Electrolux Professional EVP45GNXT Parts Manual

Vacuum Packers

Table top with HACCP Label Printer

The new range of appliances, developed for the vacuum packing of cooked and raw foods, can provide the

highest quality and hygiene, in line with every professional kitchen that requires the best conservation

standards. The range can satisfy the requirements of users at all levels: from small/medium sized restaurants

to canteens, caterings (100 to 400 servings per day), speciality food manufacturers and large butcher shops.

The model detailed in this sheet is a table top vacuum packer equipped with an HACCP label printer to provide

the essential information regarding the packaging process.

FEATURES

• Vacuum traceability on the

packet: HACCP printer allows to

print the vacuum certification

labels to apply on the single pack,

thus facilitating final storage

operations.

• Advanced user-friendly control

panel, available in 5 languages,

allows to rapidly set parameters

for the 10 available cycles and to

program the technical and

maintenance operations. The new

liquid crystal display provides

detailed packaging process

information per each cycle.

• Packaging cycle can be set by

simply selecting the category and

sub-category of product to be

sealed; this allows the packer to

automatically seal the product

according to suggested or set

values, leaving the option of

setting the expiration date.

• Pulse function allows user to

easily program the cycles, select

pre-set stored functions and

parameters.

• Additional advanced functions

can be activated: external

vacuum, soft air, condition

program, auto seal program and

sealing.

• Electronic soft air device with

different speed levels, ensures a

controlled re-admission of the air

in the sealing chamber (ideal for

products with rough edges).

• Check-up function on display

allows to run a preliminary

diagnosis of the machine to detect

any technical errors before

600048

handling the machine.

• Simple maintenance operations

(oil changing and shock absorber

substitution) can be easily

performed without dismantling the

chamber.

• Liquid or oil residues can be

removed from the pump tank

using the CP-conditioning

program (recommended after long

periods of machine inactivity).

• Pressure chamber with rounded

corners to guarantee high levels of

hygiene and ease of cleaning.

• Constructed in 304 AISI

stainless steel with a domed,

transparent Plexiglas lid, suitable

for use with food products.

• All models comply with the

standards required by the main

international approval bodies and

are H marked.

Table top with HACCP Label Printer

Vacuum Packers

EVP45NXT

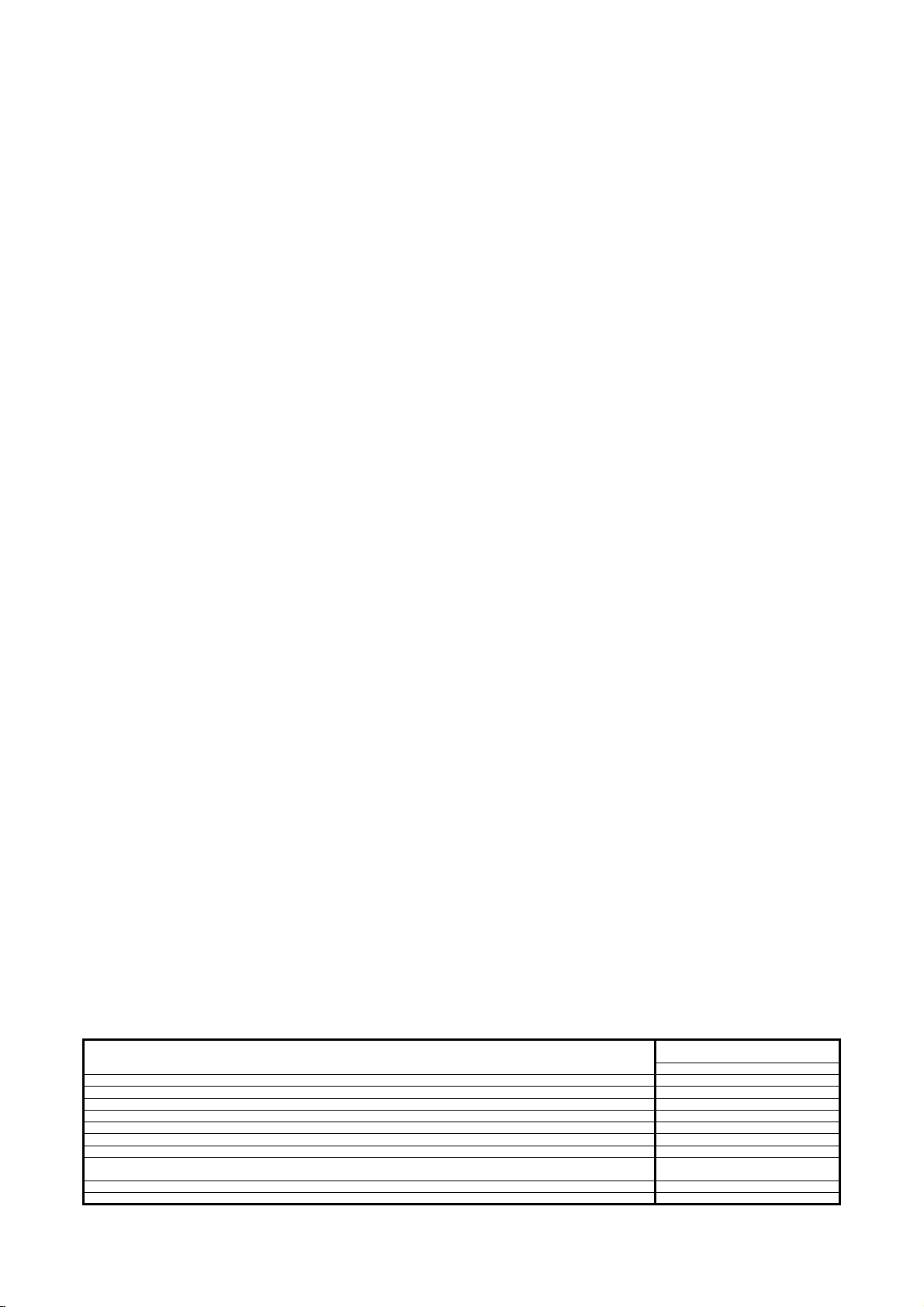

TECHNICAL DATA

Pump - m3/h 20

External dimensions - mm

width 550

depth 645

height 500

Electrical power - kW 1.1

Net weight - kg. 80

ACCESSORIES

ADAPTER FOR EXT.VACUUM PACK.-6/10/20M3/H 650008

INCL.FILLING TABLE-LIQUID PACKING-20M3/H 650010

600048

BNAB0402011-04-06Subject to change without notice

Internet: http://www.electrolux.com/foodservice

Loading...

Loading...