Bryant 355MAV User Manual

service and maintenance procedures

DELUXE 4-WAY MULTIPOISE VARIABLE-CAPACITY DIRECT-VENT CONDENSING GAS FURNACE

355MAV Series I

Cancels: SP05-57 |

SP05-64 |

|

9-04 |

A93040

NOTE: Read the entire instruction manual before starting the installation.

This symbol → indicates a change since the last issue.

WARNING: ELECTRICAL SHOCK, FIRE, OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in dangerous operation, serious injury, death, or property damage.

Improper servicing could result in dangerous operation, serious injury, death, or property damage.

-Before servicing, disconnect all electrical power to furnace.

-When servicing controls, label all wires prior to disconnecting. Reconnect wires correctly.

-Verify proper operation after servicing.

WARNING: ELECTRICAL SHOCK, FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in possible damage to this equipment, serious personal injury, or death.

The ability to properly perform maintenance on this equipment requires certain expertise, mechanical skills, tools, and equipment. If you do not possess these, do not attempt to perform any maintenance on this equipment other than those procedures recommended in the User’s Manual.

WARNING: FIRE OR EXPLOSION HAZARD

Failure to follow this warning could cause corrosion of heat exchanger, fire, personal injury, or death.

Never store anything on, near, or in contact with the furnace, such as:

1. Spray or aerosol cans, rags, brooms, dust mops, vacuum cleaners, or other cleaning tools.

2.Soap powders, bleaches, waxes or other cleaning compounds, plastic or plastic containers, gasoline, kerosene, cigarette lighter fluid, dry cleaning fluids, or other volatile fluids.

3.Paint thinners and other painting compounds, paper bags, or other paper products.

TABLE OF CONTENTS |

|

SAFETY CONSIDERATIONS ..................................................... |

1 |

GENERAL...................................................................................... |

2 |

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS........ |

2 |

CARE AND MAINTENANCE..................................................... |

3 |

Cleaning and/or Replacing Air Filter....................................... |

3 |

Blower Motor and Wheel Maintenance................................... |

3 |

Cleaning Burners ...................................................................... |

5 |

Cleaning Heat Exchangers........................................................ |

5 |

Flushing Collector Box and Drainage |

|

System ....................................................................................... |

6 |

Servicing Hot Surface Igniter................................................... |

8 |

Electrical Controls and Wiring................................................. |

8 |

Checking Heat Tape Operation |

|

(If Applicable)........................................................................... |

9 |

Winterizing................................................................................ |

9 |

WIRING DIAGRAM................................................................... |

10 |

TROUBLESHOOTING ............................................................... |

10 |

SAFETY CONSIDERATIONS

Recognize safety information. This is the safety-alert symbol . When you see this symbol on the unit and in instructions or manuals, be alert to the potential for personal injury.

. When you see this symbol on the unit and in instructions or manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, CAUTION, and NOTE. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe personal injury or death. WARNING signifies hazards which could result in personal injury or death. CAUTION is used to identify unsafe practices which may result in minor personal injury or product and property damage. NOTE is used to highlight suggestions which will result in enhanced installation, reliability, or operation.

Installing and servicing heating equipment can be hazardous due to gas and electrical components. Only trained and qualified service agency personnel should install, repair, or service heating equipment.

—1—

GENERAL

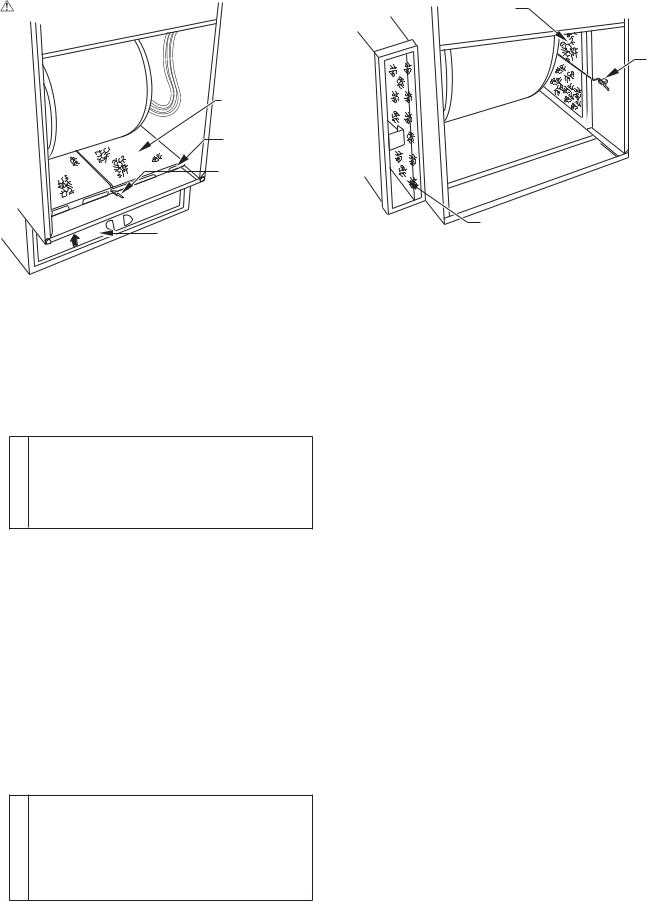

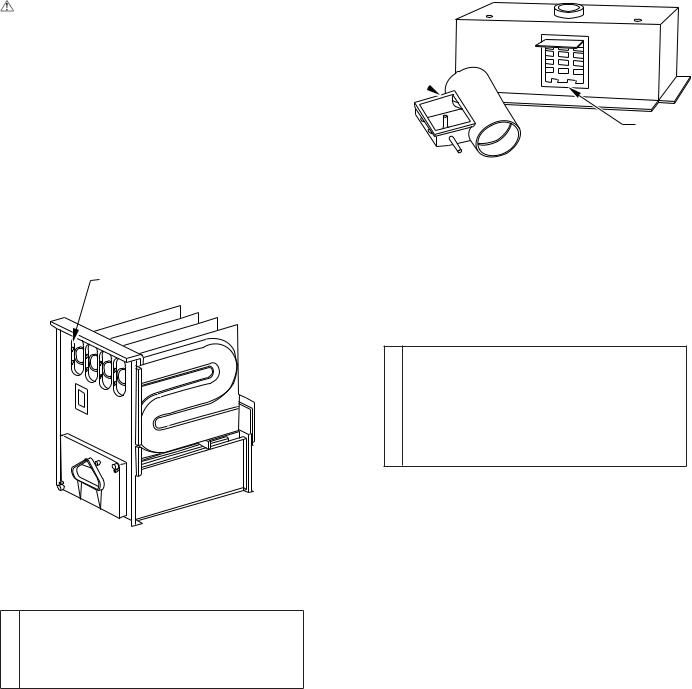

These instructions are written as if the furnace is installed in an upflow application. An upflow furnace application is where the blower is located below the combustion and controls section of the furnace, and conditioned air is discharged upward. Since this furnace can be installed in any of the 4 positions shown in Fig. 2, you must revise your orientation to component location accordingly.

AIRFLOW

UPFLOW

HORIZONTAL |

|

HORIZONTAL |

|

LEFT |

|

RIGHT |

|

|

DOWNFLOW |

|

|

AIRFLOW |

|

AIRFLOW |

|

|

AIRFLOW |

||

A98308 |

|

A93041 |

|

Fig. 1—Multipoise Furnace in Upflow Orientation

EFFICIENCY

RATING

CERTIFIED

ISO 9001:2000

CERTIFIED

REGISTERED

Untrained personnel can perform basic maintenance functions described in User’s Information Manual such as cleaning and replacing air filters. All other operations must be performed by trained service personnel. When working on heating equipment, observe precautions in the literature, on tags, and on labels attached to or shipped with the unit and other safety precautions that may apply.

CAUTION: CUT HAZARD

Failure to follow this caution may result in personal injury.

Be careful of sharp metal edges, etc. Use care and wear protective clothing, gloves, and safety glasses when removing parts.

Follow all safety codes including the National Fuel Gas Code (NFGC) NFPA 54-2002/ANSI Z223.1-2002 in the USA, CSA B149.1-00 National Standard of Canada, Natural Gas and Propane Installation Codes (NSCNGPIC) in Canada, and the Installation Standards, Warm Air Heating and Air Conditioning Systems (NFPA 90B) ANSI/NFPA 90B. Wear safety glasses and work gloves. Have a fire extinguisher available during start-up and adjustment procedures and service calls.

Fig. 2—Multipoise Orientation ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS

→CAUTION: UNIT DAMAGE HAZARD

Failure to follow this caution may damage furnace components.

Electrostatic discharge can affect electronic components.

Take precautions during furnace installation and servicing to protect the furnace electronic control. Precautions will prevent electrostatic discharges from personnel and hand tools which are held during the procedure. These precautions will help to avoid exposing the control to electrostatic discharge by putting the furnace, the control, and the person at the same electrostatic potential.

1.Disconnect all power to the furnace. DO NOT TOUCH THE CONTROL OR ANY WIRE CONNECTED TO THE CONTROL PRIOR TO DISCHARGING YOUR BODY’S ELECTROSTATIC CHARGE TO GROUND.

2.Firmly touch a clean, unpainted, metal surface of the furnace chassis which is close to the control. Tools held in a person’s hand during grounding will be satisfactorily discharged.

3.After touching the chassis, you may proceed to service the control or connecting wires as long as you do nothing that recharges your body with static electricity (for example; DO NOT move or shuffle your feet, DO NOT touch ungrounded objects, etc.).

4.If you touch ungrounded objects (recharge your body with static electricity), firmly touch furnace again before touching control or wires.

5.Use this procedure for installed and uninstalled (ungrounded) furnaces.

6.Before removing a new control from its container, discharge your body’s electrostatic charge to ground to protect the control from damage. If the control is to be installed in a furnace, follow items 1 through 5 before bringing the control or yourself into contact with the furnace. Put all used AND new controls into containers before touching ungrounded objects.

—2—

WASHABLE

FILTER

FILTER

SUPPORT

FILTER

RETAINER

WASHABLE FILTER OR

DISPOSABLE MEDIA FILTER

IN FILTER CABINET

A00232

Fig. 3—Bottom Filter Arrangement

7.An ESD service kit (available from commercial sources) may also be used to prevent ESD damage.

CARE AND MAINTENANCE

For continuing high performance and to minimize possible furnace failure, it is essential that maintenance be performed annually. Consult your local dealer for maintenance and maintenance contract availability.

WARNING: ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

Turn off the gas and electrical supplies to the unit before performing any maintenance or service. Follow the operating instructions on the label attached to the furnace.

The minimum maintenance that should be performed on this equipment is as follows:

1.Check and clean or replace air filter each month as needed.

2.Check blower motor and wheel for cleanliness annually.

3.Check electrical connections for tightness and controls for proper operation each heating season. Service as necessary.

4.Check for proper condensate drainage. Clean as necessary.

5.Check for blockages in combustion-air and vent pipes annually.

6.Check burners for cleanliness annually.

I. CLEANING AND/OR REPLACING AIR FILTER

The air filter arrangement may vary depending on the application or orientation.

WARNING: FIRE, CARBON MONOXIDE AND POISONING HAZARD

Failure to follow this warning could result in fire, personal injury, or death.

Never operate unit without a filter or with the blower access panel removed. Dust and lint on internal parts in furnace can cause a loss of efficiency.

NOTE: If the filter has an airflow direction arrow, the arrow must point toward the blower.

WASHABLE

FILTER

IN FURNACE

FILTER

RETAINER

WASHABLE FILTER OR

DISPOSABLE MEDIA

FILTER IN FILTER CABINET

A00233

Fig. 4—Filter Installed for Side Inlet

To clean or replace filters, proceed as follows:

If filter is installed in filter cabinet adjacent to furnace:

1.Turn off electrical supply to furnace.

2.Remove filter cabinet door.

3.Slide filter out of cabinet.

4.If equipped with permanent, washable filter, clean filter by spraying cold tap water through filter in opposite direction of airflow. Rinse filter and let dry. Oiling or coating of the filter is not recommended.

5.If equipped with factory specified disposable media filter, replace only with a factory specified media filter of the same size.

6.Slide filter into cabinet.

7.Replace filter cabinet door.

8.Turn on electrical supply to furnace.

If filter is installed in furnace blower compartment:

1.Turn off electrical supply to furnace.

2.Remove main furnace door and blower access panel.

3.Release filter retainer wire. (See Fig. 3 or 4.)

NOTE: Filters shown in Fig. 3 and 4 can be in furnace blower compartment or in filter cabinet, but not in both.

4.Slide filter out of furnace.

5.Furnaces are equipped with permanent, washable filter(s). Clean filter by spraying cold tap water through filter in opposite direction of airflow.

6.Rinse filter and let dry. Oiling or coating filter is not recommended.

7.Slide filter into furnace.

8.Recapture filter retaining wire.

9.Replace blower access panel and main furnace door.

II. BLOWER MOTOR AND WHEEL MAINTENANCE

To ensure long life, economy, and high efficiency, clean accumulated dirt and grease from blower wheel and motor annually.

The inducer and blower motors are pre-lubricated and require no additional lubrication. These motors can be identified by the absence of oil ports on each end of the motor.

—3—

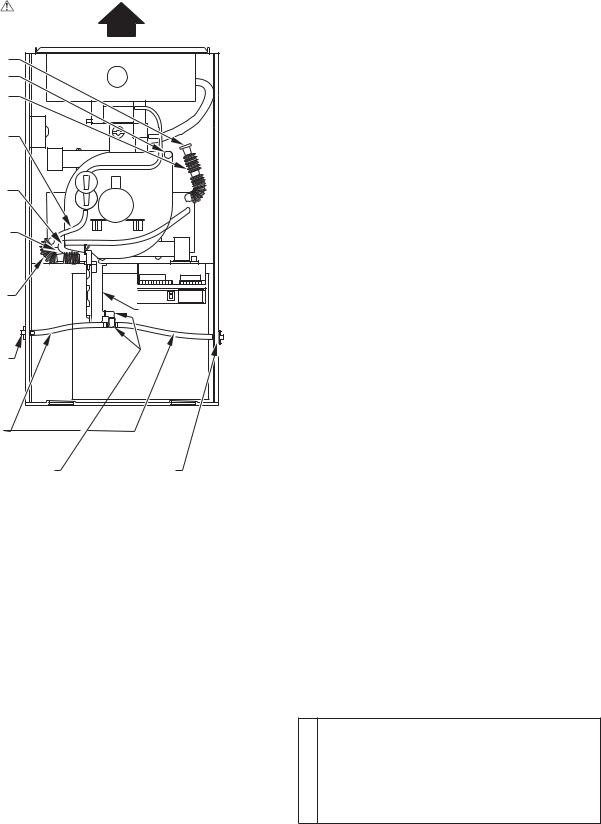

PLUG

CAP

COLLECTOR BOX DRAIN TUBE (BLUE & WHITE STRIPED)

COLLECTOR BOX TUBE (PINK)

COLLECTOR BOX TUBE (GREEN)

INDUCER HOUSING (MOLDED) DRAIN TUBE (BEHIND COLLECTOR BOX DRAIN TUBE)

COLLECTOR BOX DRAIN TUBE (BLUE)

FIELD-INSTALLED FACTORY-SUPPLIED DRAIN TUBE COUPLING (LEFT DRAIN OPTION)

CONDENSATE |

TRAP |

FIELD-INSTALLED |

|

FACTORY-SUPPLIED |

|

DRAIN TUBE |

|

FIELD-INSTALLED |

FIELD-INSTALLED |

FACTORY-SUPPLIED |

FACTORY-SUPPLIED |

1⁄2-IN. CPVC STREET |

DRAIN TUBE |

ELBOWS (2) FOR |

COUPLING (RIGHT |

LEFT DRAIN OPTION |

DRAIN OPTION) |

A01030

Fig. 5—Factory-Shipped Upflow Tube Configuration

(Shown with Blower Access Panel Removed)

The following items should be performed by a qualified service technician.

Clean blower motor and wheel as follows:

1.Turn off electrical supply to furnace.

2.Remove main furnace door and blower access panel.

3.Disconnect wires.

All factory wires can be left connected, but field thermostat connections may need to be disconnected depending on their length and routing.

4.Position control box, transformer, and door switch assembly to right side of furnace casing.

5.If condensate trap is located in leftor right-hand side of furnace casing, proceed to item 6. Otherwise remove trap and tubing as described below (See Fig. 5.):

a.Disconnect field drain connection from condensate trap.

b.Disconnect drain and relief port tubes from condensate trap.

c.Remove condensate trap from blower shelf.

6.Remove screws securing blower assembly to blower shelf and slide blower assembly out of furnace. Detach ground wire and disconnect blower motor harness plugs from blower motor.

NOTE: Blower wheel is fragile. Use care.

—4—

7.Clean blower wheel and motor by using a vacuum with soft brush attachment. Be careful not to disturb balance weights (clips) on blower wheel vanes. Do not bend wheel or blades as balance will be affected.

8.If greasy residue is present on blower wheel, remove wheel from the blower housing and wash it with an appropriate degreaser. To remove wheel:

a.Mark blower wheel location on shaft before disassembly to ensure proper reassembly.

b.Loosen setscrew holding blower wheel on motor shaft.

NOTE: Mark blower mounting arms and blower housing so each arm is positioned at the same hole location during reassembly.

c.Mark blower wheel orientation and cutoff plate location to ensure proper reassembly.

d.Remove screws securing cutoff plate and remove cutoff plate from housing.

e.Remove bolts holding motor mounts to blower housing and slide motor and mounts out of housing.

f.Remove blower wheel from housing.

g.Clean wheel per instructions on degreaser cleaner. Do not get degreaser in motor.

9.Reassemble motor and blower wheel by reversing items 8b through 8f. Ensure wheel is positioned for proper rotation. Be sure to attach ground wire and reconnect blower harness plugs to blower motor.

10.Reinstall blower assembly in furnace.

11.Reinstall condensate trap and tubing if previously removed.

a.Reinstall condensate trap in hole in blower shelf.

b.Connect condensate trap drain tubes. See Fig. 5 or tubing diagram on main furnace door for proper tube location.

(1.) Connect 1 tube (blue or blue and white striped) from collector box.

(2.) Connect 1 tube (violet or unmarked) from inducer housing.

(3.) Connect 1 tube (relief port, green or pink) from collector box.

c.Connect field drain to condensate trap.

NOTE: Ensure tubes are not kinked or pinched, as this will affect operation.

12.Reinstall control box, transformer, and door switch assembly on blower shelf.

13.Reconnect wires.

a.Refer to furnace wiring diagram and connect thermosta leads if previously disconnected. (See Fig. 17.)

WARNING: ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

Blower access panel door switch opens 115-v power to furnace control. No component operation can occur. Caution must be taken when manually closing this switch for service purposes.

14.Turn on electrical supply. Manually close blower access panel door switch. Use a piece of tape to hold switch closed. Check for proper rotation and speed changes between heating and cooling by jumpering R to G and R to Y/Y2 on furnace control thermostat terminals. (See Fig. 12.)

15.If furnace is operating properly, release blower access panel door switch, replace blower access panel, and replace main furnace door.

III. CLEANING BURNERS

The following items should be performed by a qualified service technician. If the burners develop an accumulation of light dirt or dust, they may be cleaned by using the following procedure:

1.Turn off gas and electrical supplies to furnace.

2.Remove main furnace door.

3.Remove burner box cover.

14.Reinstall burner box pressure tube to gas valve regulator fitting.

15.Reinstall gas supply pipe to furnace gas control valve using backup wrench on gas valve to prevent rotation and improper orientation.

NOTE: Use propane gas resistant pipe dope to prevent gas leaks. DO NOT use Teflon tape.

4.Using backup wrench, disconnect gas supply pipe from furnace gas valve.

→CAUTION: ELECTRICAL SHOCK AND UNIT

DAMAGE HAZARD

Failure to follow this caution may result in minor personal injury or furnace component damage.

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation.

5.Remove wires from gas valve. Note location for reassembly.

6.Remove burner box pressure tube from gas valve regulator fitting.

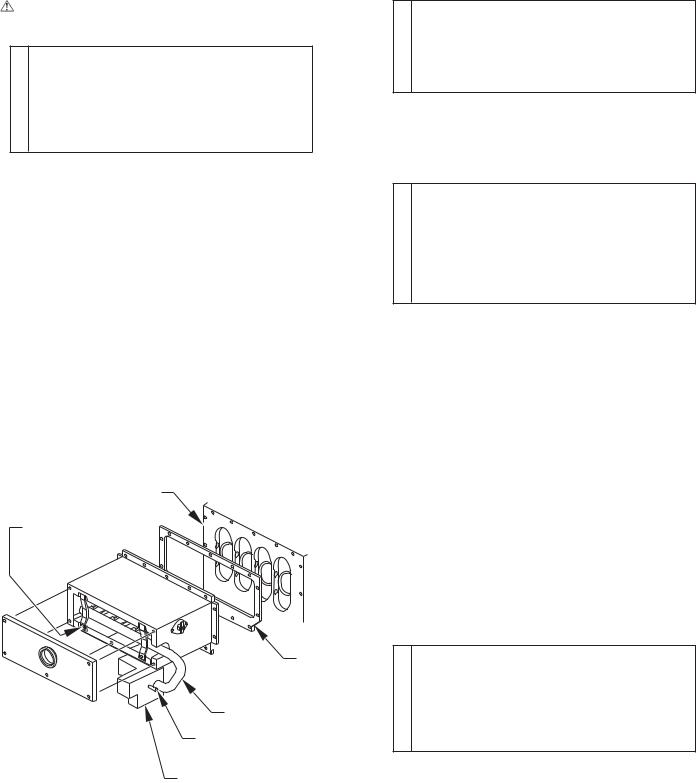

7.Remove screws that secure manifold to burner box. (See Fig. 6.)

NOTE: Do not remove burner box from cell panel.

8.Remove manifold, orifices, and gas valve as 1 assembly.

9.Remove screws attaching burner assembly in burner box.

10.Remove burner assembly from burner box.

NOTE: All burners are attached to burner bracket and can be removed as 1 assembly.

11.Clean burners with soft brush and vacuum.

12.Reinstall manifold, orifice, and gas valve assembly in burner box. Ensure manifold seal grommet is installed properly and burners fit over orifices.

13.Reconnect wires to gas valve. Refer to furnace wiring diagram for proper wire location.

CELL

PANEL

MANIFOLD

MOUNTING

SCREWS

GASKET

MANIFOLD

GAS VALVE

REGULATOR

FITTING

WARNING: FIRE, EXPLOSION, UNIT DAMAGE HAZARD

Failure to follow this warning could result in property damage, personal injury, or death.

Gas valve switch MUST be facing forward or tilted slightly.

16.Replace burner box cover.

17.Turn on gas and electrical supplies to furnace.

18.Check for gas leaks.

WARNING: FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result in serious injury, death or property damage.

Never test for gas leaks with an open flame. Use a commercially available soap solution made specifically for the detection of leaks to check all connections. A fire or explosion may result causing property damage, personal injury or loss of life.

19. Replace main furnace door.

IV. CLEANING HEAT EXCHANGERS

The following items should be performed by a qualified service technician.

A. Primary Heat Exchangers

If the heat exchangers get an accumulation of light dirt or dust on the inside, they may be cleaned by the following procedure:

NOTE: If the heat exchangers get a heavy accumulation of soot and carbon, both the primary and secondary heat exchangers should be replaced rather than trying to clean them thoroughly due to their intricate design. A build-up of soot and carbon indicates that a problem exists which needs to be corrected, such as improper adjustment of manifold pressure, insufficient or poor quality combustion air, improper vent termination, incorrect size or damaged manifold orifice(s), improper gas, or a restricted heat exchanger (primary or secondary). Action must be taken to correct the problem.

1.Turn off gas and electrical supplies to furnace.

2.Remove main furnace door.

→CAUTION: ELECTRICAL SHOCK AND UNIT DAMAGE HAZARD

Failure to follow this caution may result in minor personal injury or furnace component damage.

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and hazardous operation.

GAS |

3. |

Disconnect wires or connectors to flame rollout switch, gas |

|

CONTROL |

|||

|

valve, igniter, and flame sensor. |

||

VALVE |

|

||

A02312 |

4. |

Disconnect combustion-air intake pipe from intake housing. |

|

Fig. 6—Burner Box Assembly |

5. |

Remove the pressure switch tube from intake housing. |

|

|

—5— |

|

6.Remove screws attaching intake housing to burner box, and rotate intake housing away from burner box for removal.

7.Using backup wrench, disconnect gas supply pipe from furnace gas control valve.

8.Disconnect pressure tubing from gas valve.

9.Remove 2 screws attaching top filler panel and rotate upwards to gain access to screws attaching burner box to cell panel.

10.Remove screws attaching burner box to cell panel. (See Fig. 6.)

NOTE: Burner box cover, manifold, gas valve, and burner assembly should be removed as 1 assembly.

11.Clean heat exchanger openings with a vacuum and a soft brush. (See Fig. 7.)

NOTE: After cleaning, inspect the heat exchangers to ensure they are free of all foreign objects that may restrict flow of combustion products.

PRIMARY HX

INLET OPENINGS

A96305

Fig. 7—Cleaning Inlet Openings of Primary Heat

Exchangers

12.Reverse items 4 through 10 for reassembly.

→CAUTION: UNIT MAY NOT OPERATE

Failure to attach this ground wire to an adequate casing

ground may cause the furnace control to lock out.

The ground wire from the gas valve MUST be attached to the burner box attachment screw.

NOTE: Be sure burner box gasket is installed between burner box and cell panel. (See Fig. 6.) If gasket is damaged, replace it. NOTE: Inspect combustion-air intake housing. If foamed gasket was removed, check for any damage. If gasket is damaged in any way, it must be repaired. To repair, remove damaged gasket section, apply sealant releasing agent such as PAM cooking spray or equivalent (must not contain corn or canola oil, aromatic or halogenated hydrocarbons or inadequate seal may occur) to burner box and apply a small bead of G.E. RTV 162, G.E. RTV 6702, or Dow-Corning RTV 738 sealant to edge of combustion-air intake housing. (See Fig. 8.)

13.Refer to furnace wiring diagram and reconnect wires to flame rollout switch, gas valve, igniter, and flame sensor.

14.Reconnect pressure switch tubes to gas valve and intake housing. Refer to tube routing label on main furnace door for proper tube location. (See Fig. 9.) Be sure tubes are not kinked.

—6—

RTV

PAM

A93087

Fig. 8—Combustion-Air Intake Housing Gasket Repair

15.Turn on gas and electrical supplies to furnace.

16.Check furnace operation through 2 complete heat operating cycles. Look through sight glass in burner enclosure to check burners. Burner flames should be clear blue, almost transparent. (See Fig. 10.)

17.Check for gas leaks.

WARNING: FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result in serious injury, death or property damage.

Never test for gas leaks with an open flame. Use a commercially available soap solution made specifically for the detection of leaks to check all connections. A fire or explosion may result causing property damage, personal injury or loss of life.

18.Replace main furnace door.

B. Secondary Heat Exchangers

NOTE: The condensing side (inside) of the secondary heat exchangers CANNOT be serviced or inspected. A small number of bottom outlet openings can be inspected by removing the inducer assembly. See Flushing Collector Box and Drainage System section for details on removing inducer assembly.

V. FLUSHING COLLECTOR BOX AND DRAINAGE SYSTEM

1.Turn off gas and electrical supplies to furnace.

2.Remove main furnace door.

3.Disconnect inducer motor and pressure switch wires or connectors.

4.Disconnect pressure switch tubes.

5.Disconnect vent pipe from inducer housing outlet by loosening coupling clamp on inducer outlet.

6.Disconnect drain tube from inducer housing. (See Fig. 8.)

7.Remove inducer housing assembly by removing 4 bolts attaching assembly to cell panel.

8.Flush inside of collector box with water until discharge from condensate trap is clean and runs freely.

NOTE: Ensure the drain tube disconnected from the inducer housing is higher than the collector box opening or water will flow out tube.

9.Inspect inside area of collector box for any pieces of foreign materials and remove if present.

Loading...

Loading...