Page 1

< Series 0+-MODEL F Plus

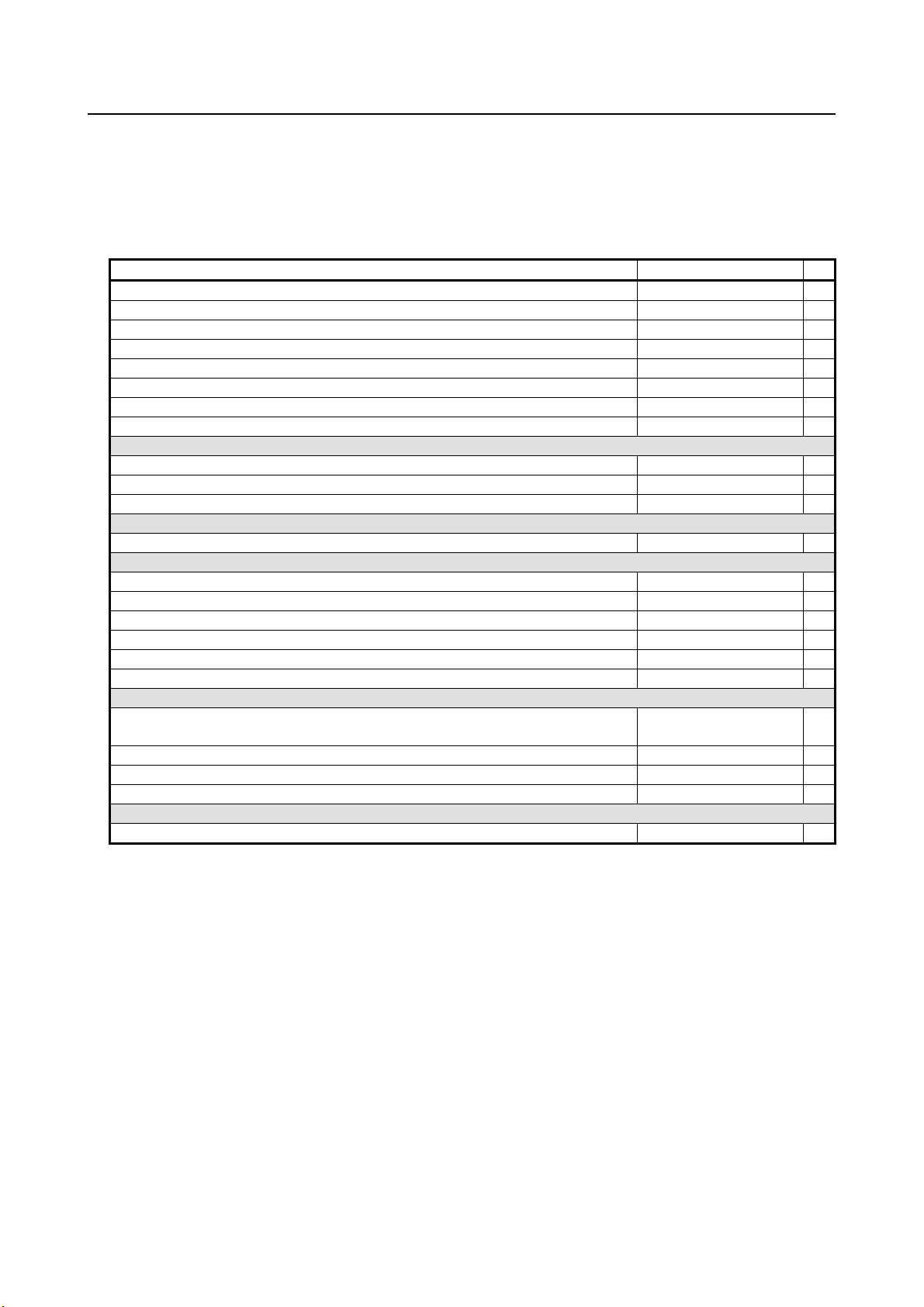

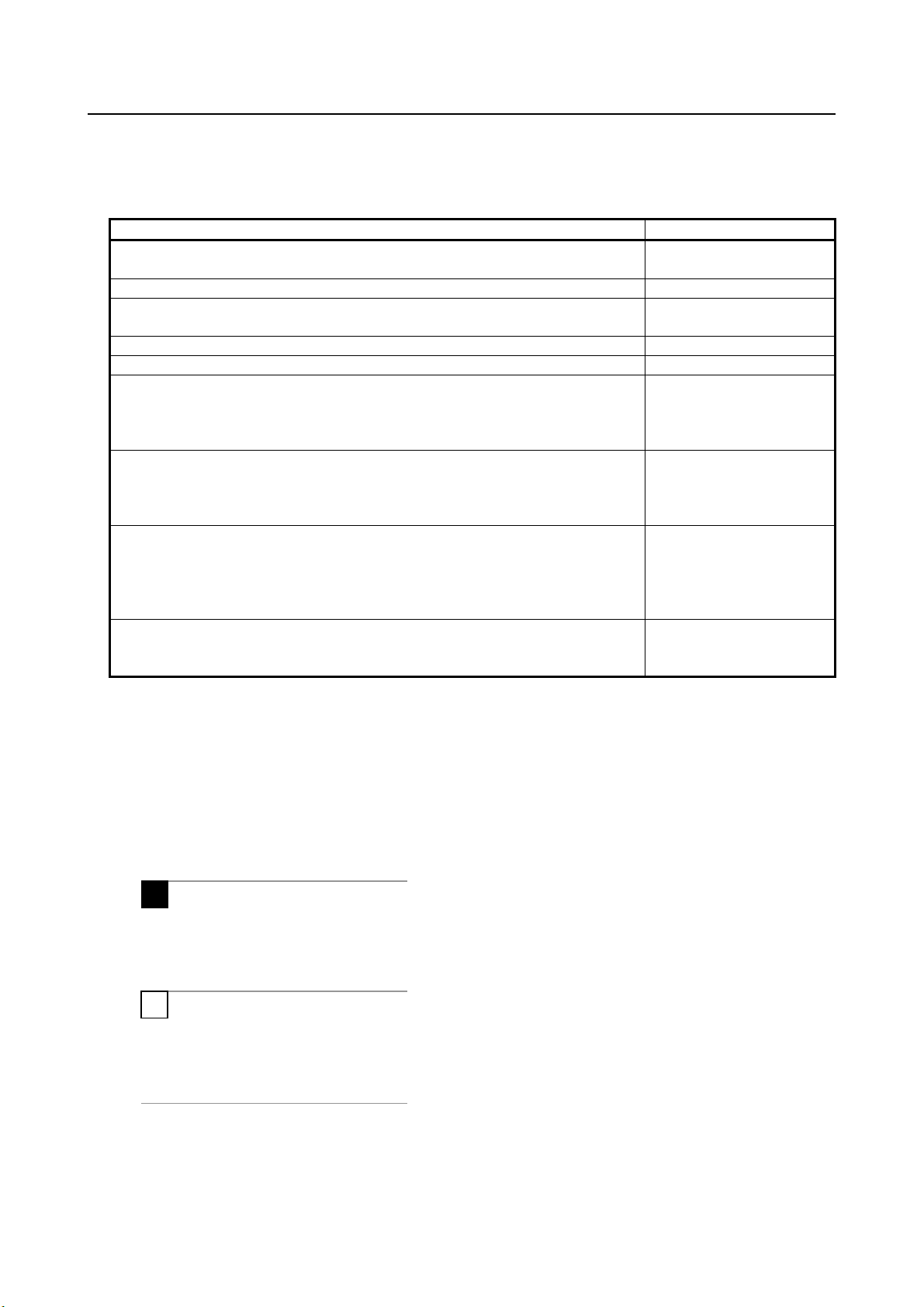

DESCRIPTIONS

B-64692EN/01

Page 2

• The appearance and specifications of this product are subject to change without notice.

this manual are controlled based on Japan's “Foreign Exchange and

The export from Japan may be subject to an export license by the

t of

Should you wish to export or re-export these products, please contact FANUC for advice.

There are, however, a very large number of operations that must not or cannot be

being possible are "not possible".

e not

followed by or in the main body.

• No part of this manual may be reproduced in any form.

The products in

Foreign Trade Law".

government of Japan.

Further, re-export to another country may be subject to the license of the governmen

the country from where the product is re-exported. Furthermore, the product may also be

controlled by re-export regulations of the United States government.

In this manual, we endeavor to include all pertinent matters.

performed, and if the manual contained them all, it would be enormous in volume.

It is, therefore, requested to assume that any operations that are not explicitly described as

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names ar

Page 3

B-64692EN/01 SAFETY PRECAUTIONS

WARNING

occur if he or she fails to observe the approved procedure.

CAUTION

approved procedure.

NOTE

CAUTION is to be indicated.

WARNING

1 Never attempt to machine a workpiece without first checking the operation of the

damage to the workpiece and/or machine itself, or injury to the user.

2 Before operating the machine, thoroughly check the entered data.

machine itself, or injury to the user.

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC units.

It is essential that these precautions be observed by users to ensure the safe operation of machines

equipped with a CNC unit (all descriptions in this section assume this configuration). Note that some

precautions are related only to specific functions, and thus may not be applicable to certain CNC units.

Users must also observe the safety precautions related to the machine, as described in the relevant manual

supplied by the machine tool builder. Before attempting to operate the machine or create a program to

control the operation of the machine, the operator must become fully familiar with the contents of this

manual and relevant manual supplied by the machine tool builder.

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine.

Precautions are classified into WARNING and CAUTION according to their bearing on safety. Also,

supplementary information is described as a NOTE. Read the WARNING, CAUTION, and NOTE

thoroughly before attempting to use the machine.

Used if a danger resulting in the death or serious injury of the user is expected to

Used if a danger resulting in the minor or moderate injury of the user or

equipment damage is expected to occur if he or she fails to observe the

Used if a supplementary explanation not related to any of WARNING and

• Read this manual carefully, and store it in a safe place.

GENERAL WARNINGS AND CAUTIONS

machine. Before starting a production run, ensure that the machine is operating

correctly by performing a trial run using, for example, the single block, feedrate

override, or machine lock function or by operating the machine with neither a

tool nor workpiece mounted. Failure to confirm the correct operation of the

machine may result in the machine behaving unexpectedly, possibly causing

Operating the machine with incorrectly specified data may result in the machine

behaving unexpectedly, possibly causing damage to the workpiece and/or

s-1

Page 4

SAFETY PRECAUTIONS B-64692EN/01

WARNING

3 Ensure that the specified feedrate is appropriate for the intended operation.

user.

4 When using a tool compensation function, thoroughly check the direction and

machine itself, or injury to the user.

5 The parameters for the CNC and PMC are factory-set. Usually, there is not need

or injury to the user.

CAUTION

phenomenon is a common attribute of LCDs and is not a defect.

NOTE

deleted data, backup all vital data, and keep the backup copy in a safe place.

Generally, for each machine, there is a maximum allowable feedrate.

The appropriate feedrate varies with the intended operation. Refer to the manual

provided with the machine to determine the maximum allowable feedrate.

If a machine is run at other than the correct speed, it may behave unexpectedly,

possibly causing damage to the workpiece and/or machine itself, or injury to the

amount of compensation.

Operating the machine with incorrectly specified data may result in the machine

behaving unexpectedly, possibly causing damage to the workpiece and/or

to change them. When, however, there is not alternative other than to change a

parameter, ensure that you fully understand the function of the param et er before

making any change.

Failure to set a parameter correctly may result in the machine behaving

unexpectedly, possibly causing damage to the workpiece and/or machine itself,

1 Immediately after switching on the power, do not touch any of the keys on the

MDI panel until the position display or alarm screen appears on the CNC unit.

Some of the keys on the MDI panel are dedicated to maintenance or other

special operations. Pressing any of these keys may place the CNC unit in other

than its normal state. Starting the machine in this state may cause it to behave

unexpectedly.

2 The Operator’s Manual and Programming Manual supplied with a CNC unit

provide an overall description of the machine's functions. Note that the functions

will vary from one machine model to another. Therefore, some functions

described in the manuals may not actually be available for a particular model.

Check the specification of the machine if in doubt.

3 Some functions may have been implemented at the request of the machine-tool

builder. When using such functions, refer to the manual supplied by the

machine-tool builder for details of their use and any related cautions.

4 The liquid-crystal display is manufactured with very precise fabrication

technology. Some pixels may not be turned on or may remain on. This

Programs, parameters, and macro variables are stored in nonvolatile memor y in

the CNC unit. Usually, they are retained even if the power is turned off.

Such data may be deleted inadvertently, however, or it may prove necessary to

delete all data from nonvolatile memory as part of error recovery.

To guard against the occurrence of the above, and assure quick restoration of

s-2

Page 5

B-64692EN/01 SAFETY PRECAUTIONS

WARNING

1

Coordinate system setting

itself, the workpiece, or cause injury to the user.

2

Positioning by nonlinear interpolation

the workpiece, or cause injury to the user.

3

Function involving a rotation axis

damage the tool, the machine itself, the workpiece, or cause injury to the user .

4

Inch/metric conversion

to the user.

5

Constant surface speed control

machine itself, the workpiece, or cause injury to the user.

6

Stroke check

workpiece, or causing injury to the user.

WARNINGS AND CAUTIONS RELATED TO PROGRAMM ING

This section covers the major safety precautions related to programming. Before attempting to perform

programming, read the supplied Operator’s Manual carefully such th at you are fully familiar with their

contents.

If a coordinate system is established incorrectly, the machine may behave

unexpectedly as a result of the program issuing an otherwise valid move

command. Such an unexpected operation may damage the tool, the machine

When performing positioning by nonlinear interpolation (positioning by nonlinear

movement between the start and end points), the tool path must be caref ully

confirmed before performing programming. Positioning involves rapid travers e. If

the tool collides with the workpiece, it may damage the tool, the machine itself,

When programming polar coordinate interpolation or normal-direction

(perpendicular) control, pay careful attention to the speed of the rotat ion axis.

Incorrect programming may result in the rotation axis speed becoming

excessively high, such that centrifugal force causes the chuck to lose its grip on

the workpiece if the latter is not mounted securely. Such mishap is likely to

Switching between inch and metric inputs does not convert the measurement

units of data such as the workpiece origin offset, parameter, and current

position. Before starting the machine, therefore, determine which measur ement

units are being used. Attempting to perform an operation with invalid data

specified may damage the tool, the machine itself, the workpiece, or cause injury

When an axis subject to constant surface speed control approaches the origin of

the workpiece coordinate system, the spindle speed may become excessively

high. Therefore, it is necessary to specify a maximum allowable speed.

Specifying the maximum allowable speed incorrectly may damage the tool, the

After switching on the power, perform a manual refer ence pos it ion r et urn as

required. Stroke check is not possible before manual reference position return is

performed. Note that when stroke check is disabled, an alarm is not issued even

if a stroke limit is exceeded, possibly damaging the tool, the machine itself, the

s-3

Page 6

SAFETY PRECAUTIONS B-64692EN/01

WARNING

7

Interference check for each path

automatic operation and specify the tool number of the tool to be used.

CAUTION

compensation function mode.

WARNING

1

Manual operation

tool, the machine itself, the workpiece, or cause injury to the operator.

A interference check for each path is performed based on the tool data specified

during automatic operation. If the tool specification does not match the tool

actually being used, the interference check cannot be made correctly, possibly

damaging the tool or the machine itself, or causing injury to the user. After

switching on the power, or after selecting a tool post manually, always start

1

Absolute/incremental mode

If a program created with absolute values is run in incremental mode, or vice

versa, the machine may behave unexpectedly.

2

Plane selection

If an incorrect plane is specified for circular interpolation, helical interpolation, or

a canned cycle, the machine may behave unexpectedly. Refer to the

descriptions of the respective functions for details.

3

Torque limit skip

Before attempting a torque limit skip, apply the torque limit. If a tor que limit s kip

is specified without the torque limit actually being applied, a move command will

be executed without performing a skip.

4

Programmable mirror image

Note that programmed operations vary considerably when a programmable

mirror image is enabled.

5

Compensation function

If a command based on the machine coordinate system or a reference position

return command is issued in compensation function mode, compensation is

temporarily canceled, resulting in the unexpected behavior of the machine.

Before issuing any of the above commands, therefore, always cancel

WARNINGS AND CAUTIONS RELATED TO HANDLING

This section presents safety precautions related to the handling of machine tools. Before attempting to

operate your machine, read the supplied Operator’s Manual carefully, such that you are fully familiar

with their contents.

When operating the machine manually, determine the current position of the tool

and workpiece, and ensure that the movement axis, direction, and feedrate have

been specified correctly. Incorrect operation of the machine may damage the

s-4

Page 7

B-64692EN/01 SAFETY PRECAUTIONS

WARNING

2

Manual reference position return

itself, the workpiece, or cause injury to the user.

3

Manual handle feed

damage the tool and/or machine, or cause injury to the user.

4

Disabled override

to the operator.

5

Origin/preset operation

injury to the user.

6

Workpiece coordinate system shift

workpiece, or causing injury to the operator.

7

Software operator's panel and menu switches

itself, the workpiece, or causing injury to the user.

8

RESET key

use the emergency stop button instead of the RESET key to ensure security.

After switching on the power, perform manual reference position return as

required.

If the machine is operated without first performing manual reference posit ion

return, it may behave unexpectedly. Stroke check is not possible before manual

reference position return is performed.

An unexpected operation of the machine may damage the tool, the machine

In manual handle feed, rotating the handle with a large scale factor, such as

100, applied causes the tool and table to move rapidly. Careless handling may

If override is disabled (according to the specification in a macro variable) during

threading, rigid tapping, or other tapping, the speed cannot be predicted,

possibly damaging the tool, the machine itself, the workpiece, or causing injury

Basically, never attempt an origin/preset operation when the machine is

operating under the control of a program. Otherwise, the machine may behave

unexpectedly, possibly damaging the tool, the machine itself, the tool, or causing

Manual intervention, machine lock, or mirror imaging may shift the workpiece

coordinate system. Before attempting to operate the machine under the c ont rol

of a program, confirm the coordinate system carefully.

If the machine is operated under the control of a program without making

allowances for any shift in the workpiece coordinate system, the machine may

behave unexpectedly, possibly damaging the tool, the machine itself, the

Using the software operator's panel and menu switches, in combination with the

MDI panel, it is possible to specify operations not supported by the machine

operator's panel, such as mode change, override value change, and jog feed

commands.

Note, however, that if the MDI panel keys are operated inadvertently, the

machine may behave unexpectedly, possibly damaging the tool, the machine

Pressing the RESET key stops the currently running program. As a result, the

servo axes are stopped. However, the RESET key may fail to function for

reasons such as an MDI panel problem. So, when the motors must be stopped,

s-5

Page 8

SAFETY PRECAUTIONS B-64692EN/01

CAUTION

modify, insert, or delete commands from a machining program while it is in use.

WARNING

electric shock hazard.

NOTE

replacement procedure.

1

Manual intervention

If manual intervention is performed during programmed operation of the

machine, the tool path may vary when the machine is restarted. Before restarting

the machine after manual intervention, therefore, confirm the s et tings of the

manual absolute switches, parameters, and absolute/incremental command

mode.

2

Feed hold, override, and single block

The feed hold, feedrate override, and single block functions can be disabled

using custom macro system variable #3004. Be careful when operating the

machine in this case.

3

Dry run

Usually, a dry run is used to confirm the operation of the machine. During a dry

run, the machine operates at dry run speed, which differs from the

corresponding programmed feedrate. Note that the dry run speed may

sometimes be higher than the programmed feed rate.

4

Program editing

If the machine is stopped, after which the machining program is edited

(modification, insertion, or deletion), the machine may behave unexpectedly if

machining is resumed under the control of that program. Basically, do not

WARNINGS RELATED TO DAILY MAINTENANCE

1

Memory backup battery replacement

When replacing the memory backup batteries, keep the power to the machine

(CNC) turned on, and apply an emergency stop to the machine. Because this

work is performed with the power on and the cabinet open, only those personnel

who have received approved safety and maintenance training may perform this

work.

When replacing the batteries, be careful not to touch the high-voltage circuits

(marked and fitted with an insulating cover).

Touching the uncovered high-voltage circuits presents an extremely dangerous

The CNC uses batteries to preserve the contents of its memory, because it m ust

retain data such as programs, offsets, and parameters even while external

power is not applied.

If the battery voltage drops, a low battery voltage alarm is displayed on the

machine operator's panel or screen.

When a low battery voltage alarm is displayed, replace the batteries within a

week. Otherwise, the contents of the CNC's memory will be lost.

Refer to the Section “Method of replacing battery” in the Operator’s Manual

(Common to Lathe System/Machining Center System) for details of the battery

s-6

Page 9

B-64692EN/01 SAFETY PRECAUTIONS

WARNING

electric shock hazard.

NOTE

of the battery replacement procedure.

WARNING

electric shock hazard.

2

Absolute pulse coder battery replacement

When replacing the memory backup batteries, keep the power to the machine

(CNC) turned on, and apply an emergency stop to the machine. Because this

work is performed with the power on and the cabinet open, only those personnel

who have received approved safety and maintenance training may perform this

work.

When replacing the batteries, be careful not to touch the high-voltage circuits

(marked and fitted with an insulating cover).

Touching the uncovered high-voltage circuits presents an extremely dangerous

The absolute pulse coder uses batteries to preserve its absolute position.

If the battery voltage drops, a low battery voltage alarm is displayed on the

machine operator's panel or screen.

When a low battery voltage alarm is displayed, replace the batteries within a

week. Otherwise, the absolute position data held by the pulse coder will be lost.

Refer to the FANUC SERVO MOTOR

i

series Maintenance Manual for details

α

3

Fuse replacement

Before replacing a blown fuse, however, it is necessary to locate and remove the

cause of the blown fuse.

For this reason, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing a fuse with the cabinet open, be careful not to touch the

high-voltage circuits (marked and fitted with an insulating cover).

Touching an uncovered high-voltage circuit presents an extremely dangerous

s-7

Page 10

SAFETY PRECAUTIONS B-64692EN/01

WARNING

4 When using the controller unit, display unit, MDI unit, or machine operator's

with a material, such as resin, possibly leading to corrosion or deterioration.

panel, prevent these units from directly exposing to chips or coolants. Even if

direct exposure to coolants is prevented, coolants containing sulfur or chlorine at

a high activation level, oil-free synthetic-type coolants, or water-soluble coolants

at a high alkali level particularly have large effects on the control unit and

peripheral units, possibly causing the following failures.

Coolants containing sulfur or chlorine at a high activation level

•

Some coolants containing sulfur or chlorine are at an extremely high activity

level. If such a coolant adheres to the CNC or peripheral units, it reacts

chemically with a material, such as resin, of equipment, possibly leading to

corrosion or deterioration. If it gets in the CNC or peripheral units, it corr odes

metals, such as copper and silver, used as component materials, possibly

leading to a defective component.

Synthetic-type coolants having a high permeability

•

Some synthetic-type coolants whose lubricating component is, for example,

PAG (polyalkylene glycol) have an extremely high permeability. If such a

coolant is used even in equipment having a high closeness, it can readily flow

into the CNC or peripheral units through, for example, gaskets. It is likely that,

if the coolant gets in the CNC or a peripheral unit, it may deteriorate the

insulation and damage the components.

Water-soluble coolants at a high alkali level

•

Some coolants whose pH is increased using alkanolamine are so strong

alkali that its standard dilution will lead to pH10 or higher. If such a coolant

spatters over the surface of the CNC or peripheral unit, it reacts chemically

s-8

Page 11

B-64692EN/01 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTIONS ............................................................................ s-1

I. GENERAL

1 GENERAL ............................................................................................... 3

2 LIST OF SPECIFICATION ...................................................................... 7

II. NC FUNCTION

1 CONTROLLED AXIS ............................................................................ 39

1.1 NUMBER OF MAXIMUM CONTROLLED AXES ......................................... 39

1.2 NUMBER OF MACHINE GROUPS ............................................................. 39

1.3 NUMBER OF CONTROLLED PATHS ......................................................... 39

1.3.1 Multi-path Control .................................................................................................. 40

1.3.2 Function for Loader Control ................................................................................... 40

1.4 NUMBER OF CONTROLLED AXES / NUMBER OF CONTROLLED

SPINDLE AXES ........................................................................................... 40

1.5 PMC AXIS CONTROL ................................................................................. 42

1.6 Cs CONTOURING CONTROL .................................................................... 42

1.7 NAMES OF AXES ....................................................................................... 42

1.7.1 Names of Axes ....................................................................................................... 42

1.7.2 Axis Name Expansion ............................................................................................ 43

1.8 ARBITRARY AXIS NAME SETTING ........................................................... 44

1.8.1 Arbitrary Axis Name .............................................................................................. 44

1.8.2 AXNUM Fun ction .................................................................................................. 44

1.9 SPINDLE NAME EXPANSION .................................................................... 45

1.10 SYNCHRONOUS / COMPOSITE CONTROL .............................................. 46

1.11 SUPERIMPOSED CONTROL ..................................................................... 48

1.12 AXIS SYNCHRONOUS CONTROL ............................................................. 49

1.13 ANGULAR AXIS CONTROL ........................................................................ 49

1.14 TANDEM CONTROL ................................................................................... 50

1.15 TANDEM DISTURBANCE ELIMINATION CONTROL ................................. 50

1.16 TORQUE CONTROL ................................................................................... 50

1.17 POLE POSITION DETECTION FUNCTION ................................................ 51

1.18 CONTROL AXIS DETACH .......................................................................... 51

1.19 DUAL CONTROL AXES SWITCHING ......................................................... 51

1.20 INCREMENT SYSTEM ................................................................................ 51

1.20.1 High Precision Program Command ........................................................................ 52

1.21 FLEXIBLE FEED GEAR .............................................................................. 52

1.22 DUAL POSITION FEEDBACK ..................................................................... 52

1.23 HRV CONTROL ........................................................................................... 53

1.24 INCH/METRIC CONVERSION .................................................................... 54

1.25 INTERLOCK ................................................................................................ 54

c-1

Page 12

TABLE OF CONTENTS B-64692EN/01

1.25.1 Start Lock ............................................................................................................... 54

1.25.2 All-axis Interlock .................................................................................................... 54

1.25.3 Each-axis Interlock ................................................................................................. 54

1.25.4 Each-axis Direction Interlock ................................................................................. 54

1.25.5 Block Start Interlock .............................................................................................. 55

1.25.6 Cutting Block Start Interlock ................................................................................. 55

1.26 MACHINE LOCK ......................................................................................... 55

1.26.1 All-axis Machine Lock ........................................................................................... 55

1.26.2 Each-axis Machine Lock ........................................................................................ 55

1.27 EMERGENCY STOP ................................................................................... 55

1.28 OVERTRAVEL ............................................................................................. 55

1.29 STORED STROKE CHECK 1 ...................................................................... 56

1.30 STORED STROKE CHECK 1 AREA EXPANSION ..................................... 56

1.31 STROKE LIMIT EXTERNAL SETTING ....................................................... 56

1.32 STORED STROKE CHECK 2 (G22, G23) ................................................... 56

1.33 STORED STROKE CHECK 3 ...................................................................... 57

1.34 STROKE LIMIT CHECK BEFORE MOVE ................................................... 57

1.35 CHECK OF THE TOOL PATH BETWEEN BLOCKS BY STROKE LIMIT

CHECK BEFORE MOVE ............................................................................. 58

1.36 CHUCK AND TAIL STOCK BARRIER ......................................................... 58

1.37 CHECKING THE STORED STROKE DURING THE TIME FROM

POWER–ON TO THE REFERENCE POSITION ESTABLISHMENT .......... 60

1.38 STROKE LIMIT AREA CHANGING FUNCTION ......................................... 60

1.39 STORED STROKE LIMIT RANGE SWITCHING FUNCTION BY SIGNAL . 60

1.40 MIRROR IMAGE .......................................................................................... 60

1.41 FOLLOW-UP ............................................................................................... 61

1.42 SERVO OFF / MECHANICAL HANDLE FEED ............................................ 61

1.43 CHAMFERING ON/OFF .............................................................................. 61

1.44 INTERFERENCE CHECK FOR EACH PATH ............................................. 61

1.45 UNEXPECTED DISTURBANCE TORQUE DETECTION FUNCTION ........ 62

1.46 POSITION SWITCH .................................................................................... 63

1.47 HIGH-SPEED POSITION SWITCH ............................................................. 63

1.48 LINEAR SCALE WITH ABSOLUTE ADDRESS REFERENCE MARK ........ 63

1.48.1 Linear Scale Interface with Absolute Address Reference Mark ............................ 63

1.48.2 Linear Scale with Absolute Address Reference Mark Expansion .......................... 63

1.49 LINEAR SCALE WITH DISTANCE-CODED REFERENCE MARKS

(SERIAL) ..................................................................................................... 64

1.50 ABSOLUTE POSITION DETECTION .......................................................... 64

1.51 TEMPORARY ABSOLUTE COORDINATE SETTING ................................. 64

1.52 DUAL CHECK SAFETY ............................................................................... 65

1.53 FUNCTION OF DECELERATION STOP IN CASE OF POWER FAILURE . 65

1.54 CORRESPONDENCE OF ROTARY SCALE WITHOUT ROTARY DATA ... 65

1.55 FLEXIBLE SYNCHRONIZATION CONTROL .............................................. 66

1.55.1 Flexible Synchronization Control .......................................................................... 66

1.55.2 Automatic Phase Synchronization for Flexible Synchronization Control .............. 66

1.55.3 Inter-path Flexible Synchronization Control .......................................................... 67

1.55.4 Skip Function for Flexible Synchronization Control ............................................. 68

1.55.5 Hob Command by Flexible Synchronization Control ............................................ 68

1.56 AXIS IMMEDIATE STOP FUNCTION ......................................................... 69

c-2

Page 13

B-64692EN/01 TABLE OF CONTENTS

1.57 FLEXIBLE PATH AXIS ASSIGNMENT ........................................................ 69

1.58 HIGH PRECISION OSCILLATION FUNCTION ........................................... 70

1.59 AXIS TOTAL TRAVEL DISTANCE DISPLAY .............................................. 71

2 OPERATION ......................................................................................... 72

2.1 OPERATION MODE .................................................................................... 72

2.1.1 Automatic Operation (Memory Operation) ............................................................ 72

2.1.2 MDI Operation ....................................................................................................... 72

2.1.3 DNC Operation ....................................................................................................... 72

2.1.4 DNC Operation with Memory Card ....................................................................... 72

2.1.5 Schedule Operation ................................................................................................ 72

2.2 PROGRAM SEARCH .................................................................................. 72

2.3 SEQUENCE NUMBER SEARCH ................................................................ 72

2.4 SEQUENCE NUMBER COMPARISON AND STOP ................................... 72

2.5 PROGRAM RESTART ................................................................................ 73

2.5.1 Auxiliary Function Outp ut in Program Restart Function ....................................... 73

2.6 QUICK PROGRAM RESTART .................................................................... 73

2.7 TOOL RETRACT AND RECOVER .............................................................. 74

2.7.1 Tool R et ract and Recover ....................................................................................... 74

2.7.2 Improvement of Tool compensation for Tool Retract and Recover ....................... 75

2.8 MANUAL INTERVENTION AND RETURN .................................................. 75

2.9 RETRACE.................................................................................................... 75

2.10 MALFUNCTION PREVENT FUNCTIONS ................................................... 75

2.11 WRONG OPERATION PREVENTION FUNCTION ..................................... 76

2.12 RETRACTION FOR RIGID TAPPING /

RETRACTION FOR 3-DIMENSIONAL RIGID TAPPING ............................ 76

2.12.1 Retraction for Rigid Tapping by Using the G30 Command ................................... 77

2.13 BUFFER REGISTER ................................................................................... 77

2.14 DRY RUN .................................................................................................... 77

2.15 SINGLE BLOCK .......................................................................................... 77

2.16 HIGH SPEED PROGRAM CHECK FUNCTION .......................................... 77

2.17 JOG FEED ................................................................................................... 77

2.18 MANUAL REFERENCE POSITION RETURN ............................................. 78

2.19 REFERENCE POSITION SETTING WITHOUT DOG ................................. 78

2.20 REFERENCE POINT SETTING WITH MECHANICAL STOPPER .............. 78

2.21 REFERENCE POINT SETTING WITH MECHANICAL STOPPER BY

GRID METHOD ........................................................................................... 79

2.22 REFERENCE POSITION RETURN FEEDRATE SETTING ........................ 79

2.23 REFERENCE POSITION SHIFT ................................................................. 79

2.24 MANUAL HANDLE FEED ............................................................................ 79

2.24.1 Manual Handle Feed (1 Unit) ................................................................................. 79

2.24.2 Manual Handle Feed (2/3 Units) ............................................................................ 80

2.24.3 Manual Handle Feed (4/5 Units) ............................................................................ 80

2.24.4 Manual Handle Feed Magnification ....................................................................... 80

2.25 3-DIMENSIONAL MANUAL FEED .............................................................. 80

2.25.1 Tool Axis Direction Handle Feed / Tool Axis Direction Jog Feed / Tool Axis

Direction Incremental Feed .................................................................................... 81

2.25.2 Tool Axis Right-Angle Direction Handle Feed / Tool Axis Right-Angle

Direction Jog Feed / Tool Axis Right-Angle Direction Incremental Feed ............. 81

c-3

Page 14

TABLE OF CONTENTS B-64692EN/01

2.25.3 Tool Tip Center Rotation Handle Feed / Tool Tip Center Rotation Jog Feed /

Tool Tip Center Rotation Incremental Feed ........................................................... 82

2.25.4 Table Vertical Direction Handle Feed / Table Vertical Dir ect ion Jog Feed /

Table Vertical Direction Incremental Feed ............................................................ 83

2.25.5 Table Horizontal Direction Handle Feed / Table Horizontal Direction Jog Feed /

Table Horizontal Direction Incremental Feed ........................................................ 83

2.26 MANUAL HANDLE INTERRUPTION .......................................................... 84

2.26.1 Manual Interruption of 3-dimensional Coordinate System Conversion ................. 84

2.27 MANUAL LINEAR/CIRCULAR INTERPOLATION ....................................... 84

2.28 HANDLE-SYNCHRONOUS FEED .............................................................. 85

2.29 FANUC SERVO MOTOR β Series (I/O OPTION) MANUAL HANDLE

INTERFACE ................................................................................................ 86

2.30 INCREMENTAL FEED ................................................................................ 86

2.31 JOG AND HANDLE SIMULTANEOUS MODE ............................................ 87

2.32 REFERENCE POSITION SIGNAL OUTPUT FUNCTION ........................... 87

2.33 MANUAL HANDLE RETRACE .................................................................... 87

2.34 AUXILIARY FUNCTION OUTPUT BLOCK REVERSE MOVEMENT FOR

MANUAL HANDLE RETRACE .................................................................... 87

2.35 MANUAL HANDLE RETRACE FUNCTION FOR MULTI-PATH .................. 87

2.36 EXTENSION OF THE MANUAL HANDLE RETRACE FUNCTION ............. 87

2.37 MANUAL 2ND/3RD/4TH REFERENCE POSITION RETURN FUNCTION . 88

3 INTERPOLATION FUNCTION .............................................................. 89

3.1 NANO INTERPOLATION ............................................................................ 89

3.2 POSITIONING ............................................................................................. 89

3.3 SINGLE DIRECTION POSITIONING .......................................................... 90

3.4 EXACT STOP MODE .................................................................................. 90

3.5 TAPPING MODE ......................................................................................... 90

3.6 CUTTING MODE ......................................................................................... 91

3.7 EXACT STOP .............................................................................................. 91

3.8 IN-POSITION CHECK SIGNAL ................................................................... 91

3.9 LINEAR INTERPOLATION .......................................................................... 92

3.10 CIRCULAR INTERPOLATION ..................................................................... 93

3.11 DWELL ........................................................................................................ 93

3.12 POLAR COORDINATE INTERPOLATION .................................................. 94

3.13 CYLINDRICAL INTERPOLATION ............................................................... 96

3.13.1 Cylindrical Interpolation ........................................................................................ 96

3.13.2 Cylindrical Interpolation by Plane Distance Command ......................................... 97

3.14 HELICAL INTERPOLATION ........................................................................ 98

3.15 SMOOTH TOLERANCE+ CONTROL .......................................................... 99

3.16 THREAD CUTTING, SYNCHRONOUS CUTTING .................................... 101

3.17 MULTIPLE THREADING ........................................................................... 102

3.18 THREADING RETRACT ............................................................................ 103

3.18.1 Threading Retract (Canned Cycle) ....................................................................... 103

3.18.2 Threading Retract (Multiple Repetitive Cycle) .................................................... 103

3.19 CONTINUOUS THREADING ..................................................................... 104

3.20 VARIABLE LEAD THREADING ................................................................. 104

3.21 CIRCULAR THREAD CUTTING ................................................................ 105

c-4

Page 15

B-64692EN/01 TABLE OF CONTENTS

3.22 ARBITRARY SPEED THREADING ........................................................... 105

3.22.1 Arbitrary Speed Threading ................................................................................... 105

3.22.2 Re-machining Thread ........................................................................................... 106

3.23 POLYGON TURNING ................................................................................ 107

3.24 POLYGON TURNING WITH TWO SPINDLES .......................................... 108

3.25 SKIP FUNCTION ....................................................................................... 108

3.25.1 Skip Function ....................................................................................................... 108

3.25.2 Multi-step Skip ..................................................................................................... 109

3.25.3 High-speed Skip ................................................................................................... 110

3.25.4 Continuous High-speed Skip Function ................................................................. 110

3.25.5 Torque Limit Skip ................................................................................................ 110

3.26 REFERENCE POSITION RETURN ........................................................... 111

3.26.1 Automatic Reference Position Return .................................................................. 111

3.26.2 Reference Position Return Check ......................................................................... 112

3.26.3 Second, Third, and Fourth Reference Position Return ......................................... 112

3.26.4 In-position Check Disable Reference Position Return ......................................... 113

3.27 NORMAL DIRECTION CONTROL ............................................................ 115

3.28 BALANCE CUTTING ................................................................................. 116

3.29 INDEX TABLE INDEXING ......................................................................... 117

3.30 GENERAL PURPOSE RETRACT ............................................................. 117

4 FEED FUNCTION ................................................................................ 118

4.1 RAPID TRAVERSE ................................................................................... 118

4.2 RAPID TRAVERSE OVERRIDE ................................................................ 118

4.3 FEED PER MINUTE .................................................................................. 119

4.4 FEED PER REVOLUTION......................................................................... 120

4.5 FEED PER REVOLUTION WITHOUT POSITION CODER ....................... 120

4.6 CONSTANT SURFACE SPEED CONTROL WITHOUT

POSITION CODER .................................................................................... 120

4.7 TANGENTIAL SPEED CONSTANT CONTROL ........................................ 121

4.8 CUTTING FEEDRATE CLAMP ................................................................. 121

4.9 AUTOMATIC ACCELERATION/DECELERATION .................................... 121

4.10 RAPID TRAVERSE BLOCK OVERLAP..................................................... 122

4.11 PROGRAMMABLE RAPID TRAVERSE OVERLAP .................................. 123

4.12 RAPID TRAVERSE BELL-SHAPED ACCELERATION/DECELERATION 124

4.13 POSITIONING BY OPTIMUM ACCELERATION ....................................... 124

4.14 OPTIMUM TORQUE ACCELERATION/DECELERATION ........................ 125

4.15 BELL-SHAPED ACCELERATION/DECELERATION AFTER CUTTING

FEED INTERPOLATION ........................................................................... 126

4.16 LINEAR ACCELERATION/DECELERATION BEFORE CUTTING FEED

INTERPOLATION ...................................................................................... 126

4.17 FEEDRATE OVERRIDE ............................................................................ 126

4.18 SECOND FEEDRATE OVERRIDE ............................................................ 127

4.19 ONE-DIGIT F CODE FEED ....................................................................... 127

4.20 INVERSE TIME FEED ............................................................................... 127

4.21 JOG OVERRIDE ........................................................................................ 127

4.22 OVERRIDE CANCEL ................................................................................ 127

4.23 MANUAL PER REVOLUTION FEED ......................................................... 128

c-5

Page 16

TABLE OF CONTENTS B-64692EN/01

4.24 EXTERNAL DECELERATION ................................................................... 128

4.24.1 Deceleration area setting ...................................................................................... 128

4.25 SPEED CONTROL WITH ACCELERATION IN CIRCULAR

INTERPOLATION ...................................................................................... 128

4.26 LINEAR ACCELERATION/DECELERATION AFTER CUTTING FEED

INTERPOLATION ...................................................................................... 129

4.27 AI CONTOUR CONTROL I / AI CONTOUR CONTROL II ......................... 130

4.28 BELL-SHAPED ACCELERATION/DECELERATION BEFORE

LOOK-AHEAD INTERPOLATION ............................................................. 131

4.29 JERK CONTROL ....................................................................................... 132

4.30 RIGID TAPPING BELL-SHAPED ACCELERATION/DECELERATION ..... 133

4.31 SPEED COMMAND EXTENSION IN LEAST INPUT INCREMENTS C .... 133

4.32 OPTIMUM ACCELERATION/DECELERATION FOR RIGID TAPPING .... 134

4.33 TIME CONSTANT OF ACCELERATION / DECELERATION AFTER

INTERPOLATION SWITCHING FUNCTION BY SIGNAL ......................... 136

4.34 SERVO LOOP GAIN / IN-POSITION WIDT H SW ITCHING FUNCTION

BY SIGNAL ................................................................................................ 136

5 PROGRAM INPUT .............................................................................. 137

5.1 PROGRAM CODE ..................................................................................... 137

5.2 LABEL SKIP .............................................................................................. 137

5.3 PARITY CHECK ........................................................................................ 137

5.4 CONTROL-IN / CONTROL-OUT ............................................................... 137

5.5 OPTIONAL BLOCK SKIP .......................................................................... 137

5.6 OPTIONAL BLOCK SKIP EXTENSION ..................................................... 138

5.7 MAXIMUM COMMAND VALUES .............................................................. 138

5.8 PROGRAM NAME ..................................................................................... 139

5.9 SEQUENCE NUMBER .............................................................................. 140

5.10 ABSOLUTE PROGRAMMING / INCREMENTAL PROGRAMMING ......... 140

5.11 DECIMAL POINT PROGRAMMING / POCKET CALCULATOR TYPE

DECIMAL POINT PROGRAMMING .......................................................... 141

5.12 INPUT UNIT 10 TIME MULTIPLY .............................................................. 141

5.13 DIAMETER PROGRAMMING / RADIUS PROGRAMMING ...................... 141

5.14 PLANE SELECTION .................................................................................. 142

5.15 ROTARY AXIS SPECIFICATION .............................................................. 143

5.16 ROTARY AXIS ROLL-OVER ..................................................................... 143

5.17 POLAR COORDINATE COMMAND .......................................................... 143

5.18 COORDINATE SYSTEM SETTING ........................................................... 144

5.18.1 Machine Coordinate System................................................................................. 144

5.18.2 Workpiece Coordinate System ............................................................................. 145

5.18.2.1 Setting a workpiece coordin ate system ............................................................ 145

5.18.2.2 Automatic coordinate system setting ............................................................... 146

5.18.2.3 Setting a workpiece coordinate system ............................................................ 146

5.18.3 Local Coordinate System ..................................................................................... 147

5.19 WORKPIECE COORDINATE SYSTEM PRESET ..................................... 148

5.20 EACH AXIS WORKPIECE COORDINATE SYSTEM PRESET SIGNALS . 148

5.21 ADDITION OF WORKPIECE COORDINATE SYSTEM PAIR ................... 148

5.22 DIRECT INPUT OF WORKPIECE ORIGIN OFFSET VALUE MEASURED149

c-6

Page 17

B-64692EN/01 TABLE OF CONTENTS

5.23 MANUAL ABSOLUTE ON AND OFF ......................................................... 149

5.24 DIRECT DRAWING DIMENSION PROGRAMMING ................................. 149

5.25 G CODE SYSTEM ..................................................................................... 150

5.25.1 G Code for Lathe System ..................................................................................... 150

5.25.2 G Code System for Machining Center ................................................................. 154

5.26 CHAMFERING AND CORNER R .............................................................. 157

5.27 OPTIONAL CHAMFERING AND CORNER R ........................................... 159

5.28 PROGRAMMABLE DATA INPUT .............................................................. 160

5.28.1 Setting the Pitch Error Compensation Data .......................................................... 160

5.28.2 Setting the Workpiece Origin Offset Value ......................................................... 161

5.28.3 Setting the Tool Compensation Offset Value ....................................................... 161

5.28.4 Setting the Tool Management Data ...................................................................... 164

5.28.4.1 Registering new tool management data ........................................................... 164

5.28.4.2 Modifying tool management data .................................................................... 165

5.28.4.3 Deleting tool management data ....................................................................... 165

5.28.4.4 Registering new cartridge management table data .......................................... 165

5.28.4.5 Modifying the cartridge management table ..................................................... 166

5.28.4.6 Deleting cartridge management table data ....................................................... 166

5.28.4.7 Naming customization data ............................................................................. 166

5.28.4.8 Naming tool life states ..................................................................................... 167

5.29 PROGRAMMABLE PARAMETER INPUT ................................................. 167

5.30 SUB PROGRAM CALL .............................................................................. 168

5.31 CUSTOM MACRO ..................................................................................... 170

5.32 ADDITION OF CUSTOM MACRO COMMON VARIABL ES ...................... 175

5.33 ADDITION OF CUSTOM MACRO COMMON VARIABL ES 1000 ............. 175

5.34 CUSTOM MACRO COMMON VARIABLES BETWEEN EACH PATH ...... 176

5.35 INTERRUPTION TYPE CUSTOM MACRO ............................................... 176

5.36 PATTERN DATA INPUT ............................................................................ 177

5.37 CANNED CYCLE ....................................................................................... 177

5.37.1 Outer Diameter/Internal Diameter Cutting Cycle................................................. 178

5.37.2 Threading Cycle ................................................................................................... 179

5.37.3 End Face Turning Cycle ....................................................................................... 181

5.38 MULTIPLE REPETITIVE CYCLE .............................................................. 182

5.38.1 Stock Removal in Turning ................................................................................... 182

5.38.2 Stock Removal in Facing ..................................................................................... 184

5.38.3 Pattern Repeating ................................................................................................. 186

5.38.4 Finishing Cycle .................................................................................................... 187

5.38.5 End Face Peck Drilling Cycle .............................................................................. 187

5.38.6 Outer Diameter / Internal Diameter Drilling Cycle .............................................. 188

5.38.7 Multiple Threading Cycle .................................................................................... 190

5.39 IN-FEED CONTROL (FOR GRINDING MACHINE) ................................... 191

5.40 CANNED GRINDING CYCLE (FOR GRINDING MACHINE) ..................... 192

5.41 CANNED CYCLE FOR DRILLING ............................................................. 192

5.42 CANNED CYCLE OVERLAP FOR DRILLING ........................................... 193

5.43 CIRCULAR INTERPOLATION BY R PROGRAMMING ............................ 194

5.44 MIRROR IMAGE FOR DOUBLE TURRET ................................................ 194

5.45 AUTOMATIC CORNER OVERRIDE ......................................................... 195

5.46 SCALING ................................................................................................... 195

5.47 COORDINATE SYSTEM ROTATION ........................................................ 197

5.48 3-DIMENSIONAL COORDINATE CONVERSION ..................................... 199

c-7

Page 18

TABLE OF CONTENTS B-64692EN/01

5.49 TILTED WORKING PLANE INDEXING ..................................................... 200

5.50 TILTED WORKING PLANE INDEXING BY TOOL AXIS DIRECT ION ....... 201

5.51 PROGRAMMABLE MIRROR IMAGE ........................................................ 202

5.52 SYNCHRONOUS, COMPOSITE, AND SUPERIMPOSED CONTROL BY

PROGRAM COMMAND ............................................................................ 203

5.53 FIGURE COPY .......................................................................................... 204

5.54 PROGRAM FORMAT FOR FANUC Series 15

(PROGRAM FORMAT FOR FANUC Series 10/11) ................................... 206

5.55 MACRO EXECUTOR ................................................................................ 206

5.56 C LANGUAGE EXECUTOR ...................................................................... 207

5.57 ADDITION OF C LANGUAGE EXECUTOR SRAM ................................... 207

5.58 CUSTOM SOFTWARE SIZE ..................................................................... 207

5.59 WORKPIECE COORDINATE SYSTEM SHIFT ......................................... 208

5.60 EMBEDDED MACRO ................................................................................ 208

5.61 SMALL-HOLE PECK DRILLING CYCLE ................................................... 209

5.62 REAL TIME CUSTOM MACRO ................................................................. 210

5.63 G CODE PREVENTING BUFFERING ....................................................... 211

6 GUIDANCE FUNCTION ...................................................................... 212

6.1 MANUAL GUIDE i ................................................................................................ 212

6.1.1 Basic Fun ction ...................................................................................................... 212

6.1.2 Milling Cycle ........................................................................................................ 212

6.1.3 Turning Cycle ....................................................................................................... 212

6.1.4 Animation ............................................................................................................. 212

6.1.5 Set-up Guidance Function .................................................................................... 212

6.2 MANUAL GUIDE i MULTI-PATH LATHE FUNCTION ............................... 213

6.3 MANUAL GUIDE 0i .............................................................................................. 213

6.3.1 Basic Fun ctions .................................................................................................... 213

6.3.2 Milling Cycle (M series) ...................................................................................... 213

6.3.3 Turning Cy cle (T Series) ...................................................................................... 213

6.3.4 Contour Programming Function ........................................................................... 213

7 AUXILIARY FUNCTION / SPINDLE SPEED FUNCTION ................... 214

7.1 AUXILIARY FUNCTION ............................................................................ 214

7.2 SECOND AUXILIARY FUNCTION ............................................................ 214

7.3 AUXILIARY FUNCTION LOCK .................................................................. 214

7.4 HIGH-SPEED M/S/T/B INTERFACE ......................................................... 215

7.5 WAITING FUNCTION ................................................................................ 216

7.6 WAITING M CODES OF HIGH-SPEED TYPE .......................................... 217

7.7 MULTIPLE COMMAND OF AUXILIARY FUNCTION ................................ 217

7.8 AUXILIARY FUNCTION OUTPUT IN MOVING AXIS ................................ 217

7.9 WAITING FUNCTION BY SPECIFYING START POINT ........................... 217

7.10 SPINDLE SPEED FUNCTION (S CODE OUTPUT) .................................. 218

7.11 SPINDLE SERIAL OUTPUT ...................................................................... 218

7.12 SPINDLE ANALOG OUTPUT .................................................................... 218

7.13 CONSTANT SURFACE SPEED CONTROL ............................................. 218

7.14 SPINDLE OVERRIDE ................................................................................ 219

7.15 ACTUAL SPINDLE SPEED OUTPUT ....................................................... 219

c-8

Page 19

B-64692EN/01 TABLE OF CONTENTS

7.16 SPINDLE ORIENTATION .......................................................................... 219

7.17 SPINDLE OUTPUT SWITCHING FUNCTION ........................................... 219

7.18 SPINDLE SYNCHRONOUS CONTROL .................................................... 219

7.19 SPINDLE COMMAND SYNCHRONOUS CONTROL ................................ 220

7.20 MULTI SPINDLE CONTROL ..................................................................... 220

7.21 SPINDLE POSITIONING ........................................................................... 222

7.22 RIGID TAPPING ........................................................................................ 223

7.23 RIGID TAPPING BY MANUAL HANDLE ................................................... 223

7.24 ARBITRARY POSITION REFERENCE SETTING FOR

Cs AXIS FUNCTION .................................................................................. 224

7.25 M CODE GROUP CHECK FUNCTION ..................................................... 224

7.26 SPINDLE SPEED FLUCTUATION DETECTION ....................................... 224

7.27 Cs CONTOUR CONTROL AXIS COORDINATE ESTABLISHMENT ........ 224

7.28 SPINDLE CONTROL WITH SERVO MOTOR ........................................... 224

7.29 SPINDLE REVOLUTION NUMBER HISTORY FUNCTION ...................... 226

7.30 SERVO/SPINDLE SYNCHRONOUS CONTROL ...................................... 226

7.31 HIGH-PRECISION SPINDLE SPEED CONTROL ..................................... 226

7.32 SIMPLE SPINDLE ELECTRONIC GEAR BOX .......................................... 226

7.33 SPINDLE SPEED COMMAND CLAMP ..................................................... 227

7.34 SPINDLE CONTROL MODE CHANGING BY PROGRAM COMMAND .... 227

8 TOOL FUNCTION / TOOL COMPENSATION FUNCTION ................. 228

8.1 TOOL FUNCTION ..................................................................................... 228

8.2 EXTENDED TOOL SELECTION FUNCTION ............................................ 228

8.3 TOOL OFFSET PAIRS .............................................................................. 229

8.4 TOOL COMPENSATION MEMORY .......................................................... 229

8.5 COMMON COMPENSATION MEMORY BETWEEN EACH PATH ........... 231

8.6 TOOL LENGTH COMPENSATION ........................................................... 231

8.7 TOOL OFFSET .......................................................................................... 233

8.8 Y-AXIS OFFSET ........................................................................................ 234

8.9 CUTTER OR TOOL NOSE RADIUS COMPENSATION ........................... 234

8.10 CUTTING POINT INTERPOLATION FOR CYLINDRICAL

INTERPOLATION ...................................................................................... 237

8.11 TOOL GEOMETRY OFFSET AND TOOL WEAR OFFSET ...................... 238

8.12 SECOND GEOMETRY TOOL OFFSET .................................................... 239

8.13 TOOL MANAGEMENT FUNCTION ........................................................... 239

8.13.1 Tool Management Extension Function ................................................................ 240

8.13.2 Tool Management Function Oversize Tools Support........................................... 240

8.14 TOOL OFFSET VALUE COUNTER INPUT ............................................... 241

8.15 TOOL LENGTH MEASUREMENT ............................................................. 241

8.16 AUTOMATIC TOOL LENGTH MEASUREMENT / AUTOMATIC TOOL

OFFSET .................................................................................................... 241

8.16.1 Automatic Tool Length Measurement .................................................................. 241

8.16.2 Automatic Tool Offset .......................................................................................... 242

8.17 DIRECT INPUT OF TOOL OFFSET VALUE MEASURED /

DIRECT INPUT OF COORDINATE SYSTEM SHIFT ................................ 243

8.18 DIRECT INPUT OF TOOL OFFSET VALUE MEASURED B ..................... 243

c-9

Page 20

TABLE OF CONTENTS B-64692EN/01

8.19 TOOL LIFE MANAGEMENT ...................................................................... 243

8.20 TOOL OFFSET FOR MILLING AND TURNING FUNCTION ..................... 245

9 ACCURACY COMPENSASION FUNCTION ...................................... 246

9.1 BACKLASH COMPENSATION .................................................................. 246

9.2 BACKLASH COMPENSATION FOR EACH RAPID TRAVERSE AND

CUTTING FEED ........................................................................................ 246

9.3 SMOOTH BACKLASH COMPENSATION ................................................. 247

9.4 STORED PITCH ERROR COMPENSATION ............................................ 247

9.5 INTERPOLATION TYPE PITCH ERROR COMPENSATION .................... 248

9.6 BI-DIRECTIONAL PITCH ERROR COMPENSATION .............................. 249

9.7 INCLINATION COMPENSATION .............................................................. 249

9.8 STRAIGHTNESS COMPENSATION ......................................................... 250

9.9 INTERPOLATION TYPE STRAIGHTNESS COMPENSATION ................. 251

10 ELECTRONIC GEAR BOX ................................................................. 252

10.1 ELECTRONIC GEAR BOX ........................................................................ 252

10.2 SPINDLE ELECTRONIC GEAR BOX ........................................................ 253

10.3 ELECTRONIC GEAR BOX AUTOMATIC PHASE SYNCHRONIZATION . 254

10.4 SKIP FUNCTION FOR EGB AXIS ............................................................. 255

10.5 ELECTRONIC GEAR BOX 2 PAIR ............................................................ 256

10.6 U-AXIS CONTROL .................................................................................... 257

10.7 SIGNAL-BASED SERVO EGB SYNCHRONOUS CONTROL ................... 258

10.8 ELECTRONIC GEAR BOX (FSSB TYPE) ................................................. 258

11 EDITING OPERATION ........................................................................ 259

11.1 PART PROGRAM STORAGE SIZE / NUMBER OF REGISTERABLE

PROGRAMS .............................................................................................. 259

11.2 PROGRAM EDITING ................................................................................. 260

11.3 PROGRAM PROTECT .............................................................................. 260

11.4 KEY AND PROGRAM ENCRYPTION ....................................................... 261

11.5 EXTENDED PART PROGRAM EDITING .................................................. 261

11.6 PLAYBACK ................................................................................................ 261

11.7 MACHINING TIME STAMP ....................................................................... 261

11.8 BACKGROUND EDITING ......................................................................... 261

11.9 MEMORY CARD PROGRAM OPERATION/EDITING .............................. 261

11.10 MULTI-PATH EDITING FUNCTION .......................................................... 262

12 SETTING AND DISPLAY .................................................................... 263

12.1 STATUS DISPLAY .................................................................................... 263

12.2 CLOCK FUNCTION ................................................................................... 263

12.3 CURRENT POSITION DISPLAY ............................................................... 264

12.4 PROGRAM DISPLAY ................................................................................ 265

12.5 PARAMETER SETTING AND DISPLAY ................................................... 267

12.6 ALARM DISPLAY ...................................................................................... 267

12.7 ALARM HISTORY DISPLAY ..................................................................... 268

12.8 OPERATOR MESSAGE HISTORY DISPLAY ........................................... 268

12.9 OPERATION HISTORY DISPLAY ............................................................. 268

c-10

Page 21

B-64692EN/01 TABLE OF CONTENTS

12.10 RUN HOUR AND PARTS COUNT DISPLAY ............................................ 269

12.11 ACTUAL CUTTING FEEDRATE DISPLAY ................................................ 270

12.12 DISPLAY OF SPINDLE SPEED AND T CODE AT ALL SCREENS .......... 271

12.13 DIRECTORY DISPLAY OF FLOPPY CASSETT E ..................................... 271

12.14 OPTIONAL PATH NAME DISPLAY ........................................................... 271

12.15 OPERATING MONITOR SCREEN ............................................................ 272

12.16 SERVO SETTING SCREEN ...................................................................... 272

12.16.1 Servo Setting Screen ............................................................................................ 272

12.16.2 Servo Motor Tuning Screen ................................................................................. 273

12.17 SPINDLE SETTING SCREEN ................................................................... 273

12.17.1 Spindle Setting Screen .......................................................................................... 273

12.17.2 Spindle Tuning Screen ......................................................................................... 274

12.17.3 Spindle Monitor Screen ........................................................................................ 274

12.18 SERVO WAVEFORM DISPLAY ................................................................ 275

12.19 MAINTENANCE INFORMATI ON SCREEN ............................................... 275

12.20 SOFTWARE OPERATOR'S PANEL .......................................................... 276

12.21 SOFTWARE OPERATOR'S PANEL GENERAL PURPOSE SWITCH ...... 277

12.22 MULTI-LANGUAGE DISPLAY ................................................................... 278

12.22.1 Changing the Display Language by PMC Signals ............................................... 278

12.23 DATA PROTECTION KEY......................................................................... 278

12.24 PROTECTION OF DATA AT EIGHT LEVELS ........................................... 279

12.25 ERASE CRT SCREEN DISPLAY .............................................................. 280

12.26 PARAMETER SET SUPPORTING SCREEN ............................................ 280

12.27 MACHINING CONDITION SELECTING FUNCTION ................................ 281

12.28 SYSTEM CONFIGURATIO N SCREEN ..................................................... 282

12.28.1 Hardware Configuration Screen ........................................................................... 282

12.28.2 Software Configuration Screen ............................................................................ 283

12.29 HELP SCREEN ......................................................................................... 284

12.29.1 Initial Menu Screen .............................................................................................. 284

12.29.2 Alarm Detail Screen ............................................................................................. 284

12.29.3 Operation Method Screen ..................................................................................... 285

12.29.4 Parameter Table Screen ........................................................................................ 286

12.30 SELF-DIAGNOSIS SCREEN ..................................................................... 286

12.31 PERIODIC MAINTENANCE SCREEN ...................................................... 287

12.32 SERVO AND SPINDLE INFORMATI ON SCREENS ................................. 287

12.32.1 Servo Information Screen ..................................................................................... 288

12.32.2 Spindle Information Screen .................................................................................. 289

12.33 GRAPHIC DISPLAY .................................................................................. 289

12.34 DYNAMIC GRAPHIC DISPLAY ................................................................. 290

12.35 TOUCH PANEL CONTROL ....................................................................... 290

12.36 EXTERNAL TOUCH PANEL INTERFACE ................................................ 290

12.37 TWO TOUCH PANELS CONTROL FOR STAND-ALONE TYPE CNC ..... 290

12.38 AUTOMATIC DATA BACKUP ................................................................... 291

12.39 SPEED DISPLAY FUNCTION OF A MI L LING TOOL WITH

SERVO MOTOR ........................................................................................ 291

12.40 MACHINE OPERATION MENU ................................................................. 292

12.41 SYSTEM ALARM HISTORY ...................................................................... 292

12.42 ROBOT CONNECTION FUNCTI ON ......................................................... 293

c-11

Page 22

TABLE OF CONTENTS B-64692EN/01

12.43 MACHINE STATE MONITO RING FUNCTION .......................................... 293

12.44 POWER CONSUMPTION M ONITOR ....................................................... 294

12.45 ENERGY SAVING LEVEL SELECTING FUNCTION ................................ 294

12.46 WARNING FUNCTION AGAI NST MODIFICATION OF SETTING ............ 295

12.47 SERVO/SPINDLE WAVEFORM DATA OUTPUT FUNCTION .................. 296

12.48 MAINTENANCE MONITOR ....................................................................... 297

12.48.1 Fan Monitor Screen .............................................................................................. 297

12.48.2 Leakage Detection Monitor Screen ...................................................................... 297

12.49 TROUBLE DIAGNOSIS ............................................................................. 298

12.50 MACHINE ALARM DIAGNOSIS ................................................................ 298

12.51 FINE SURFACE SETTING ........................................................................ 298

13 DATA INPUT/OUTPUT ....................................................................... 299

13.1 RS232C INTERFACE ................................................................................ 299

13.2 FAST DATA SERVER ............................................................................... 299

13.3 BUFFER MODE OF DATA SERVER ........................................................ 299

13.4 DATA SERVER EXPLORER CONNECTION ............................................ 300

13.5 EXTERNAL DATA INPUT .......................................................................... 300

13.5.1 External Tool Offset ............................................................................................. 300

13.5.2 External Program Number Search ........................................................................ 300

13.5.3 External Workpiece Coordinate System Shift ...................................................... 300

13.5.4 External Machine Zero Point Shift ....................................................................... 301

13.5.5 Extended External Machine Zero Point Shift ....................................................... 301

13.5.6 External Alarm Message ...................................................................................... 301

13.5.7 External Operator Message .................................................................................. 301

13.5.8 Assignment of Machined Parts Count and Required Parts Count ........................ 302

13.6 EXTERNAL KEY INPUT (KEY INPUT FROM THE PMC) ......................... 302

13.7 EXTERNAL WORKPIECE NUMBER SEARCH ......................................... 302

13.8 MEMORY CARD INPUT/OUTPUT ............................................................ 302

13.9 USB MEMORY INPUT/OUTPUT ............................................................... 303

13.10 SCREEN HARD COPY ............................................................................. 303

13.11 POWER MATE CNC MANAGER .............................................................. 303

13.12 ONE TOUCH MACRO CALL ..................................................................... 304

14 INTERFACE FUNCTION ..................................................................... 305

14.1 EMBEDDED ETHERNET .......................................................................... 305

14.2 FAST ETHERNET / FAST DATA SERVER ............................................... 306

14.2.1 Functional Differences between the Embedded Et hernet and the Fast Ethernet .. 307

14.3 FIELD NETWORKS ................................................................................... 308

14.4 INDUSTRIAL ETHERNET ......................................................................... 309

15 PMC ..................................................................................................... 311

15.1 PMC BASIC SPECIFICATIONS ................................................................ 311

15.2 MULTI-PATH PMC FUNCTION (3-PATHS) .............................................. 314

15.3 TOTAL NUMBER OF LADDER STEPS IN MULTI-PATH PMC ................. 315