Page 1

RS-3000

Power Supply Controller

User's Manual

518-028 Revision B, July 2008

Page 2

instruments

Power Supply Controller

RS-3000

Preface

Warranty

SYCON INSTRUMENTS, INC.

Policy

Sycon Instruments, Inc. (Sycon) warrants that all electronic instrumentation

equipment manufactured by Sycon shall be free from defects in materials and workmanship

for a period of 2 years from date of shipment. Mechanical vacuum components such as

feedthroughs, sensors, cables, and shutters shall be warranted for a period of six months

from the date of shipment. For the duration of the warranty period Sycon will, at its option,

either repair or replace any part which is defective in materials or workmanship without

charge to the purchaser. The foregoing shall constitute the exclusive and sole remedy of

the purchaser for any breach by Sycon of this warranty.

This warranty does not apply to any equipment which has not been used in

accordance with the specifications recommended by Sycon for the proper and normal use

of the equipment. Sycon shall not be liable under any circumstances for consequential or

incidental damages in connection with, or arising out of the sale, performance, or use of,

the equipment covered by this warranty.

This warranty is in lieu of all other warranties by Sycon, expressed or implied,

including the implied warranty of merchantability, the implied warranty of fitness for a

particular purpose, and warranty against infringement of any patent.

EQUIPMENT RETURN

Before returning any equipment to Sycon contact the Product Service Department in

your area for instructions. Obtain a Return Authorization (RA) number and indicate this

number on all shipping cartons and correspondence. Ship all items in suitable containers

with adequate protection from outside damage.

Sycon Instruments, Inc.

6757 Kinne Street

East Syracuse, New York

13057-1215

Phone (315) 463-5297

Fax (315) 463-5298

Preface

Page i

Warranty

Page 3

RS-3000

Power Supply Controller

instruments

Warranty

Page ii

Preface

Page 4

instruments

Power Supply Controller

RS-3000

Table of Contents

PREFACE ..................................................................................................................................... I

WARRANTY ...................................................................................................................................... I

TABLE OF CONTENTS .......................................................................................................................III

LIST OF TABLES ............................................................................................................................... IV

LIST OF FIGURES ..............................................................................................................................V

SECTION 1 ...................................................................................................................................1-1

DESCRIPTION OF EQUIPMENT............................................................................................................ 1-1

SECTION 2 ...................................................................................................................................2-1

CONNECTIONS.................................................................................................................................. 2-1

FRONT PANEL INTERFACE ................................................................................................................ 2-1

SECTION 3 ...................................................................................................................................3-1

SPECIFICS ........................................................................................................................................ 3-1

3.1 Program mode..............................................................................................................3-1

3.2 Manual mode................................................................................................................3-1

3.3 Ramp mode..................................................................................................................3-2

3.4 Remote mode...............................................................................................................3-2

3.5 Error/problem Conditions .............................................................................................3-3

3.6 Hardware Specifics ......................................................................................................3-3

SECTION 4 ...................................................................................................................................4-1

SPECIFICS ........................................................................................................................................ 4-1

4.1 Events and modes........................................................................................................4-1

SECTION 5 ...................................................................................................................................5-1

SERVICE........................................................................................................................................... 5-1

Preface

Page iii

Table of Contents

Page 5

RS-3000

Power Supply Controller

instruments

List of Tables

Table 3-1 Programmable Elements..........................................................................................3-1

Table 3-2 Back-panel 15-pin D-sub Male Pin Descriptions......................................................3-5

Table 3-3 Back-panel 15-pin D-sub Female Pin Descriptions..................................................3-6

Table 4-1 Manual Mode ...........................................................................................................4-1

Table 4-2 Ramp Mode..............................................................................................................4-2

Table 4-3 Remote Mode...........................................................................................................4-3

Table 4-4 Program Mode .........................................................................................................4-3

List of Tables

Page iv

Preface

Page 6

instruments

Power Supply Controller

RS-3000

List of Figures

Figure 1-1 RS-3000 Front Panel................................................................................................1-1

Figure 1-2 RS-3000 Back Panel ................................................................................................1-2

Figure 4-1 Mode Navigation ......................................................................................................4-4

Figure 4-2 Program Mode Navigation........................................................................................4-5

Preface

Page v

List of Figures

Page 7

RS-3000

Power Supply Controller

instruments

List of Figures

Page vi

Preface

Page 8

instruments

y

y

,

Power Supply Controller

RS-3000

Section 1

Description of Equipment

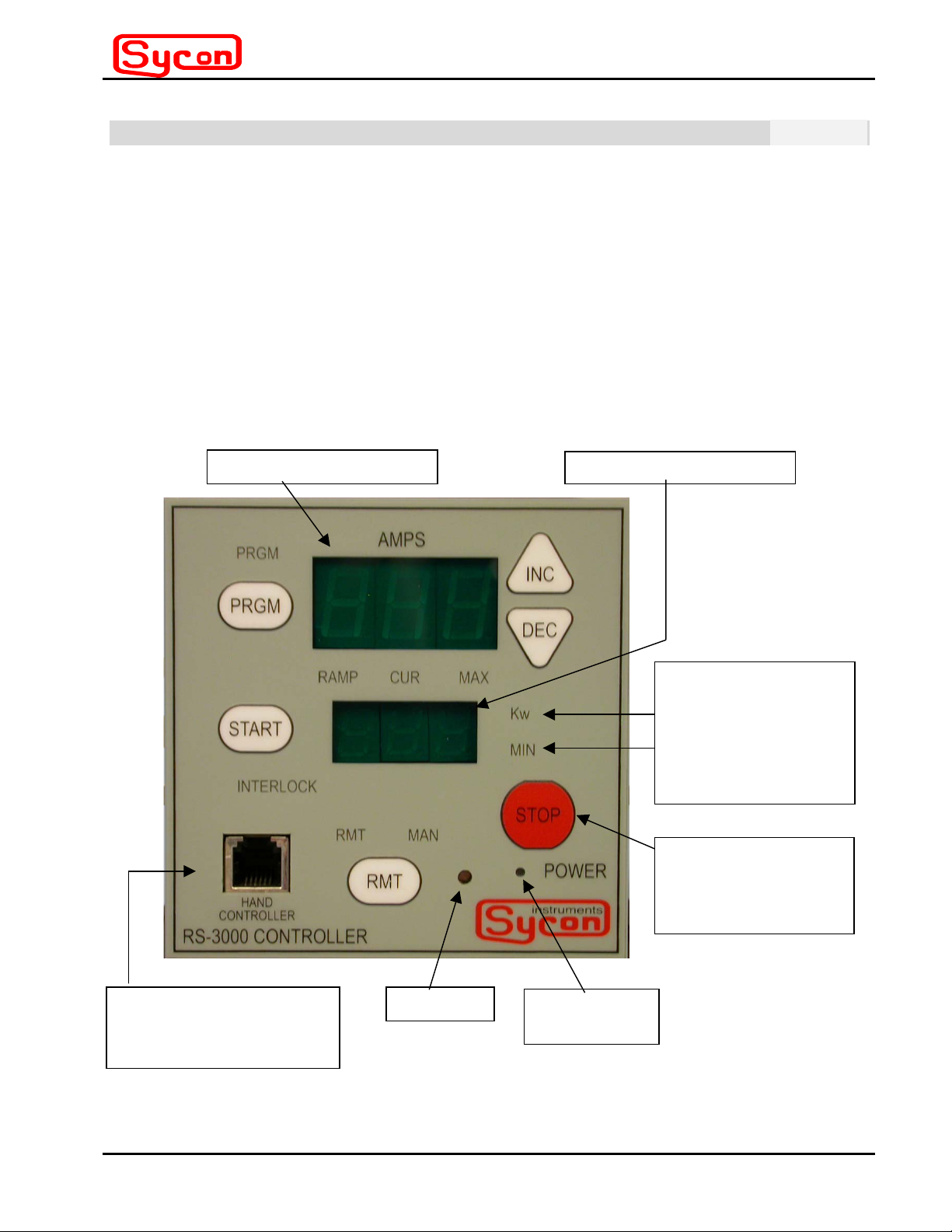

The RS-3000 functions as a user interface for the T3000 resistive power supply, and

supplies the control voltages needed to operate the T3000. The RS-3000 also displays

system faults in text message form or by indicator LEDs.

The RS-3000 can be controlled from the front panel, with a hand controller (or pendant), or

via the back-panel RS-232 connection.

Programmable parameters include: Maximum current, current ramp time, ramp current,

beeper control, and communication settings (mode, speed).

For uses requiring PID control loop capability, a remote control unit (such as the STC-2000)

can be connected to the RS-3000.

large 3 character displa

small 3 character displa

HAND CONTROLLER /

PENDANT

CONNECTOR [RJ-11]

BEEPER

Figure 1-1 RS-3000 Front Panel

POWER ON

INDICATOR

LED illuminated text

indicators (9 places):

PRGM, RAMP, CUR,

MAX, Kw, MIN,

INTERLOCK, RMT,

MAN

Pushbutton Keys

(6 places):

PRGM, INC, DEC,

START

RMT, STOP

Section 1

Page 1 - 1

Description of Equipment

Page 9

RS-3000

[

]

Power Supply Controller

To T3000 POWER

SUPPLY

15 pin D-SUB MALE

instruments

RS232/485

com port

[RJ-11]

Grounding

Stud

To ext. control (STC-

2000)

[15 pin D-SUB FEMALE]

Figure 1-2 RS-3000 Back Panel

Description of Equipment

Page 1 - 2

Section 1

Page 10

instruments

Power Supply Controller

RS-3000

Section 2

Connections

There is a 15 pin d-sub male connector at the back of the unit that is used to connect to

the T3000 power supply.

The RS-3000 is powered by the T3000 power supply.

There is a 15 pin d-sub female connector at the back of the unit that is used to connect

the RS-3000 unit to a more sophisticated control unit (such as the STC-2000).

There is a 6 pin modular connector (RJ-11) at the back of the unit for RS232/485

communication. This allows remote control of the RS-3000 by a PC.

There is a 6 pin modular connector (RJ-11) at the front of the unit for a hand controller.

The standard hand controller cord length is 6 feet when the coiled cord is fully extended.

Front Panel Interface

There are 6 front panel keys that are used to program the unit, change modes, and

start/stop the unit.

There are two 3 character displays.

The larger display is located near the top of the front panel.

The smaller display is located near the center of the front panel.

The larger display can show: mode (such as O.F.F. or Err), ramp current, and current.

If problems occur, an Error message is indicated by the letters Err appearing in the

larger display.

In program mode (current or new values can be seen or set): max current, ramp

current, beeper [on/off], speed, and address.

The smaller display can show: minutes and kilowatts

If problems occur, an error message is shown on the smaller display.

Examples are: Opn (for open boat) or Hot (for power supply over temperature

condition).

In program mode (existing or new values can be seen or set): ramp minutes,

[beeper] on/off, etc.

There are 9 LED illuminated indicators. Some indicators show the mode status: PRGM

(for program mode), RMT (for remote mode), and MAN (for manual mode). Other

indicators are associated with and show the value type of the data shown on the displays.

For example, with the first press of the program key (PRGM) the large display shows a

value, and the CUR and MAX LED indicators are illuminated. This indicates that the value

shown on the large display is the maximum current. With the second press of the program

Section 2

Page 2 - 1

Connections

Page 11

RS-3000

Power Supply Controller

instruments

key (PRGM) the large display is blanked while the small display shows a value. The LED

indicators that are illuminated now include the RAMP and MIN LEDs. This indicates that

the value shown on the small display is the ramp minutes. With the third press of the

program key (PRGM) the small display is blanked while the large display shows a value.

The LED indicators that are illuminated now include the RAMP and CUR LEDs. This

indicates that the value shown on the large display is the ramp current. In these cases, the

INC and DEC keys are used to set the values as needed. The program (PRGM) key

sequences through the programmable elements with each subsequent press until all

elements have been shown. In the programming mode, the program mode LED is

illuminated and flashing. When the program mode LED turns off the last of the

programmable elements is no longer shown and displays revert to the mode context from

which the program mode was launched.

Front Panel Interface

Page 2 - 2

Section 2

Page 12

instruments

Power Supply Controller

RS-3000

Section 3

Specifics

3.1 Program mode

Press PGRM key to enter the programmable parameter sequence.

The PGRM LED illuminates and flashes to indicate activity within the programming mode.

All programmable elements are modified by pressing the INC and DEC keys.

Table 3-1 Programmable Elements

Programmable element Where shown LED indicators/display Sequence element no.

maximum current large display CUR, MAX 1 (see descriptions below)

ramp minutes small display RAMP, MIN 2

ramp current large display RAMP, CUR 3

beeper (on/off) small display text bpr (large display) 4

comm. speed small display text Spd (large) 5

address small display text Adr (large) 6

Maximum current

number values in the range of 0-600 Amps (parallel wired outputs) or 0-300 Amps (series

wired outputs).

Ramp minutes: The INC/DEC keys increment and decrement through a sequence of

number values in the range of 0.0-99.9 minutes.

Ramp current

number values in the range of 0-600 Amps (parallel wired outputs) or 0-300 Amps (series

wired outputs).

Beeper on/off

Communication speed

of number values: 9600 baud, 38400 baud, and 115000 baud.

Address

: The INC/DEC keys increment and decrement through a sequence of number

values in the range of 0-9. RS232 is address 0 (hex address 0X10), and RS485 are

addresses 1-9 (hex addresses X52 – X5A).

All of the above elements are saved in non-volatile memory. To purge and set NV memory

to factory default values, press PRGM/DEC/RMT keys on power up (text message appears

to indicate default successful).

3.2 Manual mode

Whether the RS-3000 is in manual mode or ramp mode is determined by the

programmable value of ramp minutes. If ramp minutes is at zero, that is, 0.0, then manual

: The INC/DEC keys increment and decrement through a sequence of

: The INC/DEC keys increment and decrement through a sequence of

: The INC/DEC keys toggle between the values of on and off.

: The INC/DEC keys increment and decrement through a sequence

Section 3

Page 3 - 1

Specifics

Page 13

RS-3000

Power Supply Controller

instruments

mode will be entered when the start key is pressed. This is confirmed by the illumination of

the MAN LED indicator.

In the manual mode, the AMPS value shown in the large display can be varied using the

INC and DEC keys on the front panel or pendant. The AMPS value displayed is the basis

for what is requested from the power supply. Meanwhile, the small display alternately

shows Kilowatts and minutes. The Kilowatts value is the power being expended at the

supply output. The time value is the elapsed time from the press of the start key. The

Kilowatts and time values are differentiated by the illumination of either the Kw or MIN

LEDs. Pressing the stop key ends the manual mode which is confirmed by the display of

the text O.F.F. in the large display. The pendant stop key is equivalent to the front panel

stop key. Pressing the stop key places the RS-3000 into a quiescent state where the power

output ON/OFF signal to the T3000 is set to OFF (see section 10.1, pin 13) and the RS3000 analog output to control the T3000 power output is set to zero (see section 10.1, pin

7).

3.3 Ramp mode

Whether the RS-3000 is in manual mode or ramp mode is determined by the value of ramp

minutes. If ramp minutes is at a non-zero value, that is, any value but 0.0, then ramp mode

will be entered when the start key is pressed. This is confirmed by the fact that the MIN

value is counting down and that the MAN LED is not illuminated. Ramp mode does not

have a specific LED indicator.

In the ramp mode, the AMPS value shown in the large display changes based on the

programmed values of ramp current and ramp minutes. The AMPS value displayed is the

basis for what is requested from the power supply. Meanwhile, the small display alternately

shows Kilowatts and minutes. The Kilowatts value is the power being expended at the

supply output. The time value is the remaining time until ramping terminates at the desired

current. The Kilowatts and time values are differentiated by the illumination of either the Kw

or MIN LEDs. Pressing the stop key ends the ramp mode which is confirmed by the display

of the text O.F.F. in the large display. If the stop key is not pressed, the MINutes value will

count down to zero (while the power ramps up to the programmed value) and then the unit

will automatically go into the manual mode after zero minutes remaining has been

achieved. When in the manual mode the MINutes time will advance indefinitely at the last

power level set during the ramp mode.

Pressing the stop key during the RAMP mode or in the subsequent Manual mode, places

the RS-3000 into a quiescent state where the power output ON/OFF signal to the T3000 is

set to OFF (see section 10.1, pin 13) and the RS-3000 analog output to control the T3000

power output is set to zero (see section 10.1, pin 7).

3.4 Remote mode

This mode uses a remote controller (such as the STC-2000) to control the power supply

output.

Pressing the RMT key puts the unit into the remote mode. This is confirmed by the

illumination of the RMT LED. Pressing the RMT key again takes the unit out of the remote

Specifics

Page 3 - 2

Section 3

Page 14

instruments

Power Supply Controller

RS-3000

mode. During the remote mode, only Kilowatts and AMPS are shown. The stop key on the

front panel or pendant can also be used to cancel the remote mode.

The connection to the RS-3000 from the remote controller is through a 15 pin female DSUB connector on the back panel.

3.5 Error/problem Conditions

3.5.1 Interlock: is indicated by the illumination of the INTERLOCK LED on the front panel.

This indicates that continuity of the interlock system is open. The T3000 power

supply will not be controlled until this condition has been satisfied with a digital low

or ground (see section 3.6.10.2, pin# 3).

3.5.2 Open boat: indicated on the large and small displays in terse text as Err Opn (error

open). Indicates an open boat. This condition must be sensed after power is

applied and therefore a reset on the power supply can take a while to re-sense the

open boat condition. The T3000 power supply will not be controlled until this

condition has been satisfied with a digital low or ground (see section 3.6.10.1, pin#

1).

3.5.3 Over temperature: indicated on large and small displays in terse text as Err Hot

(error hot). Indicates an over temperature condition within the power supply. This

condition is sensed immediately and will not allow a reset on the power supply to

properly reset until the temperature has returned to a normal temperature range.

The T3000 power supply will not be controlled until this condition has been satisfied

with a digital low or ground (see section 3.6.10.1, pin# 9).

3.5.4 OOP: when indicated on both the large and small displays, this means that the

system has encountered a microcontroller induced reset from which it has

recovered. Condition indicates possible memory or microcontroller failures.

3.5.5 Err/PrG: indication for NV mem default due to error. This error condition can be

cleared by pressing the PRGM key.

3.5.5 Current maximum: when the requested current reaches the maximum value, the

MAX LED indicator blinks.

3.6 Hardware Specifics

3.6.1 Size:

7/8

3

inches wide X 3

3/4

inches high X 5

5/8

inches deep.

Rack mountable next to the T3000 power supply

3.6.2 Weight:

1.1 pounds

3.6.3 Voltage / Current requirements:

800 mA (290 mA quiescent in O.F.F. mode) for +5 VDC,

Section 3

Page 3 - 3

Specifics

Page 15

RS-3000

Power Supply Controller

2 mA for +12 VDC (use Sycon approved power supply only)

3.6.4 Beeper:

Audible (when enabled) in the 80-90 decibel range @ ~2.5 KHz

3.6.5 Case:

Aluminum with a grounding stud which is common to all connector shields.

Shield/case ground is interconnected to RS-3000 digital ground within the product

with a 1kΩ resistor.

3.6.6 Hand controller/pendant:

Has a 6 ft. coiled cord. Has an RJ-11 connector at one end and at the other end, a

module having 3 keys for remote useage of front panel keys: INCrement(↑),

DECrement (↓) and STOP. This assembly is supplied by Sycon Instruments.

Connects to RJ-11 connector on the front panel.

3.6.7 Communications cable (optional):

A six ft. coiled cord terminated with an RJ-11 at one end (mates with RS-3000 back

panel connector [RJ-11]) and a 9 pin female D-SUB at the other (RS232/485 port).

This assembly is supplied by Sycon Instruments. Used to interconnect the RS-3000

control unit with an RS232/485 port such as, what may be found on a PC. Using

communication software on the PC, the RS-3000 can be controlled as if by front

panel controls and interrogated as if observing the displays and LEDS.

3.6.8 RS-3000/T3000 Interconnect cable:

A 3 ft. or 6 ft. cable assembly, wired straight-through (that is, pin 1 to pin 1, pin 2 to

pin 2, etc.) terminated at the RS-3000 side with a 15 pin female D-sub and with a 15

pin male D-Sub connector at the T3000 side. This assembly is supplied by Sycon

Instruments. It is used to interconnect the T3000 power supply and the RS-3000

control unit (T3000 control connector).

3.6.9 RS-3000/STC-2002 Interconnect cable:

A 6 ft. cable assembly terminated at the RS-3000 side with 15 pin male D-SUB

connector and with a 15 pin female D-SUB connector on the T3000 side. It is

interconnected from the RS-3000 external control connector to the STC2000A/STC2002 control outputs connector.

instruments

Specifics

Page 3 - 4

Section 3

Page 16

instruments

Power Supply Controller

3.6.10 Description of the RS-3000 I/O:

Table 3-2 Back-panel 15-pin D-sub Male Pin Descriptions

PIN

NUMBER

1 When this line is high, the RS-3000 will indicate an Open Boat

2 Along with pin 10, this line provides the RS-3000 with +5 VDC

3 Along with pin 11, this line provides the RS-3000 with digital

4 Monitors the voltage output from the T3000 power supply

5 Alternative to T3000 Reset button (falling edge, not level

6 For future use, not implemented in software. Input

DESCRIPTION of Connector Labeled T3000 Control I/O

failure

power

ground

( 1 VDC = 1.5 VRMS )

sensitive)

direction

Input

w/ pull-up

Input

power

Input

power

Input

Output

w/ pull-up

RS-3000

7 A control voltage from the RS-3000 used to set the output

amperage of the T3000 (see note

8 Not connected N. A.

9 When this line is high, the RS-3000 will indicate an Over

Temperature failure

10 Along with pin 2, this line provides the RS-3000 with +5 VDC

power

11 Along with pin 3, this line provides the RS-3000 with digital

ground

12 This line provides the RS-3000 with +12 VDC power Input

13 A digital control voltage from the RS-3000 used to switch the

T3000 power supply output ON (w/ a digital low) or OFF (w/ a

digital high)

14 This line tells the RS-3000 how to interpret the T3000 data: as

series wired or parallel wired. Digital high = series, digital low =

parallel.

15 Monitors the amperage output of the T3000 ( 1 VDC = 100 Amps

RMS when parallel wired / 50 Amps RMS when series wired

1

Note

: 10 VDC = 600 AMPs parallel wired [or 300 AMPs series] and has a linear relationship down to zero except for a

small value range between zero volts and a small fraction of a volt where AMPs will remain at zero.

1

)

Output

Input

w/ pull-up

Input

power

Input

power

power

Output

w/ pull-up

Input

w/ pull-up

Input

Section 3

Page 3 - 5

Specifics

Page 17

RS-3000

Power Supply Controller

Table 3-3 Back-panel 15-pin D-sub Female Pin Descriptions

PIN

NUMBER

1 Analog ground of the RS-3000 presented to remote controller

2 Along with pin 10, this line presents the RS-3000 digital ground to

3 Interlock status indication: grounded (to pin 2) or digital low =

4 Process abort (digital low = process abort) Input

5 Process START event (digital falling edge = START event) Input

6 Fault reset (digital falling edge = reset event) Input

7 Remote out (digital high = remote enabled) Output

8 Ready (digital high = ready enabled) Output

9 Voltage control (remote voltage control, via RS-3000, of the

10 Along with pin 2, this line presents the RS-3000 digital ground to

11 Process timer reset (digital falling edge = reset event) Input

12 Process STOP event (digital falling edge = STOP event) Input

13 Remote/Local START mode Input

14 Busy (digital high = active) Output

15 Fault (digital high = active) Output

DESCRIPTION of Connector Labeled External Control I/O

Direction

ground

(used with Voltage control [pin #9])

the remote controller

satisfied, open or digital high = interlock error (indicated by front

panel LED)

T3000)

the remote controller

pass thru

ground

pass thru

Input

w/ pull-up

w/ pull-up

w/ pull-up

w/ pull-up

w/ pull-up

w/ pull-up

Input

ground

pass thru

w/ pull-up

w/ pull-up

w/ pull-up

w/ pull-up

w/ pull-up

instruments

Specifics

Page 3 - 6

Section 3

Page 18

instruments

Power Supply Controller

RS-3000

Section 4

Specifics

4.1 Events and modes

Various events cause mode changes. Events can include: elapsed time decremented to

zero, amperage reaching a programmed value, an over-temperature condition, an open

boat condition, loss of interlock continuity, or user interaction with front panel or pendant

keys.

Following are specific events and their effects on the various modes.

Table 4-1 Manual Mode

Event From To Description

START key O.F.F. mode MAN mode Starts Manual mode if user programmed ramp minutes

equals zero. MAN indicator is illuminated. The large display

shows requested current from the T3000. The INC and DEC

keys are used to change the requested value that is

displayed. The pendant arrow keys provide this same

function. The small display shows alternating minute and

kilowatt values. Minute and kilowatt values can be

differentiated by the illumination of the Kw and MIN

indicators and by the position of the decimal point (x.xx=Kw

format / xx.x=MIN format). In Manual mode, the time counts

up, measuring elapsed time. Upon entry into the Manual

mode, previous elapsed time values, if any, are reset to

zero.

INC + DEC MAN mode

minutes > 0

INC MAN mode

AMPs [value]

DEC MAN mode

AMPs [value]

STOP MAN mode O.F.F. mode Ends Manual mode. The pendant STOP key provides this

err: open

boat

err: hot MAN mode O.F.F. mode Error ends Manual mode.

INTERLOCK MAN mode O.F.F. mode Interlock at logical high ends Manual mode.

MAN mode O.F.F. mode Error ends Manual mode.

MAN mode

minutes = 0

MAN mode

AMPs

[value]+1

MAN mode

AMPs

[value]-1

Elapsed time can be reset to zero by pressing both the INC

and DEC keys simultaneously. The pendant arrow keys

provide this same function.

Amperage requested can be incremented by pressing the

INC key. The pendant arrow up key provides this same

function. (Large display labeled AMPS)

Amperage requested can be decremented by pressing the

DEC key. The pendant arrow down key provides this same

function. (Large display labeled AMPS)

same function.

Section 4

Page 4 - 1

Specifics

Page 19

RS-3000

Power Supply Controller

instruments

Table 4-2 Ramp Mode

Event From To Description

START key O.F.F. mode RAMP mode Starts Ramp mode if user programmed

ramp minutes does not equal zero. The

large display shows requested current from

the T3000. The requested current value is

based upon the user programmed values

of Ramp current and Ramp minutes. The

Ramp current is divided across the Ramp

minutes and is distributed in a linear

progression increasing from zero to the

user programmed value of Ramp current

just as the Ramp minutes value is reached.

For example, at 25% of elapsed time, the

current request will be at 25% of the

programmed value of Ramp current. The

small display shows alternating minute and

kilowatt values. Minute and kilowatt values

can be differentiated by the illumination of

the Kw and MIN indicators and by the

position of the decimal point (x.xx=Kw

format / xx.x=MIN format). Upon entry into

the Ramp mode, the time counts down

from the user programmed value of Ramp

minutes, measuring remaining time until

zero is reached.

Ramp minutes=0 RAMP mode MAN mode Ends Ramp mode and automatically starts

the Manual mode (see Manual mode

START).

STOP key RAMP mode O.F.F. mode Ends Ramp mode. The pendant STOP key

provides this same function.

START key RAMP mode MAN mode Ends Ramp mode and automatically starts

the Manual mode (see Manual mode

START) retaining the last current value

held in the Ramp mode.

Err: open boat RAMP mode O.F.F. mode Error ends RAMP mode.

Err: hot “ O.F.F. mode “

INTERLOCK RAMP mode O.F.F. mode Interlock at logical high ends RAMP mode.

Specifics

Page 4 - 2

Section 4

Page 20

instruments

Power Supply Controller

RS-3000

Table 4-3 Remote Mode

Event From To Description

RMT key O.F.F. mode REMOTE mode Starts Remote mode. RS-3000 needs to be

connected to an STC-2000 or equivalent. The large

display shows current and the small display shows

kilowatts. The RMT indicator is illuminated.

RMT key REMOTE mode MAN mode Toggles Remote mode off and automatically starts

the Manual mode (see Manual mode START)

retaining the last current value held in the Remote

mode. As previously described for the START key

event entering Manual mode, the large display shows

current and the small display alternates between

showing kilowatts and minutes. The RMT indicator is

now off and the MAN indicator is illuminated.

STOP key REMOTE mode O.F.F. mode Ends Remote mode. The pendant STOP key

provides this same function.

Table 4-4 Program Mode

Event From To Description

PRGM key any mode (except

the PRGM mode)

PRGM key PRGM mode PRGM mode For the 2nd press of the PRGM key while in the

PRGM mode Starts Program mode. The PRGM indicator blinks

while in the Program mode. The first in a

sequence of six user programmable parameters is

shown (that of maximum current). The INC/DEC

keys provide the means to make a value change.

Program sequence, Ramp minutes can be altered

by the INC/DEC keys (range is 0-99.9 minutes).

For the 3rd press of the PRGM key while in the

Program sequence, Ramp current can be altered

by the INC/DEC keys (range is 0-600 Amps). For

the 4th press of the PRGM key while in the

Program sequence, beeper configuration can be

altered by the INC/DEC keys (select: ON or OFF).

For the 5th press of the PRGM key while in the

Program sequence, communication speed can be

configured by the INC/DEC keys (9.6, 38.4 or 115

kbaud). For the 6th press of the PRGM key while in

the Program sequence, address can be

configured by the INC/DEC keys (0-9). The 7

press of the PRGM key while in the Program

sequence, terminates the PRGM mode and the

PRGM indicator ceases to blink. Parameters are

saved immediately as they are entered (there is

no quit without saving). If there is a lack of activity

for 30 seconds during the programming sequence,

the programming mode will auto-terminate.

th

Section 4

Page 4 - 3

Specifics

Page 21

RS-3000

Power Supply Controller

no yes

O.F.F. mode

Manual mode

(press START w/0

time)

Power up:

Version

In Remote

mode?

Remote mode

Ramp mode

(press START w/ time)

Figure 4-1 Mode Navigation

Display until corrected:

Overheated PS (Err Hot) PS

w/Open boat (Err

Remote mode

(press RMT key)

Opn)

instruments

Specifics

Page 4 - 4

Section 4

Page 22

instruments

Power Supply Controller

RS-3000

always accessible

(press PRGM key)

Program mode

(PRGM LED illuminates)

INC/DEC

INC/DEC

INC/DEC

(press PRGM key)

To exit Program mode

(PRGM LED extinguishes)

Max power

(press PRGM key)

Ramp Current

(press PRGM key)

Comm.

speed

JM 17JAN2002

(press PRGM key)

Ramp time

(press PRGM key)

Beeper

functionality

(press PRGM key)

Comm.

Address

INC/DEC

INC/DEC

Figure 4-2 Program Mode Navigation

Section 4

Page 4 - 5

Specifics

Page 23

RS-3000

Power Supply Controller

instruments

Specifics

Page 4 - 6

Section 4

Page 24

instruments

Power Supply Controller

RS-3000

Section 5

Service

The unit is best opened by removing the 4 back panel screws then the four connector

securing hardware (capturing) standoffs. Remove back panel. Remove top by sliding it

rearward. Slide main board rearward to remove (note connection to front panel board) or

service the fuses or jumpers without removing main board. Take care not to touch

electronic devices or circuitry such that a high voltage discharge path from your finger may

develop and destroy components.

There are 2 socketed internal fuses. One for VCC (labeled F1) and the other for +12 volts

(labeled F2).

The RS-3000 power-on event sequence is as follows. The green power LED is illuminated.

Next, the unit momentarily illuminates all LEDs and display segments. Then it momentarily

displays its software version number (large display) and 300 (T3000 wired in series) or 600

(T3000 wired in parallel) in the small display. If the number displayed does not match the

actual configuration, check the wiring select switch on the T3000. If there are no error

conditions, the RS-3000 will display 0.F.F. in the large display.

Section 5

Page 5 - 1

Service

Page 25

RS-3000

Power Supply Controller

instruments

Service

Page 5 - 2

Section 5

Page 26

instruments

Made in the U.S.A

Sycon Instruments

6757 Kinne Street

East Syracuse, New York 13057-1215

V (315) 463-5297 F (315) 463-5298 info@sycon.com

Loading...

Loading...