Bryant 524J User Manual

524J

Packaged Air-Handling Units 60 Hz

with Puron® (R-410A) Refrigerant Sizes 07, 08, 12, 14, 16

Installation, Start-Up and

Service Instructions

TABLE OF CONTENTS

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . 1

PRE-INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Moving and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Rigging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Uncrating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unit Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Unit Isolation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Refrigerant Piping Access. . . . . . . . . . . . . . . . . . . . . . . 11

Refrigerant Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fan Motors and Drives . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power Supply and Wiring . . . . . . . . . . . . . . . . . . . . . . . 16

Connecting Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Return-Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

START-UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SERVICE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-33

Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Fan Motor Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . 20

Fan Shaft Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Centering Fan Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fan Shaft Position Adjustment . . . . . . . . . . . . . . . . . . . 21

Individual Fan Wheel Adjustment . . . . . . . . . . . . . . . . 21

Fan Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fan Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fan Pulley Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Pulley and Drive Adjustment . . . . . . . . . . . . . . . . . . . . 22

Condensate Drains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Return-Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Coil Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cleaning Cooling Coil . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cleaning Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Replacing Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

START-UP CHECKLIST . . . . . . . . . . . . . . . . . . . CL-1, CL-2

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance, or use can cause explosion, fire, electrical shock or other conditions which may cause personal injury or property damage. Consult a qualified installer, service agency, or your distributor or branch for information or assistance. The qualified installer or agency must use factory-authorized kits or accessories when modifying this product. Refer to the individual instructions package

Follow all safety codes. Wear safety glasses and work gloves. Use quenching cloths for brazing operations and have a fire extinguisher available. Read these instructions thoroughly and follow all warnings or cautions attached to the unit. Consult local building codes and appropriate national electrical codes (in USA, ANSI/NFPA70, National Electrical Code (NEC); in Canada, CSA C22.1) for special requirements.

It is important to recognize safety information. This is the safety-alert symbol . When you see this symbol on the unit and in instructions or manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, CAUTION, and NOTE. These words are used with the safetyalert symbol. DANGER identifies the most serious hazards which will result in severe personal injury or death. WARNING signifies hazards which could result in personal injury or death. CAUTION is used to identify unsafe practices, which may result in minor personal injury or product and property damage. NOTE is used to highlight suggestions which will result in enhanced installation, reliability, or operation.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal injury or death.

Before performing service or maintenance operations on unit, always turn off main power switch to unit and install lockout tag. Unit may have more than one power switch.

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could cause personal injury, death and/or equipment damage.

Puron® (R-410A) refrigerant systems operate at higher pressures than standard R-22 systems. Do not use R-22 service equipment or components on Puron refrigerant equipment.

PERSONAL INJURY AND ENVIRONMENTAL HAZARD

Failure to follow this warning could cause personal injury or death.

Relieve pressure and recover all refrigerant before system repair or final unit disposal.

Wear safety glasses and gloves when handling refrigerants. Keep torches and other ignition sources away from refrigerants and oils.

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and wear appropriate protective clothing, safety glasses and gloves when handling parts and servicing 524J units.

UNIT OPERATION HAZARD

Failure to follow this caution could cause equipment damage.

Ensure voltage listed on unit data plate agrees with electrical supply provided for the unit.

PRE-INSTALLATION

1.The power supply (v, ph, and Hz) must correspond to that specified on unit rating plate.

2.The electrical supply provided by the utility must be sufficient to handle load imposed by this unit.

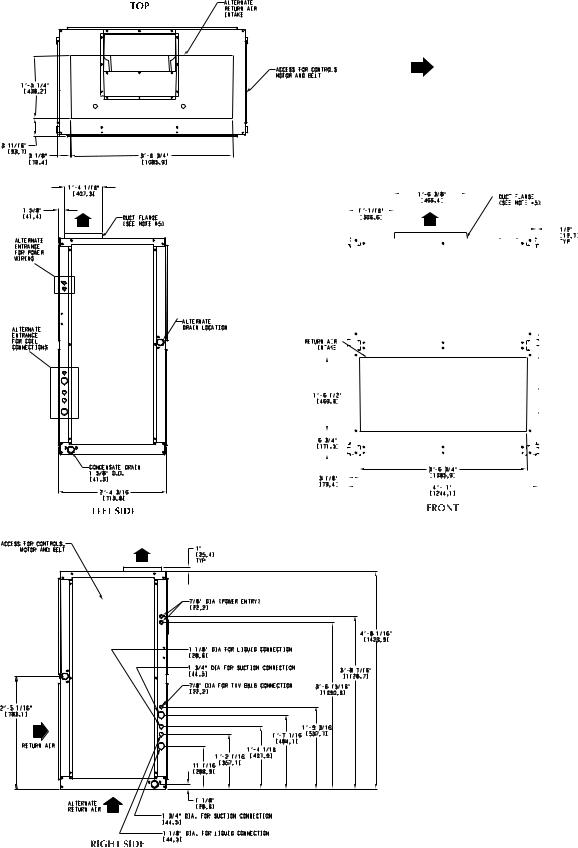

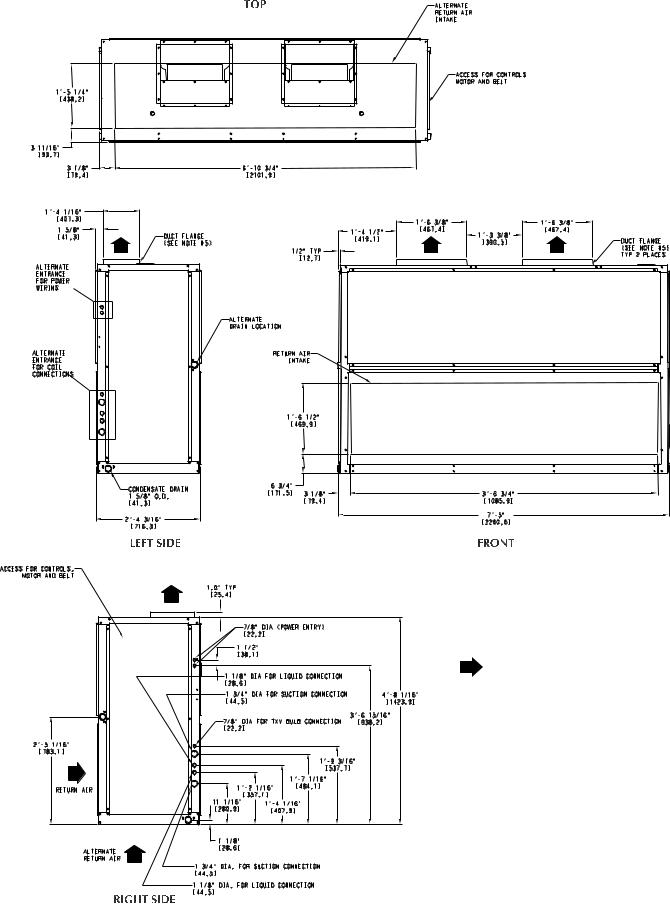

3. Refer to Installation, General section (page 2) and Fig. 1A and Fig. 1B for locations of electrical inlets, condensate drain, duct connections, and required clearances before setting unit in place.

4.This installation must conform with local building codes and with the NEC (National Electrical Code) or ANSI (American National Standards Institute)/NFPA (National Fire Protection Association) latest revision. Refer to provincial and local plumbing or wastewater codes and other applicable local codes.

Moving and Storage — To transfer unit from truck to storage site, use a fork truck. Do not stack units more than 2 high during storage. If unit is to be stored for more than 2 weeks before installation, choose a level, dry storage site free from vibration. Do not remove plastic wrap or skid from unit until final installation.

Rigging — All 524J Series units can be rigged by using the shipping skid. Units are shipped fully assembled. Do not remove shipping skids or protective covering until unit is ready for final placement; damage to bottom panels can result. Use slings and spreader bars as applicable to lift unit.

INSTALLATION

General — Allow 21/2 ft at front and side of unit for service clearance and airflow. For units equipped with an economizer, refer to the accessory installation instructions for additional clearance requirements. Be sure floor, wall, or ceiling can support unit weight (Tables 1A – 1D). See Fig. 1A and Fig. 1B for dimensions.

Uncrating — Move unit as near as possible to final location before removing shipping skid.

Remove metal banding, top skid, and plastic wrap. Examine unit for shipping damage. If shipping damage is evident, file claim with transportation agency. Remove base skid just prior to actual installation.

Check nameplate information against available power supply and model number description in Fig. 2.

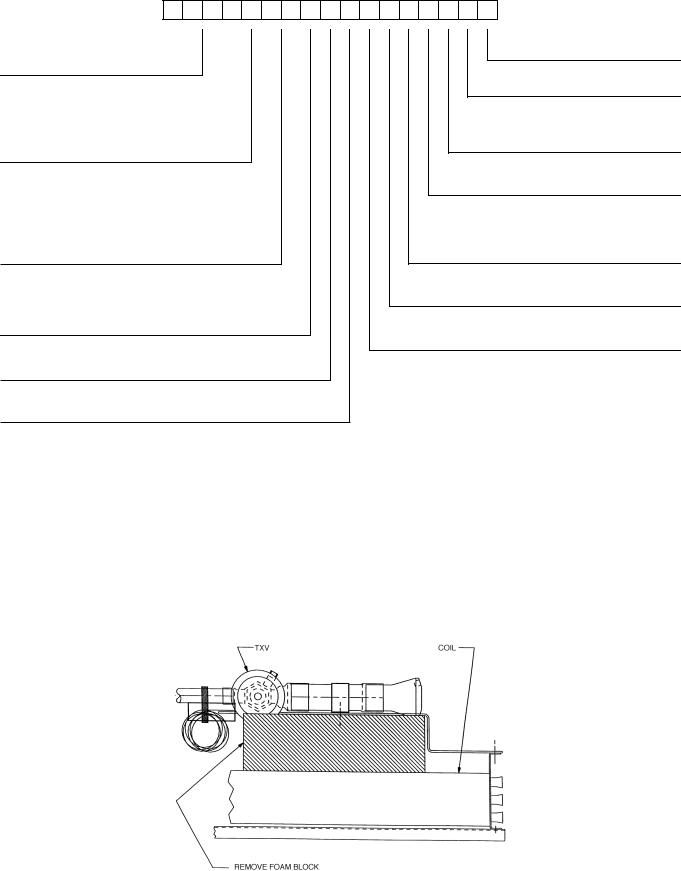

NOTE: Be sure to remove the styrofoam shipping pad from the thermostatic expansion valve (TXV). Verify that it has been removed. See Fig. 3.

Accessories — Refer to instructions shipped with each accessory for specific information.

2

Table 1A — 524J***A Physical Data, English — Cooling Units

UNIT 524J* |

07A |

|

08A |

12A |

|

14A |

|

16A |

||

NOMINAL CAPACITY (Tons) |

6 |

|

71/2 |

10 |

|

121/2 |

|

15 |

||

OPERATING WEIGHT (lb) |

|

|

|

|

|

|

|

|

||

|

Base Unit with TXV |

381 |

|

385 |

405 |

|

670 |

|

685 |

|

|

Plenum |

175 |

|

175 |

175 |

|

225 |

|

225 |

|

FANS |

|

|

|

|

|

|

|

|

||

|

Qty...Diam. (in.) |

1...15 |

|

1...15 |

1...15 |

|

2...15 |

|

2...15 |

|

|

Nominal Airflow (cfm) |

2400 |

|

3000 |

4000 |

|

5000 |

|

6000 |

|

|

Airflow Range (cfm) |

1800- |

|

2250- |

3000- |

|

3750- |

|

4500- |

|

|

3000 |

|

3750 |

5000 |

|

6250 |

|

7500 |

||

|

|

|

|

|

|

|||||

|

Nominal Motor Hp (Standard Motor) |

|

|

|

|

|

|

|

|

|

|

|

208/230-1-60 |

1.3 |

|

2.4 |

— |

|

— |

|

— |

|

|

208/230-3-60 and 460-3-60 |

2.4 |

|

2.4 |

2.4 |

|

2.9 |

|

3.7 |

|

|

575-3-60 |

1.0 |

|

2.0 |

2.0 |

|

3.0 |

|

3.0 |

|

Motor Speed (rpm) |

|

|

|

|

|

|

|

|

|

|

|

208/230-1-60 |

1725 |

|

1725 |

— |

|

— |

|

— |

|

|

208/230-3-60 and 460-3-60 |

1725 |

|

1725 |

1725 |

|

1725 |

|

1725 |

|

|

575-3-60 |

1725 |

|

1725 |

1725 |

|

1725 |

|

1725 |

REFRIGERANT |

|

|

|

R-410A |

|

|

|

|

||

|

Operating charge (lb) |

3.0 |

|

3.0 |

1.5/1.5 |

|

2.0/2.0 |

|

2.5/2.5 |

|

|

(approx per circuit† |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||

DIRECT-EXPANSION COIL |

|

|

Enhanced Copper |

Tubes, Aluminum Sine-Wave Fins |

|

|||||

|

Max Working Pressure (psig) |

|

|

|

450 |

|

|

|

|

|

|

Face Area (sq ft) |

6.67 |

|

10.0 |

|

13.25 |

|

17.67 |

||

|

|

8.33 |

|

|

||||||

|

No. of Splits |

1 |

|

1 |

2 |

|

2 |

|

2 |

|

|

No. of Circuits per Split |

12 |

|

15 |

9 |

|

12 |

|

16 |

|

|

Split Type...Percentage |

— |

|

— |

|

|

Face...50/50 |

|

||

|

Fins/in. |

15 |

|

15 |

15 |

|

15 |

|

15 |

|

PIPING CONNECTIONS, |

|

|

|

|

|

|

|

|

||

Quantity...Size (in.) |

|

|

|

|

|

|

|

|

||

|

DX Coil — Suction (ODF) |

1...11/8 |

|

1...11/8 |

2...11/8 |

|

2...11/8 |

|

2...11/8 |

|

|

DX Coil — Liquid Refrigerant (ODF) |

|

1...5/8 |

|

2...5/8 |

|

|

|||

|

Steam Coil, In (MPT) |

|

1...21/2 |

|

1...21/2 |

|

|

|||

|

Steam Coil, Out (MPT) |

|

1...11/2 |

|

1..11/2 |

|

|

|||

|

Hot Water Coil, In (MPT) |

|

1...11/2 |

|

|

1...2 |

|

|||

|

Hot Water Coil, Out (MPT) |

|

1...11/2 |

|

|

1...2 |

|

|||

|

Condensate (PVC) |

|

|

|

1...11/4 ODM/1 |

|

IDF |

|

||

FILTERS |

|

|

Throwaway — Factory Supplied |

|

||||||

|

Quantity...Size (in.) |

|

|

4...16 x 24 x 2 |

|

|

4...16 x 20 x 2 |

|||

|

|

|

|

|

||||||

|

|

|

|

|

4...16 x 24 x 2 |

|||||

|

|

|

|

|

|

|

|

|||

|

Access Location |

|

|

|

Either Side |

|

|

|

|

|

STEAM COIL** |

|

|

|

|

|

|

|

|

||

|

Max Working Pressure (psig at 260°F) |

|

|

|

20 |

|

|

|

|

|

|

Total Face Area (sq ft) |

6.67 |

|

6.67 |

|

13.33 |

|

13.33 |

||

|

|

6.67 |

|

|

||||||

|

Rows...Fins/in. |

1...9 |

|

1...9 |

1...9 |

|

1...10 |

|

1...10 |

|

HOT WATER COIL** |

|

|

|

|

|

|

|

|

||

|

Max Working Pressure (psig) |

|

|

|

150 |

|

|

|

|

|

|

Total Face Area (sq ft) |

6.67 |

|

6.67 |

|

13.33 |

|

13.33 |

||

|

|

6.67 |

|

|

||||||

|

Rows...Fins/in. |

2...8.5 |

|

2...8.5 |

2...8.5 |

|

2...8.5 |

|

2...8.5 |

|

|

Water Volume |

|

|

|

|

|

|

|

|

|

|

|

(gal) |

|

8.3 |

|

13.9 |

|

|

||

|

|

(ft3) |

|

1.1 |

|

1.85 |

|

|

||

LEGEND |

|

|

|

|

|

|

|

|

||

DX |

— Direct Expansion |

|

|

|

|

|

|

|

|

|

TXV — Thermostatic Expansion Valve |

|

|

|

|

|

|

|

|

||

† |

Units are shipped without refrigerant charge. |

|

|

|

|

|

|

|

|

|

** |

Field installed accessory only. |

|

|

|

|

|

|

|

|

|

3

Table 1B — 524J***A Physical Data, SI — Cooling Units

UNIT 524J* |

07A |

|

08A |

12A |

|

14A |

|

16A |

||

NOMINAL CAPACITY (kW) |

21 |

|

26 |

35 |

|

43 |

|

52 |

||

OPERATING WEIGHT (kg) |

|

|

|

|

|

|

|

|

||

|

Base Unit with TXV |

173 |

|

175 |

184 |

|

304 |

|

311 |

|

|

Plenum |

80 |

|

80 |

80 |

|

102 |

|

102 |

|

FANS |

|

|

|

|

|

|

|

|

||

|

Qty...Diam. (mm) |

1...381 |

|

1...381 |

1...381 |

|

2...381 |

|

2...381 |

|

|

Nominal Airflow (L/s) |

1133 |

|

1604 |

1888 |

|

2360 |

|

2831 |

|

|

Airflow Range (L/s) |

850-1416 |

|

1203-2006 |

1416-2360 |

|

1770-2949 |

|

2124-3539 |

|

|

Nominal Motor kW (Standard Motor) |

|

|

|

|

|

|

|

|

|

|

|

208/230-1-60 |

0.97 |

|

1.79 |

— |

|

— |

|

— |

|

|

208/230-3-60 and 460-3-60 |

1.79 |

|

1.79 |

1.79 |

|

2.16 |

|

2.16 |

|

|

575-3-60 |

0.75 |

|

1.49 |

1.49 |

|

2.24 |

|

2.24 |

|

Motor Speed (r/s) |

|

|

|

|

|

|

|

|

|

|

|

208/230-1-60 |

28.8 |

|

28.8 |

— |

|

— |

|

— |

|

|

208/230-3-60 and 460-3-60 |

28.8 |

|

28.8 |

28.8 |

|

28.8 |

|

28.8 |

|

|

575-3-60 |

28.8 |

|

28.8 |

28.8 |

|

28.8 |

|

28.8 |

REFRIGERANT |

|

|

|

R-410A |

|

|

|

|

||

|

Operating charge (kg) |

1.36 |

|

1.36 |

0.68/0.68 |

|

0.90/0.90 |

|

1.13/1.13 |

|

|

(approx per circuit)† |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||

DIRECT-EXPANSION COIL |

|

|

Enhanced Copper |

Tubes, Aluminum Sine-Wave Fins |

||||||

|

Max Working Pressure (kPag) |

|

|

|

3102 |

|

|

|

|

|

|

Face Area (sq m) |

0.62 |

|

0.93 |

|

0.93 |

|

1.64 |

||

|

|

0.77 |

|

|

||||||

|

No. of Splits |

1 |

|

1 |

2 |

|

2 |

|

2 |

|

|

No. of Circuits per Split |

12 |

|

15 |

9 |

|

12 |

|

16 |

|

|

Split Type...Percentage |

— |

|

— |

|

|

Face...50/50 |

|

||

|

Fins/m |

591 |

|

591 |

670 |

|

591 |

|

591 |

|

|

|

|

|

|||||||

PIPING CONNECTIONS, |

|

|

|

|

|

|

|

|

||

Quantity...Size (in.) |

|

|

|

|

|

|

|

|

||

|

DX Coil — Suction (ODF) |

1...11/8 |

|

1...11/8 |

2...11/8 |

|

2...11/8 |

|

2...11/8 |

|

|

DX Coil — Liquid Refrigerant (ODF) |

1... |

5/8 |

|

|

2...5/8 |

|

|

||

|

Steam Coil, In (MPT) |

1...21/2 |

|

|

1...21/2 |

|

|

|||

|

Steam Coil, Out (MPT) |

1...11/2 |

|

|

1..11/2 |

|

|

|||

|

Hot Water Coil, In (MPT) |

|

1...11/2 |

|

|

1...2 |

|

|||

|

Hot Water Coil, Out (MPT) |

|

1...11/2 |

|

|

1...2 |

|

|||

|

Condensate (PVC) |

|

|

|

1...11/4 ODM/1 IDF |

|

||||

FILTERS |

|

|

Throwaway — Factory Supplied |

|

||||||

|

Quantity...Size |

|

4...406 x 610 x 51 |

|

4...406 x 508 x 51 |

|||||

|

|

|

4...406 x 610 x 51 |

|||||||

|

|

|

|

|

|

|

|

|||

|

Access Location |

|

|

|

Either Side |

|

|

|

||

STEAM COIL** |

|

|

|

|

|

|

|

|

||

|

Max Working Pressure (kPag at 126°C) |

|

|

|

138 |

|

|

|

|

|

|

Total Face Area (sq m) |

0.62 |

|

0.62 |

0.62 |

|

1.24 |

|

1.24 |

|

|

Rows...Fins/m |

1...355 |

|

1...355 |

1...355 |

|

1...394 |

|

1...394 |

|

HOT WATER COIL** |

|

|

|

|

|

|

|

|

||

|

Max Working Pressure (kPag) |

|

|

|

1034 |

|

|

|

|

|

|

Total Face Area (sq m) |

0.62 |

|

0.62 |

|

1.24 |

|

1.24 |

||

|

|

0.62 |

|

|

||||||

|

Rows...Fins/m |

2...335 |

|

2...335 |

2...335 |

|

2...335 |

|

2...335 |

|

|

Water Volume |

|

|

|

|

|

|

|

|

|

|

|

(L) |

|

31.4 |

|

|

52.6 |

|

||

|

|

|

|

|

|

|||||

|

|

(m3) |

|

0.031 |

|

|

0.052 |

|

||

LEGEND |

|

|

|

|

|

|

|

|

||

DX |

— Direct Expansion |

|

|

|

|

|

|

|

|

|

TXV — Thermostatic Expansion Valve |

|

|

|

|

|

|

|

|

||

† |

Units are shipped without refrigerant charge. |

|

|

|

|

|

|

|

|

|

** |

Field installed accessory only. |

|

|

|

|

|

|

|

|

|

4

Table 1C — 524J***H Physical Data, English — Heat Pump Units

|

|

UNIT 524J* |

07H |

|

08H |

|

12H |

|

|

|

NOMINAL CAPACITY (Tons) |

6 |

|

71/2 |

|

10 |

|

|

|

OPERATING WEIGHT (lb) |

|

|

|

|

|

|

|

|

|

Base Unit with TXV |

385 |

|

385 |

|

427 |

|

|

|

Plenum |

175 |

|

175 |

|

175 |

|

|

FANS |

|

|

|

|

|

|

|

|

|

Qty...Diam. (in.) |

1...15 |

|

1...15 |

|

1...15 |

|

|

|

Nominal Airflow (cfm) |

2400 |

|

3000 |

|

4000 |

|

|

|

Airflow Range (cfm) |

1800-3000 |

|

2250-3750 |

|

3000-5000 |

|

|

|

Nominal Motor Hp (Standard Motor) |

|

|

|

|

|

|

|

|

208/230-1-60 |

1.3 |

|

2.4 |

|

— |

|

|

|

208/230-3-60 and 460-3-60 |

2.4 |

|

2.4 |

|

2.4 |

|

|

|

575-3-60 |

1.0 |

|

2.0 |

|

2.0 |

|

|

|

Motor Speed (rpm) |

|

|

|

|

|

|

|

|

208/230-1-60 |

1725 |

|

1725 |

|

— |

|

|

|

208/230-3-60 and 460-3-60 |

1725 |

|

1725 |

|

1725 |

|

|

|

575-3-60 |

1725 |

|

1725 |

|

1725 |

|

|

REFRIGERANT |

|

|

R-410A |

|

|

|

|

|

|

Operating charge (lb) |

3.0 |

|

3.0 |

|

2.0/2.0 |

|

|

|

(approx per circuit)† |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

DIRECT-EXPANSION COIL |

Enhanced Copper Tubes, Aluminum Sine-Wave Fins |

|||||

|

|

|

Max Working Pressure (psig) |

|

450 |

|

|

|

|

|

|

Face Area (sq ft) |

8.33 |

|

8.33 |

|

10.0 |

|

|

|

No. of Splits |

1 |

|

1 |

|

2 |

|

|

|

No. of Circuits per Split |

15 |

|

15 |

|

9 |

|

|

|

Split Type...Percentage |

— |

|

— |

|

— |

|

|

|

Rows...Fins/in. |

3...15 |

|

3...15 |

|

3...15 |

|

|

PIPING CONNECTIONS, |

|

|

|

|

|

|

|

|

Quantity...Size (in.) |

1...11/8 |

|

1...11/8 |

|

2...11/8 |

|

|

|

|

DX Coil — Suction (ODF) |

|

|

|||

|

|

|

DX Coil — Liquid Refrigerant (ODF) |

1...5/8 |

|

1...5/8 |

|

2...5/8 |

|

|

|

Steam Coil, In (MPT) |

1...21/2 |

|

1...21/2 |

|

1...21/2 |

|

|

|

Steam Coil, Out (MPT) |

1...11/2 |

|

1...11/2 |

|

1...11/2 |

|

|

|

Hot Water Coil, In (MPT) |

1...11/2 |

|

1...11/2 |

|

1...11/2 |

|

|

|

Hot Water Coil, Out (MPT) |

1...11/2 |

|

1...11/2 |

|

1...11/2 |

|

|

|

Condensate (PVC) |

|

|

1...11/4 ODM/1 IDF |

|

|

|

|

FILTERS |

|

|

Throwaway — |

|

|

|

|

|

|

|

|

|

Factory Supplied |

|

|

|

|

|

Quantity...Size (in.) |

|

|

4...16 x 24 x 2 |

|

|

|

|

|

Access Location |

|

|

Either Side |

|

|

|

|

STEAM COIL** |

|

|

|

|

|

|

|

|

|

Max Working Pressure (psig at 260°F) |

|

20 |

|

|

|

|

|

|

Total Face Area (sq ft) |

6.67 |

|

6.67 |

|

6.67 |

|

|

|

|

|

||||

|

|

|

Rows...Fins/in. |

1...9 |

|

1...9 |

|

1...9 |

|

|

HOT WATER COIL** |

|

|

|

|

|

|

|

|

|

Max Working Pressure (psig) |

|

150 |

|

|

|

|

|

|

Total Face Area (sq ft) |

6.67 |

|

6.67 |

|

6.67 |

|

|

|

Rows...Fins/in. |

2...8.5 |

|

2...8.5 |

|

2...8.5 |

|

|

|

Water Volume |

|

|

|

|

|

|

|

|

(gal) |

|

8.3 |

|

|

|

|

|

|

(ft3) |

|

1.1 |

|

|

|

LEGEND |

|

|

|

|

|

|||

DX |

— Direct Expansion |

|

|

|

|

|

||

TXV — Thermostatic Expansion Valve |

|

|

|

|

|

|||

† |

Units are shipped without refrigerant charge. |

|

|

|

|

|

||

** |

Field installed accessory only. |

|

|

|

|

|

||

5

Table 1D —524J***H Physical Data, SI — Heat Pump Units

|

|

UNIT 524J* |

07H |

|

08H |

|

12H |

|

|

|

NOMINAL CAPACITY (kW) |

21 |

|

26 |

|

35 |

|

|

|

OPERATING WEIGHT (kg) |

|

|

|

|

|

|

|

|

|

Base Unit with TXV |

175 |

|

175 |

|

194 |

|

|

|

Plenum |

80 |

|

80 |

|

80 |

|

|

FANS |

|

|

|

|

|

|

|

|

|

Qty...Diam. (mm) |

1...381 |

|

1...381 |

|

1...381 |

|

|

|

Nominal Airflow (L/s) |

1133 |

|

1604 |

|

1888 |

|

|

|

Airflow Range (L/s) |

850-1416 |

|

1203-2006 |

|

1416-2360 |

|

|

|

Nominal Motor kW (Standard Motor) |

|

|

|

|

|

|

|

|

208/230-1-60 |

0.97 |

|

1.79 |

|

— |

|

|

|

208/230-3-60 and 460-3-60 |

1.79 |

|

1.79 |

|

1.79 |

|

|

|

575-3-60 |

0.75 |

|

1.49 |

|

1.49 |

|

|

|

Motor Speed (r/s) |

|

|

|

|

|

|

|

|

208/230-1-60 |

28.8 |

|

28.8 |

|

— |

|

|

|

208/230-3-60 and 460-3-60 |

28.8 |

|

28.8 |

|

22.8 |

|

|

|

575-3-60 |

28.8 |

|

28.8 |

|

22.8 |

|

|

REFRIGERANT |

|

|

R-410A |

|

|

|

|

|

|

Operating charge (kg) |

1.36 |

|

1.36 |

|

0.91/0.91 |

|

|

|

(approx per circuit)† |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

DIRECT-EXPANSION COIL |

Enhanced Copper Tubes, Aluminum Sine-Wave Fins |

|||||

|

|

|

Max Working Pressure (kPag) |

|

3102 |

|

|

|

|

|

|

Face Area (sq m) |

0.77 |

|

0.77 |

|

0.93 |

|

|

|

No. of Splits |

1 |

|

1 |

|

2 |

|

|

|

No. of Circuits per Split |

12 |

|

15 |

|

9 |

|

|

|

Split Type...Percentage |

— |

|

— |

|

— |

|

|

|

Rows...Fins/m |

3...591 |

|

3...591 |

|

3...591 |

|

|

PIPING CONNECTIONS, |

|

|

|

|

|

|

|

|

Quantity...Size (in.) |

1...11/8 |

|

1...11/8 |

|

2...11/8 |

|

|

|

|

DX Coil — Suction (ODF) |

|

|

|||

|

|

|

DX Coil — Liquid Refrigerant (ODF) |

1...5/8 |

|

1...5/8 |

|

2...5/8 |

|

|

|

Steam Coil, In (MPT) |

1...21/2 |

|

1...21/2 |

|

1...21/2 |

|

|

|

Steam Coil, Out (MPT) |

1...11/2 |

|

1...11/2 |

|

1...11/2 |

|

|

|

Hot Water Coil, In (MPT) |

1...11/2 |

|

1...11/2 |

|

1...11/2 |

|

|

|

Hot Water Coil, Out (MPT) |

1...11/2 |

|

1...11/2 |

|

1...11/2 |

|

|

|

Condensate (PVC) |

|

|

1...11/4 ODM/1 IDF |

|

|

|

|

FILTERS |

|

|

Throwaway — |

|

|

|

|

|

|

|

|

|

Factory Supplied |

|

|

|

|

|

Quantity...Size (mm) |

|

|

4...406 x 610 x 51 |

|

|

|

|

|

Access Location |

|

|

Either Side |

|

|

|

|

STEAM COIL** |

|

|

|

|

|

|

|

|

|

Max Working Pressure (kPag at 126°C) |

|

138 |

|

|

|

|

|

|

Total Face Area (sq m) |

0.62 |

|

0.62 |

|

0.62 |

|

|

|

Rows...Fins/m |

1...355 |

|

1...355 |

|

1...355 |

|

|

HOT WATER COIL** |

|

|

|

|

|

|

|

|

|

Max Working Pressure (kPag) |

|

1034 |

|

|

|

|

|

|

Total Face Area (sq m) |

0.62 |

|

0.62 |

|

0.62 |

|

|

|

Rows...Fins/m |

2...335 |

|

2...335 |

|

2...335 |

|

|

|

|

|

|

|||

|

|

|

Water Volume |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(L) |

|

31.4 |

|

|

|

|

|

|

(m3) |

|

0.031 |

|

|

|

LEGEND |

|

|

|

|

|

|||

DX |

— Direct Expansion |

|

|

|

|

|

||

TXV — Thermostatic Expansion Valve |

|

|

|

|

|

|||

† |

Units are shipped without refrigerant charge. |

|

|

|

|

|

||

** |

Field installed accessory only. |

|

|

|

|

|

||

6

LEGEND

TXV — Thermostatic Expansion Valve

NOTES:

|

|

|

|

|

|

|

|

|

|

|

|

1. |

Dimensions in [ ] are in millimeters. |

||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

2. |

|

|

|

|

|

|

Direction of airflow. |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

3. |

Recommended clearance: |

||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• Rear: 3 in. [76 mm] |

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• Front: 2 ft, 6 in. [762 mm] |

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• Right Side: 2 ft, 6 in. [762 mm] |

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• Left Side: 2 ft, 6 in. [762 mm] |

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

4. |

• Local codes or jurisdiction may prevail. |

||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Liquid piping not supplied by Bryant. |

|||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

5. |

Duct flange is factory supplied and field |

||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

installed. |

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UNIT |

UNIT WEIGHT |

|

lb (kg) |

||

|

||

524J*07A |

381 (173) |

|

524J*08A |

385 (175) |

|

524J*12A |

405 (184) |

|

524J*07H |

385 (175) |

|

524J*08H |

385 (175) |

|

524J*12H |

427 (194) |

Fig. 1A — Dimensions – Sizes 07 - 12

7

LEGEND

TXV — Thermostatic Expansion Valve

NOTES:

1. |

Dimensions in [ |

] are in millimeters. |

|||

2. |

|

Direction of airflow. |

|||

3. |

Recommended clearance: |

||||

|

• Rear: 3 in. (76 mm) |

||||

|

• Front: 2 ft, 6 in. (762 mm) |

||||

|

• Right Side: 2 ft, 6 in. (762 mm) |

||||

|

• Left Side: 2 ft, 6 in. (762 mm) |

||||

|

• Local codes or jurisdiction may |

||||

4. |

prevail. |

|

|

|

|

Liquid piping not supplied by Bryant. |

|||||

5. |

Duct flange is factory-supplied and field- |

||||

|

installed. |

|

|

|

|

|

|

|

|

|

|

|

|

UNIT |

|

UNIT WEIGHT |

|

|

|

|

lb (kg) |

||

|

|

|

|

||

|

|

524J*14A |

|

670 (304) |

|

|

|

524J*16A |

|

685 (331) |

|

Fig. 1B — Dimensions – Sizes 14 and 16

8

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

5 2 4 J E 1 4 A 0 0 0 A 2 0 A A A

_____________ ____

Model Type

524J = Bryant Fan Coil

Puronr R---410A Refrigerant

Voltage

E = 460/3/60

J = 208/230/1/60 (07 and 08 Units Only)

P = 208/230/3/60 (Size 16 and Indoor Fan 3 Units Only) T = 575/3/60

Nominal Tonnage

07 = 6 Tons

08 = 7.5 Tons

12 = 10 Tons

14 = 12.5 Tons

16 = 15 Tons

Type of Coil

A = Standard DX Coil

B = High Capacity DX Coil

H = DX Coil for Heat Pump Duty

Not Used

0 = Not Used

Not Used

0 = Not Used

Packaging

A = Standard

Not Used

A = Not Used

Service Options

A = None

B = Painted Cabinet

Not Used

0 = Not Used

Indoor Fan Options

1 = Fan Drive and Motor - Low / Motor Efficency - Standard 2 = Fan Drive and Motor - Med / Motor Efficency - Standard 3 = Fan Drive and Motor - High / Motor Efficency - Standard

Coil Options

A = Al/Cu

Not Used

0 = Not Used

Fig. 2 — Model Number Nomenclature

POSITION NUMBER |

|

1 |

|

2 |

3 |

4 |

|

5 |

|

6 |

|

7 |

|

8 |

9 |

10 |

TYPICAL |

|

4 |

|

8 |

0 |

8 |

|

G |

|

1 |

|

2 |

|

3 |

4 |

5 |

|

POSITION |

|

|

|

|

|

DESIGNATES |

|

|

|

|

|

||||

|

|

1−2 |

|

|

|

Week of manufacture (fiscal calendar) |

|

|

|

|||||||

|

|

3−4 |

|

|

|

Year of manufacture (Ó08Ó = 2008) |

|

|

|

|||||||

|

5 |

|

|

|

Manufacturing location (G = ETP, Texas, USA) |

|

|

|||||||||

|

|

6−10 |

|

|

|

|

Sequential number |

|

|

|

|

|

||||

Fig. 3 — Serial Number Nomenclature

LEGEND

TXV — Thermostatic Expansion Valve

Fig. 4 — Foam Block Location

9

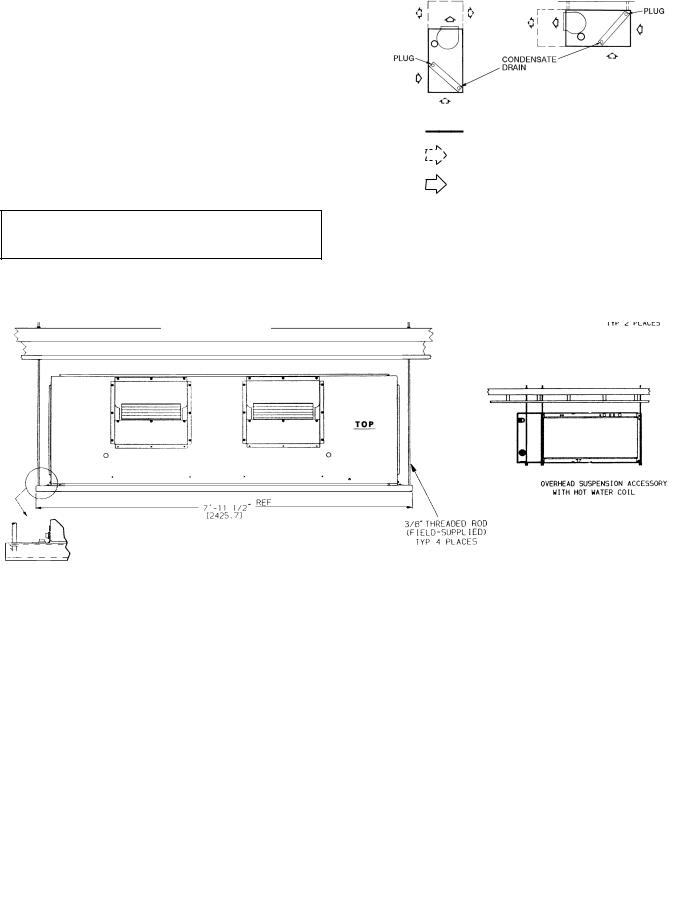

Unit Positioning — The unit can be mounted on the floor for vertical application with return air entering the face of the unit and supply air discharging vertically through the top of the unit. The unit can also be applied in a horizontal arrangement with return air entering horizontally and the supply air discharging horizontally. When applying the unit in a horizontal arrangement, ensure the condensate drain pan is located at the bottom center of the unit for adequate condensate disposal. See Fig. 5 for condensate connections for each unit position.

Typical positioning and alternate return air locations are shown in Fig. 5. Alternate return air locations can be used by moving the unit panel from the alternate return air location to the standard return air location. Refer to overhead suspension accessory drawing (Fig. 6) for preferred suspension technique. The unit needs support underneath to prevent sagging.

IMPORTANT: Do NOT attempt to install unit with return air entering top panel of unit. Condensate will not drain from unit.

LEGEND

Accessory Line

Alternate Air Intake and Discharge

Air Intake and Discharge

Note: Maintain recommended clearances per Figs. 1A–1B

Fig. 5 — Typical Unit Positioning

OVERHEAD SUSPENSION ACCESSORY

UNIT SIZES 07 - 12

UNIT SIZES 14 - 16

NOTE: Dimensions in [ ] are millimeters

Fig. 6 — Preferred Suspension Technique

10

Unit Isolation — Where extremely quiet operation is essential, install isolators between floor and base of unit, or between ceiling and top section of unit.

Be sure that unit is level and adequately supported. Use channels at front and sides of unit for reference points when leveling.

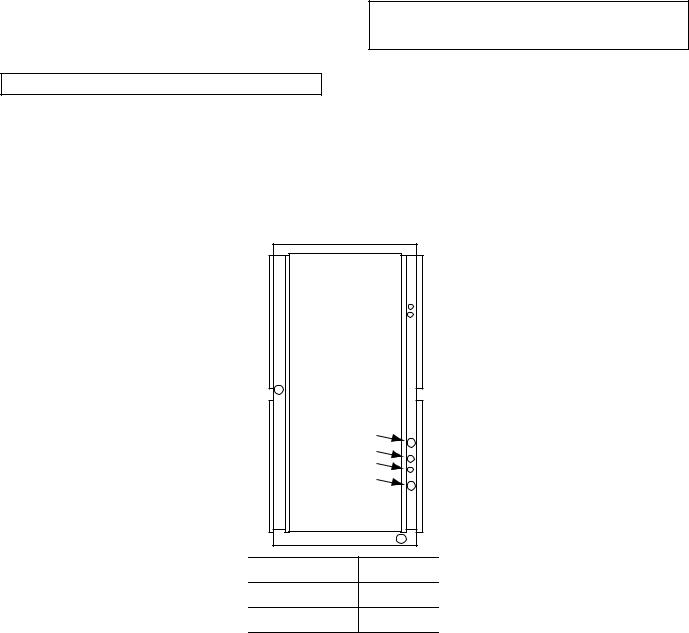

Refrigerant Piping Access — The 524J Series units come with standard knockouts for refrigerant piping. These knockouts are located on both sides of the unit for installation flexibility. The standard knockouts provide sufficient access to the unit’s coils for all 524J*07A, 08A, 12A, 14A and 16A units as well as the 524J*07H, 08H, 12H units. See Fig. 7 for the positions. Recommended access hole use is also listed for all units. Note that Fig. 7 shows the access holes on the controlbox side of the unit; this is the side of the unit with the coil headers, so it is used most often for piping access.

IMPORTANT: Do not bury refrigerant piping underground.

Refrigerant Piping — See Tables 1A – 1D for refrigerant pipe connection sizes. For ease in brazing, it is recommended that all internal solder joints be made before unit is placed in final position.

The 524J direct-expansion units have internal factory-installed thermostatic expansion valves (TXVs),

distributors, and nozzles for use with R-410A. See Table 2 for part numbers. Knockouts are provided in the unit corner posts for 524J refrigerant piping. See Fig. 7, which also lists recommended knockouts and access holes to use for each 524J unit size. Recommended fittings are listed in Table 3.

The sensor bulb capillary tubes must be routed from the TXVs inside the unit through one of the piping access holes. Clamp the TXV sensor bulb on a vertical portion of the suction line, outside the unit. See Fig. 8.

NOTE: Be sure to remove the styrofoam shipping pad from the TXV. Verify that it has been removed. See Fig. 4.

IMPORTANT: Never attach the sensor to the suction manifold. Do NOT mount the sensor on a trapped portion of the suction line.

The 524J Series evaporator coils have a face-split design. Ensure that lower circuit of coil is first on/last off when connected to the condensing unit and/or system controls. See Fig. 8.

External TXV equalizer connections are provided and factory-brazed into the coil suction manifolds.

If suction line must be horizontal, clamp bulb to suction line at least 45 degrees above bottom, at approximately the 4 o’clock or 8 o’clock position. See Fig. 9.

|

4 |

|

|

3 |

|

|

2 |

|

|

1 |

|

UNIT |

USE HOLE |

|

NUMBERS |

||

524J*07A, 08A |

||

1, 3 |

||

524J*07H, 08H |

||

|

||

524J*12A, 14A, 16A |

1, 2, 3, 4 |

|

524J*12H |

||

|

Fig. 7 — Refrigerant Piping Access Holes

11

Loading...

Loading...