Carrier 50EQ User Manual

Number One

AirConditbning

l\Mer

Division of

Carrier Corporation

Carrier Parkway • Syracuse, N Y 13221

Single-Package Heat Pumps

INSTALLATION

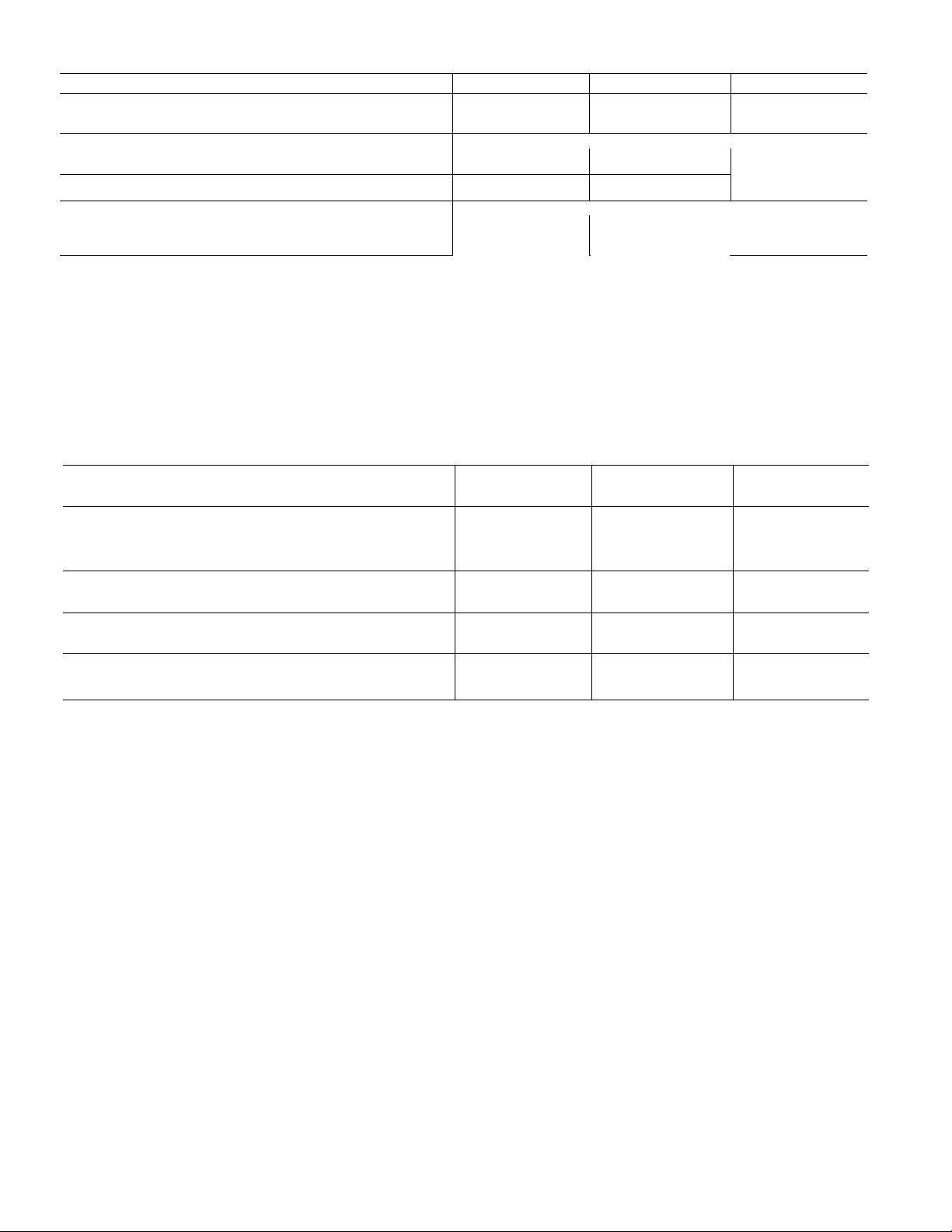

Rigging and Unit Placement — Inspect unit for

transportation damage. File claim with transporta

tion agency. Do not drop unit. Keep unit upright.

Units are designed to be hoisted only. However,

units with optional shipping skids may be moved

with a fork truck. Use spreader bars over unit to

prevent sling or cable damage to unit. Level unit by

using unit frame as reference. Leveling tolerance is

± 1 /16 in. per linear ft in any direction. See Fig. 1 for

additional information. Unit weight is shown in

Table 1.

Roof Curb — Assemble and install accessory roof

curb in accordance with instructions shipped with

accessory. (In areas of prolonged sub-freezing tem

peratures or heavy snowfall, the use of an 18-in.

high roof curb is recommended. This permits proper

drainage during defrost.) Refer to Fig. 2.

Install insulation, cant strips, roofing and flashing

as required. Ductwork can be installed to roof curb

«OTES;

t, A!i BTift (lanets jnust be in piece when rtg8^ns

2. Oo not bandte unit wsdi 'torit iruciis.

3. Use4«ei)}esan«i4"24>y-4Vor "4-by-4V'of ctenenaons

shown.

© Carrier Corporation 1979

Fig. 1 — Rigging Details

before unit is set in place. Curb should be level. Unit

leveling tolerance is ±1/16 in. per linear ft in any

direction. This is necessary to permit unit drain to

function properly.

Cut hole(s) in roof to accommodate return and

supply ducts only. Refer to accessory installation

instructions.

Roof Mount — Check building codes for weight

distribution requirements.

Alternate Unit Support Methods — Where the

preferred curb or slab mount cannot be used, sup

port unit with sleepers along unit perimeter using

unit curb-support areas. However, if sleepers cannot

be used, support long sides of unit (dimension “A,”

Fig. 3) by three 4-in. by 4-in. pads, equally spaced.

Units may sag if supported by corners only.

Positioning — Position unit so that drifting snow

does not build up on outdoor coil. Provide clear

ances around and above the unit for airflow, safety,

and service access (Fig. 3).

Do not install unit in an indoor location. Do not

locate unit air inlets near exhaust vents or other

sources of contaminated air.

Although unit is weatherproof, guard against

water from higher runoff and overhangs.

Field-Fabricated Ductwork — Secure all ducts to

building structure. Use flexible duct connectors be

tween unit and ducts as required. Insulate and

weatherproof all external ductwork, joints and all

roof openings with flashing and mastic in accord

ance with applicable codes.

Ducts passing thru unconditioned spaces must be

insulated and covered with a vapor barrier.

Unit Duct Connections — Ductwork openings

are shown in Fig. 3.

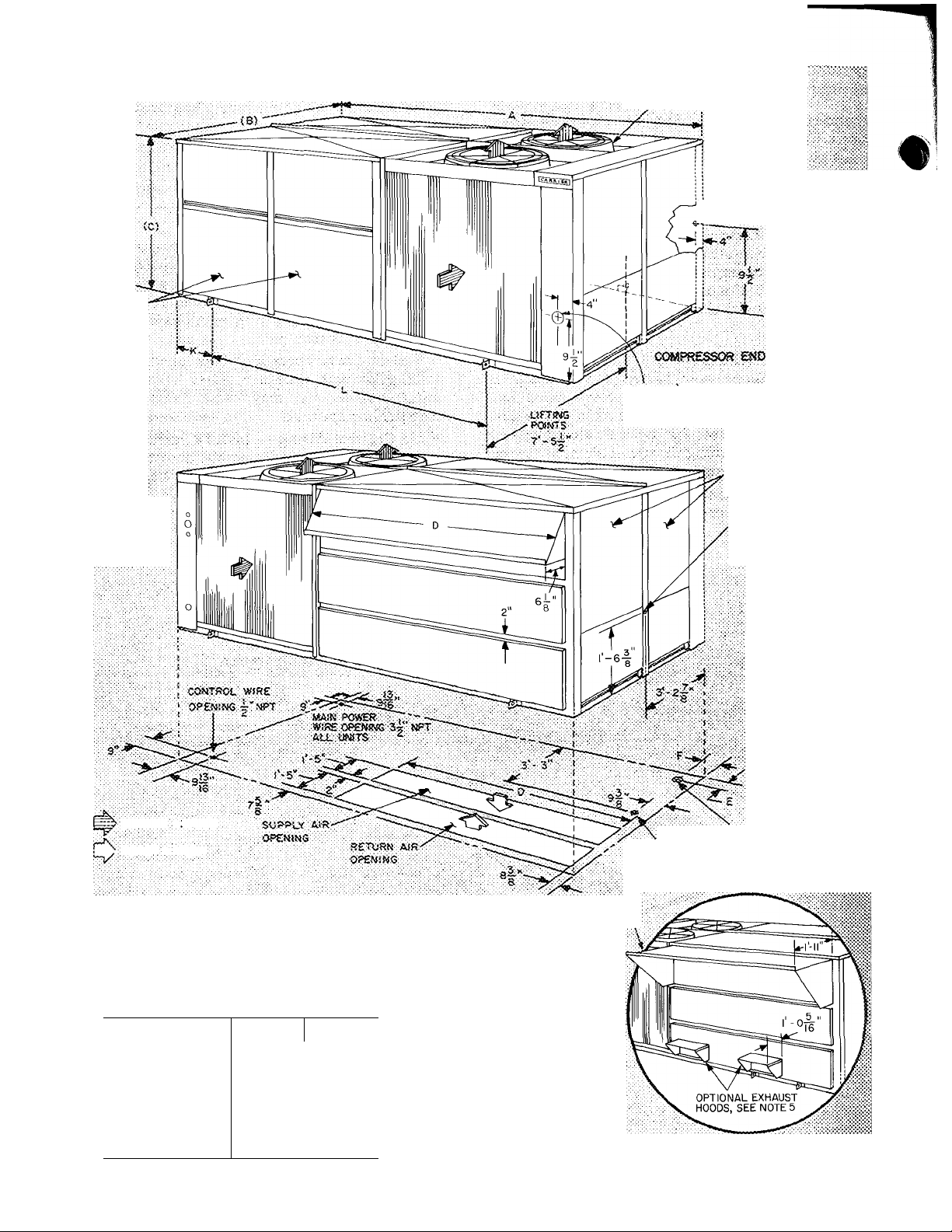

Economizer Hood Installation, Fig. 4 — The

economizer mechanism and allelectrical connections

are factory installed and adjusted. The hood assem

bly, outdoor air inlet screens and required hardware

are shipped separately and must be field installed.

NOTE: There is a linkage rod and 3 fasteners (speed

nuts) shipped with the economizer hood assembly.

This rod is not required on 50EQ units.

Install economizer hood(s) as follows:

1. Loosen unit top panel sheet metal screws above

outdoor air inlet opening.

2. Assemble hood top panel, side panels and

support channel.

Form 50EQ-4SI

Table 1 — Physical Data

UNIT MODEL

50EQ024

50EQ028

50EQ034

OPERATING WEIGHT (lb)

Base Unit

3300

3900

4550

Base Unit with Economizer

3450

4075

4750

COMPRESSOR

Serviceable, Reciprocating Hermetic

No. .Model

2 06D824

2. 06D328

2 06D537

Oil (3GS or B1) pts (per Compr) 10

10

10

REFRIGERANT CHARGE R-22

R-22

—

Sys 1*...Sys 2 (lb)

20.0...21.3

23.5..24.0

29.1..29.1

OUTDOOR AIR FANS

Direct Drive, Propeller

No. ...Hp

2 . 1

2 . 1

3 1

Frame (NEMA)

56T

56T

56T

Rpm (1-Phase)

1050

1050

1050

IIMDOOR AIR FANS

Motor

Shaft Diam (in.) — RPM 1750

Motor Frame Size

Motor Pulley Pitch Diam (in.)t

Fan Pulley Pitch Diam (in.)

Fan Speed (rpm)

Fan Shaft Diam (in )

Belt No. ...Size

Std

Opt

Std

Opt

Std

Opt

Std, A,B

Opt, A,B

Std

Opt

Std, A,B

Opt, A,B

Std

Opt

5

7-1/2

1-1/8

1-3/8

1S4T

213T

6 5 6 0

5 3 5 6

106

8

1073 991

1159 1225

1-3/16

2 3V750

2 3V670

1300

Fixed Speed Centrifugal

7-1/2

10

1-3/8

1-3/8

213T

215T

6 5 60

5 6 60

10 6

8

1073 991

1225 1312

1-3/16

2 3V750

2 3V670

1300

ELECTRIC HEATERS

Heat Anticipator Setting

Stage 1 ...2

9 25

9 25

9 25

HIGH-PRESSURE SWITCH

Cutout (psig)

Cut-in (psig)

428

320

428

320 ± 20

428 .jQ

320

LOW-PRESSURE SWITCH

Cutout (psig) 5+3

5 ± 3

5 + 3

Cut-in (psig) 20 ± 5

20 ± 5

20 + 5

INDOOR AIR FILTERS (2-in.)

Standard; No. ...Size (in.)

Throwaway; No. ...Size (in.)

6 20x25

6. .16x25

18 16x25

9 20x25

12 16x25

AIR INLET SCREENS

Manual Damper; No. ...Size (in.)

_

Economizer; No. .. Size (in.)

3 20x25

4 20x25

5 20x25

10

15

1-3/8

1-5/8

215T

254T

6 5 5 6

5 3 5 6

10 6

8

1073 925

1159 1225

1-11/16

2 3V750

4 3V710

1300

*System No 1 is bottom portion of indoor coil

fStandard fan motor supplied with standard fan drive pulleys and belts, optional fan motor supplied with optional

fan drive pulleys and belts Pulley A is installed in unit; pulley B is shipped with unit

3. Insert hood flange between unit top panel flange

and unit. Slots are provided in hood flange to

clear sheet metal screws. Tighten sheet metal

screws.

4. Secure hood side panels to outdoor air opening

flanges using screws provided.

5. Install hood support bracket(s) between U-

channel and support channel.

6. Install screen retainer on support channel using

screws in the slots. Do not tighten.

7. Install outdoor air screens.

8. Push retainers snugly against screens and tighten

screws.

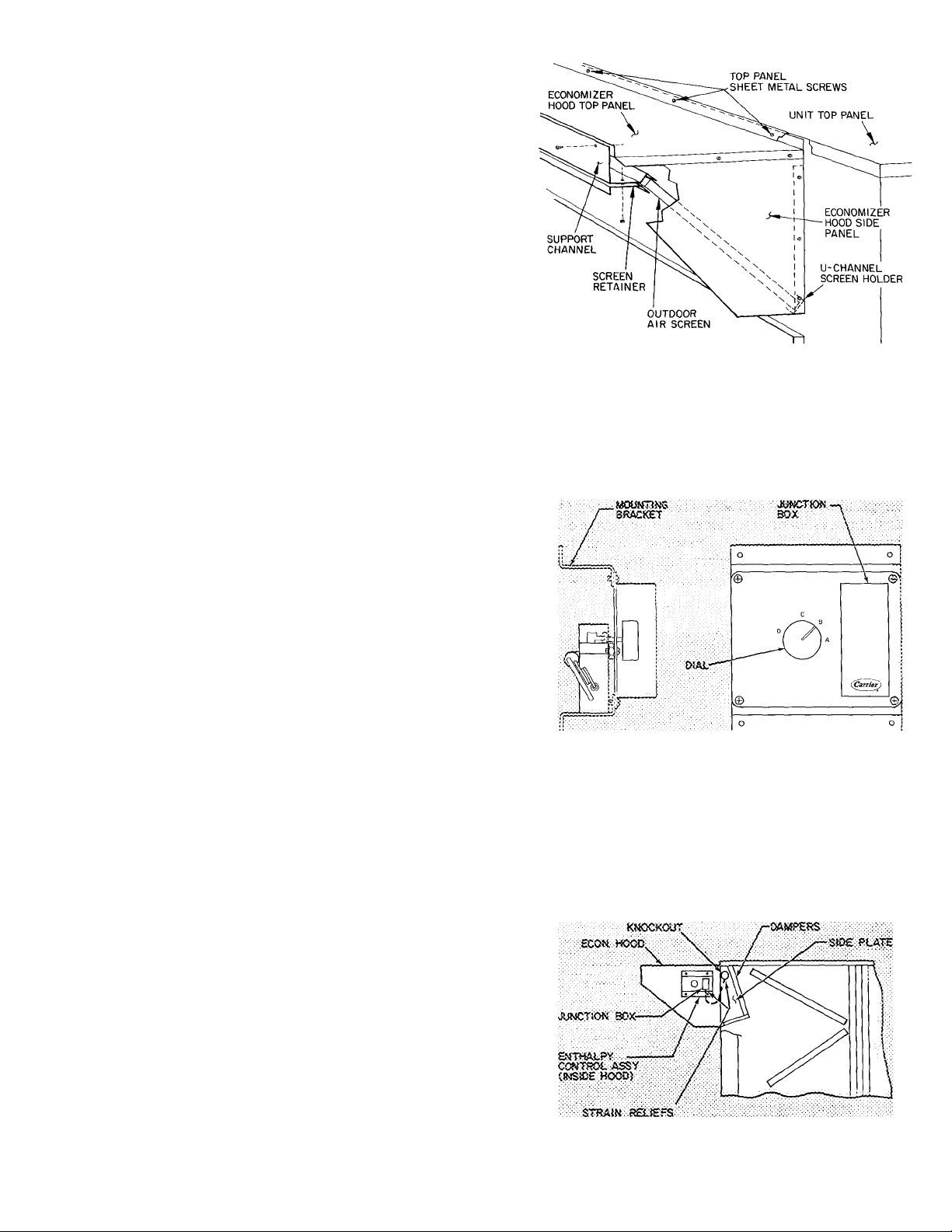

Enthalpy Control — Remove enthalpy control

assembly (Fig. 5) from shipping location on hori

zontal deck in return air filter compartment.

Using 4 no. 10-1 /2 screws from envelope in con

trol assembly junction box, mount the enthalpy con

trol assembly to the inside of economizer hood side

panel nearest condenser section (Fig. 6).

Route the 3 wires, coiled near top cover on the

condenser partition, thru knockout in side plate

(Fig. 6). Using wire connectors from envelope in

junction box, wire enthalpy control assembly as

shown in Fig. 7. Use strain reliefs from envelope in

junction box on side plate and junction box (Fig. 6).

Exhaust Air Hood Installation — The optional

power exhaust package hood assemblies and re

quired sheet metal screws are shipped in compart

ment at right of indoor air fan motor.

Using screws provided, install a hood assembly

over each exhaust air opening as shown in Fig. 3.

Power exhaust applies only to units with econo

mizer. The exhaust fan and motor assembly is

factory wired and adjusted. Refer to Service, Ex

haust Air Fan Adjustment if required.

Return Air Filters — Check to be sure return air

filters of the correct type and size are installed in

unit filter racks. Filter data is shown in Table 1. Do

not operate unit without return air filters.

Outdoor Air Inlet Screens — Be sure all outdoor

air inlet screens are in place before operating unit.

Condensate Drains — See Fig. 3 for drain loca

tions. Condensate drain is open to atmosphere and

must be trapped. Install a trapped drain line at con

nection to be used. Trap must be at least 4 in. deep

and made of flexible material or be installed so as

to prevent freeze-up.

Condensate drain pan is fitted with a 1-in. FPT

coupling. Condensate drain line may be routed thru

unit base pan or unit side as shown. A grommet is

shipped taped to this drain. Install this gasket in unit

base pan opening or alternate opening on end of unit

as required.

Field Power Wiring — All units have circuit

breakers for compressors, heaters, fan motors and

control circuits. Each unit is factory wired for

voltage shown on nameplate. The main power ter

minal block is suitable for use with aluminum or

copper wire. See Table 2 for use of aluminum wire

on electric heater terminal blocks.

Install conduit connections in unit base pan or

side panel opening provided as shown in Fig. 3.

On all units route power lines to terminal block in

control box as shown in Fig. 8. On units with electric

heat, route second power supply line thru connector

to terminal block in heater compartment.

Locate field-supplied disconnect(s) within sight of

and directly accessible from the unit. All field wiring

must comply with NEC and local requirements.

Affix crankcase heater sticker to unit disconnect

switch.

Voltage to compressor terminals during com

pressor operation must be within voltage range indi

cated on unit nameplate. Phases must be balanced

within 2%. Contact local power company for

correction of improper voltage or phase imbalance.

See Table 2 as required.

Failure due to operation of unit on improper line

voltage or with excessive phase imbalance con

stitutes abuse and may cause damage to unit

electrical components.

Field Control Wiring — Install a Carrier approved

accessory thermostat assembly according to in

stallation instructions included with the accessory.

Locate thermostat assembly in the conditioned

space where it will sense average temperature.

DIMENSIONS (ft-in.)

UNIT

ROOF CURB

MODEL NO.

A

B

C

D E F

50EQ024

50EQ900001

10- Cfl/4 4-11

—

0-6-1/4

0-5-1/8

50EQ028 50EQ900011

12-10-3/4

6-11

—

—

0-6-1/4Ì0-5-1/8

50EQ034

50EQ900021

16- 3-1/8 9- 0

4-4

0-6

0-6-1/4 0-5-7/8

NOTES

1 Certified dimension drawings are available on

req uest

2. For details of 12-in high roof curb, refer to 48DD

roof curb installation instructions

3. Two field power supplies are required for 50EQ

units with electric heat

Fig. 2 — Roof Curb Dimensions

3

st.ecT!îtc

f£ATE=i

ACCESS

PANELS

3 mo 4^ • K 0

AlTERKATE R1EL&-P0ȣR WiRlNG

ALL. l»f:TS

!NDOORA>!ifAN

AMD «LTEft

ACCESS PA MELS

ALTERMATE

CO'iTRCl. A'-SE

^OPEMiNG A-'CDNOmT

COMPRESSOR

END

ACTES-yJATE

DRAÎÎi 2|''iCO-ÎÎ'VPr

COiWi miDE)

OL'TCXÎOR A'RPLO'#

- iMOOOSr AiftELOW

Certt^,«cf dimecswR <lf3w»i>gs avaiîab!« on recjwesi.

DRAIN :

sl^OiAMit"

'■mPT conn. fNSiOEÏ

POWER WISE CPQiii«® m

EtSCTRK tCAT 0«t,V

DiMENSiONS {ft-'jn.)

UNÎT

50EQ

024

028

034

A \ Î0- 9-13''f6 13- S^1/2

: 17- 1

8

5 7- 2-1Î/16 7- 3-1/8

: 7- 3-1/8

C

1 4-10-1/2 4-10-1/2

4-10-1/2

D

? 4-11 S-11

■ 11- 0

E

I 0-10-1/4

0-10-1/4

: 0-10-1/4

F : 0- 9-7/8 0- S-7/S : C- 9-7/8

6

■ > ■ ■■ • ■ — ■■

..

■

H

1

J

: 3-1/2" N-PT

4“ NPT

; 4" MPT

K j 2- A

...;2-.:4:.:v:

i 2-10

L

; 6- 1-V2 9- 0 ■ 11- 5

CPTlOKAi.

ECOfJOMSZER HOOO

Mcrrss.

■J Aiiow 12 ft at>ove ar»t^ S ft on

f iher access panel encf and 4 ft on

fenjatnfns sfdesof unttforairfiow

attd service clearance.

2, for smaller ciearances. contact

Carrier.

3. Refer to Roof Curb Dmrensions

for details of roof openings.

4, The 50EO034ut«t contains ittree

fans.

5. Tfte50EQ034 unit contains tnree

exhaiist hoods.

€

Fig. 3 — Base Unit Dimensions

Route thermostat cable or equivalent single leads

of no. 18 AWG colored wire from subbase terminals

thru connectors in unit base pan or side panel (Fig.

3) to low-voltage connections in control box as

shown in Fig. 9. Use no. 16 AWG wire for lengths

exceeding 50 feet. Set heat anticipator settings as

indicated in Table 1.

Refer to accessory remote control panel instruc

tions as required.

Outdoor Air Thermostat — Unit is equipped with

a field adjustable outdoor air thermostat. Thermo

stat is shipped taped to right-hand side of unit

control box. Upon start-up, set the thermostat

“close setpoint” to the building load balance point

and unit capacity. Above the setpoint, the space

thermostat controls 2 stages of compression heat

and electric heat is locked out. Below the setpoint,

one stage of compression heat is available and elec

tric heat is controlled by the second stage of the

space thermostat.

Compressor(s) — Loosen compressor hold-down

bolts until sidewise movement of the washer under

each hold-down bolt head can be easily obtained.

Do not loosen completely as bolts are self-locking

and will maintain their adjustment.

Open the compressor discharge and suction

service valves. Replace and tighten valve caps to

prevent leaks.

Liquid Line Service Valves — Open the liquid line

service valves. Replace caps and tighten to prevent

leaks.

START-UP

Cooling

1. Open compressor service valves. Replace valve

caps to prevent leaks. Make sure crankcase

heater has been on for at least 24 hours to

drive out any liquid refrigerant in compressor

crankcase. Check compressor oil level. Oil sight

glass should be about half full.

2. Be sure that liquid line service valve is open.

3. Check that setscrews are tight in fan bearing

locking collar, pulley and fan blades.

4. Check pulley alignment and belt adjustment.

Remove tape on indoor fan pulley.

5. Check that internal power wire terminal screw

connections are tight.

6. On 3-phase units, check for correct fan rotation.

7. Set system selector switch at COOL and fan

switch at AUTO. Adjust thermostat at a setting

below room temperature. Compressor no. 1 will

start on closure of no. 1 contactor. An addi

tional rise in room temperature closes cooling

contactor no. 2 in thermostat, energizing no. 2

contactor, no. 2 compressor will start.

8. Check cooling effect at duct supply outlets.

9. Check unit charge. Refer to Refrigeration

Charge in Service section.

Fig. 4 — Economizer Outdoor Air Inlet

Hood Assembly

Fig. 5 — Enthalpy Control Assembly

Fig. 6 — Enthalpy Control Assembly

Installation Details

Loading...

Loading...