Page 1

Double sealed ball-bearing construction.

New motor housing design for wider

work area.

Adjustable aluminum tool-rests.

MODEL 15-625

Easy-adjust cast tool-rests.

MODEL 15-825

Heavy-duty wheel guards with dust

chute.

Equipped with eye-shield protectors.

Four rubber base mounts to reduce

vibration.

Flexible ”gooseneck” style work light.

Low RPM (1725) for sharpening wood

turning and finishing tools.

Perfect for sharpening high speed

steel cutting tools.

MODEL 15-625:

WHEEL SIZES

3

6” x

⁄

” (152 x 19 mm)

4

ARBOR SPEED

1725 RPM

ARBOR SIZE

1

⁄

” (13 mm)

2

WHEEL GRITS

36/60

MOTOR

1

⁄

HP, 110 V, 1 Ph, 3.5 A

3

WEIGHT

21 LBS (9.6 kg)

MODEL 15-825:

WHEEL SIZES

3

8” x

” (203 x 19 mm)

⁄

4

ARBOR SPEED

1725 RPM

ARBOR SIZE

5

⁄

” (16 mm)

8

WHEEL GRITS

36/60

MOTOR

1

⁄

HP, 110 V, 1 Ph, 5 A

2

WEIGHT

41.8 LBS (19 kg)

VERSION 2 - REVISION 1 (June 13th, 2011)

© Copyright General International 06/2011

Page 2

GENERAL® INTERNATIONAL

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Telephone (514) 326-1161 • Fax (514) 326-5555 • www.general.ca

THANK YOU for choosing this General International model 15-625/15-825 Low

Speed Bench Grinder. This bench grinder has been carefully tested and inspected before shipment and if properly used and maintained, will provide you with years of reliable service. To

ensure optimum performance and trouble-free operation, and to get the most from your

investment, please take the time to read this manual before assembling, installing and operating the unit.

The manual’s purpose is to familiarize you with the safe operation, basic function, and features

of this bench grinder as well as the set-up, maintenance and identification of its parts and

components. This manual is not intended as a substitute for formal woodworking instruction,

nor to offer the user instruction in the craft of woodworking. If you are not sure about the safety of performing a certain operation or procedure, do not proceed until you can confirm, from

knowledgeable and qualified sources, that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for future reference.

GENERAL ® INTERNATIONAL WARRANTY

All component parts of General® International machinery are carefully tested and inspected during all stages of

production, and each machine is thoroughly inspected upon completion of assembly. Because of our commitment to quality and customer satisfaction, General® International agrees to repair or replace, within a period of 24

months from date of purchase, any genuine part or parts which, upon examination, prove to be defective in workmanship or material. In order to obtain this warranty, all defective parts must be returned freight pre-paid to

General® International Mfg. Co., Ltd. Repairs attempted without our written authorization will void this warranty.

Disclaimer: The information and specifications in this manual pertain to

the unit as it was supplied from the factory at the time of printing.

Because we are committed to making constant improvements,General

International reserves the right to make changes to components, parts

or features of this unit as deemed necessary, without prior notice and

without obligation to install any such changes on previously delivered

units. Reasonable care is taken at the factory to ensure that the specifications and information in this manual corresponds with that of the unit

with which it was supplied. However, special orders and “after factory”

modifications may render some or all information in this manual

inapplicable to your machine. Further, as several generations of this

bench grinder and several versions of this manual may be in circulation,

if you own an earlier or later version of this unit, this manual may not

depict your machine exactly. If you have any doubts or questions

contact your retailer or our support line with the model and serial

number of your unit for clarification.

Page 3

Rules for Safe Operation

To help ensure safe operation, please take a moment to learn the machine’s applications and limitations, as well as potential hazards. General International disclaims any real or implied warranty and

hold itself harmless for any injury that may result from the improper use of it’s equipment.

1. Make sure that the operator has been proper-

ly trained and has read, and understands, the

owners’ manual before operating any machinery.

2. Do not operate this bench grinder when tired, dis-

tracted or under the effects of drugs, alcohol or any

medication that impairs reflexes or alertness.

3. Keep the work area well lit, clean and free of debris

or clutter.

4. Keep children and visitors at a safe distance; do

not permit them to operate the unit.

5. Childproof and tamper proof your shop and all

machinery with locks, master electrical switches

and switch keys, to prevent unauthorized or unsupervised use.

6. Stay alert! Give your work your undivided attention.

Even a momentary distraction can lead to serious

injury.

7. Do not wear loose clothing, gloves, bracelets, neck-

laces or other jewelry while operating machinery.

Wear protective hair covering to contain long hair

and wear non-slip footwear.

8. Fine particulate dust is a carcinogen that can

be hazardous to health. Work in a well ventilated

area and wear eye, ear and respiratory protection

devices.

9. Whenever possible use a dust collector to minimize

health hazards.

13. Never leave the power on or the machine running

while it is unattended.

14. Use recommended speed grinding wheels, acces-

sories, and work piece material.

15. Never stand or lean on the bench grinder. Serious

injury could occur if the unit is tipped or if unintentional contact is made with its’ moving parts.

16. Before starting the unit, make sure the grinding

wheels are securely installed and tight to the arbor

shaft.

17. Keep all guards and safety devices in place and in

good working order. If a guard must be removed

for maintenance or cleaning make sure it is properly re-installed before using the machine again.

18. Before performing any maintenance, repairs or ad-

justments including wheel changes, make sure the

power is off and the unit is unplugged.

19. Before plugging in and turning on the power, make

sure that any adjustment tools, keys or wrenches

have been removed and safely stored.

20. Always, make sure that switch is in "OFF" position

before plugging in the power cord.

21. Only use accessories that are made or designed

for this machine. The use of parts or accessories that

are not recommended by General International

will void any warranty claims and may result in

injury.

10. Keep hands and other body parts well away from

grinding wheels and all moving parts or other

cutting tools. Do not clear chips and grinding dust

away with hands, use a brush.

11. Make sure the grinding wheels are running at full

operating speed before grinding.

12. Do not force the grinding wheels or push too hard.

The unit will perform better, safer and more effectively at the speed or rate for which it was designed.

22. Make sure the machine is properly grounded. This

unit is supplied with a three-prong electric plug; it

should be plugged into a three-pole electrical

receptacle. Never remove the third prong.

23. Do not use this bench grinder for any purpose other

than it’s intended use. If used for other purposes,

General International disclaims any real or implied

warranty and holds itself harmless for any injury

which may result from such use.

Page 4

Additional Safety Instructions

for Bench Grinders

Because each shop situation is unique, no list of safety guidelines can ever be complete.

The most important safety feature in any shop is the knowledge and good judgement of the user.

Use common sense and always keep safety considerations, as they apply to your individual shop situation first

and foremost in mind. If you have any doubts about the safety of an operation you are about to

perform: STOP! Do not perform the operation until you have validated from qualified individuals

if the operation is safe to perform and what is the safest method to perform it.

1. LIMIT EXPOSURE TO DUST

Some dust created by power sanding, sawing,

grinding, drilling and similar operations contains

chemicals known to the state of California to cause

cancer, birth defects or other reproductive harm.

Some examples include:

• Lead from lead-based paint.

• Crystalline silica from bricks, cement and

other masonry products.

• Arsenic and chromium from chemically

treated lumber.

Your risk from these exposures varies depending on

how often you do this types of work. To reduce your

exposure to these chemicals, work in a well ventilated area and work with approved safety equipment

such as dust masks that are specially designed to

filter out microscopic particles.

2. ALWAYS USE EYESHIELDS, WHEEL GUARDS AND

SPARK GUARDS

The supplied eye shields, wheel guards and spark

guards should be maintained, properly installed on

the unit and used at all times.

3. REPLACE DAMAGED PARTS OR COMPONENTS

IMMEDIATELY

Damaged parts or components may lead to a hazardous situation that could cause serious injury.

Replace any damaged parts or components before

operating the unit.

4. INSPECT GRINDING WHEELS BEFORE EACH USE

Handle grinding wheels carefully. A damaged or

chipped grinding wheel can discharge debris

towards the operator at high speeds. Before

installing or replacing a grinding wheel as well as

before each use, take a moment to inspect the

grinding wheel(s) for cracks, chips or other visible

signs of damage. Do not use a damaged wheel.

Tighten the spindle nut enough to hold the grinding

wheel firmly but do not over tighten as excessive

clamping force can damage the wheel. Use only

the wheel flanges provided with the grinder and do

not remove the blotter or label on either side of the

grinding wheel. When replacing a grinding wheel

select only wheels that are rated to a higher maximum R.P.M. than the maximum of the Bench Grinder.

5. ADJUST TOOL RESTS AND SPARK GUARDS AS

NEEDED

The diameter of the grinding wheels will decrease

with use. Adjust the tools rests and sparks guards

accordingly to maintain a distance of 1/16” from the

wheel.

6. DO NOT STAND IN FRONT OF THE BENCH

GRINDER DURING START-UP

To avoid potential injury caused by debris ejected

from a damaged wheel, stand to one side of the

Bench Grinder when starting the unit. While standing

to the side, turn the unit on, wait one minute until the

unit comes up to full speed before grinding.

7. DO NOT OPERATE IN THE VICINITY OF FLAMMABLE MATERIALS

Bench grinders will produce sparks and debris during grinding. Be sure to keep flammable materials

from the immediate vicinity. Be sure to clean the

grinding dust from the back of the Bench Grinder

frequently.

8. DO NOT FORCE THE WORKPIECE AGAINST THE

GRINDING WHEEL

Excessive force especially to a cold grinding wheel

may damage the wheel and create a dangerous

situation. Apply the workpiece against the wheel

slowly and use firm, steady even pressure. Do not

grind against the sides of the grinding wheel and do

not apply coolant direct to the grinding wheel.

9. KEEP ALL WHEEL GUARDS IN PLACE

Do not use the bench grinder with the wheel guards

removed.

10. KEEP THE TOOL RESTS FIRMLY TIGHTENED

Inspect and re-tighten tools rests before each use.

Page 5

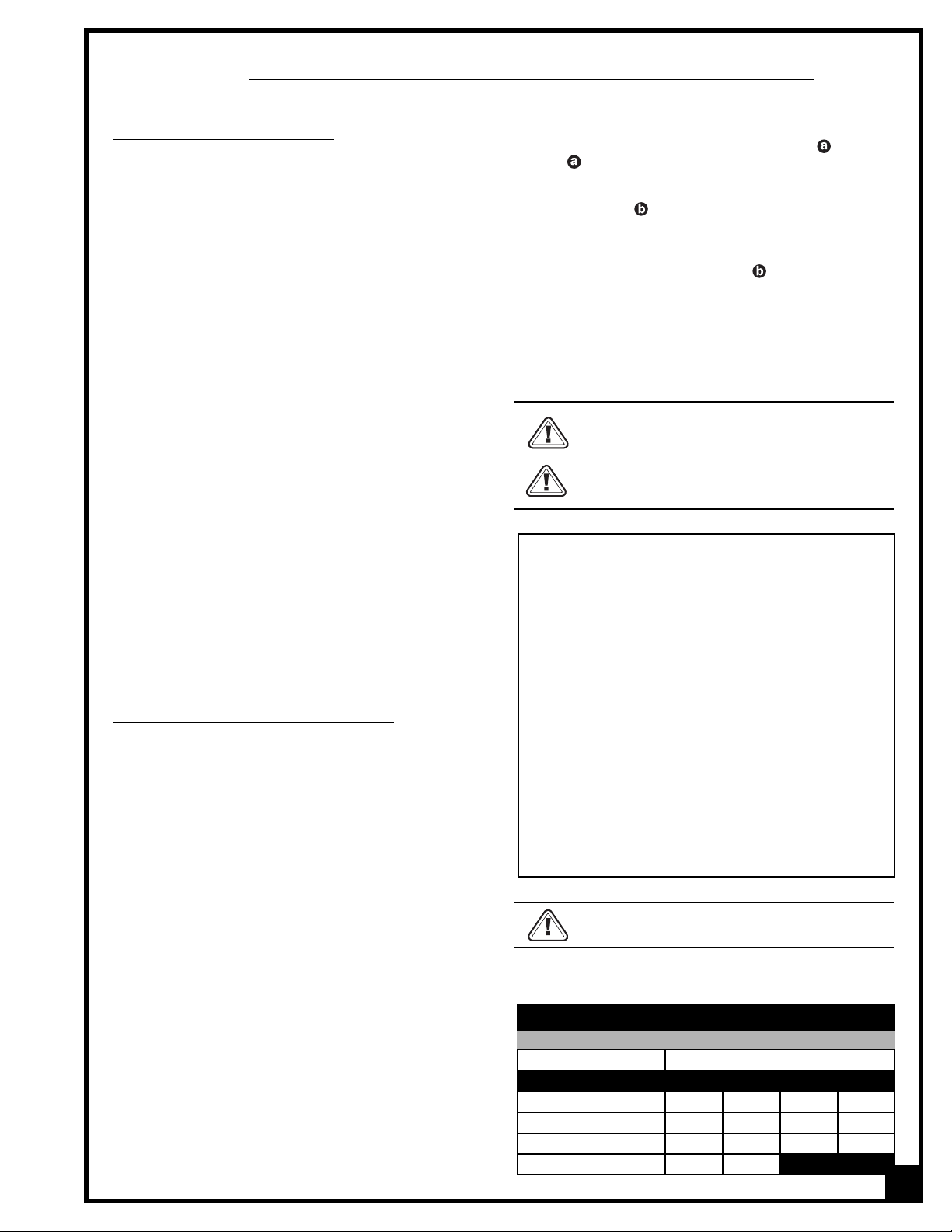

ELECTRICAL REQUIREMENTS

GROUNDING INSTRUCTIONS

IN THE EVENT OF A MALFUNCTION OR BREAKDOWN,

grounding provides a path of least resistance for electric current and reduces the risk of electric shock. This

tool is equipped with an electric cord that has an

equipment-grounding conductor and a grounding

plug. The plug MUST be plugged into a matching

receptacle that is properly installed and grounded in

accordance with ALL local codes and ordinances.

DO NOT MODIFY THE PLUG PROVIDED.

If it will not fit the receptacle, have the proper receptacle installed by a qualified electrician.

IMPROPER CONNECTION of the equipment-grounding

conductor can result in risk of electric shock. The conductor with green insulation (with or without yellow

stripes) is the equipment-grounding conductor. If

repair or replacement of the electric cord or plug is

necessary, DO NOT connect the equipment-grounding

conductor to a live terminal.

CHECK with a qualified electrician or service person if

you do not completely understand the grounding

instructions, or if you are not sure the tool is properly

grounded.

This tool is intended for use on a circuit that has a

receptacle like the one illustrated in Figure .

Figure shows a 3-prong electrical plug

and receptacle that has a grounding conductor. If a

properly grounded receptacle is not available, an

adapter (Figure ) can be used to temporarily connect this plug to a 2-contact grounded receptacle. The

temporary adapter should be used only until a properly grounded receptacle can be installed by a qualified

technician. The adapter (Figure ) has a rigid lug

extending from it that MUST be connected to a permanent earth ground, such as a properly grounded

receptacle box. The Canadian Electrical Code prohibits the use of the adapters.

In all cases, make certain the receptacle is properly grounded. If you are not sure, have a qualified electrician check the receptacle.

This tool is for indoor use only. Do not expose to

rain or use in damp locations.

USE ONLY 3-WIRE EXTENSION CORDS THAT HAVE

3-PRONG GROUNDING PLUGS AND 3-POLE RECEPTACLES

THAT ACCEPT THE TOOL’S PLUG. REPAIR OR REPLACE

DAMAGED OR WORN CORD IMMEDIATELY.

GUIDELINES FOR EXTENSION CORDS

USE PROPER EXTENSION CORD.

Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one

heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line

voltage, resulting in loss of power and cause overheating. The table below shows the correct size to

use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gauge.

The smaller the gauge number, the heavier the cord.

BE SURE YOUR EXTENSION CORD IS PROPERLY WIRED

and in good condition. Always replace a damaged

extension cord or have it repaired by a qualified person before using it. Protect your extension cords from

sharp objects, excessive heat and damp or wet areas.

Use a separate electrical circuit for your tools. This circuit must not be less than # 12 wire and should be protected with a 15 Amp time delay fuse. Before connecting the motor to the power line, make sure the switch is

in the OFF position and the electric current is rated the

same as the current stamped on the motor nameplate.

Running at a lower voltage will damage the motor.

This tool must be grounded while in use to protect

the operator from electrical shock.

MINIMUM GAUGE FOR EXTENSION CORDS (AWG)

(When using 120 volts only)

AMPERE RATING TOTAL LENGTH OF CORD IN FEET

More than not more than 25’ 50’ 100’ 150’

06 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12

not recommended

5

Page 6

6” & 8” LOW SPEED BENCH GRINDERS

15-625/15-825

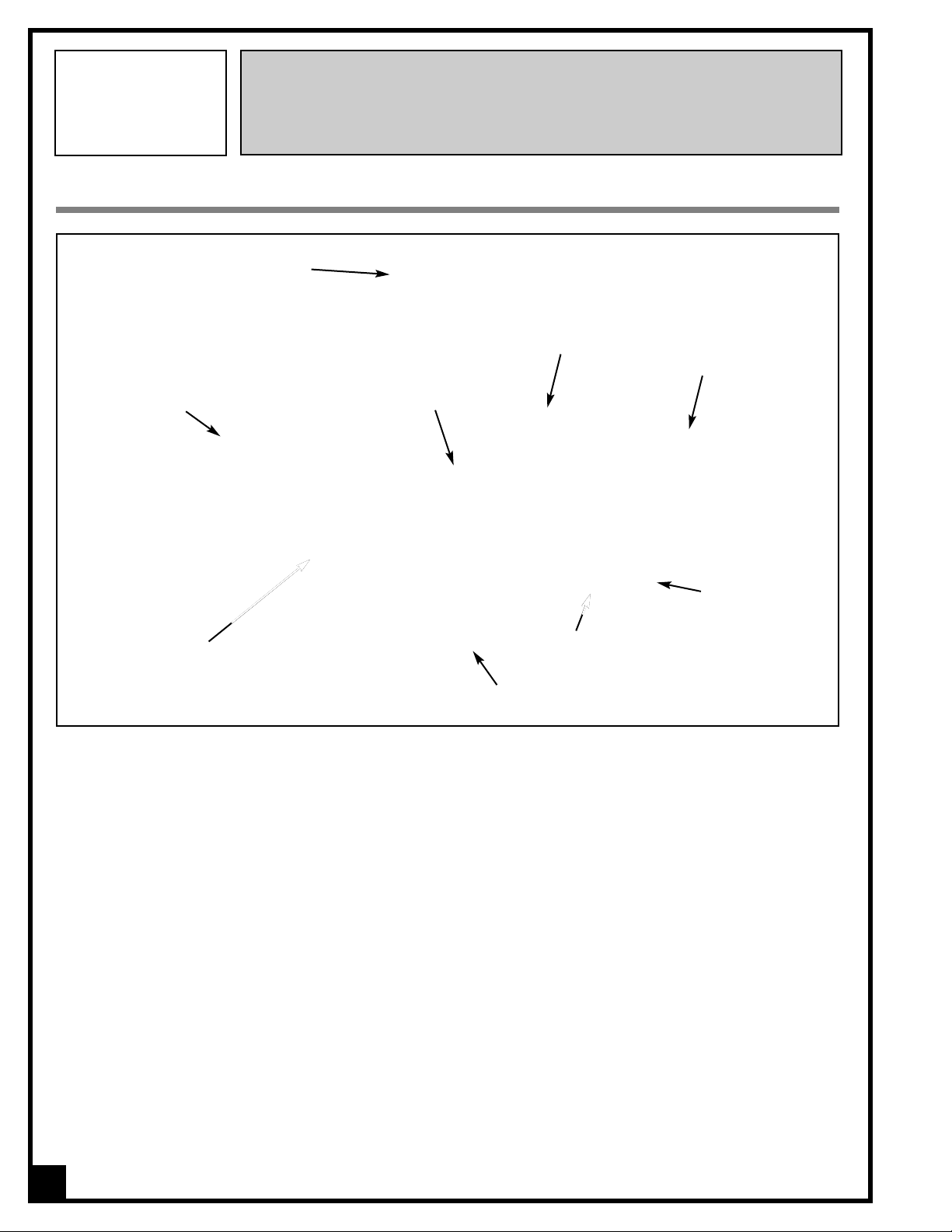

IDENTIFICATION OF PARTS & COMPONENTS

Wheel

Cover

Grinding

Wheel

Flexible

Model shown: 15-625

Work Light

Wheel

Guard

Eye Shield

Motor

Housing

Tool Rest

Tool Rest

Adjustable Supports

On/Off Switch

WHEEL GUARD – Covers the grinding wheels and protects against accidental contact.

WHEEL COVER – Covers the grinding wheels and provides access for routine maintenance.

MOTOR HOUSING – Contains the electric motor.

EYE SHIELD – Protective see- thru Lexan shields to pre-

vent any loose debris from coming into contact with

the operator.

FLEXIBLE WORK LIGHT – Illuminates the tool rest/workpiece area in front of the grinding wheel

6

TOOL REST ADJUSTABLE SUPPORTS – Allows the

operator to position the tool rest closer to the wheel as

needed as the wheel decreases in diameter due to

wear.

TOOL RESTS – Used to support the workpiece that is

being ground. Adjustable for grinding angled surfaces.

GRINDING WHEEL – Used to remove material from the

workpiece.

ON/OFF SWITCH – Used to turn “ON” and turn “OFF” the

grinder and the worklights.

Page 7

UNPACKING

Carefully unpack and remove the grinder and its components from the box and check for damaged or missing

items as per the list of contents below.

NOTE: Please report any damaged or missing items to

your General International distributor immediately.

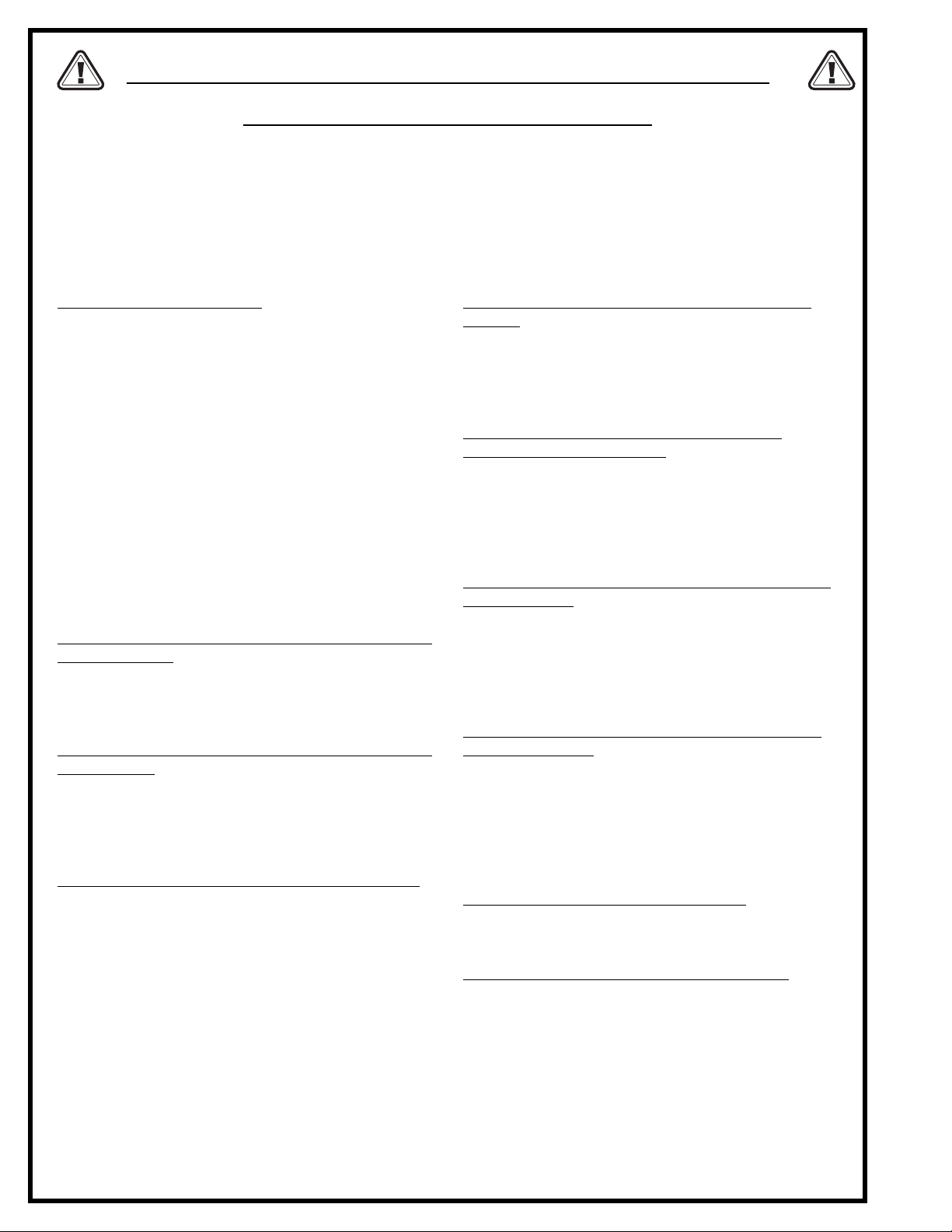

LIST OF CONTENTS (15-625)

A

aa

RIGHT TOOL REST . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

b

LEFT TOOL REST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

c

RIGHT SPARK GUARD . . . . . . . . . . . . . . . . . . . . . . . . . .1

d

LEFT SPARK GUARD . . . . . . . . . . . . . . . . . . . . . . . . . . .1

e

BRACKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

f

STEEL PLATE FOR EYE SHIELD . . . . . . . . . . . . . . . . . . . .2

g

EYE SHIELD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

h

FLAT WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

i

HEX NUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

j

PHILLIPS HEAD SCREW . . . . . . . . . . . . . . . . . . . . . . . . .4

k

FLAT WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

l

10 MM HEX BOLT . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

m

FLAT WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

n

12 MM BOLT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Qty

A

c d

e

f

a

b

g

h

j

i

k

l

B

LIST OF CONTENTS (15-825)

aa

RIGHT TOOL REST . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

b

LEFT TOOL REST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

c

TOOL REST HANDLE . . . . . . . . . . . . . . . . . . . . . . . . . . .2

d

KNOB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

e

RIGHT SPARK GUARD . . . . . . . . . . . . . . . . . . . . . . . . . .1

f

LEFT SPARK GUARD . . . . . . . . . . . . . . . . . . . . . . . . . . .1

g

STEEL PLATE FOR EYE SHIELD . . . . . . . . . . . . . . . . . . . .2

h

EYE SHIELD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

i

BRACKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

j

FLAT WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

k

10 MM HEX BOLT . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

l

FLAT WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

m

HEX NUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

n

PHILLIPS HEAD SCREW . . . . . . . . . . . . . . . . . . . . . . . . .4

o

12 MM BOLT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

p

FLAT WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

ADDITIONAL REQUIREMENTS FOR SET UP

• Phillips screwdriver

• Flat-head screwdriver

•

7 mm open-end wrench

• 10 mm open-end wrench

• 12 mm open-end wrench

• 18 mm open-end wrench

• 22 mm open-end wrench

Qty

B

m

n

m

n

a b

d

c

e f

j

k

l

g

i

h

o

p

7

Page 8

ASSEMBLY INSTRUCTIONS (15-625)

For your own safety, never connect the plug to power source outlet until all assembly and adjustment steps are

completed, and you have read and understood the safety and operating instructions.

INSTALLING THE TOOL RESTS

The grinder is supplied with two different tool rest assemblies. The

left side tool rest is entirely flat. The right side tool rest is also flat,

but has a “V” groove for sharpening drill bits.

1. Attach the tool rest (A) to the support using a 12 mm bolt (B)

through a big flat washer for 12 mm bolt (C).

2. Adjust the tool rest until it is 1/16” from the grinding

wheel. Firmly tighten the hex head bolt holding the support.

3. Repeat for the other tool rest.

INSTALLING THE SPARK GUARDS

1. Install the spark guard (D) to the inside

surface of the wheel cover (E) and put

the bracket (F) between those two parts

and tighten a little using a flat washer for

10 mm hex screw (G) and a 10 mm h e x

screw (H).

2. Adjust the spark guard to the right angle

and until it is 1/16” from the grinding

wheel. Firmly tighten the hex head bolt.

3. Repeat for the other spark guard.

H

G

C

B

A

F

E

D

INSTALLING THE EYE SHIELDS

1. Attach the eye shield (A) to the spark guard by inserting (in

this order) the Phillips head screw (B), the flat washer for

Phillips head screw (C), the steel plate for eye shield (D) and

the eye shield (E) through the spark guard bracket (F) and

by putting a hex nut (G) at the lower extremity.

2. Secure the assembly to the spark guard by tighting it until the

eye shield remains in the desired position.

3. Repeat for the other eye shield.

A

B

E

C

D

F

G

8

Page 9

ASSEMBLY INSTRUCTIONS (15-825)

For your own safety, never connect the plug to power source outlet until all assembly and adjustment steps are

completed, and you have read and understood the safety and operating instructions.

INSTALLING THE TOOL REST HANDLES

The grinder is supplied with two tool rest.

1. Attach the tool rest handle (A) to the support using two 12 mm bolts

(B) through two big flat washers for 12 mm bolt (C).

2. Repeat with the other tool rest handle.

B

C

ASSEMBLING THE TOOL REST

1. Once the tool rest handle is installed, use the knob (D) to fix the tool

rest plater (E) to the handle (F).

2. Adjust the tool rests until they are 1/16” from the grinding wheel. Firmly

tighten the hex head bolt holding the support.

3. Repeat for the other tool rest.

D

E

A

I

H

K

G

1. Install the spark guard (G) to the inside surface of

the wheel cover (H) and put the bracket (I) between those two parts and

tighten a little using a flat washer for 10 mm hex screw (J) and a 10 mm hex screw (K).

2. Adjust the spark guards to the right angle and until they are 1/16” from the grinding wheels. Firmly tighten the

hex head bolt.

3. Repeat for the other spark guard.

J

INSTALLING THE SPARK GUARDS

F

INSTALLING THE EYE SHIELDS

1. To install the eye shields (A) to spark guard, refer to model 15-625 on

page 8 - eye shields installation.

2. Repeat for the other eye shield.

SECURING THE GRINDER TO A WORK SURFACE

Note: To avoid tipping over or sliding during operations,

the grinder should be secured to the work surface or

optional stand.

1. The base of the grinder has 4 mounting holes allo-

wing the user to permanently mount the grinder to a

workbench or stand.

2. Place the grinder on the work surface, mark the holes

on the work surface and drill 3/8” holes. Use appropriate length bolts, washers and nuts to secure to

secure the grinder to the bench.

3. If the workbench moves or shakes during operation,

the workbench must be fastened to the floor.

4. The grinder is designed for use on horizontal surfaces

only. Motor damage may result when mounted on a

non-horizontal surface.

A

1. Bench grinder

2. Hex head bolt

3. Rubber washer

4. Flat washer

5. Workbench or stand

6. Flat washer

7. Lock washer

8. Hex nut

9. Jamb nut

9

Page 10

OPERATIONS

ADJUSTMENTS AND CONTROLS

POWER “ON/OFF” SWITCH

POWER ON

Make sure the switch is in the “OFF” position

before plugging in the power cord.

POWER OFF SAFETY KEY

(PREVENTS START-UP WHEN REMOVED)

Remove the switch key whenever the grinder is

not in use. Place it in a safe place and out of the

reach of children.

FLEXIBLE WORK LIGHT

The work light functions on the same switch as the grinder.

To reduce the risk of fire, use a 110V 10 Watt (or less) medium base, track light bulb. Do not use a bulb that

extends past the end of the light housing.

GRINDER OPERATION

The bench grinder is designed for hand held grinding, sharpening, and cleaning operations.

ALWAYS WEAR EYE PROTECTION! Hot sparks are produced during grinding operations.

1. The power switch must be in the “OFF” position.

2. Make sure the spark guards and tool rests are set 1/16” from the grinding wheels. Before starting the machine,

turn the grinding wheel by hand one full turn to make certain the wheels to do not come into contact with the

spark guards or tools rests.

3. Stand to the side of the bench grinder and plug in the power cord to the correct power source.

4. Remain to the side of the bench grinder and turn it “ON”.

5. Allow the grinding wheels to come up to a steady speed for at least one minute.

6. Adjust the eye shields as needed and place the workpiece on the appropriate tool rest for the desired operation.

7. Slowly move the workpiece towards the grinding wheel until it lightly touches. Move the workpiece back and

forth across the front surface of the grinding wheel removing the amount of material desired. NEVER GRIND

ON THE SIDES OF THE GRINDING WHEELS.

8. For drill bits, lay the drill bit flat in the “V” groove. Firmly hold on to the dril bit shank. Slide the drill bit toward

the grinding wheel until it lightly touches. Keep the drill bit flat to the plate and rotate the drill bit.

9. When finished grinding turn “OFF”the machine by pushing down on the Power Switch. CAUTION: It will take a few

minutes for the grinding wheels to come a complete stop.

10. Avoid contact with the housing until it is cool. Unplug the Bench Grinder and to prevent unauthorized use,

remove the switch key and store it in a safe place.

10

Page 11

CHANGING GRINDING WHEELS

To avoid injury from accidental starting, always turn the switch off and unplug the machine from the power

source before changing the wheels.

NOTE: Do not remove the cardboard discs (blotters) from the sides of a new wheel

because they work with the flanges to hold and secure the wheel on the arbor.

Inspect the new wheel for cracks or other visible signs of damage. Discard

the wheel if any such damage is found.

Two end plates will need to be removed for wheel changes.

A

1. Remove the screws and take off the

2. Hold the drive shaft on the right hand

side by inserting the tip of a large-size

plain flat head screwdriver into the

slotted end of the arbor shaft (B), and

remove the locking nut (C) with an

open end wrench.

3. Remove the wheel flange (D), slide

off the old wheel (E) and put a new

one on.

4. Re-intall the flange (D) and the nut

(C).

5. Position a screwdriver in the slot in the

arbor shaft (B), and re-tighten the nut

(C) on the arbor.

Note: Over tightening can crack the

wheel.

6. Re-install the wheel cover (A).

MAINTENANCE

wheel cover (A).

B

E

D

C

Turn the power switch “OFF” and unplug the power cord from its power source prior to any maintenance.

LUBRICATION

The Bench Grinder has sealed lubricated bearings in the motor housing that do not require any additional lubrication.

CAUTION: Remove and replace grinding wheels if there is any damage at all. FAILURE to replace a damaged

wheel can cause serious injury to the operator.

CAUTION: DO NOT USE FLAMMABLE MATERIALS to clean the Bench Grinder. A clean dry rag or brush is all that is

needed to remove dust and debris buildup.

Repairs to the Bench Grinder should be performed by qualified and trained personnel only. Contact your nearest

General International dealer for authorized service. Unauthorized repairs or replacement with non-factory parts

could cause serious injury to the operator, damage to the Bench Grinder and void the warranty.

11

Page 12

RECOMMENDED OPTIONAL ACCESSORIES

We offer a large variety of products for increased convenience, productivity, accuracy and safety when using

your Here’s a small sampling of optional accessories available from your local General International dealer.

For more information about our products, please visit our website at www.general.ca

STAND

#15-700

35 3/4” (908 mm) high

stand for 6” or 8” bench

grinder.

Heavy duty cast iron table

& base, tubular steel column.

DELUXE GRINDING

WHEEL DRESSER

#99-160

HEAVY-DUTY STAND

#15-710

34” (863 mm) high stand

for 6”, 8” or 10” bench

grinders.

Heavy duty cast iron

table & base, tubular

steel column. Water tray

Included.

12

Page 13

43

26

10

23

27

25

24

36KL

36KR

12

45

54453

46

13

16

5

15

1

11

2

10

4

48

47

2

6

8

6

9

2

3

44

7

17

2

2

4

MOTOR

28A

34A

38

42

36

39

22

18

6

20

4

19

21

28

29

30

31

35

33

34

50

52

49

32

4

2

2

4

2

37

4

2

2

2

2

4

40

4

41

51

2

2

14

55

56

36KIT

DIAGRAM 15-625

13

Page 14

14

PARTS LIST

15-625

PART N0. DESCRIPTION QTY

15625-01 STATOR & COPPER WINDING 1

15625-02 ROTOR & SHAFT 1

15625-03 BALL BEARING 2

15625-04 BEARING COVER 2

15625-05 FAN BLADE 2

15625-06 PIN 1

15625-07 MOTOR HOUSING (FRONT) 1

15625-08 MOTOR HOUSING (REAR) 1

15625-09 SPRING WASHER 6

15625-10 CROSS HD SCREW 4

15625-11 CROSS HD SCREW 2

15625-12 CAPACITOR, SQUARE 1

15625-13 CROSS HD SCREW W/WASHER 1

15625-14 TOOTH WASHER 1

15625-15 COPPER WASHER 1

15625-16 CROSS HD SCREW W/WASHER 1

15625-17 WHEEL GUARD INNER (RH) 1

15625-18 CROSS HD SCREW W/WASHER 6

15625-19 WHEEL WASHER 4

15625-20 GRINDING WHEEL A36 1

15625-21 WHEEL NUT (RH) 1

15625-22 WHEEL GUARD OUTER (RH) 1

15625-23 CROSS HD SCREW 10

15625-24 WHEEL GUARD INNER (LH) 1

15625-25 GRINDING WHEEL 1

15625-26 WHEEL NUT (LH) 1

15625-27 WHEEL GUARD OUTER (LH) 1

15625-28 TOOL REST (RH) 1

15625-28A TOOL REST KIT RH 1

15625-29 TOOL REST BRACKET 1

15625-30 TOOL REST BRACKET 2

15625-31 KNOB 2

15625-32 FLAT WASHER 4

15625-33 BOLT 4

15625-34 TOOL REST (LH) 1

15625-34A TOOL REST KIT (LH) 1

15625-35 TOOL REST BRACKET 1

15625-36KR RIGHT SIDE EYE SHIELD ASS'Y 1

15625-36KL LEFT SIDE EYE SHIELD ASS'Y 1

15625-36KIT SHIELD ASS'Y KIT 1

15625-36 EYESHIELD PLATE 2

15625-37 STEEL PLATE FOR EYESHIELD 2

15625-38 EYESHIELD BRACKET 2

15625-39 PHILLIPS HEAD SCREW 4

15625-40 FLAT WASHER 4

15625-41 HEX NUT 4

15625-42 SPARK GUARD 1

15625-43 FLAT WASHER 2

15625-44 HEX BOLT 2

15625-45 SPARK GUARD 1

15625-46 SWITCH 1

15625-47 STRAIN RELIEF BUSHING 1

15625-48 POWER CORD 1

15625-49 WORKING LIGHT ASSY. 1

15625-50 OUTLET CORD 1

15625-51 TERMINAL 1

15625-52 TERMINAL 2

15625-53 BOTTOM PLATE 1

15625-54 RUBBER FOOT W/SCREW 4

15625-55 SPRING WASHER 1

15625-56 NUT 1

15625-MOTOR MOTOR 1

Page 15

50

55

52

23

27

48

58

53

54

12

13

26

35

25

19

56

24

6

7

51

5

3

45

57

1

30

11

10

9

46

47

31

4

15

14

16

29

49

2

43

8

44

17

38

42

36

36A

36B

39

18

41

40

37

20

21

22

34N

28N

28A

MOTOR

33

32

61

60

61

59

59A

32

33

DIAGRAM 15-825

15

Page 16

16

PARTS LIST

15-825

PART N0. DESCRIPTION QTY

15825-01 STATOR AND COPPER WIRE 1

15825-02 ROTOR AND SHAFT 1

15825-03 BALL BEARING 2

15825-04 BASE 1

15825-05 FAN 1

15825-06 CROSS HEAD SCREW WITH WASHER 3

15825-07 MOTOR COVER (LH) 1

15825-08 MOTOR COVER (RH) 1

15825-09 FLAT WASHER 2

15825-10 SPRING WASHER 2

15825-11 HEX SCREW 2

15825-12 CONDENSER 1

15825-13 CROSS HEAD SCREW WITH WASHER 1

15825-14 TOOTH WASHER 1

15825-15 COPPER WASHER (L) 1

15825-16 CROSS HEAD SCREW WITH WASHER 1

15825-17 INNER COVER (R.H.) 1

15825-18 CROSS HEAD SCREW WITH WASHER 6

15825-19 WHEEL WASHER 4

15825-20 GRINDING WHEEL A60 1

15825-21 WHEEL NUT (RT) 1

15825-22 WHEEL GUARD OUTER (RH) 1

15825-23 CROSS HEAD SCREW 10

15825-24 INNER COVER (LH) 1

15825-25 GRINDING WHEEL A36 1

15825-26 WHEEL NUT (LT) 1

15825-27 WHEEL GUARD OUTER (LH) 1

15825-28N TOOL REST (LH) 1

15825-28A TOOL REST KIT (LH) 1

15825-29 SWITCH PLATE 1

15825-30 CROSS HEAD SCREW WITH WASHER 2

15825-31 FERRULE 1

15825-32 FLAT WASHER 4

15825-33 HEX SCREW 4

15825-34N TOOL REST BRACKET (LH) 1

15825-35 C-CLIP 2

15825-36A RIGHT SIDE EYE SHIELD ASS'Y 1

15825-36B LEFT SIDE EYE SHIELD ASS'Y 1

15825-36 EYE SHIELD 2

15825-37 EYE SHIELD FIXTURE 2

15825-38 EYE SHIELD BRACKET 2

15825-39 CROSS HEAD SCREW 4

15825-40 FLAT WASHER 4

15825-41 HEX NUT 4

15825-42 SPARK GUARD (RH) 1

15825-43 FLAT WASHER 2

15825-44 HEX SCREW 2

15825-45 SPARK GUARD (LH) 1

15825-46 SWITCH 1

15825-47 STRAIN CLAMP 1

15825-48 POWER CORD 1

15825-49 WORKING LAMP 1

15825-50 BAFFLE BOARD 1

15825-51 CROSS HEAD SCREW WITH WASHER 2

15825-52 TERMINAL A1 2

15825-53 BASE PLATE 1

15825-54 FOOT PAD 4

15825-55 TERMINAL A3 2

15825-56 FLAT WASHER 1

15825-57 HEX NUT 1

15825-58 CROSS HEAD SCREW WITH WASHER 4

Page 17

PARTS LIST

15-825

PART N0. DESCRIPTION QTY

15825-59 TOOL REST (RH) 1

15825-59A TOOL REST KIT (RH) 1

15825-60 TOOL REST BRACKET (RH) 1

15825-61 KNOB 2

15825-MOTOR MOTOR 1

Notes

17

Page 18

15-625 / 16-825

8360, Champ-d’Eau, Montreal (Quebec)

Canada H1P 1Y3

Tel.: (514) 326-1161

Fax : (514) 326-5565

Parts & Service

Fax : (514) 326-5555 Order Desk

orderdesk@general.ca

www.general.ca

IMPORTANT: When ordering replacement parts, always give the model number, serial number of

the machine and part number. Also a brief description of each item and quantity

desired.

Loading...

Loading...