DAEWOO DWF-5020, DWF-4220 Service Manual

DAEWOO ELECTRONICS CO., LTD.

612-1, AHYEON-DONG, MAPO-GU, SEOUL, KOREA.

C.P.O. BOX 8003 SEOUL KOREA TELEX: DWELEC K28177-8 CABLE:"DAEWOOELEC"

FAX: (02) 364-5588/5305 TEL: (02) 360/7315~7

S/M NO.: WF42200100 |

PRINTED DATE: APR. 1996 |

Service Manual

Full-Auto Electric Washing Machine

DWF-4220 (Series)

DWF-5020 (Series)

DAEWOO ELECTRONICS CO., LTD.

TABLE OF CONTENTS

1. SPECIFICATIONS.................................................................................................................................................................... |

2 |

2. FEATURE AND TECHNICAL EXPLANATION |

|

FEATURE OF THE WASHING MACHINE ............................................................................................................................... |

3 |

WATER CURRENTS TO ADJUST THE UNBALANCED LOAD .............................................................................................. |

3 |

PULSATOR SYSTEM ................................................................................................................................................................ |

4 |

AUTOMATIC DRAINING TIME ADJUSTMENT........................................................................................................................ |

4 |

SOFTENER DISPENSER........................................................................................................................................................... |

5 |

AUTOMATIC UNBALANCE ADJUSTMENT ............................................................................................................................ |

6 |

CIRCULATING-WATER COURSE AND LINT FILTER............................................................................................................. |

6 |

SYNCRONOUS MOTOR........................................................................................................................................................... |

7 |

YNCRONOUS GEAR MECHANISM ASS'Y............................................................................................................................. |

8 |

PRINCIPLE OF BUBBLE GENERATOR................................................................................................................................... |

8 |

FUNCTIONAL PRINCIPLE OF BUBBLE WASHING MACHINE ............................................................................................. |

9 |

3. STRUCTURE OF THE WASHING MACHINE..................................................................................................................... |

10 |

4. FUNCTIONS OF THE CONTROL PANEL........................................................................................................................... |

11 |

5. DIRECTIONS FOR INSTALLATION AND USE |

|

HOW TO INSTALL THE WASHING MACHINE...................................................................................................................... |

12 |

HOW TO CONNECT THE INLET HOSE................................................................................................................................. |

14 |

HOW TO GROUND THE WIRE............................................................................................................................................... |

15 |

6. PROCEDURE OF FULL-AUTOMATIC WASHING............................................................................................................. |

16 |

7. DIRECTIONS FOR DISASSEMBLY AND ADJUSTMENT |

|

GEAR MECHANISM ASS'Y REPLACEMENT........................................................................................................................ |

18 |

SYNCRONOUS MOTOR AND VALVE REPLACEMENT....................................................................................................... |

19 |

BRAKE ADJUSTMENT............................................................................................................................................................ |

19 |

8. TROUBLE SHOOTING GUIDE |

|

CONCERNING WATER SUPPLY........................................................................................................................................... |

20 |

CONCERNING WASHING...................................................................................................................................................... |

21 |

CONCERNING DRAINING...................................................................................................................................................... |

22 |

CONCERNING SPINNING...................................................................................................................................................... |

23 |

CONCERNING OPERATION .................................................................................................................................................. |

24 |

9. PRESENTATION OF THE P.C.B. ASS'Y |

|

CONCERNING ERROR MESSAGE........................................................................................................................................ |

25 |

CONFIGURATION OF FULL CIRCUITS................................................................................................................................. |

27 |

MINUTE EXPLANATION DIAGRAM FOR EACH PARTS...................................................................................................... |

28 |

APPENDIX |

|

WIRING DIAGRAM .................................................................................................................................................................. |

40 |

PARTS LIST (THE WHOLE)..................................................................................................................................................... |

42 |

PARTS DIAGRAM.................................................................................................................................................................... |

46 |

P.C.B. PARTS LIST ................................................................................................................................................................. |

49 |

CIRCUIT DIAGRAM................................................................................................................................................................. |

54 |

BARE PCB .............................................................................................................................................................................. |

56 |

1

1. SPECIFICATIONS

NO |

ITEM |

|

|

|

|

|

SPECIFICATIONS |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

1 |

POWER SOURCE |

|

|

AC 220V/60Hz |

|

AC 127V/50,60Hz |

|

AC 110V/60Hz |

AC 220V/50Hz |

AC 240V/50Hz |

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

POWER |

|

DWF-4220 |

370W |

|

370W |

|

|

370W |

330W |

330W |

|

|

|

|

|

|

|

|

|

|

|

|

|

CONSUMPTION |

|

DWF-5020 |

430W |

|

430W |

|

|

430W |

370W |

370W |

|

|

|

|

|

|

|

|

|

|

||

3 |

MACHINE |

|

DWF-4220 |

NON PUMP: NET; 30.5kg, GROSS: 35 kg |

PUMP: NET; 31.5kg, GROSS; 36kg |

||||||

|

|

|

|

|

|

||||||

|

WEIGHT |

|

DWF-5020 |

NON PUMP: NET; 31.5kg, GROSS: 36 kg |

PUMP: NET; 32.5kg, GROSS; 37kg |

||||||

|

|

|

|

|

|

|

|

|

|

||

4 |

DIMENSION (WXHXD) |

|

|

|

|

502X820X500 |

|

|

|||

|

|

|

|

|

|

|

|||||

5 |

WASHING COURSE |

|

|

FULL AUTOMATIC 4 COURSES |

|

||||||

|

|

|

|

|

|

(FUZZY, SPEED, HEAVY, WOOL) |

|

||||

|

|

|

|

|

|

|

|||||

6 |

WATER CONSUMPTION |

|

|

NORMAL 128|(131|: DWF-5020) |

|

||||||

|

|

|

|

|

|

|

|||||

7 |

WATER LEVEL |

|

DWF-4220 |

|

|

HIGH (47|), MEDIUM (38|), LOW (30|), SMALL(22|) |

|||||

|

|

|

|

|

|

|

|||||

|

SELECTOR |

|

DWF-5020 |

|

|

HIGH (48|), MEDIUM (39|), LOW (31|), SMALL(23|) |

|||||

|

|

|

|

|

|

|

|||||

8 |

OPERATING WATER PRESSURE |

|

|

0.3~8kgf/cm2 (2.9~78.4N/cm2) |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SPIN:690 (50Hz) |

|

|

|

|

|

9 |

REVOLUTION PER MINUTE |

SPIN: 750 |

|

WASH:130 |

|

SPIN: 750 |

SPIN: 690 |

||||

|

|

|

|

WASH: 140 |

|

SPIN: 750 (60Hz) |

|

WASH: 140 |

WASH: 130 |

||

|

|

|

|

|

|

WASH: 140 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

10 |

PULSATOR |

|

|

|

|

5 WINGS (Ø 321mm) |

|

||||

|

|

|

|

|

|

|

|||||

11 |

WATER LEVEL CONTROL |

|

|

ELECTRONICAL SENSOR |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

12 |

OUTER CABINET |

|

|

|

|

|

|

|

SGCC |

|

|

|

|

|

|

||||||||

13 |

GEAR MECHANISM ASS'Y |

PLANETARY GEAR ASSEMBLY OF ENGINEERING PLASTIC |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

14 |

LINT FILTER |

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

SOFTENER INLET |

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

ALARM SIGNAL |

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

17 |

AUTO WATER SUPPLY |

|

|

|

|

|

O |

|

|

||

|

|

|

|

|

|||||||

18 |

NEW WATER FLOW |

|

WATER FLOW FOR ADJUST THE UNBALANCED LOAD |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

19 |

FUNCTION FOR BUBBLE |

|

|

|

|

|

OPTION |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

20 |

MAXIMUM |

|

DWF-4220 |

|

|

|

|

|

4.2 kg |

|

|

MASS OF |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TEXTILE |

|

DWF-5020 |

|

|

|

|

|

5.0 kg |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2

2. FEATURE AND TECHNICAL EXPLANATION

FEATURE OF THE WASHING MACHINE

1)The first air bubble washing system in the world.

2)Quiet washing through the innovational low-noise design.

3)The wash effectiveness is much more enhanced because of the air bubble washing system.

4)The laundry detergent dissolves well in water because of the air bubble washing system.

5)The adoption of the water currents to adjust the unbalanced load.

6)One-touch operation system.

WATER CURRENTS TO ADJUST THE UNBALANCED LOAD

It is a function to prevent eccentricity of the clothes after washing by rotating pulsator C.W and C.C.W for 20 seconds.

MOTOR |

C.W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SIGNAL |

C.C.W |

|

|

|

|

|

|

TIME (SEC.) |

0.3 |

0.5 |

0.3 |

0.5 |

0.3 |

0.5 |

|

|

|

|

|

20 SEC. (About 13 Times) |

|

||

WATER FLOW

WASH |

I |

DRAIN |

SPIN |

FILL |

RINSE 1 |

I |

DRAIN |

SPIN |

FILL |

RINSE 2 |

I |

DRAIN |

... |

|||

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: "I" mark indicates the operation of the water currents to adjust the unbalance load.

EFFECT

It reduces vibration and noise effectively during spinning.

3

PULSATOR SYSTEM

When the new shaped pulsator is rotated C.W or C.C.W at a high speed, it makes the 'heart-shaped' water currents as shown below.

C

Rotate

B

B

A A

WATER CURRENTS

AWater is pushed up near the tub wall by rotation of the pulsator.

BWater is pulled down in the middle of the tub by rotation of the pulsator

CWater currents is generated by rotation of the pulsator.

AUTOMATIC DRAINING TIME ADJUSTMENT

This system adjusts the draining time automatically according to the draining condition.

|

Good draining |

The washer begins spin process after drainage. |

|

Draining |

|

|

|

Bad draining |

Draining time is prolonged. |

||

condition |

|||

|

|

||

No draining |

Program stops and gives the alarm. |

||

|

|||

|

|

|

FUNCTIONAL PRINCIPLE

1. The micom can remember the time from the beginning of drain to reset point when the pressure switch reaches to "OFF" point.

Drain Time |

|

Movement of the Program |

|

|

|

|

|

Less than 5 minutes |

Continue draining. |

||

|

|

|

|

More than 5 minutes |

Program stops and gives the alarm with all lamps of the "COURSE" light up. |

||

|

|

|

|

2. In case of continuous draining, residual drain time is determined by micom. |

|||

Draining time as a whole=D + 60 |

|

|

|

(T sec.) |

|

|

Residual drain time. |

|

|

||

The time remembered by micom.

|

|

|

|

|

|

(mm) |

|

|

|

TRIP POINTS |

|

* |

340 |

|

|

|

|

|

|

* |

|

280 |

|

DRAINING |

|

|

* |

|

D4 |

220 |

WATER |

|

|

D3 |

|

|

|

||

T4 |

|

|

|

|

|

|

LEVEL |

TIME |

* |

D2 |

|

|

|

160 |

|

T3 |

|

|

|

|

|||

T2 |

D1 |

|

* |

|

|

60 |

|

T1 |

* |

|

* |

* |

|

||

|

60 |

RESET POINTS |

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

SMALL |

|

LOW |

MED |

HIGH |

|

|

T1=D1+60 (Sec.) |

T2=D2+60 (Sec.) |

T3=D3+60 (Sec.) |

T4=D4+60 (Sec.) |

|

|||

|

|

4 |

|

|

|

|

|

SOFTENER DISPENSER

This is the device to dispense the softener automatically by centrifugal force.

This is installed inside the Balancer Ass'y.

FUNCTIONAL PRINCIPLE

1.Softener stays in room (A) when poured into softener inlet.

2.Softener in moved from (A) to (B) by centrifugal force during intermittent spin process.

3.Softener flows from (B) to (C) during rinse process next to intermittent spin.

4.Softener in moved from (C) to (D) by centrifugal force during second intermittent spin. After spin process is finished, the softener is added into the tub through softener outlet.

FLOW OF THE SOFTENER

|

|

|

|

|

Wash |

|

Intermittent |

|

Hold |

Intermittent |

|

Rinse |

|

Spin |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Spin |

|

|

|

|

Spin |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Normal |

|

|

|

|

|

|

|

Centrifugal |

|

|

|

|

Flow in |

Centrifugal |

|

Flow in |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

force |

|

|

|

|

|

|

|

force |

|

|

|

|

|

|

|||||||

|

Course |

|

|

(A) |

|

|

|

|

|

|

(B) |

|

|

|

(C) |

|

|

|

|

|

(D) |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

FLOW OF THE SOFTENER INSIDE OF THE BALANCER |

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

Room inside |

|

|

|

|

|

A |

|

|

B |

|

C |

|

D |

|

|

|

|

|

|

|

|

||||||||

|

the balancer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Centrifugal |

|

force |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

Flowing by |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

weight |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: Softener moves into the next room when r.p.m. of the tub is more than 100 r.p.m.

HOW TO CHECK MOVEMENT

Pour a reasonable amount of "MILK" into softener dispenser and operate the washer with no load. In final rinse cycle, make sure that the milk is added into the tub through softener outlet.

Balancer

Softener

B outlet

D

A C

Softener inlet

5

AUTOMATIC UNBALANCE ADJUSTMENT

This system is to prevent abnormal vibration during intermittent spin and spin process.

FUNCTIONAL PRINCIPLE

1.When the door is closed, the safety switch contact is "ON" position.

2.In case that wash loads get uneven during spin, the outer tub hits the safety switch due to the serious vibration, and the spin process is interrupted.

3.In case that P.C.B. ASS'Y gets "OFF" signal from the safety switch, spin process are stopped and rinse process is started automatically by P.C.B. ASS'Y.

4.If the safety switch is operated due to the unbalance of the tub, the program is stopped and the alarm is given.

Contact of safety switch door closing

door opening

Contact lever A

Position of |

|

unbalanced |

|

load(OFF) |

Normal(ON) |

|

NOTE:

The alarm finished when you close the door after opening it. Check the unbalance of the wash load and the installation condition.

CIRCULATING-WATER COURSE AND LINT FILTER

CIRCULATING-WATER

The washing and rinsing effects have been |

|

improved by adopting the water system in which |

|

water in the tub is circulated in a designed pattern. |

|

When the pulsator rotates during the washing or |

|

rinsing process, the water below the pulsator vane |

Tub |

creates a water currents as shown in figure. |

Outer tub |

Filter |

|

Water |

|

channel |

|

Pulsator |

|

6

LINT FILTER

Much lint may be obtained according to the kind of clothes to be washed and some of the lint may also stick to the clothes.

To minimize this possibility a lint filter is provided on the upper part of the tub to filter the wash water as it is discharged from the water channel. It is good to use the lint filter during washing.

Bleach inlet |

Filter |

Pulsator |

HOW TO CLEAN THE LINT FILTER

1.Pull the filter frame upward.

2.Turn the lint filter inside out, and wash the lint off with water.

3.Return the filter as it was, and fix the filter frame to the slot.

SYNCRONOUS MOTOR

STRUCTURE

Pull

Loosen

Pulley

Lever

Inductive ring

Magent

Coil of motor

Magnet of motor

FUNCTIONAL PRINCIPLE

1.When the SYNCRONOUS MOTOR connected to the power source the SYNCRONOUS MOTOR rotates and revolves the pulley by gear assembly for reducing.

2.When the pulley is rotated, the pulley winds the wire to open the drain valve.

3.Therefore, rotation of pulley is changed to the linear moving of wire.

4.The wire pulls the brake lever of Gear Mechanism Ass'y within 5 seconds.

5.After the wire pulled, gear assembly is separated from motor and condition of pulling is held by operation of the lever.

6.When the power is turned off, the drain valve is closed because the wire returns to original position.

7

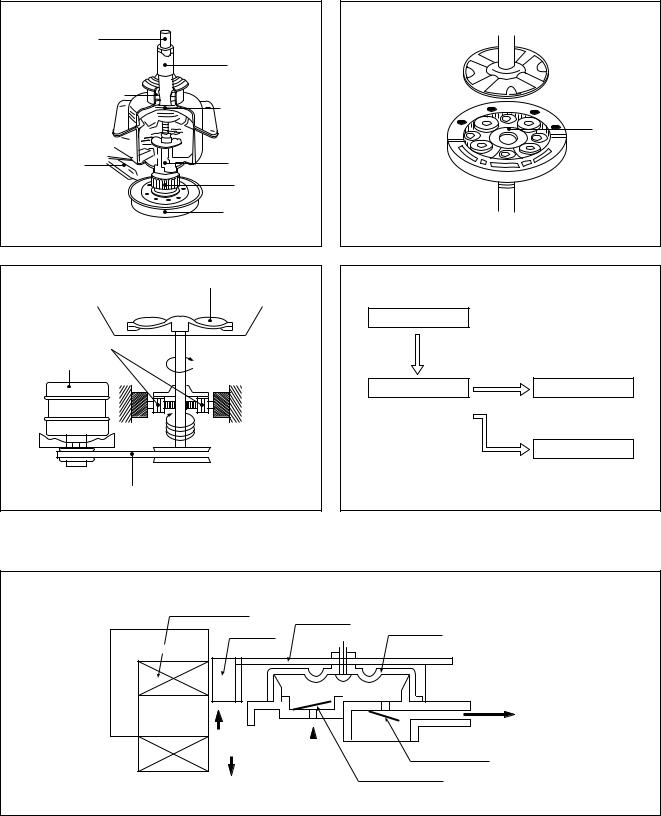

GEAR MECHANISM ASS'Y

The proper water currents is made by the rotation of pulsator at a low speed to prevent the damage to the small sized clothes.

Pulsator shaft

|

Spinner shaft |

One clutch bearing |

|

|

Planetary gear |

Brake lever |

Clutch spring |

|

Clutch boss |

|

Spinner pulley |

Sun gear

Planetary gear

Internal gear

Internal gear

Pulsator

Planetary |

|

Motor |

1 revolution |

5 revolutions

Spinner

Spinner

pulley

V.belt

PRINCIPLE OF BUBBLE GENERATOR

STRUCTURE

Motor |

|

V.BELT |

|

|

Planetary |

Spinner Pulley |

gear |

Pulsator |

|

|

1/5.0 |

|

Tub |

|

Directly |

Bobbin & coil |

Armature |

|

|

Magnet |

Bellows |

Trans core |

|

Air out hole

Air

Air

|

|

Protector A |

|

Air in hole |

|||

Protector B |

|||

|

|

||

8

PRINCIPLE OF INTAKE & OUTLET OF THE AIR

INTAKE : ARMATURE moves up, and BELLOWS inhales the air. At the same time, protector B is open and A is close. OUTLET: ARMATURE moves down, and BELLOWS exhausts the air. At the same time, protector B is close and A is

open.

FUNCTIONAL PRINCIPLE OF TRANS & MAGNET

•The phase of A.C electric power changes to 60 cycle/second.

•The magnetic pole of trans core is changed by the change of the phase of A.C electric power.

•The core repeats push and pull (3600 times/min.) of the armature magnet.

A.C |

A.C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

|

|

|

Leaf spring |

|

|

S |

|

|

|

|

||

|

|

NS |

NS |

|

||||||||||

|

|

|

|

Trans core |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S |

|

|

|

Magnet |

|

|

N |

|

|

|

|

||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FUNCTIONAL PRINCIPLE OF BUBBLE WASHING MACHINE

ACROSS SECTION

Air bubble

Tub

Outer tub

Outer tub

Pulsator

Nozzle

FUNCTIONAL PRINCIPLE

Bubble generator supplies the air from the bottom of outer tub to the inner space of pulsator, the air is dispersed by the rotation of pulsator. Air-bubble is created by the centrifugal force, and rises up.

9

3. STRUCTURE OF THE WASHING MACHINE

• SOFTENER INLET

Pour softener into the softener inlet just before wash and it will be added into the tub automatically just before the final rinse.

• BLEACH

INLET

• TUB

•CONTROL PANEL

•ADJUSTABLE LEG

ACCESSORIES

Inlet Hose (COLD) |

Water Tap Adapter |

Drain Hose |

Under Base |

Inlet Hose |

(COLD) |

Clamp |

Cover [Option] |

(HOT) [Option] |

Water Tap Adapter |

|

|

|

(HOT) [Option] |

|

|

|

|

|

UP |

In case of screw-shaped inlet hoses water tap adapters will not be provided.

•POWER SWITCH

•HOOK HOLE

•LINT FILTER

•HANDLE

•GROUND WIRE

•POWER CORD

|

Drain Hose |

Pump Model |

Non-Pump Model |

10

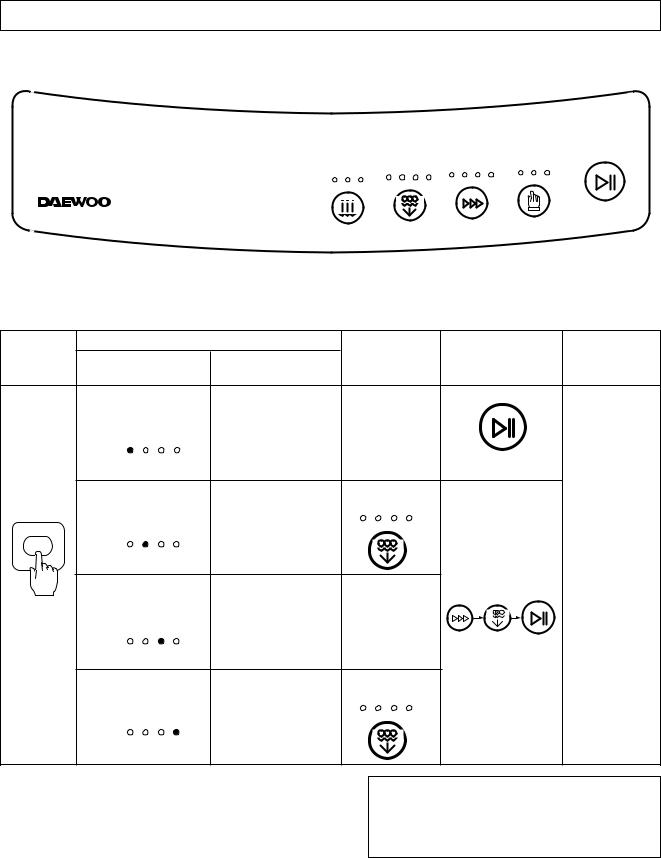

4. FUNCTIONS OF THE CONTROL PANEL

Control Panel

It has micom sensor.

As the buttons are pressed, the lamps indicating the selection of your desired washing program will light up.

|

|

|

|

|

|

|

Power Switch |

|

|

|

|

|

|

|

• Press this switch to turn |

|

|

|

|

|

|

the power ON or OFF. |

|

|

|

|

ON |

|

|

|

|

|

|

|

|

|

|

|

• After turning off the power, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

wait for more than 3 |

|

|

|

OFF |

|

|

||

|

|

|

|

|

seconds and then turn it |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

on again. |

||

|

POWER |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Start/Hold Button

•Press this button to begin operation or to stop operation temporarily.

•Operation and temporary stop are repeated as it is pressed.

HOT WARMCOLD |

HIGH MEDIUMLOW SMALL FUZZYSPEEDYHEAVYWOOL |

WASHRINSESPIN |

START/HOLD

WATER TEMP. |

WATER LEVEL |

COURSE |

PROCESS |

|

[Option]

Temperature Selection

Button

•This button is used to select the water temperature according to the clothes being washed.

•Press this button until your desired temperature indicator light comes on, and it will repeat following signs:

COLD ¤A WARM ¤A HOT

Water Level Selector

•This selector is used to select the washing water level according to the size of the wash load.

Course Selection Button

•This button is used to select the washing course according to the type of the clothes being washed.

•You can choose one of the four courses by pressing this button until your desired course indicator light comes on.

Process Selection Button

•This button is used to select the desired process of washing.

•If a full cycle of wash, rinse, and spin is not desired, the desired process can be selected by pressing this button until your desired process indicator light comes on.

11

5. DIRECTIONS FOR INSTALLATION AND USE

HOW TO INSTALL THE WASHING MACHINE Selection of the Installing Place

Install the washer on the horizontal solid floor.

If the washer is installed on an unsuitable floor, it could make considerable noise and vibration.

Never install in these places.

•The place where it would be exposed to direct sunlight.

•The place nearby a heater or heat appliances.

•The place where it would be supposed to be frozen in winter.

•The kitchen with coal gas and a damp place like a bathroom.

•The proper installation of the washing machine can increase the wash effectiveness and the life of it.

If the washer is installed on an inclined floor, it could make considerable noise and vibration and could cause a malfunction.

Use the height adjust rubber to adjust the washing machine so that it sits properly.

How to install on an Inclined Place

1. Height Setting |

2. Check the Horizontal Status |

|

|

• After controlling the height by |

• Check the position of tub above |

turning the adjustable leg, let the |

the center of the washer. |

washer put down to the ground. |

|

NOTES:

The opening must not be obstructed by carpeting when the washing machine is installed on a carpeted floor.

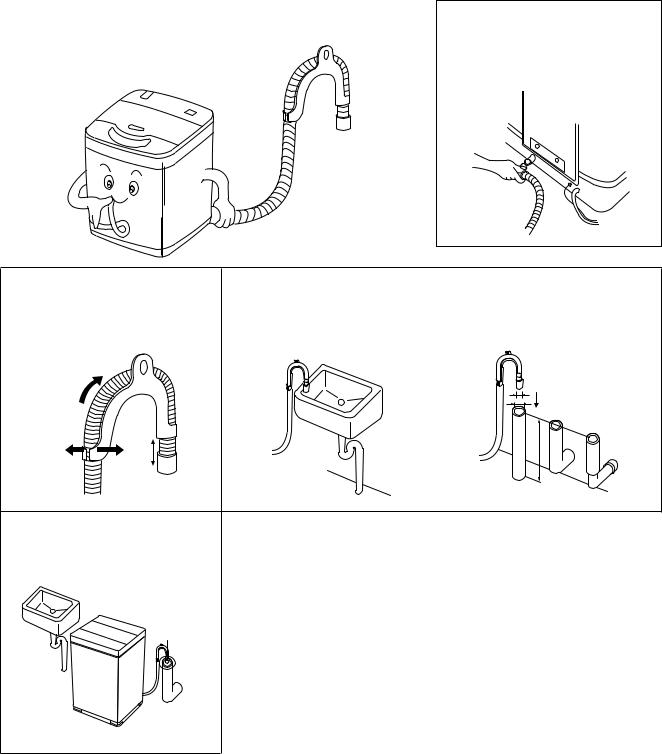

Installing the Drain Hose [Non-pump Model]

¡Indoorsill.case that it goes over a Don't let the height of the drain hose exceed 20cm from the gound.

™ |

In case of extending the drain |

£ |

Be careful that the end of the |

hose. |

drain hose is not immersed |

||

|

Don't let the total length |

|

in water. |

|

exceed 3m. |

|

|

|

|

|

|

|

|

|

|

3m

20Cm

12

Installing the Drain Hose [Pump Model]

Never forget to install drain hose before operating this washing machine. The packing box opened, there are a drain hose, a clamp, and a hose fixture.

¡Connect the drain hose to the drain outlet at the rear side of the washing machine, and fasten it tightly with the clamp supplied.

™ |

Attach the hose guide, included |

£ |

Hook the drain hose to the |

Or, connect the drain hose to a |

standpipe of a diameter greater than |

||||

|

in the accessory kit, to guide |

|

edge of the tub, paying |

that of the drain hose and at a height |

|

the drain hose over the tub or |

|

attention that there are no |

|

|

|

of min. 70cm. |

||

|

standpipe. |

|

bends or constractions along |

|

|

|

|

||

|

|

|

the drain hose. |

|

|

PULL HOSE |

|

|

|

|

THROUGH |

|

|

min |

|

|

|

|

|

|

55mm |

|

|

70Cm |

|

|

|

|

|

|

FLEX HOSE |

|

|

|

|

GUIDE |

|

|

|

|

APART |

|

|

|

¢Position the washing machine next to the wall.

MUST be ventilated

NOTES:

1.Let the highest point of the drain hose be more than 1m above the floor. If not so, the water in the washer could be drained during operation

2.Be sure that the height of the drain hose must be less than 1.5m above the floor. If not so, the water in the washer could not drain.

3.The hose guide MUST be fitted to the drain hose. The drain hose sould not extend more than 55mm from the end of the hose guide. This is to prevent ‘SYPHONING’.

If necessary the drain hose can be trimmed to length.

13

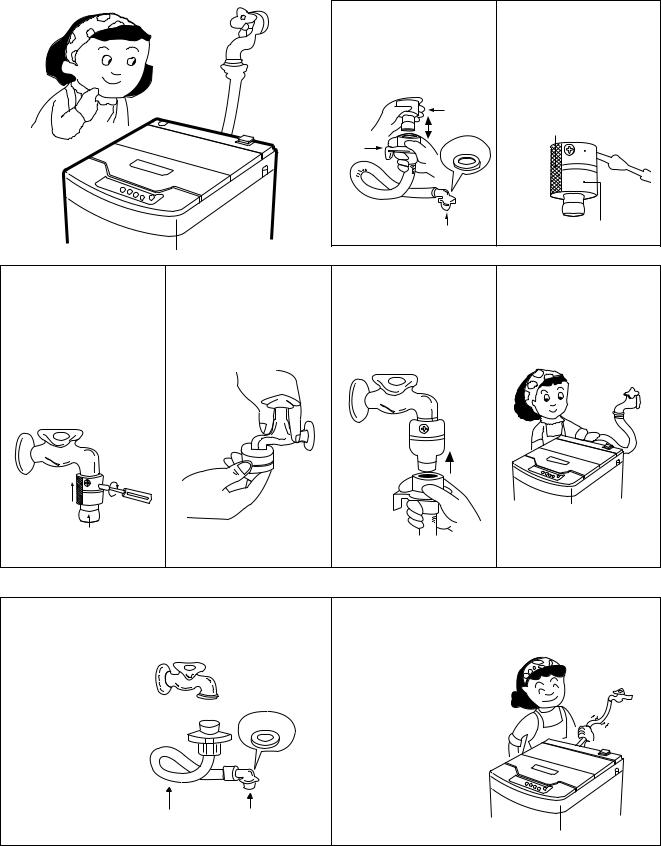

HOW TO CONNECT THE INLET HOSE

In Installing the Inlet Hose

¡ |

Pull down the collar |

|

|

of the inlet hose to |

|

|

separate it from the |

|

|

water tap adapter. |

|

|

Water Tap |

|

|

Adapter |

|

Collar |

Rubber |

|

packing |

||

|

Connector C

™Loosen the four screw at the water tap adapter, but don't loosen the screws until they are separated from the water tap adapter.

Tape

Connector A

Connector A

Tap

Adapter

Connector B

£Connect the water tap adapter to the water tap, and tighten the four screws evenly while pushing up the adapter so that the rubber packing can stick to the water tap tightly.

@

!

Connector B

¢Remove the tape, and screw connector B into connector A tightly.

Connect the inlet hose to the water tap adapter by pulling down the collar of the hose end.

§Connect the connector C of the inlet hose to the water inlet of the washer by turning it clock-wise to be fixed tightly.

•Please check the rubber packing inside the connector C of the inlet hose.

For Screw-Shaped Tap

¶Connect the inlet hose to the water tap by screwing the

connector D tightly.

Connector D

Hose

™Connect the connector C of the inlet hose to the water inlet of the

washer by turning

it clockwise to be fixed tightly.

Rubber

Packing

• Please check the rubber packing inside the connector

C of the inlet hose.

Connector C

14

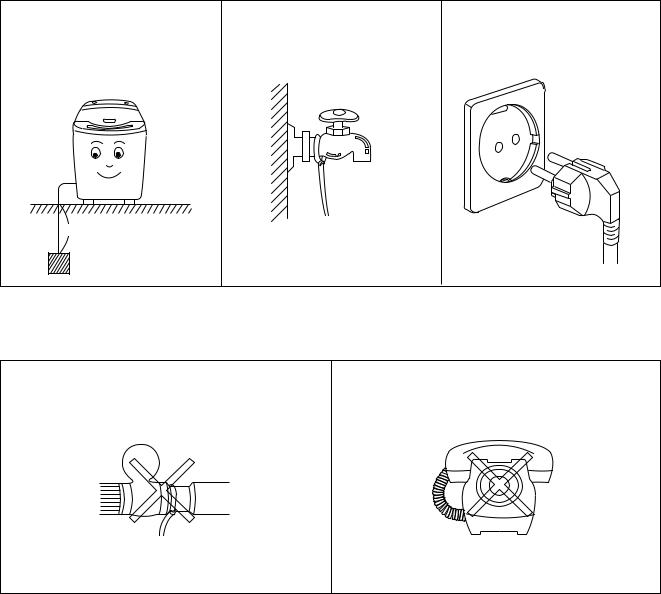

HOW TO GROUND THE WIRE

Grounding Method

•If your water tap or water pipe is not made of metal, connect the ground wire to a copper plate or a metal rod and bury it in the earth.

•If both your water tap and water pipe are made of metal, connect the ground wire to the base of the water tap.

•In case of using 3-core cord, there is no need for grounding.

20Cm |

|

|

* It is of no use connecting the |

||

|

||

|

ground wire to the water pipe |

|

|

made of plastic. |

|

|

|

Never Connect the Ground Wire to Such a Thing

•Never connect it to a gas pipe because of danger of a explosion.

•Never connect it to a telephone wire or a lightning rod because it is very dangerous at a thunderbolt.

Gas Pipe |

|

Telephone Wire |

|

|

|

15

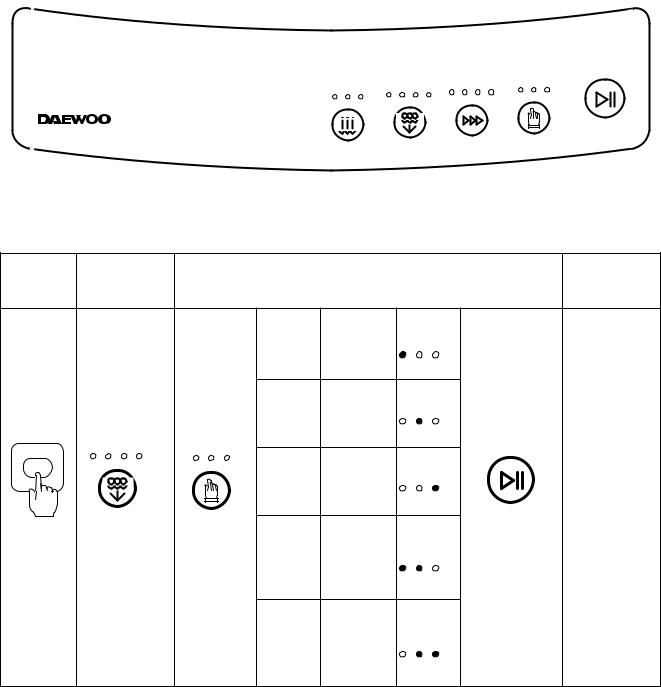

6. PROCEDURE OF FULL-AUTOMATIC WASHING

HOT WARMCOLD |

HIGH MEDIUMLOW SMALL FUZZYSPEEDYHEAVYWOOL |

WASHRINSESPIN |

|

|

|

START/HOLD |

WATER TEMP. |

WATER LEVEL |

COURSE |

PROCESS |

|

Full Automatic Course

Pressing |

|

Selecting Course |

||

the Power |

Course |

Kinds of the |

||

Switch |

Clothes |

|||

|

|

|||

|

Fuzzy |

|

General clothes |

|

|

Course |

FUZZYSPEEDYHEAVYWOOL |

|

|

|

|

|

||

|

Speed |

|

Lightly stained |

|

|

Course |

FUZZYSPEEDYHEAVYWOOL |

clothes: under- |

|

|

|

wear, T-shirts, |

||

|

|

|

||

|

|

|

Y-shirts, etc.. |

|

Selecting |

Procedure to |

Water level |

Press the Button |

• The Water |

|

level is |

|

selected |

|

automatically |

START/HOLD |

|

|

HIGH MEDIUMLOW SMALL |

|

End of Washing

Heavy

Course

FUZZYSPEEDYHEAVYWOOL

Wool

Course

FUZZYSPEEDYHEAVYWOOL

Heavily stained clothes: blue-jean, climbing clothes, ruck-sack, sports wear, etc..

Delicate clothes: Sweater, silk, lingerie, etc.

• The Water |

It is informed |

|

level is fixed |

||

by buzzer. |

||

to "HIGH" |

||

|

||

|

COURSE WATER LEVEL START/HOLD |

|

HIGH MEDIUMLOW SMALL |

|

After Operation is finished

•Close the water tap, and disconnect the inlet hose if necessary.

•Turn off the power, and disconnect the power cord from the electric outlet, being sure to take hold of the plug.

•Clean the lint filter.

16

HOT WARMCOLD |

HIGH MEDIUMLOW SMALL FUZZYSPEEDYHEAVYWOOL |

WASHRINSESPIN |

|

|

|

START/HOLD |

WATER TEMP. |

WATER LEVEL |

COURSE |

PROCESS |

|

Partial Selections Among Wash, Rinse or Spin

Pressing

Selecting

the Power Selecting Process

Water level

Switch

|

Stage 1 |

Only Wash |

|

Stage 2 |

Only Rinse |

HIGH MEDIUMLOW SMALL |

WASHRINSESPIN |

|

|

Stage 3 |

Only Spin |

WATER LEVEL |

PROCESS |

|

|

Stage 4 |

Wash and |

|

|

Rinse |

WASHRINSESPIN

WASHRINSESPIN

WASHRINSESPIN

START/HOLD

WASHRINSESPIN

End of

Process

It is informed by buzzer.

Stage 5 |

Rinse and |

|

Spin |

WASHRINSESPIN

17

Loading...

Loading...