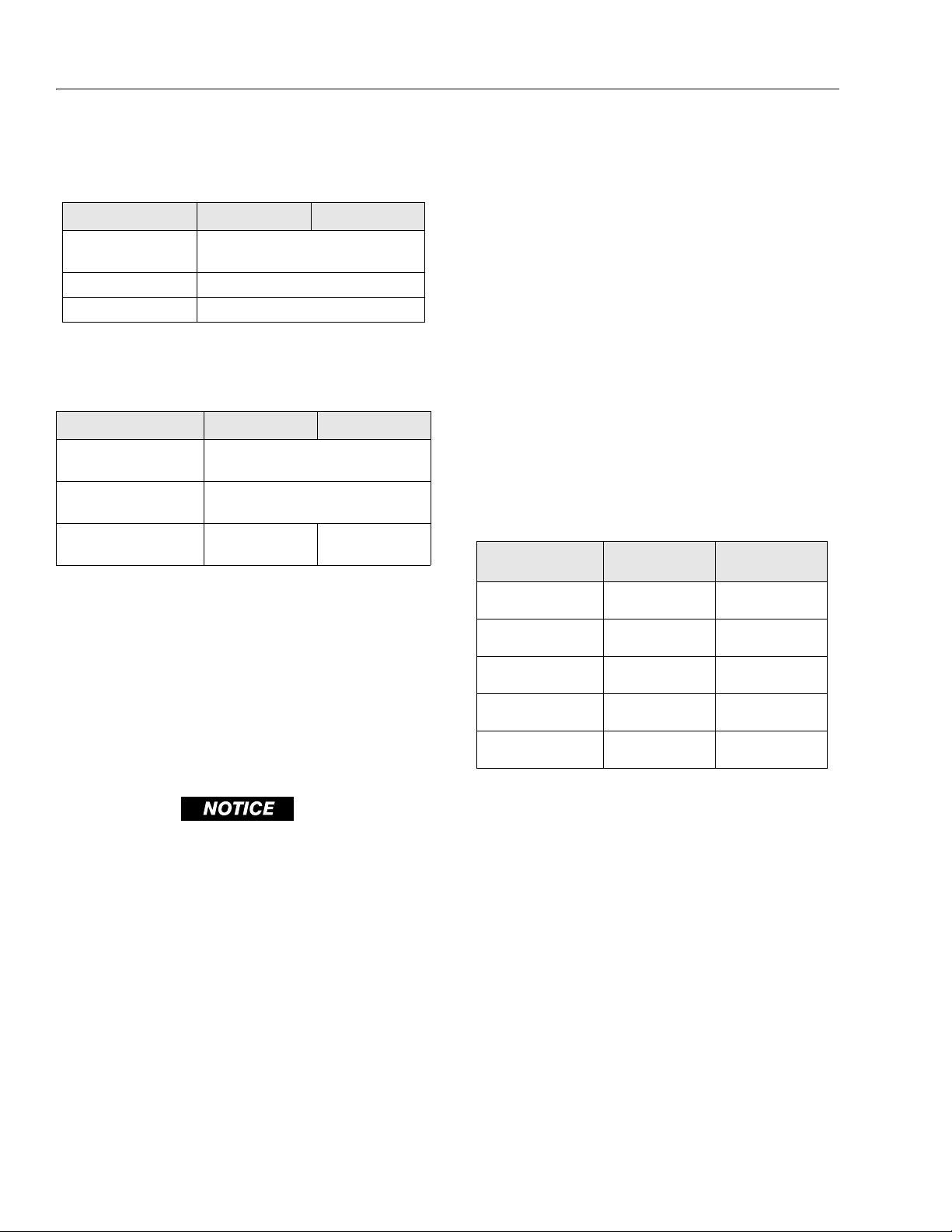

1.2 CAPACITIES

Table 1-2. Capacities

Description 3369LE/M3369 4069LE/M4069

Hydraulic Tank

Hydraulic System approx. 32.1 liters (8.5 gal)

Torque Hubs (2) 0.5 liters (17 ounces)

31.2 liters (8.25 gal)

20.4 liters (5.4 gal) @ full mark

1.3 PRESSURE SETTINGS

Table 1-3. Pressure Settings

Description 3369LE/M3369 4069LE/M4069

Main Relief (±3.5 bar)

Steer Relief

Lift Relief

179 bar

(2600 psi)

207 bar

(3000 psi)

172 bar

(2500 psi)

1.4 COMPONENT DATA

Battery Charger

Input 220 VAC, 50 HZ Input, (110 VAC,60 HZ)

Output, 48 VDC @ 23 Amp

Batteries (8)

6 Volt, 370 Amp-hour

193 bar

(2800 psi)

Drive System

Drive Motor - 48 VDC, 11.8 H.P. peak 5.5 H.P. continuous,

rotation - reversible

Drive Brake- 24 VDC, spring-applied, hydraulically

released

Steer System

Tires - IN240/55-17.5 FF

IN240/55-17.5 FF non marking

27.2/10.5LL-15.0 FF TURF - SLR - 4020 lb.@42 PSI

Toe-In 6.4 mm (1/4 inch) overall

Hydraulic Pump/Electric Motor Assembly

Pump Output - 14.6 lpm (3.86 gpm) @ 150 bar (2175 psi)

M4069/4069LE - 20 cm (8 in)

1.5 TORQUE SPECIFICATIONS

Table 1-4. Torque Specifications

DESCRIPTION

To rq ue H ub

Wheel Nuts

Fixed Axle Bolts

Drive Motor

Pump Motor Terminals

TORQUE VALUE

(DRY)

240 ft lbs

(336 Nm)

170 ft lbs

(238 Nm)

220 ft lbs

(308 Nm)

35 ft lbs

(49 Nm)

12-14 ft lbs

(14-19 Nm)

INTERVAL HOURS

500

50

500

N/A

N/A

NOTE: When maintenance becomes necessary or a fas-

tener has loosened, refer to the Section 1.12, Torque

JLG MACHINES EQUIPPED WITH DELTA Q BATTERY CHARGERS

ARE DESIGNED FOR THE BEST PERFORMANCE WITH OEM FACTORY APPROVED BATTERIES.

APPROVED JLG REPLACEMENT BATTERIES ARE AVAILABLE

THROUGH JLG' S AFTERMARKET PARTS DISTRIBUTION CENTERS OR JLG' S AFTERMARKET PROGRAMS. FOR ASSISTANCE

WITH PROPER BATTERY REPLACEMENT, PLEASE CONTACT

YOUR LOCAL JLG SUPPORT OFFICE.

BATTERIES APPROVED BY JLG HAVE BEEN TESTED FOR COMPATIBILITY WITH THE ALGORITHM PROGRAMMING OF THE

DELTA Q BATTERY CHARGER TO OPTIMIZE BATTERY LIFE AND

MACHINE CYCLE TIMES. THE USE OF NON APPROVED BATTERIES IN YOUR JLG EQUIPMENT MAY RESULT IN PERFORMANCE

ISSUES OR BATTERY CHARGER FAULT CODES. JLG ASSUMES

NO RESPONSIBILITY FOR SERVICE OR PERFORMANCE ISSUES

ARISING FROM THE USE OF NON APPROVED BATTERIES.

Charts to determine proper torque value.

1-2 – JLG Lift – 3121824

SECTION 1 - SPECIFICATIONS

1.6 LUBRICATION

Table 1-5. Hydraulic Oil

Hydraulic System Operating

Temperature Range

-18°C to -5°C (0° F to 23° F) 10W

-18°C to +99°C (0° F to 210° F) 10W-20, 10W- 0

+10°C to +99°C (50° F to 210° F) 20W-20

NOTE: Hydraulic oils must have anti-wear qualities at least

to API Service Classification GL-3, and sufficient

chemical stability for mobile hydraulic system service. JLG Industries recommends Mobil DTE 11M

hydraulic oil, which has an SAE viscosity index of

140.

Aside from JLG recommendations, it is not advisable

to mix oils of different brands or types, as they may

not contain the same required additives or be of

comparable viscosities.

SAE Viscosity Grade

Lubrication Specifications

Table 1-7. Mobil DTE 11M Specs

ISO Viscosity Grade #15

Gravity API 31.9

Pour Point, Max -40°C (-40°F)

Flash Point, Min. 166°C (330°F)

cp at -30° F 3.200

Viscosity Index 140

1.7 CYLINDER SPECIFICATIONS

Table 1-8. Cylinder Specifications

DESCRIPTION BORE STROKE ROD DIA.

Lift Cylinder

(M3369/3369LE)

Upper Lift Cylinder

(M4069/4069LE)

Lower Lift Cylinder

(M4069/4069LE)

Steer Cylinder

10.16 cm

(4.00 in)

7.62 cm

(3.00 in)

10.16 cm

(4.00 in)

5.08 cm

(2.00 in)

161.77 cm

(63.69 in)

147.65 cm

(58.13 in)

147.65 cm

(58.13 in)

16.51 cm

(6.5 in)

6.98 cm

(2.75 in)

6.98 cm

(2.75 in)

5.71 cm

(2.25 in)

2.86 cm

(1.125 in)

Table 1-6. Lubrication Specifications

KEY SPECIFICATIONS

EPGL

HO

LL Synthetic Lithium Lubricant, Gredag 741 Grease.

*MPG may be substituted for these lubricants, if necessary, but service intervals will be reduced.

NOTE: Refer to Lubrication Chart for specific lubrication pro-

ISO Viscosity Grade #15

Extreme Pressure Gear Lube (oil) meeting API service

c la ss if i ca ti on GL- 5 or MI L-S p ec MI L-L- 21 0 5

Hydraulic Oil. API service classification Gl-3, BP Ener-

gol SHS46.

cedures..

Table 1-7. Mobil DTE 11M Specs

Gravity API 31.9

Pour Point, Max -40°C (-40°F)

Flash Point, Min. 166°C (330°F)

Viscosity

at 40° C 15 cSt

at 100° C 4.1 cSt

at 100° F 80 SUS

at 210° F 43 SUS

1.8 MAJOR COMPONENT WEIGHTS

Table 1-9. Major Component Weights

Description 3369LE/M3369 4069LE/M4069

Platform 354 kg (780 lbs)

Platform Extension 163 kg (360 lbs)

Arm Assembly

(Includes Lift Cylinders)

Chassis (Includes Battery Box

and Foam filled Tires)

Foam Filled Tire and Wheel

Assembly (each)

1451 kg

(3200 lbs)

2458 kg

(5420 lbs)

81.6 kg (180 lb.)

1.9 CRITICAL STABILITY WEIGHTS

Table 1-10. Critical Stability Weights

Description 3369LE/M3369 4069LE/M4069

Platform 354 kg (780 lbs)

Platform Extension 163 kg (360 lbs)

Foam Filled Tires 94 kg (207 lbs)

Battery (Each) 55 kg (122 lbs)

1769 kg

(3900 lbs)

2502 kg

(5517 lbs)

3121824 – JLG Lift – 1-3

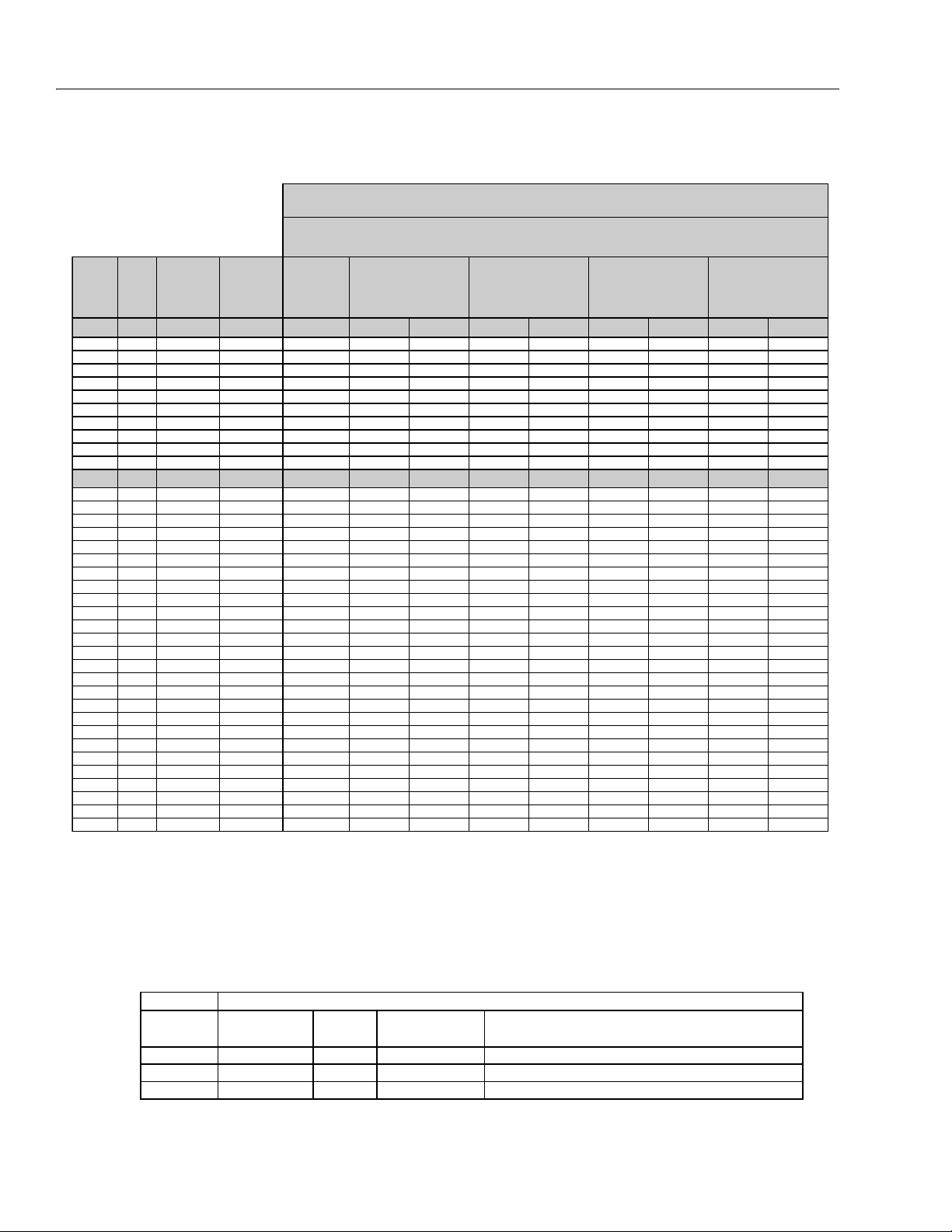

SECTION 1 - SPECIFICATIONS

Note:

500 Hrs. = 3 months

1000 Hrs. = 6 months

2000 Hrs. = 1 year

4000 Hrs. = 2 years

1

2

3,4

5

Figure 1-1. Lubrication Chart

1.10 LUBRICATION

Table 1-11. Lubrication Chart

INDEX

NUMBER

1 Sliding Wear Pads 8 Wear Pads MPG/Br ush 50 --

2 Hydraulic Oil Fill Level/Drain Plug

3 Wheel Bearings Front Wheels MPG - Repack 1200 --

4

5

6

KEY TO LUBRICANTS:

HO - Hydraulic Oil - Mobil DTE - 11M

EPGL - Extreme Pressure Gear Lube

MPG - Multi Purpose Grease

COMPONENT

Spindles/Bushing

(not shown)

Wheel Drive Hub

(not shown)

*High Pressure

Filter (not shown)

NO/TYPE LUBE

POINTS

N/A LL

Fill Plug/Half Full EPGL 1200

N/A

LUBE/METHOD

HO - Check HO Level

HO - Change HO

TO AVOID PERSONAL INJURY, USE SAFETY PROP FOR ALL

MAINTENANCE REQUIRING PLATFORM TO BE ELEVATED

NOTE: Be sure to lubricate like items on each side of the

machine.

Replaceable

Element

INTERVAL

HOURS

10/500

At Spindle Bushing

Replacement

50/250

NOTE: Recommended lubricating intervals are based on

machine operations under normal conditions. For

machines used in multi-shift operations and/or

exposed to hostile environments or conditions, lubricating frequencies must be increased accordingly.

*The high pressure filter is located in the main control valve. See figure title control valve in section 2.

Check oil every 10 hours of op eration

Change oil after every 1000 hours of operation

Check oiul level at side plug daily.

Change after first 150 hours o f operation then every

Replace filter element after first 50 hours of operation

and every 1000 hours thereafter.

COMMENTS

--

1000 hours thereafter

1-4 – JLG Lift – 3121824

SECTION 1 - SPECIFICATIONS

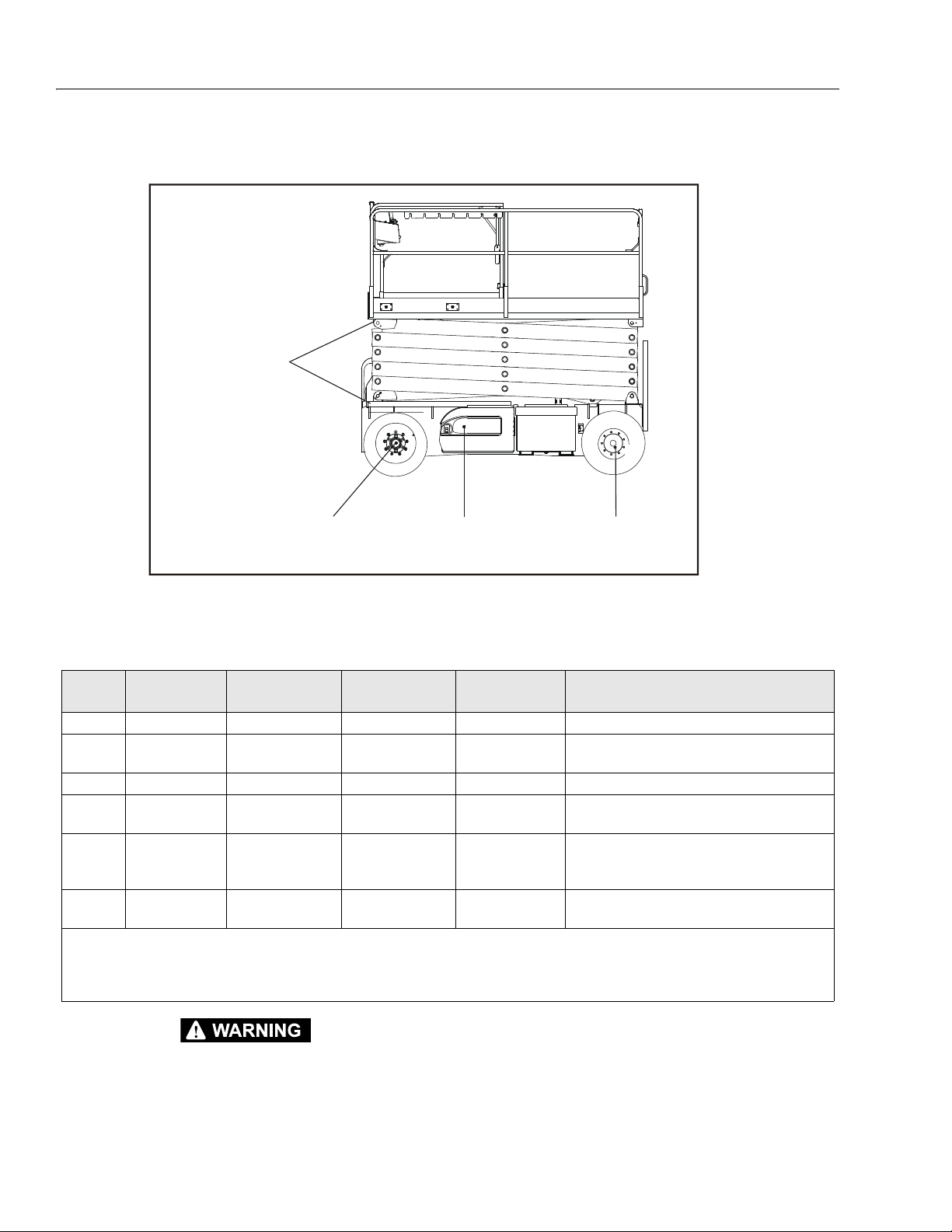

SERIAL NUMBER

PLATE

SERIAL NUMBER

STAMPED

Figure 1-2. Serial Number Location

1.11 SERIAL NUMBER LOCATIONS

For machine identification, a serial number plate is affixed to the front of the frame. If the serial number plate is damaged or

missing, the machine serial number is stamped on the left front of the machine frame.

3121824 – JLG Lift – 1-5

SECTION 1 - SPECIFICATIONS

REFERENCE JLG ANEROBIC THREAD LOCKING COMPOUND

JLG P/N Loctite® P/N ND Industries P/N

Description

0100011

242

TM

Vibra-TITE

TM

121

Medium Strength (Blue)

0100019

271

TM

Vibra-TITE

TM

140

High Strength (Red)

0100071

262

TM

Vibra-TITE

TM

131

Medium - High Strength (Red)

Size TPI Bolt Dia

Tensile

Stress Area

Clamp Load

In Sq In LB IN-LB [N.m] IN-LB [N.m] IN-LB [N.m] IN-LB [N.m]

4 40 0.1120 0.00604 380 8 0.9 6 0.7

48 0.1120 0.00661 420 9 1.0 7 0.8

6 32 0.1380 0.00909 580 16 1.8 12 1.4

40 0.1380 0.01015 610 18 2.0 13 1.5

8 32 0.1640 0.01400 900 30 3.4 22 2.5

36 0.1640 0.01474 940 31 3.5 23 2.6

10 24 0.1900 0.01750 1120 43 4.8 32 3.5

32 0.1900 0.02000 1285 49 5.5 36 4

1/4 20 0.2500 0.0318 2020 96 10.8 75 9 105 12

28 0.2500 0.0364 2320 120 13.5 86 10 135 15

In Sq In LB FT-LB [N.m] FT-LB [N.m] FT-LB [N.m] FT-LB [N.m]

5/16 18 0.3125 0.0524 3340 17 23 13 18 19 26 16 22

24 0.3125 0.0580 3700 19 26 14 19 21 29 17 23

3/8 16 0.3750 0.0775 4940 30 41 23 31 35 48 28 38

24 0.3750 0.0878 5600 35 47 25 34 40 54 32 43

7/16 14 0.4375 0.1063 6800 50 68 35 47 55 75 45 61

20 0.4375 0.1187 7550 55 75 40 54 60 82 50 68

1/2 13 0.5000 0.1419 9050 75 102 55 75 85 116 68 92

20 0.5000 0.1599 10700 90 122 65 88 100 136 80 108

9/16 12 0.5625 0.1820 11600 110 149 80 108 120 163 98 133

18 0.5625 0.2030 12950 120 163 90 122 135 184 109 148

5/8 11 0.6250 0.2260 14400 150 203 110 149 165 224 135 183

18 0.6250 0.2560 16300 170 230 130 176 190 258 153 207

3/4 10 0.7500 0.3340 21300 260 353 200 271 285 388 240 325

16 0.7500 0.3730 23800 300 407 220 298 330 449 268 363

7/8 9 0.8750 0.4620 29400 430 583 320 434 475 646 386 523

14 0.8750 0.5090 32400 470 637 350 475 520 707 425 576

1 8 1.0000 0.6060 38600 640 868 480 651 675 918 579 785

12 1.0000 0.6630 42200 700 949 530 719 735 1000 633 858

1 1/8 7 1.1250 0.7630 42300 800 1085 600 813 840 1142 714 968

12 1.1250 0.8560 47500 880 1193 660 895 925 1258 802 1087

1 1/4 7 1.2500 0.9690 53800 1120 1518 840 1139 1175 1598 1009 1368

12 1.2500 1.0730 59600 1240 1681 920 1247 1300 1768 1118 1516

1 3/8 6 1.3750 1.1550 64100 1460 1979 1100 1491 1525 2074 1322 1792

12 1.3750 1.3150 73000 1680 2278 1260 1708 1750 2380 1506 2042

1 1/2 6 1.5000 1.4050 78000 1940 2630 1460 1979 2025 2754 1755 2379

12 1.5000 1.5800 87700 2200 2983 1640 2224 2300 3128 1974 2676

NO. 5000059 REV. J

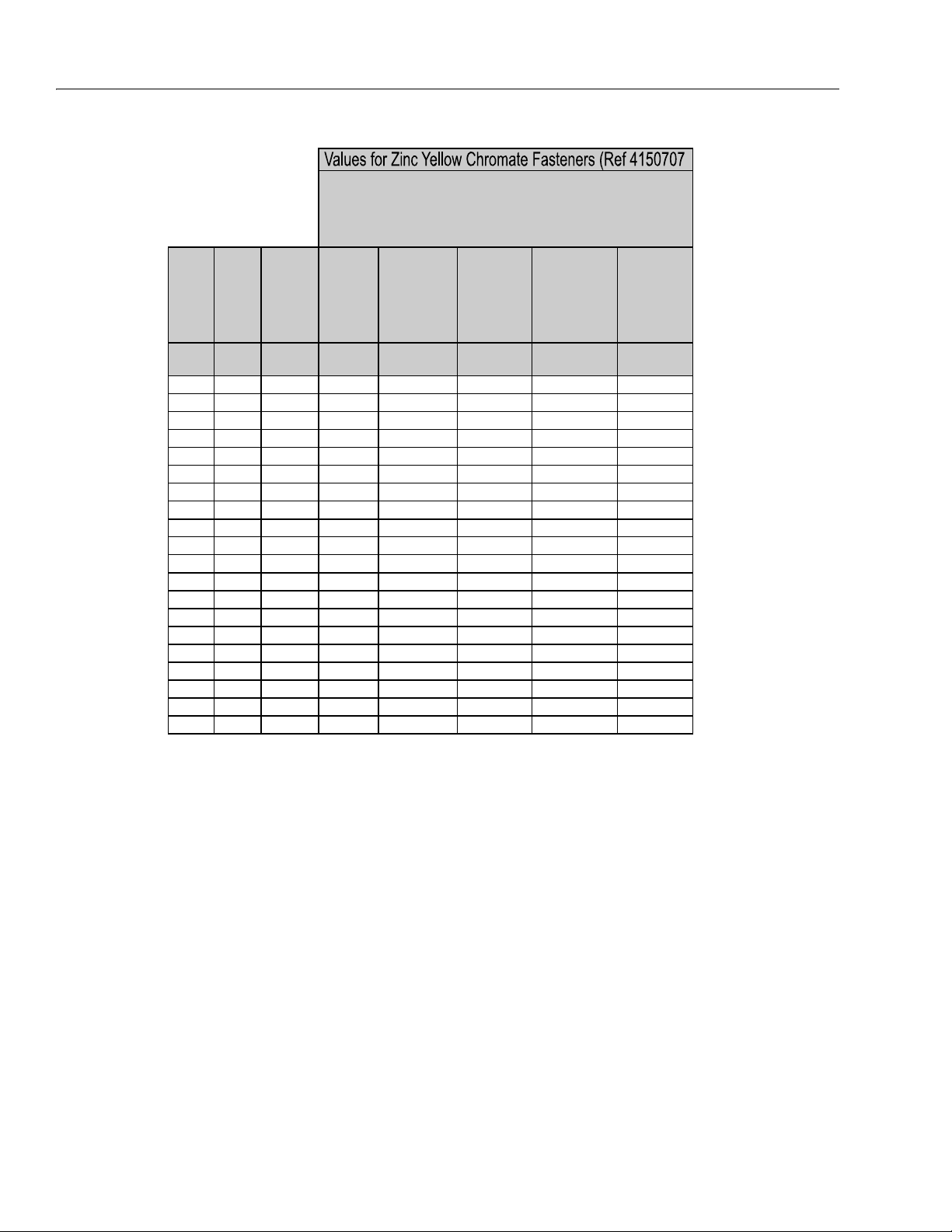

Values for Zinc Yellow Chromate Fasteners (Ref 4150707)

SAE GRADE 5 BOLTS & GRADE 2 NUTS

Torque

(Dry)

Torque

(Loctite® 262

TM

or Vibra-

TITE

TM

131)

Torque

Lubricated

Torque

(Loctite® 242

TM

or 271

TM

OR Vibra-TITE

TM

111 or

140)

3. * ASSEMBLY USES HARDENED WASHER

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT METHODS TOLERANCE = ±10%

1.12 TORQUE CHARTS

1-6 – JLG Lift – 3121824

Figure 1-3. Torque Chart (SAE Fasteners - Sheet 1 of 7)

SECTION 1 - SPECIFICATIONS

Size TPI Bolt Dia

Tensile

Stress Area

Clamp Load

In Sq In

4 40 0.1120 0.00604

48 0.1120 0.00661

6 32 0.1380 0.00909

40 0.1380 0.01015

8 32 0.1640 0.01400

36 0.1640 0.01474

10 24 0.1900 0.01750

32 0.1900 0.02000

1/4 20 0.2500 0.0318

28 0.2500 0.0364

In Sq In

5/16 18 0.3125 0.0524

24 0.3125 0.0580

3/8 16 0.3750 0.0775

24 0.3750 0.0878

7/16 14 0.4375 0.1063

20 0.4375 0.1187

1/2 13 0.5000 0.1419

20 0.5000 0.1599

9/16 12 0.5625 0.1820

18 0.5625 0.2030

5/8 11 0.6250 0.2260

18 0.6250 0.2560

3/4 10 0.7500 0.3340

16 0.7500 0.3730

7/8 9 0.8750 0.4620

14 0.8750 0.5090

1 8 1.0000 0.6060

12 1.0000 0.6630

1 1/8 7 1.1250 0.7630

12 1.1250 0.8560

1 1/4 7 1.2500 0.9690

12 1.2500 1.0730

1 3/8 6 1.3750 1.1550

12 1.3750 1.3150

1 1/2 6 1.5000 1.4050

12 1.5000 1.5800

NO. 5000059 REV. J

3. * ASSEMBLY USES HARDENED WASHER

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

2. ALL TORQUE VA LUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT METHODS TOLERANCE = ±10%

LB IN-LB [N.m] IN-LB [N.m] IN-LB [N.m]

1320 43 5

1580 60 7

1800 68 8

2860 143 16 129 15

3280 164 19 148 17

LB FT-LB [N.m] FT-LB [N.m] FT-LB [N.m

4720 25 35 20 25 20 25

5220 25 35 25 35 20 25

7000456040 553550

7900 50 70 45 60 35 50

9550 70 95 65 90 50 70

10700 80 110 70 95 60 80

12750 105 145 95 130 80 110

14400 120 165 110 150 90 120

16400 155 210 140 190 115 155

18250 170 230 155 210 130 175

20350 210 285 190 260 160 220

23000 240 325 215 290 180 245

30100 375 510 340 460 280 380

33600 420 570 380 515 315 430

41600 605 825 545 740 455 620

45800 670 910 600 815 500 680

51500 860 1170 770 1045 645 875

59700 995 1355 895 1215 745 1015

68700 1290 1755 1160 1580 965 1310

77000 1445 1965 1300 1770 1085 1475

87200 1815 2470 1635 2225 1365 1855

96600 2015 2740 1810 2460 1510 2055

104000 2385 3245 2145 2915 1785 2430

118100 2705 3680 2435 3310 2030 2760

126500 3165 4305 2845 3870 2370 3225

142200 3555 4835 3200 4350 2665 3625

Torque

(Loctite® 242

TM

or 271

TM

OR Vibra-TITE

TM

111 or

140) K=.18

Torque

(Loctite® 262

TM

or Vibra-

TITE

TM

131)

K=0.15

SAE GRADE 8 (HEX HD) BOLTS & GRADE 8 NUTS*

Torque

(Dry or Loctite® 263)

K= 0.20

3121824 – JLG Lift – 1-7

Figure 1-4. Torque Chart (SAE Fasteners - Sheet 2 of 7))

SECTION 1 - SPECIFICATIONS

Size TPI Bolt Dia

Tensile

Stress Area

Clamp Load

See Note 4

In Sq In LB IN-LB [N.m] IN-LB [N.m] IN-LB [N.m]

4 40 0.1120 0.00604

48 0.1120 0.00661

6 32 0.1380 0.00909

40 0.1380 0.01015

8 32 0.1640 0.01400

36 0.1640 0.01474

10 24 0.1900 0.01750

32 0.1900 0.02000

1/4 20 0.2500 0.0318 2860 122 14 114 13

28 0.2500 0.0364 3280 139 16 131 15

In Sq In LB FT-LB [N.m] FT-LB [N.m] FT-LB [N.m]

5/16 18 0.3125 0.0524 4720 20 25 20 25 20 25

24 0.3125 0.0580 5220 25 35 20 25 20 25

3/8 16 0.3750 0.0775 7000 35 50 35 50 35 50

24 0.3750 0.0878 7900 40 55 40 55 35 50

7/16 14 0.4375 0.1063 9550 60 80 55 75 50 70

20 0.4375 0.1187 10700 65 90 60 80 60 80

1/2 13 0.5000 0.1419 12750 90 120 85 115 80 110

20 0.5000 0.1599 14400 100 135 95 130 90 120

9/16 12 0.5625 0.1820 16400 130 175 125 170 115 155

18 0.5625 0.2030 18250 145 195 135 185 130 175

5/8 11 0.6250 0.2260 20350 180 245 170 230 160 220

18 0.6250 0.2560 23000 205 280 190 260 180 245

3/4 10 0.7500 0.3340 30100 320 435 300 410 280 380

16 0.7500 0.3730 33600 355 485 335 455 315 430

7/8 9 0.8750 0.4620 41600 515 700 485 660 455 620

14 0.8750 0.5090 45800 570 775 535 730 500 680

1 8 1.0000 0.6060 51500 730 995 685 930 645 875

12 1.0000 0.6630 59700 845 1150 795 1080 745 1015

1 1/8 7 1.1250 0.7630 68700 1095 1490 1030 1400 965 1310

12 1.1250 0.8560 77000 1225 1665 1155 1570 1085 1475

1 1/4 7 1.2500 0.9690 87200 1545 2100 1455 1980 1365 1855

12 1.2500 1.0730 96600 1710 2325 1610 2190 1510 2055

1 3/8 6 1.3750 1.1550 104000 2025 2755 1905 2590 1785 2430

12 1.3750 1.3150 118100 2300 3130 2165 2945 2030 2760

1 1/2 6 1.5000 1.4050 126500 2690 3660 2530 3440 2370 3225

12 1.5000 1.5800 142200 3020 4105 2845 3870 2665 3625

NO. 5000059 REV. J

4. CLAMP LOAD LISTED FOR SHCS IS SAME AS GRADE 8 OR CLASS 10.9 AND DOES NOT REPRESENT FULL STRENGTH

CAPABILITY OF SHCS. IF HIGHER LOAD IS REQUIRED, ADDITIONAL TESTING IS REQUIRED.

SOCKET HEAD CAP SCREWS

Magni Coating (Ref 4150701)*

Torque

(Dry) K = .17

Torque

(Loctite® 242

TM

or 271

TM

OR Vibra-TITE

TM

111 or

140 OR Precoat 85®

K=0.16

Torque

(Loctite® 262

TM

or Vibra-

TITE

TM

131)

K=0.15

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT METHODS TOL ERANCE = ±10%

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLA TED FASTENERS

*3. ASSEMBLY USES HARDENED WASHER OR FASTENER IS PLACED AGAINST PLATED STEEL OR RAW AL UMINUM

1-8 – JLG Lift – 3121824

Figure 1-5. Torque Chart (SAE Fasteners - Sheet 3 of 7)

Size TPI Bolt Dia

Tensile

Stress Area

Clamp Load

See Note 4

In Sq In LB IN-LB [N.m] IN-LB [N.m] IN-LB [N.m]

4 40 0.1120 0.00604

48 0.1120 0.00661

6 32 0.1380 0.00909

40 0.1380 0.01015

8 32 0.1640 0.01400

36 0.1640 0.01474

10 24 0.1900 0.01750

32 0.1900 0.02000

1/4 20 0.2500 0.0318 2860 143 16 129 15

28 0.2500 0.0364 3280 164 19 148 17

In Sq In LB FT-LB [N.m] FT-LB [N.m] FT-LB [N.m]

5/16 18 0.3125 0.0524 4720 25 35 20 25 20 25

24 0.3125 0.0580 5220 25 35 25 35 20 25

3/8 16 0.3750 0.0775 7000 45 60 40 55 35 50

24 0.3750 0.0878 7900 50 70 45 60 35 50

7/16 14 0.4375 0.1063 9550 70 95 65 90 50 70

20 0.4375 0.1187 10700 80 110 70 95 60 80

1/2 13 0.5000 0.1419 12750 105 145 95 130 80 110

20 0.5000 0.1599 14400 120 165 1 10 150 90 120

9/16 12 0.5625 0.1820 16400 155 210 140 190 115 155

18 0.5625 0.2030 18250 170 230 155 210 130 175

5/8 11 0.6250 0.2260 20350 210 285 190 260 160 220

18 0.6250 0.2560 23000 240 325 215 290 180 245

3/4 10 0.7500 0.3340 30100 375 510 340 460 280 380

16 0.7500 0.3730 33600 420 570 380 515 315 430

7/8 9 0.8750 0.4620 41600 605 825 545 740 455 620

14 0.8750 0.5090 45800 670 910 600 815 500 680

1 8 1.0000 0.6060 51500 860 1170 775 1055 645 875

12 1.0000 0.6630 59700 995 1355 895 1215 745 1015

1 1/8 7 1.1250 0.7630 68700 1290 1755 1160 1580 965 1310

12 1.1250 0.8560 77000 1445 1965 1300 1770 1085 1475

1 1/4 7 1.2500 0.9690 87200 1815 2470 1635 2225 1365 1855

12 1.2500 1.0730 96600 2015 2740 1810 2460 1510 2055

1 3/8 6 1.3750 1.1550 104000 2385 3245 2145 2915 1785 2430

12 1.3750 1.3150 118100 2705 3680 2435 3310 2030 2760

1 1/2 6 1.5000 1.4050 126500 3165 4305 2845 3870 2370 3225

12 1.5000 1.5800 142200 3555 4835 3200 4350 2665 3625

NO. 5000059 REV. J

4. CLAMP LOAD LISTED FOR SHCS IS SAME AS GRADE 8 OR CLASS 10.9 AND DOES NOT REPRESENT FULL STRENGTH

CAPABILITY OF SHCS. IF HIGHER LOAD IS REQUIRED, ADDITIONAL TESTING IS REQUIRED.

SOCKET HEAD CAP SCREWS

Torque

(Dry)

K = .20

Torque

(Loctite® 242TM or 271

TM

OR Vibra-TITE

TM

111 or

140 OR Precoat 85®

K=0.18

Zinc Yellow Chromate Fasteners (Ref 4150707)*

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT METHODS TOLERANCE = ±10%

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

*3. ASSEMBLY USES HARDENED WASHER OR F ASTENER IS PLACED AGAINST PLATED STEEL OR RAW ALUMINUM

Torque

(Loctite® 262

TM

or Vibra-

TITE

TM

131)

K=0.15

SECTION 1 - SPECIFICATIONS

3121824 – JLG Lift – 1-9

Figure 1-6. Torque Chart (SAE Fasteners - Sheet 4 of 7)

SECTION 1 - SPECIFICATIONS

Size PITCH

Tensile

Stress

Area

Clamp

Load

Torque

(Dry or Loctite®

263

TM

)

Torque

(Lub)

Torque

(Loctite® 262

TM

OR Vibra-

TITE

TM

131)

Torque

(Loctite®

242

TM

or 271

TM

OR Vibra-

TITE

TM

111 or

140)

Sq mm KN [N.m] [N.m] [N.m] [N.m]

3 0.5 5.03 2.19 1.3 1.0 1.2 1.4

3.5 0.6 6.78 2.95 2.1 1.6 1.9 2.3

4 0.7 8.78 3.82 3.1 2.3 2.8 3.4

5 0.8 14.20 6.18 6.2 4.6 5.6 6.8

6 1 20.10 8.74 11 7.9 9.4 12

7 1 28.90 12.6 18 13 16 19

8 1.25 36.60 15.9 26 19 23 28

10 1.5 58.00 25.2 50 38 45 55

12 1.75 84.30 36.7 88 66 79 97

14 2 115 50.0 140 105 126 154

16 2 157 68.3

219 164 197 241

18 2.5 192 83.5 301 226 271 331

20 2.5 245 106.5 426 320 383 469

22 2.5 303 132.0 581 436 523 639

24 3 353 153.5 737 553 663 811

27 3 459 199.5 1080 810 970 1130

30 3.5 561 244.0 1460 1100 1320 1530

33 3.5 694 302.0 1990 1490 1790 2090

36 4 817 355.5 2560 1920 2300 2690

42 4.5 1120 487.0 4090 3070 3680 4290

4. CLAMP LOAD LISTED FOR SHCS IS SAME AS GRADE 8 OR CLASS 10.9 AND DOES NOT

REPRESENT FULL STRENGTH CAPABILITY OF SHCS. IF HIGHER LOAD IS REQUIRED,

ADDITIONAL TESTING IS REQUIRED.

*3. ASSEMBLY USES HARDENED WASHER OR FASTENER IS PLACED AGA INST PLATED

STEEL OR RAW ALUMINUM

CLASS 8.8 METRIC BOLTS

CLASS 8 METRIC NUTS

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT

METHODS TOLERANCE = ±10%

NO. 5000059 REV. J

Figure 1-7. Torque Chart (METRIC Fasteners - Sheet 5 of 7))

1-10 – JLG Lift – 3121824

SECTION 1 - SPECIFICATIONS

Size PITCH

Tensile

Stress

Area

Clamp

Load

Torque

(Dry or Loctite®

263

TM

)

K = 0.20

Torque

(Lub OR Loctite®

242

TM

or 271TM OR

Vibra-TITE

TM

111 or

140)

K= 0.18

Torque

(Loctite® 262

TM

OR

Vibra-TITE

TM

131)

K=0.15

Sq mm KN [N.m] [N.m] [N.m]

3 0.5 5.03 3.13

3.5 0.6 6.78 4.22

4 0.7 8.78 5.47

5 0.8 14.20 8.85

6 1 20.10 12.5

7 1 28.90 18.0 25.2 22.7 18.9

8 1.25 36.60 22.8 36.5 32.8 27.4

10 1.5 58.00 36.1 70 65 55

12 1.75 84.30 52.5 125 115 95

14 2 115 71.6 200 180 150

16 2 157 97.8

315 280 235

18 2.5 192 119.5 430 385 325

20 2.5 245 152.5 610 550 460

22 2.5 303 189.0 830 750 625

24 3 353 222.0 1065 960 800

27 3 459 286.0 1545 1390 1160

30 3.5 561 349.5 2095 1885 1575

33 3.5 694 432.5 2855 2570 2140

36 4 817 509.0 3665 3300 2750

42 4.5 1120 698.0 5865 5275 4395

CLASS 10.9 METRIC BOLTS

CLASS 10 METRIC NUTS

CLASS 12.9 SOCKET HEAD CAP SCREWS M3 - M5*

4. CLAMP LOAD LISTED FOR SHCS IS SAME AS GRADE 8 OR CLASS 10.9 AND DOES NOT

REPRESENT FULL STRENGTH CAPABILI TY OF SHCS. IF HIGHER LOAD IS REQUIRED,

ADDITIONAL TESTING IS REQUIRED.

*3. ASSEMBLY USES HARDENED WASHER OR FASTENER IS PLACED AGAINST PLATED

STEEL OR RAW ALUMINUM

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT

METHODS TOLERANCE = ±10%

NO. 5000059 REV. J

3121824 – JLG Lift – 1-11

Figure 1-8. Torque Chart (METRIC Fasteners - Sheet 6 of 7)

SECTION 1 - SPECIFICATIONS

Size PITCH

Tensile

Stress

Area

Clamp Load

See Note 4

Torque

(Dry or Loctite®

263

TM

)

K = .17

Torque

(Lub OR Loctite®

242

TM

or 271

TM

OR Vibra-TITE

TM

111 or 140)

K = .16

Torque

(Loctite® 262

TM

OR Vibra-TITE

TM

131)

K = .15

Sq mm kN [N.m] [N.m] [N.m]

30.55.03

3.5 0.6 6.78

40.78.78

50.814.20

6120.1012.5 13 12 11

7128.9018.0 21 20 19

8 1.25 36.60 22.8 31 29 27

10 1.5 58.00 36.1 61 58 54

12 1.75 84.30 52.5 105 100 95

14 2 115 71.6 170 160 150

16 2 157

97.8 265 250 235

18 2.5 192 119.5 365 345 325

20 2.5 245 152.5 520 490 460

22 2.5 303 189.0 705 665 625

24 3 353 220.0 900 845 790

27 3 459 286.0 1315 1235 1160

30 3.5 561 349.5 1780 1680 1575

33 3.5 694 432.5 2425 2285 2140

36 4 817 509.0 3115 2930 2750

42 4.5 1120 698.0 4985 4690 4395

CLASS 12.9 SOCKET HEAD CAP SCREWS

M6 AND ABOVE*

4. CLAMP LOAD LISTED FOR SHCS IS SAME AS GRADE 8 OR CLASS 10.9 AND DOES NOT

REPRESENT FULL STRENG TH CAPABILITY OF SHCS. IF HIGHER LOAD IS REQUIRED,

ADDITIONAL TESTING IS REQUIRED.

*3. ASSEMBLY USES HARDENED WASHER OR FASTENER IS PLACED AGAINST PLATED

STEEL OR RAW ALUMINUM

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT

METHODS TOLERANCE = ±10%

NO. 5000059 REV. J

Magni Coating (Ref 4150701)*

Figure 1-9. Torque Chart (METRIC Fasteners - Sheet 7 of 7)

1-12 – JLG Lift – 3121824

SECTION 2. GENERAL

SECTION 2 - GENERAL

2.1 MACHINE PREPARATION, INSPECTION, AND MAINTENANCE

General

This section provides the necessary information needed

by those personnel that are responsible to place the

machine in operation readiness and maintain its safe

operating condition. For maximum service life and safe

operation, ensure that all the necessary inspections and

maintenance have been completed before placing the

machine into service.

Preparation, Inspection, and Maintenance

It is important to establish and conform to a comprehensive inspection and preventive maintenance program.

The following table outlines the periodic machine inspections and maintenance recommended by JLG Industries,

Inc. Consult your national, regional, or local regulations

for further requirements for aerial work platforms. The frequency of inspections and maintenance must be

increased as environment, severity and frequency of

usage requires.

Pre-Start Inspection

It is the User’s or Operator’s primary responsibility to perform a Pre-Start Inspection of the machine prior to use

daily or at each change of operator. Reference the Operator’s and Safety Manual for completion procedures for the

Pre-Start Inspection. The Operator and Safety Manual

must be read in its entirety and understood prior to performing the Pre-Start Inspection.

Reference the JLG Pre-Delivery and Frequent Inspection

Form and the Inspection and Preventative Maintenance

Schedule for items requiring inspection during the performance of these inspections. Reference the appropriate

areas of this manual for servicing and maintenance procedures.

Annual Machine Inspection

JLG recommends that an annual machine inspection be

performed by a Factory-Trained Service Technician on an

annual basis, no later than thirteen (13) months from the

date of the prior Annual Machine Inspection. JLG Industries, Inc. recognizes a Factory-Certified Service Technician as a person who has successfully completed the JLG

Service Training School for the subject JLG product

model. Reference the machine Service and Maintenance

Manual and appropriate JLG inspection form for performance of this inspection.

Reference the JLG Annual Machine Inspection Form and

the Inspection and Preventative Maintenance Schedule for

items requiring inspection during the performance of this

inspection. Reference the appropriate areas of this manual for servicing and maintenance procedures.

For the purpose of receiving safety-related bulletins, it is

important that JLG Industries, Inc. has updated ownership

information for each machine. When performing each

Annual Machine Inspection, notify JLG Industries, Inc. of

the current machine ownership.

Preventative Maintenance

Pre-Delivery Inspection and Frequent Inspection

The Pre-Delivery Inspection and Frequent Inspection shall

be performed by a qualified JLG equipment mechanic.

JLG Industries, Inc. recognizes a qualified JLG equipment

mechanic as a person who, by possession of a recognized degree, certificate, extensive knowledge, training, or

experience, has successfully demonstrated the ability and

proficiency to service, repair, and maintain the subject

JLG product model.

The Pre-Delivery Inspection and Frequent Inspection procedures are performed in the same manner, but at different times. The Pre-Delivery Inspection shall be performed

prior to each sale, lease, or rental delivery. The Frequent

Inspection shall be accomplished for each machine in service for 3 months or 150 hours (whichever comes first);

out of service for a period of more than 3 months; or when

purchased used. The frequency of this inspection must be

increased as environment, severity and frequency of

usage requires.

In conjunction with the specified inspections, maintenance shall be performed by a qualified JLG equipment

mechanic. JLG Industries, Inc. recognizes a qualified JLG

equipment mechanic as a person who, by possession of a

recognized degree, certificate, extensive knowledge, training, or experience, has successfully demonstrated the

ability and proficiency to service, repair, and maintain the

subject JLG product model.

Reference the Preventative Maintenance Schedule and

the appropriate areas of this manual for servicing and

maintenance procedures. The frequency of service and

maintenance must be increased as environment, severity

and frequency of usage requires.

3121824 – JLG Lift – 2-1

SECTION 2 - GENERAL

Table 2-1. Inspection and Maintenance

Typ e Frequency

Pre-Start Inspection

Pre-Delivery

Inspection

Frequent Inspection

Annual Machine

Inspection

Preventative

Maintenance

Prior to use each day; or

At each Operator change.

Prior to each sale, lease, or

rental delivery.

In service for 3 months or 150 hours,

whichever comes first; or

Out of service for a period of more than 3

months; or

Purchased used.

Annually, no later than 13 months from the

date of the prior inspection.

At intervals as specified in the Service and

Maintenance Manual.

2.2 SERVICE AND GUIDELINES

General

The following information is provided to assist you in the

use and application of servicing and maintenance procedures contained in this book.

Safety and Workmanship

Your safety, and that of others, is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of weight. Never attempt to move heavy

parts without the aid of a mechanical device. Do not allow

heavy objects to rest in an unstable position. When raising

a portion of the equipment, ensure that adequate support

is provided.

Cleanliness

Primary

Responsibility

User or Operator User or Operator Operator and Safety Manual

Owner, Dealer, or User

Owner, Dealer, or User

Owner, Dealer, or User

Owner, Dealer, or User

eign materials out of the vital components. Precautions have been taken to safeguard against this.

Shields, covers, seals, and filters are provided to

keep air, fuel, and oil supplies clean; however, these

items must be maintained on a scheduled basis in

order to function properly.

2. At any time when air, fuel, or oil lines are disconnected, clear adjacent areas as well as the openings

and fittings themselves. As soon as a line or component is disconnected, cap or cover all openings to

prevent entry of foreign matter.

3. Clean and inspect all parts during servicing or maintenance, and assure that all passages and openings

are unobstructed. Cover all parts to keep them

clean. Be sure all parts are clean before they are

installed. New parts should remain in their containers until they are ready to be used.

Service

Qualification

Qualified JLG

Mechanic

Qualified JLG

Mechanic

Factory-Trained

Service Technician

(recommended)

Qualified JLG

Mechanic

Reference

Service and Maintenance

Manual and applicable JLG

inspection form.

Service and Maintenance

Manual and applicable JLG

inspection form.

Service and Maintenance

Manual and applicable JLG

inspection form.

Service and Maintenance

Manual

Components Removal and Installation

IT IS GOOD PRACTICE TO AVOID PRESSURE-WASHING ELECTRICAL/ELECTRONIC COMPONENTS. IN THE EVENT PRESSURE-WASHING THE MACHINE IS NEEDED, ENSURE THE

MACHINE IS SHUT DOWN BEFORE PRESSURE-WASHING.

SHOULD PRESSURE WASHING BE UTILIZED TO WASH AREAS

CONTAINING ELECTRICAL/ELECTRONIC COMPONENTS, JLG

INDUSTRIES, INC. RECOMMENDS A MAXIMUM PRESSURE OF

750 PSI (52 BAR) AT A MINIMUM DISTANCE OF 12 INCHES (30.5

CM) AWAY FROM THESE COMPONENTS. IF ELECTRICAL/ELECTRONIC COMPONENTS ARE SPRAYED, SPRAYING MUST NOT

BE DIRECT AND BE FOR BRIEF TIME PERIODS TO AVOID HEAVY

SATURATION.

1. The most important single item in preserving the

long service life of a machine is to keep dirt and for-

2-2 – JLG Lift– 3121824

1. Use adjustable lifting devices, whenever possible, if

mechanical assistance is required. All slings (chains,

cables, etc.) should be parallel to each other and as

near perpendicular as possible to top of part being

lifted.

2. Should it be necessary to remove a component on

an angle, keep in mind that the capacity of an eyebolt or similar bracket lessens, as the angle between

the supporting structure and the component

becomes less than 90°.

3. If a part resists removal, check to see whether all

nuts, bolts, cables, brackets, wiring, etc., have been

removed and that no adjacent parts are interfering.

SECTION 2 - GENERAL

Component Disassembly and Reassembly

When disassembling or reassembling a component, complete the procedural steps in sequence. Do not partially

disassemble or assemble one part, then start on another.

Always recheck your work to assure that nothing has been

overlooked. Do not make any adjustments, other than

those recommended, without obtaining proper approval.

Pressure-Fit Parts

When assembling pressure-fit parts, use an anti-seize or

molybdenum disulfide base compound to lubricate the

mating surface.

Bearings

1. When a bearing is removed, cover it to keep out dirt

and abrasives. Clean bearings in nonflammable

cleaning solvent and allow to drip dry. Compressed

air can be used but do not spin the bearing.

2. Discard bearings if the races and balls (or rollers)

are pitted, scored, or burned.

3. If bearing is found to be serviceable, apply a light

coat of oil and wrap it in clean (waxed) paper. Do not

unwrap reusable or new bearings until they are

ready to install.

4. Lubricate new or used serviceable bearings before

installation. When pressing a bearing into a retainer

or bore, apply pressure to the outer race. If the bearing is to be installed on a shaft, apply pressure to the

inner race.

Hydraulic Lines and Electrical Wiring

Clearly mark or tag hydraulic lines and electrical wiring, as

well as their receptacles, when disconnecting or removing

them from the unit. This will assure that they are correctly

reinstalled.

Hydraulic System

1. Keep the system clean. If evidence of metal or rubber particles are found in the hydraulic system, drain

and flush the entire system.

2. Disassemble and reassemble parts on clean work

surface. Clean all metal parts with non-flammable

cleaning solvent. Lubricate components, as

required, to aid assembly.

Lubrication

Service applicable components with the amount, type,

and grade of lubricant recommended in this manual, at

the specified intervals. When recommended lubricants are

not available, consult your local supplier for an equivalent

that meets or exceeds the specifications listed.

Battery

Clean battery, using a non-metallic brush and a solution of

baking soda and water. Rinse with clean water. After

cleaning, thoroughly dry battery and coat terminals with

an anti corrosion compound.

Lubrication and Servicing

Components and assemblies requiring lubrication and

servicing are shown in the Lubrication Chart in Section 1.

Gaskets

Check that holes in gaskets align with openings in the

mating parts. If it becomes necessary to hand-fabricate a

gasket, use gasket material or stock of equivalent material

and thickness. Be sure to cut holes in the right location, as

blank gaskets can cause serious system damage.

Bolt Usage and Torque Application

1. Use bolts of proper length. A bolt which is too long

will bottom before the head is tight against its related

part. If a bolt is too short, there will not be enough

thread area to engage and hold the part properly.

When replacing bolts, use only those having the

same specifications of the original, or one which is

equivalent.

2. Unless specific torque requirements are given within

the text, standard torque values should be used on

heat-treated bolts, studs, and steel nuts, in accordance with recommended shop practices. (See

Torque Chart Section 1.)

3121824 – JLG Lift – 2-3

SECTION 2 - GENERAL

2.3 LUBRICATION AND INFORMATION

Hydraulic System

1. The primary enemy of a hydraulic system is contamination. Contaminants enter the system by various

means, e.g., using inadequate hydraulic oil, allowing

moisture, grease, filings, sealing components, sand,

etc., to enter when performing maintenance, or by

permitting the pump to cavitate due to insufficient

system warm-up or leaks in the pump supply (suction) lines.

2. The design and manufacturing tolerances of the

component working parts are very close, therefore,

even the smallest amount of dirt or foreign matter

entering a system can cause wear or damage to the

components and generally results in faulty operation. Every precaution must be taken to keep

hydraulic oil clean, including reserve oil in storage.

Hydraulic system filters should be checked,

cleaned, and/or replaced as necessary, at the specified intervals required in the Lubrication Chart in

Section 1. Always examine filters for evidence of

metal particles.

3. Cloudy oils indicate a high moisture content which

permits organic growth, resulting in oxidation or corrosion. If this condition occurs, the system must be

drained, flushed, and refilled with clean oil.

4. It is not advisable to mix oils of different brands or

types, as they may not contain the same required

additives or be of comparable viscosities. Good

grade mineral oils, with viscosities suited to the

ambient temperatures in which the machine is operating, are recommended for use.

NOTE: Metal particles may appear in the oil or filters of new

machines due to the wear-in of meshing components.

Hydraulic Oil

1. Refer to Section 1 for recommendations for viscosity

ranges.

3. The only exception to the above is to drain and fill

the system with Mobil DTE 13 oil or its equivalent.

This will allow start up at temperatures down to -29°

C (-20° F). However, use of this oil will give poor performance at temperatures above 49° C (120° F). Systems using DTE 13 oil should not be operated at

temperatures above 94° C (200° F) under any condition.

Changing Hydraulic Oil

1. Use of any of the recommended hydraulic oils eliminates the need for changing the oil on a regular

basis. However, filter elements must be changed

after the first 50 hours of operation and every 300

hours thereafter. If it is necessary to change the oil,

use only those oils meeting or exceeding the specifications appearing in this manual. If unable to obtain

the same type of oil supplied with the machine, consult local supplier for assistance in selecting the

proper equivalent. Avoid mixing petroleum and synthetic base oils. JLG Industries recommends changing the hydraulic oil annually.

2. Use every precaution to keep the hydraulic oil clean.

If the oil must be poured from the original container

into another, be sure to clean all possible contaminants from the service container. Always clean the

mesh element of the filter and replace the cartridge

any time the system oil is changed.

3. While the unit is shut down, a good preventive maintenance measure is to make a thorough inspection

of all hydraulic components, lines, fittings, etc., as

well as a functional check of each system, before

placing the machine back in service.

Lubrication Specifications

Specified lubricants, as recommended by the component