Page 1

BROOKFIELD R/S+ RHEOMETER

Operating Instructions

Manual No. M08-219-B1211

(for serial numbers beginning with “304”)

with oces in:

BROOKFIELD ENGINEERING LABORATORIES, INC.

11 Commerce Boulevard, Middleboro, MA 02346 USA

TEL508-946-6200

FAX508-946-6262

Boston • Chicago • London • Stuttgart • Guangzhou

or

800-628-8139

I

NTERNET

http://www

SPECIALISTS IN THE

MEASUREMENT AND

CONTROL OF VISCOSITY

(USAexcluding

.brookeldengineering.com

MA)

Brookfi eld Engineering Labs., Inc. Page 1 Manual No. M08-219-B1211

Page 2

Page 3

Table of Contents

I. General Description ....................................................................................................... 7

I.1 Use of the Rheometer ...................................................................................................7

I.2 Measuring Principle .......................................................................................................7

II. System Confi guration ............................................................................................... 8

II.1 R/S+ Rheometer ..........................................................................................................8

II.2 Measuring Geometries (Spindles or Bobs with Sample Cups) .................................... 10

II.3 Computer System Requirements .................................................................................10

III. Instrument Installation .............................................................................................. 11

III.1 Mounting the Stand .....................................................................................................11

III.2 Electrical Connections ..................................................................................................12

III.2.1 Temperature Sensor PT100 ............................................................................... 12

III.2.2 AC Adapter .........................................................................................................13

III.2.3 Printer Connection .............................................................................................13

III.3 Connecting Temperature Controlled Measuring Devices ..........................................14

III.2.4 Computer Connection ........................................................................................14

III.3.1 Connecting the Water Jacket ............................................................................. 14

III.3.2 Connecting the Optional Cone/Plate Attachment ...............................................16

III.3.3 Connecting the KE Cooling Device .................................................................... 17

IV. Environment, Handling, Cleaning and Maintenance ............................................. 19

IV.1 Operating Environment and Storage ...........................................................................19

IV.2 Handling .......................................................................................................................19

IV.3 Cleaning .......................................................................................................................19

IV.4 Maintenance ................................................................................................................ 20

V. Measuring Systems .................................................................................................. 21

V.1 Measuring Directly in the Sample Container ................................................................. 21

V.2 Measurement by Filling the Sample Cup .......................................................................22

V.3 Measurement with Water Jacket Assembly ...................................................................22

V.4 Measurement with Cone/Plate or Plate/Plate Measuring Systems ............................... 23

VI. Operation and Menu System ................................................................................... 25

VI.1 Keyboard ..................................................................................................................... 26

VI.2 Menu System of R/S+ Rheometer ...............................................................................28

VI.3 Selecting from Lists ..................................................................................................... 29

VI.4 Input of Numerical Values and Alphanumeric Texts ..................................................... 30

VI.5 Menu Entries (MAIN Menu) ......................................................................................... 31

VI.5.1 MAIN Menu → Run Single ................................................................................ 32

VI.5.2 MAIN Menu

VI.5.3 MAIN Menu → Run Program ..............................................................................34

VI.5.4 MAIN Menu → Remote .......................................................................................36

VI.5.5 MAIN Menu → Utilities .......................................................................................37

VI.5.6 MAIN Menu → Confi guration .............................................................................. 37

VI.6 Menu Entries in the Utilities Menu ............................................................................... 37

VI.6.1 Utilities → Zero Calibration .................................................................................38

→ Single Measurement .................................................................32

Page 4

VI.6.2 Utilities → Edit Program .....................................................................................38

VI.6.3 Utilities → Print Programs ..................................................................................42

VI.6.4 Utilities → Measuring Systems ...........................................................................42

VI.6.5 Utilities → Print Memory .....................................................................................43

VI.6.6 Utilities → Clear Memory ....................................................................................44

VI.6.7 Utilities → Measure Temperature ....................................................................... 44

VI.7 Menu Entries of the Confi guration Menu ..................................................................... 45

VI.7.1 Confi guration → Set Output Mode .....................................................................45

VI.7.2 Confi guration → Set MeasCount Mode .............................................................. 46

VI.7.3 Confi guration → Reset MeasCount ..................................................................... 46

VI.7.4 Confi guration → Set Time/Date ..........................................................................46

VI.7.5 Confi guration → Set RS-232 Parameters ..........................................................47

VI.7.6 Confi guration → Language .................................................................................49

VI.7.7 Confi guration → Service .....................................................................................49

VI.8 Serial Data Transfer via the RS-232 Interface .............................................................49

VII. Measurements ............................................................................................................ 51

VII.1 Measuring in Manual Mode ......................................................................................... 51

VII.2 Measuring with Water Jacket ...................................................................................... 51

VII.3 Measurement with Cone/Plate Attachment ................................................................. 51

VII.4 Measurement in Remote Mode ................................................................................... 52

VIII. Technical Data ........................................................................................................... 53

Appendix A ........................................................................................................................ 55

A.1 Data Sheets of Standard Measuring Systems ..............................................................55

A.2 Error Messages ............................................................................................................. 57

A.3 Pin Assignment of the Serial Data Cable ......................................................................60

A.4 Requirements to the AC Power Connecting Cables .....................................................60

Appendix B: Calibration Check Procedure .................................................................... 62

B.1 Using Rheo 3000 ..........................................................................................................62

B.2 Stand-alone Mode ......................................................................................................... 63

Appendix C: RS4SSTB Rheometers for Measuring in Brabender Units (BU) ...........64

C.1 Adjusting the BU Factor ................................................................................................65

C.2 Test Program ................................................................................................................. 65

Appendix D: R/S-SST+ - Soft Solid Tester ..................................................................... 66

D.1 Operating the R/S-SST+ Soft Solids Tester .................................................................. 66

D.1.1 Running a Sample Using Software Control .......................................................66

D.1.2 Soft Solids Analysis Functions ........................................................................... 66

D.1.3 Running a Sample in Stand-Alone mode. ..........................................................67

D.1.4 Editing and Running Programs .......................................................................... 68

D.2 Getting Started in Soft Solids Testing ...........................................................................68

D.2.1 The Constant Rate Test .....................................................................................68

D.2.2 The Creep Test ................................................................................................... 69

D.3 A Few Tips To Get You Started .....................................................................................70

D.3.1 Vane selection ....................................................................................................71

D.3.2 Container Dimensions ........................................................................................71

Page 5

D.3.3 Setting Up Vanes In Measuring System Editor .................................................. 71

D.4 Vane Constants For The Soft Solids Tester .................................................................72

D.4.1 Stress Constant: τ

D.4.2 Strain/Rate Constant: K-Gamma .......................................................................72

....................................................................................... 72

prom.

Appendix E: R/S Portable Rheometer ...........................................................................74

E.1 Technical Specifi cations ...............................................................................................74

E.2 Electrical Connections .................................................................................................76

E.3 Measurement Range ...................................................................................................77

E.3.1 Data Sheets of Standard Measuring Systems ...................................................77

E.4 R/S Portable Components ...........................................................................................78

E.5 Operation Under Battery Power ...................................................................................79

Appendix F: Online Help and Other Resources ...........................................................80

Appendix G: Warranty and Repair Service .................................................................... 81

Page 6

Page 7

I. General Description

This section has general information about the instrument and operating principles.

I.1 Use of the Rheometer

The R/S+ Rheometer will measure viscosity of Newtonian and Non-Newtonian materials in

controlled shear rate (CSR) or controlled shear stress (CSS) modes. The instrument can measure

simple viscosity at a given speed or shear rate, or measure fl ow properties with a fl ow curve at

shear rates up to ~1,200 sec-1.

In controlled stress mode, the instrument can do a direct yield test (stress ramp) and indicate

elasticity with creep/recovery tests.

I.2 Measuring Principle

The R/S+ Rheometer is a rotational, controlled shear stress instrument which can be operated in

controlled shear rate mode.

Concentric cylinders, measuring cones and plates are available as a measuring system. The

measuring sample is positioned in a measuring gap between the stationary measuring cup and

the rotating measuring bob (Searle-principle), respectively between the rotating cone or plate and

the stationary lower plate (cone/plate, cone/cone measuring system).

The measuring drive developed for this instrument operates with a high precision, dynamic drive

system with optical encoder for absolute position measurement of spindle geometry.

The R/S+ measuring drive can operate at a pre-set of speed (shear rate) or pre-set of torque (shear

stress). Measurements may be made in manual mode (without PC) or under PC control with Rheo

3000 software. Note that the creep measurements require a computer system with Rheo 3000

software.

Both CSR and CSS measurements can be carried out manually (without PC support) or with a

computer system and Rheo 3000 software.

Brookfi eld Engineering Labs., Inc. Page 7 Manual No. M08-219-B1211

Page 8

II. System Confi guration

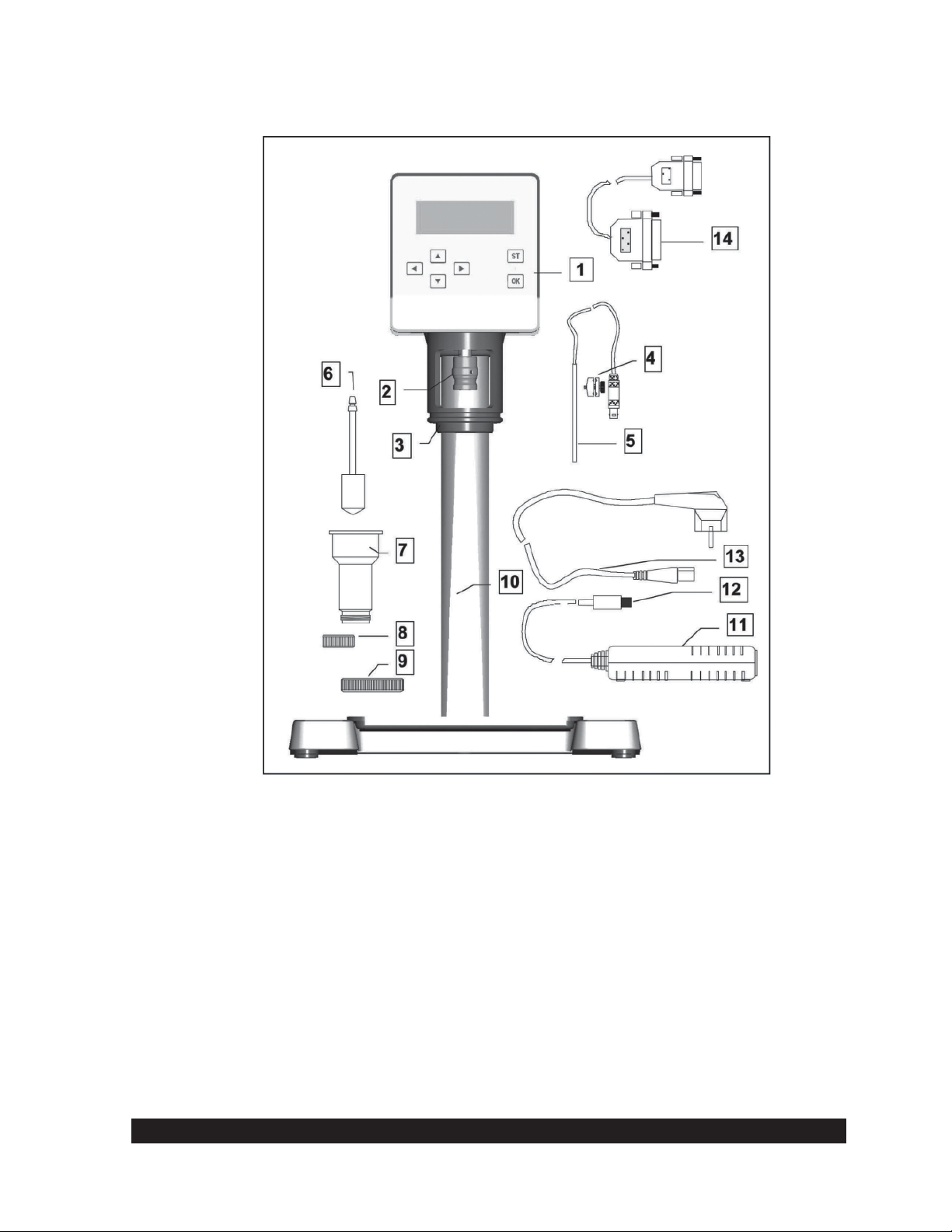

The R/S+ Rheometer system consists of:

•

Rheometer head containing electronic unit and measuring drive integrated in one

housing

•

Lab Stand with removable catchment table

•

AC Adapter

Available Accessories:

•

Coaxial cylinder measuring system (see Appendix A)*

•

Temperature measuring sensor Pt100*

•

Water jacket assembly

•

Bath/Circulator

•

Rheo 3000 software for control of R/S+ by PC

•

Vane spindles

•

BU Spindles

•

Cone/Plate and Plate/Plate Assembly

*

The accessories in bold print are necessary for a minimal confi guration. See Figure II-1

for illustration of the R/S+ Rheometer System Components.

Available Services:

•

Startup Assistance

•

Instrument Training

•

Rheo 3000 Software Training

II.1 R/S+ Rheometer

Instrument features include:

•

Digital control of rotational speed and torque

•

Automatic adjustment of control parameters during measurement

•

Direct indication of measured and calculated values of speed/shear rate, torque/shear

stress, viscosity, temperature, and time

Data storage (measured values)

•

Data output to a printer (parallel)

•

User support with LCD and keypad

•

Built-in system interface with serial standard interface (RS232) for connection to a

•

computer or other serial data-logger

Printing and serial data-transmission during the test

•

The R/S+ Rheometer can either be operated manually using the keypad on the front panel or it

can be operated under computer control. The R/S+ Rheometer is supplied with a direct current

drive by the AC Adapter.

Brookfi eld Engineering Labs., Inc. Page 8 Manual No. M08-219-B1211

Page 9

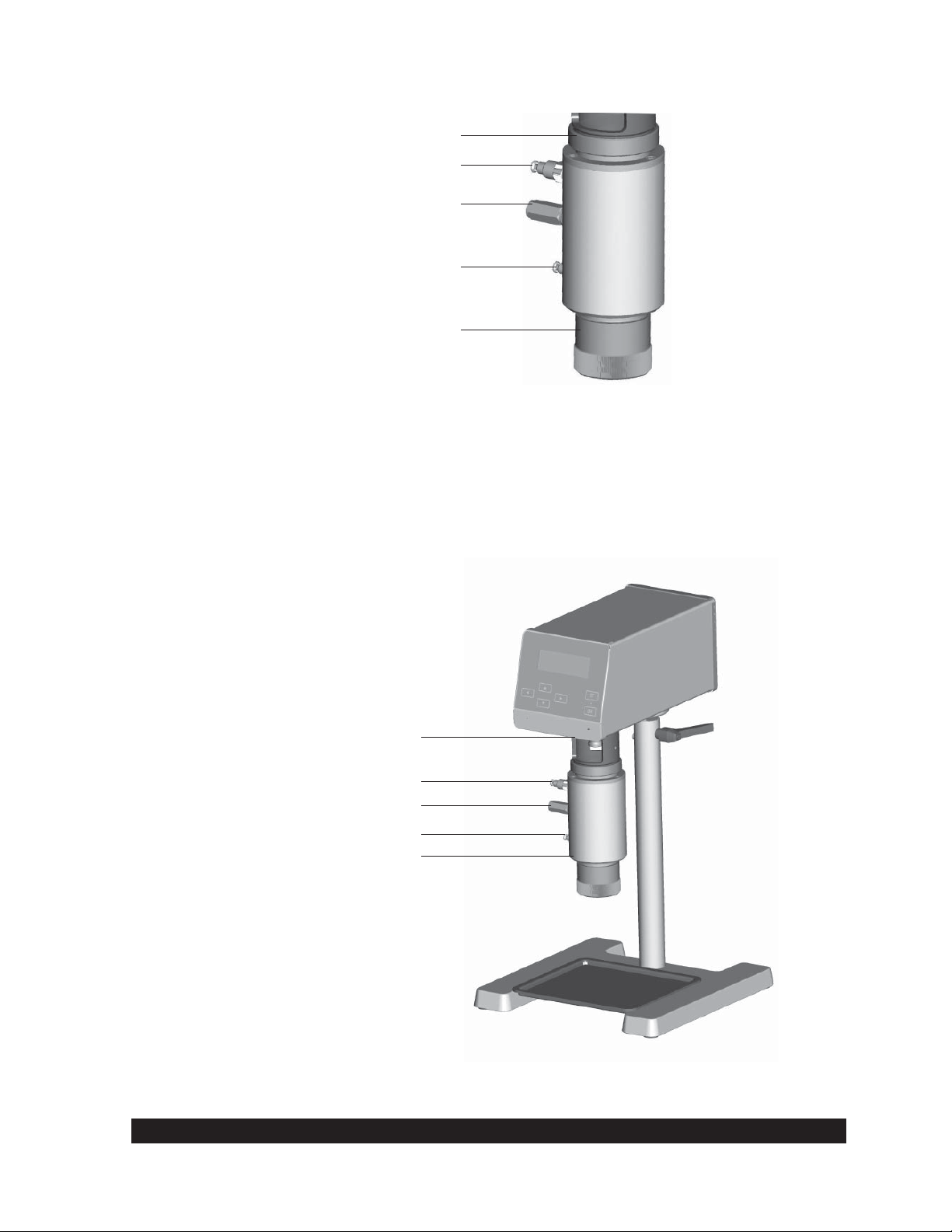

R/S+ Rheometer

1 R/S+ Rheometer Head

2 Measuring Bob Coupling

3 Mounting Flange

4 Pt100 Clamp Fixture (accessory)

5 Pt100 (temperature probe accessory)

6 Standard Measuring Bob (accessory)

7 Standard Measuring Cup (accessory)

8 Measuring Cup Bottom or Thread Protection (accessory)

9 Measuring Cup Screw Fitting

10 Lab Stand

11 AC Adapter

12 Direct Current Plug (to Rheometer head)

13 AC Power Cable

14 RS232C Cable (accessory)

Fig. II-1: Confi guration of the R/S+ Rheometer

Brookfi eld Engineering Labs., Inc. Page 9 Manual No. M08-219-B1211

Page 10

II.2 Measuring Geometries (Spindles or Bobs with Sample Cups)

Measuring devices are not included in the base instrument price and must be ordered

separately.

Measuring devices that can be used with the R/S+ include:

• Coaxial geometry measuring systems (see Appendix A) with and without built-in temperature

sensor Pt100

• Water Jacket Assembly for use with the coaxial cylinder measuring system in temperature

range -10°C to +180°C

• Vane spindles (see Appendix D) for measuring soft solids

• BU Spindle (see Appendix C) for measuring joint compound in Brabender units

• Cone/Plate Assembly for measuring small sample volumes <1mL

II.3 Computer System Requirements

The computer system control of the R/S+ is optional and provides automatic measuring, data plots,

printing (full reports or data plots) as well as analysis of results and quality control charts.

The recommended computer system has the following minimal system requirements:

- CPU / 1 GHz

- 512 MB RAM (main memory)

- 500 MB free hard disk capacity

Compatible operating system includes:

- Microsoft Windows 2000™, Windows XP™, Windows 7™ or Vista™

- mouse and keyboard

- VGA graphic card and monitor

- 1 free serial interface

Brookfi eld Engineering Labs., Inc. Page 10 Manual No. M08-219-B1211

Page 11

III. Instrument Installation

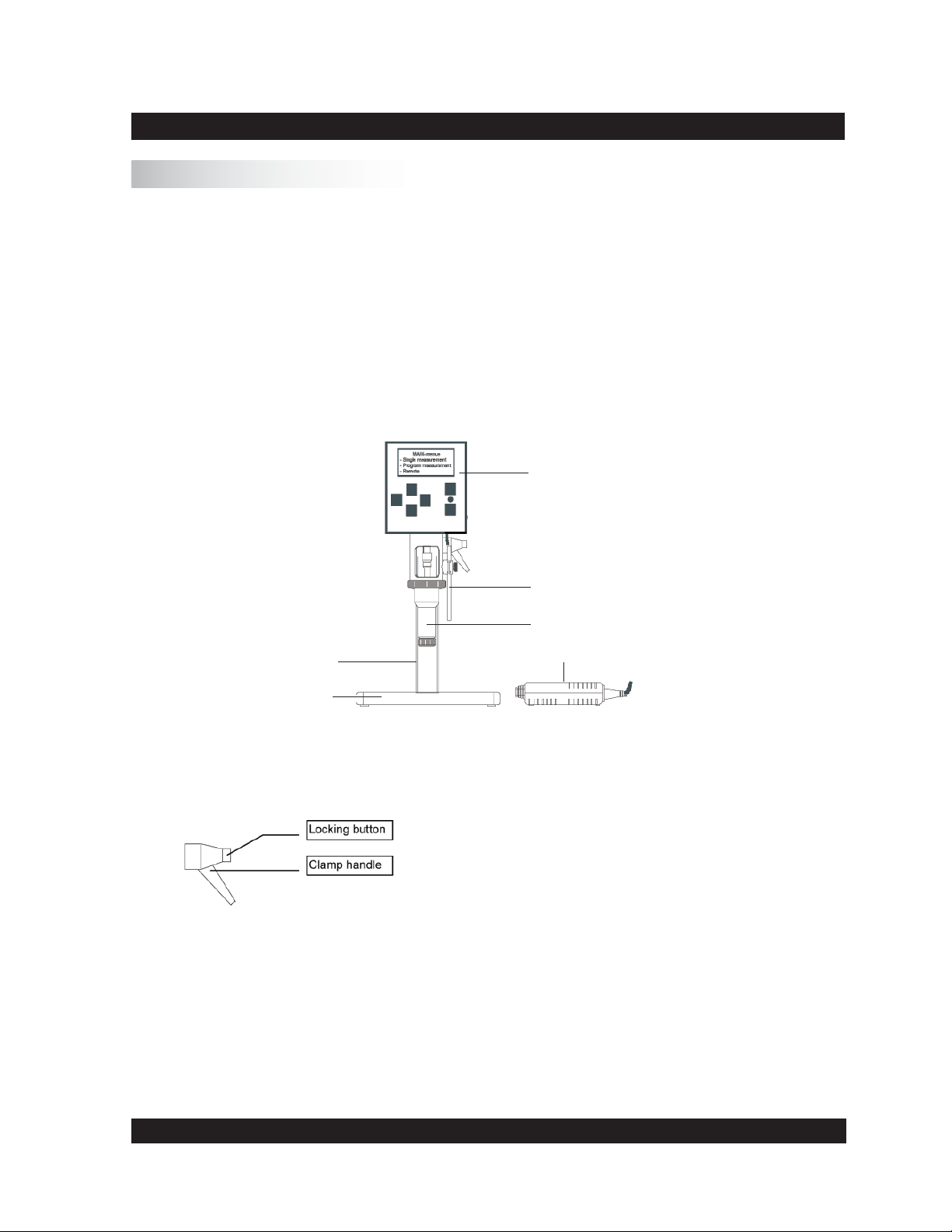

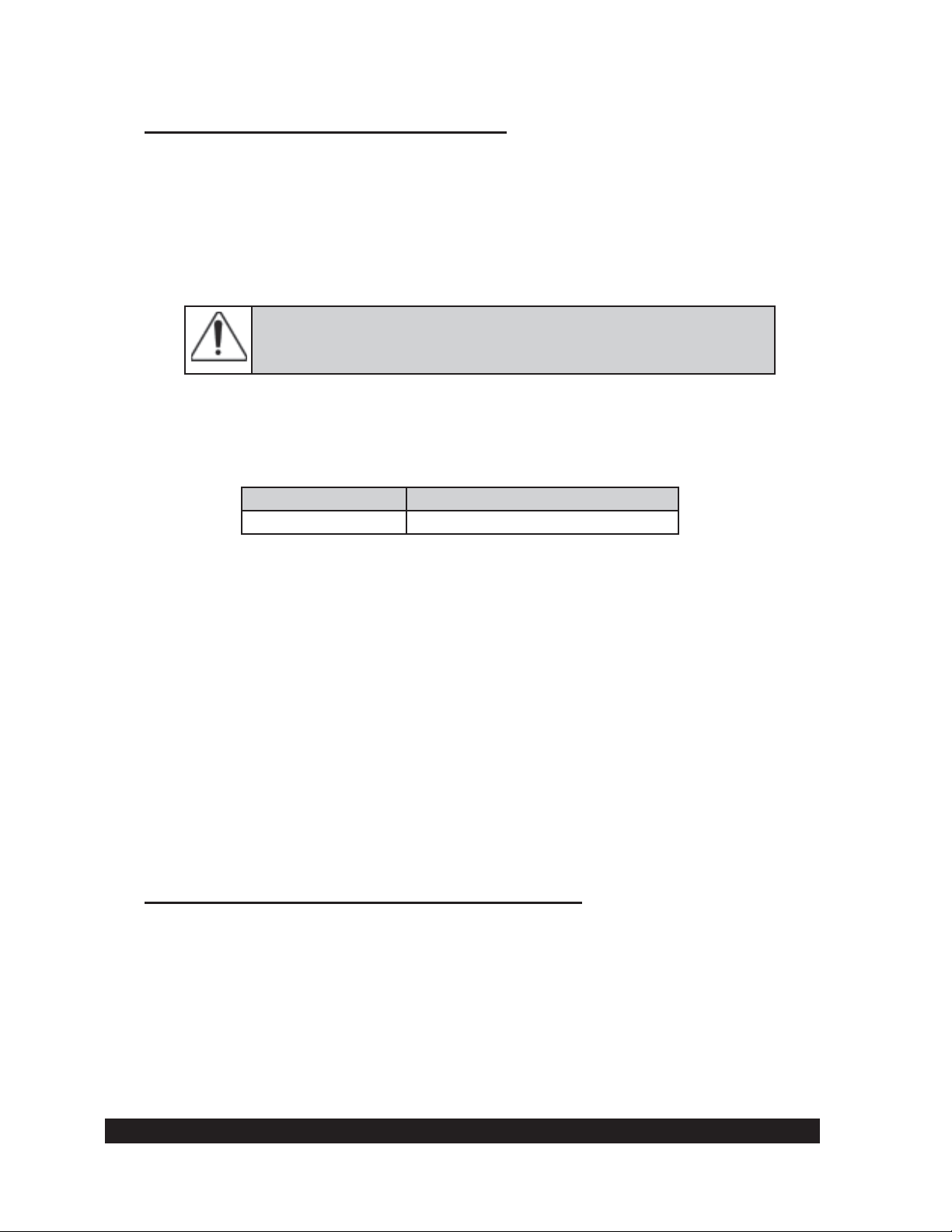

III.1 Mounting the Stand

The stand consists of:

the stand base plate

•

the stand column with rheometer

•

A 5 mm Hex wrench and bolt DIN 912 M8 x 40 are supplied for mounting.

The stand column is connected to the stand base plate with a bolt. The proper orientation of the

column is set with a pin in the bottom of the column which fi ts into a hole on the stand base.

Rheometer

Stand

Base

Fig. III-1.: Rheometer R/S+ (minimum confi guration)

Hints for height adjustment of the stand:

To change the height adjustment of the stand, you must release the

clamp handle and move the stand to the desired height.

Caution: Hold the rheometer as you release the clamp handle!

You can press the locking button to change the clamp handle position without screwing/unscrewing the thread. After adjustment of the

height screw, tighten clamp handle thread.

Fig. III-2.: Stand Height Adjustment Hints

Temperature Sensor Pt100

Coaxial Cylinder System

AC Adapter

Brookfi eld Engineering Labs., Inc. Page 11 Manual No. M08-219-B1211

Page 12

III.2 Electrical Connections

Connections for the electrical components of the R/S+ Rheometer are located on the back of the

instrument head.

Parallel Printer Connection

RS232C Computer Connection

Socket for Pt100 Temperature Probe

Socket for AC Adapter

ON/OFF Switch

Fig. III-3: Operating and connecting elements at the back side of the measuring head

All cables to and from the R/S+ Rheometer may be connected or

disconnected only when the instrument is turned off!

III.2.1 Temperature Sensor PT100

The connecting cable for the temperature sensor Pt100 (100 ohm DIN alpha RTD) is inserted into

the socket labeled “Pt100” at the back of the rheometer head.

If you use standard cylindrical measuring cups (CC8, CC14 etc.), put the Pt100 into the mounting

clamp fi xture and align it parallel to the measuring system by attaching it to the mounting fl ange

of the rheometer.

Fig. III-4: Pt100 connection and mounting

Brookfi eld Engineering Labs., Inc. Page 12 Manual No. M08-219-B1211

Page 13

Insert the plug for the Pt100 connector in the back of the rheometer head.

Since viscosity is a function of temperature, the temperature should be preferably measured in the

test fl uid. For this purpose, the standard measuring systems 8 mm to 40 mm DIN can be equipped

with a Pt100 in the measuring cup bottom when the water jacket is used. If you use a measuring

system with built-in Pt100, this is where you will insert the cable VK-Pt/RC.

III.2.2 AC Adapter

Do not use a power supply other than the AC adapter delivered by Brookfi eld for the R/S+

Rheometer.

Connect the AC adapter using a grounded plug to avoid electric

shock or damage to the system components!

Connecting the AC adapter:

Turn the R/S+ Rheometer off with the “POWER” switch at the back side of the

instrument.

Connect the RS+ power cord into the AC adapter.

Insert the socket of the DC cable into the “DC” connector port at the back side of the

instrument.

Plug the power cable into a grounded AC power socket.

Turn the R/S+ Rheometer on.

-

Do not leave the power supply plugged into the AC power socket when the cable to the

rheometer is un-plugged!

Before disconnecting the rheometer from the AC supply, be sure that the instrument is

switched off.

III.2.3 Printer Connection

A printer can be connected directly to the interface connector of the rheometer when measuring

without PC control. You must preset “Printer” as the output device to print the measuring values

during measurement (see Section VI). The printer should have a parallel printer interface. USB

printers are not supported.

Turn off the rheometer with the AC power switch at the back of the R/S+.

Insert the printer connecting cable into the “PRINTER” port on back of the

instrument.

Turn the R/S+ Rheometer on.

-

A standard printer cable can be used as a printer connecting cable. This cable is supplied with the

printer in most cases. To print data values from the R/S+ Rheometer, any (parallel) printer which

can operate in ASCII character mode may be used.

Brookfi eld Engineering Labs., Inc. Page 13 Manual No. M08-219-B1211

Page 14

III.2.4 Computer Connection

If the R/S+ Rheometer has to be used in “REMOTE” mode with a PC (Rheo 3000 program

package) or with serial data-terminal for data logging, the RS232C cable needs to be connected

to the 25 pin port labeled “RS232” on the back of the instrument.

Turn the R/S+ Rheometer off with the “POWER” switch at the back of the

•

instrument.

Turn the computer system off.

•

Connect the rheometer data cable to the 25 pin port labelled “ RS232” on the back of

•

the R/S+ Rheometer.

Connect the Peltier data cable to the port labelled “ RS232/Peltier” on the back of the

•

rheometer head.

Turn the R/S+ Rheometer and your computer system on again.

•

You must use the computer cable supplied by Brookfi eld - other cables will not work!

III.3 Connecting Temperature Controlled Measuring Devices

Water Jacket Assembly: for use with the cylinder measuring system, in the temperature

•

range of -10°C to +90°C (liquid’s temperature control).

Cooling Device KE: expands the temperature range from -20°C to +180° in conjunction

•

with the FTKY3 temperature control device or CONE/PLATE ATTACHMENT.

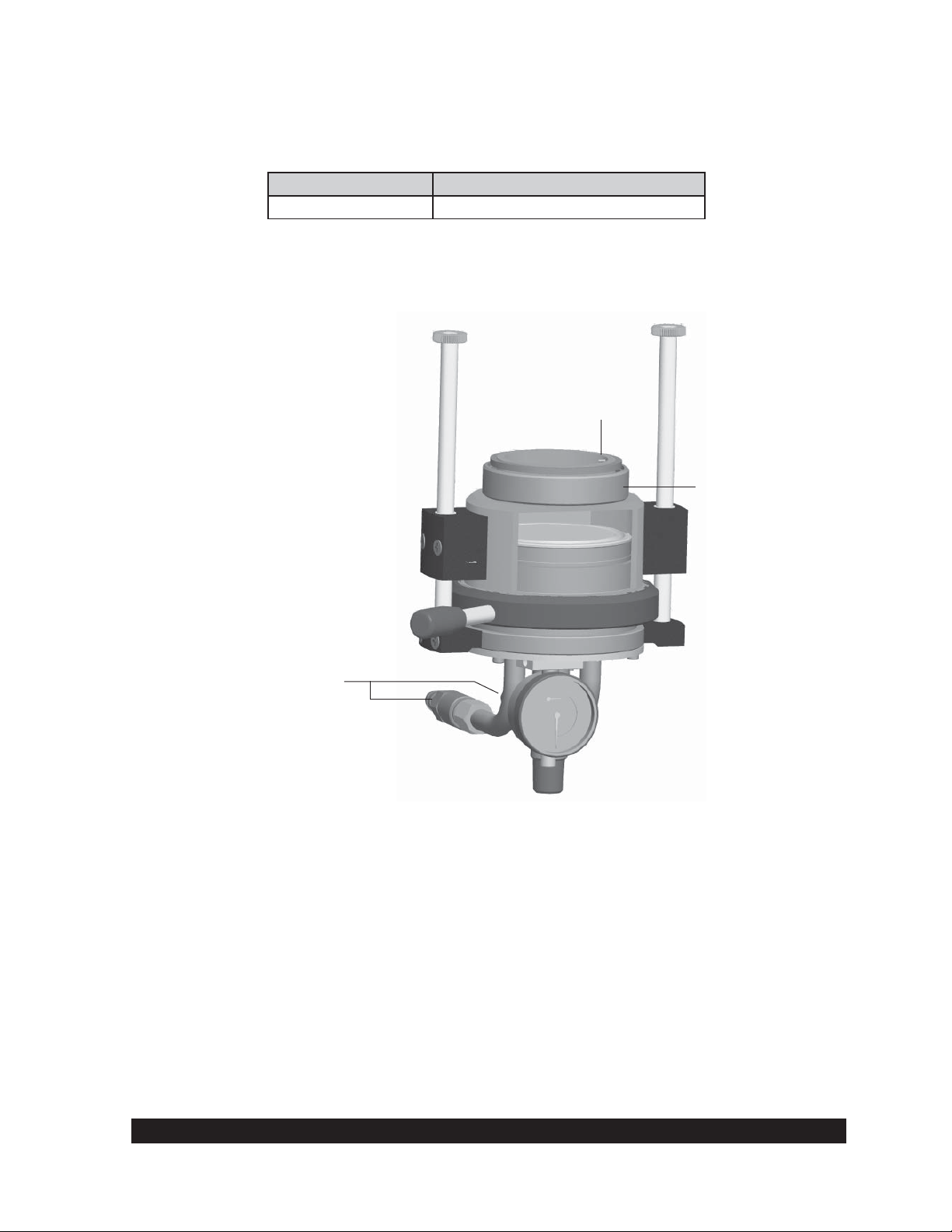

III.3.1 Connecting the Water Jacket

The Water Jacket FTKY3 is an optional accessory for use with the coaxial cylinder measuring

system in the temperature range -10°C to +90°C.

The water jacket should be used only in the temperature range

-10°C to +90°C unless the KE cooling device is installed, in which

case, the temperature range is -20°C to +180°C!

Brookfi eld Engineering Labs., Inc. Page 14 Manual No. M08-219-B1211

Page 15

Thread Joint for Connection of

Measuring Cup to Mounting Flange

Hose Connection of Flow Output

Temperature Sensor Pt100

Hose Connection of Flow Input

Measuring Cup Bottom

Fig. III-5: Water Jacket Assembly

Mounting the Water Jacket Assembly:

When using the KE cooling device, mount the cooling device fi rst (see Section

•

III.3.3).

Attach the jacket on the mounting fl ange from below and tighten the thread.

•

Connect the tubes from the water bath to the jacket.

•

Connect the jacket’s built-in Pt100 cable to the R/S+ Rheometer.

•

Cooling Device KE-FTK/RC30

Tube Connector

Temperature Sensor Pt100

Tube Connector

Water Jacket

Fig. III-6: Operation with the Water Jacket Assembly FTKY3 and Cooling Device KE

Brookfi eld Engineering Labs., Inc. Page 15 Manual No. M08-219-B1211

Page 16

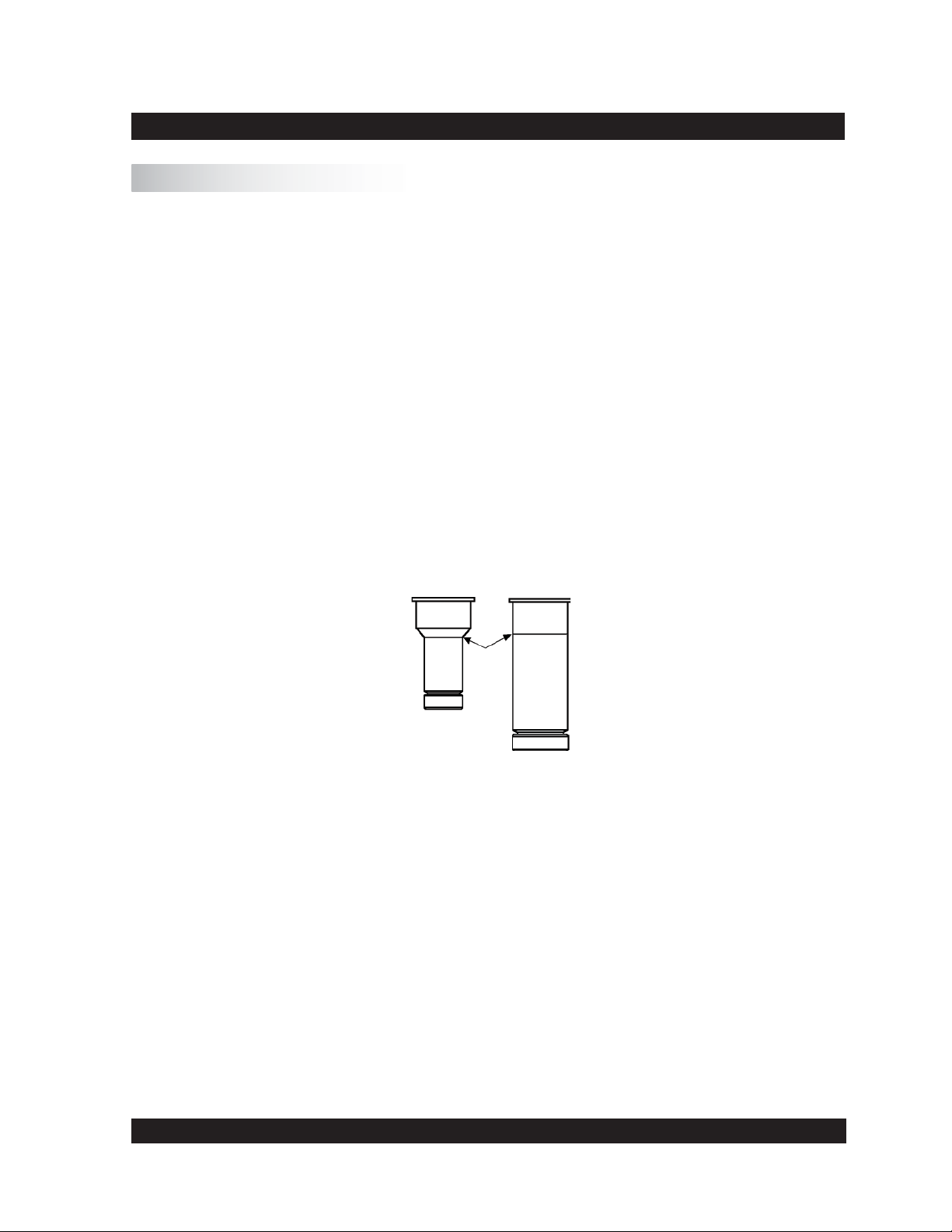

Bath/Circulator Connection to the Water Jacket

The tubes are used to connect the bath to the R/S+ water jacket.

The tubes are connected to the quick fi tting couplings on the jacket assembly. The coupling has a

female part which is put into the tubing, and a male part built into the jacket assembly. To connect

the two, pull back on the female section slide ring and put the connector onto the jacket (male)

connector, releasing the slide ring.

Water jacket without cooling device KE is only used in the

temperature range -10°C to +90°C!

The jacket FTKY3 can be used in the temperature range -20°C to +180°C when used with the

optional KE cooler (for tap water cooling of the rheometer bearings).

The following working fl uids are usually used in the temperature bath:

-10°C to +90°C Water - Glycol Mixture

-20°C to +180°C Bath Oil

Suitable bath fl uids can be ordered from BROOKFIELD.

III.3.2 Connecting the Optional Cone/Plate Attachment

Turn off the R/S+.

•

When using the KE cooling device, mount the cooling device fi rst (see Section

•

III.3.3)

Set the “CONE/PLATE ATTACHMENT” from below the mounting fl ange and tighten

•

the thread. Before tightening, check that the guide pin of the measuring device (see Fig.

III-7) is in the slot of the R/S+ mounting fl ange!

Connect the bath tubes to the “CONE/PLATE ATTACHMENT”.

•

Connect the Cone/Plate and temperature probe cable to the R/S+.

•

For mounting the cone/plate or plate/plate measuring systems to the measuring device

•

refer to Section V.

Bath/Circulator Connection to the Cone/Plate Attachment

The hoses are connected to the quick fi tting couplings on the cone/plate assembly. The coupling

has a female part which is put into the tubing, and a male part built into the jacket assembly. To

connect the two, pull back on the female section slide ring and put the connector onto the jacket

(male) connector, releasing the slide ring.

Brookfi eld Engineering Labs., Inc. Page 16 Manual No. M08-219-B1211

Page 17

The following working fl uids are usually used in the temperature bath:

-10°C to +90°C Water - Glycol Mixture

-20°C to +180°C Bath Oil

Suitable bath fl uids can be ordered from BROOKFIELD.

Guide Pin

Screw Connection for

Mounting Flange

Bath Tubing Connectors

Fig. III-7: CONE/PLATE ATTACHMENT for cone/plate and plate/plate systems

III.3.3 Connecting the KE Cooling Device

The optional cooling device KE COOLING ATTACHMENT must be used where the test

temperature is below -10°C or above 90°C. When using the KE COOLING ATTACHMENT,

the temperature range is expanded from -20°C to +180°C.

Brookfi eld Engineering Labs., Inc. Page 17 Manual No. M08-219-B1211

Page 18

Attachment Procedure

Turn off the R/S+.

•

Lift the KE COOLING ATTACHMENT to the R/S+ Rheometer from below and tighten

•

the thread.

Connect the tubes of the cooling line to the KE COOLING ATTACHMENT (see Figure

•

III.8).

Cooling Device KE

Fig. III-8: Cooling Device KE

Hose Connection

• The tubes for the KE Cooling Device are connected with quick connect couplings.

Brookfi eld Engineering Labs., Inc. Page 18 Manual No. M08-219-B1211

Page 19

IV. Environment, Handling, Cleaning and Maintenance

IV.1 Operating Environment and Storage

Find a convenient work place for the installation of the R/S+ Rheometer. There should be enough

room to place the rheometer, the measuring systems, the measuring substances and the peripheral

devices (e.g. printer, computer and bath/circulator). You need a grounded AC plug to operate

the R/S+ Rheometer and additional plugs for the connection of each peripheral device (i.e. Bath,

Peltier). Your operating environment and the place where you store the R/S+ Rheometer should

not be extremely hot, extremely cold or extremely moist. Places with large temperature and air

humidity variations should be avoided. Be sure that the R/S+ Rheometer is not exposed to the

following:

heavy dirt or dust

•

direct sun

•

•

objects that emit heat (e.g. heating radiators)

•

objects with a strong electromagnetic fi eld (e.g. loudspeakers, motors etc.)

•

liquids or corrosive chemicals

IV.2 Handling

The R/S+ Rheometer is designed to endure light bumps or vibration. Avoid dropping it or exposing

it to heavy shock!

Never lift your RS+ Rheometer at the measuring bob coupling or with

the measuring bob attached to the instrument.

Always disconnect the bob at the bob coupling before removing the

sample cup!!!!

The rheometer motor will automatically turn off if the maximum torque (50 mNm) is exceeded.

IV.3 Cleaning

The paint coat of the R/S+ Rheometer resists most usual solvents and weak acids. Use a dry, clean,

soft and nap-free piece of cloth to clean the housing. Use neutral detergent liquids, if necessary.

Do not use chemical products such as strong solvents or strong acids to

clean the housing, especially the keyboard.

Brookfi eld Engineering Labs., Inc. Page 19 Manual No. M08-219-B1211

Page 20

IV.4 Maintenance

The R/S+ Rheometer system is designed for long-term operation. Should the instrument require

repair, contact Brookfi eld or your Brookfi eld dealer.

Only authorized service personnel may work on the control

electronics, all accessories, the measuring drive, as well as the AC

Adapter and all electric circuits and connections!

Measurement accuracy can be checked by the user at any time. We recommend that the

measurements be done with Brookfi eld viscosity standard fl uids (mineral oils) as recommended

for each individual spindle geometry.

You must:

Use temperature control (i.e. water jacket and circulating bath)

•

Select the appropriate measuring system

•

Carry out measurements at the following pre-set M (‰ torque): 250‰, 500‰ and 750‰

•

Read viscosities from the display

•

In case of instrument failure (or severe deviation from the preset value), contact Brookfi eld or

your Brookfi eld Dealer.

Brookfi eld Engineering Labs., Inc. Page 20 Manual No. M08-219-B1211

Page 21

V. Measuring Systems

V.1 Measuring Directly in the Sample Container

You may immerse the measurement system directly into a container of sample by removing the

cap on the bottom of the immersion cups.

When using the double gap bob measuring system, do not damage the “O” ring which forms the

seal between the inner and outer parts of the sample cup. To clean, the inner section is removed

by unscrewing the (stainless steel) ring at the bottom and then GENTLY push the inner section

out through the bottom of the outer section. Take care not to damage or stretch the O-ring seal

during removal! Insert the inner part again and screw the ring back on.

General steps for direct immersion of the measuring system into the bath:

Lift the coupling sleeve of the measuring bob coupling (the ring is visible).

•

Insert the measuring bob into the measuring bob coupling.

•

Lower the coupling sleeve (the ring is covered).

•

Fasten the measuring cup at the measuring cup mounting fl ange with the measuring cup

•

ring.

Immerse the measuring cup into the substance up to the ring mark or up to the point where

•

the diameter of the measuring cup increases.

Fig. V-1: Depth of immersion

Do not get sample in or onto the measuring bob coupling.

After making your viscosity measurement, unscrew the measuring cup ring and remove the

measuring cup. Open the measuring bob coupling, and remove the measuring bob.

Clean the measuring cup and measuring bob carefully. Do not use abrasive cleaning tools, and

always prevent scratches! Store measuring bobs on a soft pad.

Brookfi eld Engineering Labs., Inc. Page 21 Manual No. M08-219-B1211

Page 22

V.2 Measurement by Filling the Sample Cup

Fill the measuring cup with your material (see Appendix A.1 for sample volume). Avoid air

bubbles when fi lling the sample as they can affect the repeatability of the test!

Place the measuring bob into the measuring cup. Lift the coupling sleeve (the ring is visible).

Insert the complete measuring system into the measuring cup mounting fl ange from below and

screw on using the measuring cup ring. Now, insert the measuring bob shaft completely into the

measuring bob coupling and lower the coupling sleeve (the ring is covered).

If you want to measure with temperature control, the bath/circulator must be pre-set at the desired

temperature and you should wait until bath liquid and sample are at test temperature.

To remove the measuring system after the viscosity measurement has been completed, fi rst open

the measuring bob coupling and then unscrew the measuring cup thread.

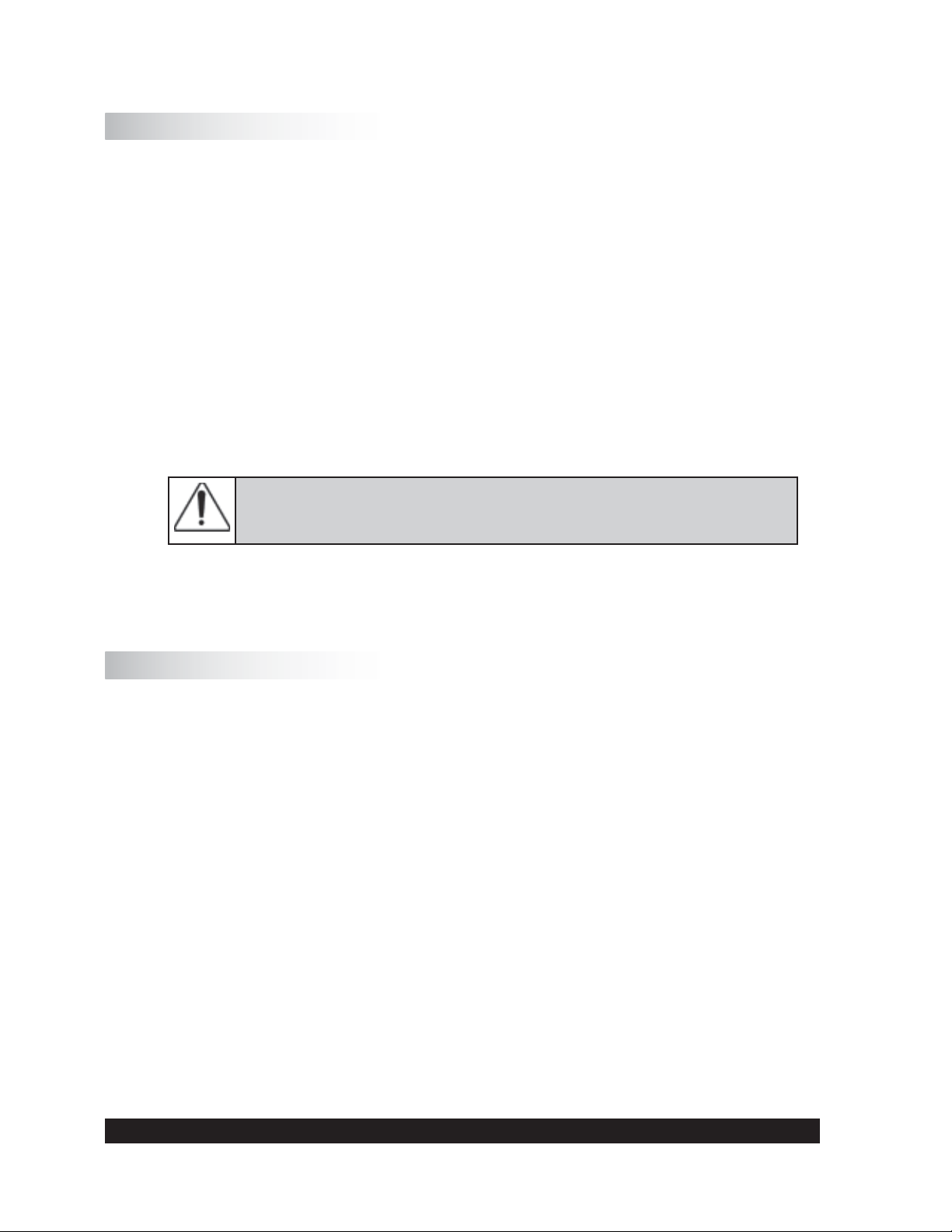

When unscrewing the measuring cup, you must hold the measuring

system tightly with one hand to avoid dropping the cup and bob!

Clean the measuring cup and measuring bob carefully with a soft cloth to avoid scratches!

V.3 Measurement with Water Jacket Assembly

Install the FTKY3 jacket by removing the measuring cup ring on the rheometer (see Figure III.5).

Attach the jacket to the rheometer using the ring built onto the top of the jacket.

Connect the tubing from the bath (the bath outlet to the bottom tubing connection of the jacket;

the bath inlet to the top of the connection on the water bath) to the jacket , and connect the Pt100

on the jacket to the Pt100 socket on the back of the rheometer.

When using disposable measuring systems, insert the disposable measuring cup into the receptacle.

Fill the measuring cup with the sample. (See Appendix A.1 for sample volumes).

Avoid air bubbles when fi lling the sample as they can affect the repeatability of the test!

Place the measuring bob in the measuring cup. Lift the coupling sleeve (ring is visible). Insert the

cup and bob into the jacket from below and screw on using the measuring cup ring. Insert the bob

shaft into the measuring bob coupling and lower the coupling sleeve (ring is covered).

Set the water bath to test temperature. After the bath is at the test temperature, wait 15 minutes

to ensure that the sample, cup and bob are at test temperature.

Brookfi eld Engineering Labs., Inc. Page 22 Manual No. M08-219-B1211

Page 23

To remove the measuring system after the measurement, fi rst open the coupling sleeve for the

bob, then unscrew the measuring cup ring.

When unscrewing the measuring cup, you must hold the measuring

system tightly with one hand to avoid dropping the cup and bob!

When using disposable measuring cups, eject the disposable measuring cup with the pusher.

V.4 Measurement with Cone/Plate or Plate/Plate Measuring Systems

Installing and adjusting the measuring cone or measuring plate

When installing a cone or plate, the lower plate must be in the down position (move the locking

lever to the left and gently pull the lower plate down).

When releasing the bayonet lock, the measuring device has to be held

tightly from below.

Loosen the set screw on the cone or plate and push the cone or plate bottom up, setting the shaft

length to the minimum.

Lift the coupling sleeve (red ring mark should be visible). Insert the cone or plate from below into

the measuring coupling. Lower the coupling sleeve (ring is covered) to attach the spindle.

Turn the adjusting screw on the plate down to the lowest position. Raise the plate to the top

position and secure it with the bayonet lock (position “closed”).

The actual distance between spindle and plate has to be adjusted to approximately 1 mm by

turning the adjusting screw up. Set the screw mark to “0” with approximately 1 mm between

cone and plate.

The dial indicator should also be set to mark “0” for distance control. Unlock the spindle shaft

to bring the spindle onto the plate, and tighten the cone set screw to fi x the shaft.

The plate is now adjusted to 50 μm. The adjustment ring lowers the plate down when turned

clockwise (looking down onto the adapter), and raises it up by turning the ring counter-clockwise.

Lower the plate to 0.5 mm by turning the adjustment ring clockwise for one complete revolution.

Now raise the plate, but not all the way back to the zero position; stop at the “5” mark in the ring

which sets the gap to 50 μm.

Brookfi eld Engineering Labs., Inc. Page 23 Manual No. M08-219-B1211

Page 24

Measurement

Open the bayonet lock and lower the plane-table. Apply the sample to be tested. Lift up the planetable and fi x the bayonet lock. Now, the measurement can start.

Remove excess sample from around the cone or plate before starting the

measurement.

If temperature control is required, a bath/circulator must be connected. The bath must be set at

the desired temperature, and you should wait until the bath and cone/plate accessory have reached

test temperature.

Brookfi eld Engineering Labs., Inc. Page 24 Manual No. M08-219-B1211

Page 25

VI. Operation and Menu System

The following section summarizes the operation and the menu system of the R/S+ Rheometer for

both manual and PC-controlled measurement.

Menu prompts for the R/S+ Rheometer in stand-alone mode are available in the following

languages:

English

•

German

•

The language is selected via the menu level Confi guration→Language (if English is active)

or Konfi guration→Sprache (if German is active). For more details on language selection, see

Section VI.7.6.

After applying power to the R/S+ Rheometer, the LCD displays the following information for

a few seconds:

name of the rheometer

•

software version of the fi rmware installed in the instrument

•

serial number of the instrument

•

date and time

•

Example:

R/S+ Rheometer

Ver.: 9.00 #xxxxxx

27.10.11 15.12

©Brookfi eld Engineering

About fi ve seconds later, the instrument checks the voltage of the power supply. The displayed

voltage should be in the range of 14.9 to 16V. If the voltage is outside this range, contact Brookfi eld

or your local Brookfi eld dealer.

Example:

Voltage Check:

VCC:15.25 V

This message is displayed for about 3 seconds and then the MAIN menu is displayed. A brief

summary, in Section VI.4, of the rheometer keyboard and the corresponding rheometer functions

may be helpful before you get to the complete description of the menu.

Brookfi eld Engineering Labs., Inc. Page 25 Manual No. M08-219-B1211

Page 26

VI.1 Keyboard

- Select previous menu entry

- Input: increment numerical

value/letter

- Select next menu entry

- Input: decrement numerical

value/letter

MAIN MENU

- Single measurement

- Program measurement

- Remote

>

R/S + RHEOMETER

ON

ST

START/STOP

- Back to parent menu

- Abort

- Start of measurement

- Abort measurement

OK

OK

- Accept

- Select

- One digit to the right

- One digit to the left

All user inputs are made using the six keys located below the LCD. Some of the keys have

multiple uses, i.e. their function depends on the current operation. The following table shows

the keyboard functions in detail.

Keypad layout of the R/S+ Rheometer

Key Operation Function of Key Example

1) Menu

2) Input of

numerical values

3) Selection from list

1) Menu

2) Input of

numerical values

3) Selection from list

1) Menu

1) Go to previous menu

entry (above active one)

2) Increment

3) List entry above active

entry (previous)

1) Go to next menu entry

(below active one

2) Decrement

3) List entry below active

entry (next)

1) Go to previous menu

entry (above active one)

1) Utilities → Remote

2) 8 → 9

A → B

3) Select meas. system

CC25/30 → CC37/30

1) Remote → Utilities

2) 5 → 4

F → G

3) Select meas. system

CC37/30 → CC25/30

1) Utilities → Remote

2) Input of

numerical values

2) One digit to the right

2) 100.00 → 100.00

Test → Test

3) Selection from list

1) Menu

3) List entry above active

entry (previous)

1) Go to next menu entry

3) Select meas. system

CC25/30 → CC37/30

1) Remote → Utilities

(below active one)

2) Input of

numerical values

2) One digit to the left

2) 100.00 → 100.00

Test → Te st

3) Selection from list

3) List entry below active

entry (next)

3) Select meas. system

CC25/30 → CC37/30

Brookfi eld Engineering Labs., Inc. Page 26 Manual No. M08-219-B1211

Page 27

Key Operation Function of Key Example

1) Menu

1) Return to parent menu

(turn page downward)

1) Utilities → Main

2) Input of numerical

values

3) Selection from list

ST

4) Measurement

5) Remote operation

1) Menu

2) Input of numerical

OK

values

3) Selection from list

2) Stop input

(only if possible)

3) Stop selection

(only if possible)

4) Start or Stop measurement

5) Go back to main menu

1) Select active menu level

(open sub-menu)

2) End of input/acceptance

3) Select active list element

3) Select meas. system →

back to menu

4) Break when measuring

Brookfi eld Engineering Labs., Inc. Page 27 Manual No. M08-219-B1211

Page 28

VI.2 Menu System of R/S+ Rheometer

Brookfi eld Engineering Labs., Inc. Page 28 Manual No. M08-219-B1211

Page 29

Menu Handling

Since the LCD of the R/S+ Rheometer cannot show all menu items simultaneously, only three

entries are displayed on the menu at a time. Arrows (>) on the right side of the display indicate

that there are more menu entries. The arrow on the 2nd line indicates there are more menu entries

above and the arrow on the 4th line indicates more menu entries below.

The currently active (but not yet selected) entry is marked by a blinking fi eld (cursor) on the left

side of the LCD.

Example:

Active entry: press

OK to select

MAIN-Menu

Run Single

-Run Program

-Remote >

This menu contains

additional entries

Using the

and

keys, you can move the cursor up and down in the menu until the

desired menu entry is reached.

Note: If there are more menu entries in the menu when you have reached the end of the display,

the next part of menu will be opened automatically (scrolling).

You can “start” the menu entry by pressing the

If you are in a submenu and wish to return to the upper menu, press the

OK

key, as well as open the related sub-menu.

ST

key.

VI.3 Selecting from Lists

The same keypad and display functions that are in the menu apply if you have to select a preexisting entry from a list. Selection from a list is required for the following:

Select a measuring system for measurement, e.g. in “Run Single” or “Edit Program”

•

Select pre-set values for measurement, e.g. in “Run Single” or “Edit Program”

•

Select a program or a measuring system you want to edit in “Edit Program” and “Measuring

•

Systems”

Answer a request “YES” ↔ “NO”.

•

Select the program to be started in “Program Measurement”

•

The

The

Brookfi eld Engineering Labs., Inc. Page 29 Manual No. M08-219-B1211

and

OK

key selects the entry; the

keys move the cursor up and down the list.

key stops the selection from the list (only if possible).

ST

Page 30

Example:

Select Meas.system:

1) DG DIN >

2) CC40

3) CC25 >

In the above screen, press OK to accept the DG DIN measuring system.

VI.4 Input of Numerical Values and Alphanumeric Texts

Most user defi ned entries are numbers. User defi ned values such as the Start and End values

of a ramp, number of measuring points, factors, time, date, etc. are entered as numbers with or

without decimal digits.

If the display shows the decimal point in a number to be entered, input of a fl oating-point number

is requested. However, the number of digits after the decimal point is limited to the number of

displayed decimal digits; i.e. the decimal point cannot be moved during input. The digit to be

changed is indicated by a bar under the digit.

The following examples indicate the input of numerical values. We will change the value of shear

rate (Val.[1/s]) from 0100.00 to 290.00.

In the example below, the cursor bar is located under the “1” in the entered shear rate (currently

100.00 s

The “1” can be changed (incremented or decremented) by using the

Press the

The cursor can be moved right or left by using the

press the

-1

).

key once to get:

key:

Input of Values:

Val.[1/s]: 0100.00

Nr. of MP: 010

Time[s]: 0100

Input of Values:

Val.[1/s]: 0200.00

Nr. of MP: 010

Time[s]: 0100

Input of Values:

Val.[1/s]: 0200.00

Nr. of MP: 010

Time[s]: 0100

and

and

keys. To change the next digit,

keys.

Brookfi eld Engineering Labs., Inc. Page 30 Manual No. M08-219-B1211

Page 31

The next digit can now be changed. In order to insert “9” in place of “0”, press the

once:

Input of Values:

Val.[1/s]: 0290.00

Nr. of MP: 010

Time[s]: 0100

key

Note: If you press and hold one of the

or

keys while entering numbers, the digit will fi rst

increment or decrement by +/- 1. However, after a short period of time, the process will

continue automatically. This corresponds to the Repeat Function of computer keyboards.

In the example above, the

key was pressed and held until the “9” was displayed. The

repeat function is only active during numerical and alphanumeric input.

When the desired number is displayed, accept it by pressing the

OK

key: the cursor now moves

to the fi rst digit of the next fi eld to be entered.

Alphanumeric inputs

Some fi elds allow for both numbers and letters. These are entered the same way as previously

discussed for numeric fi elds. The available entries are: 0 through 9, A through Z, and the blank

symbol “ ”. If you wish to change the letter “B” to the number “7”, press and hold the

key until the “7” appears in the display.

Alphanumeric input is available when assigning a name to a user defi ned program, or an ID to a

user defi ned test measurement.

VI.5 Menu Entries (MAIN Menu)

or

Menu entries (see Section VI.2) either lead to submenus (e.g. “Utilities” or “Confi guration”), or

they start one of the rheometer’s functions directly.

All gray fi elds in the tree chart in Section VI.2 that have no further right branches start functions.

Those with right branches are submenus.

Recall the keypad layout from Section VI.2. By pressing the

rectangle) moves up and down. The

key starts a function. If a submenu is assigned to the

OK

and

keys, the cursor (black

entry it will open, otherwise the function of the rheometer is started. The functions of the R/S+

Rheometer are described in detail in this section.

Brookfi eld Engineering Labs., Inc. Page 31 Manual No. M08-219-B1211

Page 32

VI.5.1 MAIN Menu → Run Single

This function carries out a measurement of shear stress or shear rate at a constant preset value.

The physical units for each type of measurement are listed as follows:

Shear Rate D[s-1]

•

Speed n[rpm]

•

Shear Stress Tau [Pa]

•

Torque M [‰] [1000‰ corresponds to 50 mNm]

•

After turning on the rheometer followed by the initial self-test (Section VI), the startup screen is

reached automatically:

Active entry: press

OK to select

VI.5.2 MAIN Menu → Single Measurement

MAIN-Menu

Run Single

-Run Program

-Remote >

This menu contains

additional entries

This function sets the shear stress or shear rate (CSS or CSR) at a single constant user defi ned

value. The user may select a choice of measurement method from the following:

Shear Rate D [s-1]

Speed n [U/min] or [rpm]

Shear Stress Tau [Pa}

Torque

M[

‰] [1000‰ corresponds to 50 mNm]

Before you can start the measurement itself, you have to input the following values:

Selection of the measuring system used (see Section VI.3: Selecting from Lists)

•

Selection of test method. This is where you decide if you want to carry out a shear rate

•

measurement (shear rate, speed) or a shear stress measurement (shear stress, torque).

Input of preset values (see Section VI.4: Input of Numerical Values).

•

- D[s

-1

] The range of values depends on the measuring system

- n[rpm] 0.1 to 1,000 rpm (U/min)

- Tau [Pa] The range of the values depends on the measuring system

- M [‰] 0 to 999 ‰

Input of desired number of measurement points (see Section VI.4: Input of Numerical

•

Values).

Input of the measurement duration in seconds. The minimum time interval depends on

•

the kind of the measurement and on the number of measurement points. The minimum

times between 2 measurement points are:

- shear rate measurement t

- shear stress measurement t

>= 4 s

MP

>= 1 s

MP

Note: The longer the time between two measured values, the higher the accuracy of the

physical values determined!

Brookfi eld Engineering Labs., Inc. Page 32 Manual No. M08-219-B1211

Page 33

Input of ID (15 character maximum) for the test measurement (see Section VI.4: Input

•

of Numerical Values)

Before starting the measurement, the rheometer will indicate where the measurement points will

be written to:

Output of MPs to:

- no output-device

- memory

< >menu <ST>START_

Start a measurement by pressing the

key or return to the main menu with the

ST

key.

This example shows that the measurement data will be written into the instrument memory. Output

devices are either a printer or the RS232 serial interface of the rheometer. Pre-selection of these

devices is described in Section VI.7.1: Confi guration → Output Mode.

If the memory is full and you want to keep the data, you should stop the “Single Measurement”

function and print out the data from the memory or send the data to a PC (see Section VI.6.5:

Utilities → Print Memory). Then you may clear the data from the memory (see Section VI.6.1:

Utilities → Clear Memory) and run your test.

Tests may still be run if the memory is full, but the results will not be saved. They will be shown

on the LCD as they come from the instrument.

When a measurement is started, the instrument shows:

Program running

Wait for 1.MP

#01

This message will be displayed until the fi rst measurement point is reached and displayed.

Torque

Duration

100.5 ‰ 000.90 1/s

Eta: 1.728Pas

Tau: 1.572Pa

04s 20.7°C #01

Temperature

User defi ned value

Measurement results

Step (in single measurement it is always 01)

If the torque is below 10‰ (scale is 0‰ to 1,000‰), the measurement results may not be as

accurate as desired. In this case, the user defi ned parameters should be changed so the torque is

higher than 10%.

Brookfi eld Engineering Labs., Inc. Page 33 Manual No. M08-219-B1211

Page 34

If the display fi eld for the torque indicates: “Mlow!”, these values are below the range of resolution

of the rheometer.

If the temperature is not displayed, the measuring sensor is not connected and the temperature

value will show as “1000.0°C” on the printout.

The display is updated with every new measurement point. The current measurement can be

cancelled at any time with the

After a measurement is completed or the

ST

key.

ST

key is pressed, the display fi eld for Step indicates

“END” or “BREAK”. The display alternates at intervals of about four seconds between the last

displayed measurement point and information about the measurement:

Reason for

break or end

Duration until

break or end

Program end

Single mode

Total time: 100s

Total #MP: 10

Type/name of

executed program

Number of measurement

points

Pressing the

key stops the alternating display and returns the user to the menu.

OK

Note: The last selected program parameters remain in the memory even after switching off the

rheometer.

VI.5.3 MAIN Menu → Run Program

The Run Program function starts one of the programs defi ned in memory. If there is no program

available, the following error message is displayed:

No valid program

Enter program fi rst!

In this case, the user has to defi ne a program fi rst (see Section VI.6.2: Utilities → Edit Program”).

Use the

key to return to the main menu.

OK

If the programs are available, a list appears to select from. Select the program to be started (see

Section VI.3: Selecting from Lists).

Select PROG to run

1) Prog xyz

2) Test

3) Prog oil 2000

Brookfi eld Engineering Labs., Inc. Page 34 Manual No. M08-219-B1211

Page 35

If the

key is used to select the program (in this example, the program named “Test”), this

OK

operation is followed by the option to enter an ID (identifi cation name for the measurement, a

maximum 15 characters of alphanumeric input can be used, see Section VI.4.).

Measurement

series

identifi cation

Input measuring id

ID-number: 125

ID: OIL2000 040596

Automatically increment at every measurement

Next, the rheometer will indicate where the measure points will be written to.

Output of MPs to:

- Printer

- memory

< >menu <ST>START_

Start a measurement by pressing the

ST

key or return back to the main menu with the

key.

In the above example, the measurement points will be saved to memory and printed to the printer

connected to the rheometer. Options for output devices include a printer, the RS232 serial

interface or no output device. In Section VI.7.1: Confi guration → Output Mode, this is described

in detail.

If the memory is full, you should consider cancelling the “Program measurement” function, printing

the data from the memory or sending it to a PC (see Section VI.6.5: Utilities → Print Memory”)

and then clearing the data from the memory (see Section VI.6.6: Utilities Clear Memory).

Measurements can be taken with the memory full but the results will only be shown on the LCD

and will be lost after completion of the measurement. If you try to send results to a printer and

it is not connected or has no paper in it, an error message will be displayed until the printer is

connected and operational or until you stop the activity.

When you start the measurement, the instrument shows:

Program running...

Wait for 1.MP

#01

Brookfi eld Engineering Labs., Inc. Page 35 Manual No. M08-219-B1211

Page 36

This message will be displayed until the fi rst measuring point is displayed:

Torque

Duration

100.5 ‰ 000.90 1/s

Eta: 1.728 Pas

Tau: 1.572 Pa

05s 20.7°C #01

Temperature

Actual pre-set value

Measurement result

Current step

If the torque is less than 30‰, the results may be out of instrument range. The user should consider

changing the user defi ned values to get a torque higher than 100‰.

If the display fi eld for the torque indicates: “Mlow!”, these values are below the range of resolution

of the rheometer.

If the temperature is not displayed, the measuring sensor is not connected and the printout of the

temperature will be printed as “---”.

The display is updated with every new measurement point. The current measurement can be

cancelled at any time with the

key.

ST

After a measurement, or after a stop, the display fi eld for step indicates “END” or “BREAK”.

The LCD alternates at intervals of about four seconds between the last displayed measurement

point and information on the measurement:

Reason for

break or end

Duration until

break or end

Program end

Single measurement

Total time: 200s

Total #MP: 40

Type/name of

executed program

Number of

measurement points

Pressing the

VI.5.4 MAIN Menu → Remote

key ends the alternating display and returns to the main menu.

OK

The “Remote” function initiates measurements to be made under PC control. In this mode, all

functions of the R/S+ Rheometer are controlled by a PC. For PC-controlled measurements, you

need the Rheo 3000 software. This software operates under Microsoft Windows 7™, Windows

2000™, Windows XP™, and Vista™. More detailed information on Rheo 3000 software can be

obtained from Brookfi eld or an authorized dealer.

After selecting the Remote option, the rheometer displays the following:

Remote

Wait for RS232...

Brookfi eld Engineering Labs., Inc. Page 36 Manual No. M08-219-B1211

<ST>=stop

Page 37

The rheometer waits for communication with a PC. Data transfer between the PC and the rheometer

is performed through the RS232 serial interface of the R/S+ Rheometer.

If Rheo 3000 software is installed on the PC, the REMOTE (MEASURE) program can be run.

This operation can also be ended at any time by pressing the

is also cancelled by pressing the

ST

key in REMOTE operation.

ST

key. The current measurement

On completion of the communication with the PC, the LCD shows: “Remote done ...” Pressing

ST

the

key will return the display to the Main Menu.

During measurement in REMOTE operation, the LCD will display troubleshooting information

in case errors occur.

VI.5.5 MAIN Menu → Utilities

Entry to open the “Utilities” submenu - see Section VI.6.

VI.5.6 MAIN Menu → Confi guration

Entry to open the “Confi guration” submenu - see Section VI.6.

VI.6 Menu Entries in the Utilities Menu

The Utilities menu contains several useful functions:

Zero Calibration Initiates the zero calibration procedure of the rheometer

Edit Programs Input or modifi cation of programs which are started with Run

Program

Print Programs Prints all parameters of all the programs in memory to the printer

Measuring Systems Input of the measuring system parameters or generation of new

measuring systems

Print Memory Output of data in memory to the printer or to the serial interface

Delete Memory Clears all data from memory

Meas. Temperature Measures temperature without running a measurement

The following sections explain these options in more detail.

Brookfi eld Engineering Labs., Inc. Page 37 Manual No. M08-219-B1211

Page 38

VI.6.1 Utilities → Zero calibration

The function “Zero Calibration” serves to calibrate the zero point of the rheometer. This function

continues for approximately 10 minutes and should be done once a week.

Before starting this function, be sure the R/S+ Rheometer has warmed up

for at least 10 minutes and that NO measuring element (spindle or bob)

is in the measuring element coupling.

To confi rm the command that the measuring system is removed, press the

ST

point calibration), or press the

key to return to the Utilities menu.

OK

key (start of zero

Zero point calibration will proceed automatically and comprises several measuring series at

different speeds. The progress of calibration is shown by the number of executed steps of the

total steps. If an error message appears during zero calibration, repeat the zero calibration. If

the error message is displayed again, there may be a technical fault (see Appendix G: Warranty

and Repair Service).

After a successful calibration, the values of the zero point are stored internally. These values are

preserved until the next calibration.

Press the

OK

key to save the values. Press any other key to return to the Utilities menu without

saving.

ST

Note: You can cancel zero point calibration at any time with the

key. The zero point values

determined up to that point will be ignored.

VI.6.2 Utilities → Edit Program

This function allows the input of new programs and the modifi cation of existing programs. These

programs may be run after a successful creation via the menu level “Program Measurement” in

the main menu.

The following values are user-defi nable in a program:

• measuring system to be used

• number of steps

• start and end value of each step

• number of measurement points for each step

• duration of each step

Brookfi eld Engineering Labs., Inc. Page 38 Manual No. M08-219-B1211

Page 39

Preset value as a function of time:

D[1/s]

100

80

60

40

20

0

0 60 120 180

t[s]

D[1/s]=f(t)

A standard measurement is shown in the following example:

1st step: shear rate increases within 60 sec from 10.00 to 100.00 s-1.

•

2nd step: shear rate remains at 100.00 s

•

3rd step: shear rate decreases from 100.00 back to 10.00 s-1 within 60 seconds

•

-1

for 60 seconds

This measurement consists of three steps, each lasting 60 seconds and containing a number of

measurement points.

The following is an example to explain the input of a program.

Apart from the shear rate D [s

speed n [rpm] = f(t)

•

torque M [‰] = f(t) and

•

shear stress Tau [Pa] = f(t)

•

-1

] = f(t), the preset value can also be defi ned as:

Steps are always linear, measurement points are also defi ned as linear; i.e. logarithmic steps are

not possible. For logarithmic measurements, you will need the Rheo 3000 software.

Preset value sub-steps in a defi ned step according to the following equation:

Preset Value = End Value - Start Value/(Number of Measuring points - 1)

The fi rst user defi ned value (= the fi rst measuring point) is always the start value of the ramp.

The last measuring point is determined as the end value of the user defi ned value range. As in

our example, to reach the values D = 10, 20, 30, ... , 100 [s

-1

] a starting value of 10 [

s-1

] is used

with increments of 10, therefore, 10 measurement points are required. To check: 100-10/(10-1)

= 10.

Number of Measurement Points = ((End Value - Start Value) / Preset Value) -1

After the selection of the menu level “Edit Program”, the user will be prompted to select the

program.

Brookfi eld Engineering Labs., Inc. Page 39 Manual No. M08-219-B1211

Page 40

Available programs

contain a name

Select program

1) Prog xyz

2) Test

3) NEW

All free (non-defi ned)

programs are marked NEW

All free programs are initially marked as NEW. To avoid overwriting existing programs, select

NEW as a program to be edited and select a measuring system. After the selection of the program

with the

OK

key, you will be requested to select a measuring system.

Attention: Any defi ned program MUST ALWAYS be executed with the same measuring system,

otherwise improper results will be calculated.

Select Meas. system:

1) CC40 >

2) CC25

3) CC14 >

After selecting the measurement system, enter the number of steps (number of ramp and straight

line functions). The number of steps can range from 1 to a maximum of 10 steps. In this

example, we need three steps, so the number “01” is changed to “03” - (see Section VI.4: Input

of Numerical Values). The message “Range error” will appear if <1 or >10 is entered.

Nr of steps: 03

Input number of

steps 1 - 10. This

example is 03.

After entering the number of steps, input the type of measurement.

Select Input:

-D[1/s]

-n[rpm]

-Tau[Pa] >

Available Measurement Types User Defi ned Range

Shear Rate D{s-1] Depends on the measuring system

Speed n[rpm] 0.1 - 1,000 rpm

Shear Stress Tau [Pa] Depends on the measuring system

Torque M[

‰]

0 - 999 promille (= 0 to 50 mNm)

Select the type of measurement and press the OK key (in our example “D[1/s]”). Now enter the

user defi ned values for each step one after the other.

Brookfi eld Engineering Labs., Inc. Page 40 Manual No. M08-219-B1211

Page 41

The following inputs have to be made for each step:

Input Step Nr1

Start[1/s]:0010.00

End Value

End[1/s]: 0100.00

Nr of MP: 010

Start Value

Number of

Measurement Points

(data points)

Minimum and maximum start and end values depend on the selected measuring system for shear

-1

rate (D[s

]) and shear stress (Tau [Pa]). At input, the rheometer checks the start and end values

and indicates the message “Range error” if out of range:

Allowed minimum

value

Range error

Start value:

Min: 0.90

Max: 1032.80

Name of value out of

range

Allowed maximum

value

For example, a range error message would be displayed if a start value for D[s-1] is not within the

range of 0.0 - 1032.8 s-1 when using measuring system CC25.

If the start value, end value and number of measuring points are acceptable, the user will be

prompted for Step Duration:

Number of steps

being edited

Input Step Nr. 1

Time[s]: 0060

Step duration

Minimum step duration:

Available Measurement Types User Defi ned Range

t

Shear Rate D{s-1]

Speed n[rpm] t

Shear Stress Tau [Pa] t

Torque M[

‰]

= number of measuring points * 4 s

min

= number of measuring points * 4 s

min

= number of measuring points * 1 s

min

t

= number of measuring points * 1 s

min

Maximum step duration: 3600 s

The instrument will automatically check the input. If there is a range error, “Range error” would

be displayed together with the allowable range.

The more time between two measuring points, the higher the accuracy

of the determined physical parameters!

Brookfi eld Engineering Labs., Inc. Page 41 Manual No. M08-219-B1211

Page 42

The input procedure for start and end value number of measurement points and step duration is

repeated for the next step. The procedure is repeated until all steps have been entered.

The program will then prompt the user for a program name.

Edit PROGRAM name:

TEST

Enter the name under which

the program is to be stored

For this example, we will use “TEST” (see Section VI.4: Input of Numerical Values). The

instrument will prompt the user to store the program name:

(2) TEST

Press <OK> to save

Press the

key to store the program.

OK

If any other key besides OK is pressed, the entries are abandoned and

those parameters that existed before editing will be preserved.

VI.6.3 Utilities → Print Programs

This function will print the parameters of the defi ned programs in memory.

If the printer is not ready for operation when the “Print Programs” function is initiated, the

following error message will be displayed:

ERROR #1

Printer not ready!

<OK>cont. <ST>stop

If this error message appears, ensure that the printer is ready and contains paper.

Press the

VI.6.4 Utilities → Measuring Systems

key to try printing again or press the

OK

key to return to the menu.

ST

This function provides a method to create new measuring systems or change existing measuring

systems.

Brookfi eld Engineering Labs., Inc. Page 42 Manual No. M08-219-B1211

Page 43

The following values can be edited:

• name of measuring system

• shear rate factor K [min/s] (k_gamma)

• shear stress factor ‰ [Pa] (tau_prom)

Only authorized personnel are permitted to change constants of the

measuring system!

After starting the function, you will be prompted to select the measuring system of which you

want to edit. Select the list item “NEW” to generate a new measuring system.

Select Meas. system:

1) CC40

2) CC25

3) CC14

After selection of the measuring system entry, the user is prompted to enter a name, tau_prom

and k_gamma.

Enter Meas. syst. #4

Name: CC25

tau_prom: 01.1418

k_gamma: 01.2910

The measuring system name is entered in alphanumeric form; the factors tau_ prom and k_gamma

are entered as numerical entries (see Section VI.4).

After entry, the system will prompt the user to store the new parameters.

Press <OK> to save

Name: CC25

tau_prom: 01.1418

k_gamma: 01.2910

Use the OK key to store the new information, otherwise press the

ST

key to return to the menu

without storing.

VI.6.5 Utilities → Print Memory

This function allows the output of the data stored in the instrument memory to either a printer or

to the RS232 serial interface of the rheometer.

Brookfi eld Engineering Labs., Inc. Page 43 Manual No. M08-219-B1211

Page 44

The instrument will prompt you to select the output device, as follows:

Sel. output-device:

-Printer

-RS232

a) Output to printer:

The printer must be connected to the rheometer and ready for operation.

b) Output to the RS232 serial interface:

The data receiving side (typically a PC) must be set to the data transfer parameters from

the rheometer. If the receiving side is not set up properly, the data will either not be

transmitted or transmitted to Null. (see Section VI.8: Serial Data Transfer).

After choosing the output device, you are prompted to select the program to be printed or

transferred.

Measurement

Series Counter

MEASCOUNT

Date of Measurement

Select Program:

-1)17.10;11:20

-2)17.10;12:30

-3)17.10;13:40

Time of Measurement

The data of the program will print as a table to a printer or will be transferred via the serial interface.

After the completion of data transfer, the rheometer returns to the Utilities Menu.

VI.6.6 Utilities → Clear Memory

This function deletes all measured data stored in the memory of the R/S+ Rheometer.

Before deleting, ensure that the data has been archived to a printer or PC. Before the memory

is cleared, the following prompt is displayed:

Delete Memory?

-NO

-YES

If “YES” is selected, the results will be cleared from the memory; if “NO” is selected, no deletions

are made and the user is returned to the main menu.

Brookfi eld Engineering Labs., Inc. Page 44 Manual No. M08-219-B1211

Page 45

VI.6.7 Utilities → Measure Temperature

This function displays the temperature with the temperature sensor connected to the rheometer.

After initiating this function, the temperature is measured continuously:

Temperature:

20.5°C

Push the

VI.7 Menu Entries of the Confi guration Menu

OK

key to return to the Utilities menu.

<OK>=return

The confi guration menu allows the user to set parameters on the rheometer.

The entries:

Set output-mode: Defi nes if data is output to a printer or to the serial interface

•

during measurement.

Set meascount mode: Defi nes whether the measurement counter MEASCOUNT is

•

reset daily or not.

Set meascount=0: Resets the MEASCOUNT counter to 0.

•

Set time/date: Inputs date and time.

•

RS232 parameters: Sets data transfer parameters of the serial interface RS232.

•

Language: Selects language for user prompts.

•

Service: For service personnel only

•

Service 2: For service personnel only

•

These functions are explained in more detail in the following sections.

VI.7.1 Confi guration → Set Output Mode

This function defi nes the output device (printer, serial interface) which will receive the results.

This setting is independent of the internal memory in the rheometer for data storage. When tests

are run, the data is automatically stored in memory in addition to being sent to the confi gured

output device.

After selecting this function, you are prompted to select an output device:

Select output-mode:

Internal memory only

Additional output

to serial interface

Brookfi eld Engineering Labs., Inc. Page 45 Manual No. M08-219-B1211

-No output-device

-Printer

-RS232

Additional output to

printer

Page 46

Choice of an output device is stored in the instrument by pressing the

OK

key. This selection

remains stored even after switching off the instrument!

The set output device is prompted before the start of every measurement (see Sections VI.5.1:

Main Menu

→ Run Single and VI.5.3: Main Menu → Run Program).

Output of MPs to

Output device now set

-Printer

-Memory

<ST>Start <^>Menu

After selecting an output device and before the start of every measurement, be sure that:

a) the printer is connected to the rheometer and is ready for operation. If the printer is not

ready, you cannot start the measurement.

or

b) the Serial Interface (RS232) is connected to the receiving device (normally a PC),

which is set to the data transfer parameters of the rheometer (see Section VI.7.5: Set

RS232 Parameters) and is ready to receive data. If the receiving side is not ready, the

data will not be transmitted or will be transmitted to Null (see Section VI.8: Serial Data

Transfer).

VI.7.2 Confi guration → Set MeasCount Mode

The measurement series counter MEASCOUNT increases by 1 before each measurement is

started. The measurement series counter serves to identify a measurement series. The counter

increments until it is reset manually (“MeasCount=0”) or automatically. The user defi nes whether

the measuring counter is reset daily or not.

Resetting only via func-

tion “Reset meascount”

Select COUNT mode:

-No reset

-Reset every day

Automatic resetting

at fi rst measurement

of the day