Follett REF20-BB Service Manual

REF 20/25 – LB REF 20/25 – PH REF 20/25 – BB

Order parts online www.follettice.com

Installation, Operation and Service Manual

Following installation, please forward this manual to the appropriate operations person.

801 Church Lane • Easton, PA 18040, USA |

|

Toll free (877) 612-5086 • +1 (610) 252-7301 |

|

www.follettice.com |

00926170R03 |

Contents

Welcome to Follett. . . . . . . . . . . . . . . . . . . . . 3

Before you begin. . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Ambients. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Electrical specifications . . . . . . . . . . . . . . . . . . . . . 4 Refrigeration specifications . . . . . . . . . . . . . . . . . . 4 Detail drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Adjust self-closing door (if necessary) . . . . . . . . . . 5 Install shelves (if equipped) and power up. . . . . . . 5 Fill product bottle. . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Remote alarm connections (if desired) . . . . . . . . . 7 Dry contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 RS-485 port . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Quick setup checklist . . . . . . . . . . . . . . . . . . . . . . . 8 Interior LED lights . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Set time & date. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Change temperature display to show degrees Fahrenheit (if desired). . . . . . . . . . . . . . . . . . . . . . . 9 High and low alarm setup. . . . . . . . . . . . . . . . . . . .10 Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Alarm muting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Alarm volume selection . . . . . . . . . . . . . . . . . . . . 13 Alarm silence . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Password PIN security (default is 3843) . . . . . . . 14 To turn password on/off . . . . . . . . . . . . . . . . . . . . 14 To make a new password PIN . . . . . . . . . . . . . . . 15 Min/max temperature logging . . . . . . . . . . . . . . . . 16 Probe calibration . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Chart recorder set up (if so equipped) . . . . . . . . . 18 Chart recorder calibration. . . . . . . . . . . . . . . . . . . 18 Changing the chart paper. . . . . . . . . . . . . . . . . . . 18 Replacing the pen. . . . . . . . . . . . . . . . . . . . . . . . . 18 Removing drawers . . . . . . . . . . . . . . . . . . . . . . . . 19 Removing slides . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Interior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Exterior cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . 20 Annual cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Refrigeration system. . . . . . . . . . . . . . . . . . . . . . . 22 Defrosting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 Controller operation . . . . . . . . . . . . . . . . . . . . . . . 23 Temperature sensor readings. . . . . . . . . . . . . . . . 23 Heated door (option) – changing cycle . . . . . . . . 24 Controller hot key . . . . . . . . . . . . . . . . . . . . . . . . . 27 Hot key upload . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 Hot key download . . . . . . . . . . . . . . . . . . . . . . . . . 28

Troubleshooting . . . . . . . . . . . . . . . . . . . . . 34

Before calling for service . . . . . . . . . . . . . . . . . . . 34

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Control key functions . . . . . . . . . . . . . . . . . . . . . . 35 Menu Navigation table . . . . . . . . . . . . . . . . . . . . . 35

Replacement parts . . . . . . . . . . . . . . . . . . . 36

Unit cooler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 Facade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 Door assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2 |

00926170 – REF20/25 LB, PH, BB |

Welcome to Follett

Follett equipment enjoys a well-deserved reputation for excellent performance, long-term reliability and outstanding after-the-sale support. To ensure that this product delivers that same degree of service, we ask that you take a moment to review this manual before beginning the installation. Should you have any questions or require technical help at any point, please call our technical service group at (877) 612-5086 or +1 (610) 252-7301.

Before you begin

After uncrating and removing all packing material, inspect the equipment for concealed shipping damage. If damage is found, notify the shipper immediately and contact Follett Corporation so that we can help in the filing of a claim, if necessary.

Check your paperwork to determine which configuration you have. Follett configuration numbers are designed to provide information about the type of refrigerator you are receiving. Following is an explanation of the different item numbers.

Model

Cubic foot capacity – 20, 25

Confi guration – LB (Laboratory - shelves), PH (Pharmacy - baskets),

BB (Blood bank - drawers)

Door hinge – R (Right hand), L (Left hand)

Door heater option – 00 (No door heater), HT (door heater)

Chart recorder option – 00 (No chart recorder), CR (Chart recorder)

REF 20 LB R 00 00

Specifications

|

REF20-LB |

REF25-LB |

REF20-PH |

REF25-PH |

REF20-BB |

REF25-BB |

Capacity |

19.7 cu ft |

24.6 cu ft |

19.7 cu ft |

24.6 cu ft |

19.7 cu ft |

24.6 cu ft |

|

(558 L) |

(697 L) |

(558 L) |

(697 L) |

(558 L)/ 280 |

(697 L)/ 360 |

|

|

|

|

|

bags (450ml) |

bags (450ml) |

|

|

|

|

|

|

|

Storage |

(4) epoxy- |

(4) epoxy- |

(6) epoxy- |

(6) epoxy- |

(6) stainless |

(6) stainless |

system |

coated shelves |

coated shelves |

coated baskets |

coated baskets |

steel drawers |

steel drawers |

|

|

|

|

|

|

|

Exterior width |

29.75" (76cm) |

29.75" (76cm) |

29.75" (76cm) |

29.75" (76cm) |

29.75" (76cm) |

29.75" (76cm) |

|

|

|

|

|

|

|

Exterior depth |

29" (74cm) |

35" (89cm) |

29" (74cm) |

35" (89cm) |

29" (74cm) |

35" (89cm) |

|

|

|

|

|

|

|

Exterior depth |

30.5" (78cm) |

36.5" (93cm) |

30.5" (78cm) |

36.5" (93cm) |

30.5" (78cm) |

36.5" (93cm) |

with handles |

|

|

|

|

|

|

|

|

|

|

|

|

|

Exterior height |

79.5" (202cm) |

79.5" (202cm) |

79.5" (202cm) |

79.5" (202cm) |

79.5" (202cm) |

79.5" (202cm) |

with casters |

|

|

|

|

|

|

|

|

|

|

|

|

|

Interior |

24" x 22.5" x 56" |

24" x 28.5" x 56" |

24" x 22.5" x 56" |

24" x 28.5" x 56" |

24" x 22.5" x 56" |

24" x 28.5" x 56" |

dimensions |

(61cm x 58cm x 143cm) |

(61cm x 73cm x 143cm) |

(61cm x 58cm x 143cm) |

(61cm x 73cm x 143cm) |

(61cm x 58cm x 143cm) |

(61cm x 73cm x 143cm) |

|

|

|

|

|

|

|

(W x H x D) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Crated weight |

395 (180kg) |

430 (196kg) |

450 (205kg) |

485 (220kg) |

475 (216kg) |

525 (239kg) |

|

|

|

|

|

|

|

Max. heat |

950 BTU/hr |

1050 BTU/hr |

950 BTU/hr |

1050 BTU/hr |

950 BTU/hr |

1050 BTU/hr |

rejection |

|

|

|

|

|

|

|

|

|

|

|

|

|

00926170 – REF20/25 LB, PH, BB |

Welcome to Follett |

3 |

|

Standard features – all models |

Door |

Dual pane, low-E glass, condensation free to 80 F (27 C) air/60% RH |

|

|

Door handle |

ADA-compliant, full length handle with integral lock |

|

|

Interior/exterior material |

Heavy-duty, corrosion resistant stainless steel |

|

|

Casters |

(4) dual-wheel swiveling casters with toe locks |

|

|

Insulation |

2.75" (7cm) thick, CFC-free foam insulation throughout |

|

|

Lighting |

(2) full length side LED lights |

|

|

Air circulation system |

Ducted air through 12 back plenum openings with front face return |

|

|

Temperature probe |

Stainless steel RTD (resistance temperature detectors) top, bottom probe standard |

|

on - BB models, available as option on -LB, -PH models, immersible with panel quick- |

|

disconnect |

|

|

Ambients

Intended for indoor use where ambient temperature typically does not exceed 80 F (27 C) and ambient relative humidity does not exceed 60% RH. A heated door is recommended for higher humidity ambients.

Clearances

The top of the refrigerator must have 10 inches (25.4cm) of clear space above the refrigerator to ensure proper ventilation of the refrigeration system.

The back of the refrigerator should have 1 inch (2.5cm) of clearance to allow for power cord clearance on unit and an additional 1 inch (2.5cm) if the unit is to be plugged in directly behind the refrigerator.

Electrical specifications

115V, 60Hz, 1 phase

Running load amps: 8.4 amps without heated door; max 9.7 amps with door heater energized 100% (adjustable).

Full load amps (90% maximum continuous current per UL 471 at 40 C): 10.5 amps

Minimum circuit ampacity: 15 amp dedicated circuit

Maximum size of branch circuit overcurrent device: 15 amp dedicated circuit

Refrigeration specifications

Refrigerant R134a, 11.4 oz (322g)

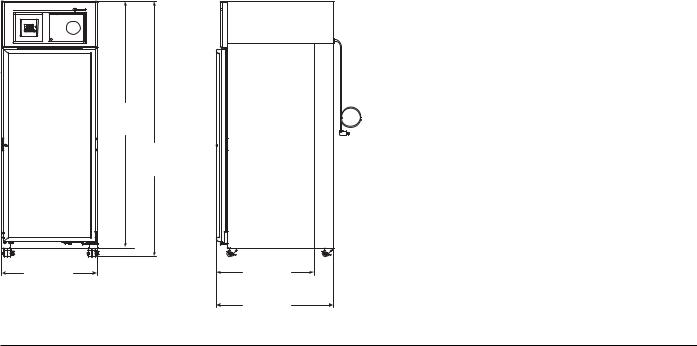

Detail drawing

|

76.75" |

|

|

(195cm) |

|

|

79.5" |

|

|

(202cm) |

|

|

29.75" |

REF20 |

|

(76cm) |

|

|

30.5" (78cm) |

|

|

|

|

|

|

REF25 |

|

|

36.5" (93cm) |

4 |

Installation |

00926170 – REF20/25 LB, PH, BB |

Installation

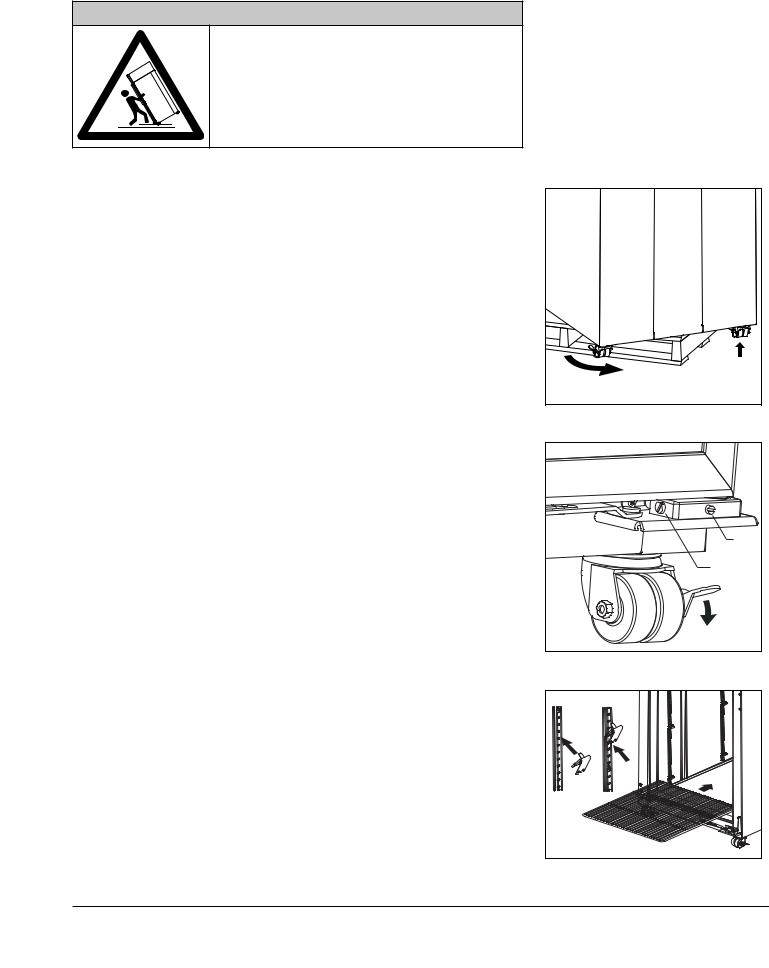

DANGER

DANGER

•Do not tilt any unit further than 30° off vertical during uncrating or installation

•Refrigeration module area contains mechanical, moving

parts. Keep hands and arms clear of this area at all times. If access to this area is required, power to unit must be disconnected first.

1.Remove key taped to side of refrigerator cabinet and unlock door.

2.Remove casters from box packed inside refrigerator.

Note: California facilities requiring wall and floor anchors – refer to wall anchor kit instructions (#00938241) packed with seismic kit before proceeding with caster installation.

3.Unbolt refrigerator from pallet.

4.Rotate refrigerator on pallet to install casters (Fig. 1.1).

5.Install casters by hand one at a time using channel locks to tighten, until caster meets against the bottom of cabinet (Fig. 1.2).

6.Peel protective film from exterior walls of stainless cabinet.

Fig. 1

2 |

1 |

Adjust self-closing door

1.Roll refrigerator to desired location and lock as many casters as possible (Fig 2.1).

2.Check door for sagging and, if necessary, turn sag adjustment screw (Fig. 2.2) to align door squarely with refrigerator cabinet.

3.Check door for closing tension and adjust if necessary. To check closing tension, open door 1" and turn screw (Fig. 2.3) counterclockwise until you achieve positive close. (Light will go out) Then, turn another half turn counterclockwise.

Fig. 2

3 |

2 |

1 |

Install shelves (if equipped) and power up

1.If refrigerator is equipped with shelves, remove bag containing shelf supports and position them in desired locations on each pilaster and insert shelves (Fig. 3).

2.Plug refrigerator into a 115V 60Hz 15 amp dedicated outlet.

Fig. 3

1 |

2 |

|

3 |

00926170 – REF20/25 LB, PH, BB |

Installation |

5 |

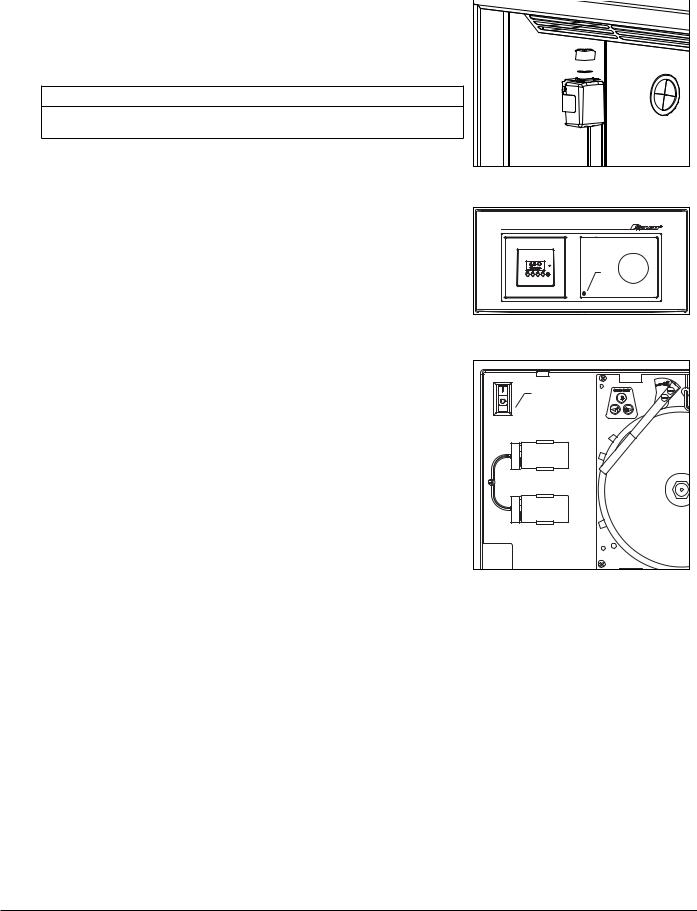

Fill product bottle |

Fig. 4 |

||||||

1. |

Remove probe and cap from the top bottle and fill with solution used at |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

your facility (e.g., 50% glycerine and 50% water) (Fig. 4). Replace cap |

|

|

|

|

|

|

|

and reinsert probe sensor. |

|

|

|

|

|

|

2. |

If equipped with a bottom probe, perform same procedure for bottom |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

bottle. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ATTENTION INSTALLER

It is imperative that the top probe bottle be filled with a solution that your facility uses to ensure proper operation of unit.

3.Press lower left corner of front facade door to access power switch inside (Fig. 5.1).

4.Press power switch to turn unit on (Fig. 6.1).

5.Install (2) 9V back-up interface batteries (Fig. 6.2) and (1) 9V chart recorder back-up battery (if equipped.)

Fig. 5

1 |

Fig. 6

1 |

2 |

6 |

Installation |

00926170 – REF20/25 LB, PH, BB |

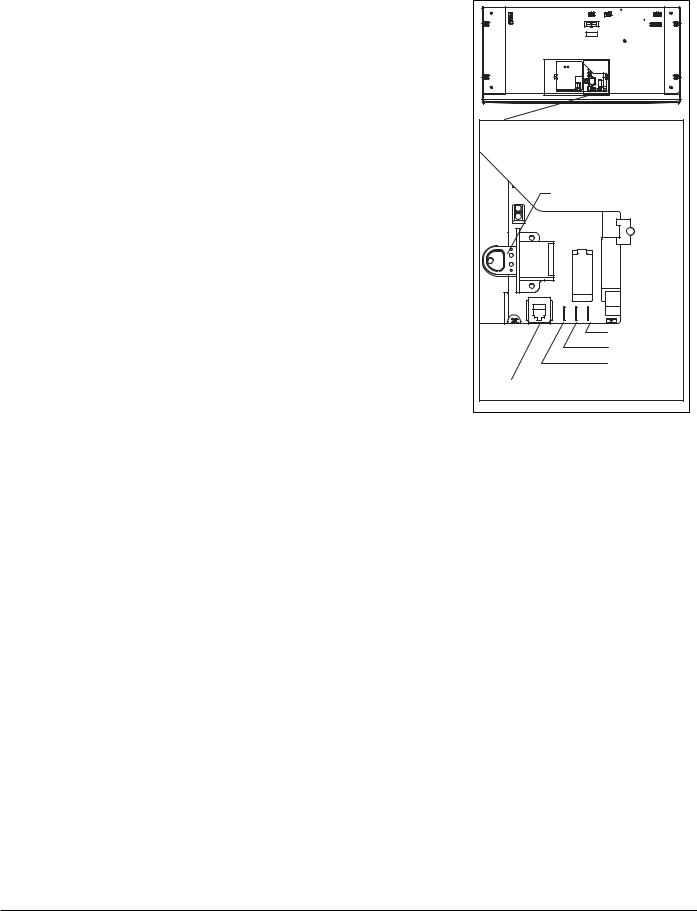

Remote alarm connections (if desired)

Remote communication connections are located on back side of top facade (Fig. 7).

Dry contacts

•Connection to NO or NC contacts provides remote alarming capability

•No temperature data is communicated

RS-485 port

•Connection provides real-time data streaming

–Temperature

–Alarms

–Refrigeration operation

•MODBUS protocol

•Uses 6 pin, 4 conductor RJ11 jack (not supplied)

Fig. 7

Hotkey |

|

|

Common |

|

N/O |

|

N/C |

RS485 Port |

Alarm Contacts |

|

|

00926170 – REF20/25 LB, PH, BB |

Operation |

7 |

Operation

Quick setup checklist

•Set time/date

•Change temperature display from factory default Celsius to Fahrenheit (if desired)

•Set high/low temperature alarms

•Select password access (if required)

•Setup chart recorder (if equipped)

•Verify solution is in bottle

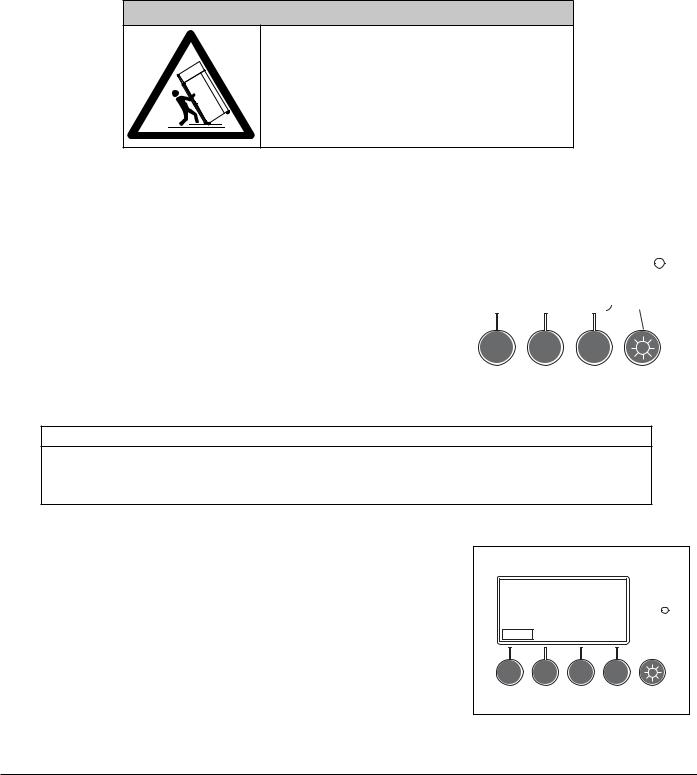

DANGER

DANGER

•Do not extend all of the drawers or baskets when fully loaded to avoid the possibility of the refrigerator tipping forward

• Refrigeration module area contains mechanical, moving parts. Keep hands and arms clear of this area at all times. If access to this area is required, power to unit must be disconnected first.

|

Fig. 8 |

|||

Interior LED lights |

|

|

|

|

4.0C |

|

|

||

Interior lighting of refrigerator with door closed is controlled by light switch |

|

|

||

(Fig 8.1) on interface. |

Bottom Temp 3.5C |

|

|

|

Lights will be on whenever door is open regardless of light switch selection. |

|

|

|

1 |

|

|

|

||

|

|

|

||

|

|

|

|

|

|

|

|

|

|

ATTENTION

•The time/date are not retained in the event of a power interruption or if the batteries are dead.

•Change batteries with the unit powered up. Change one battery at a time to retain time/date. Failure to follow this procedure will result in loss of time & date and will not provide accurate time and date stamping for high or low temperature alarms.

Fig. 9

Set time & date

Set time and date for stamping of minimum and maximum temperatures.

1. Press Menu button (Fig. 9).

4.0C

Bottom Temp 3.5C

Menu

8 |

Operation |

00926170 – REF20/25 LB, PH, BB |

2. Use

to scroll and highlight Set time/date and press Enter to select (Fig. 10).

to scroll and highlight Set time/date and press Enter to select (Fig. 10).

3.Adjust the year using

and press NEXT.

and press NEXT.

4.Adjust the month using

and press NEXT.

and press NEXT.

5.Adjust the day using

and press NEXT.

and press NEXT.

6.Adjust the hour using

and press NEXT. (24 HR Clock)

and press NEXT. (24 HR Clock)

7.Adjust the minute using

.

.

8.Press Enter to select values.

9.Press Back until the main temperature display screen is displayed.

Change temperature display to show degrees Fahrenheit (if desired)

Follett has pre-set the temperature display to read in degrees Celsius. If degrees Fahrenheit display is preferred:

1.Press Menu button (Fig. 12).

2.Use

to scroll and highlight Display Settings and press Enter to select (Fig. 13).

to scroll and highlight Display Settings and press Enter to select (Fig. 13).

3.Use

to scroll and highlight Degrees F/C and press Enter to select.

to scroll and highlight Degrees F/C and press Enter to select.

4.Use

to scroll and highlight F and press Enter to select.

to scroll and highlight F and press Enter to select.

5.Press Back button until the main temperature display screen is displayed. Temperature is displayed in degrees F.

Fig. 10

Set time/date |

4.0C |

Set Alarm Volume

Alarm Silence

Back  Enter

Enter

Fig. 11

Set year: 2009 |

3.4C |

2009 10/19 16:13

Next  Enter

Enter

Fig. 12

4.0C

Bottom Temp 3.5C

Menu

Fig. 13

Alarm Settings |

4.0C |

Display Settings

Calibration

Min/Max Temperatures

Back  Enter

Enter

00926170 – REF20/25 LB, PH, BB |

Operation |

9 |

High and low alarm setup |

Fig. 14 |

The high alarm is set to a default of 40 C (104 F) from the factory. This default setting is used so that the alarm will not sound while the unit is pulling down to temperature. The low alarm default setting is 1.0 C (33.8 F).

After the unit has been installed and the system has stabilized (approximately 1 hr), the high and low alarm set points should be adjusted to desired settings.

1.Press Menu button (Fig. 14).

2. Alarm Settings will be highlighted. Press Enter to select (Fig. 15).

4.0C

Bottom Temp 3.5C

Menu

Fig. 15

|

|

|

|

|

|

|

Alarm Settings |

4.0C |

|||

|

Display Settings |

|

|

||

|

Calibration |

|

|

||

|

Min/Max Temperatures |

|

|

||

|

|

|

|

|

|

|

|

|

Back |

Enter |

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 16

3.Use

to scroll and highlight High Alarm Set and press Enter to select (Fig. 16).

to scroll and highlight High Alarm Set and press Enter to select (Fig. 16).

|

|

|

|

|

|

|

High Alarm Set |

4.0C |

|||

|

Low Alarm Set |

|

|

||

|

|

|

|

|

|

|

|

|

Back |

Enter |

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 17

4. Use

to change set point and press Enter to accept (Fig. 17).

to change set point and press Enter to accept (Fig. 17).

High Alarm Setpoint |

4.0C |

40.0C

Back  Enter

Enter

10 |

Operation |

00926170 – REF20/25 LB, PH, BB |

Fig. 18

5.Use

to scroll and highlight Low Alarm Set and press Enter to select (Fig. 18).

to scroll and highlight Low Alarm Set and press Enter to select (Fig. 18).

|

High Alarm Set |

4.0C |

|||

|

Low Alarm Set |

|

|

||

|

|

|

|

|

|

|

|

|

Back |

Enter |

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 19

6.Use

to change set point and press Enter to accept (Fig. 19).

to change set point and press Enter to accept (Fig. 19).

7.Press Back until the main temperature display screen is displayed.

Low Alarm Setpoint |

4.0C |

1.0C

Back  Enter

Enter

00926170 – REF20/25 LB, PH, BB |

Operation |

11 |

Alarms

The refrigerator has several alarms that will sound an audible and visual alarm. Alarm type is shown on the top line of the alarm display and multiple alarms will show progressively on the display. A red LED, to the right of the display, accompanies all alarms.

All active alarms are conveyed to remote alarm relays. Remote alarm relay provides a choice of either a normally closed (NC) or normally open (NO) contact. It is recommended for use at 24V 1A (relay is rated for 250V 10A).

Alarm displayed |

Conditions |

|

|

Temp Alarm |

Only top product temperature probe activates this alarm. Bottom product temperature probe, |

|

if installed, is for display reference only. |

|

|

Top Probe Error |

Activates with loss of signal from top probe (open or short circuit). |

|

|

Bottom Probe Error |

Activates with loss of signal from bottom probe (open or short circuit). |

|

|

Door Ajar Alarm |

Activates with door open longer than 1 minute. |

|

|

AC Power Alarm |

Activates after 2 min delay with loss of AC power. |

|

Display backlight will turn off to conserve battery life, but pressing any button will brighten |

|

display for 30 seconds. |

|

|

Low Battery Alarms |

Display activates when (2) 9V controller back-up batteries decrease to 7.5V (maximum 4 hr |

|

back-up time remaining.) This alarm will audibly chirp every 5 minutes. |

|

Chart recorder – LED flashes green. |

|

All batteries should be changed at same time. Replace batteries one at a time with AC |

|

power on to keep correct time/date. |

|

|

Evap Probe Error |

Activates with loss of signal from refrigeration control evaporator probe (open or short circuit). |

|

Refrigerator goes into a fi xed on/off cycle until corrected. Default settings are 4 minutes |

|

compressor on time and 8 minutes compressor off time. Cycle on time and off time are |

|

adjustable in faulty probe cycle sub-menu of refrigeration controls menu. |

|

|

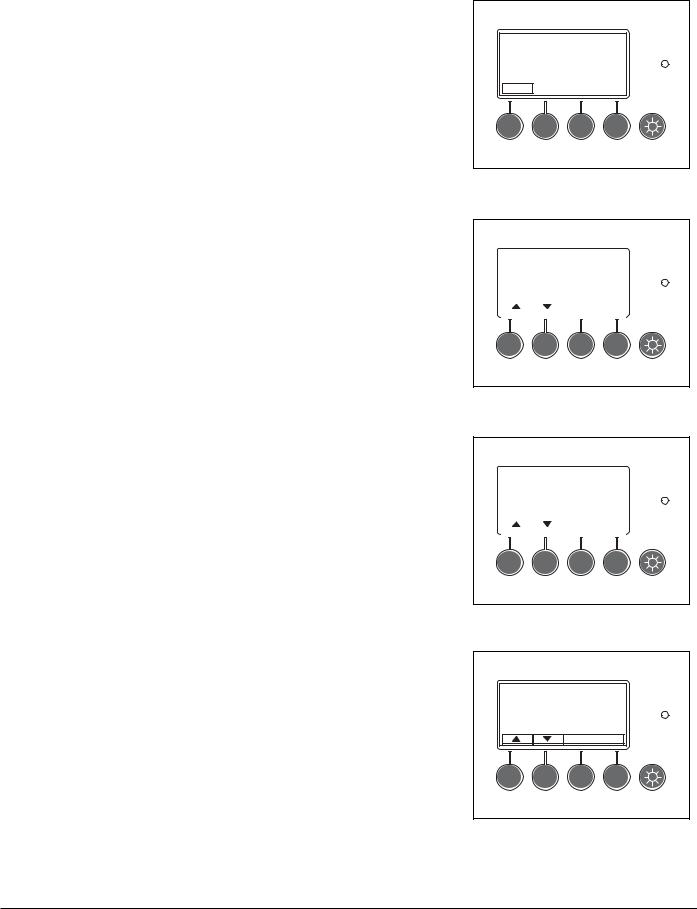

Alarm muting |

Fig. 20 |

|

|

|

|

|

|

|||

All audible alarms can be muted for up to 60 minutes in 5 minute |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

increments by pressing the MUTE button. The desired mute period will |

|

|

|

|

|

|

|

|

|

|

display, and count down, in the window adjacent the MUTE label (Fig. 20). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Door Ajar Alarm |

|

|

|||||

|

|

|

|

|

|

|||||

|

|

|

|

|

4.0C |

|

|

|||

|

|

|

|

MENU |

|

15 min |

MUTE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

Operation |

00926170 – REF20/25 LB, PH, BB |

Loading...

Loading...