Fuji Electric FRN001C1S-2U, FRNF12C1S-2U, FRN002C1S-2U, FRN003C1S-2U, FRN005C1S-2U Brochure

...

Actual size

The FRENIC-Mini features a full range of functions, compact body, simple operation, wide model

variations, and global compatibility. It will meet your needs for higher performance in machines and

equipment such as conveyors, fans, pumps, centrifugal separators and food processing machines,

as well as the needs for system integration, energy saving, labor saving, and total cost reduction.

Ideal functions to meet various needs

Flexible through optionals

New, compact design

A broad range of model variations

Simple operation

Global products

Ideal functions to meet various needs

Flexible through optionals

New, compact design

A broad range of model variations

Simple operation

Global products

Series Concepts

5HP

2

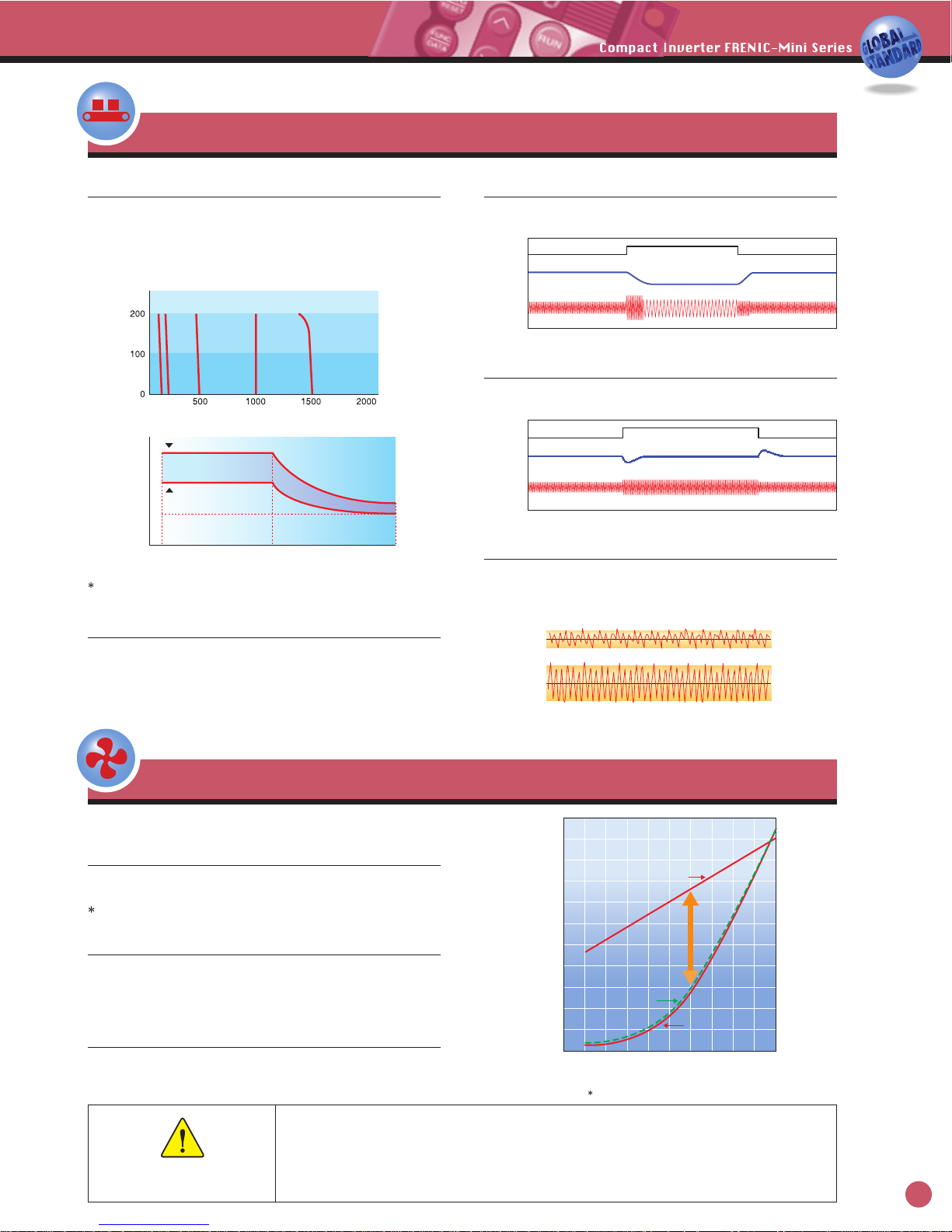

Optimum performance for traversing conveyors

Motor speed [r/min]

Torque [%]

0

Motor speed [r/min]

[Instability characteristics]

0

FRENIC-Mini

Conventional Fuji inverter

0

100

50

60

(50)

120

(100)Output frequency [Hz]

Short-time operation torque

Continuous operation

allowable range

Output

torque

[%]

150

6

(5)

100% output torque refers to

the rated torque of the motor

driven at 60 Hz.

High starting torque, at 150% or more

Equipped with Fuji,s original simplified torque-vector control

system and the automatic torque boost function, the inverter

provides consistent powerful operation (when automatic torque

boost is ON, slip compensation control is ON, and when

running at 5Hz or more).

Trip-free operation

The remarkably improved current limiting function (stall

prevention) allows trip-free operation even for an impact load.

Stable operation even for a step load

The slip compensation function permits stable operation even

when the motor load fluctuates (step load).

Braking resistor connectable to the inverter

Owing to a built-in braking transistor (1/2HP or larger), an optional

braking resistor can be connected to increase the regenerative

braking capacity for conveyance and transportation machinery that

require large braking power. For inverters of 2HP or larger, it is

possible to select the model that incorporates a braking resistor.

Reduced motor instability at low speed

Fuji,s unique control method improves voltage control

performance and reduces motor instability at low speed to about a

half or less (at 1Hz) compared with that of conventional inverters.

Automatic energy-saving provided

as a standard function

By controlling the motor loss to a minimum, FRENIC-Mini

further saves electric power when applied to fans or pumps.

Cooling fan ON/OFF control function

The inverter,s cooling fan can be turned off while the fan or

pump is stopped for noise reduction and energy savings.

PID control function

Permits motor operation while controlling temperature,

pressure, or flow rate without using an external device such as

temperature controller.

The highly used functions for fans and pumps

[Output torque characteristic data]

[Torque characteristics]

Safety Precautions

1. The contents of this catalog are provided to help you select the product model that is best for you. Before actual use, be sure

to read the Instruction Manual/User,s Manual thoroughly to assure correct operation.

2. This product is not designed and manufactured for use in machines or systems which human life is dependent upon. If you

are studying use of the products in this brochure for special purposes such as for control of nuclear power stations, in sea, air

or space craft, in medical or land transportation equipment, or any related systems, please contact the business office of Fuji

Electric. If these products are to be used in any equipment in which there is a risk to human life or the possibility of a major

loss in the event of failure, be sure to install the appropriate safety equipment.

The above graph shows an example of torque characteristics obtained when FRENIC-Mini is

combined one-to-one with Fuji,s standard three-phase motor (8-type series: 4 poles).

Energy saving rate varies with the motor characteristics.

Time

Motor speed

Load torque

Output current

Time

Motor speed

Load torque

Output current

0s 2.5s 5s 7.5s 10s 12.5s

0s 2.5s 5s 7.5s 10s 12.5s

When damper or valve is used

Energy

saved

Inverter control

(Automatic energy-saving mode)

Inverter control

(V/f control)

Air or liquid flow rate Q [%]

Required power P

[%]

110

90

80

70

60

50

40

30

20

10

0201030 40 50 60 70 80 90 100

[Energy savings effect]

Energy savings rate varies with the motor characteristics.

100

3

The ideal functions to serve a multiplicity of needs for small-capacity inverters

A transistor output is provided.

This enables an overload early warning, lifetime forecast or

other information signals to be output during operation.

Compact

4.72

(120)

3.15(80) 3.15(80)

9.45(240)

(Units: inch(mm))

(Three-phase 230V, 1HP or less)

(Three-phase 230V, 1HP or less)

(Three-phase 230V, 2HP)

3.15(80)

FVR-C11S FRENIC-Mini

RS-485

communications card

Compatible with a wide range of

frequency settings

The optimum frequency setting method can be selected to

match your machine or equipment. Setting can be done by

keypad panel ( keys, potentiometer), analog input (4 to

20mA, 0 to +10V, 0 to 5V, 1 to 5V), multistep speed settings (8

steps) etc.

Two points can be set for a non-linear

V/f pattern.

One point for the non-linear V/f pattern, which can be set as

desired, has been added (making a total of 2 points), and so

the V/f pattern can be adjusted to match the application.

Side-by-side mounting is possible.

The output frequency can be set to a

maximum of 400Hz.

The inverter can be used for equipment that requires a high

motor speed such as centrifugal separator. In this case, check

the operation in combination with the motor.

RS485 communications card (option)

can be installed internally.

This card can be installed inside the inverter,s body without

changing the dimensions. RS-485 communications are

available as option.

A model with built-in braking resistor is

available on order.

For inverters of 2HP or larger, a built-in braking resistor type

can be selected.

Since installation and wiring of a separate braking resistor is

not required, the total mounting space is reduced.

Size interchangeability with Fuji,s

FVR-C11S series is provided.

Multiple inverter units can be mounted side-by-side inside a

panel. This features helps to minimize the space used for

installation. (Ambient temperature: 40°C (104°F) or less)

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

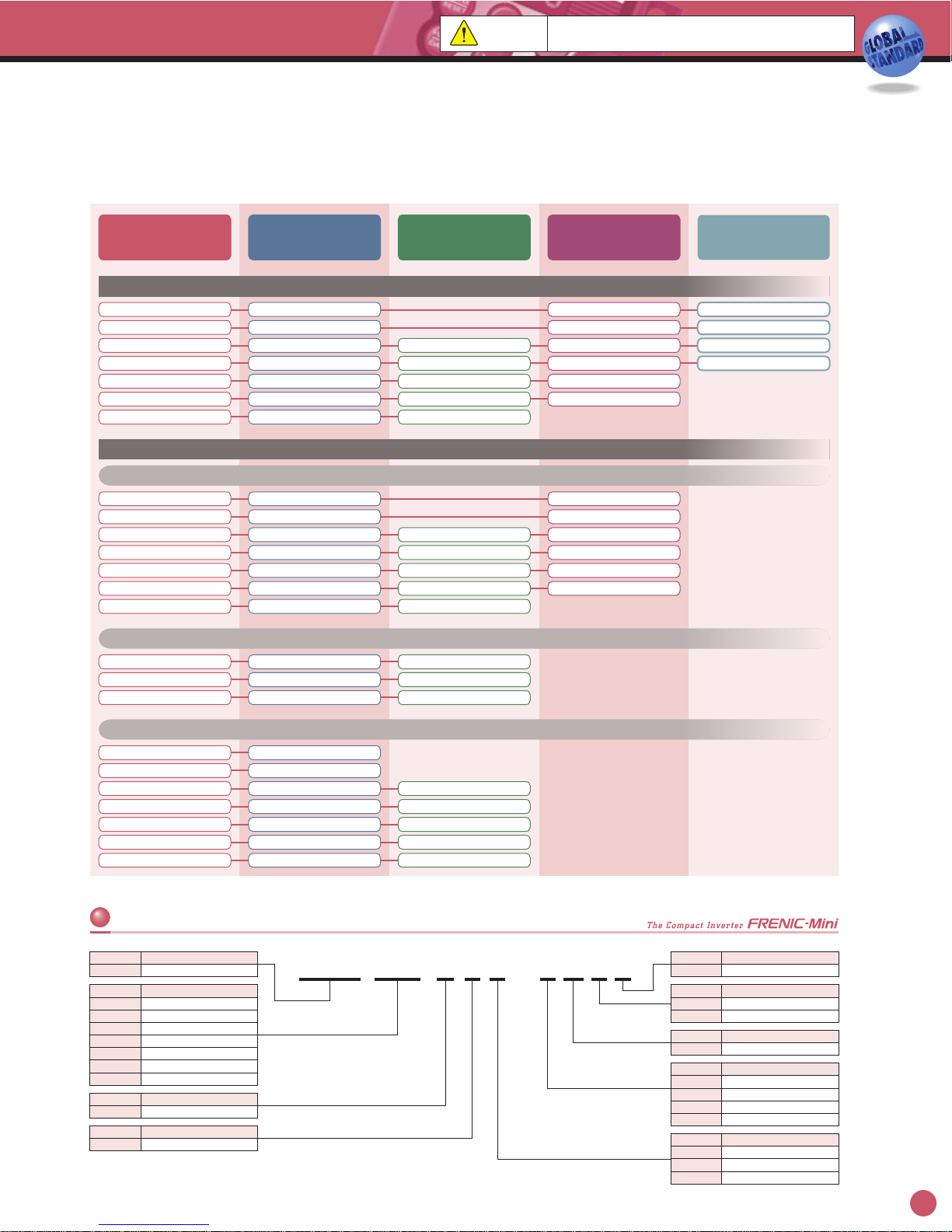

Simple operation and wiring

Frequency setting potentiometer is

standard equipment.

The frequency can be adjusted easily by hand.

A menu mode is included in the keypad.

A long-life cooling fan is included.

Cumulative running time is recorded and displayed.

The inverter records and displays the cumulative running time

(lifetime) of the inverter itself, PCB, and cooling fan.

Input/output phase loss protective function

It is possible to detect output phase loss at all times during

starting and operation.

Sink/Source can be switched.

The input/output mode (Sink/Source) of the digital input terminals

can be switched by means of an internal jumper switch.

The motor can be protected by a PTC thermistor.

In addition to the protection by an electronic thermal relay, the

The control circuit terminal block cover

and main circuit terminal block cover

can be quickly removed.

Maintenance

Interface for peripheral devices and comprehensive protective functions

Control circuit terminal block cover

Main circuit terminal block cover

All types of data can be displayed on

the keypad.

The output frequency, set frequency, load shaft speed, output

current, output voltage, alarm history, input power etc. can be

displayed.

The lifetime of the DC bus capacitor can

be estimated.

The capacitor,s condition compared with its initial state can be

confirmed.

All models are equipped with an inrush

current suppression circuit.

An inrush current suppression circuit is provided as standard

in all models, so the cost of peripheral devices such as input

magnetic contactors can be reduced.

A DC reactor (DCR) connection terminal

is provided as standard.

A terminal for connection of a DCR, necessary for suppressing

harmonics, is provided in all models.

The alarm history for the 4 latest

alarms is recorded.

Detailed information from back as far as the 4 latest alarms

can also be checked.

It is possible to output lifetime forecast

signal to the transistor output.

This signal is output when the capacitors in the DC bus circuit,

the electrolytic capacitors on the PCB or the cooling fans are

nearing the end of their service life.

,,

,,

,,

,,

,,

,,

Use of a long-life cooling fan (design life: 7 years with an

ambient temperature: 40°C (104°F) reduces maintenance work.

The menu items include the function menu for checking or

changing function codes, operation monitor , I/O check ,

maintenance info. and alarm info. See the FRENIC-Mini

User,s Manual for details.

,,

,, ,,

,,

5

Flexible through optionals

Remote operation is possible.

Remote operation can be done easily using the optional

RS-485 communications card, remote keypad and remote

operation extension cable.

Function code copy function

The optional remote keypad panel includes a built-in copy

function, so function codes can be set easily in duplicate units.

Mounting on DIN rail

Using the rail mounting base (option), the inverter can be

easily mounted on a DIN rail (35mm wide).

Wide variations

Global products

All standard models comply with the EC Directive (CE marking), UL standards and

Canadian standards (cUL certification).

All standard FRENIC-Mini inverters comply with European and North American/Canadian standards, enabling standardization of the

specifications for machines and equipment used at home and abroad.

If the model with built-in EMC filter is used, the model conforms to the European

EMC Directive.

Replacement of older models

with new ones is simple.

The latest models can be mounted without drilling additional

holes by use of the mouting adapter (option).

Inverter support loader software is

available.

The inverter support loader program (Windows based), which

simplifies setting of function codes, is provided.

The optional RS-485 communications card, remote operation

extension cable and USB-RS-485 converter are necessary.

Europe

North America/Canada

UL standard (cUL certification)EC Directives (CE making), TUV

..

Remote keypad

Extension cable for remote operation

RS-485

communications

card

6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

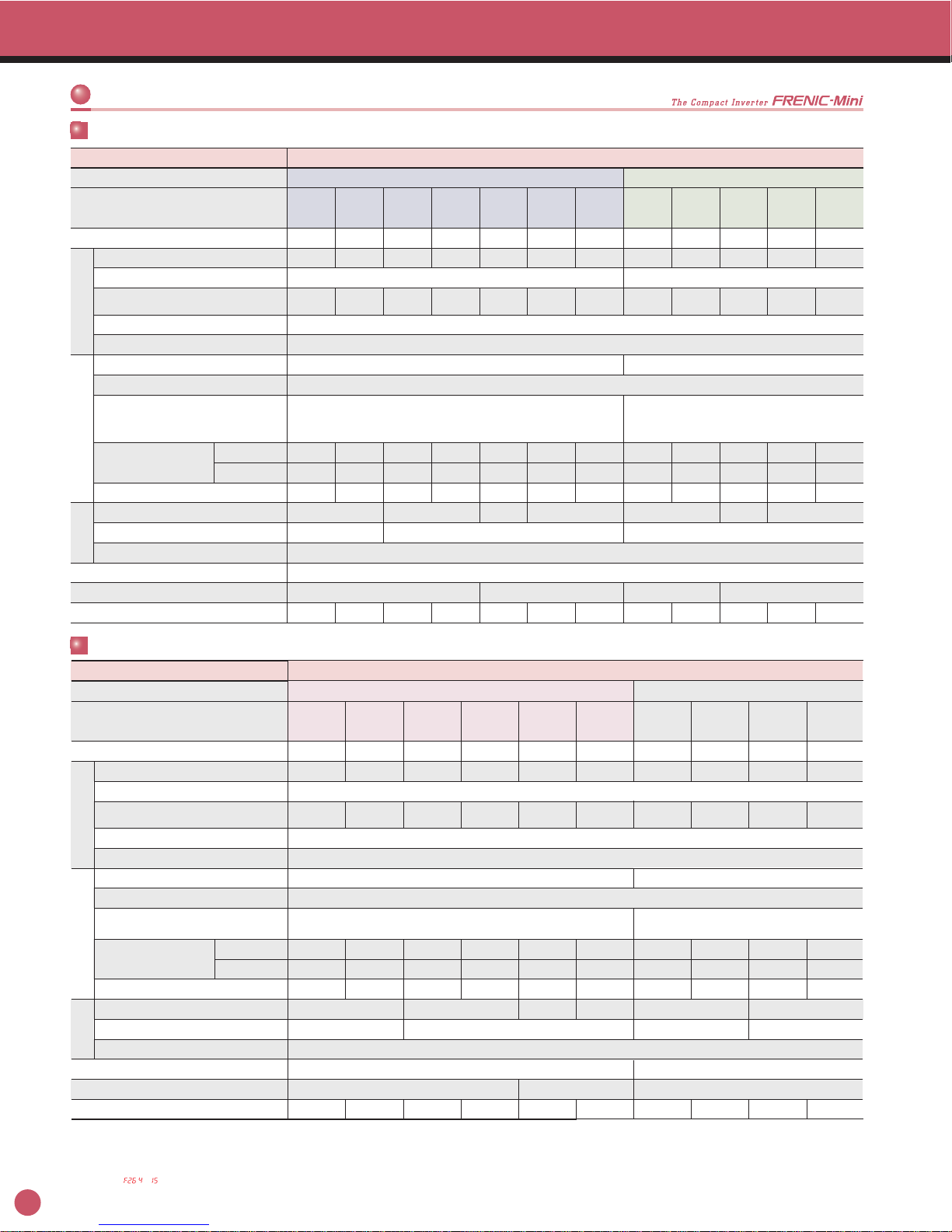

Variation

How to read the model number

FRN 001 C 1 S - 2 U 2 1

Code

FRN

Series name

FRENIC series

Code

Blank,1

Built-in option

None

Code

Blank,1

2

Brake

Standard

Braking resistor built-in type

Code

U

Version/Manual

USA / English

Code

2

4

6

7

Input power source

Three-phase 230V

Three-phase 460V

Single-phase 115V

Single-phase 230V

Code

F12

F25

F50

001

002

003

005

Applicable motor rating

[HP]

1/8

1/4

1/2

1

2

3

5

Code

C

Application range

Compact

Code1Developed inverter series

1

Code

S

E

J

Enclosure

Standard (IP20)

EMC filter built-in type (IP20)

IP40 enclosure type

Standard specifications

1/8

1/4

1/2

1

2

3

5

Applicable

motor rating

FRNF12C1S-2U

FRNF25C1S-2U

FRNF50C1S-2U

FRN001C1S-2U

FRN002C1S-2U

FRN003C1S-2U

FRN005C1S-2U

Three-phase

230V

FRNF50C1S-4U

FRN001C1S-4U

FRN002C1S-4U

FRN003C1S-4U

FRN005C1S-4U

Three-phase

460V

FRNF12C1S-7U

FRNF25C1S-7U

FRNF50C1S-7U

FRN001C1S-7U

FRN002C1S-7U

FRN003C1S-7U

Single-phase

230V

Semi-standard specifications

EMC filter built-in type (On order)

1/8

1/4

1/2

1

2

3

5

FRNF12C1E-2U

FRNF25C1E-2U

FRNF50C1E-2U

FRN001C1E-2U

FRN002C1E-2U

FRN003C1E-2U

FRN005C1E-2U

FRNF50C1E-4U

FRN001C1E-4U

FRN002C1E-4U

FRN003C1E-4U

FRN005C1E-4U

IP40 enclosure type

1/8

1/4

1/2

1

2

3

5

FRNF12C1J-2U

FRNF25C1J-2U

FRNF50C1J-2U

FRN001C1J-2U

FRN002C1J-2U

FRN003C1J-2U

FRN005C1J-2U

FRNF50C1J-4U

FRN001C1J-4U

FRN002C1J-4U

FRN003C1J-4U

FRN005C1J-4U

FRNF12C1E-7U

FRNF25C1E-7U

FRNF50C1E-7U

FRN001C1E-7U

FRN002C1E-7U

FRN003C1E-7U

Braking resistor built-in type (On order)

2

3

5

FRN002C1S-2U21

FRN003C1S-2U21

FRN005C1S-2U21

FRN002C1S-4U21

FRN003C1S-4U21

FRN005C1S-4U21

Caution

The contents of this catalog are provided to help you select the

product model that is best for you. Before actual use, be sure to read

the User's Manual thoroughly to assure correct operation.

In addition to the three-phase 230V, single-phase 230V and single-phase 115V,

three-phase 460V has been newly introduced, broadening the model selection

range.

Model variations include EMC filter built-in type and braking resistor built-in

type on order.

Note)

If “Built-in option” is “None” and “Brake” is “Standard”, the model numbers are indicated in the same format as those of the above standard specifications.

Type1(NEMA1)conformed model is available by attaching optional parts.

FRNF12C1S-6U

FRNF25C1S-6U

FRNF50C1S-6U

FRN001C1S-6U

Single-phase

115V

7

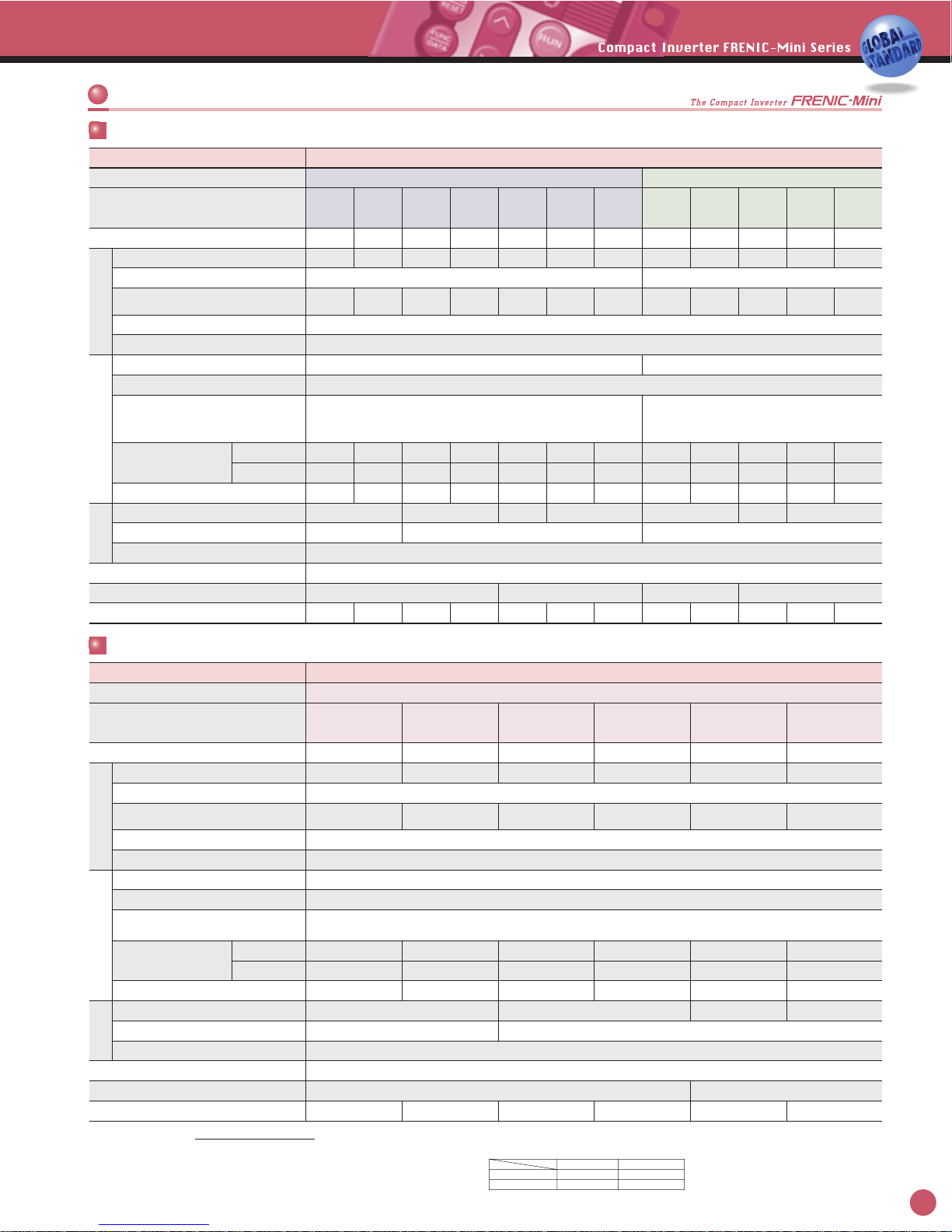

Standard Specifications

Type (FRN

C1S-U)

Applicable motor rating *1) 1/81/41/212351/21235

Enclosure (IEC 60529)

Cooling method

Weight / Mass

IP20, UL open type *11)

Natural cooling

1.3(0.6) 1.3(0.6) 1.3(0.6) 1.5(0.7) 3.7(1.7) 3.7(1.7) 5.1(2.3) 2.4(1.1) 2.6(1.2) 3.7(1.7) 3.7(1.7) 5.1(2.3)

Fan cooling Natural cooling Fan cooling

Rated capacity *2) 0.31 0.59 1.1 1.9 3.1 4.3 6.7 1.1 1.9 2.9 4.3 7.1

Rated current *4) A

%

%

lbs.(kg)

A

HP

kVA

kVA

V

A

%

%

lbs.(kg)

HP

kVA

kVA

V

0.8

(0.7)

1.5

(1.4)

3.0

(2.5)

5.0

(4.2)

8.0

(7.0)

11.0

(10.0)

17.0

(16.5)

1.5 2.5 3.7 5.5 9.0

Rated voltage *3)

Overload capability 150% of rated current for 1min, 200% of rated current for 0.5s

Rated frequency

Phases, voltage, frequency Three-phase, 200 to 240V, 50/60Hz Three-phase, 380 to 480V, 50/60Hz

Voltage/frequency variations

Required power supply capacity *7) 0.2 0.3 0.6 1.1 2.0 2.9 4.9 0.6 1.1 2.0 2.9 4.9

Torque *8) 150 100 50 30 100 50 30

Torque *9)

DC injection braking

-

150 150

Starting frequency: 0.0 to 60.0Hz Braking time: 0.0 to 30.0s Braking level: 0 to 100% of rated current

Voltage: +10 to -15% (Voltage unbalance *10) : 2% or less) Frequency: +5 to -5%

Rated current *6)

Momentary voltage dip capability *5)

(with DCR)

(without DCR)

0.57

1.1

0.93

1.8

1.6

3.1

3.0

5.3

5.7

9.5

8.3

13.2

14.0

22.2

0.85

1.7

1.6

3.1

3.0

5.9

4.4

8.2

7.3

13.0

50, 60Hz

Three-phase, 200V/50Hz, 200, 220, 230V/60Hz

Three-phase, 380, 400, 415V/50Hz, 380, 400, 440, 460V/60Hz

Input power source

FRNF12

C1S-2U

FRNF25

C1S-2U

FRNF50

C1S-2U

FRN001

C1S-2U

FRN002

C1S-2U

FRN003

C1S-2U

FRN005

C1S-2U

FRNF50

C1S-4U

FRN001

C1S-4U

FRN002

C1S-4U

FRN003

C1S-4U

FRN005

C1S-4U

Three-phase 230V

Item Specifications

Three-phase 460V

Output ratingsInput ratingsBraking

Type (FRN

C1S-U)

Applicable motor rating *1) 1/8 1/4 1/2 1 2 3

Enclosure (IEC 60529)

Cooling method

Weight / Mass

IP20, UL open type *11) IP20

Natural cooling

1.3(0.6) 1.3(0.6) 1.3(0.6) 1.8(0.8) 3.7(1.7) 5.1(2.3)

Fan cooling

Rated capacity *2) 0.31 0.59 1.1 1.9 3.1 4.3

Rated current *4)

0.8

(0.7)

1.5

(1.4)

3.0

(2.5)

5.0

(4.2)

8.0

(7.0)

11.0

(10.0)

Rated voltage *3)

Overload capability 150% of rated current for 1 min, 200% of rated current for 0.5s

Rated frequency

Phases, voltage, frequency Single-phase, 200 to 240V, 50/60Hz Single-phase, 100 to 120V, 50/60Hz

Voltage/frequency variations

Required power supply capacity *7) 0.3 0.4 0.7 1.3 2.4 3.5

Torque *8) 150 100 3050

Torque *9)

DC injection braking

-

150

Starting frequency: 0.0 to 60.0Hz Braking time: 0.0 to 30.0s Braking level: 0 to 100% of rated current

Voltage: +10 to -10% Frequency: +5 to -5%

Momentary voltage dip capability *5)

Rated current *6) A

(with DCR)

(without DCR)

1.1

1.8

2.0

3.3

3.5

5.4

6.4

9.7

11.6

16.4

17.5

24.8

50, 60Hz

Three-phase, 200V/50Hz, 200, 220, 230V/60Hz

Input power source

FRNF12

C1S-7U

FRNF25

C1S-7U

FRNF50

C1S-7U

FRN001

C1S-7U

FRN002

C1S-7U

FRN003

C1S-7U

Single-phase 230V Single-phase 115V

*12)

Item Specifications

Output ratingsInput ratingsBraking

*1) Standard 4-pole motor

*2) Rated capacity is calculated by regarding the output rated voltage as 220V for three-phase 230V

and single-phase 230V series, and as 440V for three-phase 460V series.

*3) Output voltage cannot exceed the power supply voltage.

*4) Use the inverter at the current given in ( ) or below when the carrier frequency setting is higher

than 4kHz ( : to ) or the ambient temperature is 40°C (104°F) or higher.

*5) Tested under the standard load condition (85% load for nominal applied motor).

*6) Calculated under Fuji-specified conditions.

*7) Obtained when a DC REACTOR (option) is used.

*8) Average braking torque obtained with AVR control OFF (Varies with the efficiency of the motor.)

*9) Average braking torque obtained by use of external braking resistor (standard type available as option)

Three-phase series

Single-phase series

Standard specifications

When the input voltage is 165V or more, the inverter continues operation. If it

drops below 165V, the inverter operates for 15ms.

When the input voltage is 300V or more, the inverter

continues operation. If it drops below 300V, the inverter

operates for 15ms.

1/8 1/4 1/2 1

1.3(0.6) 1.3(0.6) 1.5(0.7) 2.6(1.2)

Natural cooling

0.26 0.53 0.95 1.6

0.7 1.4 2.5 4.2

0.3 0.5 0.7 1.3

150 100

150

-

2.2

3.6

3.8

5.9

6.4

9.5

12.0

16.1

FRNF12

C1S-6U

FRNF25

C1S-6U

FRNF50

C1S-6U

FRN001

C1S-6U

When the input voltage is 165V or more, the inverter continues operation. If it

drops below 165V, the inverter operates for 15ms.

When the input voltage is 85V or more, the inverter

continues operation. If it drops below 85V, the inverter

operates for 15ms.

8

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

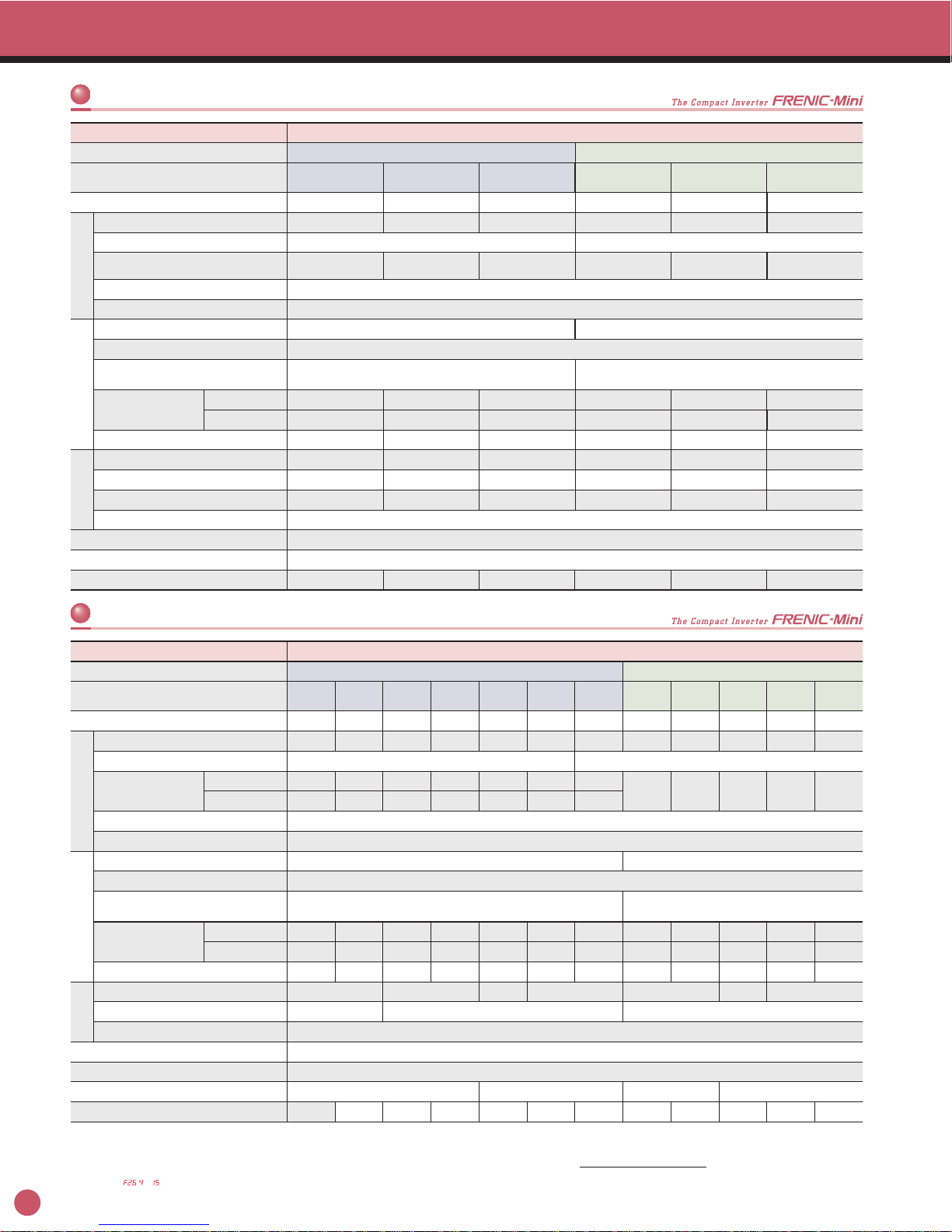

Semi-standard Specifications

Momentary voltage dip capability *5)

EMC filter built-in type

Three-phase series

Type (FRN

C1E-U)

Applicable motor rating *1) 1/8 1/4 1/2 1 2 3 5 1/2 1 2 3 5

Enclosure (IEC 60529)

Cooling method

Weight / Mass

IP20, UL open type *11)

Natural cooling Fan cooling Natural cooling Fan cooling

Rated capacity *2) 0.31 0.59 1.1 1.9 3.1 4.3 6.7 1.1 1.9 2.9 4.3 7.1

Rated current *4)

0.8

(0.7)

1.5

(1.4)

3.0

(2.5)

5.0

(4.2)

8.0

(7.0)

11.0

(10.0)

17.0

(16.5)

1.5 2.5 3.7 5.5 9.0

Rated voltage *3)

Overload capability 150% of rated current for 1min, 200% of rated current for 0.5s

Rated frequency

Phases, voltage, frequency Three-phase, 200 to 240V, 50/60Hz Three-phase, 380 to 480V, 50/60Hz

Voltage/frequency variations

Required power supply capacity *7) 0.2 0.3

1.5(0.7) 1.5(0.7) 1.5(0.7) 1.8(0.8) 5.3(2.4) 5.3(2.4) 6.4(2.9) 3.3(1.5) 3.7(1.6) 5.5(2.5) 5.5(2.5) 6.6(3.0)

0.6 1.1 2.0 2.9 4.9 0.6 1.1 2.0 2.9 4.9

Torque *8) 150 100

50 30 100 50 30

Torque *9)

DC injection braking

- 150 150

Starting frequency: 0.0 to 60.0Hz Braking time: 0.0 to 30.0s Braking level: 0 to 100% of rated current

Voltage: +10 to -15% (Voltage unbalance *10) : 2% or less) Frequency: +5 to -5%

Rated current *6)

(with DCR)

(without DCR)

0.57

1.1

0.93

1.8

1.6

3.1

3.0

5.3

5.7

9.5

8.3

13.2

14.0

22.2

0.85

1.7

1.6

3.1

3.0

5.9

4.4

8.2

7.3

13.0

50, 60Hz

Three-phase, 200V/50Hz, 200, 220, 230V/60Hz

Three-phase, 380, 400, 415V/50Hz, 380, 400, 440, 460V/60Hz

Input power source

FRNF12

C1E-2U

FRNF25

C1E-2U

FRNF50

C1E-2U

FRN001

C1E-2U

FRN002

C1E-2U

FRN003

C1E-2U

FRN005

C1E-2U

FRNF50

C1E-4U

FRN001

C1E-4U

FRN002

C1E-4U

FRN003

C1E-4U

FRN005

C1E-4U

Three-phase 230V

Item Specifications

Three-phase 460V

Output ratingsInput ratingsBraking

Type (FRN

C1E-U)

Applicable motor rating *1) 1/8 1/4 1/2 1 2 3

Enclosure (IEC 60529)

Cooling method

Weight / Mass

IP20, UL open type *11)

Natural cooling Fan cooling

Rated capacity *2) 0.31 0.59 1.1 1.9 3.1 4.3

Rated current *4)

0.8

(0.7)

1.5

(1.4)

3.0

(2.5)

5.0

(4.2)

8.0

(7.0)

11.0

(10.0)

Rated voltage *3)

Overload capability 150% of rated current for 1min, 200% of rated current for 0.5s

Rated frequency

Phases, voltage, frequency Single-phase, 200 to 240V, 50/60Hz

Voltage/frequency variations

Required power supply capacity *7) 0.3 0.4 0.7 1.3 2.4 3.5

1.5(0.7) 1.5(0.7) 1.5(0.7) 2.6(1.2) 5.3(2.4) 6.4(2.9)

Torque *8) 150 100 30

50

Torque *9)

DC injection braking

-

150

Starting frequency: 0.0 to 60.0Hz Braking time: 0.0 to 30.0s Braking level: 0 to 100% of rated current

Voltage: +10 to -10%, Frequency: +5 to -5%

Momentary voltage dip capability *5)

Rated current *6)

(with DCR)

(without DCR)

1.1

1.8

2.0

3.3

3.5

5.4

6.4

9.7

11.6

16.4

17.5

24.8

When the input voltage is 165V or more, the inverter continues operation. If it drops below 165V,

the inverter operates for 15ms.

50, 60Hz

Three-phase, 200V/50Hz, 200, 220, 230V/60Hz

Input power source

FRNF12

C1E-7U

FRNF25

C1E-7U

FRNF50

C1E-7U

FRN001

C1E-7U

FRN002

C1E-7U

FRN003

C1E-7U

Single-phase 230V

Item Specifications

Output ratingsInput ratingsBraking

kVA

A

%

%

lbs.(kg)

A

HP

kVA

kVA

V

A

%

%

lbs.(kg)

HP

kVA

A

Max voltage [V] - Min voltage [V]

Three-phase average voltage [V]

x 67 (IEC 61800-3 (5.2.3))

Single-phase series

When the input voltage is 165V or more, the inverter continues operation. If it

drops below 165V, the inverter operates for 15ms.

When the input voltage is 300V or more, the inverter

continues operation. If it drops below 300V, the

inverter operates for 15ms.

*10) Voltage unbalance [%] =

If this value is 2 to 3%, use AC REACTOR (ACR).

*11) NEMA1 kit (option) is required for the enclosure conforming to the UL standard TYPE1 (NEMA1).

Use the inverter in the ambient temperature range from -10 to +40

°C (14 to 104°F)

.

*12) When driven by 100 VAC, the single-phase 115 V class series of inverters limit their shaft output and maximum

output torque as listed below. This is to prevent their output voltage from decreasing when load is applied.

Shaft output (%) Maximum torque (%)

w/o DC reactor (DCR) 90 150

w/ DC reactor (DCR) 85 120

9

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Semi-standard Specifications

IP40 enclosure type

Type (FRN

C1J-U)

Applicable motor rating *1) 1/8

Enclosure (IEC 60529)

Cooling method

Weight / Mass

IP 40

Starting frequency: 0.0 to 60.0Hz Braking time: 0.0 to 30.0s Braking level: 0 to 100% of rated current

Natural cooling Fan cooling Fan coolingNatural cooling

Rated capacity *2) 0.31

Rated current

0.7

Rated voltage *3)

Overload capability 150% of rated current for 1min, 200% of rated current for 0.5s

Rated frequency

Phases, voltage, frequency Three-phase, 200 to 240V, 50/60Hz Three-phase, 380 to 480V, 50/60Hz

Voltage/frequency variations

Required power supply capacity *7) 0.2

150

-

1.5(0.7)

Torque *8)

Torque *9)

DC injection braking

Applicable safety standards UL508C, C22.2No.14, EN50178:1997 or equivalent

Voltage: +10 to -15% (Voltage unbalance : 2% or less *10) ) Frequency: +5 to -5%

Momentary voltage dip capability *5)

Rated input current *6)

(with DCR)

(without DCR)

High carrier (4-15kHz)

Low carrier (-3kHz)

0.57

1.1

50, 60Hz

Three-phase, 200V/50Hz, 200, 220, 230V/60Hz Three-phase, 380, 400, 415V/50Hz, 380, 400, 440, 460V/60Hz

Input power source

FRNF12

C1J-2U

1/4

0.59

1.4

0.3

1.5(0.7)

0.93

1.8

FRNF25

C1J-2U

1/2

1.1

2.5

0.6

100

150

1.5(0.7)

1.6

3.1

FRNF50

C1J-2U

1

1.9

4.2

1.1

1.8(0.8)

3.0

5.3

FRN001

C1J-2U

2

3.1

7.0

2.0

50

4.8(1.8)

5.7

9.5

FRN002

C1J-2U

3

4.3

10.0

2.9

30

4.8(1.8)

8.3

13.2

FRN003

C1J-2U

FRN005

C1J-2U

FRNF50

C1J-2U

FRN001

C1J-2U

FRN002

C1J-2U

FRN003

C1J-2U

FRN005

C1J-2U

5

6.7

16.5

4.9

5.3(2.4)

14.0

22.2

1/2

1.1

1.5

0.6

100

150

2.6(1.2)

0.85

1.7

1

1.9

2.5

1.1

2.9(1.3)

1.6

3.1

2

2.9

3.7

2.0

50

4.0(1.8)

3.0

5.9

3

4.3

5.5

2.9

30

4.0(1.8)

4.4

8.2

5

7.1

9.0

0.8 1.5 3.0 5.0 8.0 11.0 17.0

4.9

5.3(2.4)

7.3

13.0

Three-phase 230V

Item Specifications

Three-phase 460V

Output ratingsInput ratings

Braking

When the input voltage is 165V or more, the inverter continues operation. If it

drops below 165V, the inverter operates for 15ms.

When the input voltage is 300V or more, the inverter

continues operation. If it drops below 300V, the inverter

%

A

A

%

%

lbs.(kg)

HP

kVA

kVA

V

Braking resistor built-in type

Type (FRN

C1S-U21)

Applicable motor rating *1) 235235

Enclosure (IEC 60529)

Cooling method

Weight / Mass

IP20, UL open type *11)

Fan cooling

Rated capacity *2) 3.1 4.3 6.7 2.9 4.3 7.1

Rated current *4)

8.0

(7.0)

11.0

(10.0)

17.0

(16.5)

3.7 5.5 9.0

Rated voltage *3)

Overload capability 150% of rated current for 1min, 200% of rated current for 0.5s

Rated frequency

Phases, voltage, frequency Three-phase, 200 to 240V, 50/60Hz Three-phase, 380 to 480V, 50/60Hz

Voltage/frequency variations

Required power supply capacity *7) 2.0 2.9

150 100 100 150 100 100

18 12 8 18 12 8

321.5321.5

4.9 2.0 2.9 4.9

4.0(1.8) 4.0(1.8) 5.5(2.5) 4.0(1.8) 4.0(1.8) 5.5(2.5)

Torque *8)

Braking time

Duty cycle

DC injection braking Starting frequency: 0.0 to 60.0Hz Braking time: 0.0 to 30.0s Braking level: 0 to 100% of rated current

Voltage: +10 to -15% (Voltage unbalance *10) : 2% or less) Frequency: +5 to -5%

Momentary voltage dip capability *5)

Rated current *6)

(with DCR)

(without DCR)

5.7

9.5

8.3

13.2

14.0

22.2

3.0

5.9

4.4

8.2

7.3

13.0

50, 60Hz

Three-phase, 200V/50Hz, 200, 220, 230V/60Hz Three-phase, 380, 400, 415V/50Hz, 380, 400, 440, 460V/60Hz

Input power source

FRN002

C1S-2U21

FRN003

C1S-2U21

FRN005

C1S-2U21

FRN002

C1S-4U21

FRN003

C1S-4U21

FRN005

C1S-4U21

Three-phase 230V

Item Specifications

Three-phase 460V

Output ratingsInput ratings

Braking

When the input voltage is 165V or more, the inverter continues

operation. If it drops below 165V, the inverter operates for 15ms.

When the input voltage is 300V or more, the inverter continues

operation. If it drops below 300V, the inverter operates for 15ms.

A

s

A

%

%

lbs.(kg)

HP

kVA

kVA

V

*1) Standard 4-pole motor

*2) Rated capacity is calculated by regarding the output rated voltage as 220V for three-phase 230V

series, and as 440V for three-phase 460V series.

*3) Output voltage cannot exceed the power supply voltage.

*4) Use the inverter at the current given in ( ) or below when the carrier frequency setting is higher

than 4kHz ( : to ) or the ambient temperature is 40°C (104°F) or higher.

*5) Calculated under the standard overload conditions by JEMA committee (about 85% of overload

by the standard applicable motor.)

*6) Calculated under Fuji-specified conditions.

*7) Obtained when a DC reactor (DCR) is used.

*8) Average braking torque obtained with AVR control OFF (Varies with the efficiency of the motor.)

*9) Average braking torque obtained by use of external braking resistor (optional)

*10) Voltage unbalance [%] =

If this value is 2 to 3%, use AC reactor (option).

*11) NEMA1 kit (option) is required for the enclosure conforming to the UL standard TYPE1 (NEMA1).

Use the inverter in the ambient temperature range from -10 to +40°C (14 to 104°F).

Max voltage [V] - Min voltage [V]

Three-phase average voltage [V]

x 67 (Refer to IEC 61800-3.)

10

Loading...

Loading...