Follett HCD710AJS, HCD710ABS, HCD710AHS, HCD710AHT, HCD710AVS User Manual

...

HCD710A, HMD710A

Horizon Elite™ Ice Machines (Self-contained)

Order parts online

www.follettice.com

Operation and Service Manual

Following installation, please forward this manual

to the appropriate operations person.

801 Church Lane • Easton, PA 18040, USA

HCD710A, HMD710A 1

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

01223080R02

Contents

Welcome to Follett ............................................................................... 3

Before you begin ................................................................................ 3

Specications .................................................................................. 4

Operation ...................................................................................... 7

Preventive maintenance ....................................................................... 7

Weekly exterior care .......................................................................... 7

Monthly condenser cleaning (air-cooled icemaker only) .............................................. 7

Semi-annual evaporator cleaning (every 6 months) ................................................. 7

Service .......................................................................................11

Harvest system diagram .......................................................................11

Water system diagram ....................................................................... 13

Water level diagram ......................................................................... 13

Normal control board operation ................................................................ 14

DIP Switch Settings ......................................................................... 14

Error faults: ............................................................................... 15

Soft errors: ................................................................................ 15

Hard error: ................................................................................. 15

Run errors: ................................................................................ 15

Relay output indication: ...................................................................... 15

Evaporator ushing sequence: ................................................................. 15

Wiring diagram ............................................................................. 16

Mechanical System ............................................................................. 18

Reservoir/rear bushing disassembly ............................................................ 25

Refrigerant pressure data ..................................................................... 26

Refrigeration system diagram .................................................................. 26

Evacuation ................................................................................ 27

Ice capacity test ............................................................................ 27

Troubleshooting ................................................................................ 28

Replacement parts ............................................................................. 30

2 HCD710A, HMD710A

Welcome to Follett

Follett equipment enjoys a well-deserved reputation for excellent performance, long-term reliability and outstanding

after-the-sale support. To ensure that this equipment delivers the same degree of service, we ask that you review

the installation manual (provided as a separate document) before beginning to install the unit. Our instructions are

designed to help you achieve a trouble-free installation. Should you have any questions or require technical help at

any time, please call our technical service group at (877) 612-5086 or +1 (610) 252-7301.

Before you begin

After uncrating and removing all packing material, inspect the equipment for concealed shipping damage. If

damage is found, notify the shipper immediately and contact Follett LLC so that we can help in the ling of a claim,

if necessary.

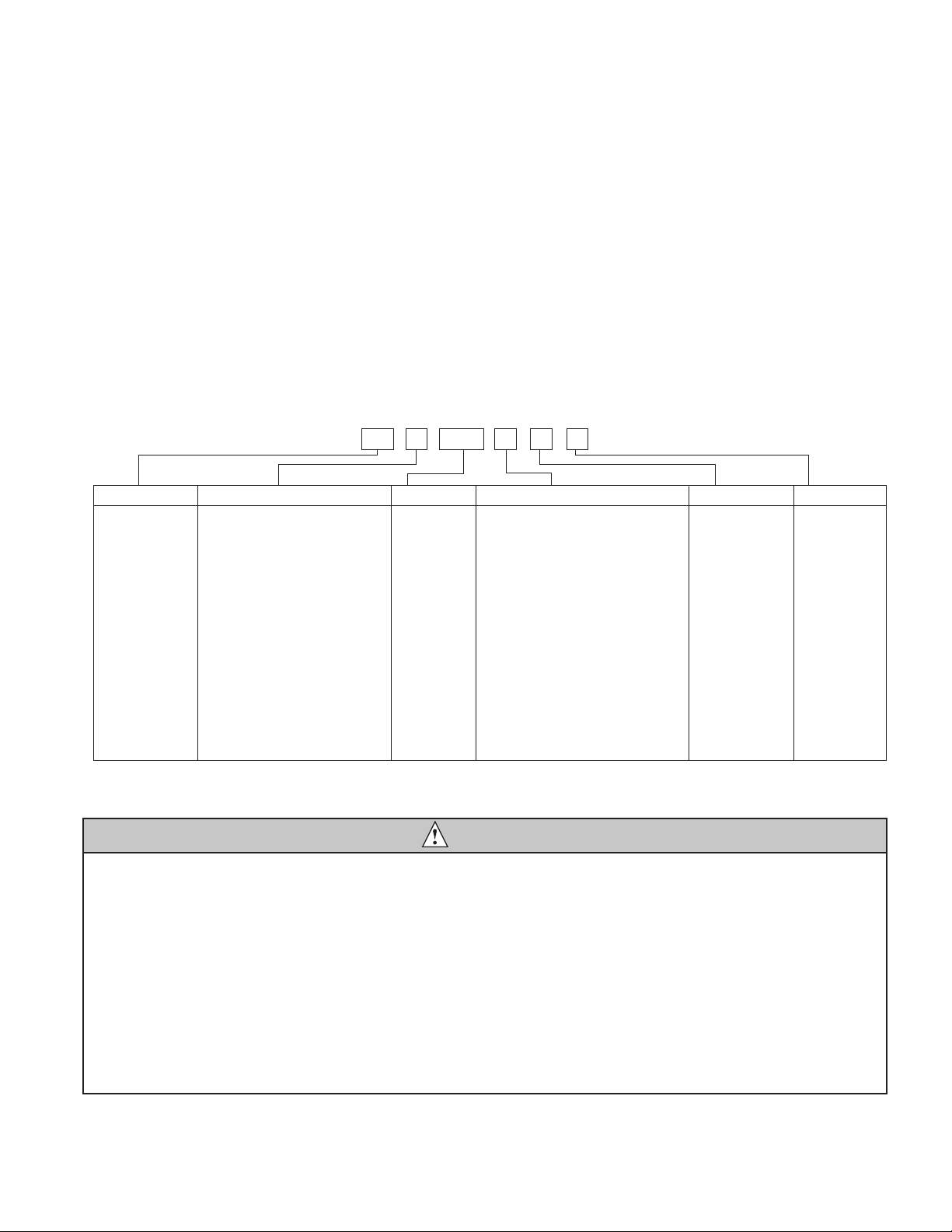

Check your paperwork to determine which model you have. Follett model numbers are designed to provide

information about the type and capacity of Follett equipment. Following is an explanation of the different model

numbers in the series.

Chewblet® Ice Machine Model Number Configurations

HC 1810D SVA

ConfigurationApplication

S RIDE™

(RIDE remote

ice delivery

equipment)

T Top-mount

MC Maestro™

Chewblet

(425 Series)

HC Horizon

Chewblet

(710, 1010,

1410, 1810,

2110 Series)

HM Horizon

Micro Chewblet

C 208-230/60/1 (icemaking head)

®

Self-contained only.

D 115/60/1 (icemaking head)

Self-contained and remote. If remote

unit, high side is 208-230/60/1.

E 230/50/1 (icemaking head)

Self-contained only.

F 115/60/1 (icemaking head)

Remote only. High side is

208-230/60/3.

425 up to

425 lbs

(193 kg)

710 up to

675 lbs

(306 kg)

1010 up to

1061 lbs

(482 kg)

1410 up to

1466 lbs

(665 kg)

1810 up to

1790 lbs

(812 kg)

2110 up to

2039 lbs

(925 kg)

CondenserSeriesVoltageIcemaker

A Air-cooled, self-contained

W Water-cooled, self-contained

R Air-cooled, remote condensing unit

N Air-cooled, no condensing unit for

connection to parallel rack system

V Vision™

H Harmony™

B Ice storage bin

J Drop-in

M Ice Manager

diverter valve

system

P Cornelius Profile

PR150

CAUTION

• Warranty does not cover exterior or outside installations.

• Moving parts. Do not operate with front cover removed.

• Hot parts. Do not operate with cover removed.

• To reduce risk of shock, disconnect power before servicing.

• Drain line must not be vented.

• Water supply must have particle ltration.

• Most ice machine cleaners contain citric or phosphoric acid, which can cause skin irritation. Read caution label

on product and follow instructions carefully.

• Ice is slippery. Maintain counters and oors around dispenser in a clean and ice-free condition.

• Ice is food. Follow recommended cleaning instructions to maintain cleanliness of delivered ice.

HCD710A, HMD710A 3

Specications

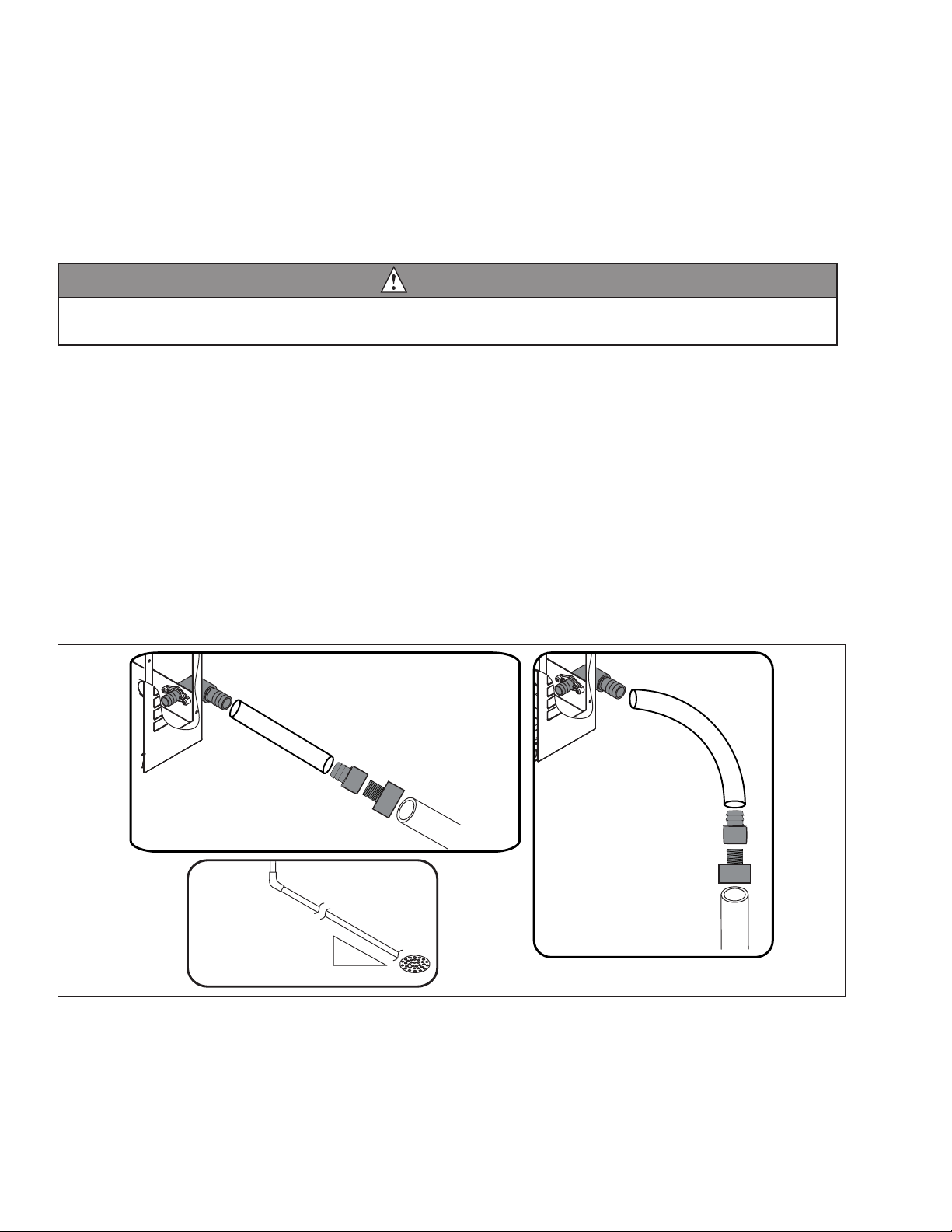

3/4" barb x 3/4" FPT

1" Stand pipe/Drain

2 ft. x 1" OD

silicone tubing

Minimum 8"

radius

3/4" MPT x 1" slip

1" PVC Drain

2 ft. x 1" OD

silicone tubing

3/4" MPT x 1" slip

3/4" barb x 3/4" FPT

1'

1/4" per foot

(6,4 mm per 0,3 m)

Electrical

Each ice machine requires its own separate circuit with electrical disconnect within 10 ft (6m).

Equipment ground required.

Standard electrical:

§ 115 V/60/1 (6 ft (2m) NEMA 5-15 cord and plug provided)

§ Amperage: 11.3A, dedicated 15A circuit required

Plumbing

WARNING

This equipment to be installed with adequate backow protection to comply with applicable federal, state,

and local codes.

§ 3/8" OD push-in water inlet (connection inside machine) - 3/8" OD tubing required

§ 3/4" MPT drain

Notes:

§ Water shut-off recommended within 10 feet (3m).

§ Water supply must have particle ltration. Follett recommends the lter system that has integral scale inhibitors.

(Follett item# 00130286).

§ Follett does not recommend the use of water softeners or bowl scale inhibitors.

Drain plumbing

§ 3/4" MPT drain connection at the rear of the machine.

§ Drain must slope 1/4" inch per foot (6 mm per 30.4 cm).

§ Drain line should not be shared with any other piece of equipment.

§ Drain line cannot be reduced to a size smaller than 1 inch.

§ Drain should be piped without a vent.

4 HCD710A, HMD710A

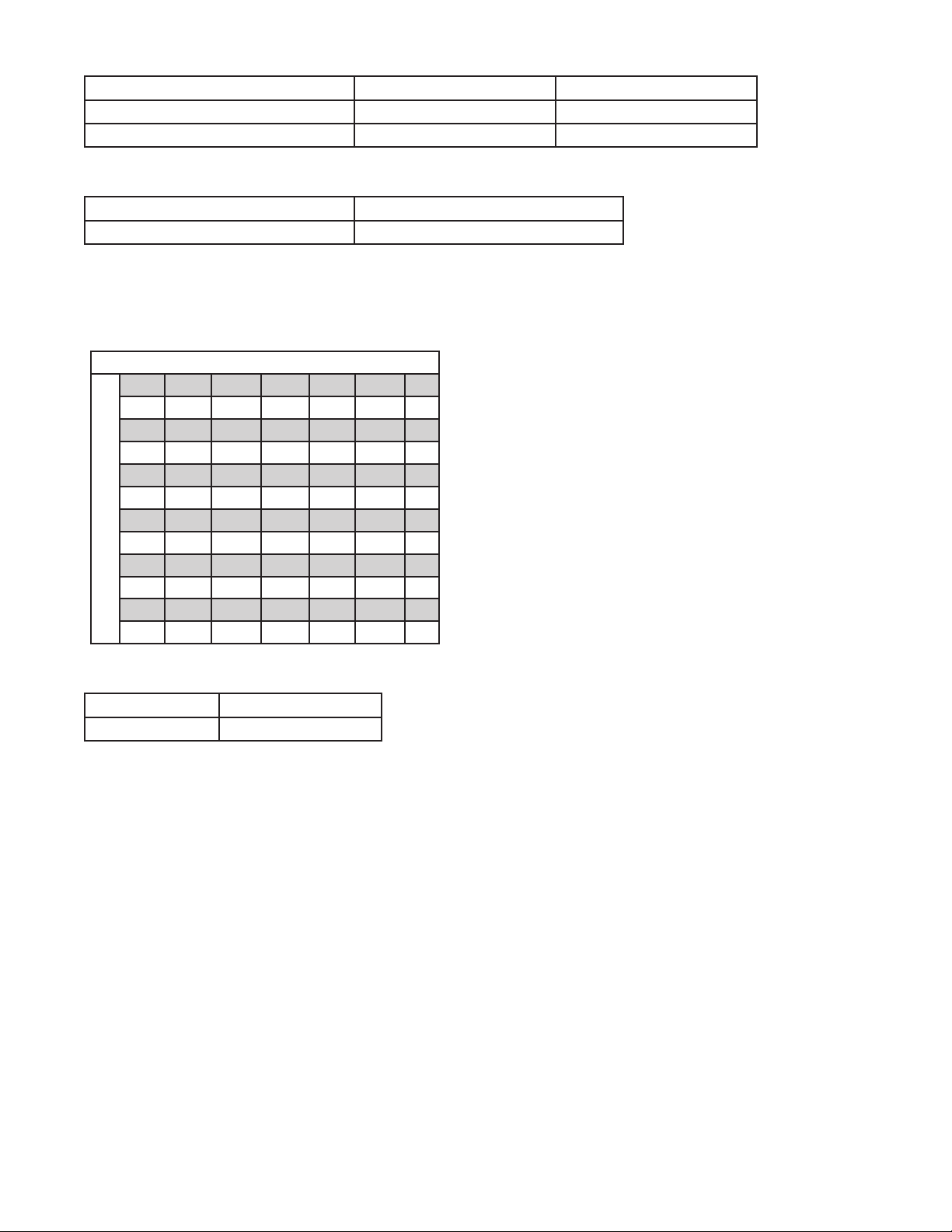

Ambient

Air temperature 100 F/38 C max. 50 F/10 C min.

Water temperature 90 F/32 C max. 45 F/7 C min.

Water pressure – potable 70 psi max. (483 kPa) 10 psi min. (89 kPa)

Heat rejection

710

Air-cooled 8,500 BTU/hr

Ice production

710 Air-cooled ice machine capacity/24 hrs.

Ambient Air Temperature F/C

F 60 70 80 90 100

C 16 21 27 32 38

50 787 759 705 639 603 lbs

10 357 344 320 290 2 74 kg

60 750 702 666 624 570 lbs

16 340 318 302 283 259 kg

70 707 681 636 586 542 lbs

21 321 309 288 266 246 kg

80 677 629 611 559 518 lbs

27 307 285 277 254 235 kg

90 642 600 580 539 497 lbs

Evap Potable Water Temperature F/C

32 291 272 263 244 225 kg

Weight

Shipping 190 lb (86.2 kg)

Net 170 lb (77.2 kg)

HCD710A, HMD710A 5

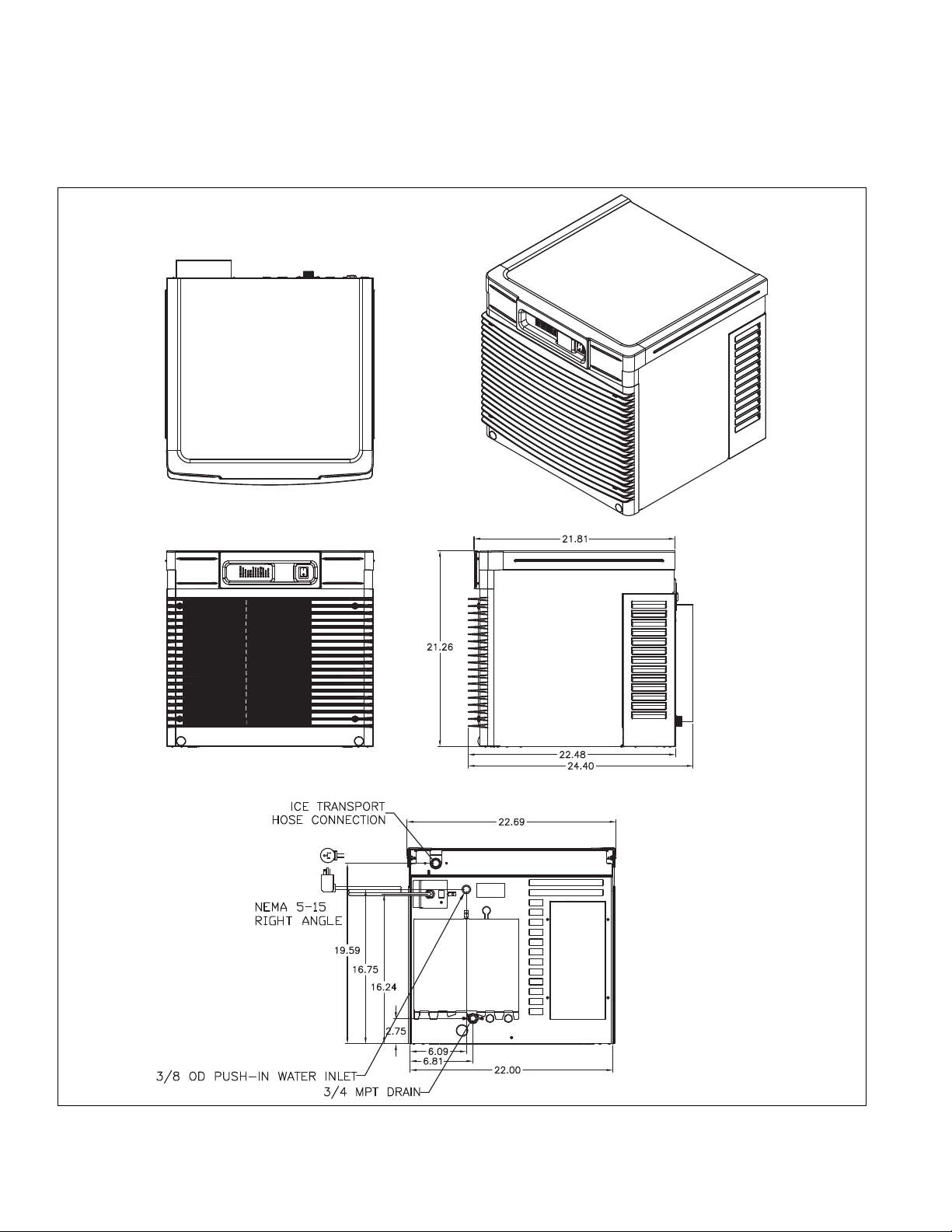

Dimensions and clearances

§ Entire front of ice machine must be clear of obstructions/connections to allow removal.

§ 1" (26 mm) clearance above ice machine for service.

§ 1" (26 mm) minimum clearance on sides.

§ The intake and exhaust air grilles must provide at least 250 sq in (1615 sq cm) of open area.

§ Air-cooled ice machines – 18" (458 mm) minimum clearance between discharge and air intake-grilles.

6 HCD710A, HMD710A

Operation

Cleaning/sanitizing and preventive maintenance (all models)

Note: Do not use bleach to sanitize or clean the icemaker.

Preventive maintenance

Periodic cleaning of Follett’s icemaker system is required to ensure peak performance and delivery of clean,

sanitary ice. The recommended cleaning procedures that follow should be performed at least as frequently as

recommended, and more often if environmental conditions dictate.

Cleaning of the condenser can usually be performed by facility personnel. Cleaning of the icemaker system,

in most cases, should be performed by your facility’s maintenance staff or a Follett authorized service agent.

Regardless of who performs the cleaning, it is the operator’s responsibility to see that this cleaning is performed

according to the schedule below. Service problems resulting from lack of preventive maintenance will not be

covered under the Follett warranty.

Weekly exterior care

The exterior may be cleaned with a stainless cleaner such as 3M Stainless Steel Cleaner & Polish or equivalent.

Monthly condenser cleaning (air-cooled icemaker only)

1. Use a vacuum cleaner or stiff brush to carefully clean condenser coils of air-cooled icemakers to ensure

optimal performance.

2. When reinstalling counter panels in front of remote icemakers, be sure that ventilation louvers line up with

condenser air duct.

Semi-annual evaporator cleaning (every 6 months)

WARNING

• Wear rubber gloves and safety goggles (and/or face shield) when handling ice machine cleaner or sanitizer.

CAUTION

• Use only Follett approved SafeCLEAN Plus™ cleaning solution.

• DO NOT USE BLEACH.

• It is a violation of Federal law to use these solutions in a manner inconsistent with their labeling.

• Read and understand all labels printed on packaging before use.

Note: Complete procedure for cleaning and sanitizing MUST be followed. Ice must be collected for

10minutes before putting ice machine back into service.

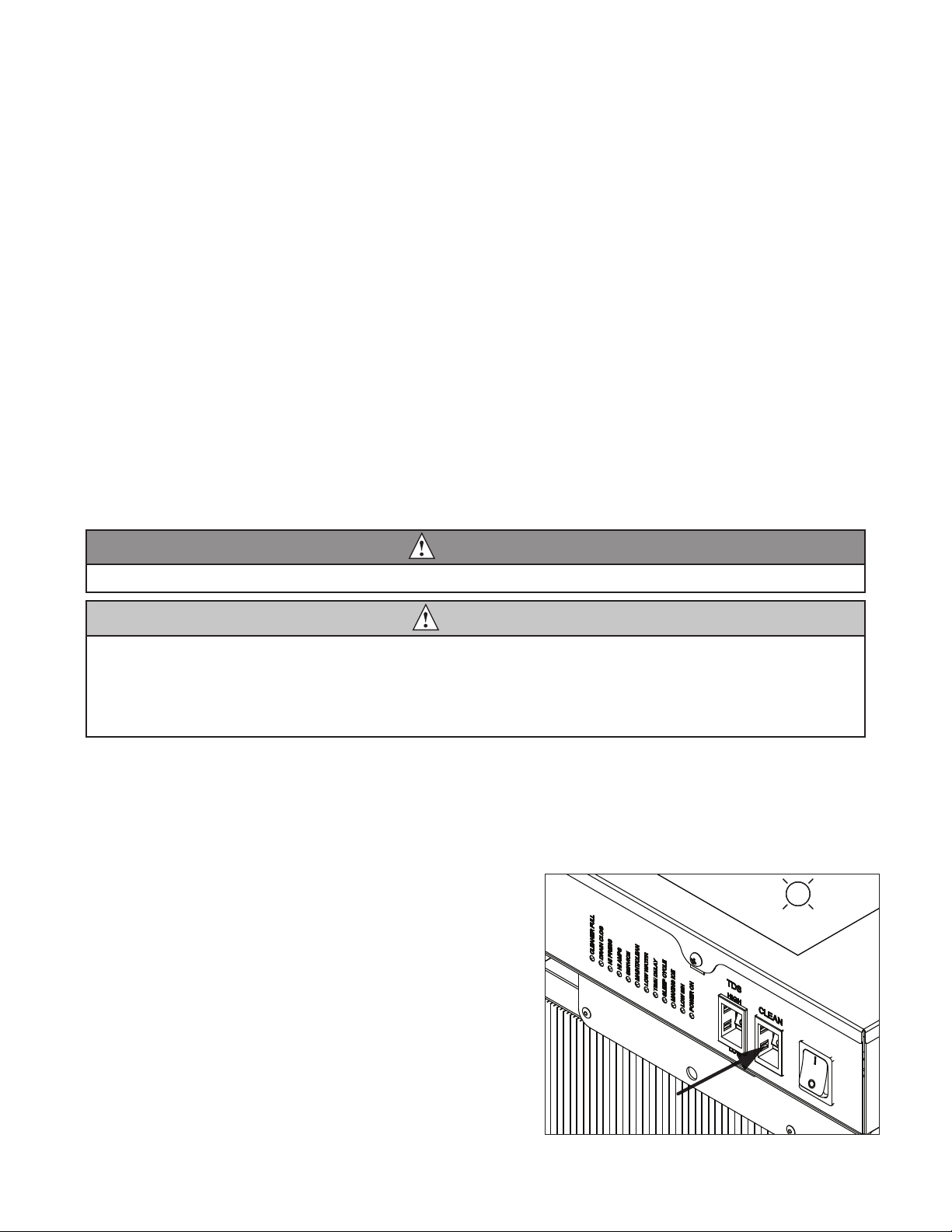

Fig. 1

1. Press the CLEAN button. The machine will drain. The

auger will run for a short time and then stop. Wait for

the LOW WATER light to come on.

LO WATER

HCD710A, HMD710A 7

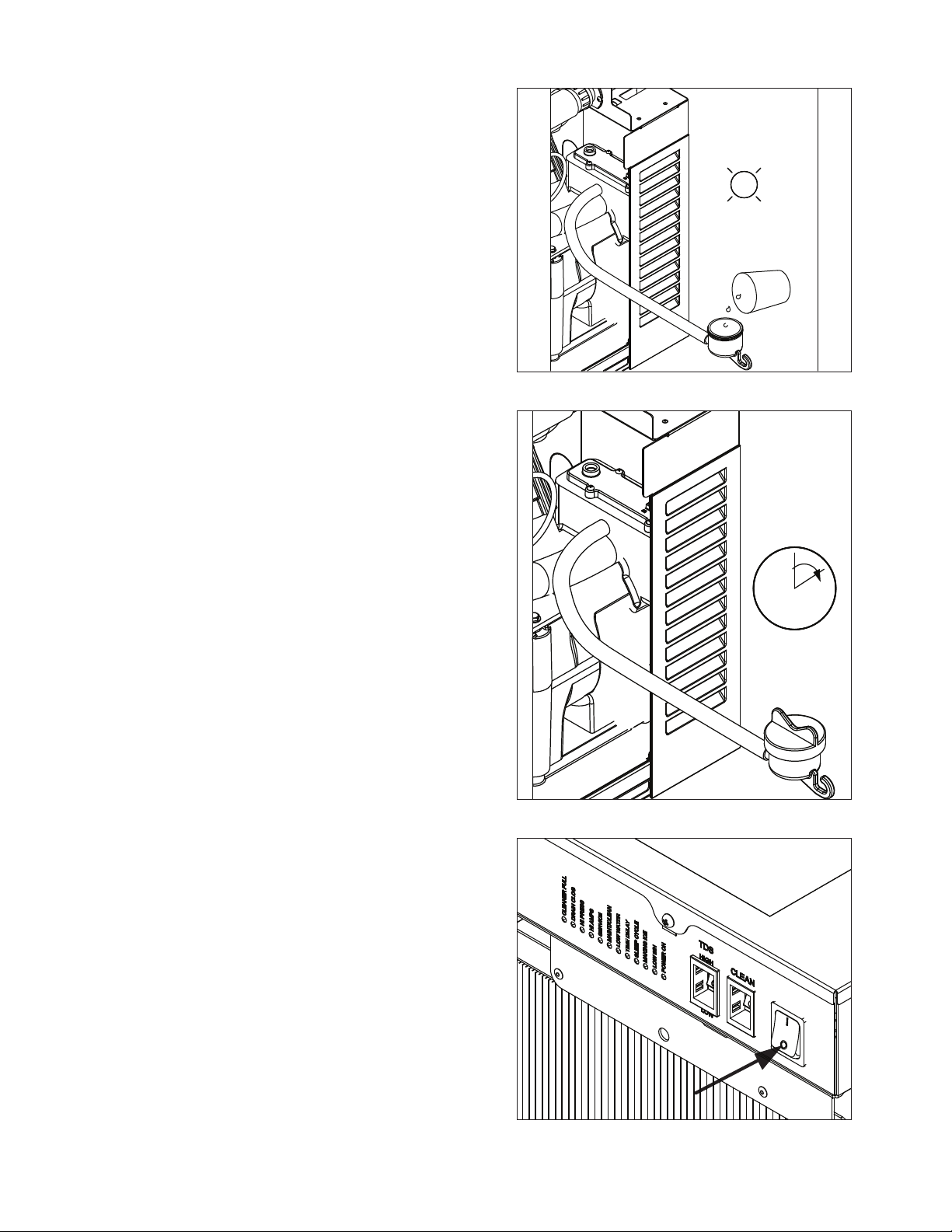

2. Follow the directions on the SafeCLEAN Plus

packaging to mix 1 gal. (3.8 L) of Follett SafeCLEAN

Plus solution. Use 100 F (38 C) water.

3. Using a 1 quart (1L) container, slowly ll cleaning cup

until CLEANER FULL light comes on. Do not overll.

4. Soak one SaniSponge™ in remaining sanitizing and

cleaning solution and retain for Step 9.

Note: Do not use bleach to sanitize or clean the icemaker.

5. Replace cover on cleaner cup. Machine will clean,

then ush 3 times in approximately 15 minutes. Wait

until machine restarts.

Fig. 2

CLEANER FULL

Fig. 3

6. To clean/sanitize ice transport tube – Press power

switch OFF

15

Fig. 4

8 HCD710A, HMD710A

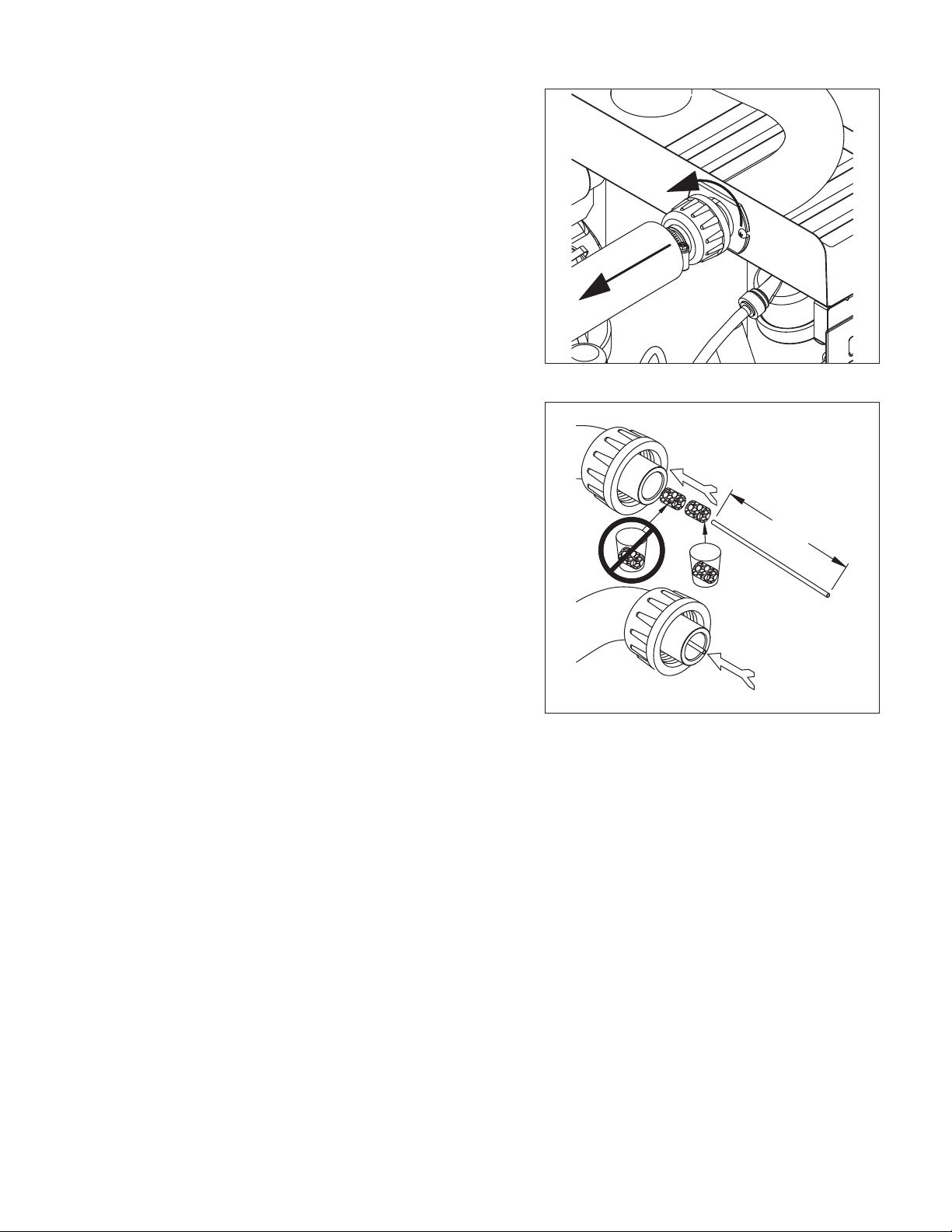

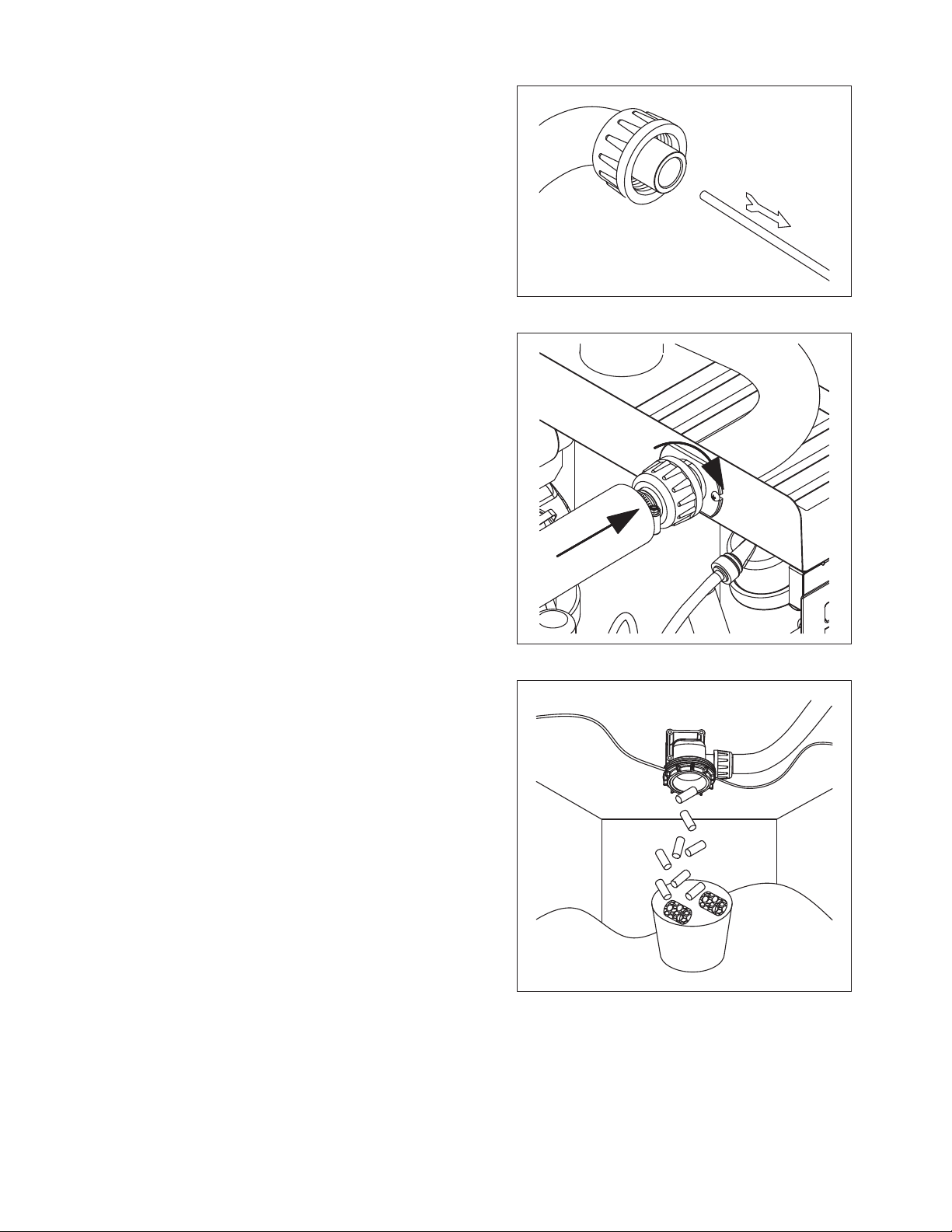

7. Disconnect coupling as shown.

8. Using disposable food service grade gloves, insert

dry SaniSponge.

9. Insert SaniSponge soaked in SafeClean Plus (from

Step 4).

10. Push both SaniSponges down ice transport tube with

supplied pusher tube.

Fig. 5

Fig. 6

1

16"

(407 mm)

2

3

HCD710A, HMD710A 9

11. Remove and discard 16 inch (407 mm) pusher tube.

12. Reconnect coupling. Press power switch ON. Ice

pushes SaniSponges through ice transport tube.

Fig. 7

Fig. 8

13. Place a sanitary (2 gal. or larger) container in bin

or dispenser to collect SaniSponges and ice for 10

minutes.

14. Collect 5.5 lbs (3 kg) of ice from unit. Discard ice and

SaniSponges.

Fig. 9

10 HCD710A, HMD710A

Service

Ice machine operation (all models)

Follett’s ice machine consists of ve distinct functional systems covered in detail as follows:

§ Water system

§ Electrical control system

§ Mechanical assembly

§ Refrigeration system

§ Bin full

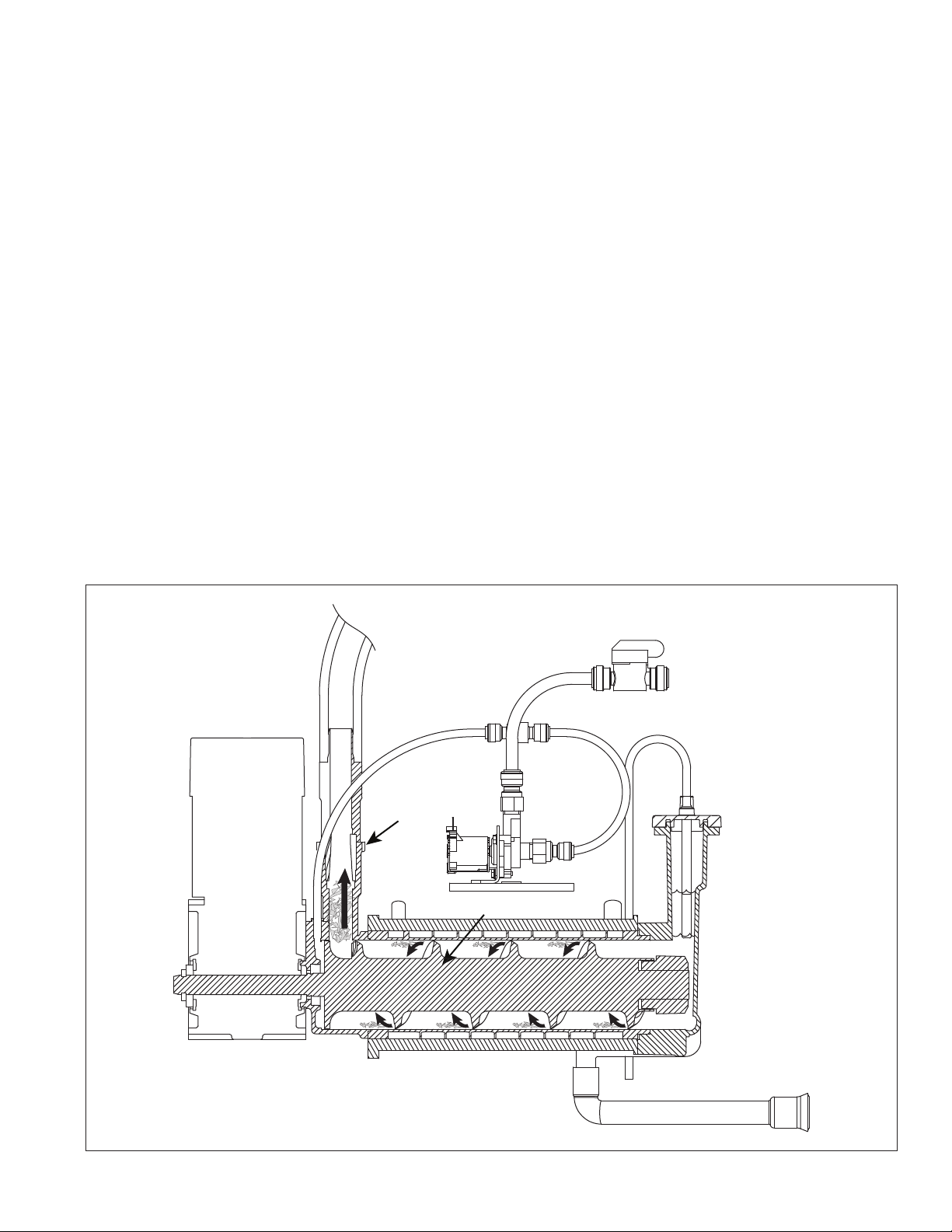

The Horizon ice machine overview

The Follett Horizon ice machine uses a horizontal, cylindrical evaporator to freeze water on its inner surface. The

refrigeration cycle is continuous; there is no batch cycle. The evaporator is ooded with water and the level is

controlled by sensors in a reservoir. A rotating auger continuously scrapes ice from the inner wall of the evaporator.

The auger moves harvested ice through the evaporator into an ice extrusion canal. The ice is forced through a

restrictive nozzle that squeezes out the water and creates the Chewblet. The continuous extrusion process pushes

the Chewblets through a transport tube into a dispenser or bin.

A solid state PC board controls and monitors the functionality of the ice machine. In addition to sequencing

electrical components, the board monitors various operational parameters. A full complement of indicator lights

allows visual status of the machine's operation. Additionally, the PC board controls the self-ushing feature of the

ice machine. The evaporator water is periodically drained and replenished to remove minerals and sediment.

A unique “bin full” detection system is incorporated in the Horizon ice machine. A switch located at the ice

discharge port of the machine detects the position of the transport tube. When the bin lls up with ice, the transport

tube moves out of the normal running position, and the switch turns the ice maker off. A domed housing at the end

of the transport tube contains the ice extrusion loads during shut down.

Harvest system diagram

Ice Transport Tube

Compression

Nozzle

Auger

Water Inlet

HCD710A, HMD710A 11

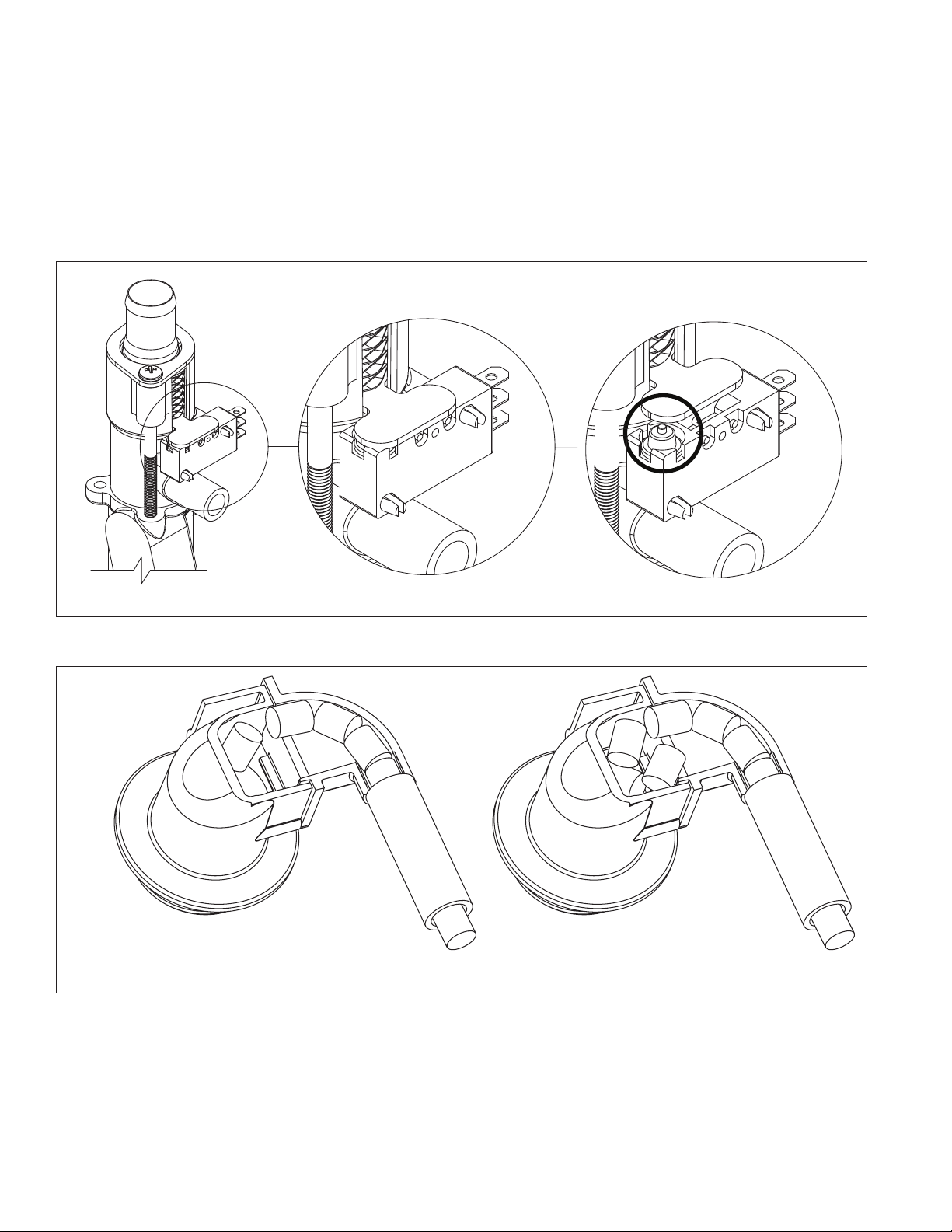

“Bin full” detection system

The Follett Horizon ice machine incorporates a unique “bin full” detection system that consists of the shuttle and

actuator. The shuttle incorporates a ag and switch. Referencing the gure below, the normal running position

of the ag is down, and the switch is closed. When the bin lls to the top and ice can no longer move through

the tube, the machine will force the shuttle ag up, opening the switch and shutting the machine off. The shuttle

actuator, located above the ice bin allows the ice to curl up within it when the bin is full. In this way, there are no

loads generated that would tend to lift off the lid of the bin.

Shuttle ag and sensor

Shuttle actuator

Running

Running Off

Off

12 HCD710A, HMD710A

Loading...

Loading...