Bryant 580F User Manual

installation, start-up and service instructions

580F DuraPac Series

SINGLE PACKAGE ROOFTOP

GAS HEATING/ELECTRIC COOLING UNITS

Sizes 180-300

15 to 25 Tons

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-25

I. Step 1 — Provide Unit Support. . . . . . . . . . . . . . . . . 1 II. Step 2 — Rig and Place Unit. . . . . . . . . . . . . . . . . . . 4 III. Step 3 — Field Fabricate Ductwork . . . . . . . . . . . . 11 IV. Step 4 — Make Unit Duct Connections . . . . . . . . . 11 V. Step 5 — Install Flue Hood and Wind Baffle . . . . . 11 VI. Step 6 — Trap Condensate Drain . . . . . . . . . . . . . . 11 VII. Step 7 — Orifice Change. . . . . . . . . . . . . . . . . . . . . 12 VIII. Step 8 — Install Gas Piping . . . . . . . . . . . . . . . . . . 13 IX. Step 9 — Make Electrical Connections . . . . . . . . . 13

X. Step 10 — Make Outdoor-Air Inlet Adjustments . . 15 XI. Step 11 — Install Outdoor-Air Hood. . . . . . . . . . . . 15 XII. Step 12 — Install All Accessories . . . . . . . . . . . . . 16 XIII. Step 13 — Adjust Factory-Installed Options . . . . . 18

XIV. Step 14 — Install Control Accessory for Optional Perfect Humidity™ Dehumidification Package . . 24

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26-34

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34-42

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . .43-47

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

START-UP CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . CL-1

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of cleaning coils and filters and replacing filters. All other operations should be performed by trained service personnel. When working on air-conditioning equipment, observe precautions in the literature, tags and labels attached to the unit, and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves. Use quenching cloth for unbrazing operations. Have fire extinguishers available for all brazing operations.

WARNING: Before performing service or maintenance operations on unit, turn off main power switch to unit and install lockout tag to disconnect switch. Electrical shock could cause personal injury.

WARNING: Before performing service or maintenance operations on unit, turn off main power switch to unit and install lockout tag to disconnect switch. Electrical shock could cause personal injury.

Cancels: II 580F-180-2 |

II 580F-180-3 |

|

3/15/06 |

WARNING:

WARNING:

1.Improper installation, adjustment, alteration, service, or maintenance can cause property damage, personal injury, or loss of life. Refer to the User’s Information Manual provided with this unit for more details.

2.Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

What to do if you smell gas:

1.DO NOT try to light any appliance.

2.DO NOT touch any electrical switch, or use any phone in your building.

3. IMMEDIATELY call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

4.If you cannot reach your gas supplier, call the fire department.

WARNING: Disconnect gas piping from unit when pressure testing at pressure greater than 0.5 psig. Pressures greater than 0.5 psig will cause gas valve damage resulting in hazardous condition. If gas valve is subjected to pressure greater than 0.5 psig, it must be replaced before use. When pressure testing field-supplied gas piping at pressures of 0.5 psig or less, a unit connected to such piping must be isolated by closing the manual gas valve(s).

WARNING: Disconnect gas piping from unit when pressure testing at pressure greater than 0.5 psig. Pressures greater than 0.5 psig will cause gas valve damage resulting in hazardous condition. If gas valve is subjected to pressure greater than 0.5 psig, it must be replaced before use. When pressure testing field-supplied gas piping at pressures of 0.5 psig or less, a unit connected to such piping must be isolated by closing the manual gas valve(s).

IMPORTANT: Units have high ambient operating limits. If limits are exceeded, the units will automatically lock the compressor out of operation. Manual reset will be required to restart the compressor.

INSTALLATION

I. STEP 1 — PROVIDE UNIT SUPPORT

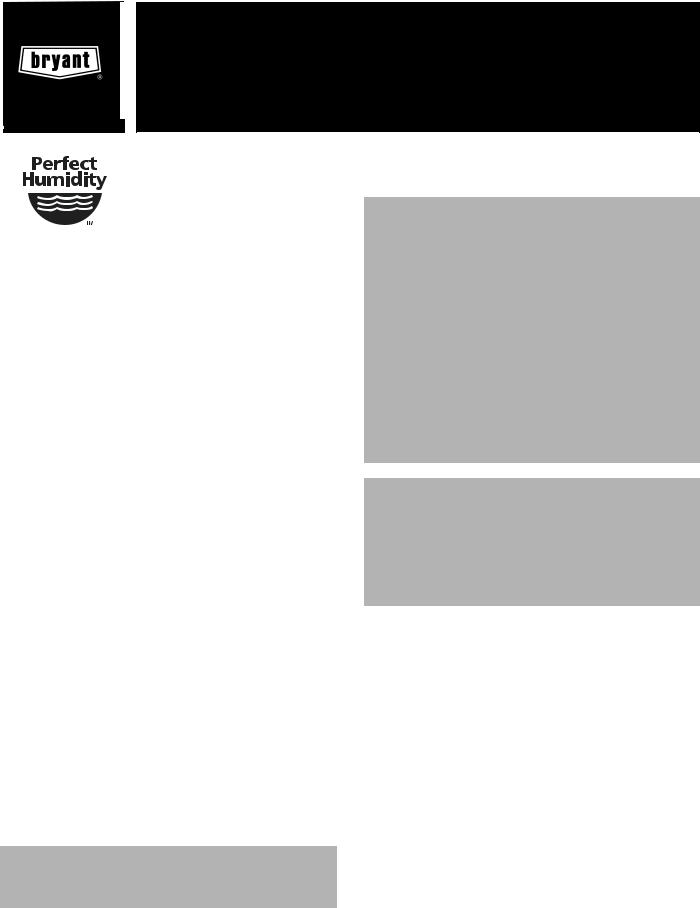

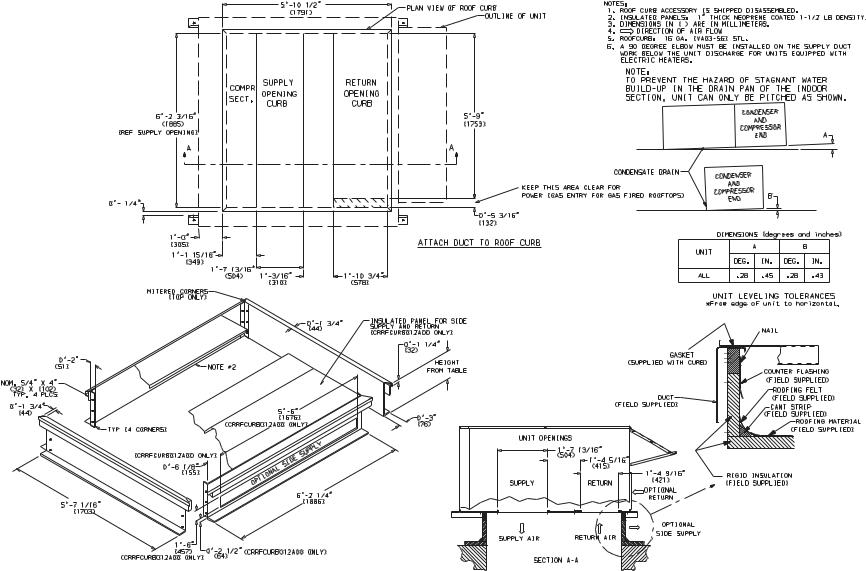

A. Roof Curb

Assemble or install accessory roof curb or horizontal adapter roof curb in accordance with instructions shipped with this accessory. See Fig. 1A, 1B, and 2. Install insulation, cant strips, roofing, and counter flashing as shown. Ductwork can be installed to roof curb or horizontal adapter roof curb before unit is set in place. Curb or adapter roof curb should be level. This is necessary to permit unit drain to function properly. Unit leveling tolerance is ± 1/16 in. per linear ft in any direction. Refer to Accessory Roof Curb or Horizontal Adapter Roof Curb Installation Instructions for additional information as required. When accessory roof curb or horizontal adapter roof curb is used, unit may be installed on class A, B, or C roof covering material.

Instructions continued on page 4.

PKG. NO. REF. |

CURB |

DESCRIPTION |

||

HEIGHT |

||||

|

|

|||

CRRFCURB010A00 |

1′− |

2″ (305) |

Standard Curb 14″ High |

|

CRRFCURB011A00 |

2′- |

0″ (610) |

Standard Curb for Units Requiring High Installation |

|

CRRFCURB012A00 |

2′- |

0″ (610) |

Side Supply and Return Curb for High Installation |

|

—2—

Fig. 1A — Roof Curb Details — 580F180-240

—3—

A

A

A

Fig. 1B — Roof Curb Details — 580F300

|

|

|

FULLY INSULATED |

|

|

|

|

SUPPLY PLENUM |

|

3 1/2" |

2" X 1/4 |

1" INSULATION |

||

SUPPORT TYP. |

1 1/2 # DENSITY, |

|||

|

|

|||

|

|

STITCH WELDED |

STICK PINNED & GLUED |

|

|

|

|

|

|

14 3/4"

23"

6"

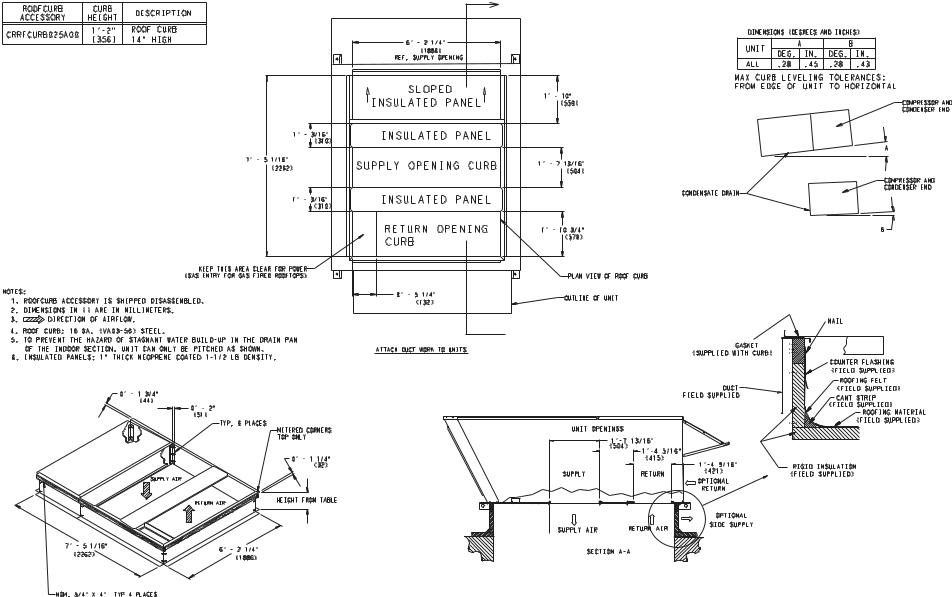

NOTE: CRRFCURB013A00 is a fully factory preassembled horizontal adapter and includes an insulated transition duct. The pressure drop through the adapter curb is negligible.

For horizontal return applications: The power exhaust and barometric relief dampers must be installed in the return air duct.

12" WIDE STANDING SEAM PANELS

ACCESSORY |

CURB |

DESCRIPTION |

|

PACKAGE NO. |

HEIGHT |

||

|

|||

CRRFCURB013A00 |

1′-11″ |

Pre-Assembled, Roof Curb, |

|

(584) |

Horizontal Adapter |

||

|

Fig. 2 — Horizontal Supply/Return Adapter Installation (580F180-240)

IMPORTANT: The gasketing of the unit to the roof curb or adapter roof curb is critical for a watertight seal. Install gasket with the roof curb or adapter as shown in Fig. 1A and 1B. Improperly applied gasket can also result in air leaks and poor unit performance.

B. Alternate Unit Support

When the curb or adapter cannot be used, install unit on a noncombustible surface. Support unit with sleepers, using unit curb support area. If sleepers cannot be used, support long sides of unit with a minimum of 3 equally spaced 4-in. x 4-in. pads on each side.

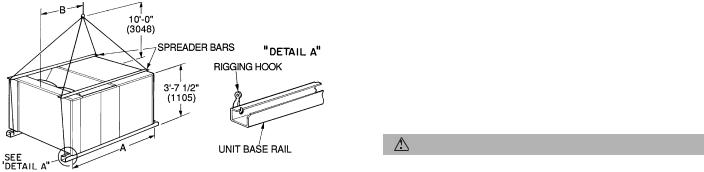

II. STEP 2 — RIG AND PLACE UNIT

Inspect unit for transportation damage. File any claim with transportation agency.

Do not drop unit; keep upright. Use spreader bars over unit to prevent sling or cable damage. Rollers may be used to move unit across a roof. Level by using unit frame as a reference; leveling tolerance is ± 1/16 in. per linear ft in any direction. See Fig. 3 for additional information. Unit operating weight is shown in Table 1.

Four lifting holes are provided in ends of unit base rails as shown in Fig. 3. Refer to rigging instructions on unit.

NOTE: On 580F300 units, the lower forklift braces must be removed prior to setting unit on roof curb.

A. Positioning

Maintain clearance, per Fig. 4-6, around and above unit to provide minimum distance from combustible materials, proper airflow, and service access.

Do not install unit in an indoor location. Do not locate air inlets near exhaust vents or other sources of contaminated air. For proper unit operation, adequate combustion and ventilation air must be provided in accordance with Section 5.3 (Air for Combustion and Ventilation) of the National Fuel Gas Code, ANSI Z223.1 (American National Standards Institute).

Although unit is weatherproof, guard against water from higher level runoff and overhangs.

Locate mechanical draft system flue assembly at least 4 ft from any opening through which combustion products could enter the building, and at least 4 ft from any adjacent building. When unit is located adjacent to public walkways, flue assembly must be at least 7 ft above grade.

B. Roof Mount

Check building codes for weight distribution requirements. Unit operating weight is shown in Table 1.

Instructions continued on page 11.

—4—

NOTES:

1.Dimensions in ( ) are in millimeters.

2.Refer to Fig. 4-6 for unit operating weights.

3.Remove boards at ends of unit and runners prior to rigging.

4.Rig by inserting hooks into unit base rails as shown. Use corner post from packaging to protect coil from damage. Use bumper boards for spreader bars on all units.

5.Weights do not include optional EconoMi$erIV. Add 90 lb (41 kg) for EconoMi$erIV weight.

6.Weights given are for aluminum evaporator and condenser coil plate fins.

CAUTION: All panels must be in place when rigging.

UNIT |

MAXIMUM |

|

|

DIMENSIONS |

|

|

||

SHIPPING WEIGHT |

|

A |

|

B |

||||

580F |

|

|

||||||

|

lb |

kg |

ft-in. |

|

mm |

ft-in. |

|

mm |

180 |

1875 |

850 |

6-111/2 |

|

2121 |

4-0 |

|

1219 |

210 |

1925 |

873 |

6-111/2 |

|

2121 |

3-2 |

|

964 |

240 |

2085 |

923 |

6-111/2 |

|

2121 |

3-4 |

|

1016 |

300 |

2445 |

1109 |

6-111/2 |

|

2121 |

3-4 |

|

1016 |

Fig. 3 — Rigging Details

—5—

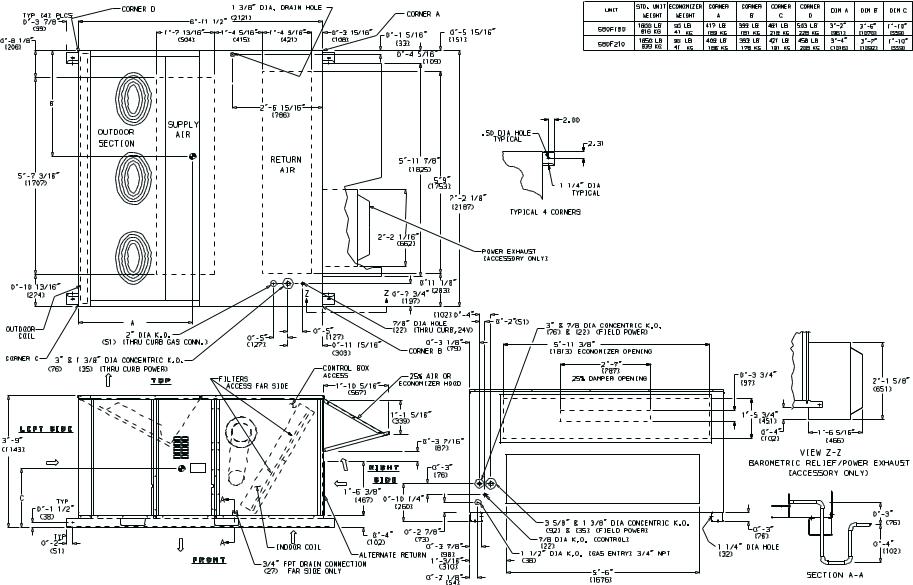

NOTES:

1. |

Refer to print for roof curb accessory dimensions. |

|||||

2. |

Dimensions in [ ] are in millimeters. |

|||||

3. |

|

|

|

|

Center of gravity. |

|

4. |

|

|

|

|

|

Direction of airflow. |

|

|

|

|

|

||

|

|

|

|

|

||

5. |

|

|

|

|

to be attached to accessory roof curb only. |

|

Ductwork |

||||||

6. |

Minimum clearance: |

|||||

|

|

• |

Rear: 7′-0″ (2134) for coil removal. This dimension can be reduced to 4′-0″ |

|||

|

|

• |

(1219) if conditions permit coil removal from the top. |

|||

|

|

4′-0″ (1219) to combustible surfaces, all four sides (includes between units). |

||||

|

|

• |

Left side: 4′-0″ (1219) for proper condenser coil airflow. |

|||

|

|

• |

Front: 4′-0″ (1219) for control box access. |

|||

|

|

• |

Right side: 4′-0″ (1219) for proper operation of damper and power exhaust if |

|||

|

|

• |

so equipped. |

|||

|

|

Top: 6′-0″ (1829) to assure proper condenser fan operation. |

||||

|

|

• |

Bottom: 14″ (356) to combustible surfaces (when not using curb). |

|||

|

|

• |

Control box side: 3′-0″ (914) to ungrounded surfaces, non-combustible. |

|||

|

|

• |

Control box side: 3′-6″ (1067) to block or concrete walls, or other grounded |

|||

|

|

• |

surfaces. |

|||

|

|

Local codes or jurisdiction may prevail. |

||||

7. |

With the exception of clearance for the condenser coil and the damper/power |

|||||

|

exhaust as stated in Note #6, a removable fence or barricade requires no clear- |

|||||

|

ance. |

|||||

8. |

Dimensions are from outside of corner post. Allow 0′-5/16″ (8) on each side for |

|||||

top cover drip edge.

—6—

Fig. 4 — Base Unit Dimensions — 580F180, 210

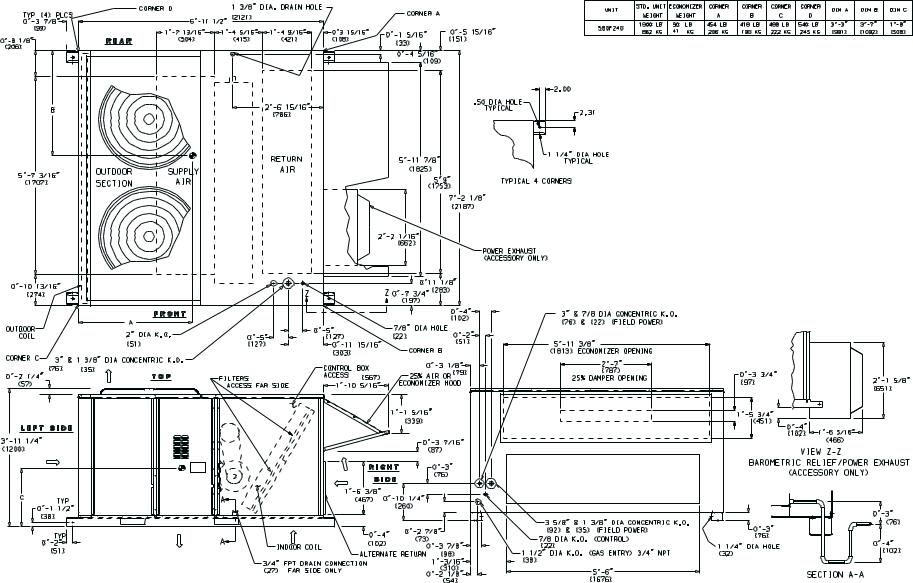

NOTES:

1. |

Refer to print for roof curb accessory dimensions. |

|||||

2. |

Dimensions in [ ] are in millimeters. |

|||||

3. |

|

|

|

|

Center of gravity. |

|

4. |

|

|

|

|

|

Direction of airflow. |

|

|

|

|

|

||

|

|

|

|

|

||

5. |

|

|

|

|

to be attached to accessory roof curb only. |

|

Ductwork |

||||||

6. |

Minimum clearance: |

|||||

|

|

• |

Rear: 7′-0″ (2134) for coil removal. This dimension can be reduced to 4′-0″ |

|||

|

|

• |

(1219) if conditions permit coil removal from the top. |

|||

|

|

4′-0″ (1219) to combustible surfaces, all four sides (includes between units). |

||||

|

|

• |

Left side: 4′-0″ (1219) for proper condenser coil airflow. |

|||

|

|

• |

Front: 4′-0″ (1219) for control box access. |

|||

|

|

• |

Right side: 4′-0″ (1219) for proper operation of damper and power exhaust if |

|||

|

|

• |

so equipped. |

|||

|

|

Top: 6′-0″ (1829) to assure proper condenser fan operation. |

||||

|

|

• |

Bottom: 14″ (356) to combustible surfaces (when not using curb). |

|||

|

|

• |

Control box side: 3′-0″ (914) to ungrounded surfaces, non-combustible. |

|||

|

|

• |

Control box side: 3′-6″ (1067) to block or concrete walls, or other grounded |

|||

|

|

• |

surfaces. |

|||

|

|

Local codes or jurisdiction may prevail. |

||||

7. |

With the exception of clearance for the condenser coil and the damper/power |

|||||

|

exhaust as stated in Note #6, a removable fence or barricade requires no clear- |

|||||

|

ance. |

|||||

8. |

Dimensions are from outside of corner post. Allow 0′-5/16″ (8) on each side for |

|||||

top cover drip edge.

—7—

Fig. 5 — Base Unit Dimensions — 580F240

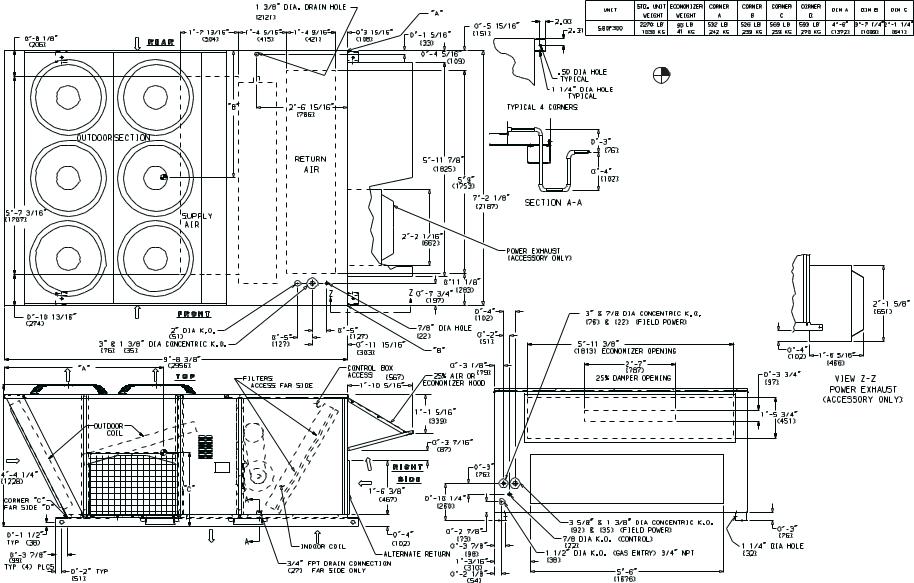

NOTES:

1. Refer to print for roof curb accessory dimensions.

2. Dimensions in ( ) are in millimeters.

3.  Center of Gravity.

Center of Gravity.

4. Direction of airflow.

5. Ductwork to be attached to accessory roof curb only. 6. Minimum clearance:

• Rear: 7′-0″ (2134) for coil removal. This dimension can be reduced to 4′-0″ (1219) if conditions permit coil removal from the top.

• 4′-0″ (1219) to combustible surfaces, all four sides (includes between units).

• Left side: 4′-0″ (1219) for proper condenser coil airflow.

• Front: 4′-0″ (1219) for control box access.

• Right side: 4′-0″ (1219) for proper operation of damper and power exhaust if so equipped.

• Top: 6′-0″ (1829) to assure proper condenser fan operation.

• Bottom: 14″ (356) to combustible surfaces (when not using curb).

• Control box side: 3′-0″ (914) to ungrounded surfaces, non-combustible.

• Control box side: 3′-6″ (1067) to block or concrete walls, or other grounded surfaces.

• Local codes or jurisdiction may prevail.

7. With the exception of clearance for the condenser coil and the damper/power exhaust as stated in Note #6, a removable fence or barricade requires no clearance.

8. Dimensions are from outside of corner post. Allow 0′-5/16 ″ (8) on each side for top cover drip edge.

9. The lower forklift brace must be removed prior to setting unit on roof curb.

—8—

Fig. 6 — Base Unit Dimensions — 580F300

Table 1 — Physical Data

|

|

UNIT 580F |

|

180 |

|

|

210 |

|

|

240 |

|

300 |

NOMINAL CAPACITY (tons) |

|

15 |

|

|

18 |

|

|

20 |

|

25 |

||

OPERATING WEIGHT |

|

1800 |

|

|

1850 |

|

|

1900 |

|

2270 |

||

EconoMi$erIV |

|

90 |

|

|

90 |

|

|

90 |

|

90 |

||

Perfect Humidity™ Dehumidification Package |

40 |

|

|

40 |

|

|

40 |

|

40 |

|||

COMPRESSOR/MANUFACTURER |

|

|

|

|

Scroll, Copeland |

|

|

|||||

Quantity...Model (Ckt 1, Ckt 2) |

|

1...ZR94KC, |

|

|

1...ZR108KC, |

|

|

1...ZR125KC, |

|

1...ZRU140KC,* |

||

|

|

|

|

|

||||||||

|

1...ZR72KC |

|

|

1...ZR94KC |

|

|

1...ZR108KC |

|

1...ZR144KC |

|||

Capacity Stages (%) |

|

|

|

|

|

|

||||||

|

60, 40 |

|

|

55, 45 |

|

|

55, 45 |

|

50, 50 |

|||

Number of Refrigerant Circuits |

|

2 |

|

|

2 |

|

|

2 |

|

2 |

||

Oil (oz) (Ckt 1, Ckt 2) |

|

85, 60 |

|

|

106, 81 |

|

|

106,106 |

|

136, 106 |

||

REFRIGERANT TYPE |

|

|

|

|

|

R-22 |

|

|

||||

Expansion Device |

|

|

|

|

|

TXV |

|

|

||||

Operating Charge (lb-oz) |

|

|

|

|

|

|

|

|

|

|

||

Circuit 1† |

|

19-8 |

|

|

19-8 |

|

|

19-11 |

|

26-13 |

||

|

|

|

|

|||||||||

Circuit 2 |

|

13-8 |

|

|

19-2 |

|

|

13-14 |

|

25-10 |

||

CONDENSER COIL |

|

Cross-Hatched 3/8-in. Copper Tubes, Aluminum Lanced, |

||||||||||

Rows...Fins/in. |

|

|

Aluminum Pre-Coated, or Copper Plate Fins |

|||||||||

|

4...15 |

|

|

4...15 |

|

|

4...15 |

|

3...15 (2 coils) |

|||

|

|

|

|

|||||||||

Total Face Area (sq ft) |

|

21.7 |

|

|

21.7 |

|

|

21.7 |

|

43.4 |

||

CONDENSER FAN |

|

|

|

|

Propeller Type |

|

|

|||||

Nominal Cfm |

|

10,500 |

|

|

10,500 |

|

|

14,200 |

|

21,000 |

||

|

|

|

|

|||||||||

Quantity...Diameter (in.) |

|

3...22 |

|

|

3...22 |

|

|

2...30 |

|

6...22 |

||

Motor Hp...Rpm |

|

1/2...1050 |

|

|

1/2...1050 |

|

|

1...1075 |

|

1/2...1050 |

||

Watts Input (Total) |

|

1100 |

|

|

1100 |

|

|

3400 |

|

2200 |

||

EVAPORATOR COIL |

|

Cross-Hatched 3/8-in. Copper Tubes, Aluminum Lanced or |

||||||||||

Rows...Fins/in. |

|

|

|

|

Copper Plate Fins, Face Split |

|

|

|||||

|

4...15 |

|

|

4...15 |

|

|

4...15 |

|

4...15 |

|||

|

|

|

|

|||||||||

Total Face Area (sq ft) |

|

17.5 |

|

|

17.5 |

|

|

17.5 |

|

17.5 |

||

EVAPORATOR FAN |

|

|

|

|

Centrifugal Type |

|

|

|||||

Quantity...Size (in.) |

|

2...12 x 12 |

|

|

2...12 x 12 |

|

|

2...12 x 12 |

|

2...12 x 12 |

||

|

|

|

|

|

||||||||

Type Drive |

|

Belt |

|

|

Belt |

|

|

Belt |

|

Belt |

||

Nominal Cfm |

|

6000 |

|

|

7200 |

|

|

8000 |

|

10,000 |

||

Motor Hp |

|

5 |

|

|

5 |

|

|

7.5 |

|

10 |

||

Motor Nominal Rpm |

|

1745 |

|

|

1745 |

|

|

1745 |

|

1740 |

||

Maximum Continuous Bhp |

|

6.13 |

|

|

5.90 |

|

|

8.7 [208/230 v] |

|

10.2 [208/230 v] |

||

|

|

|

|

|

9.5 [460 v] |

|

11.8 [460 v] |

|||||

Motor Frame Size |

|

|

|

|

|

|

|

|

||||

|

184T |

|

|

184T |

|

|

213T |

|

215T |

|||

Nominal Rpm High/Low |

|

— |

|

|

— |

|

|

— |

|

— |

||

Fan Rpm Range |

Low-Medium Static |

873-1021 |

|

|

910-1095 |

|

|

1002-1151 |

|

1066-1283 |

||

Motor Bearing Type |

High Static |

1025-1200 |

|

|

1069-1287 |

|

|

1193-1369 |

|

1332-1550 |

||

|

Ball |

|

|

Ball |

|

|

Ball |

|

Ball |

|||

Maximum Allowable Rpm |

|

1550 |

|

|

1550 |

|

|

1550 |

|

1550 |

||

Motor Pulley Pitch Diameter |

Low-Medium Static |

4.9/5.9 |

|

|

4.9/5.9 |

|

|

5.4/6.6 |

|

4.9/5.9 |

||

|

Min/Max (in.) |

High Static |

4.9/5.9 |

|

|

4.9/5.9 |

|

|

5.4/6.6 |

|

4.9/5.9 |

|

Nominal Motor Shaft Diameter (in.) |

Low-Medium Static |

11/8 |

|

|

11/8 |

|

|

13/8 |

|

13/8 |

||

Fan Pulley Pitch Diameter (in.) |

9.4 |

|

|

9.4 |

|

|

9.4 |

|

8.0 |

|||

Nominal Fan Shaft Diameter (in.) |

High Static |

8.0 |

|

|

8.0 |

|

|

7.9 |

|

6.4 |

||

Low-Medium Static |

17/16 |

|

|

17/16 |

|

|

17/16 |

|

17/16 |

|||

Belt, Quantity...Type...Length (in.) |

1...BX...50 |

|

|

1...BX...50 |

|

|

1...BX...53 |

|

2...BX...50 |

|||

Pulley Center Line Distance (in.) |

High Static |

1...BX...48 |

|

|

1...BX...48 |

|

|

1...BX...50 |

|

2...BX...47 |

||

|

13.3-14.8 |

|

|

13.3-14.8 |

|

|

14.6-15.4 |

|

14.6-15.4 |

|||

Speed Change per Full Turn of |

Low-Medium Static |

37 |

|

|

37 |

|

|

37 |

|

36 |

||

|

Movable Pulley Flange (rpm) |

High Static |

44 |

|

|

34 |

|

|

44 |

|

45 |

|

Movable Pulley Maximum Full Turns |

|

|

|

|

|

|

|

|

|

|

||

|

From Closed Position |

|

6** |

|

|

6†† |

|

|

6** |

|

6†† |

|

Factory Pulley Setting |

|

3.5 |

|

|

3.5 |

|

|

3.5 |

|

3.5 |

||

Factory Speed Setting (rpm) |

Low-Medium Static |

965 |

|

|

1002 |

|

|

1120 |

|

1182 |

||

Fan Shaft Diameter at Pulley (in.) |

High Static |

1134 |

|

|

1178 |

|

|

1328 |

|

1470 |

||

|

17/16 |

|

|

17/16 |

|

|

17/16 |

|

17/16 |

|||

|

|

LEGEND |

|

|

|

|

|

|

|

|

|

|

Bhp |

— |

Brake Horsepower |

|

|

|

|

|

|

|

|

|

|

TXV |

— |

Thermostatic Expansion Valve |

|

|

|

|

|

|

|

|

|

|

*The ZRU140KC compressor is a tandem compressor, consisting of a ZR72KC (25% total capacity) and a ZR68KC (24% total capacity).

†Circuit 1 uses the lower portion of the condenser coil and lower portion of the evaporator coils; and Circuit 2 uses the upper portion of both coils.

**Pulley has 6 turns. Due to belt and pulley size, movable pulley cannot be set to 0 to 11/2 turns open.

††Pulley has 6 turns. Due to belt and pulley size, movable pulley cannot be set to 0 to 1/2 turns open.

***Rollout switch is manual reset.

†††A Liquid Propane kit is available as an accessory.

¶The 580F300 unit requires 2-in. industrial-grade filters capable of handling face velocities up to 625 ft/min (such as American Air Filter no. 5700 or equivalent).

NOTE: The 580F units have a low-pressure switch (standard) located on the suction side.

—9—

Table 1 — Physical Data (cont)

UNIT 580F |

|

180 |

210 |

240 |

300 |

||

|

(Low Heat/High Heat) |

(Low Heat/High Heat) |

(Low Heat/High Heat) |

(Low Heat/High Heat) |

|||

|

|

|

|

||||

FURNACE SECTION |

|

|

|

|

|

||

Rollout Switch Cutout Temp (F)*** |

190 |

190 |

190 |

190 |

|||

Burner Orifice Diameter (in. ...drill size) |

|

|

|

|

|||

|

Natural Gas |

Std |

0.1285...30/0.136...29 |

0.1285...30/0.136...29 |

0.1285...30/0.136...29 |

0.1285...30/0.136...29 |

|

Thermostat Heat Anticipator Setting (amps) |

|

|

|

|

|||

|

208/230 v |

Stage 1 |

0.98 |

0.98 |

0.98 |

0.98 |

|

|

|

|

Stage 2 |

0.44 |

0.44 |

0.44 |

0.44 |

|

460 v |

Stage 1 |

0.80 |

0.80 |

0.80 |

0.80 |

|

|

|

|

Stage 2 |

0.44 |

0.44 |

0.44 |

0.44 |

|

Gas Input |

Stage 1 |

206,000/270,000 |

206,000/270,000 |

206,000/270,000 |

206,000/270,000 |

|

|

|

|

Stage 2 |

275,000/360,000 |

275,000/360,000 |

275,000/360,000 |

275,000/360,000 |

Efficiency (Steady-State) (%) |

81 |

81 |

81 |

81 |

|||

Temperature Rise Range |

15-45/20-50 |

15-45/20-50 |

15-45/20-50 |

15-45/20-50 |

|||

Manifold Pressure (in. wg) |

|

|

|

|

|||

|

Natural Gas |

Std |

3.3 |

3.3 |

3.3 |

3.3 |

|

|

Liquid Propane††† |

Alt |

3.3 |

3.3 |

3.3 |

3.3 |

|

Gas Valve Quantity |

|

1 |

1 |

1 |

1 |

||

Gas Valve Pressure Range |

|

|

|

|

|||

|

in. wg |

|

5.5-13.5 |

5.5-13.5 |

5.5-13.5 |

5.5-13.5 |

|

|

psig |

|

|

0.235-0.487 |

0.235-0.487 |

0.235-0.487 |

0.235-0.487 |

Field Gas Connection Size (in.-FPT) |

3/4 |

3/4 |

3/4 |

3/4 |

|||

HIGH-PRESSURE SWITCH (psig) |

|

|

|

|

|||

Cutout |

|

|

|

426 |

|

||

Reset (Auto) |

|

|

320 |

|

|||

LOW-PRESSURE SWITCH (psig) |

|

|

|

|

|||

Cutout |

|

|

|

27 |

|

||

Reset (Auto) |

|

|

44 |

|

|||

FREEZE PROTECTION THERMOSTAT (F) |

|

|

|

|

|||

Opens |

|

|

|

30 ± 5 |

|

||

Closes |

|

|

|

45 ± 5 |

|

||

OUTDOOR-AIR INLET SCREENS |

|

Cleanable |

|

||||

Quantity...Size (in.) |

|

|

2...20 x 25 x 1 |

|

|||

|

|

|

|

|

1...20 x 20 x 1 |

|

|

RETURN-AIR FILTERS |

|

|

Throwaway¶ |

|

|||

Quantity...Size (in.) |

|

|

4...20 x 20 x 2 |

|

|||

|

|

|

|

|

4...16 x 20 x 2 |

|

|

POWER EXHAUST |

|

1/2 Hp, 208/230-460 v Motor Direct Drive, Propeller-Fan (Factory-Wired for 460 v) |

|||||

|

|

LEGEND |

|

|

|

|

|

Bhp |

— |

Brake Horsepower |

|

|

|

|

|

TXV |

— |

Thermostatic Expansion Valve |

|

|

|

|

|

*The ZRU140KC compressor is a tandem compressor, consisting of a ZR72KC (25% total capacity) and a ZR68KC (24% total capacity).

†Circuit 1 uses the lower portion of the condenser coil and lower portion of the evaporator coils; and Circuit 2 uses the upper portion of both coils.

**Pulley has 6 turns. Due to belt and pulley size, movable pulley cannot be set to 0 to 11/2 turns open.

††Pulley has 6 turns. Due to belt and pulley size, movable pulley cannot be set to 0 to 1/2 turns open.

***Rollout switch is manual reset.

†††A Liquid Propane kit is available as an accessory.

¶The 580F300 unit requires 2-in. industrial-grade filters capable of handling face velocities up to 625 ft/min (such as American Air Filter no. 5700 or equivalent).

NOTE: The 580F units have a low-pressure switch (standard) located on the suction side.

—10—

III. STEP 3 — FIELD FABRICATE DUCTWORK

Secure all ducts to building structure. Use flexible duct connectors between unit and ducts as required. Insulate and weatherproof all external ductwork, joints, and roof openings with counter flashing and mastic in accordance with applicable codes.

Ducts passing through an unconditioned space must be insulated and covered with a vapor barrier.

IV. STEP 4 — MAKE UNIT DUCT CONNECTIONS

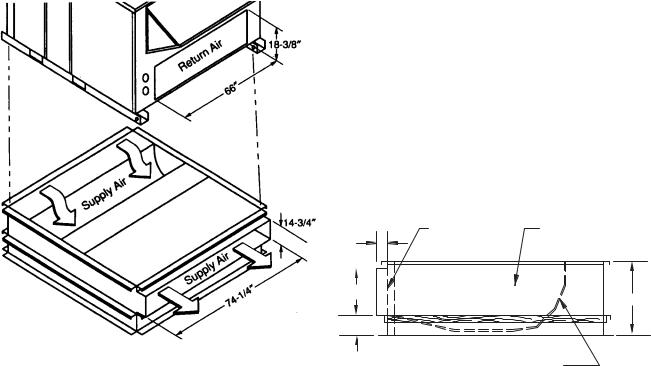

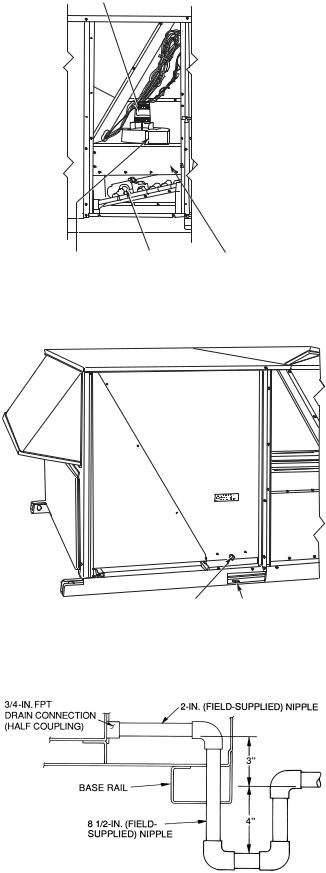

Unit is shipped for thru-the-bottom duct connections. Ductwork openings are shown in Fig. 1 and 4-6. Duct connections are shown in Fig. 7. Field-fabricated concentric ductwork may be connected as shown in Fig. 8 and 9. Attach all ductwork to roof curb and roof curb basepans.

NOTE: Do not drill in this area; damage to basepan may result in water leak.

Fig. 7 — Air Distribution — Thru-the-Bottom

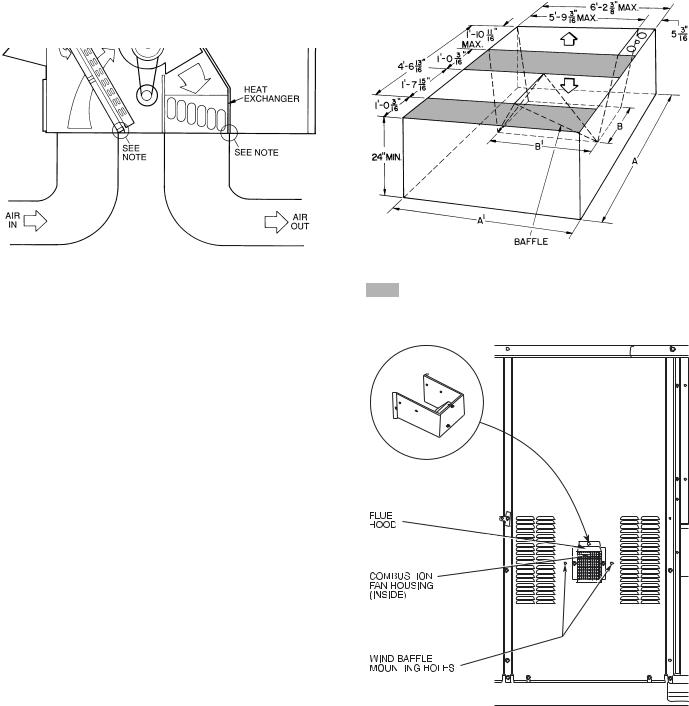

V. STEP 5 — INSTALL FLUE HOOD AND WIND BAFFLE

Flue hood and wind baffle are shipped secured under main control box. To install, secure flue hood to access panel. See Fig. 10. The wind baffle is then installed over the flue hood.

NOTE: When properly installed, flue hood will line up with combustion fan housing. See Fig. 11.

VI. STEP 6 — TRAP CONDENSATE DRAIN

See Fig. 12 for drain location. One 3/4-in. half coupling is provided inside unit evaporator section for condensate drain connection. An 81/2-in. x 3/4-in. diameter and 2-in. x 3/4-in. diameter pipe nipple, coupled to standard 3/4-in. diameter elbows, provide a straight path down through hole in unit base rails (see Fig. 13). A trap at least 4-in. deep must be used.

NOTE: Dimensions A, A′, B, and B′ are obtained from field-supplied ceiling diffuser.

Shaded areas indicate block-off panels.

Fig. 9 — Concentric Duct Details

WIND

BAFFLE

NOTE: Do not drill in this area; damage to basepan may result in water leak.

Fig. 8 — Concentric Duct Air Distribution |

Fig. 10 — Flue Hood Location |

—11—

INDUCED DRAFT

MOTOR

|

|

|

|

|

|

|

|

|

|

HEAT EXCHANGER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COMBUSTION |

MAIN BURNER |

|||||||||

FAN HOUSING |

SECTION |

SECTION |

||||||||

Fig. 11 — Combustion Fan Housing Location

3/4" FPT DRAIN |

1-3/8" |

CONNECTION |

DRAIN HOLE |

Fig. 12 — Condensate Drain Details (580F180 Shown)

Fig. 13 — Condensate Drain Piping Details

VII. STEP 7 — ORIFICE CHANGE

This unit is factory assembled for heating operation using natural gas at an elevation from sea level to 2000 ft. This unit uses orifice type LH32RFnnn, where “nnn” indicates the orifice size based on drill size diameter in thousands of an inch.

A. High Elevation (Above 2000 ft)

Use accessory high altitude kit when installing this unit at an elevation of 2000 to 7000 ft. For elevations above 7000 ft, refer to Table 2 to identify the correct orifice size for the elevation. See Table 3 for the number of orifices required for each unit size. Purchase these orifices from your local Bryant dealer. Follow instructions in accessory Installation Instructions to install the correct orifices.

Table 2 — Altitude Compensation*

ELEVATION (ft) |

NATURAL GAS ORIFICE† |

||

Low Heat |

High Heat |

||

|

|||

0-1,999 |

30 |

29 |

|

2,000 |

30 |

29 |

|

3,000 |

31 |

30 |

|

4,000 |

31 |

30 |

|

5,000 |

31 |

30 |

|

6,000 |

31 |

30 |

|

7,000 |

32 |

31 |

|

8,000 |

32 |

31 |

|

9,000 |

33 |

31 |

|

10,000 |

35 |

32 |

|

*As the height above sea level increases, there is less oxygen per cubic foot of air. Therefore, heat input rate should be reduced at higher altitudes. Includes a 4% input reduction per each 1000 ft.

†Orifices available through your Bryant dealer.

Table 3 — Orifice Quantity

UNIT |

ORIFICE QUANTITY |

|

580F180 Low Heat |

5 |

|

580F210 Low Heat, |

|

|

580F240 Low Heat, |

6 |

|

580F300 Low Heat, |

||

|

||

580F180 High Heat |

|

|

580F210 High Heat, |

|

|

580F240 High Heat, |

7 |

|

580F300 High Heat |

|

B. Conversion To LP (Liquid Propane) Gas

Use accessory LP gas conversion kit when converting this unit for use with LP fuel usage for elevations up to 7000 ft. For elevations above 7000 ft, refer to Table 4 to identify the correct orifice size for the elevation. See Table 3 for the number of orifices required for each unit size. Purchase these orifices from your local Bryant dealer. Follow instructions in accessory Installation Instructions to install the correct orifices.

Table 4 — LP Gas Conversion*

ELEVATION (ft) |

LP GAS ORIFICE† |

0-1,999 |

36 |

2,000 |

37 |

3,000 |

38 |

4,000 |

38 |

5,000 |

39 |

6,000 |

40 |

7,000 |

41 |

8,000 |

41 |

9,000 |

42 |

10,000 |

43 |

*As the height above sea level increases, there is less oxygen per cubic foot of air. Therefore, heat input rate should be reduced at higher altitudes. Includes a 4% input reduction per each 1000 ft.

†Orifices available through your Bryant dealer.

—12—

VIII. STEP 8 — INSTALL GAS PIPING

Unit is equipped for use with natural gas. Installation must conform with local building codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1.

Install field-supplied manual gas shutoff valve with a 1/8-in. NPT pressure tap for test gage connection at unit. Field gas piping must include sediment trap and union. See Fig. 14.

WARNING: Do not pressure test gas supply while connected to unit. Always disconnect union before servicing.

WARNING: Do not pressure test gas supply while connected to unit. Always disconnect union before servicing.

IMPORTANT: Natural gas pressure at unit gas connection must not be less than 5.5 in. wg or greater than 13.5 in. wg.

Size gas-supply piping for 0.5-in. wg maximum pressure drop. Do not use supply pipe smaller than unit gas connection.

Fig. 14 — Field Gas Piping

IX. STEP 9 — MAKE ELECTRICAL CONNECTIONS

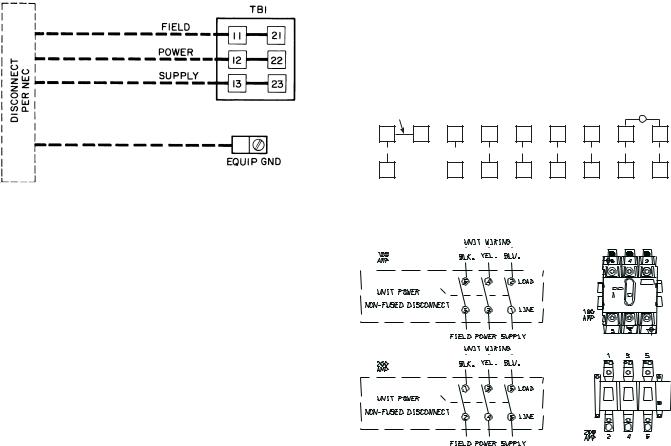

A. Field Power Supply

Unit is factory wired for voltage shown on unit nameplate. When installing units, provide a disconnect per NEC (National Electrical Code) requirements of adequate size (Table 5).

All field wiring must comply with NEC and local requirements.

Route power and ground lines through control box end panel or unit basepan (see Fig. 4-6) to connections as shown on unit wiring diagram and Fig. 15.

CAUTION: The correct power phasing is critical in the operation of the scroll compressors. An incorrect phasing will cause the compressor to rotate in the wrong direction. This may lead to premature compressor failure.

CAUTION: The correct power phasing is critical in the operation of the scroll compressors. An incorrect phasing will cause the compressor to rotate in the wrong direction. This may lead to premature compressor failure.

WARNING: The unit must be electrically grounded in accordance with local codes and NEC ANSI/NFPA 70 (National Fire Protection Association).

WARNING: The unit must be electrically grounded in accordance with local codes and NEC ANSI/NFPA 70 (National Fire Protection Association).

Field wiring must conform to temperature limitations for type ‘‘T’’ wire. All field wiring must comply with NEC and local requirements.

Transformer no. 1 is wired for 230-v unit. If 208/230-v unit is to be run with 208-v power supply, the transformer must be rewired as follows:

1.Remove cap from red (208 v) wire.

2.Remove cap from orange (230 v) spliced wire.

3.Replace orange wire with red wire.

4.Recap both wires.

IMPORTANT: BE CERTAIN UNUSED WIRES ARE CAPPED. Failure to do so may damage the transformers.

Operating voltage to compressor must be within voltage range indicated on unit nameplate. On 3-phase units, voltages between phases must be balanced within 2%.

Unit failure as a result of operation on improper line voltage or excessive phase imbalance constitutes abuse and may cause damage to electrical components.

B. Field Control Wiring

Install a Bryant-approved accessory thermostat assembly (or light commercial Thermidistat™ device for units equipped with Perfect Humidity™ option) according to the installation instructions included with accessory. Locate thermostat assembly on a solid interior wall in the conditioned space to sense average temperature.

Route thermostat cable or equivalent single leads of colored wire from subbase terminals through conduit in unit to lowvoltage connections as shown on unit label wiring diagram and in Fig. 16.

NOTE: For wire runs up to 50 ft, use no. 18 AWG (American Wire Gage) insulated wire (35 C minimum). For 50 to 75 ft, use no. 16 AWG insulated wire (35 C minimum). For over 75 ft, use no. 14 AWG insulated wire (35 C minimum). All wire larger than no. 18 AWG cannot be directly connected at the thermostat and will require a junction box and splice at the thermostat.

Set heat anticipator settings as follows:

VOLTAGE |

W1 |

W2 |

208/230 |

0.98 |

0.44 |

460 |

0.80 |

0.44 |

Settings may be changed slightly to provide a greater degree of comfort for a particular installation.

C. Optional Non-Fused Disconnect

On units with the optional non-fused disconnect, incoming power will be wired into the disconnect switch. Refer to Fig. 17 for wiring for 100 and 200 amp disconnect switches. Units with an MOCP (maximum overcurrent protection) under 100 will use the 100 amp disconnect switch. Units with an MOCP over 100 will use the 200 amp disconnect switch. Refer to the applicable disconnect wiring diagram.

To prevent breakage during shipping, the disconnect handle and shaft are shipped and packaged inside the unit control box. Install the disconnect handle before unit operation. To install the handle and shaft, perform the following procedure:

1.Open the control box door and remove the handle and shaft from shipping location.

2.Loosen the Allen bolt located on the disconnect switch. The bolt is located on the square hole and is used to hold the shaft in place. The shaft cannot be inserted until the Allen bolt is moved.

3.Insert the disconnect shaft into the square hole on the disconnect switch. The end of the shaft is specially cut and the shaft can only be inserted in the correct orientation.

—13—

|

LEGEND |

EQUIP |

— Equipment |

GND |

— Ground |

NEC |

— National Electrical Code |

TB |

— Terminal Board |

NOTE: The maximum wire size for TB1 is 2/0.

Fig. 15 — Field Power Wiring Connections

4.Tighten the Allen bolt to lock the shaft into position.

5.Close the control box door.

6.Attach the handle to the external access door with the two screws provided. When the handle is in the ON position, the handle will be vertical. When the handle is in the OFF position, the handle will be horizontal.

7.Turn the handle to the OFF position and close the door. The handle should fit over the end of the shaft when the door is closed.

8.The handle must be in the OFF position to open the control box door.

D. Optional Convenience Outlet

On units with optional convenience outlet, a 115-v GFI (ground fault interrupt) convenience outlet receptacle is provided for field wiring. Field wiring should be run through the 7/8-in. knockout provided in the basepan near the return air opening.

THERMOSTAT ASSEMBLY

REMOVABLE JUMPER |

|

|

|

|

|

|

|

|

|||

|

RH |

RC |

Y1 |

Y2 |

W1 |

W2 |

G |

C |

L |

X |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

|

Y1 |

Y2 |

W1 |

W2 |

G |

C |

|

X |

|

|

RED |

|

BLU |

PNK |

ORN |

VIO |

BLK |

BRN |

|

WHT |

|

|

|

|

|

|

|

||||||

|

|

Fig. 16 — Field Control Thermostat Wiring |

|

|

|||||||

|

|

|

|

|

|

|

|

6T3 |

4T2 |

2T1 LOAD |

|

|

|

|

|

|

|

|

|

|

|

|

|

5L3 3L2 1L1 LINE

NOTE: The disconnect takes the place of TB-1 as shown on the unit wiring diagram label and the component arrangement label.

Fig. 17 — Optional Non-Fused Disconnect Wiring

—14—

Table 5 — Electrical Data

UNIT |

NOMINAL |

VOLTAGE |

|

COMPRESSOR |

|

|

|

OFM |

|

IFM |

POWER |

COMBUSTION |

POWER |

|||||||

RANGE |

No. 1 |

No. 1A |

|

No. 2 |

|

|

EXHAUST |

FAN MOTOR |

SUPPLY |

|||||||||||

580F |

VOLTAGE |

|

|

|

|

|

|

|||||||||||||

|

(3 Ph, 60 Hz) |

Min |

Max |

RLA |

LRA |

RLA |

LRA |

|

RLA |

LRA |

Qty |

Hp |

FLA (ea) |

Hp |

FLA |

FLA |

LRA |

FLA |

MCA |

MOCP* |

|

208/230 |

187 |

253 |

32.1 |

195 |

— |

— |

|

20.7 |

156 |

3 |

0.5 |

1.7 |

5.0 |

15.8/15.8 |

— |

— |

0.57 |

82/82 |

110/110 |

180 |

|

4.6 |

18.8 |

0.57 |

86/86 |

110/110 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

460 |

414 |

508 |

16.4 |

95 |

— |

— |

|

10 |

70 |

3 |

0.5 |

0.8 |

5.0 |

7.9 |

— |

— |

0.30 |

41 |

50 |

|

|

|

|||||||||||||||||||

|

|

2.3 |

6.0 |

0.30 |

43 |

50 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

208/230 |

187 |

253 |

30.1 |

225 |

— |

— |

|

28.8 |

195 |

3 |

0.5 |

1.7 |

5.0 |

15.8/15.8 |

— |

— |

0.57 |

87/87 |

110/110 |

210 |

|

4.6 |

18.8 |

0.57 |

92/92 |

110/110 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

460 |

414 |

508 |

15.5 |

114 |

— |

— |

|

14.7 |

95 |

3 |

0.5 |

0.8 |

5.0 |

7.9 |

— |

— |

0.30 |

44 |

50 |

|

|

|

|||||||||||||||||||

|

|

2.3 |

6.0 |

0.30 |

47 |

60 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

208/230 |

187 |

253 |

42 |

239 |

— |

— |

|

33.6 |

225 |

2 |

1 |

6.6 |

7.5 |

25.0/25.0 |

— |

— |

0.57 |

124/124 |

150/150 |

240 |

|

4.6 |

18.8 |

0.57 |

129/129 |

150/150 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

460 |

414 |

508 |

19.2 |

125 |

— |

— |

|

17.3 |

114 |

2 |

1 |

3.3 |

7.5 |

13.0 |

— |

— |

0.30 |

61 |

80 |

|

|

|

|||||||||||||||||||

|

|

2.3 |

6.0 |

0.30 |

63 |

80 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

208/230 |

187.2 |

253 |

20.7 |

156 |

20.7 |

156 |

|

47.1 |

245 |

6 |

0.5 |

1.7 |

10.0 |

28.0/28.0 |

— |

— |

0.57 |

138/138 |

175/175 |

300 |

|

4.6 |

18.8 |

0.57 |

143/143 |

150/175 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

460 |

414 |

508 |

10 |

75 |

10 |

75 |

|

19.6 |

125 |

6 |

0.5 |

0.8 |

10.0 |

14.6 |

— |

— |

0.30 |

64 |

80 |

|

|

|

|||||||||||||||||||

|

|

2.3 |

6 |

0.30 |

66 |

80 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

LEGEND |

FLA |

— |

Full Load Amps |

HACR |

— |

Heating, Air Conditioning and Refrigeration |

IFM |

— |

Indoor (Evaporator) Fan Motor |

LRA |

— |

Locked Rotor Amps |

MCA |

— |

Minimum Circuit Amps |

MOCP — |

Maximum Overcurrent Protection |

|

NEC |

— |

National Electrical Code |

OFM |

— |

Outdoor (Condenser) Fan Motor |

RLA |

— |

Rated Load Amps |

*Fuse or HACR circuit breaker.

NOTES:

1.In compliance with NEC requirements for multimotor and combination load equipment (refer to NEC Articles 430 and 440), the overcurrent protective device for the unit shall be fuse or HACR breaker. Canadian units may be fuse or circuit breaker.

2.Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater than 2%. Use the following formula to determine the percent voltage imbalance.

% Voltage Imbalance

= 100 x

max voltage deviation from average voltage average voltage

EXAMPLE: Supply voltage is 460-3-60.

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage = |

452 + 464 + 455 |

|

3 |

||

|

=1371

3

=457

Determine maximum deviation from average voltage. (AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v (AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent voltage imbalance.

% Voltage Imbalance = 100 x

7

457

= 1.53%

This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact your local electric utility company immediately.

X. STEP 10 — MAKE OUTDOOR-AIR INLET ADJUSTMENTS

A. Manual Outdoor-Air Damper

All units (except those equipped with a factory-installed EconoMi$erIV) have a manual outdoor-air damper to provide ventilation air.

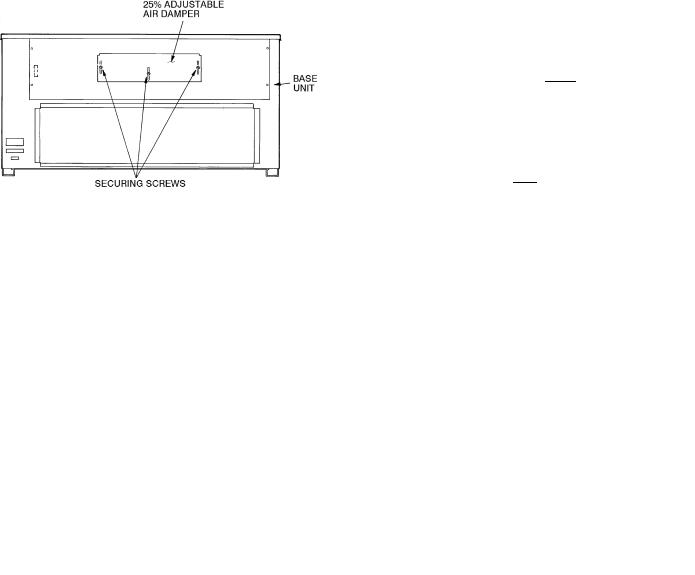

Damper can be preset to admit up to 25% outdoor air into return-air compartment. To adjust, loosen securing screws and move damper to desired setting, then retighten screws to secure damper (Fig. 18).

XI. STEP 11 — INSTALL OUTDOOR-AIR HOOD |

|

The outdoor-air hood is common to 25% air ventilation and |

|

EconoMi$erIV. If EconoMi$erIV is factory installed, all |

|

electrical connections have been made and adjusted at the |

Fig. 18 — Standard 25% Outdoor-Air Section Details |

factory. Assemble and install hood in the field. |

|

—15—

IMPORTANT: If the unit is equipped with the optional EconoMi$erIV component, move the outdoor-air temperature sensor prior to installing the outdoor-air hood. See the Optional EconoMi$erIV section for more information.

NOTE: The hood top panel, upper and lower filter retainers, hood drain pan, baffle (size 300), and filter support bracket are secured opposite the condenser end of the unit. The screens, hood side panels, remaining section of filter support bracket, seal strip, and hardware are in a package located inside the return-air filter access panel (Fig. 19).

1.Attach seal strip to upper filter retainer. See Fig. 20.

2.Assemble hood top panel, side panels, upper filter retainer, and drain pan (see Fig. 21).

3.Secure lower filter retainer and support bracket to unit. See Fig. 21. Leave screws loose on size 300 units.

4.Slide baffle (size 300) behind lower filter retainer and tighten screws.

5.Loosen sheet metal screws for top panel of base unit located above outdoor-air inlet opening, and remove screws for hood side panels located on the sides of the outdoor-air inlet opening.

6.Match notches in hood top panel to unit top panel screws. Insert hood flange between top panel flange and unit. Tighten screws.

7.Hold hood side panel flanges flat against unit, and install screws removed in Step 5.

8.Insert outdoor-air inlet screens and spacer in channel created by lower filter retainer and filter support bracket.

9.Attach remaining section of filter support bracket.

XII. STEP 12 — INSTALL ALL ACCESSORIES

After all the factory-installed options have been adjusted, install all field-installed accessories. Refer to the accessory installation instructions included with each accessory.

A. Motormaster® I Control (–20 F) Installation (580F180 and 210 Only)

Install Field-Fabricated Wind Baffles

Wind baffles must be field-fabricated for all units to ensure proper cooling cycle operation at low ambient temperatures. See Fig. 22 for baffle details. Use 20-gage, galvanized sheet metal, or similar corrosion-resistant metal for baffles. Use field-supplied screws to attach baffles to unit. Screws should be 1/4-in. diameter and 5/8-in. long. Drill required screw holes for mounting baffles.

CAUTION: To avoid damage to the refrigerant coils and electrical components, use recommended screw sizes only. Use care when drilling holes.

CAUTION: To avoid damage to the refrigerant coils and electrical components, use recommended screw sizes only. Use care when drilling holes.

Install Motormaster I Controls

One Motormaster I control is required on size 180 and 210 units. The Motormaster I control must be used in conjunction with the accessory fan motor sequencing kit and winter start kit (purchased separately). The Motormaster I device controls outdoor fan no. 1 while outdoor fans no. 2 and 3 are sequenced off by the accessory fan motor sequencing kit.

Accessory Fan Motor Sequencing Kit — Install the accessory fan motor sequencing kit per instruction supplied with accessory (purchased separately).

Winter Start Time Delay Relay Kit — Install the kit per the instructions supplied with the accessory (purchased separately).

Sensor Assembly — Install the sensor assembly in the location shown in Fig. 23.

Fig. 19 — Outdoor-Air Hood Component Location

Fig. 20 — Seal Strip Location

BAFFLE

LOWER FILTER

RETAINER

FILTER SUPPORT

BRACKET

HOOD SIDE

PANELS (2)

HOOD TOP PANEL

BAFFLE (300 ONLY)

LOWER

FILTER

RETAINER

FILTER SUPPORT

BRACKET

HOOD DRAIN PAN

UPPER FILTER RETAINER

NOTE: The outdoor-air hood comes with a baffle which is used on size 300 units only, discard baffle for size 180-240 units.

Fig. 21 — Outdoor-Air Hood Details

—16—

Loading...

Loading...