Carrier 50HJ015 User Manual

HEATING & COOLING

50HJ015,024

Single-Package Rooftop Units

Electric Cooling with Electric Heat Option

Installation, Start-Up and Service

Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS

INSTALLATION ................................................................. 1-9

Step 1 — Provide Unit Support.......................................... 1

• ROOF CURB

• ALTERNATE UNIT SUPPORT

Step 2 — Rig and Place Unit ............................................ 1

• POSITIONING

• ROOF MOUNT

Step 3 — Field Fabricate Ductwork

Step 4 - Make Unit Duct Connections .... 6

Step 5 — Trap Condensate Drain

Step 6 — Make Electrical Connections

• FIELD POWER SUPPLY

• FIELD CONTROL WIRING

Step 7 — Make Outdoor-Air Inlet

Adjustments......................................................................... 8

• MANUAL OUTDOOR-AIR DAMPER

• OPTIONAL FACTORY-INSTALLED

ECONOMIZER

Step 8 — Install Outdoor-Air Hood

START-UP....................................................................... 10-12

SERVICE

START-UP CHECKLIST...................................................CL 1

...........................................................................

...........................................

...............................

......................................

..............................

...................................

1

6

6

7

8

12-16

SAFETY CONSIDERATIONS

INSTALLATION

Step 1

ROOF CURB — Assemble and install accessory roof curb

in accordance with instructions shipped with the curb.

Accessory roof curb and information required to field

fabricate a roof curb are shown in Fig I and 2. Install in

sulation, cant strips, roofing, and counter flashing as shown.

Ductwork can be secured to roof curb before unit is set in

place.

IMPORTANT' The gasketing of the unit to the roof

curb is critical for watertightness Install gasket sup

plied with the roof curb as shown in Fig. 1. Improp

erly applied gasket can result in air leaks and poor

unit performance.

Curb should be level. This is necessary to permit unit

drain to function properly Unit leveling tolerance is

± Vi6 in. per linear ft in any direction. Refer to Accessory

Roof Curb Installation Instructions for additional informa

tion as required.

ALTERNATE UNIT SUPPORT - When the curb cannot

be used, support unit with sleepers using unit curb support

area. If sleepers cannot be used, support long sides of unit

with a minimum of 3 equally spaced 4-in. x 4-in. pads on

each side.

Provide Unit Support

Installation and servicing of air-conditioning equipment

can be hazardous due to system pressure and electrical com

ponents. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance func

tions of cleaning coils and filters and replacing filters. All

other operations should be performed by trained service

personnel. When working on air-conditioning equipment,

observe precautions in the literature, tags and labels at

tached to the unit, and other safety precautions that may

apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations. Have

fire extinguishers available for all brazing operations.

A WARNING

Before performing service or maintenance operations

on unit, turn off main power switch to unit. Electrical

shock could cause personal injury.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

BookII PC 111 Catalog No 565-125 Printed in U S A. Form 50HJ-6SI Pg 1 12-93 Replaces: New

Tab 1b

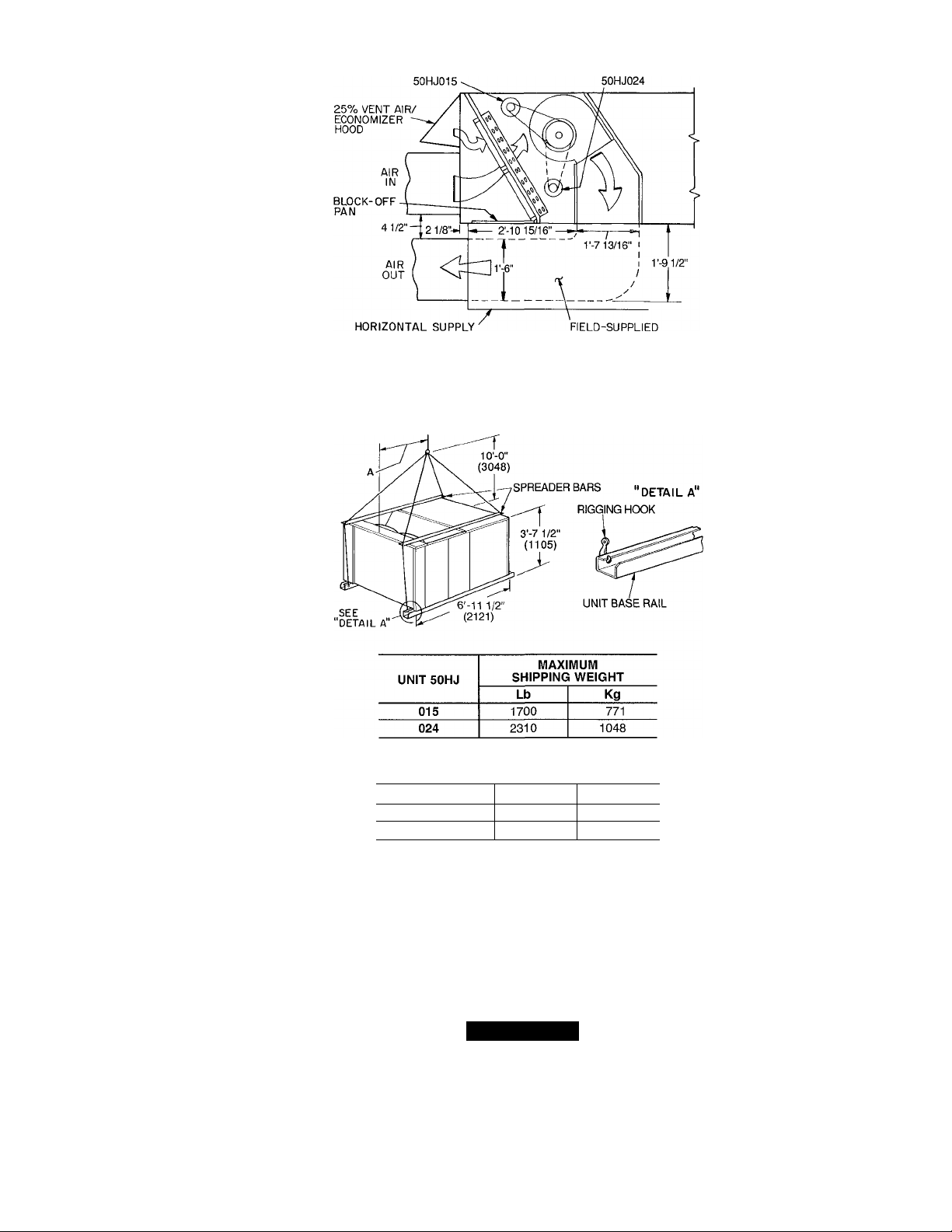

Step 2 — Rig and Place Unit — Inspect unit for

transportation damage. File any claim with transportation

agency. Keep unit upright, and do not drop. Use spreader

bars over unit to prevent sling or cable damage. Rollers

may be used to move unit across a roof. Level by using unit

frame as a reference; leveling tolerance is ± l/i6 in. per lin

ear ft in any direction. See Fig. 1 for additional leveling

tolerance information. Unit weight is shown in Table 1.

Four lifting holes are provided in ends of unit base rails

as shown in Fig. 3 Refer to rigging instructions on unit.

POSITIONING — Provide clearance around and above unit

for airflow, safety, and service access (Fig. 4).

Do not install unit in an indoor location. Do not locate

air inlets near exhaust vents or other sources of contam

inated air.

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

ROOF MOUNT — Check building codes for weight dis

tribution requirements.

NOM. 5/4 X 4

(32) X (102)

TYP 4 PLC5

0“

COMPR

SECT

1 -6

(50P0900151 ONLY) lb4)

OPENING

(457) . ^ .

SUPPLY

CURB

PLAN VIEW OF ROOF CURB

- ___

RETURN

OPEN(NG

CURB

OUTLINE

g

___________

OF UNIT

A (1753)

.Ü

INSULATED PANE', FOR SIDE

SUHPLY AND RETURN

(50P09001S1 ONLY)

5'-3'

UNIT OPENINGS

-(’so/)

1 t

SUPPLY AIR RETURN AIR

SECT ION A-A

GASKET

(SUPPLIED

WITH CURB)

COUNTER FLASHING

ROOFING FELT

(FIELD SUPPLIED)

. CANT STRIP

(FIELD SUPPLIED)

RIGID INSULATION

(FIELD SUPPLIED)

-1 -4 5/16

(415)

(FIELD SUPPLIED)

•ROOFING material

(FIELD SUPPLIED)

OPTIONAL

SIDE 5UPPLT

(305)

ATTACH DUCT TO ROOF CURB

ACCESSORY

PACKAGE NO.

50PQ900221

50PQ900141

50PQ900151

CURB

HEIGHT

V-2"

(305)

2'-0"

(610)

2'-0"

(610)

DESCRIPTION

Standard Curb —

14" High

Standard Curb

for Units Requiring

High Installation

Horizontal Supply

and Return Curb

LEGEND

COMP SECT. — Compressor Section

NOTES:

1 Roof curb accessory is shipped unassembled.

2. Insulated panels, 1-in thick neoprene-coated,

IV2 lb density.

3 Dimensions in ( ) are in millimeters.

4 Direction of airflow.

5 Roof curb 16 gage steel.

O’-S 3/16*'

&

0 32)

NOTE: To prevent the hazard of stagnant water build-up in the drain

pan of the indoor-air section, unit can only be pitched as shown.

Fig. 1 — Roof Curb Details

I

EVAPORATORFAN MOTOR

EVAPORATORFAN MOTOR

CURB (50P0900I5I)

TRANSITION DUCT

Fig. 2 — Horizontal Supply/Return Curb Details

DIMENSION A

UNIT 50HJ

015

024

Ft-in. mm

3-0 914

3-4’/2 1029

ÊJ

NOTES;

1. Dimensions in ( ) are in miilimeters

2 Refer to Tabie 1 for unit operating weights.

3. Remove boards at ends of unit and runners prior to rigging.

4 Rig by inserting hooks into unit base raiis as shown. Use corner

post from packaging to protect coii from damage. Use bumper

boards for spreader bars.

5 Weights do not inciude optionai economizer See Table 1 for econo

mizer weight.

6. Weights given are for aluminum evaporator coii plate fins and

copper condenser coii piate fins Weights of other metai combi

nations are listed in Table 1

A CAUTION

All panels must be in place when rigging.

Fig. 3 — Rigging Details

CONTROL BOX

ACCESS

•25% AIR On

''ECONOMIZER HOOD

pO -3 7/16'

i (87)

C

SECTION A-A

■ }

0’-3"

(76)

O'-l"

1(102)

I

UNIT

50HJ

015 390

024 492

‘Weights are for unit only (with aluminum evaporator and condenser

coil fins) and do not include options or crating

Lb

A

Kg

177

233

CORNER WEIGHT*

B

Lb

Kg

243 110 322 146

232

511

C D

Lb

Kg

504 229

Lb

Kg

515 234

523 237

Fig. 4 — Base Unit Dimensions

DIMENSIONS

UNIT

50HJ

A

Ft-in. mm Ft-in. mm

015 3-0

024 3-4% 1035 3-7

LEGEND

914

B C

838 1-10 559

2-9

1092 1-8 508

Ft-in. mm

KO — Knockout

NOTES;

1 Dimensions in ( ) are in millimeters

2- ® Center of gravity.

Direction of airfloiw.

Ductwork to be attached to accessory roof curb only.

Minimum clearance:

a Rear; 7'-0" (2134) for coil removal. This dimension

can be reduced to 4'-0" (1219) if conditions permit

coil removal from the top

Left side: 4'-0" (1219) for proper condenser coil

airflow

Front' 4'-0" (1219) for control box access

Right side: 4'-0" (1219) for proper operation of damper

and power exhaust (if so equipped).

e. Top: 6'-0" (1829) to assure proper condenser fan

operation.

f. Local codes or jurisdiction may prevail.

With the exception of clearance for the condenser coil

and the damper/power exhaust as stated In note no 5, a

removable fence or barricade requires no clearance

Dimensions are from outside of corner post. Allow

O'-Vie" (8) on each side for top cover drip edge

i

Table 1 — Physical Data

UNIT SIZE 50HJ

OPERATING WT (lb)

COMPRESSOR

REFRIGERANT

REFRIGERANT METERING DEVICE

CONDENSER COIL

CONDENSER FAN

EVAPORATOR COIL

EVAPORATOR FAN

HIGH-PRESSURE SWITCH

LOW-PRESSURE SWITCH

AIR INLET SCREENS

RETURN-AIR FILTERS (TYPE)

LEGEND

AI — Aluminum

Cu — Copper

'Evaporator coil fin material/condenser coil fin material.

tWeight of 14 in. roof curb.

"System 1 consists of the upper portion of condenser coil and intertwined evaporator coil, and

System 2 consists of the lower portion of the condenser coil and intertwined evaporator coil

NOTE: The 50HJ015 has adjustable pulleys The 50HJ024 has one set (2) of fixed pulleys

AI/AI*

Unit Al/Cu*

Cu/Cu*

Economizer

Roof Curbt

Number

Oil (oz)152

Charge (lb)** Sys 1, Sys 2

Upper Circuit

No. ...Length (in.)...iD/OD

Lower Circuit

No. ...Length (in.)...iD/OD

Rows

Fins/in.

Total Face Area (sq ft)

Nominal Cfm

Number...Diameter (in.)

Motor Hp (1075 Rpm)

Watts Input (Total)

Rows

Fins/in.

Total Face Area (sq ft)

Quantity...Size (in.)

Nominal Cfm

Maximum Allowable Rpm

Motor Pulley Pitch Diameter (in.)

Fan Pulley Pitch Diameter (in.)

Belt, Quantity...Type...Length (in.)

Factory Speed Setting (Rpm)

Motor Hp (Service Factor)

Motor Frame Size

Cutout (psig)

Reset (psig)_____________________

Cutout (psig)

Reset (psig)

Economizer, Quantity...Size (in.)

Quantity... Size (in.)

____________________

20.8,

6.. .25...0 055/0.125

6.. 25...0 055/0.125

6.. .25...0 055/0.125

Copper Tubes, Aluminum or Copper Plate Fins

13 6 Al or 12.4 Cu

18.9

12,000

2...26

1

2672

Copper Tubes, Aluminum or Copper Plate Fins

14.3 Al or 13.1 Cu

165

2.. 10 X 10

1 .V...41

2.. .20 X 20 X 2

3.. .16 X 20 X 2

2.. .16 X 25 X 2

Centrifugal, Fixed Pitch Belt Drive

5000

1550

3 4-4.4

6.0

1092

3 (1.15)

56

10% Efficient — 2-in Throwaway Fiberglass

R-22

I

Capillary Tubes

Propeller Type, Direct Drive

426

320

7

22

2 20 X 25 X 1

1 20 X 20 X 1

2030

2160

2270

110

200

16.25, 16.25

13. 25 .0.055/0.125

13...25.. 0.055/0 125

13.6 Al or 12.4 Cu

22 2

11,400

2 .26

1

3000

14.4 Al or 13.1 Cu

17.9

2...12 X 12

8000

1500

6.10

8.40

1. BX.. 51

1287

7V2 (1.15)

184T

4.. 20 X 20 X 2

4.. 16 X 20 X 2

Step 3 — Field Fabricate Ductwork — Secure all

ducts to building structure. Use flexible duct connectors be

tween unit and ducts as required. Insulate and weatherproof

all external ductwork, joints, and roof openings with counter

flashing and mastic in accordance with applicable codes.

Ducts passing through an unconditioned space must be

insulated and covered with a vapor barrier.

The 50HJ units with electric heat require a 1-in. clear

ance for the first 24 in. of ductwork.

Outlet grilles must not lie directly below unit discharge.

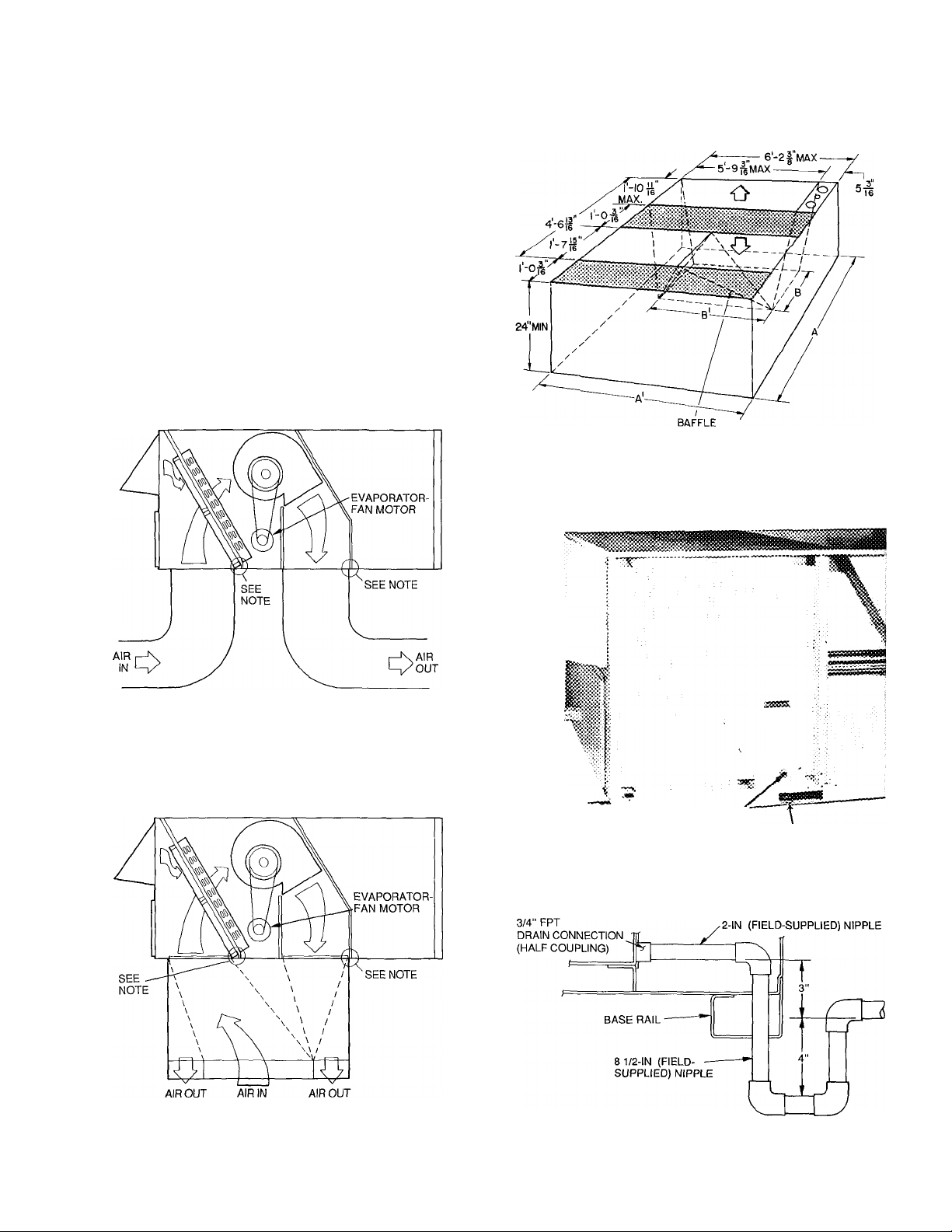

Step 4 — Make Unit Duct Connections - Unit

is shipped for through-the-bottom duct connections. Duct

work openings are shown in Fig. 5. Field-fabricated con

centric ductwork may be connected as shown in Fig. 6 and

7. Attach all ductwork to roof curb and roof curb basepans.

Refer to installation instructions shipped with accessory roof

curb for more information.

Step 5 — Trap Condensate Drain — See Fig. 4

and 8 for drain location. Plug is provided in drain hole and

must be removed when unit is operating. One V4-in. half

coupling is provided inside unit evaporator section for con

densate drain connection. An 8‘/2 in x %-in. diameter nip

ple and a 2-in. x %-in. diameter pipe nipple are coupled to

standard Y4-in. diameter elbows to provide a straight path

down through holes in unit base rails (see Fig. 9). A trap at

least 4-in. deep must be used.

i

Shaded area indicates block-off panels.

NOTE: Dimensions A, A' and B, B' are obtained from field-supplied

ceiling diffuser

Fig. 7 — Concentric Duct Details

NOTE. Do not drill in this area, as damage to basepan may resuit in

water leak.

Fig. 5 — Air Distribution — Through-the-Bottom

(50HJ024 Shown)

NOTE: Do not drill in this area, as damage to basepan may resuit in

water leak.

Fig. 6 - Concentric Duct Air Distribution

(50HJ024 Shown)

СОМЫЕстГоГ '-3/3" HOLES

Fig. 8 — Condensate Drain Details

Fig. 9 — Condensate Drain Piping Details

Loading...

Loading...