Bryant PREFERRED 265A User Manual

MODEL 265A

PREFERRED™ SERIES HEAT PUMP WITH PURON→ REFRIGERANT

SIZES 018 TO 060

1-1/2 TO 5 NOMINAL TONS

Product Data

TM

Bryant’s heat pumps with Puronr refrigerant provide a collection of features unmatched by any other family of equipment. The 265A has been designed utilizing Bryant’s Puronr refrigerant. The environmentally sound refrigerant allows consumers to make a responsible decision in the protection of the earth’s ozone layer.

As an Energy Starr Partner, Bryant Heating & Cooling Systems has determined that this product meets the Energy Star r guidelines for energy efficiency. Refer to the combination ratings in the Product Data for system combinations that meet Energy Starr guidelines.

INDUSTRY LEADING

FEATURES / BENEFITS

Energy Efficiency

S 15 SEER/11.5 EER/8 HSPF (Nominal)

New Aesthetic Design

S DuraGuard Ultrat

S Baked on powder paint S Steel louver coil guard

S Color matched cabinet screws

Extra Quiet Operation

S AeroQuiet System IIt for sound as low as 69 dBA S Quiet mount split post compressor grommets

S External AeroQuiet muffler

S Exclusive AeroQuiet Top design

S 8 Pole PSC ball bearing condenser fan motor S Forward-swept condenser fan blade

S Compressor blanket

S Quiet shift defrost

Reliability, Quality and Toughness

S Scroll compressor

S Field-installed 16 cu. in. filter drier S Back-seating service valves

S High pressure switch S Loss of charge switch

S Internal pressure relief valve S Internal thermal overload

S Suction line accumulator

S Vapor fog eliminator

Controls and Diagnostics

S Evolutiont control compatible

S On-board Bryant diagnostics

S Up to 14 point diagnostic capability·

S Long line accessory connections

Applications

SLong-line - up to 250 ft. total equivalent length, up to 200 ft. condenser above evaporator, or up to 20 ft. evaporator above condenser standard, (50 ft. w/liquid line solenoid)

SLow ambient (down to 0_F) with Evolutiont Control or accessory kit.

Limited Warranty

S Standard 10-year limited warranty on the compressor S Standard 5-year limited warranty on all parts

MODEL NUMBER NOMENCLATURE

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

14 |

N |

N |

N |

A |

A/N |

N |

N |

N |

N |

A/N |

A/N |

N |

A |

2 |

6 |

5 |

A |

N |

A |

0 |

3 |

6 |

0 |

0 |

0 |

A |

Product |

Tier |

SEER |

Major |

Voltage |

Variations |

Cooling Capacity |

Open |

Open |

Open |

Series |

||

Family |

|

|

Series |

|

|

|

|

|

|

|

|

|

2=HP |

6= |

5=15 SEER |

A=Puron |

N= 208---230---1 |

A = Standard |

|

|

|

0=Not |

0=Not |

0=Not |

A = |

|

Preferred |

|

|

or 208/230---1 |

|

|

|

|

Defined |

Defined |

Defined |

Original |

|

Series |

|

|

|

|

|

|

|

|

|

|

Series |

265A

|

|

ISO 9001:2000 |

|

|

|

|

|

||

the environmentally sound refrigerant |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

REGISTERED |

|

|

|

|

|

|||

|

|

|

|

|

As an Energy Star→ Partner, Bryant Heating |

|

|||

|

|

|

|

|

& Cooling Systems has determined that |

|

|||

|

|

|

|

|

this product meets the ENERGY STAR→ |

|

|||

|

|

|

|

|

guidelines for energy efficiency. |

|

|

||

|

|

|

|

|

Refer to the combination ratings in Product |

|

|||

|

|

|

|

|

Data for system combinations that meet |

|

|||

|

|

|

|

|

Energy Star guidelines. |

|

|

||

STANDARD FEATURES |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Feature |

018---B |

024---B |

|

030---B |

|

036---B |

042---B |

048---B |

060---B |

|

|

|

|

|

|

|

|

|

|

Puronr Refrigerant |

X |

X |

|

X |

|

X |

X |

X |

X |

|

|

|

|

|

|

|

|

|

|

15 SEER |

X |

X |

|

X |

|

X |

X |

X |

X |

|

|

|

|

|

|

|

|

|

|

Scroll Compressor |

X |

X |

|

X |

|

X |

X |

X |

X |

|

|

|

|

|

|

|

|

|

|

Louvered Coil Guard |

X |

X |

|

X |

|

X |

X |

X |

X |

|

|

|

|

|

|

|

|

|

|

Field Installed Filter Drier |

X |

X |

|

X |

|

X |

X |

X |

X |

|

|

|

|

|

|

|

|

|

|

Back---Seating Service Valves |

X |

X |

|

X |

|

X |

X |

X |

X |

|

|

|

|

|

|

|

|

|

|

Internal Pressure Relief Valve |

X |

X |

|

X |

|

X |

X |

X |

X |

|

|

|

|

|

|

|

|

|

|

Internal Thermal Overload |

X |

X |

|

X |

|

X |

X |

X |

X |

|

|

|

|

|

|

|

|

|

|

Long Line capability |

X |

X |

|

X |

|

X |

X |

X |

X |

|

|

|

|

|

|

|

|

|

|

Low Ambient capability with Kit or Evolutiont Control |

X |

X |

|

X |

|

X |

X |

X |

X |

|

|

|

|

|

|

|

|

|

|

Suction Line Accumulator |

X |

X |

|

X |

|

X |

X |

X |

X |

|

|

|

|

|

|

|

|

|

|

High Pressure Switch |

X |

X |

|

X |

|

X |

X |

X |

X |

|

|

|

|

|

|

|

|

|

|

Loss of Charge Switch |

X |

X |

|

X |

|

X |

X |

X |

X |

|

|

|

|

|

|

|

|

|

|

2

PHYSICAL DATA

UNIT SIZE SERIES |

018---B |

024---B |

030---B |

036---B |

042---B |

048---B |

060---B |

Operating Weight (lb) |

198 |

244 |

280 |

299 |

318 |

325 |

307 |

Shipping Weight (lb) |

232 |

280 |

310 |

335 |

354 |

361 |

344 |

Compressor Type |

|

|

|

Scroll |

|

|

|

REFRIGERANT |

|

|

|

Puron→ (R---410A) |

|

|

|

Control |

|

|

TXV (Puron Hard Shutoff) |

|

|

||

Charge (lb) |

6.13 |

10.4 |

12 |

14.8 |

14.2 |

12.6 |

12.5 |

COND FAN |

|

|

Propeller Type, Direct Drive |

|

|

||

Air Discharge |

|

|

|

Vertical |

|

|

|

Air Qty (CFM) |

2595 |

2595 |

3265 |

3265 |

3265 |

3673 |

3673 |

Motor HP |

1/10 |

1/10 |

1/5 |

1/5 |

1/5 |

1/4 |

1/4 |

Motor RPM |

800 |

800 |

800 |

800 |

800 |

800 |

800 |

COND COIL |

|

|

|

|

|

|

|

Face Area (Sq ft) |

16.26 |

18.3 |

20.33 |

24.4 |

24.4 |

24.4 |

22.4 |

Fins per In. |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

Rows |

1 |

1 |

1 |

2 |

2 |

2 |

2 |

Circuits |

4 |

5 |

6 |

5 |

7 |

8 |

9 |

VALVE CONNECT. (In. ID) |

|

|

|

|

|

|

|

Vapor |

5/8” |

5/8” |

3/4” |

3/4” |

7/8” |

7/8” |

7/8” |

Liquid |

|

|

|

3/8” |

|

|

|

REFRIGERANT TUBES* (In. OD) |

|

|

|

|

|

|

|

Vapor (0---80 Ft Tube Length) |

5/8” |

5/8” |

3/4” |

3/4” |

7/8” |

7/8” |

1---1/8” |

Liquid (0---80 Ft Tube Length) |

|

|

|

3/8” |

|

|

|

* For tubing sets between 80 ft. and 200 ft. horizontal or 20 ft. vertical differential (250 ft. Total Equivalent Length), consult the Long---Line Guideline. Note: See unit Installation Instruction for proper installation.

VAPOR LINE SIZING AND COOLING CAPACITY LOSS PURON 1-STAGE HEAT PUMP APPLICATIONS

LONG LINE APPLICATION: An application is considered |

|

is above indoor unit, and 80 ft. when the outdoor unit is below |

|||||||||||||

”Long line” when the total equivalent tubing length exceeds 80 |

|

the indoor unit. Refer to Accessory Usage Guideline below for |

|||||||||||||

ft. or when there is more than 20 ft. vertical separation between |

|

required accessories. See Long-Line Application Guideline for |

|||||||||||||

indoor and outdoor units. These applications require additional |

required piping and system modifications. Also, refer to the table |

||||||||||||||

accessories and system modifications for reliable system |

|

below for the acceptable vapor tube diameters based on the total |

|||||||||||||

operation. The maximum allowable total equivalent length is 250 |

|

length to minimize the cooling capacity loss. |

|

|

|||||||||||

ft. The maximum vertical separation is 200 ft. when outdoor unit |

|

|

|

|

|

|

|

|

|

|

|||||

|

Acceptable |

Acceptable |

|

|

Cooling Capacity Loss (%)Total Equivalent Line Length (ft.) |

|

|

||||||||

Unit Nominal |

Liquid Line |

Vapor Line |

|

|

|

|

|

|

|

|

|

|

|

|

|

Standard Application |

|

|

Long Line Application Requires Accessories |

|

|||||||||||

Size (Btuh) |

Diameter OD |

Diameters |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

(in.) |

OD (in.) |

25 |

50 |

80 |

80+ |

100 |

125 |

150 |

175 |

200 |

|

225 |

250 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18000 |

3/8 |

1/2 |

1 |

2 |

3 |

3 |

4 |

|

6 |

7 |

8 |

9 |

|

10 |

12 |

1---Stage Puron |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5/8 |

0 |

0 |

1 |

1 |

1 |

|

1 |

2 |

2 |

3 |

|

3 |

3 |

||

HP |

|

|

|

||||||||||||

24000 |

3/8 |

5/8 |

0 |

1 |

1 |

1 |

2 |

|

3 |

3 |

4 |

4 |

|

5 |

6 |

1---Stage Puron |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3/4 |

0 |

0 |

0 |

0 |

0 |

|

1 |

1 |

1 |

1 |

|

1 |

2 |

||

HP |

|

|

|

||||||||||||

30000 |

|

5/8 |

1 |

2 |

3 |

3 |

3 |

|

4 |

5 |

6 |

7 |

|

8 |

9 |

1---Stage Puron |

3/8 |

3/4 |

0 |

0 |

1 |

1 |

1 |

|

1 |

2 |

2 |

2 |

|

3 |

3 |

HP |

|

7/8 |

0 |

0 |

0 |

0 |

0 |

|

1 |

1 |

1 |

1 |

|

1 |

1 |

|

|

|

|

||||||||||||

36000 |

|

5/8 |

1 |

2 |

4 |

4 |

5 |

|

6 |

7 |

9 |

10 |

|

11 |

13 |

1---Stage Puron |

3/8 |

3/4 |

0 |

0 |

1 |

1 |

1 |

|

2 |

2 |

3 |

3 |

|

4 |

4 |

HP |

|

7/8 |

0 |

0 |

0 |

0 |

0 |

|

1 |

1 |

1 |

1 |

|

2 |

2 |

|

|

|

|

||||||||||||

42000 |

3/8 |

3/4 |

0 |

1 |

2 |

2 |

2 |

|

3 |

4 |

4 |

5 |

|

6 |

6 |

1---Stage Puron |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7/8 |

0 |

0 |

1 |

1 |

1 |

|

1 |

2 |

2 |

2 |

|

3 |

3 |

||

HP |

|

|

|

||||||||||||

48000 |

3/8 |

3/4 |

0 |

1 |

2 |

2 |

3 |

|

4 |

5 |

5 |

6 |

|

7 |

8 |

1---Stage Puron |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7/8 |

0 |

0 |

1 |

1 |

1 |

|

2 |

2 |

2 |

3 |

|

3 |

4 |

||

HP |

|

|

|

||||||||||||

60000 |

|

3/4 |

1 |

2 |

4 |

4 |

5 |

|

6 |

7 |

9 |

10 |

|

11 |

12 |

1---Stage Puron |

3/8 |

7/8 |

0 |

1 |

2 |

2 |

2 |

|

3 |

4 |

4 |

5 |

|

5 |

6 |

HP |

|

1 1/8 |

0 |

0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

|

1 |

2 |

|

|

|

|

|||||||||||||

Standard Length = 80 ft. or less total equivalent length

Applications in this area are long line. Accessories are required as shown recommended on Long Line Application Guidelines

Applications in this area may have height restrictions that limit allowable total equivalent length, when outdoor unit is below indoor unit See Long Line Application Guidelines

265A

3

265A

ACCESSORIES

KIT NUMBER |

KIT NAME |

018---B |

024---B |

030---B |

036---B |

042---B |

048---B |

060---B |

KAACH1201AAA |

CRANKCASE HEATER |

|

|

|

X |

X |

S |

S |

KAACH1401AAA |

CRANKCASE HEATER |

X |

X |

X |

|

|

|

|

KSACY0101AAA |

CYCLE PROTECTOR |

S |

S |

S |

S |

S |

S |

S |

KAAFT0101AAA |

FREEZE THERMOSTAT |

X |

X |

X |

X |

X |

X |

X |

KSAHS1701AAA |

HARD START (CAP/RELAY) |

X |

X |

X |

X |

X |

X |

X |

KHAIR0101AAA |

ISOLATION RELAY |

X |

X |

X |

X |

X |

X |

X |

KSALA0301410 |

LOW AMBIENT SWITCH |

X |

X |

X |

X |

X |

X |

X |

KHAOT0201SEC |

OUTDOOR THERMOSTAT |

X |

X |

X |

X |

X |

X |

X |

KHAOT0301FST |

OUTDOOR THERMOSTAT |

X |

X |

X |

X |

X |

X |

X |

KAACS0201PTC |

PTC START ASSIST |

X |

X |

X |

X |

X |

X |

X |

KHALS0401LLS |

SOLENOID VALVE |

X |

X |

X |

X |

X |

X |

X |

KSASF0101AAA |

SUPPORT FEET |

X |

X |

X |

X |

X |

X |

X |

KAATD0101TDR |

TIME DELAY RELAY |

X |

X |

X |

X |

X |

X |

X |

KSATX0201PUR |

TXV (HSO) |

X |

X |

X |

|

|

|

|

KSATX0301PUR |

TXV (HSO) |

|

|

|

X |

X |

|

|

KSATX0401PUR |

TXV (HSO) |

|

|

|

|

|

X |

|

KSATX0501PUR |

TXV (HSO) |

|

|

|

|

|

|

X |

x = Accessory S = Standard

ACCESSORY THERMOSTATS

THERMOSTAT / SUBBASE |

DESCRIPTION |

|

PKG. |

||

|

||

TSTATBBPRH01---B* |

Thermidistatt Control — Non---Programmable/Programmable Thermostat with Humidity Control (For use in |

|

Dual Fuel, AC, HP, and 2S applications. Includes Outdoor Air Temperature Sensor.) |

||

|

||

TSTATBBPHH01---B* |

Hybrid Heatt (Dual Fuel) Thermostat — Auto Changeover, 7---Day Programmable, °F/°C, Includes Outdoor |

|

Sensor (TSTATXXSEN01---B) |

||

|

||

TSTATBBPHP01---B |

Thermostat — Auto Changeover, 7---Day Programmable, °F/°C, 2---Stage Heat, 1---Stage Cool |

|

TSTATBBNHP01---C |

Thermostat — Auto Changeover, Non---Programmable, °F/°C, 2---Stage Heat, 1---Stage Cool |

|

TSTATBBSHP01 |

Standard Programmable Thermostat—Manual Changeover, 5---2 Day Programmable, °F/°C, 1---Stage Heat/ |

|

1---Stage Cool |

||

|

||

TSTATBBBHP01---B* |

Builder’s Thermostat — Heat Pump, Non---Programmable, °F/°C, 2---Stage Heat, 1---Stage Cool, Manual |

|

Changeover |

||

|

||

TSTATXXSEN01---B** |

Outdoor Air Temperature Sensor |

|

TSTATXXNBP01 |

Backplate for Non---Programmable Thermostat |

|

TSTATXXPBP01 |

Backplate for Programmable Thermostat and Thermidistatt Control |

|

TSTATXXSBP01 |

Backplate for Standard Programmable Thermostat |

|

TSTATXXBBP01 |

Backplate for Builder’s Thermostat |

|

TSTATXXCNV10{ |

Thermostat Conversion Kit (4 to 5 Wire) — 10 Pack |

*Do not use in zoning heat pump applications.

**Outdoor temperature sensor is an accessory for all Bryant electronic thermostats, except the non---programmable air conditioner version and builder;s thermostats. It allows the temperature at a remote location (outdoors) to be displayed on the thermostat. The outdoor air temperature sensor must be used with the HybridHeatt (dual fuel) thermostat.

{Thermostat conversion kit is a 24---vac accessory that can turn a 4---wire thermostat application into a 5---wire application. This kit can also be used to replace a broken thermostat wire, or add an extra wire when needed.

The outdoor air temperature sensor is included with the Thermidistat Control and HybridHeatt (dual fuel) thermostat.

4

ACCESSORY USAGE GUIDELINE

|

|

|

|

|

|

REQUIRED FOR LOW---AMBIENT |

REQUIRED FOR |

REQUIRED FOR |

|

|

LONG LINE |

SEA COAST |

||

ACCESSORY |

COOLING APPLICATIONS |

|||

APPLICATIONS* |

APPLICATIONS |

|||

|

(Below 55° F) |

|||

|

(Over 80 Ft.) |

(Within 2 miles) |

||

|

|

|||

Crankcase Heater |

Yes |

Yes |

No |

|

Evaporator Freeze Thermostat |

Yes |

No |

No |

|

Accumulator |

Standard |

Standard |

Standard |

|

Compressor Start Assist Capacitor and Relay |

Yes |

Yes |

No |

|

Motor Master→ Control or |

Standard |

Standard |

Standard |

|

Low---ambient Pressure Switch |

||||

|

|

|

||

|

|

|

|

|

Support Feet |

Recommended |

No |

Recommended |

|

Liquid Line Solenoid Valve |

No |

See Long---Line Ap- |

No |

|

plication Guideline |

||||

|

|

|

||

|

|

|

|

|

Ball Bearing Fan Motor |

Standard |

Standard |

Standard |

* For tubing line sets between 80 and 200 ft. and/or 20 ft. vertical differential (250 ft. Total Equivalent Length), refer to Long---Line Application Guideline.

Accessory Description and Usage (Listed Alphabetically)

1. Ball-Bearing Fan Motor 6. Isolation Relay

A fan motor with ball bearings which permits speed reduction while maintaining bearing lubrication.

Usage Guideline:

Required on all units when MotorMasterr is used.

2. Compressor Start Assist - Capacitor and Relay

Start capacitor and relay gives a ”hard” boost to compressor motor at each start up.

Usage Guideline:

Required for reciprocating compressors in the following applications:

Long line

Low ambient cooling

Hard shut off expansion valve on indoor coil Liquid line solenoid on indoor coil

Required for single-phase scroll compressors in the following applications:

Long line

Low ambient cooling

Suggested for all compressors in areas with a history of low voltage problems.

3. Compressor Start Assist — PTC Type

Solid state electrical device which gives a ”soft” boost to the compressor at each start-up.

Usage Guideline:

Suggested in installations with marginal power supply.

4. Crankcase Heater

An electric resistance heater which mounts to the base of the compressor to keep the lubricant warm during off cycles. Improves compressor lubrication on restart and minimizes the chance of liquid slugging.

Usage Guideline:

Required in low ambient cooling applications. Required in long line applications.

Suggested in all commercial applications.

5. Evaporator Freeze Thermostat

An SPST temperature-actuated switch that stops unit operation when evaporator reaches freeze-up conditions.

Usage Guideline:

Required when low ambient kit has been added.

An SPDT relay which switches the low-ambient controller out of the outdoor fan motor circuit when the heat pump switches to heating mode.

Usage Guideline:

Required in all heat pumps where low ambient kit has been added.

7. Liquid-Line Solenoid Valve (LLS)

An electrically operated shutoff valve which stops and starts refrigerant liquid flow in response to compressor operation. It is to be installed at the outdoor unit to control refrigerant off cycle migration in the heating mode.

Usage Guideline:

An LLS is required in all long line heat pump applications to control refrigerant off cycle migration in the heating mode. See Long Line Guideline.

8. Low-Ambient Pressure Switch Kit

A long life pressure switch which is mounted to outdoor unit service valve. It is designed to cycle the outdoor fan motor in order to maintain head pressure within normal operating limits. The control will maintain working head pressure at low-ambient temperatures down to 0_F when properly installed.

Usage Guideline:

A Low-Ambient Pressure Switch or MotorMasterr Low-Ambient Controller must be used when cooling operation is used at outdoor temperatures below 55_F (12.8_C).

9. MotorMasterr Low-Ambient Controller

A fan-speed control device activated by a temperature sensor, designed to control condenser fan motor speed in response to the saturated, condensing temperature during operation in cooling mode only. For outdoor temperatures down to -20_F (-28.9_C), it maintains condensing temperature at 100_F ±10_F (37.8_C ± -12_C).

Usage Guideline:

A MotorMasterr Low Ambient Controller or Low-Ambient Pressure Switch must be used when cooling operation is used at outdoor temperatures below 55_F (12.8_C).

Suggested for all commercial applications.

265A

5

265A

Accessory Description and Usage (Listed Alphabetically) - CONTINUED

10. Outdoor Air Temperature Sensor

Designed for use with Bryant Thermostats listed in this publication. This device enables the thermostat to display the outdoor temperature. This device also is required to enable special thermostat features such as auxiliary heat lock out.

Usage Guideline:

Suggested for all Bryant thermostats listed in this publication.

11. Outdoor Thermostat

An SPDT temperature-actuated switch which turns on supplemental electric heaters when outdoor air temperature drops below a user-selected set point.

Usage Guideline:

Electric supplemental heat applications in non-variable speed indoor units when electric heat staging is desired.

12. Secondary Outdoor Thermostat

An SPDT temperature-actuated switch which turns on third-stage of supplemental electric heaters when outdoor air temperature drops below the second-stage set point.

Usage Guideline:

Outdoor thermostat applications where electric heater is capable of 3-stage operation.

13. Sound Hood

Wraparound sound reducing cover for the compressor. Reduces the sound level by about 2 dBA.

Usage Guideline:

Suggested when unit is installed closer than 15 ft. to quiet areas, bedrooms, etc.

Suggested when unit is installed between two houses less than 10 ft. apart.

14. Thermostatic Expansion Valve (TXV) Bi-Flow

A modulating flow-control valve which meters refrigerant liquid flow rate into the evaporator in response to the superheat of the refrigerant gas leaving the evaporator.

Usage Guideline:

Accessory required to meet ARI rating and system reliability, where indoor not equipped.

Required in all heat pump applications designed with Puron refrigerant.

15. Time-Delay Relay

An SPST delay relay which briefly continues operation of indoor blower motor to provide additional cooling after the compressor cycles off.

Note: Most indoor unit controls include this feature. For those that do not, use the guideline below.

Usage Guideline:

Accessory required to meet ARI rating, where indoor not equipped.

6

ELECTRICAL DATA

|

|

|

|

|

|

|

|

MIN |

MIN |

MAX |

MAX |

MAX |

|

|

|

|

|

|

|

|

|

WIRE |

WIRE |

FUSE** |

|||

|

|

OPER VOLTS* |

COMPR |

FAN |

|

LENGTH |

LENGTH |

||||||

UNIT SIZE |

V/PH |

MCA |

SIZE |

SIZE |

or CKT |

||||||||

|

|

|

|

|

(FT)} |

(FT)} |

|||||||

|

|

|

|

|

|

|

|

{ |

{ |

BRK |

|||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

AMPS |

|

|

|

MAX |

MIN |

LRA |

RLA |

FLA |

|

60° C |

75° C |

60° C |

75° C |

||

018---B |

|

|

|

48 |

9 |

0.7 |

12 |

14 |

14 |

66 |

62 |

20 |

|

024---B |

|

|

|

58.3 |

12.8 |

0.7 |

16.7 |

14 |

14 |

46 |

44 |

25 |

|

030---B |

|

|

|

73 |

14.1 |

1.1 |

18.7 |

14 |

14 |

41 |

39 |

30 |

|

036---B |

208/230/1 |

253 |

197 |

79 |

17.9 |

1.1 |

23.4 |

12 |

12 |

55 |

52 |

35 |

|

042---B |

|

|

|

109 |

21.3 |

1.1 |

27.7 |

10 |

10 |

71 |

68 |

40 |

|

048---B |

|

|

|

117 |

21.8 |

1.3 |

28.5 |

10 |

10 |

69 |

66 |

40 |

|

060---B |

|

|

|

134 |

26.4 |

1.3 |

34.3 |

8 |

10 |

91 |

56 |

50 |

|

* Permissible limits of the voltage range at which the unit will operate satisfactorily

{If wire is applied at ambient greater than 30° C (86° F), consult table 310---16 of the NEC (ANSI/NFPA 70). The ampacity of non---metallic---sheathed cable (NM), trade name ROMEX, shall be that of 60° C (140° F) conditions, per the NEC (ANSI/NFPA 70) Article 336---26. If other than uncoated (no---plated), 60

or 75° C (140 or 167° C) insulation, copper wire (solid wire for 10 AWG or smaller, stranded wire for larger than 10 AWG) is used, consult applicable tables of the NEC (ANSI/NFPA 70).

} Length shown is as measured 1 way along wire path between unit and service panel for voltage drop not to exceed 2%. ** Time---Delay fuse.

FLA |

--- Full Load Amps |

LRA |

--- Locked Rotor Amps |

MCA |

--- Minimum Circuit Amps |

RLA |

--- Rated Load Amps |

NOTE: Control circuit is 24---V on all units and requires external power source. Copper wire must be used from service disconnect to unit. All motors/compressors contain internal overload protection.

A-WEIGHTED SOUND LEVEL (dBA)

UNIT SIZE |

STANDARD |

|

TYPICAL OCTAVE BAND SPECTRUM (without tone adjustment) |

|

|||||

RATING |

125 |

250 |

500 |

1000 |

2000 |

4000 |

8000 |

||

|

|||||||||

018---B |

70 |

57 |

57 |

63 |

62.5 |

61 |

56.5 |

47.5 |

|

024---B |

69 |

56.5 |

57.5 |

63.5 |

61.5 |

61.5 |

57 |

48.5 |

|

030---B |

71 |

59.5 |

60 |

65 |

64.5 |

61.5 |

58 |

55.5 |

|

036---B |

71 |

60 |

62 |

66 |

65 |

63 |

58 |

51.5 |

|

042---B |

71 |

60.5 |

59.5 |

63 |

64 |

62 |

58.5 |

50.5 |

|

048---B |

72 |

58.5 |

62.5 |

64.5 |

67 |

65 |

61 |

54.5 |

|

060---B |

75 |

59 |

61 |

67 |

69.5 |

64 |

59 |

54.5 |

|

CHARGING SUBCOOLING (TXV-TYPE EXPANSION DEVICE)

UNIT SIZE---SERIES |

REQUIRED SUBCOOLING (F) |

018---B |

12 |

024---B |

11 |

030---B |

11 |

036---B |

11 |

042---B |

10 |

048---B |

10 |

060---B |

11 |

265A

7

265A

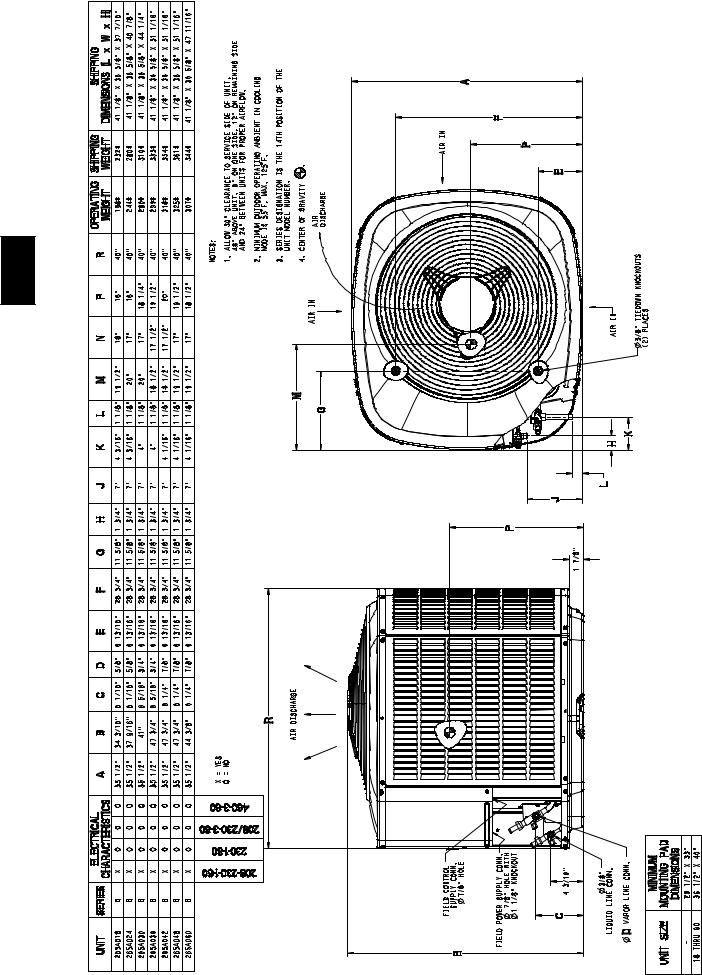

DIMENSIONS

8

9

|

|

|

|

4CNF0484CNF030 |

|

|

|

|

|

|

X |

|

|

|

|

|

|

X |

|

|

|

|

80 |

265A BALANCE POINT WORKSHEET |

F |

23.4 |

|

|

|

|

|

265ANA060--A |

|

|

|

|

|

|

FX4CNF060 |

|

|

INTEGRATEDUNITLOSS, |

MBTUHCAPACITY, |

70 |

|

|

20.5 |

kW |

|

|

265ANA048--A |

|

|||

|

|

|

|

FX4CNF060 |

|

|

|

|

60 |

|

|

17.6 |

|

|

|

|

|

265ANA042--A |

|

|

|

|

50 |

|

265ANA036--A |

14.6 |

|

|

|

|

|

FX4CNF042 |

|

|

|

|

40 |

|

265ANA030--A |

11.7 |

|

HEATBUILDING |

HEATING |

|

|

FX4CNF030 |

|

|

|

|

265ANA024--A |

|

|

||

|

|

30 |

|

F |

8.8 |

|

|

|

|

|

265ANA018--A |

|

|

|

|

|

|

FX4CNF018 |

|

|

|

|

20 |

|

|

5.9 |

|

|

|

10 |

|

|

2.9 |

|

|

|

|

BASED ON INDOOR ENT. AIR |

|

|

|

|

|

|

AT 70 ºF AND AT RATED CFM |

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

--10 |

0 |

10 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

||||||

OUTDOOR TEMPERATURE, ºF

265A

265A

COMBINATION RATINGS

|

|

|

|

|

|

|

ARI Standard Ratings |

|

|

|

||

Unit Size |

|

Cooling |

|

Cooling |

|

|

|

|

Heating |

|

|

|

Indoor Model |

|

|

|

|

High Temp |

Low Temp |

|

|

||||

--- Series |

Capacity |

Factory |

Standard |

SEER |

EER |

HSPF |

Furnace Model |

|||||

|

|

|

Enhance |

Rating |

TDR |

E |

E |

H |

H |

|

||

|

|

|

|

Capacity |

COP |

Capacity |

COP |

|

|

|||

|

|

|

|

|

|

|

|

|

||||

|

*FX4CNF018 |

17,800 |

TDR&TXV |

15.00 |

|

12.00 |

18,000 |

3.62 |

10,400 |

2.34 |

8.2 |

|

|

FE4ANF002 |

18,000 |

TDR&TXV |

15.50 |

|

12.50 |

17,800 |

3.68 |

10,300 |

2.38 |

8.3 |

|

|

FF1ENP018 |

17,400 |

TDR&TXV |

13.20 |

|

10.90 |

18,000 |

3.40 |

10,800 |

2.22 |

7.9 |

|

|

FF1ENP024 |

17,700 |

TDR&TXV |

13.50 |

|

11.10 |

18,000 |

3.46 |

10,900 |

2.24 |

8.0 |

|

|

FV4BNF002 |

18,000 |

TDR&TXV |

15.50 |

|

12.50 |

17,800 |

3.68 |

10,300 |

2.38 |

8.3 |

|

|

FX4CNF024 |

18,000 |

TDR&TXV |

15.00 |

|

12.40 |

18,000 |

3.66 |

10,400 |

2.38 |

8.3 |

|

|

FY4ANF018 |

17,400 |

TDR&TXV |

13.00 |

|

10.80 |

18,000 |

3.40 |

10,800 |

2.20 |

8.0 |

|

|

FY4ANF024 |

17,600 |

TDR&TXV |

13.20 |

|

10.90 |

18,000 |

3.40 |

10,900 |

2.22 |

8.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAP**1814A** |

17,300 |

TDR&TXV |

14.50 |

|

12.00 |

17,400 |

3.38 |

10,100 |

2.26 |

7.8 |

315(A,J)AV036070 |

|

CAP**1814A** |

17,400 |

TXV |

|

13.00 |

10.80 |

18,000 |

3.36 |

10,800 |

2.20 |

7.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAP**2414A** |

17,600 |

TDR&TXV |

15.00 |

|

12.00 |

17,600 |

3.52 |

10,200 |

2.32 |

8.0 |

315(A,J)AV036070 |

|

CAP**2414A** |

17,800 |

TXV |

|

13.50 |

11.00 |

18,000 |

3.50 |

10,900 |

2.26 |

8.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAP**2417A** |

17,700 |

TDR&TXV |

15.00 |

|

12.00 |

17,600 |

3.56 |

10,200 |

2.34 |

8.1 |

315(A,J)AV048090 |

|

CAP**2417A** |

17,700 |

TDR&TXV |

15.00 |

|

12.00 |

17,600 |

3.54 |

10,200 |

2.34 |

8.1 |

355AAV042060 |

|

CAP**2417A** |

17,800 |

TXV |

|

13.50 |

11.00 |

18,000 |

3.50 |

10,900 |

2.26 |

8.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CNPF*2418A** |

17,700 |

TXV |

|

13.50 |

10.80 |

18,000 |

3.54 |

10,900 |

2.28 |

8.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

018---B |

CNPH*2417A** |

17,600 |

TDR&TXV |

15.00 |

|

12.00 |

17,600 |

3.56 |

10,300 |

2.34 |

8.1 |

315(A,J)AV036070 |

CNPH*2417A** |

17,700 |

TDR&TXV |

15.00 |

|

12.00 |

17,600 |

3.60 |

10,300 |

2.34 |

8.2 |

315(A,J)AV048090 |

|

|

|

|||||||||||

|

CNPH*2417A** |

17,600 |

TDR&TXV |

14.50 |

|

12.00 |

17,600 |

3.58 |

10,300 |

2.34 |

8.2 |

355AAV042040 |

|

CNPH*2417A** |

17,600 |

TDR&TXV |

15.00 |

|

12.00 |

17,600 |

3.58 |

10,300 |

2.34 |

8.2 |

355AAV042060 |

|

CNPH*2417A** |

17,700 |

TDR&TXV |

15.00 |

|

12.00 |

17,600 |

3.60 |

10,300 |

2.34 |

8.2 |

355AAV042080 |

|

CNPH*2417A** |

17,700 |

TXV |

|

13.50 |

10.80 |

18,000 |

3.54 |

10,900 |

2.28 |

8.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CNPV*1814A** |

17,300 |

TDR&TXV |

15.00 |

|

12.00 |

17,400 |

3.50 |

10,200 |

2.30 |

8.0 |

315(A,J)AV036070 |

|

CNPV*1814A** |

17,400 |

TXV |

|

13.00 |

10.80 |

18,000 |

3.50 |

10,900 |

2.26 |

8.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CNPV*2414A** |

17,600 |

TDR&TXV |

15.00 |

|

12.00 |

17,600 |

3.56 |

10,300 |

2.34 |

8.1 |

315(A,J)AV036070 |

|

CNPV*2414A** |

17,700 |

TXV |

|

13.50 |

10.80 |

18,000 |

3.54 |

10,900 |

2.28 |

8.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CNPV*2417A** |

17,700 |

TDR&TXV |

15.00 |

|

12.00 |

17,600 |

3.60 |

10,300 |

2.34 |

8.2 |

315(A,J)AV048090 |

|

CNPV*2417A** |

17,700 |

TDR&TXV |

15.00 |

|

12.00 |

17,600 |

3.58 |

10,300 |

2.34 |

8.2 |

355AAV042060 |

|

CNPV*2417A** |

17,700 |

TXV |

|

13.50 |

10.80 |

18,000 |

3.54 |

10,900 |

2.28 |

8.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CSPH*2412A** |

17,600 |

TDR&TXV |

15.00 |

|

12.00 |

17,600 |

3.54 |

10,300 |

2.34 |

8.1 |

315(A,J)AV036070 |

|

CSPH*2412A** |

17,700 |

TDR&TXV |

15.00 |

|

12.00 |

17,600 |

3.58 |

10,300 |

2.34 |

8.2 |

315(A,J)AV048090 |

|

CSPH*2412A** |

17,600 |

TDR&TXV |

14.50 |

|

12.00 |

17,600 |

3.56 |

10,300 |

2.34 |

8.2 |

355AAV042040 |

|

CSPH*2412A** |

17,600 |

TDR&TXV |

15.00 |

|

12.00 |

17,600 |

3.56 |

10,300 |

2.34 |

8.1 |

355AAV042060 |

|

CSPH*2412A** |

17,700 |

TDR&TXV |

15.00 |

|

12.00 |

17,600 |

3.58 |

10,300 |

2.34 |

8.2 |

355AAV042080 |

|

CSPH*2412A** |

17,700 |

TXV |

|

13.50 |

10.80 |

18,000 |

3.54 |

11,000 |

2.28 |

8.1 |

|

|

*FX4CNF030 |

23,600 |

TDR&TXV |

15.50 |

|

12.50 |

23,800 |

3.78 |

14,000 |

2.52 |

8.5 |

|

|

FE4ANF002 |

23,400 |

TDR&TXV |

15.50 |

|

12.50 |

23,400 |

3.72 |

13,800 |

2.50 |

8.5 |

|

|

FE4ANF003 |

23,400 |

TDR&TXV |

16.00 |

|

13.00 |

23,400 |

3.72 |

13,700 |

2.52 |

8.5 |

|

|

FE5ANB004 |

24,000 |

TDR&TXV |

16.00 |

|

13.50 |

23,800 |

3.98 |

13,800 |

2.62 |

9.0 |

|

|

FF1ENP024 |

23,000 |

TDR&TXV |

13.50 |

|

11.20 |

24,000 |

3.48 |

14,600 |

2.34 |

8.1 |

|

|

FF1ENP030 |

23,000 |

TDR&TXV |

13.50 |

|

11.20 |

24,000 |

3.50 |

14,500 |

2.34 |

8.1 |

|

|

FV4BNF002 |

23,400 |

TDR&TXV |

15.50 |

|

12.50 |

23,400 |

3.72 |

13,800 |

2.50 |

8.5 |

|

|

FV4BNF003 |

23,400 |

TDR&TXV |

16.00 |

|

13.00 |

23,400 |

3.72 |

13,700 |

2.52 |

8.5 |

|

|

FX4CNF024 |

23,200 |

TDR&TXV |

15.00 |

|

12.40 |

23,600 |

3.66 |

14,000 |

2.46 |

8.4 |

|

|

FY4ANF024 |

22,800 |

TDR&TXV |

13.50 |

|

11.40 |

24,000 |

3.48 |

14,400 |

2.34 |

8.0 |

|

|

FY4ANF030 |

23,000 |

TDR&TXV |

14.00 |

|

11.50 |

24,000 |

3.58 |

14,500 |

2.38 |

8.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

024---B |

CAP**2414A** |

22,800 |

TDR&TXV |

15.00 |

|

12.50 |

23,200 |

3.56 |

13,700 |

2.44 |

8.2 |

315(A,J)AV036070 |

CAP**2414A** |

23,000 |

TXV |

|

14.00 |

11.20 |

24,000 |

3.54 |

14,600 |

2.36 |

8.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAP**2417A** |

23,000 |

TDR&TXV |

15.50 |

|

12.50 |

23,200 |

3.60 |

13,700 |

2.46 |

8.3 |

315(A,J)AV048090 |

|

CAP**2417A** |

23,000 |

TDR&TXV |

15.00 |

|

12.50 |

23,200 |

3.58 |

13,700 |

2.44 |

8.2 |

355AAV042060 |

|

CAP**2417A** |

23,000 |

TXV |

|

14.00 |

11.20 |

24,000 |

3.54 |

14,600 |

2.36 |

8.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAP**3014A** |

23,200 |

TDR&TXV |

15.50 |

|

12.50 |

23,200 |

3.58 |

13,700 |

2.46 |

8.2 |

315(A,J)AV036070 |

|

CAP**3014A** |

23,200 |

TXV |

|

14.00 |

11.50 |

24,000 |

3.56 |

14,600 |

2.38 |

8.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAP**3017A** |

23,200 |

TDR&TXV |

15.50 |

|

12.50 |

23,200 |

3.64 |

13,700 |

2.48 |

8.3 |

315(A,J)AV048090 |

|

CAP**3017A** |

23,200 |

TDR&TXV |

15.50 |

|

12.50 |

23,200 |

3.62 |

13,700 |

2.46 |

8.3 |

355AAV042060 |

|

CAP**3017A** |

23,200 |

TXV |

|

14.00 |

11.50 |

24,000 |

3.56 |

14,600 |

2.38 |

8.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CNPF*2418A** |

23,000 |

TXV |

|

13.50 |

11.20 |

24,000 |

3.60 |

14,600 |

2.38 |

8.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CNPH*2417A** |

22,800 |

TDR&TXV |

15.00 |

|

12.50 |

23,200 |

3.60 |

13,800 |

2.44 |

8.3 |

315(A,J)AV036070 |

|

CNPH*2417A** |

23,000 |

TDR&TXV |

15.00 |

|

12.50 |

23,200 |

3.64 |

13,800 |

2.46 |

8.3 |

315(A,J)AV048090 |

|

CNPH*2417A** |

23,000 |

TDR&TXV |

15.00 |

|

12.50 |

23,200 |

3.64 |

13,800 |

2.46 |

8.3 |

315(A,J)AV060110 |

|

CNPH*2417A** |

23,000 |

TDR&TXV |

15.00 |

|

12.50 |

23,200 |

3.64 |

13,800 |

2.46 |

8.3 |

315(A,J)AV066135 |

|

CNPH*2417A** |

23,000 |

TDR&TXV |

15.00 |

|

12.50 |

23,200 |

3.64 |

13,800 |

2.46 |

8.3 |

315(A,J)AV066155 |

See notes on pg. 17

10

Loading...

Loading...