Canon iR2200, iR2800, iR3300 Service Handbook

iR2200/iR2800/

iR3300

SERVICE HANDBOOK

REVISION 0

MAY 2001 |

FY8-23BD-000 |

COPYRIGHT© 2001 CANON INC. |

CANON iR2200/iR2800/iR3300 REV.0 MAY 2001 PRINTED IN JAPAN (IMPRIME AU JAPON) |

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair of products. This manual covers all localities where the products are sold. For this reason, there may be information in this manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products. When changes occur in applicable products or in the contents of this manual, Canon will release technical information as the need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or translated into another language, in whole or in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Imprimé au Japon

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

COPYRIGHT© 2001 CANON INC. |

CANON iR2200/iR2800/iR3300 REV.0 MAY 2001 PRINTED IN JAPAN (IMPRIME AU JAPON) |

CONTENTS

Contents

CHAPTER 1 MAINTENANCE AND INSPECTION

1 |

Periodically Replaced Parts .............. |

1-1 |

|

2.5 |

Cassette Feeding Unit ................ |

1-3 |

|

|

1.1 |

Reader Unit ................................ |

1-1 |

|

2.6 |

Inner 2-Way Tray-A1 ................. |

1-3 |

|

1.2 |

Printer Unit ................................ |

1-1 |

3 |

Periodical Servicing Procedure ........ |

1-4 |

|

|

1.3 |

Side Paper Deck ......................... |

1-1 |

4 |

Scheduled Servicing Chart ............... |

1-6 |

|

|

1.4 |

Cassette Feeding unit ................. |

1-1 |

|

4.1 |

Reader Unit ................................ |

1-6 |

|

1.5 |

Inner 2-Way Tray ....................... |

1-1 |

|

4.2 |

Printer Unit ................................ |

1-7 |

2 |

Consumables and Durables .............. |

1-2 |

5 |

Points to Note for Scheduled Servicing |

|||

|

2.1 |

Checking the Time of Replacement |

|

.......................................................... |

|

1-8 |

|

|

|

................................................... |

1-2 |

6 |

Cleaning the Bottom of the Developing |

||

|

2.2 |

Reader Unit ................................ |

1-2 |

|

Assembly .......................................... |

1-9 |

|

|

2.3 |

Printer Unit ................................ |

1-2 |

|

6.1 |

Cleaning the Bottom of the Devel- |

|

|

2.4 |

Side Paper Deck ......................... |

1-3 |

|

|

oping Assembly .......................... |

1-9 |

CHAPTER 2 IMAGE ADJUSTMENT BASIC PROCEDURE

1 |

Making lnitial Checks ...................... |

2-1 |

4 |

Checking the Printer Side (2/3) ........ |

2-2 |

2 |

Checking the Scanner Side ............... |

2-1 |

5 |

Checking the Printer Side (3/3) ........ |

2-2 |

3 |

Checking the Printer Side (1/3) ........ |

2-2 |

|

|

|

CHAPTER 3 STANDARDS AND ADJUSTMENTS

1 Image Adjustments ........................... |

3-1 |

1.5 |

Adjusting the Left/Right Non-Image |

||

1.1 |

Standards of Image Position ...... |

3-1 |

|

Width .......................................... |

3-5 |

1.2 |

Checking the Image Position ..... |

3-2 |

1.6 |

Adjusting the Leading Edge Non- |

|

1.3 |

Adjusting Left/Right lamge Margin |

|

Image Width ............................... |

3-6 |

|

|

................................................... |

3-3 |

2 Scanning System .............................. |

3-6 |

|

1.3.1 Adjusting the Registration for |

2.1 |

After Replacing the Scanning Lamp |

|||

|

the Cassette Rear Front ........ |

3-3 |

|

................................................... |

3-6 |

1.3.2 Adjusting the Registration for |

2.2 |

Mounting the Motor Unit ........... |

3-7 |

||

|

the Multifeeder Rear Front |

|

2.3 |

Routing the Scanner Drive Cable |

|

|

............................................. |

3-4 |

|

................................................... |

3-8 |

1.3.3 Adjusting the Registration for |

2.4 |

Adjusting the Position of the No. 1/ |

|||

|

the Deck ............................... |

3-4 |

|

No. 2 Mirror Base ...................... |

3-9 |

1.3.4 Duplex Feeding Unit ........... |

3-5 |

2.5 |

Mounting the Copyboard Glass |

|

|

1.4 |

Adjusting the Image Leading Edge |

|

................................................. |

3-11 |

|

|

Margin ........................................ |

3-5 |

2.6 |

Mounting the Reader Upper Frame |

|

|

|

|

|

................................................. |

3-12 |

CONTENTS

|

2.7 |

Points to Note When Replacing the |

|

5.5 |

Removing the Deck Pickup/Feeding |

|||

|

|

CCD Unit ................................. |

3-12 |

|

|

Roller ....................................... |

3-19 |

|

|

2.8 |

When Replacing the Reader Con- |

|

5.6 |

Orientation of the Deck Pickup/ |

|

||

|

|

troller PCB ............................... |

3-12 |

|

|

Feeding Roller .......................... |

3-20 |

|

3 |

Image Formation System ............... |

3-13 |

|

5.7 |

Adjusting the Deck Separation |

|

||

|

3.1 |

Positioning the Developing Assem- |

|

|

Roller Pressure ......................... |

3-20 |

||

|

|

bly Magnetic Seal .................... |

3-13 |

|

5.8 |

Position of the Deck Pickup Roller |

||

|

3.2 |

Mounting the Developing Assembly |

|

|

Releasing Solenoid (SL1D) ..... |

3-21 |

||

|

|

Blade ........................................ |

3-13 |

|

5.9 |

Adjusting the Height of the Side |

||

|

3.3 |

Removing the Paper Lint ......... |

3-14 |

|

|

Member .................................... |

3-22 |

|

|

3.4 |

Cleaning the Waste Toner Case |

|

|

5.9.1 |

Before Making Adjustments |

||

|

|

................................................. |

3-15 |

|

|

|

........................................... |

3-22 |

4 |

Fixing System ................................. |

3-16 |

|

5.9.2 |

Making Adjustments .......... |

3-22 |

||

|

4.1 |

Mounting the Locking Cam Unit |

6 |

Cassette Feeding Unit-W1 ............. |

3-23 |

|||

|

|

................................................. |

3-16 |

|

6.1 |

Mounting the Pedestal Main Motor |

||

5 |

Paper Deck ..................................... |

3-17 |

|

|

................................................. |

|

3-23 |

|

|

5.1 |

Mounting the Front Cover ....... |

3-17 |

7 |

Envelope Feeder Attachment .......... |

3-24 |

||

|

5.2 |

Adjusting the Paper Level Indicator |

|

7.1 |

Envelopes and Type of Spring |

|

||

|

|

................................................. |

3-18 |

|

|

................................................. |

|

3-24 |

|

5.3 |

Adjusting the Position of the Sup- |

|

7.2 |

Replacing the Spring ................ |

3-24 |

||

|

|

port Member ............................ |

3-18 |

|

7.2.1 |

Replacing the Spring ......... |

3-24 |

|

|

5.4 |

Mounting the Deck Pickup Roller |

|

7.3 |

Changing the Size .................... |

3-25 |

||

|

|

................................................. |

3-19 |

|

7.3.1 |

Changing the Size .............. |

3-25 |

|

CHAPTER 4 TROUBLESHOOTING IMAGE FAULTS/ MALFUNCTIONS

1 Making Initial Checks ...................... |

4-1 |

|

1.1 |

Checking the Site of Installation |

|

|

................................................... |

4-1 |

1.2 |

Checking the Originals .............. |

4-1 |

1.3 |

Checking the ADF Platen, |

|

|

Copyboard cover, and Copyboard |

|

|

glass (standard white plate) ........ |

4-1 |

1.4 |

Charging Roller and Static Elimina- |

|

|

tor ............................................... |

4-2 |

1.5 |

Checking the Developing Assembly |

|

|

................................................... |

4-2 |

1.6 |

Checking the Paper .................... |

4-2 |

1.7 |

Checking the Periodically Replaced |

|

|

Parts ............................................ |

4-2 |

1.8 |

Image Adjustment Basic Procedure |

|

|

................................................... |

4-2 |

1.9 |

Others ......................................... |

4-3 |

2 Samples of Image Faults .................. |

4-6 |

|

3 Troubleshooting Image Faults .......... |

4-7 |

|

3.1 |

The copy is too light (halftone area |

|

|

only) ........................................... |

4-7 |

3.2 |

The copy is too light (including |

|

|

solid black) ................................. |

4-8 |

3.3 |

The copy is too light (entire face, |

|

|

considerable) ............................ |

4-10 |

3.4 |

The copy has uneven density |

|

|

(darker at front) ........................ |

4-12 |

3.5 |

The copy has uneven density |

|

|

(lighter at front) ........................ |

4-12 |

|

|

|

|

|

CONTENTS |

|

|

|

|

|

|||

3.6 The copy is foggy (entire face) |

|

4.2.2 The lifter fails to move up |

|

|||

|

................................................. |

4-13 |

|

|

(pickup from the cassette) |

|

3.7 |

The copy is foggy (vertical) ..... |

4-14 |

|

|

........................................... |

4-31 |

3.8 The copy has a black line (vertical, |

4.2.3 The vertical path roller fails to |

|||||

|

fuzzy, thick) ............................. |

4-14 |

|

|

rotate .................................. |

4-32 |

3.9 The copy has a black line (vertical, |

4.2.4 The registration roller fails to |

|||||

|

fine) .......................................... |

4-15 |

|

|

rotate .................................. |

4-32 |

3.10 |

The copy has a white spot (vertical) |

4.2.5 Pickup from the multifeeder |

||||

|

................................................. |

4-16 |

|

|

tray fails (i.e., the pickup roller |

|

3.11 |

The copy has a white line (vertical) |

|

|

fails to rotate) ..................... |

4-33 |

|

|

................................................. |

4-16 |

4.2.6 Pickup from the multifeeder |

|||

3.12 |

The copy has a white spot (horizon- |

|

|

tray fails (i.e., the multifeeder |

||

|

tal) ............................................ |

4-17 |

|

|

holding plate fails to move up) |

|

3.13 |

The back of the copy is soiled/ |

|

|

|

........................................... |

4-33 |

|

Soiled edge ............................... |

4-18 |

4.2.7 The photosensitive drum fails to |

|||

3.14 |

The copy has a fixing fault ....... |

4-19 |

|

|

rotate .................................. |

4-34 |

3.15 |

The copy has a displaced leading |

4.2.8 The pre-exposure lamp fails to |

||||

|

edge .......................................... |

4-20 |

|

|

go ON ................................ |

4-34 |

3.16 |

The copy has a displaced leading |

4.3 |

Reader Unit .............................. |

4-35 |

||

|

edge (large margin) .................. |

4-20 |

4.3.1 The No. 1 mirror base fails to |

|||

3.17 |

The copy has a displaced margin |

|

|

move .................................. |

4-35 |

|

|

(no margin) ............................... |

4-20 |

4.3.2 The scanning lamp fails to go |

|||

3.18 |

The copy is blurred .................. |

4-21 |

|

|

ON ..................................... |

4-36 |

3.19 |

The copy is foggy (horizontal) |

|

4.4 |

Message Indication .................. |

4-37 |

|

|

................................................. |

4-22 |

4.4.1 The “Add Toner” message fails |

|||

3.20 |

The copy has inadequate sharpness |

|

|

to go OFF ........................... |

4-37 |

|

|

................................................. |

4-23 |

4.4.2 The “Control Card Set” mes- |

|||

3.21 |

The copy is completely blank |

|

|

|

sage fails to go OFF (when no |

|

|

................................................. |

4-24 |

|

|

card reader is installed) ...... |

4-37 |

3.22 |

The copy is completely black |

|

4.4.3 The “Add Paper” message fails |

|||

|

................................................. |

4-26 |

|

|

to go OFF ........................... |

4-37 |

3.23 |

The copy has a block/white dot after |

4.4.4 The “Close the Front Cover” |

|

|||

|

replacement of the drum unit |

|

|

|

massage fails to go OFF ..... |

4-38 |

|

................................................. |

4-27 |

4.5 |

Paper Deck ............................... |

4-39 |

|

3.24 |

The copy has a black line (stream |

4.5.1 |

Pickup fails ........................ |

4-39 |

||

|

reading) .................................... |

4-27 |

4.5.2 The deck lifter fails to move up |

|||

4 Troubleshooting Malfunctions ....... |

4-28 |

|

|

........................................... |

4-40 |

|

4.1 |

Power Supply System .............. |

4-28 |

5 Troubleshooting Feeding Faults ...... |

4-41 |

||

4.1.1 The AC power is absent ..... |

4-28 |

5.1 |

Paper Jams ............................... |

4-41 |

||

4.1.2 The DC power is absent |

|

5.1.1 |

Pickup Assembly ............... |

4-42 |

||

|

........................................... |

4-29 |

5.1.2 |

Separation/Feeding Assembly |

||

4.2 |

Printer Unit .............................. |

4-30 |

|

|

........................................... |

4-43 |

4.2.1 Pickup fails ........................ |

4-30 |

5.1.3 |

Fixing/Delivery Assembly, Du- |

|||

|

|

|

|

|

plex Reversing Assembly |

|

|

|

|

|

|

........................................... |

4-43 |

CONTENTS

5.1.4 |

Duplex Feeding Assembly |

|

6.3.3 |

Motors ................................ |

4-66 |

||

|

|

........................................... |

4-44 |

6.3.4 |

Sensors ............................... |

4-68 |

|

5.2 |

Faulty Feeding ......................... |

4-45 |

6.3.5 |

PCBs .................................. |

4-68 |

||

5.2.1 |

Double Feeding ................. |

4-45 |

6.4 |

2-Cassette Feeding Unit-W1 |

|

||

5.2.2 |

Wrinkles ............................ |

4-45 |

|

................................................. |

|

4-70 |

|

6 Outline of Electrical Components |

|

6.4.1 |

Clutches ............................. |

4-70 |

|||

........................................................ |

|

|

4-46 |

6.4.2 |

Solenoids and Switches ..... |

4-70 |

|

6.1 |

Introduction .............................. |

4-46 |

6.4.3 |

Motors ................................ |

4-70 |

||

6.1.1 Guide to the List ................ |

4-46 |

6.4.4 |

Sensors ............................... |

4-72 |

|||

6.1.2 |

Checking the Photointerrupters |

6.4.5 |

PCBs .................................. |

4-72 |

|||

|

|

........................................... |

4-47 |

6.5 |

Inner 2-Way Tray-A1 ............... |

4-74 |

|

6.2 E201 (reader unit/printer unit) . 4-48 |

6.5.1 |

Solenoids ........................... |

4-74 |

||||

6.2.1 |

Clutches ............................. |

4-48 |

6.5.2 |

Motors ................................ |

4-74 |

||

6.2.2 |

Solenoids, Switches ........... |

4-48 |

6.5.3 |

Sensors ............................... |

4-74 |

||

6.2.3 |

Motors (1/2) ....................... |

4-50 |

6.6 Super G3 FAX Board-J1 .......... |

4-76 |

|||

6.2.3 |

Motors (2/2) ....................... |

4-52 |

6.6.1 |

Others ................................ |

4-76 |

||

6.2.4 |

Fans .................................... |

4-54 |

6.6.2 |

PCBs .................................. |

4-76 |

||

6.2.5 |

Sensors (1/3) ...................... |

4-56 |

6.7 Variable Resistors (VR), Light- |

|

|||

6.2.5 |

Sensors (2/3) ...................... |

4-58 |

|

Emitting Diodes, and Check Pins by |

|||

6.2.5 |

Sensors (3/3) ...................... |

4-60 |

|

PCB .......................................... |

4-78 |

||

6.2.6 Lamps, Heaters, and Others |

|

6.7.1 |

Main Controller PCB ......... |

4-79 |

|||

|

|

........................................... |

4-62 |

6.7.2 |

DC Controller PCB ............ |

4-80 |

|

6.2.7 |

PCBs .................................. |

4-64 |

6.7.3 |

Reader Controller PCB ...... |

4-80 |

||

6.3 |

Side Paper Deck-L1 ................. |

4-66 |

6.7.4 Composite Power Supply PCB |

||||

6.3.1 |

Clutches ............................. |

4-66 |

|

|

........................................... |

4-81 |

|

6.3.2 |

Solenoids, and Switches ..... |

4-66 |

6.7.5 Fixing Film Sensor PCB |

|

|||

|

|

|

|

|

|

........................................... |

4-81 |

CHAPTER 5 SERVICE MODE

1 Outline of Service Mode .................. |

5-1 |

|

3.1 |

DC-CON .................................. |

5-21 |

||

1.1 |

Outline ....................................... |

5-1 |

|

3.2 |

R-CON ..................................... |

5-28 |

|

1.2 |

Starting Service Mode and Making |

|

3.3 |

MN-CON ................................. |

5-31 |

||

|

Selections ................................... |

5-2 |

|

3.4 |

FEEDER .................................. |

5-33 |

|

1.3 |

Ending Service Mode ................. |

5-3 |

|

3.5 |

SORTER .................................. |

5-35 |

|

1.4 |

Backing Up Service Mode ......... |

5-3 |

|

3.5.1 |

Finisher-J1 ......................... |

5-35 |

|

1.5 |

Using Service Mode ................... |

5-4 |

|

3.5.2 |

Saddle Finisher-G1 ............ |

5-38 |

|

1.5.1 Initial Screen ........................ |

5-4 |

|

3.5.3 Puncher Unit (Saddle Finisher- |

||||

1.5.2 Level 1/Level 2 Item Screen |

|

|

|

G1) ..................................... |

5-41 |

||

|

............................................. |

5-4 |

4 |

ADJUST Adjustment Mode ........... |

5-44 |

||

1.5.3 Level 3 Item Screen ............. |

5-5 |

|

4.1 |

COPIER ................................... |

5-44 |

||

2 DISPLAY Control Display Mode ...... |

5-6 |

|

4.2 |

FEEDER .................................. |

5-58 |

||

2.1 |

COPIER ..................................... |

5-6 |

|

4.3 |

SORTER .................................. |

5-59 |

|

2.2 |

FEEDER .................................. |

5-19 |

5 |

FUNCTION Operation/Inspection |

|

||

3 I/O, I/O Display mode .................... |

5-20 |

|

Mode |

.............................................. |

5-61 |

||

CONTENTS

5.1 |

COPIER ................................... |

5-61 |

|

6.3 |

SORTER .................................. |

5-94 |

6 OPTION Machine Settings Mode |

|

|

6.4 |

BOARD .................................... |

5-95 |

|

........................................................ |

|

5-81 |

7 |

TEST Test Print Mode ................... |

5-98 |

|

6.1 |

COPIER ................................... |

5-81 |

8 |

COUNTER Counter Mode ........... |

5-100 |

|

6.2 |

FEEDER .................................. |

5-94 |

|

|

|

|

CHAPTER 6 SELF DIAGNOSIS

1 Self Diagnosis .................................. |

6-1 |

1.3.1 Error Code of the Finisher Unit |

||

1.1 |

Detail Codes (copier) ................. |

6-3 |

................................................. |

6-38 |

1.2 |

ADF Error Codes ..................... |

6-37 |

1.4 Finisher-J1 Error Codes ........... |

6-43 |

1.3 |

Saddle Finisher-G1 Error Codes |

|

|

|

|

................................................. |

6-38 |

|

|

CHAPTER 7 UPGRADING

1 Upgrading ......................................... |

7-1 |

1.5.3 Points to Note When Formatting |

|||||

1.1 |

Outline ....................................... |

7-1 |

|

|

the Hard Disk ..................... |

7-26 |

|

1.1.1 |

Download Mode .................. |

7-1 |

1.6 |

Downloader PCB ..................... |

7-27 |

||

1.1.2 |

Making Pre-Checks ............. |

7-2 |

1.6.1 |

Purpose .............................. |

7-27 |

||

1.2 |

Data Control ............................... |

7-5 |

1.6.2 |

Downloader PCB Components |

|||

1.3 |

Downloading the System Software, |

|

|

........................................... 7-27 |

|||

|

RUI, and Language Module ....... |

7-8 |

1.6.3 |

Download Procedure ......... |

7-28 |

||

1.3.1 |

Making Connections ............ |

7-8 |

1.6.4 |

Disconnecting .................... |

7-32 |

||

1.3.2 |

Downloading ....................... |

7-8 |

1.7 |

Upgrading by Replacing the |

|

||

1.3.3 |

After Downloading ............ |

7-14 |

|

DIMM/ROM ............................ |

7-33 |

||

1.4 |

Upgrading the BOOT ROM ...... |

7-14 |

2 Backing Up Data ............................ |

7-34 |

|||

1.4.1 |

Making Preparations .......... |

7-14 |

2.1 |

Outline ..................................... |

7-34 |

||

1.4.2 |

Connection ......................... |

7-15 |

2.2 |

Backing Up Data ...................... |

7-35 |

||

1.4.3 |

Preparing BOOT ROM ...... |

7-15 |

2.2.1 |

Making Preparations .......... |

7-35 |

||

1.4.4 |

After Downloading ............ |

7-19 |

2.2.2 |

Making Connections .......... |

7-35 |

||

1.5 |

Formatting the HDD ................ |

7-20 |

2.2.3 |

Backing Up Data ............... |

7-36 |

||

1.5.1 |

Making Connections .......... |

7-20 |

2.2.4 |

Downloading Backup Data |

|

||

1.5.2 |

Starting Formatting ............ |

7-20 |

|

|

........................................... |

7-41 |

|

|

|

|

|

2.2.5 |

Managing Backup Data ..... |

7-45 |

|

APPENDIX

A. General Timing Chart ...................... |

A-1 |

E. |

Inner 2-Way Tray-A1 General Circuit |

||

B. General Circuit Diagram ................. |

A-3 |

|

Diagram ........................................... |

A-7 |

|

C. Side Paper Deck-L1 General Circuit |

|

F. |

Specifications .................................. |

A-8 |

|

Diagram ........................................... |

A-5 |

1 |

|

Main Body ................................ |

A-8 |

D. 2-Cassette Feeding Unit-W1 General |

|

1.1 |

Type .................................... |

A-8 |

|

Circuit Diagram ............................... |

A-6 |

|

1.2 |

Systems ............................... |

A-8 |

CONTENTS

1.3 |

Functions ............................ |

A-9 |

5 |

Envelope Feeder Attachment-B1 |

|

1.4 |

Others ............................... |

A-12 |

|

................................................ |

A-18 |

2 |

Side Paper Deck-L1 ................ |

A-15 |

5.1 |

Systems ............................. |

A-18 |

2.1 |

Systems ............................. |

A-15 |

5.2 |

Envelopes .......................... |

A-19 |

3 |

Cassette Feeding Unit-W1 ...... |

A-16 |

5.3 |

Guaranteed Image Area .... |

A-20 |

3.1 |

Systems ............................. |

A-16 |

G. List of Special Tools ...................... |

A-21 |

|

4 |

Inner 2way Tray-A1 ................ |

A-17 |

H. List of Solvents/Oils ...................... |

A-23 |

|

4.1 |

Type .................................. |

A-17 |

|

|

|

CHAPTER 1 MAINTENANCE AND INSPECTION

CHAPTER 1 MAINTENACE AND INSPECTION

1 Periodically Replaced Parts

Some of the parts used in the machine must be replaced on a periodical basis to ensure a specific level of product performance; be sure to replace them as indicated, as they will affect the machine functions appreciably once they fail.

If possible, plan the replacement to coincide with a scheduled visit to the user’s.

The estimates are subject to change depending on the conditions of the site of installation or how the machine is used.

1.1 Reader Unit

The reader unit does not have parts that require periodical replacement.

1.2 Printer Unit

The printer unit does not have parts that require periodical replacement.

1.3 Side Paper Deck

The side paper deck does not have parts that require periodical replacement.

1.4 Cassette Feeding unit

The cassette feeding unit does not have parts that require periodical replacement.

1.5 Inner 2-Way Tray

The inner 2-way tray does not have parts that require periodical replacement.

1 |

1-1

CHAPTER 1 MAINTENANCE AND INSPECTION

2 Consumables and Durables

Some parts of the machine may require replacement over the period of product warranty because of wear or damage. Replace them as needed.

2.1 Checking the Time of Replacement

Use service mode to find out when to replace a specific part: COPIER>COUNTER>DRBL-2.

2.2 Reader Unit

The reader unit does not have parts designated as a durable.

2.3 |

Printer Unit |

|

|

|

|

|

|

|

|

|

As of March 2001 |

No. |

Part name |

Part No. |

Q’ty |

Life (prints) |

Remarks |

|

|

|

|

|

|

1 |

Transfer roller |

FF6-0104 |

1 |

240,000 |

|

2 |

Transfer static eliminator |

FF5-7246 |

1 |

240,000 |

|

3 |

Developing cylinder |

FG6-5714 |

1 |

480,000 |

|

4 |

Fixing cleaning roller |

FG6-5709 |

1 |

150,000 |

|

5 |

Pre-exposure lamp |

FG5-6297 |

1 |

240,000 |

|

6 |

Pickup roller |

FF5-4552-020 2 |

120,000 |

Actual prints made |

|

7 |

Feeding roller |

FF5-4552-020 2 |

120,000 |

Actual prints made |

|

8 |

Separation roller |

FF5-4634-020 2 |

120,000 |

Actual prints made |

|

9 |

Pickup roller |

FB1-8581 |

1 |

240,000 |

Actual prints made |

|

(multifeeder) |

|

|

|

|

10 |

Separation pad |

FE5-4132 |

1 |

240,000 |

Actual prints made |

|

(multifeeder) |

|

|

|

|

11 |

Fixing film unit (100V) |

FG6-5712 |

1 |

150,000 |

|

12 |

Fixing film unit (115V) |

FG6-6039 |

1 |

150,000 |

|

13 |

Fixing film unit (230V) |

FG6-6041 |

1 |

150,000 |

|

T01-203-01

1-2

CHAPTER 1 MAINTENANCE AND INSPECTION

2.4 Side Paper Deck

|

|

|

|

|

As of March 2001 |

No. |

Part name |

Part No. |

Q’ty |

Life (prints) |

Remarks |

|

|

|

|

|

|

1 |

Pickup roller (front) |

FF5-7830 |

1 |

240,000 |

Actual prints made |

2 |

Pickup roller (rear) |

FF5-7829 |

1 |

240,000 |

Actual prints made |

3 |

Feeding roller |

FF5-7541 |

1 |

240,000 |

Actual prints made |

4 |

Separation roller |

FB2-7777-020 |

1 |

240,000 |

Actual prints made |

T01-204-01

2.5 Cassette Feeding Unit

|

|

|

|

|

As of March 2001 |

No. |

Part name |

Part No. |

Q’ty |

Life (prints) |

Remarks |

|

|

|

|

|

|

1 |

Pickup roller |

FF5-4552-020 |

2 |

120,000 |

Actual prints |

2 |

Feeding roller |

FF5-4552-020 |

2 |

120,000 |

Actual prints |

3 |

Separation roller |

FF5-4634-020 |

2 |

120,000 |

Actual prints |

T01-205-01

2.6 Inner 2-Way Tray-A1

The inner 2-way tray-A1 does not have parts that are designated as a durable.

1-3

CHAPTER 1 MAINTENANCE AND INSPECTION

3Periodical Servicing Procedure

1.As a rule, provide periodical servicing every 120,000 prints.

2.Before setting out on a scheduled visit, check the Service Book, and take any parts that may require replacement.

As of June 2001

Work Procedure

1.Report to the person in charge, and check the general condition.

2.Record the counter reading, and check the faulty prints.

3.Make test prints, and check them for the following: (1) image density, (2) white background for soiling, (3) characters for clarity, (4) margin, (5) fixing, registration, and back for soiling.

The margin must meet the following standards:

Leading edge: |

2.5 |

± 1.5 mm |

|

Left edge: |

2.5 |

± 1.5 mm |

|

Right edge: |

0.5 mm or more |

|

|

Trailing edge: |

2.5 |

+1.1, -1.7 mm (smaller than B4) |

<2.5 ± 2.0 mm> |

|

3.5 |

+0.6, -2.8 mm (B4 or larger) |

<3.5 ± 2.0 mm> |

|

5.5 |

+1.5, -5.0 mm (free size) |

|

< >: when the DADF-H1 picks up an original (in stream readig mode).

4. Optical Unit

Clean the following using a blower brush to clean; if the dirt is excessive, use alcohol:

(1)No. 1/2/3 mirror, (2) original illuminating reflecting plate, (3) lens, (4) original size sensor.

5.Scanner Drive System

(1)Scanner cable; check the tension, and adjust as necessary. Inspect and adjust the scanner cable only when the machine has made the first 250,000 prints.

(2)Scanner rail; clean the slide area, and apply silicone oil (FY9-6011).

1-4

CHAPTER 1 MAINTENANCE AND INSPECTION

6.Feeding System

Clean the following: (1) feeding assembly base, (2) fixing inlet guide (upper, lower), (3) transfer guide, (4) pre-registration assembly (paper lint).

7.Image Formation System

Clean the following: developing member, (2) developing assembly bottom.

8.Optical Unit

Clean the following with a special tool: (1) bending mirror.

9.Image Formation System

Inspect and, as necessary, remove the waste toner and then clean the waste toner case; or, replace the waste toner case if any:

1.Be sure to dispose of the water toner according to the standards imposed by the government concerned.

2.Do not dispose of waste toner into fire (to avoid explosion).

10.Make test copies.

11.Make sample copies.

12.Check the operation of the leakage breaker.

While the power switch is ON, press the test switch of the leakage breaker to make sure that it operates normally (i.e., the lever goes OFF to cut the power).

If the leakage breaker fails to operate normally, replace it and make a check once again. To reset,

After making a check, turn off the main power switch (the lever should go ON), and then turn on the main power switch.

13.Put the sample copies into order, and clean up the area around the machine.

14.Fill out the Service Book, and report to the person in charge; put a description of the check made on the operation of the leakage breaker in the Service Book.

1-5

CHAPTER 1 MAINTENANCE AND INSPECTION

4 Scheduled Servicing Chart

Do not use solvents or oils not indicated herein.

4.1 Reader Unit

: Clean

: Clean  : Replace ×: Lubricate

: Replace ×: Lubricate  : Adjust

: Adjust  : Inspect

: Inspect

Maintenance intervals

Unit |

Part |

Upon |

every 120,000 |

Remarks |

|

|

installation |

|

|

Scanner |

Scanner cable |

|

|

|

Optical unit |

Scanner rail |

|

× |

Silicone oil |

|

|

|

|

(S20; FY9-6011) |

|

Copyboard glass |

|

|

|

|

No. 1 through No. 3 |

|

|

|

|

mirror |

|

|

|

|

Original illumination |

|

|

|

|

reflecting plate |

|

|

|

|

Original size sensor |

|

|

|

|

Lens |

|

|

|

|

|

T01-401-01 |

|

|

1-6

CHAPTER 1 MAINTENANCE AND INSPECTION

4.2 Printer Unit

: Clean |

: Replace ×: Lubricate |

: Adjust |

: Inspect |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Maintenance intervals |

|

||

Unit |

|

Part |

|

|

|

|

Remarks |

|

|

Upon in- |

every |

Upon replace- |

|||

|

|

|

|

stallation |

120,000 |

ment of drum |

|

|

|

|

|

|

|

cartridge |

|

|

|

|

|

|

|

|

|

Laser opti- |

|

Folding mirror |

|

|

|

|

Use special tool. |

cal unit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pickup/ |

|

Feeding assembly base |

|

|

|

|

|

feeding as- |

|

Fixing inlet guide, up- |

|

|

|

|

|

sembly |

|

per/lower |

|

|

|

|

|

|

|

Pre-registration (paper |

|

|

|

|

|

|

|

lint) |

|

|

|

|

|

|

|

Transfer guide |

|

|

|

|

|

|

|

|

|

|

|

|

|

Developing |

|

Developing member |

|

|

|

|

|

assembly |

|

Base (developing as- |

|

|

|

|

|

|

|

sembly) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Waste toner |

|

Waste toner case |

|

|

|

|

Inspect/remove. |

collection |

|

|

|

|

|

|

(Remove the contents |

assembly |

|

|

|

|

|

|

and clean with alcohol. |

|

|

|

|

|

|

|

Replace the bottle if |

|

|

|

|

|

|

|

necessary.) |

|

|

|

|

|

|

|

|

1-7

CHAPTER 1 MAINTENANCE AND INSPECTION

5 Points to Note for Scheduled Servicing

Unless otherwise indicated, use lint-free paper and alcohol.

•If you used solvent, check to make sure that the solvent has dried before mounting the component back into the machine.

•Unless otherwise specified, do not use a moist cloth for cleaning.

•Provide scheduled servicing at the specified intervals.

|

|

|

|

Original size sensor |

Lens |

||||||||

|

|

|

|

Cleaning (blower brush) |

|||||||||

Reflecting shade |

|

|

|

|

|

|

|

Cleaning (blower brush) |

|||||

Cleaning (blower brush) |

|

Scanner rail |

|

|

Copyboard glass |

||||||||

|

|

|

|

|

|

|

|

|

|

||||

No. 1 through No. 3 mirrors |

|

|

|

|

Lubricating |

|

|

Cleaning |

|||||

Cleaning (blower brush) |

|

|

|

|

Scanner cable |

||||||||

|

|

|

|

|

|

|

|

Check |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bending mirror |

|

|

Cleaning (special tool) |

|

|

Developing assembly base |

|

|

Dry wiping |

|

Developing assembly bottom |

Feeding assembly base |

|

Cleaning |

||

Cleaning |

||

|

||

Inlet guide (upper/lower) |

Pre-registration guide |

|

Cleaning (solvent) |

||

Cleaning (paper lint) |

||

|

||

|

Transfer guide |

|

|

Cleaning |

Waste toner case

Checking, disposing

(Remove waste toner, and then clean the toner case, Replace the toner case, if any.)

F01-500-01

1-8

CHAPTER 1 MAINTENANCE AND INSPECTION

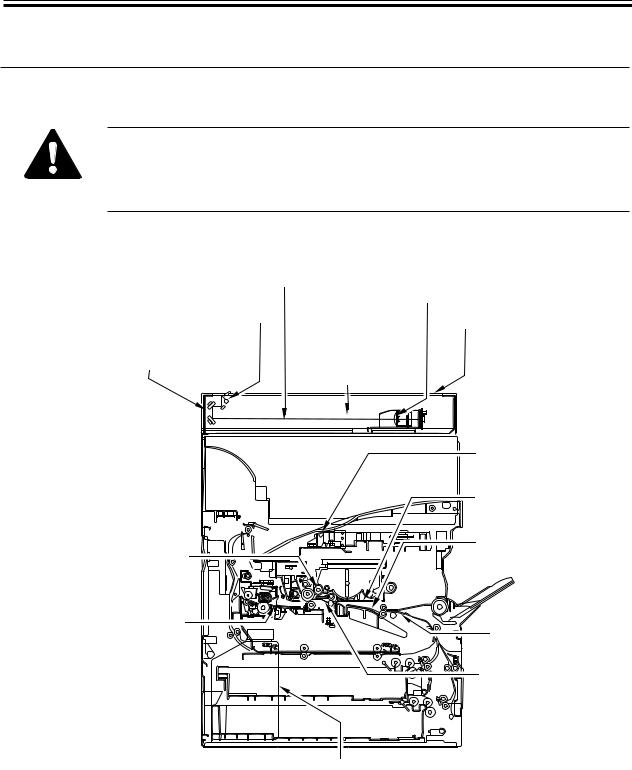

6 Cleaning the Bottom of the Developing Assembly

If the bottom of the developing assembly is not cleaned thoroughly, the residual toner can soil the back and the leading edge or left/right edges of prints. If soiling is noted, clean also the transfer guide and the static eliminator at the same time as the bottom of the developing assembly.

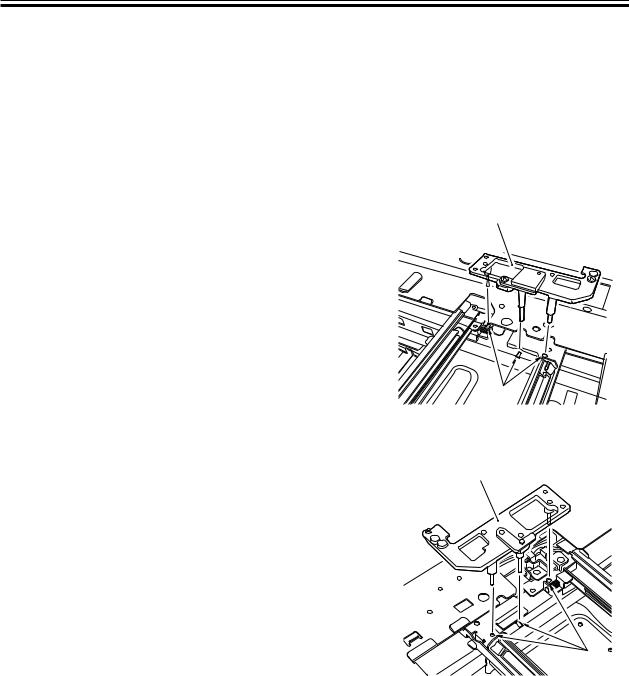

6.1 Cleaning the Bottom of the Developing Assembly

1) |

Open the front door. |

|

2) |

Slide out the developing assembly [1]. |

[1] |

3)Dry wipe the bottom of the developing assembly.

4)Slide in the developing assembly.

5)Close the front door.

F01-601-01

1-9

CHAPTER 2 IMAGE ADJUSTMENT BASIC PROCEDURE

CHAPTER 2 IMAGE ADJUSTMENT BASIC PROCEDURE

1 Making Initial Checks

Requirements:

1.Use paper fresh out of package. (Moist paper will not allow correct evaluation of images.)

2.Use paper with the highest degree of "whiteness," of all available papers.

3.Use A3 paper (11x17), if possible.

Execute 'roller clean' in user mode ('adjust/clean').

Reference:

The following will be cleaned: [1]Primary charging roller [2]Transfer charging roller

Clean the separation static eliminator.

|

|

|

Is the setting of |

NO |

|

|

|

|

||||

|

|

'exposure recalibration' |

Set it to the |

|

|

|||||||

|

|

under 'adjust/clean' in user |

|

|

|

middle setting. |

|

|

||||

|

|

mode the middle |

|

|

|

|

|

|

|

|||

|

|

|

setting? |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Is '5' indicated for |

NO |

|

|

|

|

|||||

|

|

ADJUST>DENS>DENS-ADJ |

|

|

|

Set it to '5'. |

|

|

||||

|

|

|

in user mode? |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Does the five |

|

|

|

|

|

|

|

||

|

|

items on the right in |

NO |

Enter the settings |

|

|||||||

|

|

service mode match the settings |

|

|

|

indicated on the |

|

|||||

|

|

indicated on the |

|

|

|

|

||||||

|

|

|

|

|

service label. |

|

||||||

|

|

|

service label? |

|

|

|

|

|||||

Output Condition |

YES |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||||

|

F value=5 |

|

|

|

|

|

In service mode COPIER>ADJUST, |

|||||

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||||

|

|

Using the NA3 Test Chart, make 2 copies |

|

|

|

|||||||

|

|

|

|

|

1. AE>AE-TBL |

|||||||

|

|

in the following: |

|

|

|

|||||||

|

|

|

|

|

2. DEVELOP>DE-DC |

|||||||

|

|

[1] Text mode |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

3. DEVELOP>DE-OFST |

||||

|

|

Reference: At optimum density, the copy |

|

|

|

|||||||

|

|

|

|

|

4. HV-PRI>P-DC |

|||||||

|

|

image should barely show |

|

|

|

|||||||

|

|

gray scale No. 0. |

|

|

|

5. HV-PRI>OFST1-DC |

||||||

Generate 2 test prints each of the following in COPIER>TEST>PG:

[1] TYPE4 (blank) [2] TYPE5 (halftone)

[3] TYPE6 (solid black)

|

|

|

|

|

|

|

|

If the test print has a fault, |

|

|

|

|

If the copy image has a fault, |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Go to |

|

Go to |

|

|

||||

|

2 |

Checking the Scanner Side. |

|

3 |

|

Checking the Printer Side (1/3). |

|

||

|

|

|

|

|

|

|

|

|

|

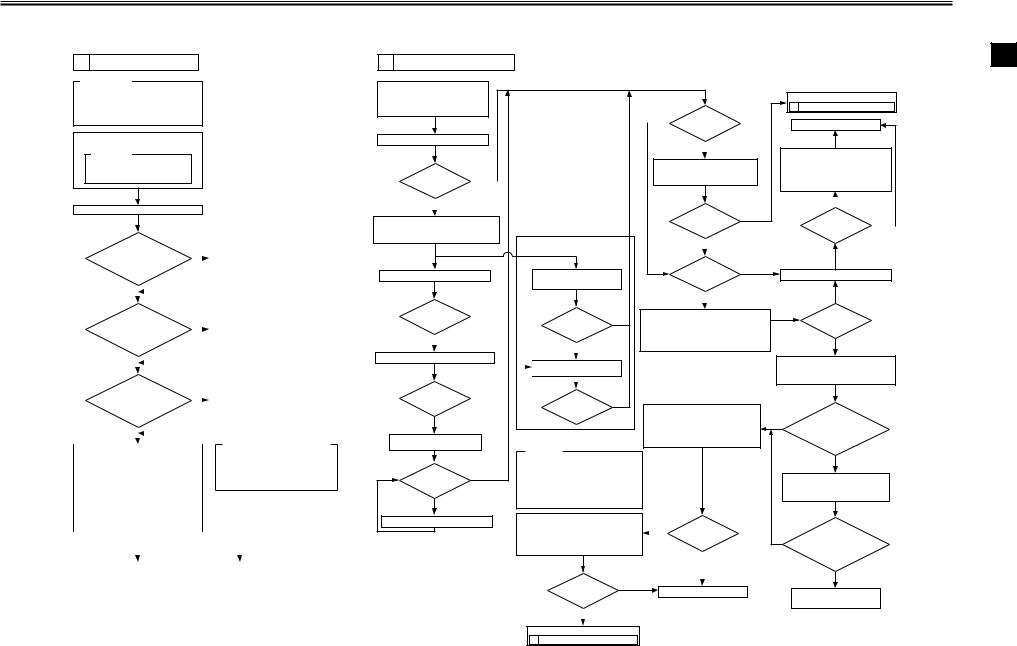

2 Checking the Scanner Side

Check/clean the following: [1] Mirrors [2] Lens

[3] Standard white plate [4] Copyboard glass

[5]Scanning lamp [6] Reflecting plate

Make a copy in text mode.

Is there a |

NO |

||

vertical line in the |

|||

|

|||

image? |

|

||

|

|

||

YES |

|

|

|

|

|

|

|

Execute the following in service mode: COPIER>FUNCTION>CCD>CCD-ADJ.

Make a copy in text mode.

Is there a |

NO |

||

vertical line in |

|||

|

|||

the image? |

|

||

|

|

||

YES |

|

|

|

|

|

|

|

Change the shading position. (Note 1)

Is there a |

NO |

|

vertical line in |

||

|

||

the image? |

|

YES

Clean the copyboard glass. (white plate position)

Is there a |

NO |

|

vertical line in |

||

|

||

the image? |

|

|

YES |

|

|

Change the shading position. |

||

Note 1: In units of 8s, increase or decrease the setting of FUNCTION>CCD >SHDG-POS. Then, execute FUNCTION>CCD>SH-PS-ST to see that 'OK!' is indicated.

If a line occurs only when the ADF is used,

Make a copy in text mode.

|

|

|

Is there a |

NO |

||

|

|

|

vertical line in |

|||

|

|

|

|

|||

|

|

|

the image? |

|

||

|

|

|

|

|

|

|

|

|

|

YES |

|

|

|

|

|

|

|

|

||

|

|

Clean the original reading |

|

|||

|

|

|

||||

|

|

face of the ADF. |

|

|||

|

|

|

|

|

|

|

YES |

Is there a |

NO |

||||

vertical line in |

||||||

|

|

|

|

|||

the image?

Reference:

Varying the setting of DENS-ADJ affects the density of all following copying modes:

•Auto

•Text

•Text/photo

•Photo (print photo/film photo)

Vary the setting in service mode: COPIER>ADJUST>DENS>DENS-ADJ.

•If the image is dark, decrease the setting.

•If the image is light, increase the setting.

Is the copy |

YES |

|

image density |

|

|

normal? |

|

|

|

|

|

NO |

|

|

|

|

|

NO |

Is the white |

||

background of the |

|||

|

|||

|

copy foggy? |

||

|

|

||

|

YES |

|

|

|

|

|

|

Execute shading in service mode: FUNCTION>CCD>CCD-ADJ.

Is the image foggy? |

YES |

|

|

||

|

|

|

NO |

|

|

|

|

|

Is the density |

YES |

|

of the copy image |

|

|

normal? |

|

|

|

|

|

NO |

|

|

|

|

|

Vary the setting in service mode: COPIER>ADJUST>DENS>DENS-ADJ.

•If the image is dark, decrease the setting.

•If the image is light, increase the setting.

Execute the following in service mode:

Go to

5 Checking the Printer Side (3/3).

End.

Vary the setting in service mode: COPIER>ADJUST>AE-AE-TBL.

•If the image is dark, decrease the setting.

•If the image is light, increase the setting.

NO |

|

|

Is the copy |

YES |

|

density normal? |

|

|

Make a copy in AE mode.

YES

Is the copy image density normal?

NO

Set '5' to the following in service mode: COPIER>ADJUST>DENS>DENS-ADJ.

COPIER>FUNCTION>DENS.

1.WHITE-ME

2.PD-DENS

3.PD-ME

NO |

Is the copy |

|

image density in text |

||

|

mode normal? |

|

|

|

|

|

YES |

|

|

|

|

End.

Is the setting of the NO following in service mode

485 A or higher: DISPLAY>HV-STS> PRIMARY?

YES

Replace the drum unit;

then, execute the following in service mode: COPIER> FUNCTION>DPC>D-GAMMA.

Is the setting of

NO the following in service mode 485 A or higher:

DISPLAY>HV-STS>

PRIMARY?

YES

Replace the composite power supply PCB.

Go to

3 Checking the Printer Side (1/3).

2 |

2-1

CHAPTER 2 IMAGE ADJUSTMENT BASIC PROCEDURE

3 |

Checking the Printer Side (1/3) |

|

4 |

Checking the Printer Side (2/3) |

|

5 |

Checking the Printer Side (3/3) |

|

|

|

|

|

|

|

|

Is there a |

NO |

|

Is the image of TYPE6 |

|

YES |

Check the image density by |

vertical line in |

|

(solid black) on test prints correct in |

||||

|

|

|

||||

the image? |

|

|

density and free |

|

|

generating test prints (TYPE5). |

|

|

|

of fuzziness? |

|

|

|

YES |

|

|

|

|

|

|

|

|

|

NO |

|

|

|

Clean the following: |

|

|

|

|

|

Is there an |

|

|

|

|

|

appreciable difference |

|

[1] Laser mirror |

|

|

|

|

|

|

|

|

|

|

|

in density between left |

|

[2] No. 1 mirror |

|

|

|

NO |

|

|

|

|

Is the image fuzzy? |

|

and right of the |

||

|

|

|

|

|

image? |

|

|

|

|

|

|

|

|

|

|

|

YES |

|

|

YES |

Is there a |

|

|

|

|

|

|

NO |

|

|

|

|

Clean the following: |

|

vertical line in |

|

|

|

|

||

|

|

|

|

|

||

the image? |

|

|

Check the following, |

|

|

[1] Laser mirror: |

|

|

|

and correct any fault: |

|

|

[2] No. 1 mirror |

YES |

|

|

[1] Feeding assembly for locking |

|

|

|

|

|

|

[2] Transfer charging roller electrode |

|

|

|

Check the surface of the |

|

Is there ea |

NO |

|

|

|

developing sleeve by the naked eye. |

|

|

|

|||

vertical line in the |

|

|

Is there a difference |

|||

|

|

|

||||

|

|

|

|

|

||

|

|

image? |

Is the image |

YES |

|

in density between left and |

|

|

|

|

right of the image? |

||

|

|

YES |

density appropriate? |

|

|

|

Is there a |

NO |

|

|

|

|

YES |

vertical line on the |

Replace the drum unit. |

NO |

|

|

||

|

|

|

|

|||

surface of the |

|

|

|

|

||

sleeve? |

|

|

|

|

|

|

|

|

|

|

YES |

|

|

|

|

|

|

|

|

Adjust the setting of the following in |

|

|

|

|

|

|

|

NO |

Are both rear and |

||||||||

|

|

|

|

|

|

|

|

|

|

Execute the following service mode: |

|

service mode: |

|

|

|

|

|

|

|

|

|

Replace the pre-exposure |

|

|

front of the pre-exposure |

|||||

Generate 10 test prints of the |

|

|

|

|

COPIER>FUNCTION>DPC>D-GAMMA. |

|

COPIER>ADJUST>DEVELOP>DE-DC. |

|

|

|

|

lamp unit. |

|

|

lamp ON? |

|||||||||||||||

|

|

|

|

(initialization) |

|

|

• If the image is light, decrease the setting. |

|

|

|

|

|

|

|

|

|

|

|||||||||||||

following in service mode: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

• If the image is dark, increase the setting. |

|

|

|

|

|

|

|

|

|

|

||||||||||||

COPIER>TEST>PG. |

|

|

|

|

|

|

|

|

|

Caution: |

|

|

|

|

|

|

|

|

|

|

|

|

|

YES |

|

|||||

TYPE6 (solid black) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Be sure to vary the setting in |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

equal amounts. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Is the setting of the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NO |

Is the developing |

||

|

|

|

|

|

|

|

|

NO |

|

following in service mode 485 |

A: |

|

|

|

|

|

|

|

|

|

|

|

|

|

Lock it securely. If the locking |

|

assembly securely locked |

|||

|

|

Is there a |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

mechanism has a fault, replace it. |

|

|

||||||||

YES |

NO |

|

|

|

DISPLAY>HV-STS> |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

in place? |

||||||||

line on the surface |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

PRIMARY? |

|

|

|

|

Is the image |

YES |

|

|

|

|

|

|

|||||||||||

|

|

of the sleeve? |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

YES |

|

|

|

|

density appropriate? |

|

|

|

|

|

|

|

|

|

|

YES |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Replace the composite power supply PCB. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Generate 10 test prints (TYPE6); |

|

YES |

Is the coating of toner |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

then, if the coating of toner on |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Replace the developing assembly, and make image |

|

|

the developing sleeve is uneven, |

|

|

on the developing |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

adjustments under |

1 |

Making Initial Checks. |

|

|

|

replace the developing assembly. |

|

|

sleeve uneven? |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Is the |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lock the feeding assembly |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(transfer charging roller) |

|

NO |

feeding assembly |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

securely; if the locking |

|

(transfer charging roller) locked |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

mechanism is faulty, replace the |

|

|

securely in place? |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

transfer charging roller unit. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NO

NO

Check the image density by |

Go to |

|

generating test prints (TYPE4). |

2 |

Checking the Scanner Side. |

|

|

|

YES

Are the printouts |

NO |

|

foggy? |

|

|

|

|

|

YES |

|

|

|

|

|

Increase the setting of the following in service mode: COPIER>ADJUST>DEVELOP>DE-DC.

Caution:

Be sure to vary the setting in equal amounts.

However, if the setting has already been changed under

3 Checking the Printer Side (1/3),

decrease the following in service mode: COPIER>ADJUST>HV-PRI>P-DC.

Caution:

Be sure to vary the setting in equal amounts.

Is the image density |

YES |

|

of the tense prints (TYPE6) |

|

|

appropriate? |

|

|

|

|

|

NO |

|

|

|

|

|

Replace the developing assembly, and make image

adjustments under |

1 |

Making Initial Checks. |

Is there a fault in the copy image?

NO

End.

YES

Replace the laser scanner unit.

2-2

CHAPTER 3 STANDARDS AND ADJUSTMENTS

CHAPTER 3 STANDARDS AND ADJUSTMENTS

1 Image Adjustments

1.1 Standards of Image Position

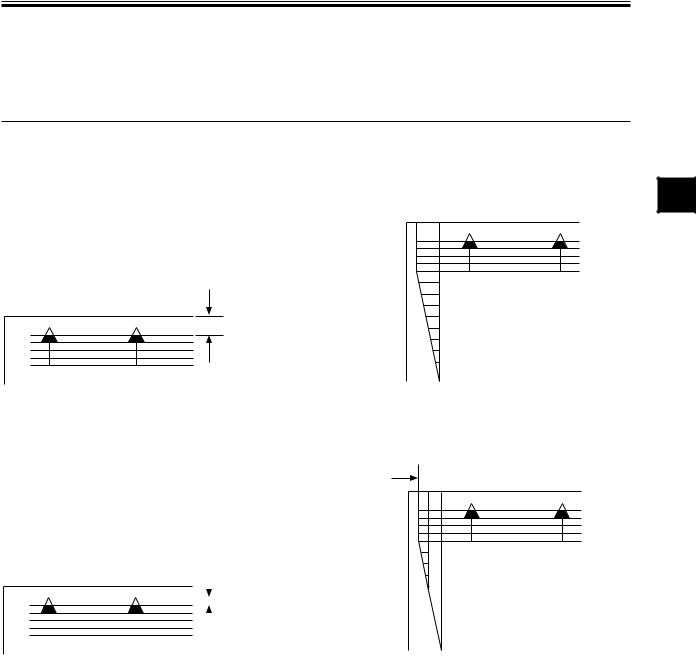

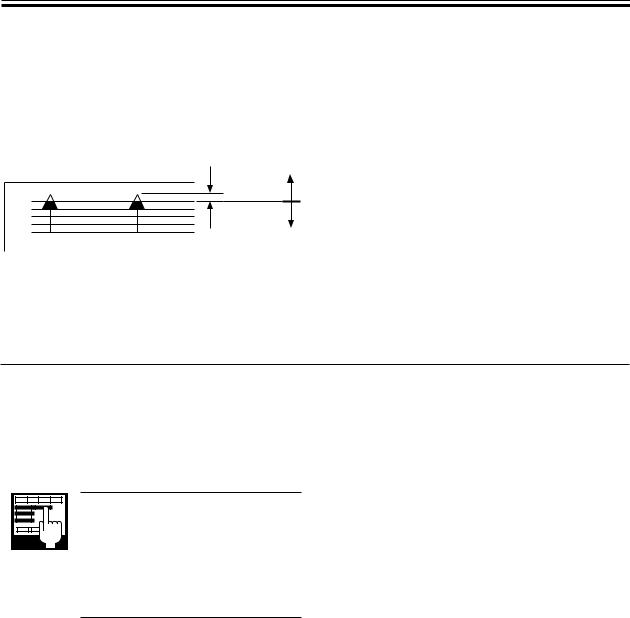

The image margin/non-image width of a print made in Direct must be as follows:

2.5±1.5mm

2.5±1.5mm

0

2

4

2.5±1.5mm

6

8

10

F03-101-01 Image Leading Edge Margin |

F03-101-02 Left/Right Image Margin |

2.5±1.5mm<2.5±2.0mm>

2.5±1.5mm<2.5±2.0mm>

|

|

|

2.5±1.5mm |

0 |

||||||

|

|

|

|

|

2 |

|||||

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

10 |

|||

F03-101-03 Leading Edge Non-Image |

F03-101-04 Left Non-Image Width |

|||||||||

|

Width |

< >: when the DADF-H1 picks up an |

||||||||

|

|

|

|

|

|

|

original |

|||

|

|

|

|

|

|

|

(in stream readig mode). |

|||

3 |

3-1

CHAPTER 3 STANDARDS AND ADJUSTMENTS

1.2 Checking the Image Position

Make prints using the following as the source of paper (10 prints each), and check to see that the image margin and the non-image width are as indicated:

•Each cassette

•Manual feed tray

•Duplex feeding unit

•Side paper deck

If not as indicated, adjust the image position in the following order:

1.Adjusting the left/right image margin (registration)

2.Adjusting the image leading edge margin (registration)

3.Adjusting the left/right non-image width (CCD read start position)

4.Leading edge non-image width (scanner image leading edge position)

3-2

CHAPTER 3 STANDARDS AND ADJUSTMENTS

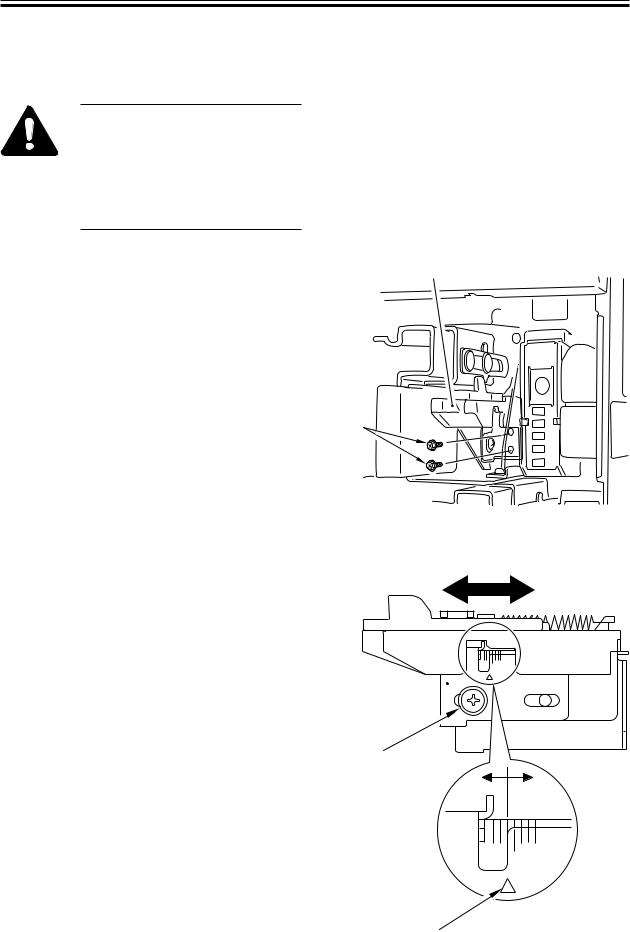

1.3 Adjusting Left/Right lamge Margin

1.3.1 Adjusting the Registration for the Cassette Rear Front

Try the following service mode first; if not corrected, perform the adjustments that follow: COPIER>FUNCTION>MISC- P>CI-ADJ-Y/C2-ADJ-Y/C3- ADJ-Y/C4-ADJ-Y

1) Remove the cassette. |

[2] |

|

2)Remove the two screws [1], and detach the horizontal registration base assembly [2].

[1]

F03-103-01

3)Loosen the screw [1], and adjust the horizontal registration plate [2].

When making adjustments, try to match the arrow [3] against the index (each graduation being about 1 mm).

[2]

[1]

[3]

F03-103-02

3-3

CHAPTER 3 STANDARDS AND ADJUSTMENTS

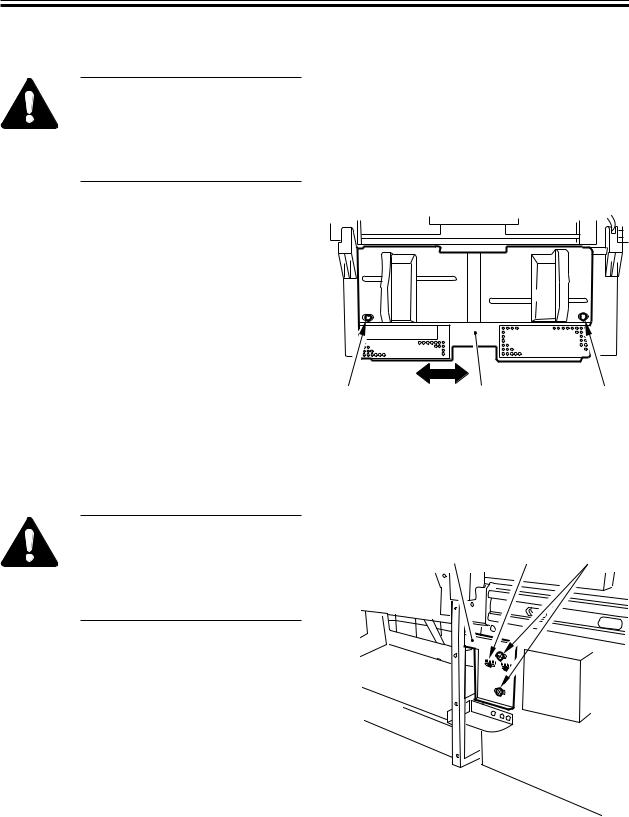

1.3.2 Adjusting the Registration for the Multifeeder Rear Front

Try the following service mode first; if not corrected, perform the adjustments that follow: COPIER>FUNCTION>MISC- P>MF-ADJ

1)Open the multifeeder tray.

2)Loosen the two screws [1], and move

the side guide plate unit [2] back and forth to adjust.

[1] |

[2] |

[1] |

1.3.3 Adjusting the Registration for the Deck

Try the following service mode first; if not corrected, perform the adjustments that follow: COPIER>FUNCTION>MISC- P>DK-ADJ-Y

1)Slide out the compartment.

2)Using the two screws [2], change the position of the latch plate [1] of the deck open solenoid (SL2D) found at the left rear. (At this time, use the index [3] on the latch plate as a reference.)

F03-103-03

[1] |

[3] |

[2] |

F03-103-04

3)Close the compartment, and check to make sure that the gap of the front cover is 3 ±1 mm.

4)If the gap is not 3 ±1 mm, adjust the front cover.

3-4

CHAPTER 3 STANDARDS AND ADJUSTMENTS

1.3.4 Duplex Feeding Unit

1)Adjust the image margin as indicated using service mode: COPIER>ADJUST>FEED- ADJ>ADJ-REFE.

1.4 Adjusting the Image Leading Edge Margin

1)Adjust the image margin in service mode so that it is as indicated: COPIER>ADJUST>FEED-ADJ>REGIST.

Decreasing the REGIST setting

(A decrease by ‘10’ will increase the margin by 1 mm.)

Edge of paper

Edge of paper

Increasing the REGIST setting

(An increase by ‘10’ will decrease the margin by 1 mm.)

F03-104-01

1.5 Adjusting the Left/Right Non-Image Width

1)Adjust the non-image width in service mode so that it is as indicated: COPIER>ADJUST>ADJ-XY>ADJ-Y.

|

|

|

|

|

|

|

|

|

|

Edge of image |

|

|

|

|

|

|

|

|

|

|

|

Decreasing the ADJ-Y setting |

|

|

|

|

|

|

Increasing the ADJ-Y setting |

|||

|

|

|

|

|||||||

|

|

|

|

|

|

|||||

(A decrease by ‘10’ will |

|

|

|

|

|

|

|

(An increase by ‘10’ will increase |

||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|||

decrease the margin by 1 mm.) |

|

|

|

the non-image width by 1 mm.) |

||||||

|

|

|

|

|

|

|

|

|

|

2.5mm±1.5 <2.5 ± 2.0 mm> |

|

|

|

|

|

|

|

|

|

|

|

0

2

4

6

8

10

< >: when the DADF-H1 picks up an original (in stream readig mode).

F03-105-01

3-5

CHAPTER 3 STANDARDS AND ADJUSTMENTS

1.6 Adjusting the Leading Edge Non-Image Width

1)Adjust the non-image width in service mode so that it is as indicated: COPIER>ADJUST>ADJ-XY>ADJ-X.

Decreasing the ADJ-X setting

(A decrease by '10' will decrease the width by 1 mm.)

Image leading edge

Increasing the ADJ-X setting

(An increase by '10' will increase the width by 1 mm.)

F03-106-01

2 Scanning System

2.1 After Replacing the Scanning Lamp

Run CCD auto adjustment in Service Mode. This updates the CCD adjustment data. Print out a new service label.

1. CCD Auto Adjust COPIER>FUNCTION>CCD> CCD-ADJ

2.CCD Adjustment Data All items under

COPIER>ADJUST>CCD.

3-6

CHAPTER 3 STANDARDS AND ADJUSTMENTS

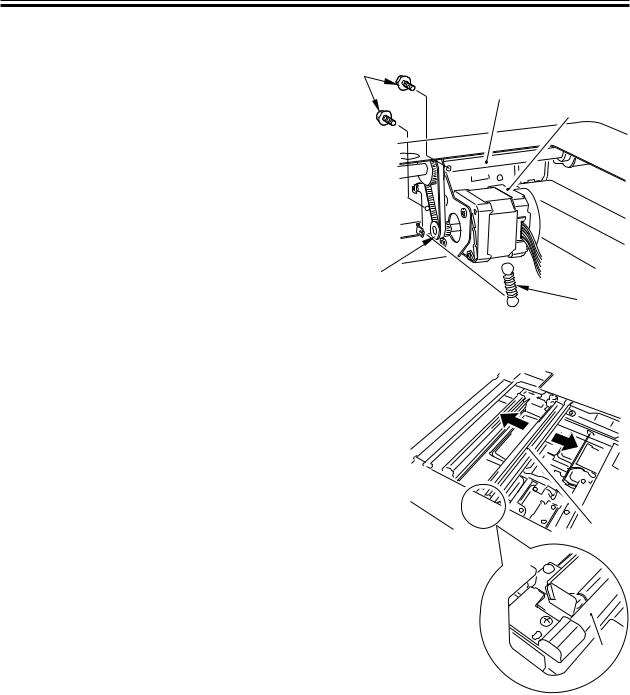

2.2 Mounting the Motor Unit

1)Engage the pulley [2] of the motor unit [1] with the belt [3].

2)Using two screws [4], mount the motor unit [1] temporarily.

3)Fit the spring [5] to apply tension to the belt [3].

4)Check to make sure that the belt [3] is vertical.

5)While taking care not to hold the scanning lamp [1] or the reflecting shade [2], move the No. 1 mirror base [3] back and forth two to three times to make a check once again.

[4]

[6]

[1]

[3]

[2]

[5]

F03-202-01

[2]

[1]

F03-202-02

6)Tighten the two screws to secure the motor unit in place.

3-7

CHAPTER 3 STANDARDS AND ADJUSTMENTS

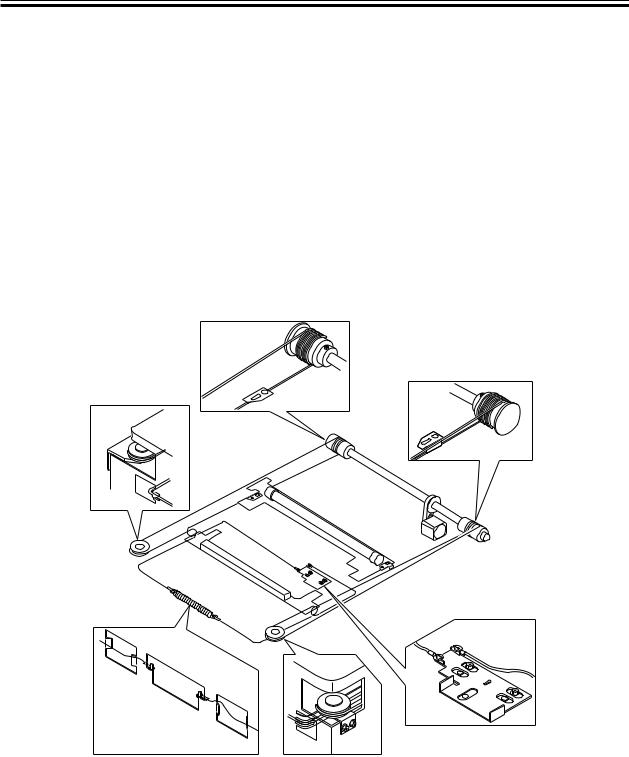

2.3 Routing the Scanner Drive Cable

Route the scanner cable as follows to the pulleys and the hook mirror base:

1)Loosen the screw on the cable fixing plate.

2)Put the ball of the cable into the hole in the drive pulley, and wind the cable firmly so that it will not turn idly (4 runs inside, 5 runs outside); then, tape it in place. At this time, check to make sure that the cable fixing is on the inside.