Page 1

Convertional Automatic Programming

Function II for Lathe

Operator's Manual

B-

61804E-2/05

Page 2

B–61804E–2/05

Table of Contents

SAFETY PRECAUTIONS s–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I. GENERAL

1. GENERAL 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION 5. . . . . . . . . . . . . . . . . .

3. NOTES ON READING THIS MANUAL 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II. EXPLANATION FOR CRT/MDI PANEL

1. EXPLANATION FOR CRT/MDI PANEL 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. KEYS EFFECTIVE IN FAPT MODE 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. SOFT KEY 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III. PROGRAMMING AND OPERATION BY SYMBOLIC FAPT

1. SYMBOLIC FAPT 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. START OF SYMBOLIC FAPT PROGRAMMING 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. EXECUTION OF SYMBOLIC FAPT 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 BLANK AND DRAWING (DRAWING AND BLANK) 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 BLANK AND PART (PART FIGURE) 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Drawing of Program Coordinate System and Blank Figure 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Part Figure Input (Input Method of with Figure) 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Input and Modification of Part Figure Data 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4 Blank Figure Input of Special Figure Blank 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.5 Part Figure Input (Directory Input System) 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.6 Batch Input Functions for Chamfering and Corner R 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.7 Pattern Figure Input Function 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.8 Function for Defining the Center of an Arc According to a Given Single Coordinate 80. . . . . . . .

3.3 MACHINE ZERO POINT AND TURRET POSITION 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 MACHINING DEFINITION 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Selection of Kinds of Machining 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 Process Change and Correction 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 Output of Only Single Process 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Page 3

T ABLE OF CONTENTS

3.4.4 Tool Data 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.5 Machining Start Position 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.6 Passing Point 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.7 Specifying the Direction and Area of Cutting 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.8 Function for Automatically Setting Area Division Points 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.9 Cutting Conditions 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.10 Setting the T ool Data and Tooling Information 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.11 Drawing a Cutting Area and Painting a Blank Figure 136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 NC DATA PREP ARATION 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Preparations of NC Data and Registrations of Machining Memory 138. . . . . . . . . . . . . . . . . . . . . .

3.5.2 Precautions to be Taken with Background Animated Simulation 142. . . . . . . . . . . . . . . . . . . . . . .

3.5.3 Display of Machining Time 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.4 Process Editing Function (Only with 2–path Control) 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.5 Special Block Output to both Programs 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.6 Outputting the NC Data of a Multiple Thread Cutting Cycle 153. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 CHECKING NC DATA (ANIMATED SIMULATION FUNCTION) 161. . . . . . . . . . . . . . . . . . . . . . . .

3.6.1 Operating Instructions 161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.2 Flow of Animation Screen 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.3 Starting an Animated Simulation 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.4 Setting of Parameters for Animated Simulation 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.5 Setting of Chuck Figure 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.6 Setting of Tailstock Figure 168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.7 Setting of Tool Holder Figure 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.8 Enlargement and Reduction in the Animated Screen 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.9 Related System Parameters 172. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.10 Input/Output of Graphic Data 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–61804E–2/05

4. SUB CYCLE FUNCTION 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 SETTING OF SUB CYCLE 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 INPUT/OUTPUT OF SUB CYCLE FILE 179. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 DEFINITION OF “SUB CYCLE” PROCESS IN DEFINITION OF MACHINING 181. . . . . . . . . . . . .

4.4 PROCESS EDITING OF SUB CYCLE (2–PATH LATHE) 184. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 OUTPUT OF NC DATA 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 CAUTIONS AND NOTES 187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. BALANCE CUT FAPT FUNCTION (2–PATH LATHE ONLY) 188. . . . . . . . . . . . . . . . . . . .

5.1 BALANCE CUTTING PROCESS 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 SPECIFICATION METHOD 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 USING THE AUTOMATIC PROCESS DETERMINATION FUNCTION 193. . . . . . . . . . . . . . . . . . . .

5.4 PROCESS EDITING SCREEN 193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 NC DATA 194. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 RELATED PARAMETERS 196. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 CONSTANT SURFACE SPEED CONTROL FOR BALANCE CUT B 196. . . . . . . . . . . . . . . . . . . . . .

5.8 CAUTION AND NOTES 197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

Page 4

B–61804E–2/05

T ABLE OF CONTENTS

6. AUTO COLLISION AVOIDANCE FUNCTION (15–TTFB ONLY) 198. . . . . . . . . . . . . . . . .

6.1 EXPLANATION OF FUNCTIONS 199. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 OPERATION 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 SYSTEM PARAMETER 204. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 NOTES 205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV. VARIOUS FILE AND DATA

1. MEMORY COMPOSITION 209. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 MAIN MEMORY AND SUBMEMORY 210. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Submemory 210. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Main Memory 211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 DISPLAY OF SUBMEMORY FILE NAME AND FILE DELETION 212. . . . . . . . . . . . . . . . . . . . . . .

1.3 ADDITIONAL P ARAMETER OF SUBMEMORY 213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 NO. OF FILES REGISTERABLE IN SUB–MEMORY 213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. INPUT/OUTPUT AND COLLATION OF DATA 214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 INPUT/OUTPUT WITH SUBMEMORY 215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 System Parameter, MTF , Setting Data 215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Family Program, Material Data, Tooling Information Sub Cycle File 215. . . . . . . . . . . . . . . . . . . .

2.1.3 File Protection 219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.4 Function For Automatically Registering Parameters and Data in Submemory 222. . . . . . . . . . . . .

2.2 COLLATION AND INPUT/OUTPUT WITH FLOPPY CASSETTE 223. . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 System Parameter, MTF , Tool Data, Setting Data, Drawing Data 223. . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Family Program, Material Data, Tooling Information, Sub Cycle File 225. . . . . . . . . . . . . . . . . . .

2.2.3 Handling of Floppy Cassette and Adapter 225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 FAPT I/O INTERFACE 227. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 REGISTRATION OF FILE NAME ONTO FLOPPY CASSETTE, HANDY FILE (OPTION) 228. . . .

2.5 FILE DATA INPUT/OUTPUT FUNCTION 229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Parameter 229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2 Screen 229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3 Input/Output Data Format 230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.4 File Name Registration in the Floppy Cassette or Handy File 231. . . . . . . . . . . . . . . . . . . . . . . . . .

V. SETTING AND DISPLAY OF DATA

1. MATERIAL DATA 235. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 MATERIAL DATA AND MATERIAL FILE 236. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 SETTING AND DATA WHICH CAN DISPLA YED 237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 OPERATION METHOD 238. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Method of Registration 238. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Method of Modification 239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 Method of Deletion 240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 INPUT/OUTPUT OF MATERIAL DATA 241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 NOTES ON MATERIAL FILES 241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

Page 5

T ABLE OF CONTENTS

B–61804E–2/05

2. TOOL DATA AND TOOLING INFORMATION 242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 TOOL DATA, TOOLING INFORMATION 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 TOOL DATA DISPLAY AND SETTING 244. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 INPUT/OUTPUT AND COLLATION OF TOOL DATA 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Tool Data Input/Output Format 249. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 TOOLING INFORMATION DISPLAY AND SETTING 251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 INITIALIZATION OF TOOLING INFORMATION 255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 TOOL FIGURE DATA AND SETTING METHOD 256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 General Lathe Setting Method 256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Vertical Lathe Setting Method 269. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. SETTING DATA, SYSTEM PARAMETER, MTF 286. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 DISPLAY AND SETTING 287. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 OUTPUT/INPUT AND COLLATION 288. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 FORMAT OF PARAMETER TAPE 289. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 ERROR DISPLAY MESSAGE 290. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VI. AUXILIARY JOBS

1. SUBMEMORY INITIALIZATION 294. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. CONVERSION OF INPUT UNIT (MM/INCH) 295. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. CHANGING THE NUMBER OF REGISTERED TOOLS 301. . . . . . . . . . . . . . . . . . . . . . . . .

VII. VARIOUS FUNCTIONS AND PRECAUTIONS OF Symbolic FAPT

1. VARIOUS FUNCTIONS OF Symbolic FAPT 305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 SKIP FUNCTION OF PAGE AND QUESTION 306. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 INCREMENTAL DESIGNATION 308. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 EXPANSION AND CONTRACTION OF GRAPHIC DISPLA Y 310. . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Designation Method 310. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 NC DATA OUTPUT BY SINGLE STEP 313. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 Single Step of Block 313. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2 Single Step of Process 314. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 RE–OUTPUT OF NC DATA BY EACH PROCESS 316. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 OUTPUT IN MAIN PROGRAM AND SUBPROGRAM FORMAT 318. . . . . . . . . . . . . . . . . . . . . . . . .

1.7 S CODE OUTPUT 320. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 SIMULTANEOUS 1 AXIS MOVEMENT IN APPROACH AND RETURN RELIEF 322. . . . . . . . . . .

1.8.1 Setting of Parameters 322. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8.2 NC Data Format 323. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9 UTILIZATION OF DIRECT INPUT OF TOOL OFFSET VALUE 325. . . . . . . . . . . . . . . . . . . . . . . . . .

1.10 APPLICA TION FOR NC CHASER LATHE 327. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–4

Page 6

B–61804E–2/05

1.11 INTERFERENCE CHECK 332. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.11.1 Interference Check by T ool Shape and Machining Shape 332. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.11.2 Interference Check in Approach and Return relief 332. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.11.3 Grooving when the T ool Width and Groove Width are the Same 334. . . . . . . . . . . . . . . . . . . . . . .

1.11.4 Approach and Relief to Inner Diameter 335. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.12 INITIAL SCREEN DISPLAY FUNCTION 336. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.12.1 Screen Flow 336. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.12.2 Setting Initial Screen Display Data 337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.12.3 Check Screen 341. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.12.4 Error Messages 342. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.12.5 System Parameters 343. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.13 OUTPUTTING NC DATA IN THE FS15T/16T FORMAT 344. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.13.1 MTF Setting 344. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.13.2 Supplementary 348. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.14 FUNCTION FOR PREPARING THE NEXT TOOL 349. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.15 OUTPUT FUNCTION FOR INTERPOLATION RIGID TAPPING 351. . . . . . . . . . . . . . . . . . . . . . . . .

T ABLE OF CONTENTS

2. CAUTIONS FOR USING Symbolic FAPT 356. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 TOOL FIGURE AND SETTING METHOD 357. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 CUTTING DIRECTION AND CUTTING EDGE ANGLE 363. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 ROUGH CUTTING DIRECTION 364. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 JUDGEMENT OF POCKETS 365. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 DIVISION OF MACHINING AREA 367. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 SURPLUS THICKNESS 370. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 Finish Allowance and Surplus Thickness 370. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Surplus Thickness and Blank 370. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.3 Closed Part 371. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.4 Definition of Optional Blank Figure 371. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 GROOVING 372. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Tool Path 372. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.2 Interference Check 373. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.3 Blank Figure in Grooving Area 373. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.4 Groove Bottom Figure 373. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.5 Concaved Parts in Groove 374. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 DEPTH OF CUT (D) IN DRILLING 375. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 THREADING 376. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9.1 Threading Direction 376. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9.2 Threading Depth 377. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9.3 Depth of Screw Thread 377. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10 CUTTING OVERHUNG PORTION 378. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11 ERROR WHEN NC DATA IS PREPARED 380. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12 OTHER PRECAUTIONS 383. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.1 Chucking Position 383. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.2 Cutting Start Position and Others 383. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.3 Method of Stopping the T ool on Z Axis 384. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.4 T ool Path in Finish Cutting and Semi–finish Cutting 385. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–5

Page 7

T ABLE OF CONTENTS

B–61804E–2/05

VIII. C–AXIS FAPT FUNCTION

1. PART FIGURE DEFINITION (MENU 2) 389. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 KIND OF MACHINING 390. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 SPECIFICATION OF C–AXIS MACHINING 391. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 DESIGNATION OF C–AXIS FIGURE DATA 392. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Inserting or Deleting C–axis Figure Data 392. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Details of C–axis Figure Data 393. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 MILLING IN MULTIPLE PLANES 407. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 C–AXIS MACHINING WITH A MACHINING PLANE SPECIFIED 408. . . . . . . . . . . . . . . . . . . . . . .

2. MACHINING DEFINITION (MENU 4) 411. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 SPECIFICATION OF C–AXIS MACHINING DEFINITION 412. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Kind of C–axis Machining Specification 412. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Tool Data for C–axis Machining 412. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3 Machining Start Position 415. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.4 Cutting Conditions 416. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.5 Specifying the Cutting Position for C–axis Machining 427. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 BLIND HOLE AND THROUGH HOLE 428. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. ANIMATED SIMULATION FUNCTION (MENU 6) 429. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 OUTLINE 430. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 SPECIFICATION 431. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 C–axis FAPT Animated Screen 431. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Parameter Screen for Animated Simulation 434. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. MATERIAL AND TOOL DATA 435. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 MATERIAL DATA 436. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 TOOL DATA 437. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Tool Data 437. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Input and Output of the Tool Data and Collation 438. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 Displaying and Setting of Tooling Informations 439. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. MTF 442. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 MTF SETTING WHEN C–AXIS FAPT FUNCTION IS USED 443. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 NC DATA OUTPUT 447. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 RIGID TAPPING NC DATA INPUT 458. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 F ACE MILLING 460. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 SIDE MILLING 466. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 G85/G89 BORING CYCLE 470. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. CAUTIONS ON C–AXIS FAPT 471. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 SIMULTANEOUS AXIS MOVE CONTROL OF APPROACH AND RETURN RELIEF 472. . . . . . .

6.1.1 Setting of Parameter 472. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Specification of Move Order at the Time of the Approach 472. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.3 Type of NC Data 472. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 SPINDLE POSITIONING METHOD 473. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–6

Page 8

B–61804E–2/05

T ABLE OF CONTENTS

7. IN–FEED MACHINING IN C–AXIS FACE MILLING PROCESS 474. . . . . . . . . . . . . . . . . .

7.1 FIGURE DEFINITION 475. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 MACHINING DEFINITION 476. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 SYSTEM PARAMETERS 478. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 MTF 478. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 TOOL PATH DRAWING 479. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IX. Y–AXIS FAPT FUNCTION

1. OVERVIEW 485. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 DRILLING 486. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 MILLING 487. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 ROTATING THE MACHINING PLANE 489. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. PART FIGURE DEFINITION (MENU 2) 490. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 SPECIFYING A Y–AXIS MACHINING PROFILE 491. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 SPECIFYING THE Y–AXIS FIGURE DATA 493. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. SPECIFYING HOME AND INDEX POSITIONS (MENU 3) 511. . . . . . . . . . . . . . . . . . . . . . .

4. DEFINING MACHINING (MENU 4) 512. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 MACHINING DEFINITION MENU 513. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 TOOL DATA 515. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 CUTTING AREA 517. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 CUTTING CONDITIONS 518. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. ANIMATED SIMULATION (MENU 6) 536. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. SYSTEM PARAMETERS 539. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. NC MACHINE TOOL FILE (MTF) 545. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 SETTING MTF PARAMETERS WHEN THE Y–AXIS FAPT FUNCTION IS SUPPORTED 554. . . .

8. NOTES 558. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X. BACK MACHINING FAPT

1. OUTLINE 561. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. SPECIFICATIONS 562. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 PROGRAMMING 563. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Material Data Input (Menu No.1) 563. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Part Figure Input (Menu No.2) 563. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3 Home Position and Turret Index Position (Menu No.3) 564. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.4 Machining Definition (Menu No.4) 564. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.5 NC Data Preparation (Menu No.5) 568. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.6 Animation Drawing (Menu No.6) 569. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–7

Page 9

T ABLE OF CONTENTS

2.2 PARAMETERS, ETC. 570. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 System Parameters 570. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 MTF 571. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.3 Tool Data 573. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 WARNINGS AND CAUTION 574. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–61804E–2/05

3. EXAMPLE OF NC DATA 575. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XI. AUTOMATIC PROCESS DETERMINATION FUNCTION

1. OUTLINE 579. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. EXECUTING AUTOMATIC PROCESS DETERMINATION 581. . . . . . . . . . . . . . . . . . . . . .

2.1 DEFINING A NEW PROCESS 582. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 MODIFYING A DEFINED PROCESS 584. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. SETTING THE MACHINING PROCEDURE 585. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. DETAILS OF AUTOMATIC PROCESS DETERMINATION AND

NOTES ON ITS USE 589. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 AUTOMATIC SELECTION OF A TOOL 590. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 DETERMINING INVERSE PROCESSES

(AUTOMATIC PROCESS DETERMINATION FUNCTION B OPTION) 592. . . . . . . . . . . . . . . . . . . .

4.3 CUTTING DIRECTION 596. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 AREA DIVISION 598. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 RESIDUAL MACHINING AND THREADING 601. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 CENTER DRILLING AND BAR FEEDING 601. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 MULTITIER DRILLING

(B OPTION FOR THE AUTOMATIC PROCESS DETERMINATION FUNCTION) 602. . . . . . . . . . .

4.8 AUTOMATIC PROCESS DETERMINATION FOR A CLOSED FIGURE 615. . . . . . . . . . . . . . . . . . .

4.9 MACHINING FOR WHICH AUTOMATIC PROCESS DETERMINATION

CANNOT BE USED 616. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. SETTING DATA 617. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XII. DOUBLE SIDED MACHINING

1. SYSTEM PARAMETER 622. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. DEFINITION OF BLANK FIGURE 623. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. DEFINITION OF PART FIGURE 624. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. HOME AND INDEX POSITIONS 625. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–8

Page 10

B–61804E–2/05

T ABLE OF CONTENTS

5. PROCESSING DEFINITION 626. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 OUTLINE 627. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 DEFINITION BY MANUAL 628. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Tool Data Screen 629. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Cutting Area Screen 630. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Cutting Condition Screen 630. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 AUTOMATIC PROCESSING DECISION FUNCTION 631. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Processing Area Division Screen 631. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Process Setting Screen 633. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Automatic Processing Decision 633. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.4 Process Area Division 634. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. NC DATA PREPARATION 636. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. MACHINING TIME DISPLAY SCREEN 638. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. SYSTEM PARAMETER 639. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. NOTES 640. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 TOOL DATA 641. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 TOOLING INFORMATION 641. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 RELATION WITH BACK–SIDE MACHINING FAPT 641. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 RELATION WITH 4–AXIS LATH 641. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XIII. ANIMATED SIMULATION FUNCTION II

1. OUTLINE 645. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. FLOW OF ANIMATED SIMULATION 646. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. OPERATION PROCEDURE FOR ANIMATED SIMULATION 647. . . . . . . . . . . . . . . . . . . .

4. ANIMATED SIMULATION SCREENS 648. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 ANIMATED SIMULATION OF TURNING 649. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 ANIMATED SIMULATION WITH GRADATION 650. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 C–AXIS ANIMATED SIMULATION 651. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Y–AXIS ANIMATED SIMULATION 652. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 INTERFERENCE CHECK FUNCTION 653. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 ANIMATED SIMULATION FOR TWO–PATH LATHE 654. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 SOFT KEYS 655. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. SYSTEM PARAMETERS 656. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. SUPPLEMENT 657. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–9

Page 11

T ABLE OF CONTENTS

B–61804E–2/05

APPENDIX

A. SETTING DATA, SYSTEM PARAMETER, MTF 661. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 SETTING DATA TABLE 662. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 SYSTEM PARAMETER T ABLE 668. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3 MACHINE TOOL FILE (MTF) TABLE 695. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4 FUNCTION TABLE (MTF 2000S) 704. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4.1 Outline 704. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4.2 Function Code 709. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4.3 Size of Function Table 720. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4.4 Reference of Function Table 725. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4.5 Referencing an Optional Function Table 740. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.5 ERROR MESSAGES 744. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.5.1 Errors Common to All Screens 744. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.5.2 Errors at Defining Figures (Menu 2) 745. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.5.3 Errors at Machining Definition (Menu 4) and NC Data Preparation (Menu 5) 746. . . . . . . . . . . . .

A.5.4 Errors at Animation Drawing (Menu 6) 746. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.5.5 Errors at Accessing the Sub–memory 747. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.5.6 Others 748. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. RESTRICTIONS ON EACH SYSTEM 749. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 MACHINING DEFINITION FOR 5700 SERIES 752. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.1 Machining Definition of Turning 752. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.1.1 Selection of kinds of machining 753. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.1.2 Process change and correction 755. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.1.3 Output of only single process 756. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.1.4 T ool data 756. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.1.5 Machining start position 761. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.1.6 Passing point 761. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.1.7 Cutting direction 763. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.1.8 Cutting conditions 764. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.1.9 Cutting area definitions 773. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.2 Cut off Machining, Bar Feed 776. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.2.1 Cut off machining 776. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.2.2 Bar feed 780. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.3 Machining Definition of C–axis Machining 784. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.3.1 Specification of C–axis machining definition 784. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.3.2 Explanatory drawing of cutting conditions 789. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.3.3 Blind hole and through hole 792. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2 AUTOMATIC PROCESS SPECIFICATION FOR 5700 SERIES 793. . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.1 Outline 793. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.2 Operation 793. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.3 Setting 797. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.3.1 Setting data 797. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.3.2 T ool data and tooling information 802. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.4 Cautions and Notes 803. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–10

Page 12

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC units. It is essential that these precautions

be observed by users to ensure the safe operation of machines equipped with a CNC unit (all descriptions in this

section assume this configuration).

Users must also observe the safety precautions related to the machine, as described in the relevant manual supplied

by the machine tool builder. Before attempting to operate the machine or create a program to control the operation

of the machine, the operator must become fully familiar with the contents of this manual and relevant manual

supplied by the machine tool builder.

s–1

Page 13

1

SAFETY PRECAUTIONS

B–61804E–2/05

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the

machine. Precautions are classified into W arning and Caution according to their bearing on safety.

Also, supplementary information is described as a Note. Read the Warning, Caution, and Note

thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

D Read this manual carefully, and store it in a safe place.

s–2

Page 14

B–61804E–2/05

2

SAFETY PRECAUTIONS

GENERAL WARNINGS

WARNING

1.

Before operating the machine, thoroughly check the entered data on the screen. Operating the

machine with incorrect data may result in the tool colliding with the workpiece and/or machine,

possibly causing damage to the machine and/or tool itself, or injury to the user.

2.

When the tool offset function is used, before activating the machine, check the direction and

value of the offset to ensure that the tool will not collide with the workpiece or machine. Any

collision may cause damage to the tool and/or machine, or injury to the user.

3.

Before starting the NC program prepared using the conversational function, thoroughly check

the contents of the NC data to ensure that the tool path and machining processes are set correctly ,

and that the tool will not collide with the workpiece or machine (including the chuck and

tailstock). Before starting a production run, perform a dry run to ensure that the tool will not

collide with the workpiece or machine (including the chuck and tailstock). For example, start

the machining program without mounting a workpiece on the machine. Any collision may cause

damage to the tool and/or machine, or injury to the user.

4.

Before using the conversational function to prepare a machining program, determine whether

the tool data, material data, setting data, system parameters, and MTF data are set as specified

by the machine tool builder. If these data values are not set appropriately, the cutting conditions

necessary for machining may not be set properly , possibly causing damage to the tool, or injury

to the user.

s–3

Page 15

I. GENERAL

Page 16

B–61804E–2/05

1

GENERAL

GENERAL

This manual is for conversational automatic programming function.

The conversational automatic programming function II is software in

which functions of an epoch–making automatic programming system

“Symbolic F APT” are assembled, and this “Symbolic F APT” allows even

unexperienced NC programmers to produce NC data for machining at

once simply by depressing buttons according to the instructions on the

graphic display CRT. The CNC can execute machining according to a

program soon after programming it at a site, or it can execute another

programming during machining.

The Symbolic FAPT produces NC data and loads them into built–in

memory (machining memory). Machining is made according to the NC

data in memory (also called NC program).

During machining, another program can also be produced by using

Symbolic FAPT function. When the machining memory has been

unloaded after machining, another program being prepared at the

automatic programming section is registered to the machining memory.

Since NC data loaded in machining memory are prepared in standard NC

language, an operator who knows the standard NC language can directly

check or modify NC data of standard NC language in machining memory

by using the CRT.

(Since NC data can be registered again to machining memory after

modifying NC data at the automatic programming section without any

need of modifying machining memory data, it is not necessary to modify

machining memory data usually.)

1. GENERAL

3

Page 17

1. GENERAL

GENERAL

B–61804E–2/05

Chapter III describes the programming and operation by Symbolic F APT .

After understanding these description, you can start machining at once,

referring to the machine tool builder’s manual.

4

Page 18

B–61804E–2/05

2

GENERAL

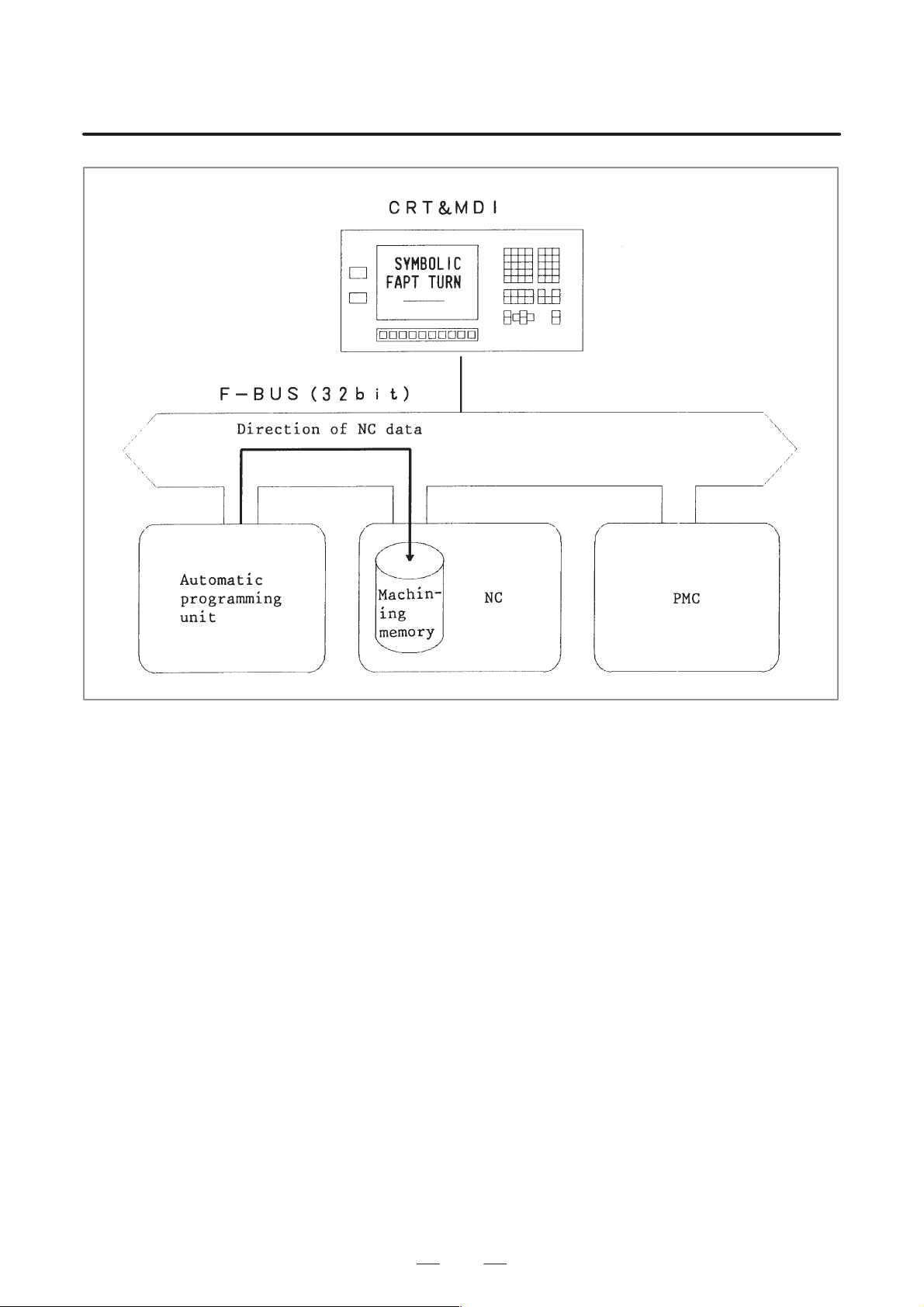

2. CONVERSA TIONAL AUTOMATIC

PROGRAMMING FUNCTION

CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION

(1)The NC data thus produced automatically by Symbolic F APT are not

directly used for machining, but they are once loaded to the machining

memory .

(2) The automatic programming unit is not capable of storing various

information of machine tools and machine control unit.

Note that control information of machine tools can be processed only

in machine control unit.

(3)The machining information can be input to CNC by the following two

methods.

(a) Method of loading automatic programming results into the

machining memory after automatic programming has been made

by using the Symbolic F APT. This is a standard method, which can

be used without any knowledge on NC tape format.

(b)Method of inputting the machining information into the machining

memory of the machine control unit by MDI operation.

Since this operation is the same as in NC unit for ordinary MDI

input, you are requested to be familiar with NC tape format, etc.

5

Page 19

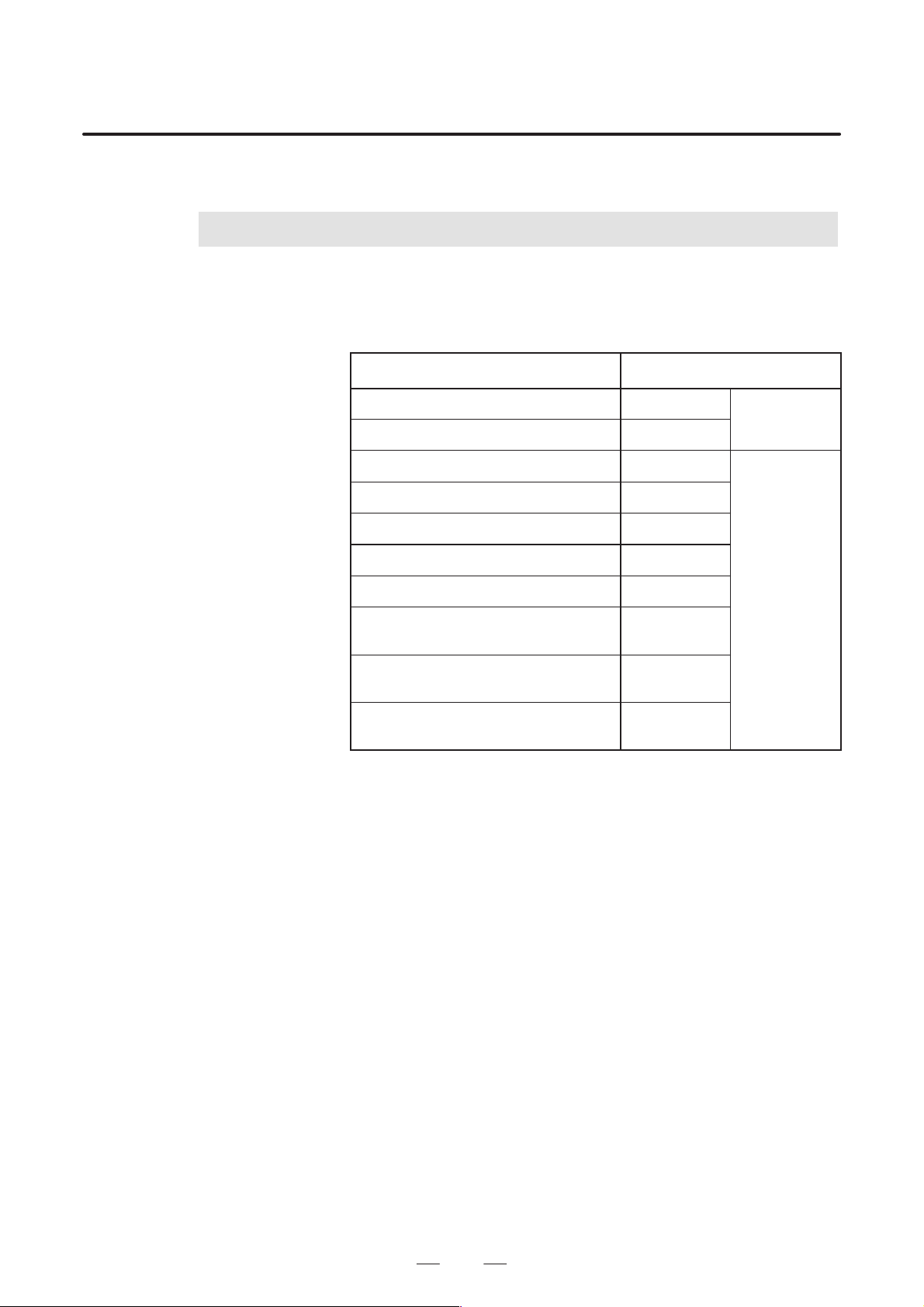

3. NOTES ON READING THIS MANUAL

15–TFB

NOTES ON READING THIS MANUAL

3

The models covered by this manual, and their abbreviations, are:

FANUC Series 15–TFB 15–TFB

FANUC Series 15–TTFB 15–TTFB

FANUC Series 16–TA (CAP II) 16–TA CAP II

FANUC Series 16/18–TB (CAP II) 16–TB CAP II

FANUC Series 16/18–TC (CAP II) 16–TC CAP II

FANUC Series 16i/18i–TA (CAP–II) 16i–TA CAP–II

GENERAL

Name of product Abbreviation

B–61804E–2/05

–

FANUC Series 16–TTA (CAP–II) 16–TTA CAP–II

FANUC Series 16/18–TB

(2–path lathe, CAP II)

FANUC Series 16/18–TC

(2–path lathe, CAP II)

FANUC Series 16i/18i–TA

(2–path lathe, CAP II)

(1)This manual does not cover the functions on the NC side.

(2)The function of an NC machine tool system does not depend only on

the NC, but on the combination of the machine tool, its magnetic

cabinet, servo system, the NC, operator’s panels, etc. It is too difficult

to describe the function, programming, and operation in various

combinations of them. This manual generally describes them from the

standpoint of the NC. So, for a particular NC machine tool, refer to

the manual issued by the machine tool builder, which should take

precedence over this manual.

(3) Notes refer to detailed and specific items. So, when a note will be

encountered, terms used in it sometimes will not have been explained

it. In such a case, first skip the note, then return to it after having read

the manual in outline for details.

(4) For 16–T CAP II, the manual covers only the 5710 system and the

5800 system series and later. The earlier series may not support some

functions described in the manual. See Appendix 2 for the

unsupported functions.

16–TB CAP II

16–TC CAP II

16i–TA CAP II

16–T CAP II

6

Page 20

II. EXPLANATION FOR

CRT/MDI PANEL

Page 21

B–61804E–2/05

1

EXPLANATION FOR CRT/MDI PANEL

EXPLANATION FOR CRT/MDI PANEL

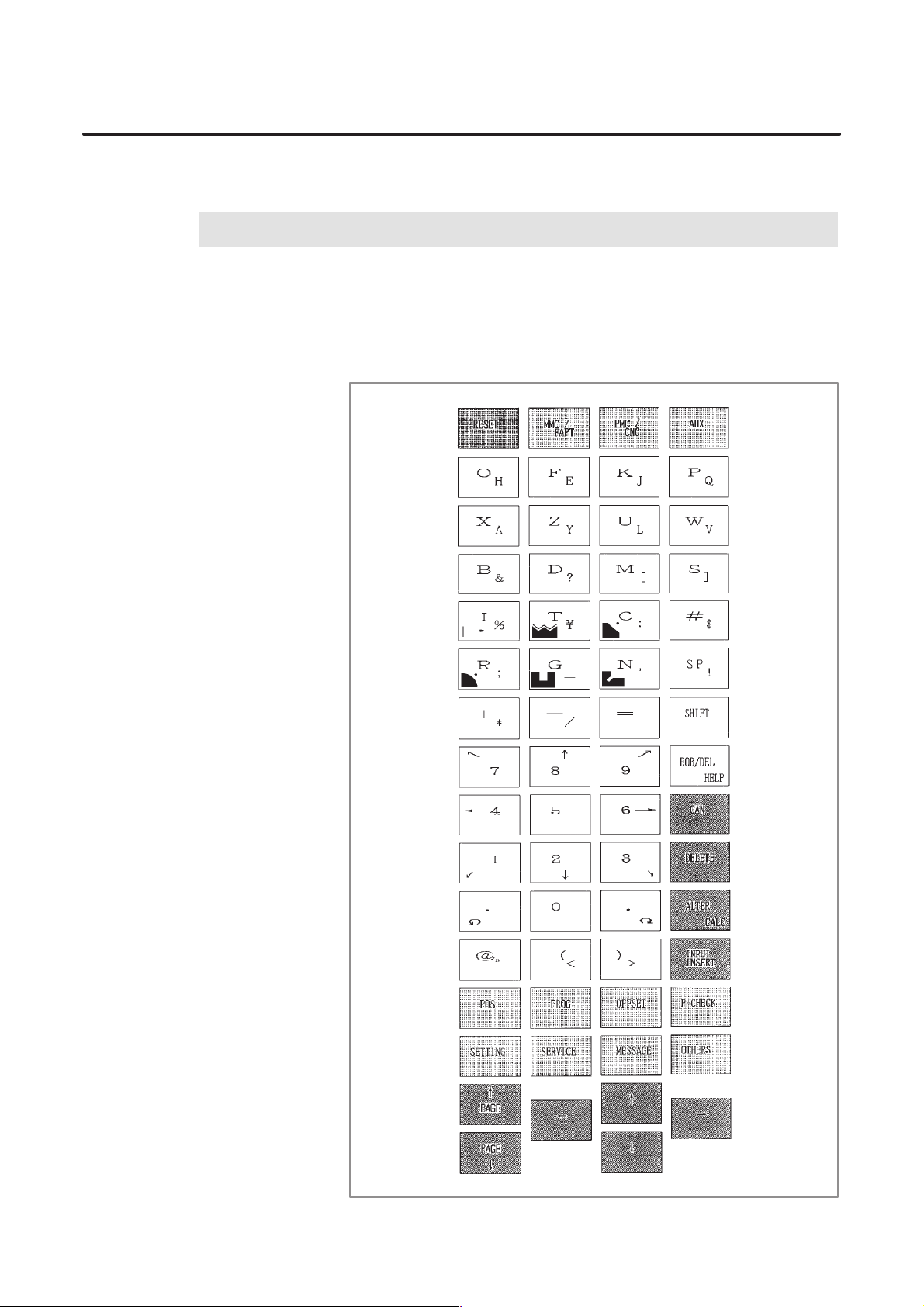

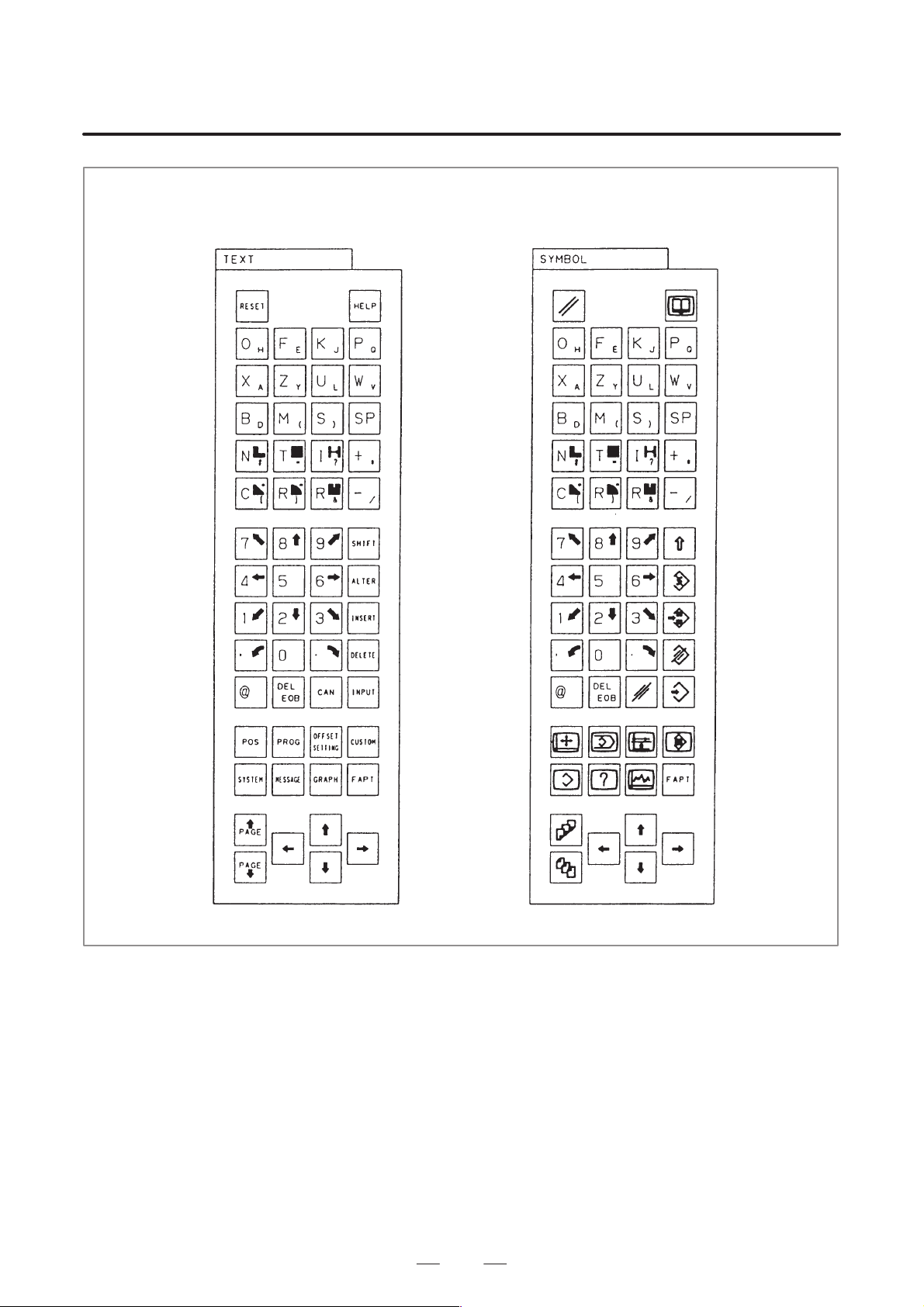

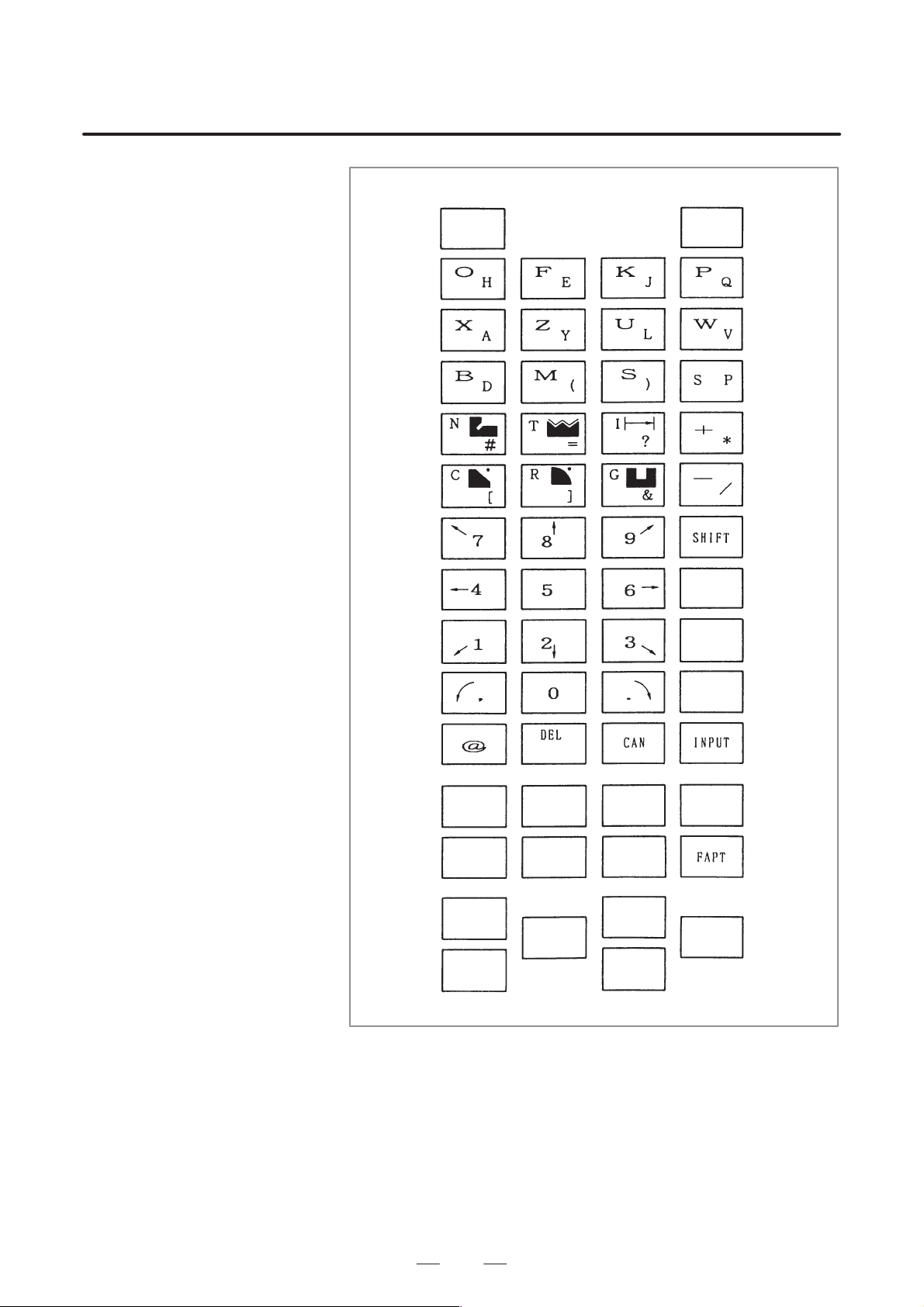

CR T/MDI panel is composed of a 14–inch CRT or 10.4–inch LCD color

graphic display and keys which consist of alphabet, numerics, and the

others. It is as shown below.

1. EXPLANA TION FOR

CRT/MDI PANEL

MDI panel for 15–TFB/15–TTFB

9

Page 22

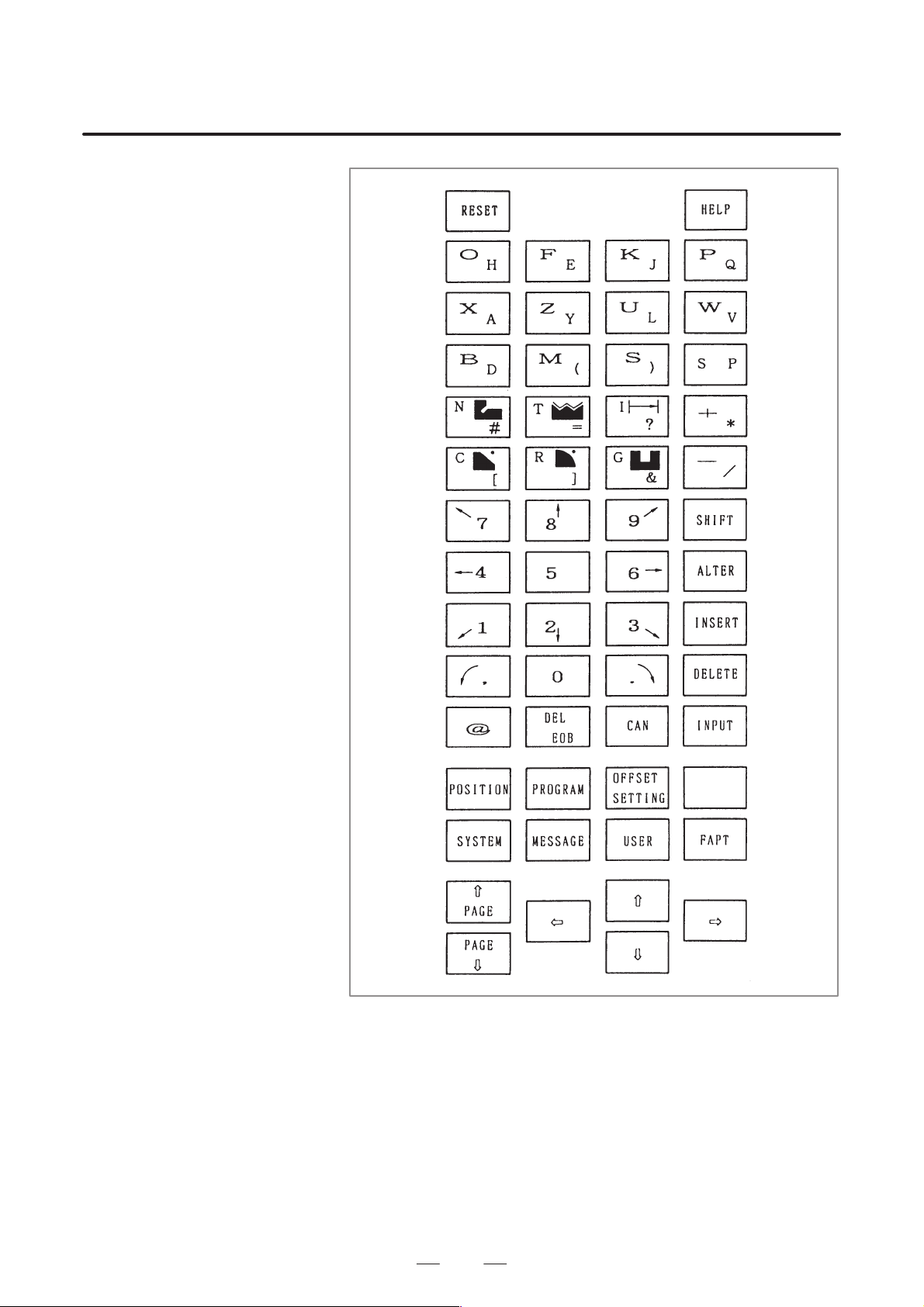

1. EXPLANATION FOR

CRT/MDI PANEL

EXPLANATION FOR CRT/MDI PANEL

B–61804E–2/05

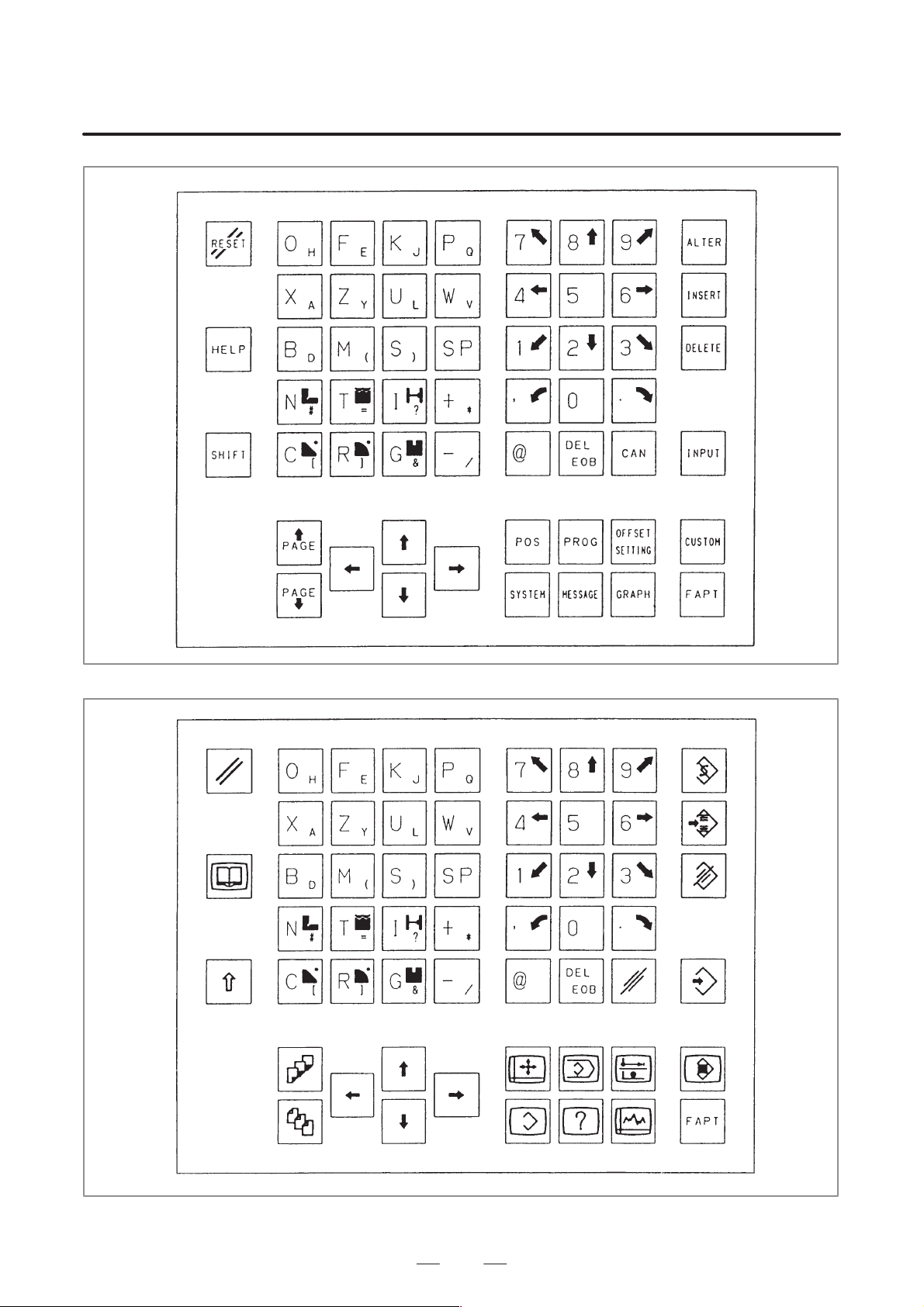

MDI panel for 16–T/16–TT CAP II

10

Page 23

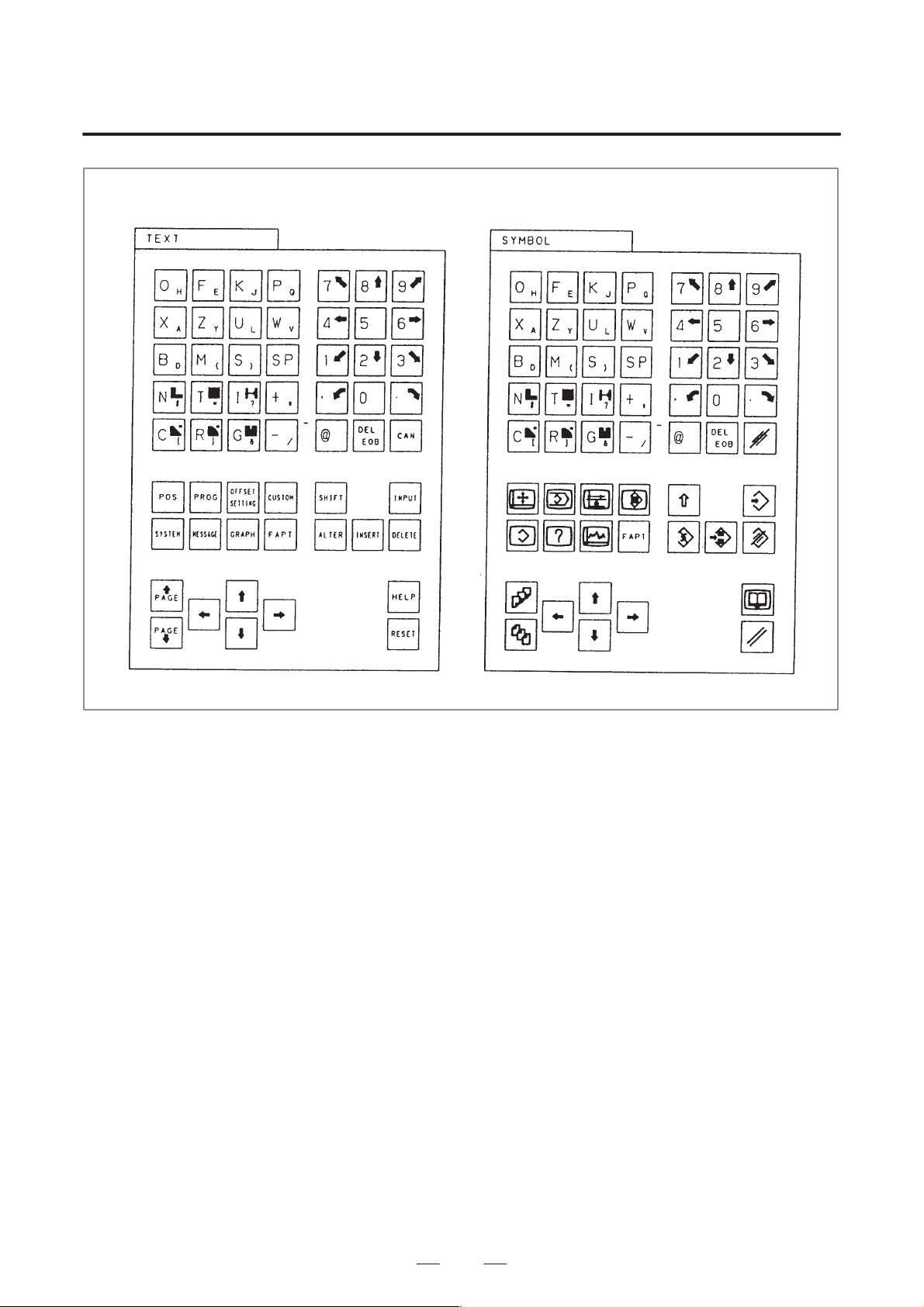

B–61804E–2/05

EXPLANATION FOR CRT/MDI PANEL

Text type Symbol type

1. EXPLANA TION FOR

CRT/MDI PANEL

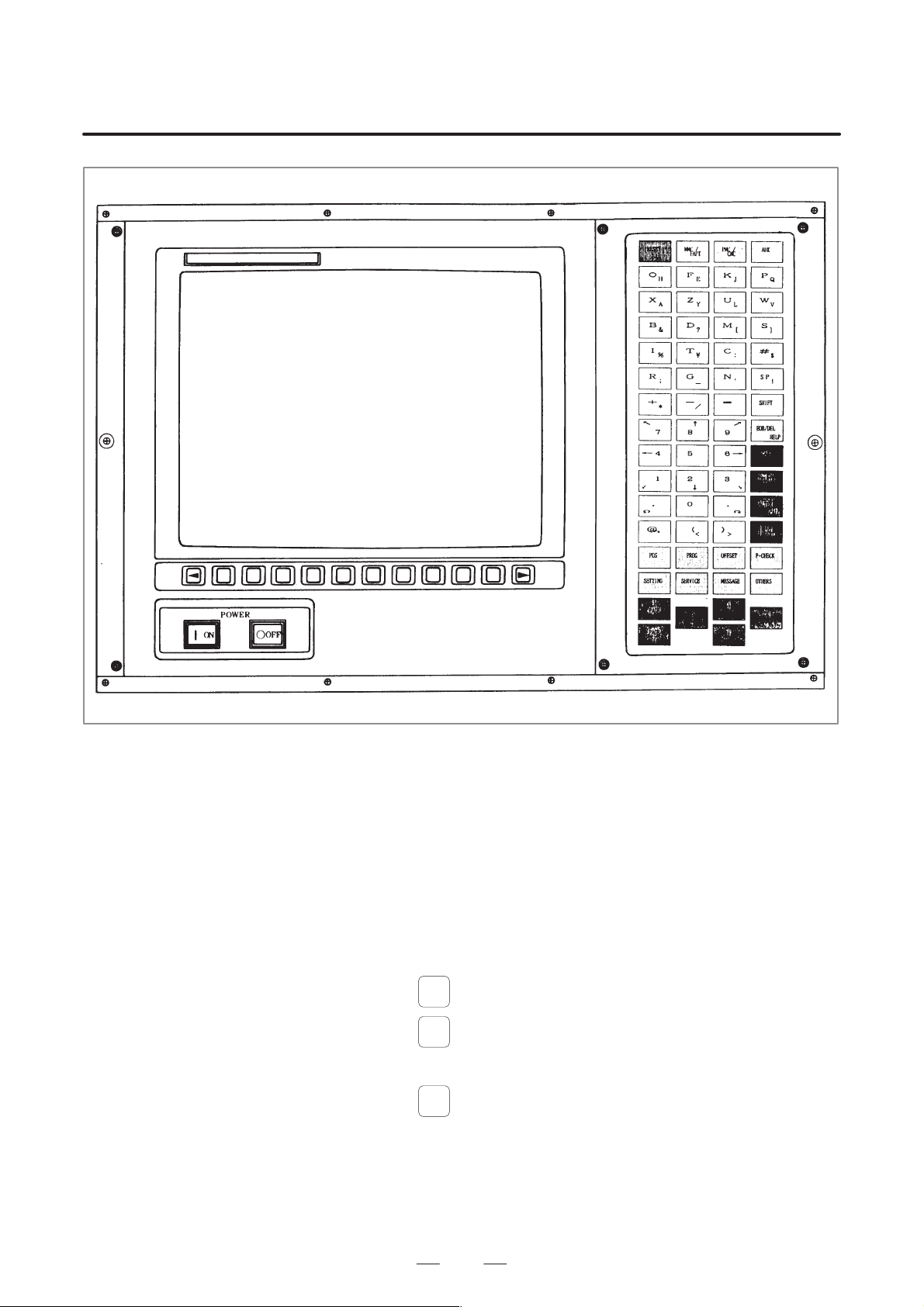

MDI panel for 16–TC/16i–TA CAP II (10.4–inch horizontal type LCD/MDI unit)

11

Page 24

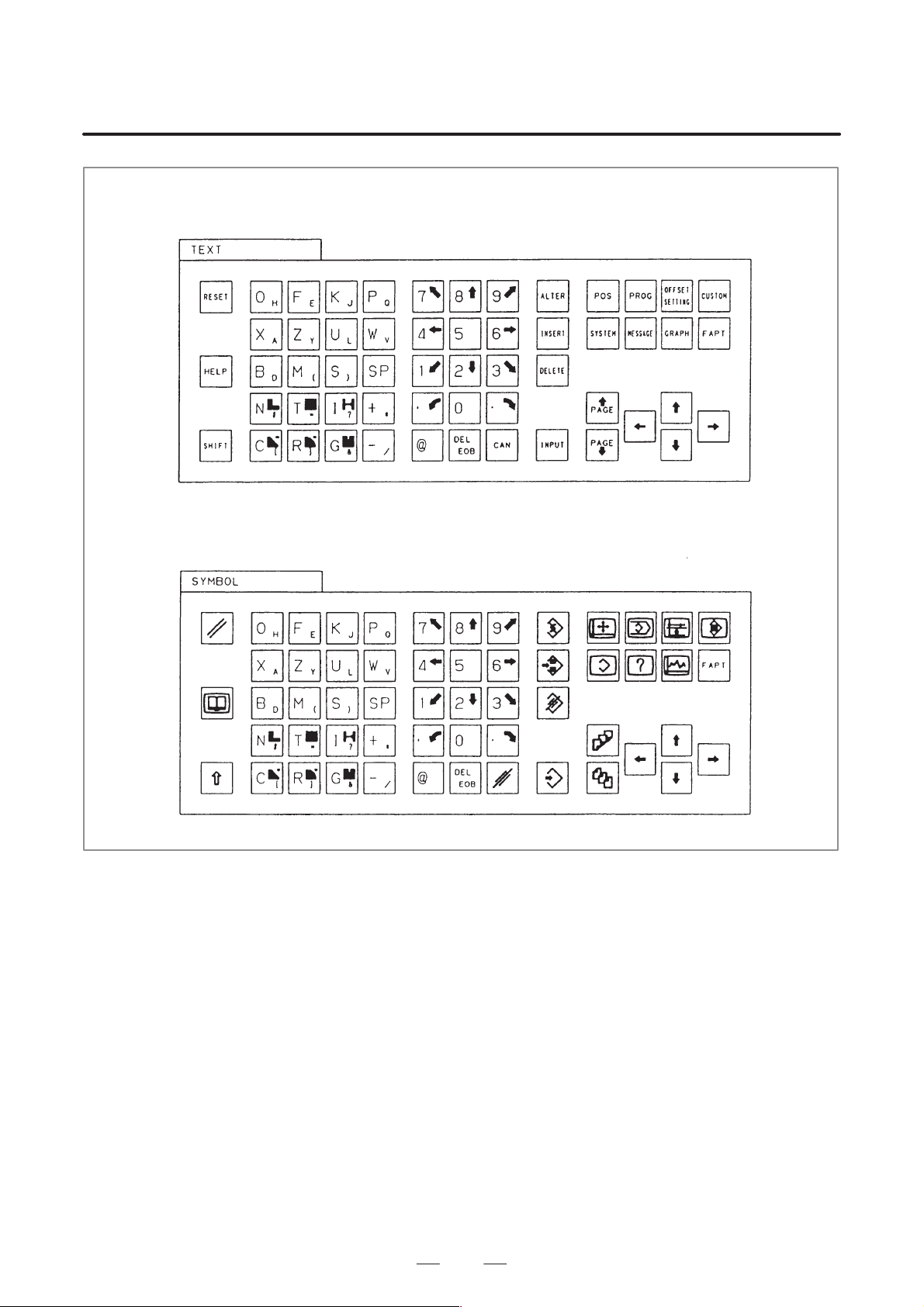

1. EXPLANATION FOR

CRT/MDI PANEL

EXPLANATION FOR CRT/MDI PANEL

Text type

Symbol type

B–61804E–2/05

MDI panel for 16–TC/16i–TA CAP II (10.4–inch vertical type LCD/MDI unit)

12

Page 25

B–61804E–2/05

EXPLANATION FOR CRT/MDI PANEL

Text type Symbol type

1. EXPLANA TION FOR

CRT/MDI PANEL

MDI panel for 16–TC/16i–TA CAP II (14–inch horizontal type CRT/MDI unit)

13

Page 26

1. EXPLANATION FOR

CRT/MDI PANEL

EXPLANATION FOR CRT/MDI PANEL

B–61804E–2/05

MDI panel for 16i–TA CAP II (separate type MDI unit: text type)

MDI panel for 16i–TA CAP II (separate type MDI unit: symbol type)

14

Page 27

B–61804E–2/05

EXPLANATION FOR CRT/MDI PANEL

1. EXPLANA TION FOR

CRT/MDI PANEL

Fig. 1 14–inch color CRT/MDI panel external view

The mode in which the CR T/MDI unit is used for the creation of CNC data

with the Symbolic FAPT is called FAPT mode. The mode in which the

CRT/MDI is used for operations related to the CNC functions, such as

editing of created data, setting and check of various parameters for CNC

machining and tool offset amounts, and check of travel during CNC

machining, is called CNC mode.

T o change the mode of the CRT/MDI unit between F APT and CNC/PMC,

press the mode selector keys with lamps as shown below.

D For 15–TFB

MMC/

When

When

is pressed, FAPT screen is displayed.

FAPT

PMC/

is pressed, CNC screen is displayed.

CNC

D For 16–T CAP II

FAPT

When

is pressed, the FAPT screen is displayed.

To display the CNC screen, press one of the other function keys.

15

Page 28

2. KEYS EFFECTIVE IN

FAPT MODE

KEYS EFFECTIVE IN FAPT MODE

2

EXPLANATION FOR CRT/MDI PANEL

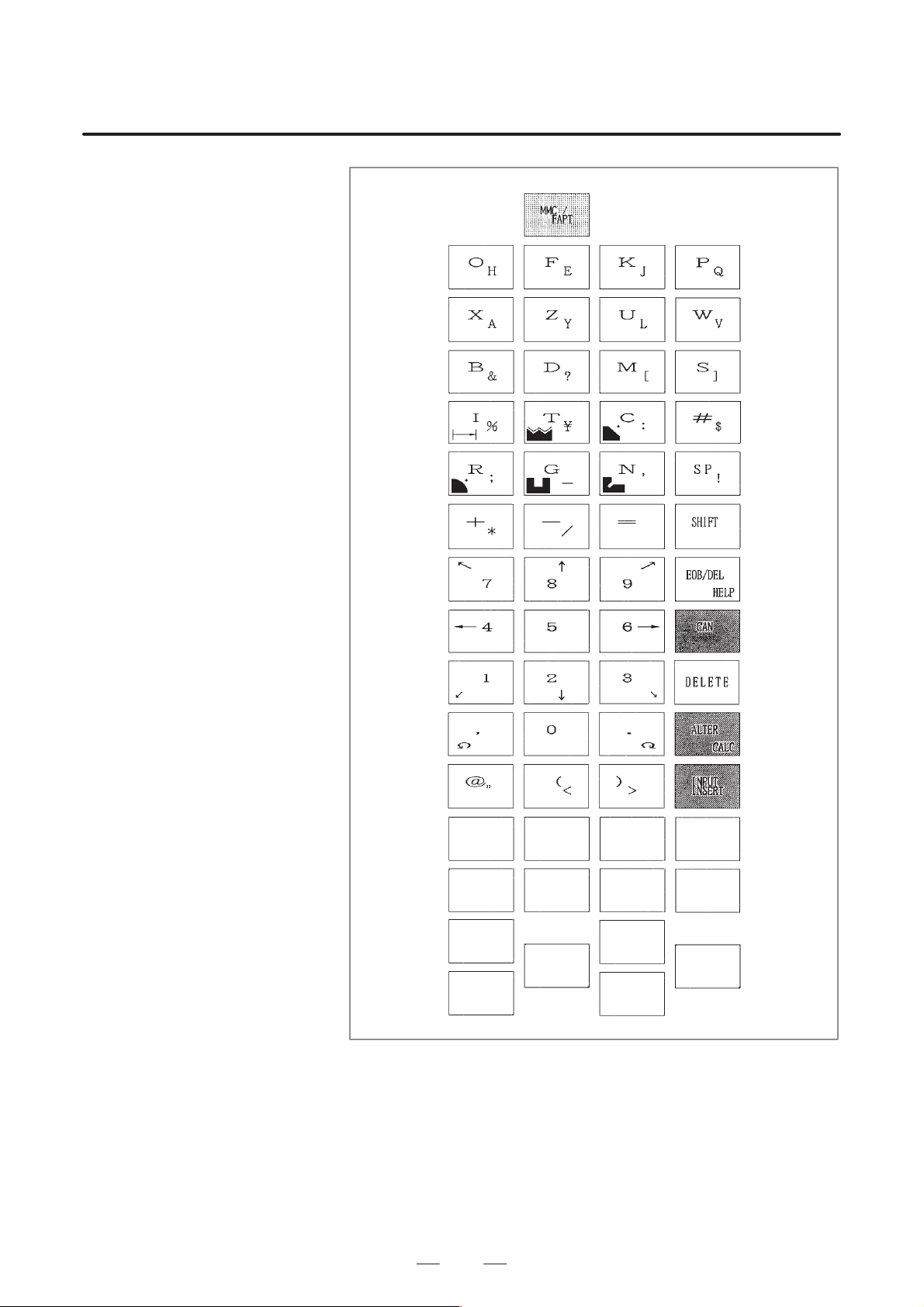

The diagram at under shows only the keys used in the Symbolic FAPT.

The symbols omitted are not used in FAPT mode.

B–61804E–2/05

16

Page 29

B–61804E–2/05

EXPLANATION FOR CRT/MDI PANEL

2. KEYS EFFECTIVE IN

FAPT MODE

17

Fig. 2 (a) 15TFB/TTFB

Page 30

2. KEYS EFFECTIVE IN

FAPT MODE

EXPLANATION FOR CRT/MDI PANEL

B–61804E–2/05

18

Fig. 2 (b) 16T/TT CAP II

Page 31

B–61804E–2/05

EXPLANATION FOR CRT/MDI PANEL

Text type Symbol type

2. KEYS EFFECTIVE IN

FAPT MODE

MDI panel for 16–TC/16i–TA CAP II (10.4–inch horizontal type LCD/MDI unit)

19

Page 32

2. KEYS EFFECTIVE IN

FAPT MODE

EXPLANATION FOR CRT/MDI PANEL

Text type

Symbol type

B–61804E–2/05

MDI panel for 16–TC/16i–TA CAP II (10.4–inch vertical type LCD/MDI unit)

20

Page 33

B–61804E–2/05

EXPLANATION FOR CRT/MDI PANEL

Text type Symbol type

2. KEYS EFFECTIVE IN

FAPT MODE

MDI panel for 16–TC/16i–TA CAP II (14–inch horizontal type CRT/MDI unit)

21

Page 34

2. KEYS EFFECTIVE IN

FAPT MODE

EXPLANATION FOR CRT/MDI PANEL

B–61804E–2/05

MDI panel for 16i–TA CAP II (separate type MDI unit: text type)

MDI panel for 16i–TA CAP II (separate type MDI unit: symbol type)

22

Page 35

B–61804E–2/05

EXPLANATION FOR CRT/MDI PANEL

(1)Keys for parts figure input

Used for increment amount input. (See CHAPTER III,

3.2.3) Can also be used for inputting the alphabet I.

Used when commanding thread. Can also be used for

inputting the alphabet T.

Used when commanding chamfer. Can also be used for

inputting the alphabet C.

Used when commanding rounding. Can also be used

for inputting the alphabet R.

Used when commanding grooving. Can also be used

for inputting the alphabet G.

2. KEYS EFFECTIVE IN

FAPT MODE

Used when commanding neck. Can also be used for inputting the alphabet N.

Called ‘delete key’. This key is used to set undefined

data.

Called the cancel key . Only 1 character is

erased if this key is proceed after inputting

data and before pressing the INPUT key.

To cancel all the data input so far, press

, .

SHIFT

CAN

Arithmetical function keys (The – can also

be used as minus signs).

23

Page 36

2. KEYS EFFECTIVE IN

FAPT MODE

EXPLANATION FOR CRT/MDI PANEL

(2)Other keys

Used when inputting the alphabet at the right bottom of the key.

All the data in the key–in buffer line is cancelled

if is pressed after pressing this key.

CAN

Used to input space.

At–mark key. Pressed before writing the file

name, to display a @, when storing or calling family programs and material files in the sub memory .

Input key. This key is used to write the entered

data into memory.

B–61804E–2/05

24

Page 37

B–61804E–2/05

3

SOFT KEY

EXPLANATION FOR CRT/MDI PANEL

The 12 keys under the CR T are called soft keys. The function of the keys

change according to the screen displayed. The function for each screen

are framed at the bottom of the screen.

3. SOFT KEY

25

Page 38

III. PROGRAMMING AND

OPERATION BY SYMBOLIC FAPT

Page 39

B–61804E–2/05

1

OPERATION BY SYMBOLIC FAPT

SYMBOLIC FAPT

The Symbolic FAPT is an epoch making NC automatic programming

system which enables even unexperienced NC operators to prepare NC

tape immediately according to the instructions on the graphic display

CRT.

Each process from design drawings to NC tape preparation is entirely

advanced by the conversational operation with the graphic display CR T.

For (1) selection of coordinate system by drawing methods (2) selection

of figures of blank and input of dimensions (3) input of parts figures and

dimensions, and (4) selection of machining process and decision or

cutting conditions etc., the operator has only to answer questions from the

CR T.

The parts figure can be input simply by depressing corresponding symbol

keys on the operator’s panel according to the profiles of a workpiece

described on design drawings.

When dimensions and various data are input, various pieces of reference

information are illustrated on the CRT from time to time, and questions

are given to the operator using daily language.

When data are input, the figure of blank and parts profile are drawn

immediately , and automatic calculations of NC command data are started.

The tool path is concurrently displayed as figures.

Unless otherwise specified, this manual uses the screens of the 15–TFB

or 16–T CAP II to describe functions.

PROGRAMMING AND

1. SYMBOLIC FAPT

29

Page 40

2. START OF SYMBOLIC

FAPT PROGRAMMING

START OF SYMBOLIC FAPT PROGRAMMING

2

PROGRAMMING AND

OPERATION BY SYMBOLIC FAPT

CAUTION

After turning on the power, do not touch the keyboard until

the initial FAPT screen is displayed. Some keys are

specifically designed for maintenance or other special

operations; if any of these keys is pressed before the initial

screen is displayed, the machine may behave

unexpectedly.

B–61804E–2/05

The programming by Symbolic FAPT can be started by turning on the

power.

The initial screen is displayed 20 seconds after turning power on.

Symbolic FAPT

side initial screen

(16–T CAP II).

After the “SYSTEM EDITION,” the series/version number will be displayed.

Immediately after the series/version number, the language of the message

currently being displayed will be indicated in English.

V arious jobs are selectable by depressing soft keys, while the initial pattern appears on CRT screen.

[FAPT EXEC] Depress this key for NC programming, while. . . . .

monitoring the CRT screen.

[FAMILY PROGRAM] For calling a family program from. . .

30

submemory, floppy cassette or paper tape,

depress this key.

For using the memory cassette, the memory

cassette adapter is necessary.

For using the paper tape, FANUC PPR is

necessary.

Page 41

B–61804E–2/05

PROGRAMMING AND

OPERATION BY SYMBOLIC FAPT

[DATA SET] This key is used for input/output and setting of. . . . . .

system parameter, machine tool file (MTF),

setting data, material file and tooling data. For

storage of material files and tooling files,the

submemory, the memory cassette or paper tape is

used.

[AUXILIARY] This key is used to initialize sub memory. . . .

“FAPT execution”

2. START OF SYMBOLIC

FAPT PROGRAMMING

Press the “FAPT execution” on the initial screen to allow the FAPT

execution procedures menu to be displayed, By pressing the Software key

“Execution”, programming is initiated according to the procedures.

Correction can be easily made by directly selecting any menu on

correcting programs. For example, press the Software key “2” for

selecting input of final parts figure. Press the “5” for creating the NC data.

However, it is not possible to execute programming in the reverse order,

namely from larger memory number to smaller one.

Press the “End” when the above screen is being displayed to return to the

initial screen.

31

Page 42

3. EXECUTION OF

SYMBOLIC FAPT

EXECUTION OF SYMBOLIC FAPT

3

PROGRAMMING AND

OPERATION BY SYMBOLIC FAPT

It is possible to perform NC programming, monitoring the drawing in the

“F APT” screen. Proceed with programming, monitoring the CR T screen

according to the following procedures:

B–61804E–2/05

32

Page 43

B–61804E–2/05

3.1

BLANK AND DRAWING (DRAWING AND BLANK)

PROGRAMMING AND

OPERATION BY SYMBOLIC FAPT

WARNING

1 Select the same material as that of the workpiece to be

machined. If a desired material option is not displayed on

the material menu, cancel the machining of the workpiece.

Failure to select the correct material may result in the

machining being performed under incorrect cutting

conditions, or the tool colliding with the workpiece and/or

machine, possibly causing damage to the machine and/or

tool itself, or injury to the user.

2 Select the blank figure corresponding to that of workpiece

to be machined. Failure to select the correct figure may

result in the tool colliding with the workpiece and/or

machine, possibly causing damage to the machine and/or

tool itself, or injury to the user.

3 Enter the correct blank dimensional data for the workpiece

to be machined. Failure to enter the correct data may result

in the tool colliding with the workpiece and/or machine,

possibly causing damage to the machine and/or tool itself,

or injury to the user.

3. EXECUTION OF

SYMBOLIC FAPT

Soft key “1”

Go to the screen for the above processes. The meaning of each question

is as follows:

(a)MATERIAL NO MN =. . . . . . . . . . . . . . . . . . . . . . . .

This is a question for selecting the material of blank. Input the number

corresponding to the material NO. For example, key in 4 when

selecting aluminum.

33

Page 44

3. EXECUTION OF

SYMBOLIC FAPT

PROGRAMMING AND

OPERATION BY SYMBOLIC FAPT

B–61804E–2/05

(b)STANDARD SURFACE ROUGHNESS NR =. . . . .

, 2. , 3. , 4. )

(1.

This is a question used to select the surface roughness. Input the

number of

“2” if nearly all areas of machining drawing have

marks on the machining drawing. For example, key in

. It is possible

to skip this question using system parameter No.10.

(c)DRAWING FORMAT DF =. . . . . . . . . . . . . . . . . . .

This question is used to select the drawing format.

When the horizontal figure drawing is performed:

1. 2.

When the vertical figure drawing is performed:

In the case of horizontal drawing, select the drawing format 1 or 3 and

2 or 4 to easily input the dimension data on programming while the

dimension value of drawing is written based on the left and right sides,

respectively. This question can be skipped by setting of the system

parameter No.9.

34

Page 45

B–61804E–2/05

PROGRAMMING AND

OPERATION BY SYMBOLIC FAPT

3. EXECUTION OF

SYMBOLIC FAPT

(d)BLANK FIGURE BF =. . . . . . . . . . . . . . . . . . . . . . .

(1. Cylinder 2. Hollow cylinder 3. Special blank)

This question is used to select the blank figure. Input the number

corresponding to the blank figure. For example, key in 1 to select the

cylinder.

BLANK SIZE

DIAMETER D =. . . . . . . . . . . . . . . . . . . . . .

INNER DIAMETER D0 =. . . . . . . . . . . . . . .

LENGTH L =. . . . . . . . . . . . . . . . . . . . . . . .

The diameter (D) and length of blank (L) are indicated.

In the case of hollow cylinder, the inner diameter (D0) is also

displayed.

BASE LINE ZP=. . . . . . . . . . . . . . . . . . . . . . . . . . .

It is used to specify at which part of blank the coordinate system (X

axis) to be programmed exists.

SURPLUS THICKNESS TX =. . . . . . . . . . . . . . . . .

TZ =

If a special blank is selected as blank figure, the X and Y components

of surplus thickness are displayed.

When data is input to the TX and TZ, it is assumed that the blank has

a constant surplus thickness. When nothing is input to the TX and TZ,

it is possible to define a free blank figure. The definition method is

described in the following item of Blank and Part (Part Figure).

DEPTH OF CHUNKING ZC =. . . . . . . . . . . . . . . . .

Input the data to determine the drawing position of chuck when the

animation drawing function option is provided. See “Chapter 3

Section 3.6 Check of NC data (animation drawing function)” for

details.

Insert the “, ” mark between data on inputting data to allow plural

number of data to be input simultaneously.

Example)

Input as in the following to to allow several data to be input

simultaneously when BF=1, L=100, D=150, and ZP=5 are input:

BF=1, 100, 150, 5

“INPUT”

Meaning of software key

[ESCAPE] It is used to return to the menu screen.. .

[HELP] It is displayed when each question regarding the. . . . .

drawing format, blank figure, blank size, position of

base line is asked.

Press this key when the meaning of each question is

unknown.

Then the following screen appears:

35

Page 46

3. EXECUTION OF

SYMBOLIC FAPT

PROGRAMMING AND

OPERATION BY SYMBOLIC FAPT

When it is pressed in the case of drawing format question:

In the case of horizontal drawing:

B–61804E–2/05

In the case of vertical drawing:

When it is pressed in the case of question for blank format, blank size, or

position of base line:

In the case of horizontal drawing:

36

Page 47

B–61804E–2/05

PROGRAMMING AND

OPERATION BY SYMBOLIC FAPT

In the case of vertical drawing:

[MAT.NAME] Press this software key to see the name of 18th. .

material or thereafter while 18 or more blank

materials are registered.

[CURSOR ±] The cursor moves in forward direction.. . .

[CURSOR ´] The cursor moves in backward direction.. . .

3. EXECUTION OF

SYMBOLIC FAPT

[NEXT PAGE] The next screen appears. If the input data contradicts. .

or there PAGE are undefined data, the following

message is displayed and it is no t po s si bl e t o move to

the next page: “KEY IN AGAIN”

NOTE

Normally, the next screen is automatically displayed when

all questions are answered on one screen. Press the

“NEXT P AGE” if it is not required to answer all questions or

data has been input to all questions. Also, it is possible to

allow the screen to keep being displayed for several

seconds after answering all questions or to disable

advancing to the next screen.

When the standard surface roughness or drawing format is

fixed, it is possible to skip these questions. See “Chapter

7 section 1.1” for the method of skipping the questions.

Set the system parameter No.19 to determine either of

horizontal or vertical drawing.

37

Page 48

3. EXECUTION OF

SYMBOLIC FAPT

3.2

BLANK AND PART (PART FIGURE)

PROGRAMMING AND

OPERATION BY SYMBOLIC FAPT

WARNING

1 After entering part figure data, check the entered data.

Failure to enter correct data may result in the tool colliding

with the workpiece and/or machine, or forced machining

occurring, possibly causing damage to the workpiece,

machine, and/or tool itself, or injury to the user.

2 For a conversational program for which machining process

data has been prepared, if part figure data is modified, the

cutting area specified in the machining definition may be

changed. Operating the machine based on NC data in

memory , with an incorrect cutting area specified, may result

in the tool colliding with the workpiece and/or machine,

possibly causing damage to the machine and/or tool itself,

or injury to the user.

B–61804E–2/05

CAUTION

1 When entering threading data, check the data that is

automatically calculated by pressing the [OUTER

THREAD], [INNER THREAD], or [SQUARE THREAD] soft

key. If this data is incorrect, the workpiece cannot be

machined properly.

2 Check the figure data that is automatically inserted by the

batch input function for chamfering/corner R. If this data is

incorrect, the workpiece cannot be machined properly.

3 Check the figure data that is automatically created by the

pattern figure input function. If this data is incorrect, the

workpiece cannot be machined properly.

4 Check the data that is automatically set by the neck corner

input function. If this data is incorrect, the workpiece cannot

be machined properly.

38

Page 49

B–61804E–2/05

PROGRAMMING AND

OPERATION BY SYMBOLIC FAPT

3. EXECUTION OF

SYMBOLIC FAPT

3.2.1

Drawing of Program Coordinate System and Blank Figure

The coordinate axis and blank figure matching the drawing format

previously selected are drawn on the screen.

D The blank is plotted by a dotted line.

D The left end of the blank is plotted by a solid line to indicate the chuck

side.

D The blank is automatically scaled so that it is accommodated with the

screen, irrespective of its dimensions.

The system requests you to input the part figure by the following display

in conversational area on the CRT screen.

3.2.2