Page 1

SERVICE MANUAL

RevisionE Color Ink jet Printer

EPSON WF-R8590

EPSON WF-R8591

EPSON WF-R8593

CONFIDENTIAL

SEMF14-006

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or

by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of

SEIKO EPSON CORPORATION.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be

detected, SEIKO EPSON would greatly appreciate being informed of them.

The contents of this manual are subject to change without notice.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this

manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

Note :Other product names used herein are for identification purpose only and may be trademarks or registered

trademarks of their respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2016 SEIKO EPSON CORPORATION

Printer CS Quality Assurance Department

Confidential

Page 3

Safety Precautions

All safety procedures described here shall be strictly adhered to by all parties servicing and maintaining this

product.

DANGER

Strictly observe the following cautions. Failure to comply could result in serious bodily injury or loss of life.

1. Always disconnect the product from the power source and peripheral devices when servicing the product or

performing maintenance.

2. When performing works described in this manual, do not connect to a power source until instructed to do so.

Connecting to a power source causes high voltage in the power supply unit and some electronic components

even if the product power switch is off. If you need to perform the work with the power cable connected to a

power source, use extreme caution to avoid electrical shock.

WARNING

Strictly observe the following cautions. Failure to comply may lead to personal injury or loss of life.

1. Always wear protective goggles for disassembly and reassembly to protect your eyes from ink in working. If

any ink gets in your eyes, wash your eyes with clean water and consult a doctor immediately.

2. When using compressed air products; such as air duster, for cleaning during repair and maintenance, the use

of such products containing flammable gas is prohibited.

PRECAUTIONS

Strictly observe the following cautions. Failure to comply may lead to personal injury or damage of the product.

1. Repairs on Epson product should be performed only by an Epson certified repair technician.

2. No work should be performed on this product by persons unfamiliar with basic safety knowledge required for

electrician.

3. The power rating of this product is indicated on the serial number/rating plate. Never connect this product to

the power source whose voltages is different from the rated voltage.

4. Replace malfunctioning components only with those components provided or approved by Epson;

introduction of second-source ICs or other non-approved components may damage the product and void any

applicable Epson warranty.

5. In order to protect sensitive microprocessors and circuitry, use static discharge equipment, such as anti-static

wrist straps, when accessing internal components.

6. Do not tilt this product immediately after initial ink charge, especially after performing the ink charge several

times. Doing so may cause ink to leak from the product because it may take some time for the waste ink pads

to completely absorb ink wasted due to the ink charge.

7. Never touch the ink or wasted ink with bare hands. If ink comes into contact with your skin, wash it off with

soap and water immediately. If you have a skin irritation, consult a doctor immediately.

Confidential

Page 4

8. When disassembling or assembling this product, make sure to wear gloves to avoid injuries from metal parts

with sharp edges.

9. Use only recommended tools for disassembling, assembling or adjusting the printer.

10. Observe the specified torque when tightening screws.

11. Be extremely careful not to scratch or contaminate the following parts.

Nozzle plate of the print head

CR Scale

PF Scale

ASF Scale

Coated surface of the PF Roller

Gears

Rollers

LCD

Scanner Sensor

Exterior parts

12. Never use oil or grease other than those specified in this manual. Use of different types of oil or grease may

damage the component or give bad influence on the printer function.

13. Apply the specified amount of grease described in this manual.

14. Make the specified adjustments when you disassemble the printer.

15. When cleaning this product, follow the procedure described in this manual.

16. When transporting this product after filling the ink in the print head, pack the printer without removing the

ink pack in order to prevent the print head from drying out. In addition, make sure to secure the CR Unit with

tape before packing the printer "5.2 Protection for Transportation (p330)".

17. Make sure to install antivirus software in the computers used for the service support activities.

18. Keep the virus pattern file of antivirus software up-to-date.

Confidential

Page 5

About This Manual

This manual, consists of the following chapters, is intended for repair service personnel and includes information

necessary for properly performing maintenance and servicing the product.

CHAPTER 1. TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 2. DISASSEMBLY / REASSEMBLY

Describes the disassembly/reassembly procedures for main parts/units of the product, and provides the

standard operation time for servicing the product.

CHAPTER 3. ADJUSTMENT

Describes the required adjustments for servicing the product.

CHAPTER 4. MAINTENANCE

Describes maintenance items and procedures for servicing the product.

CHAPTER 5. APPENDIX

Provides the following additional information for reference:

• Connector Diagram

• Protection for Transportation

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional information on a specific topic or

to warn of possible danger present during a procedure or an action. Pay attention to all symbols when they are

used, and always read explanation thoroughly and follow the instructions.

Indicates an operating or maintenance procedure, practice or condition that, if not strictly observed,

could result in serious injury or loss of life.

Indicates an operating or maintenance procedure, practice, or condition that, if not strictly observed,

could result in bodily injury, damage or malfunction of equipment.

May indicate an operating or maintenance procedure, practice or condition that is necessary to

accomplish a task efficiently. It may also provide additional information that is related to a specific

subject, or comment on the results achieved through a previous action.

Confidential

Page 6

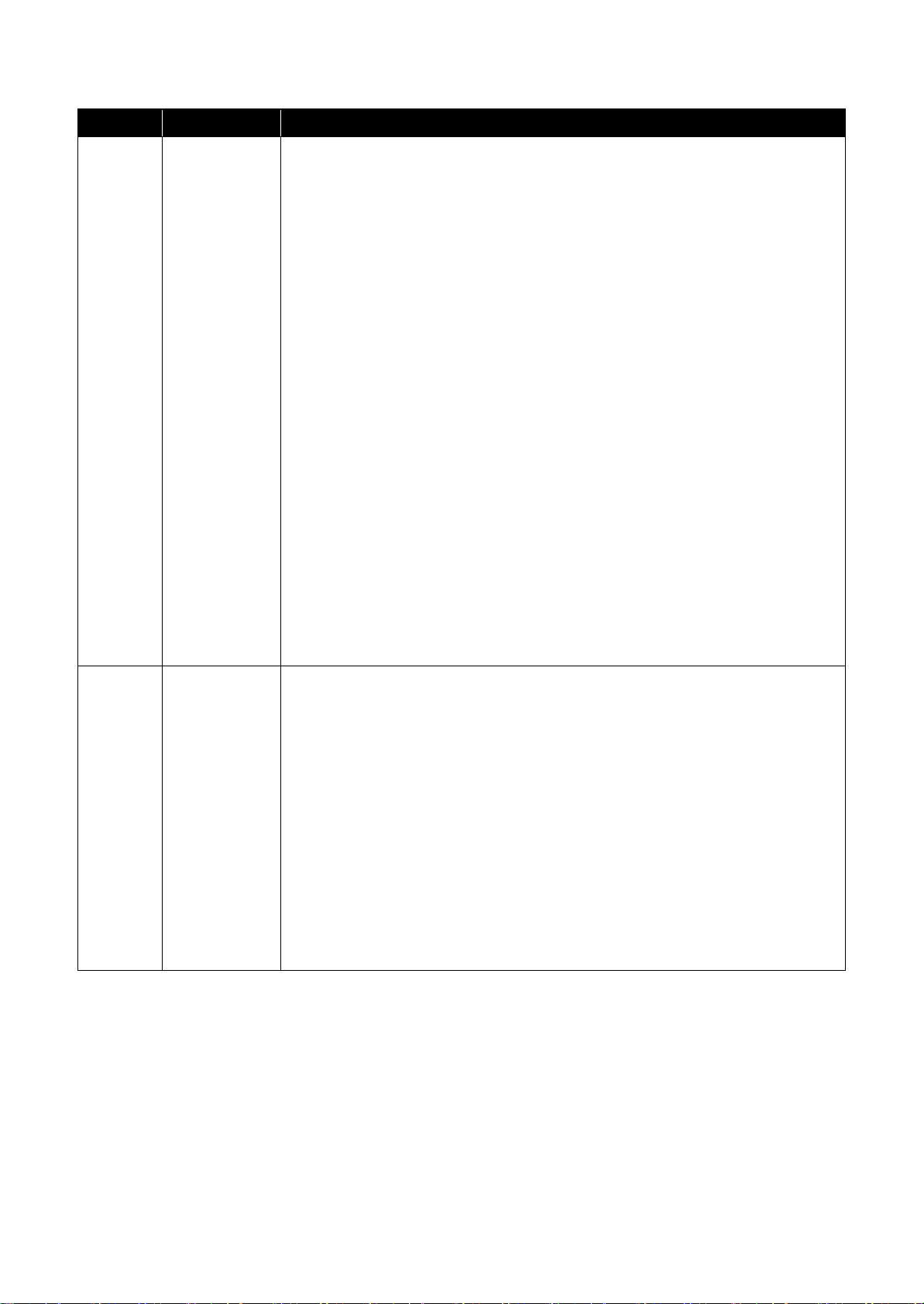

Revision Status

Revision Date of Issue Description

A July 8th, 2014 First Release

B Jan.9h, 2015 Revise content

Chapter 1

1.1.1 Troubleshooting Workflow

1.2 Power-On Sequence

1.3 Fatal Error Code List

Chapter 2

2.1.3 Standard Operation Time for servicing the product

2.3.5.4 Main Board

2.3.6.1 Print Head

2.3.6.16 Cap Unit

2.3.7.6 PF Tension Stopper

2.3.7.7 PF Tension Belt

2.3.7.8 PF Motor Assy

2.3.7.13 Sheet Guide

2.3.8.6 Ink Supply CL Assy

2.3.8.9 Tube

Chapter 3

3.2.1.1 PF Timing Belt Tension Measurement

3.2.1.3 ASF Timing Belt Tension Measurement

3.2.3 Ink Leak Check

3.2.3.2 Ink Lake Measurement jig 1

3.2.4 Head Angular Mecha Adjustment

3.2.5 SMAP Run out Adjustment

Chapter 4

4.3 Initialization of Password

C Jun 20,2015

Revise Content

Chapter 1

Fatal Error Code List (p18)

Chapter 2

Disassembly and Assembly Procedure (p59)

Chapter 3

3-3 Required Adjustment List (Adjustment using the Adjustment Program) (2/2) (p275)

Chapter 4

Firmware Update (p317)

Initialization of Password (p318)

Confidential

Page 7

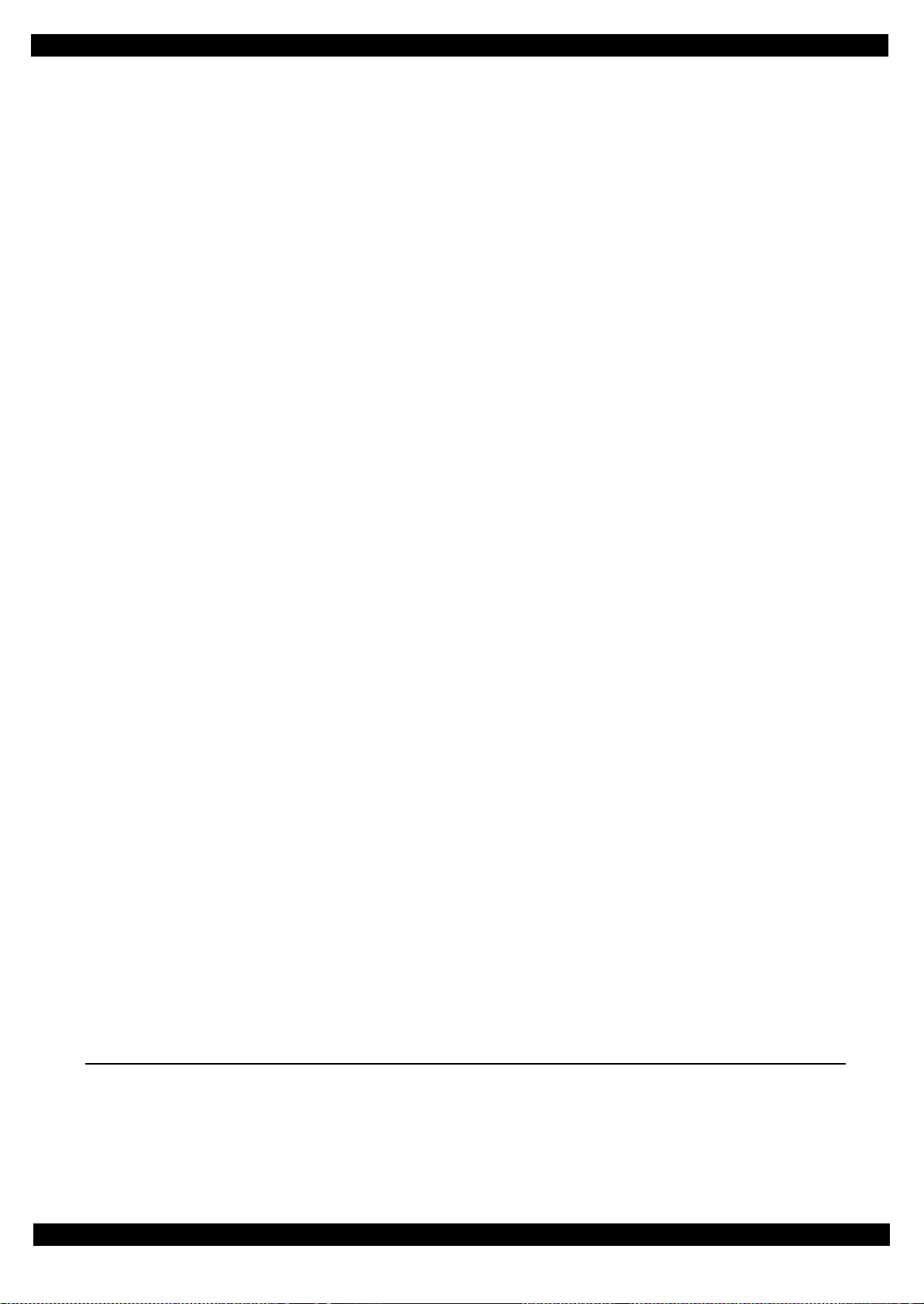

Revision Date of Issue Description

D Dec. 15.2015 Chapter 2

2.1.1 Tools (p.40)

2.1.1.1 Screw types used in the printer (p.41)

2.1.2 Standard Operation Time for servicing the product (p.42)

2.3.1.2 Ink flushing (p.61- p.62)

2.3.1.3 Initial Ink charge (p.62)

2.3.3.14 Front Housing (p.80)

2.3.5.3 Main Board Unit (p.99 - p.101)

2.3.5.8 Power Supply Unit (p.110 - p.111)

2.3.6.1 Print Head (p.113, p.114)

2.3.6.2 CR Waste Ink Pad (p.116)

2.3.6.3 CR Scale

How to install the CR Scale (p.119)

2.3.6.4 PW Sensor (p.120, p.120)

2.3.6.5 Head FFC p.121 - p.127)

2.3.6.7 Taking the ink tubes from the ink supply unit. (p.130 - p.130)

2.3.6.8 CR Unit (p.131, p.131 - p.133)

2.3.6.15 Ink Supply Unit (p.145, p.145 - p.148)

2.3.8.5 Ink Supply BK Assy (p.186)

2.3.8.6 Ink Supply CL Assy (p.188)

2.3.8.7 Ink Pack Holder (BK) (p.192)

2.3.8.8 Ink Pack Holder (Y/M/C) (p.193)

2.3.8.9 Ink Tube (p.194)

2.3.13 Mechanism Unit (p.260)

Chapter 5

5.2.2 Protection of the Ink Supply Needle (p.314)

E Apr. 4.2016 Copyright (p.2)

Chapter 1

Printer fatal error list 0x8A (p.22)

Chapter 2

2.3.1 Preparation for servicing (p.61)

2.3.2.1 Maintenance Box. (p.64)

Chapter 3

Table 3-1 Required Adjustment List (Mechanism adjustment) (p.280)

Table 3-2 Required Adjustment List (Adjustment using the Adjustment Program) (1/2) (p.281)

Table 3-3 Required Adjustment List (Adjustment using the Adjustment Program) (2/2) (p.282)

3.2.4 Head Angular Mecha Adjustment

1.Turn the printer on... (p.306)

12.Turn the printer on... (p.307)

3.2.6 Inspection Mode (p.316)

3.2.6.2 Printer Inspection Mode (p.317)

Confidential

Page 8

Revision Date of Issue Description

F May 24, 2016 Revise the contents.

Chapter 2

Made change description of the disassembly/reassembly procedure in "2.3.6.1 Print

Head (p114)".

Made change description of the disassembly/reassembly procedure in "2.3.6.15 Ink

Supply Unit (p148)".

"2.3.6.19 Print Head / Ink Supply Unit (When the printer cannot perform Ink Flushing

by fatal error) (p168)" is added newly.

Chapter 3

Made change the description of Caution Box in "3.2.2.3 PG adjustment procedure

(p293)".

New procedure is added, and changing the description in "3.2.3 Ink Leak Check

(p296)".

Confidential

Page 9

EPSON WF-R8590 Revision F

Contents

Chapter 1 Troubleshooting

1.1 Troubleshooting....................................................................................................................................................... 14

1.1.1 Troubleshooting Workflow ............................................................................................................................ 14

1.2 Power-On Sequence ................................................................................................................................................ 17

1.3 Fatal Error Code List ............................................................................................................................................... 20

1.3.1 FAX Troubleshooting ..................................................................................................................................... 32

1.3.1.1 FAX Log ................................................................................................................................................ 32

1.3.1.2 Error Code/Superficial Phenomenon-Based Troubleshooting .............................................................. 37

Chapter 2 DISASSEMBLY/REASSEMBLY

2.1 Overview ................................................................................................................................................................. 40

2.1.1 Tools ............................................................................................................................................................... 40

2.1.1.1 Screw types used in the printer .............................................................................................................. 41

2.1.2 Standard Operation Time for servicing the product ....................................................................................... 42

2.2 Parts Diagram .......................................................................................................................................................... 45

2.3 Disassembly and Assembly Procedure.................................................................................................................... 61

2.3.1 Preparation for servicing ................................................................................................................................ 61

2.3.1.1

2.3.1.2 Ink flushing ............................................................................................................................................ 62

2.3.1.3 Initial Ink charge .................................................................................................................................... 63

2.3.2 Consumables/Accessories .............................................................................................................................. 64

2.3.2.1 Maintenance Box ................................................................................................................................... 64

2.3.3 Housing........................................................................................................................................................... 65

2.3.3.1 Front Cover Assy ................................................................................................................................... 65

2.3.3.2 Paper Support Support ........................................................................................................................... 66

2.3.3.3 Stacker Assy .......................................................................................................................................... 66

2.3.3.4 Rear ASF Document Support Cover ..................................................................................................... 67

2.3.3.5 Left ADF Hinge Cover .......................................................................................................................... 67

2.3.3.6 Right ADF Hinge Cover ........................................................................................................................ 68

2.3.3.7 Paper Support......................................................................................................................................... 69

2.3.3.8 Panel Assy.............................................................................................................................................. 70

2.3.3.9 Speaker................................................................................................................................................... 71

2.3.3.10 Front Cover Microswitch ..................................................................................................................... 72

2.3.3.11 Right Upper Front Cover ..................................................................................................................... 73

2.3.3.12 Panel Lower Front Cover..................................................................................................................... 73

2.3.3.13 Panel FFC ............................................................................................................................................ 74

2.3.3.14 Front Housing ...................................................................................................................................... 75

2.3.3.15 Middle Housing ................................................................................................................................... 86

2.3.4 Cover Sensors ................................................................................................................................................. 92

2.3.4.1 Rear Cover Microswitch........................................................................................................................ 92

2.3.4.2 Rear Cover PF Sensor ............................................................................................................................ 93

2.3.4.3 Right Pick Up Roller Sensor.................................................................................................................. 94

2.3.4.4 Left Pick Up Roller Sensor.................................................................................................................... 95

2.3.4.5 Casette Microswitch .............................................................................................................................. 95

2.3.4.6 PE Sensor ............................................................................................................................................... 96

2.3.5 Electric Circuit Components .......................................................................................................................... 97

2.3.5.1 USB/FAX Cover .................................................................................................................................... 97

2.3.5.2 USB Connector Assy ............................................................................................................................. 98

2.3.5.3 Main Board Unit .................................................................................................................................... 99

Unlocking the CR Unit ......................................................................................................................... 61

9

Confidential

Page 10

EPSON WF-R8590 Revision F

2.3.5.4 Main Board .......................................................................................................................................... 107

2.3.5.5 Interface Board .................................................................................................................................... 108

2.3.5.6 Wireless LAN Module ......................................................................................................................... 109

2.3.5.7 CSIC Board (BK)................................................................................................................................. 110

2.3.5.8 Power Supply Unit ............................................................................................................................... 111

2.3.6 Carriage Mechanism/ Ink System Mechanism............................................................................................. 114

2.3.6.1 Print Head ............................................................................................................................................ 114

2.3.6.2 CR Waste Ink Pad ................................................................................................................................ 119

2.3.6.3 CR Scale .............................................................................................................................................. 120

2.3.6.4 PW Sensor............................................................................................................................................ 123

2.3.6.5 Head FFC ............................................................................................................................................. 124

2.3.6.6 CR Motor ............................................................................................................................................. 131

2.3.6.7 Taking the ink tubes from the ink supply unit. ...................................... ... ... ... .... ... ... ... ... .... .. 133

2.3.6.8 CR Unit ................................................................................................................................................ 134

2.3.6.9 Decompression Motor Assy................................................................................................................. 141

2.3.6.10 APG Gear Assy.................................................................................................................................. 142

2.3.6.11 APG Sensor........................................................................................................................................ 143

2.3.6.12 APG Motor Assy ............................................................................................................................... 144

2.3.6.13 CR Solenoid Assy .............................................................................................................................. 146

2.3.6.14 Ink End Board .................................................................................................................................... 147

2.3.6.15 Ink Supply Unit.................................................................................................................................. 148

2.3.6.16 Cap Unit ............................................................................................................................................. 157

2.3.6.17 Pump Unit .......................................................................................................................................... 164

2.3.6.18 Waste Ink Joint Tube Assy ................................................................................................................ 166

2.3.6.19 Print Head / Ink Supply Unit

(When the printer cannot perform Ink Flushing by

fatal error) ......................................................................................................................................................... 168

2.3.7 Paper Feed Mechanism................................................................................................................................. 174

2.3.7.1 Rear Cover Assy/Rear Cover Belt ....................................................................................................... 174

2.3.7.2 Rear Cover Control Lever.................................................................................................................... 174

2.3.7.3 Duplex Unit.......................................................................................................................................... 175

2.3.7.4 PF Encoder Sensor Assy ...................................................................................................................... 175

2.3.7.5 Pick Up Roller Motor Assy ................................................................................................................. 176

2.3.7.6 PF Tension Stopper.............................................................................................................................. 178

2.3.7.7 PF Timing Belt..................................................................................................................................... 179

2.3.7.8 PF Motor Assy ..................................................................................................................................... 181

2.3.7.9 PE Sensor ............................................................................................................................................. 182

2.3.7.10 PF Sensor ........................................................................................................................................... 186

2.3.7.11 Star Wheel Assy................................................................................................................................. 187

2.3.7.12 Rear ASF Unit ................................................................................................................................... 188

2.3.7.13 Sheet Guide ........................................................................................................................................ 190

2.3.7.14 Rear ASF Solenoid Assy ................................................................................................................... 191

2.3.7.15 Rear ASF Solenoid Gear Assy........................................................................................................... 192

2.3.7.16 Rear ASF PE Sensor .......................................................................................................................... 193

2.3.8 Ink Supply Mechanism......................................................................................................

2.3.8.1 Ink Supply BK Cover Assy ................................................................................................................. 195

2.3.8.2 Ink Supply CL Cover Assy ................................................................................................................. 197

2.3.8.3 Ink Supply BK Cover Open Sensor..................................................................................................... 199

2.3.8.4 Ink Supply CL Cover Open Sensor ..................................................................................................... 200

2.3.8.5 Ink Supply BK Assy ............................................................................................................................ 201

2.3.8.6 Ink Supply CL Assy............................................................................................................................. 203

2.3.8.7 Ink Pack Holder (BK) .......................................................................................................................... 207

2.3.8.8 Ink Pack Holder (Y/M/C) .................................................................................................................... 208

2.3.8.9 Tube ..................................................................................................................................................... 209

2.3.8.10 CSIC FFC .......................................................................................................................................... 211

2.3.8.11 Relay FFC (BK) ................................................................................................................................. 213

2.3.8.12 Relay FFC (CL) ................................................................................................................................. 214

2.3.9 ADF/ Scanner Unit ....................................................................................................................................... 216

2.3.9.1 ADF/ Scanner Unit .............................................................................................................................. 216

2.3.9.2 ADF Unit ............................................................................................................................................. 218

........................... 195

10

Confidential

Page 11

EPSON WF-R8590 Revision F

2.3.9.3 ADF Cover Assy.................................................................................................................................. 221

2.3.9.4 Rear ADF Cover/ Rear Sub ADF Cover ............................................................................................. 222

2.3.9.5 Front Sub ADF Cover/ Front Main ADF Cover .................................................................................. 223

2.3.9.6 Document Cover Mat Assy.................................................................................................................. 225

2.3.9.7 ADF Pad Assy ..................................................................................................................................... 225

2.3.9.8 ADF Cover Microswitch ..................................................................................................................... 226

2.3.9.9 ADF PF Encoder Sensor ...................................................................................................................... 227

2.3.9.10 ADF LD Assy .................................................................................................................................... 229

2.3.9.11 ADF PF Support Guide...................................................................................................................... 231

2.3.9.12 ADF Side Cover/ ADF Paper End Side Cover .................................................................................. 232

2.3.9.13 ADF PE Sensor A .............................................................................................................................. 233

2.3.9.14 ADF PW Sensor A............................................................................................................................. 235

2.3.9.15 ADF PW Sensor B ............................................................................................................................. 236

2.3.9.16 ADF Document Detection Sensor A ................................................................................................. 237

2.3.9.17 ADF Document Detection Sensor B.................................................................................................. 238

2.3.9.18 Right ADF Hinge ............................................................................................................................... 239

2.3.9.19 Left ADF Hinge ................................................................................................................................. 240

2.3.9.20 Top ADF Document Support Assy.................................................................................................... 241

2.3.9.21 Bottom ADF Document Support ....................................................................................................... 243

2.3.10 Cassette ....................................................................................................................................................... 244

2.3.10.1 Casette Assy....................................................................................................................................... 244

2.3.10.2 Casette End Guide ............................................................................................................................. 244

2.3.11 2nd Cassette................................................................................................................................................ 245

2.3.11.1 2nd Cassette Unit ............................................................................................................................... 245

2.3.11.2 2nd Cassette Assy .............................................................................................................................. 247

2.3.11.3 2nd Cassette Frame Assy................................................................................................................... 247

2.3.11.4 2nd Cassette Drive Assy .................................................................................................................... 251

2.3.11.5 Actuator ............................................................................................................................................. 253

2.3.11.6 Sensor................................................................................................................................................. 254

2.3.11.7 Feed Roller......................................................................................................................................... 256

2.3.12 Option Cassette ........................................................................................................................................... 257

2.3.12.1 OP Casette Unit ................................................................................................................................. 257

2.3.12.2 OP Cassette Assy ............................................................................................................................... 258

2.3.12.3 OP Casette Retard Roller Assy.......................................................................................................... 258

2.3.12.4 OP Cassette End Guide...................................................................................................................... 259

2.3.12.5 OP Cassette Edge Guide Right .......................................................................................................... 259

2.3.12.6 OP Rear Cover Assy .......................................................................................................................... 261

2.3.12.7 Stopper Belt ....................................................................................................................................... 261

2.3.12.8 OP Right Cover.................................................................................................................................. 262

2.3.12.9 OP Left Cover.................................................................................................................................... 262

2.3.12.10 OP Rear Frame Assy........................................................................................................................ 263

2.3.12.11 OP Cassette Drive Assy................................................................................................................... 266

2.3.12.12 OP Rear Cover Open Microswitch .................................................................................................. 268

2.3.12.13 OP Rear Frame Cover Assy............................................................................................................. 268

2.3.12.14 OP Cassette Microswitch................................................................................................................. 271

2.3.12.15 OP Cassette PF Sensor..................................................................................................................... 272

2.3.12.16 OP Cassette Paper Sensor ................................................................................................................ 273

2.3.12.17 OP Cassette Hopper Sensor ............................................................................................................. 274

2.3.13 Mechanism Unit ......................................................................................................................................... 275

2.4 Routing the cables and FFC .................................................................................................................................. 277

2.4.1 Around the Main Board................................................................................................................................ 277

Chapter 3 Adjustment

3.1 Required Adjustments ........................................................................................................................................... 279

3.2 Details of Adjustments .......................................................................................................................................... 283

3.2.1 PF/CR/ASF Timing Belt Tension Measurement .......................................................................................... 283

3.2.1.1 PF Timing Belt Tension Measurement ................................................................................................ 284

3.2.1.2 CR Timing Belt Tension Check........................................................................................................... 286

11

Confidential

Page 12

EPSON WF-R8590 Revision F

3.2.1.3 ASF Timing Belt Tension Measurement ............................................................................................. 287

3.2.2 PG Adjustment ............................................................................................................................................. 289

3.2.2.1 PG Adjustment procedure.................................................................................................................... 289

3.2.2.2 Preparation ........................................................................................................................................... 290

3.2.2.3 PG adjustment procedure ..................................................................................................................... 293

3.2.2.4 Checking the Platen Gap...................................................................................................................... 295

3.2.3 Ink Leak Check............................................................................................................................................. 296

3.2.3.1 Method of using the Leakage Check PET Chip. ................................................................................. 296

3.2.3.2 Method of using the Ink Leak Measurement jig.................................................................................. 298

3.2.4 Head Angular Mecha Adjustment ................................................................................................................ 306

3.2.5 SMAP Run out Adjustment .......................................................................................................................... 309

3.2.6 Inspection Mode ........................................................................................................................................... 316

3.2.6.1 To enter Inspection Mode................................................................................................... 316

3.2.6.2 Printer Inspection Mode....................................................................................................... 317

3.2.6.3 Touch Panel Adjustment...................................................................................................................... 318

3.2.6.4 To exit the Inspection Mode: ............................................................................................................... 321

Chapter 4 Maintenance

4.1 Overview ............................................................................................................................................................... 323

4.1.1 Cleaning ........................................................................................................................................................ 323

4.1.2 Lubrication.................................................................................................................................................... 323

4.2 Lubrication Points and Instructions....................................................................................................................... 324

4.3 Firmware Update ................................................................................................................................................... 326

4.4 Initialization of Password...................................................................................................................................... 327

Chapter 5 Appendix

5.1 Revision FConnector Diagram.............................................................................................................................. 329

5.2 Protection for Transportation ................................................................................................................................ 330

5.2.1 Securing the CR Unit.................................................................................................................................... 330

5.2.2 Protection of the Ink Supply Needle............................................................................................................. 331

12

Confidential

Page 13

CHAPTER 1

TROUBLESHOOTING

Confidential

Page 14

EPSON WF-R8590/WF-R8591/WF-R8593

ADF failure?

Finish

*

Turn on the printer

2

What is returned reason?

Copy an image

Copy an image by ADF

Start

ADF/Scanner

unit failure

Printer failure only

Yes

Yes

Yes

No

Does printer turn on the

power?

Yes

Is Power-on sequence

finished without error?

Yes

No

Is ADF operation finished

without trouble?

Standby condition

Is scanning operation

finished without

trouble?

1

No

Print check pattern

Is printing operation

finished without trouble?

Yes

Yes

Is printing operation

finished without error?

4

No

3

No

5

No

6

No

*: In case of “Not Trouble Found”, check fatal error code.

(p15)

(p15)

(p15)

(p16)

(p16)

(p16)

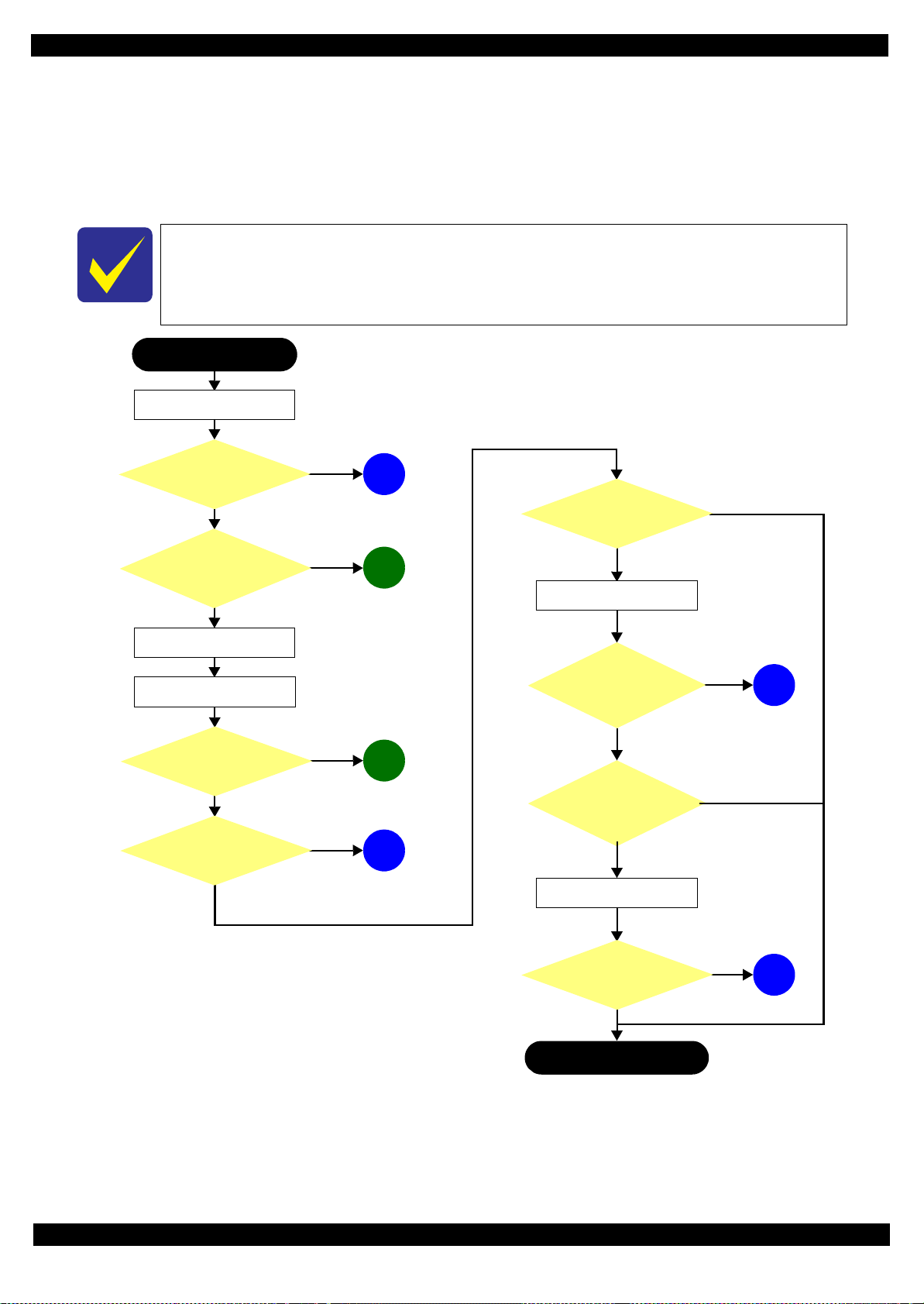

1.1 Troubleshooting

This section describes the troubleshooting workflow.

1.1.1 Troubleshooting Workflow

The following page describes the troubleshooting workflow. Follow the flow when troubleshooting problems.

This flowchart is compiled based on the following contents.

• Our experience regarding the quality problem.

• Printer Mechanism specification for WF-R8590,WF-R8591 and WF-R8593.

When FAX related error occurs, see " 1.3.1 FAX Troubleshooting (p32)".

Revision F

Troubleshooting Troubleshooting 14

Figure 1-1. Troubleshooting Workflow (1)

Confidential

Page 15

EPSON WF-R8590/WF-R8591/WF-R8593 Revision F

The power-on

1

sequence does not

start (p14)

No Power

[Presumable Cause]

• AC cable is unplugged.

• Power shuts down due to

scanner error.

• Power Supply Unit damage

• Main Board damage

• Detection failure of PW Sensor

occurred at power-on.

[Major Troubleshooting]

• Plug AC cable.

• Connect scanner harness.

• Power Supply Unit

replacement

• Main Board replacement

*

*: If the printer can turn on but turns off right away,

the protection circuit may cut off the power due to

an error such as a circuit failure.

Error is indicated during printing nozzle check pattern (p14)

3

LEDs on panel are flashing

[Presumable Cause]

• Wi-Fi connector is unplugged

• Wi-Fi Board damage

[Major Troubleshooting]

• Plug Wi-Fi connector

• Wi-Fi Board replacement

Error is indicated during

2

power-on sequence (p14)

Fatal error

Please refer to

List (p20)"

" 1.3 Fatal Error Code

for troubleshooting.

CR Fixing Tape error

[Occurrence Condition]

This error occurs if a paper jam

occurs during the power-on

sequence before initial ink charge.

[Major Occurrence Timing]

Power-on timing

(before initial ink charge)

[Major Troubleshooting]

Open the front cover and remove

the CR fixing tape.

Maintenance error

[Occurrence Condition]

This error occurs when

maintenance counter in EEPROM

exceeds the specified value.

[Major Occurrence Timing]

• Power-on timing

• Print start timing

• Paper eject timing

• Cleaning timing

• Ink pack replacement timing

[Major Troubleshooting]

• Replace Maintenance Box

No Maintenance Box error

[Occurrence Condition]

This error occurs when

Maintenance Box is not installed.

[Major Occurrence Timing]

• At power-on

• Maintenance Box monitoring

timing

[Major Troubleshooting]

• Turn the printer off once and

install Maintenance Box again,

and turn the power on.

Maintenance Box detection

[Occurrence Condition]

This error occurs when

Maintenance Box data is incorrect

or it is not recognized correctly.

[Major Occurrence Timing]

• Power-on timing

• Maintenance Box replacement

• Maintenance Box monitoring

[Major Troubleshooting]

• Remove and reinstall

• Maintenance Box replacement

• Relay Board CSIC Terminal

• Relay Board Assy replacement

• Relay Board FFC replacement

• Main Board replacement

error

timing

timing

Maintenance Box

replacement

Ink End error

[Occurrence Condition]

This error occurs when ink in Ink

pack is empty.

[Major Occurrence Timing]

• Power-on timing

• Print start timing

• Print timing

• Cleaning timing

• Ink pack replacement timing

[Major Troubleshooting]

Ink pack replacement

[NOTE]

If an error occurs during

printing, the page where the error

occurred is skipped and the

printing resumes from the next

page.

Ink pack detection error

[Occurrence Condition]

This error occurs when Ink pack

data is incorrect or Ink pack is not

recognized correctly.

[Major Occurrence Timing]

• Power-on timing

• Print start timing

• Cleaning timing

• Ink pack replacement timing

[Major Troubleshooting]

• Remove and reinstall Ink pack.

• Ink pack replacement

• CSIC Terminal replacement

• CSIC FFC replacement

• CR Contact Module

replacement

• Main Board replacement

No Ink pack error

[Occurrence Condition]

This error occurs when Ink pack

not installed.

[Major Occurrence Timing]

At power-on

[Major Troubleshooting]

Install Ink pack

Paper Jam error

Please refer to " Paper Jam error".

Cover open error

[Occurrence Condition]

This error occurs when Scanner

Unit (Printer Cover) is open.

[Major Occurrence Timing]

• At power-on

• During printing

[Major Troubleshooting]

• Close Scanner Unit (Printer

Cover) replacement

• Scanner Unit (Printer Cover)

replacement

• Cover Open Sensor

replacement

• Main Board replacement

Paper Jam error

[Occurrence Condition]

This error occurs when top/

bottom of paper is not detected by

PE Sensor or PW Sensor in the

specified steps of paper feeding

operation correctly.

[Major Occurrence Timing]

• Power-on timing

• Paper loading timing

• Paper eject timing

• Duplex print timing

[Major Troubleshooting]

1 Remove the jammed paper by

opening Printer Cover.

2 Push “Start” button.

3 If not resolved by 2), check the

following.

• Foreign material, bits of

paper

• Part come-off

• PE Lever

•PE Sensor

• Main Board

•PW Sensor

[NOTE]

* If an error occurs during

printing, the page where the error

occurred is skipped and the

printing resumes from the next

page.

* If an error occurs during duplex

printing, the following are

performed.

• If an error occurs during the

front face of duplex printing,

the page where the error

occurred and the next page

are skipped and the printing

resumes from the page after

the next.

• If an error occurs during the

back face of duplex printing,

the page where the error

occurred is skipped and the

printing resumes from the

next page.

No Paper error

[Occurrence Condition]

This error occurs when top of

paper is not detected by PE Sensor

in the specified steps of paper

loading operation correctly.

[Major Occurrence Timing]

Paper loading timing

[Major Troubleshooting]

1 Put paper in cassette and push

“START” button.

2 If a paper stops before reaching

PE Sensor, remove it and

check the paper condition.

3 A) If no damage on the paper, set

edge guide correctly after

putting paper in cassette and

push “PRINT” button again.

B) If damage on the paper, check

foreign materials / parts come off / parts transformation in

paper path.

4 If not resolved by 3-A) & 3-B),

check the following.

• Pickup Roller

• Duplex Unit

•PE Sensor

• Main Board

•PF Motor

• Casette Assy

Double Feed error

[Occurrence Condition]

This error occurs on the following

cases.

• A paper is ejected without

printing during paper loading

operation.

• Actual paper length is longer

than theoretical one.

[Major Occurrence Timing]

Paper loading timing

[Major Troubleshooting]

• PE Lever replacement

• PE Sensor replacement

• PW Sensor replacement

• Main Board replacement

No Paper Cassette error

[Occurrence Condition]

This error occurs if one of the

cassettes is not installed.

[Major Occurrence Timing]

Paper loading timing

(Front loading)

[Major Troubleshooting]

Install the Cassette Assy.

Paper Size Unmatch error

[Occurrence Condition]

This error occurs when actual

paper size is not matched to

theoretical one.

[Major Occurrence Timing]

• Duplex print timing

• FAX data print timing

[Major Troubleshooting]

1 Put correct sized paper in

cassette, and push “START”

button.

2 If not resolved by step 1),

check the following points.

• PE Lever

• PE Sensor

• PW Sensor

•Main Board

Manual Tray No Paper error

[Occurrence Condition]

When printing from Manual Tray

(MSF unit), this error occurs if

paper is not loaded at the time of

data transmission.

[Major Occurrence Timing]

Paper loading timing

(Rear loading)

[Major Troubleshooting]

• Put paper in the Manual Tray

(MSF unit).

• PE Sensor replacement

• PE Lever replacement

• Main Board replacement

Manual Feed Request error

[Occurrence Condition]

This error occurs if the printer

cannot receive the manual feed

request.

[Major Occurrence Timing]

Paper loading timing

(Rear loading)

[Major Troubleshooting]

• Send the print data.

• Main Board replacement

Excessive Manual Feed Error

[Occurrence Condition]

This error occurs when the PE

Sensor detects paper before

manual feed or when paper is

inserted too much.

[Major Occurrence Timing]

Print start timing (Rear loading)

[Major Troubleshooting]

• Eject paper with panel

operation, and load paper

again.

• Main Board replacement

• PE Sensor replacement

• PE Lever replacement

Insufficient Manual Feed

[Occurrence Condition]

This error occurs during manual

feed if the PE Sensor detects

paper but the paper is not fed by

auto loading.

[Major Occurrence Timing]

Print start timing (Rear loading)

[Major Troubleshooting]

Eject paper with panel operation,

and load paper again.

error

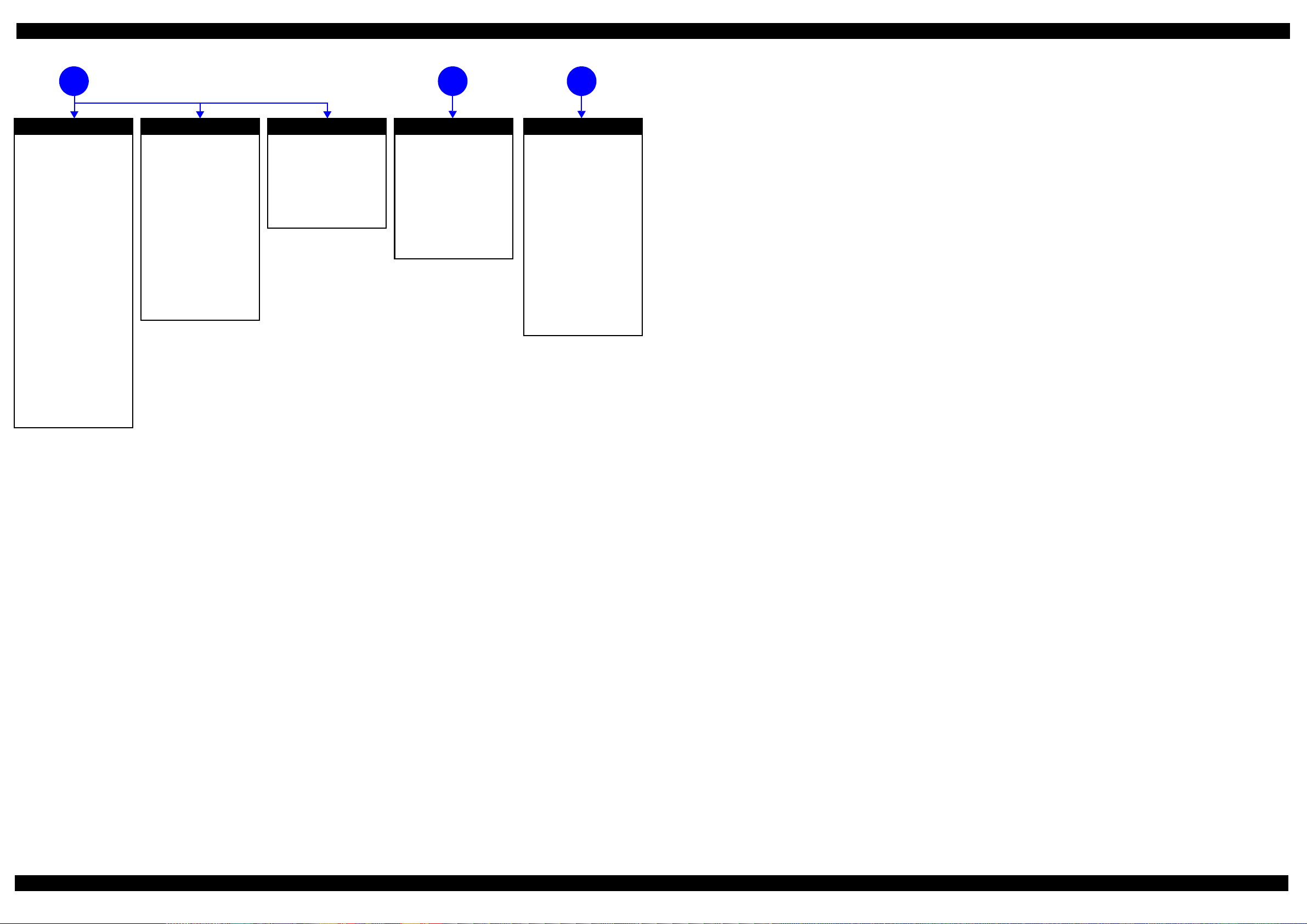

Figure 1-2. Troubleshooting Workflow (2)

15

Confidential

Page 16

EPSON WF-R8590/WF-R8591/WF-R8593 Revision F

Problems related to print result or during printing (p14)

Poor Printing

[Phenomenon]

• Poor printing quality

• Ink stain on paper

• Dot missing

• Paper eject without printing

[Presumable Cause]

• Driver / Panel mis-setting

• Contamination of CR scale

• Contamination of Printhead

Cover

• Printhead damage

• Ink clogging of Printhead

• Contamination on Cap Unit /

Wiper of Ink system Assy

• Ink system Assy damage

• Narrow PG

• PE Lever damage

• PE Sensor damage

• PW Sensor damage

[Major Troubleshooting]

• Driver / Panel re-setting

• CR Scale replacement

• Printhead cover cleaning

• Printhead cleaning

• Ink pack replacement

• Printhead replacement

• Rubber cleaning of Cap Unit of

Ink system Assy

• Ink system Assy replacement

• PG readjustment

• Printer Mechanism

replacement

• PE Lever replacement

• PE Sensor replacement

• PW Sensor replacement

Poor Paper Loading

[Presumable Cause]

• Use of 3rd party media

• Edge guide mis-setting

• Foreign material

• Parts come-off

• Contamination of paper feed

roller (Duplex Unit)

• Cassette Assy damage

• Pickup Roller deterioration,

contamination

• Contamination of PF roller

[Major Troubleshooting]

• Recommendation of EPSON

media

• Edge guide re-setting

• Foreign material removal

• Parts re-installation

• Pick Up Assy replacement

• Cassette Assy replacement

• Printer Mechanism

replacement

• Rear ASF Unit replacement

Abnormal Noise

[Presumable Cause]

• Foreign material

• Insufficient grease

• Gear damage

• Stopper Holder Idle Roller is

installed in a wrong place.

[Major Troubleshooting]

• Foreign material removal

• Lubrication of grease

• Gear replacement

Scanning cannot

be performed

5 64

successfully (p14)

Scanner failure

[Presumable Cause]

• Contamination of Scanner

Glass

• Contamination of Document

Pad

• CIS Unit bonding failure

• CIS Unit damage

• Scanner Motor damage

[Major Troubleshooting]

• Scanner Glass cleaning

• Document Pad cleaning

• Document Pad replacement

• CIS Unit replacement

• Scanner Motor replacement

ADF does

not operate

normally

(p14)

ADF failure

[Phenomenon]

• No paper feed

• Double feed

• Paper jam

• Paper skew

[Presumable Cause]

• Wear of Pickup Roller

• Wear of ADF Pad Assy

• Gear damage

• ADF Motor damage

• Contamination of Scanner

Glass

• Foreign material

• Paper Sheet damage

• ADF Cover Assy damage

• Wear of EJ Roller

• ADF Sensors damage

[Major Troubleshooting]

• ADF Cover Assy replacement

• ADF Pad Assy replacement

• Scanner Glass cleaning

• Foreign material removal

• ADF Unit replacement

Figure 1-3. Troubleshooting Workflow (3)

16

Confidential

Page 17

EPSON WF-R8590/WF-R8591/WF-R8593 Revision F

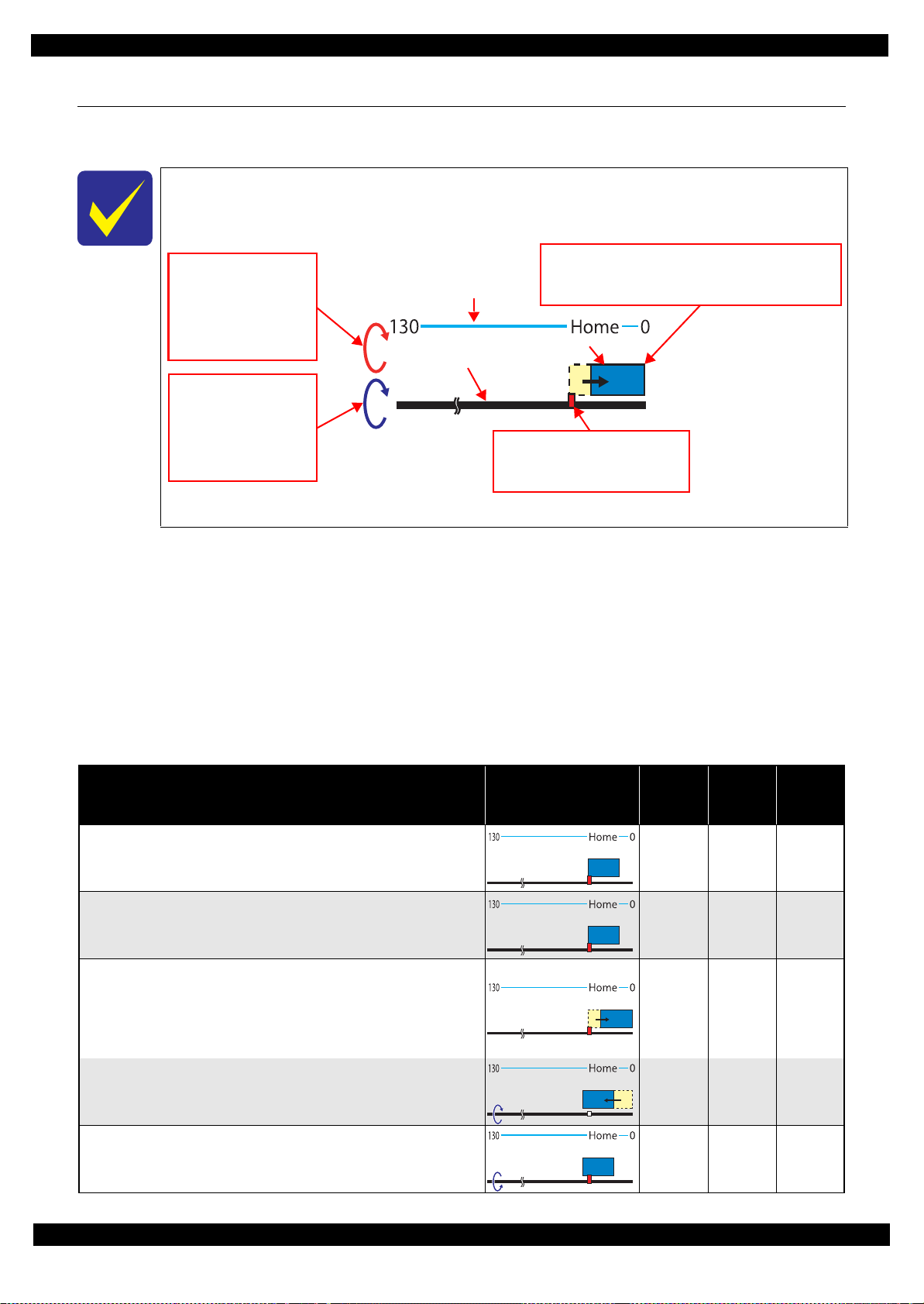

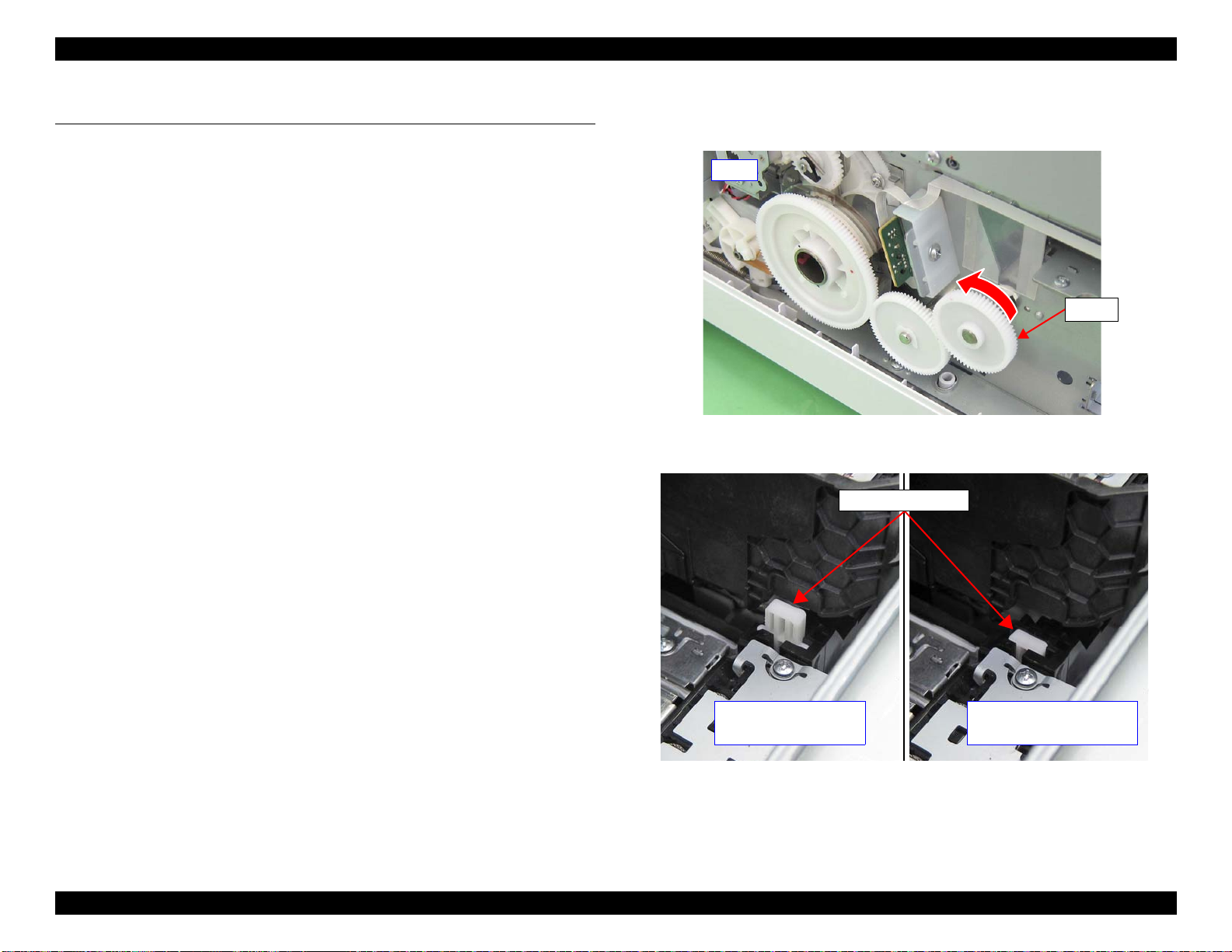

The condition of the CR lock

Red: CR lock is set

White: CR lock is released

The above shows the CR lock is set.

Carriage movement

Right-pointing arrow: Moves to the 0-digit side

Left-pointing arrow: Moves to the 130-digit side

The figure shows the carriage is moving to the 0-digit side.

Digit number of CR

PF Roller

Carriage

The rotation direction of

the ASF Motor

Clockwise:

Paper is fed normally

Counterclockwise:

Paper is fed backward

The above shows clockwise

rotation.

The rotation direction of

the PF Motor

Clockwise:

Paper is fed normally

Counterclockwise:

Paper is fed backward

The above shows clockwise

rotation.

1.2 Power-On Sequence

This section describes the power-on sequences for this product. The preconditions are as follows.

The following explains how to use the simplified diagrams in Table 1-1 or Table 1-2. The

diagrams show the movement of each component as seen from the front of the printer.

Figure 1-4. Movement of Components

Normal power-on sequence

No error occurred at the last power-on, and the power was turned off normally.

Initial ink charge has finished and every pack has sufficient ink.

No paper on the paper path.

The Printhead is capped by the cap of the Ink System.

CR Lock is engaged normally.

This indicates the Simple Sequence.

PG position is set to PG 1.

Option Cassette Unit is not installed.

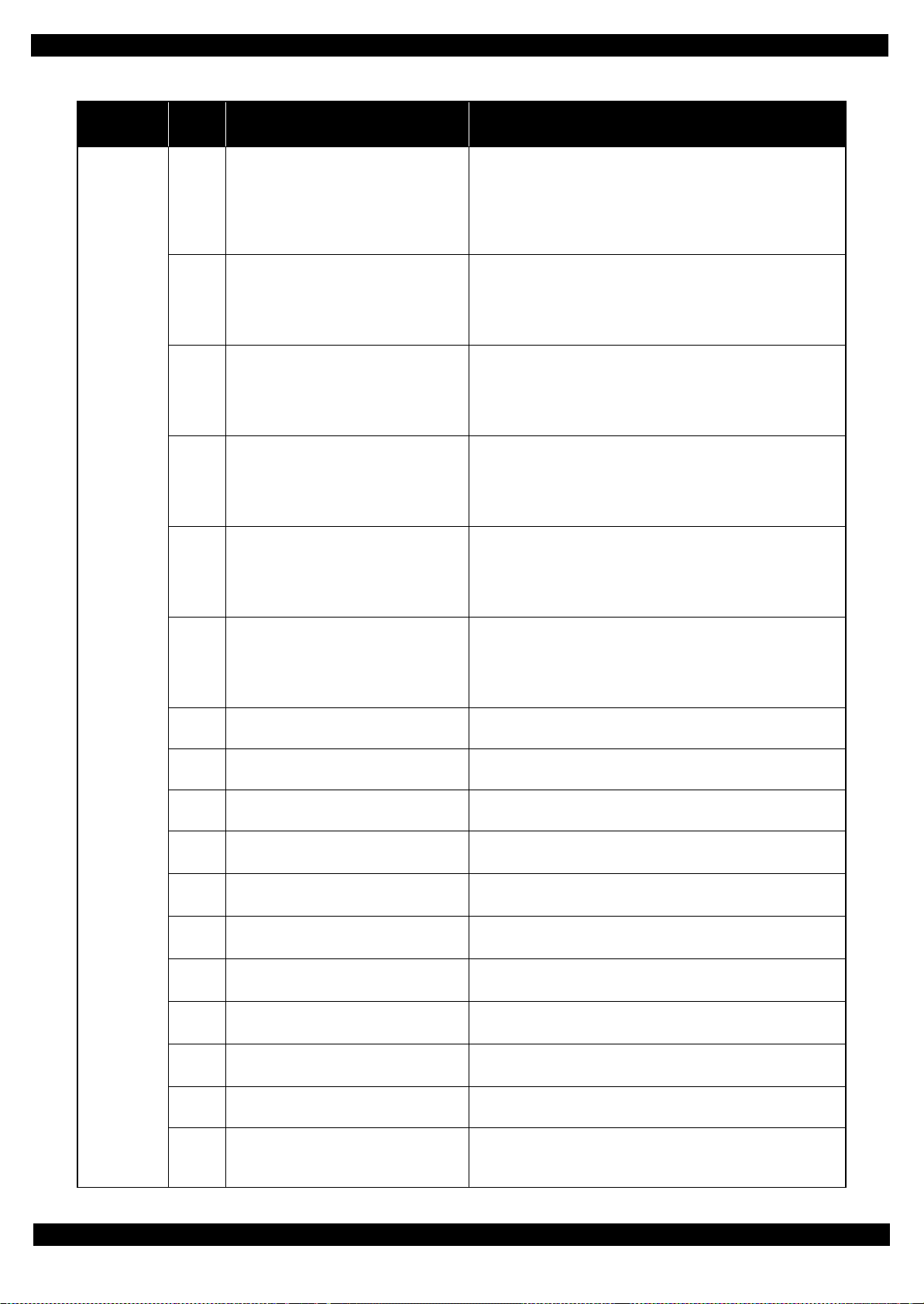

Table 1-1. Power-on Sequence

Operation

1. APG reset

1-1.If PG is other than 1, the APG Motor rotates to set PG to 1.*

2. Printhead initialization and fuse inspection

2-1.Initializes the Printhead, and checks the fuse on the printer control

circuit board.

*1

9

Movement of

Components

CR

Motor

rotation

PF

Motor

rotation

--- --- ---

--- --- ---

ASF

Motor

rotation

3. Seeking the home position

3-1.To identify the CR Unit position, the CR Motor rotates

counterclockwise and it confirms the CR Unit touches the Right Frame

slowly. It regards the point when the CR Unit touches the Right Frame

as the position specified steps away from the home position, and sets it

as the origin.

3-2.If it judges the CR Unit is in the home position, the PF Motor rotates

clockwise and resets the CR lock.

3-3.The PF Motor rotates counterclockwise and sets the CR lock.

CCW --- ---

--- CW ---

--- CCW ---

Power-On Sequence 17

Confidential

Page 18

EPSON WF-R8590/WF-R8591/WF-R8593 Revision F

Table 1-1. Power-on Sequence

Operation

3-4.The CR Motor rotates clockwise and it confirms the CR Unit touches

the Left Frame.*

3-5.The CR Motor and PF Motor stop.

3-6.The CR Motor rotates clockwise, and the CR Unit moves to the home

position, then the CR lock is set.

3-7.The PF Motor rotates clockwise and releases the CR lock.

2

4. CR measurement

4-1.The CR Motor rotates counterclockwise, and the CR Unit moves to the

0-digit side.*

3

Movement of

Components

CR

Motor

rotation

CW --- ---

--- --- ---

CW CCW ---

--- CW ---

CCW --- ---

PF

Motor

rotation

ASF

Motor

rotation

4-2.The CR Motor rotates clockwise, and the CR Unit moves to the 130-

digit side. (Measurement drive)

5. Adjustment of CR acceleration delay

5-1.The CR Motor rotates and the CR Unit moves back and forth two

times.*

4

6. Measurement of synchronized drive timing correction

6-1.The PF Motor and ASF Motor rotate.

7. Low temperature operation sequence

7-1.The PF Motor rotates clockwise, and the CR lock is unlocked.

7-2.The CR Motor rotates and the CR Unit moves back and forth two

7-3.The PF Motor rotates counterclockwise and the CR lock is set.

times.*

4

*5

8. Setting the PF Roller origin

8-1.The PF Motor rotates clockwise.

*6

CW --- ---

CW/

CCW

---

--- ---

CW/

CCW

CCW

--- CW ---

CW/

CCW

--- ---

--- CCW ---

--- CW ---

CW/

9. Sucking supply

9-1.The Decompression Motor Assy 1 rotates in turn (decompresses =>

vents to atmosphere), and the diaphragm pump sucks ink from the ink

cartridges.*

9-2.The Decompression Motor Assy 2 rotates in turn (decompresses =>

vents to atmosphere), and the diaphragm pump sucks ink from the ink

cartridges.*

8

8

10.Ink detection

10-1.Checks the ink consumption counters and the status of ink cartridges.

Power-On Sequence 18

--- --- ---

--- --- ---

--- --- ---

Confidential

Page 19

EPSON WF-R8590/WF-R8591/WF-R8593 Revision F

Table 1-1. Power-on Sequence

Operation

11.Checking for waste ink overflow

11-1.Checks the waste ink counter of the Maintenance Box if the waste ink

overflow is occurring.

12.CR lock setting

12-1.The CR Motor rotates clockwise and the CR Unit moves to the home

position.

12-2.The CR Motor rotates counterclockwise and the CR Unit moves to the

0-digit side.

12-3.The PF Motor rotates counterclockwise and the CR lock is set.

12-4.The CR Motor rotates clockwise and the CR Unit moves to the home

position.

Movement of

Components

CR

Motor

rotation

--- --- ---

CW --- ---

CCW --- ---

--- CCW ---

CW --- ---

PF

Motor

rotation

ASF

Motor

rotation

13.Set the Hopper up

13-1.The ASF Motor rotates clockwise and the Hopper is set up.

*7

--- --- CW

Note : On the premise on this table, PG does not change and the Rear ASF does not operate during the sequence.

Note "*1": If any trouble exists such as the fuse has blown, the fatal error occurs.

"*2": At this point, if the output value of the CR Motor is below the specified value, the paper jam error occurs.

"*3": If, at this point, the output value of the CR Motor is more than the specified value, the fatal error occurs.

"*4": The DC error may occur.

o

"*5": Executes when the detected temperature is under 5

"*6": If the phase of the PF Roller cannot be detected, the SMAP phase detection error occurs.

"*7": If the sensor cannot detect the Hopper, the cassette damage error occurs.

"*8": If the Front Cover is open, the front cover open error occurs.

"*9": If the sensor cannot detect the APG position, the APG error occurs.

C (41oF) by the thermistor on the Printhead.

Power-on Sequence after Recovering from a Paper Jam Error

Table 1-2. Power-on Sequence after Recovering from a Paper Jam Error

CR

Motor

rotation

CW/

CCW

Operation

Executes No.1 on the power-on sequence (Table 1-1).

1. Detecting remaining paper

1-1.The CR Motor rotates and the CR Unit moves back and forth slowly

once.

Movement of

Components

PF

Motor

rotation

--- ---

ASF

Motor

rotation

1-2.The CR Motor rotates clockwise and the CR Unit moves to the 0-digit

side slowly. At this point, if the CR lock lever, APG lever, and Suction

Unit are on the way, it evacuates them.

1-3.The CR Motor rotates and the CR Unit moves back and forth slowly

once.*

1

CW --- ---

CW/

CCW

Note : On the premise on this table, PG does not change and the Rear ASF does not operate during the sequence.

Note *1: At this point, if the output value of the CR Motor is more than the specified value, the paper jam error occurs.

Power-On Sequence 19

--- ---

Confidential

Page 20

EPSON WF-R8590/WF-R8591/WF-R8593 Revision F

1.3 Fatal Error Code List

This section describes the fatal error code and the possible cause for this product.

Printer fatal error list

Table 1-3. Fatal Error List (Printer)

Error type

Printer

Error

code

0x60 HP (Home Potion) error

0x61 Deadlock Avoidance error

0x62 Impossible contact detection error

0x63

0x64 PW sensor failure error

0x65 PW sensor detected foreign object error

0x67 APG error

0x69 Option Cassette recovery mode error

0x6A SMAP phase detection error • Misalignment of eccentric correction phase

0x6B PF runaway error

0x6C Option Cassette Connected error • Four optional cassettes or more setting error

0x6D Option Cassette Connected error • Option cassette setting error

0x6E Option Cassette Connected error • Option cassette setting error

0x6F Option Cassette Connected error • Option cassette setting error

0x70 Opt1 ASF excess load error

0x71 Opt1 ASF excess speed error

0x72 Opt1 ASF PID reverse error

Contact error at ink replacement timing

(Power-off)

Error name Possible cause

•Paper jam

• Foreign object

• Deformation of the main frame

• Foreign object

• Lock the CR Unit.

• Deformation of the main frame

•Paper jam

• Foreign object

• PW sensor failure

• Deformation of the main frame

•Paper jam

• Foreign object

• Deformation of the main frame

• Defective initial operation

• Foreign object

• PW sensor failure

• Main board failure

• Power On Sequence error

•Paper jam

• Foreign object

• Deformation of the main frame

• APG motor failure

• APG encoder failure

• Main board failure

• Option cassette board failure

• Main board failure

• PF encoder failure

• Motor driver failure

• Opt1 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt1 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt1 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt1 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt1 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt1 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

Fatal Error Code List 20

Confidential

Page 21

EPSON WF-R8590/WF-R8591/WF-R8593 Revision F

Table 1-3. Fatal Error List (Printer)

Error type

Printer

Error

code

0x73 Opt1 ASF PID lock error

0x74 Opt1 ASF load position reverse error

0x75 Opt1 ASF load position excess speed error

0x76 Opt1 ASF load position excess load error

0x77 Opt1 LFT PID excess load error

0x78 Opt1 LFT PID excess speed error

0x79 Opt1 LFT PID lock error

0x7A Opt1 LFT PID driving time error

0x7B Opt2 LFT PID driving time error

0x7C Opt3 LFT PID driving time error

0x7D Option Communication error • Main board failure (UART Parity error/ UART FIFO Overflow)

0x7E Emergency stop error • Emergency cover open error

0x7F Inspection mode error ---

0x80 Opt2 ASF PID excess load error

0x81 Opt2 ASF PID excess speed error

Error name Possible cause

• Opt1 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt1 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt1 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt1 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt1 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt1 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt1 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt1 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Protection material remains

• Opt1 LFT Motor Failure

• Opt1 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt1 LIFT driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt1 LFT Motor Failure

• Opt1 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt1 LIFT driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt1 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt1 ASF motor failure

• Opt1 LIFT driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt1 LIFT motor failure

• Opt1 LIFT driven mechanism overload (paper jam/foreign object)

• Opt2 LIFT motor failure

• Opt2 LIFT driven mechanism overload (paper jam/foreign object)

• Opt3 LIFT motor failure

• Opt3 LIFT driven mechanism overload (paper jam/foreign object)

• Opt2 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt2 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt2 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt2 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

Fatal Error Code List 21

Confidential

Page 22

EPSON WF-R8590/WF-R8591/WF-R8593 Revision F

Table 1-3. Fatal Error List (Printer)

Error type

Printer

Error

code

0x82 Opt2 ASF PID reverse error

0x83 Opt2 ASF PID lock error

0x84 Opt2 ASF load position reverse error

0x85 Opt2 ASF load position excess load error

0x86 Opt2 ASF load position excess load error

0x87 Opt2 LFT PID excess load error

0x88 Opt2 LFT PID excess speed error

0x89 Opt2 LFT PID lock error

0x8A Ink Leak error

0x8C Opt Communication error

0x8D Factor Error other than printer driver

0x8E Driver mismatch error • An unsupported drive was used.

0x8F EEPROM verify error (by command) ---

0x93 PE sensor failure

0x94 PW sensor light value adjust error

Error name Possible cause

• Opt2 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt2 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt2 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt2 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt2 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt2 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt2 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt2 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt2 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt2 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Protection material remains

• Opt2 LIFT motor failure

• Opt2 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt2 LIFT driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt2 LIFT motor failure

• Opt2 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt2 LIFT driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt2 LIFT motor failure

• Opt2 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt2 LIFT driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Ink leak at the ink supply route

• Printhead failure

• Ink Supply Unit failure

• Communication connector (Drawer Connectors) failure

• Cable disconnection

• Main board failure

This error occurs if the printer becomes a fatal error status due to a

failure of parts other than the printer such as the scanner or ADF.

• PE sensor failure

• Main board failure

• PW sensor failure

• Main board failure

Fatal Error Code List 22

Confidential

Page 23

EPSON WF-R8590/WF-R8591/WF-R8593 Revision F

Table 1-3. Fatal Error List (Printer)

Error type

Printer

Error

code

0x96 Decompress pump motor drive time error

0x97 Head drive circuit VBS over-voltage error

0x99 IES (Ink End Sensor) process check error • Main board failure

0x9A Circuit error (include blowout of a fuse)

0x9B Transistor temperature error • Main board failure

0x9C X-Hot detect error (pre printing)

0x9D X-Hot detect error (after flushing)

0x9E Head temperature error

0x9F No print inspection mode error ---

0xA0 Opt3 ASF PID excess load error

0xA1 Opt3 ASF PID excess speed error

0xA2 Opt3 ASF PID reverse error

0xA3 Opt3 ASF PID lock error

0xA4 Opt3 ASF load position reverse error

0xA5 Opt3 ASF load position excess speed error

0xA6 Opt3 ASF load position excess load error

Error name Possible cause

• Decompress motor failure

• Main board failure

• Head FFC failure

• Main board failure

• Main board failure

• Power board failure

• Printhead failure

• Printhead FFC failure

• Cooling of print head

• Print head failure

• Main board failure

• Cooling of print head

• Print head failure

• Main board failure

• Cooling of print head

• Print head failure

• Main board failure

• Opt3 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt3 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt3 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt3 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt3 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt3 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt3 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt3 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt3 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt3 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt3 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt3 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt3 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt3 ASF motor failure

• Pickup Roller driven mechanism overload (paper jam/foreign object)

• Cable disconnection

Fatal Error Code List 23

Confidential

Page 24

EPSON WF-R8590/WF-R8591/WF-R8593 Revision F

Table 1-3. Fatal Error List (Printer)

Error type

Printer

Error

code

0xA7 Opt3 LFT PID excess load error

0xA8 Opt3 LFT PID excess speed error

0xA9 Opt3 LFT PID lock error

0xAA Opt1 ASF PID driving time error

0xAB Opt2 ASF PID driving time error

0xAC Opt3 ASF PID driving time error

0xAD Opt1 ASF BS driving time error

0xAE Opt2 ASF BS driving time error

0xAF Opt3 ASF BS driving time error

0xB0

0xB1

0xB2

0xB3

0xB4

0xB5

0xB6 Opt Communication error

0xB7

Opt Communication error

(Parameter length abnormality)

Opt Communication error

(Sub function code abnormality)

Opt Communication error

(A lot of numbers of optional cassettes)

Opt Communication error

(Parameter abnormality)

Opt Communication error

(Time-out error)

Opt Communication error

(Function code abnormality)

Opt Communication error

(Number of row for optional cassette

Error name Possible cause

abnormality in power supply ON)

• Protection material remains

• Opt3 LFT Motor Failure

• Opt3 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt3 LIFT driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt3 LFT Motor Failure

• Opt3 ASF Encoder failure (contaminated/detached scale, Encoder

Board failure)

• Opt3 LIFT driven mechanism overload (paper jam/foreign object)

• Cable disconnection

• Opt3 LFT Motor Failure