Bryant 581A-B User Manual

COMMERCIAL |

580F, 579F, 581A/B |

|

DuraPac and |

||

SINGLE PACKAGE ROOFTOP UNITS |

||

DuraPac Plus Series |

||

GAS HEATING/ELECTRIC COOLING UNITS |

||

|

Sizes 036-300 |

|

|

3 to 25 Tons |

|

|

|

|

50-1242f |

|

579F180-216 |

48-910df |

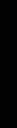

SIZES 036-073 |

50-1214df |

|

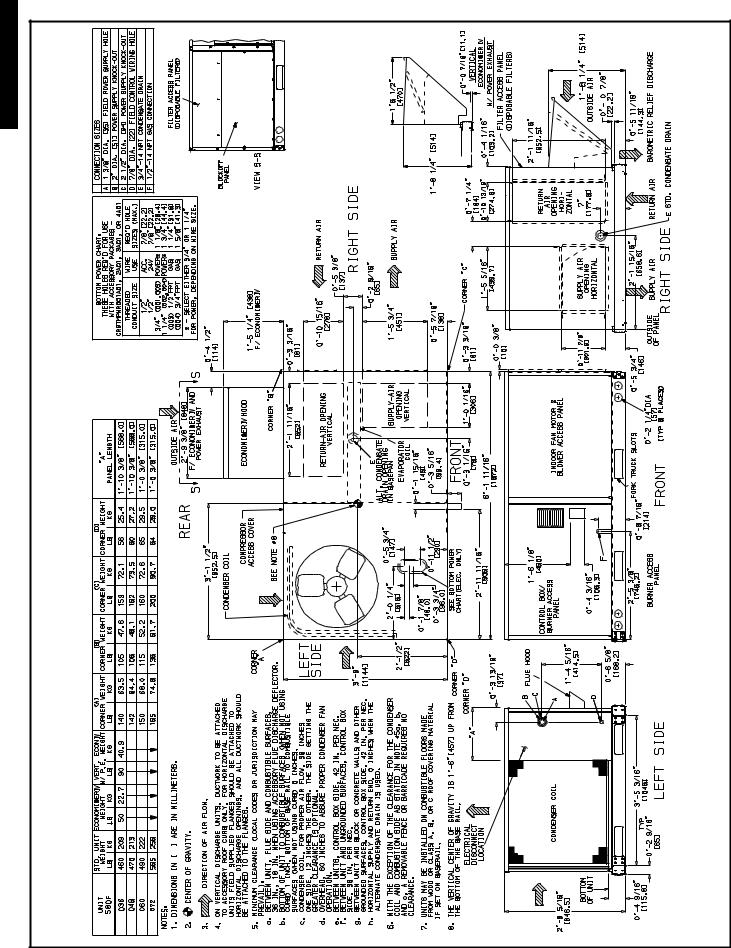

SIZES 090-151 |

|

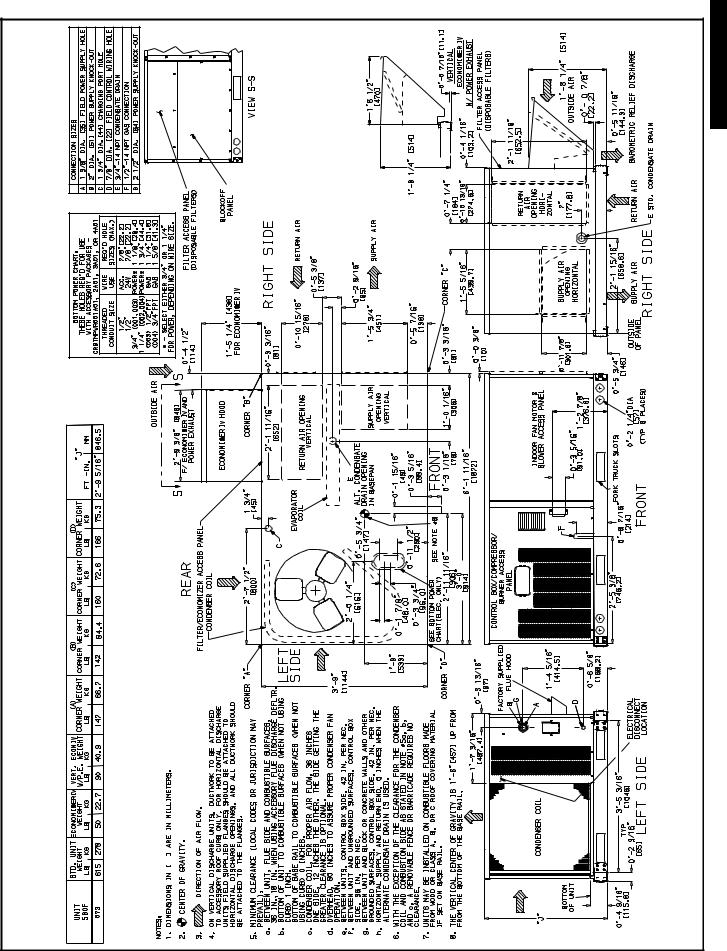

581A155,180 |

|

|

|

||

|

|

|

580F180,210 |

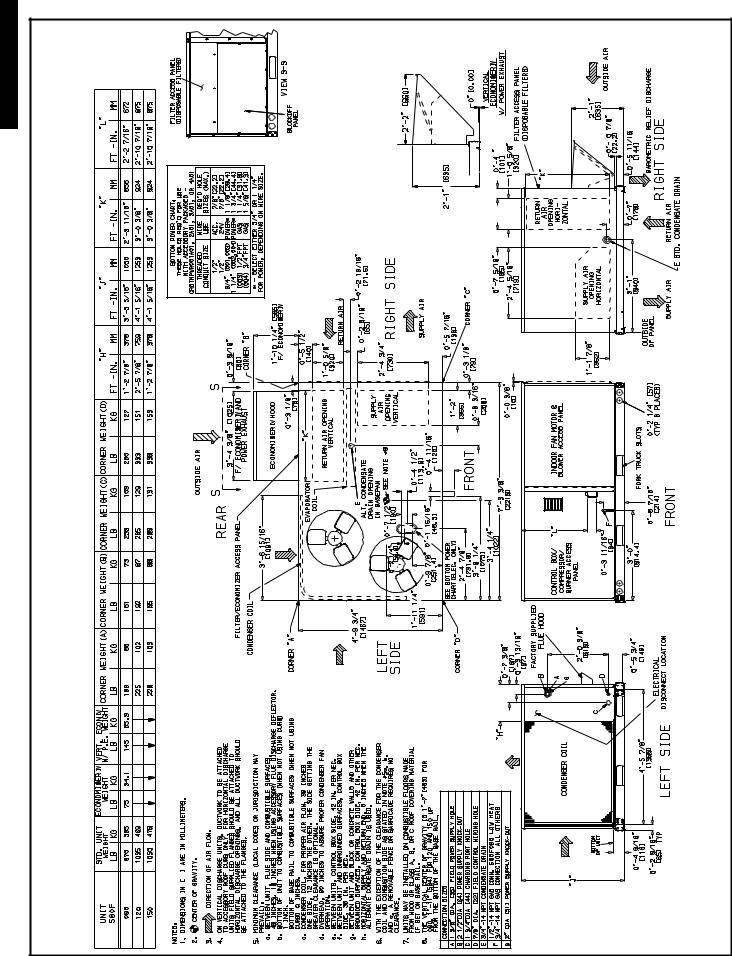

581A210-300 |

a48-8207 |

580F240 |

a48-5997 |

580F300 |

|

|

579F240-300 |

48-831df |

|

Standard efficiency units (580F072, 090, 120, 150 and 579F180-300) are available. Standard efficiency units (580F036-060, 073, 091,103,121,151, and 180-300) that meet ASHRAE 90.1-04 minimum energy efficiency requirements are also available. High efficiency units (581B036-150 and 581A155-300) well exceed ASHRAE 90.1-04 energy efficiency requirements and must comply with Energy Star high efficiency requirements. Gas heating with electric cooling rooftops offer:

•Pre-painted galvanized steel cabinet for long life and quality appearance

•Commercial strength base rails with built-in rigging capability

•Convertible design for vertical or horizontal supply/return (036-151 and 210-300 only)

•Non-corrosive, sloped condensate drain pan, meets ASHRAE 62 (IAQ)

•Two-inch return-air filters

•A wide assortment of factory-installed options available, including high-static drives that provide additional performance range

•Factory-installed optional gear driven EconoMi$er IV (vertical return for sizes 036-151 only) for use with standard rooftop unit controls (includes CO2 sensor control capability)

•Factory-installed optional gear driven EconoMi$er2 (vertical return only) for use with third party DDC controls (includes 4 to 20 mA actuator for demand control ventilation)

•Perfect Humidity™ dehumidification package (581B036-150 only)

•Hot gas reheat dehumidification package (581A181-300 only)

Heat Options

•Exclusive integrated gas control board with diagnostics

•Alumagard™ heat exchanger coating

•Induced-draft fan for gas combustion

•Tubular, dimpled heat exchangers

•Natural gas

•LP conversion kits

•Low NOX (size 036-060 only)

•Optional stainless steel heat exchangers.

FEATURES/BENEFITS

Every compact one-piece unit arrives fully assembled, charged, tested, and ready to run.

GAS HEAT MODELS — All ignition components are contained in the compact IGC (integrated gas controller) which is easily accessible for servicing. The IGC control board, designed and manufactured exclusively for Bryant rooftop units, provides built-in diagnostic capability. An LED (light-emitting diode) simplifies troubleshooting by providing visual fault notification and system status confirmation.

The IGC also contains an exclusive anti-cycle protection for gas heat operation. After 4 continuous cycles on the unit hightemperature limit switch, the gas heat operation is disabled, and an error code is issued. This feature greatly improves reliability of the rooftop unit.

The IGC also contains burner control logic for accurate and dependable gas ignition. The LED is visible without removing the unit control box access panel. This LED fault-notification system reduces service person troubleshooting time and minimizes service costs. The IGC also maximizes heating efficiency by controlling evaporator-fan on and off delays.

Tubular, dimpled gas heat exchangers optimize heat transfer for improved efficiency. The tubular design permits hot gases to make multiple passes across the path of the supply air. The dimpled design creates a turbulent gas flow to maximize heating efficiency.

Form No. PDS 580F.36.3

TABLE OF CONTENTS

Page

Features/Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Model Number Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . 5-7

ARI Capacity Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . 16-19

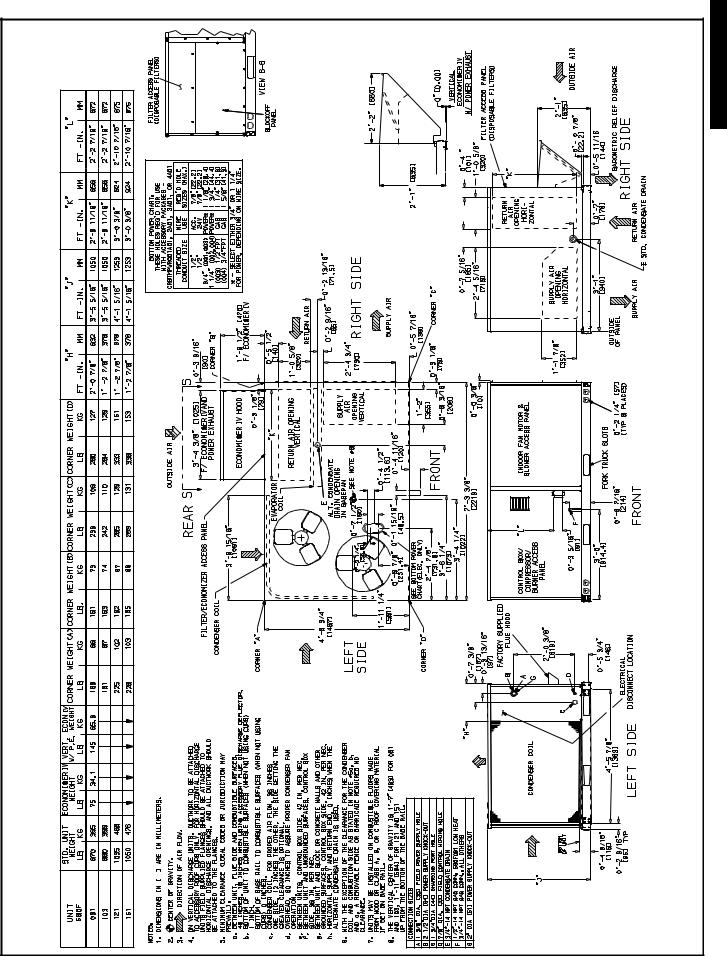

580F036-151

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-25 Base Unit Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-29 Accessory Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 30,31 Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-74 Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75-78 Typical Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . 79-81 Typical Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

581B036-150

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83-86 Base Unit Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 87,88 Accessory Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 89,90 Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91 Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92-132 Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133,134 Typical Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . 135-137 Typical Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Guide Specifications (036-151 Size Units) . . . . . . . . 139-143

579F180-300

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144,145 Base Unit Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . 146,147 Accessory Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 148-150 Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151 Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152-165 Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166 Typical Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . 167-170 Typical Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . .171

580F180-300

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172,173 Base Unit Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . 174-176 Accessory Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 177-180 Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181 Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182-191 Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .192 Typical Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . 193-195 Typical Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . .196

581A155-300

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197-200 Base Unit Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . 201,202 Accessory Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 203-206 Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207 Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208-243 Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244-246 Typical Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . 247,248 Typical Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . .249

Guide Specifications (155-300 Size Units) . . . . . . . . 250-258

Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259-262

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263-266

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .267

FEATURES/BENEFITS (cont)

The efficient in-shot burners and all ignition components are contained in an easily removable, compact assembly.

The California Air Quality Management Districts NOx requirement of 40 nanograms/joule or less is met on 036-060 size Low NOx models.

The extra thick Alumagard™ heat exchanger coating provides corrosion resistance and ensures long life (optional stainless steel heat exchangers are available).

The unsightly appearance of flue stacks is eliminated and the effects of wind on heating operations are diminished by the induced draft combustion system. The inducer fan draws hot combustion gas through the heat exchanger at the optimum rate for the most effective heat transfer. The heat exchanger operates under negative pressure, preventing flue gas leakage into the indoor supply air.

During the heating mode, the evaporator-fan relay automatically starts the evaporator fan after the heat exchanger warms up to a suitable temperature. The 30-second fan delay prevents cold air from entering the supply duct system when the conditioned space is calling for heat to maximize efficiency.

The direct-spark ignition system saves operating expense when compared to pilot ignition systems. No crossover tube is required, therefore no sooting or pilot fouling problems can occur.

All standard units are designed for natural gas, but an accessory LP (liquid propane) conversion kit is available.

All units have a flame rectification sensor to quickly sense the burner flame and ignite burners almost immediately. Fast shutdown is a certainty since the sensor reacts quickly to any flame outage or system failure. In the event of a shutdown, an error code is issued at the IGC board.

Safety is also assured due to the heating safety controls which will shut down the unit if there is a problem. If excessive temperatures develop, limit switches shut off the gas valve. After 4 continuous short cycles of the high-temperature limit switch, the IGC board locks out the gas heat cycle to prevent any further short cycles. This safety feature is provided exclusively on Bryant rooftop units. The rollout switch also deenergizes the gas valve in the event of a flame rollout.

QUIET, EFFICIENT OPERATION AND DEPENDABLE PERFORMANCE — Compressors have vibration isolators for quiet operation. Efficient fan and motor design permits operation at low sound levels.

Unit sizes 090-300 offer lower utility costs through part-load operation using 2 or 3 stages of cooling.

Quiet and efficient operation is provided by belt-driven evaporator fans (standard on all units over 5 tons). The belt-driven evaporator-fan is equipped with variable-pitch pulleys which allow adjustment within the rpm ranges of the factory-supplied pulleys.

Increased operating efficiency is achieved through computerdesigned coils featuring staggered internally enhanced copper tubes. Fins are ripple-edged for strength, lanced, and double waved for higher heat transfer.

DURABLE, DEPENDABLE CONSTRUCTION — Designed for durability in any climate, the weather-resistant cabinets are constructed of galvanized steel and bonderized, and all exterior panels are coated with a prepainted baked enamel finish. The paint finish is non-chalking, and is capable of withstanding ASTM (American Society for Testing and Materials) B117 500-hour Salt Spray Test. All internal cabinet panels are primed, permitting longer life and a more attractive appearance for the entire unit.

In addition, all size 036-151 units are designed with a single, continuous top piece to eliminate any possible leaks at seams or gasketing. Totally enclosed condenser-fan motors and permanently lubricated bearings provide additional unit dependability.

EASY INSTALLATION AND CONVERSION

All Units are Shipped in the Vertical Duct Configuration for fit-up to standard roof curbs. The contractor can order and install the roof curb early in the construction stage, before decisions on size requirements are made.

All units feature a base rail design with forklift slots and rigging holes for easier maneuvering. Durable packaging protects all units during shipment and storage.

2

FEATURES/BENEFITS (cont)

The units can be easily converted from a vertical to a horizontal duct configuration by relocating the panels supplied with the unit (size 036-150 only).

To Convert 036-151 Units from vertical to horizontal discharge, simply relocate 2 panels. The same basic unit can be used for a variety of applications and can be quickly modified at the jobsite.

To Convert 155-300 Units from vertical to horizontal discharge, use the optional horizontal supply/return adapter roof curb (581A155,180 and 579F/580F180-300) or accessory conversion kit (581A210-300). Please note that 581A210-300 units are available from the factory configured for horizontal supply/return.

Convenient Duct Openings in the unit basepans permit side- by-side or concentric duct connections (see Application data section) without requiring internal unit modification.

NOTE: On units using horizontal supply and return, the accessory barometric relief or power exhaust MUST be installed on the return ductwork.

Thru-The-Bottom Service Connection Capability comes standard with the rooftop unit to allow power and control wiring and gas connections to be routed through the unit’s basepan, thereby minimizing roof penetrations (to prevent water leaks). (Thru-the-bottom gas connection requires thru-the-bottom accessory kit.) Power, gas and control connections are made on the same side of the unit to simplify installation.

The Non-Corrosive Sloped Condensate Drain Pan (Size 036-150) permits either an external horizontal side condensate drain (outside the roof curb) or an internal vertical bottom drain (inside the roof curb). Both options require an external, field-supplied P-trap.

Standard 2-in. Throwaway Filters are easily accessed through a removable panel located above the air intake hood. No tools are required to change unit filters.

Belt-Driven Evaporator-Fan Motors (optional on 580F units under 6 tons) allow maximum on-site flexibility without changing motors or drives.

Low Voltage Wiring Connections are easily made thanks to the large terminal board which is located for quick, convenient access.

In addition, color-coded wires permit easy tracing and diagnostics.

PROVEN COMPRESSOR RELIABILITY — Design techniques feature computer-programmed balance between compressor, condenser, and evaporator. Bryant-specified hermetic compressors are equipped with compressor overcurrent and overtemperature protection to ensure dependability.

All units have Bryant’s exclusive Acutrol™ (036-150) or TXV (thermostatic expansion valve) metering device (155-300) which precisely controls refrigerant flow, preventing slugging and flood-back, while maintaining optimum unit performance. Refrigerant filter driers are standard.

INTEGRATED ECONOMIZERS AND OUTDOOR-AIR DAMPERS — Available as options or accessories, economizers and manual outdoor-air dampers introduce outdoor air which mixes with the conditioned air, improving indoor-air quality and often reducing energy consumption.

During a first stage call for cooling, if the outdoor-air temperature is below the economizer control changeover set point, the mixed-air sensor modulates the economizer outdoor-air damper open to take advantage of free cooling provided by the outside air. When second-stage cooling is called for, the compressor is energized in addition to the economizer. If the outdoor-air temperature is above the changeover set point, the first stage of compression is activated and the economizer damper stays at minimum position.

Accessory upgrade kits allow for control by differential dry-bulb temperature (outdoor vs return), outdoor air enthalpy changeover, or more precise differential enthalpy control.

Units can be equipped with different economizer options to meet specific controls applications. The factory-installed or field-installed EconoMi$er IV and EconoMi$er2 are available. The EconoMi$er IV is used with the standard rooftop unit controls and includes an industry standard, stand-alone, solid-state controller. The control can be used with a CO2 sensor for DCV (demand control ventilation) operation. For direct digital control (DDC) applications, the EconoMi$er2 can be operated using a third party control system. The EconoMi$er2 includes 4 to 20 mA actuator capability for demand control ventilation applications.

All economizers incorporate a parallel blade, gear-driven damper system for efficient air mixing and reliable control. In addition, the standard damper actuator includes a spring return to provide reliable closure on power loss. The economizers for sizes 036-151 are equipped with up to 100% barometric relief capability for high outdoor airflow operations. Economizers for unit sizes 036-151 are available, factory-installed, for vertical return only. Economizers for unit sizes 155-300 are compatible for vertical or horizontal return. An optional field-installed barometric relief package is available for size 155-300 units.

In addition, single-stage power exhaust is available as a fieldinstalled accessory for EconoMi$er IV to help maintain proper building pressure.

For units without economizer, year-round ventilation is enhanced by an optional manual outdoor-air damper. On 036150 units, a 25% or 50% manual damper is available as a fieldinstalled accessory. Unit sizes 155-300 are equipped with a manual 25% damper.

SERVICE OPTIONS (581B and 581A Units Only) — Servicing a rooftop unit has never been easier with the factory-installed service options for these rooftop units. These options include the following:

•Hinged access panels are provided for the filter/indoor-fan motor, compressors, evaporator fan, and control box areas. Quick access to major components is accomplished by simply unlatching and swinging open the various panels. Each hinged panel is permanently mounted to the unit, thereby eliminating the concern of a dropped or wind-blown panel puncturing delicate roof materials. The 4 extended access panels are also equipped with ‘‘tie back’’ retaining devices to hold the door in the open position while servicing the unit.

•An external, covered, 115-v Ground Fault Interrupt (GFI) receptacle is provided as a convenient power source for drills, lights, refrigerant recovery units, or other electrical service tools. A factory-supplied step down transformer is connected to the “load” side of the unit main power connection (size 036150). For sizes 155-300, connect the outlet to a field-supplied and properly fused branch circuit power supply.

•Slide out “motor-drive-blower” reduces service time (only on 581A210-300).

•An integral non-fused disconnect switch within the rooftop unit reduces installation time, labor and material costs. Safety is assured by an interlock which prevents access to the control box unless the switch is in the OFF position. In addition, the externally mounted handle incorporates power lockout capability to further protect service personnel.

3

FEATURES/BENEFITS (cont)

INDOOR-AIR QUALITY (IAQ) BEGINS WITH BRYANT ROOFTOPS — Sloped condensate pans minimize biological growth in rooftop units in accordance with ASHRAE (American Society of Heating, Refrigeration and Air Conditioning Engineers) Standard 62. Two-inch filters with optional dirty filter indicator switch provide for greater particle reduction in the return air. The face-split evaporator coils improve the dehumidification capability of standard units, maximize building humidity control.

Optional proportional reacting CO2 sensor is available with the EconoMi$er IV outdoor air damper option/accessory to aid the IAQ benefits.

PERFECT HUMIDITY™ ADAPTIVE DEHUMIDIFICATION SYSTEM (581B036-150 only) — Bryant’s Perfect Humidity adaptive dehumidification system is an all-inclusive factoryinstalled option that can be ordered with any 581B rooftop unit to meet the demand for providing a flexible and high performing solution to accommodate all of these design related issues. This system expands the envelope of operation of 581B rooftop products to provide unprecedented flexibility to meet year-round comfort conditions. The Perfect Humidity adaptive dehumidification system has the industry’s only dual dehumidification mode setting. The Perfect Humidity system includes two new modes of operation. The 581B rooftop coupled with the Perfect Humidity system is capable of operating in normal design cooling mode, subcooling mode, and hot gas reheat mode. Normal Design Cooling mode is when the unit will operate under its normal sequence of operation by cycling compressors to maintain comfort conditions. Subcooling mode will operate to satisfy part load type conditions when the space requires combined sensible and a higher proportion of latent load control. Hot Gas

Reheat mode will operate when outdoor temperatures diminish and the need for latent capacity is required for sole humidity control. Hot Gas Reheat mode will provide neutral air for maximum dehumidification operation.

EXCLUSIVE HOT GAS REHEAT DEHUMIDIFICATION PACKAGE (581A181-300) — The hot gas reheat dehumidification package is a result of recent advances by Bryant in controlling comfort levels. This factory-installed option significantly improves the dehumidification capability of the rooftop unit and helps control humidity levels in the building.

This option provides increased dehumidification by cooling the hot liquid refrigerant leaving the condenser coil. The hot gas reheat package consists of a subcooling coil located on the leaving-air side of the evaporator coil. The location of this coil in the indoor airstream enhances the latent capacity of the units by as much as 40%. Many buildings suffer from humidity damage or poor indoor air quality due to humid conditions. The improved latent capacity provided by the hot gas reheat option reduces the building’s humidity, eliminating potential property damage and making the space more comfortable.

The hot gas reheat option is the ideal IAQ option for hot and humid regions. The operation of the hot gas reheat package can be controlled by a field-installed, wall mounted humidistat or Thermidistat™ device. The circuit activates only when needed (using the accessory humidistat) as opposed to some dehumidification systems that operate continuously. The humidistat can be set for any humidity level between 20% and 80% relative humidity. The Thermidistat device can be set for any humidity level between 50% and 90% relative humidity.

4

|

|

|

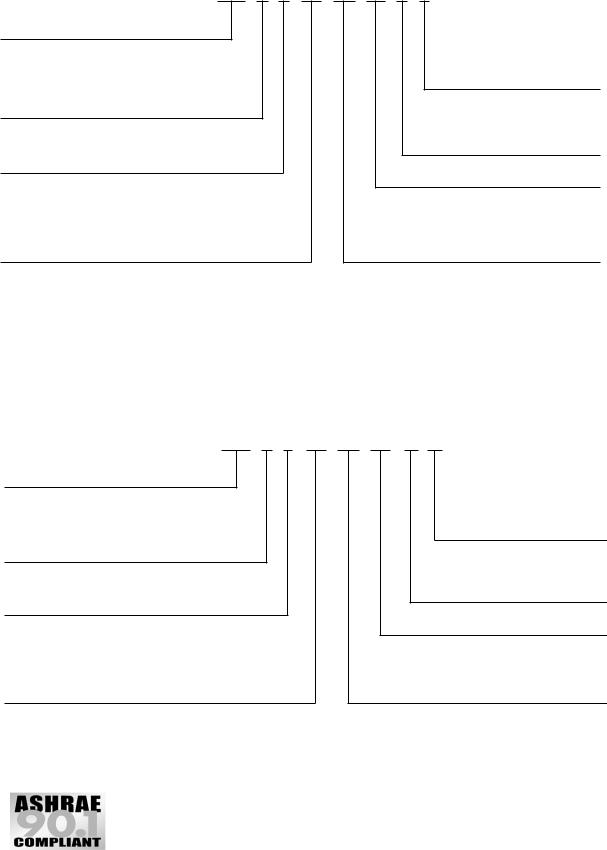

MODEL NUMBER NOMENCLATURE |

|

|

|

|

|

|

|||||||||||||||||||

|

|

580F036-150 (Standard and Medium Efficiency) 3 to 121/ Tons |

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

580F E V 060 |

120 N KB |

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

580F – Packaged Rooftop |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Factory-Installed Options Code |

||||||||||

|

Standard Efficiency |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Voltage Designation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

J – 208/230-1-60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P – 208/230-3-60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gas Heat Options |

|

|

|

|

|||

E – 460-3-60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

– Standard |

|

|

|

|

||

T – 575-3-60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

– Low NOx Unit |

|

|

|

|

||

Fuel Control Type/Heat Exchanger |

|

|

|

|

|

|

|

|

|

|

|

|

S |

– Stainless Steel Heat Exchanger |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

V – Natural Gas/Direct Spark Ignition |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

N – Low NOx Natural Gas/Direct Spark Ignition/Stainless |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Steel Heat Exchanger |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gas Heat Input (Btuh) |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Nominal Tons |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Standard Units |

Low NOx Units |

||||||

036 |

– 3 |

091 |

– 7-1/2 (Medium Efficiency) |

|

|

|

074 |

– 74,000 |

060 |

– |

60,000 |

|

||||||||||||||||

048 |

– 4 |

103 |

– 8-1/2 (Medium Efficiency) |

|

|

|

115 |

– 115,000 |

090 |

– |

90,000 |

|

||||||||||||||||

060 |

– 5 |

120 |

– 10 |

|

|

|

125 |

– 125,000 |

120 |

– 120,000 |

||||||||||||||||||

072 |

– 6 |

121 |

– 10 (Medium Efficiency) |

|

|

|

150 |

– 150,000 |

|

|

|

|

||||||||||||||||

073 |

– 6 (Medium |

150 |

– 12-1/2 |

|

|

|

180 |

– 180,000 |

|

|

|

|

||||||||||||||||

|

Efficiency) |

151 |

– 12-1/2 (Medium Efficiency) |

|

|

|

224 |

– 224,000 |

|

|

a48-8190 |

|||||||||||||||||

090 |

– 7-1/2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

250 |

– 250,000 |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: The example model number 580FEV060120NKB designates a 5-ton 460-3-60 volt Low NOx, gas/electric rooftop unit with 120,000 Btuh natural gas heat, EconoMi$er2 and alternate drive. Low NOx units must show the “N” designation in the model number.

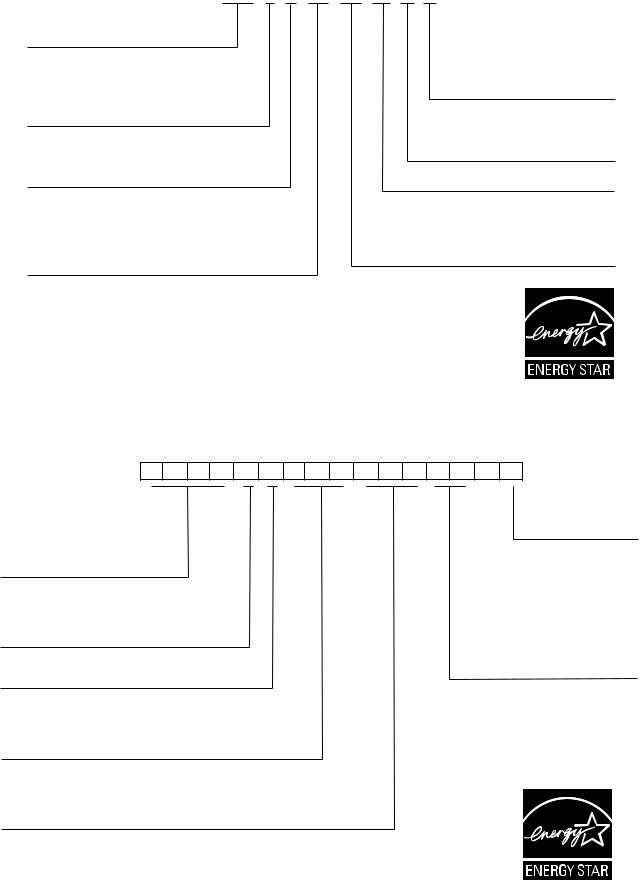

MODEL NUMBER NOMENCLATURE 581B036-150 (High Efficiency) — 3 to 121/2 Tons

581B E V 060 120 N DA

581B – Single Package

High-Efficiency

Gas/Electric Unit

Voltage Designation

E – 460-3-60

J – 208/230-1-60

P – 208/230-3-60

T – 575-3-60

Fuel Control Type/Heat Exchanger

V – Natural Gas/Direct Spark Ignition

Nominal Tons |

|

||

036 – |

3 |

090 |

– 7-1/2 |

048 – |

4 |

102 |

– 8-1/2 |

060 – |

5 |

120 |

– 10 |

072 – |

6 |

150 |

– 12-1/2 |

*Refer to the Trade Prices for ordering codes of factory-installed options.

Factory-Installed Options*

Gas Heat Options

A – Standard

N – Low NOx Unit

S – Stainless Steel Heat Exchanger

Gas Heat Input (Btuh) |

|

|

|

|||

072 |

– |

72,000 |

180 |

– |

180,000 |

|

115 |

– |

115,000 |

224 |

– |

224,000 |

|

125 |

– |

125,000 |

250 |

– |

250,000 |

|

150 |

– |

150,000 |

|

|

|

|

Low NOx |

California Compliant 3 Phase |

|||||

060 |

– |

60,000 |

071 |

– |

72,000 |

|

090 |

– |

90,000 |

114 – |

115,000 |

a48-8191 |

|

120 |

– |

120,000 |

149 |

– |

150,000 |

|

The Example model number 581BEV060120NDA designates a high efficiency 5-ton 460-3-60 volt Low NOx gas/electric roof top unit with 120,000 Btuh natural gas heat and EconoMi$er IV. Low NOx units must show an “N” in the nomenclature.

5

MODEL NUMBER NOMENCLATURE — 579F180-300

579F E V 180 230 – – C B

579F – Single-Package

Standard-Efficiency Gas/Electric Unit

Voltage Designation

E – 460-3-60

P – 208/230-3-60

T – 575-3-60

Fuel and Control Type

V – Natural Gas/Electric Relight Pilot

Nominal Tons

180 – 15 Tons

216 – 18 Tons

240 – 20 Tons

300 – 25 Tons

NOTES:

Fan Drive Option

(Standard Motor)

B – Standard Low-Medium

Fan Drive Static

Capability

D – Alternate High Fan

Drive Static Capability

Factory-Installed Outdoor-Air

and Other Upgrade Options

C – EconoMi$er IV

H – Manual Outdoor-Air Damper

Design Series Code

Gas Heat Input (Btuh) |

|

||

230 |

– 230,000 |

|

|

275 |

– 275,000 |

|

|

300 |

– 300,000 |

a48-8192 |

|

360 |

– 360,000 |

||

|

|||

1.All indoor-fan motors 5 hp and larger meet the minimum efficiency requirements as established by the Energy Policy Act of 1992 (EPACT) effective October 24, 1997.

2.The example model number 579FEV180230--CB designates a 15-ton 460-3-60 volt gas/ electric rooftop unit with 230,000 Btuh natural gas heat input, EconoMi$er IV, and the standard low-medium fan drive static capability.

MODEL NUMBER NOMENCLATURE 580F180-300

580F E V 180 275 – – C B

580F – Single Package

Medium-Efficiency Gas/Electric Unit

Voltage Designation

E – 460-3-60

P – 208/230-3-60

T – 575-3-60

Fuel and Control Type

V – Natural Gas/Electric Relight Pilot

Nominal Tons

180 – 15 Tons

210 – 18 Tons

240 – 20 Tons

300 – 25 Tons

Fan Drive Position

(Standard Motor)

B – Standard Low-Medium

Fan Drive Static

Capability

D– Alternate High Fan Drive Static Capability

Factory-Installed Outdoor-Air

and Other Upgrade Options

C – EconoMi$er IV

H – Manual Outdoor-Air Damper

Design Series Change

Gas Heat Input (Btuh) |

|

||

275 |

– 275,000 |

|

|

300 |

– |

300,000 |

a48-8193 |

360 |

– |

360,000 |

|

NOTES:

1.All indoor-fan motors 5 hp and larger meet the minimum efficiency requirements as established by the Energy Policy Act of 1992 (EPACT) effective October 24, 1997.

2.The example model number 580FEV180275--CB designates a 15-ton 460-3-60 volt gas/ electric rooftop unit with 275,000 Btuh natural gas heat input, EconoMi$er IV, and the standard low-medium fan drive static capability.

6

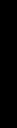

MODEL NUMBER NOMENCLATURE 581A155, 180, 181 — 13 to 15 Tons

581A E |

V 180 230 – – C B |

|

581A – Single Package |

Fan Drive Position |

|

High Efficiency Gas/Electric Unit |

(Standard Motor) |

|

|

B – Standard Low-Medium |

|

|

Fan Drive Static |

|

|

Capability |

|

Voltage Designation |

D – Alternate High Fan |

|

Drive Static Capability |

|

|

E – 460-3-60 |

|

|

|

|

|

P – 208/230-3-60 |

|

|

T – 575-3-60 |

Factory-Installed Outdoor-Air |

|

|

||

|

and Other Upgrade Options |

|

|

C – EconoMi$er IV |

|

|

H – Manual Outdoor-Air Damper |

|

Fuel and Control Type |

|

|

V – Natural Gas/Electric Relight Pilot |

Design Series Change |

|

|

|

|

|

Gas Heat Input (Btuh) |

|

Nominal Tons |

230 – 230,000 |

|

275 – 275,000 |

a48-8194 |

|

155 – 13 Tons |

300 – 300,000 |

|

180 – 15 Tons |

360 – 360,000 |

|

181 – 15 Tons with hot gas reheat* |

|

|

*See pages 213 and 214 for cooling capacity tables for 5581A181 unit. For all other data, contact application engineering.

NOTE: All indoor-fan motors 5 hp and larger meet the minimum efficiency requirements as established by the Energy Policy Act of 1992 (EPACT) effective October 24, 1997.

The example model number: 581AEV180230--CB designates a 15 ton 460-3-60 high efficiency gas/electric rooftop unit with 230,000 Btuh natural gas input, EconoMi$er IV and standard, low-medium fan drive static capability.

MODEL NUMBER NOMENCLATURE 581A210-300 — 18 to 25 Tons

5 8 1 A E A 2 1 0 2 5 0 – – A A

|

|

|

|

|

|

|

Factory-Installed |

581A – High Efficiency Rooftop |

|

|

|

|

|

Options* |

|

|

|

|

|

|

|

||

Units Gas Heating/ |

|

|

|

|

|

|

|

Electric Cooling |

|

|

|

|

|

|

|

Constant Volume |

|

|

|

|

|

|

|

Voltage Designation |

|

|

|

|

Coil Protection Options* |

||

|

|

|

|

|

|

|

|

E – 460-3-60 |

|

|

|

|

|

|

|

P – 208/230-3-60 |

|

|

|

|

|

|

|

T – 575-3-60 |

|

|

|

|

|

|

|

Indoor Fan, Orientation, Hinged Doors |

Design Series Code |

||||||

Return/Supply Smoke Detector Options* |

|

|

|

|

|

|

|

Nominal Cooling Capacity |

|

|

|

|

|

|

|

210 – 18 Tons |

|

|

|

|

|

|

a48-8208 |

240 – 20 Tons |

|

|

|

|

|

|

|

300 – 25 Tons |

|

|

|

|

|

|

|

Gas Heat Input (Btuh) |

|

|

|

|

|

|

|

250 – 250,000 |

25S-- 250,000 w/SS Heat Exchanger |

|

|

|

|

|

|

365 – 365,000 |

36S-- 365,000 w/SS Heat Exchanger |

|

|

|

|

|

|

400 – 400,000 |

40S-- 400,000 w/SS Heat Exchanger |

|

|

|

|

|

|

SS — Stainless Steel *Refer to unit price pages.

7

ARI* CAPACITY RATINGS — 580F036-151

|

|

NOMINAL |

STANDARD |

|

NET COOLING |

TOTAL |

|

|

|

SEER† |

|

SOUND |

|||||

UNIT 580F |

|

CAPACITY |

|

|

|

|

|

|

|

RATING |

|||||||

TONS |

CFM |

|

|

kW |

|

Belt Drive |

|

Direct Drive |

|

||||||||

|

|

|

(Btuh) |

|

|

|

|

(dB) |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

036 |

|

3 |

|

1200 |

|

35,000 |

4.0 |

|

10.0 |

|

|

9.7 |

|

81 |

|||

048 |

|

4 |

|

1600 |

|

47,000 |

5.3 |

|

10.0 |

|

|

9.7 |

|

81 |

|||

060 |

|

5 |

|

2000 |

|

57,000 |

6.7 |

|

10.0 |

|

|

9.7 |

|

81 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

UNIT |

|

NOMINAL |

|

NET COOLING |

|

TOTAL |

|

|

|

|

|

SOUND |

|

|

|

||

|

|

CAPACITY |

|

|

|

EER |

|

RATING |

|

IPLV |

|||||||

580F |

|

TONS |

|

|

kW |

|

|

|

|

||||||||

|

|

(Btuh) |

|

|

|

|

|

|

|

(dB) |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

072 |

|

6 |

|

72,000 |

|

|

8.0 |

|

|

9.0 |

|

81 |

|

** |

|||

073 |

|

6 |

|

71,000 |

|

|

7.0 |

|

|

10.1 |

|

80 |

|

** |

|||

090 |

|

71/2 |

|

85,000 |

|

|

9.6 |

|

|

8.9 |

|

87 |

|

9.40 |

|||

091 |

|

71/2 |

|

88,000 |

|

|

8.7 |

|

|

10.1 |

|

82 |

|

10.5 |

|||

103 |

|

81/2 |

|

100,000 |

|

|

9.9 |

|

|

10.1 |

|

82 |

|

10.4 |

|||

120 |

|

10 |

|

117,000 |

|

|

13.0 |

|

|

9.0 |

|

88 |

|

9.40 |

|||

121 |

|

10 |

|

114,000 |

|

|

11.3 |

|

|

10.1 |

|

84 |

|

11.0 |

|||

150 |

|

121/2 |

|

144,000 |

|

|

16.0 |

|

|

9.0 |

|

87 |

|

9.20 |

|||

151 |

|

121/2 |

|

136,000 |

|

|

14.3 |

|

|

9.5 |

|

86 |

|

9.70 |

|||

|

|

LEGEND |

dB |

— |

Sound Levels (decibels) |

db |

— |

Dry Bulb |

EER |

— |

Energy Efficiency Ratio |

IPLV |

— |

Integrated Part-Load Values |

SEER — |

Seasonal Energy Efficiency Ratio |

|

wb |

— |

Wet Bulb |

*Air Conditioning and Refrigeration Institute.

†Applies only to units with capacity of 65,000 Btuh or less. **The IPLV applies only to two-stage cooling units.

NOTES:

1.Rated in accordance with ARI Standards 210/240 (for sizes 036120) or 360, (for size 150 and 151) and 270.

2.ARI ratings are net values, reflecting the effects of circulating fan heat.

3.Ratings are based on:

Cooling Standard: 80 F db, 67 F wb indoor entering-air temperature and 95 F db air entering outdoor unit.

IPLV Standard: 80 F db, 67 F wb indoor entering-air temperature and 80 F db outdoor entering-air temperature.

4.All 580F036, 048, 060, 073, 091, 103, 121, 151 units are in compliance with ASHRAE 90.1-1999 Energy Standard for minimum SEER and EER requirements. Refer to state and local codes or visit the following website: http://solstice.crest.org/efficiency/bcap to determine if compliance with this standard pertains to a given geographical area of the United States.

5.All 581B036-120 units are in compliance with Energy Star high efficiency requirements.

HEATING CAPACITIES AND EFFICIENCIES (Standard-Efficiency Units) — 580F036-151

208/230-1-60 — SINGLE-STAGE GAS HEAT

UNIT |

INPUT |

OUTPUT |

TEMPERATURE |

MINIMUM HEATING |

|

EFFICIENCY |

|

580F |

CAPACITY |

CAPACITY |

RISE (°F) |

AIRFLOW (CFM) |

AFUE (%) |

|

Steady State (%) |

036074 |

74,000 |

57,000 |

25-55 |

1004 |

80 |

|

80 |

036115 |

115,000 |

89,000 |

55-85 |

1002 |

80 |

|

80 |

048074 |

74,000 |

57,000 |

25-55 |

1004 |

80 |

|

80 |

048115 |

115,000 |

91,000 |

35-65 |

1327 |

80 |

|

80 |

048150 |

150,000 |

118,000 |

50-80 |

1396 |

80 |

|

80 |

060074 |

74,000 |

57,000 |

25-55 |

1004 |

80 |

|

80 |

060115 |

115,000 |

91,000 |

35-65 |

1327 |

80 |

|

80 |

060150 |

150,000 |

118,000 |

50-80 |

1314 |

80 |

|

80 |

208/230-1-60 — SINGLE-STAGE GAS HEAT — LOW NOx

UNIT |

INPUT |

OUTPUT |

TEMPERATURE |

MINIMUM HEATING |

|

EFFICIENCY |

|

580F |

CAPACITY |

CAPACITY |

RISE (°F) |

AIRFLOW (CFM) |

AFUE (%) |

|

Steady State (%) |

036060N |

60,000 |

49,000 |

20-50 |

910 |

80 |

|

80 |

036090N |

90,000 |

73,000 |

30-60 |

1130 |

80 |

|

80 |

048060N |

60,000 |

49,000 |

20-50 |

910 |

80 |

|

80 |

048090N |

90,000 |

73,000 |

30-60 |

1130 |

80 |

|

80 |

048120N |

120,000 |

98,000 |

40-70 |

1300 |

80 |

|

80 |

060060N |

60,000 |

49,000 |

20-50 |

910 |

80 |

|

80 |

060090N |

90,000 |

73,000 |

30-60 |

1130 |

80 |

|

80 |

060120N |

120,000 |

98,000 |

40-70 |

1300 |

80 |

|

80 |

8

ARI* CAPACITY RATINGS (cont)

HEATING CAPACITIES AND EFFICIENCIES (Standard Efficiency Units) — 580F036-151 (cont)

208/230/460-3-60 — SINGLE-STAGE GAS HEAT — LOW NOx

UNIT |

INPUT |

OUTPUT |

TEMPERATURE |

MINIMUM HEATING |

|

EFFICIENCY |

|

580F |

CAPACITY |

CAPACITY |

RISE (°F) |

AIRFLOW (CFM) |

AFUE (%) |

|

Steady State (%) |

036060N |

60,000 |

49,000 |

20-50 |

910 |

80 |

|

80 |

036090N |

90,000 |

73,000 |

30-60 |

1130 |

80 |

|

80 |

048060N |

60,000 |

49,000 |

20-50 |

910 |

80 |

|

80 |

048090N |

90,000 |

73,000 |

30-60 |

1130 |

80 |

|

80 |

048120N |

120,000 |

98,000 |

40-70 |

1300 |

80 |

|

80 |

060060N |

60,000 |

47,000 |

20-50 |

910 |

80 |

|

80 |

060090N |

90,000 |

73,000 |

30-60 |

1130 |

80 |

|

80 |

060120N |

120,000 |

98,000 |

40-70 |

1300 |

80 |

|

80 |

208/230, 460, 575-3-60 — 2-STAGE GAS HEAT

UNIT |

INPUT CAPACITY |

OUTPUT CAPACITY |

TEMPERATURE |

MINIMUM HEATING |

EFFICIENCY |

|||

580F |

1st Stage |

2nd Stage |

1st Stage |

2nd Stage |

RISE (°F) |

AIRFLOW (CFM) |

AFUE (%) |

Steady State (%) |

036115 |

82,000 |

115,000 |

65,600 |

92,000 |

55-85 |

1004 |

80 |

80 |

048150 |

120,000 |

150,000 |

96,000 |

120,000 |

50-80 |

1396 |

80 |

80 |

060150 |

120,000 |

150,000 |

96,000 |

120,000 |

50-80 |

1314 |

80 |

80 |

072150 |

120,000 |

150,000 |

96,000 |

120,000 |

50-80 |

1390 |

80 |

80 |

090180 |

120,000 |

180,000 |

96,000 |

144,000 |

35-65 |

2060 |

80 |

80 |

090224 |

180,000 |

224,000 |

144,000 |

179,200 |

45-75 |

2230 |

80 |

80 |

120180 |

120,000 |

180,000 |

90,000 |

144,000 |

35-65 |

2060 |

80 |

80 |

120224 |

180,000 |

224,000 |

144,000 |

179,200 |

35-65 |

2510 |

80 |

80 |

120250 |

200,000 |

250,000 |

160,000 |

200,000 |

40-70 |

2650 |

80 |

80 |

150224 |

180,000 |

224,000 |

144,000 |

179,200 |

35-65 |

2510 |

80 |

80 |

150250 |

200,000 |

250,000 |

160,000 |

200,000 |

40-70 |

2650 |

80 |

80 |

208/230, 460, 575-3-60 — SINGLE-STAGE GAS HEAT

UNIT |

INPUT |

OUTPUT |

TEMPERATURE |

MINIMUM HEATING |

EFFICIENCY |

|

580F |

CAPACITY |

CAPACITY |

(°F) |

AIRFLOW (CFM) |

AFUE (%) |

Steady State (%) |

036074 |

74,000 |

59,200 |

15-45 |

1220 |

80 |

80 |

048074 |

74,000 |

59,200 |

15-45 |

1220 |

80 |

80 |

048115 |

115,000 |

92,000 |

35-65 |

1320 |

80 |

80 |

060074 |

74,000 |

59,200 |

15-45 |

1220 |

80 |

80 |

060115 |

115,000 |

92,000 |

35-65 |

1320 |

80 |

80 |

072074 |

74,000 |

59,200 |

15-45 |

1220 |

80 |

80 |

072115 |

115,000 |

92,000 |

35-65 |

1320 |

80 |

80 |

090125, 091125 |

125,000 |

100,000 |

20-50 |

1860 |

80 |

80 |

103125 |

125,000 |

100,000 |

20-50 |

1860 |

80 |

80 |

LEGEND

AFUE — Annual Fuel Utilization Efficiency

HEATING CAPACITIES AND EFFICIENCIES (Medium-Efficiency Units) — 580F036-151

UNIT |

HEATING INPUT (Btuh) |

OUTPUT CAPACITY |

TEMPERATURE |

MINIMUM HEATING |

AFUE |

STEADY-STATE |

580F |

Stage 2/Stage 1 |

(Btuh) |

RISE (F) |

AIRFLOW (CFM) |

(%) |

EFFICIENCY (%) |

073074 |

—/ 74,000 |

59,200 |

25-55 |

1220 |

80.0 |

80.0 |

073115 |

—/115,000 |

92,000 |

35-65 |

1320 |

80.0 |

80.0 |

073150 |

150,000/120,000 |

120,000 |

50-80 |

1390 |

80.0 |

80.0 |

091125 |

—/125,000 |

100,000 |

20-50 |

1860 |

80.0 |

80.0 |

091180 |

180,000/120,000 |

144,000 |

35-65 |

2060 |

80.0 |

80.0 |

091224 |

224,000/180,000 |

179,200 |

45-75 |

2180 |

80.0 |

80.0 |

103125 |

—/125,000 |

100,000 |

20-50 |

1860 |

80.0 |

80.0 |

103180 |

180,000/120,000 |

144,000 |

35-65 |

2060 |

80.0 |

80.0 |

103224 |

224,000/180,000 |

179,200 |

45-75 |

2180 |

80.0 |

80.0 |

121180 |

180,000/120,000 |

144,000 |

35-65 |

2060 |

80.0 |

80.0 |

121224 |

224,000/180,000 |

179,200 |

35-65 |

2510 |

80.0 |

80.0 |

121250 |

250,000/200,000 |

200,000 |

40-70 |

2650 |

80.0 |

80.0 |

151224 |

224,000/180,000 |

179,200 |

35-65 |

2510 |

80.0 |

80.0 |

151250 |

250,000/200,000 |

200,000 |

40-70 |

2650 |

80.0 |

80.0 |

9

ARI* CAPACITY RATINGS — 581B036-150

UNIT |

NOMINAL |

COOLING |

TOTAL |

SEER† |

EER |

SOUND RATING |

IPLV |

|

581B |

TONS |

(Btuh) |

kW |

dB |

||||

|

|

|

||||||

036 |

3 |

36,000 |

3.21 |

13.0 |

11.20 |

76 |

** |

|

048 |

4 |

46,000 |

4.25 |

13.0 |

11.05 |

76 |

** |

|

060 |

5 |

61,000 |

5.55 |

13.0 |

11.00 |

80 |

** |

|

072 |

6 |

73,000 |

6.70 |

— |

11.00 |

80 |

** |

|

090 |

71/2 |

90,000 |

8.18 |

— |

11.00 |

82 |

11.6 |

|

102 |

81/2 |

103,000 |

8.90 |

— |

11.60 |

82 |

12.8 |

|

120 |

10 |

120,000 |

10.91 |

— |

11.00 |

84 |

11.4 |

|

150 |

121/2 |

138,000 |

14.40 |

— |

9.6 |

86 |

10.3 |

LEGEND

EER — Energy Efficiency Ratio

IPLV — Integrated Part-Load Value

SEER — Seasonal Energy Efficiency Ratio

*Air-Conditioning & Refrigeration Institute.

†Applies only to units with capacity of 65,000 Btuh or less. **The IPLV is not applicable to single-compressor units.

NOTES:

1.Rated in accordance with ARI Standard 210/240 (036-120 units) or 360 (150 units) and 270 (036-150 units).

2.Ratings are net values, reflecting the effects of circulating fan heat. Ratings are based on:

Cooling Standard: 80 F db, 67 wb indoor entering-air temperature and 95 F db outdoor entering-air temperature.

IPLV Standard: 80 F db, 67 F wb indoor entering-air temperature and 80 F db outdoor entering-air temperature.

|

|

|

|

Sizes 036-120 |

Sizes 150 |

||

|

Only |

|

Only |

3.All 581B036-150 units are in compliance with ASHRAE 90.1-1999 Energy Standard for minimum SEER and EER requirements. Refer to state and local codes or visit the following website: http://solstice.crest.org/efficiency/bcap to determine if compliance with this standard pertains to a given geographical area of the United States.

4.All 581B036-120 units are Energy Star certified.

HEATING CAPACITIES AND EFFICIENCIES — 581B036-150

208/230-1-60 — SINGLE-STAGE GAS HEAT

UNIT |

INPUT CAPACITY |

OUTPUT CAPACITY |

TEMPERATURE |

MINIMUM HEATING |

EFFICIENCY |

||

581B |

RISE (°F) |

AIRFLOW (CFM) |

AFUE (%) |

Steady State (%) |

|||

|

|

||||||

036072 |

72,000 |

58,000 |

25-55 |

1004 |

82.8 |

82.0 |

|

036115 |

115,000 |

90,000 |

55-85 |

1002 |

80.0 |

80.0 |

|

048072 |

72,000 |

58,000 |

25-55 |

1004 |

82.8 |

82.0 |

|

048115 |

115,000 |

90,000 |

35-65 |

1320 |

81.0 |

81.0 |

|

048150 |

150,000 |

118,000 |

50-80 |

1396 |

80.4 |

80.0 |

|

060072 |

72,000 |

58,000 |

25-55 |

1004 |

82.8 |

82.0 |

|

060115 |

115,000 |

92,000 |

35-65 |

1327 |

81.0 |

81.0 |

|

060150 |

150,000 |

118,000 |

50-80 |

1314 |

80.4 |

80.0 |

|

|

LEGEND |

|

|

|

|

|

|

AFUE — Annual Fuel Utilization Efficiency. |

|

|

|

|

|||

|

|

208/230-1-60 — SINGLE-STAGE GAS HEAT — LOW NOx |

|

|

|||

|

|

|

|

|

|

||

UNIT |

INPUT CAPACITY |

OUTPUT CAPACITY |

TEMPERATURE |

MINIMUM HEATING |

EFFICIENCY |

||

581B |

RISE (°F) |

AIRFLOW (CFM) |

AFUE (%) |

Steady State (%) |

|||

|

|

||||||

036060N |

60,000 |

50,000 |

20-50 |

930 |

80.2 |

81.2 |

|

036090N |

90,000 |

74,000 |

30-60 |

1150 |

81.0 |

81.4 |

|

048060N |

60,000 |

50,000 |

20-50 |

930 |

80.2 |

81.2 |

|

048090N |

90,000 |

74,000 |

30-60 |

1150 |

81.0 |

81.4 |

|

048120N |

120,000 |

101,000 |

40-70 |

1340 |

80.7 |

82.4 |

|

060060N |

60,000 |

50,000 |

20-50 |

930 |

80.2 |

81.2 |

|

060090N |

90,000 |

74,000 |

30-60 |

1150 |

81.0 |

81.4 |

|

060120N |

120,000 |

101,000 |

40-70 |

1340 |

80.7 |

82.4 |

|

LEGEND

AFUE — Annual Fuel Utilization Efficiency.

10

ARI* CAPACITY RATINGS (cont)

HEATING CAPACITIES AND EFFICIENCIES — 581B036-150(cont)

208/230/460-3-60 — SINGLE-STAGE GAS HEAT — LOW NOx

UNIT |

|

INPUT CAPACITY |

|

OUTPUT CAPACITY |

|

TEMPERATURE |

|

MINIMUM HEATING |

|

EFFICIENCY |

||||||||||

581B |

|

|

|

|

RISE (°F) |

|

|

AIRFLOW (CFM) |

|

AFUE (%) |

|

Steady State (%) |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

036060N |

60,000 |

|

|

|

50,000 |

|

|

|

|

20-50 |

|

|

930 |

|

80.2 |

81.2 |

||||

036090N |

90,000 |

|

|

|

74,000 |

|

|

|

|

30-60 |

|

|

1150 |

|

81.0 |

81.4 |

||||

048060N |

60,000 |

|

|

|

50,000 |

|

|

|

|

20-50 |

|

|

930 |

|

80.2 |

81.2 |

||||

048090N |

90,000 |

|

|

|

74,000 |

|

|

|

|

30-60 |

|

|

1150 |

|

81.0 |

81.4 |

||||

048120N |

120,000 |

|

|

|

101,000 |

|

|

|

|

40-70 |

|

|

1340 |

|

80.7 |

82.4 |

||||

060060N |

60,000 |

|

|

|

50,000 |

|

|

|

|

20-50 |

|

|

930 |

|

80.2 |

81.2 |

||||

060090N |

90,000 |

|

|

|

74,000 |

|

|

|

|

30-60 |

|

|

1150 |

|

81.0 |

81.4 |

||||

060120N |

120,000 |

|

|

|

101,000 |

|

|

|

|

40-70 |

|

|

1340 |

|

80.7 |

82.4 |

||||

|

|

|

|

|

|

208/230/460-3-60 — SINGLE-STAGE GAS HEAT |

|

|

|

|||||||||||

|

|

|

|

|

|

|

(California Compliant Models) |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

UNIT |

|

INPUT CAPACITY |

|

OUTPUT CAPACITY |

|

TEMPERATURE |

|

MINIMUM HEATING |

|

EFFICIENCY |

||||||||||

581B |

|

|

|

|

RISE (°F) |

|

|

AIRFLOW (CFM) |

|

AFUE (%) |

|

Steady State (%) |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

036071 |

72,000 |

|

|

|

59,040 |

|

|

|

|

25-55 |

|

|

1000 |

|

82.0 |

82.0 |

||||

036114 |

115,000 |

|

|

|

93,150 |

|

|

|

|

55-85 |

|

|

1020 |

|

80.0 |

80.0 |

||||

048071 |

72,000 |

|

|

|

59,040 |

|

|

|

|

25-55 |

|

|

1000 |

|

82.0 |

82.0 |

||||

048114 |

115,000 |

|

|

|

93,150 |

|

|

|

|

30-60 |

|

|

1440 |

|

81.0 |

81.0 |

||||

048149 |

150,000 |

|

|

|

120,000 |

|

|

|

|

50-80 |

|

|

1390 |

|

80.0 |

80.0 |

||||

060071 |

72,000 |

|

|

|

59,040 |

|

|

|

|

25-55 |

|

|

1220 |

|

82.0 |

82.0 |

||||

060114 |

115,000 |

|

|

|

93,150 |

|

|

|

|

35-65 |

|

|

1330 |

|

81.0 |

81.0 |

||||

060149 |

150,000 |

|

|

|

120,000 |

|

|

|

|

50-80 |

|

|

1390 |

|

80.0 |

80.0 |

||||

|

|

|

|

|

|

208/230/460-3-60 — 2-STAGE GAS HEAT |

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

UNIT |

|

INPUT CAPACITY |

|

OUTPUT CAPACITY |

|

|

TEMPERATUR |

|

MINIMUM |

EFFICIENCY |

||||||||||

581B |

|

1st Stage |

2nd Stage |

1st Stage |

2nd Stage |

|

E |

|

|

HEATING |

AFUE (%) |

|

Steady State (%) |

|||||||

|

|

RISE (°F) |

|

|

AIRFLOW (CFM) |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

036072 |

|

50,000 |

72,000 |

41,000 |

|

59,040 |

|

|

25-55 |

|

|

|

1004 |

|

82.8 |

|

82.0 |

|||

036115 |

|

82,000 |

115,000 |

65,600 |

|

93,150 |

|

|

55-85 |

|

|

|

1002 |

|

80.0 |

|

80.0 |

|||

048072 |

|

50,000 |

72,000 |

41,000 |

|

59,040 |

|

|

25-55 |

|

|

|

1004 |

|

82.8 |

|

82.0 |

|||

048115 |

|

82,000 |

115,000 |

66,420 |

|

93,150 |

|

|

35-65 |

|

|

|

1330 |

|

81.0 |

|

81.0 |

|||

048150 |

|

120,000 |

150,000 |

96,000 |

|

120,000 |

|

|

50-80 |

|

|

|

1390 |

|

80.4 |

|

80.0 |

|||

060072 |

|

50,000 |

72,000 |

41,000 |

|

59,040 |

|

|

25-55 |

|

|

|

1004 |

|

82.8 |

|

82.0 |

|||

060115 |

|

82,000 |

115,000 |

66,420 |

|

93,150 |

|

|

35-65 |

|

|

|

1330 |

|

81.0 |

|

81.0 |

|||

060150 |

|

120,000 |

150,000 |

96,000 |

|

120,000 |

|

|

50-80 |

|

|

|

1370 |

|

80.4 |

|

80.0 |

|||

072072 |

|

50,000 |

72,000 |

41,000 |

|

59,040 |

|

|

25-55 |

|

|

|

1220 |

|

82.0 |

|

82.0 |

|||

072115 |

|

82,000 |

115,000 |

66,420 |

|

93,150 |

|

|

35-65 |

|

|

|

1330 |

|

81.0 |

|

81.0 |

|||

072150 |

|

120,000 |

150,000 |

96,000 |

|

120,000 |

|

|

50-80 |

|

|

|

1390 |

|

80.0 |

|

80.0 |

|||

090125 |

|

90,000 |

125,000 |

73,800 |

|

102,500 |

|

|

20-50 |

|

|

|

1900 |

|

82.0 |

|

82.0 |

|||

090180 |

|

120,000 |

180,000 |

98,400 |

|

147,600 |

|

|

35-65 |

|

|

|

1440 |

|

82.0 |

|

82.0 |

|||

090224 |

|

180,000 |

224,000 |

147,600 |

|

183,680 |

|

|

45-75 |

|

|

|

2230 |

|

82.0 |

|

82.0 |

|||

102125 |

|

90,000 |

125,000 |

73,800 |

|

102,500 |

|

|

20-50 |

|

|

|

1900 |

|

82.0 |

|

82.0 |

|||

102180 |

|

120,000 |

180,000 |

98,400 |

|

147,600 |

|

|

35-65 |

|

|

|

1440 |

|

82.0 |

|

82.0 |

|||

102224 |

|

180,000 |

224,000 |

147,600 |

|

183,680 |

|

|

45-75 |

|

|

|

2230 |

|

82.0 |

|

82.0 |

|||

120180 |

|

120,000 |

180,000 |

98,400 |

|

147,600 |

|

|

35-65 |

|

|

|

1440 |

|

82.0 |

|

82.0 |

|||

120224 |

|

180,000 |

224,000 |

147,600 |

|

183,680 |

|

|

35-65 |

|

|

|

2570 |

|

82.0 |

|

82.0 |

|||

120250 |

|

200,000 |

250,000 |

160,000 |

|

200,000 |

|

|

40-70 |

|

|

|

2650 |

|

80.0 |

|

80.0 |

|||

150224 |

|

180,000 |

224,000 |

147,600 |

|

183,680 |

|

|

35-65 |

|

|

|

2570 |

|

82.0 |

|

82.0 |

|||

150250 |

|

200,000 |

250,000 |

160,000 |

|

200,000 |

|

|

40-70 |

|

|

|

2650 |

|

80.0 |

|

80.0 |

|||

LEGEND

AFUE — Annual Fuel Utilization Efficiency

NOTE: Capacities for stainless steel heat exchanger units are the same as standard units.

11

ARI* CAPACITY RATINGS — 579F180-300

LOW HEAT UNITS

UNIT |

NOMINAL |

NET COOLING |

|

TOTAL |

|

SOUND |

|

CAPACITY |

|

EER |

RATING |

IPLV |

|||

579F |

TONS |

|

WATTS |

||||

(Btuh) |

|

|

(dB) |

|

|||

|

|

|

|

|

|

||

180 |

15 |

174,000 |

20,128 |

8.6 |

88 |

9.3 |

|

216 |

18 |

188,000 |

21,619 |

8.7 |

88 |

9.5 |

|

240 |

20 |

220,000 |

25,513 |

8.6 |

94 |

8.7 |

|

300 |

25 |

268,000 |

31,068 |

8.6 |

94 |

9.2 |

|

|

|

HIGH HEAT UNITS |

|

|

|

||

|

|

|

|

|

|

|

|

UNIT |

NOMINAL |

NET COOLING |

|

TOTAL |

|

SOUND |

|

CAPACITY |

|

EER |

RATING |

IPLV |

|||

579F |

TONS |

|

WATTS |

||||

(Btuh) |

|

|

(dB) |

|

|||

|

|

|

|

|

|

||

180 |

15 |

174,000 |

|

20,154 |

8.6 |

88 |

9.3 |

216 |

18 |

186,000 |

|

21,798 |

8.5 |

88 |

9.3 |

240 |

20 |

218,000 |

|

25,719 |

8.5 |

94 |

8.5 |

300 |

25 |

268,000 |

|

31,600 |

8.5 |

94 |

8.9 |

|

LEGEND |

|

|

|

|

|

|

dB |

— Sound Levels (decibels) |

|

db |

— Dry Bulb |

|

EER — Energy Efficiency Ratio |

||

IPLV |

— |

Integrated Part-Load Values |

wb |

— |

Wet Bulb |

*Air Conditioning and Refrigeration Institute.

NOTES:

1.Rated in accordance with ARI Standards 360 and 270.

2.The 579F300 is beyond the scope of the ARI Certification Program.

3.ARI ratings are net values, reflecting the effects of circulating fan heat.

4.Ratings are based on:

Cooling Standard: 80 F db, 67 F wb indoor entering-air temperature and 95 F db air entering outdoor unit.

IPLV Standard: 80 F db, 67 F wb indoor entering-air temperature and 80 F db outdoor entering-air temperature.

HEATING CAPACITIES AND EFFICIENCIES — 579F180-300

UNIT |

HEATING INPUT |

OUTPUT CAPACITY |

TEMPERATURE |

STEADY-STATE |

MINIMUM |

|

(Btuh) |

||||||

579F |

(Btuh) |

RISE (F) |

EFFICIENCY (%) |

HEATING CFM |

||

Stage 2/Stage 1* |

||||||

|

|

|

|

|

||

180230 |

230,000/172,000 |

186,000 |

15-45 |

81.0 |

3830 |

|

180300 |

300,000/225,000 |

243,000 |

30-60 |

81.0 |

3750 |

|

216275 |

275,000/206,000 |

223,000 |

15-45 |

81.0 |

4580 |

|

216360 |

360,000/270,000 |

292,000 |

20-50 |

81.0 |

5400 |

|

240275 |

275,000/206,000 |

223,000 |

15-45 |

81.0 |

4580 |

|

240360 |

360,000/270,000 |

292,000 |

20-50 |

81.0 |

5400 |

|

300275 |

275,000/206,000 |

223,000 |

15-45 |

81.0 |

4580 |

|

300360 |

360,000/270,000 |

292,000 |

20-50 |

81.0 |

5400 |

*All units are 2-stage heat.

NOTE: Minimum allowable temperature of mixed-air entering the heat exchanger during first-stage heating is 45 F. There is no minimum mixed-air temperature limitation during second-stage heating. For entering-air temperatures below 45 F both stages of heat must be energized together to minimize condensation issues and ensure proper unit operation.

AIR QUANTITY LIMITS

UNIT 579F |

MINIMUM CFM |

MAXIMUM CFM |

180 |

4500 |

7,500 |

216 |

5400 |

9,000 |

240 |

6000 |

10,000 |

300 |

7000 |

11,250 |

LOW OUTDOOR TEMPERATURE

OPERATING LIMITS (F)

UNITS |

TEMPERATURE |

All |

40 |

180 and 216 with Low Ambient Kit |

10 |

240 and 300 with Low Ambient Kit |

25 |

All with Motormaster® Head Pressure Control |

–20 |

12

ARI* CAPACITY RATINGS — 580F180-300

UNIT SIZE |

NOMINAL |

NET COOLING |

TOTAL |

|

SOUND |

|

|

580F |

EER |

RATING |

IPLV |

||||

TONS |

CAPACITY (Btuh) |

WATTS |

|||||

(Low Heat) |

|

(dB) |

|

||||

|

|

|

|

|

|||

180 |

15 |

176,000 |

17,064 |

9.5 |

88 |

9.5 |

|

210 |

18 |

202,000 |

21,166 |

9.7 |

88 |

10.2 |

|

240 |

20 |

236,000 |

24,832 |

9.5 |

94 |

10.1 |

|

300 |

25 |

278,000 |

28,535 |

9.7 |

94 |

10.4 |

|

|

|

|

|

|

|

|

|

UNIT SIZE |

NOMINAL |

NET COOLING |

TOTAL |

|

SOUND |

|

|

580F |

EER |

RATING |

IPLV |

||||

TONS |

CAPACITY (Btuh) |

WATTS |

|||||

(High Heat) |

|

(dB) |

|

||||

|

|

|

|

|

|||

180 |

15 |

176,000 |

17,179 |

9.5 |

88 |

9.5 |

|

210 |

18 |

202,000 |

21,301 |

9.7 |

88 |

10.1 |

|

240 |

20 |

236,000 |

24,832 |

9.5 |

94 |

10.0 |

|

300 |

25 |

277,000 |

29,067 |

9.5 |

94 |

10.0 |

|

LEGEND |

Bels |

— Sound Levels (1 bel = 10 decibels) |

db |

— Dry Bulb |

EER — Energy Efficiency Ratio |

|

IPLV |

— Integrated Part-Load Values |

wb |

— Wet Bulb |

*Air Conditioning and Refrigeration Institute.

NOTES:

1.Rated in accordance with ARI Standards 360 and 270.

2.ARI ratings are net values, reflecting the effects of circulating fan heat.

3.Ratings are based on:

Cooling Standard: 80 F db, 67 F wb indoor entering-air temperature and 95 F db air entering outdoor unit.

IPLV Standard: 80 F db, 67 F wb indoor entering-air temperature and 80 F db outdoor entering-air temperature.

4.All 580F180-300 units are in compliance with ASHRAE 90.1- 1999 Energy Standard for minimum SEER and EER requirements. Refer to state and local codes or visit the following website: http://solstice.crest.org/efficiency/bcap to determine if compliance with this standard pertains to a given geographical area of the United States.

HEATING CAPACITIES AND EFFICIENCIES — 580F180-300

UNIT |

HEATING INPUT |

OUTPUT CAPACITY |

TEMPERATURE |

STEADY-STATE |

MINIMUM |

|

(Btuh) |

||||||

580F |

(Btuh) |

RISE (F) |

EFFICIENCY (%) |

HEATING CFM |

||

Stage 2/Stage 1* |

||||||

|

|

|

|

|

||

180275 |

275,000/206,000 |

223,000 |

15-45 |

81.0 |

3750 |

|

180360 |

360,000/270,000 |

292,000 |

20-50 |

81.0 |

3830 |

|

210275 |

275,000/206,000 |

223,000 |

15-45 |

81.0 |

4580 |

|

210360 |

360,000/270,000 |

292,000 |

20-50 |

81.0 |

5400 |

|

240275 |

275,000/206,000 |

223,000 |

15-45 |

81.0 |

4580 |

|

240360 |

360,000/270,000 |

292,000 |

20-50 |

81.0 |

5400 |

|

300275 |

275,000/206,000 |

223,000 |

15-45 |

81.0 |

4580 |

|

300360 |

360,000/270,000 |

292,000 |

20-50 |

81.0 |

5400 |

*All units are 2-stage heat.

NOTE: Minimum allowable temperature of mixed-air entering the heat exchanger during first-stage heating is 45 F. There is no minimum mixed-air temperature limitation during second-stage heating. For entering-air temperatures below 45 F both stages of heat must be energized together to minimize condensation issues and ensure proper unit operation.

AIR QUANTITY LIMITS (Cooling)

UNIT 580F |

MINIMUM CFM |

MAXIMUM CFM |

180 |

4500 |

7,500 |

210 |

5400 |

9,000 |

240 |

6000 |

10,000 |

300 |

7000 |

11,250 |

COOLING OPERATION

LOW OUTDOOR TEMPERATURE OPERATING LIMITS (F)

UNITS |

TEMPERATURE |

All — Standard Unit |

40 |

180 and 210 with Low Ambient Kit |

10 |

240 and 300 with Low Ambient Kit |

25 |

All with Motormaster® Head Pressure Control |

–20 |

13

ARI* CAPACITY RATINGS — 581A155,180

LOW HEAT UNITS

UNIT |

NOMINAL |

NET COOLING |

|

TOTAL |

|

SOUND |

|

CAPACITY |

|

EER |

RATING |

IPLV |

|||

581A |

TONS |

|

WATTS |

||||

(Btuh) |

|

|

(dB) |

|

|||

|

|

|

|

|

|

||

155230 |

13 |

134,000 |

|

12,209 |

10.60 |

88 |

11.4 |

180275 |

15 |

180,000 |

|

17,064 |

10.50 |

88 |

11.4 |

|

|

|

HIGH HEAT UNITS |

|

|

|

|

|

|

|

|

|

|

|

|

UNIT |

NOMINAL |