Page 1

Service Manual

Getinge Ultrasonic

Ultrasonic Cleaning Units

english

Page 2

Content

2

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

Content

General............................................................................. 4

1.1 How to use the Service Manual................................ 4

1.2 Contents of the Service Manual ............................... 4

1.3 Demands on the service staff ................................... 5

1.4 Testing equipment, tools and measuring instruments5

2 Important safety warnings ......................................... 6

3 Organizational details ................................................. 7

3.1 Warranty .................................................................. 7

3.2 Warranty period ....................................................... 7

3.3 Ordering of spare parts ............................................ 7

3.4 How to find out the year of manufacturing ................ 8

4 Product description ..................................................... 9

4.1 Unit features – front view ......................................... 9

4.2 Description operating elements ...............................10

4.3 Technical details .....................................................11

4.4 Operating and display functions ..............................12

4.5 Circuit diagram Getinge Ultrasonic ..........................15

5 Trouble shooting / Table of malfunctions .................. 16

5.1 Table of malfunctions ..............................................17

6 How to open the unit ................................................ 24

6.1 Getinge Ultrasonic 30, 40, 70, 80 ............................24

6.2 Getinge Ultrasonic 60, 100 – 300 ............................25

6.3 How to close the unit / How to mount the bottom

plate ........................................................................25

7 How to remove / replace the turning knobs .............. 26

7.1 How to remove the turning knobs ............................26

7.2 How to mount the turning knobs ..............................27

8 How to replace the PCB control ............................... 28

8.1 Electric connections ................................................28

8.2 How to remove the PCB control ..............................29

8.3 How to mount the PCB control ................................30

9 How to replace the PCB interference filter................ 31

9.1 Getinge Ultrasonic 30 - 40 ......................................31

9.1.1 How to remove the PCB interference filter ...........32

9.1.2 How to mount the PCB interference filter .............33

9.2 Getinge Ultrasonic 60 - 100 ....................................35

9.2.1 How to remove the PCB interference filtern .........36

9.2.2 How to mount the PCB interference filter .............37

Page 3

Content

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

3

9.3 Getinge Ultrasonic 120 - 300 ..................................39

9.3.1 How to remove the PCB interference filter ...........39

9.3.2 How to mount the PCB interference filter .............40

10 How to replace the potentiometer for the cleaning

period / for temperature ......................................... 42

11 How to replace the front panel ............................... 43

12 How to replace the PCB support ........................... 44

13 How to replace the heating .................................... 45

14 Replacement of piezoceramics ............................. 47

15 Replacement of transducer tank ............................ 52

16 Replacement of drain duct ..................................... 55

16.1 How to replace the turning knob drain duct .............55

16.2 How to replace the ball valve ..................................56

17 Replace the handle................................................ 58

18 Putting into operation / Trial run ............................ 59

18.1 How to fill cleaning liquid .........................................59

18.2 Cleaning media .......................................................60

18.3 Heating of the cleaning liquid ..................................60

18.4 Check ultrasound ....................................................60

19 Putting out of operation and disposal .................... 62

20 Contact address .................................................... 62

21 Conclusion ............................................................. 62

Page 4

General

4

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

Safety warnings

Product description

Operation

Trouble shooting

Repair

Putting into

operation / Trial run

Circuit diagrams

Spare parts lists

General

Carefully read the Service Manual before you carry out any

repair works, in particular the Important safety warnings,

section 2.

We assume that the person carrying out the described repair

works is sufficiently educated in the field of safety and

electronics skills. The basic safety instructions are not explicitly

given for each repair work.

We reserve the right to carry out technical modifications on the

units due to advanced development.

Reprints, translations and copying of any kind, even of parts of

the document, are subject to prior written authorization by the

editor.

The copy right remains with the editor.

1.1 How to use the Service Manual

For trouble shooting we recommend to use the table of possible

malfunctions (section 5).

Further useful information on the operation of the unit can be

found in the description of the unit (section 4).

Please observe the important safety warnings (section 2), and

the information on initial operation (section 17).

In case of any further queries Getinge will be glad to assist. For

our technical support and contact address please see the last

page.

1.2 Contents of the Service Manual

Carefully read and observe before you carry out any repair

works

Description of operating elements and unit feature

Instructions on the intended use and operation of the present

unit

Table of malfunctions, possible causes and remedies for the

different unit types (no guarantee on completeness)

Easy-to-follow instructions on the replacement of faulty

components; individual unit types are listed separately where

necessary

Instructions on initial operation / putting into operation, cleaning

media, heating of the cleaning liquid, etc.

Appendix A contains circuit diagrams for each unit type showing

the relevant data

Appendix B contains the spare parts lists, divided into separate

lists for each unit type. The lists indicate the standard spare

parts. Should you require any further components, please

contact the manufacturer.

Page 5

General

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

5

Multimeter

Torque wrench

Wattmeter

Adjustable

interrupting

transformer

ESD protective

measures

Room

Staff

Packing

1.3 Demands on the service staff

The present Service Manual is intended for authorized service

points and specialized service staff.

Legitimate users of the Service Manual are persons who do not

require to be specifically instructed on the risks caused by

electric equipment.

Special knowledge on electric unit and safety-relevant

knowledge are prerequisite for carrying out any repair works on

ultrasonic cleaning units.

1.4 Testing equipment, tools and measuring instruments

All testing and measuring tools and instruments must be

connected to a grounded socket only.

Apart from the standard electromechanical tools the follwoing

measuring and testing equipment is required for carrying out

the measuring and repair works described in the present

Service Manual:

For electric measuring inside the unit, e.g. resistance and

throughline measuring.

Adjusting range up to approx. 100 Nm. For tests and repair

works which require the opening of the transducer system. After

opening, the transducer system must be screwed with the

correct torque (see section Transducer system). The wrong

torque can cause malfunctions and a breakdown of the unit.

For checking the power consumption of the ultrasonic generator

and the heating.

Power 4 Ampere or more. For the separation of the unit from

the mains and for the safe and controlled upward-adjustment of

the mains voltage.

Certain components on the electronic PCB can be damaged

through electrostatic charges. Therefore, it is absolutely

necessary for the service staff to discharge statically before

they touch the electronic PCB and to remain earthed when

handling the component.

The following items are required for arranging an ESD

protected workplace:

ESD work pad; ESD floor surface; Tools

ESD earthing connection from the wrist of the person to the

work pad; ESD shoes

ESD protective bag; ESD boxes / cartons

Page 6

Important safety warnings

6

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

Intended use

Authorized

specialized staff

Check for damage

Placement

Prevention of

electrical accidents

Mains connection

Cleaning liquid

Mains connection

Original spare parts

Exclusion of liability

2 Important safety warnings

Carefully read and observe before inspection and

reoperation of the unit!

The present ultrasonic cleaning unit has been designed for the

treatment of items and liquids only.

Repair and maintenance works which require the unit to be

opened and connected must be carried out by authorized

specialized staff only.

Check the unit and the mains cable for transport damages. In

case of any visible damage do not operate the unit!

Place the unit on a dry and solid surface; ensure that the

workplace is sufficiently ventilated. Keep workplace, unit

housing and operating elements dry. Protect the unit from

entering humidity!

Separate the unit from the mains before you open it.

In order to prevent damages from persons and/or from the unit

all connected electric measuring instruments and the ultrasonic

unit must be connected via an interrupting transformer.

Parts of the ultrasonic generator and the transducer system

carry high-frequency AC voltage during operation.

Due to piezoelectric effects there can be high voltages

produced by exchanging the transducer disks. Earth these

voltages before you touch the transducer disks.

100 – 120 V or 220 – 240 V

1 phase / 1 N / 1 PE shockproof grounded socket

Fill the cleaning tank with a sufficient quantity of a suitable

cleaning liquid before switch-on. Do not use flammable liquids

directly in the cleaning tank: risk of fire and explosion!

For safety reasons, the present unit must be connected to a

correctly grounded socket only. The technical details indicated

on the nameplate must correspond with the available mains

connection details, in particular those of the mains voltage and

the current connected value.

In order to guarantee compliance with the valid safety

regulations and the CE conformity faulty parts must be replaced

by original spare parts only.

The manufacturer cannot be held liable for damages on

persons, on the unit or on the workshop equipment caused by

improper use or wrong repair.

Page 7

Organizational details

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

7

New units

Repair

3 Organizational details

3.1 Warranty

The warranty covers all claims based on material and

manufacturing faults. Excluded from the warranty are:

Transport damages; these must be reported to the

forwarding agent immediately upon detection.

Damages caused by improper use of the unit:

e.g. damages on the transducer tank caused by wrong

cleaning media, cleaning items placed directly on the tank

floor, dry running of the unit, etc.

Damages caused by humidity which has entered the unit

from outside.

Unauthorized repair works on the unit.

Improper use and/or operation against the Operating

Instructions.

Wear and tear; example: the transducer tank is a wear part

with regard to the cavitational erosion around the sound-

giving surfaces.

3.2 Warranty period

The limitation period of warranty claims is 2 years (from the

date of purchase). If no proof of purchase can be produced,

Getinge can find out the date of manufacturing by means of the

serial number (nameplate).

Getinge grant a limitation period of 2 years on all exchange

parts and on any repair works carried out.

Please ensure that all documentation concerning the service

works carried out are safely stored.

3.3 Ordering of spare parts

Getinge guarantee the availability of spare parts according to

the valid regulations over a period of 10 years after production

and sale of a unit have stopped. Standard spare parts will be

available for older units.

For your spare parts order we need to know the following data:

Type of unit

Voltage (115 V or 230 V)

Serial number (nameplate)

Page 8

Organizational details

8

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

A

B

C

3.4 How to find out the year of manufacturing

The year of manufacturing of a unit can be taken from the serial

number indicated on the nameplate.

The serial number is required e.g. for revision purposes, for

spare parts orders and for the determination of the warranty

period.

The first figure (A) – starting from the left – represents the

decade.

The second and third figures (B) – starting from the right –

represent the month.

The first figure (A) – starting from the right – represents the

year.

Example:

S/N 1 0 4 8 0 0 0 4 3

April 2013

Page 9

Product description

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

9

A B C

D

B A D

C

4 Product description

4.1 Unit features – front view

Illustration 4.1.1 Front view Getinge Ultrasonic 30

Maximum filling level indication (indicates the recommended

maximum filling level. This level should not be exceeded even

with immersed cleaning items.

Plastic handles (on Getinge Ultrasonic 30 and larger) for the

safe transportation of the unit, even when heated.

Turning knob for draining the transducer tank (on Getinge

Ultrasonic 30 and larger)

Vertical position: drain open

Horizontal position: drain shut.

Operating elements for the control of the unit functions

description see sections 4.2.

Page 10

Product description

10

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

A

B C D

E

F G H

A

F G E B D

C

H

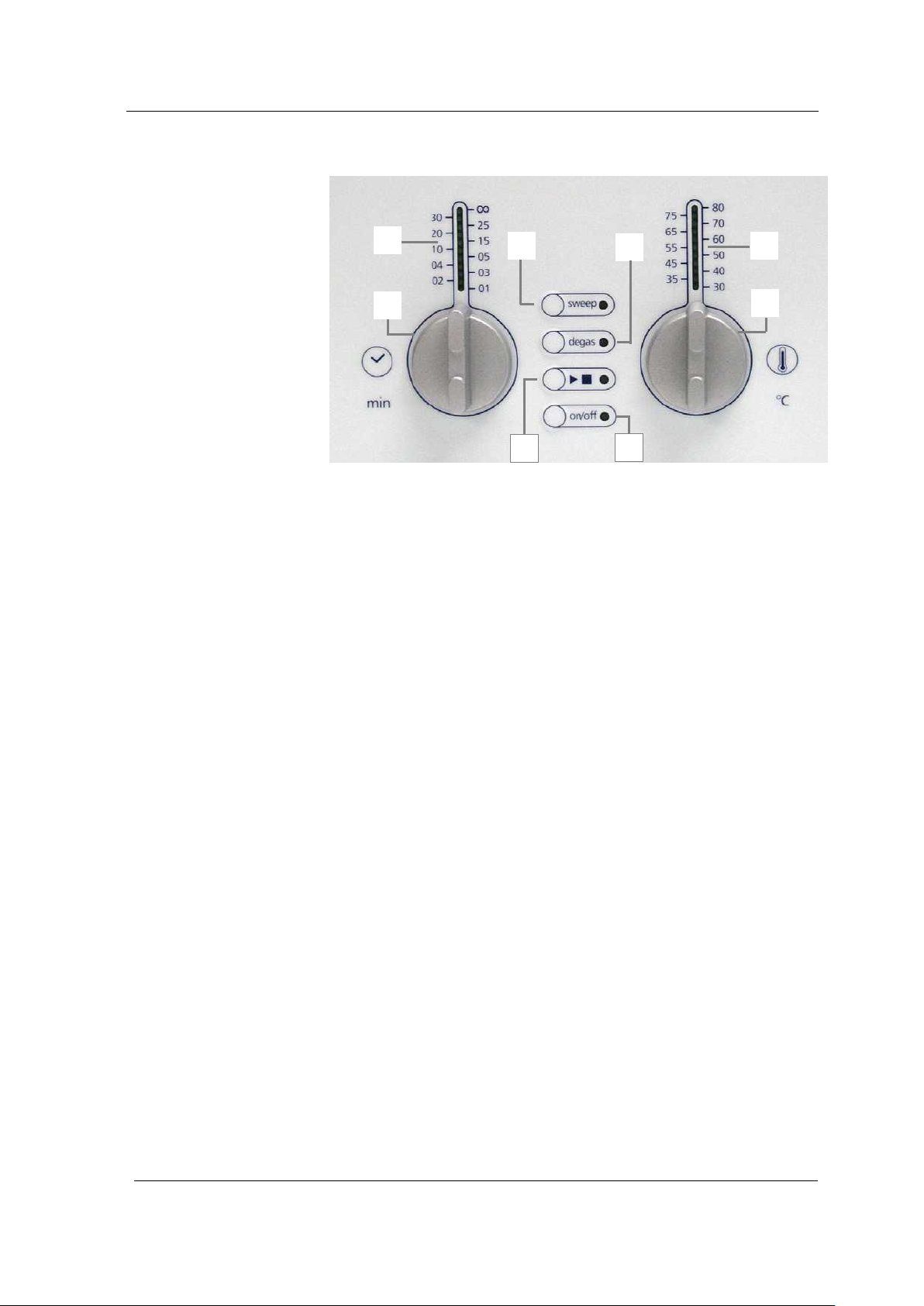

4.2 Description operating elements

Illustration 4.2.1 View operating elements, unit with heating

Turning knob cleaning period * Available options: short-term

operation: 1; 2; 3; 4; 5; 10; 15; 20; 25; 30 min (with automatic

switch-off).

Permanent operation ∞ . Switch-off by hand.

For reasons of safety the unit is automatically switched off after

12 h permanent operation.

LED display cleaning period for set period and remaining

period indication.

Turning knob temperature * on units with heating.

Temperature range adjustable in 5 °C steps between 30 and

80 °C.

LED display temperature on units with heating.

Display of set temperature and actual temperature of the liquid.

Key sweep function for the optimum sound field distribution in

the cleaning bath. Sweep LED.

Kea degas function (by hand and Auto Degas – see Table

4.7) Degas function for the efficient degassing of the cleaning

liquid and for special laboratory cleaning jobs. Degas LED.

Key ultrasonic operation and temperature-controlled

ultrasonic operation. Ultrasound LED

Key on/off for switching the unit on and off.

On/off LED

* setting of the required value: turn clockwise

reset: turn anti-clockwise

Page 11

Product description

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

11

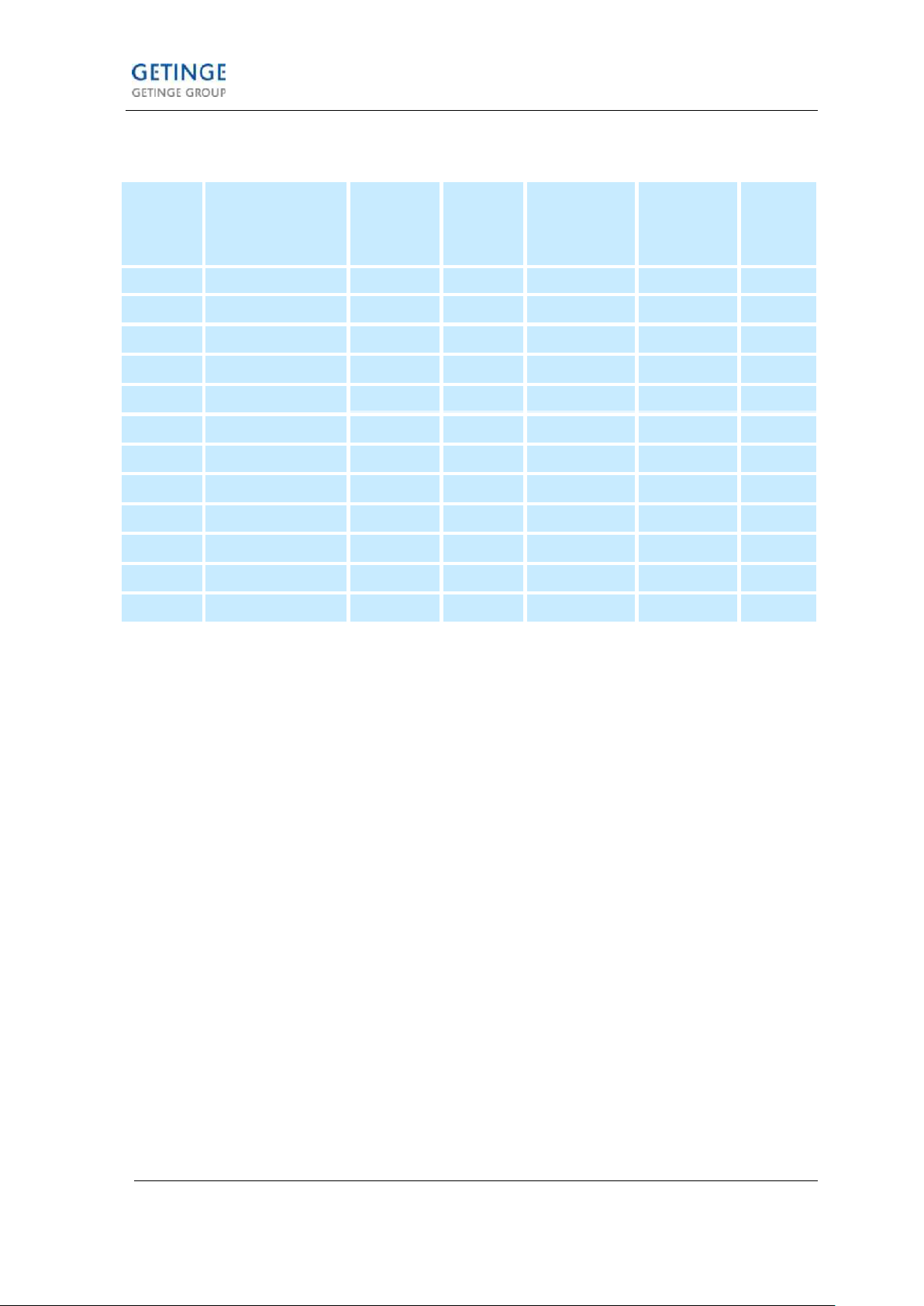

Mains voltage unit

variants

(Vac)

Ultrasoun

d

frequency

(kHz)

Power

consumpti

on total

(W)

Ultrasonic

power RMS

(W)

Ultrasonic

maximum

peak power*

(W)

Heating

power

(W)

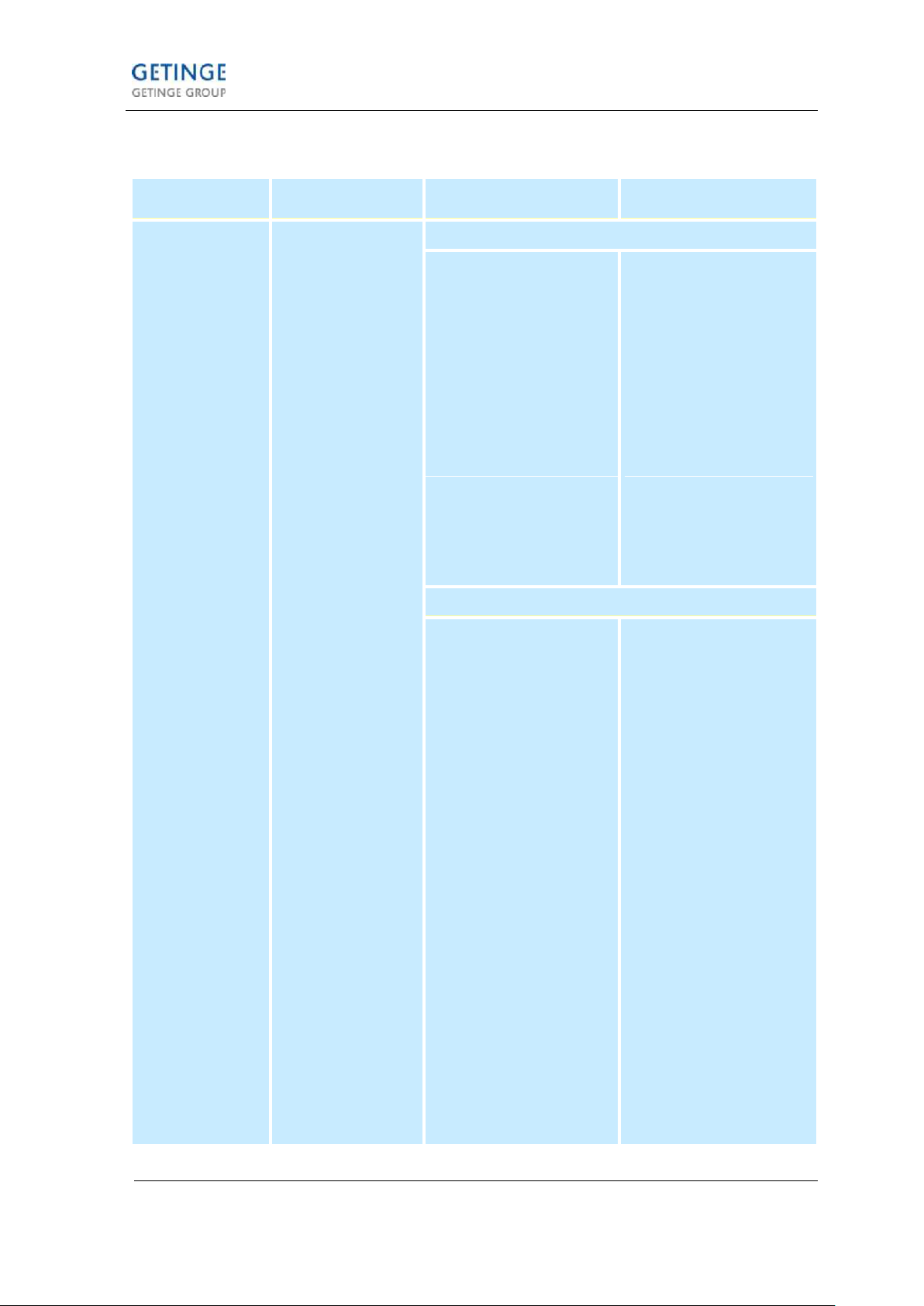

30

100-120 | 220-240

37

280

80

320

200

40

100-120 | 220-240

37

340

140

560

200

60

100-120 | 220-240

37

550

150

600

400

70

100-120 | 220-240

37

750

150

600

600

80

100-120 | 220-240

37

750

150

600

600

90

100-120 | 220-240

37

550

150

600

400

100

100-120 | 220-240

37

550

150

600

400

120

100-120 | 220-240

37

1000

200

800

800

130

100-120 | 220-240

37

1100

300

1200

800

150

100-120 | 220-240

37

300

300

1200

-

180

100-120 | 220-240

37

1000

200

800

800

300

100-120 | 220-240

37

1500

300

1200

1200

4.3 Technical details

*: Impulse sound; 30 – 300: Double half-wave sound. The form of signal has been adapted to the geometry of

the transducer tank. Depending on the form of signal the peak of the ultrasonic power is 4 or 8-fold.

Page 12

Product description

12

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

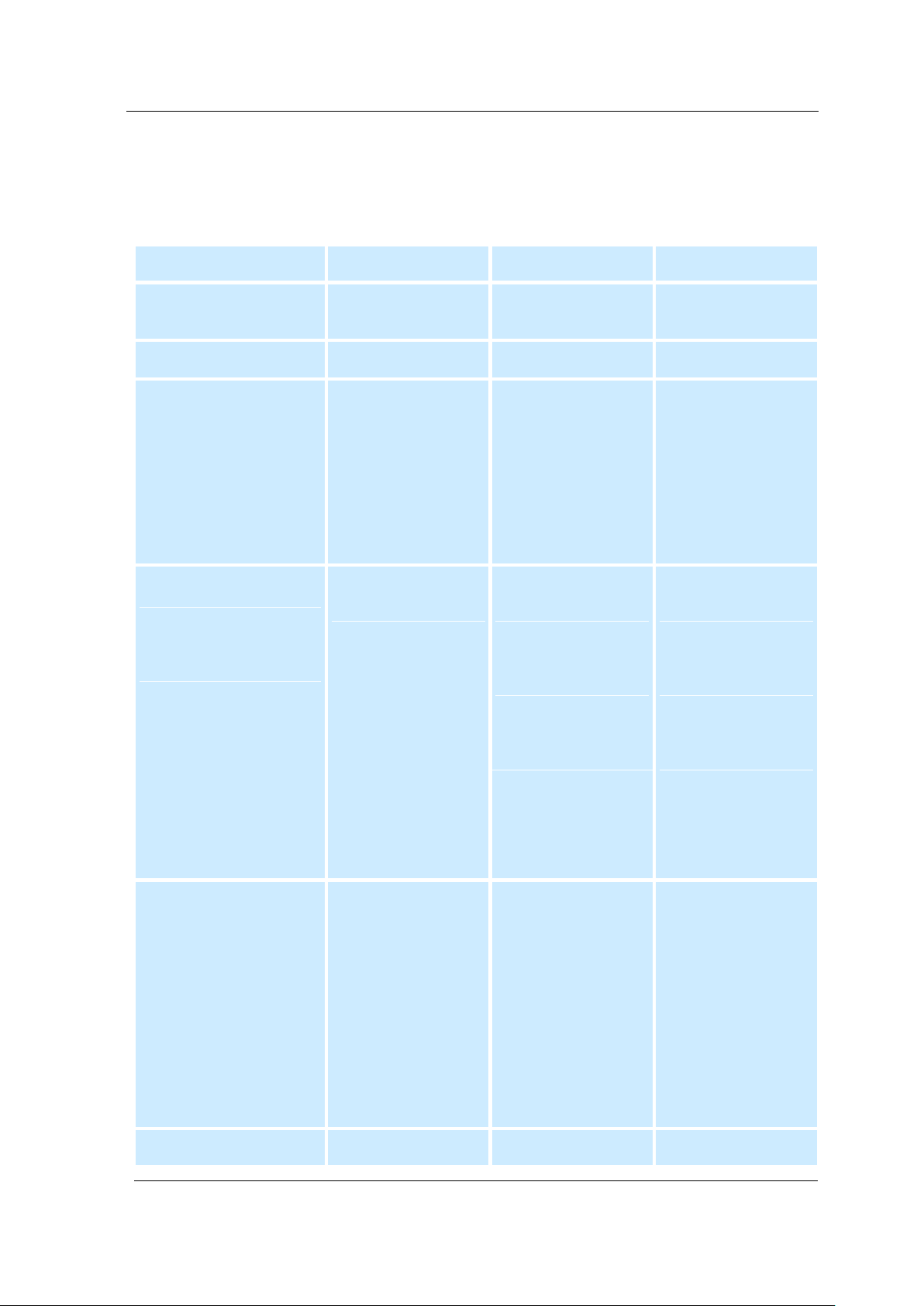

Action

To do

Result

Display

Switch on the unit

press on/off key

unit is ready for

operation

on/off LED is on

Switch off the unit

press on/off key

unit is off

all displays dark

Start the ultrasound

- now -

set the required

period at the turning

knob for cleaning

period

press ►■ key

(ultrasound)

ultrasound operates

LED ultrasound is on

set period is indicated

by LED

LED indicating

remaining period

flashes (only in timer

operating mode)

Start the ultrasound

- temperature-controlled*;

with revolution of cleaning

bath –

* if set temperature >

actual temperature;

only on units with heating

set required period

set temperature at

turning knob

keep key ►■

pressed (> 2 sec.)

heating operates

ultrasound starts

automatically when

the set temperature is

reached

set period of

ultrasonic activity runs

down

LED ultrasound

flashes

LED set period

flashes

LED ultrasound is

turned on when set

temperature is

reached

LED set period is

turned on

LED remaining period

flashes

Stop ultrasound by hand

set required period to

„0“

or

press ►■ key

ultrasound is turned

off

LED ultrasound is

turned off

LED set period is

turned on

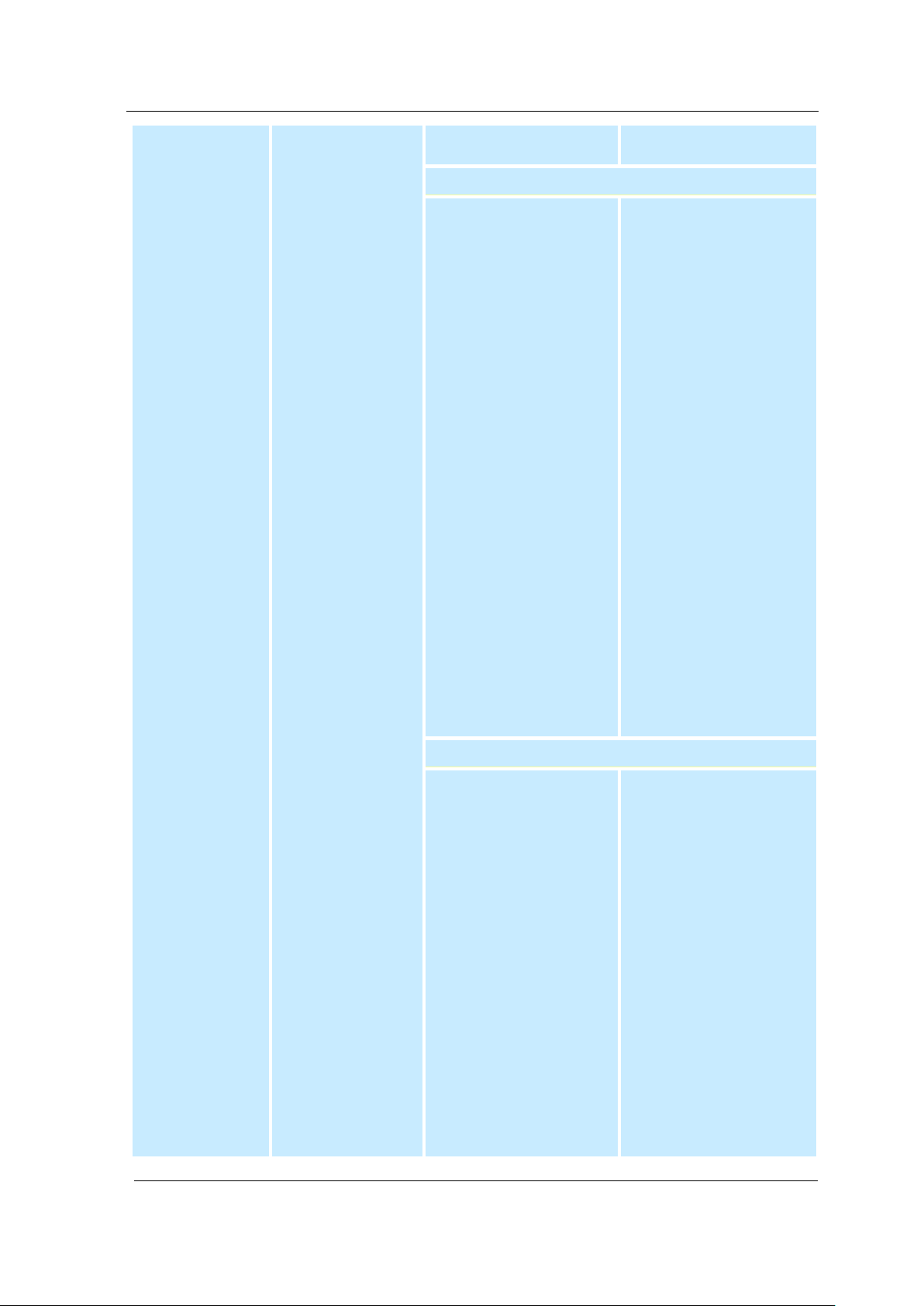

4.4 Operating and display functions

For your information: Specific displays of the unit types Getinge

Ultrasonic 30 - 300 are listed separately.

Page 13

Product description

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

13

Action

To do

Result

Display

Switch on heating*

*only on units with heating

set required

temperature

heating operates

LED set temperature

is turned on

LED actual

temperature flashes

and moves towards

set temperature

When actual = set

temperature only the

LED set temperature

is on

When actual > set

temperature the LED

actual temperature

starts flashing again

Switch off heating by

hand

set temperature to „0“

position

heating switches off

LED actual

temperature flashes

Switch on sweep function*

* Sweep and degas

cannot be operated at the

same time

set the required

period

press ►■ key

press Sweep key

ultrasound operates

in sweep mode

LED ultrasound is

turned on

LED sweep is turned

on

LED set temperature

is turned on

LED remaining period

flashes

Switch on degas function*

* Sweep and Degas

cannot be operated at the

same time

set the required

period

press ►■ key

press Degas key

ultrasound operates

in degas mode

LED degas is turned

on

LED ultrasound is

turned on

Getinge Ultrasonic

30 - 300: LED set

period is turned on

LED remaining period

flashes

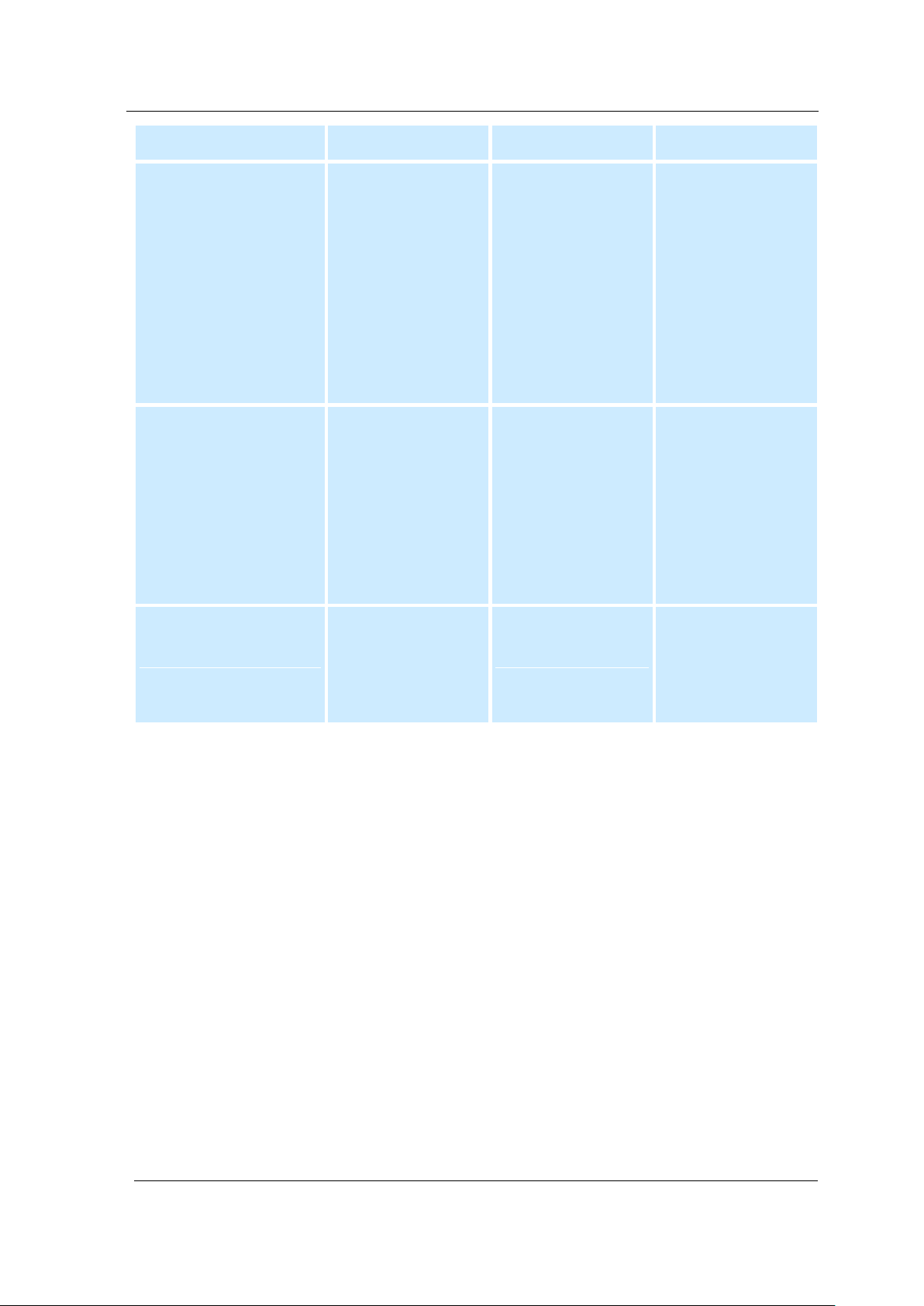

Page 14

Product description

14

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

Action

To do

Result

Display

Switch off sweep-function

press Sweep key

sweep function is

switched off

ultrasound continues

operation in standard

mode

LED sweep is turned

off

LED ultrasound is

turned on

LED set period is

turned on

LED remaining period

flashes

Switch off degas function

press Degas key

Degas function is off

Ultrasound continues

operating in standard

mode

LED degas is turned

off

LED ultrasound is on

LED set temperature

is on

LED remaining period

flashes

Switch on Auto-Degas

function*

* Sweep and Degas

cannot be operated at the

same time

press ►■ key

keep Degas key

pressed (> 2 sec.)

Ultrasound operates

in Auto-Degas mode

for 10 minutes and

switches off

subsequently

LED degas flashes

LED ultrasound is

turned on

Page 15

Product description

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

15

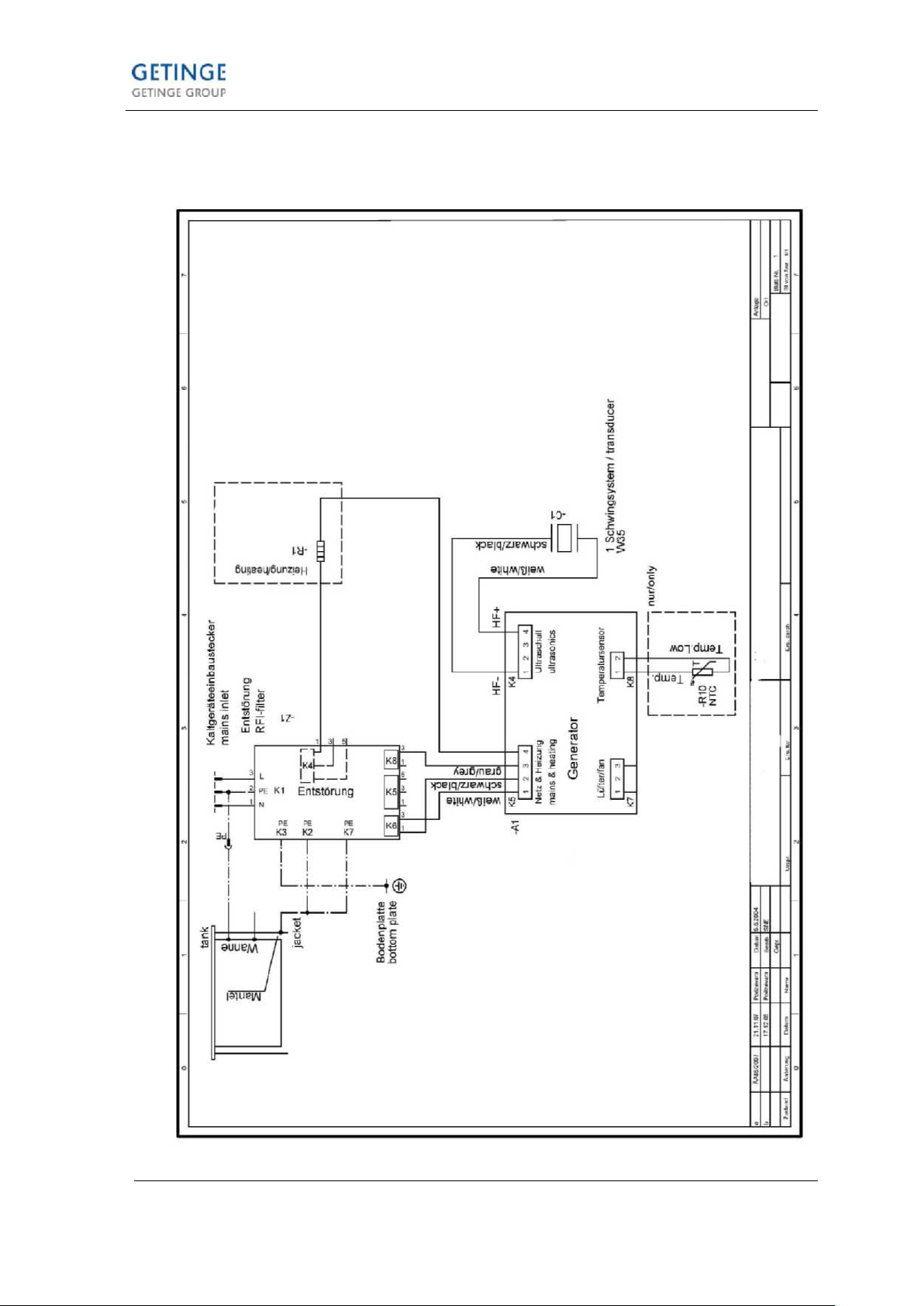

4.5 Circuit diagram Getinge Ultrasonic

Page 16

Trouble shooting / Table of malfunctions

16

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

Improper use

Faulty unit

LED display

malfunction

Ultrasound

malfunction

Temperature

malfunction

5 Trouble shooting / Table of malfunctions

Find out if the malfunction is caused by a fault on the unit or by

improper use. Examples for malfunctions due to improper use:

The cleaning result is not satisfactory:

The cleaning medium, the cleaning temperature or the

duration of the cleaning cycle are not suitable for the

cleaning task.

The cleaning result can also be impaired by a wrong or

insufficient filling level and/or very dirty cleaning liquid.

The unit does not heat up correctly:

For an efficient heating up of the cleaning liquid switch on

the ultrasound (see section 4.5. Start the ultrasound –

temperature-controlled*;with revolution of the cleaning bath)

and use a cover.

Check and find out if the fault is in the heating or in the

ultrasonic system.

Check housing and bottom plate of the unit for any visible

damage and check the tank for leaks before you connect the

unit to an interrupting transformer.

Then connect the unit to an adjustable interrupting transformer

for a functional check. You can easily and safely check the unit

for a short circuit by slowly adjusting the mains voltage upwards

and observing the current consumption. At the same time you

can find out which functions of the unit have broken down.

Various malfunctions are indicated by a flashing LED display:

Getinge Ultrasonic 30 - 300: LED display cleaning period

flashes fast („running light“) / LED display in the ultrasound key

flashes fast:

There is a fault on the PCB control, on the connection between

ultrasound >> transducer system or on the transducer system.

Getinge Ultrasonic 30 - 300: LED display heating temperature

flashes fast („running light“) / LED display in the ultrasound key

flashes fast:

There is a fault in the temperature measuring, e.g. interrupted

connection to temperature gauge or a faulty gauge.

Page 17

Trouble shooting / Table of malfunctions

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

17

5.1 Table of malfunctions

Malfunction

Cause

Measuring

Result >> Action

No unit function:

No ultrasound

and

no heating (on

units with

heating)

and

all LED displays

dark

Broken/interrupted

mains cable

or

mains supply

socket damaged

or

interruption on pcb

interference filter

or

interruption in

connecting cable

PCB interference

filter >> PCB

control

or

fault on PCB

control

1. measure mains supply voltage

Check if there is mains

voltage at input

interference filter.

How to proceed:

Open the unit

(see section 6 )

Mesure the voltage at the

fuses on the input side

(see illustration 5.1.A)

or check the fuse for

throughline with ohmmeter

No mains moltage at

input side of fuses:

Check the mains cable for

damage and check electric

throughline

Check mains supply socket

for damage and check

electric throughline

Action:

Replace faulty parts by

original spare parts

Voltage at input side of

fuses: (see illustration

5.1.A)

Continue with 2.

2. Check fuses on interference filter

Measure mains voltage on

output side of fuses or

check throughline of fuses

Fuses are OK

Continue with 3.

Fuses are faulty:

Check fuse data (see

spare parts list)

Fuses are faulty and fuse

data are wrong:

Mount fuses with correct

data

Fuses are faulty, fuse

data are correct:

There is a short circuit in

the unit (e.g. heating

element; PCB control,

PCB; interference filter).

Check for transport

damage or humidity inside

the unit.

Continue with 5.

Page 18

Trouble shooting / Table of malfunctions

18

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

...

No unit function:

No ultrasound

and

no heating (on

units with

heating)

and

all LED displays

dark

Measuring

Result >> Action

3. Check PCB interference filter for interruption

Measure mains voltage

at output of PCB

interference filter:

How to proceed:

Check if there is mains

voltage between the

contacts of the voltage

supply to the heating

element and of the voltage

supply PCB interference

filter. (See illustration

5.1.B.)

or check fuse through-line

with ohmmeter

4. Check mains voltage

of PCB control

No mains voltage at

output of PCB

interference filter:

There is an electrical fault

on the PCB interference

filter.

Action:

Replace PCB interference

filter by original spare part.

How to proceed:

see section 9

There is mains voltage at

the output of the PCB

interference filter:

There is probably a fault on

the PCB control.

Possible the connecting

cable between PCB

interference filter and PCB

control is interrupted.

4. Check voltage supply from control PCB

Check connecting cable

between PCB

interference filter and

PCB control for

interruption

How to proceed:

Pull off the plug of the

connection wire (from

interference filter) and

measure at the contacts 1

(white) + 2 (black).

No mains voltage:

The connecting cable

between PCB interference

filter and PCB control has

been interrupted.

Action:

Replace complete cable

No mains voltage at

input PCB control:

PCB control is faulty.

Action:

Replace PCB control (see

section 9)

Page 19

Trouble shooting / Table of malfunctions

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

19

...

No unit function:

No ultrasound

and

no heating (on

units with

heating)

and

all LED displays

dark

Measuring

Result >> Action

5. Check unit for short circuit (of fuses on PCB

interference filter faulty, fuse data correct)

Probably there is a short

circuit in the unit (PTC

heating element; PCB

control; PCB interference

filter).

How to proceed:

The individual components

must be checked

separately.

6. check filter PCB for short circuit

How to proceed:

Check for scorchings /

traces of water in the

mains socket

Mount new fuses into PCB

interference filter

Pull off the connecting

cable between PCB

interference elimination

and PCB control,

preferably at the PCB

control.

Separate the supply wire

from the PTC heating

element at the respective

plug contact on the PCB

interference filter.

Connect the unit to the

mains for testing

purposes.

Fuses on PCB

interference filter are

blown again:

Short circuit on PCB

interference filter. Replace

interference filter (see

section 9)

Fuses on PCB

interference filter are not

blown:

PCB interference filter is

OK.

Short circuit is probably in

PTC heating element or

PCB control

Continue with 7.

7. Check heating element for short circuit

Separate the heating

element from the mains

How to proceed:

Separate the supply wire

from the heating element

at the respective plug

contacts on the

interference filter.

Connect the unit to the

mains.

Fuses on the

interference filter are not

blown:

Short circuit in the heating

element. Replace the

heating element (see

section 13)

Fuses on the

interference filter are

blown:

Heating element is OK.

Probably short circuit in

PCB control

Continue with 8

Page 20

Trouble shooting / Table of malfunctions

20

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

...

No unit function:

No ultrasound

and

no heating (on

units with

heating)

and

all LED displays

dark

8. Check PCB control for short circuit

Separate PCB control

from the mains

How to proceed:

Pull off the connecting

cable between PCB

interference filter and PCB

control, preferably at the

plug of the PCB control.

Connect the unit to the

mains.

Fuses on the PCB

interference filter are not

blown:

Short circuit on PCB

control.

Replace PCB control (see

section 8).

Fuses on PCB

interference filter are

blown again:

Check unit for:

loose or wrongly plugged

cables, loose unit

components, entered

humidity.

Malfunction

Cause

Measuring

Result >> Action

No ultrasound

and

Display LEDs for

ultrasound are

flashing in

malfunction

indicating mode

Faulty PCB control

Check voltage supply of PCB control

How to proceed:

Pull off the plug of the

connecting cable (from

PCB interference filter)

and measure at contacts 1

(white) + 2 (black).

No mains voltage:

Action:

Replace complete cable

Check PCB interference

filter and connecting cable

for faults (continue with 3.

and 4)

Mains voltage at input of

PCB control:

PCB control is faulty.

Action:

Replace PCB control (see

section 8)

Page 21

Trouble shooting / Table of malfunctions

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

21

Malfunction

Cause

Measuring

Result >> Action

No ultrasound

and

Display LEDs for

ultrasound are

flashing in

malfunction

indicating mode

Faulty PCB control

Faulty transducer

system

Electric cable to

transducer system

is interrupted

Connection

between the

transducer

systems (if more

than one) is

interrupted

1. Check electric cables of the transducer system

How to proceed:

Check connecting cables

between PCB control and

transducer system with

ohmmeter for throughline.

No electric throughline

can be measured:

Replace cable

Electric throughline can

be measured:

Continue with 2.

2. Check transducer system visually

How to proceed:

Carry out the following

visual checks:

Check transducer system

for damages, scorchings,

tears of the PXE disks,

poor connections between

the electric cables

Visible faults in the

transducer system:

Repair the transducer

system (see section 14

Replacement of

piezoceramics)

No visible faults in the

transducer system:

Probably faulty PCB

control.

How to proceed:

Continue with replacement

of PCB control (see section

8)

3. Replace PCB control

Very probably faulty PCB

control.

How to proceed:

Continue with replacement

of PCB control (see section

8).

Malfunction

Cause

Measuring

Result >> Action

Heating element

does not heat up

or

Heating element

heats up

permanenty

(Set value LED

for heating is

turned on)

Interruption in the

heating supply

cable

Faulty triac on

PCB control

1. Check heating supply cable

Measure mains voltage

at output of PCB

interference filter

How to proceed:

Check if there is mains

voltage between the

respective contacts of the

voltage supply to the

heating element

No mains voltage:

Check PCB interference

filter for interruption.

Mains voltage:

Probably the triac on the

PCB control is faulty

How to proceed:

Continue with 2

Page 22

Trouble shooting / Table of malfunctions

22

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

2. Check triac on PCB control

How to proceed:

Check triac for short circuit

with ohmmeter (see

illustration 5.4.B)

Short circuit on triac

How to proceed:

Continue with replacement

of PCB control (see section

8) or with repair of triac.

Heating does not

heat up

and

LEDs for heating

are flashing in

malfunction

indicating mode

Faulty temperature

sensor

Faulty supply

cable temperature

sensor

Check temperature sensor and supply cable

Measure resistance of the

temperature sensor with

ohmmeter:

At 25 °C approx. 10 kOhm

(see illustration 5.3.A)

Faulty temperature

sensor:

If the measured resistance

is not within this range the

component is faulty.

How to proceed:

Continue with replacement

of temperature sensor

Malfunction

Cause

Measuring

Result >> Action

No unit function:

and

LED displys for

heating and

ultrasound are

flashing in

malfunction

indicating mode

Fault in the

programme

or

Faulty PCB control

Check PCB control

How to proceed:

Switch unit off and on

again

Malfunction indication

continues:

Continue with repalcement

of PCB control (see

section 8)

Unit function OK, no

malfunction indicated:

Malfunction has been

remedied

Measuring points

interference filter

Getinge Ultrasonic

30-300

A B C

Illustration 5.2. Measuring points PCB interference filter

Page 23

Trouble shooting / Table of malfunctions

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

23

Measuring points

PCB control

temperature sensor A B

A

A

Illustration 5.3. Measuring points PCB control

Measuring points temperature sensor. For measuring pull off

contact. At 25 °C approx. 10 kOhm

Measuring points triac (outside connections). At a measured

resistance below 100 Ohm the triac is faulty.

Illustration 5.4. Measuring points triac (here PCB control S10H)

Page 24

How to open the unit

24

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

Live parts inside the unit.

Risk of electrocution!

Opening of the unit by authorized specialized staff only.

Always pull the mains plug before you open the unit.

For checks that require the unit to be connected use a

mains interrupting transformer.

DANGER

Fastening of bottom

plate

How to proceed

A

B B B

6 How to open the unit

6.1 Getinge Ultrasonic 30, 40, 70, 80

The bottom plate with the unit feet is fastened to the unit

housing by clips. In addition, the bottom plate is screwed to the

cooling body of the PCB control by two screws.

1. Pul the mains plug!

2. Place the unit onto the workplace upside down.

3. Unscrew the two visible recessed head screws

(illustration 6.2.A). Not on S 450 H and S 900 H.

4. On several unit types there are further fastening screws that

need to be loosened (illustration 6.2.B).

5. Carefully lever the bottom plate loose with a screw driver or

a similar tool (illustration 6.1.).

Illustration 6.2. Unscrew the two recessed head screws

Page 25

How to open the unit

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

25

Fastening of bottom

plate

How to proceed

2x

4x

6.2 Getinge Ultrasonic 60, 100 – 300

The bottom plate is screwed to the unit through the unit feet. In

addition, the bottom plate is screwed to the cooling body of the

PCB control with 2 screws.

1. Pull the mains plug!

2. Place the unit onto the workplace upside down.

3. Unscrew the 4 unit feet.

4. Unscrew the two visible recessed head screws.

5. Carefully lever the bottom plate loose with a screw driver or

a similar tool illustration 6.1.).

Ilustration 6.3. Unscrew the two recessed head screws and the 4 unit

feet

6.3 How to close the unit / How to mount the bottom plate

Follow the instructions on opening the unit in reverse order.

Ensure that all electric wires are connected correctly and no

electric wires are pinched by the bottom plate before you close

the unit.

Page 26

How to remove / replace the turning knobs

26

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

Fastening

Without opening the

unit

How to proceed

A

B

7 How to remove / replace the turning knobs

The turning knobs are plugged onto the unit front. The turning

knobs are connected to the relevant potentiometer on the PCB

control by a shaft.

7.1 How to remove the turning knobs

There are two ways to remove the turning knobs:

This method is useful if only the turning knobs are to be

replaced. However, when pulling the turning knobs off, it is

possible that the shaft (illustration. 7.2.A.) slides out of the shell

of the turning knob (illustration 7.4.B.) and remains connected

to the potentiometer on the PCB control. If this happens the

shaft can be pulled out with pliers or side nippers.

Pull off the turning knob exactly square to the unit.

Illustration 7.1. Pull off the turning knob

Illustration 7.2. View turning knob

Page 27

How to remove / replace the turning knobs

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

27

With opening the unit

Proceed as follows

How to proceed

A

B

This method is useful if the unit must be opened anyway, e.g.

for repair purposes (exchange of PCB control).

1. Pull the mains plug!

2. Open the unit as described in section 6.

3. Push the shaft of the turning knob out from inside (A) and

pull the knob off from outside at the same time (B).

Illustration 7.3. Pull off the turning knob with opened unit.

7.2 How to mount the turning knobs

Put the turning knob square onto the unit. Ensure that the

turning knob is positioned correctly: The cog of the turning knob

(A) must correspond with the stop position on the PCB support

(B).

Page 28

How to replace the PCB control

28

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

NOTE

A B A

D

C

B

Illustration 7.4. Put on the turning knob

8 How to replace the PCB control

The PCB control is clipped into the unit. It can be removed

without any tool.

Some of the electronic components on the PCB control are

sensitive against electrostatic charging. These charges may

destroy the component. Therefore, for the correct handling of

the PCB control please observe the instructions on ESD

protection (section 1.4).

8.1 Electric connections

Illustration 8.1. Connections PCB control

Page 29

How to replace the PCB control

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

29

A

B C D

How to proceed

A

A

A

Connection temperature gauge

Connection fan (on S120H and larger)

Voltage supply PCB (mains voltage)

Connection transducer system(s) (high frequency)

8.2 How to remove the PCB control

1. Open the unit as described in section 6.

2. Remove the turning knobs as described in section 7.1.

3. Carefully bend the two clips (illustration 8.2.A) of the PCB

support upwards and remove the PCB control by tilting it to

the inside.

4. Separate the electric plug connections and take the PCB

control out of the unit.

Note: All plug connections are coded and cannot be

interchanged.

Illustration 8.2. Bend the two clips upwards …

Abb. 8.3. … and tilt the PCB control to the inside

Page 30

How to replace the PCB control

30

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

How to proceed

A

B C D

C

B

D

A

8.3 How to mount the PCB control

1. Connect the electric plug connections (see illustrations 8.1.

and 8.4.). Note: All plug connections are coded and cannot

be interchanged when mounted.

2. Place the PCB control into the groove of the lower fixation of

the PCB support (illustration 8.3.A.). The horizontal

adjustment of the component depends on the lighted diodes

on the PCB control and the recesses in the PCB support

and the potentiometers.

3. Clip the correctly positioned PCB control into the upper

fastening clips (see illustration 8.2. / 8.3.).

4. Mount the turning knobs as described in section 7.2.

5. Close the bottom plate as described in section 6.4.

Illustration 8.4. Electric connections on PCB control

Connection for temperature gauge

Connection for fan (on S120H and larger)

Voltage supply PCB / voltage supply heating element(s)

(mains voltage)

Connections transducer system(s) (high frequency)

Page 31

How to replace the PCB interference filter

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

31

9 How to replace the PCB interference filter

9.1 Getinge Ultrasonic 30 - 40

The PCB interference filter is screwed to the back of the unit.

The mains input socket is soldered to the PCB interference filter

and must be replaced with the PCB.

Illustration 9.4. Circuit diagram version 11.2005 and later

Illustration 9.5. block diagram

Page 32

How to replace the PCB interference filter

32

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

How to proceed

B

A

C

A

A

9.1.1 How to remove the PCB interference filter

Illustration 9.6. Fastening of the PCB interference filter

1. Open the unit as described in section 6.

2. Mark the electric plug connections (to avoid interchanging

when they are reconnected) and loosen them.

3. Pull both two-part plastic pins (illustration 9.6.A) that arrest

the mains input socket. For this, lever the pins out of the

housing, e.g. with a knife (illustration 9.7.A).

4. Unscrew the two screws (illustration 9.6.B) that fasten the

PCB interference filter to the back of the unit.

5. Take the PCB interference filter out of the unit.

Illustration 9.7. Removal of the plastic pins

Page 33

How to replace the PCB interference filter

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

33

How to proceed

A

B

9.1.2 How to mount the PCB interference filter

When ordered as spare part only the new version of the PCB

interference filter is delivered (manufactured in 2006 or later). If

an older version had been mounted in the unit please note that

the connections for the heating element(s) have been modified.

1. Position the PCB in the unit and fasten it to the back of the

unit with the two screws (illustration 9.6.B).

2. Insert the two plastic pins (illustration 9.7.A) that arrest the

mains input socket. Insert the inner part first (illustration

9.8.A), then insert the outer part (illustration 9.8.).

3. Connect the electric plug connections to the plug contacts.

Ensure that all connections are plugged correctly.

If the unit had been fitted with an old PCB interference filter,

it is now recommendable to connect the heating elements

directly to the PCB interference filter (illustration 9.9.B and

D).

4. Check again if all contacts and positioning of PCB are

correct.

5. Close the bottom plate as described in section 6.4.

Illustration 9.8. Insert plastic pins

Page 34

How to replace the PCB interference filter

34

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

A B C

D

A

B C D

Illustration 9.9. Electric connections for 1 heating element (e.g. S 30

H)

Voltage supply for PCB control (phase – black).

Voltage supply for PCB control (zero – white).

Connection for heating control (grey).

Connection for heating control (white).

Page 35

How to replace the PCB interference filter

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

35

9.2 Getinge Ultrasonic 60 - 100

The PCB interference filter is screwed to the back of the unit.

The mains input socket is soldered to the PCB interference filter

and must be replaced with the PCB.

Illustration 9.13 Circuit diagram version of 11.2005 or later

Illustration 9.14. block diagram

Page 36

How to replace the PCB interference filter

36

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

How to proceed

B

A

C

A

A

9.2.1 How to remove the PCB interference filtern

Illustration 9.15. Fastening of PCB interference filter

1. Open the unit as described in section 6.

2. Mark the electric plug connections (to avoid interchanging

when they are reconnected) and loosen them.

3. Pull both two-part plastic pins (illustration 9.15.A) that arrest

the mains input socket. For this, lever the pins out of the

housing, e.g. with a knife (illustration 9.16.A).

4. Unscrew the two screws (illustration 9.15.B) that fasten the

PCB interference filter to the back of the unit.

5. Take the PCB interference filter out of the unit.

Illustration 9.16. Removal of the plastic pins

Page 37

How to replace the PCB interference filter

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

37

How to proceed

A

B

9.2.2 How to mount the PCB interference filter

When ordered as spare part only the new version of the PCB

interference filter is delivered (manufactured in 2006 or later). If

an older version had been mounted in the unit please note that

the connections for the heating element(s) have been modified.

1. Position the PCB in the unit and fasten it to the back of the

unit with the two screws (illustration 9.15. B).

2. Insert the two plastic pins (illustration 9.16.A) that arrest the

mains input socket. Insert the inner part first (illustration

9.17.A), then insert the outer part (illustration 9.17.B).

3. Connect the electric plug connections to the plug contacts.

Ensure that all connections are plugged correctly. If the unit

had beed fitted with an old PCB interference filter, it is now

recommendable to connect the heating elements directly to

the PCB interference filter (illustration 9.18. / illustration

9.19.B and D).

4. Check again if all contacts and positioning of PCB are

correct.

5. Close the bottom plate as described in section 6.4.

Illustration 9.17. Insert plastic pins

Page 38

How to replace the PCB interference filter

38

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

A

B C D

A

B C D

D

Illustration 9.18. Electric connections with 2 heating elements

Voltage supply for PCB control (black/white). Polarization of the

cables is irrelevant.

Connections for 1 – 3 heating elements. All contacts are

bridged and have the same potential: One cable per heating

element is connected.

Connections for heating control (black/grey). Polarization of the

cables is irrelevant.

Connections for 1 – 3 heating elements (underneath the PCB).

All contacts are bridged and have the same potential: One

cable per heating element is connected.

Illustration 9.19. Electric connections with 2 heating elements

Page 39

How to replace the PCB interference filter

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

39

How to proceed

B A C

9.3 Getinge Ultrasonic 120 - 300

The PCB interference filter is screwed to the back of the unit.

The mains input socket is soldered to the PCB interference filter

and must be replaced with the PCB.

9.3.1 How to remove the PCB interference filter

Illustration 9.21. Fastening of PCB interference filter

1. Open the unit as described in section 6.

2. Mark the electric plug connections (to avoid interchanging

when they are reconnected) and loosen them.

3. Pull both two-part plastic pins (illustration 9.21.A) that arrest

the mains input socket. For this, lever the pins out of the

housing, e.g. with a knife (illustration 9.22.A).

4. Unscrew the two screws (illustration 9.21.B) that fasten the

PCB interference filter to the back of the unit.

5. Take the PCB interference filter out of the unit.

Page 40

How to replace the PCB interference filter

40

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

How to proceed

A

A

A

B

Illustration 9.22. Removal of the plastic pins

9.3.2 How to mount the PCB interference filter

When ordered as spare part only the new version of the PCB

interference filter is delivered (manufactured in 2006 or later). If

an older version had been mounted in the unit please note that

the connections for the heating element(s) have been modified.

1. Position the PCB in the unit and fasten it to the back of the

unit with the two screws (illustration 9.21.B).

2. Insert the two plastic pins (illustration 9.22.A) that arrest the

mains input socket. Insert the inner part first (illustration

9.23.A), then insert the outer part (illustration 9.23.B).

3. Connect the electric plug connections to the plug contacts.

Ensure that all connections are plugged correctly.

If the unit had been fitted with an old PCB interference filter,

it is now recommendable to connect the heating elements

directly to the PCB interference filter (illustration 9.31.B and

D).

4. Check again if all contacts and positioning of PCB are

correct.

5. Close the bottom plate as described in section 6.4.

Illustration 9.23. Mount plastic pins

Page 41

How to replace the PCB interference filter

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

41

A

B

C

D

A B C

D

Illustration 9.24. Electric connections with 4 heating elements

Voltage supply for PCB control (black/white). Polarization of

the cables is irrelevant.

Connections for up to 6 heating elements. All contacts are

bridged and have the same potential: One cable per heating

element is connected.

Connections for heating control (black/grey). Polarization of

the cables is irrelevant.

Connections for up to 6 heating elements. All contacts are

bridged and have the same potential: One cable per heating

element is connected.

Page 42

How to replace the potentiometer for the cleaning period / for temperature

42

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

Cause of breakdown

How to proceed

10 How to replace the potentiometer for the

cleaning period / for temperature

Setting of the cleaning period and the temperature is carried out

via potentiometer which are soldered to the PCB control.

A breakdown can be caused by heavy mechanical forces such

as shock or transport damages.

To replace the component it is necessary to open the bottom

plate and to take out the PCB control. Proceed as follows:

1. Open the unit as described in section 6.

2. Pull off the turning knob as described in section 7.

3. Remove the PCB control as described in section 7.

4. Carefully unsolder the faulty potentiometer (soldering points

see illustration 10.1.).

5. Position the new potentiometer on the 4 soldering points

and solder it. Coding by 2 plastic pins at potentiometer.

6. Mount the PCB control as described in section 8.1.

7. Mount the turning knob as described in section 7.2.

8. Mount the bottom plate; close the unit. Ensure that all plug

contacts are correctly plugged and that no cables are

pinched.

Illustration 10.1. Soldering points for potentiometer

Page 43

How to replace the front panel

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

43

How to proceed

11 How to replace the front panel

The front panel consists of adhesive foil. There is no further

adhesive necessary.

The unit does not require to be opened.

To replace the front panel proceed as follows:

1. Pull off the turning knobs as described in section 7.

2. Carefully pull off the front panel (see illustration 11.1.).

3. Put on the new adhesive front panel.

4. Mount the turning knobs.

Illustration 11.1. Pull off the front panel. (Illustration with open unit)

Page 44

How to replace the PCB support

44

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

Cause of breakdown

Consequence

How to proceed

12 How to replace the PCB support

The PCB support fastens the PCB control in the unit.

The plastic material of this component can break by mechanical

forces, e.g. shock, or due to transport damages.

The operating keys no longer operate perfectly.

1. Open the unit as described in section 6.

2. Pull off the turning knob as described in section 7.

3. Remove the PCB control as described in section 8.

5. Carefully pull off the front panel (see illustration 11.1.).

4. Take out the faulty PCB support, remove it upwards (see

illustration 12.1.).

5. Push the new PCB support downwards into the housing.

6. Remount the front panel.

7. Mount the PCB control as described in section 8.

8. Mount the turning knob as described in section 7.1.

9. Mount the bottom plate; close the unit. Ensure that all plug

contacts are plugged correctly and that no cable is pinched.

Illustration 12.1. Pull out / push the PCB support vertically into the

housing

Page 45

How to replace the heating

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

45

Cause of breakdown

Consequence

Exchange of

component

How to proceed

13 How to replace the heating

The PTC heating element is safe to run dry. If the level of the

liquid falls below the position of the heating element, it

automatically reduces the current consumption and thereby

reduces the heating energy.

The performance of the heating element does not change

during its service life. The only possible cause of a breakdown

of this type of heating is a short circuit in the component

(humidity, faulty insulation, etc.)

No function:

In most cases the fault current breaker or the fuse automatic of

the relevant socket is released.

The fuses on the interference filter are faulty.

The aluminum casing of the heating element is pushed into to

supporting rails and secured against displacement with silicone.

On many units the heating element can be replaced without

removal of the transducer tank tank.

Exceptions: Getinge Ultrasonic 60, 100, 120, 180; 300. On

these units the transducer tank must be removed first as

described in section 15.

On all other units proceed as follows:

1. Open the unit as described in section 6.

2. Find the faulty heating elements (if there are more than one

heating element), e.g. by separately connecting the

individual heating elements to the voltage supply. Caution:

in addition to the electric supply cable to the heating

element, the earthing must be provided.

3. Loosen the connecting cables from the faulty heating

element.

4. Cut the silicone fixation (which secures the heating element

against displacement) in the area between the support rails

and the heating element see illustration 13.1.A / 13.2.A /

13.3.A.

5. Push the aluminum profile of the heating element

horizontally out of the guiding rails, e.g. with a large fork

wrench, a wood block, etc. and a plastic hammer.

6. Use a file to round off the two edges of the aluminum profile

of the new heating element where it will enter the supporting

rails.

7. Carefully push the heating element into the supporting rails.

8. Secure the heating element against displacement with

silicone.

Page 46

How to replace the heating

46

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

Removed tank

Getinge Ultrasonic

30-300

A B B

Tank unremoved

Getinge Ultrasonic

30-300

B

C

A

B C A

Illustration 13.1. Transducer tank removed, with horizontally mounted

heating element. Broken lines: cut the silicone fixation (A). Push the

heating element out of the support rails as indicated by the arrows.

Cut the silicone fixation (A) with a knife.

Push the heating element in direction (B) out of the supporting

rails.

Prepare the new heating element: The new heating element

can be pushed in more easily if the edges of the aluminum

profile have been rounded off with a file.

Insert the new heating element (position C) into the supporting

rails. Push it into the supporting rails, be careful not to jam the

heating element. Then secure against displacement with

silicone.

Illustration 13.2. Transducer tank unremoved, with horizontally

mounted heating element. Broken line: cut the silicone to remove.

Page 47

Replacement of piezoceramics

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

47

Cause of breakdown

Trouble shooting

14 Replacement of piezoceramics

The piezoceramics must be replaced if one or more of the disks

are torn or damaged by scorching.

The transducer system should be opened only when all other

possible causes of a malfunction have been checked and if

both the know-how and the required tools are available.

The piezoceramics are selected capacitively in each unit and

are mounted in full sets only. This means that all piezoceramics

in one transducer system must show the exact electric

behaviour in order to guarantee a homogeneous ultrasonic

performance of the transducer system. The consequence of an

asymmetric charge of the transducer systems would be a

higher risk of breakdown and an increased cavitational erosion

on one side of the tank. (This does not apply to units with a

single transducer system.)

Therefore, all transducer disks should be replaced even if only

individual piezoceramics are faulty. Getinge deliver preselected

sets of piezoceramics.

Piezoceramics can be damaged for different reasons (mostly

tears): e.g. by heavy cleaning items put directly onto the tank

floor, excessive bath temperatures with intensive ultrasonic

operation (> 85 °C).

High relative humidity of air or liquid inside can cause

scorchings on and inside the transducer system.

Illustration 14.1. Torn and broken piezoceramics

In some cases torn disks or scorchings can be visible without

opening the unit. However, to make sure it is necessary to open

and examine the piezoceramics and the insulating duct.

Page 48

Replacement of piezoceramics

48

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

Tool

Electric load

How to open the

transducer system

It is possible that torn piezoceramics remain undetected,

because output, transducer performance and current diagram

are normal.

To carry out this repair work a torque wrench is indispensable!

Caution! Risk of electrocution due to high amount of electricity

on the piezoceramics!

The piezoceramic is charged with a high amount of electricity

when the transducer system is opened or tightened. This can

be branched off by short circuiting between two terminal lugs,

e.g. with a screw driver. For the same reason, also short circuit

the plug contacts of the electric cables of the transducer

system.

The electric charge is also built up by temperature changes,

e.g. cooling of a piezoceramic.

Do not touch charged piezoceramics!

Replace faulty piezoceramics as follows:

1. Place the unit upside down on a solid surface and secure it

against displacement (e.g. with screw clamps and wood

ledges).

2. Open the unit as described in section 6.

3. Open the transducer system screw(s) with the torque

wrench.

Caution! Do not tear the transducer system by jamming the

torque wrench.

The torque wrench must be held vertically to the transducer

system during the complete process of unscrewing. The

power given to the handle of the tool must be exactly

countered by the hand that centers the tool (see illustration

14.2.).

4. Check each transducer disk for hair cracks and scorchings,

check the insulating sleeves for scorchings. Always

exchange the aluminum washers when you open the

system.

Page 49

Replacement of piezoceramics

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

49

How to assemble the

transducer system

For assembly of the transducer system ensure that all contact

surfaces are clean.

The transducer disks mus be poled correctly. Observe the

markings on the piezoceramics see illustration 14.3. and 14.4.:

The marking must always point to the plus connection of the

transducer system.

1. Put a drop of Loctite or similar onto the thread of the

coupling piece (to lock the screw).

2. Assemble the individual parts of the transducer system

exactly as shown in the illustration.

3. Important! The black markings must point to the plus

terminal lug.

4. Screw in the transducer system screw and fix it with the

torque wrench.

Systems with 1 piezoceramic (E35) at 46 Nm.

Systems with 2 piezoceramics (W35) at 58 Nm.

Caution: The transducer disk is charged with electricity

when the transducer system screw is tightened. Branch off

the electric charge by short circuiting between two terminal

lugs, e.g. with a screw driver.

Illustration 14.2. Always hold the torque wrench vertically. Do not tilt

the tool!

Page 50

Replacement of piezoceramics

50

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

Structure of

transducer system

with 2 piezoceramics

(W 35)

A B

C

D E F

G

A E F C B

E

D

Illustration 14.4. Transducer system with 2 piezoceramics

Pressure piece

Terminal lug minus connection

Piezoceramic

Terminal lug plus connection

Aluminum washer

Aluminum coupling piece

Insulating disk

Page 51

Replacement of piezoceramics

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

51

Fig 7

transducer system scew

pressure piece

insulating duct

terminal lug "-"

insulat. disk

terminal lug "+"

PXE transducer disk

aluminum washer

coupling piece

PXE transducer disk

aluminum washer

M8

M10

M 10

M 8

W 35 E 35

Illustration 14.5.

on the left: structure of transducer system with 2 piezoceramics

on the right: structure of transducer system with 1 piezoceramic

Page 52

Replacement of transducer tank

52

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

Cavitational erosion

15 Replacement of transducer tank

If the tank floor is heavily damaged by cavitational erosion or

due to leaks the tank must be replaced.

The transducer tank is a wear part due to the cavitational

erosion around the sound-giving surfaces. This process is

increased by improper use (aggressive cleaning media,

cleaning items put directly on the tank floor, deposits and

remains on the tank floor, etc.).

Illustration 15.1. Heavy cavitational erosion at the spot where the

transducer system is fixed

Illustration 15.2. Leaking tank floor with traces of liquid

Page 53

Replacement of transducer tank

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

53

Tank complete with

transducer system

Tank without

transducer system

How to proceed

There are two ways to replace the transducer tank:

Replacement by a complete transducer tank with mounted

transducer system (and heating, if required). We recommend to

use a complete tank if the transducer system is damaged and if

you do not have the necessary know-how for a replacement of

piezoceramics.

Replacement by a preassembled tank with coupling piece(s)

and the support for the heating element(s), but without

transducer system. We recommend to use the preassembled

tank if the transducer system on the old tank is without fault and

can be mounted on the new tank. For this you need a torque

wrench. We recommend to carry out this repair only if you have

the required know-how for replacing piezoceramics.

For instructions on the replacement of the transducer system

and / or of the piezoceramics please see section 14.

1. Place the unit upside down on a solid workplace.

2. Open the unit as described in section 6.

3. On units with heating: Interrupt the electric supply cables to

the heating(s) and separate the temperature sensor from

the unit.

Caution! Mark all electric cables to avoid interchanging

when you assemble the unit: risk of damage.

4. On units with drain duct: Loosen the screw connections of

the drain duct. Note: The screw connections are secured

with Loctite 586. The screw connections can be loosened

more easily after heating the duct in the threaded area with

a hot air fan (see section 16).

5. Remove the transducer tank from the housing:

Carefully heat the tank edge around the sealing e.g. with a

hot air fan to make the sealing material flexible (see

illustration 15.3.A). Caution! The handles can be damaged

by hot temperatures.

6. Cut the sealing between the tank edge and the housing with

a narrow and flexible knife (see illustration 15.4.A.).

7. Carefully lever the tank out of the housing; cut the sealing

further with the knife if necessary; use the knife to loosen

the tank from the housing (see illustration 15.4.B).

8. Remove the remains of the sealing at the transducer tank

and the housing edge with a knife.

9. Degrease and clean the glueing surfaces of the housing

edge of the (new) tank with alcohol.

10. Fill new sealing material (e.g.Teroson) evenly elong the

edge of the transducer tank.

11. Position the unit housing in the sealing mass. Ensure

correct front and backside positioning.

Page 54

Replacement of transducer tank

54

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

Heat up tank edge

Cut the sealing

A

A

B

12. Let the sealing mass harden (approx. 12 h / or according to

the instructions of the manufacturer).

13. On units with drain duct:

Mount the drain duct: Wipe all duct threads with a wire

brush to remove any sealing remains and clean with

alcohol. Seal the thread e.g. with Loctite 586 or Teflon tape

(see section 16).

14. Reconnect all electric cables.

Illustration 15.3. Heat up the edge of the transducer tank with a hot air

fan

Illustration15.4. Cut the sealing and lever the housing.

Page 55

Replacement of drain duct

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

55

How to proceed

16 Replacement of drain duct

16.1 How to replace the turning knob drain duct

The ball valve for opening and shutting the drain duct is

actuated by the turning knob via a plastic extension. Both parts

are connected with the ball valve by a hexagon socket screw.

The turning knob can be replaced without opening the unit.

For the removal of the transducer tank or of the ball valve the

turning knob drain duct must be dismounted.

1. Open the hexagon socket screw with a hexagon socket

screw key (3 mm) anti-clockwise (illustration 16.1.).

2. Remove the turning knob with extension (illustration 16.2.).

3. To replace the turning knob the extension must be pulled

out of the turning knob and then be inserted into the new

turning knob.

4. Mounting: Position the new turning knob with inserted

extension and fasten with the hexagon socket screw.

Illustration 16.1. Open the hexagon socket screw anti-clockwise

Illustration 16.2. Pull the turning knob with extension out of the unit

Page 56

Replacement of drain duct

56

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

Cause of breakdown

How to proceed

16.2 How to replace the ball valve

The ball valve is screwed onto the drain duct and sealed with

Loctite. For unscrewing the ball valve the ducting around the

thread must be heated, e.g. by means of a hot air fan, to

dissolve the sealing material.

Deposits of dirt particles in the drain system can damage the

Teflon sealing in the ball valve. Damage can also be caused by

aggressive cleaning media.

1. Open the unit (see section 6.).

2. Remove the turning knob drain duct (see section 16.1.).

3. Heat up the barrel nipple around the screw connections

(illustration 16.3.B) by means of a hot air fan to dissolve the

Loctite sealing.

4. Unscrew the barrel nipple (illustration 16.3.C ) with a pipe

wrench anti-clockwise. Arrest the ball valve (illustration

16.3.A) with a fork wrench ( 21 mm) during the process in

order to avoid bending the tank floor.

5. Heat up the ball valve around the screw connections

(illustration 16.4.E) by means of a hot air fan to dissolve the

Loctite sealing.

6. Unscrew the ball valve with a fork wrench (21 mm) anti-

clockwise. Arrest the 90° duct bow (illustration 16.4.D) with

a pipe wrench in order to avoid bending the tank floor.

7. Remove any remains of Loctite from the thread of the drain

duct and clean the thread e.g. with alcohol.

8. Clean the inner thread of the new ball valve and the

ductings e.g. with alcohol.

9. Prepare the thread of the ball valve and of the drain duct

with Teflon tape or Loctite. Observe hardening period of

sealing material (before filling the transducer tank with

water).

10. Mount the ball valve, screw on the barrel nipple and fasten

the turning knob drain duct.

Page 57

Replacement of drain duct

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

57

B

A

C D E

Illustration 16.3. Open the barrel nipple with a pipe wrench. Arrest the

ball valve with a fork wrench during the process.

Illustration 16.4. Open the ball valve with a pipe wrench. Arrest the

ball valve with a fork wrench during the process.

Page 58

Replace the handle

58

SM_Getinge-Ultrasonic_07.2013_EN

© Getinge Group

How to proceed

17 Replace the handle

The handles are fixed with 2 split pins.

1. Open the unit as described in section 6.

2. Press the 2 split pins with a suitable tool ( for example a

screwdriver and a hammer) downwards out of the handle.

Direction see illustration 1.

3. Remove the old handle outwards the housing.

Illustration 1. Remove the split pins

4. Place the new handle in correct installation position.

5. Fix the handle with the 2 new spilt pins:

push the 2 new split pins, e.g. with a long tweezers, into the

handle.

6. Fix the 2 new split pins and the handle, e.g. with silicone.

Page 59

Putting into operation / Trial run

© Getinge Group

SM_Getinge-Ultrasonic_07.2013_EN

59

Risk of electrocution due to entering humidity!

Keep the unit dry.

The unit inside is splash-proof. To prevent electrical accidents

and damage keep the workplace and the unit housing dry.

Dry running of the transducer tank can damage the unit.

Ensure that the cleaning tank is correctly filled during operation

(marking on the tank wall).

CAUTION

Ambient conditions

Mains connections

Observe filling level

NOTE

Suitable cleaning

media

Prohibited cleaning

media

Degassing of the

liquid

18 Putting into operation / Trial run

For checking and trial operation of the unit after repair please