Fuji Electric PXF5 Operating Manual

- 1 -

Model : PXF5/9

Micro Control X

Instruction Manual

INP-TN2PXF5/9a-E

Grobal Sales Section

Instrumentation & Sensors Planning Dept.

1, Fuji-machi, Hino-city, Tokyo 191-8502, Japan

http://www.fujielectric.com

Phone: +81-42-514-8930 Fax: +81-42-583-8275

http://www.fujielectric.com/products/instruments/

Thank you for purchasing the Fuji module type temperature controller.

Once you have conrmed that this is the product you ordered, please use it in accordance with the following

instructions.

For detailed information on operating this equipment, please refer to the separate user's manual.

In addition, please keep this instruction manual within easy reach of the actual person using this equipment.

Please Read First (Safety Warnings)

Please read this section thoroughly before using and observe the mentioned safety warnings fully.

Safety warnings are categorized as “Warning” or “Caution”. Failure to follow the instructions may

result in a safety hazard.

Warning

mishandling may lead to minor or serious personal injury, re, and/or property damage.

Caution

Mishandling may cause injury to the user or property damage.

If the equipment is used in a manner not specied by the manufacturer, the protection provided by the

equipment may be impaired.

1. Warning

1-1. Limitations in Use

This product is a temperature controller which was developed, designed and manufactured on the

premise that it would be used for general machinery.

In particular, if this product is to be used for applications that require the utmost safety as described

below, please take into consideration of the safety of the entire system and the machine by adopting

such means as a fail-safe design, a redundancy design as well as the conducting of periodical

inspections.

• Safety devices for the purpose of protecting the human body

• Direct control of transportation equipment

• Airplanes

• Space equipment

• Atomic equipment, etc.

Please do not use this product for applications which directly involve human lives.

CAUTION

The contents of this manual are subject to change without notice.

This manual is complied with possible care for the purpose of accuracy, however,

Fuji Electric shall not be held liable for any damages, including indirect damage, caused by

typographical errors,

absence of information or use of information in this manual.

1-2. Installation and Wiring

► This equipment is intended to be used under the following conditions.

Ambient temperature -10 °C to 50 °C

Ambient humidity 90% RH or below (with no condensation)

Overvoltage category II

by IEC 61010-1

Pollution degree 2

Recommended fuse

250VAC, 0.1A T(Time-Lag) for 100 to 240V AC Power supply,

400V DC/400V AC, 1A T(Time-Lag) for 24V DC/24V AC Power supply

Usage environment Indoor use

► If accessible Safety Extra Low Voltage (SELV) circuits are to be connected to Signal input terminal,

SSR Drive output terminal, Current output terminal or Communication (RS485) terminal, ensure

to provide a basic insulation between the SELV circuits and these terminals (For example, use

transformer which has a basic insulation or higher degree of insulation). The basic insulation

requires a clearance at least 1.5 mm and a creepage of at least 3.0 mm. If such insulation is not

provided, the UL61010 and EN61010 safety compliance may become invalid.

► For 24V DC/AC power supply model, if the equipment is connected to the Safety Extra Low

Voltage (SELV) circuit, a basic insulation must be provided between the SELV circuit and the

power input terminals. Otherwise, the power input terminals must be connect to Extra Low Voltage

(ELV) circuit so as to prevent the electric shock.

► For CT input, use Current Transfer which has specication as shown below in order to prevent the

electric shock and spread of re.

1) Over Voltage Category II

2) Pollution Degree 2

3) Required level of Insulating

BASIC INSULATION, SUPPLYMENTARY INSULATION,

or REINFORCED INSULATION

4) Maximum Voltage line to neutral 300Vac rms or 300Vdc

About safety standard

Please observe the following instructions to meet the requirements of safety standard.

Failure to observe these instructions violates safety standards. (This product is not a safety equipment.)

………………………………………………………………………………………………………………………………

● Install a recommended fuse, which is specied in the instruction manual, between the external main power

(mains circuit) and this equipment.

● If accessible Safety Extra Low Voltage (SELV) circuits are to be connected to Signal input terminal, SSR

Drive output terminal, Current output terminal or Communication (RS485) terminal, ensure to provide a

basic insulation between the SELV circuits and these terminals (For example, use transformer which has a

basic insulation or higher degree of insulation). The basic insulation requires a clearance at least 1.5 mm

and a creepage of at least 3.0 mm. If such insulation is not provided, the UL61010 and EN61010 safety

compliance may become invalid.

● Whole this equipment must be mounted in an enclosure in order to prevent the electric shock and spread

of re.

● Be sure to install an appropriate external protective circuit to prevent excessive temperature rise etc.

● When performing wiring work, be sure to turn the power off and to wear protection gloves or safety glasses,

to prevent an electric shock.

● Set proper parameter input signals which correspond to each input to be connected. Be careful not to

confuse voltage input with current input, or vice versa.

● Do not use this equipment for the measurement of circuits which falls under measurement categories II, III,

or IV.

● Do not use this equipment for measurement of signals to which a voltage over 30 VRMS or over 60 V DC is

applied.

● If there is a risk that anyone may come into contact with the terminal while the instrument is being

energized, attach the terminal cover (optional) to prevent an electric shock. Before removing a terminal

cover, turn off all the power.

………………………………………………………………………………………………………………………………

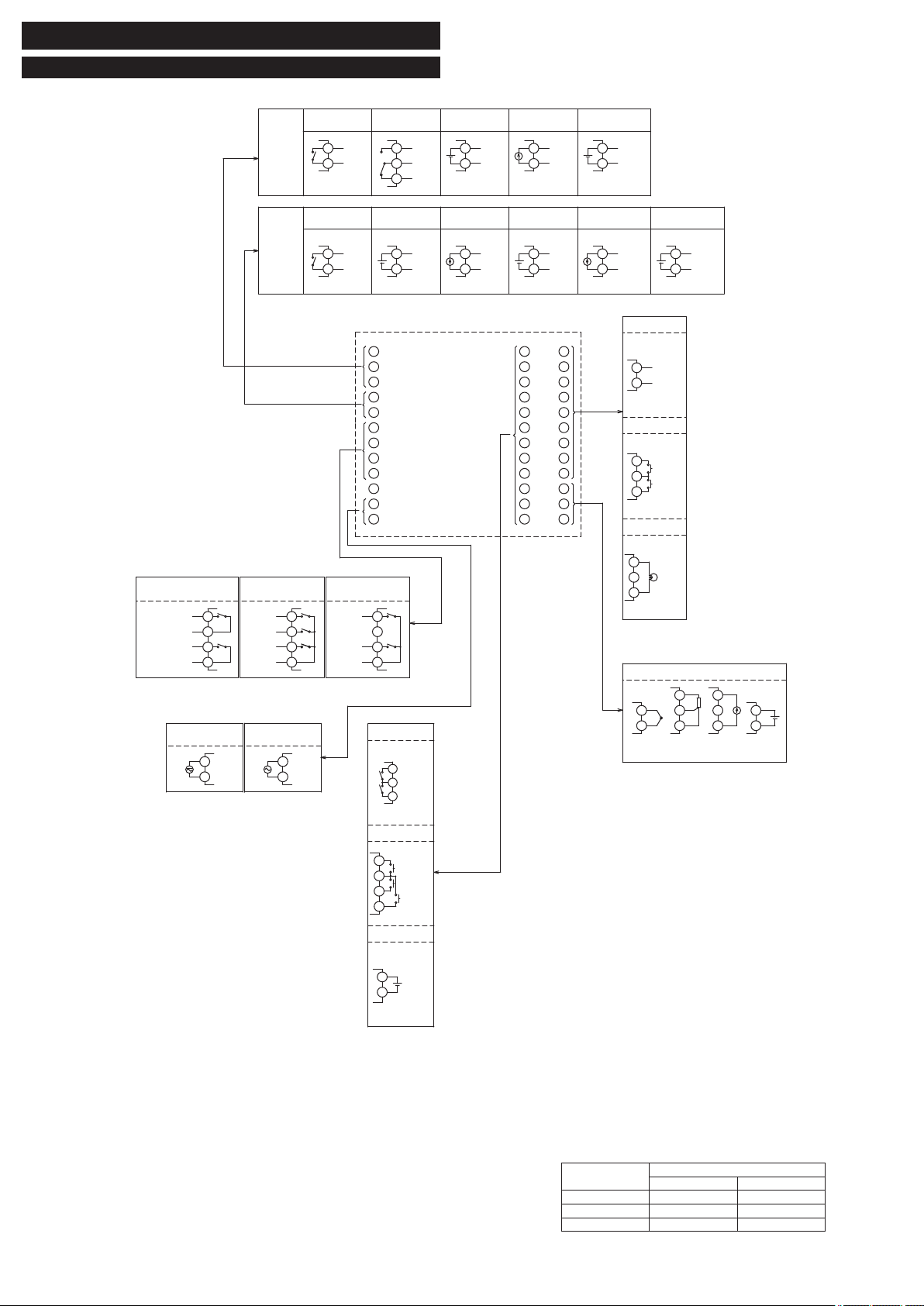

► Note that the insulation class for this equipment is as follows. Before installing, please conrm that

the insulation class for equipment meets usage requirements.

Internal circuit

Process value input

Remote SV input

CT input

Valve position feedback

(PFB) input

Control output 1

(SSR drive, current, voltage)

Valve position feedback

(PFB) input

Control output 1

(SSR drive, current, voltage)

Control output 2 (SSR drive, current,

voltage) or Transfer output

Control output 2 (SSR drive, current,

voltage) or Transfer output

Digital input 1 to 5

Communication (RS-485)

Power supply (100 to 240V AC)

Control output 1 (relay contact)

or

Motorized valve OPEN output

Control output 2 (relay contact)

or

Motorized valve CLOSE output

Alarm output 1

(relay contact)

Alarm output

1 to 3

(relay contact)

Alarm output 2

(relay contact)

Control output 1 (relay contact)

or

Motorized valve OPEN output

Control output 2 (relay contact)

or

Motorized valve CLOSE output

Alarm output 1

(relay contact)

Alarm output

1 to 3

(relay contact)

Alarm output 2

(relay contact)

Basic insulation (1500 V AC) Functional insulation (500 V AC) No insulation

(1) (2) (1) (2)

Internal circuit

Process value input

Remote SV input

CT input

Digital input 1 to 5

Communication (RS-485)

Power supply (24V DC/24V AC)

Alarm output 4 and 5 (relay contact) Alarm output 4 and 5 (relay contact)

(1):When the 9th code is "J" AL 1 and 2: independent common

(2):When the 9th code is other than "J" AL 1 to 3: shared common

● A power switch or a circuit breaker should be installed within the power supply facility.

● A power switch or a circuit breaker should be properly installed within easy reach of an operator.

● A power switch or a circuit breaker should be identied as the one for this product.

● Electrical wiring must be made by the qualied personnel only and in accordance with your local

and national standards.

● For power supply wiring, use wire equal to 600V vinyl insulated wire or above.

● To prevent damage and failure of the equipment, provide the rated power voltage.

● To prevent shock and equipment failure, do not turn the power ON until all wiring is complete.

● Before turning on power, conrm that clearance space has been secured to prevent shock or re.

● Do not touch the terminal while the machine is on. Doing so risks shock or equipment errors.

● Never disassemble, convert, modify or repair this equipment. Doing so risks abnormal operation,

shock or re.

● If any failure occurs, please contact the manufacturer and return the product.

● Output relay is the part has a limited life. When output relay contact comes to the end of its life, it

might remain on-state, or off-state. For safety, use a protective circuit outside.

● The factory default setting of this equipment is as follows. Change the setting as necessary so

as the equipment to meet your application. Please note that the improper settings may result in

overheat or unexpected damage.

For the details of operation, refer to the separate volume, "Operation Manual (INP-TN5A2400-E)".

Control output 1: heating control

Control output 2 (optional): cooling control

Alarm output 1 (optional): no alarm

Alarm output 2 (optional): no alarm

Alarm output 3 (optional): no alarm

Alarm output 4 (optional): no alarm

Alarm output 5 (optional): no alarm

● Symbols on the instrument

: Read this instruction manual thoroughly before using the product, and usethe product safely.

1-3. Maintenance

● When installing or removing the equipment, turn the power OFF. Otherwise, shock, operational

errors or failures may be caused.

● Periodic maintenance is recommended for continuous and safe use of this equipment.

● Some parts installed on this equipment have a limited life and/or may deteriorate with age.

● The warranty period for this unit (including accessories) is three years after the date of manufacture,

if the product is used properly.

Conrming Specications and Accessories

Before using the product, confirm that it

matches the type ordered.

(For model code, please refer to pages 22 - 23.)

Conrm that all of the following accessories are

included.

Temperature Controller 1 unit

Instruction Manual 1 copy

Panel mounting adapter 2 pc

Waterproof packing 1 pc

Related Information

Refer to the following reference materials

for details about the items described in this

manual.

Document Reference No.

Data sheet

EDS11-179

EDS11-180

Micro Controller (Model: PXF)

Operation Manual

INP-TN5A2400-E

Micro Controller (Model: PXF)

Communication Functions

Manual (MODBUS)

INP-TN5A2227-E

The latest manuals can also be downloaded at the

following URL:

http://www.fujielectric.com/products/instruments/

Option

Name Quantity Order No.

Terminal cover* 1 pc ZZPPXF1-B100

PC loader

communication cable

1 cable ZZP*TQ501923C3

Shunt resistor

(250Ω ± 0.1%)

1 pc ZZPPXR1-A190

*For PXF9, two terminal covers are necessary for one unit.

- 2 -

- 3 -

2. Caution

2-1. Cautions when Installing

Please avoid installing in the following locations.

● Locations in which the ambient temperature falls outside the range of –10 to 50°C when equipment

is in use. (If the power supply is 200V AC, the recommended maximum ambient temperature is

45°C.)

● Locations with rapid temperature changes, leading to dew condensation

● Locations with corrosive gases (especially sulde gas, ammonia, etc.) or ammable gases.

● Locations with vibration or shock directly. (Vibration and shock may cause output relay malfunction.)

● Locations in contact with water, oil, chemicals, steam or hot water.

(If the equipment gets wet, there is a risk of electric shock or fire, so have it inspected by Fuji

distributor.)

● Locations with high concentrations of atmospheric dust, salt or iron particles.

● Locations with large inductive interference, resulting in static electricity, magnetic elds or noise

● Locations in direct sunlight.

● Locations that build up heat from radiant heat sources, etc.

Recommended site conditions

● A place where the ambient humidity during operaion is between 45 to 85%RH.

About EMC standard

● This equipment is a class A , for industrial locations, equipment. Do not use this equipment in domestic

establishment, such as residential areas, or it may cause radio interference. If you use this equipment in

domestic locations, take adequate measures on the outside of the equipment to reduce radio interference.

● Under the requirement of EMC standard, the maximum length of external cable including a sensor to be

connected to this equipment is 30 m. Do not connect the sensor longer than 30 m.

2-2. Cautions when Attaching to the Panels

● Please attach the PXF5/PXF9 with the included fixtures (2 pieces) to the top and bottom, and

tighten with a screwdriver.

● The clamp torque is approximately 0.15 N/m (1.5 kg/cm)

It is designed such that overtightening will cause left/right cracking to the central area of the Fixtures

and hence reduce the torque.

Cracking to the central area will not cause any problems in terms of usability of the equipment.

(However, do exercise caution in not applying too much torque because the casing is made of

plastic.)

● The front of this equipment is waterproof in compliance with NEMA-4X standards (IP66- equivalent).

To effect waterproof, the included packing is shall be attached between the controller and the

panel according to the guidelines below. (Incorrect attachment may cause the equipment to lose its

waterproof capabilities.)

(1) As shown in Fig. 1, insert to the panel after attaching the packing to the equipment case.

(2) As shown in Fig. 2, tighten the xture screws so that no gaps can remain between the equipment

face, the packing and the panels. Once nished, conrm that there are no changes in shape

such as displaced or improperly-tted packing, etc. as shown in Fig. 3.

● If the panel does not have enough strength, gaps may develop between the packing and the panel

to lose waterproong capabilities.

Fig. 1 Fig. 2 Fig. 3

Packing

Packing

Case

Case

(Bad)

(Good)

Unit

Front

Panel

Screw

Screw

Panel

Packing

Mounting fixture

Mounting fixture

Attachment on vertical surface

(Horizontal attachment)

Caution

● In order to aid heat dissipation, do not block the sides of the equipment.

● Do not block the air vents on the top and bottom of the case.

2-3. Cautions for Wiring

● For thermocouple input, use the designated compensation lead; for resistance bulb input, use wires

with small lead wire resistance and without any resistance difference among the three wires.

● To avoid noise conductor effects, input signal wires should be separated from electric power lines or

load lines.

● Input signal wire and output signal wire should be separated each other. And both should be shield

wire.

● If there is a lot of noise from the power source, adding an insulation transducer and using a noise

lter is recommended.

(Example: ZMB22R5-11, noise lter, Manufacturer: TDK)

Always attach a noise lter to a panel that is grounded securely, and keep the wiring between the

noise lter output side and the measuring equipment power terminal wiring to a minimum length.

Please do not attach fuses and switches, etc. to the noise lter output wiring; otherwise the lter’s

effectiveness will be decreased.

● Twisting the power wires is effective when connecting the wires. (The shorter the pitch of the twist,

the more effective the connection is against noise.)

● Operation preparation time is required for the contact output when power is turned on. If using it as

a signal to an external interlock circuit, please couple it with a delayed relay.

● Concerning the output relay, connecting the maximum rated load will shorten

the product’s life; so please attach an auxiliary relay. If the output operation

frequency is high, selecting a SSR/SSC drive output type is recommended.

[Proportionate cycles] Relay output: 30 seconds or more, SSR/SSC drive

output: 1 second or more

● If you selected the version with the heater break alarm, use a common

power line for the heater and the controller.

● When inductive loads such as magnetic opening/closing equipment, etc.

as relay output equipment are connected, use of a surge absorber is

recommended in order to protect the contacts against opening/closing

surges and to ensure long-term use.

Recommended specication for the surge absorber

Voltage Nominal varistor voltage

100 V 240 V

200 V 470 V

Attachment position: between the relay control output contacts.

(Example)

12

11

10

9

8

7

36

35

34

33

32

31

6

5

4

3

2

1

25

26

27

28

29

30

2-4. Key Operation Cautions/Error Operations

● The alarm function does not work properly when an error takes place unless the settings are made

correctly. Always verify its setting before operation.

● If the input wiring breaks, the display will read "UUUU". When replacing the sensor, always turn the

power OFF.

2-5. Others

● Please do not wipe the equipment with organic solvents such as alcohol or benzene, etc. If wiping

is necessary, use a neutral cleaning agent.

● Do not use mobile phones near this equipment (within 50 cm). Otherwise a malfunction may result.

● Trouble may occur if the equipment is used near a radio, TV, or wireless device.

● This equipment should be treated as an industrial waste when it is disposed of.

For Proper Usage

Please confirm that the model delivered matches your order.

"15 Model Specifications" (page 22)

Terminal connections diagram

"4 Wiring" (page 4)

Changing set value

Basic Operation Methods

Parameter List

Input/Output/Control

"5 Display and Operations" (page 6)

"5 Display and Operations" (page 6)

"6 Parameter List" (page 8 to 13)

"7 Functions" (page 14)

Setting of input sensor and input range

Selecting control method

Controlling through auto-tuning

tomatic setting parameters

"8-1 Input Setting" (page 18)

"8-3 Control Setting" (page 18)

"7-7 Auto-tuning" (page 15)

"7-3 Fuzzy PID Control", "7-4 Self-tuning Control" (page 14)

Display during equipment error

"9 Error Indications" (page 18)

External dimensions

• Panel cut dimensions

• Mounting the panel

"3 Installation and Mounting" (page 3)

Confirmation of model code

2

Wiring Connection

3 Display and Operations

4 Parameter List

5 Functions of the Temperature Controller

Turn Power On

6 Advanced Usage

7 Error Indications

Operation

1 Installation and Mounting

Caution

Wait 30 minutes for the controller to stabilized thermally. Operations such as

measurements should be taken after the equipment has been on for 30 minutes

or more.

- 3 -

3. Installation and Mounting

3-1. External/Panel Cut Dimensions

1-12

13-24 25-36

25-36

1-12

13-24

Installing multiple controllers

50 or more

(48 × n - 3)

92

+0.8

0

+0.8

0

Close mounting in horizontal direction (n units)

45

+0.6

0

92

0

116 or more

116 or more

+0.8

Installing multiple controllers

92

+0.8

0

92

+0.8

0

100 or more

Terminal block is not attached to unused terminals

(from terminal 13 to 24) depending on model.

Terminal screw

Rear view

6.2

Terminal block is not attached to unused terminals

(from terminal 13 to 24) depending on model.

Rear view

6.2

Terminal screw

Panel

Terminal cover

(Option)

Terminal cover

(Option)

48

96

Water proof

packing

8.7 57

2

MTG. Fixture MTG. Fixture

91.4

110.4

If with terminal cover

72.2

If with terminal cover

72.2

8.7 57

2

93.7

110.4

96

96

Water proof

packing

Terminal cover

93.7

Terminal cover

Panel

91.4

Horizontally close mounting does not meet

NEMA4X/IP66 (front waterproof specification),

because packing cannot be used in this mounting.

PXF5 PXF9

t (panel thickness) 1 ≤ t ≤ 8

*

* When using the parameter loader with PXF being mounted

on a panel: t (panel thickness) 1 ≤ t ≤ 4

t (panel thickness) 1 ≤ t ≤ 8

*

* When using the parameter loader with PXF being mounted

on a panel: t (panel thickness) 1 ≤ t ≤ 4

Caution

Panel cut dimensions should also meet the above dimensions after the panel is coated.

Cautions when Close Fit Mounting:

● When the power supply is AC 200V, keep the maximum ambient temperature at 45°C.

● If any equipment or walls which have a depth of 70 mm exist around this instrument,

keep a clearance of at least: 30 mm on the both sides, 50 mm below, 30 mm above.

Cautions when wiring:

● Start by wiring from the left-hand terminals (terminals 1 to 12).

● Use a screw that is the right size on terminals and tighten them with a torque of about 0.8

N/m.

● Do not attach anything to unused terminals. (Do not use relay terminals.)

- 4 -

- 5 -

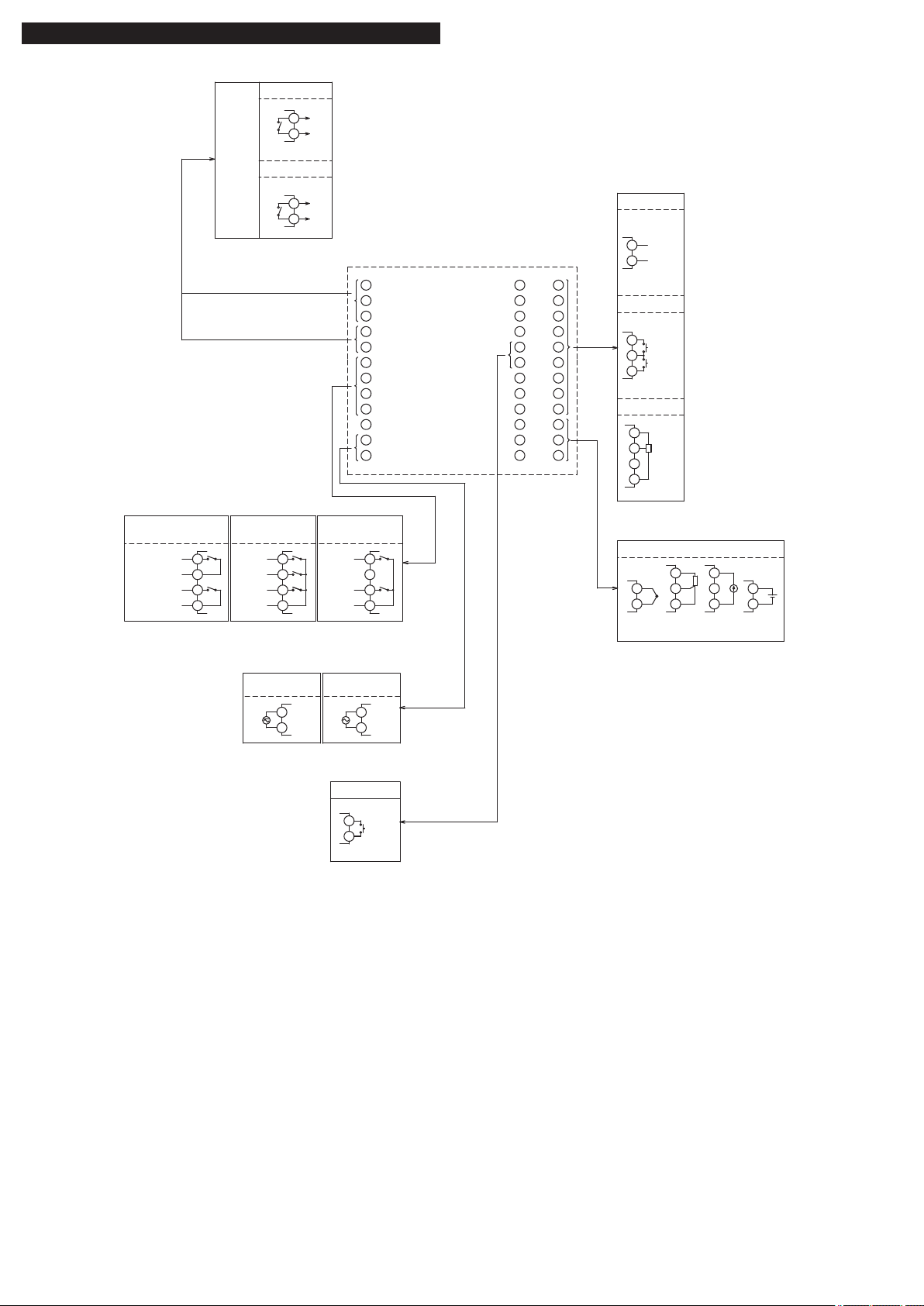

4. Wiring

4-1. Terminal Connection Diagram (Syandard type)

Alarm output

1 or 2 points3 points

2 points

(independent common)

9

8

7

6

9

8

7

6

9

8

7

6

AL1

AL2

AL2 COM

AL1 COM

AL1

AL3

COM

AL2

AL1

AL2

COM

Non-C

(Note 1)

Note 1: Power supplies for AL1 and AL2 must be of the same type,

either AC or DC.

Option

Digital input

DI2

DI1

DI-COM

RS-485

Remote SV input

CT input

CT1

RS485

+

–

Digital output

Digital input

Option

Standard type

-

+

-

+

–

+

–

+

–

+

–

+

–

+

–

+

-

+

Power supply

24VAC/24VDC

+

–

A

B

B

+

–

+

–

35

34

36

35

34

36

35

36

35

36

5

4

6

7

8

9

10

11

12

2

3

1

17

16

18

19

20

21

22

23

24

14

15

13

29

28

30

31

32

33

34

35

36

26

27

25

100-240VAC

50/60Hz 50/60Hz

12

11

12

11

26

25

28

29

27

32

33

31

DI4

DI5

DI3

DI-COM

AL5

AL4

COM

14

15

13

Relay output

(SPST)

2

1

5

4

5

4

5

4

5

4

5

4

5

4

Relay output

(SPDT)

Control

output 1

Control

output 2

SSR

Current

Voltage

2

1

2

1

2

1

2

3

1

COM

OUT1

COM

OUT1

COM

OUT1

COM

NC

NO

OUT1

OUT1

COM

OUT2

COM

OUT2

COM

OUT2

COM

OUT2

COM

OUT2

OUT2

Relay output

(SPST)

SSR

VoltageCurrent

Re-transmission

output (current)

Re-transmission

output (voltage)

RSV1

17

18

19

20

23

24

Process value input

Universal input

RTD Current

input

Voltage

input

Thermocouple

Control output 1

● Relay output (SPST)

250 V AC, 3 A (resistive load)

● Relay output (SPDT)

250 V AC, 5 A (resistive load)

● SSR output

12 V DC, 20 mA

● Current output

4 to 20 mA/0 to 20 mA (up to 500 Ω)

● Voltage output

0 to 5 V/1 to 5 V/0 to 10 V/2 to 10 V (MIN. 10 kΩ)

Control output 2

● Relay output

250 V AC, 3 A (resistive load)

● SSR output

12 V DC, 20 mA

● Current output

4 to 20 mA/0 to 20 mA (up to 500 Ω)

● Voltage output

0 to 5 V/1 to 5 V/0 to 10 V/2 to 10 V (MIN. 10 kΩ)

Alarm output 1 to 5

● Relay output

250 V DC, 1 A (resistive load)

Note) If you use PXF as a substitute for PXR or PXG which was used with

SSR output, be careful about the contlol voltage of SSR, for it is different

among PXR, PXG, and PXF.

Model

Output voltage range [V]

min max

PXF 10.7 13.2

PXR 17.0 25.0

PXG 18.0 24.0

Note) It is not necessary to make a mistake in the wiring for themeasurements

input terminal. There is a possibility that theinput circuit breaks when it

makes a mistake in wiring.

- 5 -

4-2. Terminal Connection Diagram (Motorized valve control type)

Alarm output

1 or 2 points3 points

2 points

(independent common)

9

8

7

6

9

8

7

6

9

8

7

6

AL1

AL2

AL2 COM

AL1 COM

AL1

AL3

COM

AL2

AL1

AL2

COM

Non-C

(Note 1)

Note 1: Power supplies for AL1 and AL2 must be of the same type,

either AC or DC.

I–

I+

Option

Digital input

Valve

control

output 1

Close

COM

Open

Valve Control

Valve Control

Motorized valve control type

COM

2

1

5

4

Power supply

24VAC/24VDC

100-240VAC

50/60Hz 50/60Hz

12

11

12

11

Digital input

DI2

DI1

DI-COM

RS-485

PFB input

PFB

RS485

Option

–

+

+

–

A

B

B

+

–

+

–

35

34

36

35

34

36

35

36

35

36

5

4

6

7

8

9

10

11

12

2

3

1

17

16

18

19

20

21

22

23

24

14

15

13

29

28

30

31

32

33

34

35

36

26

27

25

26

25

28

29

27

30

31

32

33

DI3

DI-COM

17

18

RTD Current

input

Voltage

input

Thermocouple

Universal input

Process value input

Valve control output 1

● Relay output

250 V AC, 3 A (resistive load)

Alarm output 1 to 3

● Relay output

250 V DC, 1 A (resistive load)

- 6 -

- 7 -

5. Display and Operations

5-1. Part names and functions

Operation parts

USER key

SEL key

USER + key

USER + key

key

key

USER Key

Press this key once in PV/SV display to switch between SV display and MV display.

Press and hold this key in PV/SV display to start the assigned function.

Press this key once in operation control mode, channel-selection mode, or setup mode to return to

PV/SV display.

SEL key

Press this key once in operation mode to move to operation control mode.

Press and hold this key in operation mode to move to channel selection mode.

Press this key once in channel selection mode to move to setup mode.

Press and hold this key in setup mode to move to channel selection mode.

Press this key once in parameter selection submode of setup mode to enter parameter editing

submode.

Press this key once in parameter editing submode to save the change and return to parameter

selection submode.

key

Use this key to select the digit when changing values.

keys

Use this key to change SV value when in PV/SV screen.

Press this key in operation control mode, channel selection mode, or setup mode, to change

parameters to be displayed.

Use this key to edit parameter when in parameter setting submode.

USER+

key

Press and hold this key in PV/SV display to start the assigned function.

(The factory set function for this key is switching between RUN and standby.)

USER+ key

Press and hold this key in PV/SV display to start the assigned function.

(The factory set function for this key is switching between start/stop of auto-tuning.)

Display

(3)

(1)

(16)

(2)

(9) (18)

(6)

(7)

(8)

(12)

(11)

(5)

(4)

PXF5

(2)

(1)

(17)

(3) (18)(9)(12)

(11)

(15)

(14)

(13)

(10)

(4) (5) (6) (7) (8)

PXF9

(17)

(13)

(14)

(15)

(10)

(16)

(1) Process value (PV)

Indicates process value. Shows parameter name when in parameter setting.

(2) Set point (SV)

Shows set point. Shows parameter set value when in parameter setting.

(3) Screen No.

Shows screen No. when in parameter setting.

(4) OUT 1 indicator

Lights during control output 1 is ON.

(5) OUT 2 indicator

Lights during control output 2 is ON.

(6) EV 1, EV 2, EV 3 indicators

Lights during digital output 1 to 3 are ON.

(7) STBY indicator

Lights during standby.

(8) MANU indicator

Lights during manual mode.

(9) Lock indicator

Lights during key lock.

(10) No. indicator

Lights during indicating screen No.

(11) RUN/HOLD/END indicators

Lights during ramp/soak operation.

(12) AT indicator

Lights during auto tuning.

(13) MV indicator

Lights during MV is indicated on SV display.

(14) TM indicator

Lights during the time is indicated on SV display.

(15) RMN indicator

Lights during remaining time is indicated on SV display.

(16) °C/°F indicator

Shows the temperature unit under use.

(17) A/%/kW/h indicator

Shows the unit under use for the values indicated on SV display.

(18) Bar graph display

Displays a bar graph of control output (MV) during operation.

- 7 -

5-2. Basic Operations

The below gure illustrates the mode transition and the key operations.

Operation mode

Operation control mode

Channel selection mode

Setup mode

In this mode the normal operation is performed. The process value (PV) and the set value (SV) are displayed. The device starts in this mode when you turn on the

power. You can change the set value (SV) in this mode. You can check the output value (MV) and the amount of electric ower by switchin the screen.

In this mode you can put the device to standby or change the alarm set value.

In this mode you can select the parameter channel to be displayed.

In this mode you can setup each parameter. This mode includes the parameter selection submode and the parameter editing submode, which can be switched by

SEL key. In the parameter selection submode, you can switch between parameters by using ΛV keys. In the parameter editing submode, you can change parameter

values by using ΛV keys.

Power ON

Operation

mode

(Operation

screen)

PV/SV display

PV/power

PV/MV display

AUTO/MANUAL

Press

and hold

P

Press

and hold

in the selected channel

Parameter

ex) ch1 PID

Parameter

Operation

control mode

Setup mode

Channel

selection mode

Ch1 Ch2 Ch3 Ch4 Ch5 Ch6

PID PLT PRG MON ALM SET

Ch7 Ch8 Ch9 Ch11 Ch12 Ch13

SYS MATH COM DSP CFG PASS

i

d

Channel

5-3. Changing values on operation screen

● Changing SV (set values)

Change the display to PV/SV display (shown when you turn on the power and the SV lamp is

lit).

Change the SV with the

keys.

Press the

key to save the values.

(The value will be automatically saved after 3 seconds even if a key is not pressed.)

1

2

3

● Changing MV (control output values)

Switch to manual mode.

Change the display to PV/MV display (MAN/AT/SELF lamp is lit).

(Pressing the

key in manual mode toggles between PV/SV display and PV/MV display.)

Change the MV with the

keys.

(Changes are reected to the MV as it is changed.)

See “7-8 Manual Output” (page 15) for more about changing to manual mode.

1

2

3

- 8 -

- 9 -

6. Parameter List

The following explains each channel parameter.

● The list also shows the operational range of set values for parameters that are limited.

● When the PV input lower limit (Pvb), PV input upper limit (PvF), or decimal place position (Pvd) is

changed, recongure all the initial parameter setting values.

● When the parameter that has [RESET] on its Remarks column is changed, turn off the power once,

and then re-start the controller.

Operation control parameter

Parameter

Function Setting range Initial value Remarks

№ Display Name

1

Switchover between auto and manual

mode

Switchover between auto and manual modes oFF (auto) / on(manual) oFF This parameter is not displayed in default setting. If you

need to change this parameter, change the setting of

"Ch11 dSP" so that it appears.

2 Switchover between RUN and standby Switchover the operation mode between RUN and standby oFF(RUN) / on(standby) oFF

3

Local/remote switchover Switches the operation between local/remote SV. LoCL (local)/ REM (remote) LoCL

4

Ramp soak control command Changes ramp soak run states oFF (stop)rUn (run)hLd (hold) oFF Displays End (when ending) or GS (during guaranty

soak).

5 Auto-tuning run command Runs auto-tuning. oFF (stop/nish) on (normal type)

L-oN (low PV type)

oFF

6

Alarm output latch release command Cancels the alarm output latch state oFF / rST (latch resets) oFF

7

SV selection Chooses the SV No. used for control LoCL

Sv1

Sv2

Sv3

Sv4

Sv5

Sv6

Sv7

di (depending on DI)

LoCL "When changing the SV with the front key, do not

change the “Svn” parameter via communication.

Otherwise, the changed SV may not be stored

correctly."

8 PID selection Chooses the PID No. used for control LoCL

Pid 1 (PID group No. 1)

Pid 2 (PID group No. 2)

Pid 3 (PID group No. 3)

Pid 4 (PID group No. 4)

Pid 5 (PID group No. 5)

Pid 6 (PID group No. 6)

Pid 7 (PID group No. 7)

di (depending on DI)

LoCL

9

ALM1 set value

Sets the alarm value for ALM1. Absolute value alarm: 0 to 100% FS

Deviation alarm: -100 to 100% FS

2.50%FS

10

11

12

ALM2 set value

Sets the alarm value for ALM2. Absolute value alarm: 0 to 100% FS

Deviation alarm: -100 to 100% FS

2.50%FS

13

14

15

ALM3 set value

Sets the alarm value for ALM3. Absolute value alarm: 0 to 100% FS

Deviation alarm: -100 to 100% FS

2.50%FS

16

17

18

ALM4 set value

Sets the alarm value for ALM4. Absolute value alarm: 0 to 100% FS

Deviation alarm: -100 to 100% FS

2.50%FS

19

20

21

ALM5 set value

Sets the alarm value for ALM5. Absolute value alarm: 0 to 100% FS

Deviation alarm: -100 to 100% FS

2.50%FS

22

23

27 Electric power calculation command Switches among on/off/hold of electric power calculation. oFF (stop calculation)

rUn (run calculation)

hLd (suspend calculation)

oFF

28 Key lock Sets the key lock to prevent wrong operation oFF (no lock)

ALL (all lock)

PArA (All but SV locked)

oFF

Ch1 PID (control parameters)

Parameter

Function Setting range Initial value Remarks

№ Display Name

50

Proportional band (%) Sets the proportional band of the PID parameter. 0.1 to 999.9% 5.0%

51

Integration time "Sets the integration time of the PID parameter.

Setting ""0"" will turn off integration."

0 to 3200 sec 240 sec

52

Differential time "Sets the differential band of the PID parameter.

Setting ""0"" will turn off differentiation."

0.0 to 999.9 sec 60.0 sec

53 ON/OFF control hysteresis Sets the hysteresis width for the ON/OFF control. 0 to 50%FS 0.25%FS

54

Cooling proportional band coefcient "Sets the proportional band coefcient for cooling.

Setting ""0.0"" will turn the cooling into an ON/OFF control."

0.0 to 100.0 1.0

55 Dead band (%) Shifts the cooling proportional band from the set value -50.0 to 50.0% 0.0%

56

Output convergence value (%) Offset value which is added to the MV output value -100.0 to 100.0% 0/50 (single/dual)

57

Anti-reset windup Sets the range of integration control 0 to 100%FS 100%FS

58

Normal/reverse operations "Selects single control or dual control. Sets the control action

(normal or reverse)."

rv-- (heat (reverse)/cool (none))

no-- (heat (normal)/cool (none))

rvno (heat (reverse)/cool (normal))

norv (heat (normal)/cool (reverse))

rvrv (heat (reverse)/cool (reverse))

nono (heat (normal)/cool (normal))

rv--/rvno

(single/dual)

[RESET]

59 SV limit (lower) Sets the lower limit of SV 0 to 100%FS 0.00%FS Note 1)

60

SV limit (upper) Sets the upper limit of SV 0 to 100%FS 100.00%FS Note 1)

61

OUT1 proportion cycle "Sets the proportion cycle of the control output (OUT1)

(contacts, SSR drive)"

1 to 150 sec 30 (relay)

2 (SSR)

1 (current)

62 OUT2 proportion cycle "Sets the proportion cycle of the control output (OUT2)

(contacts, SSR drive)"

1 to 150 sec 30 (relay)

2 (SSR)

1 (current)

63

OUT1 lower limit Sets the lower limit of the control output(OUT1) -5.0 to 105.0% -5.0%

64

OUT1 upper limit Sets the upper limit of the control output(OUT1) -5.0 to 105.0% 105.0%

65

OUT2 lower limit Sets the lower limit of the control output(OUT2) -5.0 to 105.0% -5.0%

66

OUT2 upper limit Sets the upper limit of the control output(OUT2) -5.0 to 105.0% 105.0%

67

Type of output limiter Sets the type of output limiter 0 to 15 0

73

Alpha Sets 2-degrees-of-freedom coefcient α -199.9to 300.0% 40.0%

74

Beta Sets 2-degrees-of-freedom coefcient β 0.0 to 999.9% 100.0%

Note 1: “SvL” and “Svh” must be set so that SvL < Svh. When you change the values for “SvL” and “Svh”, check SV 1 (“Sv1 Ch2”) through SV 7 (“Sv7 Ch2”).

Loading...

Loading...