Page 1

INSTALLATION

INSTR UCTIONS

Wash

disinfector

S-606

Serial no. 970001-

5000375-00

0301

Produced: 1999

Page 2

Installation

Foreword

These Operating Instructions are standard for all models referred to below:

W all-mounted

Free-standing with tipping protection

The models are supplied with different levels of equipment:

Rotator

Process or spray dispensing

De-scaler dispensing

Rinse-aid dispensing

Inserts

Central steam supply

Models are also available for different voltages.

2 Edition 990426 5000375-00

Page 3

Installation

Contents

Foreword _______________________________________________ 2

Safety regulations ________________________________________ 4

General safety rules ______________________________________ 4

Isolating device _________________________________________ 4

Description ____________________________________________ 4

W arning symbols ________________________________________ 4

Unpacking ______________________________________________ 5

Installing the wash disinfector_______________________________ 6

Free-standing___________________________________________ 6

W all-mounted __________________________________________ 7

Connection of water ___________________________________ 8

Connection to the drain _________________________________ 8

Electrical connection ___________________________________ 9

Functional check _________________________________________ 10

T echnical data ___________________________________________ 11

Component list ___________________________________________ 12

Electrical wiring diagram ___________________________________ 13

5000375-00 Edition 990426 3

Page 4

Safety regulations

The design of this machine incorporates a number of built-in safety

devices. To avoid personal injury, it is very important not to render these

safety devices ineffective by by-passing them.

General safety rules

• The machine shall be connected in accordance with the installation

instructions.

• The machine shall not be operated by minors.

• Installation and service operations shall be performed by personnel

with the appropriate training for this machine.

• The machine's lid lock shall not be by-passed under any circumstances.

• Leakage in the system, e.g. a worn lid seal, shall be repaired

immediately.

Installation

• Before performing any repair or service operations, the personnel

concerned shall study the relevant handbooks and service manuals.

• The machine must not be washed down with water.

• Care shall be taken when using corrosive detergents.

• Safety precautions in the presence of hot water and steam.

Isolating device

The machine shall always be provided with a separate isolating device in

the mains power supply mounted in a readily accessible position on a wall.

Description

The wash disinfector is intended for the cleaning and disinfection of reusable items such as basins, hand bowls and urinals. Disinfection in this

context means the destruction of all vegetative bacteria, fungal spores and

viruses, but not bacterial spores.

Warning symbols

This handbook contains various warnings, directions and advice of such

importance that we have decided to mark them specially. The following

layout and symbols are used:

This symbol marks a warning in the handbook text. Failure to heed this

warning can lead to more or less severe personal injury and, in some

cases, danger to life.

The symbol also marks warnings intended to prevent damage to the

appliance.

4 Edition 990426 5000375-00

Page 5

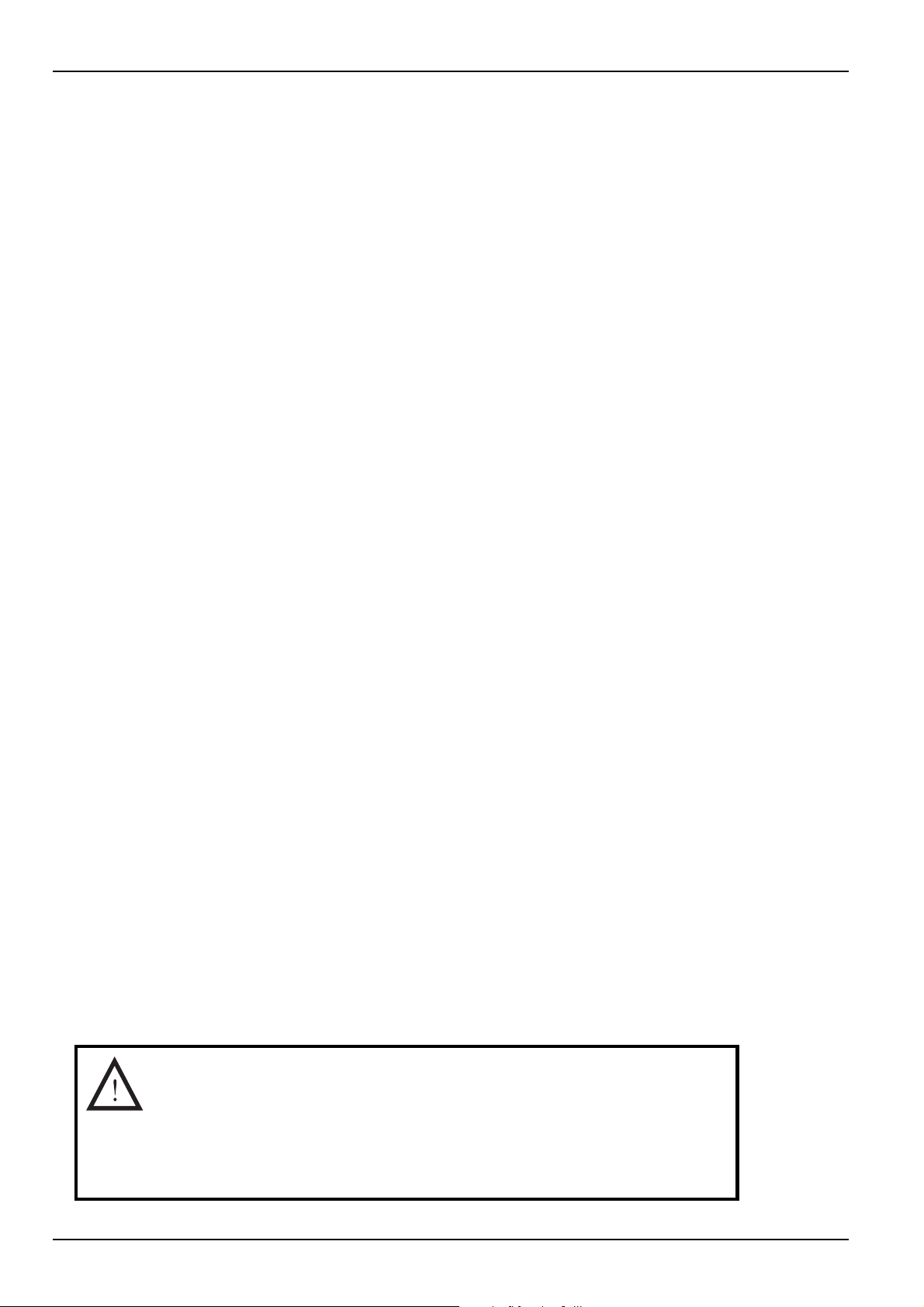

Unpacking

The wash disinfector is supplied bolted securely to a

freight pallet. Remove the packaging.

The following items shall accompany the delivery of the

wash disinfector:

1 wall bracket, plus 2 or 4 legs

1 folder containing documentation

N.B.

Before installation, check that the wash

disinfector has not suffered any transport

damage.

Care shall be taken when cutting the strap

over the lid. The lid opens of its own accord.

Installation

V670

V698

5000375-00 Edition 990426 5

Page 6

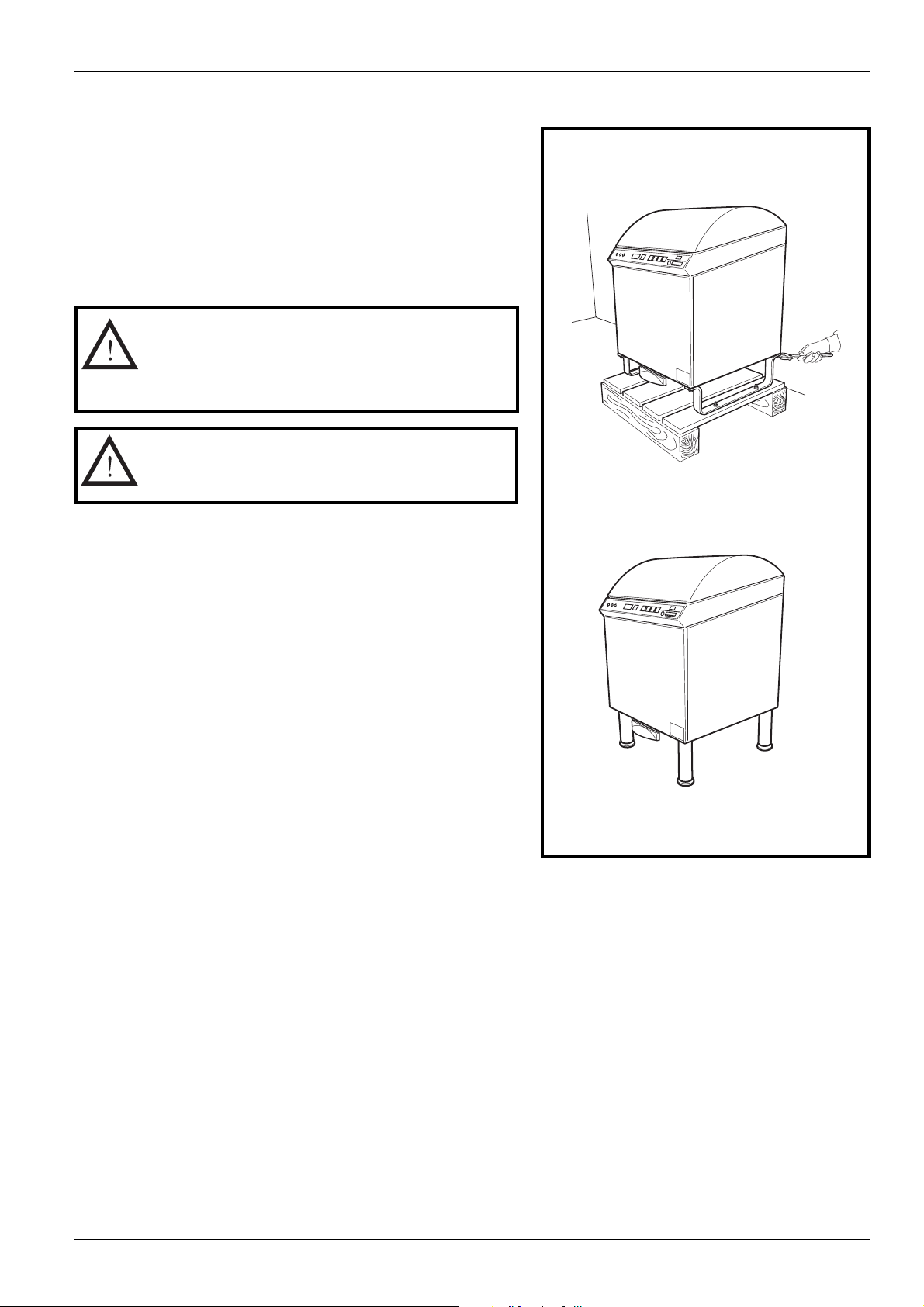

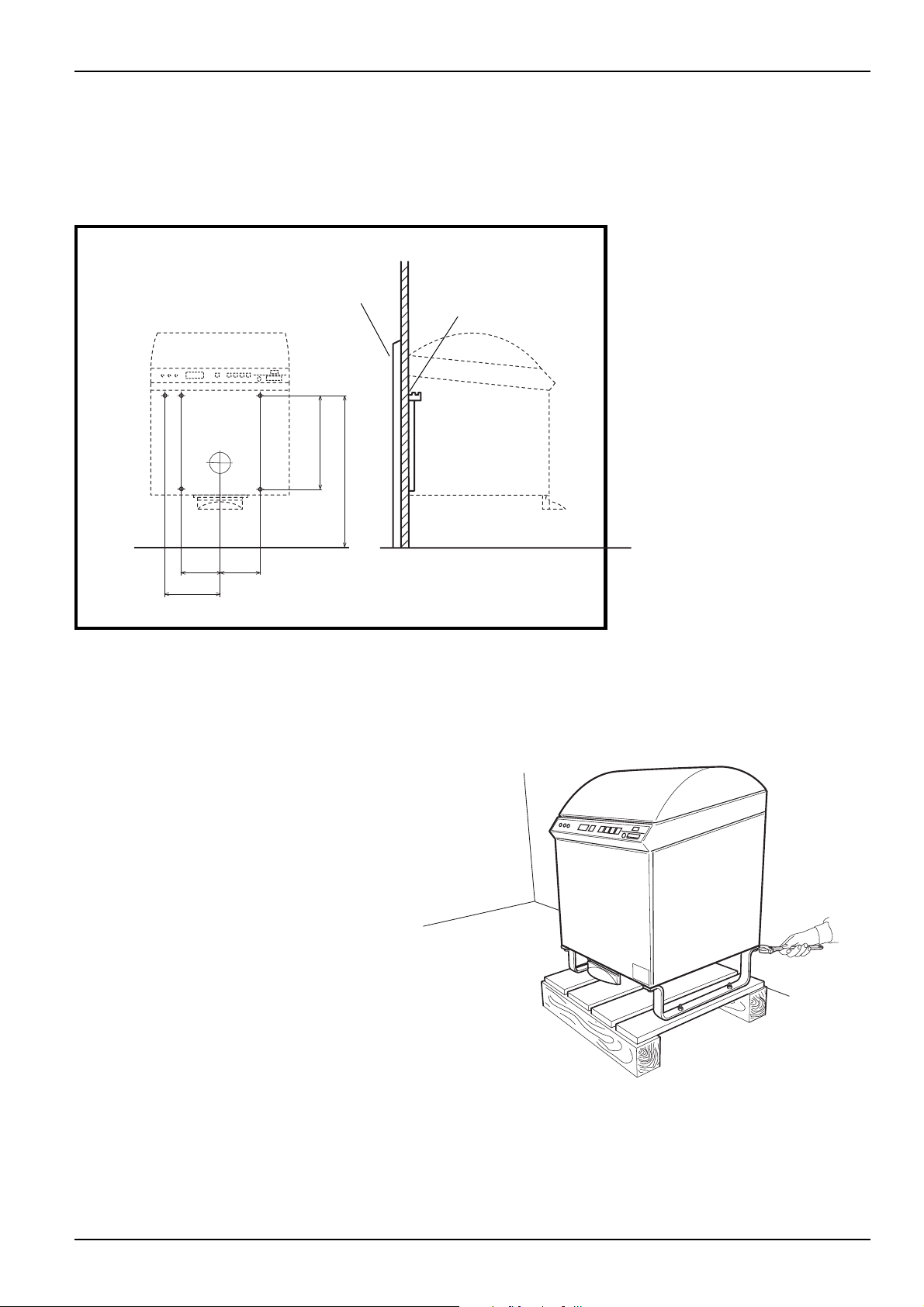

Installing the wash disinfector

3

Installation

900/930/960

800/830/860

1 2

180 180

255 255

V660

Free-standing

590

5

6

440/470/500

4

110

615

1. Hot water connection 1/2"

2. Cold water connection 1/2"

3. Drain connection, P, w all ø110 mm

4. Drain connection, S, floor ø110 mm

5. Electrical connection, cable 4 m

6. External steam supply 1/2"

250/280/310

Carry out the installation in the following sequence:

1 Remove the transport protection means used to anchor

the wash disinfector in the pallet. Fit the legs.

2. Connect the water connections.

3. Connect the drain connection.

4. Carry out the electrical installation.

5. Install the tipping protection.

V698

6 Edition 990426 5000375-00

Page 7

Wall-mounted

Carry out the installation in the following sequence:

1. Drill the hole pattern for the wall bracket, see the

Figure below:

Installation

Wall fixture

350

806

179,5

179,5

235,5

235,5

V669

2. Fit the wall bracket, using the wall fixture if the wall is

too weak.

Wall bracket

3. Remove the transport protection means, and hook the

machine on the wall bracket.

4. Connect the water connections.

5. Connect the drain connection.

6. Carry out the electrical installation.

V670

5000375-00 Edition 990426 7

Page 8

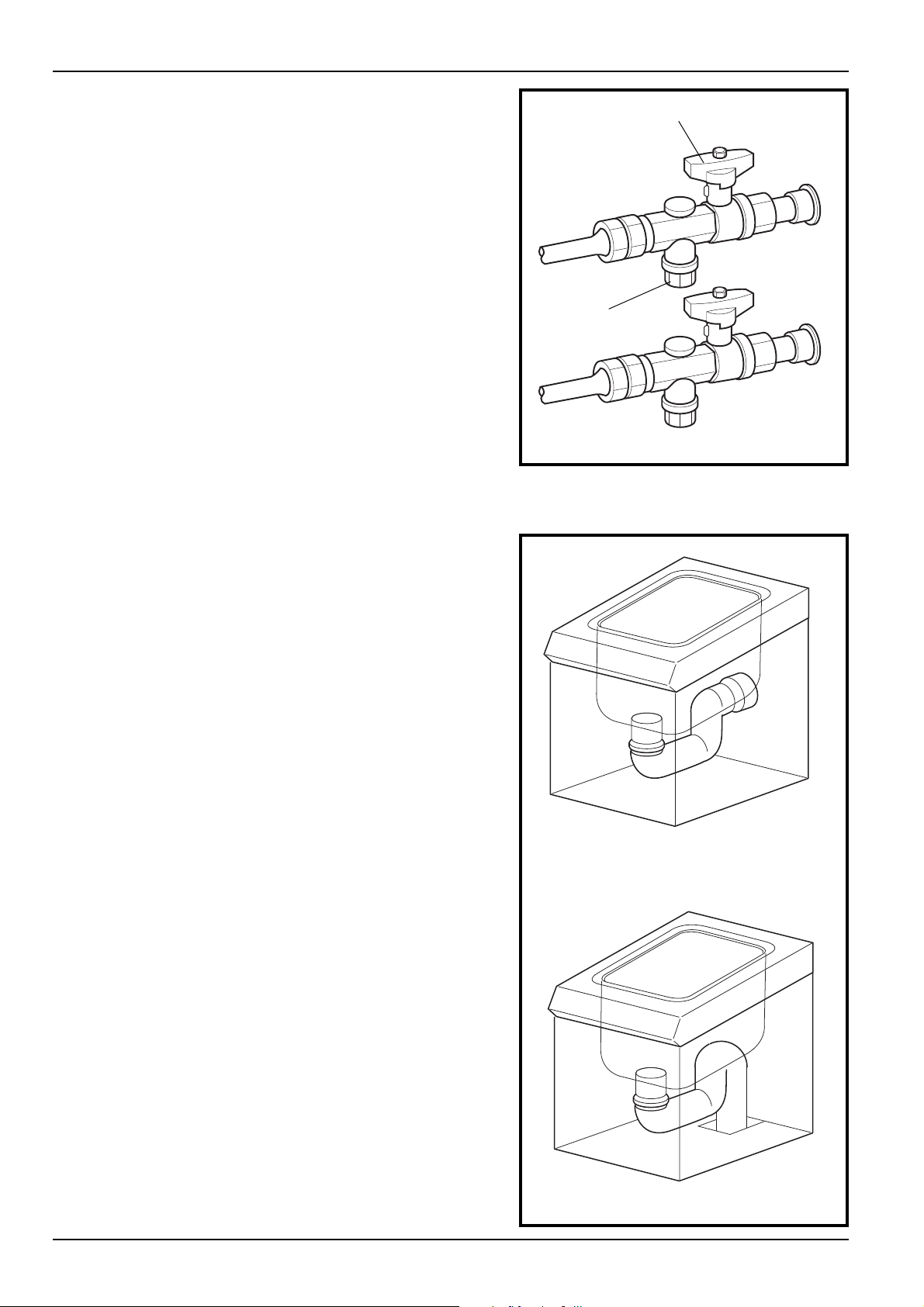

Connection of water

1. Flush through the water pipes that are to be

connected to the machine, to prevent blockage of the

filter and valves.

2. Connect the wash disinfector to the cold and hot

water .

The water connections must satisfy the following

requirements:

Installation

Shut-off valve

• The pipe dimensions shall permit a minimum water

flow of 20 l/min at 1 bar .

• The hot water temperature must be at least

+45°C.

3. Seal the connections with T eflon tape.

Connection to the drain

Connect the disinfector to the drain. The drain can be

connected either rearwards or downwards. The pipe

diameter is 110 mm.

Filter

V553

V661

V662

8 Edition 990426 5000375-00

Drain connection P in wall

Drain connection S in floor

Page 9

Installation

Electrical connection

1. Connect the cables to an isolating device, with a 3

mm breaking distance, positioned on the wall.

2. Connect to a protective earth and to the voltage

supply indicated on the rating plate. Check that the

connection is properly fused. The correct fuse value is

stated on the rating plate.

Isolating device

V659

5000375-00 Edition 990426 9

Page 10

Installation

Functional check

• Check that the wash disinfector is connected to the right voltage, as

indicated ion the rating plate.

• Open the water valves and switch on the operating switch. The message

”Ready for use. Select program” shall appear in the displa y window.

• If the machine is provided with metering of the cleaning agent: Presss

and check that the lamp in the button lights.

• Check that the incoming hot water is at the right temperature. The temperature shall be in the range 45 - 60°C.

• Start the Intensive program with the machine empty , and check that:

- the yellow lamp at L lights,

- the temperature increases continuously until the cooling phase starts,

- the pause for heating does not exceed ca. 10 minutes,

- the temperature reaches 90 °C,

- the green lamp at M lights, and the display window shows Program

ready .

Process running

S-606dekal

Process completed

&=q

• If the machine has a system for the cleaning agent and/or de-scaling agent:

Measure out the agent in a measuring glass. Ensure that the suction hose is

filled with the agent. Start a normal programme, and check that the

disinfector consumes the right quantity . For cleaning agent, the quantity/

programme is usually ca. 20 ml and for de-scaling agent is ca. 1.5 - 4.0 ml

(follow the supplier's recommendations).

• If the machine is equipped with a peripheral washing program:

Press button

running. N.B. Keep the button depressed during the entire process (ca. 10

seconds).

vv

v and check that the peripheral washing programme is

vv

• Check for the absence of water leaks. Tighten the connections and pipe

couplings, if necessary .

10 Edition 990426 5000375-00

Page 11

Installation

Technical data

Weight 90 - 105 kg

Width 590 mm

Depth 640 mm

Height 9 95 mm

Environmental requirements:

Maximum air humidity 80% at 31 °C

Room temperature 5-40 °C

Water consumption (without cooling*)

Economy programme 9 l/process

Normal programme 2 1 l/process

Intensive programme 2 4 l/process

* cooling ca 3 l.

Cold water

Connection 15 (1/2") m m

Pressure 70-800 kPa

Flow 20 l/min

Hot water

T emperature 45-60 °C

Connection 15 (1/2") m m

Pressure 70-800 kPa

Flow 20 l/min

Steam

connection 15 (1/2") mm

Pressure 30-300 kPa

consumption 0 , 3 kg/process

Drain ø 110 mm

Max. external temperature 4 0 °C

Noise level 60 dB(A)

Variant Electrical connection Fuse Po wer req.

L1 230 V, 1N+PE 50 Hz (TN) 1x20A 4.35 kW

L 2 230 V, 3+PE 50 Hz (TN) 3x16 A 5.36 kW

L 3 230/400 V, 3N+PE 50 Hz (TN) 3x10 A 5.36 kW

V 2 230 V, 1N+PE 50 Hz (TN) 1x10 A 1.01 kW

L 5 240 V, 2+PE 60 Hz (TN) 2x20 A 4.35 kW

V 3 240 V, 2+PE 60 Hz (TN) 2x10 A 1.36 kW

L 9 208 V, 2+PE 60 Hz (TN) 2x25 A 4.35 kW

V 4 208 V, 2+PE 60 Hz (TN) 2x10 A 1.36kW

L1 4 200 V, 2+PE 50 Hz (TN) 2x25 A 4.35 kW

V 5 200 V, 2+PE 50 Hz (TN) 2x10 A 1.01 kW

L1 8 200 V, 2+PE 60 Hz (TN) 2x25 A 4.35 kW

V 6 200 V, 2+PE 60 Hz (TN) 2x10 A 1.36 kW

L2 2 230V !N+PE 60 Hz (TN) 1x20A 4.35 kW

L2 4 230/400V3N+PE 60 Hz (TN) 3x10A 5.71 kW

V 7 230V 1N+PE 60 Hz (TN) 1x10A 1.36 kW

5000375-00 Edition 990426 11

Page 12

Installation

Component list

-S2

-S3

-S5

-S4

-A11

-M3

-TE1

-S7

-Y2

-Y5

-LS1

-LS2

-LS3

-LS4

-LS6

-S1

-M7

-T2

-M1

-LS5

V654

-A1 Control system, processor card

-A21 Control system, expansion card (option)

-A11 Control panel

-E1 Electric element in steam generator

-F1 Fuse for auxiliary transformer

-F2 24V fuse on processor card

-F3 Fuse for control voltage, phase 1

-F4 Fuse for control voltage, phase 2 (some connection

alternatives)

-F11 Overheating protection, steam generator

-K2 Contactor, element in steam generator

-LS1 Level sensor, tank

-LS2 Level sensor, de-scaling

-LS3 Level sensor, spray agent (option)

-LS4 level sensor, process (option)

-LS5 Leakage sensor

-LS6 Level sensor, rinse aid (option)

-M1 Motor, main pump

-M2 Motor pump, spray agent (option)

-M3 Motor pump, cleaning agent (option)

-M4 Motor pump, de-scaling

-Y1

-Y7

-S11

-M2

-E1

-Y6

-M6

-M9

-M4

-F11

-XPE

-S8

-K2

-A1

-F1, F2

-T1

-A21

-F3

-F4

-M6 Motor, door actuation/door lock

-M7 Motor pump, rinse-aid (option)

-M9 Motor, rotator (option)

-S1 Limit switch, disengages anti-trapping protection

-S2 Limit switch, anti-trapping protection

-S3 Limit switch, door closed

-S4 Limit switch, door open

-S5 Safety switch, door closed

-S7 Limit switch, rotator down (option)

-S8 Limit switch, rotator up (option)

-S11 Push-button for pedal

-T1 Control current transformer

-TE1 Temperature sensor PT 1000

-Y1 Solenoid valve, cold water (KV)

-Y2 Solenoid valve, hot water (VV)

-Y5 Solenoid valve, external cooling (option)

-Y6 Valve, external steam (option)

-Y7 Solenoid valve, condense cooling

-XPE Protective earthing rail

-T2 Transformer, 200-240/230V

N.B. Some components are extra equipment.

12 Edition 990426 5000375-00

Page 13

Installation

Electrical wiring diagram

5000375-00 Edition 990426 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Den här produkten är tillverkad av:

GETINGE DISINFECTION AB, Ljungadalsgatan 11, Box 1505, 351 15 Växjö, Sweden

Loading...

Loading...