DADD 3D7408S-5, 3D7408S-4, 3D7408S-3, 3D7408S-2, 3D7408S-1 Datasheet

...

3D7408

Doc #96003 DATA DELAY DEVICES, INC. 1

12/2/96 3 Mt. Prospect Ave. Clifton, NJ 07013

MONOLITHIC 8-BIT

PROGRAMMABLE DELAY LINE

(SERIES 3D7408)

FEATURES

• All-silicon, low-power CMOS technology

• TTL/CMOS compatible inputs and outputs

• Vapor phase, IR and wave solderable

• Auto-insertable (DIP pkg.)

• Low ground bounce noise

• Leading- and trailing-edge accuracy

• Increment range: 0.25 through 5.0ns

• Delay tolerance: 1% (See Table 1)

• Temperature stability: ±3% typical (0C-70C)

• Vdd stability: ±1% typical (4.75V-5.25V)

• Minimum input pulse width: 10% of total

delay

• Programmable via 3-wire serial or 8-bit

parallel interface

FUNCTIONAL DESCRIPTION

The 3D7408 Programmable 8-Bit Silicon Delay Line product

family consists of 8-bit, user-programmable CMOS silicon

integrated circuits. Delay values, programmed either via the

serial or parallel interface, can be varied over 255 equal steps

ranging from 250ps to 5.0ns inclusively. Units have a typical

inherent (zero step) delay of 12ns to 17ns (See Table 1). The

input is reproduced at the output without inversion, shifted in time

as per user selection. The 3D7408 is TTL- and CMOScompatible, capable of driving ten 74LS-type loads, and features

both rising- and falling-edge accuracy.

The all-CMOS 3D7408 integrated circuit has been designed as a reliable, economic alternative to hybrid

TTL programmable delay lines. It is offered in a standard 16-pin auto-insertable DIP and a space saving

surface mount 16-pin SOIC.

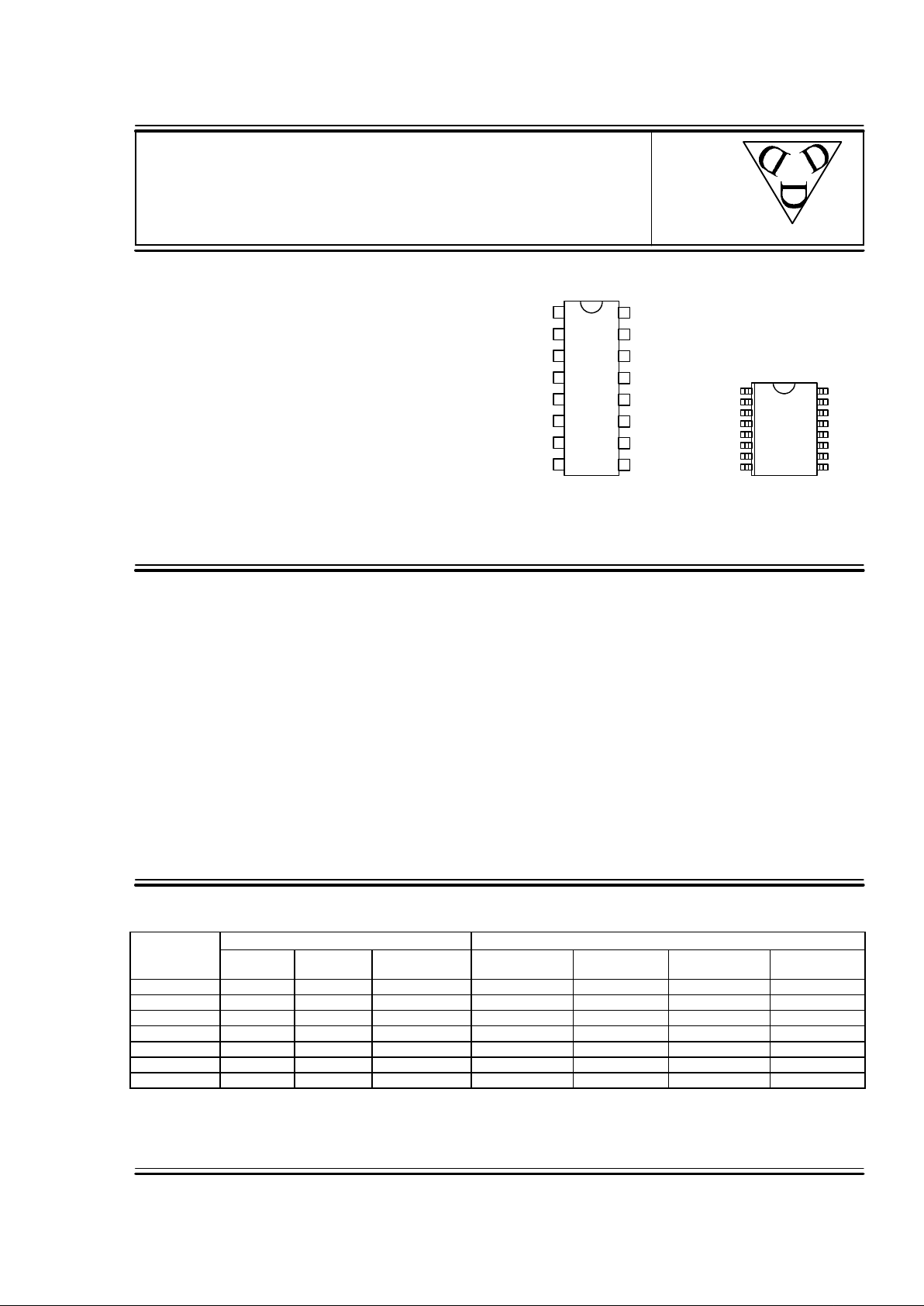

PACKAGES

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

IN

AE

SO/P0

P1

P2

P3

P4

GND

VDD

OUT

MD

P7

P6

SC

P5

SI

3D7408 DIP

3D7408G Gull Wing

(300 Mil)

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

IN

AE

SO/P0

P1

P2

P3

P4

GND

VDD

OUT

MD

P7

P6

SC

P5

SI

3D7408S

SOIC

(300 Mil)

data

delay

devices, inc.

3

(For mechanical data, see Case Dimensions document)

PIN DESCRIPTIONS

IN Signal Input

OUT Signal Output

MD Mode Select

AE Address Enable

P0-P7 Parallel Data Input

SC Serial Clock

SI Serial Data Input

SO Serial Data Output

VCC +5 Volts

GND Ground

TABLE 1: PART NUMBER SPECIFICATIONS

PART DELAYS AND TOLERANCES INPUT RESTRICTIONS

NUMBER

Step 0

Delay (ns)

Step 255

Delay (ns)

Delay

Increment (ns)

Max Operating

Frequency

Absolute Max

Oper Freq

Min Operating

P.W.

Absolute Min

Oper P.W.

3D7408-0.25

12 ± 2 75.75 ± 4.0 0.25 ± 0.15

6.25 MHz 90 MHz 80.0 ns 5.5 ns

3D7408-0.5

12 ± 2 139.5 ± 4.0 0.50 ± 0.25

3.15 MHz 45 MHz 160.0 ns 11.0 ns

3D7408-1

12 ± 2 267.0 ± 5.0 1.00 ± 0.50

1.56 MHz 22 MHz 320.0 ns 22.0 ns

3D7408-2

14 ± 2 522.0 ± 6.0 2.00 ± 1.00

0.78 MHz 11 MHz 640.0 ns 44.0 ns

3D7408-3

17 ± 2 782.0 ± 8.0 3.00 ± 1.50

0.52 MHz 7.5 MHz 960.0 ns 66.0 ns

3D7408-4

17 ± 2 1037 ± 9.0 4.00 ± 2.00

0.39 MHz 5.5 MHz 1280.0 ns 88.0 ns

3D7408-5

17 ± 2 1292 ± 10 5.00 ± 2.50

0.31 MHz 4.4 MHz 1600.0 ns 110.0 ns

NOTES: Any delay increment between 0.25 and 5.0 ns not shown is also available.

All delays referenced to input pin 1996 Data Delay Devices

3D7408

Doc #96003 DATA DELAY DEVICES, INC. 2

12/2/96 Tel: 973-773-2299 Fax: 973-773-9672 http://www.datadelay.com

APPLICATION NOTES

The 8-bit programmable 3D7408 delay line

architecture is comprised of a number of delay

cells connected in series with their respective

outputs multiplexed onto the Delay Out pin

(OUT) by the user-selected programming data.

Each delay cell produces at its output a replica of

the signal present at its input, shifted in time.

INPUT SIGNAL CHARACTERISTICS

The Frequency and/or Pulse Width (high or low)

of operation may adversely impact the specified

delay and increment accuracy of the particular

device. The reasons for the dependency of the

output delay accuracy on the input signal

characteristics are varied and complex.

Therefore a Maximum and an Absolute

Maximum operating input frequency and a

Minimum and an Absolute Minimum operating

pulse width have been specified.

OPERATING FREQUENCY

The Absolute Maximum Operating Frequency

specification, tabulated in Table 1, determines

the highest frequency of the delay line input

signal that can be reproduced, shifted in time at

the device output, with acceptable duty cycle

distortion.

The Maximum Operating Frequency

specification determines the highest frequency of

the delay line input signal for which the output

delay accuracy is guaranteed.

To guarantee the Table 1 delay accuracy for

input frequencies higher than the Maximum

Operating Frequency, the 3D7408 must be

tested at the user operating frequency.

Therefore, to facilitate production and device

identification, the part number will include a

custom reference designator identifying the

intended frequency of operation. The

programmed delay accuracy of the device is

guaranteed, therefore, only at the user specified

input frequency. Small input frequency variation

about the selected frequency will only marginally

impact the programmed delay accuracy, if at all.

Nevertheless, it is strongly recommended

that the engineering staff at DATA DELAY

DEVICES be consulted.

OPERATING PULSE WIDTH

The Absolute Minimum Operating Pulse

Width (high or low) specification, tabulated in

Table 1, determines the smallest Pulse Width of

the delay line input signal that can be

reproduced, shifted in time at the device output,

with acceptable pulse width distortion.

The Minimum Operating Pulse Width (high or

low) specification determines the smallest Pulse

Width of the delay line input signal for which the

output delay accuracy tabulated in Table 1 is

guaranteed.

To guarantee the Table 1 delay accuracy for

input pulse width smaller than the Minimum

Operating Pulse Width, the 3D7408 must be

tested at the user operating pulse width.

Therefore, to facilitate production and device

identification, the part number will include a

custom reference designator identifying the

intended frequency and duty cycle of operation.

The programmed delay accuracy of the device is

guaranteed, therefore, only for the user specified

input characteristics. Small input pulse width

variation about the selected pulse width will only

marginally impact the programmed delay

accuracy, if at all. Nevertheless, it is strongly

recommended that the engineering staff at

DATA DELAY DEVICES be consulted.

SPECIAL HIGH ACCURACY

REQUIREMENTS

The Table 1 delay and increment accuracy

specifications are aimed at meeting the

requirements of the majority of the applications

encountered to date. However, some systems

may place tighter restrictions on one accuracy

parameter in favor of others. For example, a

channel delay equalizing system is concerned in

minimizing delay variations among the various

channels. Therefore, because the inter channel

skew is a delay difference, the programmed

delay tolerance may need to be considerably

decreased, while the increment and its tolerance

are of no consequence. The opposite is true for

an under-sampled multi-channel data acquisition

system.

3D7408

Doc #96003 DATA DELAY DEVICES, INC. 3

12/2/96 3 Mt. Prospect Ave. Clifton, NJ 07013

APPLICATION NOTES (CONT’D)

The flexible 3D7408 architecture can be

exploited to conform to these more demanding

user-dictated accuracy constraints. However, to

facilitate production and device identification, the

part number will include a custom reference

designator identifying the user requested

accuracy specifications and operating conditions.

It is strongly recommended that the

engineering staff at DATA DELAY DEVICES

be consulted.

POWER SUPPLY AND

TEMPERATURE CONSIDERATIONS

The delay of CMOS integrated circuits is strongly

dependent on power supply and temperature.

The monolithic 3D7408 programmable delay line

utilizes novel and innovative compensation

circuitry to minimize the delay variations induced

by fluctuations in power supply and/or

temperature.

The thermal coefficient is reduced to 600

PPM/C, which is equivalent to a variation, over

the 0C-70 C operating range, of ±±3% from the

room-temperature delay settings. The power

supply coefficient is reduced, over the 4.75V-

5.25V operating range, to ±±1% of the delay

settings at the nominal 5.0VDC power supply

and/or ±±2ns, whichever is greater.

It is essential that the power supply pin be

adequately bypassed and filtered. In

addition, the power bus should be of as low

an impedance construction as possible.

Power planes are preferred.

PROGRAMMED DELAY (ADDRESS)

UPDATE

A delay line is a memory device. It stores

information present at the input for a time equal

to the delay setting before presenting it at the

output with minimal distortion. The 3D7408 8-bit

programmable delay line can be represented by

256 serially connected delay elements

(individually addressed by the programming

data), each capable of storing data for a time

equal to the device increment (step time). The

delay line memory property, in conjunction with

the operational requirement of “instantaneously”

connecting the delay element addressed by the

programming data to the output, may inject

spurious information onto the output data stream.

In order to ensure that spurious outputs do not

occur, it is essential that the input signal be idle

(held high or low) for a short duration prior to

updating the programmed delay. This duration is

given by the maximum programmable delay.

Satisfying this requirement allows the delay line

to “clear” itself of spurious edges. When the new

address is loaded, the input signal can begin to

switch (and the new delay will be valid) after a

time given by t

PDV

or t

EDV

(see section below).

PROGRAMMED DELAY (ADDRESS)

INTERFACE

Figure 1 illustrates the main functional blocks of

the 3D7408 delay program interface. Since the

3D7408 is a CMOS design, all unused input pins

must be returned to well defined logic levels,

VCC or Ground.

TRANSPARENT PARALLEL MODE

(MD = 1, AE = 1)

The eight program pins P0 - P7 directly control

the output delay. A change on one or more of

the program

pins will be reflected on the output delay after a

time t

PDV

, as shown in Figure 2. A register is

required if the programming data is bused.

LATCHED PARALLEL MODE

(MD = 1, AE PULSED)

The eight program pins P0 - P7 are loaded by

the falling edge of the Enable pulse, as shown in

Figure 3. After each change in delay value, a

settling time t

EDV

is required before the input is

accurately delayed.

SERIAL MODE (MD = 0)

While observing data setup (t

DSC

) and data hold

(t

DHC

) requirements, timing data is loaded in

MSB-to-LSB order by the rising edge of the clock

(SC) while the enable (AE) is high, as shown in

Figure 4. The falling edge of the enable (AE)

activates the new delay value which is reflected

at the output after a settling time t

EDV

. As data is

shifted into the serial data input (SI), the previous

contents of the 8-bit input register are shifted out

of the serial output port pin (SO) in MSB-to-LSB

order, thus allowing cascading of multiple

devices by connecting the serial output pin (SO)

of the preceding device to the serial data input

Loading...

Loading...