Fuji Electric FRENIC-Mini C2 Quick Start Guide

FRENIC-Mini (C2) Quick Reference Guide |

|

|

|

|

|

|

|

|

|

|||||||

Control Card Terminals |

|

|

|

|

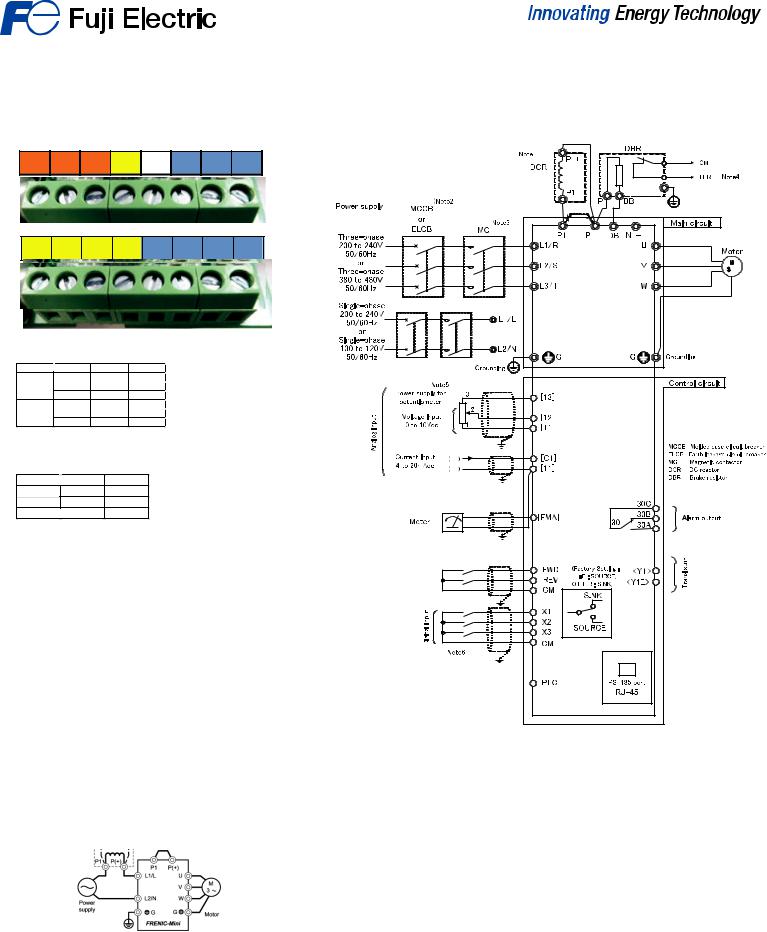

FRENIC-Mini (C2) Control Wiring |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Y1 |

Y1E |

FMA |

C1 |

PLC |

X1 |

X2 |

X3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11 |

12 |

13 |

11 |

CM |

FWD REV |

CM |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Orange = Outputs, Yellow = Analog Inputs, Blue = Digital Inputs |

|

|

|

|

|

|

|

|

|

|||||||

• FWD, Rev, plus 3 Digital inputs configurable for Source or Sink. |

|

|

|

|

|

|

|

|

|

|||||||

Item |

Min. |

|

Max. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Operating |

ON level |

0V |

|

2V |

|

|

|

|

|

|

|

|

|

|

|

|

Voltage |

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

(Sink) |

O level |

22V |

|

27V |

|

|

|

|

|

|

|

|

|

|

|

|

Operating |

ON level |

22V |

|

27V |

|

|

|

|

|

|

|

|

|

|

|

|

Voltage |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Sink) |

O level |

0V |

|

2V |

|

|

|

|

|

|

|

|

|

|

|

|

• 0-10VDC analog inputs. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

• 4-20mA analog input. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

• Transistor outputs. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Item |

|

Max. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Operating |

ON level |

2V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Voltage |

O level |

27V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Maximum Current at on. |

50m A |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

• Form C contact relay |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

o (250VAC 0.3A, cosØ=0.3), (48VDC, .5A). |

|

|

|

|

|

|

|

|

|

|||||||

• 24VDC max 200mA DC output power. |

|

|

|

|

|

|

|

|

|

|

|

|||||

• 10VDC output for potentiometer. |

|

|

|

|

|

|

|

|

|

|

|

|

||||

• 24 VDC 50mA power source |

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Other Control Terminal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

• RJ-45 keypad connection port. |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Note 1:

When connecting a DC REACTOR (DCR) (option), remove the jumper bar from across the terminals [P1] and [P (+)].

For single-phase 100V input series, DCR shall be connected to the point that is shown below.

Note 2:

Install a recommended molded-case circuit breaker (MCCB) or an earth leakage circuit breaker (ELCB) (with an overcurrent protection function) in the primary circuit of the inverter to protect wiring. At this time, ensure that the circuit breaker capacity is equivalent to or lower than the recommended capacity.

Note 3:

Install a magnetic contactor (MC) recommended for each inverter to separate the inverter form the power supply, apart from the MCCB or ELCB, when necessary. Connect a surge suppressor in parallel when installing a coil such as the MC or solenoid near the inverter.

Note 4:

(THR) is available when one of terminal functions for X1 to X3, FWD, REV (function code E01 to E03, E98 or E99) is set to the data “9”.

Note 5:

Frequency can be set by connecting a frequency setting device (external potentiometer) among the terminals 11, 12 and 13 instead of inputting voltage signal (0 to +10V DC, 0 to +5V DC or +1 to +5V DC) between the terminals 12 and 11.

Note 6:

For the control signal wires, use shielded or twisted wires. Ground shielded wires. To prevent malfunction due to noise, keep the control circuit wiring away from the main circuit wiring as far as possible (recommended: 10cm(3.94inches) or more), and never set them in the same wire duct.

When crossing the control circuit wiring with the main circuit wiring, set them at right angles. Note 7:

Three –phase 4wire cable is recommended for motor wiring to reduce the noise emitted. Connect the motor grounding wire to the inverter grounding terminal G

G

Loading...

Loading...