Brookfield TC-101 User Manual

Operators Manual

Circulating Bath

with

Programmable Controller

110-119

rev. A

3

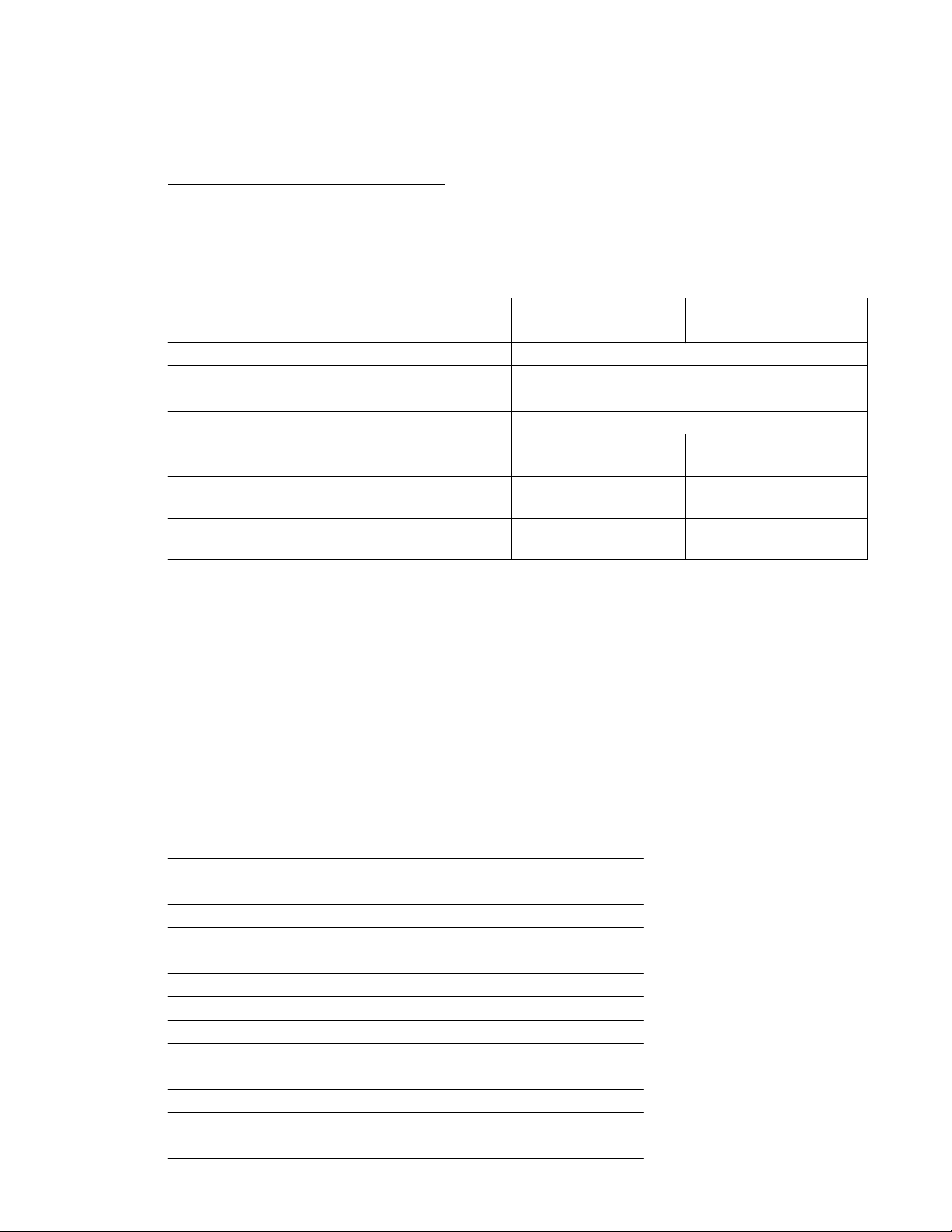

Table of Contents

Section 1. General Information

1.1 Unpacking

1.2 Package Contents

1.3 Description of Circulating Baths

1.4 Specification Chart

Section 2. Set Up

2.1 Location

2.2 Filling the Reservoir

2.3 Reservoir Fluids

2.4 Fluid Connections

2.5 Pump

2.6 Open Bath Circulation

2.7 Closed Loop Circulation

2.8 Power Supply

Section 3. Programmable Controller

3.1 To Set Temperature

3.2 To Change Pump Speed

3.3 System Set Up

— Adjust Display Contrast

— Set Temperature High & Low Limits

— Change Readout - °C, °F, °U

— Change Resolution - .1°, .01°, .001°

— External Probe

— Function Tuning

(Pump Speed and Controller Optimization)

— Pump Speed Selection

— Fluid Volume

— Flow Rate

— Specific Heat

— °U Cal, User Defined Temperature Scale

— RS232

— Auto Refrig

3.4 Setting the Safety Thermostat

Section 4. Programming

4.1 Writing A Program

4.2 Entering A Program Into Memory

4.3 Running A Program

Section 5. Maintenance

5.1 Heater

5.2 Pump Motor

5.3 Condenser and Air Vents (Refrigeration Units)

5.4 Cleaning

5.5 Maintaining Clear Bath Water

Section 6. Troubleshooting

6.1 Unit Disabled, Service Required

6.2 No Pumping or Insufficient Pumping

6.3 No Cooling or Insufficient Cooling

6.4 No Heating or Insufficient Heating

6.5 Triac Failure

6.6 Default Settings

Section 7. After-sale Support

Section 8. Warranty

Section 1. General Information

4

1.1 Unpacking

Your circulator is shipped in a special carton. Retain the carton and all packing materials until the unit is

completely assembled and working properly. Set up and run the unit immediately to confirm proper operation.

Beyond one week, your unit may be warranty repaired, but not replaced. If the unit is damaged or does not

operate properly, contact the transportation company, file a damage claim and contact the company where your

unit was purchased.

1.2 Package Contents

Circulator Bath

Operators Manual 110-119

RS-232 Communication Cable 225-173

3

/16in., 1/4in., and 3/8in. Nylon Barbed Tubing Adapters 510-011

6 ft. of 1/4in. ID Latex Tubing 300-299

Beaker Platform(s) for Bath Reservoir — 600 ml 701-402 701-402

— 1000ml 701-403

Deck Lid(s) — solid 510-209 510-209

— w/beaker holes 510-211 510-209 510-211

1

Blue Hole Plugs — 3

Note: Do NOT Use Above 120°C — 41/4inch 300-296

/2inch 300-295 300-295

All TC-101P TC-201P TC-501P

(qty 2)

(qty 2)

701-402

300-295

Note:

Work area "opening" is designed to measure samples directly in the bath. If additional viscometer height

is required (spindle/guard clearance), either a 4 inch rod extension (part number BLM-4E)used with type A lab

stand or an 18 inch rod replacement (part mumber VS-38)used with type S lab stand are available from

Brookfield or an authorized dealer.

1.3 Description of Circulating Baths

The PROGRAMMABLE circulating baths are designed to provide precise temperature control of fluids for

circulation to external equipment or to be used as a stand alone bath. The reservoir may be used for immersing

samples while the unit is connected to an external device. All wetted parts are corrosion resistant 300 series

stainless steel. Models are equipped with various size reservoirs and refrigeration capacities.

1.4 Specification Chart

Controller Programmable

Temperature Range (Non-Refrigerated) Ambient +5° to 200°C

Temperature Range (Refrigerated) -20° to 200°C

Temperature Stability ±.01°C

Readout LCD

Readout Accuracy ±0.25°C

Pump Duplex

Pump Flow Rate (Pressure) @ 120V, 60Hz 11 to 24 lpm

Pump Flow Rate (Suction) 8 to 18 lpm

Overtemp/Safety Cutoff Yes (Adjustable)

RS232 Interface Yes

Remote Probe Optional

Inlet / Outlet

Heater 1000 Watts

1

/4inch NPT (female)

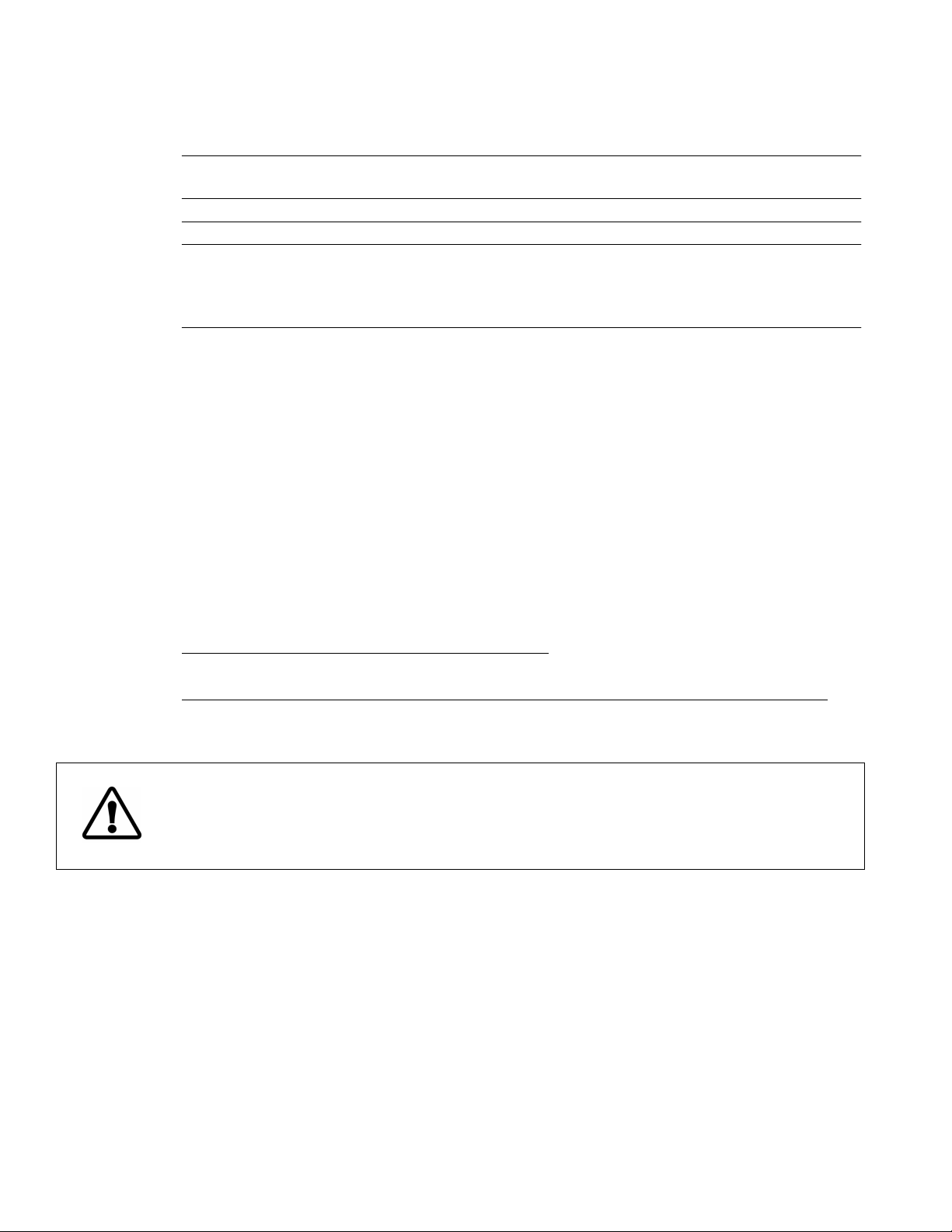

1.4 Specification Chart, continued

5

Model TC-101P TC-201P TC-501P

Dimensions (in.) 143/4x 81/4x 14 131/4x 141/4x 131/

(l x w x h) (cm) 37.5 x 13.3 x 35.6 33.7 x 36.2 x 33.7 40 x 47.6 x 43.2

Unit Weights 22 lbs (10.0 kg) 28 lbs (12.7 kg) 63 lbs (28.6 kg)

Reservoir Volumes 6 liters 10 liters 6 liters

Power Requirement 9A @ 115V / 1 / 60Hz 9A @ 115V / 1 / 60Hz 10A @ 115V / 1 / 60Hz

(105V - 125V) (105V - 125V) (105V - 125V)

4.5A @ 240V / 1 / 50Hz 4.5A @ 240V / 1 / 50Hz 5A @ 240V / 1 / 50Hz

(200V - 260V) (200V - 260V) (200V - 260V)

Section 2. Set Up

2.1 Location

Locate your circulator on a level surface free from drafts and direct sunlight. Do not place it near corrosive

fumes, excessive moisture, high room temperatures, or excessively dusty areas. Refrigerated circulators

must be four inches minimum away from walls or vertical surfaces so air flow is not restricted. Avoid voltage

drops by using properly grounded power outlets wired with 14 gauge or larger diameter wire and close to

the power distribution panel. To avoid low line voltage problems, do not use an extension cord.

4

153/4x 183/4x 17

2.2 Filling the Reservoir

Maximum fill level is one inch below the top of the reservoir. When in operation, add additional fluid to

compensate for any additional volume needed for external circulation.

Minimum liquid depth is enough to fully cover the heater, pump, and one inch of the temperature sensor

the proper fluid level is not maintained the heater coil may become exposed and possible damage to the

heater may result.

Warning: These units are equipped with Over Temperature Protection (OTP). Failure due to low

liquid level or failure to set OTP and properly immerse the heater may result in heater burnout

and triac failure. While operating, do not allow the heater to contact any potentially flammable

materials, such as plastic racks, as a fire hazard may result.

2.3 Reservoir Fluids

Use distilled water for temperatures from 10° to 90°C or a mixture of laboratory grade ethylene glycol and

water for temperatures -20° to 100°C. A variety of fluids can be used depending upon your needs. The fluid

must be chemically compatible with the reservoir and with 300 series stainless steel in the pump and heater.

The fluid must also be able to produce the temperature range desired.

For temperature stability of ±0.01°C, the viscosity should be 50 centistokes or less at the lowest operating

temperature to allow good fluid circulation and to minimize heating from the pump. Most single type of fluids

will be able to stabilize to ±0.01°C over a 100°C range. Use fluids that will satisfy safety, health, and

equipment compatibility requirements.

. If

The following chart will help in selecting a fluid for your application. Stay within the fluid’s normal range for

best temperature stability, low vaporization, and safety.

You are responsible for proper selection and use of the fluids.

6

Extreme range operation should be avoided.

FLUID DESCRIPTION SPECIFIC HEAT NORMAL EXTREME

@25°C RANGE RANGE

Water 1.00 10°C — 90°C 2°C — 100°C

Ethylene Glycol 30% / Water 70% .90 0°C — 95°C -15°C — 107°C

Ethylene Glycol 50% / Water 50% .82 -20°C — 100°C -30°C — 100°C

Ethylene Glycol 100% .62 50°C — 125°C 0°C — 125°C*

Dynalene-HC 50™ .76 -50°C — 60°C -62°C — 60°C

DC510 50 cs Silicone Oil .39 50°C — 150°C 5°C — 270°C*

DC550 125 cs Silicone Oil .42 100°C — 200°C 80°C — 315°C*

*WARNING - Fluid’s flashpoint temperature.

DC fluids are manufactured by Dow Corning. Dynalene HC is a registered TM of Advanced Fluid Technologies, Inc.

DO NOT use the following fluids:

1. Automotive antifreeze with additives*

2. Hard tap water*

3. Deionized water with a specific resistance > 1 meg ohm

4. Any flammable fluids

5. Concentrations of acid or bases

6. Solutions with halides: chlorides, fluorides, bromides, iodides or sulfur

7. Bleach (Sodium Hypochlorite)

8. Solutions with chromates or chromium salts

* At temperatures above 40°C, additives or mineral deposits can adhere to the heater. If allowed to build up, the heater may

overheat and fail. Higher temperatures and higher concentrations of additives will cause a faster deposit build up. If buildup

occurs see Section 5.1 Maintenance - Heater.

WARNING: Do not use a flammable liquid as a fire hazard may result.

APPLICATION NOTES

At fluid's low temperature extreme:

1. Presence of ice or slush will adversely affect temperature stability.

2. Viscosity above 10 centistokes will adversely affect temperature uniformity.

3. High fluid viscosity and high speed pumping will generate heat in the fluid.

At fluid’s temperature above ambient without using refrigeration:

1. Without refrigeration and within 15°C of room temperature the viscosity should be 10 centistokes or less to

avoid friction heating of the fluid. Encourage heat loss by uncovering the fluid and lowering pump speed.

At fluid’s high temperature extreme:

1. Heat loss from vapor will cause poor temperature stability.

2. A fume hood may be required to prevent the buildup of vapors inside the room.

3. Use a cover and/or floating hollow balls to help prevent heat and vapor loss.

4. Fluid lost from vapor will have to be frequently replenished.

2.4 Fluid Connections

7

The pump inlet and outlet are threaded with female 1/4inch NPT to allow use of barbed tubing adapters or

hard plumbing.

Select tubing and fittings that are compatible with bath fluid and temperature range. If the pump inlet and

outlet are not used for external circulation, connect the inlet and outlet pipes with a short length of insulated

tubing. Or, plug the pipes with male nylon plugs (supplied) or with metal plugs (not supplied) for high

temperature use.

The nylon barbed tubing adapter fittings supplied are for applications from -20° to 93°C. Brass,

stainless steel or Teflon® fittings are recommended for applications above 93°C. Quick connectors are

not recommended as they restrict flow rate.

Some programmable models are not equipped with a refrigeration system. For operation of these nonrefrigerated models, the included cooling coil may be used to achieve bath temperatures within 15°C above

the ambient room temperature. The cooling coil also permits the bath temperature to be lowered more

rapidly, after operation at an elevated temperature. The cooling coil connections are located between the

circulating pump’s inlet and outlet connections at the rear of the bath’s controller. To use the cooling coil, slide

1

/4in. ID latex tubing from the water source over one of the coil’s connections and route another length of

the

tubing from the other coil connection to the drain.

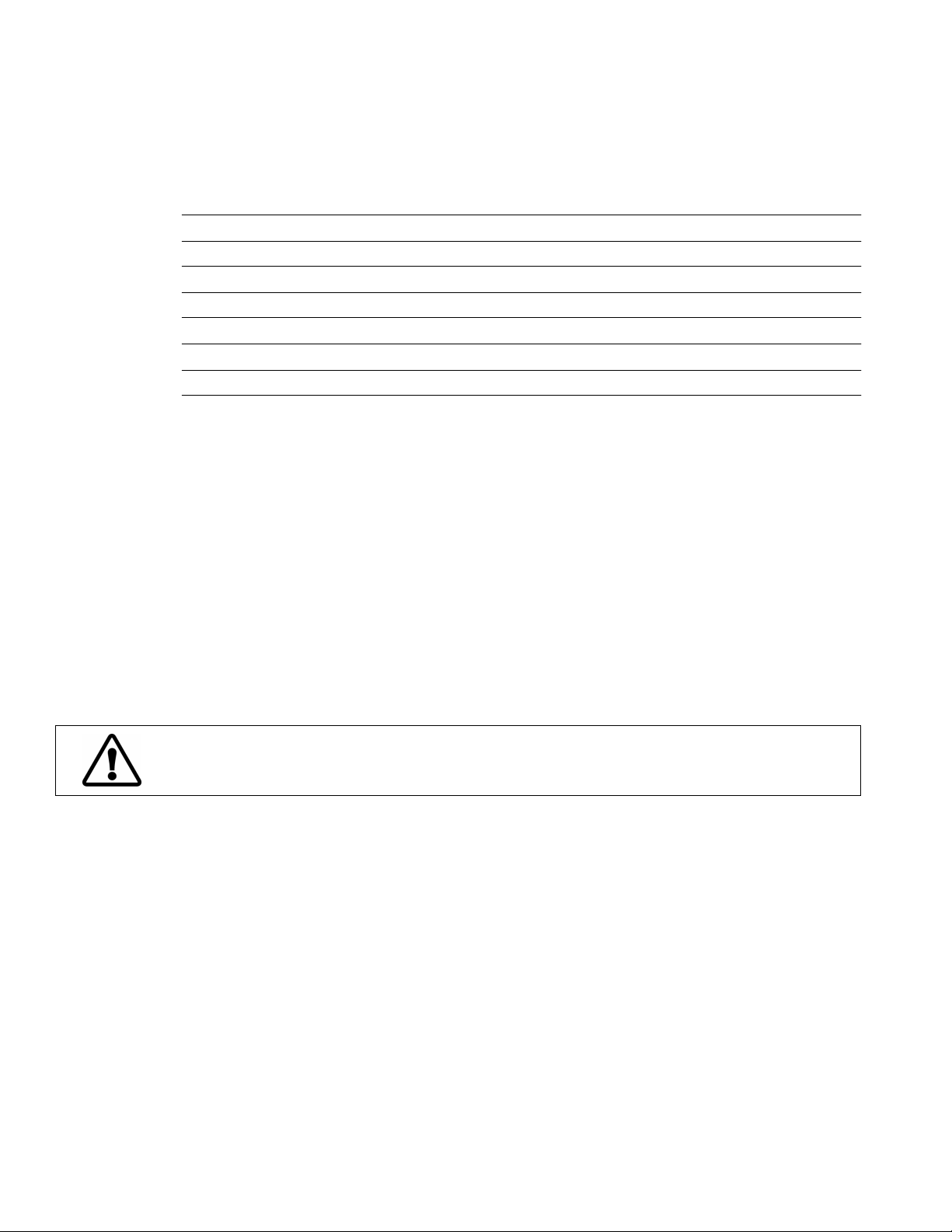

2.5 Pump

A pressure & suction (DUPLEX) pump is built into each unit. The 5-speed DUPLEX pump is found in all

programmable controller circulators. It may be used for direct immersion of samples, closed loop circulation,

or circulating to an open bath. Speed selection is in the FUNCTION TUNINGmenu. (See Section 3.2)

Note:

When reducing the speed of a duplex pump, there may be a faint sound that is synchronous with the

flashing of the POWER light. The sounds are the pulses coming from the motor speed controller and are

normal.

MAXIMUM OUTLET RATINGS

PUMP SELECTION SPEED PUMP TYPE 120V, 60Hz

1 = FULL 24 lpm / 5 psi

2 = HIGH 17.5 lpm / 2 psi

3 = MEDIUM 13.5 lpm / 1 psi

4 = LOW 12.5 lpm / 0.8 psi

5 = SLOW 11 lpm / 0.5 psi

The table uses the following criteria:

1. Maximum pump outlet flow rate is measured with no restriction on the pump outlet.

2. Maximum pump outlet pressure is measured in pounds per square inch (psi) at no flow.

3. The figures above were measured with water as the circulation fluid. Water has a viscosity of one

centistoke. High viscosity, low density fluid will reduce these figures.

4. Duplex pump suction inlet vacuum ratings are 75 percent of the outlet ratings shown.

5. When inlet and outlet are plugged, flow rate refers to internal bath circulation.

6. For 50Hz operation derate 60Hz values by 17%.

Loading...

Loading...