Page 1

SETUP & OPERATION MANUAL

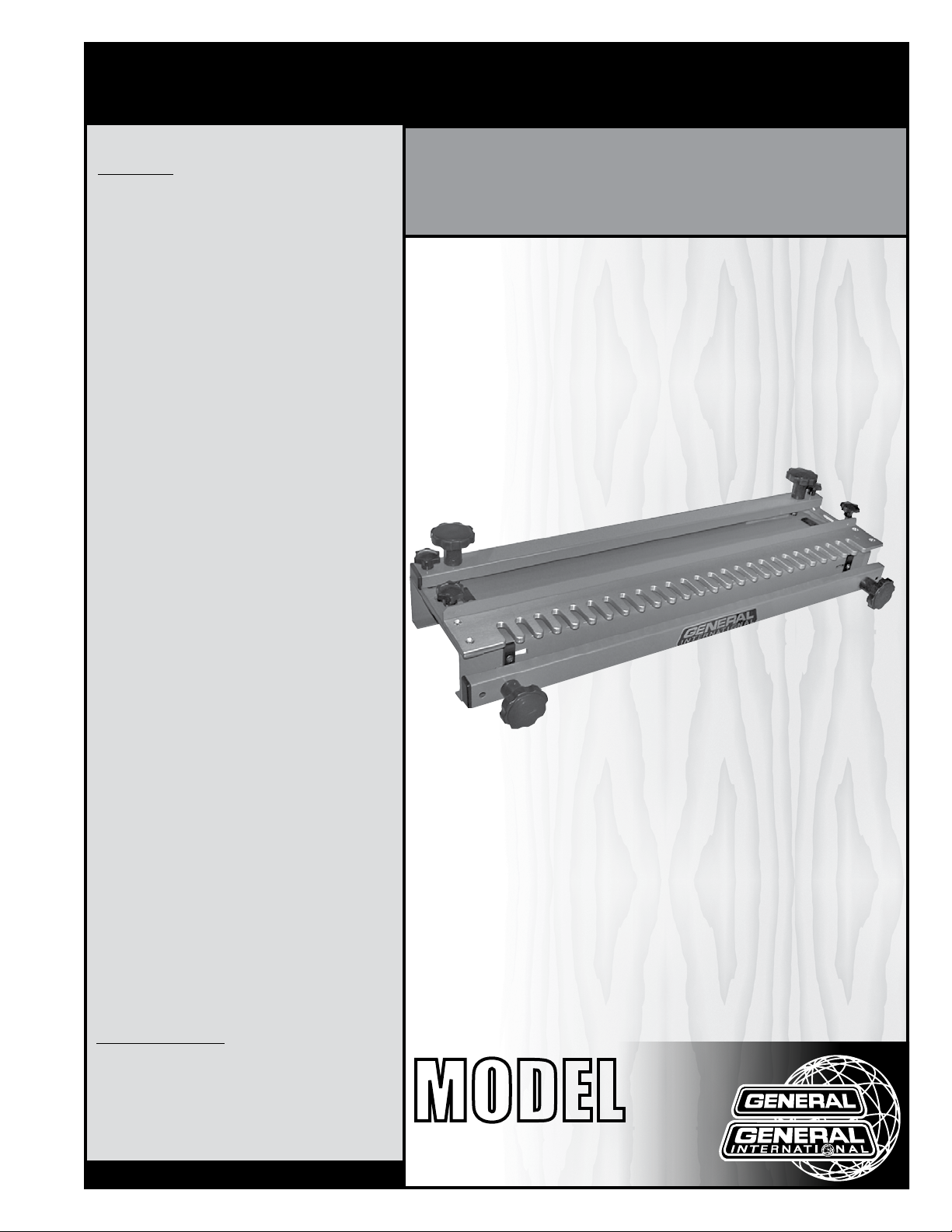

FEATURES

Male and female dovetail joints are cut simultaneously, to ensure perfectly matched dovetail

joints.

Side stops provided, allow repeated precise

dovetail joint cutting with one initial setting.

Comes with 1/2” half-blind template (#40-022).

24” DOVETAIL JIG

SPECIFICATIONS

• Thickness capacity

1/2” - 1 1/4” (13 mm - 32 mm)

• Dimensions

30 1/8” x 11 x 6 3/4” (765 x 280 x 170 mm)

• Weight

29 LBS (13 kg)

Version 2 / Revision 1 - June 2014

© Copyright General International 2014

MODEL

#

40-020

Page 2

GENERAL® INTERNATIONAL

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Telephone (514) 326-1161 • Fax (514) 326-5555 • www.general.ca

THANK YOU

for choosing this General® International item 40-020 (24”)

Dovetail jig. This dovetail jig has been carefully tested and inspected before shipment and if

properly used and maintained, will provide you with years of reliable service. For your safety,

as well as to ensure optimum performance and trouble-free operation, and to get the most

from your investment, please take the time to read this manual before assembling, installing

and operating the unit.

The manual’s purpose is to familiarize you with the safe operation, basic function, and features

of this dovetail jig as well as the set-up, maintenance and identification of its parts and

components. This manual is not intended as a substitute for formal woodworking instruction,

nor to offer the user instruction in the craft of woodworking. If you are not sure about the safety

of performing a certain operation or procedure, do not proceed until you can confirm, from

knowledgeable and qualified sources, that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for future reference.

DISCLAIMER: The information and specifications

in this manual pertain to the unit as it was supplied

from the factory at the time of printing. Because we

are committed to making constant improvements,

General® International reserves the right to make

changes to components, parts or features of this unit

as deemed necessary, without prior notice and without

obligation to install any such changes on previously

delivered units. Reasonable care is taken at the factory

to ensure that the specifications and information in

this manual corresponds with that of the unit with

which it was supplied. However, special orders and

“after factory” modifications may render some or all

information in this manual inapplicable to your unit.

Further, as several generations of this model of dovetail

jig and several versions of this manual may be in

circulation, if you own an earlier or later version of this

unit, this manual may not depict your unit exactly. If you

have any doubts or questions contact your retailer or

our support line with the model and serial number of

your unit for clarification.

Page 3

GENERAL® INTERNATIONAL WARRANTY

All component parts of General® International and Excalibur by General International® products

are carefully inspected during all stages of production and each unit is thoroughly inspected upon

completion of assembly.

Limited Lifetime Warranty

Because of our commitment to quality and customer satisfaction, General® International agrees to

repair or replace any part or component which upon examination, proves to be defective in either

workmanship or material to the original purchaser for the life of the tool. However, the Limited Lifetime

Warranty does not cover any product used for professional or commercial production purposes nor

for industrial or educational applications. Such cases are covered by our Standard 2-year Limited

Warranty only. The Limited Lifetime Warranty is also subject to the “Conditions and Exceptions” as listed

below.

Standard 2-Year Limited Warranty

All products not covered by our lifetime warranty including products used in commercial, industrial

and educational applications are warranted for a period of 2 years (24 months) from the date of

purchase. General® International agrees to repair or replace any part or component which upon

examination, proves to be defective in either workmanship or material to the original purchaser during

this 2-year warranty period, subject to the “conditions and exceptions” as listed below.

To file a Claim

To file a claim under our Standard 2-year Limited Warranty or under our Limited Lifetime Warranty,

all defective parts, components or machinery must be returned freight or postage prepaid to

General® International, or to a nearby distributor, repair center or other location designated by

General® International. For further details call our service department at 1-888-949-1161 or your local

distributor for assistance when filing your claim.

Along with the return of the product being claimed for warranty, a copy of the original proof of

purchase and a “letter of claim” must be included (a warranty claim form can also be used and can

be obtained, upon request, from General® International or an authorized distributor) clearly stating the

model and serial number of the unit (if applicable) and including an explanation of the complaint or

presumed defect in material or workmanship.

CONDITIONS AND EXCEPTIONS:

This coverage is extended to the original purchaser only. Prior warranty registration is not required but

documented proof of purchase i.e. a copy of original sales invoice or receipt showing the date and

location of the purchase as well as the purchase price paid, must be provided at the time of claim.

Warranty does not include failures, breakage or defects deemed after inspection by

General®International to have been directly or indirectly caused by or resulting from; improper use,

or lack of or improper maintenance, misuse or abuse, negligence, accidents, damage in handling

or transport, or normal wear and tear of any generally considered consumable parts or components.

Repairs made without the written consent of General® International will void all warranty.

Page 4

TABLE OF CONTENTS

Rules for safe operation .................................................................................................... 5

Identification of main parts and components .................................................................6

Unpacking ........................................................................................................................ 7

Assembly instructions .......................................................................................................7

Operating & set up......................................................................................................... 7-8

Fitting & adjusting ............................................................................................................. 8

Required tools based of template being used.................................................................9

Recommended optional accessories ..............................................................................9

Parts list & diagram ........................................................................................................10

Contact information ....................................................................................................... 12

Page 5

RULES FOR SAFE OPERATION

To help ensure safe operation, please take a moment to learn the machine’s applications and limitations,

as well as potential hazards. General

harmless for any injury that may result from the improper use of it’s equipment.

1. Learn the machine’s applications and limitations, as

well as the specific potential hazards particular to

this machine. Follow available safety instructions

and safety rules carefully.

2. Keep working area clean and be sure adequate

lighting is available.

3. Do not wear loose clothing, gloves, bracelets, neck-

laces, or ornaments. Wear face, eye, ear, respiratory

and body protection devices, as indicated for the

operation or environment.

4. Keep hands well away from router bits and all moving

parts. Do not clear chips and sawdust away wi

hands. Use a brush.

5. M

ake sure the router bit is moving at opera

speed before cutting.

6. Do not push the router bit to hard. The router bit will

perform better and be safer working at the rate for

which it was designed.

®

International disclaims any real or implied warranty and hold itself

13. Do not force the machine. It will do the job better

and be safer at a rate for which it was designed.

14. Keep guards in place and in working order. If a

guard must be removed for maintenance or clean ing make sure it is properly attached before using

the tool again.

15. Be sure that key and adjusting wrenches have been

removed before turning power on.

16. Use only accessories designed for the machine.

17. Make sure tool is properly grounded. If tool is equip-

th

ped with three-prong plug, it should be plugged into

a three-pole electrical receptacle. Never remove

the third prong.

tion

18. Always disconnect tool before servicing and when

changing accessories such as router bits.

19. Make sure that switch is in “OFF” position before

plugging in cord.

7. Whenever possible use a dust collector with shaving

hood to minimize health hazards.

8. Never leave the machine with the power on.

9. Keep children away. Make sure that visitors are kept

at a safe distance from the work area.

10. Use recommended speed router bit, accessory, and

workpiece material.

11. Never stand on tool. Serious injury could occur if the

tool is tipped or if the cutting tool is unintentionally

contacted.

12. Be sure the router bit is securely locked in the

machine.

20. Hold material firmly against the table.

21. Use ONLY recommended accessories. Use of acces sories NOT recommended by General International

may result in a risk of injury.

22. Do not use this dovetail jig for any purpose other

than its intended use. If used for other purposes,

General

plied warranty and holds itself harmless for any injury, which may result from that use.

®

International disclaims any real or im-

5

Page 6

IDENTIFICATION OF MAIN PARTS AND COMPONENTS

40-020

B

G

D

E

C

B

D

A

A. VERTICAL CLAMPING KNOB

B. HORIZONTAL CLAMPING KNOB

C. TEMPLATE LOCK KNOB

D. FENCE LOCK KNOB

A

F

E. TEMPLATE

F. VERTICAL STOP (2)

G. HORIZONTAL STOP (2)

6

Page 7

UNPACKING

Right

Carefully unpack and remove the unit and its components from its shipping container and check for missing or

damaged items.

NOTE: PLEASE REPORT ANY DAMAGED OR MISSING ITEMS TO YOUR GENERAL® INTERNATIONAL DISTRIBUTOR IMMEDIATELY.

LIST OF CONTENTS QTY

A.

24” DOVETAIL JIG .................................................................... 1

B. 1/2”ALUMINIUM TEMPLATE (INSTALLED ON JIG) ................... 1

A

OPERATION & SET-UP

You can mount the jig to a workbench through the two

mounting holes found at the rear of the jig. You can

also mount the jig to piece of plywood so that it can be

clamped to your workbench when needed.

TIP: ALWAYS SET-UP AND PRACTICE ON A TEST PIECE.

3

Left

4

(INSIDE)

Back

(INSIDE)

The 24” dovetail jig comes with a 1/2” aluminum template. It should be used with a 1/2” dovetail router bit

(1/4” shank, 14°), and a 1/2” guide bushing.

1. Lay out the workpieces and mark according to the

finished position as shown.

2. Slide the workpiece marked “Front” or “Back” B un-

der the horizontal clamping assembly as shown B.

The side marked inside should face up.

3. Set the horizontal stop E so that the edge of the workpiece lines up in the centre of one of the template

fingers as shown B.

4. Remove the template G by tightening the four screws

F.

5. Remove the vertical clamping assembly by unscrew-

ing the two knobs H.

6. Mark the workpiece 1/2” from the edge for template

finger width G. Adjust the vertical stop against the

square I.

7. Re-install the template and the vertical clamping assembly.

8. Slide the workpiece marked “Left” or “Right” under the

vertical clamping assembly. The side marked “inside”

should face out. Match up the numbers you marked.

9. Adjust the clamping pressure knobs so that the bar

is just over the workpiece. The workpiece should still

move freely, hold the workpiece in place by pushing

the lever. Excessive force should not be necessary to

clamp the workpiece.

10. Set the template back from the front edge of the

workpiece by approximately 1/8” as shown K.

Front

(OUTSIDE)

C

D

E

F

G

H

I

CENTRE

2

(OUTSIDE)

1

B

J

7

Page 8

11. Loosen the two knobs L to position the template.

Measure from the two ends of the workpiece to the

template to make sure the template is parallel to te

front edge of the workpiece.

12. The fence N should be set from the template finger

tip according to a simple equation found in “Calculating distance from fence to template finger”. Loosen the the two fence lock knobs M to position the

fence.

13. Set the router bit so it is approximately 11/16” lower

than the router base.

14. Rout off the front edge of the workpiece following

along the template fingers. Rout out the rest of the

material.

15. Remove the workpieces and verify for fit.

CALCULATING DISTANCE FROM FENCE TO TEMPLATE FINGER

EQUATION

STOCK THICKNESS TIMES TWO, PLUS ROUTER BASE RADIUS*, MINUS BIT RADIUS,

EQUALS DISTANCE FROM TEMPLATE FINGER TO FENCE.

L

M

N

K

Example

Stock thickness is 1/2”

1/2” x 2 = 1”

*Radius = Diameter ÷ 2

Router base radius is 3”

1” + 3”= 4

Router base bit

radius is 1/4”

4−1/4” = 3 3/4”

Then distance from

fence to template

finger is 3 3/4”

FITTING & ADJUSTING

• If the dovetail fit is too tight; decrease the router bit distance from router base slightly.

• If the dovetail fit is too loose increase the router bit distance from the router base slightly.

• If the pins on the side piece fit too deeply in the tails of the front or the back piece; then the cut is too deep. Move

• the fence forward the same amount the pins are exposed.

• If the side piece sticks out from the front or the back piece; then the cut is too shallow. Move the fence back the

same amount the sides stick out.

• If the edges on the front and side piece do not match adjust the stop. The front stop must be offset from the top

stop the width of the template finger at 1/2”.

• When you have the jig properly adjusted, you can dovetail the actual drawer parts.

NOTES

• Joints for the left front corner and the right rear corner of a drawer or a box are cut on the left side of the jig. Joints

for the right front corner and the left rear corner of a drawer or a box are cut on the right side of the jig.

• The drawer sides should be cut to the finished height. They can be left longer and cut to the finished length later.

• Once the desired router bit height is established make a simple gauge block out of a hardwood to quickly get the cor rect setting in the future.

• Once the stops are set properly and you have obtained the desired results use a scribe to mark the stop locations.

8

Page 9

REQUIRED TOOLS BASED ON TEMPLATE BEING USED

Dovetail template

1/4” (6 mm) 1/4” (6 mm) x 8° 5/16” (8 mm) 5 mm

1/2” (13 mm) 1/2” (13 mm) x 14° 3/8” (9.5 mm) 12.4 mm

1/2” (13 mm) 1/2” (13 mm) x 14° 7/16 (11 mm) 6.4 mm

1/2” (13 mm) 5/8” (14 mm) x 14° 15/16” (12 mm) 9.6 mm

1/2” (13 mm) 5/8” (14 mm) x 14° 1/2” (13 mm) 12.4 mm

Box joints

1/4” (6.35 mm) 1/4” 5/16” (8 mm)

3/8” (9.5 mm) 3/8” 1/2” (13 mm)

1/2” (13 mm) 1/2” 5/8” (14 mm)

Router bit (1/4” shank) Guide bushing Depth of cut

Straight Bit (1/4” shank)

Guide bushing Depth of cut

RECOMMENDED OPTIONAL ACCESSORIES

Here is a sampling of optional accessories available from your local General International dealer.

For more information about our products, please visit our website at www.general.ca

Exact thick-

ness of the

workpiece

Item #40-026 - 1/4”, #40-027 - 3/8”, #40-028 - 1/2” (Box joint template).

Item #40-021 - 1/4”, #40-022 - 1/2” (Half-blind template).

ALUMINUM DOVETAIL TEMPLATES

9

Page 10

DIAGRAM & PARTS LIST

4

14

15

10

6

12

3

16

8

5

5

1

"

2

9

11

7

2

9

4

1

3

13

10

IMPORTANT: When ordering replacement parts, always give the model number, serial number of the

machine and part number. Also a brief description of each item and quantity desired.

NO. PIECE DESCRIPTION SPECIFICATION QTY

40020-01 BASE 1

40020-02 THREADED BUSHING 4

40020-03 CLAMP BRACKET 2

40020-04 CLAMP KNOB 4

40020-05 KNOB 4

40020-06 FENCE 1

40020-07 BRACKET 2

40020-08 1/2” HALF BLIND DOVETAIL TEMPLATE (#40-022) 1

40020-09 STOPS (LONG) 2

40020-10 STOPS (SHORTS) 2

40020-11 FLAT WASHER 2

40020-12 SPRING 4

40020-13 THREADED BRACKET 4

40020-14 END CAP 4

40020-15 FLAT PHILLIPS MACHINE SCREW 10-24 X 5/8” 8

40020-16 FLAT PHILLIPS MACHINE SCREW 1/4”-20 X 3/8” 4

10

Page 11

NOTES

11

Page 12

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Tel.: (514) 326-1161

Fax: (514) 326-5565 - Parts & Service / (514) 326-5555 - Order Desk

orderdesk@general.ca

www.general.ca

Follow us:

12

Loading...

Loading...