Page 1

Instructions for Use

LABSIDE

Empress

®

CAD

IPS

Empress®System

IPS

Page 2

Product Information

2

Table of Contents

General

Information

Practical

Working Steps

Fabrication of the IPS Empress CAD Restorations

IPS Empress CAD – Product Information 4

Material

Uses

Composition

Block concept

Product overview and description

Accessories and equipment

IPS Empress CAD – Practical Working Steps 17

Preparation guidelines and minimum thicknesses

Shade determination

Cementation

IPS Empress CAD – Inlays / Onlays – stained / glazed 22

Finishing and preparing for the stain and glaze firing

2-in-1 technique and staining and glaze firing in one step

Corrective firing

IPS Empress CAD – Veneers / Anterior Crowns – stained / glazed 25

Finishing

Preparing for staining

Stain and characterization firing

Glaze firing

Corrective firing

IPS Empress CAD – Veneers / Anterior Crowns – Cut-back and layered 30

Cut-back technique

Preparing for veneering

Wash firing

Incisal / Transparent firing

Finishing and preparing for stain and glaze firing

Stain and glaze firing

Corrective firing

IPS Empress CAD – General Information 38

Preparing for cementation

Firing parameters

Combination table

Page 3

3

Nearly 20 years ago, IPS Empress revolutionized the processing of ceramic and thanks

to its many advantages, such as aesthetics, IPS Empress has been established as the

"benchmark". More than 33 million restorations fabricated of IPS Empress throughout

the world and the use of "IPS Empress" as a synonym for all-ceramics speak for the

durable life-like appearance, the ongoing success, and the high quality standard of the

material.

In addition to the tried-and-tested PRESS technology, the CAD/CAM technology has

also developed in the area of all-ceramics. In order to supply the "benchmark" for this

technology as well, the future IPS Empress System will comprise products for both

processing technologies. You will be able to benefit from roughly 20 years of clinical

experience and convincing aesthetics, irrespective of whether the restorations were

fabricated with the PRESS or CAD/CAM technique.

IPS Empress Esthetic is available for the PRESS technology, while IPS Empress CAD

is used in the CAD/CAM technology. Both products consist of the highly aesthetic,

leucite-reinforced glass-ceramic that has been clinically tried-and-tested for many years.

The two ceramics are characterized by excellent strength values and outstanding

aesthetic appearance. They may thus be used for the fabrication of fully anatomic

single-unit restorations, such as inlays, onlays, veneers, and crowns.

Both products may subsequently be stained and/or glazed using IPS Empress

Universal Shades/Stains, or individually veneered using the IPS Empress Esthetic

Veneer layering ceramic.

In this way, the IPS Empress System will remain synonymous for highly aesthetic, fully

anatomical all-ceramic restorations, irrespective of the processing technology.

Empress

®

– the Original

IPS

PRESS

Technology

CAD / CAM

Technology

Empress

Esthetic

IPS

Empress

IPS

Empress

IPS

EmpressCAD

IPS

Universal Shade/Stains

Esthetic Veneer

Page 4

4

Empress CAD –

Product Information

IPS

Material

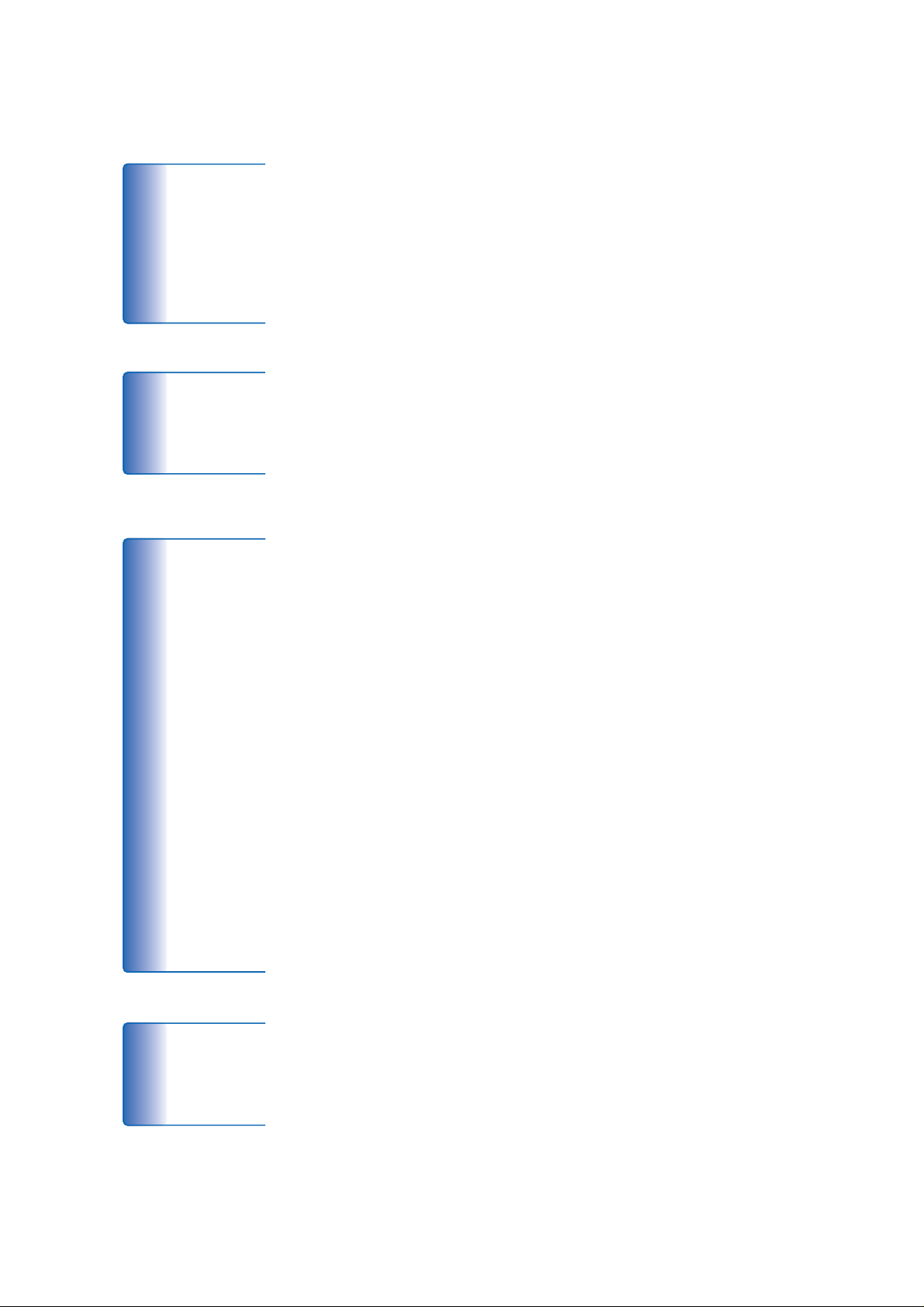

IPS Empress CAD is used for the fabrication of highly aesthetic, fully

anatomical single-unit restorations by means of the CAD/CAM

technology.

IPS Empress CAD blocks are made of a leucite-reinforced glassceramic which consists of a glass and a crystal phase. Leucite

crystals of few microns evenly grow in a multi-stage process directly

from the amorphous glass phase. During the fabrication of the

blocks, the semi-finished product in powder form is pressed to

blocks in a fully automated procedure, which enables a maximum of

homogeneity. Given the difference in the coefficients of thermal

expansion (CTE) between the glass phase and the crystal phase

(leucite), cooling after sintering produces compressive stress in the

glass phase. This mechanism results in an increase in strength and

enables IPS Empress CAD to achieve a flexural strength of 160 MPa.

This type of material has been successful, as well as proven. for

almost 20 years. The milled restorations feature

excellent accuracy of fit and a homogeneous surface. Subsequently,

the restorations may be stained using IPS Empress Universal Stains

and/or veneered using IPS Empress Esthetic Veneer.

CTE (100–400°C) [10-6/K] 16.6

CTE (100–500°C) [10-6/K] 17.5

Flexural strength (biaxial) [MPa]* 160

Fracture toughness [MPa m

0.5

] 1.3

Vickers hardness [MPa] 6200

Chemical resistance [µg/cm2]* 25

*according to ISO 6872

Page 5

5

Uses

Indications

IPS Empress CAD blocks can be used for the following adhesively cemented restorations. Depending on

the type and size of the restoration, the respective HT (High Translucency), LT (Low Translucency), or

Multi Block is recommended. IPS Empress CAD restorations may be cemented either polished,

stained/glazed, or veneered.

For further processing of IPS Empress CAD restorations, users have the following options:

– Aesthetic characterization and glazing of fully anatomical restorations using IPS Empress Universal

Shades, Stains, and Glaze pastes.

– Aesthetic veneering in the incisal third of reduced restorations (veneers and anterior crowns) using

IPS Empress Esthetic Veneer materials

Contraindications

– Bridge reconstructions

– Conventional cementation

– Very deep, subgingival preparations

– Patients with severely reduced residual dentition

– Bruxism

– Fully (circularly) veneered anterior and posterior crowns using IPS Empress Esthetic Veneer

Important processing restrictions

Failure to observe the following restrictions may compromise the success achieved with IPS Empress CAD:

– The fully anatomical IPS Empress CAD restorations must not fall below the required minimum

thickness

– The reduced (cut-back) IPS Empress CAD restorations must not fall below the required minimum

thickness

– The maximum layer thickness of IPS Empress Esthetic Veneers layering materials must not be exceeded

– IPS Empress CAD restorations must not be stained using materials other than IPS Empress Universal

Shades, Stains, and Glaze

– Powder materials must not be mixed with paste materials

– The blocks must not be milled in a non-compatible CAD/CAM system

Side effects

If patients are known to be allergic to any of the ingredients of IPS Empress CAD, the material should

not be used.

HT Blocks

(High Translucency)

Higher translucency and

chameleon effect

Lower brightness value

– Inlays

– Onlays

– Veneers

LT Blocks

(Low Translucency)

Lower translucency and

chameleon effect

Higher brightness value

– Anterior and posterior crowns

– Partial crowns

– Veneers

Multi Blocks

True-to-nature transition

of shade, translucency, and

fluorescence

– Anterior and posterior crowns

– Partial crowns

– Veneers

Page 6

6

Composition

– IPS Empress CAD Blocks

Components: SiO

2

Additional contents: Al2O3, K2O, Na2O, CaO, and other oxides, pigments

– IPS Empress Esthetic Veneer

Components: SiO

2

Additional contents: Al2O3, K2O, Na2O, CaO, oxides and pigments

– IPS Empress Universal Shades, Stains, and Glaze Paste

Components: Oxides, glycerine, butandiol

– IPS Empress Esthetic Veneer Build-Up Liquid

Components: water, butandiol, chloride

– IPS Empress Universal Glaze and Stain Liquid

Components: Butandiol

– IPS Contrast Spray Labside

Components: Pigment suspension in ethanol; the propellant is a propane/butane mixture

– IPS Natural Die Material

Components: Polyester urethane dimethacrylate, paraffin oil, SiO2and copolymers

– IPS Natural Die Material Separator

Components: Wax dissolved in hexane

– IPS Ceramic Etching Gel

Components: Hydrofluoric acid

Warnings

– Butandiol is irritating - avoid contact with skin and eyes and do not inhale the vapours.

– Hexane is highly flammable and detrimental to health. Avoid contact with skin and eyes. Do not

inhale the vapours and keep away from sources of ignition.

– Do not inhale ceramic grinding dust during processing - use suction equipment and a face mask.

– Etching gel contains hydrofluoric acid. Avoid contact with skin, eyes, and clothing at any time, since

the material is highly toxic and corrosive. The etching gel is intended for professional use only and

must not be applied intra-orally (in the oral cavity).

Page 7

7

Block concept

IPS Empress CAD Blocks

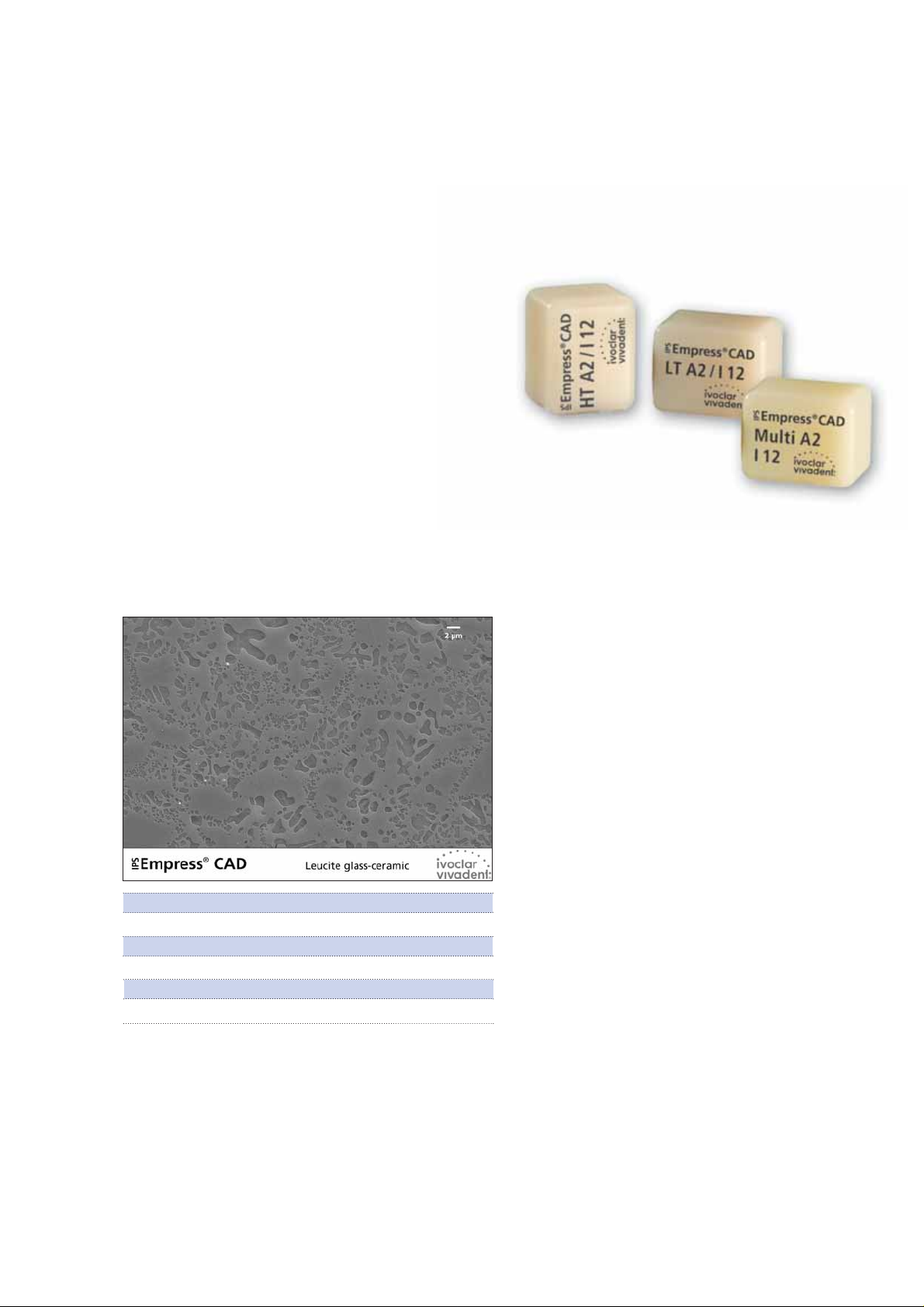

The shading and translucency control of the IPS Empress CAD Blocks is based on a newly developed translucency concept

built on the A-D, Chromascop, and Bleach BL shade guides.

The IPS Empress CAD Blocks are available in two degrees of translucency and as a polychromatic block. The blocks are

precisely coordinated with the respective indications and thus enable excellent shade match with the corresponding shade

guide. Depending on the indication, the blocks provide a true-to-nature chameleon effect, life-like brightness value, or a

natural shade transition.

IPS Empress CAD HT (High Translucency)

These blocks are available in the 9 most popular A–D shades, 3 Chromascop shades, and 4 sizes. Given their high

translucency, HT blocks are ideally suitable for the fabrication of smaller restorations (e.g. inlays and onlays). Restorations

made of HT blocks convince users with their true-to-nature chameleon effect and outstanding adaptation to the residual

tooth structure. The blocks demonstrate life-like fluorescence in order to permit optimum integration into the natural

residual tooth structure under different light conditions.

IPS Empress CAD LT (Low Translucency)

These blocks are available in the 9 most popular A–D shades, 3 Chromascop shades, 4 Bleach BL shades, and 4 sizes. Given

their high brightness value compared to the HT blocks, the LT blocks are ideal for the fabrication of larger restorations (e.g.

anterior and posterior crowns). Restorations made of LT blocks convince users with their true-to-nature brightness value

and chroma, which prevents a greying of the incorporated restorations. The blocks demonstrate a life-like fluorescence in

order to enable optimum integration into the natural environment, even under varying light conditions. Restorations made

of LT blocks are also ideally suitable for the cut-back technique.

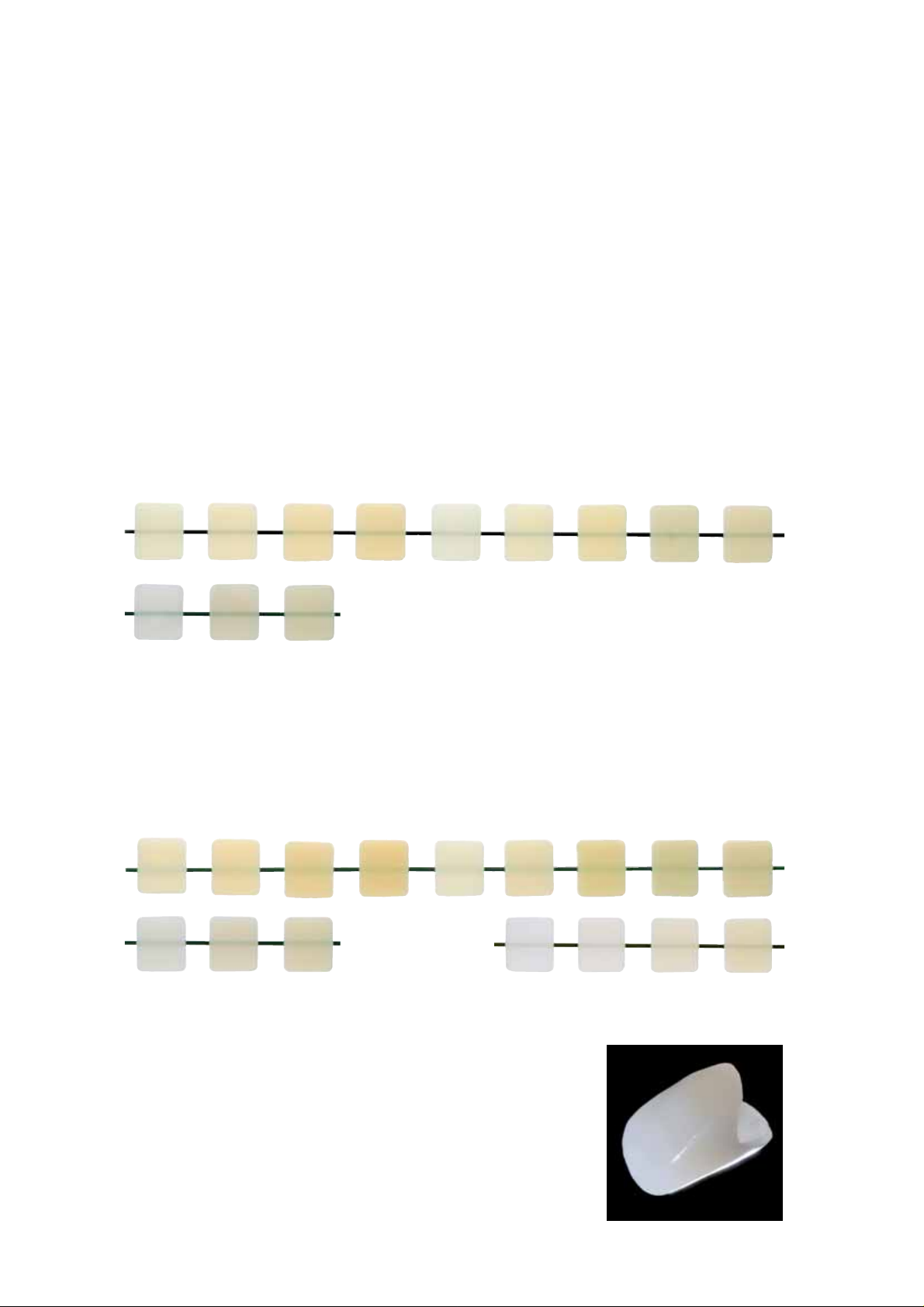

IPS Empress CAD Multi

These blocks are available in the 5 most popular A–D shades and 3 sizes. Given the

natural shade gradient from the dentin to the incisal areas, restorations made of

IPS Empress CAD Multi Blocks demonstrate a maximum of aesthetics and naturalness. In

conjunction with the flexible positioning of the restoration within the block, the true-tonature opacity and translucency gradient enables a multitude of aesthetic possibilities.

The IPS Empress CAD Multi Block features a transition of fluorescence very similar to

that of natural teeth, which results in excellent integration into the residual dentition.

Given the innovative combination of true-to-nature transition of shade, translucency,

and fluorescence, highly aesthetic restorations are fabricated in an easy way.

A–D

Chromascop

A–D

Chromascop Bleach BL

Page 8

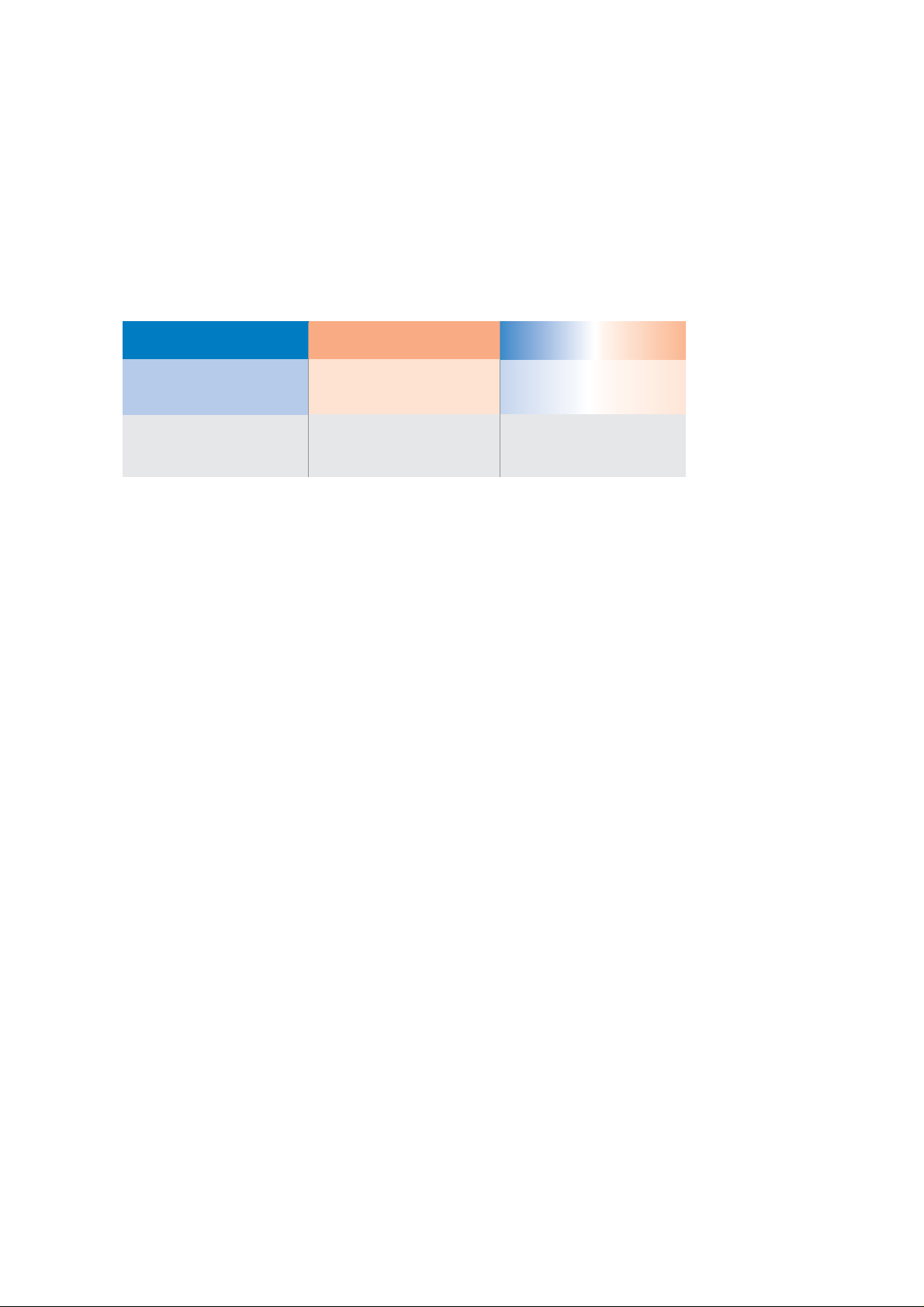

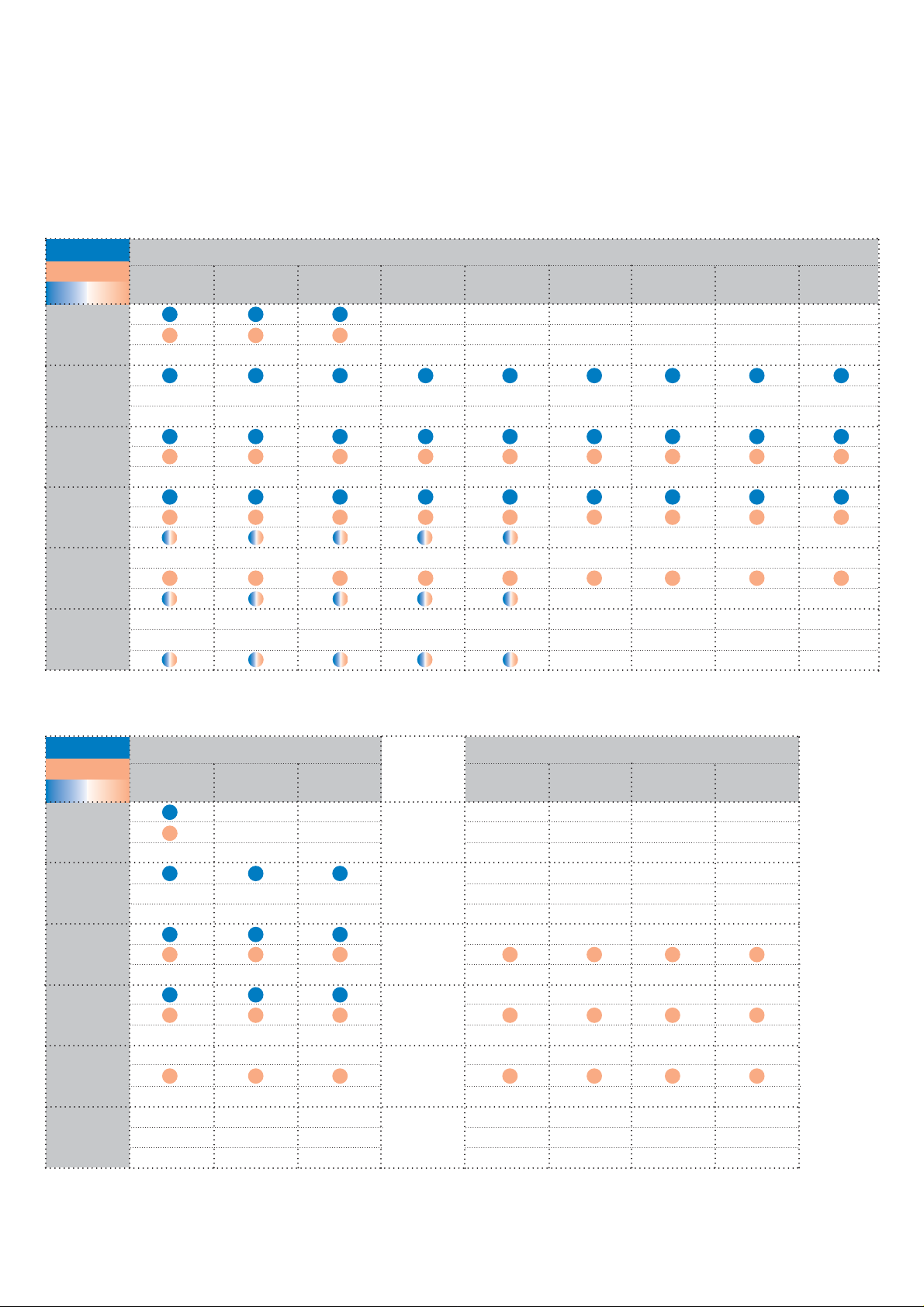

Overview of blocks - shades and sizes*

IPS Empress CAD Blocks are available in the following shades and sizes as Refill vials containing 5 blocks each.

*The available product range may vary from country to country.

A1

A2

A3

A3.5 B1 B2 B3 C2 D3

A–D

V 12

I 8

I 10

I 12

C 14

C14L

LT

Low Translucency

HT

High Translucency

Multi

100

200

300

BL1 BL2 BL3 BL4

Chromascop Bleach BL

V 12

I 8

I 10

I 12

C 14

C14L

LT

Low Translucency

HT

High Translucency

Multi

Page 9

99

Overview of blocks – translucency

Translucency

Opacity

A–D Shades

A1 A2 A3 A3.5 B1 B2 B3 C2 D3

Translucency

Opacity

Chromascop

100 200 300

Bleach BL

BL1 BL2 BL3 BL4

HT Block LT Block

Page 10

10

Product overview and description

IPS Empress CAD for inLab Trial Kit A–D

The Trial Kit contains a small selection of block shapes in A–D

shades, as well as stains and the IPS Empress Esthetic Veneer layering

materials. The Trial Kit thus provides all the necessary products for

the first IPS Empress CAD restorations.

Delivery form:

IPS Empress CAD for inLab Trial Kit A–D

– 5x 1 IPS Empress CAD for CEREC and inLab HT Block;

Shades/sizes: A1/I 10, A2/I 10, A1/I 12, A2/I 12, A3/I 12

– 5x 1 IPS Empress CAD for CEREC and inLab LT Block;

Shades/sizes: A1/I 12, A2/I 12, A1/C 14, A2/C 14, A3/C 14

– 4x IPS Empress CAD for CEREC and inLab Multi Blocks;

Shades/sizes: A1/C 14, A2/C 14, A1/C 14 L, A2/C 14 L

– 3x 1 g IPS Empress Esthetic Veneer Wash Paste;

Shades: neutral, MM light-salmon, MM yellow-orange

– 2x 5 g IPS Empress Esthetic Veneer;

Shades: Incisal Opal HT, Incisal Opal LT

– 1x 3 g IPS Empress Universal Shade; Shade: A2/A3/A3.5

– 1x 3 g IPS Empress Universal Shade Incisal; Shade: I1

– 2x 1 g IPS Empress Universal Stains; Shades: white, mahogany

– 1x 3 g IPS Empress Universal Glaze Paste

– 1x 5 ml IPS Empress Universal Glaze and Stain Liquid

– 1x 5 ml IPS Empress Esthetic Veneer Build-Up Liquid

IPS Empress CAD for inLab Basic Kit A–D

The Basic Kit contains a selection of block shapes in the most

popular A–D shades, as well as the necessary accessories, e.g.

IPS Contrast Spray Labside. Therefore, the Basic Kit provides all the

necessary products for the complete laboratory fabrication

procedure. The Basic Kit is supplied in the new material cabinet and

can be supplemented with any other Ivoclar Vivadent all-ceramic

assortment, e.g. IPS e.max.

Delivery form:

IPS Empress CAD for inLab Basic Kit A–D

– 4x 5 IPS Empress CAD for CEREC and inLab HT Blocks;

Shades/sizes: A1/I 12, A2/I 12, A3/I 12, B1/I 12

– 5x 5 IPS Empress CAD for CEREC and inLab LT Blocks;

Shades/sizes: A1/C 14, A2/C 14, A3/C 14, B1/C 14, BL2/C 14

– 3x IPS Empress CAD for CEREC and inLab Multi Blocks;

Shades/sizes: A1/C 14 L, A2/C 14 L, A3/C 14 L

– 1x 200 ml IPS Contrast Spray Labside

– 1x 12 g IPS Object Fix

– 1x Bleach BL shade guide

Information on the inLab

®

System can be obtained from:

Sirona Dental Systems GmbH

Fabrikstrasse 31

64625 Bensheim

Germany

E-mail: contact@sirona.de

www.sirona.com

inLab®is a registered trademark of Sirona

Dental Systems GmbH

Page 11

11

IPS Empress Veneer Kit

The IPS Empress Veneer Kit comprises a selection of the most

popular wash pastes and layering materials for the cut-back

technique of IPS Empress restorations (Esthetic and CAD). With the

wash pastes, an excellent and homogeneous bond with the reduced

restoration is achieved. The leucite-reinforced layering materials

feature incisal-like fluorescence and a true-to-nature opalescence.

The additional wash pastes and layering materials available as Refills

are indicated on the materials shade guide supplied with the Kit.

Delivery form:

IPS Empress Veneer Kit

– 6x 1 g IPS Empress Esthetic Veneer Wash Pastes;

Shades: neutral, Low Value, High Value, MM light-salmon,

MM yellow-orange, MM red-orange

– 6x 20 IPS Empress Esthetic Veneer;

Shades: Incisal Opal LT, Incisal Opal MT, Incisal Opal HT, Incisal

white, Transpa neutral, Transpa blue

– 1x 20 g IPS Empress Add-On 770°C/1418°F

– 1x 60 ml IPS Empress Esthetic Veneer Build-Up Liquid

– 1x 3 g IPS Empress Universal Glaze Paste

– 1x 15 ml IPS Empress Universal Glaze and Stain Liquid

– 1x 12 g IPS Object Fix

– 1x IPS Empress Esthetic Veneer Material Shade Guide

– Var. accessories

IPS Empress Universal Shade/Stains Kit

(A–D and Chromascop)

The IPS Empress Universal Shade/Stains Kits comprise a selection of

the most popular Dentin and Intensive stains. The stains are suitable

to apply surface characterizations. For the final glazing of the

IPS Empress restorations, a smooth and fine-grained glazing paste is

provided.

Delivery form:

IPS Empress Universal Shade/Stains Kit A–D

– 6x 3 g IPS Empress Universal Shade;

Shades: A1, A2/A3/A3.5, B1, B2/B3/B4, C1/C2, D2/D3

– 2x 3 g IPS Empress Universal Shade Incisal;

Shades: I1, I2

– 5x 1 g IPS Empress Universal Stains;

Shades: white, orange, mahogany, khaki, maroon

– 1x 3 g IPS Empress Universal Glaze Paste

– 1x 15 ml IPS Empress Universal Glaze and Stain Liquid

– Var. accessories

Delivery form:

IPS Empress Universal Shade/Stains Kit Chromascop

– 6x 3 g IPS Empress Universal Shade;

Shades: 110/120, 130, 140/210, 220/230, 310, 410/420

– 2x 3 g IPS Empress Universal Shade Incisal;

Shades: I1, I2

– 5x 1 g IPS Empress Universal Stains;

Shades: white, orange, mahogany, khaki, maroon

– 1x 3 g IPS Empress Universal Glaze Paste

– 1x 15 ml IPS Empress Universal Glaze and Stain Liquid

– Var. accessories

Page 12

12

IPS Empress Esthetic Veneer Wash Pastes

Given the 2 : 1 effect of the wash pastes, i.e. bonding and

characterization in one step, highly aesthetic restorations can be

fabricated very efficiently.

The Wash Paste neutral produces the direct bond to the reduced

restorations and is always applied first on the restoration; it enables

a homogeneous bond.

Delivery form:

– 3x 1 g IPS Empress Esthetic Wash Paste neutral

Subsequently, the reduced restorations are individually characterized

using the 5 Standard Wash Pastes. Ideal shade gradations permit

individualized characterizations of the highest order.

Delivery form:

– 5x 1 g IPS Empress Esthetic Wash Paste;

Shades: low value, high value, MM light-salmon,

MM yellow-orange, MM reddish-orange

The 5 standard wash pastes may then be individually shaded using

the 5 Wash-Paste Modifiers or the neutral paste.

Delivery form:

– 5x 1 g IPS Empress Esthetic Wash Paste;

Shades: Modifier copper, Modifier orange, Modifier sky blue,

Modifier basic yellow, Modifier basic red

IPS Empress Esthetic Veneer Incisal Opal

These opalescent materials are available in three different gradations

(low, medium, and high translucency). They feature an incisal-like

fluorescence and true-to-nature opalescence. The high stability and

excellent modelling properties permit detailed layering of life-like

incisal edges. The opalescent effect demonstrates high firing stability

and is thus clearly visible even after several firing cycles.

Delivery form:

– 3x 20 g IPS Empress Esthetic Veneer Incisal Opal;

Shades: low translucent, medium translucent, high translucent

IPS Empress Esthetic Veneer Incisal

These Incisal materials are available in 6 shade nuances and are used

for additional characterizations in the incisal area.

Delivery form:

– 6x 20 g IPS Empress Esthetic Veneer Incisal;

Shades: white, grey, orange, edge, yellow, orange-pink

Page 13

13

IPS Empress Esthetic Veneer Transpa

The Transparent materials in 2 shade nuances are used for the trueto-nature reproduction of transparent areas, particularly in the incisal

third.

Delivery form:

– 2x 20 g IPS Esthetic Veneer Transpa;

Shades: blue, neutral

IPS Empress Esthetic Veneer Chroma Modifier

These materials support the shade intensity of the reduced

restoration and are available in shades 110/A1 and 210/A3.

Delivery form:

– 2x 20 g IPS Empress Esthetic Veneer Chroma Modifier;

Shades: 110/A1, 210/A3

IPS Empress Esthetic Veneer Brightener

Used to increase the brightness value.

Delivery form:

– 1x 20 g IPS Empress Esthetic Veneer Brightener

IPS Empress Add-On 770°C/1418°F

IPS Empress Add-On 770 °C/1418 °F is a low-fusing add-on material

for subsequent adjustment, e.g. proximal and occlusal contact

points, of IPS Empress Esthetic and IPS Empress CAD restorations.

Delivery form:

– 1x 20 g IPS Empress Add-On 770°C/1418°F

IPS Empress Esthetic Veneer Build-Up Liquid

The Build-Up Liquid is used to mix the IPS Empress Esthetic Veneer

materials and the IPS Empress Add-On corrective material. IPS

Empress Esthetic Veneer Build-Up Liquid must be used since other

build-up liquids may contain organic additives thad could leave a

residue.

Delivery form:

– 1x 60 ml IPS Empress Esthetic Veneer Build-Up Liquid

Page 14

14

IPS Empress Universal Shade

The IPS Empress Universal Shades are available in 9 A–D and

15 Chromascop shades. They are used for the exact reproduction of

the A-D and Chromascop shades.

Delivery form:

– 9x 3 g IPS Empress Universal Shade;

A–D Shades: A1, A2/A3/A3,5, A4, B1, B2/B3/B4, C1/C2, C3/C4,

D2/D3, D4

– 15x 3 g IPS Empress Universal Shade;

Chromascop Shades: 110/120, 130, 140/210, 220/230, 240, 310,

320, 330, 340, 410/420, 430/440, 510, 520, 530, 540

IPS Empress Universal Shade Incisal

These 2 pastes are especially suitable for fully anatomical

restorations. They are used to imitate the incisal area and provide the

incisal third with optical translucency and an in-depth effect.

Delivery form:

– 2x 3 g IPS Empress Universal Shades Incisal;

Shades: I1, I2

IPS Empress Universal Stains

These intensive stains are available in 14 different shades. They are

used to reproduce natural characteristics. With the three

complementary shades basic blue, basic red, and basic yellow, the

shades can be individually adjusted.

Delivery form:

– 14x 1 g IPS Empress Universal Stains;

Shades: white, mahogany, khaki, orange, grey, vanilla, crackliner,

olive, yellow, black, maroon, basic red, basic blue, basic yellow

IPS Empress Universal Glaze Paste

IPS Empress Universal Glazing Paste is used to apply the final glaze to

IPS Empress restorations. The glazing paste demonstrates a smooth,

fine-grained consistency and thus permits easy and quick application

of the glazing material layer.

Delivery form:

– 1x 3 g IPS Empress Universal Glaze Paste

IPS Empress Universal Glaze and Stain Liquid

The IPS Empress Universal Glaze and Stain Liquid is used to adjust

the consistency of all materials in paste form (Wash pastes, Shades,

Stains, and Glaze). No other liquid may be used for this purpose,

since those liquids contain various organic additives that do not fire

without leaving residue at the defined firing temperatures, which

may result in discolouration.

Delivery form:

– 1x 15 ml IPS Empress Universal Glaze and Stain Liquid

Page 15

15

Accessories and equipment

IPS Contrast Spray Labside

The Contrast Spray Labside is used to achieve optimum scans for CAD/CAM

restorations. IPS Contrast Spray Labside balances out the different optical properties of

the stone model, thus enabling an excellent scan. With the atomizing nozzle, an

optimum covering layer with a detailed representation of the edges is achieved easily

and efficiently with only a short spray discharge.

Delivery form:

– 1x 200 ml [275 ml] IPS Contrast Spray Labside

IPS Natural Die Material

The light-curing IPS Natural Die Material simulates the shade of the prepared tooth

and thus is the optimum basis for true-to-nature shade match with the oral situation

during fabrication of the all-ceramic restorations. The IPS Natural Die Material Kit

comprises 9 shades. The shade arrangement was newly designed. The assortment

contains all the shade variants necessary for the fabrication of life-like all-ceramic

restorations. New items in the assortment are as follows:

– 1 shade for the imitation of bleached preparations (ND1)

– 1 shade for the imitation of intensively shaded secondary dentin (ND 6)

– 1 shade for the imitation of severely discoloured / devitalized preparations (ND 9)

Delivery form:

IPS Natural Die Material Kit

– 9x 8 g IPS Natural Die Material,

Shades: ND 1, ND 2, ND 3, ND 4, ND 5, ND 6, ND 7, ND 8, ND 9

– 1x IPS Natural Die Material Separator 20 ml

– 8x 10 IPS Condensers

– 8x 10 IPS Condenser Tips

– 2x Universal Holders

– 1x IPS Natural Die Material Shade Guide

IPS Object Fix

IPS Object Fix is an auxiliary firing paste to support all-ceramic restorations during

firing. The paste is used for easier securing of the restorations on the metal pins of

the honey-comb firing tray. Due to its consistency, IPS Object Fix is easy to apply and

convenient to remove after firing.

Delivery form:

– 1x 12 g IPS Object Fix

ND 1

–

ND 2

St 9

ND 3

St 1

ND 4

St 2

ND 5

St 3

ND 6

–

ND 7

St 8

ND 8

St 5

ND 9

–

IPS Natural Die Material

IPS Empress Die Material

The arrangement and designations of the IPS Natural Die shades compared to the IPS Empress Die is as follows:

IPS Contrast Spray Labside must not be applied intra-orally.

Page 16

16

IPS®Ceramic Etching Gel

IPS Ceramic Etching Gel is used to produce retentive bonding surfaces on ceramic restorations in the composite cementation technique. It enhances the bonding effect between the luting composite

and the ceramic surface. IPS Ceramic Etching Gel is exclusively

intended for professional use and must not be applied in the oral

cavity.

Advantages

– Usable in conjunction with most glass-ceramic materials

– No environmental pollution due to neutralization

Contraindications

– Application in the oral cavity

– Enamel etching of natural teeth

– Use in conjunction with oxide ceramics

Delivery form:

IPS Ceramic Etching Gel Kit

– 1x 5 ml IPS Ceramic Etching Gel

– 1x 30 g Neutralization Powder

– 1 Measuring Spoon

Programat®P300

The Programat P300 features a convincing and easy operating

concept. A simple menu structure with clearly arranged symbols

guides the user during the application of the programs. The furnace

is equipped in the factory with preset programs for IPS e.max,

IPS d.SIGN, IPS InLine, and the IPS Empress System and it convinces

users with its modern, timeless design.

Delivery form:

Programat P300 Basic Equipment

– Programat P300

– Power Cord, Vacuum Hose, Calibration Test Package,

Programat Firing Tray Kit

Programat®P500

Optimum firing results of glazing materials, stains, and ceramic

materials can be achieved with the user-friendly Programat P500

ceramic furnace. This new ceramic furnace combines high-tech and

design. The combination of the membrane-sealed keypad and the

large, clearly-arranged graphic display with touch function facilitate

operation. The homogeneous heat emission due to the new muffle

technology, the easy, precise and automatic temperature calibration,

as well as the 300 firing programs make the P500 and indispensable

companion in the laboratory.

Delivery form:

Programat P500 Basic Equipment

– Programat P500

– Power Cord, Vacuum Hose, Calibration Test Package,

Programat Firing Tray Kit

Page 17

17

Preparation guidelines and minimum thicknesses

Successful results with IPS Empress CAD can only be achieved if the guidelines below and minimum layering thicknesses

are strictly observed. The following minimum thicknesses are required for IPS Empress CAD restorations.

Inlays and Onlays

Static and dynamic antagonist contacts must be taken into consideration. The preparation margins must not be located on

centric antagonist contacts.

A preparation depth of at least 1.5 mm and an isthmus width of at least 1.5 mm must be observed in the fissure area.

Prepare the proximal box with slightly diverging walls and observe an angle of 100–120° between the proximal cavity walls

and the prospective proximal inlay surfaces. For inlays with pronounced convex cavity walls without adequate support by

the proximal shoulder, marginal ridge contacts should be avoided. Round out internal edges in order to prevent stress

concentration within the ceramic material. Eliminate the proximal contacts on all sides. Do not prepare slice-cuts or feather

edges.

Provide at least 2 mm of space in the cusp areas. The shoulder must not show any inclinations, i.e. it must show a 90°

angle to the residual tooth structure. Onlays are indicated if the preparation margin is less than approximately 0.5 mm

away from the cusp tip, or if the enamel is severely undermined.

Empress CAD –

Practical Working Steps

IPS

4°

>1.5

100-120°

>1.5

>2.0

4°

>1.5

>1.5

90°

Page 18

18

Veneers

If possible, the preparation should be entirely located in the enamel. The incisal preparation margins should not be located

in the area of the abrasion surfaces or dynamic occlusal surfaces. By preparing orientation grooves using a depth marker,

controlled enamel reduction can be achieved. Dissolution of the proximal contacts is not required.

For preparations without involving reduction of the incisal edge (only labial reduction), the preparation depth in the

cervical area should be at least 0.6 mm and at least 0.7 mm in the labial area.

For preparation involving reduction of the incisal edge (labial/incisal reduction), the preparation depth in the cervical

area should be at least 0.6 mm, and at least 0.7 mm in the labial area. The incisal edge must be reduced by 1.0 mm. The

extent of the incisal reduction depends on the desired translucency of the incisal area to be built up. The more transparent

the incisal edge of the intended veneer, the more pronounced the reduction should be. Discoloured teeth may require

more preparation.

Anterior and posterior crowns

The anatomical shape is evenly reduced while observing the given minimum thicknesses. A circumferential shoulder is

prepared with rounded inner edges or a chamfer. The width of the circular shoulder should be at least 1 mm. The

incisal/occlusal third is reduced by 2 mm. For anterior crowns, the labial and/or palatal/lingual part of the tooth should be

reduced by at least 1.5 mm. The incisal width of the preparation should measure at least 1 mm (milling tool geometry) in

order to permit optimum milling of the incisal edge during CAD/CAM processing.

> 0.6

>0.7

>0.7

> 0.6

>1.0

>1.0

>1.0

1.5

1.0

2.0

>1.0

1.5

2.0 2.0

1.5

1.5

>1.0

1.5

>1.0

Page 19

19

Shade determination

The correct tooth shade is the basis for a restoration with a life-like appearance. After tooth cleaning, the tooth shade of

the non-prepared tooth and/or the adjacent teeth is determined. Individual characteristics have to be taken into consideration when determining the tooth shade. If a crown preparation is planned, for example, the cervical shade should also be

determined. In order to achieve true-to-nature results, shade determination should be carried out at daylight. Furthermore,

the patient should not wear clothes of intensive colours and/or lipstick. Basically, it has to be kept in mind that the final

shade of the restoration is the result of the following individual shades:

– Die shade

– Shade of the ceramic block

– Shade of the layering ceramic

– Shade of the cementation material

IPS Natural Die Material

In order to facilitate the reproduction of the tooth shade, the shade

of the prepared tooth can be determined with the help of the

IPS Natural Die Material shade guide. This facilitates the fabrication

of the all-ceramic restoration and the individual characteristics of the

preparation may also be taken into consideration. By fabricating a

working die made of IPS Natural Die Materials in the respective

shade of the preparation, the shade and brightness value of the

IPS Empress CAD restorations may be checked during the individual

fabrication steps.

Page 20

20

Cementation

For cementation, the IPS Empress CAD restoration must be conditioned. For this

purpose, the completed restoration is etched with IPS Ceramic Etching Gel and

subsequently silanated using Monobond-S.

Total Etch

For the preparation of adhesive cementation with Variolink II/

Variolink Veneer, Total Etch is used. It is an enamel etching and

dentin conditioning gel used during the adhesive cementation of

all-ceramic restorations.

For the adhesive cementation of IPS Empress CAD restorations, you may choose

between tried-and-tested luting composites from Ivoclar Vivadent. Adhesive

cementation achieves an excellent bond between the preparation and the restoration.

Veneers

Inlays

Onlays

Partial crowns

Anterior and posterior crowns

Variolink

®

(Variolink II, Variolink Veneer)

Multilink

®

(Multilink, Multilink Automix)

––

indicated

contraindicated

––

Page 21

21

Variolink®II

The dual-curing luting composite Variolink II has been used for more

than ten years and in over 20 million restorations. It is the world's

leading highly aesthetic material concept. Numerous awards as the

best product in the category of adhesive luting composites and

excellent results from clinical long-term studies are testimony to this

success.

Variolink®Veneer

Purely light-curing luting composite in 7 "Value" shades for the

adhesive cementation of translucent all-ceramic restorations with a

layer thickness of < 2.0 mm (veneers, inlays, onlays).

Multilink®Automix

The universal, self-curing (with light-curing option) resin based luting

cement Multilink offers a broad range of indications and produces

very high adhesive strength on all material surfaces. Together with

the self-etching Primer, which is applied as a simple preliminary layer

on enamel and dentin, Multilink is processed quickly and efficiently.

Page 22

22

The 2-in-1 technique is suitable for efficient glazing and staining of inlays, onlays, and partial crowns. In this technique, the

glaze and stain firing is conducted in one single step. This technique does not permit as many shade adjustments as a

separate stain firing. If more intensive and extensive shade adjustments are desired, we recommend conducting a separate

stain and characterization firing (as described in the following chapter).

IPS Empress CAD Inlays / Onlays – stained/glazed

Please refer to the corresponding Operating Instructions and/or Manuals of the respective CAD/CAM system

for further information on the CAD/CAM processing procedure. The instructions by the manufacturer must be

observed.

Finishing and preparing for stain and glaze firing

For finishing glass-ceramics, appropriate grinding instruments are indispensable. If the

wrong grinding instruments are used, marginal chipping and local overheating my occur.

The following procedure is recommended for finishing IPS Empress CAD restorations:

– Use only suitable, fine-grained (grain size < 60 µm), ceramic-bonded grinding instruments

or diamonds at a speed of up to 20,000 rpm and little pressure.

– Overheating the glass-ceramic must be prevented.

– Smooth out attachment point of the holder and take the proximal contact points into

account.

– Carry out individual shape adjustments, if required.

Before the stain and glaze firing, the restorations must be free of dirt and grease. Avoid any

contamination after cleaning. Observe the following procedure.

– Clean the restoration with ultrasound in a water bath or blast with Al2O3at 0.5 bar

pressure (Caution: abrasive) and clean under running water or using the steam jet.

– Certain blasting devices require different settings for the intended blasting procedure.

2-in-1 Technique – Stain and glaze firing using IPS Empress Universal

Once the restoration has been cleaned, apply the stains and glazing material in 2 steps. First, the glazing paste is applied,

followed by the stains, which are applied on the unfired glaze layer. The following working procedure should be observed.

Step 1 – Application of the glazing material

– Extrude IPS Empress Universal Glazing Paste from the syringe and mix thoroughly.

– Thin the material to the desired consistency using IPS Empress Universal Glaze and Stain Liquid. Do not excessively dilute

the material, since this may render the glazing procedure difficult to control.

– Apply the glazing material on the entire outer surfaces of the restoration.

– The glazing material must not come into contact with the inner aspects of the restoration.

– Avoid pooling and excessively thick glazing material layers.

– Too thin glazing material layers result in an unsatisfactory gloss.

Fabrication of an IPS Empress CAD Restoration

Clean the restoration before staining.

Smooth out attachment point and take proximal contacts into account.

Page 23

23

Step 2 – Application of Shades / Stains

– Extrude IPS Empress Universal Shade or Stains from the syringe and mix thoroughly.

– Thin the material to the desired consistency using IPS Empress Universal Glaze and Stain Liquid.

– Apply the mixed Shade material directly into the unfired glazing material layer.

– Intensify the corresponding dentin shade in the cervical and occlusal areas using IPS Empress Universal Shades.

– To imitate the incisal area and translucency in the incisal third, use IPS Empress Universal Shade Incisal.

– Apply individualized effects and characterizations on cusps and in fissures using the Stains materials. Only apply the

Stains once staining with the Shade materials has been completed.

– Apply the Stains thinly and in a controlled manner on the unfired glazing material layer using a brush.

Apply the mixed Shade material directly into the unfired glazing material layer.

Intensify the corresponding dentin shade in the cervical and occlusal areas and imitate the incisal area using Shade Incisal.

Apply individualized effects and characterizations on cusps and in fissures using the Stains

materials.

Evenly apply the glazing material on the entire outer surfaces of the restoration.

Page 24

24

Completed IPS Empress CAD restoration,stained and glazed in one step.

IPS Empress CAD with IPS Empress Universal B S t T H V

1

V

2

Stain and Glaze firing 403°C 6' 100°C 790°C 1–2' 450°C 789°C

757°F 6' 180°F 1454°F 1–2' 842°F 1453°F

Firing parameters for the Stain and Glaze firing (note the temperature control)

Optional

Subsequent adjustment

After completion, additional adjustment (e.g. contact points) may become necessary. For that purpose,

IPS Empress Add-On 770 °C/1418 °F is available.

Processing:

– Before the adjustment, the restoration must be free from dirt and grease. For that purpose, thoroughly clean the

restoration using the steam jet.

– Mix IPS Empress Add-On 770 °C / 1418 °F to a workable consistency. Make sure that the add-on material and liquid are

evenly mixed so that an optimum firing result can be achieved.

– Apply the mixed add-on material on the cleaned, desired areas using a brush and slightly blot them with an absorbent

cloth.

– Position the adjusted restoration on the firing tray and fire in the ceramic furnace.

– After firing, manually polish the supplemented areas to a high gloss.

IPS Empress CAD with B S t T H V1 V2

IPS Empress Add-On 770°C/1418°F

Corrective firing 403°C 4' 60°C 770°C 2' 450°C 769°C

757°F 4' 108°F 1418°F 2' 842°F 1417°F

Firing parameters for the corrective firing

Place the objects on the honey-comb firing tray and start

the firing program

After glazing and staining, the glaze and stain firing is conducted in a compatible ceramic furnace (e.g. P500).

The following points should be observed when placing the restoration in the furnace and setting the firing parameters:

– Support inlays, onlays, and partial crowns with a firing pillow and place them on a honey-comb firing tray.

– Place veneers as well as anterior and posterior crowns on metal pins and position them on the honey-comb firing tray.

– As an alternative to the firing pillow and to better secure the restoration

on the metal pins (particularly with veneers), a small amount of

IPS Object Fix may also be used.

– Restorations supported with a firing pillow on the honey-comb tray are

exposed to less heat due to their lower position in the firing chamber.

Therefore, in order to achieve a true-to-nature gloss, it is recommended

to extend the holding time from 1 minute to 2 minutes.

– Make sure that the firing pillow is regularly replaced in order to prevent

contamination. Keep firing pillows used for all-ceramic materials

separated from those for metal-ceramics to avoid cross-contamination.

Page 25

25

If more intensive and excessive shade adjustments are desired, we recommend conducting them in several working steps.

To reproduce the tooth shade easily and reliably, an individual control die may be fabricated using the

IPS Natural Die Material. The IPS Empress Universal Shades and Stains are then applied in a first step and separately fired.

The shade result can be checked after firing. If required, the shade of the restoration may be intensified and adjusted to

the individual patient case by repeated application of the materials. Once the desired shade has been achieved and the

individualized characterizations completed, the glaze firing is conducted.

IPS Empress CAD Veneers / Crowns – stained/glazed

Please refer to the corresponding Operating Instructions and/or Manuals of the respective CAD/CAM system

for further information on the CAD/CAM processing procedure. The instructions by the manufacturer must be

observed.

Finishing

For finishing glass-ceramics, appropriate grinding instruments are indispensable. If the wrong grinding instruments are

used, marginal chipping and local overheating may occur.

The following procedure is recommended for finishing IPS Empress CAD restorations:

– Use only suitable, fine-grained (grain size < 60 µm), ceramic-bonded grinding instruments or diamonds at a speed of up

to 20,000 rpm and little pressure.

– Carefully finish the restoration margins using rubber and silicone polishers

(Speed: <10,000 rpm)

– Overheating the glass-ceramic must be prevented.

– Smooth out attachment point of the holder and take the proximal

contact points into account.

– Carry out individual shape adjustments, if required.

– Design the surface structure somewhat more pronounced, if necessary,

since it will be toned down by the glazing procedure.

Optional

Die fabrication using IPS Natural Die Material

The light-curing IPS Natural Die Material simulates the shade of the prepared tooth. Fabricate a control die of the selected

shade. This control die supports the optimum shade adaptation of the restoration to reproduce the given oral situation.

– Coat the inner surfaces of the ceramic restorations with IPS Natural Die Material Separator and allow it to react for a

short time.

– Apply die IPS Natural Die Material in the corresponding shade to the inner aspects of the restoration using the

IPS Condenser and adapt so that the entire inner aspect is coated and filled.

– Completely fill the restoration cavity and insert an IPS Die Holder into

the material and adapt excess material around the holder. Make sure

that the Die Material is well adapted to the restoration margins and

that no gaps are present.

– Polymerize the IPS Natural Die Material die with a commercial

polymerization light for 60 seconds.

– After polymerization, the die can be finished and or smoothed, if

required.

The control die made of IPS Natural Die Material is the optimum basis

for a true-to-nature all-ceramic restoration.

Design individual shape adjustments and a true-to-nature

surface structure

Page 26

26

Preparing for staining

Before the stain and characterization firing, the restorations must be free

of dirt and grease. Avoid any contamination after cleaning.

Observe the following procedure.

– Clean the restoration with ultrasound in a water bath or blast with

Al2O3at 0.5 bar pressure (Caution: abrasive) and clean under running

water or using the steam jet.

– Certain blasting devices require different settings for the intended

blasting procedure.

Stain and glaze firing using IPS Empress Universal Shade and Stains

Once the restoration has been cleaned, the stain and characterization firing is conducted. Observe the following working

procedure:

– Extrude IPS Empress Universal Shade or Stains from the syringe and mix thoroughly.

– Thin the material to the desired consistency using IPS Empress Universal Glaze and Stain Liquid.

– For better wetting of the stains, a small quantity of IPS Empress Universal Glaze and Stain Liquid may be slightly rubbed

into the surface.

– Apply the mixed Shade material directly unto the surface.

– Intensify the corresponding dentin shade in the cervical and central crown thirds using IPS Empress Universal Shades.

– Excessively thick or thin material layers should be prevented.

– More intensive shades are achieved by repeated staining, rather than by applying thicker layers.

– To imitate the incisal area and translucency in the incisal third, use IPS Empress Universal Shade Incisal.

– Design individualized affects and characterizations using the Stains material.

– Apply the Stains thinly and in a controlled manner using a brush.

The dentin body is intensified using IPS Empress Universal Shade

Individualized effects and characterizations are designed using IPS Empress Universal Stains

The incisal area is imitated using IPS Empress Universal Shade Incisal

Before staining, clean the restoration using the steam jet

Page 27

27

After staining, the stain and characterization firing is conducted in a compatible ceramic furnace (e.g. P500). The following

points should be observed when placing the restoration in the furnace and setting the firing parameters:

– Place veneers as well as anterior and posterior crowns on metal pins and position them on the honey-comb firing tray.

– To better secure the restoration on the metal pins (particularly with veneers), a small amount IPS Object Fix may also be

used.

IPS Empress CAD with IPS Empress Universal B S t T H V1 V2

Stain and Characterization firing 403°C 6' 100°C 790°C 1' 450°C 789°C

757°F 6' 180°F 1454°F 1' 842°F 1453°F

Firing parameters for the Stain and Characterization firing (note the temperature control)

Place the objects on the honey-comb firing tray and start the firing program

Optional

Shade check

To check the tooth shade after the first stain and characterization firing,

proceed as follows:

– Wet inner aspects of the restoration with IPS Contour Glaze and Stain

Liquid using a brush.

– Place the restoration on the individual control die and check the tooth

shade, as well as the individualized effects.

– If adjustments are required, apply the corresponding stains and fire

them using the above firing program.

Shade check. If necessary,the shade intensity can be increased

by additional staining.

Page 28

28

Glaze firing with IPS Empress Universal Glaze

Once the desired shade has been achieved and the individualized characterizations completed, the glaze firing is

conducted. Observe the following working procedure::

– Extrude IPS Universal Glazing Paste from the syringe and mix thoroughly.

– Thin the material to the desired consistency using IPS Empress Universal

Glaze and Stain Liquid. Do not excessively dilute the material, since this

may render the glazing procedure difficult to control.

– Apply the glazing material on the entire outer surfaces of the restoration.

– The glazing material must not come into contact with the inner aspects

of the restoration.

– Avoid pooling and excessively thick glazing material layers.

– Excessively thin glazing material layers result in an unsatisfactory gloss.

– The objects are positioned on the honey-comb firing tray same as for

the previous firing procedure.

– Then, the glaze firing is conducted in a compatible ceramic furnace

(e.g. Programat P500).

– If the gloss is unsatisfactory after the first glaze firing, further glaze

firing procedures may be conducted using the same firing parameters.

Place the objects on the honey-comb firing tray and start

the firing program.

Evenly apply the glazing material on the entire outer surfaces

of the restoration.

IPS Empress CAD with IPS Empress Universal B S t T H V1 V2

Glaze firing 403°C 6' 100°C 790°C 1–2' 450°C 789°C

757°F 6' 180°F 1454°F 1–2' 842°F 1453°F

Firing parameters for the glaze firing (note the temperature control)

Completed, stained,and glazed IPS Empress CAD crown and veneer.

Page 29

29

Optional

Subsequent adjustment

After completion, additional adjustment (e.g. contact points) may become necessary. For that purpose,

IPS Empress Add-On 770 °C/1418 °F is available.

Procedure:

– Before the adjustment, the restoration must be free from dirt and grease. For that purpose, thoroughly clean the

restoration using the steam jet.

– Mix IPS Empress Add-On 770 °C / 1418 °F to a workable consistency. Make sure that the add-on material and liquid are

evenly mixed so that an optimum firing result can be achieved.

– Apply the mixed add-on material on the cleaned, desired areas using a brush and slightly blot them with an absorbent

cloth.

– Position the adjusted restoration on the firing tray and fire in the ceramic furnace.

– After firing, manually polish the supplemented areas to a high gloss.

IPS Empress CAD with B S t T H V1 V2

IPS Empress Add-On 770°C/1418°F

Corrective firing 403°C 4' 60°C 770°C 2' 450°C 769°C

757°F 4' 108°F 1418°F 2' 842°F 1417°F

Firing parameters for the corrective firing

Page 30

30

In order to individualize restorations in the incisal area so that they correspond with their natural model, the IPS Empress

CAD restoration is additionally veneered using opalescent IPS Empress Esthetic Veneer ceramic materials. The cut-back

technique is very efficient if the fully anatomical anterior crown or the veneer are first designed according to the definite

final shape. After that, the incisal third is reduced and subsequently provided with an individualized aesthetic veneer.

IPS Empress CAD Veneers / Anterior Crowns – Cut-back and layered

Please refer to the corresponding Operating Instructions and/or Manuals of the respective CAD/CAM system

for further information on the CAD/CAM processing procedure. The instructions by the manufacturer must be

observed.

IPS Empress Esthetic Veneer

Wash Pastes

neutral low value high value MM

light-

salmon

MM

yelloworange

MM

reddish-

orange

Modifier

copper

Modifier

orange

Modifier

sky blue

Modifier

basic yellow

Modifier

basic red

IPS Empress Esthetic Veneer

Layering Materials

Incisal

Opal

HT = high

translucent

Incisal

Opal

MT = medium

translucent

Incisal

Opal

LT= low

translucent

Transpa

blue

Transpa

neutral

Incisal

edge

Incisal

white

Incisal

grey

Incisal

orange

Incisal

yellow

Incisal

orange-

pink

Chroma

Modifier

110/A1

Chroma

Modifier

210/A3

Brightener

Fully anatomical, milled veneer and anterior crown,which are reduced in the incisal area.

0.5 mm

0.5 mm

0.5 mm

approx.

0.5–1.0 mm

Veneer

Minimum thickness

of the milled objects

after the

corresponding

reduction

= 0.5 mm

Layer thickness =

Limited layering area:

labial, incisal third

0.5 mm

approx.

0.5–1.0 mm

Minimum thickness

of the milled objects

after the

corresponding

reduction

= 0.5 mm

Layer thickness =

Limited layering area:

labial, incisal third

Anterior crown

Page 31

31

Cut-back technique

Before the cut-back is carried out, the following points must be observed:

– Use only suitable, fine-grained (grain size < 60 µm), ceramic-bonded grinding instruments or diamonds at a speed of up

to 20,000 rpm and little pressure.

– Carefully finish the restoration margins using rubber and silicone polishers (Speed: <10,000 rpm)

– Overheating the glass-ceramic must be prevented.

– If the wrong grinding instruments are used, marginal chipping and local overheating may occur.

– Smooth out attachment point of the holder and take the proximal contact points into account.

– Before the cut-back the veneer or anterior crown should correspond with the final tooth shape.

– The incisal length must be exactly defined and the occluding surfaces taken into account.

– A palatal silicone key is used as a reference for the cut-back.

– The silicone key should slightly embrace the incisal edge.

Please see page 25 for information about the

fabrication of a control die using IPS Natural Die

Material.

Before the cut-back the veneer or anterior crown should correspond with the final tooth shape. Fabricate a palatal silicone key.

The control die made of IPS Natural Die Material is the optimum basis for sound

shade reproduction.

Page 32

32

The cut-back is conducted in 3 steps. Only in this way is a targeted and controlled reduction possible. The following

working procedure should be observed:

– Use only suitable grinding instruments for the cut-back (e.g. ceramic-bonded grinding instruments and diamonds) at low

speed.

– Too much pressure and excess heat development during grinding must be prevented.

– The thickness of the reduced IPS Empress CAD restoration must not fall below the required minimum of 0.5 mm.

– Step 1: Proximal cut-back - the mesial and distal ridges are reduced.

– Step 2: Labial/incisal cut-back - volume and length are tapered and reduced

– Step 3: Mamelon cut-back - design life-like mamelons using abrasive silicone disks at low pressure.

– Refrain from designing too extreme mamelons with undercuts.

Too much pressure and excess heat development during cut-back must be prevented. Step 1: Proximal cut-back – the mesial and distal ridges are reduced.

Step 2: Labial/incisal cut-back – volume and length are tapered and reduced.

Completed cut-back of the incisal third.

Step 3: Mamelon cut-back – design lifelike mamelons using abrasive silicone disks.

Refrain from designing too extreme mamelons with undercuts.

Page 33

33

Preparing for veneering

Before veneering, the restorations must be free of dirt and grease. Avoid any contamination after cleaning.

Observe the following procedure:

– Clean the restoration carefully by blasting with Al2O3at 0.5 bar pressure (Caution: abrasive) and clean with ultrasound

in a water bath or using the steam jet.

– Certain blasting devices require different settings for the intended blasting procedure.

Veneering of IPS Empress CAD with IPS Empress Esthetic Veneer

The IPS Empress CAD restoration is veneered and finished in 3 steps:

Step 1: IPS Empress Esthetic Veneer Wash Paste for an excellent bond and in-depth shading

Step 2: IPS Empress Esthetic Veneer for individualized aesthetics in the incisal third

Step 3: IPS Empress Universal Shade/Stains and Glaze for final staining and glazing

Wash firing with IPS Empress Esthetic Veneer Wash Pastes

The wash firing enables an optimum bond to the reduced IPS Empress CAD restorations.

The following working procedure should be observed:

– Extrude IPS Empress Esthetic Veneer Wash Paste neutral from the syringe and thin it with a small amount of IPS Empress

Universal Glaze and Stain Liquid, if required.

– Apply IPS Empress Esthetic Veneer Wash Paste neutral thinly on the entire surface to be veneered, in order to enable an

optimum bond.

– Depending on the individual patient situation, design mamelons.

– Apply internal effects using Modifier (pure or diluted).

– The mamelons and internal effects are applied on the unfired Wash Paste neutral layer.

– Note: The shade intensity will not be noticeably changed during firing.

– Place veneers and anterior crowns on the honey-comb firing tray with the help of metal pins. Additionally support the

veneers with a small amount IPS Object Fix.

Carefully blast the restoration with Al2O3at 0.5 bar pressure (Caution: abrasive) Clean the restoration with ultrasound in a water bath or using the steam jet

Apply IPS Empress Esthetic Veneer Wash Paste neutral thinly on the entire surface to be

veneered, in order to enable an optimum bond.

Apply mamelons and internal effects.

Page 34

34

Place restorations on the honey-comb firing tray and fire.

Build up the materials in accordance with the reduction.

For a life-like incisal third,combine various materials and layer.

Firing parameters for the Wash firing (note the temperature control)

IPS Empress CAD with B S t T H V1 V2

IPS Empress Esthetic Veneer

Wash firing 403°C 4' 60°C 840°C 2' 450°C 839°C

757°F 4' 108°F 1544°F 2' 842°F 1543°F

Firing parameters for the 1stIncisal/Transpa firing (note the temperature control)

IPS Empress CAD with B S t T H V1 V2

IPS Empress Esthetic Veneer

1stIncisal/Transpa firing 403°C 4' 60°C 830°C 2' 450°C 829°C

757°F 4' 108°F 1526°F 2' 842°F 1525°F

1stIncisal/Transpa firing with IPS Empress Esthetic Veneer

The incisal third is built-up according to the silicone key. The matching layering materials are listed in the Combination

Table on Page 41. The following working procedure should be observed:

– Mix IPS Empress Esthetic Veneer ceramic materials with the IPS Empress Esthetic Veneer Build-Up Liquid.

– The mixed material should demonstrate good stability. If this is not the case, either too much or too little Build-Up Liquid

was added.

– Build up the materials in accordance with the reduction using a ceramic brush.

– If a life-like incisal third is desired, various materials maybe combined and layered.

– Once the tooth shape has been completed, allow the ceramic material to dry for a short period of time.

– Place veneers and anterior crowns on the honey-comb firing tray with the help of metal pins. Additionally support the

veneers with a small amount of IPS Object Fix.

Page 35

35

2ndIncisal/Transpa firing (corrective firing) with IPS Empress Esthetic Veneer

After firing, carefully place the restoration on the model and rework. Proceed as follows for the 2ndfiring:

– Clean the restoration with ultrasound in a water bath or with the steam jet and completely dry it.

– Already mixed ceramic material may be rewetted with distilled water, or mix fresh IPS Empress Esthetic Veneer materials

with the Build-Up Liquid.

– Complete the missing areas taking the final tooth shape into account.

– Once the tooth shape has been completed, allow the ceramic material to dry for a short period of time.

– Place veneers and anterior crowns on the honey-comb firing tray with the help of metal pins. Additionally support the

veneers with a small amount IPS Object Fix.

Complete the tooth shape with the 2ndfiring and fire using the firing parameters below.

Finish the restoration with diamonds and give it a true-to-nature shape and surface structure.

Firing parameters for the 2ndIncisal/Transpa firing (note the temperature control)

IPS Empress CAD with B S t T H V

1

V

2

IPS Empress Esthetic Veneer

2ndIncisal/Transpa firing 403°C 4' 60°C 830°C 2' 450°C 829°C

757°F 4' 108°F 1526°F 2' 842°F 1525°F

Finishing and preparing for stain and glaze firing

Before the stain and glaze firing, the restoration has to be finished as follows:

– Finish the restoration using diamonds and give it a true-to-nature shape and surface structure, such as growth lines and

convex/concave areas.

– The surface structure may have to be worked out more strongly, since it has been weakened by the glazing procedure.

– The areas that are not covered with layering ceramic have to be smoothed out and prepolished using silicone disks in

order to obtain an even gloss on the surface after glaze firing.

Page 36

36

Clean restoration with ultrasound in a water bath or using the steam jet. Evenly apply the glazing material to the entire outer surfaces of the restoration.

Apply the mixed Shades directly into the unfired glazing material layer. Completely layered IPS Empress CAD crown and veneer fabricated in the cut-back technique.

Stain and glaze firing with IPS Empress Universal

The stain and glaze firing is carried out using IPS Empress Universal Shade, Stains, and Glaze material. Depending on the

situation, they can be conducted together or one after the other (see pages 22–24 for further details). Before the stain and

glaze firing, the restoration must be free of dirt and grease. Any contamination after cleaning must be prevented.

The following working procedure should be observed:

– Before staining and glazing, clean the restoration with ultrasound in a water bath or using the steam jet.

– To check the shade, wet the inner aspects of the restoration with IPS Empress Universal Glaze and Stain Liquid, position

the restoration on the control die, and check shade and effects.

– Extrude IPS Empress Universal Glazing Paste from the syringe and mix thoroughly.

– Thin the material to the desired consistency using IPS Empress Universal Glaze and Stain Liquid. Do not excessively dilute

the material, since this may render the glazing procedure difficult to control.

– Apply the glazing material a little thicker on areas that are not covered with layering ceramic. In this way, an even gloss

can be achieved.

– The glazing material must not come into contact with the inner aspects of the restoration.

– Avoid pooling and excessively thick glazing material layers.

– Excessively thin glazing material layers result in an unsatisfactory gloss.

– To intensify the dentin shade in the cervical and central crown third, mix the corresponding Shade material and apply it

directly into the unfired glazing material layer.

– Place veneers and anterior crowns on the honey-comb firing tray with the help of metal pins. Additionally support the

veneers with a small amount IPS Object Fix.

Firing parameters for the Stain and Glaze firing (note the temperature control)

Optional

– If the restoration has been optimally prepolished (silky-mat gloss) in the cervical area (not covered with layering ceramic),

the glazing material can be applied in these areas only. The layering ceramic features a true-to-nature gloss without the

glazing materials.

– If a more intensive shade is required in the cervical area, we recommend conducting a separate stain firing.

IPS Empress CAD with IPS Empress Universal B S t T H V1 V2

Stain and Glaze firing 403°C 6' 100°C 790°C 1–2' 450°C 789°C

Zahnform mit dem 2. Brand komplettieren und analog den Brennparametern brennen.

757°F 6' 180°F 1454°F 1–2' 842°F 1453°F

Page 37

37

Optional

Subsequent adjustment

After completion, additional adjustment (e.g. contact points) may become necessary. For that purpose,

IPS Empress Add-On 770 °C/1418 °F is available.

Procedure:

– Before the adjustment, the restoration must be free from dirt and grease. For that purpose, thoroughly clean the

restoration using the steam jet.

– Mix IPS Empress Add-On 770 °C / 1418 °F to a workable consistency. Make sure that the add-on material and liquid are

evenly mixed so that an optimum firing result can be achieved.

– Apply the mixed add-on material on the cleaned, desired areas using a brush and slightly blot them with an absorbent

cloth.

– Position the adjusted restoration on the firing tray and fire in the ceramic furnace.

– After firing, manually polish the supplemented areas to a high gloss.

IPS Empress CAD with B S t T H V1 V2

IPS Empress Add-On 770°C/1418°F

Corrective firing 403°C 4' 60°C 770°C 2' 450°C 769°C

757°F 4' 108°F 1418°F 2' 842°F 1417°F

Firing parameters for the corrective firing

IPS Empress CAD cut-back and layered – the ideal combination for highly aesthetic, CAD/CAM fabricated restorations.

Page 38

38

Empress CAD –

General Information

IPS

Conditioning of the ceramic surface in preparation for cementation is decisive for generating a sound bond between the

luting material and the all-ceramic restoration. The following working procedure should be observed:

– Leucite-reinforced glass-ceramic materials are generally etched with IPS Ceramic Etching Gel and subsequently silanated

using Monobond-S.

Preparing for cementation

IPS Empress CAD

Indication Veneers, inlays, onlays, partial crowns, anterior and posterior crowns

Cementation method Adhesive cementation

Etching of the restoration 60 seconds, using IPS Ceramic Etching Gel

Conditioning / Silanating

Monobond-S

of the restoration

Cementation system Variolink II or Variolink Veneer

Multilink Automix

Conventional cementation and blasting of finished IPS Empress CAD restoration is contraindicated!

Page 39

39

Firing of leucite-reinforced glass-ceramic restorations

– Always use the honey-comb firing tray to fire the restorations.

- Support inlays, onlays, and partial crowns with a firing pillow and place them on the honey-comb firing tray.

- Place veneers as well as anterior and posterior crowns on metal pins and position them on the honey-comb firing tray.

- As an alternative to the firing pillow and to better secure the restoration on the metal pins (particularly with veneers), a

small amount of IPS Object Fix may also be used.

- The firing temperatures must be observed at all times. Increasing the firing temperature will result in severe vitrification

between the framework and the veneering ceramic, which may lead to crack formation later on.

- Depending on the working habits, the glaze and stain firing procedures may also be conducted with a temperature

increase rate of 60 °C/108 °F per minute.

- If a vacuum pump is available, the stain and glaze firing procedures may also be carried out with a vacuum in place.

- Restorations supported with a firing pillow on the honey-comb tray are exposed to less heat due to their lower position

in the firing chamber. In order to achieve a true-to-nature gloss nonetheless, it is recommended to extend the holding

time from 1 minute to 2 minutes.

- The firing parameters specified in this Instructions for Use are coordinated with the Ivoclar Vivadent ceramic furnaces

(tolerance range ±10 °C/18°F).

– If furnaces other than those from Ivoclar Vivadent are used, temperature adjustments may be necessary.

Firing parameters

– These firing parameters represent standard values applicable to the ceramic furnaces from Ivoclar Vivadent.The

temperatures indicated also apply to furnaces of older generations,e.g. P20, P90, P95, P80, P100, P200. If one of these

furnaces is used, however,the temperatures may deviate by ± 10°C/18°F, depending on the age and type of the heating

muffle..

– If a non-Ivoclar Vivadent furnace is used,temperature corrections may be necessary.

– Regional differences in the power supply or the operation of several electronic devices by means of the same circuit

may render adjustments of the firing and press temperatures necessary.

Page 40

40

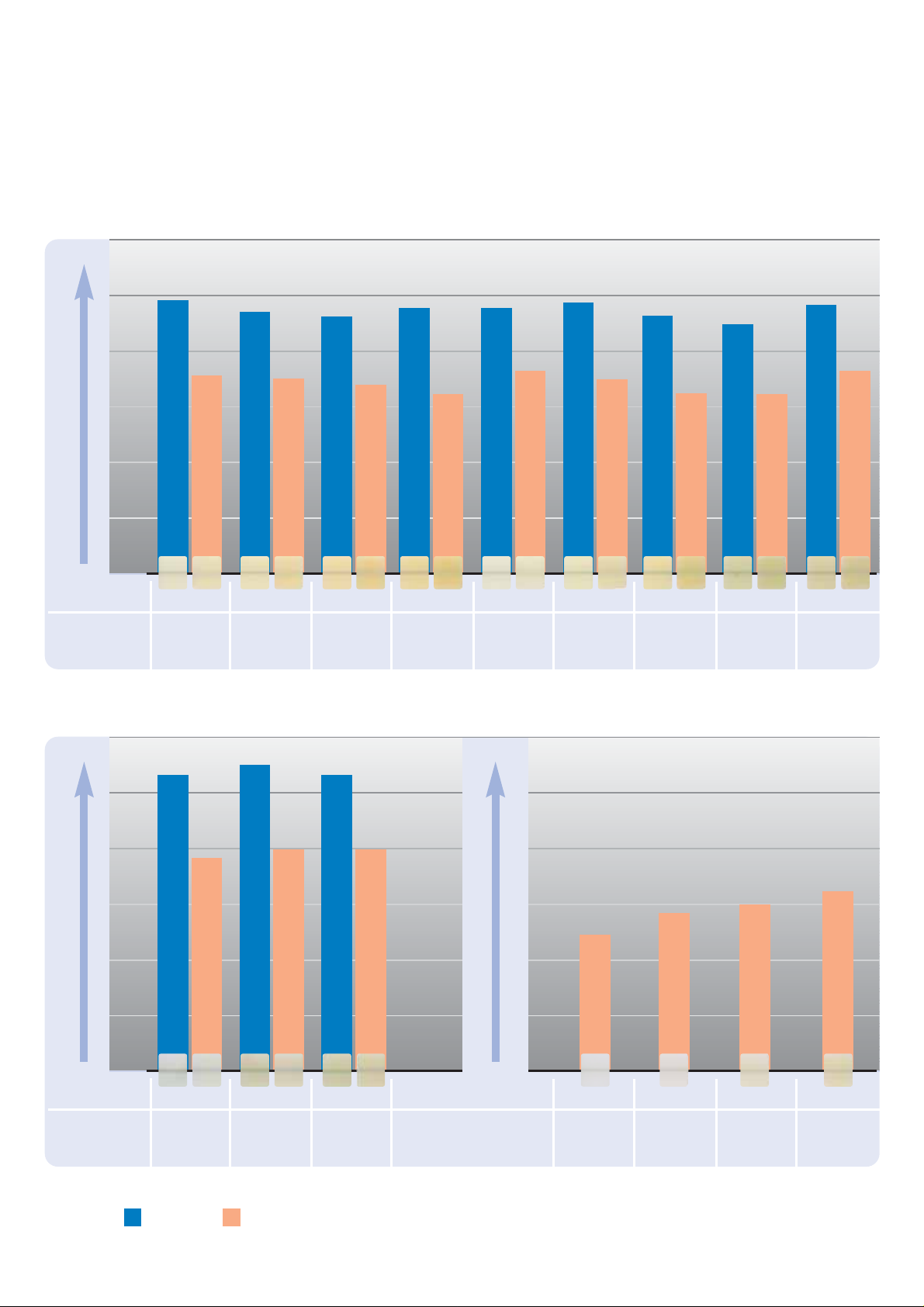

IPS Empress CAD with IPS Empress Universal – stained

IPS Empress CAD with IPS Empress Universal B S t T H V1 V2

2-in-1 Technique

Stain and Glaze firing 403°C 6' 100°C 790°C 1–2' 450°C 789°C

757°F 6' 180°F 1454°F 1–2' 842°F 1453°F

Corrective firing 403°C 4' 60°C 770°C 2' 450°C 769°C

IPS Empress Add-On 770°C/1418°F 757°F 4' 108°F 1418°F 2' 842°F 1417°F

IPS Empress CAD with IPS Empress Esthetic Veneer – veneered

IPS Empress CAD with B S t T H V1 V2

IPS Empress Esthetic Veneer

Cut-back and veneered

Washbrand 403°C 4' 60°C 840°C 2' 450°C 839°C

757°F 4' 108°F 1544°F 2' 842°F 1543°F

1

st

Incisal/Transpa firing 403°C 4' 60°C 830°C 2' 450°C 829°C

757°F 4' 108°F 1526°F 2' 842°F 1525°F

2

nd

Incisal/Transpa firing 403°C 4' 60°C 830°C 2' 450°C 829°C

757°F 4' 108°F 1526°F 2' 842°F 1525°F

Stain and Characterization firing 403°C 6' 100°C 790°C 1' 450°C 789°C

757°F 6' 180°F 1454°F 1' 842°F 1453°F

Glaze firing 403°C 6' 100°C 790°C 1–2' 450°C 789°C

757°F 6' 180°F 1454°F 1–2' 842°F 1453°F

Corrective firing 403°C 4' 60°C 770°C 2' 450°C 769°C

IPS Empress Add-On 770°C/1418°F 757°F 4' 108°F 1418°F 2' 842°F 1417°F

IPS Empress CAD with IPS Empress Universal B S t T H V1 V2

Stain and Characterization firing 403°C 6' 100°C 790°C 1' 450°C 789°C

757°F 6' 180°F 1454°F 1' 842°F 1453°F

Glaze firing 403°C 6' 100°C 790°C 1–2' 450°C 789°C

757°F 6' 180°F 1454°F 1–2' 842°F 1453°F

Corrective firing 403°C 4' 60°C 770°C 2' 450°C 769°C

IPS Empress Add-On 770°C/1418°F 757°F 4' 108°F 1418°F 2' 842°F 1417°F

B = Stand-by temperature °C / °F

S = Closing time/minutes

t

= Temperature increase rate °C/min./ °F/min.

T = Firing temperature °C /°F

H = Holding time / min.

V

1

= Vacuum-on temperature °C / °F

V

2

= Vacuum-off temperature °C / °F

Page 41

41

Empress®CAD – Combination Tables

IPS

A1

A1

ND 2

A2

A2

ND 2

A3

A3

ND 3

A3.5

A3.5

ND 4

A4

A3.5

ND 8

B1

B1

ND 2

B2

B2

ND 2

B3

B3

ND 5

B4

B3

ND 5

C1

B1

ND 2

C2

C2

ND 7

C3

C2

ND 7

C4

C2

ND 7

D2

C2

ND 7

D3

D3

ND 2

D4

D3

ND 3

HT LT MT MT MT HT LT LT LT MT MT MT MT MT MT MT

A1

I1 I1 I1 I2

A4

I2

B1

I1 I1 I1 I1 I2 I2 I2 I2 I2 I2

D4

I2

neutral

low value, high value

MM l-s, MM y-o, MM r-o

copper, orange, sky blue, basic yellow, basic red

T neutral, T blue

I white, I grey, I orange, I edge, I yellow, I orange-pink

110/A1, 210/A3

white, mahogany, khaki, orange, grey, vanilla, crackliner, olive, yellow, black, maroon, basic red, basic blue, basic yellow

A-O

A2/A3/A3.5

B2/B3/B4

C1/C2 C3/C4

D2/D3

A–D

IPS Empress CAD Blocks

IPS Natural Die Material

IPS Empress Esthetic Veneer

Wash Paste

IPS Empress Esthetic Veneer

Wash Paste Value

IPS Empress Esthetic Veneer

Wash Paste Mamelon

IPS Empress Esthetic Veneer

Wash Paste Modifier

IPS Empress Esthetic Veneer

Incisal Opal

IPS Empress Esthetic Veneer

Transpa

IPS Empress Esthetic Veneer

Incisal

IPS Empress Esthetic Veneer

Incisal Chroma Modifier

IPS Empress Esthetic Veneer

Brightener

IPS Empress Universal

Shade

IPS Empress Universal

Shade Incisal

IPS Empress Universal

Stains

IPS Empress Add-On

770°C/1418°F

Brightener

Combination Tables

The listed combinations are standard combinations. The A–D and Chromascop shades that are not available as IPS Empress CAD Blocks may be achieved using the following procedure:

– Selection of the closest block shade

– Staining and intensifying of the dentin shade using IPS Empress Universal Shade and Shade Incisal.

Page 42

42

110

ND 2

120

ND 2

130

ND 2

140

ND 2

210

ND 3

220

ND 3

230

ND 4

240

ND 4

310

ND 5

320

ND 5

330

ND 5

340

ND 5

410

ND 7

420

ND 7

430

ND 7

440

ND 7

510

ND 8

520

ND 8

530

ND 8

540

ND 8

HT LT LT LT MT MT MT MT LT MT MT MT MT MT MT MT MT MT MT MT

I1 I1

130

I1 I1 I1 I1 I1

240

I2

310

I1

320

I1

330

I2

340

I2 I2 I2 I2 I2

510

I2

520

I2

530

I2

540

I2

neutral

low value, high value

MM l-s, MM y-o, MM r-o

copper, orange, sky blue, basic yellow, basic red

T neutral, T blue

I white, I grey, I orange, I edge, I yellow, I orange-pink

110/A1, 210/A3

white, mahogany, khaki, orange, grey, vanilla, crackliner, olive, yellow, black, maroon, basic red, basic blue, basic yellow

A-O

110/120

140/210

220/230

100 200

300

200

300

410/420 430/440

Chromascop

IPS Empress CAD Blocks

IPS Natural Die Material

IPS Empress Esthetic Veneer

Wash Paste

IPS Empress Esthetic Veneer

Wash Paste Value

IPS Empress Esthetic Veneer

Wash Paste Mamelon

IPS Empress Esthetic Veneer

Wash Paste Modifier

IPS Empress Esthetic Veneer

Incisal Opal

IPS Empress Esthetic Veneer

Transpa

IPS Empress Esthetic Veneer

Incisal

IPS Empress Esthetic Veneer

Incisal Chroma Modifier

IPS Empress Esthetic Veneer

Brightener

IPS Empress Universal

Shade

IPS Empress Universal

Shade Incisal

IPS Empress Universal

Stains

IPS Empress Add-On

770°C/1418°F

Brightener

Page 43

43

BL1

BL1

ND 1

BL2

BL2

ND 1

BL3

BL3

ND 1

BL4

BL4

ND 1

LT LT LT LT

I1 I1 I1 I1

neutral

low value, high value

MM l-s, MM y-o, MM r-o

copper, orange, sky blue, basic yellow, basic red

T neutral, T blue

I white, I grey, I orange, I edge, I yellow, I orange-pink

110/A1, 210/A3

white, mahogany, khaki, orange, grey, vanilla, crackliner, olive, yellow, black, maroon,

basic red, basic blue, basic yellow

A-O

Brightener

Bleach BL

IPS Empress CAD Blocks

IPS Natural Die Material