Page 1

Troubleshooting Guide

Eaton Gen III Automated

Transmissions

TRTS0930 EN-US

August 2013

UltraShift®

AutoShift®

UltraShift® PLUS Linehaul Active Shifting (LAS)

UltraShift® PLUS Linehaul Small Step Efficiency (LSE)

UltraShift® PLUS Multipurpose Extreme Performance (MXP)

UltraShift® PLUS Multipurpose High Performance (MHP)

UltraShift® PLUS Vocational Active Shifting (VAS)

UltraShift® PLUS Vocational Construction Series (VCS)

UltraShift® PLUS Vocational High Performance (VHP)

UltraShift® PLUS Vocational Multipurpose Series (VMS)

UltraShift® PLUS Vocational Extreme Performance (VXP)

UltraShift® PLUS Passenger Vehicle (PV)

Page 2

Model:

F-5405B-DM3

F-6405B-DM3

F-14E316B-LSE

F-15E316B-LSE

F-17E316B-LSE

FM-15E316B-LSE

FM-14D310B-LST

FM-15D310B-LST

FO-16D313E-LEP

FO-5406B-DM3

FO-6406A-AW3

FO-6406B-AW3

FO-8406A-AW3

FOM-16D313E-LEP

RTLO-14918A-AS3

RTLO-16913L-DM3

RTLO-16918A-AS3

RTO-10910B-DM3

RTO-12910B-AS3

RTO-12910B-DM3

RTO-14910B-AS3

RTO-14910B-DM3

RTO-14910C-AS3

RTO-16910B-AS3

RTO-16910B-DM3

RTO-16910C-AS3

RTO-18910B-AS3

FO-10E310C-VAS

FO-12E310C-VAS

FO-14E310C-VAS

FO-16E310C-VAS

FOM-14E310C-VAS

F-5505B-DM3

F-6505B-DM3

RTLO-18918A-AS3

RTLO-20918A-AS3

RTLO-22918A-AS3

RTLOM-16913L-DM3

RTO-10910B-AS3

RTOM-16910B-DM3

FO-14E310C-LAS

FO-16E310C-LAS

FO-18E310C-LAS

FOM-14E310C-LAS

FOM-15E310C-LAS

FOM-16E310C-LAS

FM-14E310B-LAS

FM-15E310B-LAS

EO-11E406B-PV

FOM-15E310C-VAS

FOM-16E310C-VAS

FO-10E308LL-VCS

FO-11E308LL-VCS

FO-12E308LL-VCS

FO-14E308LL-VCS

FO-16E308LL-VCS

FO-17E308LL-VCS

FO-16E313A-VHP

FO-18E313A-VHP

FO-20E313A-VHP

FO -10E309A LL-VMS

FO -11E309ALL-VMS

FO -12E309ALL-V MS

FO -14E30 9ALL-VMS

FO -16E309ALL-VM S

FO -17E309ALL-V MS

FO-14E313B-MHP

FO-16E313B-MHP

FO-18E313B-MHP

FO-20E313B-MHP

FO-14E318B-MXP

FO-16E318B-MXP

FO-18E318B-MXP

FO-20E318B-MXP

FO-22E318B-MXP

FO-14E318B-VXP

FO-16E318B-VXP

FO-18E318B-VXP

FO-20E318B-VXP

FO-22E318B-VXP

EO-11E406B-PVER

EO-11E406B-PVHR

EO-11E406B-PV

Page 3

TRTS0930

Table of Contents

T

able of Contents

General Information

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . .1

Suggested Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Transmission Models Included . . . . . . . . . . . . . . . . . . .3

Diagnostic Procedures. . . . . . . . . . . . . . . . . . . . . . . . . .6

Fault Code Retrieval/Clearing

Retrieving Fault Codes Manually . . . . . . . . . . . . . 10

Clearing Fault Codes Manually . . . . . . . . . . . . . . . 11

Retrieving Fault Codes with ServiceRanger . . . . . 11

Clearing Fault Codes with ServiceRanger. . . . . . . 12

Fault Code Isolation Procedure Index . . . . . . . . . . . . .13

Symptom-Driven Diagnostics Index . . . . . . . . . . . . . .15

Product Diagnostic (PD) Mode . . . . . . . . . . . . . . . . . .16

Electrical Pretest Procedures

Electrical Pretest . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

TECU Power Harness. . . . . . . . . . . . . . . . . . . . . . 19

Heavy-Duty Electric Clutch Actuator (ECA)

Power Harness. . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Preferred +12 Volt Connections . . . . . . . . . . . . . . 22

Preferred +24 Volt Connections . . . . . . . . . . . . . . 24

TECU Ignition Circuit . . . . . . . . . . . . . . . . . . . . . . 26

J1939 Data Link. . . . . . . . . . . . . . . . . . . . . . . . . . 27

Electrical Pretest . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Power-Up Sequence Test. . . . . . . . . . . . . . . . . . . . . . .32

Fault Isolation Procedures

Fault Code 11 - No TECU Operation. . . . . . . . . . . . . . .40

Fault Code 12 - Improper ECU Configuration. . . . . . . .44

Fault Code 13 - J1939 Shift Control Device . . . . . . . . .48

Fault Code 14 - Invalid Shift Lever Voltage

(without Park Pawl) . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Fault Code 14 - Invalid Shift Lever Voltage

(with Park Pawl) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Fault Code 15 - HIL Shift Device Configuration . . . . . . 64

Fault Code 16 - High Integrity Link (HIL) . . . . . . . . . . .68

Fault Code 17 - Start Enable Relay

Fault Code 18 - ECA Communication Fault. . . . . . . . . .84

Fault Code 19 - CAN ECA Message Fault . . . . . . . . . . .88

Fault Code 21 - Auto Neutral Park Brake Switch . . . . . 92

Fault Code 22 - ABS CAN Message Fault . . . . . . . . . . . 98

Fault Code 26 - Clutch Slip . . . . . . . . . . . . . . . . . . . .102

Fault Code 27 - Clutch Disengagement . . . . . . . . . . .106

(SER) Circuit . . . . .80

Fault Code 28 - Clutch System. . . . . . . . . . . . . . . . . .112

Fault Code 29 - Remote Throttle Enable. . . . . . . . . . .118

Fault Code 31 - Momentary Engine Ignition

Interrupt Relay (MEIIR) Test . . . . . . . . . . . . . . . . . . .122

Fault Code 32 - Loss of Switch Ignition Power Test .128

Fault Code 33 - Low Battery Voltage Supply . . . . . . . 132

Fault Code 34 - Weak Battery Voltage Supply

Fault Code 35 - J1939 Communication Link . . . . . . . 144

Fault Code 36 - J1939 Engine Message. . . . . . . . . . . 150

Fault Code 37 - Power Supply . . . . . . . . . . . . . . . . . .156

Fault Code 41 - Range Failed to Engage. . . . . . . . . . . 162

Fault Code 42 - Splitter Failed to Engage . . . . . . . . . .168

Fault Code 43 - Range Solenoid Valve . . . . . . . . . . . . 174

Fault Code 44 - Inertia Brake Solenoid Coil . . . . . . . . 180

Fault Code 45 - High Capacity (HCIB)

or Low Capacity (LCIB) Inertia Brake Failure . . . . . . .186

Fault Code 46 - Splitter Direct and

Solenoid Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

Fault Code 51 - Rail Position Sensor . . . . . . . . . . . . .196

Fault Code 52 - Gear Position Sensor . . . . . . . . . . . .202

Fault Code 56 - Input Shaft Speed Sensor . . . . . . . . . 208

Fault Code 57 - Main Shaft Speed Sensor . . . . . . . . .214

Fault Code 58 - Output Shaft Speed Sensor. . . . . . . . 218

Fault Code 61 - Rail Select Motor . . . . . . . . . . . . . . .224

Fault Code 63 - Gear Select Motor. . . . . . . . . . . . . . .230

Fault Code 64 - ECA Fault . . . . . . . . . . . . . . . . . . . . .236

Fault Code 65 - ECA Speed Sensor Fault . . . . . . . . . . 240

Fault Code 66 - ECA Battery Voltage Fault . . . . . . . . .248

Fault Code 67 - ECA Ignition Voltage Fault. . . . . . . . . 254

Fault Code 68 - Grade Sensor . . . . . . . . . . . . . . . . . . 260

Fault Code 71 - Unable to Disengage Gear. . . . . . . . .264

Fault Code 72 - Failed to Select Rail. . . . . . . . . . . . . .270

Fault Code 73 - Failed to Engage Gear . . . . . . . . . . . .276

Fault Code 74 - Engine Speed Response Fault. . . . . .282

Fault Code 75 - Power Down In Gear. . . . . . . . . . . . . 286

Fault Code 81 - Gear Engagement Detected. . . . . . . . 290

Fault Code 83 - Shift Lever Missing. . . . . . . . . . . . . .294

Fault Code 84 - Shift Control

Fault Code 85 - Shift Control Device Incompatible. . . 302

Fault Code 99 - Direction Mismatch. . . . . . . . . . . . . .306

Indirect

Device Not Configured . 298

. . . . . . 138

2013.08.7

© 2013 Eaton Corporation. All rights reserved

i

Page 4

Table of Contents TRTS0930

Symptom Isolation Procedures

Up/Down Button Test. . . . . . . . . . . . . . . . . . . . . . . . .310

Start Enable Relay Contact Test . . . . . . . . . . . . . . . . .314

J1587 Data Link Test . . . . . . . . . . . . . . . . . . . . . . . . .320

Front Box Control Test . . . . . . . . . . . . . . . . . . . . . . . .326

AutoShift Will Not Engage a Gear

from Neutral Test . . . . . . . . . . . . . . . . . . . . . . . . . . . .332

Heavy-Duty UltraShift PLUS Will Not Eng

a Gear from Neutral Test . . . . . . . . . . . . . . . . . . . . . .340

UltraShift DM3 Will Not Engage a Gear

from Neutral Test . . . . . . . . . . . . . . . . . . . . . . . . . . . .348

UltraShift AW3 Clutch Engagement Test

AutoShift AS3 Shift Complaint Test . . . . . . . . . . . . . .358

Heavy-Duty UltraShift PLUS Shift Co

UltraShift DM3 Shift Complaint Test . . . . . . . . . . . . .378

UltraShift AW3 Shift Complaint Test . . . . . . . . . . . . .388

Shift Lever Back Light Test . . . . . . . . . . . . . . . . . . . .396

age

. . . . . . . . . .354

mplaint Test . . .368

Appendix

Connector Pin Descriptions

Non-ECA Products Transmission Controller

38-Way (Vehicle Interface Connector) . . . . . . . . 402

Push Button Shift Control 30-Way Connector . . 403

Cobra Lever 8-Way Connector . . . . . . . . . . . . . . 403

Non-ECA Products Transmission Controller

38-Way (Eaton Supplied Assembly). . . . . . . . . . 404

Heavy-Duty & Medium-Duty UltraShift PLUS

Transmission Controller

38-Way (Vehicle Interface Connector) . . . . . . . . 405

Heavy-Duty UltraShift PLUS T

Controller 38-Way (Eaton Supplied Assembly

Medium-Duty UltraShift PLUS T

Controller 38-Way (Eaton Supplied Assembly

Wiring Diagrams

UltraShift DM3 6-Speed Wiring Diagram

with Analog Shifter. . . . . . . . . . . . . . . . . . . . . . . 408

UltraShift DM3 6-Speed Wiring Diagram

with Push Button Shifter . . . . . . . . . . . . . . . . . . 410

UltraShift AW3 6-Speed Wiring Diagram

with Analog Shifter. . . . . . . . . . . . . . . . . . . . . . . 412

UltraShift AW3 6-Speed Wiring Diagram

with Push Button Shifter . . . . . . . . . . . . . . . . . . 414

Medium-Duty UltraShift PLUS Mo

Diagram with Analog Shifter . . . . . . . . . . . . . . . 416

Medium-Duty UltraShift PLUS Mo

Diagram with Push Button Shifter . . . . . . . . . . . 418

AutoShift 10-Speed Wiring Diagram

with Analog Shifter. . . . . . . . . . . . . . . . . . . . . . . 420

ransmission

) . 406

ransmission

) . 407

dels Wiring

dels Wiring

AutoShift 10-Speed Wiring Diagram

with Push Button Shifter . . . . . . . . . . . . . . . . . . 422

UltraShift 10-Speed Wiring Diagram

with Analog Shifter. . . . . . . . . . . . . . . . . . . . . . . 424

UltraShift 10-Speed Wiring Diagram

with Push Button Shifter . . . . . . . . . . . . . . . . . . 426

UltraShift 13-Speed Wiring Diagram

with Analog Shifter. . . . . . . . . . . . . . . . . . . . . . . 428

UltraShift 13-Speed Wiring Diagram

with Push Button Shifter . . . . . . . . . . . . . . . . . . 430

AutoShift 18-Speed Wiring Diagram

with Analog Shifter. . . . . . . . . . . . . . . . . . . . . . . 432

AutoShift 18-Speed Wiring Diagram

with Push Button Shifter . . . . . . . . . . . . . . . . . . 434

Heavy-Duty UltraShift PLUS Mo

Wiring Diagram with Analog Shifter. . . . . . . . . . 436

Heavy-Duty UltraShift PLUS Mo

Wiring Diagram with Push Button Shifter . . . . . 438

Eaton Cobra Lever Wiring Diagram . . . . . . . . . . 440

OEM Shift Lever Wiring Diagram . . . . . . . . . . . . 441

Eaton Push Button Wiring Diagram . . . . . . . . . . 442

OEM J1939 Shift Input Device Wiring Diagram . 444

Heavy Duty UltraShift PLUS Mo

ECA Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . 445

Proper Clutch Operation

Check For Proper Clutch Operation

Confirm Proper Clutch Adjustment

and Clutch Brake Contact . . . . . . . . . . . . . . . . . . 447

Clutch Grease Interval Service Procedure . . . . . 448

ServiceRanger Procedure . . . . . . . . . . . . . . . . . . . . .449

dels

dels

dels

. . . . . . . . . . 446

ii

© 2013 Eaton Corporation. All rights reserved

2013.08.7

Page 5

TRTS0930 General Information | Warnings and Cautions

!

!

!

Warnings and Cautions

Warning: Follow the specified procedures in the indicated

order to avoid personal injury

Note: Additional relevant information not covered in the

service procedure.

Before starting a vehicle:

• Ensure adequate fuel level

• Sit in the driver's seat

• Place shift lever in neutral

• Set the parking brake

Before working on a vehicle or leaving the cab

with engine running:

• Ensure ignition is off while hands are within the

clutch housing area.

• Place shift lever in neutral

• Set the parking brake

• Block the wheels

When parking the vehicle or leaving the cab:

• Place shift lever in neutral

• Set the parking brake

Caution: Follow the specified procedures in the indicated

order to avoid equipment malfunction or damage.

Caution: Do not release the parking brake or attempt to

select a gear until the air pressure is at the correct

level.

To avoid damage to the transmission during

towing:

1. Place shift lever in neutral

2. Lift the drive wheels off of the ground or disconnect the driveline

Do not operate the vehicle if Alternator light is lit or if

gauges indicate low voltage.

2013.08.6

© 2013 Eaton. All rights reserved

1

Page 6

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Page 7

Suggested Tools | General Information TRTS0930

Suggested Tools

Air Gauges

• 2 (0-100) PSI Air Gauges

Volt/Ohm Meter

• Roadranger Pin Out Adapter Jumper Kit

• RR1009HY

PC-based Service Tool

• ServiceRanger 3

• Contact Eaton: 1 (800) 826-4357

Shift Lever Tester

• Eaton Service Parts: 1 (800) 826-4357

• P/N 691795

Publication Title

Eaton Test Adapter Kit

• SPX / Kent-Moore 1 (800) 328-6657

• P/N J-43318

6-Pin Deutsch Diagnostic Adapter

• SPX / Kent-Moore 1 (800) 328-6657

• P/N J-38500-60A

9-Pin Deutsch Diagnostic Adapter

• SPX / Kent-Moore 1 (800) 328-6657

• P/N J-44012

Service Publications

TRSM0930 Fuller UltraShift Transmission Service Manual

TRTS0930 Fuller UltraShift Transmission Troubleshooting Guide

TRDR0930 Fuller AutoShift Transmission Driver Instructions

TRDR0940 Fuller UltraShift Transmission Driver Instructions

TRDR1110 Fuller UltraShift PLUS Transmission Driver Instructions

For more information call 1-800-826-HELP (826-4357)

2

© 2013 Eaton. All rights reserved

2013.08.6

Page 8

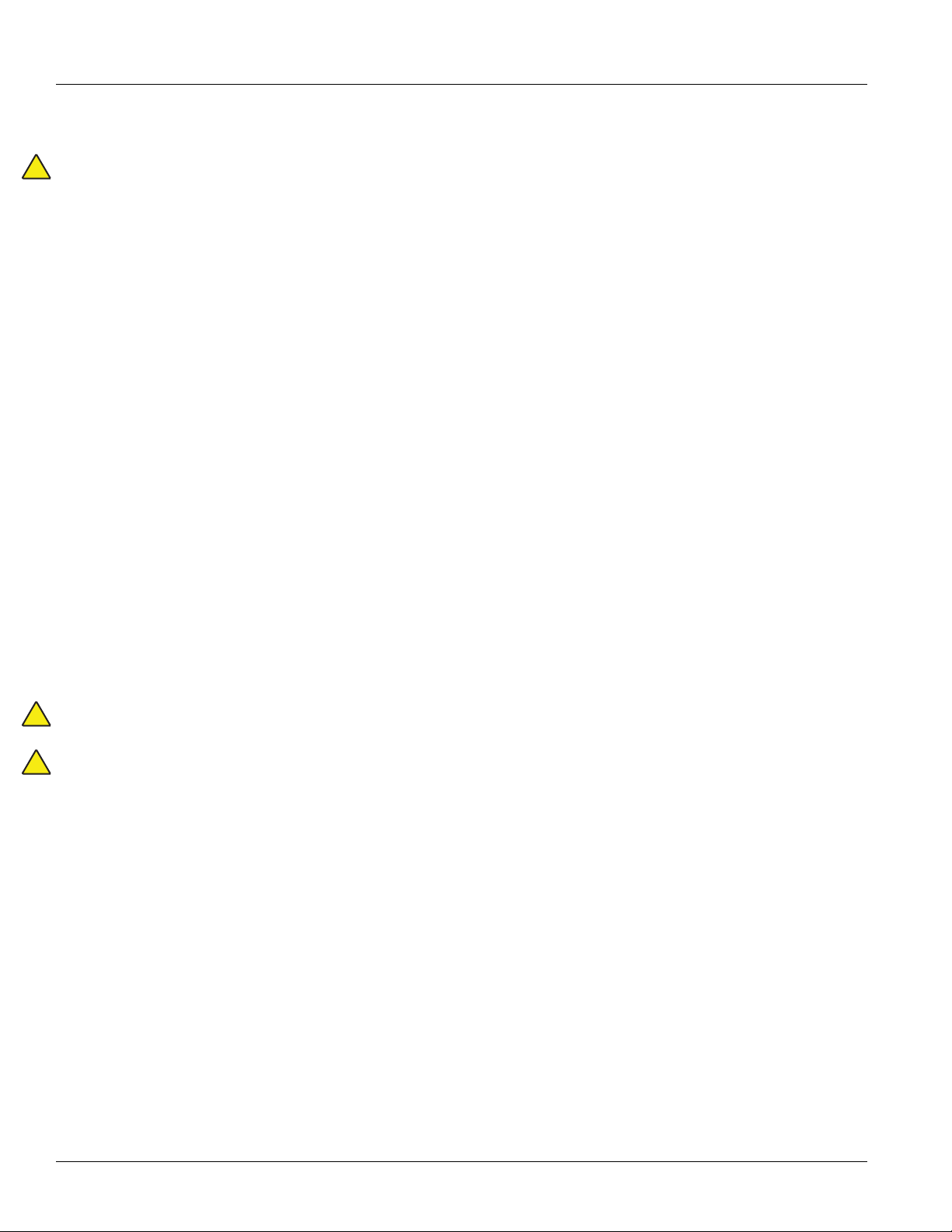

TRTS0930 General Information | Transmission Models Included

RTO-1X910-AS3

RTO(M)-1X910-DM3

RTLO-1X918-AS3

RTLO(M)-1X913-DM3

F(0)-X406X-AW3

F(0)-X405X-DM3

F(0)-X406X-DM3or

Transmission Models Included

2013.08.7

© 2013 Eaton. All rights reserved

3

Page 9

Transmission Models Included | General Information TRTS0930

F(M)-1XE316-LSE

FO-1XE309LL-VMS, FO-1XE308LL-VCS

FO-1XE318-VXP/MXP, FO-1XE313-MHP/VHP

F(O)(M)-1XE310-LAS/VAS

EO-11E406B-PV(ER)(HR)

4

© 2013 Eaton. All rights reserved

2013.08.7

Page 10

TRTS0930 General Information | Transmission Models Included

2013.08.7

© 2013 Eaton. All rights reserved

5

Page 11

Diagnostic Procedures | General Information TRTS0930

Diagnostic Procedures

Overview

None

Detection

None

Fallback

None

Possible Causes

None

6

© 2013 Eaton. All rights reserved

2013.08.16

Page 12

TRTS0930 General Information | Diagnostic Procedures

Component Identification

None

2013.08.16

© 2013 Eaton. All rights reserved

7

Page 13

Diagnostic Procedures | General Information TRTS0930

Diagnostic Procedures

Purpose: Observe the transmission gear display.

A

1. Key on.

2. Observe gear display.

Note: An “88” may show up in the dash at key on.

This indicates the Transmission Electronic

Control Unit (TECU) has completed

power-up. If the transmission and gear display power-up at the same time, you may

not see an “88”.

• If blank gear display, go to Step

• If “-” (1 dash) on gear display, go to Step D.

• If “--” (2 dashes) or “**” (2 stars) on gear dis-

play, go to Step

• “#” (gear number) on gear display

- Verify shift lever or push button is in neutral.

- Turn key off and wait 2 minutes.

- Hold clutch half way to the floor. (If

equipped)

- Turn key on.

- If problem continues, call 1-800-826-HELP

(4357)

D.

B.

Purpose: Confirm that the engine will crank and

B

start.

1. Attempt to start engine

• No engine crank, lever is in neutral and gear

display is “N” (neutral). See “Start Enable

Relay Contact Test” on page 314.

• No engine crank, lever is in neutral and gear

display is blank. See “Power-Up Sequence

Test” on page 32.. If no problems found, refer

to OEM for gear display problem.

• No engine crank and lever is NOT in neutral.

- Verify shift lever or push button is in neutral.

- Turn key off and wait 2 minutes.

- Hold clutch half way to the floor. (If

equipped)

- Turn key on.

- If problem continues, call 1-800-826-HELP

(4357)

• Engine cranks and gear display is blank. Refer

to OEM for gear display problem.

• Engine cranks and gear display is “N” (neutral), go to Step

C.

• Fault Code F on gear display, go to Step

• Neutral “N” on gear display, go to Step B.

D.

8

© 2013 Eaton. All rights reserved

2013.08.16

Page 14

TRTS0930 General Information | Diagnostic Procedures

Purpose: Confirm the transmission will engage a

C

gear from neutral.

1. Engage a gear.

Note: AutoShift will not engage a gear from neutral

test. UltraShift will not engage a gear from

neutral test. UltraShift PLUS Product will not

engage a gear from neutral test, or UltraShift

AW3 Clutch Engagement test depending on

transmission type.

• Unable to engage gear (ie. flashing gear dis-

play with down arrows, or solid “N”).

• Solid “#” (gear number) but no drive. See

“Front Box Control Test” on page 326. Gear

engaged and drives, go to Step

E.

Purpose: Check for active or Inactive fault codes.

D

1. Check for active fault codes.

Note: If no problem found, refer to OEM for display

problem.

• If codes are present, See “Fault Code Isolation

Procedure Index” on page 13.

• If no codes and gear display is “-” (1 dash)

- Verify shift lever or push button is in neutral.

- Turn key off. Wait 2 minutes.

- Hold clutch half way to the floor. (If

equipped)

- Turn on key.

- If problem continues, call 1-800-826-HELP

(4357)

See “Front Box Control Test” on page 326.

• If no codes and gear display is“--” (2 dashes)

or “**” (2 stars), See “Power-Up Sequence

Test” on page 32.

Purpose: Drive vehicle and attempt to duplicate a

E

fault code.

1. Record and clear Inactive fault codes.

2. Drive vehicle and attempt to reset code.

• If no codes are present, test complete.

• If Inactive transmission component or Fault

Codes, record codes an call 1-800-826-HELP

(4357).

• If active transmission component or Fault

Codes, See “Fault Code Isolation Procedure

Index” on page 13.

2013.08.16

© 2013 Eaton. All rights reserved

9

Page 15

Fault Code Retrieval/Clearing | General Information TRTS0930

Fault Code Retrieval/Clearing

Retrieving Fault Codes Manually

Retrieve fault codes by enabling the system’s self-diagnostic mode.

Note: You can also use a PC- based service tool, such as

ServiceRanger to retrieve fault codes.

1. Place the shift lever in neutral.

2. Set the parking brake.

3. Turn key on with engine off.

Note: If the engine is already running, you may still

retrieve codes; however, do not engage the

starter if the engine stalls.

4. To Retrieve Active Codes: Key on. Turn key off and

on 2 times within five seconds ending with the key

on. After 5 seconds, the Service light begins flashing two-digit fault codes. If no faults are active, the

service light will flash code 25 (no codes). This is

also the procedure to enter, See “Product Diagnostic (PD) Mode” on page 16. for details.

Note: An “88” may show up in the dash at key on,

which is a normal power-up test of the display.

6. Observe the sequence of flashes on the service

light and record the codes. A 1- to 2-second pause

separates each stored code, and the sequence

automatically repeats after all codes have been

flashed.

1 Flash

SERVICE

Short

Code 13

pause

(1/2 sec)

3 Flashes

SERVICE

SERVICE

SERVICE

Long Pause

(3-4 sec)

2x

off

on

5. To Retrieve Inactive Codes: Turn key on. Turn the

key off and on 4 times within five seconds ending

with the key in the on position. After 5 seconds, the

Service light begins flashing two-digit fault codes.

If no faults are active, the service light will flash

code 25 (no codes).

4x

off

on

• Two digit fault codes will be displayed in the gear

display. Some vehicle may be equipped with a service light.

Code 21

2 Flashes

SERVICE

1 Flash

SERVICE

SERVICE

Short

pause

(1/2 sec)

10

© 2013 Eaton. All rights reserved

2013.08.6

Page 16

TRTS0930 General Information | Fault Code Retrieval/Clearing

Clearing Fault Codes Manually

The following procedure clears all Inactive fault codes from

the TECU’s memory. Active fault codes are automatically

cleared when the fault has been corrected.

Note: You may use a PC-based service tool, such as Ser-

viceRanger, to clear fault codes.

1. Place shift lever in neutral.

2. Set parking brake.

3. Turn key on with engine off.

4. Turn key off and on 6 times within 5 seconds ending with key on.

6x

off

Note: If the codes have been successfully cleared, the

Service light will come on and stay on for five

seconds. The gear display will show 25 (no

codes).

5. Turn the key off and allow the system to power

down.

on

Retrieving Fault Codes with

ServiceRanger

This section determines if the TECU is communicating on

the vehicle's J1939 data link and if the component has set

any fault codes. Proper system operation requires the TECU

to communicate with other ECUs on the vehicle's J1939

data link.

Note: This procedure requires ServiceRanger 3.0 or later

and an approved RP1210A communications adapter

that supports J1939 communications.

Detecting Components

1. Connect the service PC to the vehicle's 9-way

J1939 diagnostic port connector with an approved

RP1210A communications adapter.

2. Start the ServiceRanger program and verify that a

connection has been established with the vehicle's

J1939 data link.

• If the TECU is not detected by ServiceRanger,

proceed to the Electrical Pretest procedure to

ensure the TECU has power, and that all components are properly connected the vehicle's

J1939 data link.

Viewing Fault Codes

View the Vehicle Fault Codes screen in ServiceRanger and

verify if any Active or Inactive codes have been set.

1. If an Active code is present, record the vehicle fault

information and proceed to Diagnostic Procedure

in this manual for the Active code. Do not clear any

codes at this time.

2. If only Inactive codes are present, record the vehicle fault information and clear all fault codes. Road

test the vehicle to verify proper operation.

2013.08.6

© 2013 Eaton. All rights reserved

11

Page 17

Fault Code Retrieval/Clearing | General Information TRTS0930

Clearing Fault Codes with ServiceRanger

After all repairs have been made and the system is functioning normally, clear all vehicle codes before placing the vehicle back into service.

Clearing Fault Code

1. Connect the service PC to the vehicle and start ServiceRanger.

2. View the Vehicle Fault Codes screen and select

Clear All.

3. Refresh the screen to verify all Inactive codes have

been cleared, and that no Active codes are present.

12

© 2013 Eaton. All rights reserved

2013.08.6

Page 18

TRTS0930 General Information | Fault Code Isolation Procedure Index

Fault Code Isolation Procedure Index

Fault Codes SPN PID SID FMI Description

11 629 254 12 No ECU operation

12 629 254 13, 14 Improper ECU configuration

13 751 231 8, 11 J1939 Shift Control device

14

(without Park

Pawl)

14

(with Park

Pawl)

15 751 18 9 HIL Shift Device communication

16 625 248 2 High Integrity Link (HIL)

17 1321 237 3, 4, 14 Start Enable Relay Coil

18 520200 34 9 ECA communication

19 520273 248 9 CAN ECA message

21 70 70 14 Auto Neutral Park Brake Switch

22 563 49 9, 14 ABS CAN message fault

25 NO CODES

26 522 55 10 Clutch slip

27 788 55 7, 13 Clutch disengagement

28 788 52,55 3, 4, 5, 7 Clutch system

29 969 372 4, 5 Remote throttle enable

31 1485 218 2, 3, 4, 5, 14 Momentary Engine Ignition Interrupt Relay

32 158 43 2 Loss of Switch Ignition power test

33 168 168 4 Low Battery voltage supply

34 168 168 14 Weak Battery voltage supply

35 639 231 2 J1939 communication link

36 639 231 14 J1939 engine message

37 627 251 5 Power supply

41 768 35 7 Range failed to engage

41 769 36 7 Range failed to engage

42 770 37 7 Splitter failed to engage

42 771 38 7 Splitter failed to engage

43 768 35 3, 4, 5 Range High Solenoid Valve

43 769 36 3, 4, 5 Range Low Solenoid Valve

44 787 54 3, 4, 5 Inertia Brake Solenoid Coil

45 787 54 7 Intertia Brake performance

46 770 37 3, 4, 5 Splitter Direct Solenoid Valve

751 18, 19 2, 3, 4, 5 Invalid Shift Lever voltage

18, 19 2, 3, 4, 5 Invalid Shift Lever voltage

(will show “F” in display)

(MEIIR)

2013.08.16

© 2013 Eaton. All rights reserved

13

Page 19

Fault Code Isolation Procedure Index | General Information TRTS0930

Fault Codes SPN PID SID FMI Description

46 771 38 3, 4, 5 Splitter Indirect Solenoid Valve

51 60 60 2, 3, 4, 10 Rail Position Sensor

52 59 59 2, 3, 4, 7 Gear Position Sensor

56 161 161 2, 3, 4, 5,10 Input Shaft Speed Sensor

57 160 160 2, 3, 4, 5 Main Shaft Speed Sensor

58 191 191 2, 3, 4, 5, 6, 8 Output Shaft Speed Sensor

61 772 39 1, 5, 6, 12 Rail Select Motor

63 773 40 1, 5, 6, 12 Gear Select Motor

64 788 34 2, 7, 12 ECA fault

65 5052 192 5, 2 ECA Speed Sensor fault

66 520271 34 3, 4 ECA Battery Voltage fault

67 520274 158 3, 4, 5 ECA Ignition Voltage fault

68 520274 227 14 Grade Sensor

68 520321 227 13, 14 Grade Sensor

71 560 60 7 Unable to disengage gear

72 772 59 7 Failed to select rail

73 781 58 7 Failed to engage gear

74 518 93 7 Engine speed response fault

74 898 190 7 Engine torque response fault

75* 560 60 14 Power down in gear

81 780 47 7 Gear engagement detected

83 751 18 14 Shift Lever missing

83 752 19 7, 12 Shift Lever missing

84 751 18 13 Shift Control device not configured

84 752 19 13 Park mechanism not calibrated

85 751 18 12 Shift Control device incompatible

99 781 58 14 Direction mismatch

* This code will only be set Inactive

• J1939 Source Address (SA) for Eaton transmissions is 3

• J1587 Module Identifier (MID) for Eaton transmissions is 130

14

© 2013 Eaton. All rights reserved

2013.08.16

Page 20

TRTS0930 General Information | Symptom-Driven Diagnostics Index

Symptom-Driven Diagnostics Index

Symptom Isolation Procedure

Unable to shift transmission with Up/Down button Up/Down Button Test

Engine starting system complaint Start Enable Relay Contact Test

No J1587 communication J1587 Data Link Test

Gear display shows a dash Front Box Control Test

AutoShift will not engage a gear from Neutral AutoShift Will Not Engage a Gear from Neutral Test

UltraShift DM will not engage a gear from Neutral UltraShift DM Will Not Engage a Gear from Neutral Test

UltraShift AW3 will not engage a gear from Neutral UltraShift AW3 Clutch Engagement Test

AutoShift AS3 shift complaint AutoShift AS3 Shift Complaint Test

UltraShift

DM shift complaint UltraShift DM Shift Complaint Test

UltraShift AW3 shift complaint UltraShift AW3 Shift Complaint Test

Shift Lever back light does not work Shift Lever Back Light Test

UltraShift PLUS will not engage a gear from Neutral UltraShift PLUS Will Not Engage a Gear from Neutral

Test

UltraShift PLUS shift complaint UltraShift PLUS Shift Complaint Test

2013.08.6

© 2013 Eaton. All rights reserved

15

Page 21

Product Diagnostic (PD) Mode | General Information TRTS0930

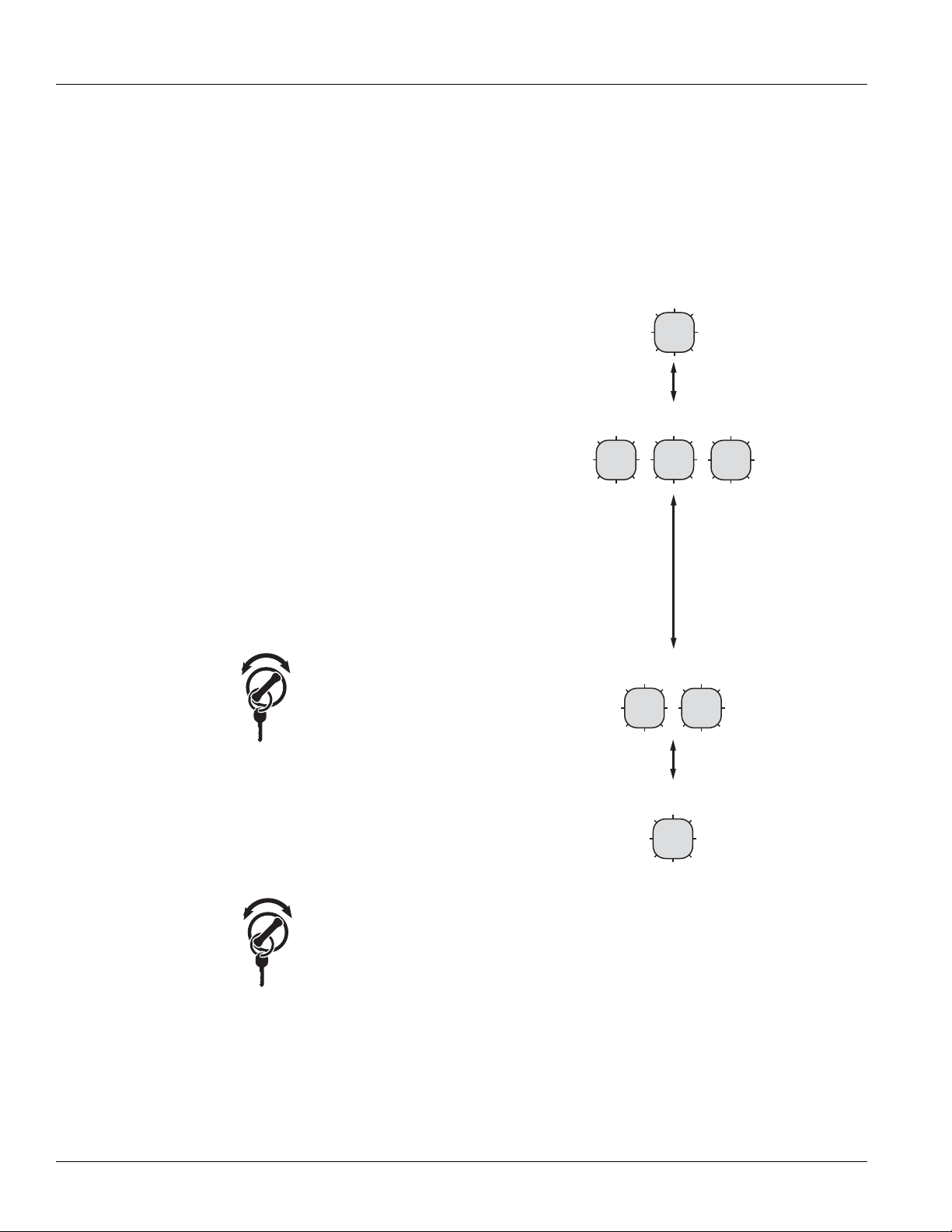

Product Diagnostic (PD) Mode

Product Diagnostic (PD) Mode

PD Mode is used to help diagnose Inactive codes that may

have been set during normal driving. This diagnostic mode

increases the sensitivity of the fault sensing capability

This procedure tests loose, degraded and intermittent connections. Use the Active Fault Isolation Procedure to guide

you to the wiring and connectors that are associated with

the Inactive fault codes. Flex the wiring harness and connectors and attempt to recreate the fault after activating PD

Mode.

PD Mode is only to be used by a trained service technician

in an authorized dealer.

This procedure is to be used prior to performing fault isolation procedures for component-type codes when there are

no Active codes present.

To enter PD Mode:

Note: Vehicle will not start in PD Mode. You must turn vehi-

cle key off to exit PD Mode.

1. Vehicle must be stationary, engine off, set vehicle

parking brake.

• If the fault is detected during PD Mode the gear display will display the active fault. The warning tone

will only sound when the fault is active and the tone

will stop when the fault is Inactive. The fault will

stay in the gear display until the system is powered

down.

Note: Active codes set during PD Mode will not be

stored as Inactive.

7. If a fault is detected, exit PD Mode and perform the

corresponding Fault Isolation Procedure.

8. To exit PD Mode, turn the key off.

PD Mode works with the following

Inactive codes:

11, 13, 14, 15,16, 17, 18, 19, 21, 22, 29, 33, 34, 35, 36, 43,

44, 46, 51, 52, 56, 57, 58, 61, 63, 65, 66, 67, 74, and 99.

2. Turn the key off and on 2 times, starting with key

on and ending with key on.

Note: Dash may display an 88 at key on. This is a nor-

mal power-up test of the display.

3. The gear display will flash a 25 then a solid PD

(Product Diagnostic Mode) and the mode will be

activated.

4. The service light shall flash code 25 once indicating

no codes. The service light shall then illuminate

solid to indicate PD Mode until such time that an

Active code is detected or PD Mode is exited.

5. Refer to PD Mode section in Fault Isolation procedure for the Inactive fault to be diagnosed.

6. PD will remain in gear display until an active fault

has been set during the PD Mode fault isolation

procedure.

16

© 2013 Eaton. All rights reserved

2013.08.16

Page 22

TRTS0930 General Information | Product Diagnostic (PD) Mode

2013.08.16

© 2013 Eaton. All rights reserved

17

Page 23

Electrical Pretest | Electrical Pretest Procedures TRTS0930

Electrical Pretest

Overview

The pretest does not relate to any specific fault code, but

must be completed before performing Fault Code Isolation

table procedures. The pretest verifies the batteries are fully

charged.

All Generation 3 products require the OEM to supply power

to the Electronic Control Unit (ECU) and to the optional

Electric Clutch Actuator (ECA).

Detection

There is no detection process specifically for the basic electrical supply; however, failures of this type are generally

detected by the transmission or driver as some other type

of fault code or symptom.

Fallback

There is no fallback for the electrical pretest; however, it

may affect other systems.

Possible Causes

The pretest can be used for:

• Low batteries

• Starter/Battery connections

• Main power harness to the Transmission Electronic

Control Unit (TECU)

Additional Tools

• Basic hand tools

• Eaton Test Adapter Kit

• Digital Volt/Ohm meter

• Troubleshooting Guide

• Battery Load tester

• ServiceRanger a PC-based service tool

18

© 2013 Eaton. All rights reserved

2013.08.23

Page 24

TRTS0930 Electrical Pretest Procedures | Electrical Pretest

J1

-+

1.

2.

Component Identification

TECU Power Harness

OEM is responsible for overcurrent protection on this circuit.

2013.08.23

1. 30 AMP Fuse

2. TECU Connector (Vehicle Interface)

© 2013 Eaton. All rights reserved

19

Page 25

Electrical Pretest | Electrical Pretest Procedures TRTS0930

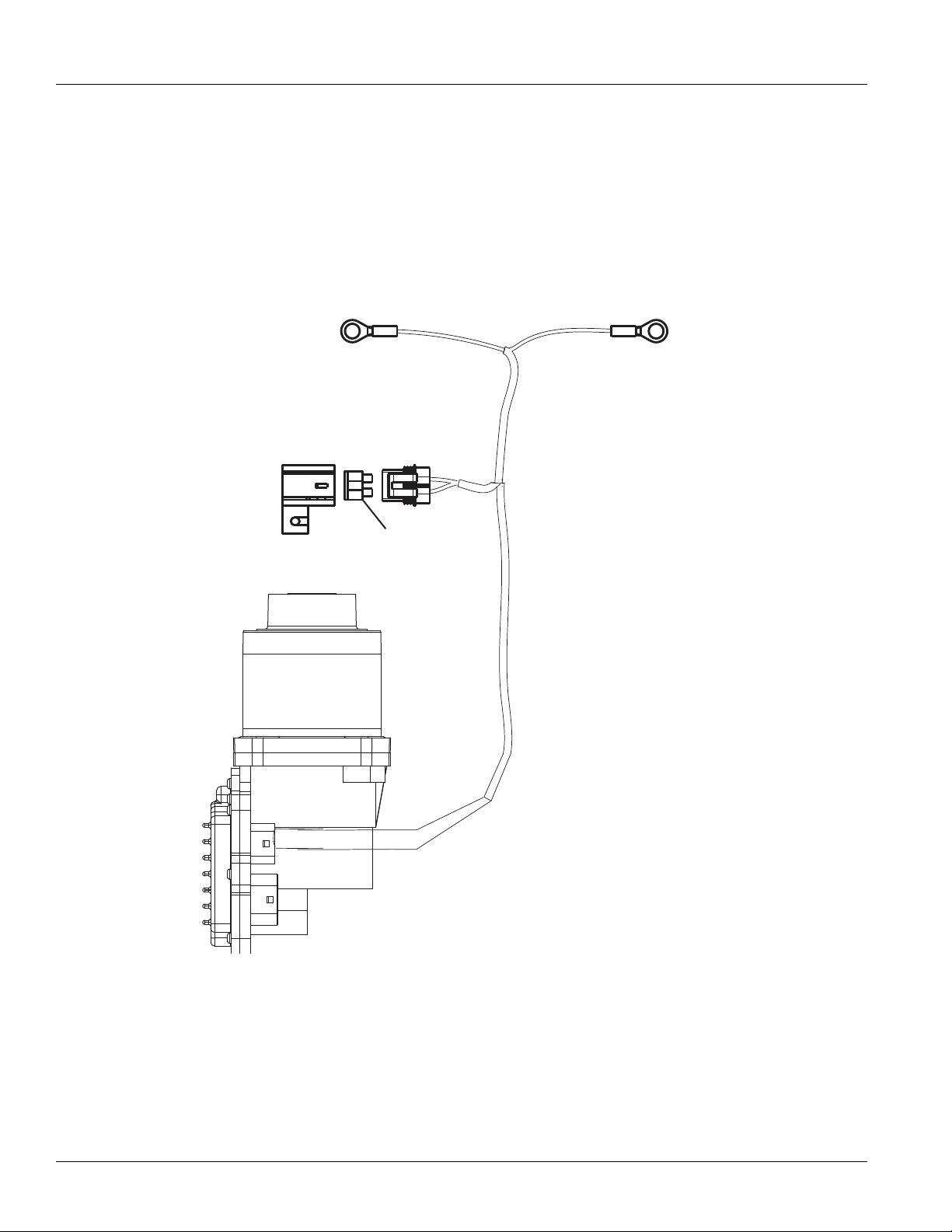

Heavy-Duty Electric Clutch Actuator

(ECA) Power Harness

OEM is responsible for overcurrent protection on this circuit. ECA products are 12-volt only.

-+

1. 50 AMP Fuse

1.

J1

20

© 2013 Eaton. All rights reserved

2013.08.23

Page 26

TRTS0930 Electrical Pretest Procedures | Electrical Pretest

Heavy-Duty Electric Clutch Actuator

(ECA) Power Harness

Important: The TECU and ECA must be wired to a

non-switched power source at the battery. If a disconnect

switch is required, the recommended practice is to wait a

minimum of three minutes before using the disconnect

switch.

It is the OEM responsibility to provide power and ground to

the TECU and ECA from the battery which supplies the

starter.

The power (+) connection must include overload protection

per Federal Motor Carrier Safety Regulations, Section

393.31. The TECU main power and ground must be a direct

connection from the battery posts to the TECU connector.

At 120° C, these conductors must be able to carry 30 amps

@ 9 volts with no more than 0.05 ohms per wire (0.1 ohms

total) for a total voltage drop from the battery posts to the

TECU connector not to exceed 3.0 volts. ECA main power

and ground must be able to carry 50 amps @ 9 volts with

no more than 0.025 ohms per wire (.05 ohms total) at 120°

C. Duration of the 50 amp current draw will not exceed 20

milliseconds.

The main power 30-amp fuse connection for the TECU must

be identified with a tag at the battery.

The main power 50-amp fuse connection for the ECA must

be identified with a tag at the battery.

The battery positive post and negative post must be disconnected PRIOR to any type of welding on any Fuller Automated Transmission-equipped vehicles.

Removal of fuses is not recommended as the method of

disconnecting power from the ECU. Making and breaking a

circuit through tin plated terminals (e.g. ring terminals,

fuses, most connectors) will destroy the plating on the terminal. Opening a switch contact or the main power link is

the recommended method of interrupting power.

Application of more than 36 volts to the system (such as

jump-starting) will cause system shutdown and possible

electrical component damage.

Do not switch off the battery and ignition power and ground

to the TECU during the engine start process.

2013.08.23

© 2013 Eaton. All rights reserved

21

Page 27

Electrical Pretest | Electrical Pretest Procedures TRTS0930

R

ETRATST

T

AB

ERYP LUS2

RETRAT

SETTABRYM INUS2

RETRATSETTABRYM IN

US 1

RET

RAT

S

TTA

BERY

P LUS

1

+-

BATTERY

12 VOLT

+-

BATTERY

12 VOLT

+-

BATTERY

12 VOLT

+-

BATTERY

12 VOLT

RATS OT SREPMUJ LAUD - KNAB REP SEIRETTAB OWT - SKNA

B YRETTAB OWT

TER

REWOP 3 NEG

.SRIAP YB LELLARAP NI

DETCENNOC ERA SEIRETTAB

SUPPLIED BY

A SU

LP HTOB( RE

TRATS OT TSE

SOL

C YRETTAB

NDMINUS)

RETRATS

ET

TABRY

M I

NUS 1

RETRATSTTABERYP LUS1

+-

BATTERY

12 VOLT

+-

BATTERY

12 VOLT

+-

BATTERY

12 VOLT

+-

BATTERY

12 VOLT

AMG

LERAY

ENNOCSID HTIW KNAB REP SEIRETTAB OWT - SKNAB YRETTAB OWT CT

E

V DNA BA

C ROF

T

C

E

NNOCSID - SR

IA

P

Y

B LE

LLARA

P NI DETCENNOC ERA SEIRETTA

B H

ICL

E

START

-

PAC TNEMN

IATRET

NE DNA TRO

FMOC BAC

"EGRAHCSID PEE

D" S

EDIVORP RIA

P

DETCEN

NOCS

I

D ABILITY.

C DNA RETRATS OT TSESOLC TES YRETTAB MORF DEILPPUS REWOP 3 NEG

OMMONTO

CAB POWER

ETTAB UCE 3 NEGR

YMI

NUS

T

A

B

UCE 3 NEGTERYPL

U

S

ETTAB UCE 3 NEGRY

M

INU

S

RETRATSETTABRYM INUS 1

RETRATSTTABERYP LUS 1

+-

BATTERY

12 VOLT

+-

BATTERY

12 VOLT

+-

BATTERY

12 VOLT

+-

BATTERY

12 VOLT

IRETTAB RUOF - KNAB YRETTAB ENOES

REWOP 3 NEG .LELLARAP NI DETCENNOC ERA SEIRETTAB SUPPLIED FROM

HTOB( .REWOP BAC HTI

W RE

TRATS OT TSESOLC YRETTABPLU

S

AND MINUS)

TAB UCE 3 NEGTERYPLUS

ETTAB UCE 3 NEGRYM

I

NUS

TTAB BACERYPLUS

TAB UCE 3 NEGTE

R

YPLUS

TTAB BAC ERY PLUS

Preferred +12 Volt Connections

22

© 2013 Eaton. All rights reserved

2013.08.23

Page 28

TRTS0930 Electrical Pretest Procedures | Electrical Pretest

Preferred +12 Volt Connections

N

A

T

B UCE 3 NEGRY M

U

E

I

S

B UC

T

E 3 NEGTERY PLUS

A

T

+-

12 VOLT

BATTERY

+-

12 VOLT

BATTERY

EIRET

TAB ERY CLOOT TS

GEN 3 ECU BATTERY PLUS

+-

12 VOLT

BATTERY

RETRATS EHT OT TSESOLC ISCONNECT SW ITCH

+-

12 VOLT

BATTERY

NOITUBIRTSID REWOP M ODULE

+-

12 VOLT

BATTERY

+-

12 VOLT

BATTERY

P TA DETCENNOCSID ERA SEIRETTAB RSUPPLIED

+-

12 VOLT

BATTERY

CAB BATTERY PLUS

Starter Battery Plus

+-

12 VOLT

BATTERY

YRETTABM INU

AB RETRATSTTERYPL

S

TIWS TCENNOCSID EVITAGEN YRETTAB - SKNAB YRETTAB OWTCH

(POWER BUS AND

OVER CURRENT

DISTRIBUTION

DEVICES)

MODULE

POWER

+-

12 VOLT

BATTERY

WOL ROF DEZIMITPO HTGNEL DNA EZIS SELBAC .RETRATSVOLTAGEDROP

AB RETRATSTTERYPLU

TAB RETRATSTERY MINUS

TTAB NO DETCENNOC SUNIM DNA SULP REWOP ,LELLARAP NI DETCENNOC ERA S

+-

12 VOLT

BATTERY

STARTER

US

VE

EWOP 3 NEG .EDISNI DEROTS ELCIHEV NEHW NWOD REWO

T NOITCENNOC ELBAC ELCIHEV FO TNIOP TA NOITCENNOC EVITAGEN .

D O

S

S

E

TAB RETR

YMINU

ATSTER

TAB ELCIHE

RY MINUS

T

MBATTER

FRO

TAB UCE 3 NEGTERYPLUS

ETTAB UCE 3 NEGRYMINUS

EHT

S

Y

2013.08.23

GEN 3 ECU BATTERY MINUS

STARTER BATTERY CONNECTION

GEN 3 POWER PLUS AND MINUS CONNECTED ON BATTERY CLOSEST TO THE STARTER.

+-

12 VOLT

BATTERY

ONE BATTERY BANK - TWO BATTERIES

BATTERIES ARE CONNECTED IN PARALLEL. GEN 3 POWER SUPPLIED FROM

BATTERY CLOSEST TO STARTER WITH CAB POWER. (BOTH PLUS AND MINUS)

+-

12 VOLT

BATTERY

STARTER BATTERY MINUS

CAB BATTERY PLUS

GEN 3 ECU BATTERY PLUS

STARTER BATTERY PLUS 1

GEN 3 ECU BATTERY MINUS

STARTER BATTERY MINUS 1

© 2013 Eaton. All rights reserved

23

Page 29

Electrical Pretest | Electrical Pretest Procedures TRTS0930

STARTER BATTERY PLUS

2

STARTER BATTERY MINUS

2

STARTER BATTERY MINUS

1

+ -

BATTERY

12 VOLT

+ -

BATTERY

12 VOLT

+ -

BATTERY

12 VOLT

+ -

BATTERY

12 VOLT

TWO BATTERY BANKS - TWO BATTERIES IN SERIES PER BANK - DUAL JUMPERS TO

STARTER

BATTERIES ARE CONNECTED IN SERIES/PARALLEL BY PAIRS. GEN 3 POWER

SUPPLIED BY BATTERY CLOSEST TO STARTER (BOTH PLUS AND MINUS)

+ -

BATTERY

12 VOLT

+ -

BATTERY

12 VOLT

+ -

BATTERY

12 VOLT

+ -

BATTERY

12 VOLT

MAG

RELAY

TWO BATTERY BANKS - TWO BATTERIES PER BANK WITH DISCONNECT

BATTERIES ARE CONNECTED IN SERIES/PARALLEL BY PAIRS - DISCONNECT FOR CAB AND VEHICLE

START - DISCONNECTED PAIR PROVIDES "DEEP DISCHARGE" CAB COMFORT AND ENTERTAINMENT

CAPABILITY. GEN 3 POWER SUPPLIED FROM BATTERY SET CLOSEST TO STARTER AND COMMON TO

CAB POWER

GEN 3 ECU BATTERY

PLUS

GEN 3 ECU BATTERY

MINUS

STARTER BATTERY MINUS

1

STARTER BATTERY PLUS

1

+ -

BATTERY

12 VOLT

+ -

BATTERY

12 VOLT

+ -

BATTERY

12 VOLT

+ -

BATTERY

12 VOLT

ONE BATTERY BANK - FOUR BATTERIES - ONE CABLE PAIR TO STARTER

BATTERIES ARE CONNECTED IN SERIES/PARALLEL BY PAIRS. GEN 3 POWER

SUPPLIED FROM BATTERY CLOSEST TO STARTER WITH CAB POWER. (BOTH PLUS

AND MINUS)

GEN 3 ECU BATTERY

PLUS

GEN 3 ECU BATTERY

MINUS

CAB BATTERY

PLUS

STARTER BATTERY PLUS

1

STARTER BATTERY MINUS

1

STARTER BATTERY PLUS

1

GEN 3 ECU BATTERY

MINUS

CAB BATTERY

PLUS

GEN 3 ECU BATTERY

PLUS

Preferred +24 Volt Connections

24

© 2013 Eaton. All rights reserved

2013.08.23

Page 30

TRTS0930 Electrical Pretest Procedures | Electrical Pretest

+-

BATTERY

12 VOLT

+-

BATTERY

12 VOLT

+-

BATTERY

12 VOLT

+-

BATTERY

12 VOLT

TWO BATTERY BANKS - BATTERY NEGATIVE DISCONNECT SWITCH

BATTERIES ARE DISCONNECTED AT POWER DOWN WHEN VEHICLE STORED INSIDE. GEN 3 POWER SUPPLIED FROM BATTERY

CLOSEST TO THE STARTER. NEGATIVE CONNECTION AT POINT OF VEHICLE CABLE CONNECTION TO DISCONNECT SWITCH

BATTERY

MINUS

STARTER BATTERY

PLUS

STARTER BATTERY

MINUS

VEHICLE BATTERY

MINUS

GEN 3 ECU BATTERY

PLUS

GEN 3 ECU BATTERY

MINUS

STARTER BATTERY

MINUS

STARTER BATTERY

PLUS

+-

BATTERY

12 VOLT

+-

BATTERY

12 VOLT

+-

BATTERY

12 VOLT

+-

BATTERY

12 VOLT

POWER DISTRIBUTION MODULE

BATTERIES ARE CONNECTED IN SERIES/PARALLEL, POWER PLUS AND MINUS CONNECTED ON BATTERY CLOSEST TO THE

STARTER. CABLES SIZE AND LENGTH OPTIMIZED FOR LOW VOLTAGE DROP

GEN 3 ECU BATTERY

PLUS

GEN 3 ECU BATTERY

MINUS

POWER

DISTRIBUTION

MODULE

(POWER BUS AND

OVER CURRENT

DEVICES)

STARTER BATTERY

MINUS

STARTER BATTERY

PLUS

STARTER

CAB BATTERY

PLUS

GEN 3 ECU BATTERY

MINUS

GEN 3 ECU BATTERY

PLUS

STARTER BATTERY CONNECTION

GEN 3 POWER PLUS AND MINUS CONNECTED ON BATTERY CLOSEST TO THE STARTER.

Preferred +24 Volt Connections

© 2013 Eaton. All rights reserved

2013.08.23

25

Page 31

Electrical Pretest | Electrical Pretest Procedures TRTS0930

TECU Ignition Circuit

1.

J1

35

4.

37

13

35

1. TECU connector (vehicle interface)

2. 10 AMP only, manual resetting circuit breaker OR

10 AMP fuse

3. Ignition Key Switch

29 30

23

14

15

7389

1

24 25

16

2

2.

3.

31

17

32 33

26

27 28

19

18

10611 12

5

4

34

20

38

21

22

36

Note: Run to main power lead that feeds the ignition

bus (OEM responsible for overcurrent protection

on this line)

4. TECU Connector (vehicle interface) front view

From To

J1-35 VIGN

Battery and ignition power and ground to the TECU must

not be switched off during the engine start process.

26

© 2013 Eaton. All rights reserved

2013.08.23

Page 32

TRTS0930 Electrical Pretest Procedures | Electrical Pretest

+ Battery

10

11

C

D

B

F

G

A

A

F

J

E

G

H

D

C

B

J1

J1939 Low

J1939 High

1.

2.

3.

J1939 Data Link

1. TECU connector (vehicle interface)

2. J1587 Data Link

3. 9-Way, for transmission diagnostics

J1939 Troubleshooting

1. Check the resistance of the J1939 Data Link.

2. Key off. Measure resistance between the 9-way

diagnostic connector Pin C and Pin D and record

the reading. The reading should be 60 ohms of

resistance (between 50 and 70.)

3. Check resistance between Pin C and Pin A and the

resistance between Pin D and Pin A. These two

readings should be 10K ohms or greater (open circuit).

Note: Pin C = J1939+, Pin D = J1939-, Pin A is a chas-

sis ground

• If an Inactive data link fault code is being reported

by the TECU, See “Product Diagnostic (PD) Mode”

on page 16. PDM should be utilized before any fur-

ther steps are taken.

2013.08.23

© 2013 Eaton. All rights reserved

27

Page 33

Electrical Pretest | Electrical Pretest Procedures TRTS0930

50 AMP fuse

Battery power

(Non-switched power)

run to Battery

B

C

ECA 3-Way

Connector

ECA

A

B

C

+

–

+

–

Batteries

30 AMP fuse

Transmission ECU

4-Pin Diagnostic Port

(Located at the left rear

corner of the transmission.)

4-Pin Diagnostics Port

4-way

B - Service Bat. +

C - Service Bat. A - Service Ignition +

VOLTS

V

COM

A

Battery Negative Post

B

A

D

C

Warning! - Do Not Load Test at Diagnostic Port

Electrical Pretest

Purpose: Measure battery voltage. Visually inspect

the batteries, inline fuse and power and ground

A

supplies at the batteries and ECA (if equipped).

1. Key off.

Purpose: Verify proper ground path between the

batteries and the transmission harness 4-way diag-

B

nostic connector.

2. Remove and clean all battery and battery-to-frame

connections.

3. Remove and clean ground supply to engine ECU.

4. Inspect starter/battery and inline 30 amp fuse

holder connections for corrosion or damaged contacts. Also, inspect the 50 amp fuse holder on vehicles equipped with an Electronic Clutch Actuator

(ECA).

5. Measure voltage across batteries.

• If voltage is 11 to 13 volts on a 12- volt system

or 22 to 26 on a 24 volt system, refer to OEM

guidelines for battery load test. Repair or

replace batteries as required. Go to Step

B.

1. Locate diagnostic port on Transmission Harness.

2. Key on.

3. Measure voltage between Pin C and the battery

negative post.

• If voltage is 0.70 volts or less, go to Step

C.

• If voltage is outside of range, repair battery

ground supply to Transmission Electrical Control Unit (TECU). Repeat test.

28

• If voltage is outside of range, repair or replace

batteries and charging system as required.

Repeat this step.

© 2013 Eaton. All rights reserved

2013.08.23

Page 34

TRTS0930 Electrical Pretest Procedures | Electrical Pretest

4-Pin Diagnostics Port

4-way

B - Service Bat. +

C - Service Bat. A - Service Ignition +

B

A

D

C

4-Pin Diagnostic Port

(Located at the left rear

corner of the transmission.)

Warning! - Do Not Load Test at Diagnostic Port

!

Purpose: Measure proper battery voltage at the

C

transmission harness 4-way diagnostic connector.

1. Locate diagnostic port on Transmission Harness.

2. Key on.

3. Measure voltage between Pin B and Pin C.

• If voltage is within 0.6 volts of battery voltage,

go to Step

D.

• If voltage is outside of range, Repair battery

power supply to TECU. Fuse may be blown.

Repeat test.

Purpose: Measure proper ignition voltage at the

D

transmission harness 4-way diagnostic connector.

1. Key on.

Warning: Do not load test at the diagnostic port.

2. Measure voltage between Pin A and Pin C.

Warning! - Do Not Load Test at Diagnostic Port

4-Pin Diagnostics Port

B

A

D

C

4-way

4-Pin Diagnostic Port

(Located at the left rear

corner of the transmission.)

B - Service Bat. +

C - Service Bat. A - Service Ignition +

• If voltage is within 0.6 volts of battery voltage,

For non-ECA products, test complete. See

“Diagnostic Procedures” on page 6. Go to

Step

E.

• If voltage is outside of range, repair ignition

power supply to TECU. Fuse may be blown.

Repeat test.

2013.08.23

© 2013 Eaton. All rights reserved

29

Page 35

Electrical Pretest | Electrical Pretest Procedures TRTS0930

Transmission ECU

30

29

29

F

G

F

G

50 AMP fuse

Battery power

(Non-switched power)

run to Battery

Engine Flywheel Speed Sensor

(Eaton Supplied)

B

C

Terminating

Resistor

ECA 8-Way

Connector

ECA 3-Way

Connector

ECA

13

30

E C

E C

B A

B A

A

B

C

Purpose: Measure battery voltage supplied to the

E

Electronic Clutch Actuator (ECA).

1. Key off.

2. Disconnect battery negative.

3. Disconnect ECA 3-way connector.

4. Reconnect battery negative.

5. Measure voltage between Pin B and Pin C of 3-way

connector.

• If voltage is within 0.6 volts of battery voltage,

test complete. See “Diagnostic Procedures” on

page 6.

• If voltage is outside of range, repair battery

power supply to ECA. Fuse may be blown.

Repeat test.

30

© 2013 Eaton. All rights reserved

2013.08.23

Page 36

TRTS0930 Electrical Pretest Procedures | Electrical Pretest

2013.08.23

© 2013 Eaton. All rights reserved

31

Page 37

Power-Up Sequence Test | Electrical Pretest Procedures TRTS0930

Power-Up Sequence Test

Overview

This test does not relate to any specific fault code, but must

be completed if the self check fails at power-up.

Detection

The TECU checks the program memory every time the key

is turned on.

Fallback

This causes an In-Place fallback while moving and a

self-check failure if it occurs during power-up.

Possible Causes

This fault code can be caused by any of the following:

• Vehicle Harness

• Shift Control Device

• TECU

32

© 2013 Eaton. All rights reserved

2013.08.23

Page 38

TRTS0930 Electrical Pretest Procedures | Power-Up Sequence Test

4.

VOLUME

CONTROL

SERVICE

SHIFT

Eaton Fuller

Transmissions

L

H

D

N

R

1.

2.

3.

Component Identification

1. Side view of pushbutton shift control

2. Transmission controller 30-way connector

3. Top view of pushbutton shift control

4. Eaton Cobra Lever

2013.08.23

© 2013 Eaton. All rights reserved

33

Page 39

Power-Up Sequence Test | Electrical Pretest Procedures TRTS0930

Power-Up Sequence Test

Purpose: Measure battery voltage. Visually inspect

the batteries, inline fuse and power and ground

A

supplies at the batteries.

1. Key off.

2. Remove and clean all battery and battery-to- frame

connections.

3. Remove and clean ground supply to engine ECU.

4. Inspect starter/battery and inline 30-amp fuse

holder connections for corrosion or damaged contacts.

5. Measure voltage across batteries.

• If voltage is 11 to 13 volts on a 12-volt system

or 22 to 26 on a 24-volt system, proceed with

battery load test. Repair or replace batteries as

required. Go to Step

• If voltage is outside of range, repair or replace

batteries and charging system as required.

Repeat this step.

B.

Purpose: Measure proper battery voltage at the

C

transmission harness 4-way diagnostic connector.

1. Locate diagnostic port on Transmission Harness.

2. Key on.

3. Measure voltage between Pin B and Pin C.

Warning: Do not load test at the diagnostic port.

!

• If voltage is within 0.6 volts of battery voltage,

go to Step

• If voltage is outside of range, repair battery

power supply to TECU. Fuse may be blown.

Repeat test.

Purpose: Measure proper ignition voltage at the

D

transmission harness 4-way diagnostic connector.

D.

Purpose: Verify proper ground path between the

batteries and the transmission harness 4-way diag-

B

nostic connector.

1. Locate diagnostic port on Transmission Harness.

2. Key on.

3. Measure voltage between Pin C and the battery

negative post.

• If voltage is 0.70 volts or less, go to Step

• If voltage is outside of range, repair battery

ground supply to TECU. Repeat test.

C.

1. Key on.

2. Measure voltage between Pin A and Pin C.

• If voltage is within 0.6 volts of battery voltage,

go to Step

• If voltage is outside of range, repair Ignition

power supply to ECU. Fuse may be blown.

Repeat test.

E.

34

© 2013 Eaton. All rights reserved

2013.08.23

Page 40

TRTS0930 Electrical Pretest Procedures | Power-Up Sequence Test

Purpose: Visually identify if the vehicle is equipped

E

with a shift lever or push button.

1. Is vehicle equipped with an Shift Lever?

• If vehicle is not equipped with a Shift Lever, go

to Step

• If vehicle is equipped with a Shift Lever, go to

Step

Purpose: Visually identify if the push button is an

Eaton built push button or an OEM built J1939

F

push button.

1. Is it an Eaton Push Button or OEM J1939 Shift

Device?

• If an Eaton Push Button Shift Control, go to

Step

• If an OEM J1939 Shift Device, refer to OEM for

troubleshooting procedures.

F.

K.

G.

Purpose: Visually observe the Service light during

G

key-on power up.

1. Key on.

2. Observe Service light.

Note: If Service light is flashing, go to Diagnostics

Procedure.

• If Service light illuminates for 1 second and

turns off, test complete.

• If Service light never lights, go to Step

• If Service light is on steady, replace Shift Con-

trol. Go to Step V.

Purpose: Measure the voltage supply at the Shift

H

Control device.

1. Key off.

2. Disconnect Shift Control 30-way connector.

H.

3. Key on.

4. Measure voltage between Pin C1 and Pin J3 on the

Shift Control 30-way.

• If voltage is within 1 volt of battery voltage

replace Shift Control

• If voltage is outside of range, go to Step I.

. Go to Step V.

2013.08.23

© 2013 Eaton. All rights reserved

35

Page 41

Power-Up Sequence Test | Electrical Pretest Procedures TRTS0930

Purpose: Verify that a proper ground path is being

supplied to the Shift Control Device through the Ve-

I

hicle Harness and test for a short to ground.

1. Key off.

2. Disconnect negative battery cable.

3. Disconnect 38-way Vehicle Harness from TECU.

4. Measure resistance between TECU Pin 25 and Shift

Control connector Pin J3 and from then from Pin

J3 to ground.

• If resistance from Pin 25 to J3 is

0 to 0.3 ohms and resistance from J3 to

ground is OL / Open, go to Step

• If resistance is outside of range, repair the

Vehicle Harness. Go to Step

J.

V.

Purpose: Visually identify if the shift lever is an Ea-

K

ton built shift lever or an OEM built shift lever.

1. Is vehicle equipped with an Eaton supplied Shift

Lever or an OEM supplied Shift Lever.

• If Eaton Cobra Lever, go to Step

• If OEM Shift Lever, go to Step R.

Purpose: Visually observe the Service light during

L

key-on power up.

1. Key on.

2. Observe Service light.

Note: If Service light is flashing, See “Diagnostic

Procedures” on page 6.

L.

Purpose: Measure the resistance of the ignition

voltage supply wire to the Shift Control Device

J

through the Vehicle Harness and test for a short to

ground.

1. Measure resistance between TECU Pin 31 and Shift

Control connector Pin C1 and then from Pin C1 to

ground.

• If resistance from Pin 31 to C1 is 0 to 0.3

ohms and resistance from C1 to ground is 10K

or OL, replace the TECU. Go to Step

• If resistance is outside of range, repair the

Vehicle Harness. Go to Step

V.

V.

• If Service light illuminates for 1 second and

turns off, test complete.

• If Service light never comes on, go to Step

• If Service light is on steady, go to Step M.

O.

36

© 2013 Eaton. All rights reserved

2013.08.23

Page 42

TRTS0930 Electrical Pretest Procedures | Power-Up Sequence Test

Purpose: Measure the voltage supply to the Service

M

light during key-on power up.

1. Disconnect Shift Lever 8-way connector.

2. Key on.

3. Measure voltage at Pin 6 and ground.

• If voltage is within 2 volts of battery voltage for

one second, then 0 volts, replace the Eaton

Cobra Lever

• If voltage is constant, go to Step N.

Purpose: - Test the Service light voltage supply for

N

short to power through the Vehicle Harness.

1. Key off.

2. Disconnect negative cable.

3. Disconnect 38-way Vehicle Harness connector.

4. Measure resistance between Pin 6 and Pin 4.

• If resistance is OL, replace the:

- Medium-Duty Transmission Electronic Control Unit (TECU)

- Heavy-Duty Transmission Electronic Control Unit (TECU)

Go to Step V.

• If resistance is less than 10K, repair the Vehi-

cle Harness and go to Step

. Go to Step V.

V.

Purpose: Measure the voltage supply to the Service

O

light during key-on power up.

1. Key off.

2. Disconnect Shift Lever 8-way connector.

3. Key on.

4. Measure voltage between Pin 3 and Pin 6.

• If within 1 volt of battery replace Eaton Cobra

Lever, go to Step V.

• If voltage is outside of range, go to Step N.

Purpose: Verify that a proper ground path is being

supplied to the Shift Lever through the Vehicle Har-

P

ness and test for a short to ground.

1. Key off

2. Disconnect 38-way Vehicle Harness connector on

TECU.

3. Measure resistance between Pin 3 on the 8-way

connector and Pin 25 on the 38-way connector and

from Pin 25 to ground.

Note: On Peterbilt disconnect Gear Display,

• If resistance between Pin 3 and Pin 25 is 0 to

0.3 ohms and resistance from Pin 25 to

ground is OL, go to Step

• If resistance is outside of range, repair the

Vehicle Harness between the Vehicle Harness

38-way connector Pin 25 and Vehicle Harness

8-way connector Pin 3. Go to Step

Q.

V.

2013.08.23

© 2013 Eaton. All rights reserved

37

Page 43

Power-Up Sequence Test | Electrical Pretest Procedures TRTS0930

Purpose: Measure the resistance of the ignition

voltage supply to the Shift Lever through the Vehi-

Q

cle Harness and test for a short to ground.

1. Key off.

2. Measure resistance between:

- Vehicle Harness 38-way connector Pin 31 and

Vehicle Harness 8-way connector Pin 4

- Vehicle Harness 38-way connector Pin 31 and

ground

• If resistance between Pin 31 and Pin 4 is 0 to

0.3 ohms and if resistance between Pin 31 and

ground is OL, replace the:

- Medium-Duty Transmission Electronic Control Unit (TECU)

- Heavy-Duty Transmission Electronic Control Unit (TECU)

Go to Step V.

• If any of the above conditions are not met,

replace the Vehicle Harness between Vehicle

Harness 38-way connector Pin 31 and Vehicle

Harness 8-way connector Pin 4. Go to Step

V.

Purpose: Measure the voltage supply to the Service

R

light during key-on power up.

1. Key off.

2. Locate Service light connector on Vehicle Harness.

3. Key on.

4. Measure voltage across Pin A and Pin B on the Ser-

vice light connector

• If voltage is within 2 volts of battery voltage for

1 second, then 0 volts, test complete.

• If no voltage is measured, go to Step

• If voltage is within 2 volts of battery voltage

continuously, go to Step

T.

S.

38

© 2013 Eaton. All rights reserved

2013.08.23

Page 44

TRTS0930 Electrical Pretest Procedures | Power-Up Sequence Test

Purpose: Measure the resistance of the service

light supply wire to the Shift Lever through the Ve-

S

hicle Harness and test for a short to ground.

1. Key off.

2. Disconnect negative battery cable.

3. Disconnect 38-way connector.

4. Measure resistance from Pin A of the OEM connec-

tor to Pin 23 of the 38-way and from Pin 23 to

ground.

• If resistance from Pin A to Pin 23 is 0 to 0.3

ohms and resistance to ground is 10K or

greater, replace the:

- Medium-Duty Transmission Electronic Control Unit (TECU)

- Heavy-Duty Transmission Electronic Control Unit (TECU)

Go to Step V.

• If resistance is outside of range, repair the

Vehicle Harness and go to Step

V.

Purpose: Test for a short to power at the Shift Le-

T

ver Service light.

1. Key off.

2. Disconnect negative battery cable.

3. Disconnect TECU 38-way connector.

4. Measure voltage across Service light connector Pin

A and Pin B.

• If no voltage is measured, replace the:

- Medium-Duty Transmission Electronic Control Unit (TECU)

- Heavy-Duty Transmission Electronic Control Unit (TECU)

Go to Step V.

• If voltage is within 2 volts of battery voltage,

repair Vehicle Harness as required. Go to Step

V.

Purpose: Verify that the system will properly power

V

up.

1. Key off.

2. Reconnect all connectors and the negative battery

cable.

3. Key on.

• If Power-Up Sequence Test completes, test

complete.

• If Power-Up Sequence Test fails go to Step

find error in testing.

A.

2013.08.23

© 2013 Eaton. All rights reserved

39

Page 45

Fault Code 11 - No TECU Operation | Fault Isolation Procedures TRTS0930

Fault Code 11 - No TECU Operation

J1939: SA 3 SPN 629 FMI 12

J1587: MID130 PID FMI 12

Overview

This fault code indicates an internal failure of the Transmission Electronic Control Unit (TECU).

Detection

The TECU checks the program memory every time the key

is turned on and throughout operation. If the TECU is able

to detect a failure within its own memory, it sets this fault

code.

Fallback

This fault causes a vehicle In Place fallback while moving

and a self-check failure if it occurs during power-up.

Possible Causes

This fault code can be caused by the following:

• TECU

40

© 2013 Eaton. All rights reserved

2013.08.23

Page 46

TRTS0930 Fault Isolation Procedures | Fault Code 11 - No TECU Operation

1.

Component Identification

1. TECU

2013.08.23

© 2013 Eaton. All rights reserved

41

Page 47

Fault Code 11 - No TECU Operation | Fault Isolation Procedures TRTS0930

Fault Code 11 - No TECU Operation

Purpose: Check for active or Inactive fault codes

A

1. Key on.

2. Retrieve codes. See “Fault Code Retrieval/Clearing”

on page 10.

• If Fault Code 11 is Active, replace the:

- Medium-Duty Transmission Electronic Control Unit (TECU)

- Heavy-Duty Transmission Electronic Control Unit (TECU)

• If Fault Code 11 is Inactive, test complete.

42

© 2013 Eaton. All rights reserved

2013.08.23

Page 48

TRTS0930 Fault Isolation Procedures | Fault Code 11 - No TECU Operation

2013.08.23

© 2013 Eaton. All rights reserved

43

Page 49

Fault Code 12 - Improper ECU Configuration | Fault Isolation Procedures TRTS0930

Fault Code 12 - Improper ECU Configuration

J1939: SA 3 SPN 629 FMI 13,14

Overview

This fault code indicates the Transmission Electronic Control Unit (TECU) is not reading valid information from memory, including the transmission table and calibration values.

Detection

The TECU checks the configuration every time the key is

turned on. If the transmission is not able to detect the

proper configuration, it sets this fault code.

Fallback

This fault causes a power up no crank.

Possible Causes

This fault code can be caused by the following:

• Improper TECU configuration software

44

© 2013 Eaton. All rights reserved

2013.08.23

Page 50

TRTS0930 Fault Isolation Procedures | Fault Code 12 - Improper ECU Configuration

1.

Component Identification

1. TECU

2013.08.23

© 2013 Eaton. All rights reserved

45

Page 51

Fault Code 12 - Improper ECU Configuration | Fault Isolation Procedures TRTS0930

Fault Code 12 - Improper ECU Configuration

Purpose: Check for active or Inactive fault codes.

A

1. Key on.

2. Retrieve codes. See “Fault Code Retrieval/Clearing”

on page 10.

• If Fault Code 12 is Active, Customer - Call

Eaton at 1-800-826-HELP (4357). CSC - Call

Technician Service.

• If Fault Code 12 is Inactive, test complete.

46

© 2013 Eaton. All rights reserved

2013.08.23

Page 52

TRTS0930 Fault Isolation Procedures | Fault Code 12 - Improper ECU Configuration

2013.08.23

© 2013 Eaton. All rights reserved

47

Page 53

Fault Code 13 - J1939 Shift Control Device | Fault Isolation Procedures TRTS0930

Fault Code 13 - J1939 Shift Control Device

J1587: MID130 PID 231 FMI 8, 11

J1939: SA 3 SPN751 FMI 8, 11

Overview

This fault indicates communication has been lost, or does

not correspond with the neutral request input from the

J1939 Shift Device.

When troubleshooting an Inactive code, See “Product Diagnostic (PD) Mode” on page 16.

Detection

Starting at key on and throughout operation, the Transmission Electronic Control Unit (TECU) constantly monitors

communication with the J1939 Shift Device. If a neutral

request from the J1939 Shift Device does not match the

neutral signal or is not received from the J1939 Shift

Device, Fault Code 13 is set.

Fallback

This fault causes a downshift-only fallback. Once the transmission re-engages the start gear, there will be no upshifts

as long as the code is active.

Possible Causes

This fault code can be caused by the following:

• OEM J1939 Shift Control Device

• Vehicle Harness

48

© 2013 Eaton. All rights reserved

2013.08.23

Page 54

TRTS0930 Fault Isolation Procedures | Fault Code 13 - J1939 Shift Control Device

J1

J1939

16

17

1.

2.

3.

4.

5.

Component Identification

1. TECU Connector (vehicle interface)

2. Bulkhead connector located at firewall

3. OEM J1939 Shift Device

4. Battery Power (Non-switches power run to battery

or starter)

5. Switched Power

2013.08.23

© 2013 Eaton. All rights reserved

49

Page 55

Fault Code 13 - J1939 Shift Control Device | Fault Isolation Procedures TRTS0930

OHMS

V

COM

A

OHMS

V

COM

A

31

24 25

29 30

15 16

26

20

34

27 28

32 33

18 19

7389

12 6

11 12

45

22

21

38

36

37

13 14

35

10

17

23

31

24 25

29 30

15 16

26

20

34

27 28

32 33

18 19

7389

12 6

11 12

45

22

21

38

36

37

13 14

35

10

17

23

J1939

Fault Code 13 - J1939 Shift Control Device

Purpose: Verify continuity of Neutral Request Sig-

A

nal wire

1. Key off.

2. Disconnect negative battery cable.

3. Disconnect Vehicle Harness 38-way connector.

4. Measure resistance between 38-way connector Pin

16 and corresponding OEM pin at J1939 Shift

Device and Pin 16 and ground (see OEM wiring for

correct pin location)

OHMS

V

29 30

37

13 14

35

37

13 14

35

31

24 25

23

17

15 16

7389

12 6

29 30

31

24 25

23

15 16

17

7389

12 6

32 33

26

27 28

18 19

10

11 12

45

32 33

26

27 28

18 19

10

11 12

45

34

38

22

21

20

36

34

38

20

22

21

36

COM

J1939

OHMS

V

• If resistance is 0 to 0.3 ohms between Pin 16

and the corresponding OEM pin and resistance

to ground is 10K ohms or greater, go to Step

B.

• If resistance is out of range, replace the:

- Medium-Duty Transmission Harness

- Heavy-Duty Transmission Harness

Go to Step V.

Purpose: Verify continuity of Neutral Request Re-

B

turn wire

1. Measure resistance between 38-way connector Pin

17 and corresponding OEM pin at J1939 Shift

Device and Pin 17 and ground (see OEM wiring for

correct pin location).

A

A

COM

• If resistance is 0 to 0.3 ohms between Pin 17

and the corresponding OEM pin and resistance

to ground is 10K ohms or greater, problem

exists with the J1939 Shift Device, or J1939

Shift Device power, ground or data link wiring.

Contact your OEM for repair strategy. Go to

Step

V.

• If resistance is out of range, replace the:

- Medium-Duty Transmission Harness

- Heavy-Duty Transmission Harness

Go to Step V.

50

© 2013 Eaton. All rights reserved

2013.08.23

Page 56

TRTS0930 Fault Isolation Procedures | Fault Code 13 - J1939 Shift Control Device

Purpose: Verify repair.

V

1. Key off.

2. Reconnect all connectors and the negative battery

cable.

3. Key on.

4. Clear codes. See “Fault Code Retrieval/Clearing” on

page 10.

5. Drive vehicle and attempt to reset the code.

6. Check for codes. See “Fault Code Retrieval/Clear-

ing” on page 10.

• If no fault codes, test complete.

• If Fault Code 13 appears go to Step

error in testing.

• If fault code other than 13 appears, See “Fault

Code Isolation Procedure Index” on page 13.

A. to find

2013.08.23

© 2013 Eaton. All rights reserved

51

Page 57

Fault Code 14 - Invalid Shift Lever Voltage (without Park Pawl) | Fault Isolation Procedures TRTS0930

Fault Code 14 - Invalid Shift Lever Voltage (without Park Pawl)

J1587: MID 130 SID 18, 19 FMI 2, 3, 4, 5

J1939: SA 3 SPN 751 FMI 2, 3, 4, 5

Overview

This fault code indicates an electrical failure of the Eaton

Cobra Lever or OEM Shift Lever.

When troubleshooting an Inactive code See “Product Diagnostic (PD) Mode” on page 16.

Detection

Starting at key on and throughout operation the Transmission Electronic Control Unit (TECU) constantly monitors the

signal from the Park Pawl Position Sensor. The transmission monitors both sensor signals, if one signal to the TECU

is out of range the code will set.

Fallback

This fault may cause a downshift only fallback mode. The

transmission will re-engage the start gear when returned to

a stop, but will not upshift as long as the code is active.

Possible Causes

This fault code can be caused by any of the following:

• Eaton Cobra Lever or OEM Shift Lever

• Vehicle Harness

• TECU

52

© 2013 Eaton. All rights reserved

2013.08.23

Page 58

TRTS0930 Fault Isolation Procedures | Fault Code 14 - Invalid Shift Lever Voltage (without Park Pawl)

1.

2.

Component Identification

1. Eaton Cobra Lever 8-way connector

2. TECU 38-way connector

2013.08.23

© 2013 Eaton. All rights reserved

53

Page 59

Fault Code 14 - Invalid Shift Lever Voltage (without Park Pawl) | Fault Isolation Procedures TRTS0930

OHMS

V

COM

A

OHMS

V

COM

A

31

24 25

29 30

15 16

26

20

34

27 28

32 33

18 19

7389

12 6

11 12

45

22

21

38

36

37

13 14

35

10

17

23

1

2

3

4

5

6

7

8

31

24 25

29 30

15 16

26

20

34

27 28

32 33

18 19

7389

12 6

11 12

45

22

21

38

36

37

13 14

35

10

17

23

Fault Code 14 - Invalid Shift Lever Voltage (without Park Pawl)

Purpose: Visually identify the lever type: Eaton or

A

OEM manufactured.

1. Is vehicle equipped with an Eaton supplied Shift

Lever or an OEM supplied Shift Lever?

• If Eaton Cobra Lever, go to Step

B.

• If OEM Shift Lever, contact OEM for trouble-

shooting procedures.

Purpose: Install the Shift Lever tester and monitor

Transmission Range in ServiceRanger. Utilize the

B