Page 1

Service Manual

Fuller Heavy Duty Transmissions

TRSM0580

October 2007

FRLO-14410C-T2

FRLO-15410C

FRLO-15410C-T2

FRLO-16410C

FRLO-16410C-T2

FRLOF-14410C

FRLOF-14410C-T2

FRLOF-15410C

FRLOF-15410C-T2

FRLOF-16410C

FRLOF-16410C-T2

Page 2

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Page 3

Page 4

Warnings and Precautions

Introduction

Before starting a vehicle always be seated in the driver’s seat, place the transmission in neutral, set the parking brakes and

disengage the clutch.

Before working on a vehicle place the transmission in neutral, set the parking brakes and block the wheels.

Before towing the vehicle place the transmission in neutral, and lift the rear wheels off the ground, remove the axle shafts,

or disconnect the driveline to avoid damage to the transmission during towing.

The description and specifications contained in this service publication are current at the time of printing.

Eaton Corporation reserves the right to discontinue or modify its models and/or procedures and to change specifications at any

time without notice.

Any reference to brand name in this publication is made as an example of the types of tools and materials recommended for use

and should not be considered an endorsement. Equivalents may be used.

Always use genuine Eaton replacement parts.

This symbol is used throughout this

manual to call attention to procedures

where carelessness or failure to follow

specific instructions may result in

personal injury and/or component

damage.

Departure from the instructions, choice

of tools, materials and recommended

parts mentioned in this publication

may jeopardize the personal safety

of the service technician or vehicle

operator.

WARNING: Failure to follow indicated

procedures creates a high risk of personal

inj ury to t he servici ng technici an.

CAUTION: Failure to follow indicated

procedures may cause component

damage or malfunction.

IMPORTANT: Highly recommended

procedures for proper service of this unit.

Note: Additional service information not

cover ed in the servic e proce dures .

Service Procedure

Tip: Helpful removal and installation

procedures to aid in the service of this unit.

0

Page 5

Lightning Breakdown

Overview

Control Unit:

Electronic Control Unit:

ECU

Auxiliary Components:

Rear Bearing Cover

Control Unit:

Shift Knob

Control Unit:

Levers/Housings

& Isolators

Auxiliary Components:

Range Cylinder

Auxiliary Components:

Countershaft & Brgs

Front Section:

Reverse Idler

Auxiliary Components:

Mainshaft & Synchro

Air System:

Air Filter/Regulator

Front Section:

Case Assembly

Front Section:

Case Assembly

Auxiliary Components:

Splitter Cylinder

Front Section:

Integral Oil Cooler

Auxiliary Components:

Countershaft & Brgs

Front Section:

Countershaft Assy

106008-7-99

Control Unit:

Shift Shaft Assy

Front Section:

Reverse Idler

Front Section:

Countershaft Assy

Front Section:

Mainshaft Assy

Front Section:

Input Shaft & Drive Gear

Page 6

Table of Contents

Introduction

Warnings and Precautions ........................................... i

Overview ..................................................................... ii

General Service Practices and Part Inspection ............ 1

Purpose and Scope of Manual .................................... 5

Serial Tag Information and Model Nomenclature ........ 6

Torque Chart ............................................................... 9

Lubrication Information ............................................ 11

Recommended Tools ................................................14

Preventive Maintenance ............................................ 17

Oil Leak Inspection Process ...................................... 19

RTV Sealant Application Procedures ......................... 20

Power Flow ............................................................... 22

Gear Sets to be Timed ............................................... 27

Timing Procedures .................................................... 28

In-Vehicle Service Procedures

How to Remove the ECU ........................................... 31

How to Install the ECU .............................................. 32

How to Remove the Air Filter/Regulator .................... 33

How to Install the Air Filter/Regulator ....................... 34

How to Remove the Shift Knob ................................. 35

How to Install the Shift Knob .................................... 36

How to Remove the Gear Shift Lever/Remote

Shift Control ....................................................... 37

How to Install the Gear Shift Lever/Remote

Shift Control ....................................................... 38

How to Adjust the Remote Shift

Control (LRC Type) ............................................ 39

Neutral Switch Operation and Testing .......................41

How to Remove the Neutral Switch ........................... 42

How to Install the Neutral Switch .............................. 43

Reverse Switch Operation and Testing ...................... 44

How to Remove the Reverse Switch ......................... 45

How to Install the Reverse Switch ............................. 46

How to Remove the Shift Shaft Seal ......................... 47

How to Install the Shift Shaft Seal ............................. 48

How to Remove the Oil Seal -

Magnetic Speedometer ...................................... 50

How to Install the Output Shaft Oil Seal -

Magnetic Speedometer ...................................... 52

How to Remove the Output Bearing Cover ................ 54

How to Install the Output Bearing Cover ................... 56

How to Remove the Oil Cooler Fitting ....................... 58

How to Install the Oil Cooler Fitting ........................... 59

How to Remove the Auxiliary Countershaft

Bearing Cover .................................................... 60

How to Install the Auxiliary Countershaft

Bearing Cover .................................................... 61

How to Remove the Range Piston and

Range Bar O-Ring .............................................. 62

How to Install the Range Piston and

Range Bar O-Ring .............................................. 64

How to Remove the Splitter Piston ............................66

How to Install the Splitter Piston ...............................68

How to Remove the Clutch Access Cover ..................70

How to Install the Clutch Access Cover .....................71

Transmission Overhaul

Procedures-Bench Service

How to Disassemble the Gear Shift Lever ..................72

How to Assemble the Gear Shift Lever ......................74

How to Remove Output Yoke .....................................76

How to Remove the ECU ............................................77

How to Remove the Auxiliary Countershaft

Bearing Cover .....................................................78

How to Orient Transmission for Overhaul ..................79

How to Remove and Disassemble

Input Shaft and Oil Pump ...................................80

How to Remove and Disassemble Clutch

Housing/Front Cover ..........................................83

How to Remove Output Bearing Cover ......................85

How to Remove and Disassemble Front

Countershaft .......................................................86

How to Remove and Disassemble Mainshaft .............88

How to Remove and Disassemble the Shift Shaft ......91

How to Remove and Disassemble Reverse Idler ........94

How to Disassemble Splitter System .........................96

How to Remove and Disassemble Auxiliary

Countershaft .......................................................99

How to Remove and Disassemble Range System ....102

How to Remove and Disassemble Auxiliary

Mainshaft Assembly .........................................104

How to Remove Cooler and Fittings .........................106

How to Install Cooler and Fittings ............................107

How to Assemble and Install Auxiliary

Mainshaft Assembly .........................................108

How to Assemble and Install Range System ............111

How to Assemble and Install Auxiliary

Countershaft .....................................................114

How to Assemble Splitter System ............................117

How to Assemble and Install Reverse Idler ..............119

How to Assemble and Install the Shift Shaft ............121

How to Assemble and Install the Mainshaft .............123

How to Assemble and Install Front

Countershaft Assembly ....................................127

How to Install Output Bearing Cover ........................128

How to Assemble Clutch Housing / Front Cover ......129

How to Assemble Input Shaft and Oil Pump ............131

How to Install the Auxiliary Countershaft

Bearing Cover ...................................................134

How to Install the ECU .............................................135

How to Install Output Yoke ......................................136

M/S Endplay Shimming Procedure ..........................137

Page 7

Introduction

General Service Practices and Part Inspection

Safety

Always keep personal safety in mind when working on heavy truck transmissions. Do not ignore common sense.

Use appropriate safety equipment including:

• Safety glasses

• Safety shoes

• Gloves

• Proper transmission jack or lift with safety chains

• Guards and protective devices for presses, pullers, and drivers.

• Wheel chocks

Disassembly Tips

Cleanliness

The workplace must be clean to prevent dirt or other foreign material from contaminating the transmission during repairs. Dirt is

abrasive and can damage bearings. Eaton® recommends cleaning the outside of the unit before beginning disassembly.

Disassembling Assemblies

As components are removed from assemblies, lay the parts on a clean bench in the order in which they are removed. By laying the

parts out in order, they are less likely to be lost, and reassembly will be easier.

If bearings are to be reused, they must be removed with the proper bearing pullers, or they can be damaged. After removing bearings, carefully wash and lubricate them, and wrap them protectively in clean shop rags or towels until they are to be installed in

the transmission.

Input Shaft Removal

The input shaft assembly contains the transmission lube pump. The special procedure for removal and disassembly is located in

the “Transmission Overhaul Procedures” section.

Snap Ring Removal

Snap rings should be removed with snap ring pliers to avoid overstretching or deforming them.

Removing Parts Using Tools

Use care when removing parts with pullers or drivers to prevent damage to components. Never apply force to driven parts after

they stop solidly. Eaton® recommends using only soft hammers, soft bars, mauls, and the special tools indicated in the procedures for all disassembly work.

Marking Parts

To aid in reassembly and prevent unnecessary work, use a toolmaker’s die to mark the countershaft parts and rear bearing cover

to indicate position. Mark the countershaft parts, including the countershaft, gears, bearings, and shims, as “upper” or “lower”.

Mark the rear bearing cover to indicate the original position to the cover.

Parts Cleaning

WARNING

DO NOT USE GASOLINE TO CLEAN PARTS AS IT IS HIGHLY EXPLOSIVE.

Clean bearings and ground or polished parts in a cleaning solvent. To prevent corrosion, DO NOT clean ground or polished parts

in a hot solution tank, with water, or in alkaline solutions.

Housings can be cleaned with a cleaning solvent or in a hot solution tank with a mild alkaline solution. Dry and oil parts immedi-

ately after removal to prevent machined surfaces from corroding. Be careful cleaning aluminum parts; some cleaning solutions

may damage them.

1

Page 8

Introduction

Inspection

Gears

Inspect gear teeth for frosting, pitting, spalling, or other damage. Gears with frosting can usually be reused. Often, frosting on

gears heals with continuous use of the transmission and more serious pitting does not occur. Gears with light pitting can have

considerable life left and can also be reused. For gears with severe pitting, spalling, damage, or confirmed noise issues, the complete gear set (mainshaft gear and both countershaft gears) must be replaced.

Inspect the internal clutching teeth for excessive wear or rounding. Replace the gear and sliding clutch if necessary.

For additional information on wear of gear teeth, including full color photographs, refer to Eaton® Fuller® publication TRSM0913, Understanding Spur Gear Life.

Bearings

Inspect balls, rollers, races, and thrust surfaces for pitting, spalling, or discoloration. Check for excessive axial (up and down) or

radial (side-to- side) play. Replace the bearings as necessary.

Lubricate bearings with clean oil and rotate them to check for tightness or roughness. Replace the bearings as necessary.

Splined Shafts

Inspect splines for twisting, cracking, or wear. Replace splined shafts as necessary.

Note: Worn splines may indicate excessive torsional vibration. Make sure the vehicle system is corrected to prevent recurring

damage to the transmission.

Thrust Washers

Inspect thrust washers for wear or scoring, and replace them as necessary.

Snap Rings

Inspect snap rings for wear, twisting, stretching, or other damage. Snap rings must fit tightly in their grooves. Replace them as

necessary.

Housings

Inspect housings for cracks. Replace any cracked housings.

Inspect threaded holes for damage, and repair them as necessary.

Inspect bearing bores for wear. Light wear is acceptable. Housings with moderate to heavy wear in the bearing bores must be

replaced.

Introduction

Sliding Clutches

Inspect the clutching teeth for excessive wear or rounding. Light wear or rounding is acceptable. Replace clutches with moderate

to heavy tooth wear.

Inspect the yoke slots of the clutches for excessive wear. Replace worn clutches.

Range Synchronizer

Inspect the friction material for excessive wear of damage. Replace the synchronizer as necessary.

Inspect the blocker pins for excessive wear on the chamfered corners, looseness, or torsional vibration damage. If the blocker

pins are damaged, replace the range synchronizer.

Fit the low and high range synchronizers in their respective gears. Check for synchronizer bottoming on or in the gears. If bottoming occurs, replace the synchronizer assembly.

Inspect the synchronizer mating surface on the gears for signs of excessive heat. If signs of excessive heat are present, replace

the synchronizer assembly.

2

Page 9

Introduction

Clutch Housing

Inspect the pilot diameter where the clutch housing mates with the engine. Replace the clutch housing if the pilot diameter is

excessively worn.

Inspect the bushings for the clutch release linkage. Replace the bushings if they are worn.

O-Rings and Seals

Inspect o-rings and seals for wear, gouges, or permanent set, and replace them as necessary.

Shifting Mechanism

Inspect the shift yokes for excessive wear in the fork area. Light wear is acceptable. Replace any moderately or heavily worn shift

yokes.

Inspect the shift shaft for burrs or raised metal, and check the notches for excessive wear. Repair or replace parts as necessary.

Inspect the shift shaft, shift block, bias plate, shift key, detent key, plungers, and actuator parts for excessive wear or scoring.

Replace any of these parts as necessary.

Range Cylinder Assembly

Inspect the O-rings and piston seal for wear, damage, or permanent set, and replace them as necessary.

Inspect the piston bar, piston bores, and cylinder bores for wear or scoring. Replace any of these parts as necessary.

Shift Lever

Inspect the shift lever tip and spade pin groove for wear. Replace the parts as necessary.

Inspect the spade pin bore in the shift lever housing for excessive wear. Replace the housing as necessary

Input Shaft Seal

The input shaft seal is a lip type seal. Inspect the input shaft grooves and the inside of the front bearing cover for damage.

Replace any damaged parts.

Front Bearing Cover

If an input-shaft-mounted clutch brake is used on the transmission, inspect the clutch brake mating surface on the front bearing

cover for excessive wear. Replace the front bearing cover if the mating surface is excessively worn.

Gasket Surfaces

Inspect flanges and gasket surfaces for burrs, nicks, and scratches. Repair or replace parts as necessary.

Output Seal System

Inspect the output seal mating surface for wear, scratches, burrs, or other damage. Replace the seal surface if it is worn or damaged. Do not attempt to salvage the seal surfaces with crocus cloth, filing, etc.

For additional information, refer to the Eaton/Fuller® brochure TCSM-0912 “Seal Maintenance Guide”.

Reassembly Tips

Cleanliness

Make sure that parts are kept clean during reassembly. Prevent dirt or other foreign material from contaminating the transmisssion. Dirt is abrasive and can damage bearings.

Use lint-free shop rags when handling and cleaning parts. Too much lint inside the transmission can clog the oil pump pickup

screen.

Bearing Installation

To avoid damaging bearings, use a driver that contacts both the inner and outer race of the bearing. If the bearing balls/rollers or

bearing cage is damaged, the bearing must be replaced.

3

Page 10

Introduction

Capscrews

Make sure the threaded holes are clean and free of debris. If necessary, use a tap to clean the threads.

Make sure the capscrew threads are in good condition. If necessary, replace the capscrew.

Use a thread seal/locker compound on all capscrews. Use Eaton® Fuller® P/N 71295 thread sealant of equivalent.

Torque all capscrews to the recommended tightness.

Initial Lubrication

Unless stated specifically, lubricate all mating or sliding parts with transmission oil.

Lubricate all bearings with transmission oil.

Air System Lubrication

Lubricate all air system O-rings, seals, and cylinders with a light coating of silicone lubricant such as Eaton® Fuller® P/N 71203

(8fl.oz.) or P/N 71206 (0.14 fl.oz/).

Snap rings

Eaton® recommends using new snap rings for reassembly. A properly installed snap ring fits tightly in its groove and cannot be

easily rotated. All loose or overstretched snap rings must be replaced.

Introduction

4

Page 11

Introduction

Purpose and Scope of Manual

This manual is designed to provide detailed information necessary to service and repair the Eaton® Fuller® transmissions listed

on the front cover.

How to Use This Manual

The service procedures have been divided into two sections: In-Vehicle Service Procedures and Transmission Overhaul Procedures-Bench Service. In-Vehicle Service Procedures contain procedures that can be performed while the transmission is still

installed in the vehicle. Transmission Overhaul Procedures contain procedures that are performed after the transmission has

been removed from the vehicle.

The procedure sections are laid out with a general heading at the top outside edge of each page, along with more specific headings on the top left of the page and the specific procedures below. To find the information you need, first go to the section that

contains the correct procedure (In-Vehicle Service Procedures, Transmission Overhaul Procedures-Bench Service). Then look for

the correct heading at the top left of each page and follow the steps.

The sections located in front of the repair procedures are intended to give you information that is not included in the Service

Repair Procedures.

5

Page 12

Model Designations

Serial Tag Information and Model Nomenclature

Transmission model designation and other transmission identification information are stamped on the serial tag. To identify the

transmission model and serial number, locate the tag on the transmission and then locate the numbers as shown. Figure 1-1

below shows a tag and the tag location on the transmission.

When calling for service assistance or parts, have the model and serial numbers handy

Do not remove or destroy the transmission identification tag!

Model Designations

Model Number

The model number gives basic information about the transmission and is explained below. Use this number when calling for service assistance or replacement parts.

Serial Number

The serial number is the sequential identification number of the transmission. Before calling for service assistance, write the

number down.

Bill of material or Customer number

This number may be located below the model and serial numbers. It is a reference number used by Eaton®.

6

Page 13

Model Designations

Model Options

Torque Rating

The torque rating of the transmission specified in the model number is the input torque capacity in lb-ft. Various torque ratings

are available. For more information, call your Eaton Fuller regional sales and service office at 1-800-826-HELP (4357).

Shift System

Two types of shift systems are available for this transmission. Both are described and shown below.

Standard

The standard shift system has a gear shift lever opening located toward the rear of the transmission.

Forward Opening

The forward opening shift system has a gear shift lever opening located three inches closer to the front of the transmission than

the standard opening. This forward design allows greater flexibility in mounting the transmission and is indicated by an “F” in the

model number.

Standard Opening

Lubrication Pumps

Standard internal pump

Power Take Off (PTO) Usage

The 6 bolt openings are standard with the transmission. The PTO is mounted to the opening on either side and driven from the

countershaft gear.

Rear Mount

The thru-shaft PTO mounts are on the rear of the transmission. The thru-shaft PTO configuration is standard on the Lightning

transmission.

7

Forward Opening

Page 14

Contact Information for Lightning compatible PTO’s

Chelsea Power Take-Off Products

Dana Corporation

Model Designations

P.O. Box 321

Toledo, OH 43697-0321

Phone 1-800-729-3262

www.chelseapower.com

Muncie Power Products

P.O. Box 548

Muncie, IN 47308-0548

Phone 1-800-FOR-PTOS (1-800-367-7867) or 1-765-284-7721

www.munciepower.com

Model Designations

8

Page 15

Specifications

Torque Chart

The chart below lists the torque values for all the fasteners used on this model transmission. The torque values are also given in

the procedures any time a fastener must be tightened.

Table

Description Torque Value lb·ft

(Nm)

Shift Knob Jam Nut 35–45 (48–61) 1/2” X 13

Shift Lever Housing Capscrews 47–52 (63–70) M10 X 1.5

Remote Shift Control Mounting Capscrews

Clutch Release Yoke Capscrews 35–45 (48–61) 3/8” X 24

Clutch Release Adjusting Arm Capscrews

Clutch Housing Flange Capscrews See engine manufacturer recommendations

Rear Support Studs 60 Minimum (81) M16 X 2.0 Drive until bottomed (When using plugs apply

Rear Support Stud Nuts 170-190 (230-

Speed Sensor Retaining Capscrews 20-23 (27-31) M8 X 1.25

PTO Cover Capscrews/Studs 47-52 (63-70) M10 X 1.5

47–52 (63–70) M10 X 1.5

35–45 (48–61) 3/8” X 24

257)

Thread Size

X30MM

X30MM

for type, size, and assembly torque.

71206 sealant)

M16 X 1.5

X20MM

External Attachment Stud Nuts 20-23 (27-31) M8 X 1.25

Thermocouple Plug 47-52 (63-70) 1/2" NPT Use thread sealant

Oil Fill Plug 35-50 (47-67) 1 1/16" X 12 O-ring plug

Oil Drain Plug 35-50 (47-67) 1 1/16" X 12 O-ring plug

Air System Diagnostic Port Plugs 84-120 lb. in. 1/16"-27 Use thread sealant

Oil Level Site Glass 60-70 (81-95) 1 5/8" X 12 O-ring fitting

Air Filter/Regulator Capscrews 9-10 (12-14) M6 X 1.0 X

55MM

Neutral Switch 15-20 (20-27) M16 X 1.5 O-ring seal

Reverse Switch 15-20 (20-27) M16 X 1.5 O-ring seal

Splitter Detent Plug 15-20 (20-27) M16 X 1.5 O-ring seal

Output Shaft Nut 450-500 (610-

677)

Cooler Inlet & Outlet Fittings 40-50 (54-67) 7/8" UNF O-ring fitting

Main Case Breather 15-20 (20-27) 1/4" X 18 Use thread sealant

M48 X 2.0 Oil at yoke installation

9

Page 16

Table

Specifications

Description Torque Value lb·ft

(Nm)

ECU Breather 84-120 lb-in (9.5-

13.6)

Clutch Housing / Front Cover Capscrews

Front Bearing Cover Capscrews 35-40 (48-55) M10 X 1.5 X

Front Cover Oil Dam Plate Capscrew 20-23 (27-31) M8 X 1.25 X

Oil Trough Capscrews 20-23 (27-31) M8 X 1.25 X

Rear Countershaft Bearing CoverCapscrews

Output Shaft Bearing Cover Capscrews

Vehicle Wiring Harness Connector

Retaining Screw at ECU

ECU Mounting Capscrews 20-23 (27-31) M8 X 1.25 X

47-52 (63-70) M10 X 1.5

47-52 (63-70) M10 X 1.5 X

47-52 (63-70) M10 X 1.5 X

7-13 lb-in (.8-1.5) 10 X 24 Part of connector assembly

Thread Size

1/8" X 27 Use thread sealant

35MM

12MM

12MM

30MM

45MM

70MM

Specifications

ECU Position Sensor Capscrews 22-28 lb-in (2.4-

3.2)

ECU Solenoid Pack Capscrews 22-28 lb-in (2.4-

3.2)

Range Piston Retaining Nut 25-35 (34-47) M10 X 1.5

Eccentric Pump Setscrew 3 Maximum (4)

maximum

Shift Shaft Neutral Detent Plunger

Plug

Shift Shaft Reverse Bias Detent Plug 15-20 (20-27) M18 X 1.75

Reverse Idler Retaining Capscrews 47-52 (63-70) M10 X 1.5 X

Cooler Retaining Capscrews 20-23 (27-31) M8 X 1.25 X

15-20 (20-27) M16 X 1.5

M4 X.75 X

16MM

M4 X.75 X

16MM

M4 X.75 X

25MM

30MM

12MM

Drive until the setscrew bottoms into pump

eccentric

10

Page 17

Lubrication Information

Lubrication Information

Proper lubrication procedures are the key to a good all-around maintenance program.

Eaton® Fuller® Transmissions are designed so internal parts operate in an oil circulating bath created by the motion of the gears

and shafts.

All parts will be properly lubricated if these procedures are closely followed:

a. Maintain oil level and inspect regularly.

b. Follow maintenance interval chart.

c. Use the correct grade and type of oil.

d. Buy from a reputable dealer.

Maintain Proper Oil Level

Make sure the oil is level with the filler opening. Being able to reach the oil with your finger does not mean the oil is at The proper

level. (One inch of oil level is about one gallon of oil.)

IMPORTANT

When adding oil, never mix engine and gear oils in the same transmission.

Hole

Improper Oil Level

Hole

Proper Oil Level

11

Page 18

Lubrication Information

Oil Capacity is 27 pints

Maintenance Interval Chart

Eaton® Roadranger® CD50 Transmission Fluid

HIGHWAY USE-Heavy duty and Mid-Range initial Fill with Eaton® Roadranger® CD50 E500 (PS-164)

HIGHWAY

Every 10,000 miles Check fluid level. Check for leaks.

Every 500,000 miles Change transmission lubricant.

OFF-HIGHWAY USE

First 30 hours Change transmission lubricant on new units.

Every 40 hours Inspect lubricant level. Check for leaks.

Every 1,000 hours Change transmission fluid where severe dirt conditions exist.

Every 2,000 hours Change transmission fluid (Normal off-highway use).

If your vehicle has a transmission oil filter, you must change the filter when fluid or lubricant is changed.

The use of lubricants not meeting these requirements will affect warranty coverage.

For a list of Eaton Approved Synthetic Lubricants, see TRSM-0911 or call 1-800-826-HELP (4357).

Buy from a Reputable Dealer

For a complete list of approved and reputable dealers, write to:

Eaton Corporation

Global Marketing Services

P.O. Box 4013

Kalamazoo, MI 49003

Lubrication Information

Transmission Operating Angles

If the transmission operating angle is more than 12 degrees, improper lubrication will occur. The operating angle is the transmission mounting angle in the chassis plus the percent of upgrade (expressed in degrees).

For operating angles over 12 degrees, the transmission must be equipped with an oil pump or cooler kit to insure proper lubrication.

12

Page 19

Lubrication Information

Operating Temperatures with Oil Coolers

The transmission must not be operated consistently at temperatures above 250°F. However, intermittent operating temperatures

to 300°F do not harm the transmission. Operating temperatures above 250°F increase the lubricant’s oxidation rate and shortens

its effective life. When the average operating temperature is above 250°F, the transmission can require more frequent oil changes

or external cooling.

Oil coolers are standard on Lightning transmissions.

The following conditions in any combination can cause operating temperatures of over 250°F:

a. Operating consistently at slow speed.

b. High ambient temperatures.

c. Restricted air flow around transmission or engine radiator.

d. Exhaust system too close to transmission.

e. High horsepower operation.

f. Restricted engine coolant flow to transmission cooler.

Oil coolers are effective in reducing operating temperatures when the above conditions are encountered.

Oil Cooler Chart

Transmission Oil Coolers are:

Recommended

With engines of 350 H.P. and above.

Required

With engines 399 H.P. and above and GCW’s over 90,000 lbs.

With engines 399 H.P. and above and 1400 lb-ft or greater torque.

With engines 450 H.P. and above.

13

Page 20

Tools

Recommended Tools

Some repair procedures pictured in this manual show the use of specialized tools. Their actual use is recommended as they

make transmission repair easier, faster, and prevent costly damage to critical parts.

But for the most part, ordinary mechanic’s tools such as socket wrenches, screwdrivers, etc., and other standard shop items

such as a press, mauls and soft bars are all that is needed to successfully disassemble and assemble any Eaton Fuller Transmission.

Recommended Tools

The following tables list and describe the typical tools required to properly service this model transmission above and beyond the

necessary basic wrenches, sockets, screwdrivers, and prybars.

General Tools

The following tools are available from several tool manufacturers such as Snap-On, Mac, Craftsman, OTC, and many others.

General Tools

Tools

TOOL PUPOSE

0 - 100 lb·ft 1/2" drive Torque Wrench. General torquing of fasteners. (Typically 15-80 lb·ft.)

0 - 600 lb·ft 3/4" or 1" drive Torque Wrench. Torquing of output nut to 500 lb·ft.

0 - 150 lb·in 3/8" drive Torque Wrench. Torquing of pipe plugs 60-120 lb·in.

70 MM or 2 3/4" Socket - Standard Depth To remove/install the output yoke nut

5/64” Allen Wrench Driver To remove/install eccentric pump set screw

Snap Ring Pliers - small external To remove/install snap ring at input shaft thrust washer

Snap Ring Pliers - medium external To remove/install snap ring at rear of mainshaft

Snap Ring Pliers - small internal To remove/install snap ring at range cylinder

Dial Indicator and Magnetic Base To check mainshaft endplay

(2) Rolling Head (Crow's Foot) Prybars To remove the rear auxiliary countershaft bearings

Air Pressure Gauge 0 - 100 PSI (0-1034 kPa) To troubleshoot and verify correct air system operation

14

Page 21

Tools

Eaton Fuller Model Special Tools

The following special tools are designed for this Eaton® Fuller® transmission. The addresses and phone numbers of the tool

suppliers are listed after the table. This list is provided as a convenience to our customers. These tools are manufactured by independent companies with no relationship to Eaton Fuller. Eaton Fuller does not warrant the fit or function of the listed tools. To

obtain the tools, contact the tool supplier directly.

Special Tools

REFERENCE

NUMBER

T1 Output Yoke Puller Required to remove an output yoke. 7075**

T2 Transmission Jack Adapter

T3 Transmission Service

T4 Bearing Puller To remove front countershaft bearings

T5 Bearing Race Puller To remove input shaft bearing race J-44077

T6 Bearing Race Puller To remove front countershaft bearing

T7 Bearing Race Puller To remove auxiliary countershaft front

T8 Bearing Puller To remove auxiliary countershaft front

T9 Bearing Race Puller To remove shift shaft bushing from

T10 Bearing, Race, & Bushing

TOOL PURPOSE KENT MOORE

TOOL NUMBER

Plate

Mounting Plate

Installer Kit

Provides stable base for removing the

transmission from the truck

Allows for correct orientation of transmission during bench service

from clutch housing

races

bearing races from front countershafts

roller bearings

front cover

To install all bearings, bearing races,

and bushings

J-44076

J-44075

J-44096

J-44352

J-44353

J-44354

J-44098

J-44751

OTC TOOL NUMBER

T11 Seal Puller/Installer To remove and install the rear shift

shaft seal

T12 Seal Puller To remove output shaft seal J-44355

T13 Transmission/Engine Stand Supports transmission service mount-

ing plate during bench service

** OTC 7070A kit includes 7075 yoke puller

15

J-44099

1726

Page 22

Tools

Tool Suppliers

The following vendor makes tools specifically for Eaton® Fuller® Lightning transmissions:

SPX / Kent-Moore

28635 Mound Road

Warren, MI 48092–3499

Phone: 800-328–6657

Fax: 800–578–7375

The specialized tools can be obtained from a tool supplier or made from tool prints as required by the individual user. Detailed

Eaton Fuller Transmission Tool Prints are available upon request by writing to:

Eaton Corporation

Truck Components Operations

Technical Service

P.O. Box 4013

Kalamazoo, Michigan 49003

Eaton Aftermarket Parts

The following tools are available through Eaton Aftermarket Parts. To obtain any of the tools listed, contact your local Eaton®

parts distributor.

Aftermarket Parts

TOOL PURPOSE EATON PART NUMBER

Output Seal Driver To Install Output Seal 5564509 adapter with 5564501 driver - both parts included in complete

Eaton Seal Kit P/N TCMT-0912

Tension Spring Driver Install Shift Lever Spring T-11938 Eaton Transmission Print

Tools

16

Page 23

Preventive Maintenance

Preventive Maintenance

The preventive maintenance items below are necessary to prevent costly transmission failures that may not be covered by warranty. Parts of the transmission to be checked or accessed for preventive maintenance are shown.

2

1

7

8

3

4

5

6

1. Clutch Release Bushings

2. Oil Fill Plug

3. Shift Tower

4. Air filter/Regulator

5. Output Seal

6. Oil Drain Plug

7. Oil fill Sight Glass

8. Clutch Inspection Cover

ECU

• Avoid any heat source close to the transmission. The exhaust system or any other source of heat must be at least four

(4) inches from the transmission ECU.

• Maintain vehicle electrical system in proper working condition.

• Check for clogged or plugged vents on ECU.

Transmission Oil

• Check transmission weekly for oil leaks. Repair promptly to prevent oil loss and subsequent transmission failure.

• Check transmission oil level at every engine oil change interval. Add transmission oil as necessary.

• Drain and replace transmission oil as recommended by the schedule in the lubrication interval chart.

17

Page 24

Preventive Maintenance

Air System

• Drain moisture from the vehicle air system daily.

• Listen for air leaks daily, and repair them promptly.

• This model requires an air dryer. Confirm the air dryer system is working properly. Repair as necessary.

• Service the vehicle air compressor as required to prevent oil from entering the vehicle air system.

Master Clutch System

• Have the clutch checked and adjusted if any of the following occurs:

Clutch does not disengage completely.

Clutch brake does not function.

Clutch pedal free-play is less than 1/2".

• When replacing the clutch, use a high quality spring damped replacement unit without free travel.

Drivetrain

• Inspect the driveshaft for loose or worn U-joints weekly. Repair promptly to prevent excessive driveline vibration.

• Inspect air ride suspension ride height per OEM requirements.

Overall Inspection

• Inspect the transmission at the chassis lubrication interval for loose or missing capscrews and fasteners.

• Pay particular attention to the capscrews that attach the transmission to the engine.

Preventative Maintenance

18

Page 25

Preventive Maintenance

Oil Leak Inspection Process

Inspect for Oil Leak

Determine if it is a Weep or a Leak

Weep: Stained, damp, no drips, light oil film,

dirt adhered to the contaminated area.

Gasket Rear Seal Leak

1. Clean suspected oil weep

area with a clean dry cloth

or mild soluble degreaser.

2. Ensure lube is to proper

level.

3. Notify the customer that it

is only a weep and it is not

considered to be detrimental

to the life of the transmission.

4. Repair is complete.

1. Do not repair: Rear seal is

designed to allow min

seepage (refer to Roadranger

TCSM-0912 Seal Maintance

Guide).

2. Ensure lube is to proper

level.

imal

Leak: Extremely wet or dripping of oil in the

contaminated area.

Step 1

1. Determine the origin of the leak path.

2. If origin of leak is obvious skip to Step 3.

3. If the origin of the oil leak is not obvious then

use either of the two following steps to determine

the oil leak:

Note: Do not use a high pressure spray washer to

clean the ar

force contamination into the area of concern and

temporarily disrupt the leak path.

i. Clean area with a clean dry cloth or mild

soluble degreaser and fill the transmission to

the proper lube level.

OR

ii. Clean the area as noted above and insert tracer

dye into the tr

transmission to proper lube level.

ea. Use of a high pressure spray may

ansmission lube and fill

Step 2

Operate vehicle to normal transmission operating

temperature and inspect the area for oil leak(s)

visually or if tracer dye was introduced use an UVL

(Ultraviolet Light) to detect the tracer dye’s point

of origin.

Note: When i

make sure the assumed leak area is not being

contaminated by a source either forward or above

the identified area such as the engine, shift tower,

shift bar housing, top mounted oil cooler, etc...

nspecting for the origin of the leak(s)

Step 3

Once the origin of the leak is identified, repair the

oil leak using proper repair proced

designated model service manual.

ures from the

Step 4

After the repair is completed, verify the leak is

repaired and operate the vehicle to normal

transmission operating temperature.

Inspect repaired area to ensure oil leak has been

eliminated. If the leak(s) still occurs, repeat steps

or contact the Roadranger Call Center at

1-800-826-4357.

19

Page 26

Sealant Application

RTV Sealant Application Procedures

1. Clean and remove all foreign material from surfaces to be sealed.

2. Use solvent to prep surface before application.

3. Use the precut applicator nozzle to apply a continuous and even 1/8” bead to one of the surfaces to be assembled.

4. Apply the sealant bead inboard of all capscrew holes.

5. Parts must be assembled with 10 minutes of application, maximum RTV cure is achieved after 90 minutes.

6. Reference bead paths shown below for exact location for applying sealant.

7. Follow assembly instructions and torque specifications shown in the Lightning Series Manual. Eaton literature # TRSM0580

Sealant Bead Pattern for Main Case to Front Cover

Sealant Application

20

Page 27

Sealant Application

Sealant Bead Pattern for Main Case Rear Bearing Covers

Sealant Bead Pattern for Main Case PTO Covers

21

Page 28

Transmission Power Flow

Power Flow

An understanding of the engine’s power flow through a transmission in each particular gear assists the technician in troubleshooting and servicing a transmission.

The Eaton Fuller Lightning series transmission is really two transmissions combined into one unit. The first transmission or front

section contains three sets of forward gears and one reverse gear controlled by the driver’s movement of the shift lever. The second transmission called the auxiliary, or back box contains three sets of gears with two air shift cylinders. However, unlike other

Eaton Fuller Roadranger products, you cannot separate the front section from the auxiliary of the transmission for servicing.

Troubleshooting of the mechanical subsystem is similar to current Eaton Fuller mechanical products, although transmission disassembly may now be necessary to inspect the internal components.

The unique design of the Lightning transmission uses concentric countershafts. The front box countershaft fits through the hollow center of the auxiliary countershaft providing support for the auxiliary countershaft. The illustration shows the transmission

gearing with a cross sectional view of how the front section countershaft fits through the auxiliary countershaft.

The Lightning transmission uses constant mesh helical gearing throughout. When in operation, all gears rotate together even

though a few transfer power to the driveline at any one time.

Transmission Power Flow

1 2

1. Front Section

2. Auxiliary Section

22

Page 29

Transmission Power Flow

Understanding power flow can help to isolate the individual gear set when diagnosing noise or shift complaints. However, complete knowledge of truck systems benefits the technician when diagnosing either of these complaints.

The figure illustrates the transmission with the main components called out. Note specifically, the sectional view of the auxiliary

countershaft showing how the front box countershaft supports the auxiliary countershaft. Left out of the picture is the clutch

housing. The clutch housing pilots into the transmission case with dowel pins and supports the transmission’s front section

gearing and input shaft.

11

12

12

10

9

8

7

6

3

Component Nomenclature and Auxiliary Countershaft Sectional View

1. Input Shaft

2. Main Drive Gear

3. Front Section Countershaft

4. Auxiliary Countershaft

5. Shaft Splined For PTO

6. Synchronizer Assembly

23

7. Output Shaft (Auxiliary Mainshaft)

8. Auxiliary Splitter Gear (Auxiliary Mainshaft)

9. Auxiliary Drive Gear

10. Auxiliary Countershaft Support Bearings

11. Sliding Clutches

12. Countershaft Drive Gear

13. Reverse Gear

13

5

4

Page 30

Transmission Power Flow

Power Flow by Gear

Note: The heavy lines in all figures represent the power flow path.

All the gearing in the transmission is constantly rotating because the transmission uses constant mesh gearing. However, only

the engaged gears have power (torque) transmitted across the gear set. Sliding clutches located on the front section and auxiliary section mainshafts slide forward or rearward to engage into a selected gear. Torque comes through the gear set only after

the sliding clutch engages the gear.

a. Power (torque) from the vehicle’s engine is transferred to the transmission’s input shaft.

b. The input shaft rotates the main drive gear through internal splines in the hub of the gear.

c. The main drive gear meshes with both countershaft drive gears splitting the engine torque equally across both gears.

d. Only those gears selected by the sliding clutches have torque across them even though all gears in the transmission

turn all the time.

e. The following illustrations show the torque path in all ten (10) gears and both reverse gears.

Transmission Power Flow

Low Reverse Gear

1. Sliding Clutch Rearward

2. Splitter Clutch Rearward

3. Synchronizer in Low Range

1

1st Gear

1. Sliding Clutch Forward

2. Splitter Clutch Rearward

3. Synchronizer in Low Range

231

2

1

3

High Reverse Gear

1. Sliding Clutch Rearward

2. Splitter Clutch Forward

3. Synchronizer in Low Range

3

2

2

1

3

2nd Gear

1. Sliding Clutch Forward

2. Splitter Clutch Forward

3. Synchronizer in Low Range

24

Page 31

Transmission Power Flow

21

3rd Gear

1. Sliding Clutch Rearward

2. Splitter Clutch Rearward

3. Synchronizer in Low Range

1

5th Gear

1. Sliding Clutch Forward

2. Splitter Clutch Rearward

3. Synchronizer in Low Range

3

1

3

2

4th Gear

1. Sliding Clutch Rearward

2. Splitter Clutch Forward

3. Synchronizer in Low Range

3

2

1

2

3

6th Gear

1. Sliding Clutch Forward

2. Splitter Clutch Forward

3. Synchronizer in Low Range

123

7th Gear

1. Sliding Clutch Rearward

2. Splitter Clutch Rearward

3. Synchronizer in High Range

25

1

8th Gear

1. Sliding Clutch Rearward

2. Splitter Clutch Forward

3. Synchronizer in High Range

3

2

Page 32

Transmission Power Flow

1

9th Gear

1. Sliding Clutch Forward

2. Splitter Clutch Rearward

3. Synchronizer in High Range

2

2

3

1

3

Transmission Power Flow

10th Gear

1. Sliding Clutch Forward

2. Splitter Clutch Forward

3. Synchronizer in High Range

26

Page 33

Timing

Gear Sets to be Timed

Auxiliary Mainshaft

Drive Gear Set

3rd/4th Gear Set

Splitter Gear Set

27

Page 34

Timing

Timing Procedures

Special Instructions

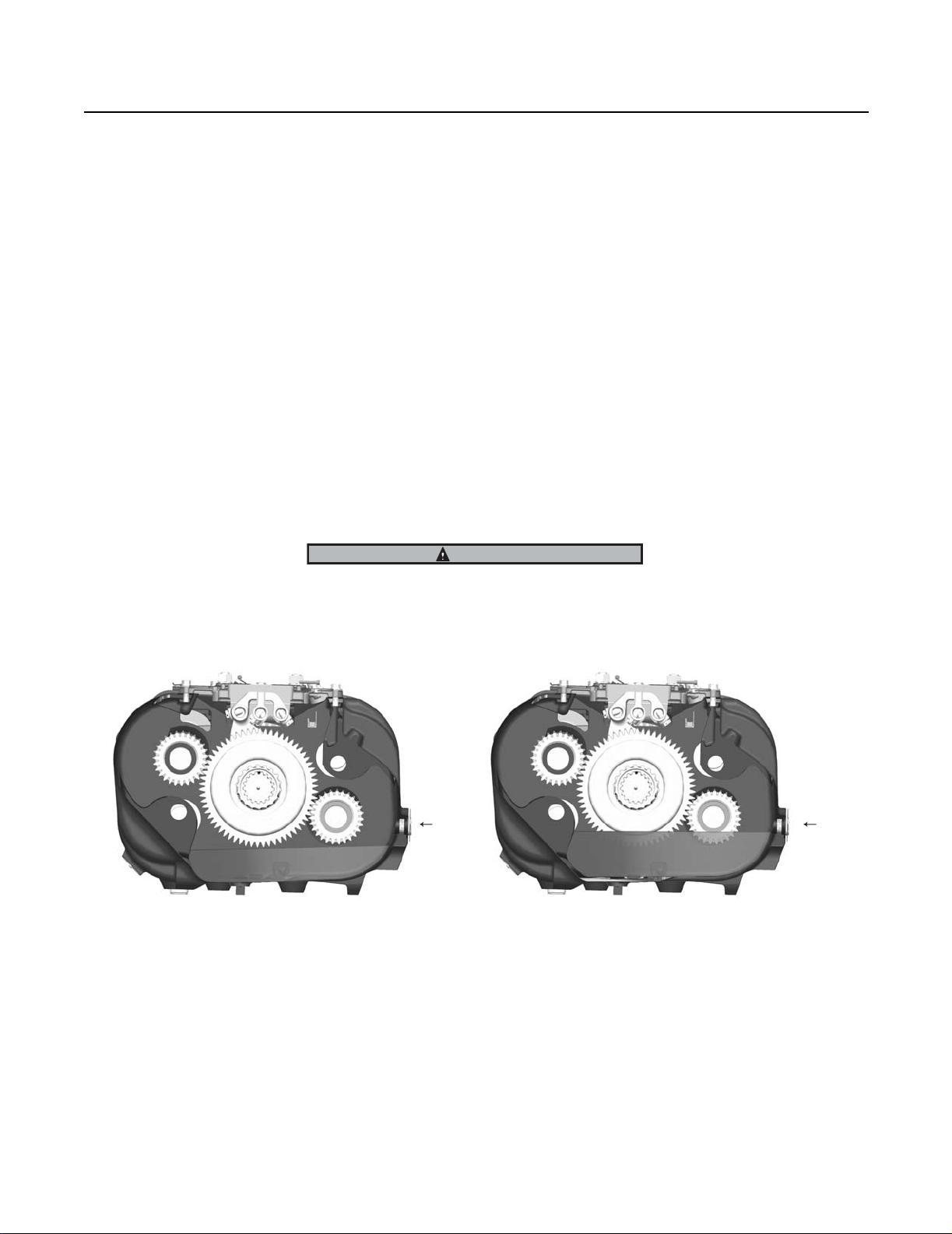

Both front and rear countershaft assemblies must be "timed". Correct timing assures the mainshaft gears will be properly centered

between the countershafts.

Timing is a simple service procedure completed by marking the appropriate teeth of a gear set prior to installation and placing

them in proper mesh during assembly. Since Lightning models are assembled as a single unit, there are three critical gear sets

that must be timed. In the order in which they are assembled, these gears include: the splitter gear set, the auxiliary mainshaft

drive gear set, and the 3rd/4th gear set.

Since Lightning transmission models contain all helical style gearing and the countershafts are single piece units, the process of

marking the gear teeth is unique compared to other models.

Special Tools

• Tool Markers Dye

Procedure -

Timing

1. Marking the auxiliary mainshaft splitter gear

2. Prior to installing the splitter gear on the end of the auxiliary

mainshaft, clearly mark any two teeth that are directly opposite of each other. Mark the teeth on the front side of the gear

identified by the internal clutching teeth.

3. There should be an equal number of unmarked gear teeth

between the marked teeth.

1. Marking the auxiliary countershaft gears

2. Locate the timing mark on the rear side of the forward most

gear (auxiliary coutershaft driven gear) and mark the two adjacent teeth next to the timing mark as shown.

3. Repeat the procedure for the two teeth on the next gear (auxiliary countershaft splitter gear) that line up exactly with the

timing mark on the drive gear.

28

Page 35

Timing

1. Marking the mainshaft gears

2. Prior to building the mainshaft assembly the auxiliary countershaft drive gear and the 3rd /4th mainshaft gear must be

marked for timing purposes. Clearly mark any two teeth that

are directly opposite of each other. Mark the teeth on the

front side of the gear so the teeth can be identified during

transmission assembly.

3. There should be an equal number of unmarked gear teeth

between the marked teeth.

1. Marking the front countershaft gears

2. Locate the timing mark on the flat section of the countershaft between the two smallest gears.

3. Mark the two adjacent teeth on the 3rd/4th gear that line up

with the timing mark.

1. Meshing the marked gearing during assembly

2. Install the splitter gear.

3. Install the auxiliary countershafts in the transmission case

with the timing marks lined up with the splitter gear marked

teeth.

29

Page 36

4. Install the mainshaft assembly with the marked teeth on the

auxiliary drive gear lined up between the marked teeth on the

auxiliary countershaft driven gears.

5. Install the countershafts with the two adjacent marked teeth

lined up on each side of the marked tooth on the mainshaft

gears.

6. Follow the assembly procedures in the "Bench Service" section.

Timing

Timing

30

Page 37

In-Vehicle Service Procedures

How to Remove the ECU

Special Instructions

None

Special Tools

• Typical Service Tools

Procedure -

1. Place the transmission in the reverse gear position.

2. Drain the vehicle air tanks.

3. Disconnect the vehicle wire harness connector from the ECU

using a 1/4" nut driver.

4. Remove the nine ECU capscrews.

5. Remove the ECU, spacer plate, sealing plate, and actuating

washer.

31

Page 38

How to Install the ECU

Special Instructions

None

Special Tools

• Typical Service Tools

Procedure -

1. Place the transmission in the reverse gear position.

2. Position the actuating washer onto the end of the shift shaft

and make sure it is rotated fully clockwise.

In-Vehicle Service Procedures

In-Vehicle Service Procedures

3. Assemble the ECU, spacer plate, and sealing plate.

4. Position the ECU assembly over the actuating washer so the

finger lines up with the range position sensor.

5. Make sure the ECU is fully seated against the case and install

the nine ECU capscrews.

6. Torque the ECU capscrews to 20-23 lb-ft (27-31 Nm).

7. Attach the vehicle interface harness to the ecu, tighten connector screw to 7–13 lb-in (.8–1.5 Nm).

32

Page 39

In-Vehicle Service Procedures

How to Remove the Air Filter/Regulator

Special Instructions

The air filter/regulator has two (2) O-rings located between the filter/regulator and the transmission case mounting surface.

Special Tools

• Typical Service Tools

Procedure -

1. Drain pressure from the vehicle air system.

2. Disconnect the air supply line from vehicle air system.

3. From the air filter/regulator, remove the two (2) capscrews.

4. From the main case, remove the air filter/regulator.

5. From the air filter/regulator, remove the two (2) O-rings.

6. Inspect the O-rings for cracks or distortion.

7. Remove the air supply fitting.

33

Page 40

In-Vehicle Service Procedures

How to Install the Air Filter/Regulator

Special Instructions

The air filter/regulator has two (2) O-rings located between the filter/regulator and the transmission case.

Special Tools

• Typical Service Tools

Procedure -

1. Insure the two o-rings are positioned in the recessed ports

located on the air filter/regulator mounting surface on the

transmission case.

2. Install the vehicle air supply line fitting with pipe thread sealant and position for correct air line routing.

In-Vehicle Service Procedures

3. Position the air filter/regulator assembly on the transmission case.

4. Apply Eaton/Fuller Sealant #71205 or equivalent to the two

(2) retaining capscrews.

5. Install the two (2) retaining capscrews, tighten to 9-10 lb-ft

(12-14 Nm) of torque.

6. Connect the air supply line from the vehicle air supply.

7. Charge the vehicle air system and inspect for air leaks.

34

Page 41

In-Vehicle Service Procedures

How to Remove the Shift Knob

Special Instructions

None

Special Tools

• Typical Service Tools

Procedure -

1. Pull down on the skirt portion of the shift knob to reveal the

electrical connector and the jam nut.

2. Disconnect the three-wire electrical connector.

3. Loosen the jam nut at the base of the knob.

4. Unscrew the knob from the shift lever.

5. If the skirt is to be removed from the lever, note the location

of the wire harness or harnesses in the skirt slots, and remove the jam-nut before removing the skirt section.

35

Page 42

How to Install the Shift Knob

Special Instructions

None

Special Tools

• Typical Service Tools

Procedure -

1. Slide the skirt over the shift lever and position the electrical

harness or harnesses into the appropriate slots, so the alignment pins on the skirt match the alignment holes in the knob

when installed.

In-Vehicle Service Procedures

In-Vehicle Service Procedures

2. Thread the jam nut and shift knob on the shift lever. Position

the shift knob so the splitter button faces the driver’s side of

the vehicle.

3. Tighten the jam nut against the bottom of the shift knob and

torque the nut to 35-45 lb-ft.

4. Attach the electrical connector from the lever harness to the

shift knob.

5. Slide the skirt up to the shift knob and position the electrical

connector in the skirt. Line up the pins from the skirt to the

holes on the shift knob and snap the skirt on the shift knob.

Note: The shift knob skirt is designed to snap correctly on

the knob only one way. If it is installed in the opposite

direction it will not line up correctly.

36

Page 43

In-Vehicle Service Procedures

How to Remove the Gear Shift Lever/Remote Shift Control

Special Instructions

Remote control housings are removed the same way as gear shift levers.

Special Tools

• Typical Service Tools

Procedure -

1

1. Remove the four retaining capscrews from the shift lever

base.

2

1. Housing

2. Capscrew

3. Gasket

3

2. To break the gasket seal, lightly strike the gear shift control

housing.

3. Remove the gear shift lever control housing to expose the

gasket.

4. Remove the gasket and clean the surface area the replacement gasket will contact.

37

Page 44

In-Vehicle Service Procedures

How to Install the Gear Shift Lever/Remote Shift Control

Special Instructions

Remote control housings are installed the same way as gear shift levers.

Special Tools

• Typical Service Tools

Procedure -

1. Position a new gasket on the shift lever/shift control housing

mounting surface.

In-Vehicle Service Procedures

2. Install the gear shift lever base/shift control housing. Make

sure the tip (finger) of the shift lever fits into the round hole

in the shift block.

3. Apply Eaton®Fuller® thread sealant #71205 or equivalent to

the retaining capscrews.

1. Housing

2. Capscrew

3. Gasket

4. Install the retaining capscrews and tighten to 40-45 lb-ft

(54-61 Nm) of torque.

Final Check

Make sure the capscrews are properly torqued.

Make sure you can shift the transmission.

1

2

3

38

Page 45

In-Vehicle Service Procedures

How to Adjust the Remote Shift Control (LRC Type)

Special Instructions

The following is a typical adjustment procedure for an LRC type slave control. It is recommended that the OEM Chassis Service

Manual be consulted first.

Procedure -

1

1. Move the gear shift lever forward or backward to the neutral

2

position.

D

3

4

B

A

6

5

7

2. Move the gear shift lever sideways, toward reverse, until you

feel resistance from the reverse plunger spring. DO NOT

shift to reverse. The shift finger must remain in this position

while you are making all the adjustments.

3. Remove the cotter pin, castle nut and ball joint A from the

selection lever. Do not remove the ball joint from the pivot

link.

4. Loosen the capscrew B and remove the shift arm from the

inner shift shaft. Do not disconnect the selection lever from

the shift arm.

1. Reach Rod

2. Turnbuckle

3. Selection Lever

4. Inner Shift Finger

5. Shift Arm

6. Pivot Link Assembly

7. Inner Shift Shaft

39

2

90

5. Turn the shift arm until it is at a right angle (90°) to the selection lever as viewed from the side.

Note: Ideally, the shift arm should be adjusted 90° to the se-

lection lever as described, but in some chassis configurations it may be necessary to index the shift arm in

1

the vertical position. Indexing the shift lever is done to

prevent shift lever jump out. This type of adjustment

will cause an unequal amount of gear shift lever travel

between neutral and a forward lever position as compared to neutral and a rearward lever position.

1. Selection Lever

2. Shift Arm

Page 46

6. Install the shift arm on the splines of the inner shift shaft.

You may have to move the shift arm 4° or 5° to align the

splines of the two parts. Disregard any movement of the

gear shift lever at this point. The gear shift lever will be adjusted later.

7. Tighten the capscrew B on the shift arm.

In-Vehicle Service Procedures

8. Connect the pivot link assembly ball joint to the selection lever. Secure it with the castle nut and cotter pin.

9. Loosen the jam nuts C on the pivot link.

1. Selection Lever

2. L.H. Thread

3. R.H. Thread

4. Shift Arm

5. Parallel

10. Check to be sure the inner shift finger is still in place.

11. Rotate the pivot link until the curved end of the selection lever is parallel with the shift arm as viewed from the rear .

12. Tighten the pivot link jam nuts C .

13. Loosen both capscrews on the turnbuckle D .

14. Check to be sure inner shift finger is still in place.

15. Rotate the turnbuckle to obtain the proper forward-backward neutral position of the gear shift lever in the cab.

1

2

C

3

C

In-Vehicle Service Procedures

4

5

1

2

D

3

4

16. Tighten one turnbuckle D capscrew .

17. Move the gear shift lever to the desired position.

18. Turn the second turnbuckle D capscrew.

19. Check for linkage obstructions in all gear positions.

B

A

6

5

7

40

Page 47

In-Vehicle Service Procedures

Neutral Switch Operation and Testing

Special Instructions

The neutral switch is a normally closed switch. An electrical current flows through it when the transmission shifter is in the neutral

position. When the transmission shifter is in gear, the switch is open and no current flows through it. Likewise, the switch is open

when the ball is depressed. The switch is actuated by the shift rail.

Special Tools

• Typical Service Tools

Procedure -

R

1

2

2

3

5

4

6

1

7

9

8

10

1. Disconnect the wiring from the switch.

2. Connect an ohm meter to check for continuity or a small

reading.

3. Place the transmission shift lever in the neutral position. The

ohm meter should register continuity or a small reading. If it

does, go to the next step. If it does not, remove the switch

and replace it.

4. Shift the transmission into all gear positions. The ohm meter

should read open or infinity. If it does not, remove the

switch. Then, depress the switch ball and check for continuity. The ohm meter should read open or infinity when the ball

is depressed.

1. Central Neutral Position (Neutral Switch Active)

2. Shift Position Diagram

5. Look into the neutral switch hole and verify the neutral

switch pin moves as the transmission is shifted from neutral

into gear.

If it does, replace the switch.

If not, remove and inspect the neutral switch pin for excessive wear. Replace, if necessary, or refer to bench service

procedures for disassembly of the shift shaft for inspection.

41

Page 48

How to Remove the Neutral Switch

Special Instructions

None

Special Tools

• Typical Service Tools

Procedure -

1. Remove the switch using a 7/8" deep well socket or box end

wrench.

In-Vehicle Service Procedures

In-Vehicle Service Procedures

42

Page 49

In-Vehicle Service Procedures

How to Install the Neutral Switch

Special Instructions

None

Special Tools

• Typical Service Tools

Procedure -

1. Install a new gasket.

2. Install the neutral switch. Tighten it to 15-20 lb-ft (20-27

Nm) of torque.

3. Connect the wiring to the switch.

43

Page 50

In-Vehicle Service Procedures

Reverse Switch Operation and Testing

Special Instructions

The reverse switch is a normally open ball switch. When the transmission is shifted into reverse, a ramp on the reverse yoke bar

contacts and raises a pin. The pin depresses the ball on the switch, which closes the switch contact, allowing current to flow

through the switch and light up the vehicle's backup lights.

Special Tools

• Typical Service Tools

Procedure -

1

1. Disconnect the wiring from the switch.

2. Connect an ohm meter to check for continuity.

3. Place the transmission shift lever in any position except reverse. If the switch is working properly, the ohm meter

should read open or infinity. If it is not, remove the switch

and recheck it for continuity. Replace as necessary.

R

3

4

7

8

In-Vehicle Service Procedures

1. Reverse Position (Rev Switch Active)

2. Shift Position Diagram

4. Place the transmission shift lever in the reverse position. If

the switch is working properly, the ohm meter should register continuity, or a small reading. If it does not, remove the

switch and recheck it for continuity. Replace as necessary.

Also, check for sticking or excessive wear of the reverse pin.

1

2

2

5

6

9

10

44

Page 51

In-Vehicle Service Procedures

How to Remove the Reverse Switch

Special Instructions

None

Special Tools

• Typical Service Tools.

Procedure -

1. Remove the switch using a 7/8" deep well socket or box end

wrench.

45

Page 52

How to Install the Reverse Switch

Special Instructions

None

Special Tools

• Typical Service Tools

Procedure -

1. Insert the reverse pin in the reverse switch bore (only if pin

is removed).

2. Install new gasket on switch.

3. Install the reverse switch. Tighten it to 15-20 lb-ft (20-27

Nm) of torque.

In-Vehicle Service Procedures

In-Vehicle Service Procedures

4. Connect the wiring to the switch.

46

Page 53

In-Vehicle Service Procedures

How to Remove the Shift Shaft Seal

Special Instructions

None

Special Tools

• Typical Serivce Tools

Procedure -

1. Place the transmission in the reverse gear position.

2. Drain the vehicle air tanks.

3. Disconnect the vehicle wire harness connector from the ECU

using a 1/4" nut driver.

4. Remove the nine ECU capscrews.

5. Remove the ECU, spacer plate, sealing plate, and actuating

washer.

6. Locate the two opposing holes on the metal sleeve of the

seal assembly and insert the tips of the seal pulling tool

(Tool ID T11, SPX P/N J44099). Then slide the seal out of

the shift shaft bore.

47

Page 54

How to Install the Shift Shaft Seal

Special Instructions

None

Special Tools

• Typical Service Tools

Procedure -

1. Lubricate the seal with transmission oil.

2. Slide the seal into the shift shaft bore until it is flush with the

edge of the hole.

In-Vehicle Service Procedures

In-Vehicle Service Procedures

3. Place the transmission in the reverse gear position.

4. Position the actuating washer onto the end of the shift shaft

and make sure it is rotated fully clockwise.

5. Assemble the ECU, spacer plate, and sealing plate.

6. Position the ECU assembly over the actuating washer so the

finger lines up with the range position sensor.

48

Page 55

In-Vehicle Service Procedures

7. Make sure the ECU is fully seated against the case and install

the nine ECU capscrews.

8. Torque the ECU capscrews to 20-23 Lb-ft (27-31 Nm).

9. Attach the vehicle interface harness to the ECU and tighten

connector screw to 7–13 lb-in (.8–1.5 Nm).

49

Page 56

In-Vehicle Service Procedures

How to Remove the Oil Seal - Magnetic Speedometer

Special Instructions

Prior to replacing the seal, carefully inspect the transmission to make sure the oil leakage is coming from the seal. Pay particular

attention to the speedometer parts, rear bearing cover gasket surfaces, rear countershaft bearing covers, and shift bar housing.

For additional information on rear seal service, refer to the Seal Maintenance Guide TCSM-0912.

Special Tools

• Brass drift

• Item T1: Output yoke puller

• Item T15: Slide hammer

See Tool Information

Procedure -

1. Disconnect the driveshaft and U-joint from the output yoke

according to the OEM or driveshaft manufacturer’s instructions.

In-Vehicle Service Procedures

2. Shift the transmission into 1st gear or low gear (Low Range)

to prevent the output yoke from turning when loosening the

output yoke nut.

3. Remove the output yoke nut using a 70 mm or 2 3/4" socket.

4. Use an output yoke puller to remove the output yoke (Tool

ref. ID T1).

5. Remove the speedometer sensors from the rear bearing

cover.

TIP: If the sensor is a thread in type, note the number of

threads exposed so the sensor can be reinstalled to the

same depth. If the sensor is a push in type, remove the hold

down capscrew and pull the sensor out of the bore.

6. Remove the speedometer rotor/seal sleeve and the O-ring.

50

Page 57

In-Vehicle Service Procedures

7. Pry the seal out using a large screwdriver or prybar in the

metal groove of the seal.

NOTE: The seal will be damaged during removal and must be

replaced.

8. Remove seal slinger from the speedometer rotor/seal sleeve

using a brass drift and hammer.

9. Inspect all parts of the oil seal for wear, scratches, burrs, or

other damage.

NOTE: Replace the seal surface if it is worn or damaged. Do

not attempt to salvage the seal mating surface with crocus

cloth, filing, etc.

51

Page 58

In-Vehicle Service Procedures

How to Install the Output Shaft Oil Seal - Magnetic Speedometer

Special Instructions

To prevent oil leaks, do not touch the seal lip, and make sure the seal driver is clean.

Special Tools

• Oil seal driver

• Oil seal slinger driver

See Tool Information, Eaton Aftermarket Tools for part numbers.

Procedure -

1. Place a seal on the oil seal driver, and drive the new seal into

the rear bearing cover. The seal is fully installed when the

flange on the seal is flush with the shoulder in the bore.

In-Vehicle Service Procedures

2. Install the new slinger on speedometer rotor/seal sleeve using a slinger driver.

3. If previously removed, install the O-ring over the output

shaft.

Note: To avoid creating oil leaks, make sure the speedome-

ter rotor/seal sleeve is free from contaminants.

4. Install the speedometer rotor/seal sleeve over the output

shaft, and install the speedometer sensors.

5. Install the output yoke over the output shaft. The yoke

should slide on and stop before contacting the speedometer

rotor. As the output shaft nut is installed, the output yoke will

contact the speedometer rotor.

6. Inspect the output shaft nut for damage and wear. If the nylon locking material is damaged or excessively worn, use a

new output nut.

Note: The nylon locking material must be in good condition

so the nut does not loosen when the vehicle is in use.

52

Page 59

In-Vehicle Service Procedures

7. Lightly oil the output shaft threads and the output nut

threads, and install the nut. Torque the nut to 450-500 Lb ft (610-677 Nm).

8. Connect the driveshaft and U-joint according to the OEM or

driveshaft manufacturer's instructions.

53

Page 60

How to Remove the Output Bearing Cover

Special Instructions

None

Special Tools

• Typical Service Tools

Procedure -

1. Disconnect the driveshaft and universal joint from the output

yoke according to OEM or driveshaft manufacturer's instructions.

2. Drain the transmission oil.

3. Shift the transmission into 1st gear or low gear to prevent

the output yoke from turning when you loosen the output

yoke nut.

In-Vehicle Service Procedures

In-Vehicle Service Procedures

4. Remove the output yoke nut using a 70 mm or 2 3/4" socket.

5. Remove the output yoke. Use an output yoke puller (Tool ref.

ID T1).

6. Remove the speedometer sensor from the rear bearing cover.

7. Remove the six bearing cover capscrews.

54

Page 61

In-Vehicle Service Procedures

8. Use a pry-bar to break the bearing cover loose from the case,

note the orientation of the speed sensor openings for later

re-assembly.

Note: If the sensor is a thread in type, note the number of

threads exposed so the sensor can be reinstalled to

the same depth. If the sensor is a push in type, remove the hold down capscrew and pull the sensor out

of the bore.

9. Remove the speedometer rotor/seal sleeve and the O-ring.

10. Pry the seal out using a large screwdriver or prybar in the

metal groove of the seal.

Note: The seal will be damaged during removal and must be

replaced.

11. Remove seal slinger from the speedometer rotor/seal sleeve

using a brass drift and hammer.

12. Inspect all parts of the oil seal for wear, scratches, burrs, or

other damage.

Note: Replace the seal surface if it is worn or damaged. Do

not attempt to salvage the seal mating surface with

crocus cloth, filing, etc.

55

Page 62

How to Install the Output Bearing Cover

Special Instructions

None

Special Tools

• Typical Service Tools

Procedure -

1. Thoroughly clean and inspect the sealing surfaces on the

transmission case and the output bearing cover for gouges

or distortion, replace if necessary.

2. Apply RTV sealant per application guidelines to the transmission case.

3. Place the bearing cover on the case in the same orientation

as the one removed.

In-Vehicle Service Procedures

In-Vehicle Service Procedures

4. Install the six bearing cover retaining capscrews.

5. Torque the capscrews to 47-52 lb-ft (63-70 Nm).

6. Make sure the output shaft O-ring seal is in place and install

the speedometer rotor/spacer and output yoke. The yoke

should slide on and stop before contacting the speedometer

rotor. As the output shaft nut is installed, the output yoke will

contact the speedometer rotor and output yoke nut. Tighten

the output yoke nut to 450-500 lb-ft (610-677 Nm).

56

Page 63

In-Vehicle Service Procedures

7. Install the output speed sensor and retaining capscrew.

Tighten capscrew to 20-23 lb-ft (27-31Nm).

8. Add required amount of oil per transmission oil fill specifications.

9. Connect vehicle driveshaft to output yoke per vehicle OEM

and driveshaft manufacturer’s instructions.

57

Page 64

How to Remove the Oil Cooler Fitting

Special Instructions

None

Special Tools

• Typical Service Tools

Procedure -

1. Locate the vehicle transmission cooler lines running to the

rear of the transmission.

If the vehicle is equipped with cooler line shut-off valves,

close the cooler shut-off valves and drain the cooler lines.

If the vehicle is not equipped with cooler line shut-off valves,

completely drain the engine cooling system and cooler lines

running to the transmission according to vehicle OEM

guidelines.

In-Vehicle Service Procedures

In-Vehicle Service Procedures

2. Remove the transmission drain plug and drain the transmission oil.

3. Disconnect the cooler lines at the rear of the transmission.

Remove the cooler hose adapter fittings that thread into the

transmission cooler interface fittings. Note the orientation of

the hose fittings for future reassembly.

58

Page 65

In-Vehicle Service Procedures

How to Install the Oil Cooler Fitting

Special Instructions

None

Special Tools

• Typical Service Tools

Procedure -

1. Install new O-rings on existing fittings or replace the complete fittings if damaged.

2. Generously coat the cooler fitting internal and external Orings with Eaton Fuller silicon lubricant #71206 or equivalent

before installing them into the transmission case.

3. Pilot the fitting over the ends of the cooler tube and slide into

the threaded fitting bore, until the threads on the fitting contact the threads in the bore. Because of the tight O-ring fit

both into the bore and over the end of the tube, you must

push the fitting into the borewhile turning to engage the

threads. Tighten fittings to 40-50 lb-ft (54-67 Nm).

4. Install the O-ring type cooler hose adapter fittings into the

transmission interface fittings. Then adjust the inlet and outlets in the direction they were removed, and tighten the locking nuts on the fittings.

5. Install the cooler hoses to the transmission and open the

cooler line shut-off valves, or refill the vehicle cooling system according to the vehicle OEM guidelines.