Page 1

Troubleshooting Guide

Lightning Series

TRTS0580

January 2008

FRLO-14410C-T2

FRLO-15410C

FRLO-15410C-T2

FRLO-16410C

FRLO-16410C-T2

FRLOF-14410C

FRLOF-14410C-T2

FRLOF-15410C

FRLOF-15410C-T2

FRLOF-16410C

FRLOF-16410C-T2

Page 2

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Page 3

General Warnings

General Warnings

Before starting a vehicle:

1. Sit in driver’s seat

2. Place shift lever in neutral

3. Set the parking brake

working on a vehicle or leaving the cab with engine run-

Before

g:

nin

1. Place shift lever in neutral

2. Set parking brake

3. Block wheels

not release the parking brake or attempt to select a gear un-

Do

the air pressure is at the correct level.

til

parking the vehicle or leaving the cab:

When

1. Place shift lever in neutral

2. Set the parking brake

not operate if alternator lamp is lit or if gauges indicate low

Do

.

voltage

Suggested Tools

• Volt/Ohm Meter

SPX

/ Kent-Moore 1 (800) 328-6657

P/N

5505027

• PC-based Service Tool “ServiceRanger”

Contac

t your OEM

• Data Link Tester

Ea

ton Service Parts 1 (800) 826-4357

P/N MF-KIT-04

• Eaton Test Adapter Kit

SPX

/ Kent-Moore 1 (800) 328-6657

P/N J-43318

• 6-Pin Deutsch Diagnostic Adapter

/ Kent-Moore 1 (800) 328-6657

SPX

P/N

J-38500-60A

Related Publications

• TRIG-0580 - Lightning Installation Guide

• TRDR-0580 - Lightning Driver Instructions

• TRSM-0580 - Lightning Service Manual

more information call 1-800-826-HELP (4357) or visit

For

Roadranger.com.

www.

Page 4

Table of Contents

Section 1: Basic Troubleshooting

Diagnostic Procedure for Lightning Models .............1-2

Operational Check List .............................................1-3

Basic System Troubleshooting ................................. 1-4

What To Do If The Transmission

Is Not Operating Properly ................................1-5

Retrieving Fault Information .....................................1-6

Fault Code Table for Lightning Transmission ...........1-7

Symptom Complaints ...............................................1-8

Air System Troubleshooting

Vehicle Air Supply Requirement .............................1-12

Air System - Overview ............................................1-13

Air System - ECU ...................................................1-14

Air System - Splitter Subsystem ............................1-15

Air System - Range Subsystem ..............................1-16

Clutch Housing Breather Leak Overview ................1-18

Clutch Housing Breather Leak ................................1-19

Transmission ECU Breather Leak Overview ............1-20

Transmission ECU Breather Leak ...........................1-21

Range Cylinder Test Overview ................................1-22

Range Cylinder Test ...............................................1-23

Splitter Cylinder Test Overview ..............................1-26

Splitter Cylinder Test ..............................................1-27

Electronic System Troubleshooting

Electrical System Requirements .............................1-30

Wiring Diagram ......................................................1-31

Pinouts ...................................................................1-32

Power-Up Sequence Test Overview .......................1-34

Power-up Sequence Test .......................................1-35

Electrical Pretest Overview .....................................1-38

Electrical Pretest ....................................................1-39

Shift Knob Test- No Fault Codes Overview .............1-42

Shift Knob Test- No Fault Codes ............................1-43

J-1587 Data Link Test Overview .............................1-46

J-1587 Data Link Test ............................................1-47

Section 2: Fault Isolation Procedures

Component Code 11(SID 254, FMI 12)

Transmission ECU ............................................ 2-1

Component Code 33 (PID 158 or 168, FMI 3 or 4)

System Voltage Fault ........................................ 2-3

Component Code 35 (SID 231, FMI 2)

J-1939 Data Link Test ...................................... 2-5

Component Code 36 (SID 48 or 49, FMI 2)

Position Sensor Test ...................................... 2-13

Component Code 43 (SID 36, FMI 4, 5, 6)

Low Range Solenoid ...................................... 2-15

Component Code 46 (SID 37, FMI 4, 5, 6)

Splitter Solenoid ............................................. 2-17

Component Code 48 (SID 35, FMI 4, 5, 6)

High Range Solenoid ...................................... 2-19

Component Code 58 (PID 191, FMI 2)

Output Shaft Speed Sensor ............................ 2-21

System Code 66 (SID 58, FMI 1)

Unconfirmed Torque Path .............................. 2-25

System Code 71 (SID 61, FMI 7)

Range or Splitter Stuck in Gear ...................... 2-29

Component Code 73 (SID 58, FMI 11)

Transmission Missed Synchronous ............... 2-31

System Code 74 (SID 14, FMI 7)

Engine Missed Synchronous .......................... 2-33

System Code 93 (SID 231, FMI 14)

J-1939 Engine Message Fault ......................... 2-33

Reverse Switch Test Overview ............................... 2-39

Reverse Switch Test .............................................. 2-40

Neutral Switch Test Overview ................................ 2-43

Neutral Switch Test ................................................ 2-44

Table of Contents

1-1

Page 5

Fault Isolation Procedures

Diagnostic Procedure for Lightning Models

Key On

Service light

comes on for a

few seconds

then turns off

Yes

Retrieve active

fault codes

Active Codes?

No

(Code 25)

Retrieve inactive

fault codes

No

Yes

- Perform vehicle electrical test

- Perform "No service light test"

- Solid service light? - Replace ECU

- Perform vehicle electrical test

- Follow troubleshooting guide

diagnostics for all Actives Codes

- Clear Inactive Codes/test drive &

confirm code(s) have not reset

1-2

Inactive

Codes?

No

(Code 25)

Symptom?

No

Test Complete

Yes

Yes

- Record & clear inactive fault codes

- Verify complaints / test drive

- If fault code is reset after clearing,

perform vehicle electrical test, and

following diagnostics for symptom

driven faults

- Perform vehicle electrical test

- Perform pneumatic test

- Isolate transmission / clutch issues

- Follow basic troubleshooting/symptom

driven diagnostic procedures

Page 6

Fault Isolation Procedures

Operational Check List

When operating properly, the lightning transmission will act in the following manner:

• Top-2 feature will not function with cruise control turned off.

• Service light flashes once at vehicle initial power up.

• Service light flickers at vehicle power down.

• Service light flashes continuously with an active fault code.

• Synchronizer will not trigger with key off.

• Synchronizer will not trigger in neutral with key on and vehicle stationary.

• Synchronizer will trigger with key on, vehicle stationary and lever moved into a high range gear.

• Synchronizer will not downshift into low range if lever is moved into a low range gear at too high of road speed.

• If started in a high range gear the vehicle accelerator pedal will be “dead”.

• If driver beats the range up-shift with lever movement to a high range gear the accelerator pedal is “dead” until synchronous is made.

• Splitter will not trigger with key off.

Fault Isolation Procedures

• Splitter will trigger with key on and in any lever position.

• Accelerator pedal is “dead” when splitter is up shifting if the driver attempts to accelerate before splitter synchronous is

made.

• Engine accelerates when splitter downshifts if the driver doesn’t control engine RPM for proper synchronous.

• Aggressive splitter shifts below 1100 engine RPMs and whenever the transmission has a fast deceleration of the output

shaft.

• Aggressive splitter shifts with clutch disengaged or foot resting on clutch pedal disengaging clutch switch.

• Aggressive splitter shifts with clutch switch wired improperly – check for engine brake and cruise control functionality.

1-3

Page 7

Fault Isolation Procedures

Basic System Troubleshooting

Following is information to help a vehicle operator start basic troubleshooting of the transmission system.This is not a complete

list. In many cases, the vehicle needs to be evaluated by a trained and experienced transmission technician.

Problem Possible Causes

Growl/Rattle in a “float” or

coast condition.

At idle Check for damaged or defective master clutch, master clutch release bearing, or clutch linkage,

Growl/Rattle on a “pull” Check for engine problem, which would result in noise or excessive vibration.Check master clutch

Lever Check for loose or damaged shift lever, which may vibrate and cause noise. Check for components

All other conditions Check for loose clutch housing bolts. Check transmission oil for excessive metal particles, which

Problem Possible Causes

Hard Lever Shifting Check for damaged or binding shift lever or shift control system.Check for lever interference with

Check for damaged, worn, or defective driveshaft, support bearing, or u-joints, which would result

in noise or vibration. Check for improper vehicle ride height, which would cause improper u-joint

operating angles. Check for axle problem, which would result in noise or vibration. Check for tire

problem, which would result in noise or vibration.

which would result in noise or vibration. Check for loose components, brackets, exhaust system,

and hoses in transmission area, which would result in noise or vibration.

for defects in dampening devices.

added to the shift lever; such as, cruise control, which may vibrate and cause noise.

may indicate internal problem. Check for damaged or worn gearing.

cab floor. Check for upper or lower shift boot tugging on shift lever. Check for a defective or damaged master clutch, which would result in clutch drag. Check for improper clutch brake engagement. Check that proper shifting procedures are followed.

Problem Possible Cause

Transmission is operating

at higher than normal temperature

1-4

If transmission is equipped with an internal cooler, check for pinched engine coolant hoses or

closed shut off valves. See section on Operating Temperatures with Coolers. Check oil level.

Page 8

Fault Isolation Procedures

What to Do if the Transmission is Not Operating Properly

If a problem occurs with the transmission or vehicle system, the transmission may not shift correctly. These effects may include:

• Harsh, slow, or grinding button only shifts.

• No button shifts (5 gear ratios only).

• No range shift (low range or high range gear ratios only).

The Service Light on the Shift Knob may be on continuously, may be flashing, or may not illuminate at all.

If the Transmission is Not Operating Properly, Try the Following Steps:

1. Check the dash air gauge to make sure at least 90 PSI is available in both primary and secondary air systems.

2. Try resetting the Transmission Electronic Control Unit (ECU) - See procedure below.

3. If vehicle and road conditions permit, you may be able to operate the transmission as a 5 speed (no button shifts).

Transmission Reset Procedure

In some cases, “resetting” the transmission Electronic Control Unit (ECU) can restore proper transmission operation. Use the following procedure to reset the ECU.

• When it is safe to do so, stop the vehicle.

• Place the transmission shift lever in neutral and turn the ignition key to the “off” position.

• Wait 5 seconds.

• Restart the engine.

• If the problem continues, proceed to page 9 and identify the symptom.

Transmission Diagnostics

The Lightning Series Transmission ECU has self-diagnostic capability. The transmission recognizes when a problem occurs and

“stores” the information about these problems (faults) in the ECU memory. This information can be retrieved by the following

methods:

• Retrieve basic fault information (flash codes) by counting flashes of the service light.

• Some OEM vehicles have an electronic dashboard, which displays fault information. Refer to the specific OEM chassis

operator instructions for the procedure.

• Connect an applicable hand-held or PC diagnostic tool to the vehicle’s SAE J-1587 diagnostic connector.

Fault Isolation Procedures

1-5

Page 9

Retrieving Fault Information

Fault Isolation Procedures

The transmission Electronic Control Unit (ECU) turns on the

service lamp, located on the shift knob, in the event the ECU

detects an electronic fault and at initial power-up. Once the

ECU has successfully powered-up, the ECU turns off the service lamp. The power-up sequence usually takes a few seconds. The service lamp remains on continuously if the ECU

execution malfunctioned at power-up. The ECU begins code diagnostics only after the ECU has successfully powered-up. The

service lamp flashes steadily if the ECU has detected an Active

fault code.

Note: Any Active code detected at vehicle start-up immediately

starts flashing the service light on the shift knob.

The service light provides access to diagnostic fault information, which has been logged in the transmission ECU. The service light flashes a sequence of on/off pulses, which can be

translated into specific “flash codes”. The flash codes can then

be used to identify a specific fault in the transmission system.

Transmission faults are classified as either Active (current

problem) or In-Active (non-current problem). An Active fault is

logged when the ECU recognizes a problem with the transmission. During an Active fault, the service light flashes steadily or

may stay on continuously. If during vehicle operation, the

problem corrects itself, the service light stops flashing and the

fault is logged as an In-Active fault.

Retrieving In-Active Fault Codes:

1. Use the procedure to retrieve Active fault codes except, turn the key off and on four (4) times within five

seconds ending with the key in the on position.

2. Observe the flash sequence of the service light on the

shift knob. A one or two second pause separates each

stored code, and the sequence automatically repeats

itself after flashing all codes.

Clearing Fault Codes:

The following procedure clears all In-Active fault codes from

the ECU’s memory.

1. Place the shift lever in neutral.

2. Set the parking brakes.

3. Turn the ignition key on but do not start the engine.

4. Start with the key in the on position. Turn the key off

and on six (6) times within five seconds ending with

the key in the on position. The service light will flash

on for 5 seconds confirming the codes are cleared.

Example of Flash Codes

How to Retrieve Fault Codes

Retrieve Lightning fault codes by enabling the Lightning system’s self-diagnostic mode.

Note: You can also use a P.C. based diagnostic tool such as

ServiceRanger to retrieve fault codes.

Retrieving Active Fault Codes:

1. Place the shift lever in neutral.

2. Set the parking brakes.

3. Turn the ignition key on but do not start the engine.

4. Starting with the key in the on position. Turn the key

off and on two (2) times within five seconds ending

with the key in the on position.

5. Observe the flash sequence of the service light on the

shift knob. Flash codes may take 5 seconds to begin

flashing. A one or two second pause separates each

stored code, and the sequence automatically repeats

itself after flashing all codes.

Fault Code 35 Fault Code 11

Short Pause Long Pause Short Pause

Service Light

1-6

Page 10

Fault Isolation Procedures

Fault Code Table for Lightning Transmission

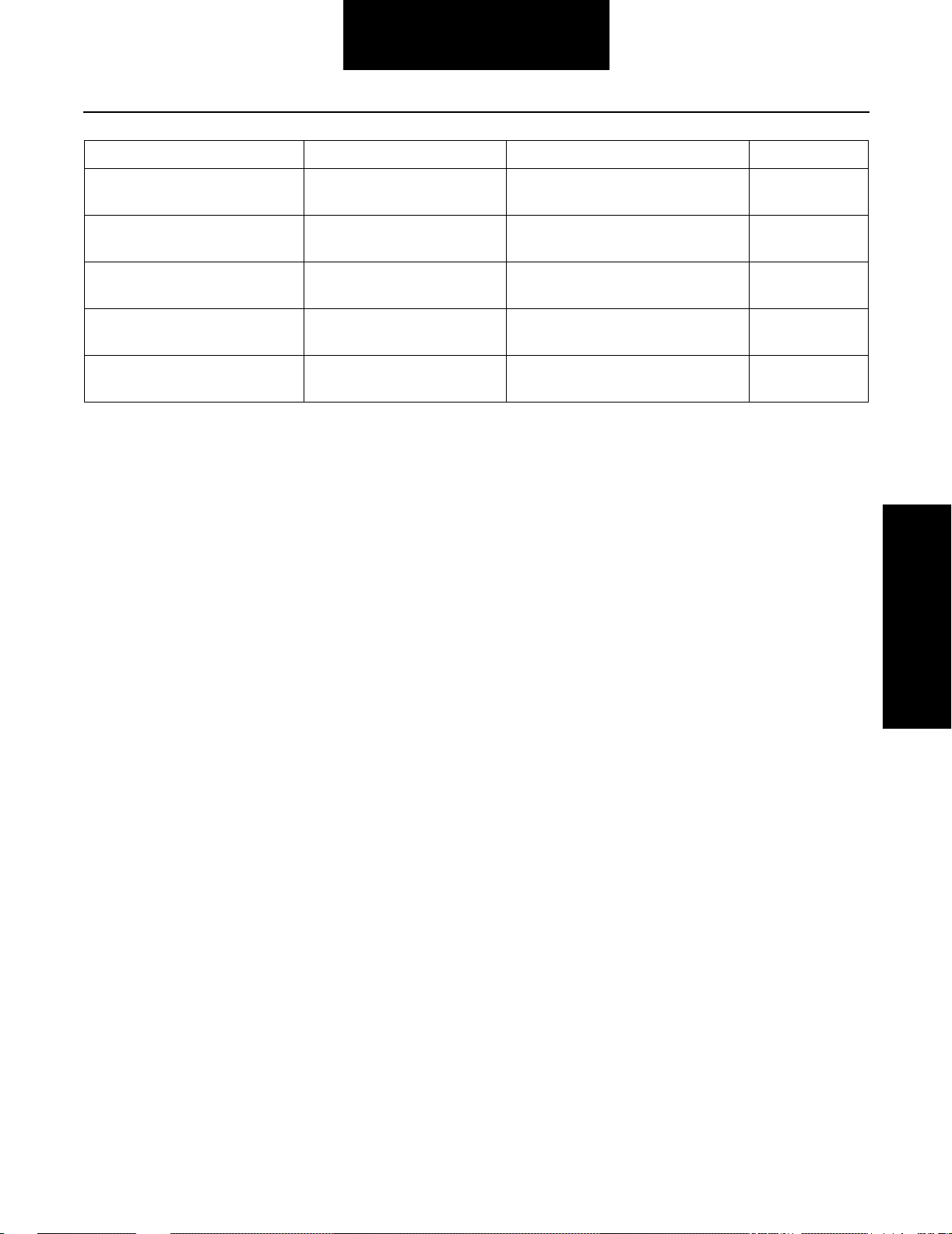

Component Fault Codes*

Flash

Code

11 Transmission ECU 130 254 12

25 No Codes 130

33 Ignition/Battery Voltage Low or High 130 158 or 168 3 or 4

35 Engine to Transmission J1939

36 Shift Lever Position Sensor 130 48 or 49 2

43 Low Range Shift Solenoid 130 36 4, 5, or 6

46 Splitter Shift Solenoid 130 37 4, 5, or 6

48 High Range Shift Solenoid 130 35 4, 5, or 6

58 Output Speed Sensor 130 191 2

Description MID PID SID FMI

130 231 2

Communication Link

System Fault Codes **

Flash Code Description MID PID SID FMI

66 Unconfirmed Torque Path (Input speed and

output speed do not equal known gear ratio)

71 Splitter or Range Stuck in Gear 130 61 7

130 58 1

Fault Isolation Procedures

73 Transmission Missed Synchronization 130 58 11

74 Engine/Transmission Missed

Synchronization

93 J-1939 Engine Message Fault 130 231 14

*Component Fault Codes specifically isolate problems that may arise with the electronic components used in the Lightning series

transmissions. These codes occur at initial vehicle power-up if not induced by intermittent vibration or heat problems.

**System Fault Codes specifically isolate problems that may arise from a mechanical or pneumatic problem that has prevented

or missed a shift in the Lightning transmission. System fault codes are only active during vehicle operation and are not detected

at initial vehicle power-up.

Note: System fault codes also indicate problems with other components that affect the performance of the transmission such as

low air pressure. Troubleshoot the code properly to isolate the component causing the fault to become active.

130 14 7

# Hand Held Codes

MID – Message ID Assignment. In this case, MID 130 represents the transmission.

PID – Parameter ID Assignment. Generally represents a status or value.

SID – Subsystem ID Assignment. Identifies a failure in a subsystem.

FMI – Failure Mode ID. Describes the type of failure detected in the subsystem

1-7

Page 11

Fault Isolation Procedures

Symptom Complaints

Symptom Possible Condition Remedy Reference

No service light Electrical circuit is open,

grounded, or blown VIGN fuse

or faulty light

Service light on continuously Light circuit grounded to VBATT,

transmission performance not

affected

Transmission ECU internal failure;

3 speed operation only;

No splitter or range shifts

Top 2 option not functioning Cruise control turned off Turn on cruise control.

Top 2 option stops functioning

as a result of another problem

No button shifts after cruise control if turned off while in Top 2

mode

Hold Mode Normal Operation. Lever must be

No fault codes set. Performance of

transmission not affected by nonfunctioning light. Check fuse then if

necessary, perform service light

test.

Repair vehicle wiring harness.

Perform vehicle electrical test, if OK

- replace transmission ECU.

Repair for other faults such as Output Speed Sensor Position Sensor.

Look for other complaints such as

engine brake or cruise not functioning.

cycled through neutral to regain button function.

Harsh or aggressive splitter shifts ECU Malfunction Active Fault Code 11. page 1

Before proceeding, see note at

bottom of page.

(any shift using the splitter button) Engine Missed Synchronization Active Fault Code 74. page 33

Grinding or Raking Splitter Shifts Out-Of-Synchronous or shifts

(Shifts from 1st to 2nd, 3rd. to 4

th, 5th to 6th, 7 th to 8 th, and 9 th

to 10th. Shift grinds but engages.)

Position Sensor Malfunction Active Fault Code 36. page 13

Lever/Splitter shifts attempted in an

Engine Synchronous speed outof-limit of operating range

Low or high air pressure Faulty Air Regulator.

Splitter leak or partial blocked air

system

Driver resting foot on Clutch

Pedal so as to disengage clutch

switch but still has clutch engaged

out-of-synchronous condition. Re-

view Driver Instruction Book -

TRDR-0580 - for proper driving

techniques.

Perform Splitter Cylinder Test. page 26

Remove foot from clutch pedal ex-

cept when necessary to shift, start or

stop the vehicle.

1-8

Page 12

Fault Isolation Procedures

Symptom Possible Condition Remedy Reference

Clutch Switch Contamination

built up on switch, for example,

dirt, ice, etc. or Mechanical

Clutch Linkage

Note: Aggressive splitter shifts may occur normally under the following conditions.

1. Low speed splitter shifts below 1100 RPMs. - This is normal operation.

2. Splitter shifts on grades with heavily loaded vehicle. - This is normal operation.

3. Anytime the vehicle has a fast deceleration of the transmission output shaft. For example, making a hard left-hand turn

and moving the splitter at the same time. - This is normal operation.

Symptom Possible Condition Remedy Reference

Harsh shifts (Lever Only) Out-Of-Synchronous Shifts Lever shifts attempted in an out-of-

(Skip shifts. i.e. 1 st to 3 rd., or 3

rd. to 5 th.)

Clutch Drag Adjust Clutch and check for clutch

Clutch Brake Check for improper clutch brake en-

Cruise control and engine brake is

also inoperative when the clutch

switch malfunctions. Refer to OEM

manual for troubleshooting clutch

switch.

synchronous condition. Review Driver’s Instruction Book for proper techniques.

slippage and drag.

gagement.

Fault Isolation Procedures

Slow/grinding/raking or inoperative Range Shift (Shift from 6 th to

7 th or from 7 th to 6 th.)

Five speed transmission. (Only

Even or Odd Numbered Gears.)

Low or High Air Pressure Perform Range Cylinder Test. page 22

Air System Leaks

Reduced Air Flow

Damaged Mechanical parts internal to the transmission

ECU Malfunction Active Fault Code 11. page 1

Unconfirmed torque path

through transmission

Splitter stuck in gear Active Fault Code 71. page 29

Output Speed Sensor Malfunction

Splitter System Air Leak Perform Splitter Cylinder test. page 26

Shift Knob Malfunction No Active Fault Codes. Perform Shift

Active Fault Code 66. page 25

Review Air System Overview. page 13

Repair for damaged internal parts.

Perform Output Shaft Speed Sensor

test.

Knob test.

page 21

page 42

1-9

Page 13

Fault Isolation Procedures

Symptom Possible Condition Remedy Reference

Six speed transmission. (Only 1st

through 6th gears.)

Splitter Solenoid Short or Open Active Fault Code 46. Perform Sole-

noid test.

Loss of communication with

engine

Range system air leak Perform Range Cylinder test. page 22

Position sensor malfunction Active Fault Code 36. page 13

Low Range Solenoid Malfunction

High Range Solenoid Malfunction

Range stuck in gear. Active Fault Code 71. page 29

Transmission missed synchronous.

High Range Synchronizer Mechanical Failure

Active Fault Code 35 and gears 1, 3, 5,

7, 9. J-1939 communication link broken.

Active Fault Code 43. page 15

Active Fault Code 48. page 19

Active Fault Code 73. page 31

Perform Range Cylinder test prior to

disassembly, then replace damaged

synchronizer parts if required. Refer

to “Synchronizer” repair strategy item

TRSM-0915 (Note: after 12/31/04 this

publication will be TRMT-0001) for

repair details.

page 17

page 5

page 22

Four Speed Transmission. (Only 7

th through 10 th gears.)

Three Speed Transmission (Only

1 st, 3 rd., 5 th gears)

Low Range Solenoid Malfunction

Range System Air Leak Perform Range Cylinder test. page 22

High Range Solenoid Malfunction

Range stuck in gear. Active Fault Code 71. page 29

Low Range Synchronizer Mechanical Failure

Low System Voltage Active Fault Code 33. page 3

Loss of air pressure to transmission.

ECU Malfunction. Active Fault Code 11. page 1

Active Fault Code 43. page 15

Active Fault Code 48. page 19

Perform air system test prior to disassembly, then replace damaged synchronizer parts if required. Refer to

“Synchronizer” repair strategy item

TRSM-0915 (Note: after 12/31/04 this

publication will be TRMT-0001) for

repair details.

Check vehicle air pressure.

Service light on continuously. Replace

ECU.

1-10

Page 14

Fault Isolation Procedures

Symptom Possible Condition Remedy Reference

Software download unsuccessful

Two Speed Transmission (only 7

th, 9 th gears)

Neutral Switch Wheel Chair Lift / PTO etc. not

Reverse Switch Reverse Light / Beeper not

ECU malfunction service light

on continuously

operating

Engine will not crank (some applications)

functioning.

Replace ECU.

Replace ECU.

Perform Neutral Switch Test per OEM

recommendations.

Perform Neutral Switch Test per OEM

recommendations.

Perform Reverse Switch Test per

OEM recommendations.

Fault Isolation Procedures

1-11

Page 15

Fault Isolation Procedures

Vehicle Air Supply Requirement

The transmission filter/regulator assembly provides the inlet port for transmission supplied air. You will find the filter/regulator

located at the rear of the transmission on the driver’s side of the truck. The filter/regulator assembly regulates the transmission

supply to 80 PSI (551 kPa) maximum.

Filter / Regulator

Inlet Air Pressure Required 90-130 PSI (620-896 kPa)

Air Dryer Required

Inlet Port Size SAE 3/8” – 18 NPT

1-12

Page 16

Fault Isolation Procedures

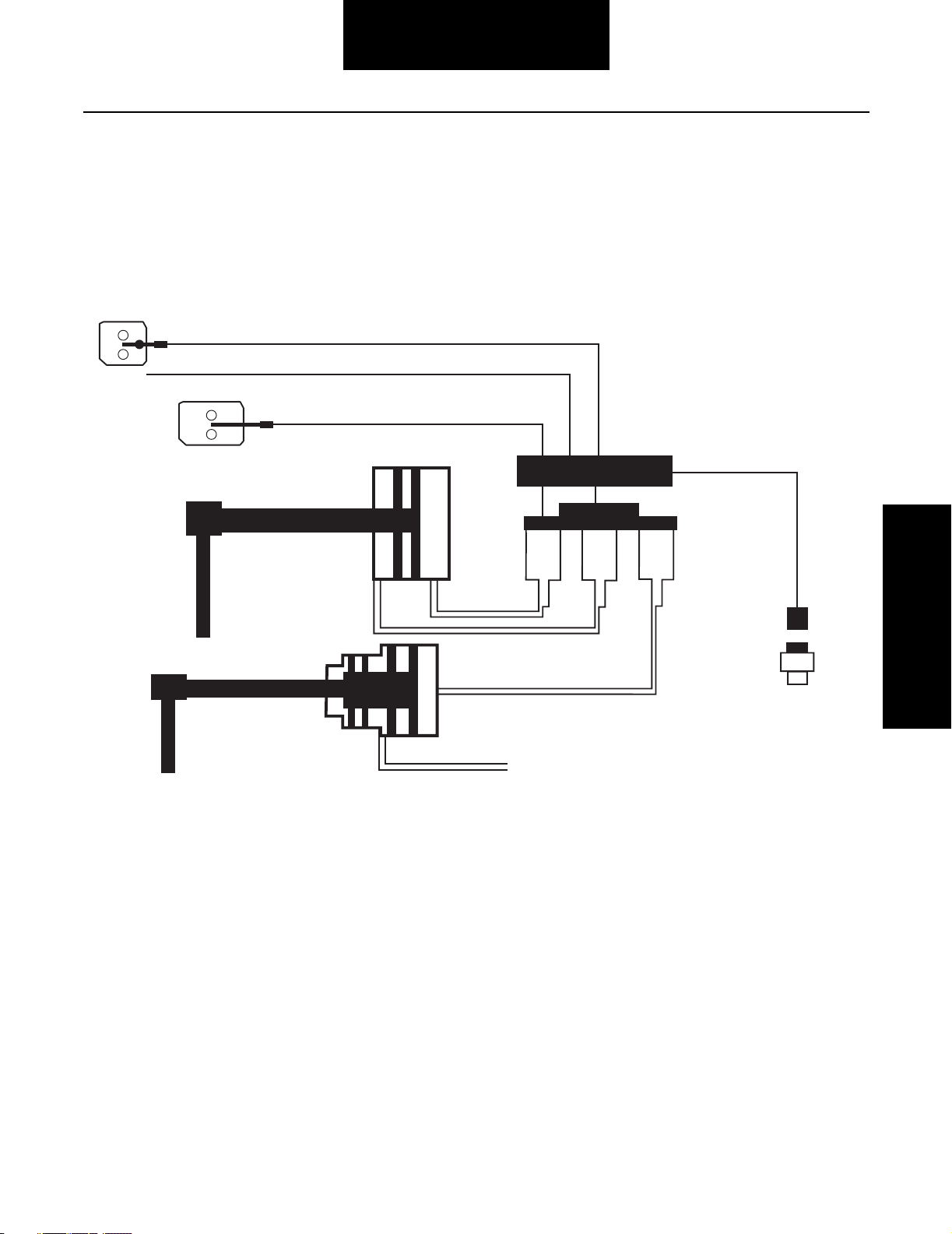

Air System - Overview

The Lightning series transmission uses an automatically controlled range cylinder to manage the air operated range shift between

6th and 7th gear. The button on the shift knob controls the splitter shift. Splitter shifts occur every time the transmission shifts

consecutive from one gear to the next gear or when the button is moved from one state to the next.

The simple block diagram below shows the relationship between the air system and electronic controls.

Splitter Signal from Shift Knob

Engine Communication (J1939)

Diagnostic Communication (J1587)

H

L

Non-Contacting Sensor to

sense desired range position

ECU

Splitter

Range

H L S

Charge Air

Constant Air

Solenoid

Pak

Output Speed

Sensor

The Lightning series transmission utilizes an electric over air concept for actuating the splitter and range cylinders. An electric

signal is sent to the ECU. The ECU then, enables a solenoid valve, which in turn directs air to the appropriate cylinder. A switch in

the shift knob directs the splitter shift. The position of the switch indicates to the ECU the desired splitter state. The ECU makes

the shift automatically when the proper conditions are achieved. The signal to the ECU for a range shift is automatically made when

the shift lever passes from the middle rail (6th gear) to the outside rail (7th gear). A sensor detects the movement and signals the

ECU to actuate the range valve. As with the splitter shift, the range shift only occurs when a specific set of conditions is achieved.

Fault Isolation Procedures

1-13

Page 17

Fault Isolation Procedures

Air System - ECU

The transmission’s electronic control unit (ECU) activates solenoids in the ECU, which opens up internal air passages. The transmission air filter/regulator is the only external air system component.

The air moves through passages internal to the transmission and the seal plate of the ECU. The illustration below shows the air

passages as viewed through the ECU.

Splitter Diagnostic Port

Supply to Valves

Range HI

Diagnostic Port

To HI Range

Splitter

80 PSI Supply

from Regulator /

Constant Air

to Splitter

To Splitter

Cylinder

Range Cylinder

O-ring

Seal Plate

Range

Supply to

Valves

HI Range Valve

LO Range Valve

Splitter Valve

From Splitter Valve

To LO Range

1-14

Splitter Cylinder

O-rings

Exploded View of Air System

Electronic Control Unit

(ECU)

Page 18

Fault Isolation Procedures

Air System - Splitter Subsystem

The ECU controls the operation of the splitter solenoid function, responding to driver input from the splitter button on the shift

knob or Top-2 operation.

The splitter cylinder has three distinct positions, forward (overdrive), rear (direct) and intermediate (neutral). The forward position

is achieved by activating the splitter solenoid valve, which applies air pressure to the rearward side of the piston. This is the splitter

state for the even numbered gears (2, 4, 6, 8 and 10)

The rearward position is achieved by de-activating the splitter solenoid valve, which exhausts the air pressure from the rearward

side of the splitter piston. The constant air pressure then forces the piston rearward. This is the splitter state for the odd numbered

gears (1, 3, 5, 7 and 9).

The intermediate or neutral state is achieved by the ECU rapidly turning on and off the splitter solenoid valve. This condition results

in a pressure on the rearward side of the splitter piston that is between 0 and full system pressure. This neutral state is used to

allow the gears to synchronize prior to engagement, thereby significantly improving the shift quality.

Constant Air Pressure

Splitter in

Direct

Constant Air Pressure

Constant Air Pressure

Signal Air Pressure

Splitter in

Overdrive

Fault Isolation Procedures

Signal Air Pressure

Splitter in

Neutral

1-15

Page 19

Fault Isolation Procedures

Air System - Range Subsystem

The ECU controls the operation of all range solenoid valve functions. The driver’s movement of the shift lever accomplishes a

change in the position of the range from high range to low range or vice versa.

The range piston has two distinct positions. Both the forward and rearward positions are a function of mechanical stops. Only one

side of the piston has air pressure at any one time. The ECU automatically selects either high or low range as the lever passes

through neutral when making an up-shift from 6th gear to 7th gear or the downshift from 7th gear to 6th gear.

In either case, the distinct sound of the range shifting is audible outside the cab, standing next to the stationary truck.

Air

Pressure

Low Range High Range

HI

R

LO

R

2

1

Low Range

3

5

8

4

7

10

6

9

High

Range

Pressure

Air

1-16

Page 20

Fault Isolation Procedures

This page left blank intentionally.

Fault Isolation Procedures

1-17

Page 21

Fault Isolation Procedures

Clutch Housing Breather Leak Overview

Overview

Air leaks out the breather located on top of clutch housing.

An air operated PTO with an air leak can pressurize the

transmission and cause air to leak out the transmission

breather.

Detection

Audible Air Leak

Fallback

There is no fallback mode for this failure.

Possible Leak Paths

Required Tools

• Basic Hand Tools

Possible Causes

• Splitter Cylinder O-Rings

• Range Cylinder O-Ring

• Air operated PTO leak

1-18

Splitter Cylinder Range Cylinder

Page 22

Fault Isolation Procedures

Clutch Housing Breather Leak

Step A Procedure Condition Action

1. Key on.

2. Vehicle stationary and secured,

air system fully charged, engine

not running.

3. Listen for air leaking

out the breather while

moving the shift lever

to make the range

cylinder shift from low

range to high range.

When stationary, the

lever must be moved

in and out of a high

range gear to make the

synchronizer shift.

Note: Oil leaking out the

breather may be a sign

indicating an air leak

internal to the

transmission.

Air leaks in both positions Repair the splitter cylinder, and

replace all cylinder o-rings. Go to

Step V.

Air leaks only in low

range

Repair the range cylinder, and

replace all cylinder o-rings. Go to

Step V.

Step V Procedure Condition Action

1. Fully charge air

system on vehicle and

check for

effectiveness of repair.

Breather still leaks Go to Step A.

Breather does not leak Test Complete.

Clutch Housing Breather

Leak

1-19

Page 23

Fault Isolation Procedures

Transmission ECU Breather Leak Overview

Overview

Air leaks out the breather on the ECU.

The breather exhausts a slight amount of air every time

the transmission makes a range shift and when the splitter

shifts to any odd numbered gear.

Detection

Audible Air Leak.

Fallback

There is no fallback mode for failure.

Possible Leak Paths

Required Tools

• Basic Hand Tools

Possible Causes

This fault can be caused by any of the following:

• Splitter or Range Cylinder O-rings

• Solenoid Seals or O-rings (ECU)

• Seal Plate

Possible Leak Path

1-20

Splitter Cylinder Range Cylinder

Solenoid

(Non-Serviceable - Inside ECU)

Page 24

Fault Isolation Procedures

Transmission ECU Breather Leak

Step A Procedure Condition Action

1. Key on, vehicle stationary and

secured, air system fully

charged, engine not running.

2. Cycle the splitter

cylinder by moving the

button on the shift

knob from the down

position to the up

position.

Leak stops with the

button in the up position.

Leaks in either position Go to Step B.

Replace the splitter cylinder orings and clean out any

contamination in the cylinder. If leak

continues after making this repair,

then replace the transmission ECU

and seal plate. Go to Step V.

Step B Procedure Condition Action

1. Key on, vehicle stationary and

secured, air system fully

charged, engine not running.

2. Cycle the range

cylinder by moving the

shift lever into high

range (the 7/8 gear

position) then back into

neutral. The

synchronizer makes a

distinct audible noise

when shifting.

Leak stops when in high

range.

Leak stops when in low

range.

Replace the range cylinder piston

and clean out any contamination in

the cylinder. If leak continues after

making this repair, then replace the

transmission ECU and seal plate.

Go to Step V

Replace the range cylinder piston

and clean out any contamination in

the cylinder. If leak continues after

making this repair, then replace the

transmission ECU and seal plate.

Go to Step V.

Transmission ECU

Breather Leak

Step V Procedure Condition Action

1. Charge the vehicle air

system and test

repairs for

effectiveness.

No Leaks Test Complete

Air still leaks out breather

on ECU.

Repeat test procedures for air leaks.

1-21

Page 25

Fault Isolation Procedures

Range Cylinder Test Overview

Overview

The range cylinder test does not relate to any specific fault

code, but must be performed prior to disassembly of the

transmission if a range system mechanical failure is suspected. The range cylinder test verifies the basic air system inputs are operating correctly, before proceeding with

disassembly. The driver complaint must be confirmed or

duplicated before preceding with the testing.

Detection

There is no detection process specifically for the Range

Cylinder. However, failures of this type are generally detected by the driver as a symptom such as the transmission range shift may grind, rake, or fail to operate.

Fallback

There is no fallback for the Range Cylinder Test.

Required Tools

• Basic Hand Tools

Possible Causes

This fault can be caused by any of the following:

• Truck air pressure out of range

• Faulty air/filter regulator

• Air system contamination

• Friction material worn or damaged on synchronizer

• Other internal mechanical failure

1-22

Page 26

Fault Isolation Procedures

Range Cylinder Test

Step A Procedure Condition Action

1. Start vehicle and

build up air pressure

to maximum. Shut off

vehicle.

Vehicle's primary and

secondary air supply is

less than 90 PSI or leaks

down

Vehicle air pressure is

Repair vehicle's air system and go

to Step V.

Go to Step B.

greater than 90 PSI and

no leaks.

Step B Procedure Condition Action

1. Drain air tanks to prevent injury.

2. Remove one of three plugs in

transmission filter/regulator and

insert pressure gauge.

3. Start vehicle and build

up air pressure to

maximum. Shut off

vehicle.

Front of

Transmission

Transmission filter/

regulator pressure less

than or greater than 77 to

82 PSI.

Regulator pressure

between 77 and 82 PSI.

Air Inlet

Port

Replace filter/regulator

assembly. Go to Step V.

Go to Step C.

Filter / Regulator

Range Cylinder Test

Regulated

Air Pressure

1-23

Page 27

Fault Isolation Procedures

Range Cylinder Test, continued

Step C Procedure Condition Action

1. Drain air tanks to prevent injury.

2. Remove either the plug for the

high range test port or low range

test port located on the top of

the transmission and insert

pressure gauge.

3. Start vehicle and build up air

pressure to maximum. Shut off

vehicle.

4. Key in the on position, do not

start vehicle.

5. Have an assistant move the

lever to cycle the range cylinder

by moving the lever in and out of

a high range gear position.

6. Watch the reaction of

the pressure gauge

and listen for the range

to shift.

Gauge response is

sudden and immediate.

Gauge reads between 77

to 82 PSI and the distinct

sound of the range

shifting is audible.

Gauge is slow to respond

or the range shift is not

audible.

Go to Step D.

Remove transmission ECU and

clean out any contamination in air

passages or cylinders. Go to Step

V.

Splitter Test Port

High Range Test Port

Low Range Test Port

1-24

Clean the area around the plugs prior

to removal to prevent dirt or other

contamination from falling into the

ports after removing the plugs.

Page 28

Fault Isolation Procedures

Range Cylinder Test, continued

Step D Procedure Condition Action

1. Remove and disassemble

transmission.

2. Inspect all

synchronizer parts.

Synchronizer parts

excessively worn or

damaged. Refer to

publication TRSM-0915

for synchronizer

replacement guidelines.

No parts worn or

damaged

Replace damaged parts. Go to Step

V.

Go to Step V.

Step V Procedure Condition Action

1. Start vehicle and road

test to determine

repair effectiveness.

Range shifts properly Test complete

Range still grinds/rakes

or inoperative

Repeat test procedures

1-25

Range Cylinder Test

Page 29

Fault Isolation Procedures

Splitter Cylinder Test Overview

Overview

The Splitter Cylinder Test does not relate to any specific

fault code, but must be performed prior to disassembly of

the transmission if a splitter system mechanical failure is

suspected. The splitter cylinder test verifies the basic air

system inputs are operating correctly, before proceeding

with transmission disassembly.

Required Tools

• Basic Hand Tools

Possible Causes

Detection

There is no detection process specifically for the splitter

cylinder. However, failures of this type are generally detected by the driver as a symptom such as the transmission splitter shift may grind, rake, or fail to operate. The

driver complaint must be confirmed or duplicated before

proceeding with the testing.

Fallback

There is no fallback for the Splitter Cylinder Test.

This fault can be caused by any of the following:

• Truck air pressure out of range

• Faulty air/filter regulator

• Air system contamination

• Faulty shift knob / splitter switch or

vehicle wiring

• Internal mechanical failure

1-26

Page 30

Fault Isolation Procedures

Splitter Cylinder Test

Step A Procedure Condition Action

1. Review driver's instruction for

proper driving technique.

2. Test drive truck with

operator.

Driver operating splitter

improperly

Driver operating splitter

Provide instruction and end test.

Go to Step B.

properly

Step B Procedure Condition Action

1. Start vehicle and build

up air pressure to

maximum. Shut off

vehicle.

Vehicle's primary and

secondary air supplies

less than 90 PSI or leaks

down

Vehicle air pressure is

greater than 90 PSI and

no leaks

Repair vehicle's air system and

go to Step V.

Go to Step C.

Step C Procedure Condition Action

1. Drain air tanks to prevent injury.

2. Remove one of three plugs in

transmission filter/regulator and

insert pressure gauge.

Splitter Cylinder Test

3. Start vehicle and build

up air pressure to

maximum. Shut off

vehicle.

Front of

Transmission

Regulated

Air Pressure

Filter / Regulator

Air Inlet

Port

Transmission filter/

regulator pressure less

than or greater than 77 to

82 PSI

Regulator pressure

between 77 and 82 PSI

Replace filter/regulator assembly.

Go to Step V.

Go to Step D.

1-27

Page 31

Fault Isolation Procedures

Splitter Cylinder Test, continued

Step D Procedure Condition Action

1. Drain air tanks to prevent injury.

2. Remove the plug for the splitter

test port located on the top of

the transmission and insert

pressure gauge. See illustration

below.

3. Start vehicle and build up air

pressure to maximum. Shut off

vehicle.

4. Key in the on position, do not

start vehicle.

5. Have an assistant move the

button to cycle the splitter

cylinder.

6. Watch the reaction of

the pressure gauge

and listen for the

splitter to shift.

Gauge response is

sudden and immediate.

Gauge reads between 77

to 82 PSI with button in

the up position and the

faint sound of the splitter

shifting is audible

Gauge is slow to respond

or the splitter shift is not

audible

No response on gauge.

Gauge reads “0”.

Go to Step E.

Remove transmission ECU and

clean out any contamination in air

passages or cylinders. Go to Step

V.

Perform “Shift Knob Test - No Fault

Codes Overview” on page 42.

1-28

Page 32

Fault Isolation Procedures

Splitter Cylinder Test, continued

Step D Procedure Condition Action

Splitter Test Port

High Range Test Port

Low Range Test Port

Clean the area around the plugs prior

to removal to prevent dirt or other

contamination from falling into the

ports after removing the plugs.

Step E Procedure Condition Action

1. Remove and disassemble

transmission.

2. Inspect all splitter

parts.

Splitter parts excessively

worn or damaged

No parts worn or

damaged

Replace damaged parts. Go to Step

V.

Go to Step V.

Step V Procedure Condition Action

1. Start vehicle and road

test to determine

repair effectiveness.

Splitter shifts properly Test Complete.

Splitter still grinds/rakes

or inoperative

Repeat test procedures.

Splitter Cylinder Test

1-29

Page 33

Fault Isolation Procedures

Electrical System Requirements

This transmission requires an electronically managed engine, which complies with current SAE J-1939 provisions. The transmission electronic control unit (ECU) communicates with the engine ECU over the J-1939 communication link. The OEM also provides

the J-1939 and J-1587 data-link to the transmission.

Shift Knob

Connection

Reverse Switch

Location

Neutral Switch

Location

ECU

Assembly

Output

Speed Sensor

18-pin

ECU Connector

Transmission Electrical Attachment Points

1-30

Page 34

Fault Isolation Procedures

Wiring Diagram

The Lightning transmission uses a single 18-pin connector at the ECU. The transmission receives input to manage splitter shifts,

into this connector from the engine, shift knob, and output speed sensor. The drawing below illustrates these connections:

T

R

A

N

S

M

I

S

S

I

O

N

E

C

U

A1

B1

Note: Power source connections must be reliable and as close to

the actual source as possible. Relay connections are not advisable.

10 AMP FUSE

10 AMP FUSE

A3

B3

VBATT

A = J1587(+)

A2

B2

B = J1587(-)

Sensor Supplied by Eaton

A A

B B

D1

D2

A = Speed Sensor (+)

B = Speed Sensor (-)

D3

F3

E3

E1

RESERVED FOR

E2

F1

ENGINE CRUISE CONTROL

AND ENGINE RETARDER

+ 12 V (VBATT)

SWITCHED

IGNITION (VIGN)

GROUND (GND1)

GROUND (GND2)

C

A

B

E

A

B

C

A = Service Light Power

B = Shift Knob Ground

C = Voltage Signal

ATA

J1587

Output Shaft

Speed Sensor

SHIFT

KNOB

Fault Isolation Procedures

F2

C3

C2

C1

Terminating

resistor

J-1939/11 data link

(OEM supplied)

Note: Shield Not Used with J1939 Lite.

C = Shield

B = J1939(-)

A = J1939(+)

+

Battery

Shield

termination

_

Engine ECM

Terminating

resistor

1-31

Page 35

Fault Isolation Procedures

18-way Pinout

Circuit Pin Location Description Notes

VBATT A1 Battery Positive Voltage 12 volt 10 Amp Fuse or auto reset (thermal) circuit

breaker required

VIGN B1 Switch Battery Positive Voltage

Switched Ignition - 12 volt

GND1 A3 Battery Negative Connection required at or near vehicle ground

GND2 B3 Battery Negative Connection required at or near vehicle ground

J-1939+ C1 Serial Communication- Engine J-1939 Configured per J-1939 physical layer specifi-

J-1939- C2 Serial Communication- Engine J-1939 Configured per J-1939 physical layer specifi-

CAN_Shield (J-

1939)

J-1587+ A2 Serial Communication - Diagnostics J-

J-1587- B2 Serial Communication - Diagnostics J-

SPD1+ D1 Transmission Output Speed

SPD1- D2 Transmission Output Speed

Knob_Gnd F3 Shift Knob Ground

C3 Serial Communication- Engine Configured per J-1939 physical layer specifi-

1587- High

1587- Low

10 Amp Fuse or auto reset (thermal) circuit

breaker required

point

point

cation

cation

cation

Srv_ Light D3 Power to Knob mounted service light

Splitter_SW E3 Voltage Signal to Splitter Switch

Cruise / Retarder E1, E2, F1, F2 Reserved for engine cruise / engine re-

tarder

Note: Always use the correct connector pin lead adapters from Eaton Test Adapter Kit when performing pin-out diagnostics. This

will prevent damage to the connector pins.

1-32

Not available as of January 1, 1999

Page 36

Fault Isolation Procedures

Fault Isolation Procedures

This page left blank intentionally.

1-33

Page 37

Fault Isolation Procedures

Power-Up Sequence Test Overview

Overview

The power-up Sequence Test is used to identify a faulty

component as the result of a failure during the transmission self-check.

Detection

The power-up self-check is performed automatically each

time the key is turned on. Turn the key on and watch the

service lamp located on the driver's side of the shift knob.

If power-up stops with the service lamp constantly on or

it never comes on, self-check has failed. There are no fault

codes to identify a failure of the self-check.

Fallback

If the self-check fails, the transmission may have full functionality or range and splitter function may be lost.

Required Tools

• Basic Hand Tools

Possible Causes

This fault can be caused by any of the following:

• Shift Knob

• Wiring harness or connectors from 18-way connector to shift knob

• Transmission ECU

Transmission ECU

Connection

OEM Interface

Connection

Typical OEM Wiring Harness

and Connections

Speed Sensor

Connection

Shift Knob

Connection

1-34

Page 38

Fault Isolation Procedures

Power-Up Sequence Test

Step A Procedure Condition Action

1. Key on.

2. Observe service lamp. If service lamp lights for

Test Complete.

one second and turns off.

Light comes on Go to Step B.

If test fails Go to Step V.

Step B Procedure Condition Action

1. Key off.

2. Remove 18-way connector from

transmission ECU.

3. Using a 1.5 volt DC

battery connect the

positive (+) side of the

battery to pin D3 and

the negative (-) side of

the battery to pin F3.

This should illuminate

the light.

Light comes on Replace Transmission ECU.

If test fails Go to Step C.

Power-up Sequence Test

A3

A2

A1

B3 C3

B2 C2

B1

E3

D3

D2

C1

D1

E2E1F2

F3

Dry Cell

F1

1.5 Volts

1-35

Page 39

Fault Isolation Procedures

Power-Up Sequence Test, continued

Step C Procedure Condition Action

1. Remove skirt from bottom of

shift knob and disconnect shift

knob from wiring harness

2. Using a 1.5 volt DC

battery, connect the

positive (+) side of the

battery to pin A and the

negative (-) side of the

battery to pin B. This

should illuminate the

light.

Note: Raised ribs on the

connector identify pin

locations

Dry Cell

1.5 Volts

A B C

Light comes on Repair or replace damaged wiring

harness.

If test fails Replace shift knob.

Step V Procedure Condition Action

1. Perform Electrical Pre-Test.

2. Using a 1.5 volt DC

battery, connect the

positive (+) side of the

battery to pin A and the

negative (-) side of the

battery to pin B. This

should illuminate the

light.

1-36

Pre-test fails Repair vehicle harness or electrical

system according to OEM

specifications.

Pre-test passes Replace Transmission ECU.

Page 40

Fault Isolation Procedures

Power-Up Sequence Test, continued

This page left blank intentionally.

Power-up Sequence Test

1-37

Page 41

Electrical Pretest Overview

Fault Isolation Procedures

Overview

The pretest does not relate to any specific fault code, but

must be completed before performing Fault Code Isolation Table procedures. The pretest verifies the basic electrical inputs before testing individual circuits.

Detection

There is no detection process specifically for the basic

electrical supply. However, failures of this type are generally detected by the transmission or driver as different

symptom or fault code.

Fallback

There is no fallback for the electrical pretest, however, it

may effect other systems.

Required Tools

• Basic Hand Tools

• Digital Volt/Ohm Meter

• Troubleshooting Guide

Possible Causes

This pretest can be used for any of the following:

• Corroded Power Contacts

• Blown Fuse

• Wiring Harness

• Low Batteries

1-38

Page 42

Fault Isolation Procedures

Electrical Pretest

Step A Procedure Condition Action

1. Key off.

2. Check VBATT and

ignition fuse or circuit

breaker.

Note: System has two fuses or

circuit breakers, one for

switched ignition and the

other for VBATT.

Fuses or circuit breakers

blown or tripped.

Fuses or circuit breakers

good.

Replace or reset the fuse. Check for

short to ground on VBATT or VIGN.

Go to Step V.

Go to Step B.

Step B Procedure Condition Action

1. Key on - Engine Running.

2. Check truck charging

system including

alternator, regulator

and batteries. Check

per OEM or

manufacturer

recommendations.

Truck charging system

does not meet OEM

specifications for

charging requirements.

Charging system meets

OEM specifications.

Repair charging system, i.e.

alternator, batteries, etc., and Go

to Step V.

Go to Step C.

Electrical Pretest

Step C Procedure Condition Action

1. Key off

2. Locate transmission

power and ground

connections (2 of

each) and inspect for

looseness or

corrosion.

Connections loose or

corroded

Connections clean and

tight

Repair connections and Go to Step

V.

Go to Step D.

1-39

Page 43

Fault Isolation Procedures

Electrical Pretest, continued

Step D Procedure Condition Action

1. Key off.

2. Disconnect 18-way connector

from transmission.

3. Disconnect negative (-) battery

cable from battery.

4. Measure resistance

between ECU

If resistance is 0 to 0.3

ohms

Go to Step E.

connector pin A3 and

negative battery cable

and between

connector pin B3 and

negative battery cable.

If resistance is outside of

range

Repair ground path for

transmission and repeat this step.

Step E Procedure Condition Action

1. Key off.

2. Reconnect negative (-) battery

cable removed from previous

test.

3. Leave 18-way connector

disconnected from

transmission.

4. Check voltage from A1

to A3 and from A1 to

B3.

Voltage across pins

greater than or less than

specified system voltage

or 12 to 13 volts.

Repair truck harness or electrical

system according to OEM

specification and go to Step V.

1-40

VOLTS

V COM

Voltage equals specified

system voltage of 12 to

13 volts.

E3

A3

B3 C3

A2

B2 C2

B1

A1

D3

F3

E2E1F2

D2

C1

D1

F1

Go to Step F.

Page 44

Fault Isolation Procedures

Electrical Pretest, continued

Step F Procedure Condition Action

1. Leave 18-way connector

disconnected from

transmission.

2. Key on.

3. Check voltage across

pins A1 to A3 and

across B1 to B3 of the

harness.

Voltage across pins

greater than or less than

specified system voltage

or 12 to 13 volts.

Voltage equals specified

system voltage of 12 to

Repair truck harness or electrical

system according to OEM

specification and go to Step V.

System OK. Go to Symptom

Driven/Trouble Code Diagnostics.

13 volts.

VOLTS

E3

A3

B3 C3

A2

B2 C2

B1

A1

V COM

Step V Procedure Condition Action

D3

F3

E2E1F2

D2

C1

D1

F1

Electrical Pretest

1. Road test vehicle for

repair effectiveness.

Condition does not

Test complete

reoccur

Condition reoccurs Repeat test procedures.

1-41

Page 45

Fault Isolation Procedures

Shift Knob Test - No Fault Codes Overview

Overview

Perform the Shift Knob test if there is no splitter function

when the splitter switch on the Shift Knob is moved up or

down, and no active fault codes are logged.

Detection

The splitter does not change from low to high or high to

low when the splitter switch on the shift knob is changed.

There are no fault codes for a splitter switch failure.

Fallback

Odd number gears only 1st, 3rd, 5th, 7th, and 9th.

Required Tools

• Basic Hand Tools

Possible Causes

This fault can be caused by any of the following:

• Faulty Shift Knob

• Harness Between Shift Knob and Transmission

ECU

• Transmission ECU

Transmission ECU

Connection

OEM Interface

Connection

Typical OEM Wiring Harness

and Connections

Speed Sensor

Connection

Shift Knob

Connection

1-42

Page 46

Fault Isolation Procedures

Shift Knob Test - No Fault Codes

Step A Procedure Condition Action

1. Key off.

2. Remove 18-pin connector from

the transmission ECU.

3. Measure resistance

across pins F3 and E3

of the harness with the

splitter button in the

down position then in

the up position.

OHMS

V COM

A3

B3 C3

A2

B2 C2

B1

A1

D3

D2

C1

D1

E3

E2E1F2

If the button down

position meter reads .5

Replace transmission ECU. Go to

Step V.

ohms or less and button

up position meter reads

infinite ohms

If either position falls

Go to Step B.

outside this range

Shift Knob Test - No Fault

F3

F1

Codes

1-43

Page 47

Fault Isolation Procedures

Shift Knob Test - No Fault Codes, continued

Step B Procedure Condition Action

1. Gently remove the shift knob

skirt being careful not to damage

electrical connections.

2. Disconnect 3-way connector

located under skirt.

3. Measure resistance

across pins B and C of

the connector with the

splitter button in the

down position then in

the up position.

Note: Raised ribs on the

connector identify pin

locations.

OHMS

V COM

In the button down

position meter reads .5

ohms or less and Button

up position meter reads

infinite ohms

If either position falls

outside this range

A B C

Replace or repair wiring harness

between shift knob and

transmission ECU. Go to Step V.

Replace shift knob. Go to Step V.

Step V Procedure Condition Action

1. Reconnect all connectors.

2. Key on.

3. Drive vehicle to test for

repair effectiveness.

1-44

Transmission has all

available gears

Transmission still has

only five available gears

Test Complete.

Review tests procedures and check

for any active fault codes. Re-run

necessary tests.

Page 48

Fault Isolation Procedures

Shift Knob Test - No Fault Codes, continued

This page left blank intentionally.

Shift Knob Test - No Fault

Codes

1-45

Page 49

Fault Isolation Procedures

J-1587 Data Link Test Overview

Overview

Does not affect transmission operation. Any tool connected to the ATA J-1587 Data Link connector does not work

correctly.

Detection

The service technician observes the failure when operating the PC-based Service Tool. To observe this failure,

simply connect the PC-based Service Tool to the transmission via the J-1587 diagnostic connector located in the

cab.

Fallback

There is no fallback mode for J-1587 Data Link. The PCBased Service Tool will not work correctly.

Required Tools

• Basic Hand Tools

• Digital Volt/Ohm Meter

• Troubleshooting Guide

• Service Tool

Possible Causes

This fault can be caused by any of the following:

• J-1587 data link

• Transmission ECU

• Service Tool

+12

volts

battery

J-1587 data link

GROUND

6-way

diagnostic connector

9-way

diagnostic connector

A Ground

A ATA+

B ATA–

C + Battery

D

E Ground

F

J

D

F

B

A

E

C

D

C

H

B

G

E

A

F

B + Battery

C

D

E

F ATA+

G ATA-

H

J

All OEM responsible wiring shown is "typical". Consult specific application.

+12 volt non-switched from battery

Communication from and to the ECU

1-46

Page 50

Fault Isolation Procedures

J-1587 Data Link Test

Step A Procedure Condition Action

1. Key on.

2. Measure voltage

between pins C and E

If voltage is within .6

volts of battery voltage

Go to Step B

on the 6-way

diagnostic connector

or pins B and A on the

9-way connector.

If voltage is outside of

range

Repair battery or ground line to

vehicle diagnostic connector. Go to

Step V.

VOLTS

F

B

A

E

C

D

V COM

H

JCD

B

G

E

A

F

VOLTS

V COM

Step B Procedure Condition Action

1. Disconnect Transmission ECU

18-way connector.

2. Measure resistance

across 18-way

connector pin A2 and

either 6-way diagnostic

connector pin A or 9way diagnostic

connector pin F.

If resistance is 0 to .3

ohms

If resistance is outside of

range

J-1587 Data Link Test

Go to Step C.

Repair vehicle's interface harness

and go to Step V.

1-47

Page 51

Fault Isolation Procedures

J-1587 Data Link Test, continued

Step C Procedure Condition Action

1. Measure resistance

across either 6-way

diagnostic connector

pin A or 9-way

diagnostic connector

pin F and ground.

OHMS

F

E

V COM

Ground

If resistance is greater

Go to Step D.

than 10K ohms or infinite

If resistance is less than

10K ohms

OHMS

B

A

C

D

V COM

Ground

H

JCD

B

G

E

A

F

Repair vehicle's harness and go to

Step V.

1-48

Page 52

Fault Isolation Procedures

J-1587 Data Link Test, continued

Step D Procedure Condition Action

1. Measure resistance

across 18-way

connector pin B2 and

either 6-way

diagnostic connector

pin B or 9-way

diagnostic connector

pin G.

E3

A3

B3 C3

A2

B2 C2

B1

A1

D3

E2E1F2

D2

C1

D1

If resistance is 0 to .3

Go to Step E.

ohms

If resistance is outside of

range

Repair vehicle's harness and go to

Step V.

OHMS

F3

F1

COM

V

F

B

A

E

C

D

J-1587 Data Link Test

OHMS

J

D

C

E3

D3

A3

B3 C3

A2

B2 C2

C1

B1

A1

F3

D2

E2E1F2

D1

F1

COM

V

H

E

B

A

G

F

1-49

Page 53

Fault Isolation Procedures

J-1587 Data Link Test, continued

Step E Procedure Condition Action

1. Measure resistance

between either 6-way

diagnostic connector

pin B or 9-way

diagnostic connector

pin G and ground.

OHMS

F

E

V COM

Ground

If resistance is greater

Go to Step F.

than 10K ohms or infinite

If resistance is less than

10K ohms

OHMS

B

A

D

V COM

Ground

H

JCD

B

G

E

A

F

Repair vehicle's harness and go to

Step V.

1-50

Page 54

Fault Isolation Procedures

J-1587 Data Link Test, continued

Step F Procedure Condition Action

1. Disconnect all data links to the

vehicle's diagnostic connector

leaving only the transmission

connected.

2. Connect the data link tester

across the diagnostic connector

pins A and B for the 6-way

diagnostic connector or F and G

of the 9-way diagnostic

connector.

3. Key on.

4. Place the Data Link

Tester in the

communication test

mode.

Black

B

F

A

C

H

E

JCD

B

G

D

A

F

Red

Red

E

Black

Data Link Tester

CONTINUITY TEST

SELF TEST

OFF

COMMUNICATION

TEST

Part No. 691582

Data Link Tester

CONTINUITY TEST

SELF TEST

OFF

COMMUNICATION

TEST

Part No. 691582

If test passes Problem exits with service tool in

one of the following area.

Communication Box, Cables or the

PC. Repair as required and go to

Step V.

If test fails Replace transmission ECU and go

to Step V.

OFF

J-1587 Data Link Test

OFF

Step V Procedure Condition Action

1. Key on.

2. Connect tool to J-

1587.

If service tool functions

correctly

If service tool does not

function correctly

Test Complete.

Return to Step A and

repeat procedure.

1-51

Page 55

Fault Isolation Procedures

Component Code 11 (SID 254, FMI 12) Transmission ECU

Overview

This fault code indicates an internal failure of the transmission ECU.

Detection

The transmission ECU detects an internal solenoid power

supply problem or three consecutive attempts to read or

write program memory information each time the ignition

key is turned on. Active fault code 11 cannot be accessed

using the key switch method to access flash codes. An

electronic diagnostic tool such as ServiceRanger or ProLink must be used to confirm active fault code 11.

Fallback

Required Tools

• Basic Hand Tools

• Diagnostic Tool

Possible Causes

This fault can be caused by any of the following:

• Transmission ECU

Depending on the failure mode, shift performance may

not be affected. The driver may have only odd number

gears in either low or high range, or he may have 6-speed

shifting with low range only.

Transmission ECU

2-1

Page 56

Fault Isolation Procedures

Code 11 (SID 254, FMI 12) Transmission ECU

Step A Procedure Condition Action

1. Key on.

2. Retrieve codes. Active Code Replace Transmission ECU.

In-Active Code Test Complete.

2-2

(SID 254, FMI 12)

SideTitle Code 11

Page 57

Fault Isolation Procedures

Component Code 33 (PID 158,168, FMI 3,4) System Voltage Fault

Overview

This fault code indicates vehicle ignition or battery voltage

supplied to the transmission ECU connector pins A1 or B1

is outside the acceptable operating range.

Required Tools

• Basic Hand Tools

Possible Causes

Detection

The fault code can be set during initial power up or during

normal operation if either of the following conditions occur:

1. Vehicle battery power supplied to transmission ECU

connector pin A1 falls below 9 volts for 5 seconds.

2. Vehicle ignition power is lost at transmission ECU connector pin B1 longer than 60 seconds and J1939 data link

remains active.

Fallback

Detection mode 1 results in fallback to 1st, 3rd, and 5th

gears only.

Detection mode 2 results in fallback to odd gears only 1st, 3rd, 5th, 7th, 9th.

This fault can be caused by any of the following:

• Truck charging system

• Battery or ground connections

• Fuses or circuit breakers

• Transmission ECU

2-3

Page 58

Fault Isolation Procedures

Code 33 (PID 158,168, FMI 3,4) System Voltage Fault

Step A Procedure Condition Action

1. Perform Vehicle

Electrical Pretest.

Vehicle Passes Test Go to Step V.

Vehicle Fails Test Repair according to manufacturers

recommendations. Go to Step V.

Step V Procedure Condition Action

1. All connectors secure and in

place on transmission

2. Clear all fault codes from

transmission ECU.

3. Key on.

4. Wait 5 minutes and

look for fault code 33 to

reappear.

Fault reoccurs Replace transmission ECU.

Fault does not reoccur Test complete.

PID 158,168, FMI 3,4)

Code 33

2-4

Page 59

Fault Isolation Procedures

Component Code 35 (SID 231, FMI 2) J-1939 Data Link Test

Overview

This fault code indicates J1939 data link communication

between the transmission and all other J1939 devices has

failed.

Detection

15 seconds after key-on and throughout vehicle operation

the transmission constantly monitors communication

with all other J1939 devices. If communication to or from

the engine or other devices is lost for more than a fraction

of a second and there is a shift request, Fault Code 35 will

be logged and the service light will begin flashing. If communication is lost and there is no shift request (steady

speed condition), the fault code will not be set as long as

communication is reestablished before a shift request. If

communication is reestablished after an active fault code

is set, the light will stop flashing and the fault will be

logged as inactive.

Required Tools

• Basic Hand Tools

• Digital Volt/Ohm Meter

• Troubleshooting Guide

• Data Link Tester

Possible Causes

This fault can be caused by any of the following:

• J-1939 data link

• J- 1939 data link connectors

• Engine ECM

• Transmission ECU

Fallback

An active J-1939 fault causes the transmission to default

to a 5-speed fallback mode in either low or high split depending on last known gear position. Range shift now

triggers in neutral with engine running and the vehicle stationary.

Engine ECM

Terminating

resistor

J-1939/11 data link

(OEM supplied)

+

termination

_

Shield

Terminating

resistor

2-5

Battery

Page 60

Fault Isolation Procedures

Code 35 (SID 231, FMI 2) J-1939 Data Link Test

Step A Procedure Condition Action

1. Key off

2. Disconnect transmission ECU

18-way connector.

3. Disconnect engine ECM's

connector, which contains the

J-1939 data link.

4. Measure resistance across

vehicle interface harness from:

• Transmission

ECU 18-way

connector and

engine ECM

+J-1939 pin

(See OEM

Engine pinout).

• Transmission

ECU 18-way connector C1

and ground.

A3

B3 C3

A2

B2

B1

A1

If resistance between pin

Go to Step B.

C1 and engine ECM

+J-1939 pin is 0 to .3

ohms and if resistance

between pin C1 and

ground is greater than

10K.

If resistance is outside of

this range

Repair J-1939 data link harness

between ECM and transmission

ECU, then go to Step V.

(SID 231, FMI 2)

OHMS

E3

D3

F3

D2

C2

E2E1F2

D1

F1

COM

V

A3

B3 C3

A2

B2 C2

B1

A1

E3

D3

F3

D2

E2E1F2

D1

F1

OHMS

V

Code 35

COM

Ground

J1939 (+)

J1939 (-)

Shield

EATON

Lightning

18-Way ECU

Connector

C1

C2

C3

Engine ECM

+ J1939 pin

2-6

Page 61

Fault Isolation Procedures

Code 35 (SID 231, FMI 2) J-1939 Data Link Test, continued

Step B Procedure Condition Action

1. Measure resistance across:

• Transmission

ECU 18-way

connector C2 and

Engine ECM -J1939 pin (See

OEM Engine

pinout).

• Transmission

ECU 18-way

connector C2 and

ground.

A3

A2

A1

B3 C3

B2

B1

If resistance between pin

C2 and engine ECM

-J-1939 pin is 0 to .3

If equipped with J-1939 Lite. Go to

Step D. If not equipped with J1939 Lite Go to Step C.

ohms and if resistance

between pin C2 and

ground is greater than 10K ohms.

If resistance is outside of

this range

Repair J-1939 data link harness

between ECM and transmission

ECU Go to Step V.

OHMS

E3

D3

F3

D2

E2E1F2

D1

C1

F1

COM

V

A3

B3 C3

A2

B2

B1

A1

C1

E3

D3

F3

D2

E2E1F2

D1

F1

OHMS

COM

V

Ground

J1939 (+)

J1939 (-)

Shield

EATON

Lightning

18-Way ECU

Connector

C1

C2

C3

Engine ECM

+ J1939 pin

2-7

Page 62

Fault Isolation Procedures

Code 35 (SID 231, FMI 2) J-1939 Data Link Test, continued

Step C Procedure Condition Action

1. Measure resistance

across Transmission

ECU 18-way

connector C3 and

Engine ECM Shield

pin (See OEM Engine

pinout).

J1939 (+)

J1939 (-)

Shield

If resistance between pin

C3 and engine ECM

Shield pin is 0 to .3

ohms.

If resistance is outside of

this range

EATON

Lightning

18-Way ECU

Connector

C1

C2

C3

Go to Step D. If working with Mack

engine Step E.

Repair J-1939 data link harness

between ECM and transmission

ECU, then go to Step V.

OHMS

B3 C3

B2

B1

D3

F3

D2

E2E1F2

D1

C1

F1

V

COM

Engine ECM

+ J1939 pin

A3

A2

A1

E3

(SID 231, FMI 2)

Code 35

2-8

Page 63

Fault Isolation Procedures

C1

Code 35 (SID 231, FMI 2) J-1939 Data Link Test, continued

Step D Procedure Condition Action

1. Key off.

2. Measure resistance on

vehicle interface