Page 1

GESTRA

GESTRA Steam Systems

NRG 111-11

Installation Instructions 810898-01

Level Electrode

NRG 111-11

1

Page 2

Contents

Page

Important Notes

Usage for the intended purpose .............................................................................................................. 4

Safety note ............................................................................................................................................. 4

Danger ................................................................................................................................................... 4

Classification pursuant to article 1 of the Pressure Equipment Directive (PED) ........................................ 4

Explanatory Notes

Scope of supply...................................................................................................................................... 4

Description............................................................................................................................................. 5

Function ................................................................................................................................................. 5

System components ............................................................................................................................... 5

Design ................................................................................................................................................... 5

Technical Data

NRG 111-11 ........................................................................................................................................... 6

Corrosion resistance .............................................................................................................................. 7

Sizing ..................................................................................................................................................... 7

Name plate /marking ............................................................................................................................. 7

Dimensions ............................................................................................................................................ 8

Design

NRG 111-11 ........................................................................................................................................... 9

Key ...................................................................................................................................................... 11

Functional Elements

NRG 111-11 ......................................................................................................................................... 10

Key ...................................................................................................................................................... 11

Installation

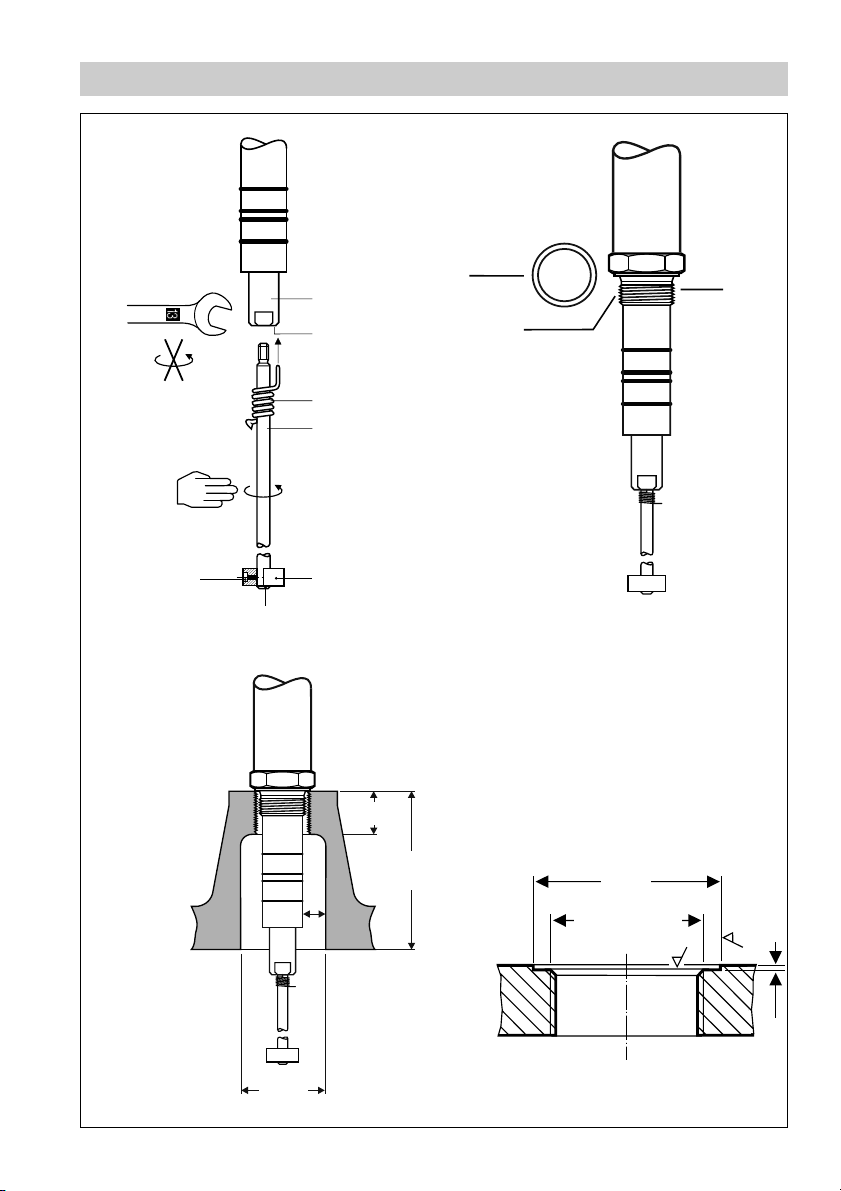

NRG 111-11, step 1 ............................................................................................................................. 12

NRG 111-11, step 2 ............................................................................................................................. 12

Tools .................................................................................................................................................... 13

Examples of installation ....................................................................................................................... 14

Key ...................................................................................................................................................... 15

Wiring

NRG 111-11 ......................................................................................................................................... 15

Wiring diagram .................................................................................................................................... 16

Voltage table ........................................................................................................................................ 17

Tools .................................................................................................................................................... 17

2

Page 3

Contents – continued –

Page

Commissioning

Check wiring ........................................................................................................................................ 17

Apply mains voltage ............................................................................................................................. 17

Operation

Water level limiter ................................................................................................................................ 18

Operation Malfunctions

Fault finding list for troubleshooting ..................................................................................................... 18

Annex

Declaration of Conformity ..................................................................................................................... 19

3

Page 4

Important Notes

Usage for the intended purpose

Use level electrode type NRG 111-11 only in conjunction with NRS 1-7 as water level limiter

(low level alarm). The equipment must not be used in explosion risk areas.

Safety Note

The equipment must only be installed and commissioned by qualified and adequately trained

personnel.

Maintenance and retrofitting must only be performed by entrusted personnel who – through adequate

training – have achieved a recognized level of competence.

Danger

When loosening the electrode steam or hot water might escape. This presents the danger

of severe scalding. It is therefore essential not to remove the electrode unless the boiler

pressure is verified to be 0 barg.

The electrode is hot during operation. This presents the danger of severe burns to hands

and arms. Installation and maintenance work should only be carried out when the system

is cold.

If the internal ceramic insulation breaks hot steam may escape through the lateral relief

vent of the electrode stem.

This presents the danger of severe scalding!

Do not stand close to the electrode during operation.

Classification pursuant to article 1 of the Pressure Equipment Directive (PED)

Category IV

Designation Safety accessory

CE marking CE 0525

Explanatory Notes

Scope of supply

NRG 111-11

1 Level electrode NRG 111-11

1 Gasket 33x 39 DIN 7603-1.4301

1 Sealing plug for M 20 connection

1 Surface extension disk with grub screw

1 Lock washer

1 Installation manual

4

Page 5

Explanatory Notes – continued –

Description

The level electrode NRG 111-11 detects the min. liquid level (low level alarm) in a steam boiler. The

operation of the electrode is based on the conducitivity measuring principle using the electrical

conductivity of water for signalling one liquid level:

■ Low level alarm (MIN alarm)

The NRG 111-11 is designed for use in conjunction with level switch NRS 1-7 as a self-monitoring low

level limiter with periodic self-checking (SMART) feature.

Application in steam and pressurised hot water plants in accordance with TRD 604, sheet 1 and sheet 2

(24h/72h operation) as well as EN 12952 and 12953.

The electrical equipment meets the requirements of the Regulations on Protection Circuits DIN VDE

0116 (prEN 501565-1).

Function

The water level limiter comprises the level electrode type NRG 111-11 and GESTRA level switch NRS

1-7. The level electrode NRG 111-11 consists of two concentrically arranged electrodes (measuring

electrode and compensating electrode) which are isolated from each other by special insulating

seals.

The level limiter operation is based on the conductive measuring principle using the electrical

conductivity of water for signalling water level. During normal, trouble-free operation the level

electrode tip is immersed in boiler water and no low level alarm is given. A low level alarm will only

be raised if the electrode tip is exposed for more than 3 seconds. A low level alarm will also be

activated if the insulating seals placed between the electrodes and the body are no longer pressure

tight, allowing water to penetrate into the cavities between the body, tube and stud. However in this

instance the alarm is caused by a malfunction of the electrode, and confirmation should always be

done by checking if there is water in the gauge glass. The equipment combination NRG 111-11 and

NRS 1-7 provides fail safe protection against a first fault in accordance with TRD 604.

If the internal ceramic insulation breaks steam and hot water may escape through the lateral relief

vent of the electrode stem.

System Components

NRS 1-7

Level switch NRS 1-7, 0.5 µS version. The limiter features a two channel circuit (redundancy) and an

automatic periodic self-checking routine in accordance with DIN VDE 0116 (prEN 50156-1).

Design

NRG 111-11:

Level electrode with screwed connection 1" BSP, ISO 228-1. Fig. 1

5

Page 6

Technical Data

NRG 111-11

Type approval no.

TÜV· WB· 01-354

EG 01 202 931-B-01-0077-01

Service pressure

NRG 111-11: 183 barg (at 357 °C)

Connection

1" BSP (to ISO 228-1)

Flange PN 320, DN 50, DIN 2501-1 (optional)

Flange PN 250, DN 80, DIN 2501-1 (optional)

Materials

Body 3.2161 G AlSi8Cu3

Stem 1.4529,

Measuring electrode

Electrode insulation: Special ceramic material

Lengths available

500 mm

1000 mm

1500 mm

2000 mm

2500 mm

3000 mm

pH value

Max. admissible: 10

Cell constant C

0.13 cm

Response sensitivity

0.5 µS/cm up to 400 µS/cm at 25 °C

Cable entry

Cable gland with integrated cable clamp

M 20 (2) (PG 16)

Protection

IP 65 to DIN EN 60529

Max. admissible ambient temperature

70 °C

Weight

Approx. 1.8 kg

X39CrMo17-1

1.4401,

X5CrNiMo17-12-2

-1

with measuring surface extension

6

Page 7

Technical Data – continued –

Corrosion Resistance

If the unit is used for the intended purpose, its safety is not impaired by corrosion.

Sizing

The housing must not be subjected to sharp increases in pressure. Welds and flanges are designed to

withstand dynamic loading (bending and alternative stress). The dimensional allowances for corrosion

reflect the latest state of technology.

Name Plate / Marking

Designation

Fig. 1

7

Page 8

Technical Data – continued –

Dimensions

175

140

≥ 185

500, 1000, 1500,

2000, 2500, 3000

400

b = 70

1" BSP, ISO 228-1

136

30

8

Fig. 2

Page 9

Design NRG 111-11

H

A

B

C

D

E

G

Fig. 3 Fig. 4

F

30

J

I

110

14

Fig. 5 Fig. 6

∅ 58

∅ 40

1" BSP, ISO 228-1

N8

N10

0.5

9

Page 10

Functional Elements

Fig. 7

MAX 70 °C

MAX 95 %

K L M L

10

P

Fig. 8

O

N

Page 11

Key

Electrode rod

A

Bore

B

Spring

C

Electrode tip

D

Disk (measuring surface extension)

E

Retaining ring

F

Grub screw

G

Gasket D 33x 39 DIN 7603-1.4301

H

Seating surface

I

Electrode thread

J

Housing screws M 4

K

Cable entry M 20x1.5

L

Housing cover

M

Terminal strip

N

PE connection

O

Plug

P

11

Page 12

Installation

NRG 111-11, step 1

1. Screw electrode tip D into measuring electrode A. Fig. 3

2. Carefully determine required measuring length of electrode. Observe min. length, Fig. 2

3. Mark length of electrode tip D.

4. Unscrew electrode tip D from measuring electrode A and cut tip.

5. After visual inspection screw electrode tip D into measuring electrode A. Slide spring C along

electrode tip D, so that its bent end completely enters into small bore B.

6. Fit surface extension disk E to electrode tip end and make sure that electrode tip protrudes 2 mm

beyond the bottom of the surface extension disk. Fix the surface extension disk in this position with

the grub screw G. Push lock washer F over electrode tip end against surface extension disk E.

NRG 111-11, step 2

1. Check seating surfaces. Fig. 6

2. Place joint ring E onto seating surface F of electrode. Fig. 4

3. Apply a light smear of silicone grease G (e. g. Molykote

4. Screw level electrode into threads or flange provided on vesssel and tighten with a 41 mm open-end

spanner. The torque required is 475 Nm when cold.

Attention

■ The seating surfaces of the standpipe or the flange provided on the vessel must be

accurately machined, see fig. 6.

■ Do not bend electrode tip when mounting.

■ Use only ring joint (of stainless steel 1.4301) D 33x39 DIN 7603 supplied with the

electrode.

■ Do not lag electrode body above the hexgonal section.

■ Do not insulate electrode thread with hemp or PTFE tape.

■ The leakage path between electrode and flange (mass) must be at least 14 mm, fig. 5

■ Observe minimum distances and spacing dimensions when installing the electrode,

fig. 5

®

111) to electrode thread.

Molykote® 111 is a registered trademark of DOW Corning Corp., Midland Michigan, USA

12

Page 13

Installation – continued –

Note

■ For the approval of the boiler standpipe the relevant regulations

must be considered.

■ Refer to page 14 for four typical installation examples.

■ The inclination angle of the electrode must not exceed 45°. The max. length of the

electrode rod is 1600 mm.

Tools

■ Open-end spanner 13 mm A. F.

■ Open-end spanner 41 mm A. F.

■ Hacksaw

■ Flat file, medium cut

13

Page 14

Examples of Installation

1" BSP

DN 50

∅ 20

4

1

2

3

20

5

7

8

Fig. 9 Fig. 10

≤ 90°

∅ 20

≥10

9

0

1

1

Centre distance

1" BSP

DN 80

1

14

Fig. 11

1

Page 15

Key

Flange PN 320, DN 50, DIN 2505-1

1

Flange PN 250, DN 80, DIN 2505-1

For the approval of the boiler standpipe with connecting flange the relevant regulations must be

2

considered.

Vent hole Provide vent hole as close to the boiler wall as possible!

3

High water (HW)

4

Electrode rod d = 8 mm

5

Protection tube DN 100

7

Electrode distance ≥ 14 mm

8

Low water (LW)

9

Reducer DIN 2616-2, K-88.9 x 3.2- 42.4x 2.6 W

0

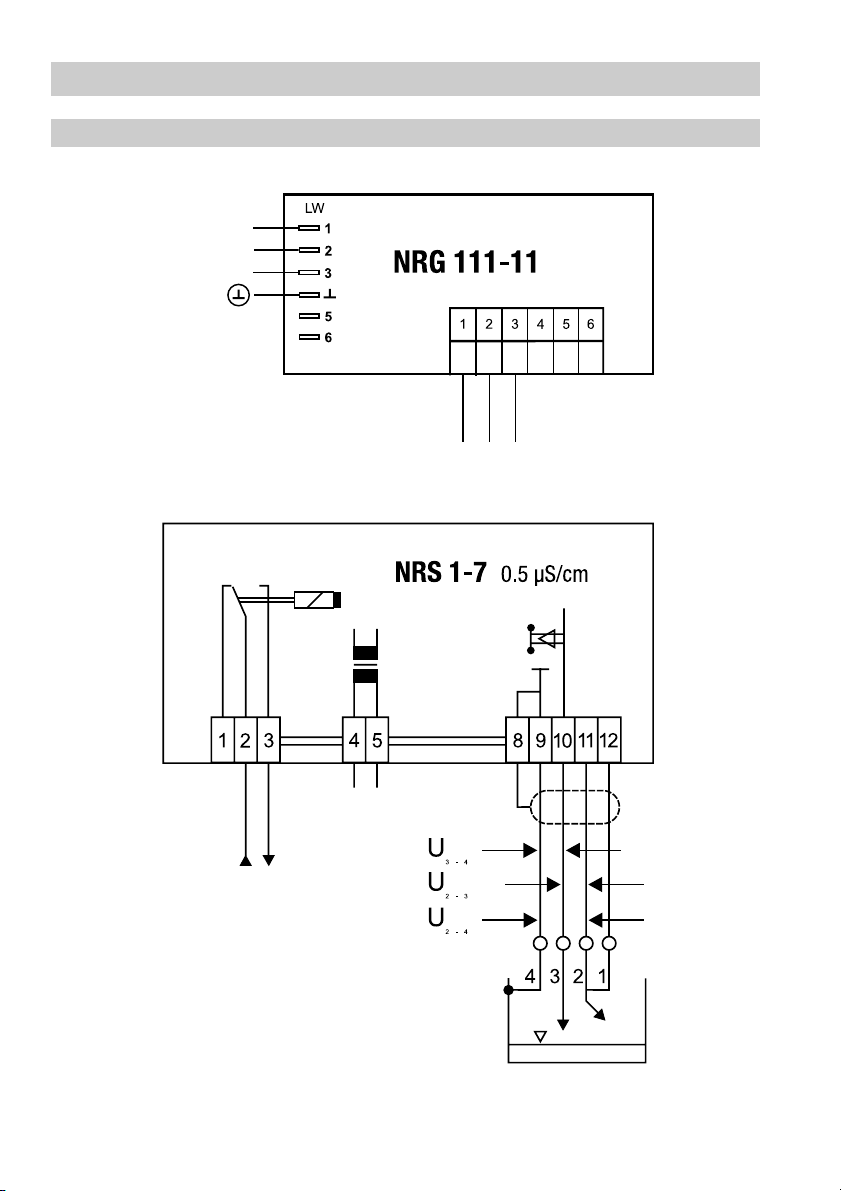

Wiring

NRG 111-11

2

Note that screened four-core cable, e. g. I-Y(St)Y 2 x 2 x 0.8 or LIYCY 4 x 0.5 mm

to the electrode.

Max. cable length 30 m with water conductivity from 0.5 µS/cm.

Max. cable length 15 m with water conductivity from 0.5 µS/cm when used in conjunction with inverter

URN 1 (24 d. c.).

1. Undo screws K and remove housing cover M. Fig. 7

2. Unscrew union nuts of cable entry L.

3. Slacken plug P with 18 mm open-end spanner but do not remove, fig. 8

The electrode terminal box can now be turned through +/–180°.

4. Turn electrode terminal box into desired position (+/–180°).

5. Tighten plug P slightly.

6. Remove terminal strip N from board.

7. Connect terminal strip according to wiring diagram.

8. Affix terminal strip.

9. Re-attach housing cover M and fix it with screws K.

is required for wiring

15

Page 16

Wiring – continued –

Wiring Diagram

Compensation electrode

Compensation electrode

Measuring electrode

Fig. 12

16

Page 17

Wiring – continued –

Attention

■ Use sealing plug for cable entry L if only one cable runs to the terminal box.

Insert sealing plug supplied with the electrode (IP 65)!

Voltage table

Use this voltage table to check whether the level electrode is submerged or if there is a malfunction.

Observe the wiring diagram of the NRS 1-7, fig. 12

U

10 V

eff

C=0.13 cm

1-2

0.5 µS/cm,

-1

U

1-4

submerged exposed

U

1-2

<

2

U

1-2

≥

2

malfunction (submerged / alarm)

U

2-4

≤

U

1-4

Note

■

The self-checking routine of the amplifier NRS 1-7 reduces U

to 0 volt!

every 40 sec.

1-2

Tools

■ Screwdriver for cross head screws, size 1

■ Screwdriver for slotted screws, size 2.5, completely insulated according to DIN VDE 0680-1

■ Open-end spanner 18 (19) mm A. F.

Commissioning

Check wiring

Make sure that the electrode NRG 111-11 is connected to the level switch NRS 1-7 according to the

wiring diagram. Fig. 12

Apply mains voltage

Apply mains voltage to level switch NRS 1-7.

17

Page 18

Operation

Water level limiter

Application in conjunction with level switch NRS 1-7 in steam and pressurised hot water plants in

accordance with TRD 401, TRD 602, TRD 604, EN 12952, EN 12953 or according to other national

regulations.

Note

■

To analyse and eliminate malfunctions use “Fault finding list for troubleshooting” on

page 18!

Operation Malfunctions

Fault finding list for troubleshooting

Level electrode immersed – low level alarm

Fault: Mains voltage not applied.

Remedy: Apply mains voltage. Connect electrode according to wiring diagram.

Fault: The electrode body does not have earth connection to the boiler.

Remedy: Clean seating surfaces and insert metal joint ring (of stainless steel 1.4301)

D 33 x 39 to DIN 7603.

Do not insulate level electrode with hemp or PTFE tape!

Fault: The internal insulation of the electrode rod is damaged.

Remedy: Replace level electrode.

Level below “low level limit” – no function

Fault: The electrode rods have earth contact.

Remedy: Check and change installation position if necessary.

Fault: The vent hole in the protection tube does not exist, is obstructed or flooded.

Remedy: Check protection tube and, if necessary, provide vent hole.

Fault: The isolating valves of the external measuring pot (optional extra) are closed.

Remedy: Open isolating valves.

If faults occur that are not listed above or cannot be corrected, please contact our service centre or

authorized agency in your country.

18

Page 19

Annex

Declaration of Conformity

We hereby declare that the equipment NRG 111-11 conforms to the following European guidelines:

■

LV guideline 73/23/eec version 93/68/eec

■

EMC guideline 89/336/eec version 93/68/eec

■

Pressure Equipment Directive (PED) No. 97/23/eec of 29 May 1997

The electrodes are safety accessories as defined in paragraph 1, section 2.1.3 PED.

Applied conformity assessment procedure: Annex III, Module B and D.

The guidelines and directives are based on the following harmonised standards:

■

LV standard DIN EN 50178

■

EMC standard DIN EN 50 081-2, DIN EN 61000-6-2

Other technical regulations applied: VdTÜV Bulletin “Wasserstand 100”

(= Water Level 100) 04.1990 and draft 08.2001.

This declaration is no longer valid if modifications are made to the equipment without consultation

with us.

Bremen, 10th October 2003

GESTRA AG

Dipl.-Ing. Stefan Bode

(Academically qualified engineer)

Head of R & D Dept. Electronics

Dipl.-Ing. Lars Bohl

(Academically qualified engineer)

Quality Assurance Manager

19

Page 20

Weltweite Vertretungen finden Sie unter:

www.gestra.de

GESTRA

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 00 34 91/ 51 52 032

Fax 0034 91/ 41 36 747; 51 52 036

E-mail: aromero@flowserve.com

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Fax 00 44 14 44 / 31 45 57

E-mail: gestraukinfo@flowserve.com

Italia

Flowserve S.p.A.

Flow Control Division

Via Prealpi, 30

l-20032 Cormano (MI)

Tel. 00 39 02/ 66 32 51

Fax 0039 02/ 66 32 55 60

E-mail: infoitaly@flowserve.com

Poland

GESTRA POLONIA Spolka z.o.o.

Ul. Schuberta 104

PL - 80-172 Gdansk

Tel. 00 48 58 /306 10 -02 od 10

Fax 00 48 58 /306 33 00

E-mail: gestra@gestra.pl

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 00351 22 /6 1987 70

Fax 0035122/6107575

E-mail: jtavares@flowserve.com

USA

Flowserve DALCO Steam Products

2601 Grassland Drive

Louisville, KY 40299

Tel.: 00 15 02 / 4 95 01 54, 4 95 17 88

Fax: 00 15 02 / 4 95 16 08

E-Mail: dgoodwin@flowserve.com

GESTRA AG

Postfach 10 54 60, D-28054 Bremen

Münchener Str. 77, D-28215 Bremen

Telefon +49 (0) 421 35 03- 0

Telefax +49 (0) 421 35 03- 393

E-Mail gestra.ag@flowserve.com

Internet www.gestra.de

810898-01/1004c · © 2003 GESTRA AG · Bremen · Printed in Germany

20

Loading...

Loading...