Page 1

EXIT MANUAL

The letters PACS stand for Programmable Autoclave Control System.

The object of the control system is to produce command s and transmit

these to the sterilizer components enabling for a number of sterilization

processes to be accomplished in accordance with a predicted pattern.

The command signals are generated by the control unit comput er program in combination with measurements of the process paramete r values. The latter consist mainly of times, temperatures and pressures.

Various equipment can be connected to the control unit for programming, monitoring and recording the sterilization processes.

The operator communicates with the control unit via a control p anel or

a standard PC (OPC). The control panel is available in the versions OP1

and OP2, where OP1 is the smallest type and consists of two door operation keys and eight sig nal light diodes onl y.

The OP2 panel has a 102 x 25 mm LCD, six program selector keys, signal lights and up-dow n and right-left keys to display desir ed information in preprogramm ed windows. Programm ing can also be done by

means of the OP2, but this is limited to numeral values. The OP2 panel

is mainly designed for entering operator adjustable parameters.

There are connection ports in the PACS 2000 all owing a maximum of

two OP1s, two OP2s or one of each. Simultaneously with this combination, OPC can be connected , but only on e of all these can be the commanding unit at a time.

All operating panel s are made for monitoring the pro c esses by displaying any set parameter value as well as current values on request. All relevant data associated with a particular process such as batch No.,

operator No., date, etc., may be entered by the operator using OPC.

Documentation of programs, system definitions and process data can be

made by connecting a printer to OPC. A host computer can also be connected direct to the co ntrol unit CPU.

Where the demand requires a measuring an d monito ring system, co mpletely indepen de n t o f t h e control system, a PA CS SUPERVISOR system may be connected. This con tains a CPU, OP2 an d interfaces wi th

the CPU of the sterilizer control unit. The SUPERVISOR measurements are made by its own separate temperature and pressure sensors.

The computer contains a program for automatic calibration of temperature and pressure transducers. Alternatively correction constants, when

known, may be entered manually. Among PACS 2000 test fu nctions

there are facilities for activating analog and digital outputs and monitoring analog and digital inputs. With OPC or OPH, up to 16 service

alarms, flagged as display codes, can be programmed, based either upon

operation tim e in hours or number of ste rilizing c ycles. In bo th cases th e

maximum programmable d igits are 9999. Service a larms are displayed

also by OP2, but this panel will not allow for programming of these.

The hardware of the steri lizer control system contains the operating

panels easily locate in a suitable place. The CPU and po wer pack are

Click here to

Click here to

EXIT Manual

EXIT Manual

1

Page 2

placed in a separate electrical enclosure, connected to the operating panels.

Description of terms

STERILIZATION means the whole series of treatments to form a process in order to attain total killing of all viable organisms. This is in connection with autoclaves usually made up by air removal, heat treatment

and a drying phase.

STERILIZING means the actual killin g part, th e heat treatmen t, of the

total process.

Analogous to the two expressions above, STERILIZATION TIME

means the durability of the total process from the start until the goods

can be unloaded. PROCESS TIME is equal to sterilization time.

STERILIZING TIME represents that part of the process on ly during

which the programmed STERILIZING TEMPERATURE prevails in

the chamber.

EXIT MANUAL

PARAMETER in this context means the ELEMENTS WHICH

INFLUENCE the sterilization course. Examples of parameters in the

sterilization process are temperature, pressure, time, gas concentration,

etc. The PARAMETER VALUES may be fixed in the program or operator adjustable.

F

-VALUE is a time defined by the equ ation

0

t

T

k1–

t

()

------------------k

2

F

10

=

∫

0

0

×

dt

t = Time in minutes

T(t) =

k

= Constant within the range 0.0 - 150.0 oC. Usually 121.1 oC

1

= Constant withi n the range 0.0 - 99.9 oC. Usually 10.0 oC

k

2

The F

Load temperature at time t

. value is based upon the sterilizing time, required for the temper-

0

ature prevailing in each moment, being recalculated to the base temperature for steam sterilization, 121.1

o

C

The use of F

value is most common in the pharmaceutical field, where

0

often the time control of sterilization processes is based upon this value,

thereby utilizing t he heat appl ied du ring heat ing u p and cooli ng down .

By this method, heat sensitive products do not need to be exposed to

high temperatures for a longer period of time than required in obtaining

a sterile result.

2

Page 3

OP C

EXIT MANUAL

OP C is a standard IBM compatible PC with DOS and with backup utilities on hard disk and flop py. OP C is intend ed to be used for progra m

development. The menu tree includes menus for loading data on diskette or hard disk. OP C communicates with the PACS 2000 via a standard RS232 serial interface connected as COM1. COM2, if installed,

may be used for connecting a printer or a PROM programmer. In Local

mode it is possible to run the program without any PACS connected.

OP H

OP His identical to OP C with the extension that it can be connected to

a network includ ing more than one PAC S. OP H communicates wi th the

PACS 2000 via a standard RS485 serial interface. OP H is communicating with one PACS at a time.

3

Page 4

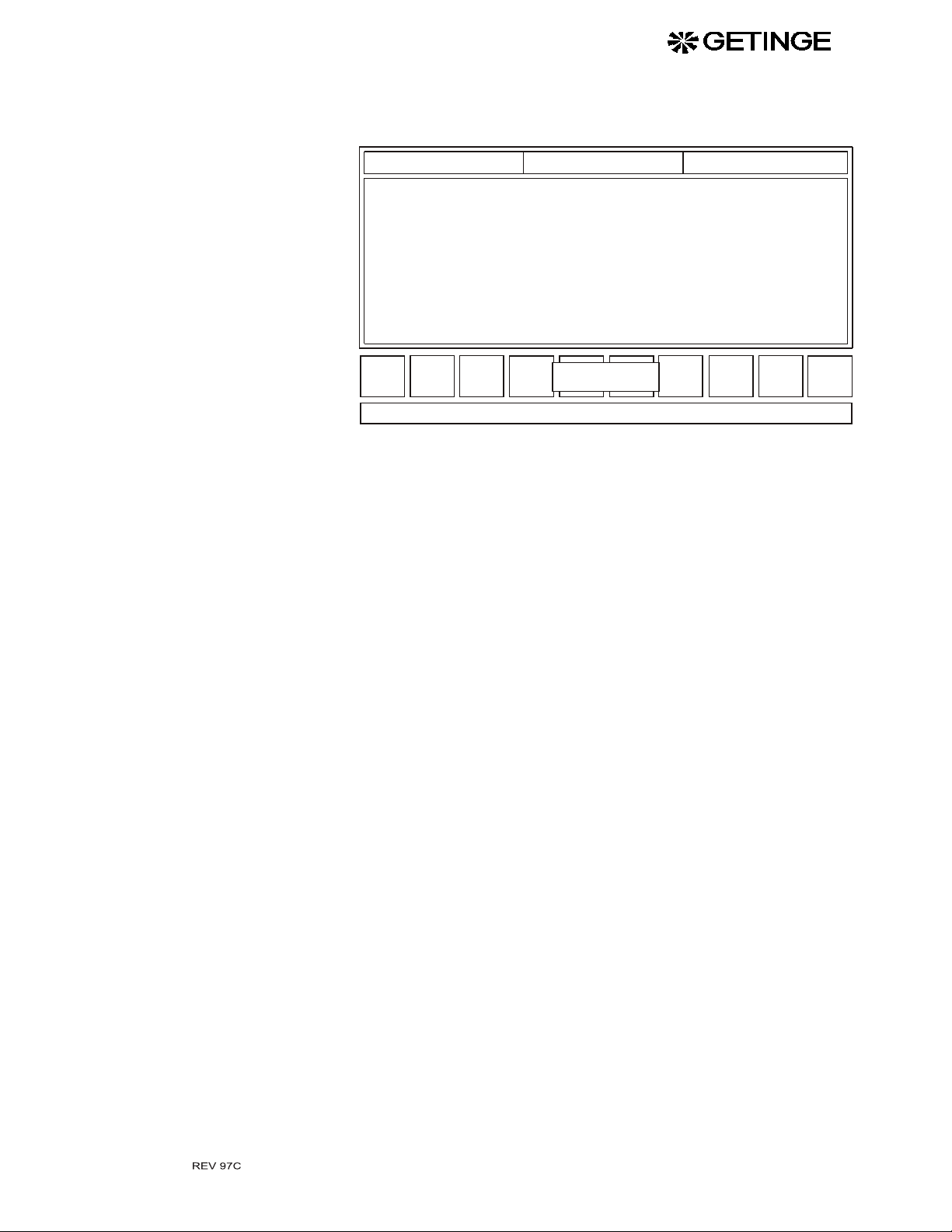

Screen lay-out

EXIT MANUAL

The screen is divided into six wind ows, each one displ aying differe nt

kind of information.

WINDOW 1

F1

PREV HELP

F2

F3

F4 F5 F6

WINDOW 2

WINDOW 4

WINDOW 5

WINDOW 6

F7

WINDOW 3

F8 F9

F10

Window 1 shows system date and time

shows connected sterilizer name and n umb er on

OP H

Window 2 shows sequence number and symbolic name for the

active PACS prog ra m in on -l i ne mo de a nd pr og ra m

version number in local mode

Window 3 shows symbolic name and sub-phase number for the

Window 4 shows all menu functions in the menu tree. Active

Window 5 describes the active function of the keys F1-F10

Window 6 shows menu handling messages for all menus except

Function keys F1-F10

The function of these keys are depending on the menu selected i n the

menu tree and will be shown in fully written out text in a window on the

display close to the appropriate key.

active PACS phase in on-line mode. Shows the text

”LOCAL MODE” when in that mode.

menu headline is displayed in the upper right corner

of the window.

process pictures.

In process pictures the left part of the window is used

for PACS error texts and the right part for PACS

information text s

4

Page 5

On line / Local mode

OP can operate in two modes, ONLINE mode and LOCAL mode. In

On-line mode the communicat ion link between OP and PACS is activated and the data base in the two units contain i dentical data . In local

mode OP works remote ly without any communi cation with PACS.

Local modes are available in version OPH and OPC.

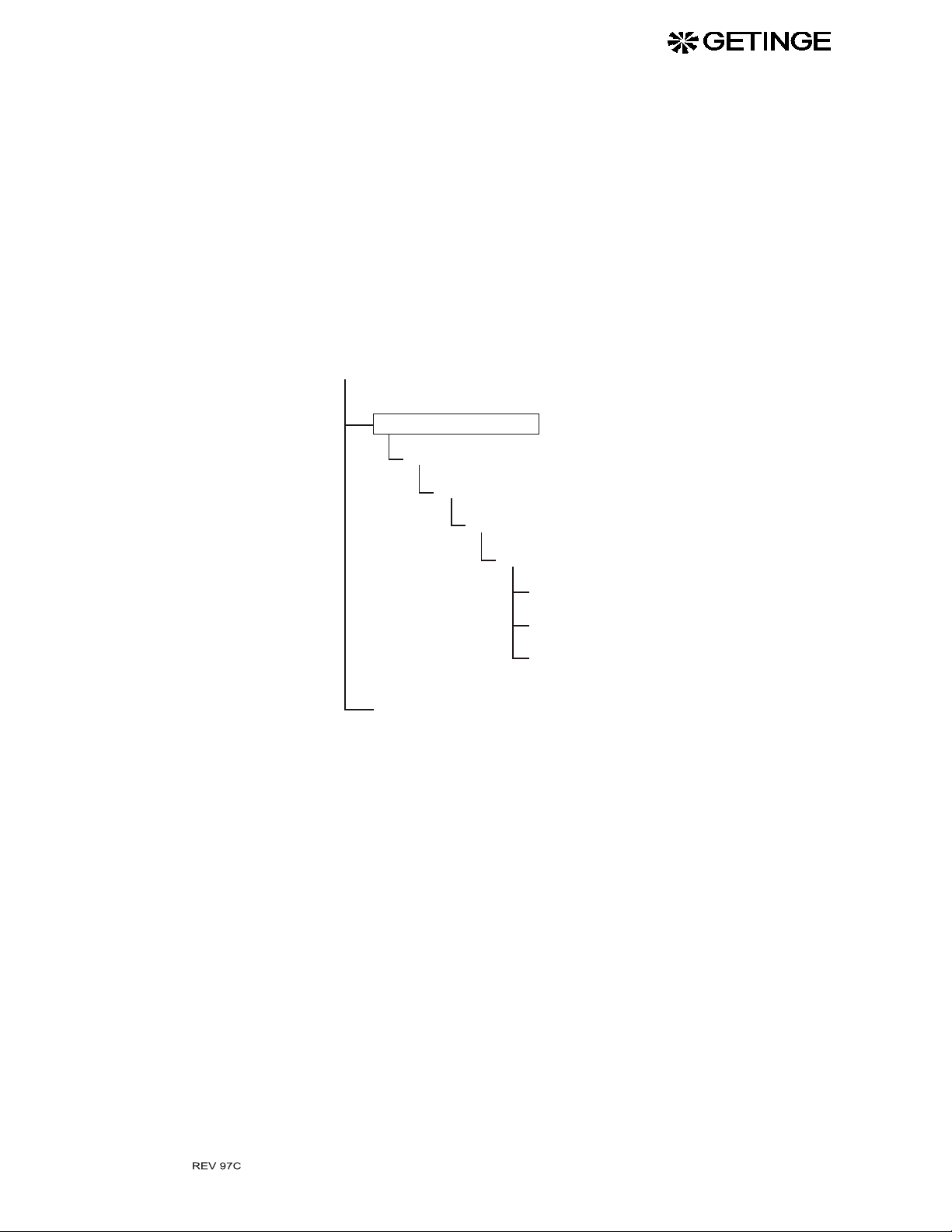

The OPC / OPH menu tree

Below follows that part of the menu tree which is of use for the operator.

MODE MENU

MAIN MENU

Menu in frame is not available in Local Mode

START PROGRAM

ACTIVATE PROGRAM

EXIT MANUAL

PARAMETER INPUT

BATCH DEFINITION

SYSTEM MODE

Pass word level 1 required

NORMAL PROCESS PICTURE 1

NORMAL PROCESS PICTURE 2

ENLARGED PROCESS PICTURE

PLOT PROCESS PICTURE

Pass word level 2 required

5

Page 6

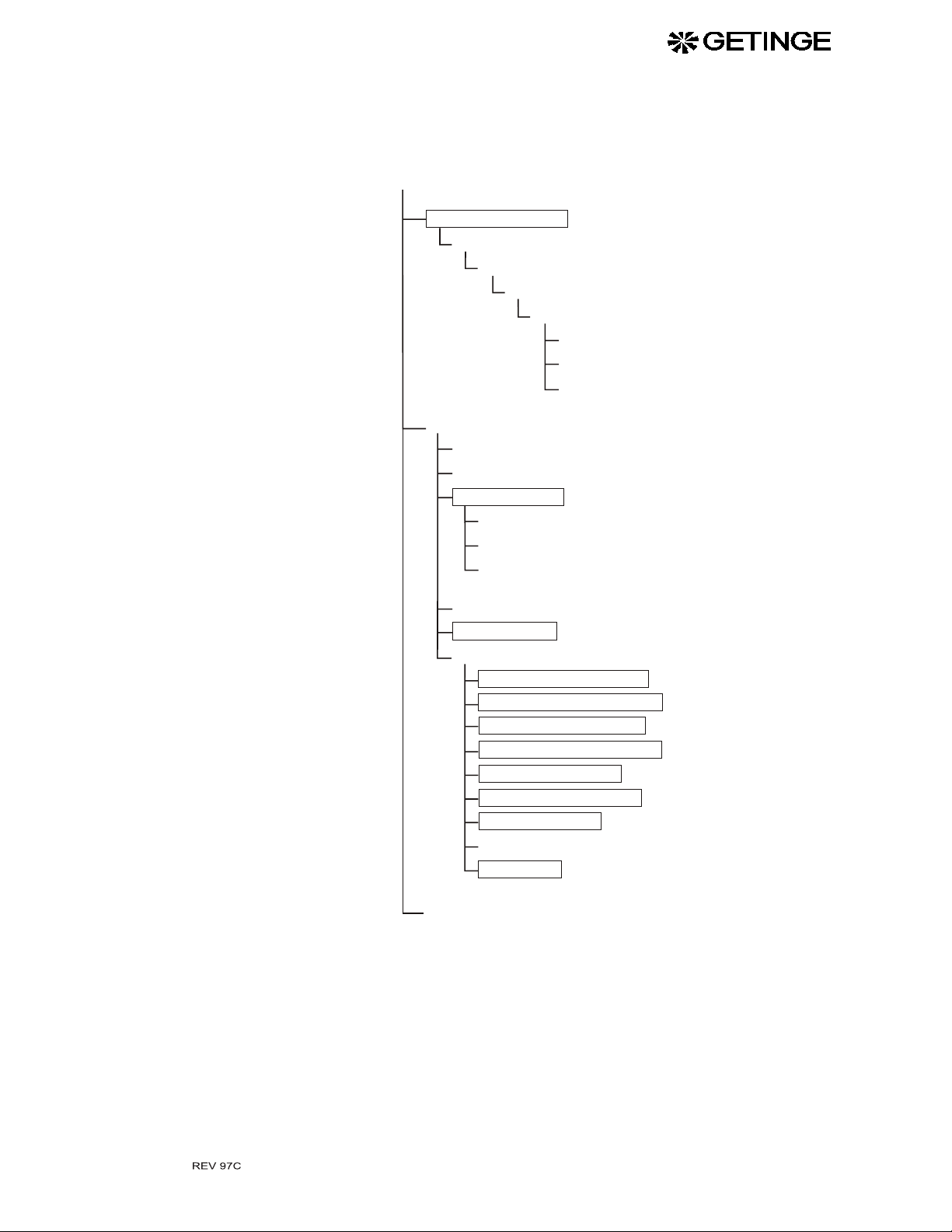

The OPC / OPH menu tree

Below follows that part of the menu tree which is of use for the service

man.

MODE MENU

MAIN MENU

EXIT MANUAL

START PROGRAM

ACTIVATE PROGRAM

PARAMETER INPUT

BATCH DEFINITION

SYSTEM MODE

SYSTEM PROGRAMMING

CALENDAR

CALIBRATION

ANALOG INPUT MANUAL CALIBRATION

ANALOG INPUT AUTOMATIC CALIBRATION

ANALOG OUTPUT MANUAL CALIBRATION

SERVICE

ERROR LOG

TEST FUNCTION

TEST ANALOG INPUT

TEST ANALOG OUTPUT

TEST DIGITAL INPUT

TEST DIGITAL OUTP UT

TEST USER FLAG

TEST SYSTEM FLAG

TEST PICTURE

TEST PRINTER

TEST LED

Menu in frame is not available in Local Mode

NORMAL PROCESS PICTURE 1

NORMAL PROCESS PICTURE 2

ENLARGED PROCESS PICTURE

PLOT PROCESS PICTURE

Pass word level 2 required

Pass word level 1 required

Pass word level 3 required

LOG-FILES

OP H only

6

Page 7

Passwords

EXIT MANUAL

Four passwor ds exists in the PACS 2000 and consists of four digits

0000-9999. The passwords are

operator password

•

needed to start restricted processes and to open doors after a process

failure

parameter password

•

needed to accept change of pr ogram parameters

service password

•

needed for entering maintenance menus

program password

•

needed for entering programming menus

The parameter password may, as an option, be exchanged to a pass key

connected to a dig ita l in put. The pass k ey overri des the para meter password.

Passwords at delivery:

The passwords set in the con trol system is revealed in a special docu ment delivered in a sealed envelope together with the sterilizer manuals.

Menu descriptions

Mode menu

This is the first menu shown after power-up. Here the operator can

choose which mode the OP should work in.

ON-LINE MODE for connection with PACS 2000 or

LOCAL MODE for stand alone op eration.

Alternative 3 in the menu ter m inates the program and returns to DOS.

Parameter code is required to use this alternative.

92/09/25 08:18:17

MODE MENU

1. ONLINE MODE

2. LOCAL MODE

3. EXIT

P 1 PROGRAM 1

STANDBY 01

F1 F2

PREV

F3

F4

F5 F6

F7

BAUDR

F8 F9

HELP

F10

MOM.EPS

7

Page 8

EXIT MANUAL

An alternative is highlighted with

alternative can also be highlighted by pressing the number of the desired

alternative.

Before ON-LINE MODE is activated PACS 2000 communication

baud rate can be altered. F7 sho ws a window were the operator can

choose betwee n the alterna tives 1200 , 2400, 4800 and 9600 vi a a choice

list. Default value is 9600 baud.

Valid only for OP H: If ON-LINE MODE is chosen a window i s

shown where the operator can specify which sterilizer he like to be connected to. Allowed values are: 1 - 99.

ON-LINE / LOCAL MODE

OP can operate in two modes, O N-LINE MO DE and LOCA L MOD E.

In ON-LINE MODE the communication link between OP and PACS

2000 is activated and the data bases in the two units contain s identical

data. In LOCAL MODE OP works without any communication to

PACS.

LOCAL MODE is avai lable on v ersion OP H and OP C while OP 3

always requires ON-LINE MODE.

Following menu functions are not available in LOCAL MODE:

ÏÐ

and selected with ENTER. A

•

START PROGRAM and all under lying menus.

•

CALIBRATION MENU and all underlying menus.

•

ERROR LOGG

•

TEST ANALOG INPUT

•

TEST ANALOG OUTPUT

•

TEST DIGITAL INPUT

•

TEST DIGITAL OUTPUT

•

TEST USER FLAG

•

TEST SYSTEM FLAG

•

TEST PICTURE

•

TEST LED

Function keys:

F1 PREV - Previous menu

F7 BAUDR - Activate PACS 2000 baud rate window

F9 HELP - Help text

8

Page 9

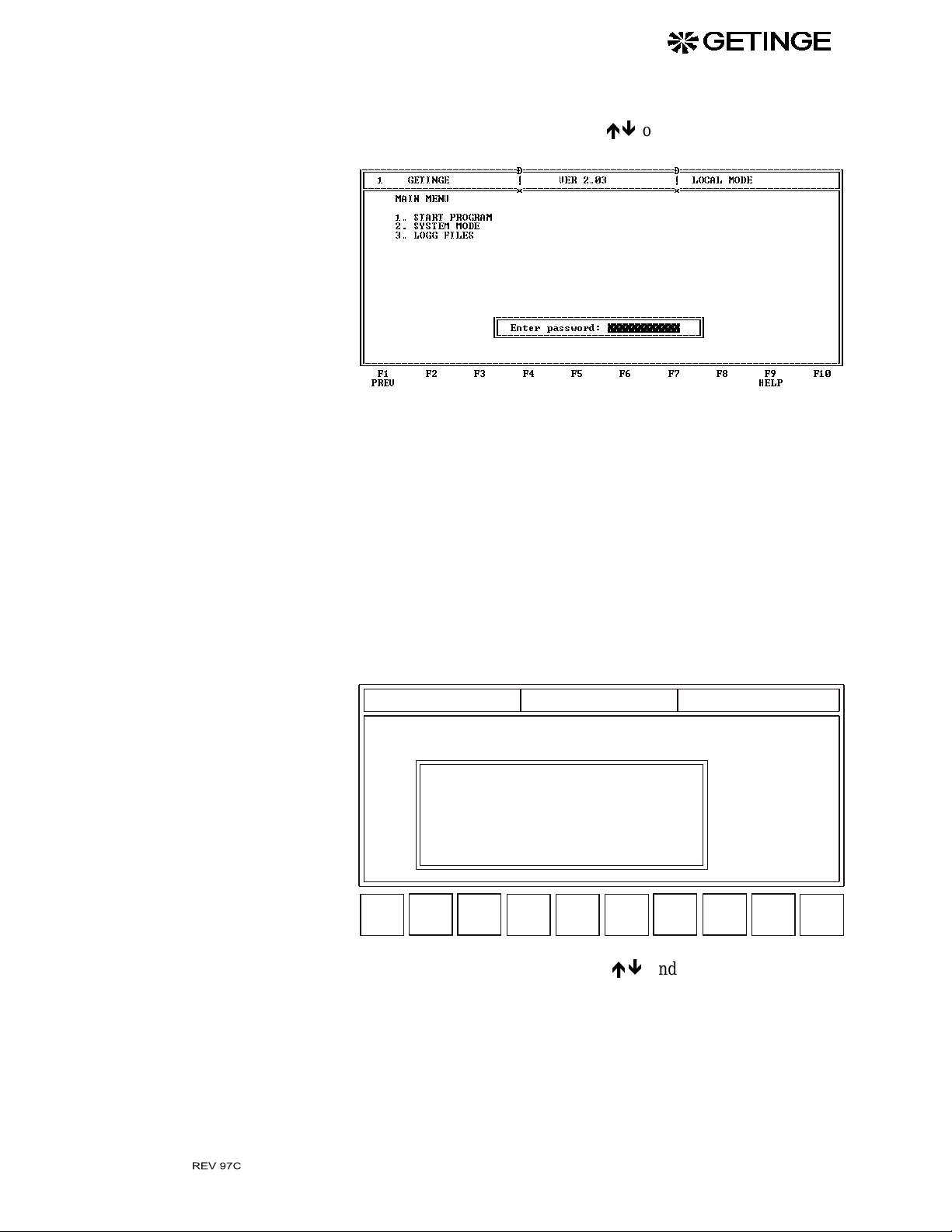

Main menu

EXIT MANUAL

Select either START PROGRA M, SYSTEM MODE or LOG FILES by

highlighting the desired text usin g

then push ENTER.

Activation of SYSTEM MODE or LOG FILE requires a password with

level 2 (service passwo r d) or hig he r. No n acc epted p asswo rd re su lt s in

a message in window 6.

ÏÐ

or typing the leading number,

Activate program

NOTE!

Item 3 LOG FILES on the menu is only available with OP H.

F1 PREV - Previous menu

F9 HELP - Help text

Activate desired prog ram , from the scrollable list.

94/02/23 08:18:17

ACTIVATE PROG RAM

PACS PROGRAM DIRECTORY

P01 PROGRAM_1

P02 PROGRAM_2

P03 PROGRAM_3

P04 PROGRAM_4

P05 PROGRAM_5

P06 PROGRAM_6

P07 PROGRAM_11

P08 PROGRAM_7

P09 PROGRAM_12

F1 F2

PREV HELP

F3

P1

P 1 PROGRAM 1

94/02/23 10:38

94/02/23 10:38

94/02/23 10:38

94/02/23 10:38

94/02/23 10:38

94/02/23 10:38

94/02/23 10:38

94/02/23 10:38

94/02/23 10:38

F4

P2

F5 F6

P3

P4 P5

STANDBY 01

F7

F8 F9

F10

NEXT

Highlight de sired program using

ÏÐ

and confirm selection wi th

ENTER.

The first five programs in the list may also be activated by pushing

F3-F7.

Activation of a program is automatically followed by PARAMETER

INPUT menu.

9

Page 10

Parameter input

EXIT MANUAL

Functio n keys:

F1 PREV - Previous menu

F3-F7 P1 - P5 - Activate first five progra ms in li st

F9 HELP - Help text

F10 NEXT - Go to PARAMETER INPUT menu without activating any

new program.

This menu will not be shown if the select ed program do es not contain

any adjustable parameter.

With PACS in stand by mode only, this menu allows for the operator to

change adjustable parameters for the previously selected progr a m.

92/09/25 08:18:17

PARAMETER INPUT

PARAMETER

STERIL TEMP

STERIL TIME

F1

BACK

F2

F3

P 1 PROGRAM 1

SET VALUE LIMIT LO

121.0

00:20:00

Enter pas sword:

F4 F5 F6

00:02:00

STANDBY 01

LIMIT HI

100.0

01:00:00

F7

F8 F9

135.0

HELP

UNIT

C

F10

NEXT

The parameter pas sword m ust be en tered to enable for an y paramet er to

be changed. If password in put is disabl ed with F1, th e parameter list can

only be scrolled through but no parameters c an be changed.

If KEY password mode is enabled, the password window never occurs

on screen. The status of the specified key input then decides whether the

parameters are allowed to be changed or just d isplayed.

Parameter inputs are checked against the high and low limits shown on

screen. Inputs beyond limits are met with a message in Window 6.

Functio n keys:

F1 BACK - Go to ACTIVATE PROGRA M menu.

F9 HELP - Help text.

F10 NEXT - Go to NORMAL PROCESS PICTURE 1 menu. If bar

code is installed, go to BATCH DE FINITION menu.

10

Page 11

Batch definition

EXIT MANUAL

Data in this menu are part of the information found in the printer log and

should be entered prior to start of a process with PACS in stand by

mode.

92/09/25 08:18:17

BATCH DEFINITION

OPERATOR:

ARTICLE:

F1

BACK

F2

F3

P 1 PROGRAM 1

F4 F5 F6

STANDBY 01

F7

F8 F9

HELP

F10

NEXT

Each input contains max imum 16 character s. Only b atch fields ha ving

field prompts de f in e d are shown in this menu. Th e ba t c h f iel d prompts,

maximum 6 fields, are defined in the PRINTER LOG DEFINITION.

If the definition prescribes field entry as a requirement, the field can not

be left without any character entered.

Function keys:

F1 BACK - Go to ACTIVATE PROGRAM menu.

F9 HELP - Help text.

F10 NEXT - Go to NORMAL PROCESS PIC.1 menu.

Normal process picture 1

This menu continuou sly displays PAC S data on screen . No data en try

possible.

Active process tim e and phase t ime are sh own on th e same li ne as the

heading.

11

Page 12

EXIT MANUAL

The left column shows the current values of the continuing process

parameters. These are parameters defined in the 15 first entries of NORMAL PROCESS PICTURE DEFINITION.

The right column shows the set values of the continuing process 15 first

A and I parameters. These will not be updated.

PACS error text is shown on the fir st half of line 25 a nd informat ion text

on remaining half.

Operator password will be prompted for on this line after a process failure.

Function keys:

F1 BACK - Go to ACTIVATE PROGRAM menu.

F2 NPIC1 - No function in this menu.

F3 NPIC2 - Go to NORMAL PROCESS PICTURE 2.

F4 EPIC - Go to ENLARGED PROCESS PICTURE.

F5 PPIC - Go to PLOT PROCESS PICTURE.

F6-F10 Name and function defined by PACS program.

Normal process picture 2

This menu continuou sly displays PAC S data on screen . No data en try

possible.

Active process tim e and phase t ime are sh own on th e same li ne as the

heading.

The left column shows the current values of the continuing process

parameters. These ar e para meters def ined in the 16 - 30 fir st entr ies of

NORMAL PROCESS PICTURE DEFINITION .

The right column shows the cu rrent values of the contin uing process

parameters. These ar e para meters def ined in the 31 - 45 fir st entr ies of

NORMAL PROCESS PICTURE DEFINITION .

PACS error text is show n on the first half of li ne 25 and inform ation

text on the remaining half.

12

Page 13

Enlarged picture

EXIT MANUAL

Function keys:

F1 BACK - Go to ACTIVATE PROGRAM menu.

F2 NPIC1 - Go to NORMAL PROCESS PICTURE 1.

F3 NPIC2 - No function in this menu.

F4 EPIC - Go to ENLARGED PROCESS PICTURE.

F5 PPIC - Go to PLOT PROCESS PICTURE.

F6-F10 Name and function defined by PACS program.

This menu continuou sly displays PAC S data on screen . No data en try

possible.

Data is displayed with enlarged character s in order to facilitate dista nt

readings.

Active process tim e and phase t ime are sh own on th e same li ne as the

heading.

Maximum 4 par am et ers can be shown in t hi s me n u. Ac t ua l p a rame te rs

are defined in ENLARGED PROCESS PICTURE DEFINITION.

PACS error text is show n on the first half of li ne 25 and inform ation

text on remaining half.

Function keys:

F1 BACK - Go to ACTIVATE PROGRAM menu.

F2 NPIC1 - Go to NORMAL PROCESS PICTURE 1.

F3 NPIC2 - Go to NORMAL PROCESS PICTURE 2.

F4 EPIC - No function in this menu.

F5 PPIC - Go to PLOT PROCESS PICTURE.

F6-F10 Name and function defined by PACS program.

13

Page 14

Plot process picture

This menu plots real time signals in a diagram on the screen.

Signal names and corresponding Y-axis are listed above the plot.

Active process and phase ti mes are shown on the same line as the

header.

EXIT MANUAL

Maximum 2 Y-axis and 6 si gn als can be disp lay ed. Si gn als and Y-axi s

are defined in the me nu PLOT PROCESS PICTURE DEFINITION.

PACS error text is shown on the fir st half of line 25 a nd informat ion text

on remaining half.

The length of the X-axis will auto matically adapt to the duration of the

active process.

Function keys:

F1 BACK - Go to ACTIVATE PROGRAM menu.

F2 NPIC1 - Go to NORMAL PROCESS PICTURE 1.

F3 NPIC2 - Go to NORMAL PROCESS PICTURE 2.

F4 EPIC - Go to ENLARGED PROCESS PICTURE.

F5 PPIC - No function in this menu.

F6-F10 Name and function defined by PACS program.

System mode menu

Highlight desired altern ative using

push ENTER.

ÏÐ

down or leading n umber then

14

Page 15

EXIT MANUAL

Activation of SYSTEM PROGRA MMING requires entering a passwords with level 4.

Calendar

92/09/25 08:18:17

SYSTEM MODE MENU

1. SYSTEM PROG RAMMING

2. CALENDAR

3. CALIBRATION

4. SERVICE

5. ERROR LOGG

6. TEST FUNCTIONS

F1

PREV

F2

F3

P 1 PROGRAM 1

F4 F5 F6

STANDBY 01

F7

F8 F9

Function keys:

F1 PREV - Previous menu.

F9 HELP- Help text.

Changing date and system time is made in this menu.

94/02/23 15:40:30

CALENDAR

P 1 PROGRAM 1

STANDBY 01

F10

HELP

DATE: 1994 / 02 / 23 YYYY / MM / DD

TIME: 15 : 40 : 30 HH : MM : SS

F1

PREV

F2

F3

F4 F5 F6

F7

F8 F9

HELP

F10

EXIT

The format of date depe nds on the way it is specif ied in the SYSTEM

CONFIGURATION menu.

Possible formats are:

SW - yy/mm/dd

US - mm/dd/yy

EU - dd/mm/yy

Ranges for time field are 00:00:00 - 23:59:59

Function keys:

F1 PREV - Abort menu and cancel setting

F9 HELP- Help text.

15

Page 16

F10 EXIT - Exit menu and activate setting

Calibration menus

Highlight desired alter native using

push ENTER.

ÏÐ

or leading number and then

EXIT MANUAL

92/09/25 08:18:17

CALIBRATION MENU

1. ANALOG I NPUT MANUAL CALIBRAT ION

2. ANALOG I NPUT AUTOMATIC CALIBRATION

3. ANALOG OUTPUT MANUAL CALIBRATION

F1

PREV

F2

F3

Function keys:

F1 PREV - Previous menu

F9 HELP- Help text.

Analog input manual calibration

The calibration const ants gain (A) an d offset (B) for analog input signals should be set in this menu.

P 1 PROGRAM 1

F4 F5 F6

STANDBY 01

F7

F8 F9

HELP

F10

92/09/25 08:18:17

ANALOG INPUT MANUAL CALIBRATION

SYMBOLIC NAME

AI00

CHAMBER TEMP

AI01

JACKET TEMP

AI02

CONTROL TEMP

AI03

PRESSURE

F1

PREV

F2

F3

F4 F5 F6

P 1 PROGRAM 1

TYPE

PT100

PT100

PT100

PRESS

UNIT

STANDBY 01

A-GAIN

F7

0.000

0.000

0.000

0.000

C

C

C

BAR

B-OFFSET

0.000

F8 F9

HELP

0.0

0.0

0.0

F10

EXIT

The number of AI shown in the scrollable list is defined by the AI-modules specified in the SYSTEM CONFIGURATION MENU. A maximum of 32 AI-channels on 10 AI-modules can be specified.

A-gain is a value between 0.000 and 9.999.

The format (unit) of the B-offset is the same as that of the actual sensor.

Input is limited to ±10% of the range of the actual, AI-sensor.

16

Page 17

Function keys:

F1 PREV - Abort menu and skip all changes

F9 HELP- Help text.

F10 EXIT - Exit menu and save changes.

Analog input automatic calibration

Selection of analog inputs

First of all the operator has to select the group of sensor to be calibrated

by highlighting these.

EXIT MANUAL

92/09/25 08:18:17

SELECT ANALOG INPUT FOR AUTO MATIC CALIBRATION

SYMBOLIC NAME

AI00

CHAMBER TEMP

AI01

JACKET TEMP

AI02

CONTROL TEMP

AI03

PRESSURE

F1

PREV

F2

F3

P 1 PROGRAM 1

TYPE

PT100

PT100

PT100

PRESS

F4 F5 F6

UNIT

STANDBY 01

CALIBRATE

C

C

C

BAR

F7

YES

YES

NO

NO

F8 F9

HELP

F10

CALIB

The number of AI shown in the scrollable list is defined of the AI-modules specified in the SYSTEM CONFIGURATION MENU. A maximum of 32 AI-channels on 10 AI-modules can be specified.

A YES in the CALIBR ATE field in dicates tha t the sensor sh ould be

included in the calibra tion. The operato r can toggle bet ween the alternatives YES / NO with the button SPACE.

Function keys:

F1 PREV - Skip changes and go back to previous menu

F9 HELP - Help text

F10 CALIB - Go to automatic calibr ation.

17

Page 18

Automatic calibration

This menu is used for automatic calibration of analog inputs.

EXIT MANUAL

92/09/25 08:18:17

ANALOG INPUT AUTOMATIC CALIBRATION

SYMBOLIC NAME

AI00

CHAMBER TEMP

AI01

JACKET TEMP

F1

PREV

F2

F3

LOW

P 1 PROGRAM 1

VALUE

135,0

121,0

F4 F5 F6

HIGH PROT

UNIT

C

C

STANDBY 01

A-GAIN

0.000

0.000

B-OFFSET

F7

0.0

0.0

F8 F9

HELP

REFERENCE

LOW 0.8

HIGH 138.2

F10

Selected sensors are listed on the screen. A maximum of 14 sensors can

be calibrated at the same t ime. Measured value and calc ulated A-gain

and B-offset are continu ously updated for selected se nsors.

Calibration steps:

A Subject the sensors to the low reference medium and wait until the

measured value is stable.

B Write the measured value in LOW REFERENCE field and push F3

to send the value to PACS .

C Subject the sensors to the high reference medium and wait until the

measured value is stable.

D Write the measured value in HIGH REFERENCE field and push F5

to send the value to PACS .

At this time, PACS calculates new gain and offset constants. Calculated constants and measured sensor values are continuously

updated on the screen.

By pushing F7, a calibration protocol is printed out. Before starting the

print out, the operator may enter his signature in a pop up window,

thereby including this signature in the protocol.

Function keys:

F1 PREV - Abort menu

F3 LOW - Send low reference to PACS

F5 HIGH - Send high reference to PACS and calculate new constants

F9 HELP- Help text.

F7 PROT - Print calibration protocol

18

Page 19

Analog output manual calibration

This menu is to set calibration constants such as gain (A) and offset (B)

for analog outputs.

EXIT MANUAL

92/09/25 08:18:17

ANALOG OUTPUT MANUAL CALIBRATION

SYMBOLIC NAME

AO00

AO01

AO02

F1

PREV

F2

F3

LOW

P 1 PROGRAM 1

F4 F5 F6

HIGH

STANDBY 01

A-GAIN

0.000

0.000

0.000

F7

B-OFFSET

0.0

0.0

0.0

F8 F9

HELP

F10

EXIT

The number of AO shown in the scrollable list is defined by the number

of AO-modules specified in the SYSTEM CONFIGURATION menu.

Each module contains 2 channels.

A maximum of 4 AO-modules, i. e. 8 channels can be specified.

A-GAIN is a value between 0.000 - 9.999

B-OFFSET is a value between 000.0 - 100.0

A-GAIN and B-OFFSET are set directly by pressing F10 when the fac-

tors have been modified.

Otherwise calibration can be made in accordance with following procedure:

A Enter A-GAIN and B-OFFSET for the channel to be calibrated.

B Mark calibration channel by placing the cursor in any field of this

line.

C Activate LOW calibration by pushing F3. On this command, PACS

will set actual AO-channel to 10.0% of maxim um output using

entered gain and offset constants.

D Activate HIGH calibrat ion by pushing F5. On this command,

PACS will set actual AO-channel to 90.0% of maximum output

using entered gain and offset constants.

E Output value will be measured. Step A - D should be repeated until

output measure is correct.

Function keys:

F1 PREV - Abort menu and skip all changes

F3 LOW - Activate low value calibration

F5 HIGH - Activate high va lu e c al i bra t i on

F9 HELP- Help text

19

Page 20

Service

EXIT MANUAL

F10 EXIT - Exit menu and save changes

This menu is to supervise the service intervals of the sterilizer. These

can be based either on time or on n umber of cycles. Ei ght of each can

be defined.

When a time or cycle limit is obtained, the SERVICE system flag SF17

is set.

Error log

92/09/25 08:18:17

SERVICE

ACTIVITY INTERVAL ACT .VAL

1.

WEEKLY SERVICE

2.

MONTHLY SERVICE

3.

3-MONTH SERVICE

4.

6-MONTH SERVICE

5.

12-MONTH SERVICE

6.

7.

8.

1.

REPLACE AIR FILT

2.

COOLER CHECK

3.

VALIDATION

4.

F1

PREV

F2

F3

LIST EXIT

P 1 PROGRAM 1

40

176

530

1056

2112

0

0

0

600

4224

0

0

14

152

506

506

506

0

0

0

112

0

0

0

F4 F5 F6

STANDBY 01

ON

ON

ON

ON

ON

OFF

OFF

OFF

ON

ON

OFF

OFF

COMMAND

F8 F9

UNIT STAUS

HOUR

HOUR

HOUR

HOUR

HOUR

HOUR

HOUR

HOUR

CYCLE

CYCLE

CYCLE

CYCLE

F7

START

--

--

--

--

--

--

RESET

--

START

--

--

--

--

--

HELP

F10

F1 PREV - Previous menu

F3 LIST - Show choice list

F9 HELP- Help text.

F10 EXIT - Exit menu and save changes

This menu displays the error log. This contains type of error, date, time

and the name of the program in which it occurred.

92/09/25 08:18:17

ERROR LOGG

ERROR DATE

1

TEMP SENS. ERROR

2

3

4

5

6

7

8

9

10

F1

PREV

F2

F3

P 1 PROGRAM 1

93/12/13

F4 F5 F6

STANDBY 01

TIME

13:22:10

F7

PRINTSTORE

PROGRAM

UTENSILS

F8 F9

F10

HELP

The error log cont ains information about th e latest 20 errors. This

means that the oldest message is erased each time a ne w error message

is stored.

20

Page 21

Function keys:

F1 PREV - Previous menu

F2 STORE - Store error log on file

F7 PRINT - Print error log

F9 HELP - Help text

Test function menus

Test function menu.

EXIT MANUAL

Analog input test

92/09/25 08:18:17

TEST FUNCTION MENU

1. TEST ANALO G INPUT

2. TEST ANALO G OUTPUT

3. TEST DIG ITAL INPUT

4. TEST DIG ITAL OUTPUT

5. TEST USER FLAG

6. TEST SYST EM FLAG

7. TEST PICTURE DIGITAL

8. TEST PRINT ER

9. TEST LED

F1

PREV

Use

F2

F3

ÏÐ

to highlight your choice, then push ENTER.

P 1 PROGRAM 1

F4 F5 F6

STANDBY 01

F7

F8 F9

HELP

F10

Function keys:

F1 PREV - Previous menu

F9 HELP - Help text

This menu shows all defined analog inputs in two columns on screen.

Actual values are continuously updated.

92/09/25 08:18:17

TEST ANALOG INPUT

AI00 CHAMBER TEMP

AI01 JACKET TEMP

AI02 CONTROLTEMP

AI03 PRESSURE

F1

PREV

F2

F3

P 1 PROGRAM 1

120.9 C

121.5 C

118.7 C

1.058 BAR

F4 F5 F6

Function keys:

F1 PREV - Previous menu

STANDBY 01

F7

F8 F9

F10

21

Page 22

Analog output test

The operator is, by setting the mode to MANUAL, disabling

the built in safety system!

Make sure beyond all doubts that it is safe to set the output

to manual mode before doing it.

In this menu, analog outputs can be set to desired values.

Actual values are continuously updated.

EXIT MANUAL

92/09/25 08:18:17

TEST ANALOG OUTPUT

SYMBOLIC NAME

AO00

AO01

F1

PREV

F2

F3

P 1 PROGRAM 1

MODE

AUTO

MANUAL

F4 F5 F6

STANDBY 01

SET

VALUE %

F7

0.0

0.0

F8 F9

SEND

0.0

0.0

HELP

F10

EXIT

In AUTO mode the output is controlled by the PACS program

In MANUAL mode the output can be set to desired v a lue.

The number of AO shown in scrollable form is defined of how many

AO-modules are specified in SYSTEM CONF IGURATION menu.

Each module contains 2 channels. A maximum of 4 AO-modules can be

specified i. e. 8 channels.

MODE fields specify whether the output is in AUTO or MANUAL

mode. Operator can, when in these fields, toggle between the two alternatives using the SPACE bar.

In the SET field the operator can specify the value to which the output

should be set. Limits for the value field is 0.0 - 100.0%. Note that MANUAL mode must be selected, otherwise SET will be ignored by PACS.

With F8 entered values can be sent to PACS without leaving this menu.

Function keys:

F1 PREV - Abort test.

F8 SEND - Send entered values and mode to PACS.

F9 HELP - Help text

22

Page 23

Digital input test

EXIT MANUAL

F10 EXIT - Send entered valu es a nd mode to PACS and exit menu.

Remember to reset the mode to AUTO before leaving the

menu.

This menu shows all define d digi tal inpu ts in three c olu mns on scr een.

Actual values are continuously updated.

92/09/25 08:18:17

TEST DIGITAL INPUT

DI00 SYMBOLIC NAME 0

DI01 SYMBOLIC NAME 1

DI02 SYMBOLIC NAME 0

DI03 SYMBOLIC NAME 1

DI04 SYMBOLIC NAME 1

F1

PREV

F2

F3

P 1 PROGRAM 1

F4 F5 F6

Function key:

F1 PREV - Previous menu

STANDBY 01

F7

F8 F9

F10

23

Page 24

Digital output test

The operator is, by setting the mode to MANUAL, disabling

the built in safety system!

Make sure beyond all doubts that it is safe to set the output

to manual mode before doing it.

In this menu, digital outp uts can be set to desired status.

Actual values are continuously updated.

EXIT MANUAL

92/09/25 08:18:17

TEST DIGI TAL OUTPUT

SYMBOLIC NAME

DO00

DO01

DO02

DO03

DO04

DO05

DO06

F1

PREV

F2

F3

P 1 PROGRAM 1

MODE

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

F4 F5 F6

SET

0

0

0

0

0

0

0

STANDBY 01

STATUS

1

0

1

1

0

0

0

F7

F8 F9

SEND

HELP

F10

EXIT

In AUTO mode the output is controlled by the PACS program.

In MANUAL mode the output can be set to desired st atus.

The number of DO sho wn i n scr ollab le fo rm is d efi ned of the numbe r

of DO-modules specifi ed in SYSTEM CONFIGURATI ON menu. Each

module contains 8 channels. A maxim um of 8 DO-modules can be

specified i. e. 64 channels.

MODE fields specify whether the output is in AUTO or MANUAL

mode. Operator can, when in this field, toggle between the two alternatives using the SPACE bar.

In the SET fields the operator specifies the output statu s. Operator

can, when in these fields and in MANUAL mode, toggle between 0 and

1 using the SPACE key

With F8 entered status can be sent to PACS without leaving this menu.

Function keys:

F1 PREV- Abort test.

F8 SEND - Send entered values and mode to PACS.

F9 HELP - Help text

24

Page 25

Test user flag

EXIT MANUAL

F10 EXIT - Send entered valu es a nd mode to PACS and exit menu.

Remember to reset the mode to AUTO before leaving the

menu.

This menu shows all defined user flags in a scrollable list on screen.

Actual values are continuously updated.

Test system flag

92/09/25 08:18:17

USER FLAG TEST PICTURE

SYMBOLIC NAME

UF000

UF001

UF002

UF003

UF004

UF005

UF006

UF007

F1

PREV

F2

F3

P 1 PROGRAM 1

STATUS

0

0

0

0

0

0

0

0

F4 F5 F6

STANDBY 01

F7

F8 F9

HELP

F10

Function key:

F1 PREV - Previous menu

F9 HELP - Help text

This menu shows all defined system flags in a sc rollable list on screen.

Actual values are continuously updated.

92/09/25 08:18:17

SYSTEM FLAG TEST PICTURE

SYMBOLIC NAME

SF000 INT I2C ERROR

SF001 OP1 I2C ERROR

SF002 OP2 I2C ERROR

SF003 OP31 COM ERROR

SF004 OP32 COM ERROR

SF005 OP33 COM ERROR

SF006 PRINT CO M ERROR

SF007 AUX COM ERROR

F1

PREV

F2

F3

P 1 PROGRAM 1

F4 F5 F6

Function key:

F1 PREV - Previous menu

F9 HELP - Help text

STATUS

0

0

0

0

0

0

0

0

STANDBY 01

F7

F8 F9

HELP

F10

25

Page 26

Test picture

EXIT MANUAL

This menu shows the status of all d igital in puts and ou tputs in th e system. Status are continuously updated.

Test printer

92/09/25 08:18:17

DIGITAL TEST PICTURE

DI MOD 0

DO MOD 0

DO MOD 1

F1

PREV

F2

F3

P 1 PROGRAM 1

00000000 7input

00000000 7output

00000000 15

F4 F5 F6

STANDBY 01

F7

F8 F9

F10

The number of shown D I / DO modules are specified in SYSTEM

CONFIGURATION menu.

Function key:

F1 PREV - Previous menu

This menu sends test strings to connected printer.

Test LED

92/09/25 08:18:17

TEST PRINTER

Strings sent to printer:

PRINTER TEST FOLLOWS

!"#$%&'()*+,-./0123456789:;<=>?@ABCDEFG

HIJLKMNOPQRSTUVWXYZ[]^_`abcdefghijklmno

pqrstuvwxyz<|>~

Press <Enter> to continue <F1> to abort.

F1

PREV

F2

F3

P 1 PROGRAM 1

F4 F5 F6

STANDBY 01

F7

F8 F9

F10

Shown test str ings are sent to prin ter by pressing ENTER. Test is

aborted with F1.

Function key:

F1 PREV - Previous menu

When this menu is activated, a command is sent to PACS.

On this command, PACS makes all LED’s flash for about 5 seconds on

all connected operat ing panels.

26

Page 27

Log-files (OP H only)

This menu handles the log-fi le functions. the O P H program can store

log-files from connected sterilizers on separate files.

Highlight desired alt ernative using the a rrow-keys or simply ent er the

leading digit an d pre ss ENTER.

Function key:

F1 PREV - Previous menu

EXIT MANUAL

Print log-file

Display log-file

Print the selected log-file on a printer connected to the PC.

Highlight desired sterilizer number using the arrow-keys and press

ENTER.

Select the log-file to be printed and press ENTER.

Function key:

F1 PREV - Previous menu

The selected file is displayed on screen.

Highlight desired sterilizer number using the arrow-keys and press

ENTER.

Select the log-file to be shown and press ENTER.

Function keys:

F1 PREV - Previous menu

F6 BACK - Previous page of the log -fi l e

F7 NEXT - Next page of the log-file

Copy log-file

The selected log-file is copied to disk and directory as decided.

Highlight desired sterilizer number using the arrow-keys and press

•

ENTER.

27

Page 28

Delete log-file

EXIT MANUAL

•

Select the log-file to be copied an d press ENTER.

•

Specify the path and press F10 to copy the file.

Function keys:

F1 PREV - Previous menu

F10 EXIT - Copy the fi le and leave menu

A previously copied log-file is deleted.

Highlight desired sterilizer number using the arrow keys and press

ENTER.

Select the log-file to be deleted and press ENTER.

Note! Only files that have been copied can be deleted.

Function keys:

F1 PREV - Previous menu

Plot log-file

The log-file may be plotted on screen in almost the same way as is

described under heading ”PLOT PROCESS PICTURE”. The difference

is that the plot is not d epending on settings made in ”PLOT PROCESS

PICTURE DEFINITION” but on settings made in this menu.

Highlight desired sterilizer number using the arrow keys and press

ENTER.

Select the log-file to be plotted and press ENTER.

Definition:

The plot picture can contain up to six signals and two y-axis.

Y-AXIS DEFINITION

Two Y-axis can be defined, A and B. An Y-axis is defined by unit, low

value and high value.

Unit is specified via a choice list where t he operator can choose

between C/F, BAR/kPa/PSI, % and F0. The unit for temperature and

28

Page 29

EXIT MANUAL

pressure is depending on selections made in the SYSTEM CONFIGURATION menu.

Formats and limits for high and low values are determined by the

active unit.

UNIT FORMAT RANGE

C xxx.x 0.0 - 999.9

F xxx.x 0.0 - 999.9

BAR x.xxx 0.000 - 9.999

kPa xxx.x 0.0 - 999.9

PSI xx.xx 0.00 - 99.99

% xxx.x 0.0 - 100.0

F0 xxx.x 0.0 - 999.9

Print summary

An Y-axis is as activated if the value in high is greater than that in

low. If Y-axis A i s no t a c t iv a ted it wi l l n ot be sh ow n. If Y-axis B is not

activated it is shown unmarked.

PLOT SIGNAL DEFINITION

Process picture signals are specified via a two step choice list where the

operator can c hoose b etw een d efi ned AI, AO , F0, C P, DF an d TP fu nctions.

Y-AXIS defines which Y-ax is a signal is related to. The operator can

toggle between the alternatives A/B with SPACE when in thes e fi elds.

Function keys:

F1 PREV - Abort menu and skip all changes

F3 LIST - Show choice list

F5 CLEAR - Clear active field

F9 HELP - Help text

F10 EXIT - Exit menu and save changes

An abstract co ntaini ng the info rmation l isted be low is se nt to th e printer

connected to the PC.

•

Header

•

All phase shifts accompanied with a log.

•

All errors together with log.

29

Page 30

Log-file definition

EXIT MANUAL

This menu manages the definition of the log-file. Up to 20 sterilizers

may be defined.

PACS ID is the unique nu mber of the steri lizer as set in th e SYSTEM

CONFIGURATION MENU.

LOG-PATH describes the full way to the direct ory wher e the log- file is

to be stored.

The following steps has to be taken before logging can be star ted.

•

OP33 in SYSTEM CONFIGURATION MENU set on.

•

System flag SF29 PC DISK LOG set.

The file name is composed in the following way :

<STERILIZER No:><MONTH><DAY><RUNNIN G No .>.LOG

Function keys:

F1 PREV - Abort menu and skip all changes

F5 CLEAR - Clear active field

F9 HELP - Help text

F10 EXIT - Exit menu and save changes

30

Page 31

Technical data

PACS 2000 Ver. 2.0

Adaptation to line voltage by means of transformer 2 * 18 ±10% VAC,

50 - 60 Hz

Power consumptio n depending on the degr ee of extension < 100 VA

o

Operating ambient temperature +10 - +60

C

EXIT MANUAL

Humidity resistance control system

front panels

Water and dust protection of control system

front panel

Electromagnetic compatibility FCC 15 J, CIS PR22,

PC board performance according to CSA and UL

Maximum distanc e between operator panel and control unit 10 m

System sampli ng rate for all in- and outputs 4 Hz

Type of digital input s supplied from system Opto-coupled 24 V DC

Number of digital input modules Maximum 8

Number of inputs with each mo dule 8

Type of digital outputs Relays, contact rating

Number of digital output modules Maximum 8

90% rel.

100% rel.

IP43

IP65

EN 50081, EN 50082 ,

IEC 801

12 A

Number of digital outputs with each module 8

Number of analog input modules Maximum 10

Number of analog inputs.- PACS 2000 alone

if PACS Supervisor is

connected

Number and kind of analog inputs with module type: 1. 3 RTD Pt100

2. 3 thermocouple type K

3. 6 RTD Pt100

Maximum 32

Maximum 24

1 pressure

1 pressure

31

Page 32

Analog inputs ty pe : A. Temperature

EXIT MANUAL

4. 6 thermocouple type K

5. 2 RTD Pt100

2 pressures

6. 4 general purpose

0 - 20 mA

0 - 5 V

0 - 10 V

4 - 20 mA

*1

Sensor

Resolution

Inaccuracy

Range

B. Temperature

Sensor

Resolution

Inaccuracy

Range

C. Temperature

Sensor

Resolution

Inaccuracy

Range

Pt100 4-wire only

o

0.1

C

o

C

±0.1

-5 - +150

o

C

TC type K,

Chromel-Alumel

o

0.1

C

o

±0.2

C

-5 - +150

o

C

TC type K,

Chromel-Alumel

o

0.2

C

o

C

±0.4

-5 - +800

o

C

D. Pressure

Sensor

Resolution

Inaccuracy

Range

Wheatstone bridge

0 - 500 mV/v

0.001 bar(a)

±0.01 bar(a) for 0 - 1

bar(a) ± 1% of a ct ual

value for 1 - 5 bar(a)

0 - 5 bar(a)

32

Page 33

E. Pressure

EXIT MANUAL

Sensor

Resolution

Inaccuracy

Range

F. General purpose

Sensor

Inaccuracy

Range

G. Scale

Sensor

Wheatstone bridge

0 - 300 mV/v

0,001 bar(a)

±0.001 bar(a)

0 - 1.5 bar(a)

0 - 20 mA, 4 - 20 mA

0 - 5 V, 0 - 10 V

0.1% of span

As above

0 - 20 mA, 4 - 20 mA

0 - 5 V, 0 - 10 V

*1

*1

,

,

Inaccuracy

Range

0.1% of span

0 - 500 kg

H. Concentration

Sensor

0 - 20 mA, 4 - 20 mA

0 - 5 V, 0 - 10 V

Inaccuracy

Range

0.1% of span

0 - 1200 mg/l

Analog outputs 0 - 20 mA, 4 - 20 mA,

0 - 5 V, 0 - 10 V

Resolution 0.4%

Activation rate 4 Hz

Number of analog output modules Maximum 4

Number of analog outputs with each module 2

*1. All four inputs on the module will be set for 4 - 20 mA when this alternative is used.

*1

,

33

Loading...

Loading...