Page 1

DESIGNJET T120/T520 ePrinter Series

Service Manual

Page 2

© 2012 Hewlett-Packard Development

Company, L.P.

1st edition, August 2012

Legal notices

This document contains proprietary

information that is protected by copyright. All

rights are reserved. No part of this document

may be photocopied, reproduced, or translated

to another language without the prior written

consent of Hewlett-Packard Company.

Page 3

Notices

Warranty

The information contained in this

document is subject to change without

notice.

Hewlett-Packard makes no warranty

of any kind with regard to this

material, including, but not limited to,

the implied warranties of

merchantability and fitness for a

particular purpose.

Hewlett-Packard shall not be liable for

errors contained herein or for incidental

or consequential damages in connection

with the furnishing, performance, or use

of this material.

WARNING

The procedures described in this manual are to

be performed by HP-qualified service

personnel only.

Electrical Shock Hazard

Serious shock hazard leading to death or injury

may result if you do not take the following

precautions:

●

Ensure that the AC power outlet (mains)

has a protective earth (ground) terminal.

●

Disconnect the printer from the power

source prior to performing any

maintenance.

●

Prevent water or any other liquids from

running onto electrical components or

circuits, or through openings in the

enclosure.

Electrostatic Discharge

See the beginning of Chapter 4's Introduction

on page 137 of this manual, for precautions

you should take to prevent damage to the

printer circuits from electrostatic discharge.

WARNING

The Warning symbol calls attention to a

procedure, practice, or the like, which, if

not correctly performed or adhered to,

could result in personal injury. Do not

proceed beyond a Warning symbol until

the indicated conditions are fully

understood and met.

CAUTION

The Caution symbol calls attention to an

operating procedure, practice, or the like,

which, if not correctly performed or

adhered to, could result in damage to or

destruction of part or all of the printer.

Do not proceed beyond a Caution symbol

until the indicated conditions are fully

understood and met.

Customer Assurance

Customer Experience Section

Large Format Printing Division

Hewlett-Packard Española, S.A.

Avenida Graells, 501

08174 Sant Cugat del Vallès

Spain

Safety Symbols

General definitions of safety symbols are given

immediately after the table of contents.

ENWW iii

Page 4

Using this manual

This service manual contains information necessary to test, maintain, and service the following:

HP Designjet T120 Basic Printer 24 inch CQ891A

HP Designjet T520 Pro Printer 24 inch CQ890A

HP Designjet T520 Pro Printer 36 inch CQ893A

For information about using these printers, see the user's guide.

Readership

The procedures described in this service manual are to be performed by HP Certified service personnel only.

Part numbers

Part numbers for printer service parts are located in Parts and diagrams on page 119.

ENWW v

Page 5

Table of contents

1 Printer fundamentals .................................................................................................................................... 1

Overview ................................................................................................................................................................ 1

Using the front panel ............................................................................................................................................. 1

Start-up sequence ................................................................................................................................................. 3

Subsystems ............................................................................................................................................................ 5

2 Troubleshooting .......................................................................................................................................... 33

Printer troubleshooting flowchart ...................................................................................................................... 34

Basic printer troubleshooting ............................................................................................................................. 35

System error codes .............................................................................................................................................. 38

Paper troubleshooting ........................................................................................................................................ 57

Communication troubleshooting ........................................................................................................................ 62

Ink-supplies troubleshooting .............................................................................................................................. 66

Print-quality troubleshooting ............................................................................................................................. 78

Update the firmware ........................................................................................................................................... 91

3 Support menus ............................................................................................................................................ 95

Entering the support menus ............................................................................................................................... 96

Support menu ...................................................................................................................................................... 98

Extended Support menu ................................................................................................................................... 117

4 Parts and diagrams .................................................................................................................................... 119

Introduction ....................................................................................................................................................... 119

Printer support .................................................................................................................................................. 120

Covers ................................................................................................................................................................ 121

Roll covers ......................................................................................................................................................... 122

Right-hand assemblies ..................................................................................................................................... 123

Left-hand assemblies ........................................................................................................................................ 125

Carriage assembly ............................................................................................................................................. 127

Paper path (front) .............................................................................................................................................. 129

Paper path (rear) ............................................................................................................................................... 130

Roll supports ..................................................................................................................................................... 131

Sensor Kit ........................................................................................................................................................... 132

Miscellaneous parts ........................................................................................................................................... 133

ENWW vii

Page 6

5 Removal and installation ........................................................................................................................... 135

Introduction ....................................................................................................................................................... 137

Customer Self Repair parts ............................................................................................................................... 139

Videos available ................................................................................................................................................. 140

Recommended checks after replacing parts .................................................................................................... 140

Top Cover ........................................................................................................................................................... 141

Front Cover ........................................................................................................................................................ 144

Right Cover ........................................................................................................................................................ 147

Ink Cartridge Cover ............................................................................................................................................ 150

Left Cover .......................................................................................................................................................... 152

Roll Cover ........................................................................................................................................................... 154

Back Cover ......................................................................................................................................................... 157

Front Panel ........................................................................................................................................................ 159

Front Panel Cable .............................................................................................................................................. 165

Central Cover ..................................................................................................................................................... 166

Upper-Roll Paper Guide ..................................................................................................................................... 171

Left Roll Support ............................................................................................................................................... 174

Right Roll Support ............................................................................................................................................. 179

Top Cover Sensor ............................................................................................................................................... 182

Top Cover Sensor Cable ..................................................................................................................................... 185

Encoder Strip ..................................................................................................................................................... 187

Ink Cartridge Cover PCA Assembly .................................................................................................................... 192

Power Supply ..................................................................................................................................................... 196

Main PCA ............................................................................................................................................................ 198

Paper Motor ....................................................................................................................................................... 204

Encoder PCA and Index ...................................................................................................................................... 206

Encoder Disk ...................................................................................................................................................... 210

Trailing Cable ..................................................................................................................................................... 213

Service Station ................................................................................................................................................... 220

Prime Pump ....................................................................................................................................................... 226

Carriage and Belt ............................................................................................................................................... 229

Carriage Belt ...................................................................................................................................................... 235

Right Gear Train Module .................................................................................................................................... 237

Starwheel Assembly .......................................................................................................................................... 239

Output Shaft ...................................................................................................................................................... 241

Output Tray ........................................................................................................................................................ 249

Multi-Sheet Tray Assembly ............................................................................................................................... 252

Multi-Sheet Tray Assembly Extensions ............................................................................................................ 253

Output Platen .................................................................................................................................................... 255

Carriage Motor ................................................................................................................................................... 260

Cutter Assembly ................................................................................................................................................ 264

Cutter Guide ....................................................................................................................................................... 271

Out-Of-Paper Sensor ......................................................................................................................................... 273

Out-Of-Paper Sensor Cable ............................................................................................................................... 276

viii ENWW

Page 7

Output Tray Sensor Assembly ........................................................................................................................... 278

Output Tray Extender Sensor Cable .................................................................................................................. 281

Carriage Line Sensor .......................................................................................................................................... 284

Bundle Board ..................................................................................................................................................... 288

Bundle Board FFC cable ..................................................................................................................................... 290

Pinchwheels ....................................................................................................................................................... 295

Left Spittoon ...................................................................................................................................................... 301

6 Preventive maintenance ............................................................................................................................ 305

Preventive maintenance ................................................................................................................................... 306

Preventive maintenance kits ............................................................................................................................ 312

7 Appendices ................................................................................................................................................ 315

Important links .................................................................................................................................................. 316

Front-panel home screen and menu map ........................................................................................................ 317

Support menu tree ............................................................................................................................................ 327

Extended Support menu tree ............................................................................................................................ 328

How to check whether your computer is connected to your network ............................................................. 329

Wireless troubleshooting report error cases .................................................................................................... 332

CSR fliers ............................................................................................................................................................ 341

ENWW ix

Page 8

1 Printer fundamentals

●

Overview

●

Using the front panel

●

Start-up sequence

●

Subsystems

Overview

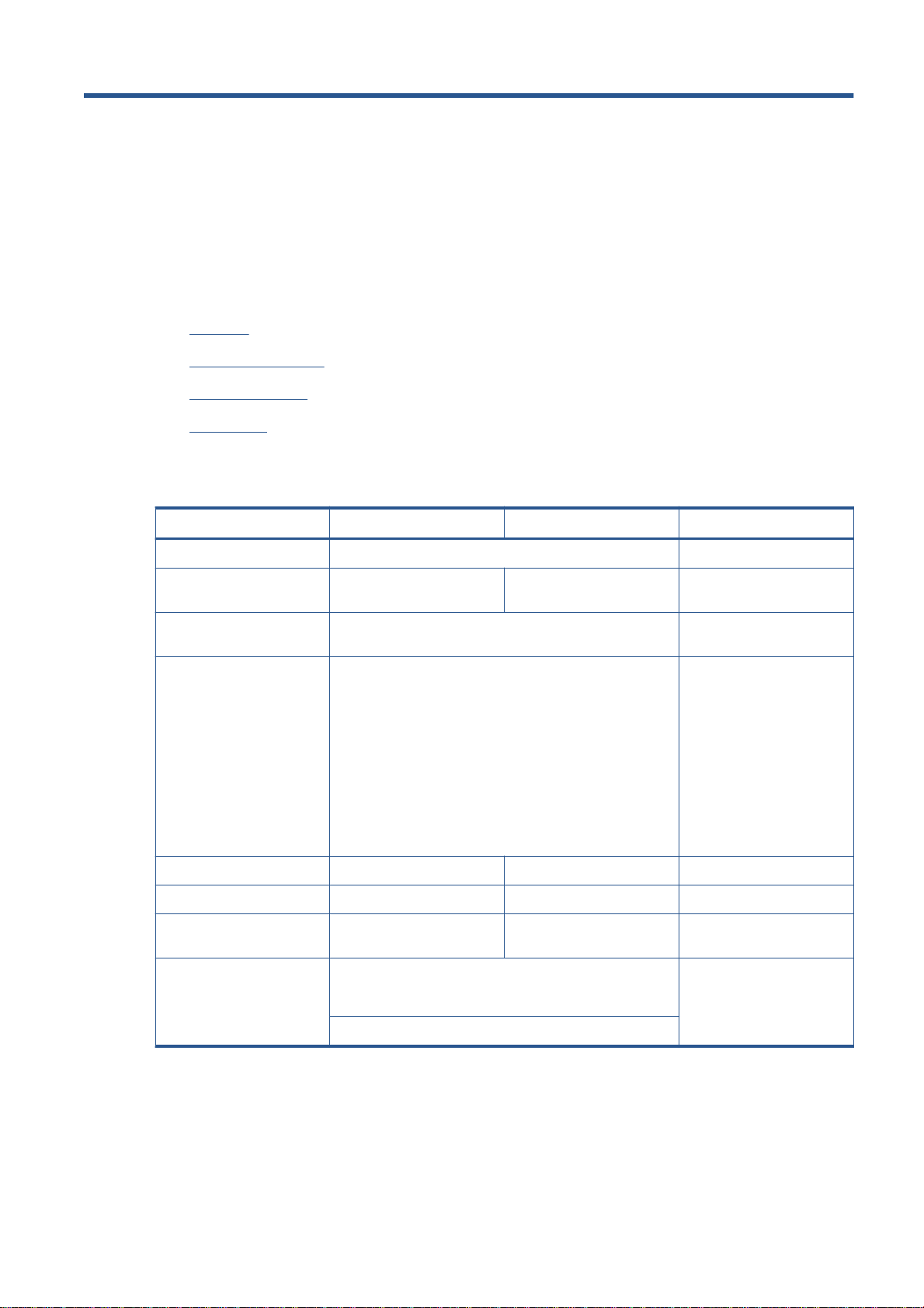

Feature HP Designjet T120 HP Designjet T520 More information

Paper source Roll and multi-sheet tray See the user's guide

Hardware differences Stand as an accessory, no roll

cover

Connectivity Wi-Fi, Fast Ethernet LAN, USB Important! LAN and Wi-Fi are

Web Services Automatic firmware upgrade

HP Designjet ePrint & Share

Printing by email

Speed 70 s per page on A1/D 35 s per page on A1/D

Resolution Up to 1200 × 1200 dpi Up to 1200 × 2400 dpi

Memory and languages 256 MB, HP-PCL3 (processing

in printer)

Supplies HP 711 29 ml Cyan, Magenta, Yellow

HP 711 38 ml and 80 ml Black

One on-axis printhead for all colors

Stand in box, roll cover

1 GB, HP-GL/2 (processing in

computer)

not compatible

The printer needs to be

Internet-connected: Web

Services do not work with a

USB connection. For some

configurations, the latest

firmware release is needed.

Manual firmware upgrade is

available in both printers via

HP Designjet Utility (Windows)

or HP Utility (Mac OS). The

same firmware file is used for

T120 and T520.

Ink cartridges and printhead

can be replaced by the

customer.

Using the front panel

The front panel is a touch-sensitive screen with a graphical user interface; it is located on the front left of the

printer. It gives you complete control of your printer: from the front panel, you can print, view information

ENWW Overview 1

Page 9

about the printer, change printer settings, perform calibrations and tests, and so on. The front panel also

displays alerts (warning and error messages) when needed.

The front panel has a large central area to display dynamic information and icons. On the left and right sides

you can see up to six fixed icons at different times. Normally they are not all displayed at the same time.

To the right of the front panel is the Power key, with which you can turn the printer on or off. The key is

illuminated when the printer is on. It flashes when the printer is in transition between on and off.

Left and right fixed icons

●

shows the status of the wireless connection: if the blue light is shining, the wireless connection is active.

●

Press to return to the home screen.

●

Press to view help about the current screen.

●

Press to go to the previous item.

●

Press to go to the next item.

●

Press to go back to the previous screen.

●

Press to cancel the current process.

Home screen dynamic icons

The following items are displayed only on the home screen.

●

At the top left of the home screen is a message telling you which paper source is active.

●

Press to view Web Services status and display your printer’s email address.

●

Press to view connectivity status information and to perform network configuration. If a network cable

is connected, is displayed instead.

NOTE: It is not possible to use wireless and wired network connections simultaneously.

●

Press to view ink information.

●

Press to change printer settings.

●

Press to load, unload, and change options for roll paper.

●

Press to change options for the multi-sheet tray, or to activate it.

●

Press to load, unload, and change options for single sheets.

●

Press to access HP Designjet ePrint & Share.

NOTE: The active paper source is indicated by a slightly larger icon, with a white tick in a green circle: .

2 Chapter 1 Printer fundamentals ENWW

Page 10

If the printer is left idle for some time, it goes into sleep mode and switches off the front-panel display. To

change the time that elapses before sleep mode, press , then Printer preferences > Sleep. You can set a time

between 5 and 240 minutes.

The printer wakes from sleep mode and switches on the front-panel display whenever there is some external

interaction with it.

The following table shows an overview of the two types of support menu available, for more details see

Entering the support menus on page 96.

NOTE: The icons mentioned in this table will not be visible in the front panel: you must press the front panel

in the places where they normally appear, as shown in the front panel illustration at the start of this section.

Label Description

Support menu: This can be used by customers under the

guidance of phone call agents assisting remotely. Using this

menu, customers can perform troubleshooting tasks and access

printer information.

Extended Support menu: Service engineers only From the Home screen, press the following icons one after the

Start-up sequence

There are three states between power-on and the Home screen:

1. Electronics initialization

2. Firmware initialization

3. Mechanical initialization

State 1: Electronics initialization

1. The front panel moves from flashing white light to turning dark.

2. The printer reads the firmware.

From the Home screen, press the following icons one after the

other: , ,, .

If there is a system error, you may not be able to reach the home

screen. In this case, press the Power button and hold it down for

15 seconds.

other: , , , .

NOTE: At this stage, if something is broken, it will not be possible to enter the Support menu. To diagnose

what is happening, go to the front panel blank troubleshooting. (and add here the link). Subsequently, you

can enter the Support menu to troubleshoot if necessary.

State 2: Firmware initialization

1. The HP logo appears with a static bar.

2. Bundle board and ASICs are initialized.

ENWW Start-up sequence 3

Page 11

3. The HP logo changes.

State 3: Mechanical initialization

1. A basic check of servos

2. A check that the Scan Axis and Paper Axis are unobstructed by scraps of paper or other items

3. Paper and print system initialization

Initialization flow summary

Time (sec) Printer state Visual and acoustic information

0 Power on Using the Power button

10 Electronics initialization

27 Mechanical initialization

1. Basic check of servos Sound of the printer's motors

2. Scan Axis, Paper Axis check Carriage movement

3. Paper and print system initialization Paper movement

45 Ready state

NOTE: Initialization lasts around 45 s if there was a clean power-off (using the front panel Power button). If

there was a dirty power-off, the printer will require more time to inititialize (to ensure that the printhead is in

a good state).

4 Chapter 1 Printer fundamentals ENWW

Page 12

Subsystems

Covers

Functionality

These parts cover the printing mechanism and act as protection from potential knocks or dust. They also

prevent the customer from coming into contact with unsafe parts during the operation of the printer. Finally,

the covers complement the style and aesthetics of the printer.

The T120 and T520 printers have covers of different colors, and a different configuration of the roll cover, as

seen in the following table:

HP Designjet T120 HP Designjet T520

Roll Cover Not Present Transparent

Top Cover Opaque Black Transparent

Output Platen Black-Blackberry Black-Olive

Output Tray Black-Olive Black-Olive

Components

Other than the cosmetic aspects of the covers, there are several sensors related to the subsystem covers.

The sensors are designed to detect the status of the cover, open or closed.

ENWW Subsystems 5

Page 13

●

The Ink Cartridge Cover Sensor senses whether the Ink Cartridge Cover is open or closed. Opening the

Ink Cartridge Cover starts ink cartridge replacement automatically. The sensor is hosted in the printer

chassis.

●

The Central Cover hosts the Top Cover Sensor to sense whether the Top Cover is open or closed.

IMPORTANT: Be careful to avoid damaging the sensor while removing the Central Cover. See Central

Cover on page 166.

●

The Output Tray Sensor senses whether the Output Tray is open or closed. To avoid paper jams while

printing on roll paper, the tray should be closed.

IMPORTANT: Damage to the covers can cause the sensors to malfunction.

Removal and installation

In order to proceed with the removal and installation of the covers its important to bear in mind their

cosmetic aspects, some surfaces of the covers have a glossy finish, which requires maximum attention as

they are very delicate and susceptible to scratches and finger marks. It is recommended that you use gloves

for any service operation involving the covers.

Due to the layout of the covers, it is important to bear in mind that some parts require removal before you

can remove a specific cover.

●

Right Cover requires Front Cover removal.

●

Left Cover requires Front and Ink Cartridge Cover removal.

●

Roll Cover requires Right and Left Cover removal.

●

Top Cover requires Front Panel assembly removal.

●

Central Cover requires Right Cover and Left Cover removal.

Related tests

Sensor tests for the Top Cover, Ink Cartridge Cover, and Output Tray operation. See Diagnostics menu

on page 100.

Electronics

Other than the sensor boards, there are no electronics related to this subsystem.

Printhead health systems: Service Station, Primer system, and Left Spittoon

Functionality

The service station is responsible for printhead maintenance. It takes action to clean ink residues and service

ink nozzles, and prevents ink from drying in critical zones by capping the printhead once printing has

finished.

The Primer system provides the necessary air pressure to the printhead to perform initialization. This system

also provides pressure to the necessary printhead service operations (by boosting air which pushes ink out

through the printhead nozzles, cleaning residues of dried ink and other particles).

The Left spittoon is a small container located to the left of the print-zone area, this is the area used by the

printhead to “spit” a small amount of ink at the end/beginning of the printing swath in order to ensure

correct nozzle heath for left-to-right printing.

6 Chapter 1 Printer fundamentals ENWW

Page 14

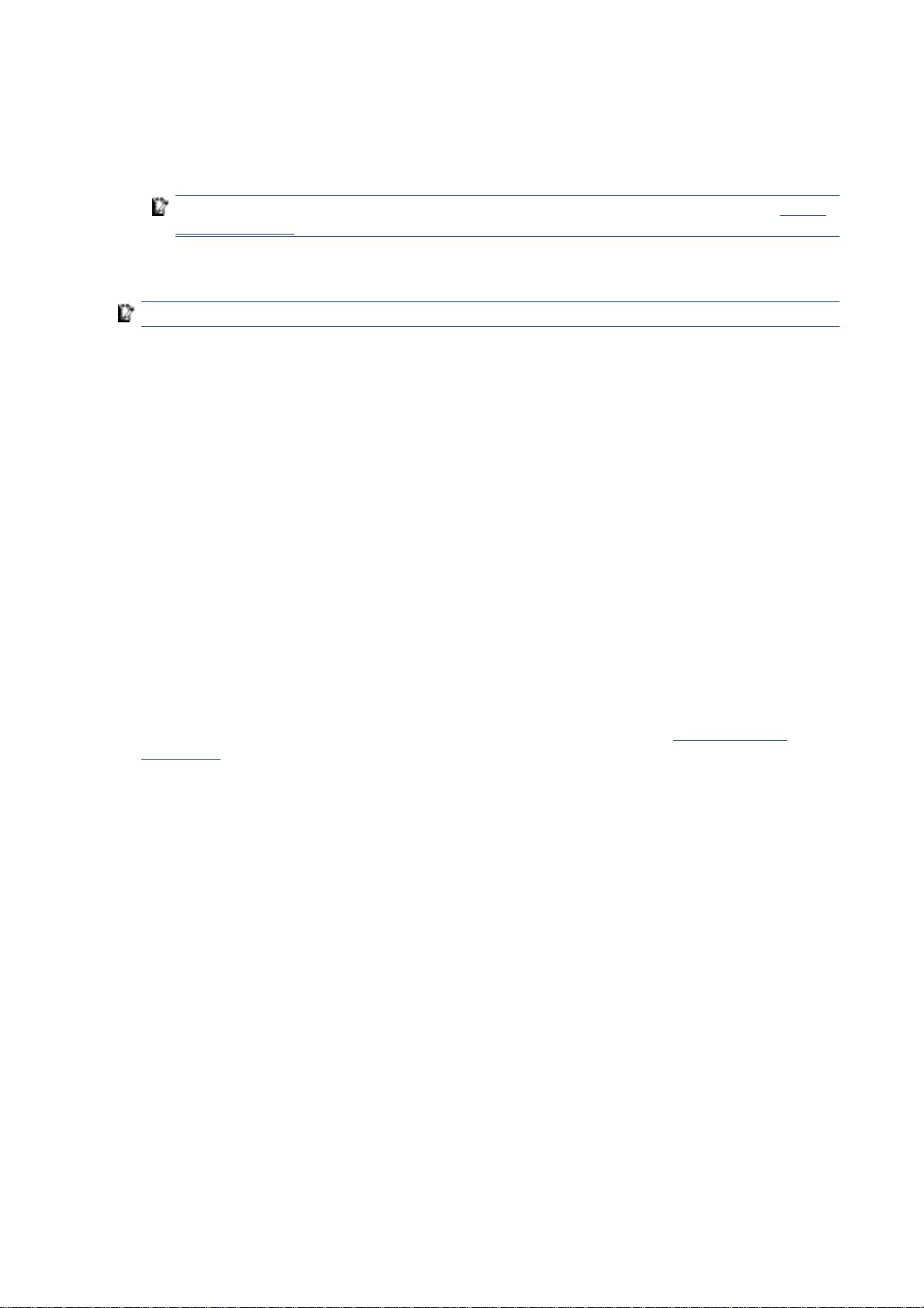

Components

Item Function

Off-axis coupling assembly This is a rubber spring link located on the side plate of the scan

axis (area where the Carriage moves). It links the primer system

with the Carriage when the Carriage is located in its maximum left

position. This system ensures the pressure from the primer

reaches the printhead for nozzle servicing.

Prime Pump This is an air pump which provides the necessary pressure for

Primer Tubes The tubes take the air from the Prime Pump to the off-axis

Notes and considerations

Any leakage in the primer system will generate poor or no priming, this will affect nozzle heath (or even

cause the printhead startup to fail). Bear in mind that the system is not just for the Prime Pump and tubes,

the prime pressure is transmitted via the off-axis coupling to the Carriage and from there to the printhead

assembly and from there to the cartridges.

printhead servicing and nozzle repair. The Prime Pump is

suspended on a rubber holder to minimize the noise that the

Prime Pump makes while in operation.

coupling. There is a T link feature connected to a tube that goes

inside the service station; the purpose of this tube is to release

the air pressure from the system. The tube is pinched by the

shuttle of the service station when reaching a certain position;

this action closes the circuit and allows the system to be

pressurized. With the movement of the service station the tube is

released, allowing the pressure from the system to escape.

ENWW Subsystems 7

Page 15

NOTE: There is no pressure sensor in the system. The Prime Pump operates at a certain time to reach a

specific pressure level, the system is depressurized by releasing the pinching of the release tube in the

Service Station (by moving the service station).

NOTE: It is important to ensure the Carriage reaches the maximum left position; if not, the off-axis coupling

will not connect the Prime Pump with the Carriage. Also, the coupling is made of a rubbery material,

degradation of the material will affect Primer performance due to air leaks.

Electronics

The control driver of the Prime Pump is located on the remote controller board located on the right-hand side

of the printer. There is no encoder for the Prime Pump. This pump is managed only by a DC motor activated

for a certain period of time to create the required priming pressure.

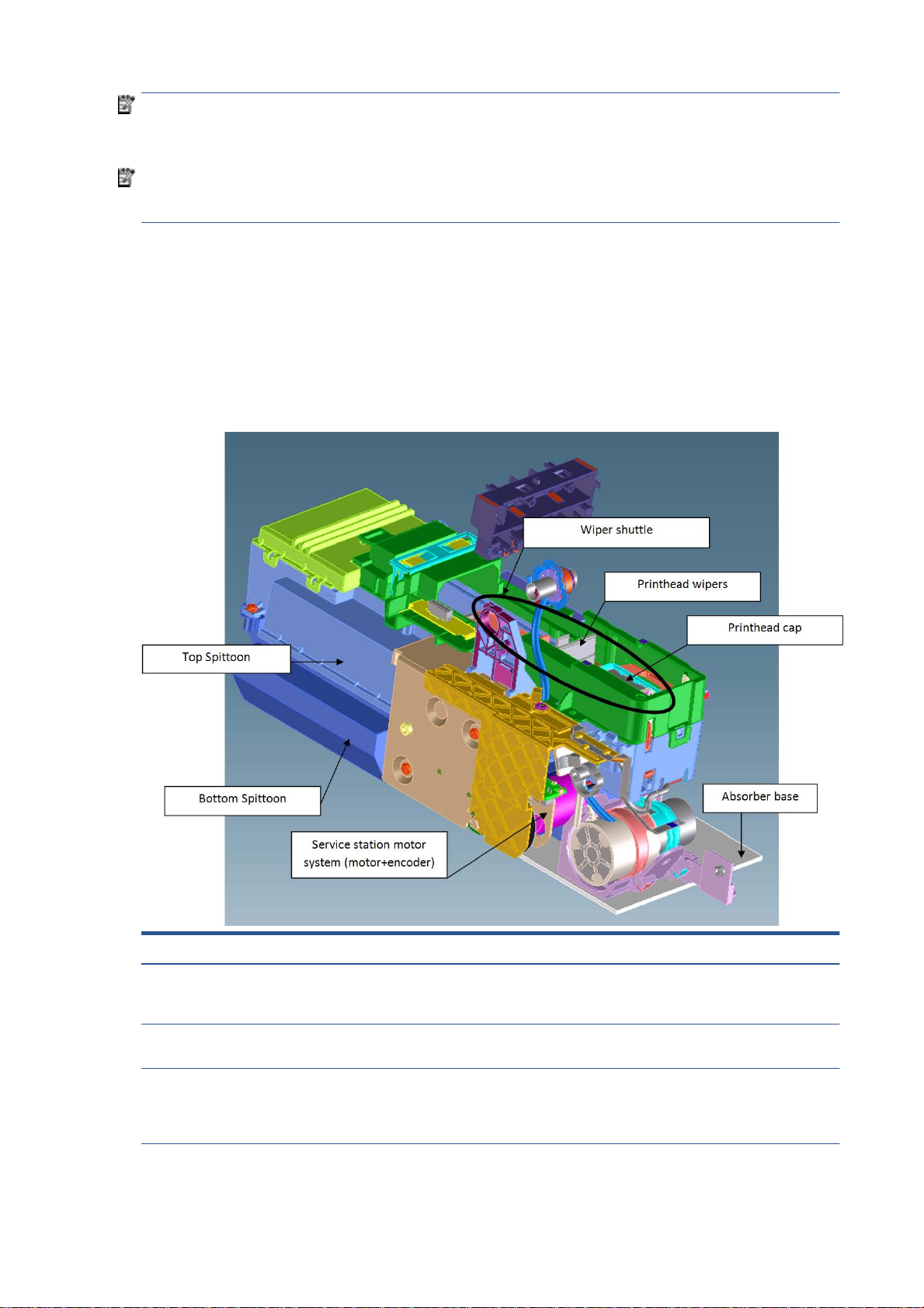

Service Station system

Functionality

Item Function

Printhead Wipers These are rubber paddles that are passed through the nozzle

plate of the printhead with the Service Station movement. They

clean the excess ink from the nozzle plate with a rubbing action.

Printhead Cap This caps and protects the nozzles from drying when they are not

printing.

Service Station Motor system This moves the shuttle with the wiper and the cap so that these

two items can perform their functions. The system is composed

of a DC motor and an encoder disk with an encoder sensor to read

the motor position.

8 Chapter 1 Printer fundamentals ENWW

Page 16

Item Function

Bottom Spittoon This part acts as an ink reservoir when spitting and nozzle health

operations are performed. It contains diapers that prevent the ink

becoming liquid.

Top Spittoon This seals the reservoir and completes the main body of the

service station.

Absorber Base This is made of foam and is located under the service station on

top of the printer structure. It works as an additional diaper in

case ink spills out of the Service Station.

Wiper Shuttle This mobile part is propelled by the motor that contains the Wiper

and Cap. Depending on the position, spitting, wiping, capping, or

priming can take place:

Spitting: The printhead “spits” a little ink into the spittoon to get

the nozzles conditioned and ready for the next swath of printing.

Wiping: A physical action to pass the rubber wipers through the

printhead nozzles.

Capping: Parking the printhead to maintain nozzle heath during

printer inactivity, with a surrounding seal.

Priming: Squirts ink through the nozzles to clean and unblock

them.

Notes and considerations

The service station is offered as a complete service part for full replacement. The failures from this

subsystem are usually related to the mobile parts: motor or encoder failures that prevent the shuttle from

reaching the positions for capping or uncapping.

With the life primer system, tube pinching can present an issue (although it is designed to function for the life

of the printer).

When the Service Station is replaced, it is mandatory to reset the Preventive Maintenance Kit for the Service

Station, this will trigger a simple calibration that is done with the Service Station on the next printer startup.

The calibration measures the length of the Service Station (shuttle front bump to shuttle rear bump), which

ensures a correct capping position.

Electronics

All the controlled movements for the Service Station are done from the remote-controlled board located on

the right-hand side of the printer. Issues with the Service Station can also be related to this control board.

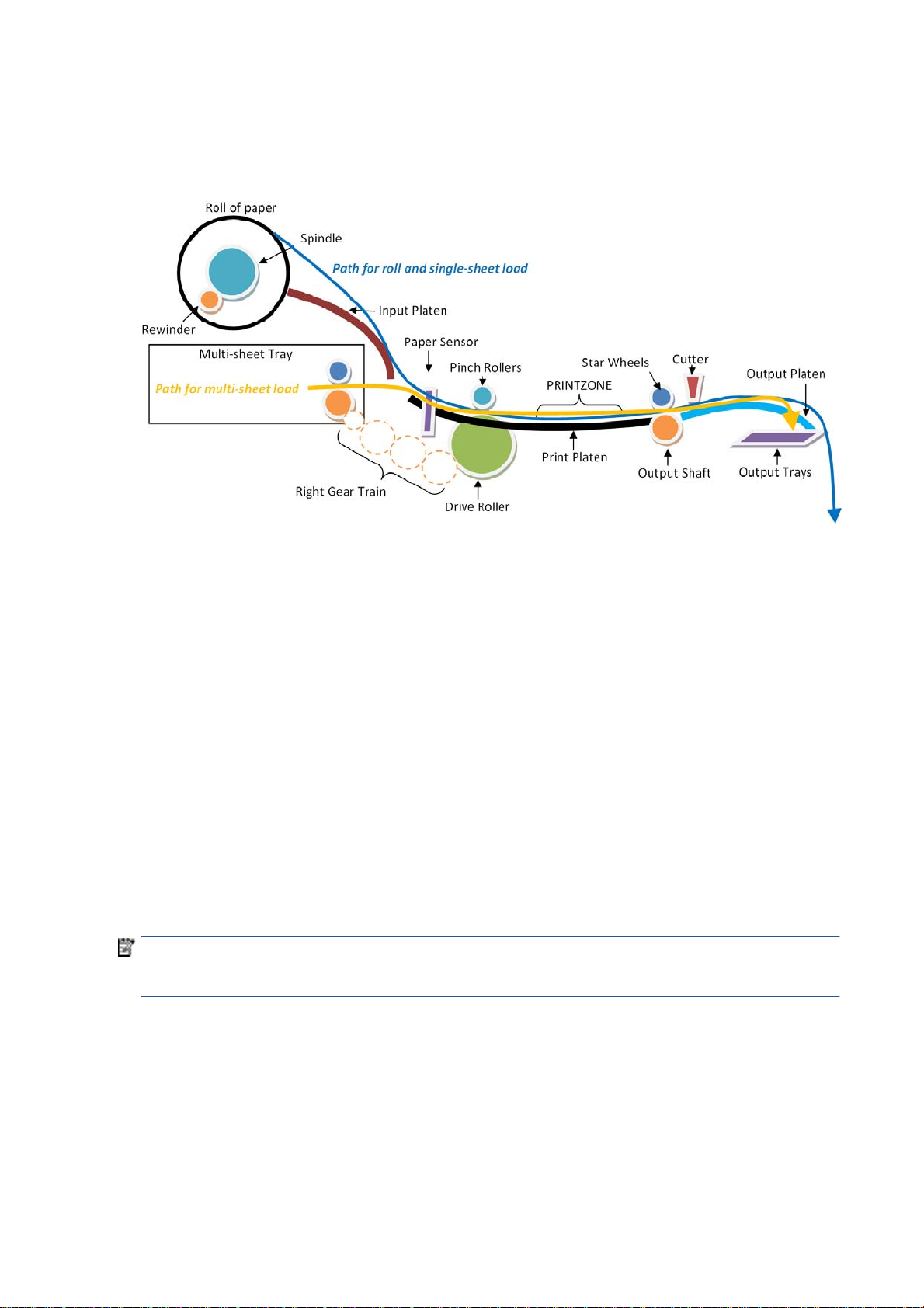

Paper path and Cutter

Functionality

The paper path

This comprises all the elements of the printer in contact with the paper, designed to hold, move, and manage

it in a controlled manner in order to print.

Paper can be loaded using a roll, which is mounted on the rear spindle, or single sheets loaded from the

Multi-Sheet Tray, or single sheets loaded singly.

The paper passes from its source (Roll, Single Tray, or Multi-Sheet Tray) until it touches the Out-Of-Paper

Sensor, when the printer detects the presence of the paper and proceeds to load it.

ENWW Subsystems 9

Page 17

To perform the paper feed, the printer catches the paper in between the Drive Roller and the Pinch Rollers

(Pinch Rollers are spring-loaded pushing the paper down on top of the Drive Roller), then the paper is pushed

forwards on top of the Print Platen in the print zone, which is where the printing operation is performed. The

paper advance is provided by a motor that moves the Drive Roller. The exact position of the Drive Roller and

hence the paper is controlled by an Encoder Disk located on the roller axis.

The printed paper then passes between the Output Shaft and the Starwheels (which keep the paper tension

as flat as possible for printing) to exit on the Output Platen, where it is held in case of cut sheet or is cut to

fall on the output basket in the case of roll paper.

The Output Shaft is designed to over-advance the Drive Roller movement slightly, and hence create the

necessary paper tension to keep the paper as flat as possible. The Starwheels are spring-loaded and are

designed to create force on top of the paper, this is done so as to leave the paper unmarked and at the same

time allow the Output Shaft force to be appropriately transmitted.

In the Roll configuration, the rewinder module generates back force while printing to facilitate paper control.

A key electrical element of the paper path is the Paper Sensor (also known as the Out-Of-Paper Sensor or

OOPS). This sensor is located at the beginning of the Print Platen; it detects paper insertion for roll load and

single-sheet load.

Electronics

In the paper-path driving system, the only electrically active element is the Drive Roller. The Drive Roller is

impelled by the drive roller motor and it contains an Encoder Disk on the axis to determine its position. The

Encoder Disk is read by two sensors. One, the “encoder sensor”, designed to read the encoder, counts the

Encoder Disk (the Encoder Disk outer marks) and another one, the “encoder index sensor”, determines the

start position (the 0 position) of the Drive Roller by reading the inner thicker lines of the Encoder Disk.

NOTE: Every time the printer starts up, it searches for the 0 position of the Drive Roller. If this search fails

(which means that the index sensor is faulty), the printer will give a system error and will be unable to

initialize.

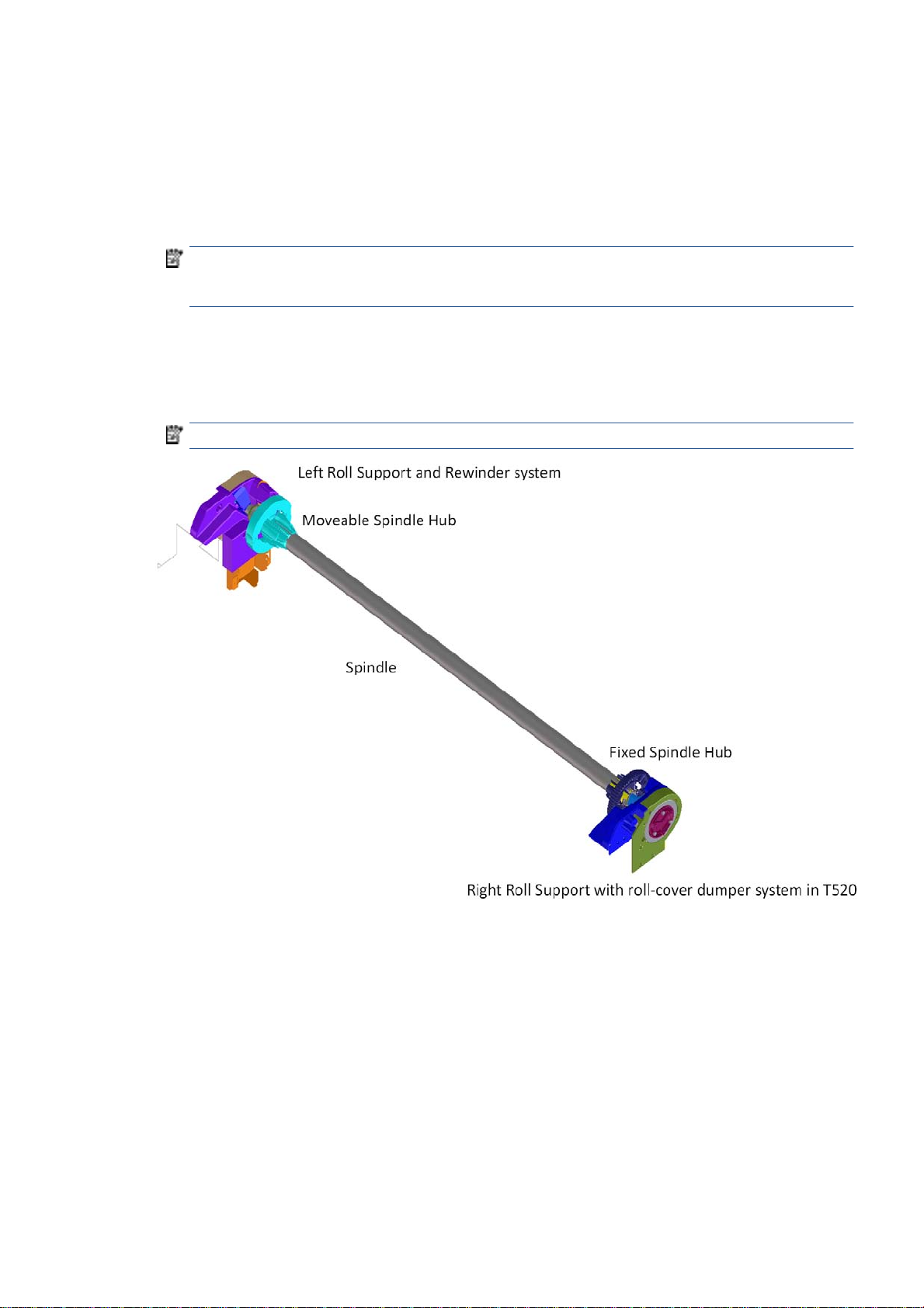

The roll paper input system

Functionality

This system keeps the roll in place and ensures controlled rotation.

It contains the rewinder, which rewinds the paper for paper ejection, and provides an opposite tension to the

paper advance for better paper control.

10 Chapter 1 Printer fundamentals ENWW

Page 18

●

The Left Support encloses the Rewinder Motor and Encoder, containing a set of gears that transmit the

Rewinder motion to the spindle. There is a V-shaped spring to load and fix the spindle in position.

●

The Right Support holds the spindle in position to rotate over passive rollers.

In the T520, the right support also contains the dampers for the roll cover opening movement control

(the internal dampers perform a braking action preventing sudden movement during the opening

operation).

NOTE: The right support for the T120 models does not contain dampers. The T120 and T520 have two

different assemblies from the factory, nevertheless both can be replaced by the damper option of T520

(identical from the external point of view), and there is only one service part available.

●

The spindle is designed to hold the paper rolls, and receive the motion from the rewinder gear in the

Left Support. It consists of a central bar and two hubs; the right hub is fixed to determine the right-side

loading position of the paper, and the moveable left hub adjusts to the width of the paper.

●

The Roll Cover (T520 only) shields the roll from dust.

NOTE: The Roll Cover is a passive part, with no sensor: the printer does not know its status.

Electronics

The Rewinder Motor and Encoder system are directly controlled by the Main PCA.

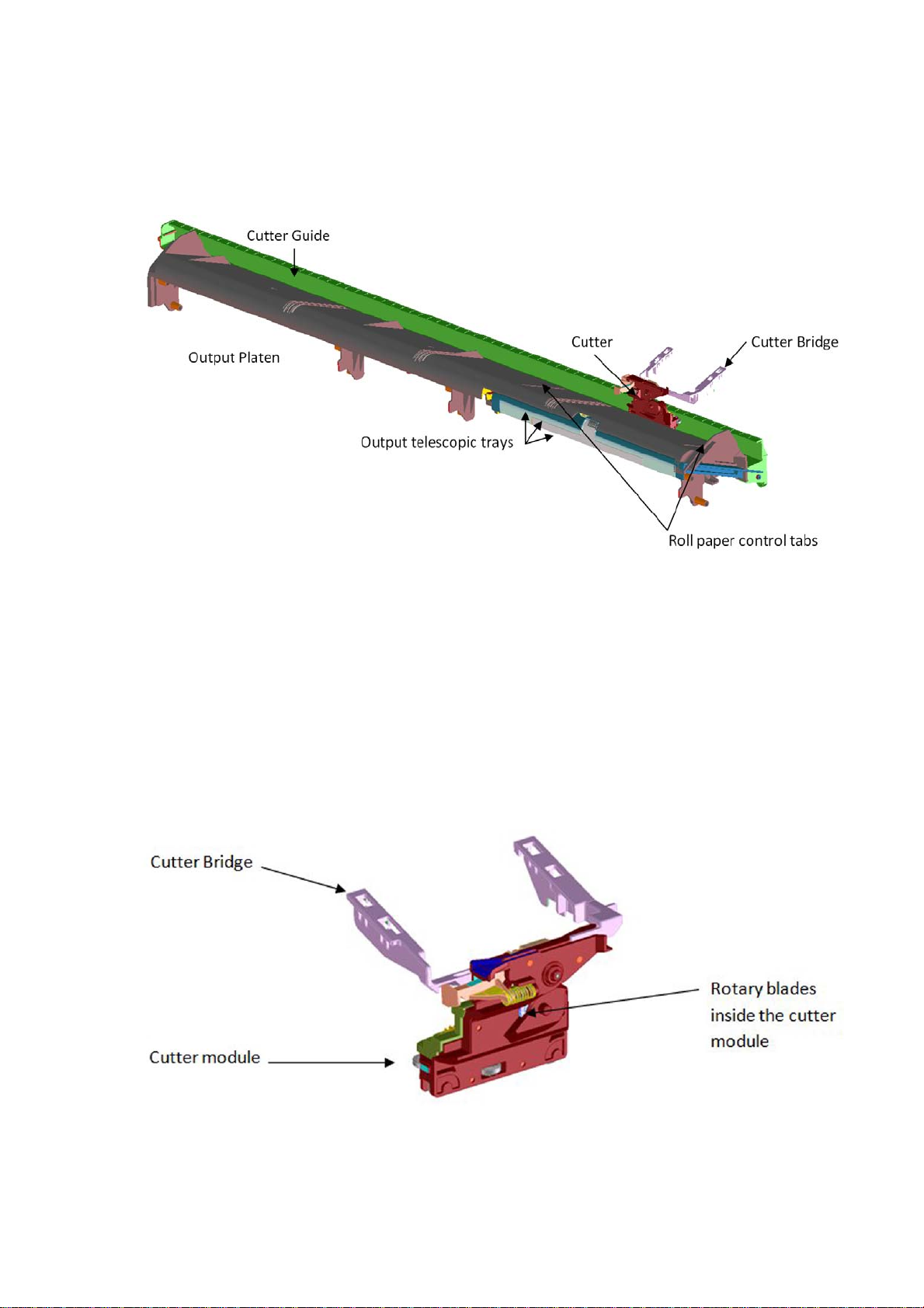

The paper output system

Functionality

The system ensures that the printed paper follows a controlled path and acquires a certain shape in order to

be delivered properly to the user. It also has a cosmetic function.

The system includes a set of three telescopic trays, which are extended to collect the cut-sheet paper printed

from the Multi-Sheet Tray.

ENWW Subsystems 11

Page 19

There are two roll-paper control tabs that are deployed automatically when the telescopic trays of the

Output Tray are in the closed position. This is a purely mechanical action as the tabs are pushed up by the

output trays when closed. The purpose of those tabs is to control the shape of the roll paper when coming

out of the paper path.

The Front Cover is located underneath the Output Platen.

Electronics

The only electronic component related to the Output Platen is the Output Tray Sensor located underneath

the output trays. The sensor is activated when the three output trays are fully closed. The sensor cable is

routed via the front of the machine and is directly connected to the main PCA.

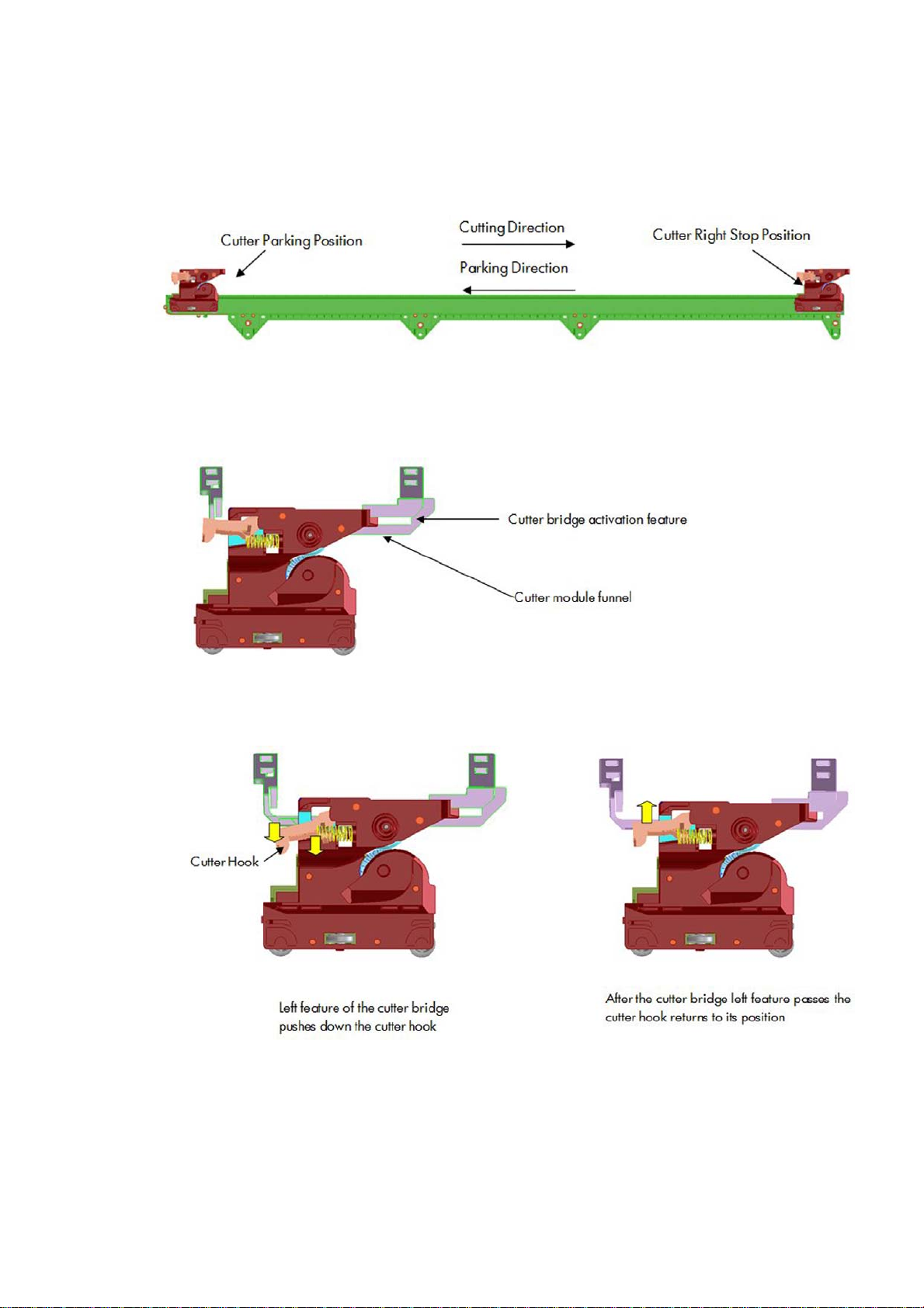

The Cutter system

The Cutter cuts the paper after the print has completed.

It comprises 1) a cutter module that cuts the paper with two rotary blades, 2) a Cutter Bridge attached to the

Carriage that catches and releases the Cutter to perform the cutting operation and then to leave it in capping

position, 3) a Cutter Guide that holds the movement of the Cutter along the printer width.

In order to operate the Cutter, it needs to be in the parked position. If not, the Cutter will not be engaged by

the Cutter Bridge and the printer will not perform the cutting action.

12 Chapter 1 Printer fundamentals ENWW

Page 20

Whenever the printer initializes, it performs a parking movement with the Carriage to ensure that the Cutter

is left in the appropriate position.

The printer does not have any feedback about the cutter engagement action. Hence, if for any reason the

engagement is not performed correctly, the printer will continue operating as if the engagement has

occurred.

How activation works

1. Pre-activation phase: The Cutter Engagement Feature of the Bridge gets into the funnel of the Cutter

Module grooving the Cutter to ensure the correct position for activation.

2. Hook catching: The cutter bridge continues moving to the left pushing down the cutter hook (in orange),

after the left side of the cutter bridge passes the Carriage stops and the cutter hook returns to its

position due to its spring motion.

ENWW Subsystems 13

Page 21

3. Cutter action: The left feature of the cutter bridge pushes the cutter to the left, performing the cutting

operation.

How deactivation works

1. Disengagement: Hook Bridge changes direction moving now from right to the left, so that Cutter Hook

slides out of the Cutter Catch Feature.

14 Chapter 1 Printer fundamentals ENWW

Page 22

2. Move-away action: the Cutter Hook deactivates from the bridge by passing in front of it.

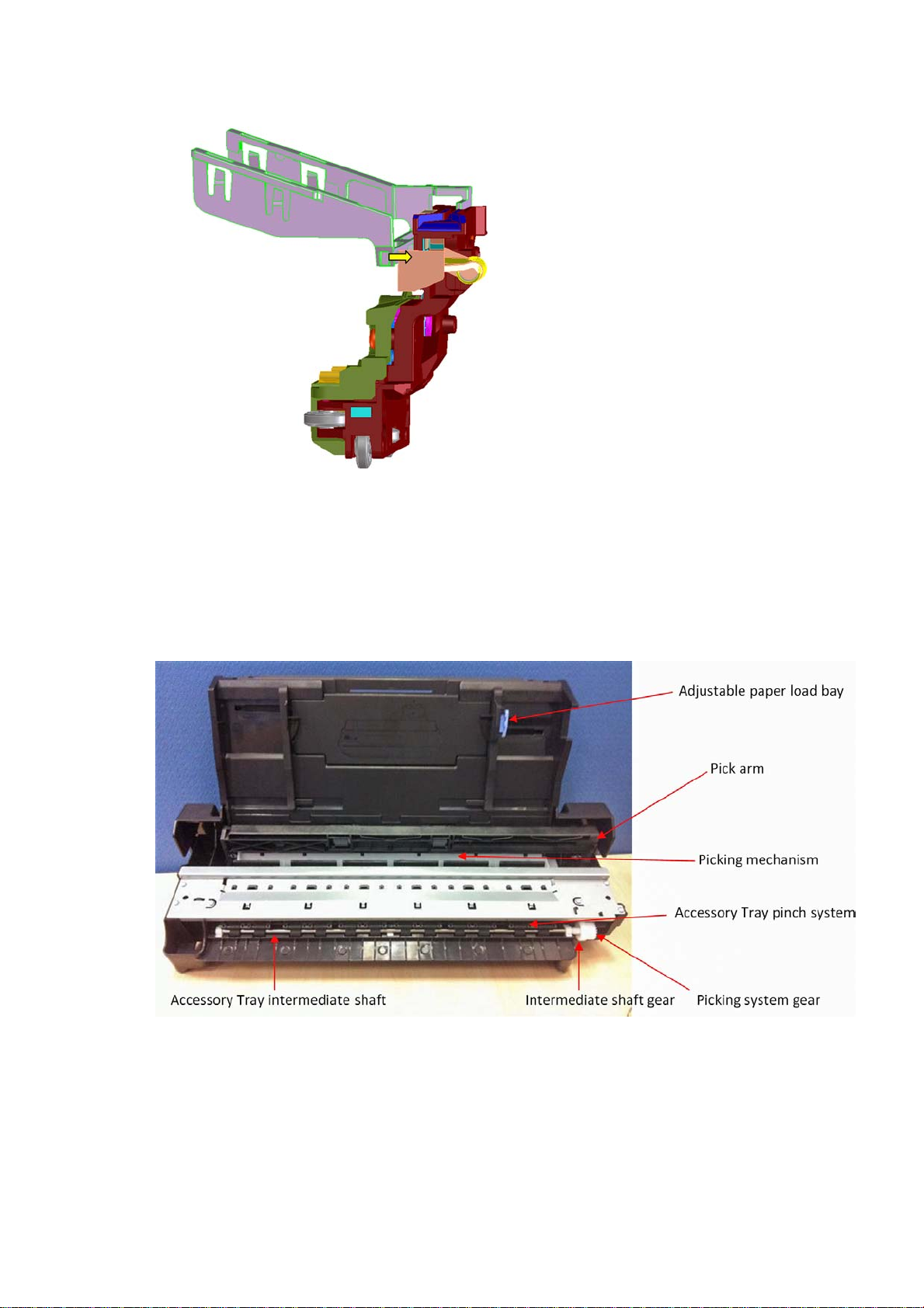

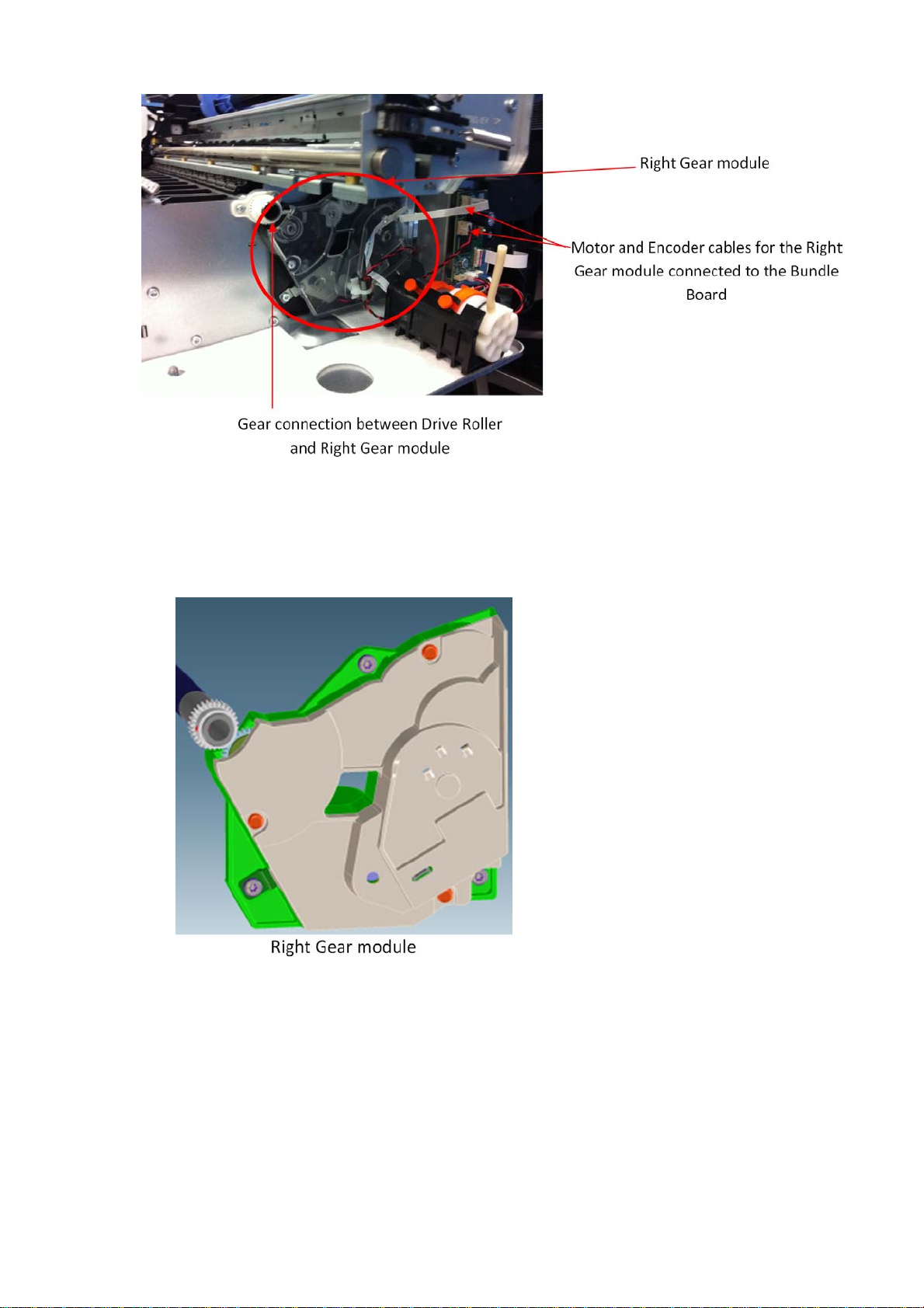

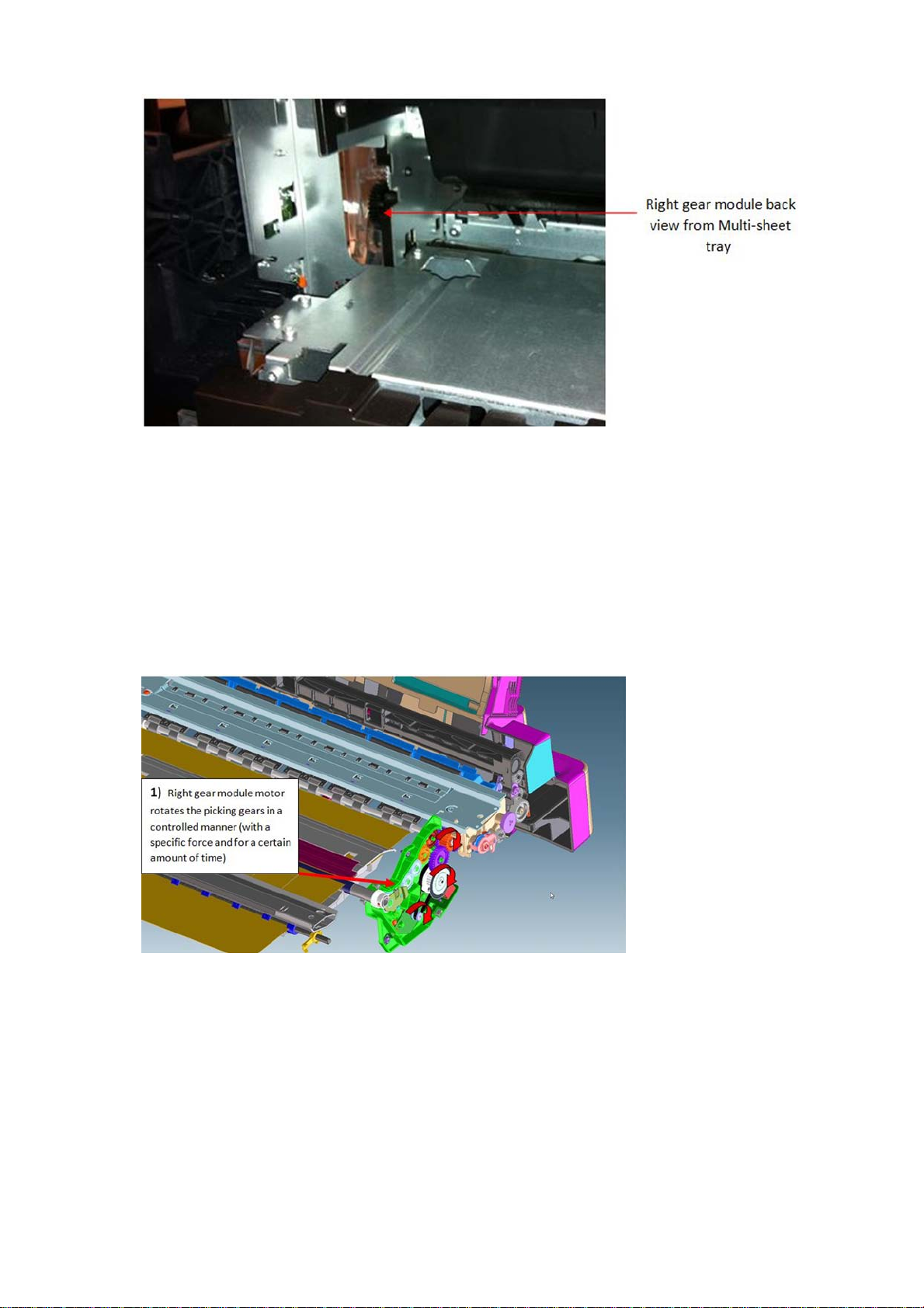

Accessory tray and right gear module

Functionality

The accessory tray holds and loads the cut-sheet paper for the printer. The accessory tray itself is a

completely mechanical system with no electronics or motors. All the motion drives for both picking and paper

drive are or created or transmitted by the Right Gear module located on the right-hand side of the printer,

behind the Service Station.

The Right Gear module has two main functions. It contains the motor encoder and gear drive system for the

picking mechanism, and it contains the gear train system to transmit the movement from the drive roller to

the accessory tray.

ENWW Subsystems 15

Page 23

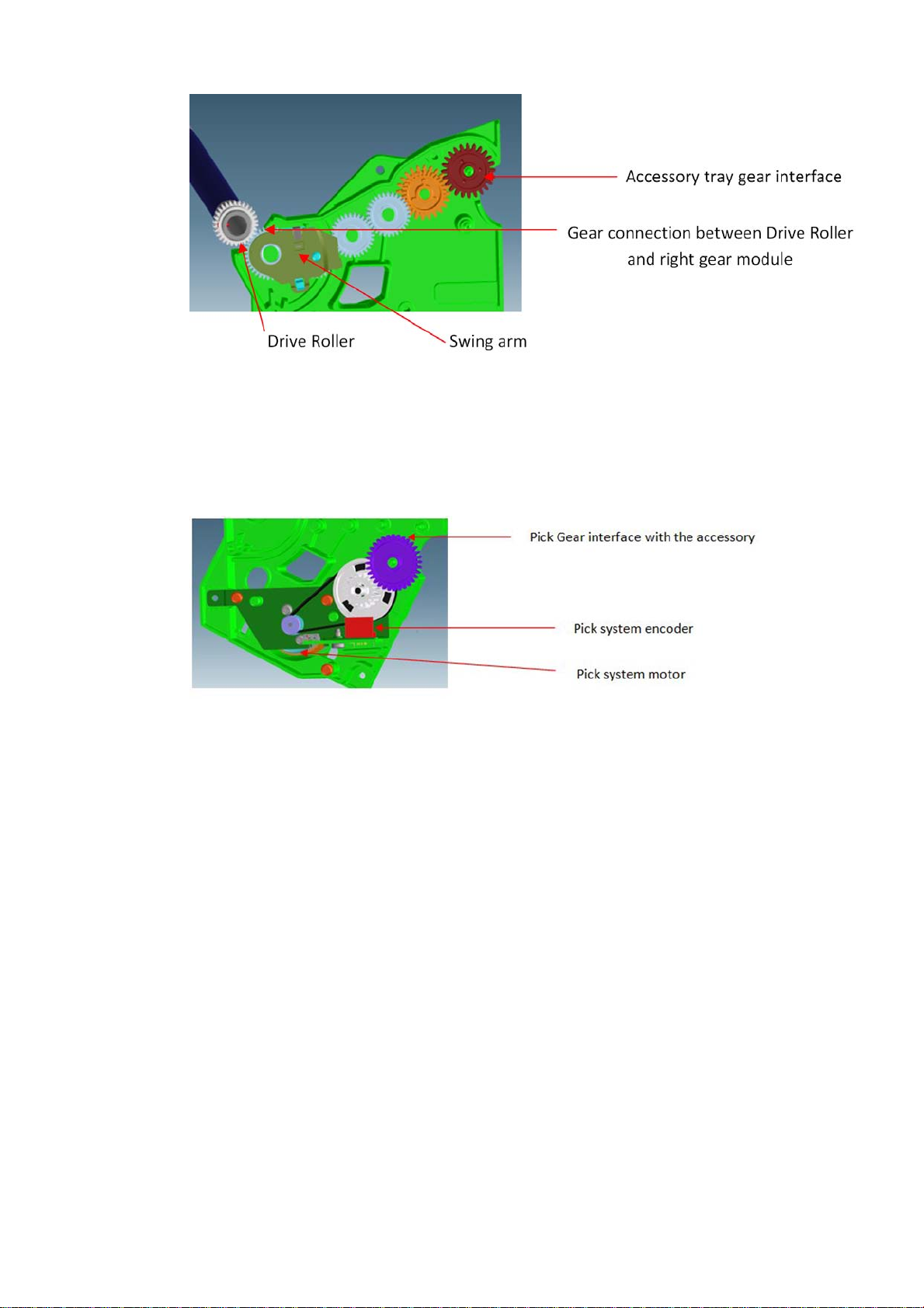

Right Gear module functionality

The Right Gear module has two different functions associated with the Multi-Sheet Tray.

1. The paper drive from the Multi-Sheet Tray into the platen area (until the cut sheet reaches the drive

roller area).

16 Chapter 1 Printer fundamentals ENWW

Page 24

The intermediate shaft in the Multi-Sheet Tray is driven by the drive roller through a gear train inside

the Right Gear module. The intermediate shaft meshes with the Multi-Sheet Tray gear interface (red

gear in the picture) at the end of the train. A swing arm engages the gear train when the Drive Roller is

driven backwards (as shown in the picture), driving the intermediate shaft forwards. When the Drive

Roller is driven forwards, the swing arm disengages from the gear train and the intermediate shaft is

not driven. This action is to prevent reverse paper movement to be transmitted to the Multi-Sheet Tray.

2. Picking functionality drive system

The Multi-Sheet Tray pick drive assembly is mounted in the right side gear module. The assembly

contains a DC motor and pinion, belt, cluster pulley, and gear. An encoder (not shown, but it is located in

front of the white gear shown in the picture) is read by the encoder sensor (in red in the picture) to

servo-control the pick drive.

Right Gear and Multi-Sheet Tray interface

The two gears from the Right Gear module interface with the Multi-Sheet Tray by location once the MultiSheet Tray is locked in position; both gears can be considered fully engaged.

ENWW Subsystems 17

Page 25

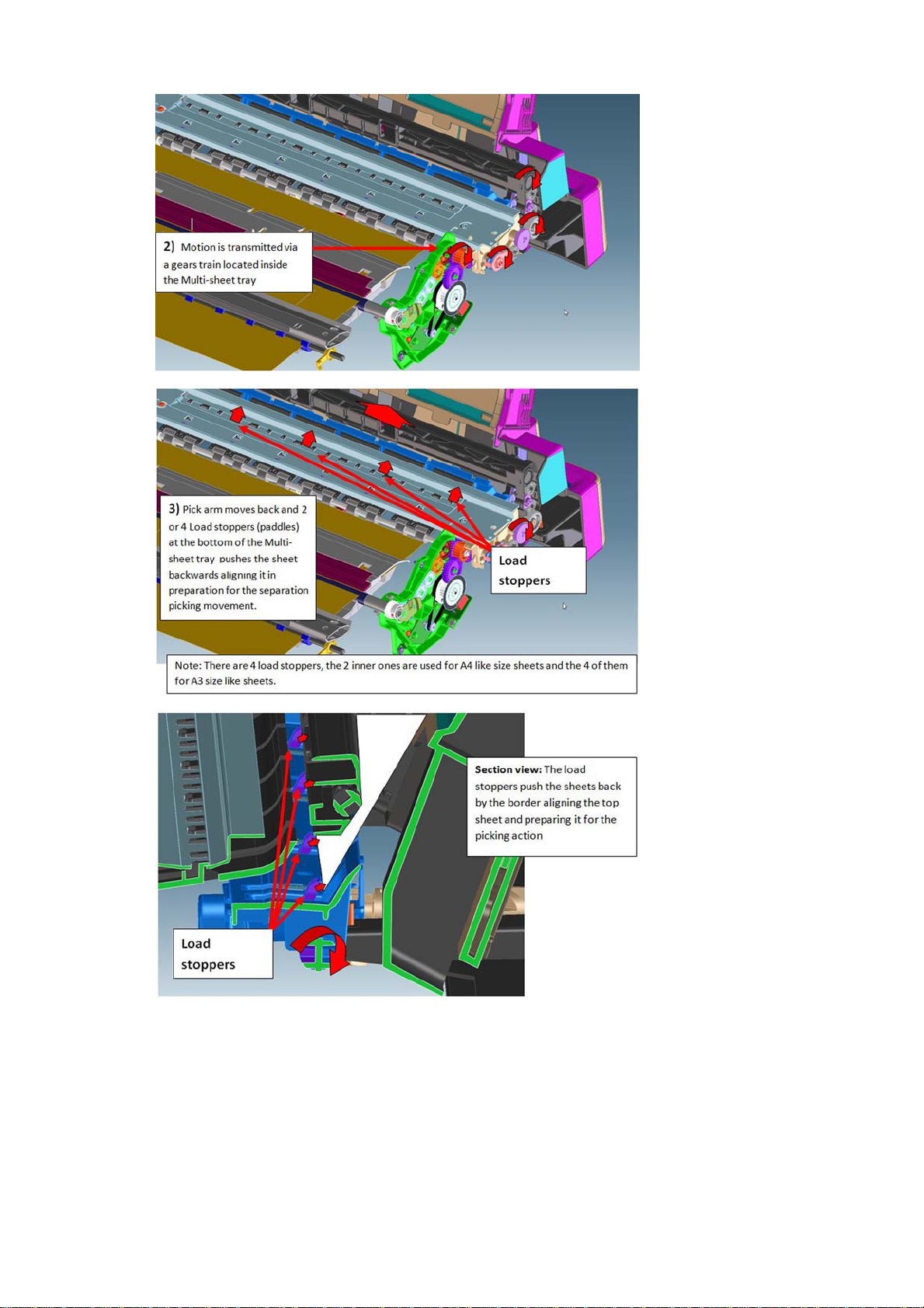

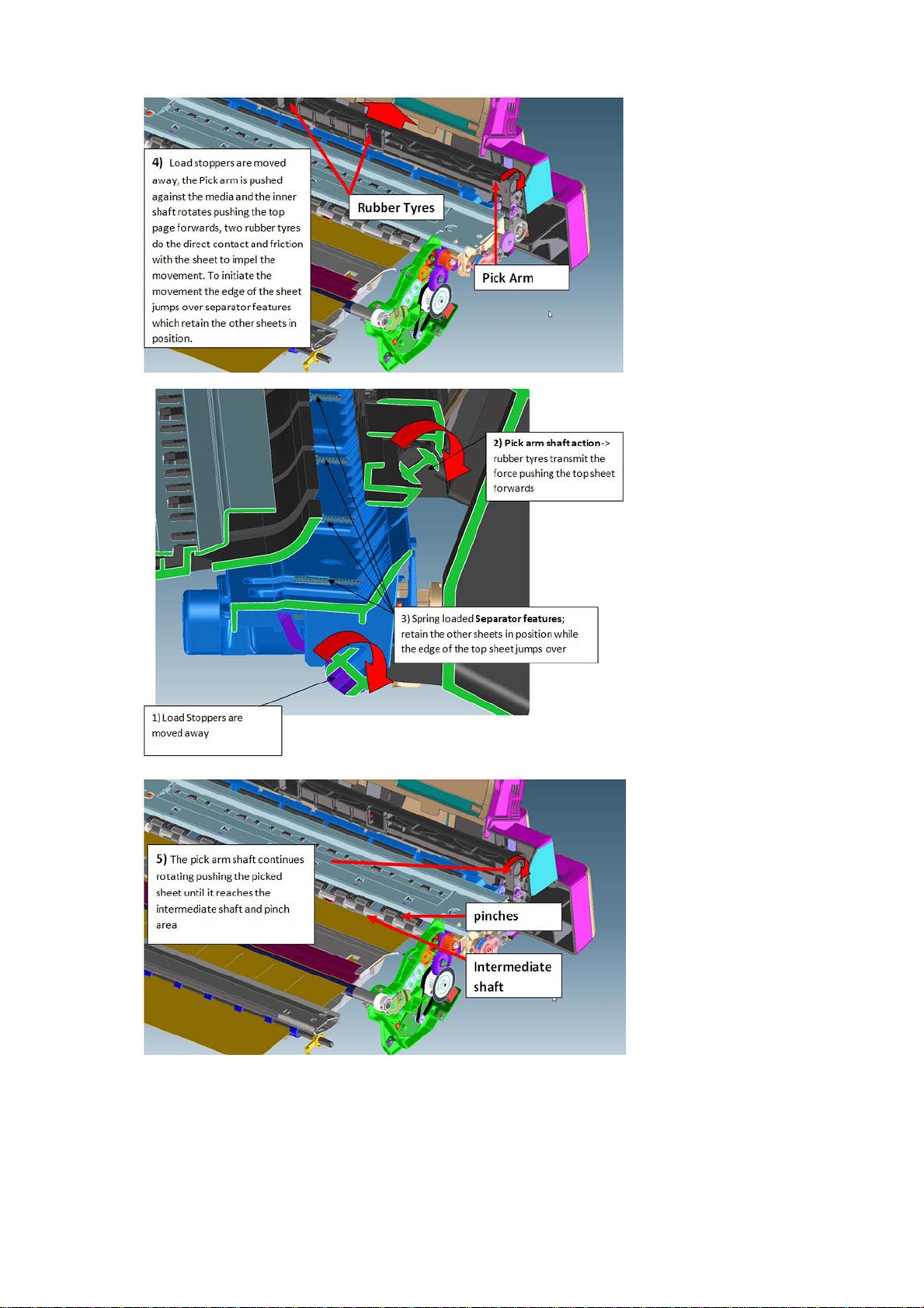

Multi-Sheet Tray functionality

The function of the Multi-Sheet Tray is to pick and feed the cut-sheet paper until the paper is grabbed by the

drive roller (drive roller and pinch system).

The actions performed for those operations are (1) sheet pick and (2) sheet input.

1. Sheet pick

This movement is transmitted through a lateral gear chain in the Multi-Sheet Tray towards the swing arm,

which is pushed towards the paper, and the picking mechanism located at the bottom of the Multi-Sheet

Tray, which separates the top sheet from the stack of pages.

18 Chapter 1 Printer fundamentals ENWW

Page 26

ENWW Subsystems 19

Page 27

2. Sheet input

Once the paper is in the intermediate shaft area, the drive roller is rotated, impelling the intermediate shaft

through the right gear module, pushing the sheet towards the inside of the printer, so that it will be grabbed

by the drive roller and main printer pinch system, proceeding with the standard paper drive motion (as with

roll paper).

20 Chapter 1 Printer fundamentals ENWW

Page 28

NOTE: The printer considers the load successful if, after the picking and sheet input procedures, the sheet

is detected by the printer's Paper Sensor. Hence, a correct function of the Paper Sensor is required also for

the accessory tray loading action.

NOTE: It is possible to reproduce the picking and loading motions by extracting the Multi-Sheet Tray and

rotating the gears with the hand, to validate module performance and troubleshoot any possible mechanical

issues.

NOTE: Different elements of the Multi-Sheet Tray are not serviceable, the whole module requires

replacement in case of failure.

Electronics

Both the encoder and motor-drive system are managed by the Bundle PCA located on the right-hand side of

the printer.

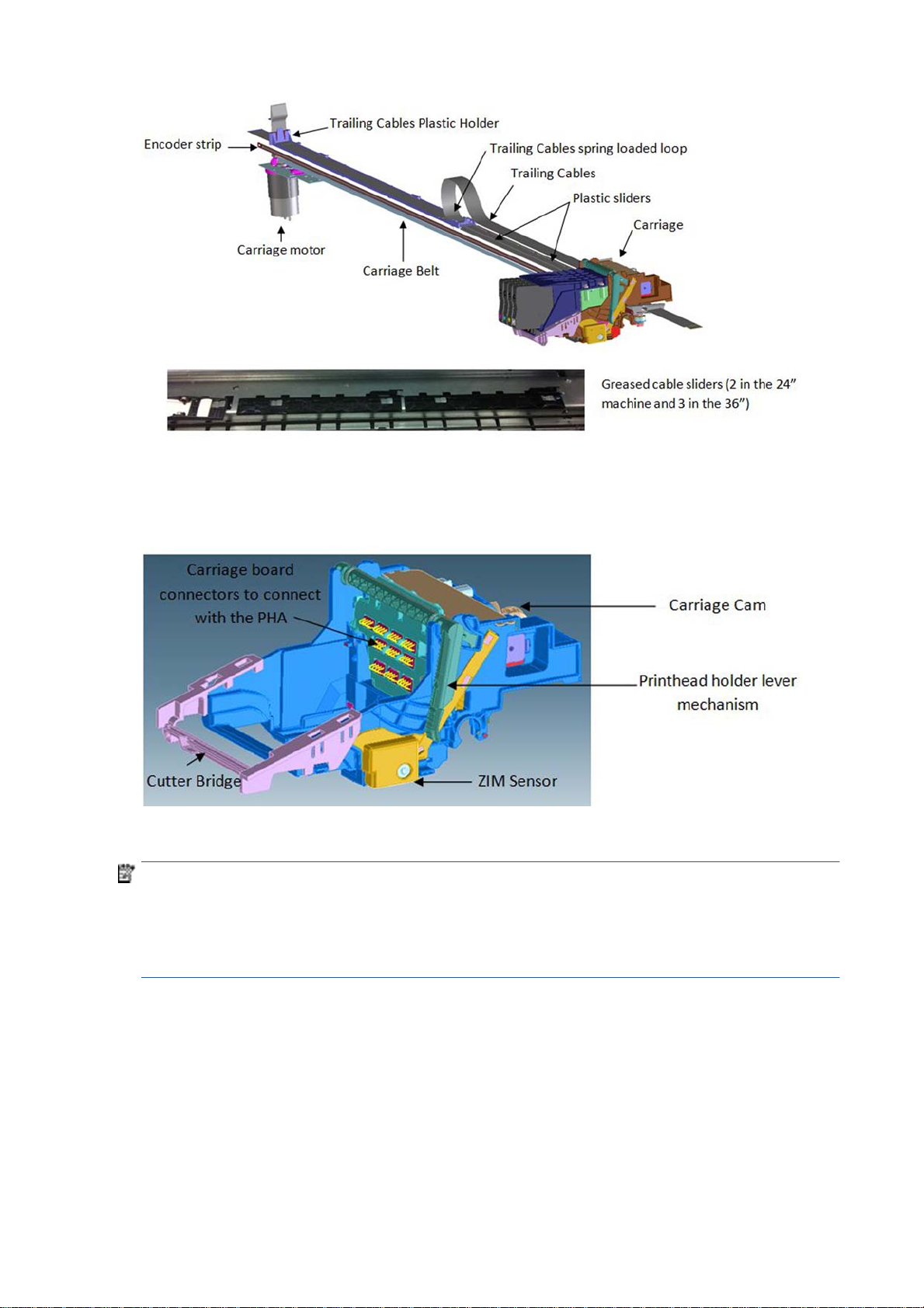

Scan Axis system: Carriage and Carriage impelling

This system moves the Carriage from left to right and right to left of the printer on top of the paper in a

controlled manner to perform printing, cutting, paper detection, and any other Carriage movements for

servicing and final capping process.

The system comprises the Carriage sliding on the scan axis rod, on which rotates and whose position is

determined by a cam mounted on the Carriage, which slides touching the bottom surface of the anti-rotation

rail.

There are two trailing cables mounted one on top of the other, which connect the Carriage with the main

electronics control board. A scan-axis encoder strip is needed for the Carriage to determine its position, and a

Carriage Motor which impels the Carriage via a belt.

The trailing cable is held in position by a plastic holder, which clips onto the scan axis structure. A springloaded loop ensures follow-up action of the cables with the Carriage movement. Two plastic cable sliders are

also placed to ensure minimum contact of the trailing cables with the scan axis structure. The plastic sliders

are greased to prevent ink spray (aerosol) deposits from accumulating on them, generating a sticky surface

which could retain the cables and then be damaged by Carriage movement.

ENWW Subsystems 21

Page 29

The Encoder Strip Sensor is located inside the Carriage, once the Carriage is assembled the Encoder Strip

crosses the Carriage, passing by the detection area of the sensor inside the Carriage.

The main function of the Carriage is to hold the printhead in position, to enable cartridge insertion, and to

move the printhead in a controlled manner in order to print.

The Carriage holds all the necessary interface electronics for the main board to interact with the printhead

via the trailing cables. A set of spring-loaded connectors are the main interface Carriage-printhead.

NOTE: It is very important that the contacts are clean, free of dust/ink to ensure a correct connection

between printhead and Carriage, as high-speed data are transmitted through this connection, and dust could

cause sporadic system errors. This is particularly important when replacing the printhead, as the removal of

the old printhead (extraction with a rotary movement) can cause the nozzle plate to touch those contacts and

create contamination that could cause problems with the new printhead. However, manual cleaning of the

contacts is not recommended.

The Carriage also has additional functionality:

1. Transmits the pressure from the Prime Pump via off-axis coupling to each of the four cartridges

●

Off-axis coupling connects with the Carriage via the side connection bay:

22 Chapter 1 Printer fundamentals ENWW

Page 30

●

An internal passage of the Carriage transmits the air pressure towards the printhead.

●

The rear hole of the printhead receives the air pressure which is distributed towards the four air

ports inside the printhead.

●

Each of the air ports transmits the air pressure to the cartridges, and the air pushes the inner

chambers, expelling the ink during the priming operation.

2. Holds the cutter bridge

The cutter bridge impels the Cutter for cutter operations (see additional information in the cutter

section).

ENWW Subsystems 23

Page 31

3. Holds the Carriage Line Sensor

The Carriage Line Sensor (also known as the ZIM Sensor) is located on the right of the printer and is used

to detect the edges of the paper to determine the paper dimensions and start position. This sensor is

also the tool used to detect the position of printed lines to perform calibrations (Paper Advance

calibration and printhead alignment).

The Line Sensor is a reflective tool that generates a beam of LED light, whose reflection is detected by a

luminance sensor. The signal from this sensor is used to determine the position of lines or paper edge

according to the position of the Carriage.

NOTE: Both LED emitter and receiver sensor inside the line sensor are protected by a transparent

plastic cover. If this cover becomes dirty, the signal to detect edges or lines will be affected, which could

cause intermittent issues during the paper load.

It can also detect printed lines from short signals when the sensor crosses the lines:

24 Chapter 1 Printer fundamentals ENWW

Page 32

Carriage CAM and Auto PPS adjustment

At the back of the Carriage there is a sliding cam that determines the PRS (Print to platen Rib Space) of the

Carriage. In manufacturing, the anti-rotation rail (area in which the PRS cam slides) is adjusted to calibrate

the nozzle plate position of the printhead, at around 1.6 mm all along the scan axis width. This calibration is

not service-adjustable and should remain constant throughout the printer's life.

As there are different paper thicknesses, the printer is able to rotate this sliding cam automatically to three

different positions, changing the PRS distance to accommodate it to the appropriate printing distance.

This rotation is performed by taking the Carriage to a feature on the left-hand side of the scan axis, different

side movements of the Carriage at different speeds allow this feature to grab and rotate the cam accordingly.

The Cam has three different areas for three different PRS adjustments.

Auto-PRS feature located on the left-hand side of the scan axis.

Back part of the Carriage with auto-PPS cam, after being activated in position 1.

Carriage impelling system

ENWW Subsystems 25

Page 33

Carriage encoder system

The encoder strip tension is also fixed by a tensioning spring. However, there is a mechanism to hold it in

position after the spring places the strip at one specific tension. This is to prevent the spring from continually

applying force over the encoder strip; which, over time and temperature changes, could make it creep.

NOTE: When assembling the encoder strip, ensure that it is placed in the right orientation using the smiling

symbol located on the sides of the encoder strip.

NOTE: Due to the proximity of the encoder strip to the greased sliding rod, it is easy to dirty the strip with

grease when performing any repair operation in the area. Please clean any grease from the encoder strip if

necessary. A dry cloth can be used for this purpose, to prevent any deformation or strain on the encoder strip

while performing the cleaning.

26 Chapter 1 Printer fundamentals ENWW

Page 34

Printer electronics, power supply, and cables

The printer contains several electronics boards and electrical and electronic components in different

locations.

●

There are two main active boards (Main PCA and Bundle PCA).

●

One WiFi Module, which provides the WiFi functionality to the printer.

●

One interface board (Carriage PCA), which provides and converts the appropriate signals for the Carriage

(printhead interface and line sensor signaling) .

●

Three on/off sensor PCAs (Top Cover Sensor, Out Of Paper Sensor or OOPS, Output Tray Sensor), which

indicate the open/closed status of the different elements.

●

One active on/off sensor (the Ink Cartridge Cover sensor). Apart from indicating the open/closed status

of the ink cartridge cover, it includes the backup memory for all factory calibration values.

●

One encoder sensor and a feed index sensor (other than the encoder sensors located inside the

Rewinder, the Right Gear Module, and the Service Station).

●

One Power Button PCA. Located in the front panel, it is used to power the printer on and off.

●

One Power Supply (PSU), which converts the AC power line (110–240 V AC) into the DC power needed by

the printer (32 V and 12 V).

The standard wiring used in the printer is Flat Flexible Cables (FFCs), to interconnect all boards (including

sensors and encoders) and distributed cables for power signals to the motors.

NOTE: It is important to bear in mind that FFCs are relatively delicate, so please ensure cable connectors

are not touched or dirtied during manipulation for assembly and disassembly operations.

NOTE: Ensure that you are properly grounded for any electronics or wiring manipulation.

ENWW Subsystems 27

Page 35

The Main PCA

The Main PCA is located on the left-hand side of the printer. This board is the “brain” of the printer: where all

the processing and printer management occurs; control of the overall machine (digital and mechatronics)

with the battery for the Real-Time Clock.

There are two versions depending on memory size: Basic (256 MB) for the T120 and Pro (1 GB) for the T520.

The Main PCA also contains other elements with the following functions:

●

●

●

●

Battery: To maintain the internal clock up and running. The internal clock is used to remember the

actual date, used for cartridge life counting and warranty accounting.

WiFi module: Attached to the top of the board with some plastic locators, provides WiFi functionality to

the printer.

USB dongle: Where the firmware of the printer is stored.

NOTE: This dongle does not operate as a standard USB drive. It is a customized device designed to

interact with the main electronics, and all the data are appropriately encrypted.

Buzzer: To provide acoustic signals to the user.

28 Chapter 1 Printer fundamentals ENWW

Page 36

The Bundle Board

The Bundle Board is located on the right-hand side of the printer, this board includes a driver ASIC to control

and manage the motor, encoder, and sensors located on the right-hand side of the printer.

IMPORTANT: The pick encoder and Service Station cables are not poka-yoke cables: it is possible to

connect them incorrectly, in which case a system error will result.

Electrical system

The following diagram describes the connections between components and electronic boards, the voltage,

and the type of data line.

ENWW Subsystems 29

Page 37

●

The printer contains a total of 11 printed circuit boards (PCA).

●

The OOP sensor, Top Cover, and Feed Index are exactly the same board.

●

The WiFi PCA, although included in the Main PCA Service Kit, is a different board used in other products.

Part Brief technical function

Main PCA (PRO/BASIC) Has two versions depending on memory size: Basic (256 Mb) and

Pro (1Gb)

Bundle Board Mechatronics driver for the right part of the machine motors and

encoder

Front panel and power button Tactile color visual screen with buzzer for machine power up and

down, control, and user interface

Ink Cartridge cover Sensor Ink Cartridge Cover opening state control

Carriage PCA => Part of Carriage assembly Carriage control and feed for printhead spitting

OOPS Paper presence detection

Output Tray sensor Front tray state control (open or closed)

Top Cover sensor Top Cover state control (open or closed)

Feed index Encoder to detect the paper placement (absolute)

Feed encoder Encoder to control the exact advance of the paper (relative)

Wifi PCA Radio module (including antenna) to give wireless capabilities

(802.11 b/g)

30 Chapter 1 Printer fundamentals ENWW

Page 38

Locations of the PCAs

ENWW Subsystems 31

Page 39

2 Troubleshooting

●

Printer troubleshooting flowchart

●

Basic printer troubleshooting

●

System error codes

●

Paper troubleshooting

●

Communication troubleshooting

●

Ink-supplies troubleshooting

●

Print-quality troubleshooting

●

Update the firmware

ENWW 33

Page 40

Printer troubleshooting flowchart

Use the following as a guide to troubleshooting issues with the printer:

34 Chapter 2 Troubleshooting ENWW

Page 41

Basic printer troubleshooting

The printer does not print

If all is in order (paper loaded, all ink components installed, and no file errors), there are still reasons why a

file you have sent from your computer may not start printing when expected:

1. You may have an electrical power problem. If there is no activity at all from the printer, and the front

panel does not respond, check that the power cord is connected correctly and that there is power

available at the socket.

2. You may be experiencing unusual electromagnetic phenomena, such as strong electromagnetic fields or

severe electrical disturbances, which can cause the printer to behave strangely or even stop working. In

this case, turn off the printer using the power key on the front panel and unplug the power cord, wait

until the electromagnetic environment has returned to normal, then turn it on again. If you still

experience problems, please contact your customer service representative.

3. You may not have installed in your computer the correct driver for your printer.

4. If you are printing on a sheet, you must specify Printer Autoselect or Single-Sheet or Multi-Sheet Tray

as the paper source in your printer driver.

The Front Panel is blank (the printer does not start)

If the printer does not start (the front panel is blank), try the following:

Remote troubleshooting

1. Ask the customer to unplug and plug in the power cord. The customer should check when the power

cord is plugged in that the front panel is illuminated (white) for a few moments, after which the printer

should start the initialization process.

2. If the front panel is still blank (does not show a flashing white screen), and the printer does not start up,

then ask the customer to hold down the Power key for a few seconds and ask to check whether the

Power LED button turns orange while the key is held down.

3. If the customer does not see the orange light, no power is reaching the printer; ask to check that the

power cord is correctly plugged in. If the problem persists, there is a problem with the power supply.

Arrange a service engineer visit to replace the Power Supply, see Power Supply on page 196.

●

Main Power Supply – CQ890-67025

4. If the customer sees the orange light, ask to unplug and plug in the power cord and to listen and wait for

around 30 seconds for the printer to make a beeping sound.

5. Three beeps mean that the Front Panel has failed or the Front Panel cable is disconnected or damaged.

Arrange a service engineer visit to check the cable and replace the Front Panel if needed, see Front

Panel on page 159.

●

Front Panel – CQ890-67026

6. One long beep means an electronic problem. Arrange for a service engineer visit to replace the Main

PCA. To check that the Main PCA is broken you can ask the customer to open the Ink Cartridge Cover and

check whether there is a green light (heartbeat LED) flashing in the left bottom part .

ENWW Basic printer troubleshooting 35

Page 42

If there is no light or it is not flashing the Main PCA should be replaced.

●

Main PCA Basic: CQ891-67003

●

Main PCA Pro: CQ890-67023

7. If the printer initializes and the Carriage moves but the front panel is still blank, the Front Panel should

be replaced, see Front Panel on page 159.

●

Front Panel – CQ890-67026

See also the troubleshooting flowchart for this issue on the next page.

36 Chapter 2 Troubleshooting ENWW

Page 43

ENWW Basic printer troubleshooting 37

Page 44

System error codes

Understanding system error codes

Error messages are generally used to report internal system errors. The following pages contain a list of

system error codes and their respective descriptions and recommended corrective actions. Try only one

recommended action at a time, in the order that they appear, and check whether the error code has

disappeared.

Advisory error messages

Advisory error messages communicate that some action must be performed, such as adding paper or

clearing a paper jam. Take the appropriate action to continue printing.

Problem type Message (with customer

troubleshooting)

Printhead missing/Not detected/

Incompatible

Ink Cartridge problem The following cartridges appear to be

Ink Sensor failure (sensor inside the PHA) Ink Sensor failure This error is continuable (the customer can

Paper mismatch Paper detected does not match paper size

Paper jam There is a paper jam (or misfeed). Clear the

The printhead appears to be missing, not

detected, or incorrectly installed.

missing or damaged [list of affected

supplies]

or type selected.

jam and press Resume on the printer.

There is a paper jam (or misfeed) in the

scan path. Clear the jam or re-insert the

document and restart the task.

Details for call agent

See Printhead troubleshooting

on page 75.

Replace the listed supplies. See Replace an

ink cartridge on page 66.

press OK and keep working). However if

the message appears continuously after

restarting the printer or while sending new

jobs, it is very likely that the Carriage PCA

is not working properly. Arrange a service

engineer visit to change the Carrriage.

If the paper size is correct, check that the

line sensor is OK by running the Line

Sensor diagnostic from the Support Menu.

This occurs when trying to load the paper.

There is no need to turn off the printer.

Run the Carriage Servo and Paper Servo

diagnostics from the Support Menu.

This occurs when the paper is already

loaded. There is no need to turn off the

printer. Run the Carriage Servo diagnostic

from the Support Menu.

The printer is out of paper Load more paper and press Resume on the

front of the printer.

Incompatible Cartridge(s) The cartridge is not intended for use in this

printer.

Ink Cartridge Cover open Replace ink cartridges and close the ink

cartridge cover.

Top Cover open Please close Top Cover Perform the Top Cover sensor diagnostic

Load paper The printer is not able to complete the

load because it cannot detect the paper

Out of memory Out of memory Job sent to the printer too complex, see

Run OOP sensor diagnostic from the

Support Menu.

Ask the customer to install the correct ink

cartridge.

Perform the ink cartridge cover sensor

diagnostic from the Support Menu.

from the Support Menu.

Perform the OOP sensor diagnostic from

the Support Menu.

the user's guide for more details.

38 Chapter 2 Troubleshooting ENWW

Page 45

Problem type Message (with customer

troubleshooting)

Details for call agent

Improper shutdown To avoid damage, use the On button to

shut down. Do not use a power strip or

wall switch to shut down.

Printer or ink system error There is a problem with the printer or ink

system. Turn printer off, then on. If the

problem persists, contact HP.

Follow the front-panel message.

Ask the customer to retrieve the Error

History, see 1.5 Error history on page 98.

Ask the customer which of these 2 errors

are logged:

●

26:10

●

27:10

Follow the applicable error

troubleshooting.

ENWW System error codes 39

Page 46

Severe error codes

Severe error messages inform you of a device failure. Some of these messages can be cleared by pressing

the Power button to turn off the printer, and then pressing it again to turn the printer back on. If a severe

error persists, service is required.

System error Component/System

01.1:10 Main PCA (MPCA) failure

01.1:19 Incorrect Main PCA installed

01.3:10 Bundle Board failure

02:10 Carriage Board Failure

03.1:10 Battery of Real-Time Clock ran down

08:10 Front Panel does not respond

21:10 Service Station (SS) failure

21.1:10 Pump motor failure

26:10 Ink system failure

27:10 Generic printhead error

41:10 Paper servo error

41.1:10 Right Rear Gear Train (picking motor) failure

41.2:10 Paper/Feed motor failure

42:10 Carriage servo error

42.1:10 Carriage motor failure

45:10 Rewinder motor failure

51:10 Top Cover sensor failure

51.1:10 Ink Cartridge Cover Sensor failure

53.1:10 OOP sensor failure

53.2:10 Output Tray sensor failure

55:10 Line Sensor failure

59.1:19 Main PCA and Ink Cartridge Sensor PCA replaced at the same time

59.2:19 An unsupported or reused NVM has been installed

79:03 Generic printer error (NVM reseated)

79:04 Generic printer error (FW assert)

85.1:10 Feed Index Sensor failure

85.2:10 Feed Encoder Sensor failure

87:10 Encoder Strip failure

How to interpret severe error codes

The severe error codes can be composed of five fields:

40 Chapter 2 Troubleshooting ENWW

Page 47

The two first fields before the (:) are the service part and the service index (if there is more than one, as in

PCAs or motors). For call agents and service engineers the most important parts to know are the fields WHO

DOES THE ACTION and ACTION TO PERFORM. These two fields can give guidance as to the most appropriate

course of action if this error code is displayed.

Who should perform action Action to perform

0 User 0 Replace

1 Service engineer 1 Reseat/Reconnect/Clean/Adjust (manually)

2 Calibrate/Adjust (using Automatic Process)

3 Power Off and Restart the Printer

4 Upgrade System Firmware

5 Upgrade Driver or Computer Software

6 Add Accessory

7 Escalate

8 Send Print Again

9 Wrong Part Installed

System error code troubleshooting

This section describes each of the severe errors that may be encountered while using the printer, and

provides the diagnostic method and the actions required to solve the problem detected.

In general, each error is explained for two different situations:

1. For a call agent to solve remotely with the customer

2. If necessary, for an onsite service engineer to solve

NOTE: When more than one component could be affected by the system error, replace one component at a

time and check whether the error has gone before replacing another component. Do not replace two

electronic parts at same time! Using this procedure you will be able to determine exactly which component

failed.

System error: 01.1:10 (Equal to 1 long beep during startup sequence)

Problem description: Communication with Main PCA (MPCA) failed

ENWW System error codes 41

Page 48

Other potential parts

associated:

WiFi module, Trailing Cable, Bundle PCA FFC cable, cables kit

How to solve. Follow this

procedure:

Remote troubleshooting (call agent)

1. This error never appears in the Front Panel, it’s only logged into the Error History and is

equivalent to 1 long beep during printer startup. It happens when the MPCA communication

fails.

2. To troubleshoot this error, see The Front Panel is blank (the printer does not start) on page 35.

3. If a service engineer visit should be arranged to replace the Main PCA, take into account the

model of the printer (the Main PCA is different for Pro and Basic models).

Onsite troubleshooting and solution (service engineer)

1. Remove covers and check that all the cables in the MPCA are correctly connected, and that

none of them are damaged. If any cable is disconnected then reconnect it, and power on the

printer again to check if the error message has disappeared. Important note: If any cable is

damaged replace the cable:

●

Cables Sk – CQ890-67021

2. Replace Main PCA (MPCA), see Main PCA on page 198).

●

Main PCA Basic: CQ891-67003

●

Main PCA Pro: CQ890-67023

NOTE: We recommend updating the printer’s firmware after this procedure. See Update the

firmware on page 91.

NOTE: If printer was connected to the Internet before repair, we recommend performing

Web Services Setup. See the user's guide.

System error: 01.1:19

Problem description: Incorrect Main PCA installed

Other potential parts

associated:

How to solve. Follow this

procedure:

System error: 01.3:10

Problem description: Bundle board communication failure

Other potential parts

associated:

How to solve. Remote troubleshooting (call agent)

None

Onsite troubleshooting and solution (service engineer)

▲

This system error happens if a Main PCA Basic is assembled in a Pro printer. To solve the issue,

install the correct Main PCA Pro in the printer.

●

Main PCA Basic: CQ891-67003

●

Main PCA Pro: CQ890-67023

See Main PCA on page 198 for the installation instructions.

Bundle FFC, Main PCA

1. Switch the power off and disconnect the power cord. Reconnect the power cord and power on

the printer.

2. The call agent should arrange a service engineer visit to change the Bundle PCA and follow

steps below on Onsite Troubleshooting:

42 Chapter 2 Troubleshooting ENWW

Page 49

3. If a different system error is displayed then the call agent should perform the applicable

Onsite troubleshooting and solution (service engineer)

1. Remove covers and check that all the cables in the Bundle PCA and associated parts are

2. Replace the Bundle PCA, see Bundle Board on page 288.

3. Replace the Bundle FFC cable, see Bundle Board FFC cable on page 290.

4. Replace the Main PCA (MPCA See Main PCA on page 198)

System error: 02:10

●

Bundle Board – CQ890-67022

troubleshooting procedure.

correctly connected, and that none of them is damaged. If any cable is disconnected then

reconnect it, and power on the printer again to check whether the system error has

disappeared. Important note: If any cable is damaged then order a Cable Service Kit:

●

Cables Sk – CQ890-67021

●

Bundle Board – CQ890-67022

●

Main PCA Basic: CQ891-67003

●

Main PCA Pro: CQ890-67023

Problem description: Carriage PCA communication failure

Other potential parts

associated:

How to solve. Onsite troubleshooting and solution (service engineer)

Trailing Cables, Printhead, Encoder Strip

1. Remove covers and check that the Trailing cables are connected from the Main PCA or from

the Carriage PCA. If any cable is disconnected then reconnect it, and power on the printer again

to check whether the error message has disappeared.

2. Go to Support Menu, see Entering the Extended Support Menu for service engineers

on page 96 and perform 2.1 Carriage Servo, see 2.1 Carriage servo on page 100 to check

that the error has disappeared.

3. Replace the Encoder Strip, see Encoder Strip on page 187 and run the Carriage Servo

diagnostics to see if the error has disappeared.

4. Replace the Carriage, see Carriage and Belt on page 229.

●

Carriage assembly w/belt (24) – CQ890-67002

●

Carriage assembly w/belt (36) – CQ893-67011

5. No calibrations needed, but the PMK 1 should be reset, see 3.4 PMK1 on page 117.

6. Replace the Main PCA, see Main PCA on page 198.

●

Main PCA Basic: CQ891-67003

●

Main PCA Pro: CQ890-67023

System error: 03.1:10

Problem description: Real Time Clock (RTC) Battery ran down.

ENWW System error codes 43

Page 50

Other potential parts

associated:

How to solve. Remote troubleshooting (call agent)

System error: 08:10 (Equals to 3 beeps during start up sequence)

None

1. The call agent asks the customer to go to the Support Menu by pressing the Power key

continuously for 15 seconds.

2. Go to the Diagnostics Menu and select RTC Battery Status to check whether the RTC Battery

has actually expired, see 2.11 RTC battery status on page 109.

3. If yes, the call agent should arrange a service engineer visit to replace the RTC battery by

replacing the Main PCA, see Main PCA on page 198.

●

Main PCA Basic: CQ891-67003

●

Main PCA Pro: CQ890-67023

Onsite troubleshooting and solution (service engineer)

1. Replace the Main PCA, see Main PCA on page 198.

2. Switch on the printer and go to Extended Support Menu. Select RTC Battery Expired option

from the Reset Menu in order to reset the RTC battery expired flag.

3. Go back and select Set Date and Time from the Service Menu. Set the correct date and time.

Problem description: Front Panel does not respond

Other potential parts

associated:

How to solve. Remote troubleshooting (call agent)

System error: 21:10

Problem description: Service Station does not work properly or communication lost

Other potential parts

associated:

Corrective action: Remote troubleshooting (call agent)

None

1. This error never appears in the Front Panel, it is only logged into the Error History, and is

equivalent to the 3 beeps during printer startup.

2. It happens when there is no communication between the Front Panel and the Main PCA, see

The Front Panel is blank (the printer does not start) on page 35.

Bundle PCA

1. Switch the power off and disconnect the power cord. Reconnect the power cord and power on

the printer.

2. The call agent should arrange a service engineer visit to change the Service Station, and follow

the Onsite troubleshooting below:

●

Service station assy – CQ890-67045

3. If a different system error is displayed then the call agent should perform the applicable

troubleshooting procedure.

Onsite troubleshooting and solution (service engineer)

1. Remove covers and check that the cables from the Service Station to the Bundle PCA are

correctly connected and not damaged. Important note: If any cable is disconnected then

reconnect it, and power on the printer again to check whether the system error has

disappeared. If any cable is damaged then order a Cable Service Kit.