Page 1

Service Manual

HP LaserJet 2100

Page 2

Copyright

©

Hewlett-Packard Company

1999

All Rights Reserved.

Reproduction, adaptation, or

translation without prior written

permission is prohibited,

except as allowed unde r the

copyright laws.

Publication number

C4170-90959

First edition, February 1999

Trademark Credits

Adobe and PostScript are

trademarks of Adobe Systems

Incorporated which may be

registered in certain

jurisdictions.

Windows is a U.S. registered

trademark of Microsoft

Corporation.

Warranty

The information contained in

this document is subject to

change without notice.

Hewlett-Packard makes no

warranty of any kind with

regard to this material,

including, but not limited to, the

implied warranties or

merchantability and fitness for

a particular purpose.

Hewlett-Packard shall not be

liable for errors contained

herein or for incidental or

consequential damages in

connection with the furnishing,

performance, or use of this

material.

WARNING

Electrical Shock Hazard

To avoid electrical shock, use

only supplied power cords and

connect only to properly

grounded wall outlets.

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714 U.S.A.

Page 3

Conventions

This manual uses the following conventions:

The names of major printer parts and assemblies are Capitalized.

Color is used to emphasize items which are important to the material under discussion.

Bold is used for emphasis, particularly in situations where

Italic type

NOTE: Notes contain important information set off from the text.

CAUTION: Caution messages alert you to the possibility of damage to equipment or loss of data.

WARNING! Warning messages alert you to the possibility of personal injury.

is used to indicate related documents or emphasis.

italic

type would be confusing.

C4170-90959 3

Page 4

Chapter Descriptions

Chapter 1: Product Information

This chapter describes features of the printer, including locations of external and internal

assemblies, and gives safety and regulatory information. Use this chapter to form a basic

service approach, and to get technical assistance.

Chapter 2: Operating Requirements

Chapter 2 details site requirements, including space and environmental specifics. The

chapter also defines specifications for paper and other media with this printer.

Chapter 3: Printer Configuration

Learn to use the control panel, perform an engine test, and reset the printer. Chapter 3

contains options for configuring the printer through service mode, and also details about

installing and using the Remote Control Panel. Network and IR printing is also explained.

Chapter 4: Printer Maintenance

This chapter discusses service check points, procedures for cleaning the printer, and how to

use toner cartridges effectively.

Chapter 5: Functional Overview

The functional overview discusses each of the printer’s stages to form and develop an

image. This chapter details the engine control system, the formatter system, the paper feed

system, and the sequence of printer operation.

Chapter 6: Troubleshooting

Use the systematic troubleshooting process to solve printing problems. This process

contains a preliminary troubleshooting flowchart, with explanations of each step throughout

the chapter. Explanations include a tab le with descriptions and recommended actions for all

control panel messages, image defect samples, troubleshooting problems with media, and

diagrams showing the locations of components that may be causing problems.

Chapter 7: Removal and Replacement

Step-by-step procedures show how to replace field replaceable units (FRUs) in the printer.

Chapter 8: Parts and Diagrams

Exploded view drawings and part number listings are included for all replaceab le parts in the

printer. The composite table of replaceable parts is sorted alphabetically by part name, and

also sorted numerically by part number. Both tables are cross-referenced to the diagr ams in

the chapter.

4 C4170-90959

Page 5

Index

The index is an alphabetical, cross-referenced listing of information found in the main body

of the manual.

C4170-90959 5

Page 6

Contents

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1 Product Information

Printer Description and Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

External Assembly Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Internal Assembly Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Laser Statement for Finland . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

LED Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Toner Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Ozone Emission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Environmental Product Stewardship Program . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Protecting the Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

FCC Regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Service Approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Bench Repair Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

HP Express Exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Ordering Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Ordering Consumables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ordering Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Technical Assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

HP ASAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

HP FIRST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

HP AUDIO-TIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

HP Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Customer Support Worldwide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Worldwide Sales and Service Offices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

EN

2 Operating Requirements

Site Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Operating Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Printer Space Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Media Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

General Media Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Guidelines for Selecting Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Media Input Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Tray 1 Media Sizes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Tray 2 and Optional Tray 3 Paper Sizes. . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Envelope Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Label Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Transparency Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Storing Print Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Shipping Print Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Fillers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6

Page 7

Testing Media Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3 Printer Configuration

Using the Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Display LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Job Cancel Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Go Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Printing Demo Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Printing Self-Test/Configuration Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Continuous Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Engine Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Accessing Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Setting the Page Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Setting the Cold Reset Default. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Resetting the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Cold Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

NVRAM Initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Remote Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Installing the Remote Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Network Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Installing an HP JetDirect EIO Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

IR Printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4 Printer Maintenance

Service Check Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Cleaning the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

General Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Internal Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Toner Cartridge Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Handling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Refilled Toner Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Recycling Toner Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Toner Cartridge Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Toner Cartridge Life Expectancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Saving Toner with EconoMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Redistributing the Toner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5 Functional Overview

Sequence of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Power On Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Timing Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Printer Functionality and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Formatter System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Formatter Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Formatter Subsystems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Resolution Enhancement technology (REt - 600 dpi only). . . . . . . . . . . . . . 73

Print Density Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

EconoMode (600 dpi only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Memory Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Printer Job Language (PJL) Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Engine Control System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Laser Scanner Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

C4170-90959 7

Page 8

Paper Feed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Microswitch Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Fusing Assembly Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Power Supply and Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Image Formation System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Toner Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Cleaning Stage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Conditioning Stage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Writing Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Developing Stage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Transferring Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Fusing Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Paper Pick and Feed System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Paper Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Paper Size Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Paper Jam Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6 Troubleshooting

Troubleshooting Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Preliminary Operating Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Basic Fault Isolation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Troubleshooting Process Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Troubleshooting with Control Panel Messages. . . . . . . . . . . . . . . . . . . . . . . . . . 94

Control Panel LED Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Paper Handling Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Print Test Pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Engine Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Self-Test / Configuration Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Paper Jam Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Media and Paper Handling Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Evaluate the Test Pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Status Log Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Verify installed options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Image Formation Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Half Self-Test Functional Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Drum Rotation Functional Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Media Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

A Paper or Printer Problem? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Isolate a Paper Path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Isolate a Paper Brand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Isolate a Paper Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Evaluate Paper User Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Evaluate Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Communication Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Communications Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Test Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

EIO Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

JetDirect Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Reference Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Timing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Sensors and Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

8 C4170-90959

Page 9

7 Removal and Replacement

Removal and Replacement Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Parts Removal Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Toner Cartridge Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Tray 2 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Transfer Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Tray 2 Pickup Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Tray 2 Pickup Roller Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

I/O Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

EIO Card Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

DIMM Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

DIMM Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Formatter PCB Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

EIO Shield and Guide Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Rear Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Fusing Assembly Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Fusing Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Fusing Film Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Pressure Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Engine Controller Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Top Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Upper Output Delivery Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Lower Output Delivery Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Laser Scanner Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Transport Belts and Rollers Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Transport Belts and Rollers Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 199

Ribbon Cable Harness Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Printer Drive Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Main Motor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Motor Plate Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Printer Drive Assembly Gear Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Tray 1 Pickup Roller Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Tray 1 Separation Pad Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . 212

Tray 1 Paper Sensor Lever Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Tray 1 Paper Sensor Lever Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 216

Tray 1 Solenoid Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Tray 2 Pickup Roller Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Tray 2 Solenoid Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Intermediate PCB Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Registration Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Fusing Assembly Ground Clip Replacement . . . . . . . . . . . . . . . . . . . . . . . 227

Tray 3 Assembly Connector Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Left Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Cooling Fan Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Toner Cartridge Guide Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Tray 1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Tray 1 Pickup Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Tray 1 Separation Pad Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

DC Bias Voltage Contacts (Leaf Springs) Removal. . . . . . . . . . . . . . . . . . 242

DC Bias Voltage Contacts Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Tray 3 Cassette Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Tray 3 Pickup Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Tray 3 Paper Feeder Drive Assembly Removal. . . . . . . . . . . . . . . . . . . . . 249

Tray 3 Solenoid Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

C4170-90959 9

Page 10

8 Parts and Diagrams

External Covers and Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Top Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Internal Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Fuser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Printer Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Paper Feeder Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Paper Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Paper Tray Pickup Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Paper Tray External Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Paper Tray Internal Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Hardware Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Alphabetical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Numerical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

10 C4170-90959

Page 11

1

Product Information

Contents

Printer Description and Features - - - - - - - - - - - - - - 2

Identification - - - - - - - - - - - - - - - - - - - - - - - - 4

Specifications - - - - - - - - - - - - - - - - - - - - - - - 5

Product Overview - - - - - - - - - - - - - - - - - - - - - 6

Safety Information - - - - - - - - - - - - - - - - - - - - - 9

FCC Regulations - - - - - - - - - - - - - - - - - - - - - 15

Service Approach - - - - - - - - - - - - - - - - - - - - 16

Technical Assistance - - - - - - - - - - - - - - - - - - - 18

C4170-90959

Contents

1

Page 12

Printer Description and Features

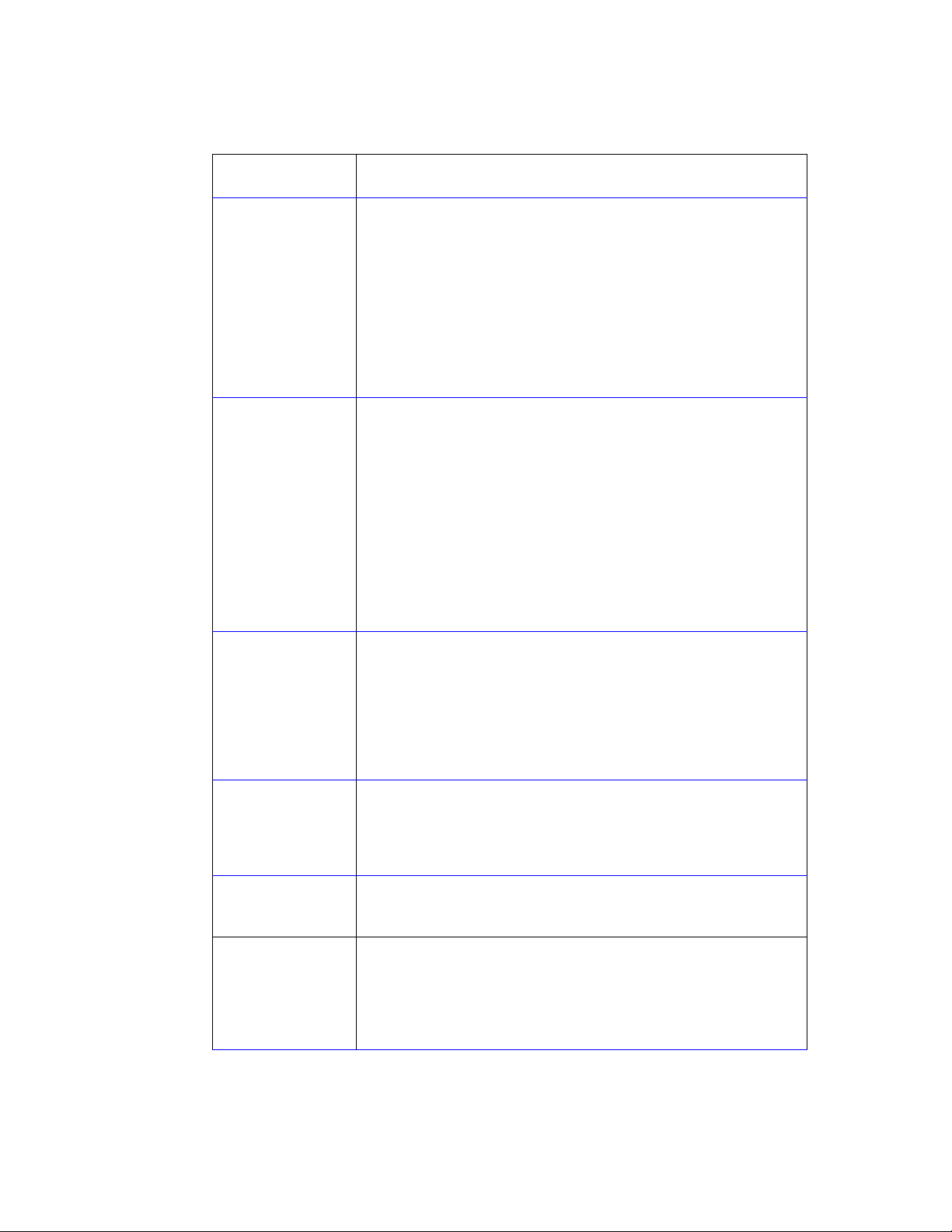

Table 1-1. Printer Description and Features

Print Speed

Print Quality

Paper Handling

●

10 pages-per-minute printing (with Intel 80960JD 66 MHz RISCbased formatter and 33 MHz BUS).

●

True 1200 x 1200 dots per inch (dpi) text and graphics.

●

Resolution Enhancement technology (REt) (600 dpi only).

●

Adjustable settings to optimize print quality and performance:

Best Quality: 1200 x 1200 dpi

Faster Performance: 600 x 600 dpi

Custom: User Defined Settings

●

HP UltraPrecise toner cartridge. Cartridge capacity equals

approximately 5000 pages at 5% toner cover.

●

Adjustable Tray 1 for letterhead, envelopes, labels, transparencies,

custom-sized media, postcards, and heavy paper. Tray capacity

equals approximately 100 sheets of standard paper or 10 standard

envelopes.

●

Adjustable 250-Sheet Tray 2 for standard sizes of paper.

●

Top output bin (for printing face down).

●

Rear output bin (for printing face up).

●

Straight-through paper path capability from Tra y 1 to the rear output

bin.

Accessories

PCL Printer

Language and Fonts

PS Language and

Fonts

Automatic Language

and I/O Switching

●

Optional Tray 3 with a 250-sheet capacity.

●

Enhanced Input Output (EIO) cards.

●

Three dual in-line memory module (DIMM) slots.

●

PostScript™ Lev el 2 Emulation (PS) DIMM. F actory installed on the

2100 M and 2100 TN.

●

Fast printing performance, built-in Intellifont and TrueType scaling

technologies, built-in HP-GL/2 vector graphics, and advanced

imaging capabilities are benefits of the PCL 6 printer language.

This also includes 45 scalable TrueType fonts and one bitmapped

Line Printer font.

●

The HP LaserJet 2100 M and 2100 TN printers include the

HP PostScipt Level 2 printer language emulation with 35 built-in PS

language fonts.

●

When optional printer languages (such as PostScript emulation) are

installed, the printer automatically determines and switches to the

appropriate language for the print job.

●

With I/O Switching the printer switches back and forth between

active I/Os.

2 Chapter 1 Product Information C4170-90959

Page 13

Table 1-1. Printer Description and Features (continued)

Wireless Infrared

Printing

Interface Connections

Networking

Enhanced Memory

and Memory

Expansion

Energy Savings

●

Fast infrared (IR) printing when printing from an IrDA-compliant

device, such as a laptop, notebook computer, or a Personal Digital

Assistant (PDA).

●

JetSend IR enabled devices can also use the IR port.

●

IEEE-1284 compliant Type B parallel port

Data Transfer Rate: approximately 4 MB/second

●

LocalTalk por t

●

Enhanced Input/Output (EIO) Slot

●

Wireless Infrared port (IrDA compliant)

Date Transfer Rate: approximately 4 MB/second

●

The printer provides an EIO Slot for HP JetDirect print servers.

●

The HP LaserJet 2100 printer comes with 4 MB of memory and can

be expanded to 52 MB using the three available memory (DIMM)

slots.

●

The HP LaserJet 2100 M and 2100 TN printers come with 8 MB of

memory and can be expanded to 40 MB with the two available

memory (DIMM) slots. The third slot is used for the HP PostScript

language DIMM.

●

The printer automatically conserves electricity by substantially

reducing power consumption when not printing.

●

As an E

determined that this product meets E

NERGY STAR

partner, Hewlett-Packard Company has

NERGY STAR

guidelines for

energy efficiency.

●

Economical Printing

EconoMode (600 dpi only), manual duplexing, and N-up printing

lets the user save paper, toner, and time.

Duty Cycle

●

Approximately 15,000 pages per month.

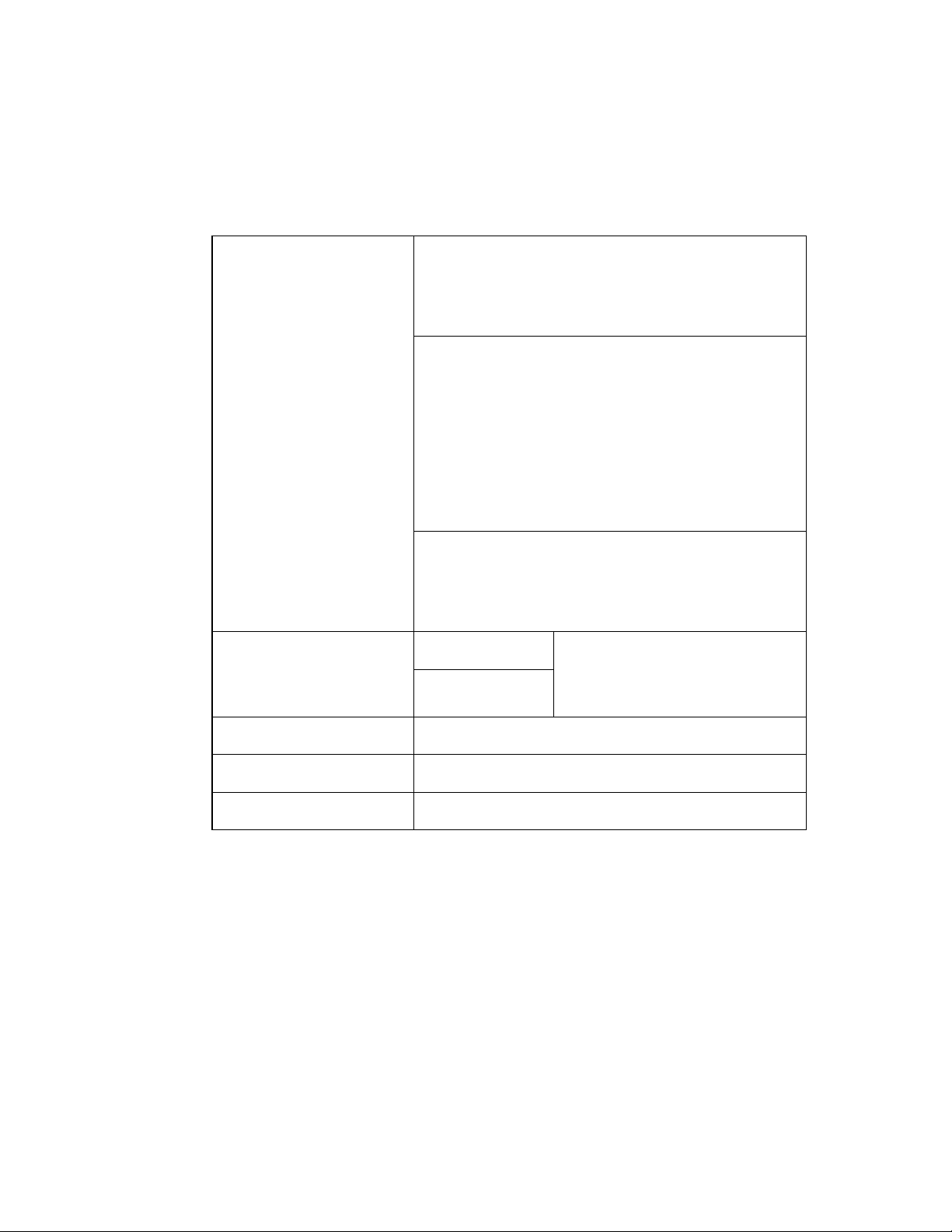

Table 1-2. Comparison of HP LaserJet 2100, 2100 M, and 2100 TN

HP LaserJet

2100

PS DIMM Optional Standard Standard

Standard Memory

Maximum Memory

JetDirect 600 N print

server

4 MB

52 MB

Optional Optional Standard

HP LaserJet 2100 M HP LaserJet

2100 TN

8 MB

40 MB

8 MB

40 MB

C4170-90959

Printer Description and Features

3

Page 14

Identification

The serial number and the model number are listed on the identification label located on the

rear output bin.

The serial number contains information about the Country of Origin, the Revision Level, the

Production Code, and the production number of the printer.

As shown in figure 1-1, the label also contains power rating and regulatory information.

NOTE: These values vary by region.

Figure 1-1 Sample Identification Label

4 Chapter 1 Product Information C4170-90959

Page 15

Specifications

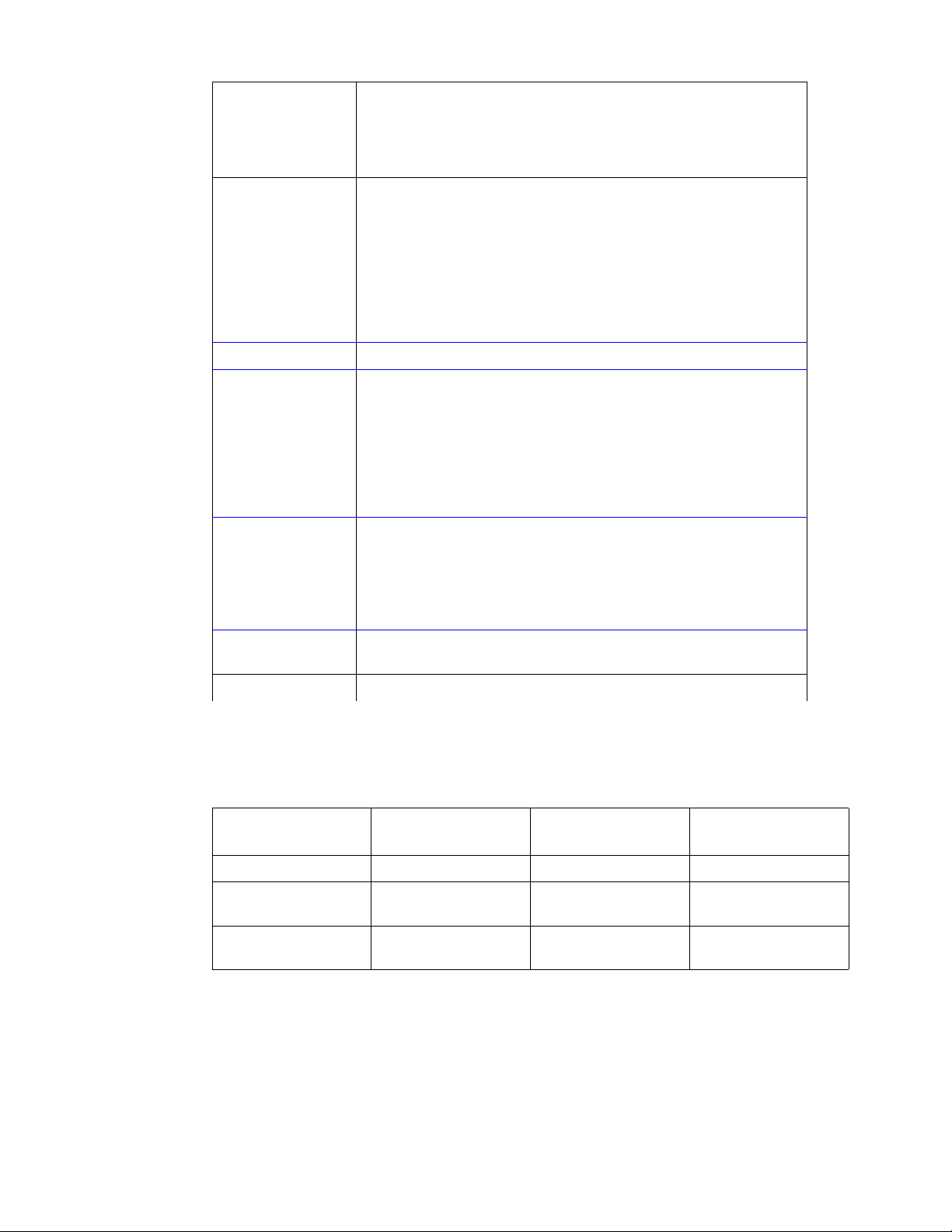

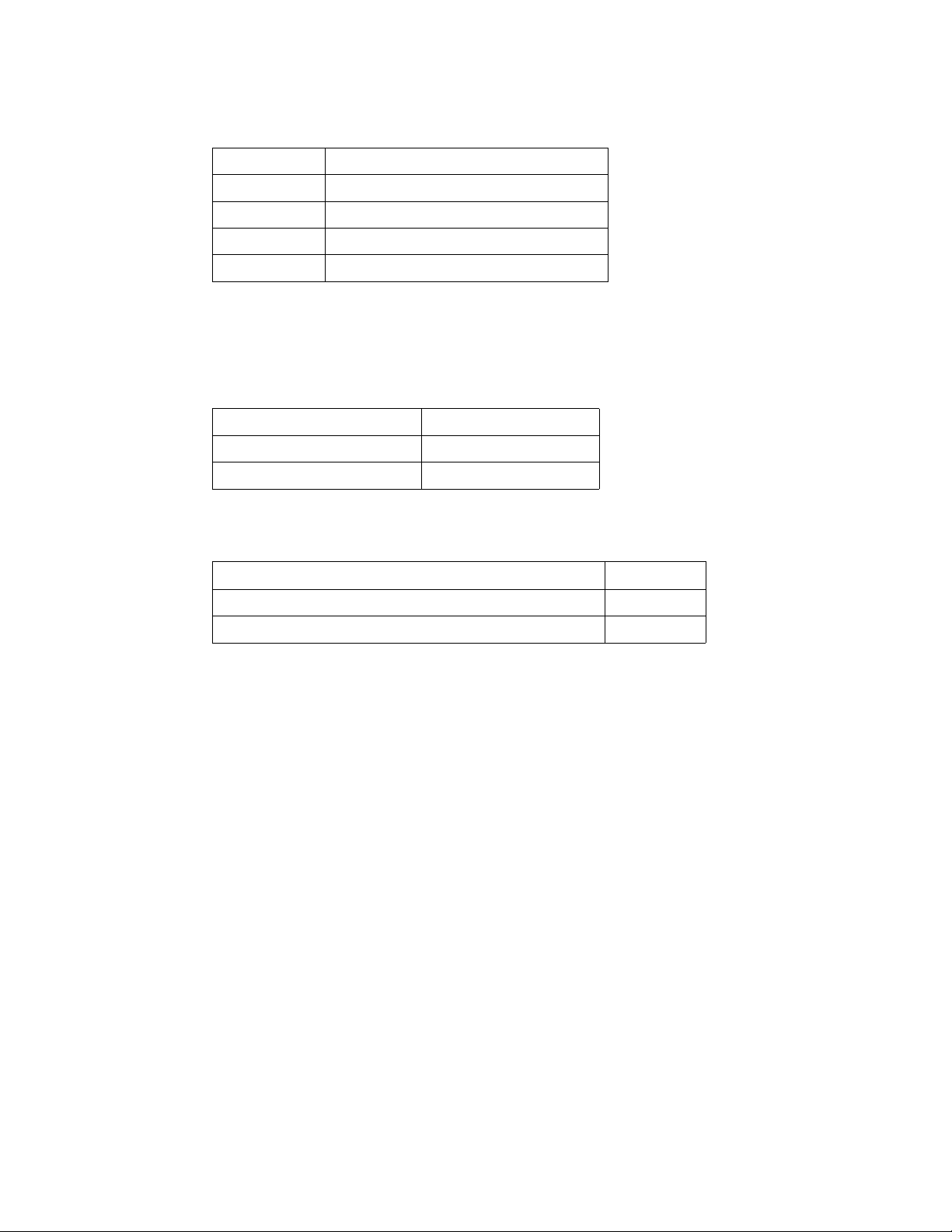

Table 1-3. Physical Specifications

Height 230 mm (9 in.) 309 mm (12.2 in.)

Width 406 mm (15.9 in.) 406 mm (15.9 in.)

Depth (body) 420 mm (16.5 in.) 420 mm (16.5 in.)

Weight (with toner cartridge) 11.5 kg (25.4 lbs) 14.4 kg (31.7 lbs)

Table 1-4. Electrical Specifications

HP LaserJet 2100 HP LaserJet 2100 with

Optional Tray 3

100-127V (+/- 10%)

50/60Hz (+/- 2Hz)

Typical Power Consumption Printing 225 W (average)

Standby 12 W (instant power

save)

Power save mode 12 W

Off mode 0 W

Minimum recommended

circuit capacity

5 Amps 2.5 Amps

220-240V (+/- 10%)

50/60 Hz (+/- 2Hz)

Printing 225 W (average)

Standby 14 W (instant power

save)

Power save mode 14 W

Off mode 0 W

WARNING! Po wer requirements are based on the region where the printer is sold. Do not convert operating

voltages. This may damage the printer and void the product warranty.

Table 1-5. Environmental Specifications

Operating Printing Storage/Standby

Temperature

15 degrees to 32.5 degrees C

-20 degrees to 40 degrees C

C4170-90959

(printer and toner cartr i dge)

Relative humidity 10% to 80% 10% to 90%

(59

degrees to 89 degrees F)

(-4 degrees to 104 degrees F)

Table 1-6. Acoustic Emissions (Per ISO 9296)

Operator Position Bystander (1m) Sound Power

Printing (HP

LaserJet 2100 at

10 ppm)

Power Save

In this mode, the printer is essentially quiet.

L

55dB(A) L

pAm

48dB(A) L

pAm

WAd

6.2 bels(A)

Specifications

5

Page 16

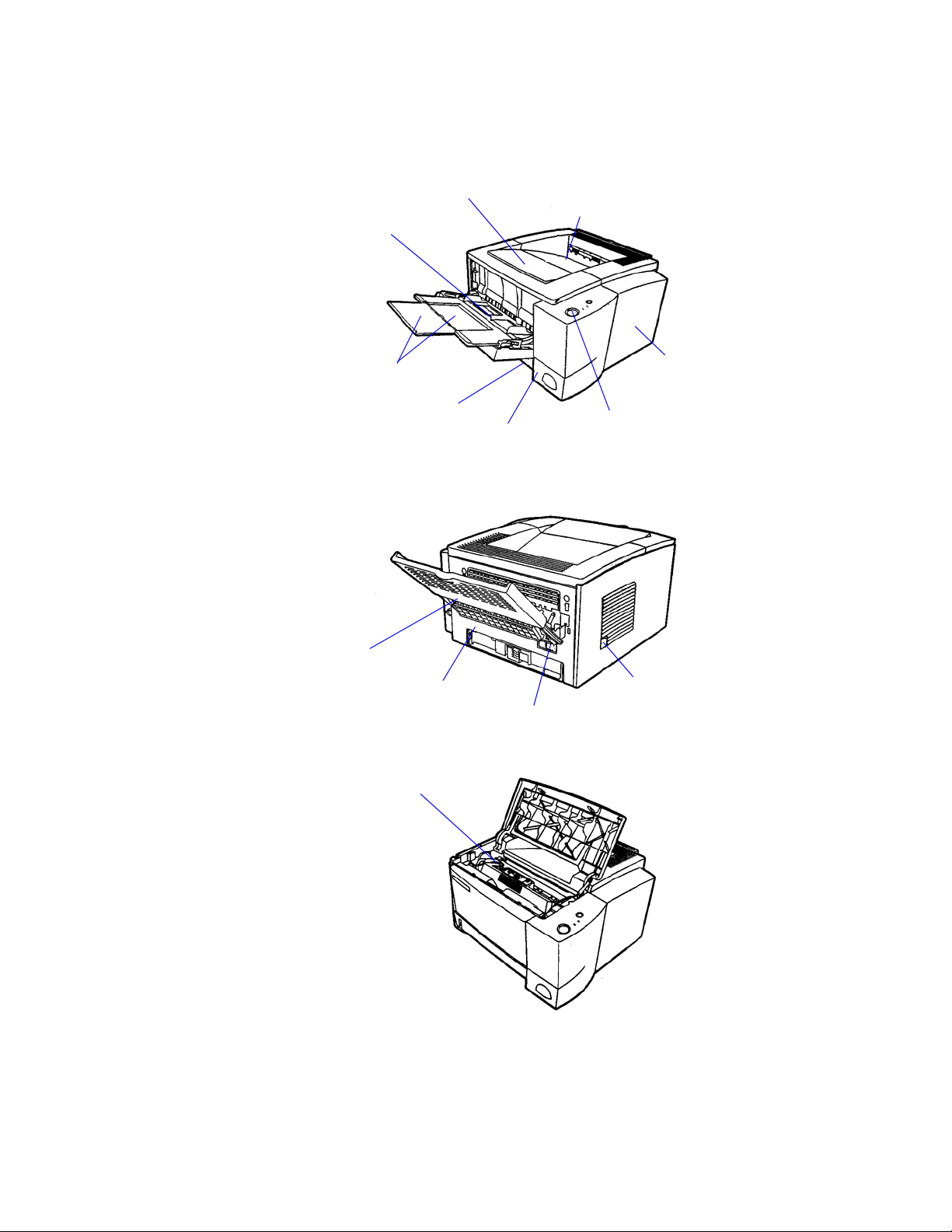

Product Overview

External Assembly Locations

Figure 1-2 External Assembly Locations (1 of 4)

Tray 1

Top cover

Top output bin (face-down)

Expansion trays

Tray 2

DIMM cover

Figure 1-3 External Assembly Locations (2 of 4)

Rear output bin (face-up)

Engine test

Power receptacle

Figure 1-4 External Assembly Locations (3 of 4)

Toner cartridge

I/O cover

Control panel

Power switch

6 Chapter 1 Product Information C4170-90959

Page 17

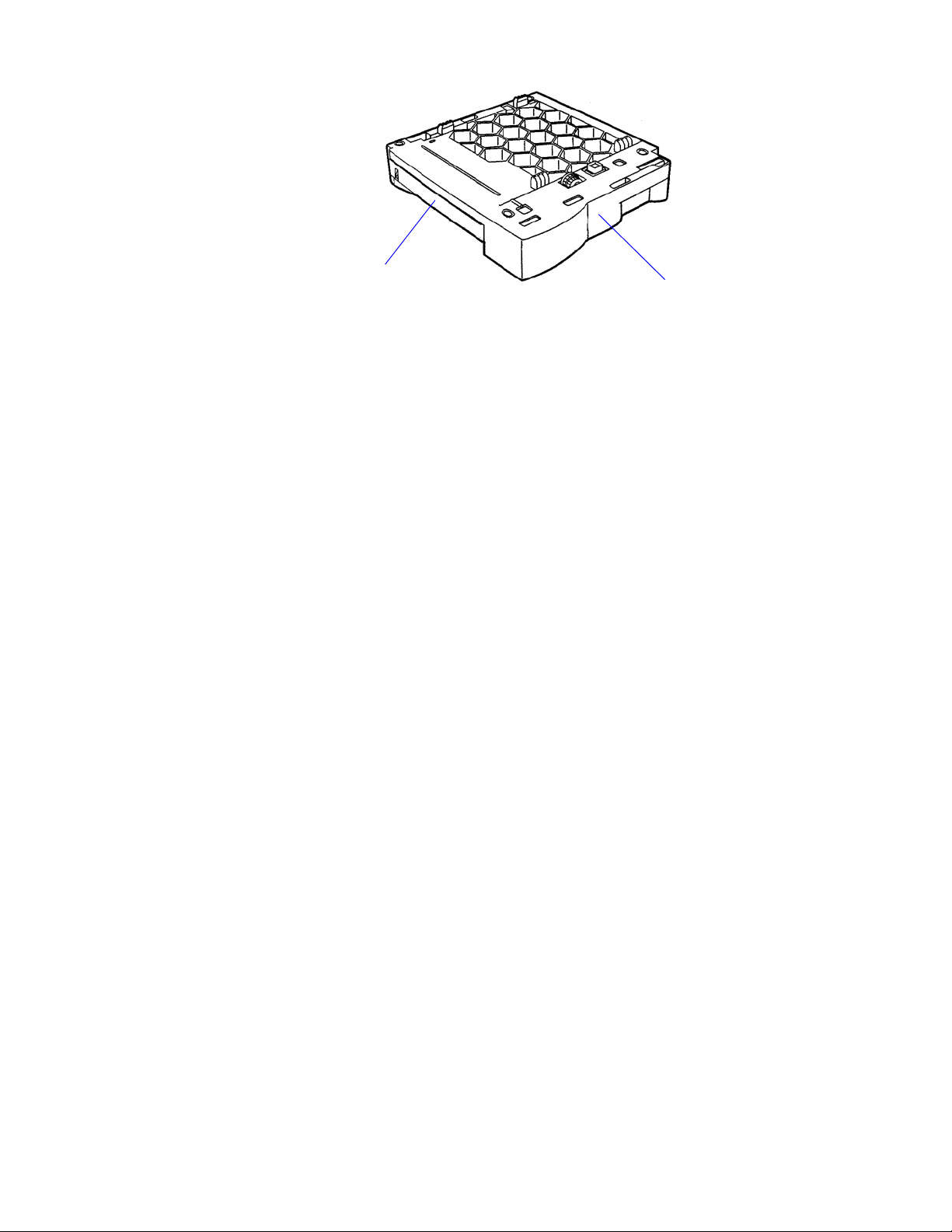

Figure 1-5 External Assembly Locations (4 of 4)

Tray 3

Tray 3 assembly

C4170-90959

Product Overview

7

Page 18

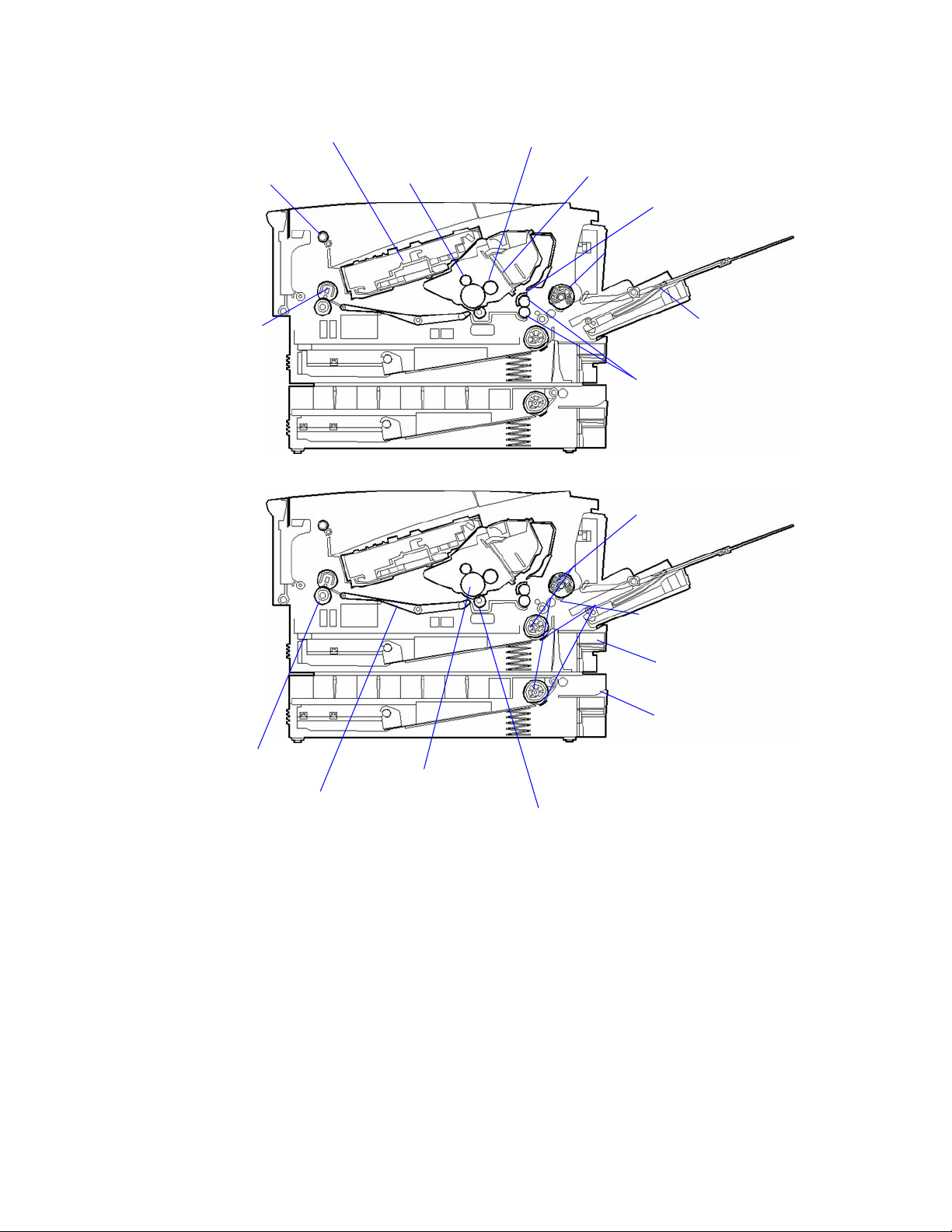

Internal Assembly Locations

Figure 1-6 Internal Assembly Locations (1 of 2)

Laser scanner assembly

Delivery roller

Fusing film

Figure 1-7 Internal Assembly Locations (2 of 2)

Primary charging

roller

Developing cylinder

Toner cartridge

Registration shutter

Tray 1 pickup roller

Tray 1

Registration rollers

Tray pickup rollers

Pressure roller

Feed belt

Tray Separation pads

Tray 2

Tray 3

Photosensitive drum

Transfer charging roller

8 Chapter 1 Product Information C4170-90959

Page 19

Safety Information

Laser Safety

The Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug

Administration has implemented regulations for laser products manuf actured since Au gust 1,

1976. Compliance is mandatory for products marketed in the United States. The printer is

certified as a Class 1 laser product under the U.S. Department of Health and Human

Services (DHHS) Radiation Performance Standard according to the Radiation Control for

Health and Safety Act of 1968.

Since radiation emitted inside the printer is completely confined within protective housings

and external covers, the laser beam cannot escape during any phase of normal user

operation.

WARNING! Using controls, making adjustments, or performing procedures other than those specified in

this service manual may result in exposure to hazardous laser radiation.

Laser Statement for Finland

LASERTURVALLISUUS

LUOKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

HP LaserJet 2100 -laserkirjoitin on käyttäjän kannalta turvallinen luokan 1 laserlaite.

Normaalissa käytössä kirjoittimen suojakotelointi estää lasersäteen pääsyn laitteen

ulkopuolelle.

Laitteen turvallisuusluokka on määritetty standardin EN 60825-1 (1993) mukaisesti.

VAROITUS!

Laitteen käyttäminen muulla kuin käyttöohjeessa mainitulla tav alla saattaa altistaa käyttäjän

turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

VARNING!

Om apparaten används på annat sätt än i bruksanvisning specificerats, kan användaren

utsättas för osynlig laserstrålning, som överskrider gränsen för laserklass 1.

HUOLTO

C4170-90959

Safety Information

9

Page 20

HP LaserJet 2100 -kirjoittimen sisällä ei ole käyttäjän huolletta vissa olevia k ohteita. Laitteen

saa avata ja huoltaa ainoastaan sen huoltamiseen koulutettu henkilö. Tällaiseksi

huoltotoimenpiteeksi ei katsota väriainekasetin vaihtamista, paperiradan puhdistusta tai

muita käyttäjän käsikirjassa lueteltuja, käyttäjän tehtäväksi tarkoitettuja ylläpitotoimia, jotka

voidaan suorittaa ilman erikoistyökaluja.

VARO!

Mikäli kirjoittimen suojakotelo avataan, olet alttiina näkymättömälle lasersäteilylle laitteen

ollessa toiminnassa. Älä katso säteeseen.

VARNING!

Om laserprinterns skyddshölje öppnas då apparaten är i funktion, utsättas användaren för

osynlig laserstrålning. Betrakta ej strålen.

Tiedot laitteessa käytettävän laserdiodin säteilyominaisuuksista:

Aallonpituus 770-795 nm

Teho 5 mW

Luokan 3B laser

LED Safety

The infrared port on the control panel of this printer is classified as a Class 1 LED (light

emitting diode) device according to International Standard IEC 825-1 (EN 60825-1). This

device is not considered harmful, but the following precautions are recommended.

• Avoid direct eye exposure to the infrared LED beam.

• Be aware that the beam is invisible light and cannot be seen.

• Do not attempt to view the infrared LED beam with any type of optical device.

10 Chapter 1 Product Information C4170-90959

Page 21

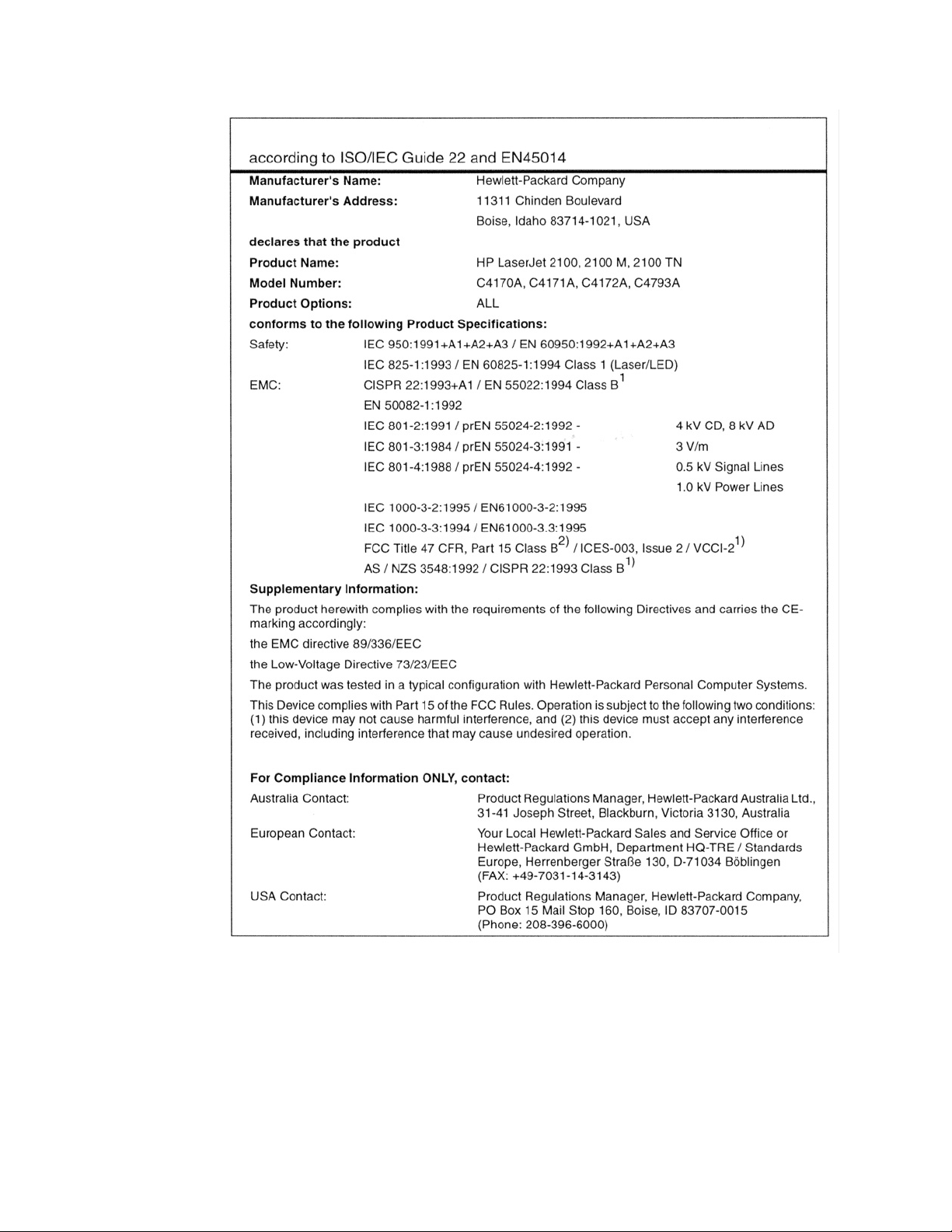

Declaration of Conformity

C4170-90959

Safety Information

11

Page 22

Toner Safety

Composed of plastic and minute colored components, toner is a non-poisonous substance.

If toner adheres to skin or clothes, remove as much of it as possible with dry tissue paper,

and then wash with cold water. Hot water causes toner to gel and become difficult to

remove.

NOTE: Avoid letting toner come into contact with vin yl because it easily breaks down the vinyl material.

Material Safety Data Sheet

The Toner Cartridge/Drum MSDS can be obtained by contacting the HP LaserJet Supplies

web site at:

http://www.hp.com/go/msds

If access to the Internet is not available, call the U.S. HP FIRST (Fax Information Retrieval

Service Technology) at (1) (800) 231-9300. Use Index number 7 for a listing of the Toner

Cartridge/Drum Material/Chemical Safety Data Sheets. Non-US customers should refer to

“Technical Assistance” (page 18) for phone numbers and information.

Ozone Emission

The printer uses charging rollers in the electrophotographic process and therefore generates

no appreciable ozone gas (O3).

12 Chapter 1 Product Information C4170-90959

Page 23

Environmental Product Stewardship Program

Protecting the Environment

Hewlett-Packard Company is committed to providing quality products in an environmentally

sound manner. This HP LaserJet printer has been designed with several attributes to

minimize impacts on our environment.

This HP LaserJet printer design reduces:

Energy consumption

Energy usage drops to as little as 12 W (110V) and 14 W (220V) while in low-power

(PowerSave) mode. Not only does this save natural resources, but it also saves money

without affecting the high performance of this printer. This product qualifies for

E

NERGYSTAR

development of energy-efficient office products.

. E

NERGYSTAR

is a voluntary program established to encourage the

C4170-90959

E

NERGY STAR

partner, Hewlett-Packard Company has determined that this product meets E

Guidelines for energy efficiency.

is a U.S. registered service mark of the U.S. EPA. As an E

NERGYSTAR

NERGYSTAR

Toner Consumption

EconoMode uses significantly less toner, which might extend the life of the toner cartridge.

Paper Use

Depending on the type of software program in use, users can request f or a number of pages

of their documents to be printed on one sheet of paper. This N-up printing practice and the

printer’s automatic/manual duplexing feature, which pro vides tw o-sided printing, can reduce

paper usage and the resulting demands on natural resources.

The design of this HP LaserJet printer facilitates the recycling of:

Environmental Product Stewardship Program

13

Page 24

Plastics

Plastic housing parts have markings according to international standards that enhance the

ability to identify plastics for recycling purposes at the end of the printer’s life.

HP LaserJet Printing Supplies

In many countries, this product’s printing supplies (e.g., toner cartridge, drum, fuser) can be

returned to HP through the HP Planet Partners Printing Supplies Environmental Program.

An easy-to-use takeback component of the program is available in over 20 countries. Multilingual program information and instruction are included in every new HP LaserJet Toner

Cartridge and Consumables box.

HP Planet Partners

Since 1990, the HP LaserJet Toner Cartridge Recycling Program has collected more than

12 million used LaserJet toner cartridges that otherwise might have been discarded in the

world’s landfills. The HP LaserJet toner cartridges go to a collection center and are bulkshipped to our recycling partners who disassemble the cartridge parts for recycling. After a

through quality inspection, minor parts, such as nuts, screws, and clips are reclaimed f or use

in new cartridges. Remaining materials are separated and converted into raw materials for

use by other industries to make a variety of useful products.

Paper

This printer is suited for the use of recycled papers when the paper meets the guidelines

outlined in the

suitable for the use of recycled paper according to DIN 19 309.

The design of this HP LaserJet printer facilitates the recycling of:

HP LaserJet Printer Family Paper Specifications Guide

. Also, this printer is

Printer and Parts

HP provides a product return system for customers in Germany. Many of the functional parts

are recovered, tested, and reused as fully warranted service parts. Used parts are not

placed into new product manufacturing. Remaining product parts are recycled, if possible.

For product return information, contact the local HP Sales and Service office.

To ensure longevity of the HP LaserJet printer, HP provides the following:

Extended warranty

HP SupportPack provides coverage for the HP hardware product and all HP-supplied

internal components. The hardware maintenance covers a three-year period from date of

the HP product purchase. The customer must purchase HP SupportPack within 90 days of

the HP product purchase. Information on HP SupportPack is available in fax format by

calling HP FIRST (fax-on-demand service). The document number is 9036. Customers

should refer to the front of this manual for appropriate HP FIRST phone numbers and

information.

Spare Parts and Consumables Availability

Spare parts and consumable supplies for this product will be made available for at least 5

years after production has stopped.

14 Chapter 1 Product Information C4170-90959

Page 25

FCC Regulations

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy. If this equipment is not

installed and used in accordance with the instructions, it may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a

particular installation; the presence of interference can be determined by turning the

equipment off and on. If this equipment does cause harmful interference to radio or

television communications, the user is encouraged to try to correct the interference by one

or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase distance between the equipment and the receiver.

• Connect the equipment to an outlet on a circuit different from that to which the receiver

is located.

• Consult the dealer or an experienced radio/television technician.

NOTE: Any changes or modifications to the printer that are not expressly approv ed by HP could v oid

the user’s authority to operate this equipment.

Use of a shielded interface cable is required to comply with the Class B limits of Part 15 of

FCC rules.

C4170-90959

FCC Regulations

15

Page 26

Service Approach

Bench Repair Warranty

The warranty for this product is “return to bench” for a period of one year from the date of

purchase. This means that customers needing warranty repair must return their printer to an

HP repair center or an Authorized Service Provider (ASP).

HP Express Exchange

Through Customer Care Centers In the United States and Canada, customers have an

option to initiate Express Exchange. Under this option, customers may have a factory

refurbished printer sent to them within 24 hours.

1 The customer contacts the local HP Customer Care Center listed in the product

documentation. A technician troubleshoots the situation and determines whether the

printer has actually failed. If so, the technician refers the customer to the HP Service

Center.

2 A representative from the service center requests product and customer information. In

some regions, collateral may also be requested.

3 HP ships a refurbished replacement unit to arrive the next day. (Geographic distance

might prevent next-day shipping.)

4 The customer sends the defective printer to Hewlett-Packard at HP's expense.

Customers with on-site support service provided by HP should work directly with the local

Customer Care Center instead of following the steps outlined here.

Exchanged units carry the remainder of the original unit’s warranty or 90 days, whichever is

greater. The faster turnaround from HP Express Exchange minimizes downtime over

traditional service programs that require the user to ship the failed unit to the manufacturer,

and then wait for it to be repaired and returned. Because HP pays the shipping charges , the

user incurs no hidden costs for the service.

Ordering Parts

Field replaceable part numbers are listed in Chapter 8: Parts and Diagrams. Replacement

parts can be ordered from HP’s Parts Direct Ordering or HP’s Parts Center Europe.

Addresses and telephone numbers for both organizations are as follows:

Parts Direct Ordering Parts Center Europe

Hewlett-Packard Company

Support Materials Organization

8050 Foothills Blvd.

Roseville, CA 95678

Hewlett-Packard Company

Parts Center Europe

Wolf-Hirth Strasse 33

D-7030 Boeblingen, Germany

1-800-227-8164 (U.S. only)

16 Chapter 1 Product Information C4170-90959

(49 7031) 14-2253

Page 27

Ordering Consumables

Consumables and accessories can be ordered directly from Hewlett-Packard. Telephone

numbers for ordering consumables are as follows:

U.S. 1-800-538-8787

Canada 1-800-387-3154

Toronto 416-671-8383

United Kingdom 0734-441212

Germany 0130-3322

Ordering Related Documentation

The following tab le shows where to order related documentation. Telephone numbers f or the

various sources are as follows:

PDO (Parts Direct Ordering) 1-800-227-8164 (U.S. only)

PCE (Parts Center Europe) 49 7031 14-2253

HPD (HP’s Distribution Center) 303-353-7650 (U.S. only)

Related Documentation

Description Part Number

HP LaserJet Printer Family Paper Specification Guide 5040-9092

HP LaserJet 2100, 2100 M, and 2100 TN Printers User Guide C4170-90901

C4170-90959

Service Approach

17

Page 28

Technical Assistance

HP ASAP

HP ASAP (Automated Support Access Program) provides free technical support information

24 hours a day, 7 days a week. HP ASAP includes HP FIRST and HP AUDIO-TIPS, which

are both explained below. HP ASAP requires a touch-tone telephone.

HP FIRST

HP FIRST (Fax Information Retrieval Support Technology) is a telephone-in fax service

providing technical information for HP LaserJet users as well as service personnel.

Receiving a fax requires a group 3 facsimile machine or fax card. Service-related

information includes:

• Service notes (HP Authorized dealers)

• Application notes

• Product data sheets

• Material Safety Data Sheets (MSDS)

• Typeface and accessory information

• Printer support software information

• Toner information

• Driver request form and Software Matrix

HP FIRST, U.S.

To use HP FIRST in the U.S. call HP ASAP and follow the instructions. The telephone

number for HP ASAP in the U.S. is 1-800-333-1917. For all other areas, contact the local

service provider.

HP FIRST, Europe

To use HP FIRST in Europe, call HP ASAP and follow the instructions. The telephone

numbers for HP ASAP in Europe are as follows:

U.K. 0800-96-02-71

Belgium (Dutch) 078-111906

Switzerland (German) 155-1527

Netherlands 06-0222420

Germany 0130-810061

Austria 0660-8128

For English service outside the above countries, (31) 20-681-5792

18 Chapter 1 Product Information C4170-90959

Page 29

HP AUDIO-TIPS

HP AUDIO-TIPS, available within HP ASAP, is an interactive voice response system

providing pre-recorded answers to the questions most frequently asked by HP LaserJet

printer users. Helpful “System Maps” to the HP AUDIO-TIPS recordings are a vailable by fax

through HP FIRST.

HP Support

Online Services: W orld Wide W eb URL

plus product and support information may be obtained from the

following URLs:

in the U.S.: http://www.hp.com

in Europe: http://www2.hp.com

Obtaining software utilities,

drivers, and electronic

Information for U.S. and

Canada:

For European English:

HP Service Information:

HP Service Agreements:

America Online

U.S., France, Germany, and UK - Printer drivers, updated HP printer

software, and support documentation to help answer questions about

HP products are available. Use Keyword HP to start the tour or call

1-800-827-6364 preferred customer # 1118 to subscribe. In Europe,

call the appropriate number below:

Austria: 0222 58 58 485

France: ++353 1 704 90 00

Germany: 0180 531 31 64

Switzerland: 0848 80 10 11

United Kingdom: 0800 279 1234

CompuServe -

interactive sharing of technical information with other members is

available on CompuServe’s “HP User’s forums” (GO HP), or call

1-800-524-3388 and ask for representative #51 to subscribe.

(CompuServe is also available in the U.K., France, Belgium,

Switzerland, Germany, and Austria.)

Phone:

(805) 257-5565

Fax:

(805) 257-6866

For U.K., call (44) (142) 986-5511. For Ireland and outside U.K.,

call (44) (142) 986-5511.

To locate HP-Authorized Dealers, call 1-800-243-9816 (U.S.) or

1-800-387-3867 (Canada).

Call 1-800-835-4747 (U.S.) or 1-800-268-1221 (Canada).

Extended Service 1-800-446-0522.

- America Online/Bertelsmann is available in the

Printer drivers, updated HP printer software, and

- Printer drivers, updated HP printer software,

Mail:

Hewlett-Packard Co.

P.O. Box 1754

Greeley, CO 80632

U.S.A.

C4170-90959

Technical Assistance

19

Page 30

Customer Support Worldwide

Customer Support and Product Repair

Assistance for the U.S. and Canada:

European Customer Support Center Language and In-Country Options Available

Open Monday through Friday 8:30–18:00 CET

English

662-5525

512-5202

(171) 512-5202

Dutch

626-8806

(20) 606-8751

French

62-3434

626-8807

(84) 880-1111

German

525-8143

0660-6386

Ireland: (353) (1)

UK: (44) (171)

International: (44)

Belgium: (32) (2)

Netherlands: (31)

France: (33) (01) 43-

Belgium: (32) (2)

Switzerland: (41)

Germany: (49) (180)

Austria: (43) (1)

In-country support numbers:

and Service Offices” (page 21) for more information.

Argentina 787-8080 Mexico (Mexico City) 01 800-22147

Brazil 022-829-6612 Mexico (outside MexicoCity) 01 800-90529

Canada (1) (208) 323-2551 Poland (48-22) 608-77-00

Chile 800-360999 Portugal (351) (1) 301-7330

Czech Republic (42) (2) 613-07111 Russia (7) (95) 923-5001

Greece (30) (1) 689-6411 Turkey (90) (1) 224-5925

Hungary (36) (1) 343-0310

Call (1) (208) 323-2551 Monday throug h F riday from 6am

to 10 pm, Saturday 9 am to 4 pm (Mountain Time).

Call 1-800-243-9816 to locate the nearest HP-Authorized

service provider, or call 208-223-2551 for HP centralized

service dispatch.

Norwegian

Danish

Finnish

Swedish

Italian

Spanish

Polish

Portuguese

If the desired country is not listed below, see “Worldwide Sales

Norway: (47) 2211-6299

Denmark: (45) 3929-4099

Finland: (358) (9) 0203-47288

Sweden: (46) (8) 619-2170

Italy: (39) (2) 264-10350

Spain: (34) (90) 232-1123

Poland: (48-22) 608-77-00

Portugal: (351) (1) 441-7199

20 Chapter 1 Product Information C4170-90959

Page 31

Worldwide Sales and Service Offices

Argentina Australia

Hewlett-Packard Argentina S.A.

Montañeses 2140/50/60

1428 Buenos Aires

Phone: (54) (1) 787-7100

Fax: (54) (1) 787-7213

Austria Belgium

Hewlett-Packard GmbH

Lieblgasse 1

A-1222 Vienna

Phone: (43) (1) 25000-555

Fax: (43) (1) 25000-500

Brazil Canada

Edisa Hewlett-Packard SA

Alameda Rio Negro 750

06454-050 Alphaville - Barueri-SP

Phone: (55) (11)- 7296-8000

Hewlett-Packard Australia Ltd.

31-41 Joseph Street

Blackburn, VIC 3130

Phone: (61) (3) 27 2-28 95

Fax: (61) (3 ) 898-7831

Hardware Repair Center:

Phone: (61) (3) 27 2-80 00

Extended Warranty Support:

Phone: (61) (3) 272-2577

Customer Information Center:

Phone: (61) (3) 27 2-80 00

Hewlett-Packard Belgium S.A. NV

Boulevard de la Woluwe-Woluwedal 100-102

B-1200 Brussels

Phone: (32) (2) 77 8-31 -11

Fax: (32) (2 ) 763-06-13

Hewlett-Packard (Canada) Ltd.

17500 Trans Canada Highway

South Service Road

Kirkland, Quèbec H9J 2X8

Phone: (1) (514) 697-4232

Fax: (1) (514) 697-6941

Canada Chile

Hewlett-Packard (Canada) Ltd.

5150 Spectrum Way

Mississauga, Ontario L4W 5G1

Phone: (1) (905) 206-4725

Fax: (1) (905) 206-4739

Hewlett-Packard de Chile

Avenida Andres Bello 2777 of. 1

Los Condes

Santiago, Chile

China Colombia

China Hewlett-Packard Co. Ltd.

Level 5, West Wing Office

China World Trade Center

No. 1, Jian Guo Men Wai Avenue

Beijing 100004

Phone: (86) (10) 6505-3888,x. 5450

Fax: (86) (10) 6505-1033

Hardware Repair Center and Extended Warranty

Support:

Phone: (86) (10) 6262-5666x. 6101/2

(86) (10) 6261-4167

Hewlett-Packard Colombia

Calle 100 No. 8A -55

Torre C Oficina 309

Bogotá, Colombia

Czech Republic Denmark

Hewlett-Packard s. r. o.

Novodvorsk· 82

CZ-14200 Praha 4

Phone: (42) (2) 613-07111

Fax: (42) (2) 471-7611

Hewlett-Packard A/S

Kongevejen 25

DK-3460 Birkerød

Denmark

Phone: (45)3929 4099

Fax: (45) 42 81-5810

C4170-90959

Technical Assistance

21

Page 32

Far East Region Finland

Hewlett-Packard Asia Pacific Ltd.

17-21/F Shell Tower, Times Square

1 Matheson Street, Causeway Bay

Hong Kong

Phone: (852) 2599-7777

Fax: (852) 2506-9261

Hardware Repair Center:

Phone: (852) 2599-7000

Extended Warranty Support:

Phone: (852) 2599-7000

Customer Information Center:

Phone: (852) 2599-7066

Hewlett-Packard Oy

Piispankalliontie 17

FIN-02200 Espoo

Phone: (358) (9) 887-21

Fax: (358) (9) 887-2477

France Germany

Hewlett-Packard France

42 Quai du Point du Jour

F-92659 Boulogne Cedex

Phone: (33) (146) 10-1700

Fax: (33) (146) 10-1705

Hewlett-Packard GmbH

Herrenberger Straße 130

71034 Böblingen

Phone: (49) (180 ) 53 2-6222

Fax: (49) (1 80) 531-6122

Greece Hungary

Hewlett-Packard Hellas

62, Kifissias Avenue

GR-15125 Maroussi

Phone: (30) (1) 689-6411

Fax: (30) (1) 689-6508

Hewlett-Packard Magyarorszag Kft.

Erzsébet királyne útja 1/c.

H-1146 Budapest

Phone: (36) (1) 34 3-05 50

Fax: (36) (1 ) 122-369

Hardware Repair Center:

Phone: (36) (1) 34 3-03 12

Customer Information Center:

Phone: (36) (1) 34 3-03 10

(49) (180) 525-8143

India Italy

Hewlett-Packard India Ltd.

Paharpur Business Centre

21 Nehru Place

New Delhi 110 019

Phone: (91) (11) 647-2311

Fax: (91) (11) 646-1117

Hardware Repair Center and Extended Warranty

Support:

Phone: (91) (11) 642-5073

(91) (11) 682-6042

Hewlett-Packard Italiana SpA

Via Giuseppe di Vittorio, 9

Cernusco Sul Naviglio

I-20063 (Milano)

Phone: (39) (2) 92 1-21

Fax: (39) (2 ) 921-04473

Japan Korea

Hewlett-Packard Japan, Ltd.

3-29-21 Takaido-higashi

Suginami-ku, Tokyo 168

Phone: (81) (3) 3335-8333

Fax: (81) (3) 3335-8338

Hardware Repair Center:

Phone: (81) (4) 7355-6660

Fax: (81) (4) 7352-1848

Hewlett-Packard Korea

25-12,

Yoido-dong, Youngdeungpo-ku

Seoul 150-010

Phone: (82) (2) 76 9-01 14

Fax: (82) (2 ) 784-7084

Hardware Repair Center:

Phone: (82) (2) 3270-0700

(Hardware)

Extended Warranty Support:

Phone: (82) (2) 3770-0365 (Bench)

(82) (2) 707-2174 (DeskJet)

(82) (2) 3270-0710

(82) (2) 769-0500 (Onsite)

22 Chapter 1 Product Information C4170-90959

Page 33

Latin American Headquarters Mexico

5200 Blue Lagoon Drive Suite 950

Miami, FL 33126,USA

Phone: (1) (305) 267-4220

Hewlett-Packard de México, S.A. de C.V.

Prolongacion Reforma No. 700

Lomas de Santa Fe

01210 México, D.F.

Phone: 01-800-22147

Outside Mexico City

Phone: 01 800-90529

Middle East/Africa Netherlands

ISB HP Response Center

Hewlett-Packard S.A.

Rue de Veyrot 39

P.O. Box 364

CH-1217 Meyrin - Geneva Switzerland

Phone: (41) (22) 780-4111

Hewlett-Packard Nederland

BV Startbaan 16

NL-1187 XR Amstelveen

Postbox 667

NL-1180 AR Amstelveen

Phone: (31) (020 ) 60 6-87-51

Fax: (31) (0 20) 547-7755

New Zealand Norway

Hewlett-Packard (NZ) Limited

Ports of Auckland Building

Princes Wharf, Quay Street

P.O. Box 3860

Auckland

Phone: (64) (9) 356-6640

Fax: (64) (9) 356-6620

Hardware Repair Center and Extended Warranty

Support:

Phone: (64) (9) 0800-733547

Customer Information Center:

Phone: (64) (9) 0800-651651

Hewlett-Packard Norge A/S

Postboks 60 Skøyen

Drammensveien 169

N-0212 Oslo

Phone: (47) 2273 -5 600

Fax: (47) 22 73-5610

Poland Russia

Hewlett-Packard Polska

Al. Jerozolimskic 181

02-222 Warszawa

Phone: (48-22 ) 60 8-77 00

Fax: (48- 22) 608-7600

AO Hewlett-Packard

Business Complex Building #2

129223, Moskva, Prospekt Mira VVC

Phone: (7) (95) 928-6885

Fax: (7) (95) 974-7829

Singapore Spain

Hewlett-Packard Singapore

(Sales) Pte Ltd

450 Alexandra Road

Singapore (119960)

Phone: (65)275-3888

Fax: (65)275-6 83 9

Hardware Repair Center and Customer Information

Center:

Phone: (65) 272-5300

Extended Warranty Support:

Phone: (65) 272-5333

Hewlett-Packard Española, S.A.

Carretera de la Coruña km 16.500

E-28230 Las Rozas, Madrid

Phone: (34) (1) 62 6-16 00

Fax: (34) (1 ) 626-1830

Sweden Switzerland

Hewlett-Packard Sverige AB

Skalholtsgatan 9

S-164 97 Kista

Phone: (46) (8) 444-2000

Fax: (46) (8) 444-2666

Hewlett-Packard (Schweiz) AG

In der Luberzen 29

CH-8902 Urdorf/Zürich

Phone: (41) (084 ) 88 0-11-11

Fax: (41) (1 ) 753-7700

Warranty Support:

0800-55-5353

C4170-90959

Technical Assistance

23

Page 34

Taiwan Thailand

Hewlett-Packard Taiwan Ltd.|

8th Floor

337, Fu-Hsing North Road

Taipei, 10483

Phone: (886)(02)717-0055

FAX: (886)(02)514-0276

Hardware Repair Center, call:

North (886)(02) 717-9673

Central (886)(04) 327-0153

South (886)(080)733-733

Extended Warranty Support Contact:

Phone: (886)(02) 714-8882

Hewlett-Packard (Thailand) Ltd.

23-25/f Vibulthani Tower II|

2199 Rama 4 Rd, Klongton

Klintoey, Bangkok 10110

Thailand

Phone: (66) (2) 66 6-39 00-34

Fax: (66) (2 ) 666-3935-37

Hardware Repair Center and Extended Warranty

Support Contact:

Phone: (66) (2) 661-3900 ext. 6001/

6002

Customer Information Center:

Phone: (66) (2) 661-3900 ext. 3211

Fax: (66) (2 ) 661-3943

Turkey United Kingdom

Hewlett-Packard Company

Bilgisayar ve Ölçüm Sistemleri A.S.

19 Mayis caddesi Nova

Baran Plaza K.12

80220 Sisli-Istanbul

Phone: (90) (212) 224-5925

Fax: (90) (212) 224-5939

Hewlett-Packard Ltd.

Cain Road

Bracknell

Berkshire RG12 1HN

Phone: (44) (134 ) 43 6-9222

Fax: (44) (1 34) 436-3344

Venezuela

Hewlett-Packard de Venezuela S.A.

Los Ruices Norte

3A Transversal

Edificio Segre Caracas 1071

Phone: (58) (2) 239-4244

Fax: (58) (2) 239-3080

24 Chapter 1 Product Information C4170-90959

Page 35

2

Operating Requirements

Contents

Site Requirements - - - - - - - - - - - - - - - - - - - - 26

Media Specifications - - - - - - - - - - - - - - - - - - - 28

C4170-90959

Contents

25

Page 36

Site Requirements

Operating Environment

The electrical and environmental specifications listed in “Specifications” (page 5) must be

maintained to ensure the proper operation of this printer. Consider the following points

before installing the printer:

• Install in a well-ventilated, dust-free area.

• Install on a level, flat, and continuous surface which can support the printer’s weight.

Make sure all four printer feet are level. Do not install on carpet or other soft surfaces.

• Ensure adequate power supply circuitry. Electrical specifications are listed in

“Specifications” (page 5).

• Install where there is stable temperature and humidity, with no abrupt changes (away

from water sources, humidifiers, air conditioners, refrigerators, or other major

appliances). Environmental specifications are listed in “Specifications” (page 5).

• Install away from direct sunlight, areas with vibration, open flames, ultrasonic heaters,

ammonia fumes, or magnets and devices that emit a magnetic field. If the printer is

placed near a window, make sure the window has a curtain or blind to block any direct

sunlight.

• Maintain enough space around the printer for proper access and ventilation. See

“Printer Space Requirements” (page 27) for more information.

26 Chapter 2 Operating Requirements C4170-90959

Page 37

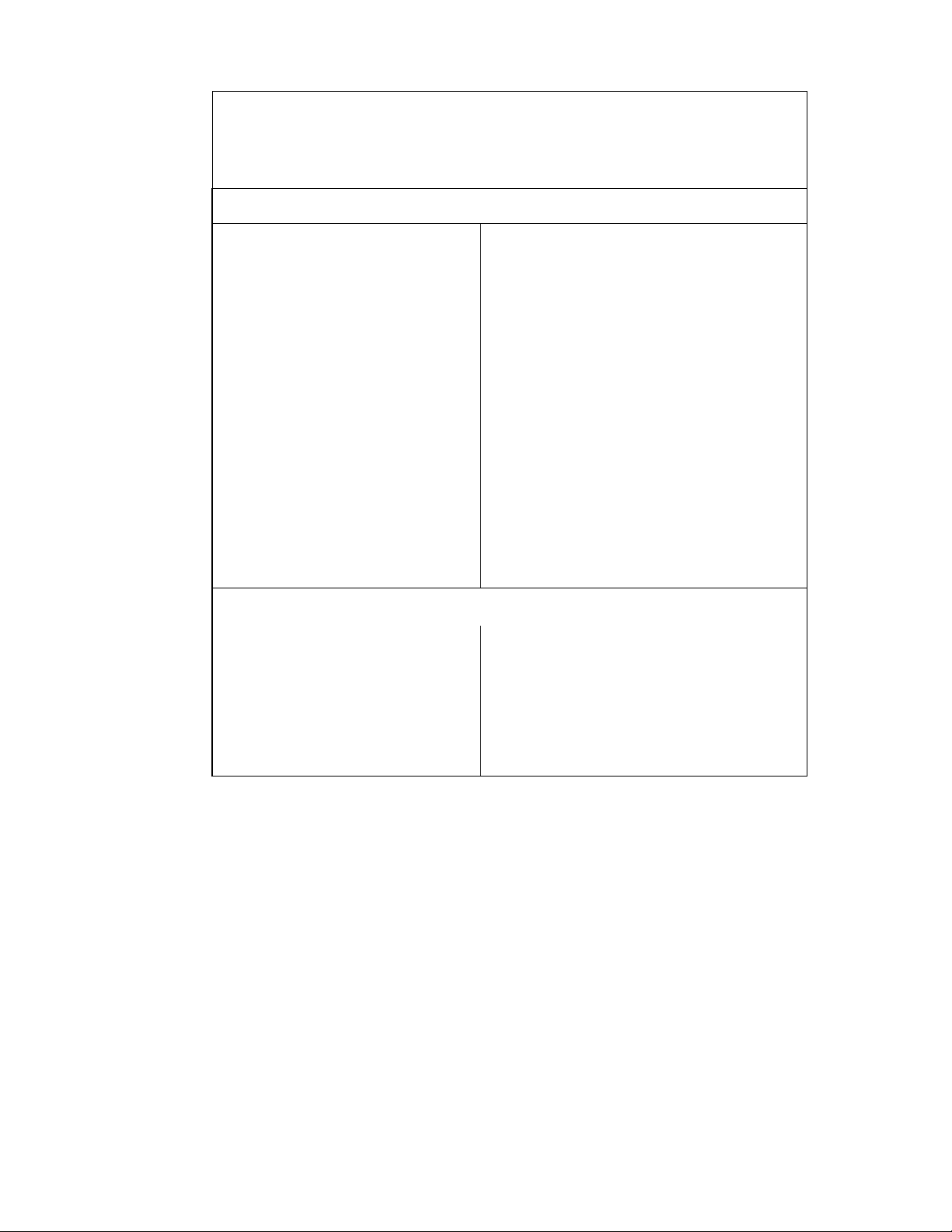

Printer Space Requirements

Figure 2-1 Printer Space Requirements

C4170-90959

Site Requirements

27

Page 38

Media Specifications

General Media Specifications

NOTE: Advise users always to test a sample of paper bef ore purchasing large quantities. Paper

suppliers should understand the requirements specified in the

Paper Specification Guide

The HP LaserJet 2100 printer accepts a variety of media, such as cut-sheet paper (including

up to 100% recycled fiber content paper), envelopes, labels, transparencies, and customsize paper. Properties such as weight, composition, grain, and moisture content are

important factors affecting printer performance and output quality. Paper that does not meet

the guidelines outlined in this manual can cause the following problems:

• Poor print quality.

• Increased paper jams.

• Premature wear on the printer, requiring repair.

NOTE: Some paper may meet all of the guidelines in this manual and still not produce satisfactory

results. This might be the result of improper handling, unacceptable temperature and humidity

levels, or other variables over which Hewlett-Packard has no control.

and this chapter.

HP LaserJet Printer Family

CAUTION: Using paper that does not meet HP specifications may cause problems f or the printer, requiring

repair. This repair is not covered by the Hewlett-Packard warranty or service agreements.

28 Chapter 2 Operating Requirements C4170-90959

Page 39

Guidelines for Selecting Paper

To achieve the best possible print quality, use only high-quality, copier-grade 24 lb (90 g/m2)

paper. Make sure the paper is of good quality, and free of cuts, nicks, tears, spots, loose

particles, dust, wrinkles, voids, and curled or bent edges.

The following problems with paper can cause print quality deviations, jamming, or even

damage to the printer.

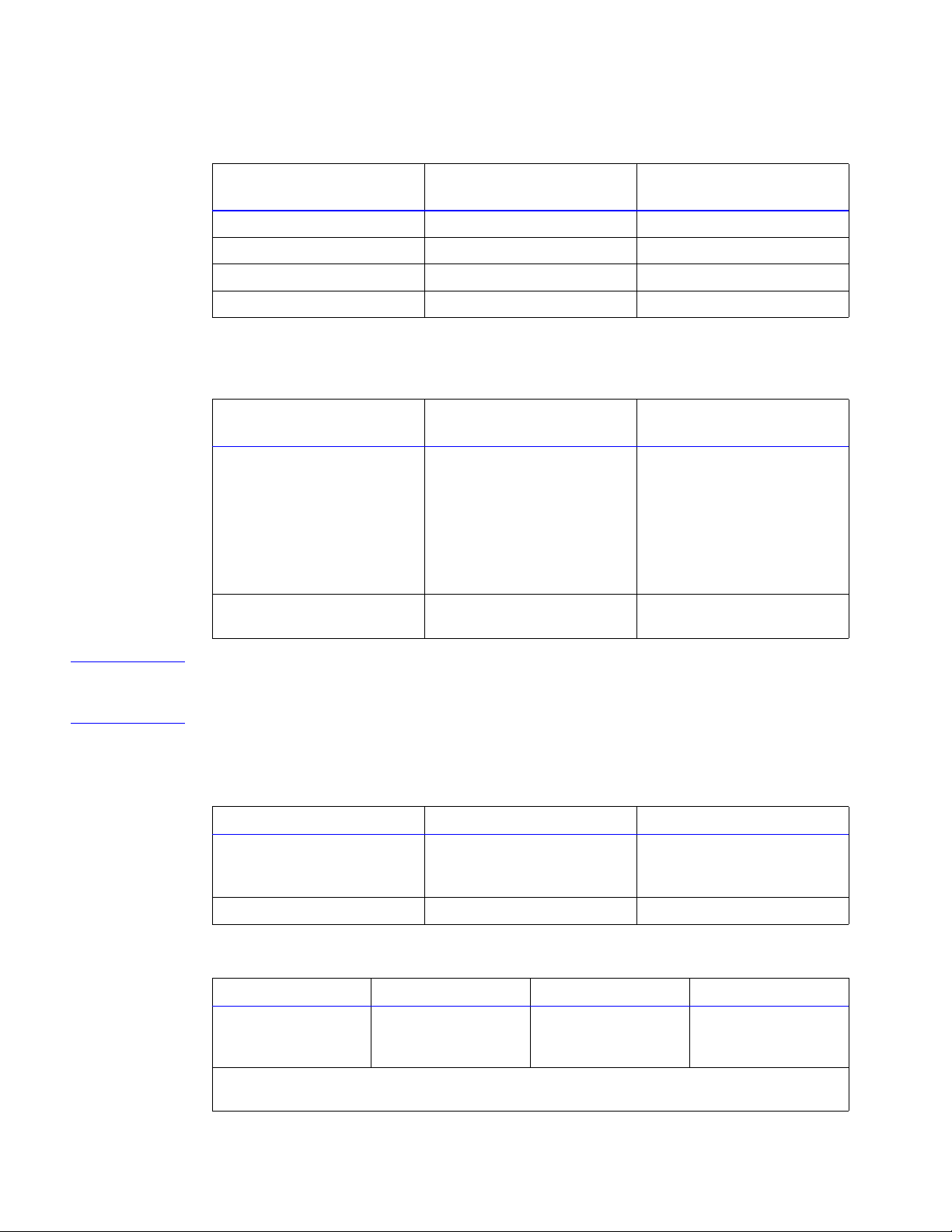

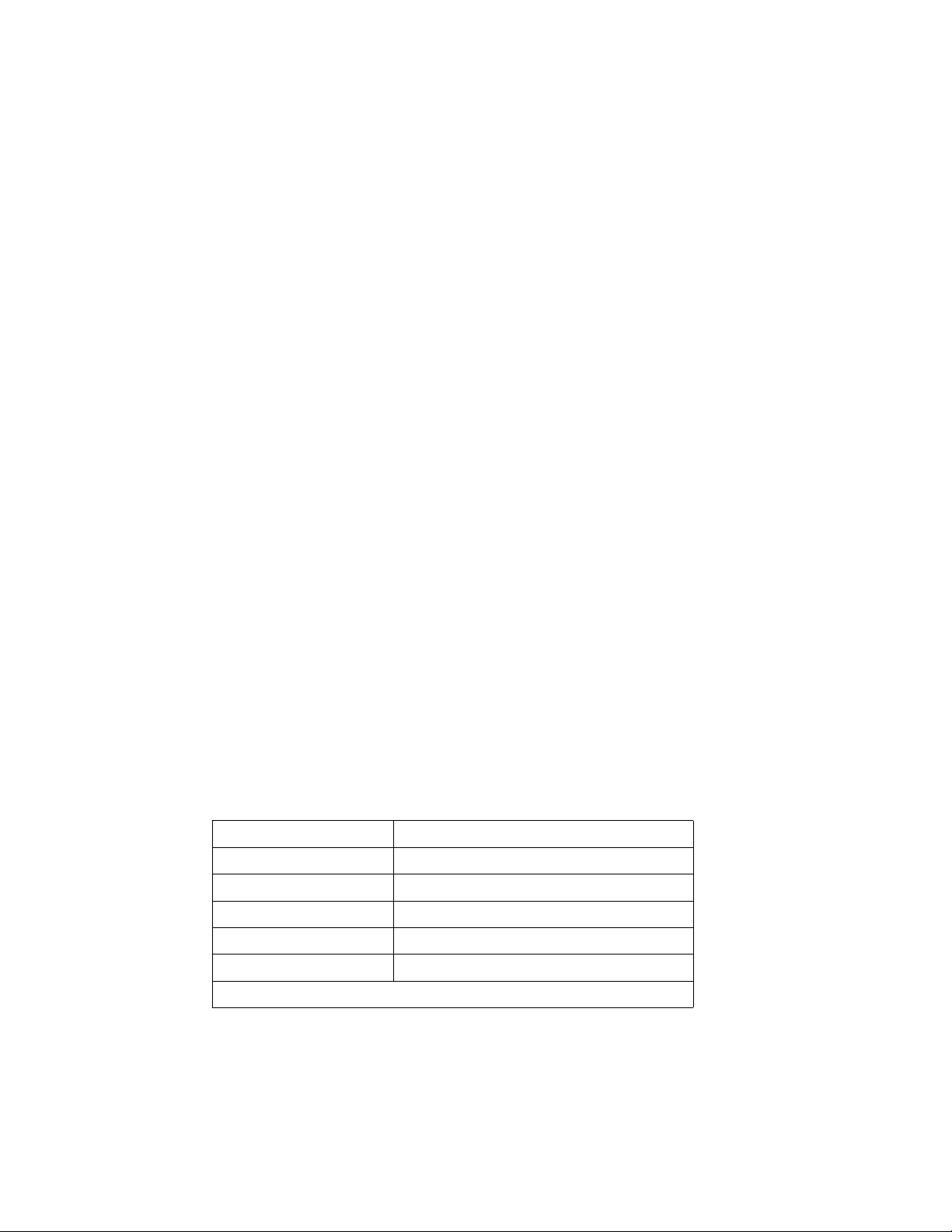

Table 2-1. Guidelines for Selecting Paper

Symptom Problem with Paper Solution

Poor print quality or toner

adhesion

Problems with feeding

Dropouts, jamming, curl Stored improperly Store paper flat in its moisture-

Increased gray background

shading/printer wear

Excessive curl

problems with feeding

Jamming, damage to printer Cutouts or perforations Do not use paper with cutouts

Problems with feeding Ragged edges Use good quality paper

Too moist, too rough, too

smooth, or embossed;

faulty paper lot

Too heavy Use lighter paper, open the rear

Too moist, wrong grain

direction or short-grain

construction

Try another kind of paper,

between 100-250 Sheffield,

4-6% moisture content

proof wrapping

output bin

Open the rear output bin

Use long-grain paper

or perforations

C4170-90959

Media Specifications

29

Page 40

Media Input Options

The printer comes with two paper trays. By default, the printer draws first from Tray 1. If

Tray 1 is empty, the printer draws from Tray 2 (or optional Tray 3 if it is installed).

Tray 1

Tray 2

Optional Tray 3

30 Chapter 2 Operating Requirements C4170-90959

Page 41

Tray 1 Media Sizes

Tray 1 adjusts for sizes from 76 by 127 mm (3 by 5 inches) to 216 by 356 mm (8.5 by

14 inches). Tray 1 should be used when printing the following:

• Envelopes

• Labels

• Transparencies

• Custom-sized media or cardstock

• Postcards

Table 2-2. Tray 1 Media Sizes

Tray 1 Dimensions Weight Capacity

Minimum Size

(custom)

Maximum Size

(custom)

76 by 127 mm (3 by 5

in.)

216 by 356 mm (8.5 by

14 in.)

60 to 163 g/m

43 lb Bond)

2

(16 to

100 sheets of 80 g/m2

(20 lb Bond) paper

Transparency Same as minimum and

maximum paper sizes

listed above.

Labels Thickness:

Envelopes

Thickness:

.10 to .14 mm (0.0039

to 0.0055 in.)

.10 to .14 mm (0.0039

to 0.0055 in.)

Up to 90 g/m

2

(16-24 lb)

75 typical

50 typical

up to 10

NOTE: The printer supports a wide range of media sizes. Check the printer software for supported

sizes. Capacity may vary depending on media weight and thickness, and environmental

conditions. Smoothness should be between 100 to 250 (Sheffield).

For information about measuring basis weight, see “Basis Weight Field Test” (page 38).

For information about measuring caliper, see “Caliper Field Test” (page 39).

For information about smoothness, see “Paper Finish Field Test” (page 40)

NOTE: Users may experience some paper jams when using any media with a length less than

178 millimeters (7 inches.). This may be caused by paper that has been affected by

environmental conditions. For optimum performance, make sure that users are storing and

handling the paper correctly.

C4170-90959

Media Specifications

31

Page 42

Tray 2 and Optional Tray 3 Paper Sizes

Tray 2 and optional Tray 3 hav e settings f or the paper siz es sho wn in the f ollo wing tabl e. Use

only standard copier paper when printing from Tray 2 or optional Tray 3. Other types of

printable media might jam when printing from Tray 2 or optional Tray 3.

Table 2-3. Tray 2 and Optional Tray 3 Paper Sizes

Tray 2 or Tray 3 Dimensions Weight Capacity

Letter 216 by 279 mm

(8.5 by 11 in.)

A4 210 by 297 mm

(8.3 by 11.7 in.)

Executive 191 by 267 mm

(7.3 by 10.5 in.)

Legal 216 by 356 mm

)8.5 by 14 in.)

B5 (ISO) 176 by 250 mm

(6.9 by 9.9 in.)

B5 (JIS) 182 by 257 mm

(7.2 by 10 in.)

A5 148 by 210 mm

(5.8 by 8.2 in.)

60 to 105 g/m

28 lb bond)

2

(16 to

250 sheets of (80 g/m2)

(20 lb bond) paper

8.5 x 13 in. 216 by 330 mm

(8.5 by 13 in.)

NOTE: Capacity may vary depending on media weight and thickness , and environmental conditions .

For information about measuring basis weight, see “Basis Weight Field Test” (page 38).

Envelope Specifications

Envelope construction is critical. Env elope fold lines can v ary considerably, not only between

manufacturers, but also within a box from the same manufacturer. Successful printing on

envelopes depends upon the quality of the envelopes. When selecting envelopes, consider

the following components:

• Weight: The weight of the envelope paper should not exceed 105 g/m

jamming may occur.

• Construction: Prior to printing, envelopes should lie flat with less than 6 mm (0.25 in.)

curl, and should not contain air.

• Condition: Envelopes should not be wrinkled, nicked, or otherwise damaged.

• Temperature: Use envelopes that are compatible with the heat and pressure of the

printer.

2

(24 lb) or

• Size: Use only envelopes within the following size ranges.

Minimum Maximum

76 by 127 mm

(3 by 5 in.)

216 by 356 mm

(8.5 by 14 in.)

32 Chapter 2 Operating Requirements C4170-90959

Page 43

NOTE: Use only Tray 1 to print envelopes.

Some paper jams might occur when using any media with a length less than 178 mm (7 in.).

This might be caused by paper that has been affected by environmental conditions.

Envelopes might meet the general specifications listed in table 2-4 and still not print

satisfactorily because of the printing environment or other variables over which HP has no

control.

Table 2-4. Envelope Specifications

Description Specification

Paper Paper used for envelope construction must meet the paper

specifications listed in this manual and the

Specifications Guide

Basis Weight 16 to 27# (60 to 100 g/m2), single thickness. Jamming might result if

27# (100

(page 38).

Finish Avoid using envelopes with adhesive exposed to the printer.

Envelopes must be fo lded accurately (+/- 0.04 inch) so that there are

no more than two thicknesses of paper anywhere along the leading

edge. All folds must be well scored and sharply creased, and

construction must be tight (not baggy). A void using en velopes that are

stuck together with excess seam gum.

g/m

HP LaserJet Printer Paper

(except for those listed below).

2

) is exceeded. See “Basis Weight Field Test”

Fusing Compatibility All inks, adhesives , and other materials used in the env elope m ust be

compatible with the heat and pressure of the fusing process.

Materials must not discolor, melt, offset, or release hazardous

emissions when heated to 200 degrees Celsius

(392 degrees Fahrenheit) for 0.1 second. See “Fusing Compatibility

Field Test” (page 42).

Curl (Pre-Printed) Envelopes must lie flat, with no more than 5 mm (0.2 inch) curl across

the entire surface. See “Curl Field Test” (page 41).

Caliper 0.084 to 0.14 mm (3.3 to 5.5 mils), single thickness. See “Caliper

Field Test” (page 39).

Envelopes with Adhesive Strips or Flaps

Envelopes with a peel-off adhesive strip or with more than one flap that folds over to seal

must use adhesives compatible with the heat and pressure in the printer . The e xtra flaps and

strips might cause wrinkling, creasing, or jams and may even damage the fuser.

Envelope Storage

Proper storage of envelopes contributes to print quality. Envelopes should be stored flat. If

air is trapped in an envelope, creating an air bubble, then the envelope may wrinkle during

printing.

C4170-90959

Media Specifications

33

Page 44

Envelopes with Double Side Seams

Double side-seam construction has vertical seams at both ends of the envelope rather than

diagonal seams. This style may be more likely to wrinkle. Be sure the seam extends all the

way to the corner of the envelope as illustrated below.

Correct

Incorrect

Envelope Margins

The following gives typical address margins for a commercial #10 or DL envelope.

Table 2-5. Envelope Margins

Type of Address Top Margin Left Margin

Return address 15 mm (0.6 in.) 15 mm (0.6 in.)

Delivery address 51 mm (2 in.) 89 mm (3.5 in.)

NOTE: For the best print quality, position margins no closer than 15 mm (0.6 in.) from the edges of

the envelope .

Avoid printing over the area where the envelope seams meet.

34 Chapter 2 Operating Requirements C4170-90959