Bosch GWS 18-125 L, GWS 18-125 PL, GWS 18-125 SL, GWS 18-125 SPL, GWS 18-150 L User Manual

...

OBJ_DOKU-65233-001.fm Page 1 Thursday, December 14, 2017 10:32 AM

|

|

|

Robert Bosch Power Tools GmbH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

70538 Stuttgart |

GWS Professional |

|

|

||

|

|

|

GERMANY |

|

|

|||

|

|

|

www.bosch-pt.com |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

1 609 92A 3ZY (2017.12) O / 77 |

18-125 L | 18-125 PL | 18-125 SL | 18-125 SPL | |

|

|||

|

|

|

|

|

||||

|

|

|

|

18-125 L Inox | 18-125 PL Inox | 18-150 L | 18-150 PL |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

en Original instructions cn tw

ko

th id Petunjuk-Petunjuk untuk

Penggunaan Orisinal

vi Bản gốc hướng dẫn sử dụng

OBJ_BUCH-3473-001.book Page 2 Thursday, December 14, 2017 10:33 AM

2 |

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . Page 6 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 17 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 26 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 34 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 43 |

Bahasa Indonesia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

Halaman 53 |

Tiếng Việt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . Trang 64 |

|

1 609 92A 3ZY | (14.12.17) |

|

|

Bosch Power Tools |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 3 Thursday, December 14, 2017 10:33 AM

| 3

|

Bosch Power Tools |

|

|

1 609 92A 3ZY | (14.12.17) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 4 Thursday, December 14, 2017 10:33 AM |

|

|

4 | |

|

|

|

|

3 |

|

1 |

|

|

2 |

|

|

|

4 |

24 |

|

|

|

|

5 |

7 |

12 |

14 |

|

||

8 |

8 |

8 |

|

13 |

15 |

9 |

|

|

10 |

10 |

10 |

11 |

11 |

11 |

1 609 92A 3ZY | (14.12.17) |

|

Bosch Power Tools |

OBJ_BUCH-3473-001.book Page 5 Thursday, December 14, 2017 10:33 AM |

|

|

|

|

| 5 |

|

23 |

21 |

|

|

|

5 |

|

8 |

|

|

22 |

|

|

10 |

|

|

11 |

6 |

|

|

16 |

16 |

|

17 |

20 |

25 |

18 |

|

|

19 |

|

|

Bosch Power Tools |

|

1 609 92A 3ZY | (14.12.17) |

OBJ_BUCH-3473-001.book Page 6 Thursday, December 14, 2017 10:33 AM

6 | English

English

Safety Notes

General Power Tool Safety Warnings

WARNING Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless) power tool.

Work area safety

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body is earthed or grounded.

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges and moving parts. Damaged or entangled cords increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards.

Power tool use and care

Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power tools.

Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed.

Use of the power tool for operations different from those intended could result in a hazardous situation.

Service

Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

|

1 609 92A 3ZY | (14.12.17) |

|

|

Bosch Power Tools |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 7 Thursday, December 14, 2017 10:33 AM

Safety Warnings for Angle Grinder

Safety Warnings common for Grinding, Sanding, Wire Brushing or Abrasive Cutting Off Operations

This power tool is intended to function as a grinder, sander, wire brush or cut-off tool. Read all safety warnings, instructions, illustrations and specifications provided with this power tool. Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury.

Operations such as polishing are not recommended to be performed with this power tool. Operations for which the power tool was not designed may create a hazard and cause personal injury.

Do not use accessories which are not specifically designed and recommended by the tool manufacturer.

Just because the accessory can be attached to your power tool, it does not assure safe operation.

The rated speed of the accessory must be at least equal to the maximum speed marked on the power tool. Accessories running faster than their rated speed can break and fly apart.

The outside diameter and the thickness of your accessory must be within the capacity rating of your power tool. Incorrectly sized accessories cannot be adequately guarded or controlled.

Threaded mounting of accessories must match the grinder spindle thread. For accessories mounted by flanges, the arbour hole of the accessory must fit the locating diameter of the flange. Accessories that do not match the mounting hardware of the power tool will run out of balance, vibrate excessively and may cause loss of control.

Do not use a damaged accessory. Before each use inspect the accessory such as abrasive wheels for chips and cracks, backing pad for cracks, tear or excess wear, wire brush for loose or cracked wires. If power tool or accessory is dropped, inspect for damage or install an undamaged accessory. After inspecting and installing an accessory, position yourself and bystanders away from the plane of the rotating accessory and run the power tool at maximum no-load speed for one minute. Damaged accessories will normally break apart during this test time.

Wear personal protective equipment. Depending on application, use face shield, safety goggles or safety glasses. As appropriate, wear dust mask, hearing protectors, gloves and workshop apron capable of stopping small abrasive or workpiece fragments. The eye protection must be capable of stopping flying debris generated by various operations. The dust mask or respirator must be capable of filtrating particles generated by your operation. Prolonged exposure to high intensity noise may cause hearing loss.

Keep bystanders a safe distance away from work area. Anyone entering the work area must wear personal protective equipment. Fragments of workpiece or of a

English | 7

broken accessory may fly away and cause injury beyond immediate area of operation.

Hold the power tool by insulated gripping surfaces only, when performing an operation where the cutting accessory may contact hidden wiring or its own cord. Cutting accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

Position the cord clear of the spinning accessory. If you lose control, the cord may be cut or snagged and your hand or arm may be pulled into the spinning accessory.

Never lay the power tool down until the accessory has come to a complete stop. The spinning accessory may grab the surface and pull the power tool out of your control.

Do not run the power tool while carrying it at your side.

Accidental contact with the spinning accessory could snag your clothing, pulling the accessory into your body.

Regularly clean the power tool’s air vents. The motor’s fan will draw the dust inside the housing and excessive accumulation of powdered metal may cause electrical hazards.

Do not operate the power tool near flammable materials. Sparks could ignite these materials.

Do not use accessories that require liquid coolants. Using water or other liquid coolants may result in electrocution or shock.

Kickback and related warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad, brush or any other accessory. Pinching or snagging causes rapid stalling of the rotating accessory which in turn causes the uncontrolled power tool to be forced in the direction opposite of the accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched by the workpiece, the edge of the wheel that is entering into the pinch point can dig into the surface of the material causing the wheel to climb out or kick out. The wheel may either jump toward or away from the operator, depending on direction of the wheel’s movement at the point of pinching. Abrasive wheels may also break under these conditions.

Kickback is the result of power tool misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions as given below.

Maintain a firm grip on the power tool and position your body and arm to allow you to resist kickback forces. Always use auxiliary handle, if provided, for maximum control over kickback or torque reaction during start-up. The operator can control torque reactions or kickback forces, if proper precautions are taken.

Never place your hand near the rotating accessory. Accessory may kickback over your hand.

Do not position your body in the area where power tool will move if kickback occurs. Kickback will propel the tool in direction opposite to the wheel’s movement at the point of snagging.

|

Bosch Power Tools |

|

|

1 609 92A 3ZY | (14.12.17) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 8 Thursday, December 14, 2017 10:33 AM

8 | English

Use special care when working corners, sharp edges, etc. Avoid bouncing and snagging the accessory. Corners, sharp edges or bouncing have a tendency to snag the rotating accessory and cause loss of control or kickback.

Do not attach a saw chain woodcarving blade or toothed saw blade. Such blades create frequent kickback and loss of control.

Safety warnings specific for Grinding and Abrasive Cut- ting-Off operations

Use only wheel types that are recommended for your power tool and the specific guard designed for the selected wheel. Wheels for which the power tool was not designed cannot be adequately guarded and are unsafe.

The grinding surface of the centre depressed wheels must be mounted below the plane of the guard lip. An improperly mounted wheel that projects through the plane of the guard lip cannot be adequately protected.

The guard must be securely attached to the power tool and positioned for maximum safety, so the least amount of wheel is exposed towards the operator. The guard helps to protect operator from broken wheel fragments, accidental contact with wheel and sparks that could ignite clothing.

Wheels must be used only for recommended applications. For example: do not grind with the side of the cut-off wheel. Abrasive cut-off wheels are intended for peripheral grinding; side forces applied to these wheels may cause them to shatter.

Always use undamaged wheel flanges that are of correct size and shape for your selected wheel. Proper wheel flanges support the wheel thus reducing the possibility of wheel breakage. Flanges for cut-off wheels may be different from grinding wheel flanges.

Do not use worn down wheels from larger power tools.

Wheel intended for larger power tool is not suitable for the higher speed of a smaller tool and may burst.

Additional safety warnings specific for abrasive cutting off operations

Do not “jam” the cut-off wheel or apply excessive pressure. Do not attempt to make an excessive depth of cut.

Overstressing the wheel increases the loading and susceptibility to twisting or binding of the wheel in the cut and the possibility of kickback or wheel breakage.

Do not position your body in line with and behind the rotating wheel. When the wheel, at the point of operation, is moving away from your body, the possible kickback may propel the spinning wheel and the power tool directly at you.

When wheel is binding or when interrupting a cut for any reason, switch off the power tool and hold the power tool motionless until the wheel comes to a complete stop. Never attempt to remove the cut-off wheel from the cut while the wheel is in motion otherwise kickback may occur. Investigate and take corrective action to eliminate the cause of wheel binding.

Do not restart the cutting operation in the workpiece. Let the wheel reach full speed and carefully re-enter the cut. The wheel may bind, walk up or kickback if the power tool is restarted in the workpiece.

Support panels or any oversized workpiece to minimize the risk of wheel pinching and kickback. Large workpieces tend to sag under their own weight. Supports must be placed under the workpiece near the line of cut and near the edge of the workpiece on both sides of the wheel.

Use extra caution when making a “pocket cut” into existing walls or other blind areas. The protruding wheel may cut gas or water pipes, electrical wiring or objects that can cause kickback.

Safety warnings specific for sanding operations

Do not use excessively oversized sanding disc paper. Follow manufacturers recommendations, when selecting sanding paper. Larger sanding paper extending beyond the sanding pad presents a laceration hazard and may cause snagging, tearing of the disc, or kickback.

Safety warnings specific for wire brushing operations

Be aware that wire bristles are thrown by the brush even during ordinary operation. Do not overstress the wires by applying excessive load to the brush. The wire bristles can easily penetrate light clothing and/or skin.

If the use of a guard is recommended for wire brushing, do not allow any interference of the wire wheel or brush with the guard. Wire wheel or brush may expand in diameter due to work load and centrifugal forces.

Additional safety warnings

Wear safety goggles.

Use suitable detectors to determine if utility lines are hidden in the work area or call the local utility company for assistance. Contact with electric lines can lead to fire and electric shock. Damaging a gas line can lead to explosion. Penetrating a water line causes property damage or may cause an electric shock.

Release the On/Off switch and set it to the off position when the power supply is interrupted, e. g., in case of a power failure or when the mains plug is pulled. This prevents uncontrolled restarting.

Do not touch grinding and cutting discs before they have cooled down. The discs can become very hot while working.

Secure the workpiece. A workpiece clamped with clamping devices or in a vice is held more secure than by hand.

Products sold in GB only: Your product is fitted with an BS 1363/A approved electric plug with internal fuse (ASTA approved to BS 1362).

If the plug is not suitable for your socket outlets, it should be cut off and an appropriate plug fitted in its place by an authorised customer service agent. The replacement plug should have the same fuse rating as the original plug.

|

1 609 92A 3ZY | (14.12.17) |

|

|

Bosch Power Tools |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 9 Thursday, December 14, 2017 10:33 AM

The severed plug must be disposed of to avoid a possible shock hazard and should never be inserted into a mains socket elsewhere.

Product Description and

Specifications

Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Intended Use

The machine is intended for cutting, roughing and brushing of metal and stone materials without the use of water.

For cutting with bonded abrasives, a special cutting guard (accessory) must be used.

When cutting in stone, provide for sufficient dust extraction. With approved sanding tools, the machine can be used for sanding with sanding discs.

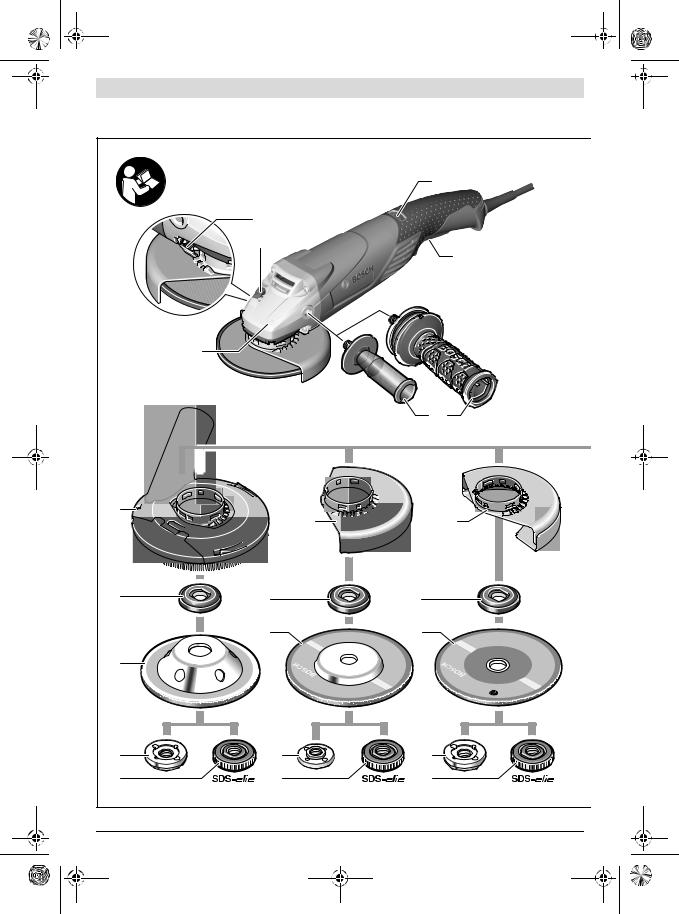

Product Features

The numbering of the product features refers to the illustration of the machine on the graphics page.

1 Release lever for protection guard

2 Spindle lock button

3Thumbwheel for speed preselection (GWS 18-125 SL/GWS 18-125 SPL)

Technical Data

English | 9

4 On/Off switch

5 Auxiliary handle (insulated gripping surface)

6 Grinder spindle

7 Extraction hood for sanding *

8 Mounting flange with O-ring

9 Carbide grinding head*

10Clamping nut

11Quick-clamping nut

*

*

12Protection guard for grinding

13Grinding wheel *

14Protection guard for cutting *

15Cutting disc *

16Hand guard*

17Rubber sanding plate*

18Sanding sheet*

19Round nut *

20Cup brush *

21Cutting guide with dust extraction protection guard *

22Diamond cutting disc *

23Handle (insulated gripping surface)

24Direction-of-rotation arrow for grinding spindle

25Diamond core cutter *

*Accessories shown or described are not part of the standard delivery scope of the product. A complete overview of accessories can be found in our accessories program.

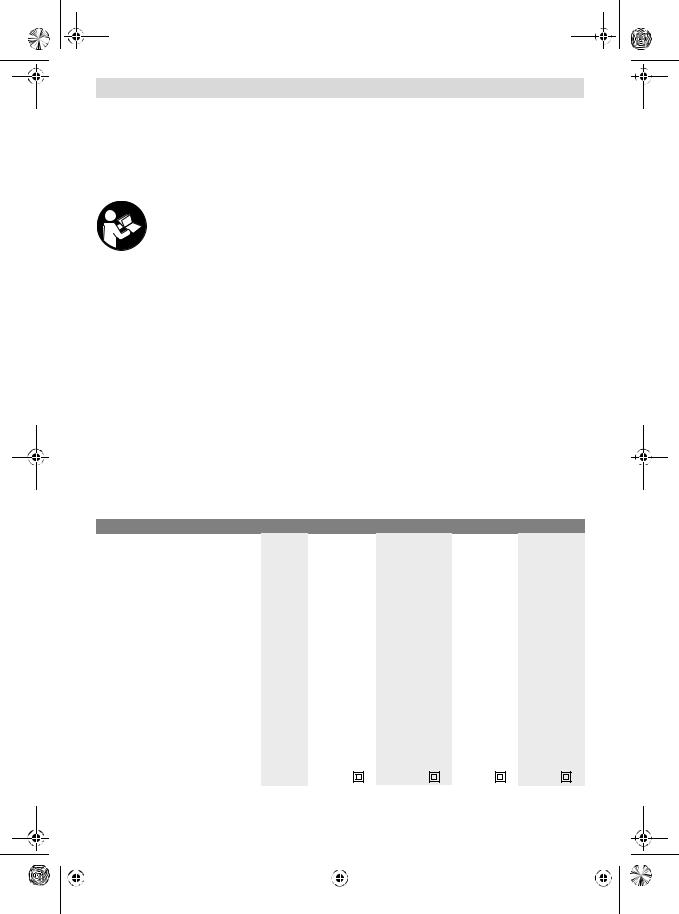

Angle Grinder |

GWS ... |

18-125 L |

18-125 PL |

18-125 SL |

18-125 SPL |

Article number |

3 601 ... |

GA3 0.. |

GA3 1.. |

GA3 2.. |

GA3 3.. |

Rated power input |

W |

1 800 |

1 800 |

1 800 |

1 800 |

Output power |

W |

1 145 |

1 145 |

1 145 |

1 145 |

Rated speed |

min-1 |

12 000 |

12 000 |

12 000 |

12 000 |

Speed control adjustment |

min-1 |

– |

– 2 800 – 12 000 |

2 800 – 12 000 |

|

Grinding disc diameter, max. |

mm |

125 |

125 |

125 |

125 |

Thread of grinder spindle |

|

M 14 |

M 14 |

M 14 |

M 14 |

Thread length (max.) of grinder spindle |

mm |

22 |

22 |

22 |

22 |

Kickback stop |

|

|

|

|

|

Restarting Protection |

|

|

|

|

|

Reduced starting current |

|

|

|

|

|

Constant electronic control |

|

|

|

|

|

Speed preselection |

|

– |

– |

|

|

Weight according to EPTA-Procedure |

|

|

|

|

|

01:2014 |

kg |

2.5 |

2.5 |

2.5 |

2.5 |

– with vibration-damping auxiliary handle |

|||||

– with standard-auxiliary handle |

kg |

2.3 |

2.3 |

2.3 |

2.3 |

Protection class |

|

/ II |

/ II |

/ II |

/ II |

The values given are valid for a nominal voltage [U] of 230 V. For different voltages and models for specific countries, these values can vary.

|

Bosch Power Tools |

|

|

1 609 92A 3ZY | (14.12.17) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 10 Thursday, December 14, 2017 10:33 AM

10 | English

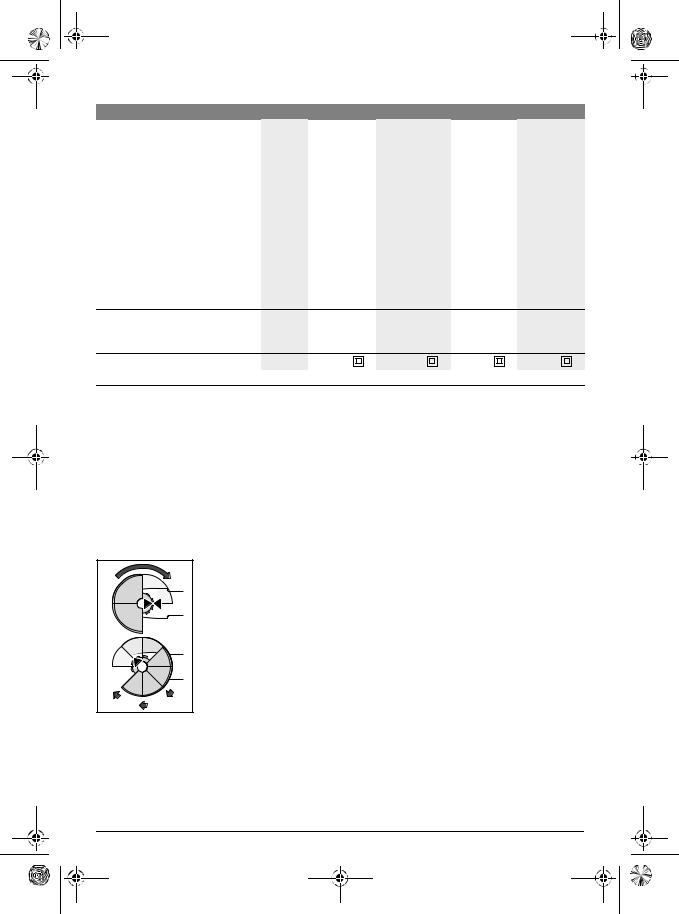

Angle Grinder |

GWS ... |

18-125 L Inox |

18-125 PL Inox |

18-150 L |

18-150 PL |

Article number |

3 601 ... |

GA4 0.. |

GA4 1.. |

GA5 0.. |

GA5 1.. |

Rated power input |

W |

1 800 |

1 800 |

1 800 |

1 800 |

Output power |

W |

1 145 |

1 145 |

1 145 |

1 145 |

Rated speed |

min-1 |

8 100 |

8 100 |

10 000 |

10 000 |

Speed control adjustment |

min-1 |

– |

– |

– |

– |

Grinding disc diameter, max. |

mm |

125 |

125 |

150 |

150 |

Thread of grinder spindle |

|

M 14 |

M 14 |

M 14 |

M 14 |

Thread length (max.) of grinder spindle |

mm |

22 |

22 |

22 |

22 |

Kickback stop |

|

|

|

|

|

Restarting Protection |

|

|

|

|

|

Reduced starting current |

|

|

|

|

|

Constant electronic control |

|

|

|

|

|

Speed preselection |

|

– |

– |

– |

– |

Weight according to EPTA-Procedure |

|

|

|

|

|

01:2014 |

kg |

2.5 |

2.5 |

2.5 |

2.5 |

– with vibration-damping auxiliary handle |

|||||

– with standard-auxiliary handle |

kg |

2.3 |

2.3 |

2.4 |

2.4 |

Protection class |

|

/ II |

/ II |

/ II |

/ II |

The values given are valid for a nominal voltage [U] of 230 V. For different voltages and models for specific countries, these values can vary.

Assembly

Mounting the Protective Devices

Before any work on the machine itself, pull the mains plug.

Note: After breakage of the grinding disc during operation or damage to the holding fixtures on the protection guard/power tool, the machine must promptly be sent to an after-sales service agent for maintenance. For addresses, see section “Af- ter-sales Service and Application Service”.

Protection Guard for Grinding

Place the protection guard 12 onto the spindle collar as shown in

the illustration. The triangle marks

on the protection guard must cor-

respond with the respective marks on the gear case.

Press the protection guard 12 onto the spindle collar until the

shoulder of the protection guard

is seated against the flange of the machine, and turn the protection guard until it can clearly be heard

to engage.

Adjust the position of the protection guard 12 to the requirements of the work process. For this, press the release lever 1 upward and turn the protection guard 12 to the required position.

Adjust the protection guard 12 in such a manner that sparking is prevented in the direction of the operator.

The protection guard 12 may be turned only upon actuation of the release lever 1! Otherwise the power tool may not continue to be used under any circumstances and must be taken to an after-sales service agent.

Note: The encoding keys on the protection guard 12 ensure that only a protection guard that fits the machine type can be mounted.

Protection Guard for Cutting

For cutting with bonded abrasives, always use the protection guard for cutting 14.

Provide for sufficient dust extraction when cutting stone.

The protection guard for cutting 14 is mounted in the same manner as the protection guard for grinding 12.

Cutting Guide with Dust Extraction Protection Guard

The cutting guide with dust extraction protection guard 21 is mounted in the same manner as the protection guard for grinding 12.

Extraction Hood for Sanding

The extraction hood 7 can be used for low-dust sanding of paint, varnish and plastics in conjunction with the carbide grinding head 9 or the rubber sanding plate 17 with a sanding sheet 18. The extraction hood 7 is not suitable for working metals.

A suitable Bosch vacuum cleaner can be connected to the extraction hood 7.

The extraction hood 7 is mounted in the same manner as the protection guard 12. The brush collar is exchangeable.

|

1 609 92A 3ZY | (14.12.17) |

|

|

Bosch Power Tools |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 11 Thursday, December 14, 2017 10:33 AM

Auxiliary Handle

Operate your machine only with the auxiliary handle 5.

Screw the auxiliary handle 5 on the right or left of the machine head depending on the working method.

Hand Guard

For operations with the rubber sanding plate 17 or with the cup brush/wheel brush/flap disc, always mount the hand guard 16.

The hand guard 16 is fastened with the auxiliary handle 5.

Mounting the Grinding Tools

Before any work on the machine itself, pull the mains plug.

Do not touch grinding and cutting discs before they have cooled down. The discs can become very hot while working.

Clean the grinder spindle 6 and all parts to be mounted.

For clamping and loosening the grinding tools, lock the grinder spindle with the spindle lock button 2.

Actuate the spindle lock button only when the grinder spindle is at a standstill. Otherwise, the machine may become damaged.

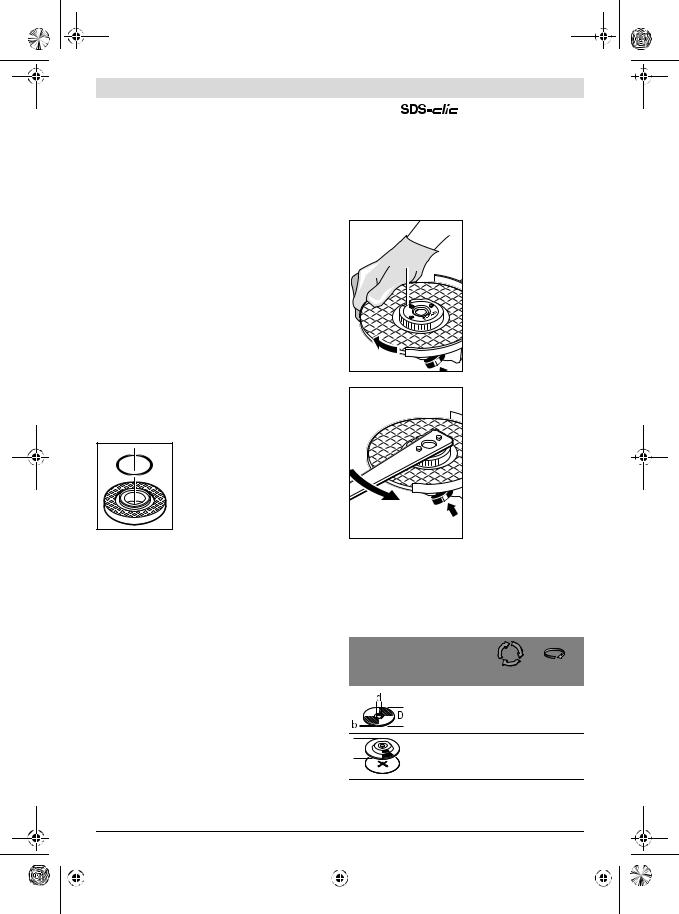

Grinding/Cutting Disc

Pay attention to the dimensions of the grinding tools. The mounting hole diameter must fit the mounting flange without play. Do not use reducers or adapters.

When using diamond cutting discs, pay attention that the di- rection-of-rotation arrow on the diamond cutting disc and the direction of rotation of the machine (see direction-of-rotation arrow on the machine head) agree.

See graphics page for the mounting sequence.

To fasten the grinding/cutting disc, screw on the clamping nut 10 and tighten with the two-pin spanner; see Section “Quickclamping Nut ”.

After mounting the grinding tool and before switching on, check that the grinding tool is correctly mounted and that it can turn freely. Make sure that the grinding tool does not graze against the protection guard or other parts.

A plastic part (O-ring) is fitted around the centring collar of mounting flange 8.

If the O-ring is missing or damaged, the mounting flange 8 must be replaced before resuming operation.

Flap Disc

For operations with the flap disc, always mount the hand guard 16.

Rubber Sanding Plate

For operations with the rubber sanding plate 17, always mount the hand guard 16.

See graphics page for the mounting sequence.

English | 11

Screw on the round nut 19 and tighten with the two-pin spanner.

Cup Brush/Disc Brush

For operations with the cup brush/wheel brush, always mount the hand guard 16.

See graphics page for the mounting sequence.

The cup brush/disc brush must be able to be screwed onto the grinder spindle until it rests firmly against the grinder spindle flange at the end of the grinder spindle threads. Tighten the cup brush/disc brush with an open-end spanner.

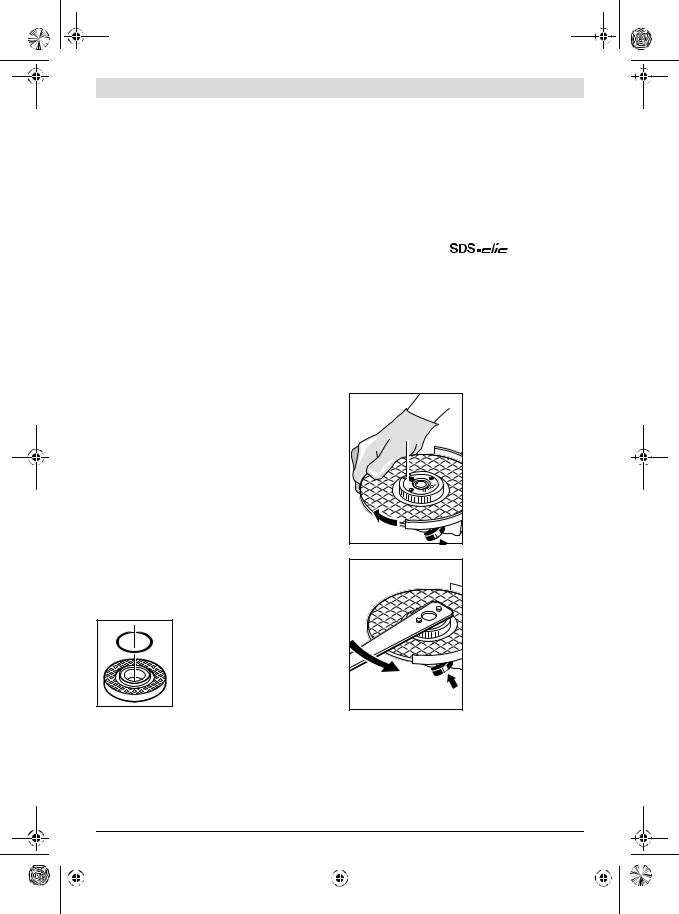

Quick-clamping Nut

For convenient changing of grinding tools without the use of additional tools, you can use the quick-clamping nut 11 instead of the clamping nut 10.

The quick-clamping nut 11 may be used only for grinding or cutting discs.

Use only a flawless, undamaged quick-clamping nut 11.

When screwing on, pay attention that the side of the quick-clamping nut 11 with printing does not face the grinding disc; the arrow must point to the index mark 26.

26 |

Lock the grinder spindle with the spindle lock button 2. To tighten the quick-clamping nut, firmly turn the grinding disc in clockwise direction.

A properly attached, undamaged quick-clamping nut can be loosened by hand when turning the knurled ring in anticlockwise direction.

Never loosen a tight quickclamping nut with pliers. Always use the two-pin spanner. Insert the two-pin spanner as shown in the illustration.

Approved Grinding Tools

All grinding tools mentioned in these operating instructions can be used.

The permissible speed [min-1] or the circumferential speed [m/s] of the grinding tools used must at least match the values given in the table.

|

Bosch Power Tools |

|

|

1 609 92A 3ZY | (14.12.17) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 12 Thursday, December 14, 2017 10:33 AM

12 | English

Therefore, observe the permissible rotational/circumferential speed on the label of the grinding tool.

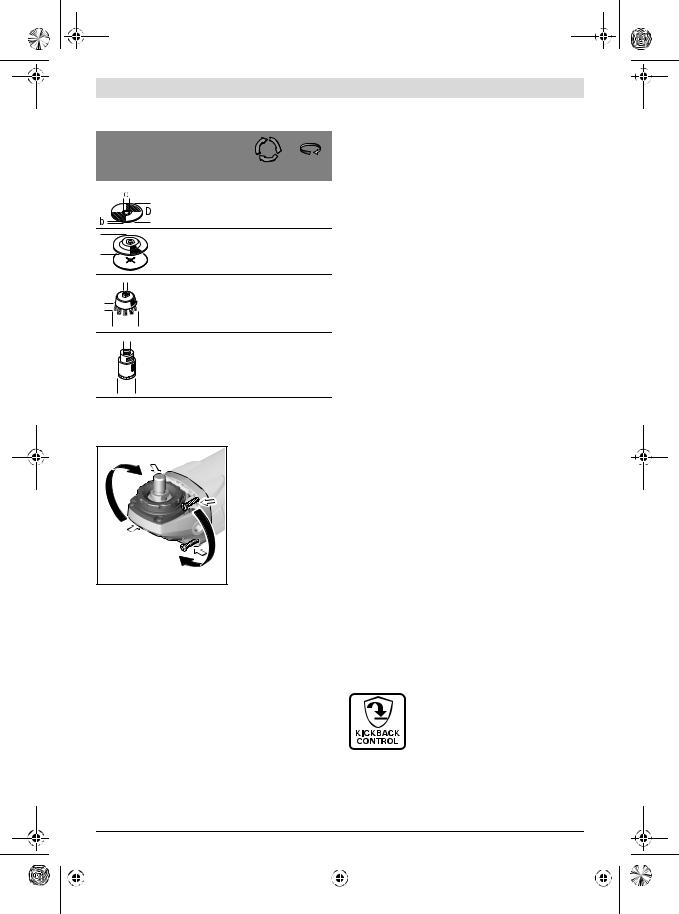

|

max. |

[mm] |

|

|

|

|

[mm] |

|

|

||

|

D |

b |

d |

[min-1] |

[m/s] |

|

115 |

7 |

22.2 |

12 000 |

80 |

|

125 |

7 |

22.2 |

12 000 |

80 |

|

150 |

7 |

22.2 |

10 000 |

80 |

D |

115 |

– |

– |

12 000 |

80 |

|

125 |

– |

– |

12 000 |

80 |

|

d |

|

|

|

|

b |

75 |

30 |

M 14 |

12 000 |

45 |

|

D |

|

|

|

|

|

d |

|

|

|

|

|

82 |

– |

M 14 |

12 000 |

80 |

D

Rotating the Machine Head

Before any work on the machine itself, pull the mains plug.

The machine head can be rotated with respect to the machine housing in 90° steps. In this man-

ner, the On/Off switch

can be brought into a more convenient posi-

tion for special working

situations, e. g., for cutting operations using the cutting guide with dust extraction protection guard 21 or for lefthanded persons.

Completely unscrew the four screws. Rotate the machine head carefully, without removing it from the housing, to the new position. Screw in and tighten the four screws again.

Dust/Chip Extraction

Dust from materials such as lead-containing coatings, some wood types, minerals and metal can be harmful to one’s health. Touching or breathing-in the dust can cause allergic reactions and/or lead to respiratory infections of the user or bystanders.

Certain dust, such as oak or beech dust, is considered carcinogenic, especially in connection with wood-treatment additives (chromate, wood preservative). Materials containing asbestos may only be worked by specialists.

–As far as possible, use a dust extraction system suitable for the material.

–Provide for good ventilation of the working place.

–It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the materials to be worked.

Prevent dust accumulation at the workplace. Dust can easily ignite.

Operation

Starting Operation

Observe correct mains voltage! The voltage of the power source must agree with the voltage specified on the nameplate of the machine. Power tools marked with 230 V can also be operated with 220 V.

Products sold in AUS and NZ only: Use a residual current device (RCD) with a rated residual current of 30 mA or less.

When operating the machine with power from mobile generators that do not have sufficient reserve capacity or are not equipped with suitable voltage control with starting current amplification, loss of performance or untypical behavior can occur upon switching on.

Please observe the suitability of the power generator being used, particularly with regard to the mains voltage and frequency.

Switching On and Off

To start the power tool, press the On/Off switch 4 forward and then down.

To lock-on the pressed On/Off switch 4, push the On/Off switch 4 further forward.

To switch off the power tool, release the On/Off switch 4, or when it is locked, briefly press the On/Off switch 4 and then release it.

Switch Version without Lock-on (country-specific):

To start the power tool, press the On/Off switch 4 forward and then down.

To switch off the machine, release the On/Off switch 4.

Check grinding tools before using. The grinding tool must be mounted properly and be able to move freely. Carry out a test run for at least one minute with no load. Do not use damaged, out-of-centre or vibrating grinding tools. Damaged grinding tools can burst and cause injuries.

Kickback stop

In case of a sudden drop in speed, e.g., caused by a jammed disc while cutting, the power supply to the motor is electronically

interrupted.

To restart the operation, switch the On/Off switch 4 to the Off position and start the machine again.

|

1 609 92A 3ZY | (14.12.17) |

|

|

Bosch Power Tools |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 13 Thursday, December 14, 2017 10:33 AM

Restarting Protection

The restarting protection feature prevents uncontrolled restarting of the machine after an interruption in the power supply.

To restart the operation, switch the On/Off switch 4 to the Off position and start the machine again.

Reduced starting current

The electronic reduced starting current limits the power consumption when switching the tool on and enables operation from a 13 ampere fuse.

English | 13

Note: When the machine runs with full speed after switching on, the reduced starting current, the restarting protection and the kickback stop features have failed. The power tool must promptly be sent to an after-sales service agent for maintenance. For addresses, see Section „After-sales Service and Application Service“.

Constant Electronic Control

Constant electronic control holds the speed constant at noload and under load, and ensures uniform working performance.

Speed preselection (GWS 18-125 SL/GWS 18-125 SPL)

The required speed can be preselected with the thumbwheel 3 (also while running).

The data in the following table are recommended values.

Material |

Application |

Accessory |

Thumbwheel 3 |

Metal |

Removing paint |

Sanding disc |

2 – 3 |

Wood, metal |

Brushing, rust removal |

Cup brush, sanding disc |

3 |

Metal, masonry |

Grinding |

Grinding disc |

4 – 6 |

Metal |

Rough grinding |

Grinding disc |

6 |

Masonry, stone |

Cutting |

Cutting disc and cutting guide |

6 |

|

|

(Cutting masonry/stone is permitted only with use of |

|

|

|

the cutting guide) |

|

Metal |

Cutting |

Cutting disc |

6 |

The values specified for speed levels are guide values.

The rated speed of the accessory must be at least equal to the maximum speed marked on the power tool. Accessories running faster than their rated speed can break and fly apart.

Speed prese- |

GWS 18-125 ... |

GWS 18-150 ... |

lection level |

[min-1] |

[min-1] |

1 |

2 800 |

2 800 |

2 |

4 500 |

4 100 |

3 |

6 300 |

5 400 |

4 |

8 200 |

6 700 |

5 |

9 800 |

8 000 |

6 |

12 000 |

10 000 |

Working Advice

Exercise caution when cutting slots in structural walls; see Section “Information on Structures”.

Clamp the workpiece if it does not remain stationary due to its own weight.

Do not strain the machine so heavily that it comes to a standstill.

After heavily straining the power tool, continue to run it at no-load for several minutes to cool down the accessory.

Do not touch grinding and cutting discs before they have cooled down. The discs can become very hot while working.

Do not use the power tool with a cut-off stand.

Rough Grinding

Never use a cutting disc for roughing.

The best roughing results are achieved when setting the machine at an angle of 30 ° to 40 °. Move the machine back and forth with moderate pressure. In this manner, the workpiece will not become too hot, does not discolour and no grooves are formed.

Flap Disc

With the flap disc (accessory), curved surfaces and profiles can be worked.

Flap discs have a considerably higher service life, lower noise levels and lower sanding temperatures than conventional sanding sheets.

Cutting Metal

For cutting with bonded abrasives, always use the protection guard for cutting 14.

When cutting, work with moderate feed, adapted to the material being cut. Do not exert pressure onto the cutting disc, tilt or oscillate the machine.

Do not reduce the speed of running down cutting discs by applying sideward pressure.

|

Bosch Power Tools |

|

|

1 609 92A 3ZY | (14.12.17) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 14 Thursday, December 14, 2017 10:33 AM |

||

14 | English |

|

|

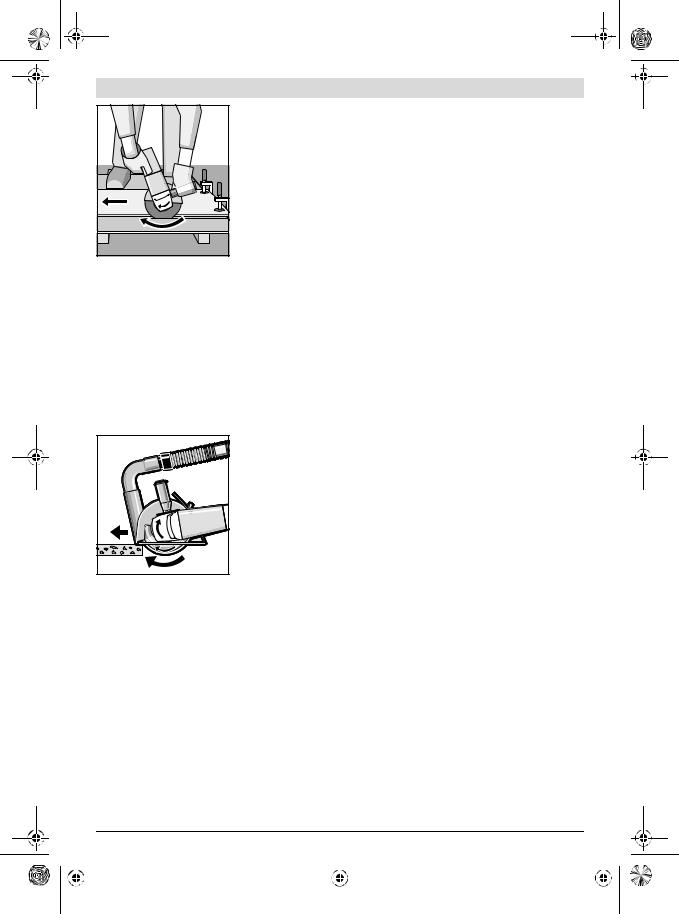

The machine must al- |

Maintenance and Service |

|

ways work in an up- |

|

|

grinding motion. Other- |

Maintenance and Cleaning |

|

wise, the danger exists |

Before any work on the machine itself, pull the mains |

|

of it being pushed un- |

||

plug. |

||

controlled out of the |

||

For safe and proper working, always keep the machine |

||

cut. |

||

|

and ventilation slots clean. |

|

|

In extreme conditions, always use dust extraction as |

|

|

far as possible. Blow out ventilation slots frequently |

|

|

and install a portable residual current device (PRCD). |

|

|

When working metals, conductive dust can settle in the in- |

|

|

terior of the power tool. The total insulation of the power |

|

|

tool can be impaired. |

|

When cutting profiles and square bar, it is best to start at the |

If the replacement of the supply cord is necessary, this has to |

|

smallest cross section. |

||

be done by Bosch or an authorized Bosch service agent in or- |

||

Cutting Stone |

||

der to avoid a safety hazard. |

||

Provide for sufficient dust extraction when cutting |

Please store and handle the accessory(-ies) carefully. |

|

stone. |

After-sales Service and Application Service |

|

Wear a dust respirator. |

||

|

The machine may be used only for dry cutting/grinding.

For cutting stone, it is best to use a diamond cutting disc.

When using the cutting guide with dust extraction protection guard 21, the vacuum cleaner must be approved for vacuuming masonry dust. Suitable vacuum cleaners are available from Bosch.

Switch on the machine

and place the front part

and place the front part

of the cutting guide on the workpiece. Slide the

machine with moderate feed, adapted to the material to be worked.

For cutting especially hard material, e. g., concrete with high pebble content, the diamond cutting disc can overheat and become damaged as a result. This is clearly indicated by circular sparking, rotating with the diamond cutting disc.

In this case, interrupt the cutting process and allow the diamond cutting disc to cool by running the machine for a short time at maximum speed with no load.

Noticeably decreasing work progress and circular sparking are indications of a diamond cutting disc that has become dull. Briefly cutting into abrasive material (e. g. lime-sand brick) can resharpen the disc again.

Information on Structures

Slots in structural walls are subject to the Standard DIN 1053 Part 1, or country-specific regulations.

These regulations are to be observed under all circumstances. Before beginning work, consult the responsible structural engineer, architect or the construction supervisor.

Our after-sales service responds to your questions concerning maintenance and repair of your product as well as spare parts. Exploded views and information on spare parts can also be found under:

www.bosch-pt.com

Bosch’s application service team will gladly answer questions concerning our products and their accessories.

In all correspondence and spare parts orders, please always include the 10-digit article number given on the nameplate of the product.

Cambodia

Robert Bosch (Cambodia) Co., Ltd

Unit 8BC, GT Tower, 08th Floor, Street 169,

Czechoslovakia Blvd, Sangkat Veal Vong

Khan 7 Makara, Phnom Penh

VAT TIN: 100 169 511

Tel.: +855 23 900 685

Tel.: +855 23 900 660

www.bosch.com.kh

People’s Republic of China China Mainland

Bosch Power Tools (China) Co., Ltd. 567, Bin Kang Road

Bin Jiang District 310052 Hangzhou, P. R. China Tel.: 4008268484

Fax: (0571) 87774502

E-Mail: contact.ptcn@cn.bosch.com www.bosch-pt.com.cn

HK and Macau Special Administrative Regions

Robert Bosch Co. Ltd.

21st Floor, 625 King’s Road North Point, Hong Kong

Customer Service Hotline: +852 2101 0235 Fax: +852 2590 9762

E-Mail: info@hk.bosch.com www.bosch-pt.com.hk

|

1 609 92A 3ZY | (14.12.17) |

|

|

Bosch Power Tools |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 15 Thursday, December 14, 2017 10:33 AM

India

Bosch Service Center

69, Habibullah Road, (Next to PSBB School), T. Nagar Chennai – 600077

Phone: (044) 64561816

Bosch Service Center Rishyamook

85A, Panchkuin Road

New Delhi – 110001

Phone: (011) 43166190

Bosch Service Center

79, Crystal Bldg., Dr. Annie Besant Road, Worli Mumbai – 400018

Phone: (022) 39569936 / (022 )39569959 / (022) 39569967 / (022) 24952071

Indonesia

PT Robert Bosch

Palma Tower 10th Floor

Jalan RA Kartini II-S Kaveling 6

Pondok Pinang, Kebayoran Lama

Jakarta Selatan 12310

Tel.: (21) 3005-5800

www.bosch-pt.co.id

Malaysia

Robert Bosch Sdn. Bhd.(220975-V) PT/SMY No. 8A, Jalan 13/6

46200 Petaling Jaya Selangor

Tel.: (03) 79663194 Toll-Free: 1800 880188 Fax: (03) 79583838

E-Mail: kiathoe.chong@my.bosch.com www.bosch-pt.com.my

Pakistan

Robert Bosch Middle East FZE – Pakistan Liaison Office 2nd Floor Plaza # 10, CCA Block, DHA Phase 5 Lahore, 54810

Phone: +92(303)4444311 Email: Faisal.Khan@bosch.com

Philippines

Robert Bosch, Inc.

28th Floor Fort Legend Towers, 3rd Avenue corner 31st Street, Fort Bonifacio, Global City, 1634 Taguig City

Tel.: (632) 8703871

Fax: (632) 8703870 www.bosch-pt.com.ph

English | 15

Singapore

Powerwell Service Centre Ptd Ltd

Bosch Authorised Service Centre (Power Tools) 4012 Ang Mo Kio Ave 10, #01-02 TECHplace Singapore 569628

Tel.: 6452 1770

Fax: 6452 1760

E-Mail: ask@powerwellsc.com www.powerwellsc.com www.bosch-pt.com.sg

Thailand

Robert Bosch Ltd.

Liberty Square Building

No. 287, 11 Floor

Silom Road, Bangrak

Bangkok 10500

Tel.: 02 6393111

Fax: 02 2384783

Robert Bosch Ltd., P. O. Box 2054

Bangkok 10501

www.bosch.co.th

Bosch Service – Training Centre

La Salle Tower Ground Floor Unit No.2

10/11 La Salle Moo 16

Srinakharin Road

Bangkaew, Bang Plee

Samutprakarn 10540

Tel.: 02 7587555

Fax: 02 7587525

Vietnam

Branch of Bosch Vietnam Co., Ltd in HCMC Floor 10, 194 Golden Building

473 Dien Bien Phu Street

Ward 25, Binh Thanh District, Ho Chi Minh City Tel.: (08) 6258 3690

Fax: (08) 6258 3692 Hotline: (08) 6250 8555 www.bosch-pt.com.vn

Armenia, Azerbaijan, Georgia, Kyrgyzstan, Mongolia, Tajikistan, Turkmenistan, Uzbekistan

TOO “Robert Bosch” Power Tools, After Sales Service Rayimbek Ave., 169/1

050050, Almaty, Kazakhstan

Service Email: service.pt.ka@bosch.com

Official Website: www.bosch.com, www.bosch-pt.com

Bahrain

Hatem Al Juffali Technical Equipment Establishment. Kingdom of Bahrain, Setra Highway, Al Aker Area Phone: +966126971777-311

Fax: +97317704257

Email: h.berjas@eajb.com.sa

|

Bosch Power Tools |

|

|

1 609 92A 3ZY | (14.12.17) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 16 Thursday, December 14, 2017 10:33 AM

16 | English

Egypt

Unimar

20 Markaz kadmat

El tagmoa EL Aoul – New Cairo Phone: + 20 2224 76091-95 Phone: + 20 2224 78072-73 Fax: + 20 2224 78075

Email: adelzaki@unimaregypt.com

Iran

Robert Bosch Iran

3rd Floor, No 3, Maadiran Building Aftab St., Khodami St., Vanak Sq. Tehran 1994834571

Phone: +982186092057

Iraq

Sahba Technology Group

Al Muthana airport road

Baghdad

Phone: +9647901906953

Phone Dubai: +97143973851

Email: bosch@sahbatechnology.com

Jordan

Roots Arabia – Jordan

Nasser Bin Jameel street, Building 37 Al Rabiah 11194 Amman

Phone: +962 6 5545778 Email: bosch@rootsjordan.com

Kuwait

Al Qurain Automotive Trading Company

Shuwaikh Industrial Area, Block 1, Plot 16, Street 3rd P.O. Box 164 – Safat 13002

Phone: 24810844 Fax: 24810879

E-mail: josephkr@aaalmutawa.com

Lebanon

Tehini Hana & Co. S.A.R.L.

P.O. Box 90-449

Jdeideh

Dora-Beirut

Phone: +9611255211

Email: service-pt@tehini-hana.com

Libya

El Naser for Workshop Tools

Swanee Road, Alfalah Area

Tripoli

Phone: +218 21 4811184

Oman

Malatan Trading & Contracting LLC

P.O. Box 131

Ruwi, 112 Sultanate of Oman

Phone: +968 99886794

Email: malatanpowertools@malatan.net

Qatar

International Construction Solutions W L L P. O. Box 51, Doha

Phone: +974 40065458 Fax: +974 4453 8585 Email: csd@icsdoha.com

Saudi Arabia

Juffali Technical Equipment Co. (JTECO) Kilo 14, Madinah Road, Al Bawadi District Jeddah 21431

Phone: +966 2 6672222 Ext. 1528 Fax: +966 2 6676308

Email: roland@eajb.com.sa

Syria

Dallal Establishment for Power Tools

P.O. Box 1030

Aleppo

Phone: +963212116083

Email: rita.dallal@hotmail.com

United Arab Emirates

Central Motors & Equipment LLC, P.O. Box 1984 Al-Wahda Street – Old Sana Building

Sharjah

Phone: +971 6 593 2777 Fax: +971 6 533 2269

Email: powertools@centralmotors.ae

Yemen

Abualrejal Trading Corporation

Sana’a Zubiery St. Front to new Parliament Building Phone: +967-1-202010

Fax: +967-1-279029

Email: tech-tools@abualrejal.com

Ethiopia

Forever plc

Kebele 2,754, BP 4806,

Addis Ababa

Phone: +251 111 560 600

Email: foreverplc@ethionet.et

Ghana

C.WOERMANN LTD.

Nsawam Road/Avenor Junction, P.O. Box 1779

Accra

Phone: +233 302 225 141

Kenya

Robert Bosch East Africa Ltd

Mpaka Road P.O. Box 856

00606 Nairobi

Nigeria

Robert Bosch Nigeria Ltd.

52 – 54 Isaac John Street P.O. Box

GRA Ikeja – Lagos

Republic of South Africa

Customer service

Hotline: (011) 6519600

|

1 609 92A 3ZY | (14.12.17) |

|

|

Bosch Power Tools |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 17 Thursday, December 14, 2017 10:33 AM

Gauteng – BSC Service Centre

35 Roper Street, New Centre Johannesburg

Tel.: (011) 4939375

Fax: (011) 4930126 E-Mail: bsctools@icon.co.za

KZN – BSC Service Centre

Unit E, Almar Centre

143 Crompton Street Pinetown

Tel.: (031) 7012120

Fax: (031) 7012446

E-Mail: bsc.dur@za.bosch.com

Western Cape – BSC Service Centre

Democracy Way, Prosperity Park

Milnerton

Tel.: (021) 5512577

Fax: (021) 5513223

E-Mail: bsc@zsd.co.za

Bosch Headquarters

Midrand, Gauteng

Tel.: (011) 6519600

Fax: (011) 6519880

E-Mail: rbsa-hq.pts@za.bosch.com

Tanzania

Diesel & Autoelectric Service Ltd.

117 Nyerere Rd., P.O. Box 70839

Vingunguti 12109, Dar Es Salaam

Phone: +255 222 861 793/794

Australia, New Zealand and Pacific Islands

Robert Bosch Australia Pty. Ltd.

Power Tools

Locked Bag 66

Clayton South VIC 3169

Customer Contact Center

Inside Australia:

Phone: (01300) 307044

Fax: (01300) 307045

Inside New Zealand:

Phone: (0800) 543353

Fax: (0800) 428570

Outside AU and NZ:

Phone: +61 3 95415555

www.bosch-pt.com.au

www.bosch-pt.co.nz

Disposal

The machine, accessories and packaging should be sorted for environmental-friendly recycling.

Do not dispose of power tools into household waste!

Subject to change without notice.

| 17

!

!

" "

发事故。

尘或气体。

中会使操作者失去对工具的控制。

险。

如果你身体接地会增加电击危险。

电动工具将增加电击危险。

部件。

接软线。

使用剩余电流动作保护器RCD RCD

瞬间的疏忽会导致严重人身伤害。

诸如适当条件下使用防尘面具、防滑安全鞋、安全 帽、听力防护等装置能减少人身伤害。

/

|

Bosch Power Tools |

|

|

1 609 92A 3ZY | (14.12.17) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 18 Thursday, December 14, 2017 10:33 AM

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

||

|

||

|

||

|

||

|

||

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

||

|

||

|

||

1 |

||

|

||

|

||

/ |

||

|

||

|

||

|

||

|

|

|

|

||

|

||

|

||

|

||

|

||

|

||

|

||

|

检查零件破损情况和影响电动工具运行的其他状

事故由维护不良的电动工具引发。

刃的刀具不易卡住而且容易控制。

于那些与其用途不符的操作可能会导致危险。

性。

说明将导致电击、着火和/

外露的金属零件带电并使操作者发生电击危险。

转附件中。

可能会抓住表面并拉动电动工具而让你失去对工具 的控制。

件可能会缠绕你的衣服而使附件伤害身体。

燃这些材料。

能导致电腐蚀或电击。

|

1 609 92A 3ZY | (14.12.17) |

|

|

Bosch Power Tools |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 19 Thursday, December 14, 2017 10:33 AM

| 19

|

|

具在卡住点产生与附件旋转方向相反的运动。

在卡住点的运动方向。在此条件下砂轮也可能碎 裂。

/

" "

旋转砂轮和电动工具朝你推来。

砂轮卡住的原因。

反弹力。

手。

件的趋势并引起反弹的失控。

工件靠近切割线处和砂轮两侧近工件边缘处放置支 承。

" "

|

|

|

|

|

|

|

||

|

||

|

||

|

||

|

||

/ |

||

|

||

|

||

|

||

|

||

|

||

|

||

|

罩帮助操作者免于受到爆裂砂轮片和偶然触及砂轮

|

|

|

|

|

|

|

|

小砂轮破裂的可能性。切割砂轮的法兰盘可以不同 于砂轮法兰盘。

于大规格电动工具上的砂轮不适于较小规格工具的 高速工况并可能会爆裂。

位置。

|

Bosch Power Tools |

|

|

1 609 92A 3ZY | (14.12.17) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 20 Thursday, December 14, 2017 10:33 AM

20 |

/ /

比用手持握工件更牢固。

火灾并且/

罩。

行砂纸研磨。

1

2

(GWS 18-125 SL/GWS 18-125 SPL)

4

5

6

7 *

8 O

9 *

11

*

*

13*

14*

15*

16*

17*

18*

19*

20*

21*

22*

25*

*

|

|

|

GWS ... |

18-125 L |

18-125 PL |

18-125 SL |

18-125 SPL |

|

|

||||

|

|

|

3 601 ... |

GA3 0.. |

GA3 1.. |

GA3 2.. |

GA3 3.. |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1800 |

1800 |

1800 |

1800 |

|

|

||||

|

|

|

|

1145 |

1145 |

1145 |

1145 |

|

|

||||

|

|

|

/ |

12000 |

12000 |

12000 |

12000 |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

/ |

|

– |

– |

2800 – 12000 |

2800 – 12000 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

125 |

125 |

125 |

125 |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M 14 |

M 14 |

M 14 |

M 14 |

|

|

|||

|

|

|

|

22 |

22 |

22 |

22 |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

– |

|

|

|

|

|

||

|

|

EPTA-Procedure 01:2014 |

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

|

2,5 |

2,5 |

2,5 |

2,5 |

|

|

||||

|

|

– |

|

2,3 |

2,3 |

2,3 |

2,3 |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

/II |

/II |

/II |

|

/II |

|

|

||

|

|

230 V |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 609 92A 3ZY | (14.12.17) |

|

|

|

|

|

|

Bosch Power Tools |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 21 Thursday, December 14, 2017 10:33 AM

|

|

|

|

|

| 21 |

|

GWS ... |

18-125 L Inox |

18-125 PL Inox |

18-150 L |

18-150 PL |

|

3 601 ... |

GA4 0.. |

GA4 1.. |

GA5 0.. |

GA5 1.. |

|

|

|

|

|

|

|

|

1800 |

1800 |

1800 |

1800 |

|

|

1145 |

1145 |

1145 |

1145 |

|

/ |

8100 |

8100 |

10000 |

10000 |

|

|

|

|

|

|

|

/ |

– |

– |

– |

– |

|

|

125 |

125 |

150 |

150 |

|

|

|

|

|

|

|

|

M 14 |

M 14 |

M 14 |

M 14 |

|

|

|

|

|

|

|

|

22 |

22 |

22 |

22 |

|

|

|

|

|

|

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

– |

– |

– |

EPTA-Procedure 01:2014 |

|

|

|

|

|

– |

|

2,5 |

2,5 |

2,5 |

2,5 |

– |

|

2,3 |

2,3 |

2,4 |

2,4 |

|

|

/II |

/II |

/II |

/II |

230 V |

|

|

|

||

|

|

: 12 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

||||

|

|

14 |

|

|

|

|

|

||||

/ |

12 14 |

||||

" |

|

|

|

|

|

" |

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|||

|

21 |

|

|

||

12 |

|

|

|||

|

|

|

|||

|

|

|

|||

|

|

|

|

||

|

9 18 17 |

||||

|

|

||||

12 |

|

7 |

|||

|

7 |

|

|

|

|

|

7 |

|

|||

|

12 |

7 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

||

5 |

|

||||

1 |

|

||||

|

|

|

|

||

12 |

|

5 |

|||

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

17 |

||||

12 |

16 |

|

|||

|

5 16 |

|

|

||

|

|

|

|

||

Bosch Power Tools |

|

|

1 609 92A 3ZY | (14.12.17) |

||

OBJ_BUCH-3473-001.book Page 22 Thursday, December 14, 2017 10:33 AM

22 |

|

|

拔出插头。

/ /

6

2

可能会损坏电动工具。

/

10 /" "

生磨擦。

|

8O O O 8

16

17

16

19

/

手片16

//

11 10

11

11

11 26

26 |

2

|

以用手朝著逆时针方向转 松快速螺母。

考插图安装双销扳手。

//

/

|

|

|

|

|

|

|

[ ] |

[ ] |

|

|

|

|

D |

b |

d |

[ / ] [ / ] |

|

|

115 |

7 |

22,2 |

12000 |

80 |

|

125 |

7 |

22,2 |

12000 |

80 |

|

150 |

7 |

22,2 |

10000 |

80 |

D |

115 |

– |

– |

12000 |

80 |

|

125 |

– |

– |

12000 |

80 |

|

1 609 92A 3ZY | (14.12.17) |

|

|

Bosch Power Tools |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-3473-001.book Page 23 Thursday, December 14, 2017 10:33 AM

|

|

|

|

|

|

|

[ ] |

[ ] |

|

|

|

|

D |

b |

d |

[ / ] [ / ] |

|

|

d |

|

|

|

|

b |

75 |

30 |

M 14 |

12000 |

45 |

|

D |

|

|

|

|

|

d |

|

|

|

|

|

82 |

– |

M 14 |

12000 |

80 |

D

拔出插头。

每一段的旋转角度为90 21

4 4

/

吸道疾病。

工含石棉的物料。

–P2

燃。

| 23

上标示的电压一致。

可能在开动机器时发生功率不足或其它不寻常的反 应。

使用正确的电压和电频率。

/

4

4

4

4 4

( ):

4

4

1

–

4

地再度起动。

4

16 A

关闭功能失灵了。此时必须即刻将电动工具交给顾客 服务处修理。地址可以参考""

|

Bosch Power Tools |

|

|

1 609 92A 3ZY | (14.12.17) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Loading...

Loading...