Page 1

CNC PILOT 4290

NC Software

368 650-xx

V7

User’s Manual

English (en)

10/2004

Page 2

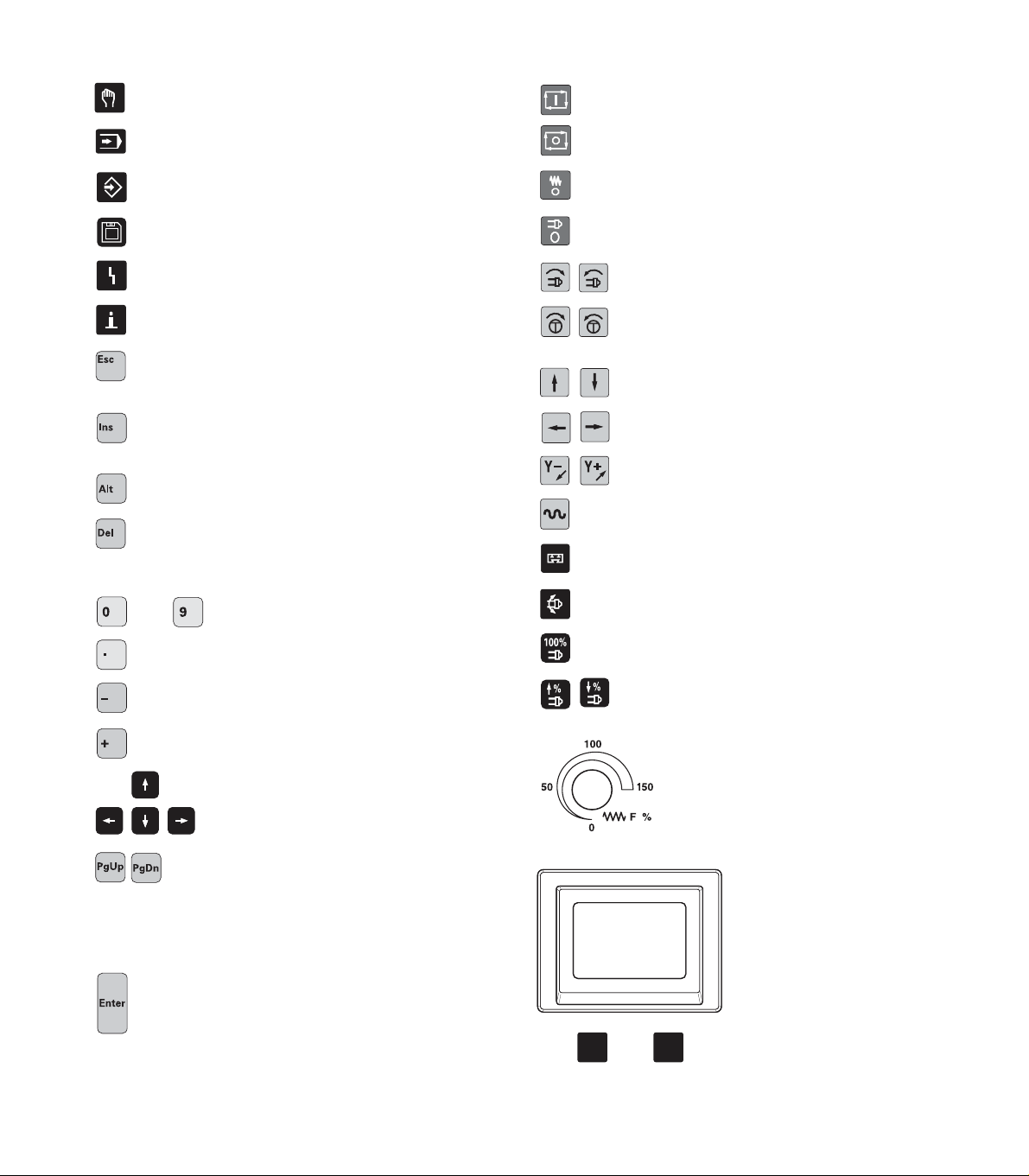

Data input keypad

Manual operating mode

Machine operating panel

Cycle Start

Automatic mode

Programming modes (DIN PLUS, simulation, TURN

PLUS)

Organization modes (parameter, service, transfer)

Display error status

Call the info system

ESC (escape)

■ Go back by one menu level

■ Close dialog box, do not save

INS (insert)

■ Insert list element

■ Close dialog box, save data

ALT (alter)

■ Change the list element

DEL (delete)

■ Deletes the list element

■ deletes the selected character or the character to

the left of the cursor.

. . . Numbers for value input and soft-key

selection

Decimal point

Cycle Stop

Feed Stop

Spindle Stop

Spindle on – M3/M4 direction

Spindle jog – M3/M4 direction (The

spindle turns until you press the key.

Manual direction keys +X/–X

Manual direction keys +Z/–Z

Manual direction keys +Y/–Y

Rapid traverse key

Slide change key

Spindle change key

Spindle speed at the programmed value

Minus as algebraic sign

”Continue key” for special functions (e.g. marking)

Arrow keys

Page forward, page backward

■ Change to previous/next screen page

■ Change to previous/next dialog box

■ Switch between input windows

Enter – Confirmation of input

Increase/decrease spindle speed by 5%

Override dial for feed rate

Touch pad with right and left

mouse key

Page 3

Page 4

CNC PILOT 4290, Software and

Functions

This manual describes functions that are available in the CNC PILOT

4290 with NC software number 368 650-xx (Release 7.0). For

programming the Y-axis, please refer to the User's Manual ”CNC

PILOT 4290 with Y-Axis”. It is not described in this manual.

The machine manufacturer adapts the features offered by the control

to the capabilities of the specific lathe by setting machine parameters.

Therefore, some of the functions described in this manual may not be

among the features provided by the CNC PILOT on your machine tool.

Some of the CNC PILOT functions which are not available on every

machine are:

■ Machining with the C axis

■ Machining with the Y-axis

■ Full-surface machining

■ Tool monitoring

■ Graphically supported interactive contour definition

■ Automatic or graphically supported interactive DIN PLUS program

generation

Please contact your machine manufacturer for detailed information on

the features that are supported by your machine tool.

Many machine manufacturers and HEIDENHAIN offer programming

courses for the CNC PILOT controls. We recommend these courses

as an effective way of improving your programming skills and sharing

information and ideas with other CNC PILOT users.

HEIDENHAIN also offers the PC software DataPilot 4290, which is

designed for use with the CNC PILOT 4290. The DataPilot is suitable

for both shop-floor programming as well as off-location program

creation and testing. It is also ideal for training purposes. DataPilot

can be run on WINDOWS 95, WINDOWS 98, WINDOWS ME,

WINDOWS NT 4.0 or WINDOWS 2000.

Intended place of operation

The CNC PILOT 4290 complies with EN 55022, Class A, and is

intended primarily for operation in industrially zoned areas.

Page 5

Contents

Introduction and Fundamentals

1

Basics of operation

Manual Control and Automatic Modes

DIN PLUS

Graphic Simulation

TURN PLUS

Parameter

Operating Resources

Service and Diagnosis

Transfer

Tables and overviews

2

3

4

5

6

7

8

9

10

11

Contents

HEIDENHAIN CNC PILOT 4290

I

Page 6

1 Introduction and Fundamentals..... 1

1.1 The CNC PILOT..... 2

1.2 The Operating Modes..... 5

Contents

1.3 Expansion Stages (Options)..... 6

1.4 Fundamentals..... 7

1.5 Tool Dimensions..... 10

2 Basics of Operation..... 11

2.1 User Interface..... 12

2.1.1 Screen Displays..... 12

2.1.2 Controls and Displays..... 13

2.1.3 Selection of Operating Modes..... 14

2.1.4 Selection of Functions, Data Input..... 14

2.2 The Info System..... 16

2.3 The Error System..... 17

2.3.1 Direct Error Messages..... 17

2.3.2 Error Display, PLC Display..... 17

2.4 Data Backup..... 19

2.5 Explanation of Terms..... 19

3 Manual Control and Automatic mode..... 21

3.1 Switch-On, Switch-Off, Reference Run..... 22

3.1.1 Switch-On and Traversing the Reference Marks..... 22

3.1.2 Switch-Off..... 23

3.2 Manual Operating Mode..... 24

3.2.1 Entering machine data..... 25

3.2.2 M Commands..... 25

3.2.3 Manual Turning Operations..... 26

3.2.4 Handwheel..... 26

3.2.5 Spindle and Axis Direction Keys..... 27

3.2.6 Slide/Spindle change key..... 27

3.3 Tool Lists, Tool Life Management..... 28

3.3.1 Setting Up a Tool List..... 29

3.3.2 Comparing a Tool List with an NC Program..... 31

3.3.3 Transferring the Tool List from an NC Program..... 32

3.3.4 Tool Life Management..... 33

3.4 Setup Functions..... 34

3.4.1 Defining the Tool Change Position..... 34

3.4.2 Shifting the Workpiece Datum..... 35

3.4.3 Defining the protection zone..... 36

3.4.4 Setting up the Chucking Table..... 37

3.4.5 Setting up Machine Dimensions..... 38

3.4.6 Measuring Tools..... 39

II

Contents

Page 7

3.5 Automatic Mode of Operation..... 41

3.5.1 Program Selection..... 41

3.5.2 Defining a Start Block..... 42

3.5.3 Program Sequence Modification..... 43

3.5.4 Compensation..... 44

3.5.5 Tool Life Management..... 45

3.5.6 Inspection Mode..... 46

3.5.7 Block Display..... 48

3.5.8 Graphic Display..... 49

3.5.9 Post-Process Measuring Status Display..... 51

3.6 Machine Display..... 52

3.7 Load Monitoring..... 54

3.7.1 Reference Machining..... 54

3.7.2 Production Using Load Monitoring..... 55

3.7.3 Editing Limit Values..... 56

3.7.4 Analyzing Reference Machining..... 57

3.7.5 Machining Using Load Monitoring..... 57

3.7.6 Load Monitoring Parameters..... 58

4 DIN PLUS..... 59

4.1 DIN Programming..... 60

4.1.1 Introduction..... 60

4.1.2 DIN PLUS Screen..... 61

4.1.3 Linear and Rotary Axes..... 62

4.1.4 Units of Measurement..... 63

4.1.5 Elements of the DIN Program..... 63

4.2 Programming Notes..... 65

4.2.1 Parallel Editing..... 65

4.2.2 Address Parameters..... 65

4.2.3 Contour Programming..... 66

4.2.4 Tool Programming..... 68

4.2.5 Fixed cycles..... 69

4.2.6 NC Subprograms..... 70

4.2.7 Template Control..... 70

4.2.8 NC Program Interpretation..... 70

4.3 The DIN PLUS Editor..... 71

4.3.1 Main Menu..... 72

4.3.2 Geometry Menu..... 75

4.3.3 Machining Menu..... 76

4.3.4 Block Menu..... 77

Contents

HEIDENHAIN CNC PILOT 4290

III

Page 8

4.4 Program Section Codes..... 79

Contents

4.5 Geometry Commands..... 84

4.6 Machining Commands..... 110

4.7 Turning Cycles..... 122

4.8 Thread Cycles..... 140

4.9 Drilling cycles..... 143

4.10 C-Axis Machining..... 148

4.11 Milling Cycle Group..... 152

4.12 Special functions..... 159

4.4.1 PROGRAMMKOPF [PROGRAM HEAD]..... 79

4.4.2 TURRET..... 80

4.4.3 CHUCKING EQUIPMENT..... 82

4.4.4 Contour Definition..... 82

4.4.5 BEARBEITUNG [MACHINING]..... 83

4.4.6 UNTERPROGRAMM [SUBPROGRAM]..... 83

4.5.1 Definition of Blank..... 84

4.5.2 Basic Contour Elements..... 84

4.5.3 Contour Form Elements..... 86

4.5.4 Help Commands for Contour Definition..... 92

4.5.5 Contour Position..... 95

4.5.6 Front and Rear Face Contours..... 96

4.5.7 Lateral Surface Contours..... 102

4.5.8 Circular Pattern with Circular Slots..... 108

4.6.1 Assigning the Contour to the Operation..... 110

4.6.2 Tool Positioning without Machining..... 110

4.6.3 Simple Linear and Circular Movements..... 111

4.6.4 Feed Rate and Spindle Speed..... 113

4.6.5 Cutter Radius Compensation (TRC/MCRC)..... 115

4.6.6 Zero Point Shift..... 116

4.6.7 Oversizes, Safety Clearances..... 118

4.6.8 Tools, Types of Compensation..... 120

4.7.1 Contour-Based Turning Cycles..... 122

4.7.2 Simple Turning Cycles..... 134

4.10.1 General C-Axis Functions..... 148

4.10.2 Front/Rear Face Machining..... 149

4.10.3 Lateral Surface Machining..... 150

4.12.1 Chucking Equipment in Simulation..... 159

4.12.2 Slide Synchronization..... 160

4.12.3 Spindle Synchronization, Workpiece Transfer..... 161

4.12.4 Contour Follow-Up..... 164

4.12.5 In-Process Measuring..... 165

IV

Contents

Page 9

4.12.6 Post-Process Measuring..... 166

4.12.7 Load Monitoring..... 167

4.13 Other G Functions..... 168

4.14 Data Input and Data Output..... 173

4.14.1 Input/Output of # Variables..... 173

4.14.2 Input/Output of V Variables..... 174

4.15 Programming Variables..... 175

4.15.1 # Variables..... 175

4.15.2 V Variables..... 177

4.15.3 Program Branches, Program Repeats, Conditional Block Execution..... 179

4.16 Subprograms..... 182

4.17 M Functions..... 183

4.18 Programming Notes and Examples..... 184

4.18.1 Programming Machining Cycles..... 184

4.18.2 Contour Repetitions..... 184

4.18.3 Full-Surface Machining..... 187

5 Graphic Simulation..... 195

5.1 Simulation Mode of Operation..... 196

5.1.1 Graphic Elements, Displays..... 197

5.1.2 Basics of Operation..... 200

5.2 Main Menu..... 201

5.3 Contour Simulation..... 203

5.3.1 Contour-Simulation Functions..... 203

5.3.2 Dimensioning..... 204

5.4 Machining Simulation..... 205

5.5 Motion Simulation..... 207

5.6 Zoom Function..... 208

5.7 3-D View..... 209

5.8 Checking the

5.9 Time Calculation..... 212

5.10 Synchronous Point Analysis..... 213

6 TURN PLUS..... 215

6.1 TURN PLUS Mode of Operation..... 216

6.2 Program Management..... 217

6.2.1 TURN PLUS Files..... 217

6.2.2 Program Head..... 218

6.3 Workpiece Description..... 219

6.3.1 Entering the Contour of a Blank Part..... 219

6.3.2 Input of the Finished Part Contour..... 220

6.3.3 Superimposing form elements..... 221

6.3.4 Integrating a Contour Train..... 222

Contents

HEIDENHAIN CNC PILOT 4290

V

Page 10

Contents

6.4 Contours of Workpiece Blanks..... 228

6.5 Contour of Finished Part..... 229

6.6 C-Axis Contours..... 242

6.7 Manipulating Contours..... 256

6.8 Importing DXF Contours..... 263

6.9 Assigning attributes..... 267

6.10 User Aids..... 273

6.11 Preparing a Machining Process..... 277

6.3.5 Entering Contours Machined with the C Axis..... 223

6.3.6 Basics of Operation..... 225

6.3.7 Help Functions for Element Definition..... 226

6.5.1 Basic Contour Elements..... 229

6.5.2 Form elements..... 232

6.5.3 Overlay Elements..... 239

6.6.1 Contours on the Front and Rear Face..... 242

6.6.2 Contours of the Lateral Surface..... 249

6.7.1 Editing the Contours of a Blank Part..... 256

6.7.2 Trimming..... 256

6.7.3 Change..... 258

6.7.4 Deleting..... 259

6.7.5 Inserting..... 260

6.7.6 Transformations..... 261

6.7.7 Connect..... 262

6.7.8 Resolve..... 262

6.8.1 Fundamentals..... 263

6.8.2 Configuring the DXF Import..... 264

6.8.3 DXF-Import..... 266

6.8.4 Transferring and Organizing DXF Files..... 266

6.9.1 Attributes for Workpiece Blanks..... 267

6.9.2 Oversize..... 267

6.9.3 Feed rate/peak-to-valley height..... 267

6.9.4 Precision stop..... 268

6.9.5 Separation Points..... 268

6.9.6 Machining Attributes..... 269

6.10.1 Calculator..... 273

6.10.2 Digitizing..... 274

6.10.3 Inspector – Checking Contour Elements..... 274

6.10.4 Unresolved Contour Elements..... 275

6.10.5 Error Messages..... 276

6.11.1 Chucking a Workpiece..... 277

6.11.2 Setting Up a Tool List..... 284

VI

Contents

Page 11

6.12 Interactive Working Plan Generation (IWG)..... 286

6.12.1 Tool call..... 287

6.12.2 Cutting Data..... 288

6.12.3 Cycle specification..... 288

6.12.4 Roughing..... 289

6.12.5 Recessing..... 294

6.12.6 Drilling..... 299

6.12.7 Finishing..... 301

6.12.8 Thread Machining(G31)..... 306

6.12.9 Milling..... 307

6.12.10 Special Machining Tasks (SM)..... 309

6.13 Automatic Working Plan Generation (AWG)..... 310

6.13.1 Generating a Machining Plan..... 310

6.13.2 Machining Sequence..... 311

6.14 Control Graphics..... 321

6.15 Configuration..... 322

6.16 Machining Information..... 324

6.16.1 Tool Selection, Turret Assignment..... 324

6.16.2 Cutting Parameters..... 325

6.16.3 Coolant..... 325

6.16.4 Hollowing..... 326

6.16.5 Inside Contours..... 326

6.16.6 Drilling..... 328

6.16.7 Full-Surface Machining..... 328

6.16.9 Shaft Machining..... 330

6.17 Example..... 332

7 Parameters..... 337

7.1 Parameter Mode of Operation..... 338

7.1.1 Parameters..... 338

7.1.2 Editing Parameters..... 339

7.2 Machine Parameters..... 341

7.3 Control Parameters..... 348

7.4 Set-Up Parameters..... 355

7.5 Machining Parameters..... 357

Contents

HEIDENHAIN CNC PILOT 4290

VII

Page 12

8 Operating Resources..... 371

8.1 Tool Database..... 372

8.1.1 Tool Editor..... 372

Contents

9 Service and Diagnosis..... 401

10 Transfer..... 411

11 Tables and overviews..... 425

8.1.2 Tool Types (Overview)..... 375

8.1.3 Tool Parameters..... 377

8.1.4 Multipoint Tools, Tool Life Monitoring..... 384

8.1.5 Explanation of Tool Data..... 385

8.1.6 Tool Holder, Mounting Position..... 387

8.2 Chucking Equipment Database..... 390

8.2.1 Chucking Equipment Editor..... 390

8.2.2 Chucking Equipment Data..... 392

8.3 Technology Database (Cutting Values)..... 399

9.1 Service Mode of Operation..... 402

9.2 Service Functions..... 402

9.2.1 Access Authorization..... 402

9.2.2 System Service..... 403

9.2.3 Fixed-Word Lists..... 404

9.3 Maintenance System..... 405

9.4 Diagnosis..... 408

10.1 The Transfer Mode of Operation..... 412

10.2 Transfer Systems..... 413

10.2.1 General Information..... 413

10.2.2 Configuring for Data Transfer..... 414

10.3 Data Transfer..... 417

10.3.1 Enabling, Data Types..... 417

10.3.2 Transmitting and Receiving Files..... 418

10.4 Parameters and Operating Resources..... 420

10.4.1 Converting Parameters and Operating Resources..... 420

10.4.2 Saving Parameters and Operating Resources..... 422

10.5 File Organization..... 423

11.1 Undercut and Thread Parameters..... 426

11.1.1 Undercut DIN 76, Parameters..... 426

11.1.2 Undercut DIN 509 E, Parameters..... 427

11.1.3 Undercut DIN 509 F, Parameters..... 427

11.1.4 Thread Parameters..... 428

11.1.5 Thread Pitch..... 429

11.2 Technical Information..... 433

11.3 Peripheral Interfaces..... 437

VIII

Contents

Page 13

1

Introduction and Fundamentals

Page 14

1.1 The CNC PILOT

The CNC PILOT is a contouring control designed for

lathes and turning centers. In addition to turning

operations, you can perform milling and drilling

operations with the C-axis or the Y-axis. The CNC PILOT supports parallel machining of up to 4

workpieces in programming, testing and production.

Full-surface machining is supported on lathes with:

■ Rotating gripper

■ Movable opposing spindle

■ Multiple spindles, slides and tool carriers

1.1 The CNC PILOT

The CNC PILOT controls up to 6 slides, 4 spindles and

2 C axes.

Programming

Depending on the type and complexity of the parts to

be machined and your organization, you can choose

the type of programming best suited to your tasks.

In TURN PLUS you describe the contour of the blank

and finished part with interactive graphics. Then you

call the automatic working plan generation (AWG),

and the NC program will be generated fully

automatically at a keystroke. Alternately, you can

choose the interactive working plan generation (IWG).

When using the IWG, you determine the sequence of

machining and other technical details.

Every working step is shown in the control graphics

and can be corrected immediately. The result of program creation with TURN PLUS is a structured DIN

PLUS program.

TURN PLUS minimizes the number of entries

required, but it requires that the the tool data and

cutting data has already been entered.

If TURN PLUS fails to create the optimal NC program

for technologically sophisticated machining

operations, or if you primarily want to reduce the

machining time, program the NC program in DIN

PLUS.

DIN PLUS supports the separation of the geometric

description from the machining of the workpiece.

Powerful cycles are available for programming in DIN

PLUS. The ”simple geometry programming” function

calculates coordinates if the dimensions used in the

drawing are not suitable for NC programs.

Alternately, you can machine your workpiece in DIN

PLUS with linear and circular movements and simple

turning cycles, as you are accustomed to in

conventional DIN programming.

Both TURN PLUS and DIN PLUS support machining with the C-axis or

Y-axis and full-surface machining.

The Graphic Simulation feature enables you to subject your NC

programs to a realistic test. The CNC PILOT displays the machining of

up to 4 workpieces in the working space. Workpiece blanks and

finished parts, chucking equipment and tools are shown to scale.

You can program your NC programs and test them -even during

machining operations- directly on the machine.

Regardless of whether you are machining a simple or complex part,

producing a single part or a series of parts, or a whole batch on a

turning center, the CNC PILOT always gives you optimum support.

1 Introduction and Fundamentals2

Page 15

The C-axis

With a C-axis you can drill and mill a workpiece on its

front, back and lateral surfaces.

During use of the C-axis, one axis interpolates linearly

or circularly with the spindle in the given working plane, while the third axis interpolates linearly.

The CNC PILOT supports part program creation with

the C-axis in:

■ DIN PLUS

■ TURN PLUS contour definition

■ TURN PLUS working plan generation

TheY-axis

With a Y-axis you can drill and mill a workpiece on its

front, back and lateral surfaces.

During use of the Y-axis, two axes interpolate linearly

or circularly in the given working plane, while the third

axis interpolates linearly. This enables you to machine

slots or pockets, for example, with plane floors and

perpendicular edges. By defining the spindle angle,

you can determine the position of the milling contour

on the workpiece.

The CNC PILOT supports part program creation with

the Y-axis in:

■ DIN PLUS

■ TURN PLUS contour definition

■ TURN PLUS working plan generation

1.1 The CNC PILOT

3HEIDENHAIN CNC PILOT 4290

Page 16

Full-surface machining

The CNC PILOT supports full-surface machining for all

common machine designs. The features include anglesynchronous part transfer with rotating spindle,

traversing to a stop, controlled parting, and coordinate

transformation. This ensures efficient full-surface

machining and simple programming.

The CNC PILOT supports full surface machining in:

■ DIN PLUS

■ TURN PLUS contour definition

■ TURN PLUS working plan generation

1.1 The CNC PILOT

1 Introduction and Fundamentals4

Page 17

1.2 The Operating Modes

The functions of the CNC PILOT are grouped into the following

operating modes:

Manual operating mode

In the Manual mode you set up the machine and move the

axes manually.

Automatic mode

The NC programs are run in Automatic mode. You control and

monitor the machining of the workpiece.

DIN PLUS programming mode

In ”DIN PLUS,” you can create structured NC programs. You

first define the geometry of the blank and finished part, and

then program the individual operations.

Simulation programming mode

The Simulation mode shows a graphic representation of

programmed contours, the paths of traverse and cutting

operations.The working space, tools and chucking equipment

are shown true to scale.

During simulation, the CNC PILOT calculates the machining

and idle-machine times for every tool. For lathes with several

slides, the Synchronous point analysis enables you to

optimize your NC program.

TURN PLUS programming mode

In ”TURN PLUS” you describe the contour of the workpiece

using interactive graphics. For Automatic Working plan Generation (AWG), you select the material and chucking equipment.

The CNC PILOT will generate the NC program automatically at

a keystroke. As an alternative, you can create the working

plan with the aid of interactive graphics (IAG).

Parameter organization mode

The system behavior of the CNC PILOT is controlled with

parameters. In this mode, you set the parameters to adapt the

control to your situation.

In addition, in this mode you describe the operating resources

(tools and chucking equipment) and the cutting values.

Service organization mode

In ”Service” mode, you log on for password-protected

functions, select the conversational language and make the

system settings. This operating mode also provides diagnostic

functions for commissioning and checking the system.

Transfer organization mode

In ”Transfer” you exchange the files with other systems,

organize your programs and make data backups.

The actual control is not accessible to the machinist.

You should know, however, that your CNC PILOT has

an integrated hard disk on which all TURN PLUS and

DIN PLUS programs that you enter are stored. This

allows you to save a vast number of programs.

For data exchange and data backup, you can use the

Ethernet interface. Data exchange is also possible

over the serial interface. (RS232).

1.2 Modes of Operation

5HEIDENHAIN CNC PILOT 4290

Page 18

1.3 Expansion Stages (Options)

The machine manufacturer configures the CNC PILOT according to

the capabilities of the specific lathe. The following upgrades (options)

are available, which enable you to adapt the control to your specific

requirements:

■ TURN PLUS

Graphically supported interactive contour definition

■ Graphic description of the workpiece for blank and finished part

■ Geometry-programming function for calculating and displaying

missing contour data

■ Simple input of standard form elements like chamfers, rounding

arcs, recesses, undercuts, threads, fits, etc.

■ Easy-to-use transformations like shifting, rotating, mirroring or

multiplying

DIN PLUS program generation with interactive graphics

■ Selection of the appropriate machining method

■ Selection of the tools and definition of the cutting data

Expansion Stages (Options)

■ Direct graphic control of machining process

■ Immediate compensation possibility

Automatic DIN PLUS program generation

■ Automatic selection of tools

■ Automatic generation of working plan

■ TURN PLUS – extension by C-axis or Y-axis

■ C-axis: representation of programmed contour in the following

views: XC plane (front/rear end) and ZC plane (unrolled surface)

■ Y-axis: representation of programmed contour in the following

views: XY plane (front/rear end) YZ plane (side view)

■ Hole and figure patterns

■ Fixed cycles

■ Interactive or automatic working plan generation – also for

machining with the C-axis or Y-axis

■ TURN PLUS – extension by opposing spindle

■ Rechucking with expert program

■ Interactive or automatic generation of working plan – also for

rechucking and 2nd setup

■ In-process measuring

■ With triggering probe

■ For measuring tools

■ For measuring workpieces

■ Post-process measuring

■ Connection of measuring system via RS-232 interface

■ Evaluation of measuring results in Automatic mode

This operating manual describes all

options.The operating sequences

described in this manual may therefore

deviate from those on your machine

whenever a certain option is not supported

by your system.

Options can usually be retrofitted. Your machine manufacturer can

give you more information on retrofitting.

1 Introduction and Fundamentals6

Page 19

1.4 Fundamentals

Axis designations

The cross slide is referred to as the X-axis and the saddle as the Z-

axis.

All X-axis values that are displayed or entered are regarded as

diameters. In TURN PLUS you can define whether the X-axis values

are to be interpreted as diameters or radii.

Lathes with Y-axis: The Y-axis is perpendicular to the X-axis and Z-axis

(Cartesian system).

When programming paths of traverse, remember to:

■ Program a positive value to depart the workpiece.

■ Program a negative value to approach the workpiece.

Coordinate system

The coordinates entered for the principal axes X, Y and Z are

referenced to the workpiece zero point – exceptions to this rule will be

indicated.

Angles entered for the C-axis are referenced to the ”zero point of the

C-axis” (precondition: the C-axis has been configured as a principal

axis).

1.4 Fundamentals

Absolute coordinates

If the coordinates of a position are referenced to the workpiece zero

point, they are referred to as absolute coordinates. Each position on a

workpiece is clearly defined by its absolute coordinates.

7HEIDENHAIN CNC PILOT 4290

Page 20

Incremental coordinates

Incremental coordinates are always referenced to the last

programmed position. They specify the distance from the last active

position and the subsequent position. Each position on a workpiece is

clearly defined by its incremental coordinates.

1.4 Fundamentals

Polar coordinates

Positions located on the face or lateral surface can either be entered

in Cartesian coordinates or polar coordinates.

When programming with polar coordinates, a position on the

workpiece is clearly defined by the entries for diameter and angle.

You can enter polar coordinates as absolute or incremental values.

Units of measurement

You can program and operate the CNC PILOT either in the metric or

inch system. The units of measurement listed in the table below apply

to all inputs and displays.

Measure Metric inch

Coordinates mm inch

Lengths mm inch

Angles Degrees Degrees

Spindle speed rpm rpm

Cutting speed m/min ft/min

Feed per revolution mm/rev inch/rev

Feed per minute mm/min inch/min

Acceleration m/s

2

ft/s

2

1 Introduction and Fundamentals8

Page 21

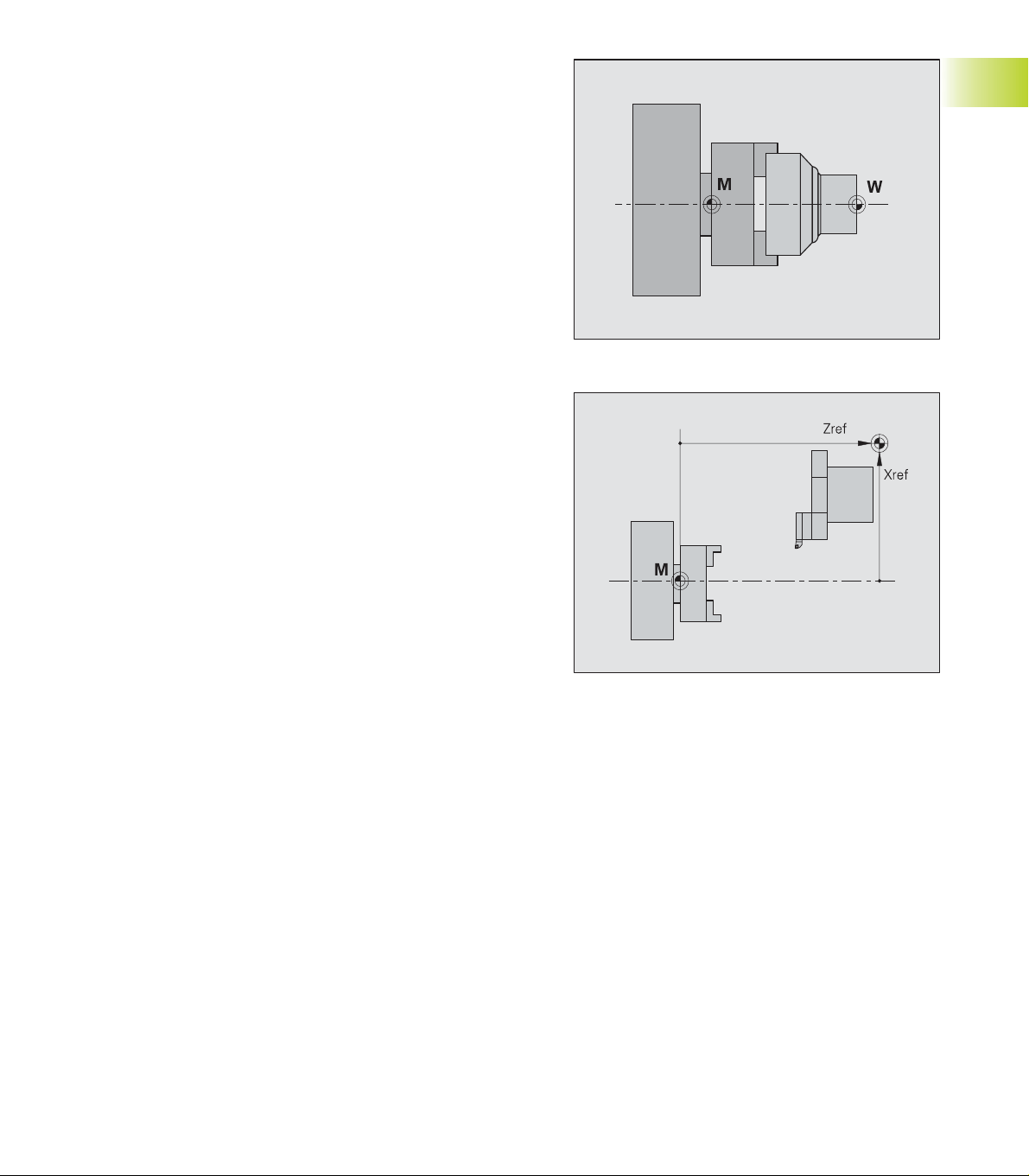

Machine reference points

Machine zero point

The point of intersection of the X-axis with the Z-axis is called the

machine zero point. On a lathe, the machine zero point is usually the

point of intersection of the spindle axis and the spindle surface. The

machine zero point is designated with the letter M.

Workpiece zero point

For machining a workpiece, it is easier to reference all input data to a

zero point located on the workpiece. By programming the zero point

used in the workpiece drawing, you can take the dimensions directly

from the drawing, without further calculation. This point is the

”workpiece zero point.” The workpiece zero point is designated with

the letter W.

Reference marks

Whether the control ”forgets” the positions of the machine axes

when it is switched off depends on the position encoders used. If the

positions are lost, you must pass over the fixed reference points after

switching on the CNC PILOT. The system knows the distances of the

reference points to the machine datum.

1.4 Fundamentals

9HEIDENHAIN CNC PILOT 4290

Page 22

1.5 Tool Dimensions

The CNC PILOT requires information on the specific tools for a variety

of tasks, such as calculating the cutting radius compensation or the

proportioning of cuts.

Tool length

All position values that are programmed and displayed are referenced

to the distance between the tool tip and workpiece zero point. Since

the control only knows the absolute position of the tool carrier (slide),

it needs the dimensions XE and ZE to calculate and display the

position of the tool tip. For milling and drilling tools operating with the Yaxis, the CNC PILOT additionally needs the dimension in Y.

1.5 Tool Dimensions

Tool compensation

The tool tip is subjected to wear during machining processes. To

compensate for this wear, the CNC PILOT uses compensation values.

The system automatically adds the compensation values to the

values for length.

Tooth and cutter radius compensation (TRC)

The tip of a lathe tool has a certain radius. When machining tapers,

chamfers and radii, this results in inaccuracies which the CNC PILOT

compensates with its cutting radius compensation function.

Programmed paths of traverse are referenced to the theoretical tool

tip S. The TRC function compensates for this error by calculating a

new path of traverse, the equidistant line.

Milling cutter radius compensation (MRC)

In milling operations, the outside diameter of the milling cutter

determines the contour. When the MRC function is not active, the

system defines the center of the cutter as reference point for the

paths of traverse. The MRC function compensates for this error by

calculating a new path of traverse, the equidistant line.

1 Introduction and Fundamentals10

Page 23

Basics of Operation

2

Page 24

2.1 User Interface

1

2.1.1 Screen Displays

1 Operating mode line

Show the status of the operating modes.

■ The active mode of operation is shown with a

dark-gray background.

■ Programming and organization modes:

– The selected mode is shown at the right of the

symbol

2.1 User Interface

– Additional information such as the selected program, submode, etc. are shown below the

operating mode symbol.

2 Menu bar and pull-down menus

For function selection

3 Working window

Size and content depend on the operating mode.

Some programming and organization modes

overlap the machine display.

4 Machine display

Current status of the machine (tool position, the

cycle and spindle situation, active tool, etc.). The

machine display is configurable.

5 Status line

■ Simulation, TURN PLUS: display of current

settings or information on the next operating steps

■ Other operating modes: display of the last error

message

6 Calendar date and service ”traffic light”

■ Display of date and time

■ A color background signals a error or a PLC

message

■ The ”service traffic light” shows the servicing

state of the machine (see ”

system”)

7 Soft-key row

Shows the current meaning of the soft keys.

8 Vertical soft-key row

Shows the current meaning of the soft keys. For

more information: see the machine manual

9.3

Maintenance

2

3

4

5

7

8

6

2 Basics of Operation12

Page 25

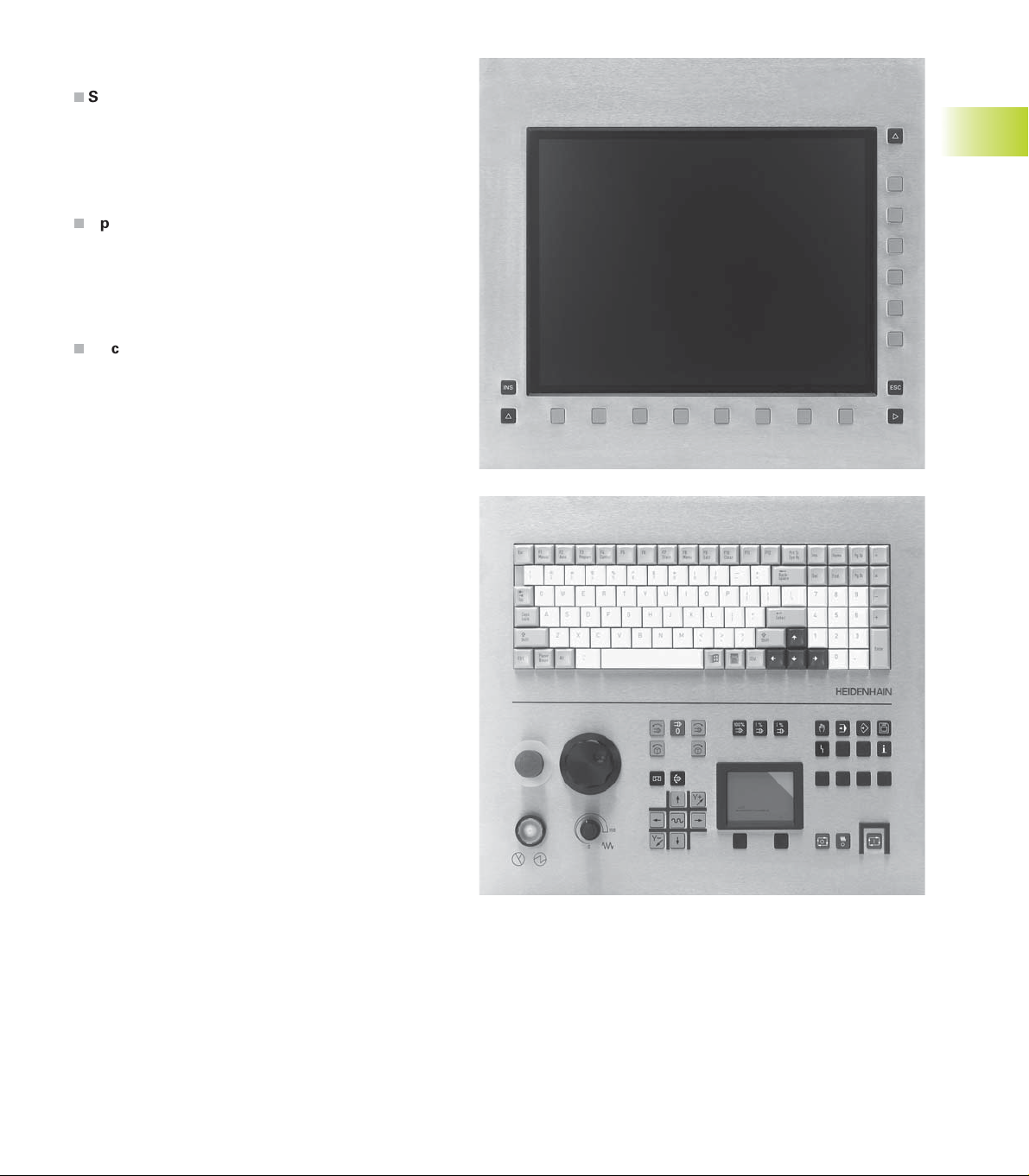

2.1.2 Controls and Displays

n

Screen with

■ Horizontal and vertical soft keys: The meaning is

shown above or next to the soft keys

Additional keys (same function as on the operating

panel):

■ ESC

■ INS

n

Operating panel with

■ Alphanumeric keyboard with integrated

numeric keypad

■ Keys for Operating mode selection

■ Touch pad: For cursor positioning (menu or soft

key selection, selection from lists, selecting edit

boxes, etc.)

n

Machine operating panel with

■ Operating elements for the manual and

automatic operation of the lathe (cycle keys,

manual direction keys, etc.)

■ Handwheel for exact positioning in manual

operation

■ Override button for feed-rate override

Operation of the touch pad

Normally, you can use the touch pad as an alternative

to the cursor keys. In the following, the keys below

the touch pad are referred to as the left and right

mouse keys.

The functions and operation of the touch pad are

similar to the mouse operation of the Windows

operating systems.

■ Single click of the left mouse key or single touch on

the touch pad:

■ The cursor is positioned in lists or input windows.

■ Menu items, soft keys or buttons are activated

■ Double-click of the left mouse key or double touch

on the touch pad: In lists, the selected element is

activated (the input window is activated)

■ Single-click with the right mouse key:

■ Same function as the ESC key – prerequisite: the

ESC key is allowed in this situation (for example to

go back by one menu level)

■ Same function as the left mouse key when

selection soft keys or buttons

2.1 User Interface

13HEIDENHAIN CNC PILOT 4290

Page 26

2.1.3 Selection of Operating Modes

You can switch the operating mode at any time. After the change, the

new mode starts in the function in which it was last exited.

In the programming and organization modes a difference is made

between the following situations:

■ No operating mode is selected (no entry next to the operating mode

symbol): Select the desired mode from the menu.

■ Operating mode selected (indicated next to the operating mode

symbol): The functions of this operating mode are available. Within

2.1 User Interface

the programming or organization modes, you can switch the modes

by soft key or by repeatedly pressing the corresponding mode key.

2.1.4 Selection of Functions, Data Input

Menu bar and pull-down menu

The individual menu items are preceded by a 9-field symbol with one

field highlighted. This field represents the field on the numeric keypad.

Press the key whose position corresponds to the position of the

highlighted field.

The function selection begins in the menu row, then goes to the pulldown menus. In the pull-down menu, press again the numeric key

assigned to the menu item – or alternatively, select the menu item

with touch pad or with the ”page up/page down” keys and press

Enter.

Soft-key row

The meaning of the soft keys is dependent on the current operating

situation.

Some soft keys work like ”toggle switches”. A function is active when

the associated field in the function-key row is highlighted in color. The

setting remains in effect until the function is switched off.

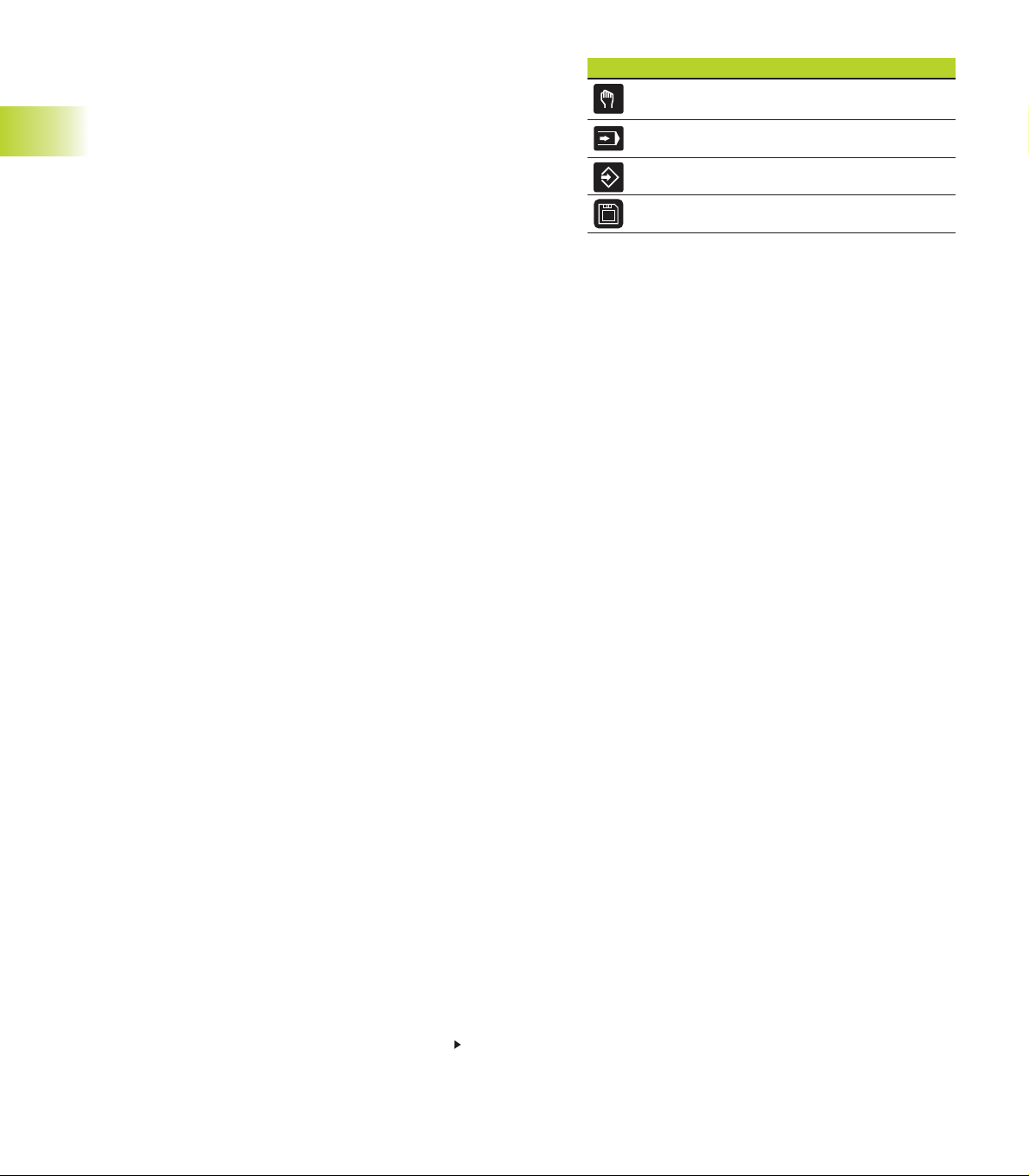

Keys for operating mode selection:

Manual operating mode

Automatic operating mode

Programming modes

Organization modes

List Operations

DIN PLUS programs, tool lists, parameter lists, etc. are displayed as

lists. You can scroll through a list with the touch pad or arrow keys to

check data, to select the position where you wish to enter data, or to

highlight items for operations like deleting, copying, editing, etc.

After having selected the desired list position or a list item, press the

ENTER, INS, ALT or DEL key to execute the operation.

Continued

2 Basics of Operation14

Page 27

Data Input

Data are entered and edited in input windows. An

input window consists of severalinput fields. You

position the cursor with the touch pad or with the

page up/page down keys to the input box.

Once the cursor is located in the box, you can enter

your data. Existing data are overwritten. With the

right/left arrow keys you can place the cursor on a

position within the input box in order to delete or add

characters. The up/down arrow keys or Enter confirm

and terminate the entry.

Some dialogs have more input fields than a window

can show. In these cases, more than one input

window appears on the screen, one superimposed on

the other. You will recognize this through the window

number in the top line. To toggle between input

windows, use the Page Up/Page Dn keys.

By pressing the ”OK” button, you confirm the data

entered or edited. Independent of the position of the

cursor, you can press the INS key as an alternative. If

you leave the input window by pressing the ”Cancel”

button or the ESC key, entries or changes will be lost.

If the dialog consists of more than one input window,

you already confirm the data when pressing the

PageUp/PageDn key.

Buttons

The CNC PILOT allows you to choose various options

via different buttons such as the ”OK” and ”Cancel”

buttons for terminating a dialog box or the buttons

contained in the ”Extended inputs” window.

Select the required button and press ENTER.

Note: Instead of selecting the ”OK” or ”Cancel”

button, you can press the INS or ESC key.

2.1 User Interface

15HEIDENHAIN CNC PILOT 4290

Page 28

2.2 The Info System

The info system calls excerpts from the User's Manual to the screen. The system is structured in info

topics comparable to the chapters of a book. In the

top line of the information window, the topic you

selected and the page number are shown.

The info system gives you information on the current

operating situation (context-sensitive help). Also, you

can select the info topics through the table of

contents or the subject index. Simply select the

desired topic or word and click ”Topic select” (or

2.2 The Info System

Enter).

Cross references in the text are highlighted. Place

the cursor on the desired cross reference and call the

topic with ”Topic select.” ”Topic return” switches

back to the previous topic.

Error display

When an error message occurs, press the info key, or

place the cursor on the error message in the ”display

of errors” and then press the info key, to get further

information on the respective error.

Call the info system

End the info system

Soft keys

Calls the

■ Selected cross reference

■ Topic from the table of contents

■ Topic from the subject index

Returns to the most recent info topic

Calls the table of contents with the overview of info

topics. The table of contents is arranged in several

levels.

Calls the subject index

Switches to the previous topic.

Switches to the next topic.

(or page up key) previous info page

(or page down key) next info page

2 Basics of Operation16

Page 29

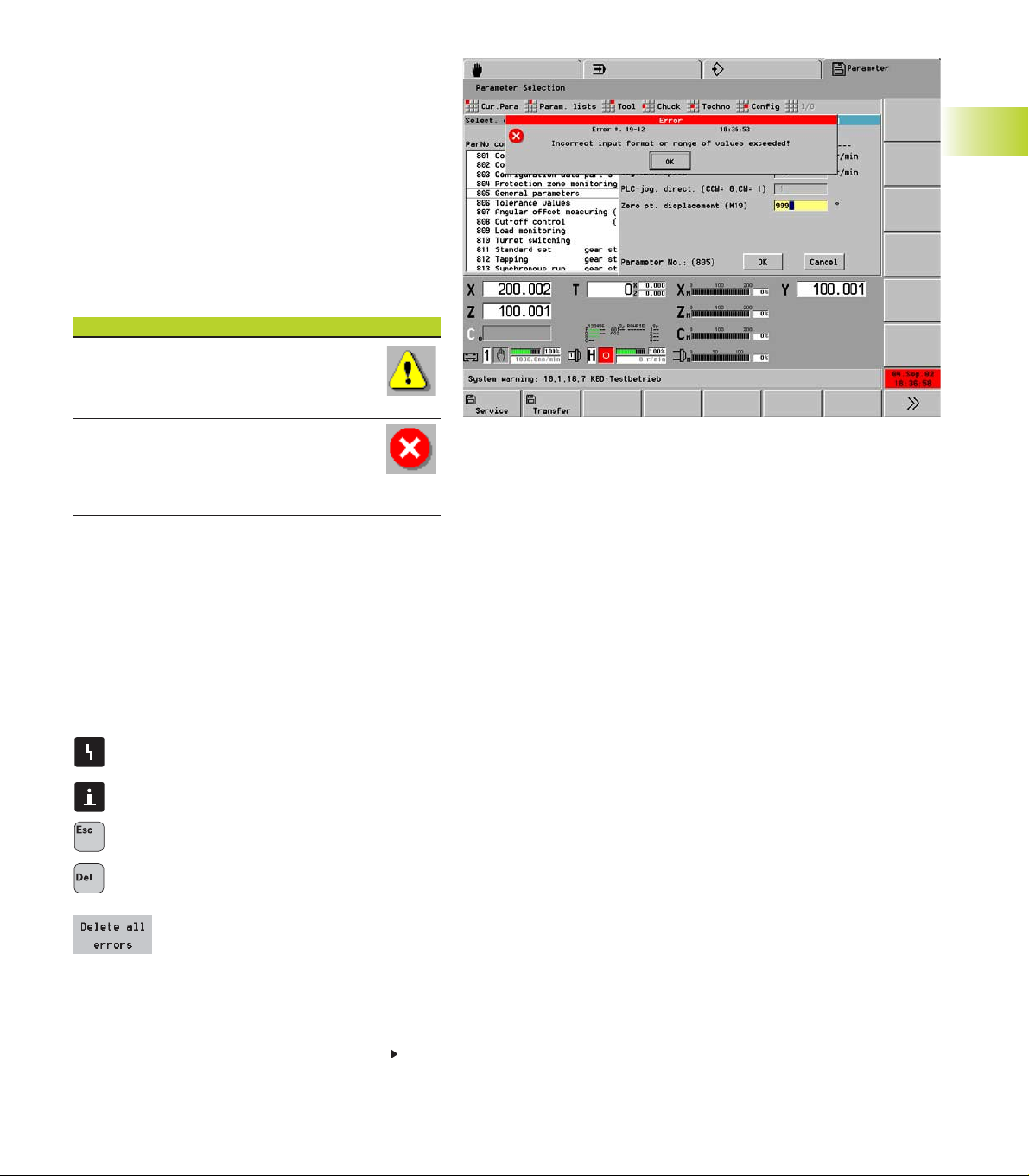

2.3 The Error System

2.3.1 Direct Error Messages

Direct error messages appear whenever immediate

error correction is possible. Confirm the message by

pressing ENTER and correct the error. Example: The

input value of the parameter is out of range.

Information of the error message:

■ Error description: Explains the error

■ Error number: For service inquiries

■ Time of day When the error occurred (for your

information).

Symbols

Warning

The program run/operation continues. The

CNC PILOT indicates the problem.

Error

The program run/operation is stopped. Yo u

must correct the error before you can

continue the current job.

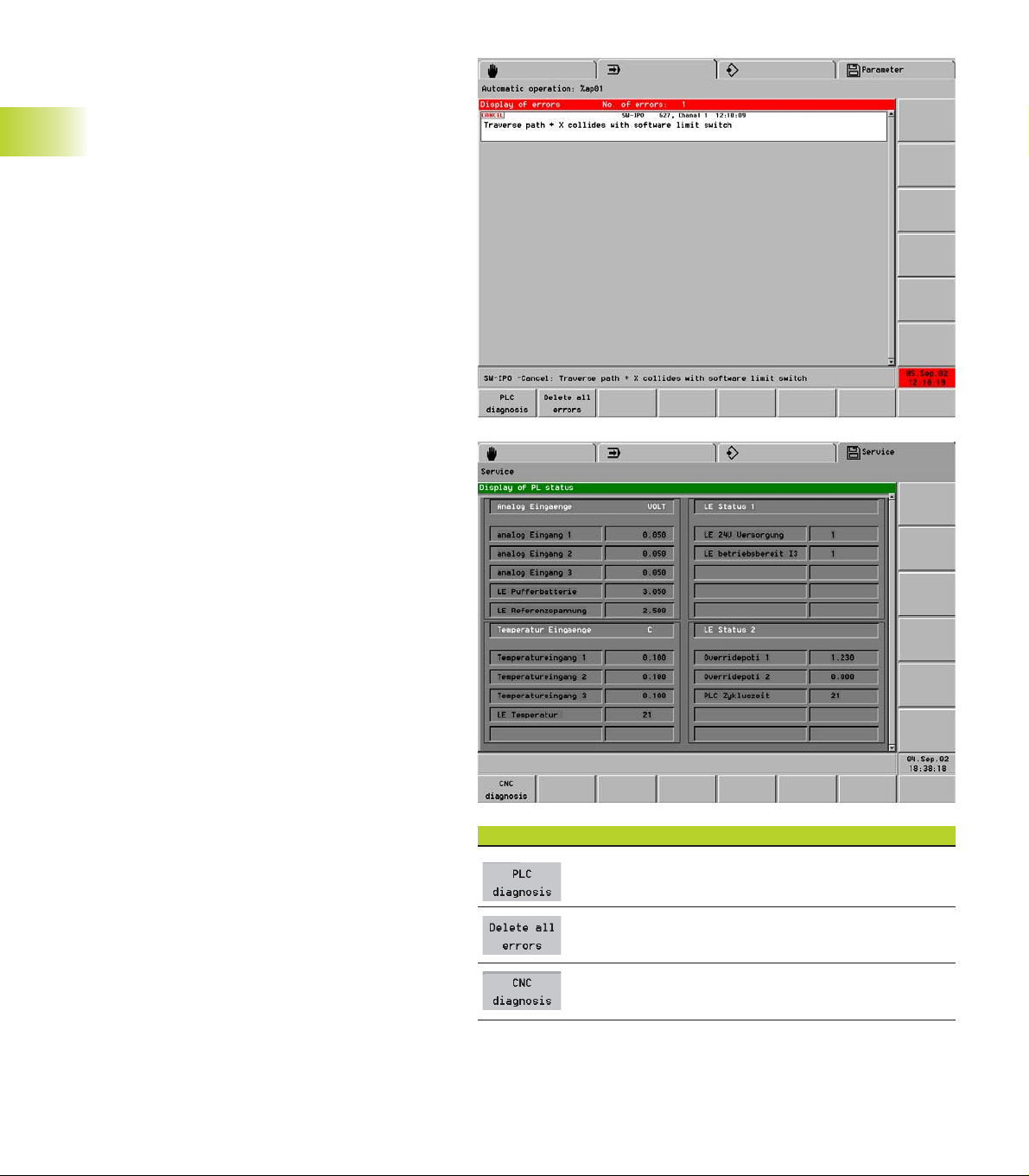

2.3.2 Error Display, PLC Display

Error Display

If during the system start or during program run or

other operation an error occurs, it is indicated in the

date box, displayed in the status line, and saved in

the error display.

The date and time remain highlighted in red until all of

the errors have been canceled.

Notes on using TURN PLUS:

Opens the ”error display”

2.3 The Error System

Further information on the error marked with

the cursor

Exits the error display

Deletes the error message marked with the

cursor

Deletes all error messages.

Continued

17HEIDENHAIN CNC PILOT 4290

Page 30

Information of the error message:

■ Error description: Explains the error

■ Error number: For service inquiries

■ Channel number: Slide for which the error

occurred.

■ Time of day When the error occurred (for your

information).

■ Error class (only with errors):

■ Background: The message serves for

information only, or it is a minor error.

■ Cancel: The running process (cycle run, traverse

command, etc.) was aborted. You can resume

2.3 The Error System

operation once the error has been cleared.

■ Emergency stop: Traverse and the execution of

the DIN program were stopped. You can resume

operation once the error has been cleared.

■ Reset: Traverse and the execution of the DIN pro-

gram were stopped. Switch off the control for a

moment, then restart. Contact your machine

manufacturer if the error occurs again.

System Error, Internal Error

If a system error or internal error occurs, write

down all information on the displayed message and

inform your machine manufacturer. You cannot

correct an internal error. Switch off the control and

restart.

Warnings during Simulation

In the event of problems during simulation of an NC

program, the CNC PILOT displays a warning in the

5.1.2

status line (see ”

Notes on Operation”).

PLC display

The PLC window is used for PLC messages and the

PLC diagnosis. Your machine manual provides more

detailed information on the PLC window.

To call the PLC window, open the error window with

the Error status key and then press ”PLC Diagnosis”

soft key.

To exit the PLC status display, press the ESC key; to

switch to the error window, use the ”CNC Diagnosis”

soft key.

Soft keys

Switch to PLC display

Deletes all error messages

Return to error display

2 Basics of Operation18

Page 31

2.4 Data Backup

The CNC PILOT stores NC programs, operating-resource data and

parameters on the hard disk. Since the possibility of damage to the

hard disk due to excessive vibration or shock cannot be eliminated,

HEIDENHAIN recommends making regular backup copies of your

programs, operating resource data and parameters on a PC.

You can use DataPilot 4290, the WINDOWS ”Explorer” or other

suitable programs for backing up your data on a PC.

For data exchange and data backup, you can use the Ethernet

interface. Data exchange is also possible over the serial interface

(RS-232) (see ”

10.2

Data Transfer Methods”).

2.5 Explanation of Terms

■ Cursor: In lists, or during data input, a list item, an input box or a

character is highlighted. This ”highlight” is called a cursor.

■ Arrow keys: The cursor is moved with the ”page up/page down”

arrow keys or the touch pad.

■ Navigate: You can move the cursor within a list or an input box to

any position you would like to check, change, delete or add to. In

other words, you ”navigate” through the list.

■ Active/inactive functions, menu items: Functions or soft keys

that currently unavailable are shown dimmed.

■ Dialog box: Dialog boxes are also called input windows.

■ Editing: ”Editing” is changing, deleting and adding to parameters,

commands, etc., within programs, tool data or parameters.

■ Default value: If the parameters of DIN commands or other

parameters are preassigned values, these values are referred to as

”default values.”

■ Bytes: The capacity of a storage disk is indicated in ”bytes.” Since

the CNC features a hard disk, the individual program lengths (file

sizes) are expressed in bytes.

■ Extension: File names consist of the actual file name and the ”file

name extension.” The name part and the extension part are

separated by ”.”.The extension indicates the type of file. Examples:

■ ”*.NC” DIN programs

■ ”*.NCS” DIN subprograms

■ ”*.MAS” Machine parameters

2.4 Data Backup; 2.5 Explanation of Terms

19HEIDENHAIN CNC PILOT 4290

Page 32

Page 33

3

Manual Control

and Automatic mode

HEIDENHAIN CNC PILOT 4290

21

Page 34

3.1 Switch-On, Switch-Off,

Reference Run

3.1.1 Switch-On and Traversing the

Reference Marks

In the screen dialog line, the CNC PILOT shows you

step by step how to proceed when starting the

system. The the CNC PILOT asks you to select an

operating mode.

Whether the reference run is necessary depends on

the encoders installed in your machine:

■ EnDat encoder: Reference run is not necessary

■ Distance-coded encoders: The position of the axes

is ascertained after a short reference run

■ Standard encoder: The axes move to familiar,

machine-based points

”Reference automatic” means that all axes make

reference runs. ”Reference jog” only one axis does.

Reference automatic (all axes)

Select ”Ref – Reference automatic.”

<

3.1 Switch-On, Switch-Off, Reference Run

”Status of reference run approach” informs you of

the current status. Axes that have not been

referenced are shown in gray.

<

Either set the slides that need to find a reference or

set ”All slides” (”reference automatic” dialog box)

<

The axis move to find the reference

Interrupts the reference run. Cycle

start resumes the run.

Cancels the reference run

<

After completion of the reference run:

■ The position display is activated.

■ The automatic mode is selectable.

■ The Sequence, in which the axis make their reference

run is defined in machine parameters 203, 253, .. .

■ Exiting the ”Reference automatic” dialog box: Press

Cycle stop

The software limit switches are active only after you

have traversed the reference marks.

Monitoring the EnDat encoders

If your machine is equipped with EnDat encoders, the control saves

the axis positions during switch-off. During switch-on, the CNC PILOT

compares for each axis the position during switch-on with the position

saved during switch-off.

If there is a difference, one of the following messages appears:

■ ”Axis was moved after the machine was switched off.”

Check the current position and confirm it if the axis was in fact

moved.

■ ”Saved encoder position of the axis is invalid”

This message is correct if the control has been switched on for the

first time, or if the encoder or other control components involved

were exchanged.

■ ”Parameters were changed. Saved encoder position of the axis is

invalid.”

This message is correct if configuration parameters were changed.

The cause for one of the messages listed above could be a defect in

the encoder or in the control. Please contact your machine supplier if

the problem recurs.

3 Manual Control and Automatic mode22

Page 35

Reference jog (single axis)

Select ”Ref – Reference jog.”

<

”Status of reference run approach” informs you of

the current status. Axes that have not been

referenced are shown in gray.

<

Set slides and axes (”reference jog” dialog box)

<

The reference run is continued as long

as you keep pressing the key. To

interrupt the reference run, release the

key.

Cancels the reference run

<

After completion of the reference run:

■ The position display is active for the axis that has

been referenced.

■ If all axes have been referenced, you can select

automatic mode.

Exiting the ”Reference jog” dialog box: Press cycle stop

The software limit switches are only active after you

have traversed the reference marks.

3.1 Switch-On, Switch-Off, Reference Run

3.1.2 Switch-Off

Switching off the CNC PILOT. Confirm

the subsequent request with OK. The

control is shut down in an orderly

manner. After a few seconds, CNC

PILOT requests you to switch off the

machine.

”Shutdown” is available in the programming and

organization modes if no operating mode is selected.

Proper switch-off is recorded in the error log file.

HEIDENHAIN CNC PILOT 4290

23

Page 36

3.2 Manual Operating Mode

The Manual control mode offers various functions for

setting up the machine, for measuring tool dimensions

and for manually machining workpieces.

The machine display in the lower section of the

screen shows the tool position and further machine

data.

Options of operation:

■ Manual mode of operation

With the ”machine keys” and the handwheel, you

can control the spindle and move the axes to

machine the workpiece.

■ Setting up the machine

Functions for entering the tools being used, setting

the workpiece zero point, the tool change position,

the protective-zone dimensions, etc.

■ Measuring tool dimensions

Functions for measuring the tool by touching the

workpiece or by use of measuring devices.

■ Configuring the screen display

3.2 Manual Control Operating Mode

The CNC PILOT supports various types of machine

display.

In Automatic mode, the data are entered

and displayed in 1 millimeters or in

inches, depending on the setting of the

control parameter 1.

Remember: If the machine has not been

referenced:

■ The position display is not valid

■ The software limit switches are

nonoperational.

Soft keys

■ Assigns a handwheel to an axis

■ Defines the handwheel interpolation factor

Switches the machine display

Turret one position backward

Turret one position forward

3 Manual Control and Automatic mode24

Page 37

3.2.1 Entering machine data

”F” (feed rate) pull-down menu:

■ Feed per revolution

Select ”Feed per revolut.”

Enter the feed rate in mm/rev (or inches/rev)

■ Feed per minute

Select ”Feed per minute.”

Enter the feed rate in mm/min (or inches/min) and

press OK.

”S” (spindle speed) pull-down menu:

■ Spindle speed

Select ”Speed S.”

Enter the speed in rpm

■ Constant cutting speed

Select ”V constant.”

Enter the cutting speed in m/min (or ft/min) and

press OK.

■ Spindle point stop

To switch to the required spindle, press the

Spindle change key.

Select ”Spindle point stop.”

Enter position

Cycle start: The spindle is positioned

Cycle stop: Exit the dialog box

Menu item ”T” (Tool):

Select ”T”

Enter the turret position

You can enter a constant cutting speed only for slides with

an X axis.

3.2 Manual Control Operating Mode

Tool change functions:

■ Moving the tool into position

■ Offsetting ”new” tool dimensions

■ Showing the ”new” actual values in the position display.

3.2.2 M Commands

”M” (M functions) pull-down menu:

■ The M number is known: Select ”M direct” and

enter the number.

■ M menu: To select the M function, use the menu.

After input/selection of the M function:

Cycle start: The M function is executed

Cycle stop: Exit the dialog box

The content of the M menu depends on

the machine. Yours may differ from the

example shown here.

HEIDENHAIN CNC PILOT 4290

25

Page 38

3.2.3 ManualTurning Operations

”Manual” pull-down menu:

n

Simple longitudinal and transverse turning

operations

Select ”Constant feed.”

Select the direction of feed (”Constant feed”

dialog box).

Control the feed rate with the cycle keys.

n

G functions

Select ”G function.”

Enter the G number and the function parameter;

press OK.

The G function is executed.

The following G functions are permitted:

■ G30 – Rear-face machining

■ G710 – Adding tool dimensions

■ G720 – Spindle synchronization

■ G602..G699 – PLC functions

n

Manual NC programs

Depending on the configuration of a lathe, the

machine manufacturer can includes NC programs

3.2 Manual Control Operating Mode

supporting the machinist in manually operating the

lathe (Example: Switching to rear-face machining).

Refer to the machine manual.

With constant speed, a feed rate per revolution must be

defined.

3.2.4 Handwheel

Assign the handwheel to one of the

principle axes or the C axis, and enter

the feed rate or angle of rotation per

handwheel increment (”Handwheel

axes” dialog box).

The handwheel assignment and speed ratio are

shown in the machine display (the axis letter and the

decimal place of the handwheel traverse ratio are

marked).

The cancel the handwheel assignment, press the

”Handwheel” soft key with opened dialog box.

The handwheel assignment is canceled by:

■ Switching to another slide.

■ Changing the operating mode.

■ Pressing an axis direction key.

■ Selecting the handwheel assignment again.

3 Manual Control and Automatic mode26

Page 39

3.2.5 Spindle and Axis Direction Keys

The keys of the machine operating panel are used for

machining a workpiece manually and for special

functions such as positioning or determining

compensation values (actual position capture,

scratching, etc.).

To activate tools, define the spindle speed and feed

rate, etc., use the menus.

To move the slide diagonally, press the X

and Z-axis direction keys simultaneously.

Spindle keys

Switch the spindle on in M3/M4 direction.

Jog the spindle in M3/M4 direction. The spindle

rotates as long as the key is held. Jog speed:

machine parameters 805, 855, ...

Spindle stop

Axis direction keys (jog keys)

Move slide in X direction.

Move slide in Z direction.

Move slide in Y direction.

3.2.6 Slide/Spindle change key

■ On lathes with more than one slide, the axis

direction keys control the selected slide.

■Selection of the slide: Slide change key

■ Display of the selected slide: Machine display

■ On lathes with more than one spindle, the spindle

keys on the selected spindle.

■ Select the spindle: Spindle change key

■ Display of the selected spindle: Machine display.

■ For setup functions referring to one slide or spindle

(workpiece zero point, tool change point, etc.), you

specify the slide/spindle with the slide/spindle

change key.

■ The machine display usually contains display

elements for spindle and slide. To switch between

these elements, use the Slide/Spindle change key

3.6

(see

”Machine Display”).

To move the slide in rapid traverse: Simultaneously

press the rapid traverse key and the axis direction

key. Rapid traverse velocity: Machine parameters

204, 254, ...

Slide/Spindle change key

Switch over to the next slide

Switch over to the next spindle

3.2 Manual Control Operating Mode

HEIDENHAIN CNC PILOT 4290

27

Page 40

3.3 Tool Lists, Tool Life

Management

The tool list (turret table) indicates the current tool

carrier assignment. To compile a tool list, enter the ID

numbers of the tools.

You can use the entries in the TURRET section of the

NC program to set up the tool list. The ”Compare list”

and ”Accept list” functions refer to the NC program

last interpreted in automatic mode.

Tool life data

Apart from ID numbers and tool type descriptions, the

tool list includes data for tool life management:

■ Status

Shows the remaining tool life/quantity.

■ Ready for use

When the tool life has expired/the defined number

of parts has been produced, the tool is ”not ready

for use” any longer.

■ Atw (replacement tool)

If a tool is ”not ready for use,” a replacement tool is

3.3 Tool Lists, Tool Life Management

inserted.

Simple tools

With the setup functions, you can only enter tools

registered in the database. If the NC program uses

”simple tools,” proceed as follows:: Run an

interpretation of the NC program; the CNC PILOT

automatically updates the tool list.h

If the positions in the tool list are occupied by ”old”

tools, the confirmation request - ”Update tool list?”

- appears. The tools are only entered after you have

confirmed the request.

Tools that are not registered in the database are

identified by the code ”_AUTO_xx” (xx: T number),

and not by an ID number.

■ The parameters of simple tools are defined in the NC

program

■ The tool life data are evaluation only if the tool life

management is active.

Danger of collision

■ Compare the tool list with the current tool carrier

assignment and check the tool data before running a

program.

■ The tool list and the dimensions of the tools entered

must correspond to the actual facts, because the CNC

PILOT uses the data for slide movements, protective-zone

monitoring, etc.

3 Manual Control and Automatic mode28

Page 41

3.3.1 Setting Up a Tool List

A tool list can also be set up without using an NC

program.

Enter a new tool

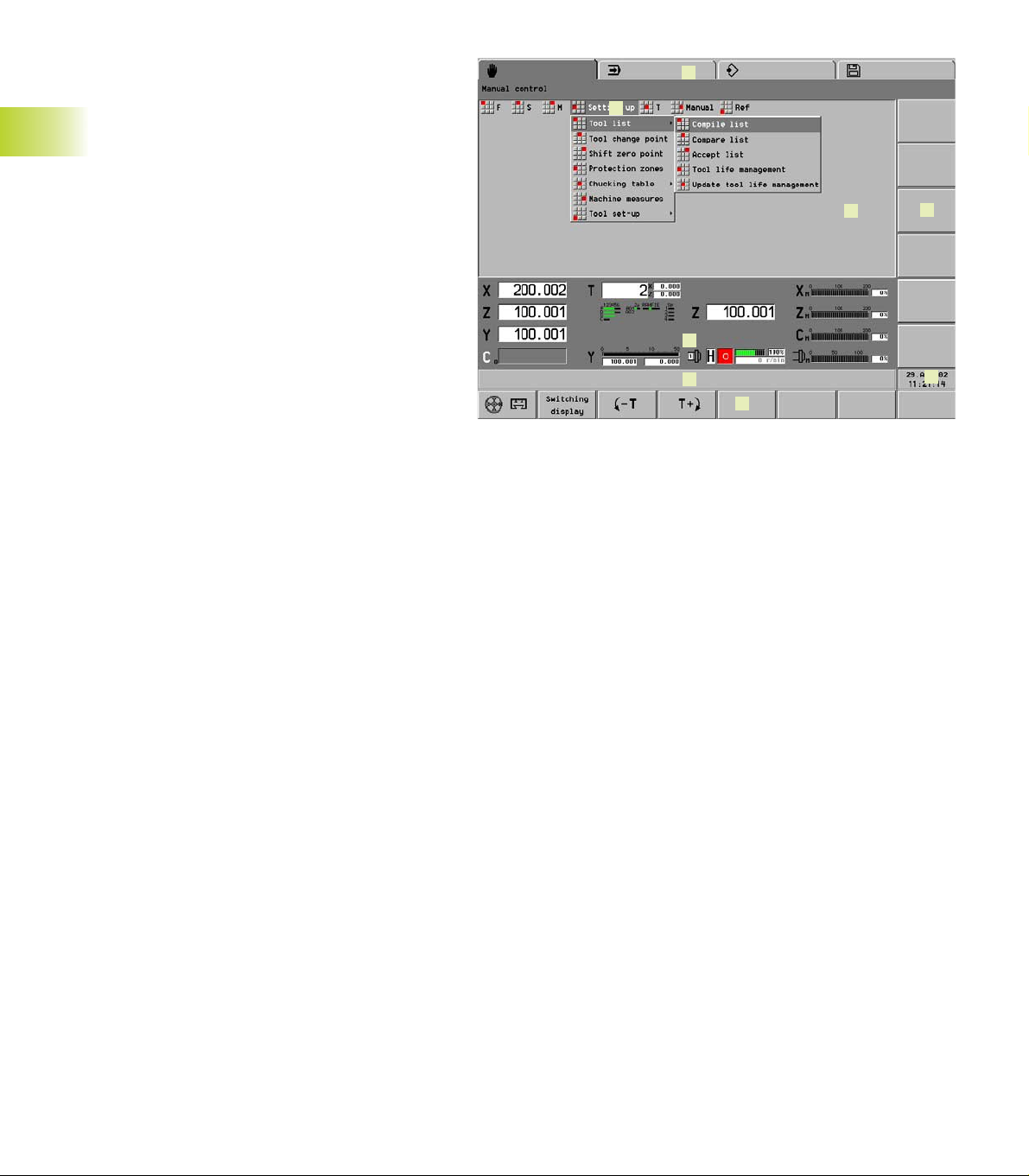

Select ”Setting up - Tool list - Compile list”

<

Select the tool location

<

ENTER (or INS key) – opens the setup dialog box

<

Enter the ID number

Take the tool from the database

Enter the tool type – the CNC PILOT

displays all tools of this type mask

Enter the ID number – the CNC PILOT

displays all the tools of this ID mask

<

Select the tool

<

Take the tool from the database

3.3 Tool Lists, Tool Life Data

Soft keys

Delete tool

Take the tool from the ”ID number clipboard”

Delete the tool and place in the ”ID number clipboard”

<

Exit the tool database

Delete the tool

Select ”Setting up - Tool list - Compile list”

<

Select the tool location

<

or the DEL key deletes the tool

HEIDENHAIN CNC PILOT 4290

Edit the tool parameters

Entries in the tool database - sorted by tool typep

Entries in the tool database - sorted by tool ID number

Continued

29

Page 42

Changing the tool pocket

Select ”Setting up - Tool list - Compile list”

<

Select tool location

<

Deletes the tool and saves it in the ”ID

number clipboard”

<

Select a new tool location

<

Take the tool from the ”ID number

clipboard”

3.3 Tool Lists, Tool Life Data

If the location was occupied, the

previous tool is taken into the

clipboard.

3 Manual Control and Automatic mode30

Page 43

3.3.2 Comparing a Tool List with an NC

Program

The CNC PILOT compares the current tool list with

the entries in the NC program last translated in

automatic mode.

Comparing a tool list

Select ”Setting up - Tool list - Compare list” The

CNC PILOT shows the current contents of the tool

list and marks deviations from the programmed

tool list.

<

Select marked tool location

<

Nominal-actual comparison

Press ENTER (or INS key). The CNC PILOT opens

the ”nominal-actual comparison” dialog box.

<

Accept the ID number of the ”nominal

tool” in the tool list

or

Look for the tool in the database

3.3 Tool Lists, Tool Life Data

Soft keys

Delete the tool

Take the tool from the ”ID number clipboard”

The CNC PILOT shows the following tools marked:

■ Actual tool ≠ nominal tool

■ Actual – not occupied; nominal – occupied

The entries in the TURRET section are considered

nominal tools (reference:TURRET section of the NC

program most recently interpreted in Automatic

mode).

Tool locations that are not assigned in the NC

program cannot be selected.

Danger of collision

■ Tool pockets that are occupied but,

according to the NC program, are not

needed, are not marked.

■ The CNC PILOT compensates the tool

actually entered – even if it does not

match the nominal assignment.

HEIDENHAIN CNC PILOT 4290

Delete the tool and place in the ”ID number clipboard”

Edit the tool parameters

Entries in the tool database - sorted by tool typep

Entries in the tool database - sorted by tool ID numberr

Accept the ID number of the ”nominal tool” in the tool

list

31

Page 44

3.3.3 Transferring theTool List from an

NC Program

The CNC PILOT transfers the new tool assignment

from the TURRET section (reference: the NC program

last interpreted in Automatic mode).

Transferring the tool list

Select ”Setting up - Tool list - Accept list”

Depending on the previous turret assignment, the

following might occur:

■ Tool not used

The CNC PILOT enters the new tools in the tool list.

Positions that were occupied in the old tool list, but

3.3 Tool Lists, Tool Life Data

are not used in the new list, are retained. If a tool

shall remain in the tool carrier, no further action is

required; if not, delete the tool:

■ Actual tool location differs from location in tool

list

A tool is not entered when its newly assigned

location differs from the location specified in the

tool list. The CNC PILOT displays a message

indicating this error. Change the tool location.

As long as a tool position differs from the nominal

assignment it remains highlighted.

Soft keys

Delete the tool

Take the tool from the ”ID number clipboard”

Danger of collision

■ Tool locations that are occupied but,

according to the NC program, are not

needed, are kept.

■ The CNC PILOT compensates the tool

actually entered – even if it does not

match the nominal assignment.

Delete the tool and place in the ”ID number clipboard”

Edit the tool parameters

Entries in the tool database - sorted by tool typep

Entries in the tool database - sorted by tool ID number

3 Manual Control and Automatic mode32

Page 45

3.3.4 Tool Life Management

The tool life management allows you to define the

sequence of exchange and declare the tool to be

ready for use. The tool life/quantity is defined in the

tool database (see section ”

Life Monitoring”).

The ”Tool life management” dialog box is used both

for entering and displaying the tool life data.

You can use the variable-programming function in

your NC program to evaluate sequential events that

you enter in ”Event 1” and ”Event 2” (see section

4.15.2

V Variables”).

”

Tool life management parameters

■ Repl. tool (replacement tool): T number (turret

position) of the replacement tool

■ Event 1: Sequential event that is triggered when

the life of a tool has expired/a tool has produced the

defined quantity – Event 21..59

■ Event 2: Sequential event that is triggered when

the life of the last tool of the interchange chain has

expired/the tool has produced the defined quantity –

Event 21..59

■ Ready for use: Set the tool to ”ready for use” or

”not ready for use” (applies to tool life management

only).

Entering the tool life parameters

Select ”Setting up – Tool list – Tool life

management”; the CNC PILOT displays the tools

entered.

<

Select the tool location.

<

Press ENTER – the CNC PILOT opens the ”Tool life

management” dialog box.

<

Enter the replacement tool and the tool life

parameters; press OK.

”New cutter” sets the tool life/quantity to the value

programmed in the database and sets the tool to

ready for use.

8.1.7

Multiple Tools, Tool

3.3 Tool Lists, Tool Life Data

Update tool life management data

Select ”Setting up - Tool list – Update tool life management.”

<

Confirm the confirmation request with OK; the CNC PILOT sets the

tool life/quantity to the value defined in the database and sets all

tools in the tool list to ready for use.

<

The CNC PILOT displays the ”Tool list - tool life management” for

inspection.

Application example: The cutting edges of all tools used have been

replaced. Part production is to be continued, using the tool life

management function.

HEIDENHAIN CNC PILOT 4290

33

Page 46

3.4 Setup Functions

3.4.1 Defining the Tool Change Position

With the ISO command G14, the machine slide

moves to the tool change point. Always program

the tool change point as far from the workpiece as

possible to allow the turret to rotate to any position.

Defining the tool change position

For more than one slide: Define the desired slide

(with the Slide change key)

3.4 Setup Functions

<

Select ”Setting up – Tool change point.”

<

The CNC PILOT displays the currently valid position

in the ”Set tool change point” dialog box.

<

Entering the tool change point

Enter a new position

Soft keys

Capture tool change point

Move slide to the tool change position

Confirms the slide position as tool

change point

or

Confirms the position of individual axes

The tool change point is managed in the setup

parameters (Select: „Act. Para – Setting up (menu) –

Tool change point – ..“).

The coordinates of the tool change position

are entered and displayed as distance

between machine datum and tool carrier

datum. Since these values are not shown

in the position display, it is advisable to

move to the tool change point and

”capture” the position.

■ Assigns a handwheel to an axis

■ Defines the handwheel interpolation factor

Switch the machine display

Enter the feed per revolution

Enter the constant surface speed

Enter the M function

Accept the axis position as tool change point(or Y or Z

axis)

Accept the slide position as tool change point

3 Manual Control and Automatic mode34

Page 47

3.4.2 Shifting theWorkpiece Datum

Shifting the Workpiece Datum

For more than one slide: Define the desired slide

(with the Slide change key)

<

Position the tool

<

Select ”Setting up - Shift zero point.”

<

The ”Shift zero point” dialog box displays the

current workpiece zero point.

<

Enter the workpiece zero point

Enter a ”zero point shift”

Contact position = tool zero point

Touch the end face with the tool

Accept the tool contact position as

workpiece zero point

Workpiece zero point relative to the contact

position

Touch the end face with the tool

Accept the tool contact position

3.4 Setup Functions

Soft keys

■ Assigns a handwheel to an axis

■ Defines the handwheel interpolation factor

Switches the machine display

Enter the feed per revolution

Enter the measured value (distance

of the tool contact position from the

workpiece zero point)

The tool zero point is managed in the setup

parameters (Select: „Act. Para – Setting up (menu) –

Tool zero point – ..“).

■ The ”displacement” is with respect to

the machine zero point.

■ You can also offset the workpiece zero

point for the X and Y axes.

HEIDENHAIN CNC PILOT 4290

Enter the constant surface speed

Enter the M function

Define the Z position as tool zero point (or X or Y

position)

Specify the tool zero point relative to the current Z

position (or X or Y position)

35

Page 48

3.4.3 Defining the protection zone

Defining the protection zone

Insert any tool (T0 is not permitted).

<

Select ”Setting up - Selection zones”

<

Enter the protection zone parameters

Enter the limit values.

3.4 Setup Functions

Capturing the protection zone parameters per

axis

For each input box:

Select the input field

Position the tool to the protection zone limit

Accept the axis position as protection

zone parameter

Capturing positive/negative protection zone

parameters

Select any positive or negative input field

Position the tool to the protection zone limit

Accept all positive/negative axis

positions

Soft keys

■ Assigns a handwheel to an axis

■ Defines the handwheel interpolation factor

Switch the machine display

Enter the feed per revolution

The parameters serve for protection zone

monitoring - not as software limit switches.

Protection zone parameters:

■ are expressed with respect to the

machine zero point

■ are managed in the machine parameters

1116, 1156, ..

■ X value are radius dimensions

■ 99999/–99999 means: no monitoring of

this side of the protection zone

Enter the constant surface speed

Enter the M function

Accept the X position as ”protection zone –X”

parameter (or +X, –Y, +Y, –Z, +Z position)

Accept the axis positions as positive/negative

protection zone parameter

3 Manual Control and Automatic mode36

Page 49

3.4.4 Setting up the ChuckingTable

The chucking table is evaluated by the concurrent

graphics.

Setting up the chucking table

Select ”Setting up – Chucking table – Main spindle

(or Tailstock)

<

Select the ID number from the chucking database

Chucking equipment for spindles

The definition of the clamping form (”Grip. form”)

presupposes the definition of the chuck jaws. Set the

clamp form by soft key – it is graphically illustrated.

To switch to the chucking assignment of further

spindles, press the Page Up/Page Dn keys.

Parameters for ”spindle x” (main spindle, spindle 1, ..)

■ Chucking ID (identification number): Reference to

database.

■ Chuck jaws ID (identification number): Reference to

database.

■ Chuck supplement ID (identification number):

Reference to database.

■ Clamp form (for chuck jaws): Define internal/

external chucking and the level of chuck jaws used

■ Clamping diameter: The diameter at which the

workpiece is clamped. (Workpiece diameter when

clamped externally; inside diameter when internal

clamping is used)

”Tailstock” parameters

■ Sleeve center ID (identification number): Reference

to database.

3.4 Setup Functions

Soft keys

Edit the chucking equipment parameters

Entries in the chucking database – sorted by chuck type

Entries in the chucking database – sorted by chuck ID

number

”Continue” – Define the clamp form

HEIDENHAIN CNC PILOT 4290

37

Page 50

3.4.5 Setting up Machine Dimensions

You can evaluate machine dimensions in the variable

programming of the NC program.

The ”Set machine dimensions” function accounts for

the dimensions 1..9 and the ”configured axes” for

each dimension.

Setting up machine dimensions

Select ”Setting up - Machine dimensions.”

<

3.4 Setup Functions

Enter the machine dimension number

<

Enter the machine dimensions

Enter the values (”Set machine dimension x” dialog

box).

Capturing a single machine dimension

Select the input field

Move the axis to the desired position

Confirm the axis position as machine

dimension (or Y or Z position)

Soft keys

■ Assigns a handwheel to an axis

■ Defines the handwheel interpolation factor

Capturing all machine dimensions

Move the slides to the desired positions

Confirm the axis positions of the slides

as machine dimensions

<

OK – enter the next machine dimension

Cancel – Exit the machine dimension setup

Machine dimensions are managed in machine

parameter 7.

Machine dimensions are given with

respect to the machine zero point.

Switch the machine display

Enter the feed per revolution

Enter the constant surface speed

Enter the M function

Accept the axis position as machine dimension X (or Y or

Z axis)

Accept the axis positions of the slides as machine

dimensions

3 Manual Control and Automatic mode38

Page 51

3.4.6 MeasuringTools

Define the type of tool measurement in machine

parameter 6:

■ 0: Contact with tool

■ 1: Measure with touch probe

■ 2: Measure with measuring optics

MeasuringTools

Position the tool

<

Select ”Setting up - Tool setup – Tool measuring.”

The ”Tool measuring T...” dialog box indicates the

current tool dimensions.

<

Enter the machine dimensions

Enter the dimensions

Find the tool dimensions by touching the

workpiece with the tool

Select the input field ”X”

Touch off the diameter, retract in Z direction

Confirm the diameter as measured

value

Select the Z input field

Touch the face with the tool, then retract in the X

direction

Confirm the Z position of the tool as the

measured value

3.4 Setup Functions

Soft keys

■ Assign a handwheel to an axis

■ Define the handwheel interpolation factor

Switch the machine display

Enter the feed per revolution

Enter the constant surface speed

Measuring tools with the touch probe

for each input field:

Select the X/Z input field

Move the tool tip in X/Z direction to the probe; the

CNC PILOT saves the X/Z dimension

Retract the tool – retract the touch probe

Measuring the tools with measuring optics

For each input field

Select the X/Z input field

Align the tool point in the X/Z direction with the

cross hairs

Accept the value

HEIDENHAIN CNC PILOT 4290

Enter the M function

Accept the X position as measured value X (or Y or Z

position)

■ The entries in the ”Enter measured value” dialog box are

given with respect to the workpiece zero point.

■ The compensation values of the tool are deleted.

■ The measured tool dimensions are entered in the

database.

Continued

39

Page 52

Determining tool-compensation values

Move the tool into position

<

Select ”Setting up - Tool setup – Tool compensation”

<

Assign the handwheel to the X axis – move the tool

by the compensation value

<

Assign the handwheel to the Z axis – move the tool