B&K Precision 4011A User Manual [en, es]

1

INSTRUCTION

MANUAL

MANUAL DE

INSTRUCCIONES

MODEL 4011A

MODELO 4011A

5 MHz FUNCTION

GENERATOR

with DIGITAL DISPLAY

5MHz GENERADOR DE FUNCIONES

CON DIGITOS INDICADOR

2

TEST INSTRUMENT SAFETY

WARNING

Normal use of test equipment exposes you to a certain amount of danger from electrical shock because testing must sometimes be

performed where exposed voltage is present. An electrical shock causing 10 milliamps of current to pass through the heart will stop most

human heartbeats. Voltage as low as 35 volts dc or ac rms should be considered dangerous and hazardous since it can produce a lethal

current under certain conditions. Higher voltages pose an even greater threat because such voltage can more easily produce a lethal

current. Your normal work habits should include all accepted practices to prevent contact with exposed high voltage, and to steer current

away from your heart in case of accidental contact with a high voltage. You will significantly reduce the risk factor if you know and

observe the following safety precautions:

1. Don't expose high voltage needlessly. Remove housings and covers only when necessary. Turn off equipment while making test

connections in high-voltage circuits. Discharge high-voltage capacitors after removing power.

2. If possible, familiarize yourself with the equipment being tested and the location of its high voltage points. However, remember that

high voltage may appear at unexpected points in defective equipment.

3. Use an insulated floor material or a large, insulated floor mat to stand on, and an insulated work surface on which to place

equipment; and make certain such surfaces are not damp or wet.

4. Use the time proven "one hand in the pocket" technique while handling an instrument probe. Be particularly careful to avoid

contacting a nearby metal object that could provide a good ground return path.

5. When testing ac powered equipment, remember that ac line voltage is usually present on some power input circuits such as the on-

off switch, fuses, power transformer, etc. any time the equipment is connected to an ac outlet, even if the equipment is turned off.

(continued on inside back cover)

3

Instruction Manual

for

MODEL 4011A

5 MHz

FUNCTION

GENERATOR

with DIGITAL DISPLAY

22820 Savi Ranch Parkway • Yorba Linda, CA 92887-4610

4

TABLE OF CONTENTS

page

TEST INSTRUMENT ..................SAFETY inside front cover

INTRODUCTION . ............................................................. 5

SPECIFICATIONS ............................................................. 6

CONTROLS AND INDICATORS ...................................... 8

OPERATING INSTRUCTIONS .........................................10

Frequency and Waveform Selection....................................10

Considerations ...................................................................11

Duty Cycle Control ............................................................12

TTL/CMOS Output ...........................................................13

Voltage Controlled Frequency Operation ...........................13

Output Protection Guidebook.............................................14

page

MAINTENANCE ........................................ 15

Fuse Replacement ........................................ 15

Instrument Repair Service............................. 15

CUSTOMER SUPPORT ............................... 16

WARRANTY SERVICE INSTRUCTIONS ... 17

LIMITED TWO-YEAR WARRANTY .......... 18

SPANISH MANUAL.................................... 20

5

INTRODUCTION

The B+K Precision Model 4011A Function Generator

is a versatile signal source which combines several

functions into one unit. Additionally, the instrument

provides the added convenience of a built-in frequency

counter. This permits more accurate determination of

output frequency than is possible with a simple calibrated

dial. Coarse and fine tuning controls permit precision

settability of the output frequency. High stability assures

that the output frequency does not drift.

With this versatility, the unit has a vast number of

applications in both analog and digital electronics in the

engineering, manufacturing, servicing, educational, and

hobbyist fields.

The heart of the function generator is a VCG (voltage-

controlled generator) that produces precision sine, square,

or triangle waves over the 0.5Hz to 5MHz range. This

encompasses subaudible, audio, ultrasonic, and RF

applications. A continuously variable dc offset allows the

output to be injected directly into circuits at the correct bias

level.

Variable symmetry of the output waveform converts the

instrument to a pulse generator capable of generating

rectangular waves or pulses, ramp or sawtooth waves, and

slewed sine waves.

In addition to the above features, an external signal may

be used to sweep the output frequency or control operating

frequency. This is useful in situations where an externally

controlled frequency is desirable.

6

SPECIFICATIONS

FREQUENCY CHARACTERISTICS

Waveforms

Sine, Square, Triangle, ± Pulse, ± Ramp

Range

0.5Hz to 5MHz in 7 ranges

Resolution

4 digits

Tuning Range

Coarse: 10:1, Fine: ±5% of Coarse Setting

Variable Duty Cycle

15:85:15 Continuously Variable

Operating Modes

Normal, VCG (Voltage Controlled Generator)

Frequency Stability

Output frequency will not change more than 0.09% in 15

minutes after 1 hour warmup.

OUTPUT CHARACTERISTICS

Impedance

50 Ω ±10%

Level

20V p-p Open-circuit, 10V p-p into 50 Ω

Amplitude Control

Variable, 20dB range typical

Attenuation

-20 dB ±1 dB

DC Offset

Preset: ±0.1V typical

Variable: ±10V open-circuit, ±5V into 50 Ω

SINE WAVE

Distortion

3% typical at 1kHz

Flatness

±5% (.45 dB)

SQUARE WAVE

Symmetry

0.5Hz to 100kHz ≤2%

Rise Time

≤20nS

TRIANGLE WAVE

Linearity

≥98% to 100kHz

7

SPECIFICATIONS

NOTE: Specifications and information are subject to change without notice. Please visit www.bkprecision.com

for the most current product

information.

TTL OUTPUT

Level > 2.4V

Rise Time ≤20nS

Duty Cycle 50% typical

CMOS OUTPUT

Max Frequency 2MHz

Level 4V to 14V ±0.5V p-p,

Continuously variable

Rise Time ≤120nS

VCG (Voltage Controlled Generator) INPUT

Input Voltage

0 - 10V ±1V causes a 100:1 frequency change

Impedance

10 kΩ ±5%

FREQUENCY COUNTER

Accuracy

Time Base Accuracy ±1 count

Time Base Accuracy

±10 PPM (23 °C ±5 °C)

Display

4 digit LED

POWER SOURCE

120 / 230VAC ±10%, 50 / 60Hz, internal jumper

selectable

DIMENSIONS (H x W x D)

10-3/8" x 3-3/8" x 11-7/16" (26.4cm x 8.6cm x 29.1cm)

WEIGHT

4 lb. (1.8 kg.)

ACCESSORIES

Instruction Manual

Output Cable, BNC to Alligator Clips

8

CONTROLS AND INDICATORS

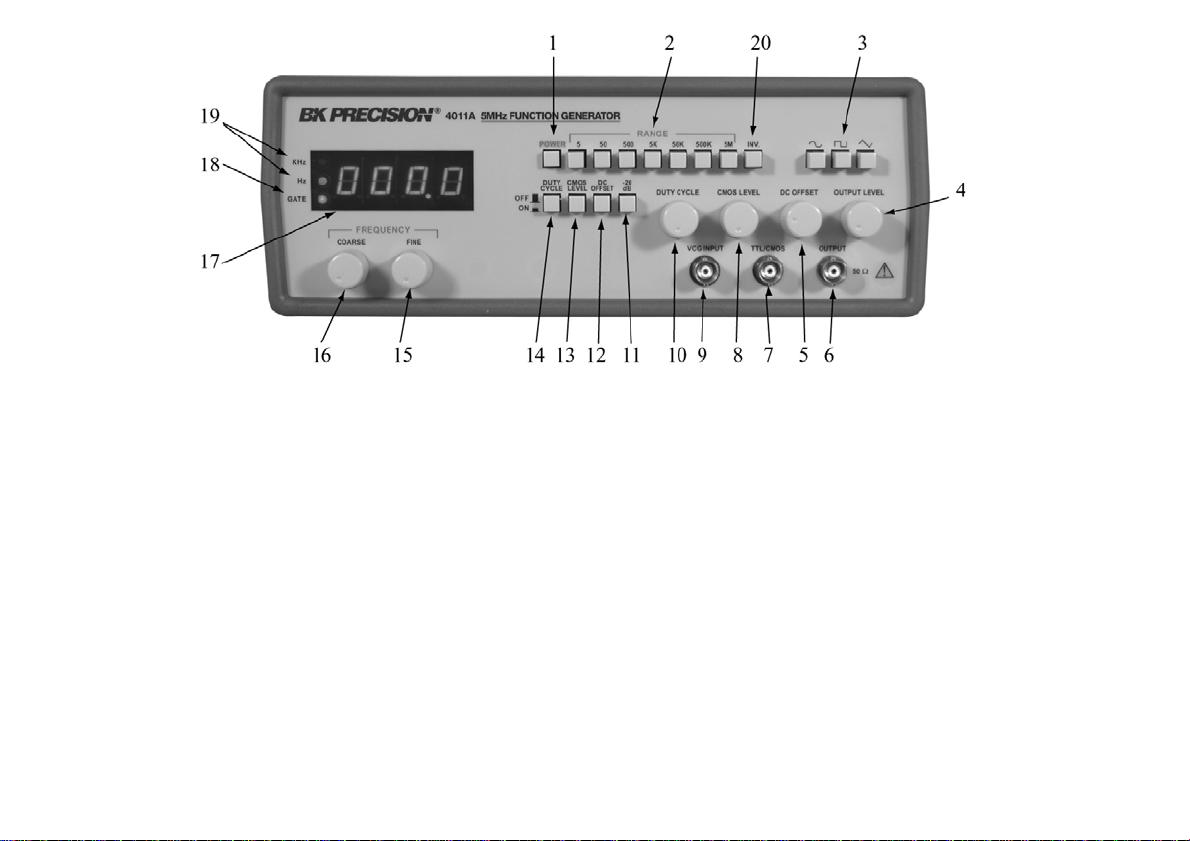

FRONT PANEL (Refer to Fig. 1)

1. POWER Switch. Turns power on and off.

2. RANGE Switch. Selects output frequency range. Seven

ranges from 5Hz to 5MHz. Switch indicates maximum

frequency of range and is adjusted with COARSE

FREQUENCY control to 0.1 times the maximum. For

example, if the 500kHz range is selected, the output

frequency can be adjusted from 50kHz to 500kHz.

3. FUNCTION Switch. Selects sine, square, or triangle

waveform at OUTPUT jack.

4. OUTPUT LEVEL Control. Controls the amplitude of the

signal at the OUTPUT jack. Output level can be decreased

by approximately 20 dB with this control.

5. DC OFFSET Control. Enabled by the DC OFFSET

Switch (12). Clockwise rotation from center changes the

DC offset in a positive direction while counterclockwise

rotation from center changes the DC offset in a negative

direction.

6. OUTPUT Jack. Waveform selected by FUNCTION

switch as well as the superimposed DC OFFSET voltage

is available at this jack.

7. TTL/CMOS Jack. TTL or CMOS square wave,

depending on the position of the CMOS LEVEL

switch (13) is output at this jack. This output is

independent of the OUTPUT LEVEL and DC

OFFSET controls.

8. CMOS LEVEL Control. Rotating this control

clockwise increases the amplitude of the CMOS

square wave at the TTL/CMOS jack.

9. VCG Jack. Voltage Controlled Generator input.

Permits external control of generator output

frequency by a DC voltage input at this jack. A

positive voltage will decrease frequency.

10. DUTY CYCLE Control. Enabled by the DUTY

CYCLE Switch (14). Rotation from center position

adjusts the duty cycle of the main OUTPUT signal.

11. -20dB Switch. When engaged, the signal at the

OUTPUT jack is attenuated by 20dB.

12. DC OFFSET Switch. When engaged, enables

operation of the DC OFFSET control (5).

9

Figure 1. Model 4011A Controls and Indicators.

13. CMOS LEVEL Switch. When engaged, changes

the TTL signal to CMOS signal at the TTL/CMOS

jack.

14. DUTY CYCLE Switch. When engaged, enables

operation of DUTY CYCLE control (10).

15. FINE FREQUENCY Control. Vernier adjustment

of the output frequency for ease of setting frequency.

16. COARSE FREQUENCY Control. Coarse

adjustment of the output frequency from 0.1 to 1

times the selected range.

17. COUNTER DISPLAY. Displays frequency of internally

generated waveform.

18. GATE LED. Indicates when the frequency counter display is

updated. When the 50K through 5M ranges are selected, the

LED will flash 10 times per second (every 0.1 seconds).

When the 50 through 5K ranges are selected, the LED will

flash once every second and when the 5 range is selected, the

LED will flash every 10 seconds. As the LED turns off, the

display is updated.

19. Hz and KHz LED. Indicates whether the counter is reading

in Hz or kHz.

20 Inverter Switch

10

OPERATING INSTRUCTIONS

The B+K Precision Model 4011A Function Generator is a

versatile instrument, capable of producing a variety of output

waveforms over a broad range of frequencies. To gain a working

familiarity with the unit, it is recommended that it be connected

initially to an oscilloscope, so that the effects of the various controls

on the output waveforms can be observed. Use this manual as

required for reference until becoming accustomed to the operating

procedures.

FREQUENCY AND WAVEFORM SELECTION

l. Initially, verify that the DUTY CYCLE (14), CMOS LEVEL

(13), DC OFFSET (12), -20dB (11) switches are in the OUT

position (released). This will produce a symmetrical waveform

unaffected by the other controls.

2. Plug the unit into an appropriate power source and turn it on by

engaging the POWER switch (1).

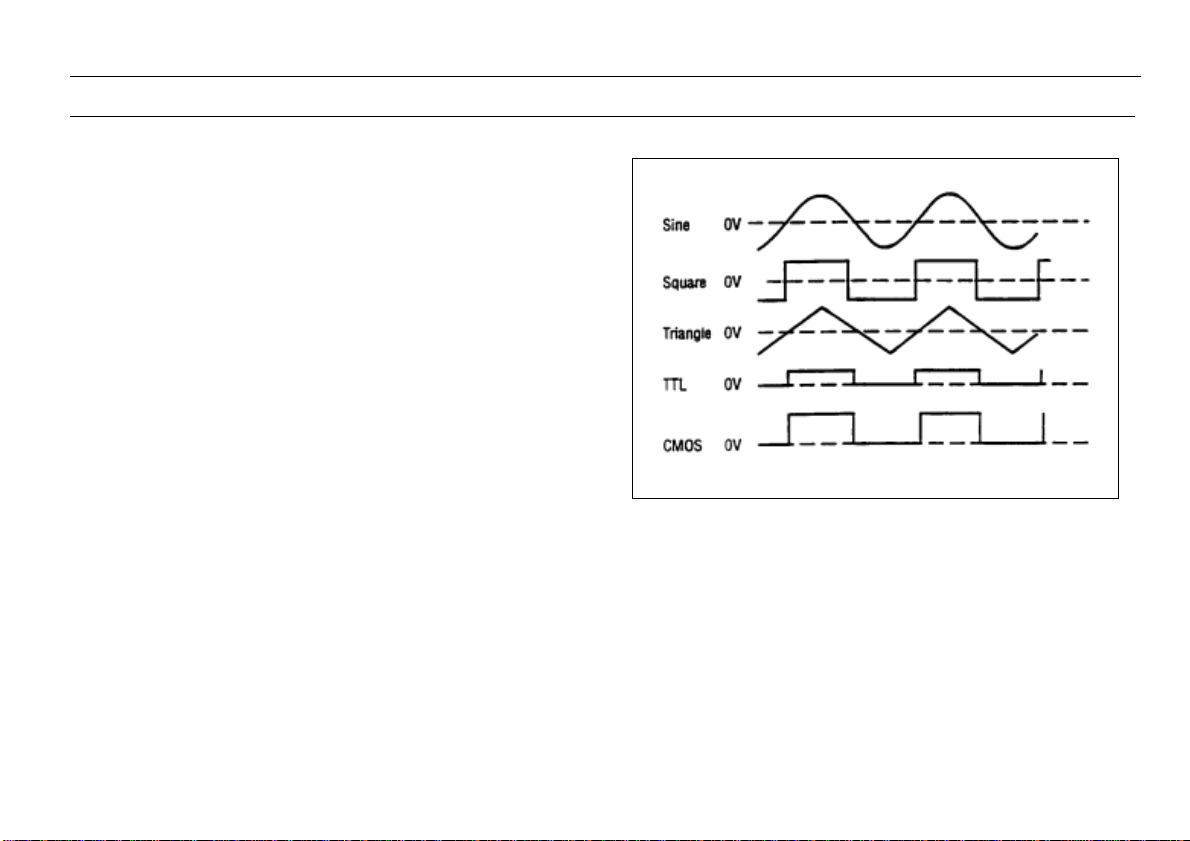

3. Select the desired waveform (SINE, SQUARE, or TRIANGLE)

by engaging one of the FUNCTION switches (3). Phase

relationships of the waveforms are shown in Fig. 2.

4. Select the frequency of the waveform by engaging one of the

RANGE switches (2). The output frequency is displayed, along

with the appropriate measurement units, kHz or Hz (19), on the

LED display.

5. Rotate the COARSE (16) frequency control to quickly set the

output frequency to the approximate desired value. The FINE

(15) frequency control can then be used to easily set the output

to the specific desired value. The frequency selected is available

at the OUTPUT jack (6). In addition, a digital signal, either TTL

or CMOS is available at the TTL/CMOS jack (7) (refer to the

“TTL/CMOS OUTPUT” section of this manual).

6. Adjust the amplitude of the output as desired using the

OUTPUT LEVEL control (4). Rotation of this control

varies the amplitude from maximum to 20dB below

maximum. An additional attenuation of -20dB is

available by pushing in the -20dB switch (11). The

attenuation factors can be combined for a total of -40dB.

The maximum si

g

nal level is 10V

p

-

p

(

into 50 Ω

)

.

Fi

g

ure 2. Out

p

ut Waveform and Phase Relationshi

p

11

OPERATING INSTRUCTIONS

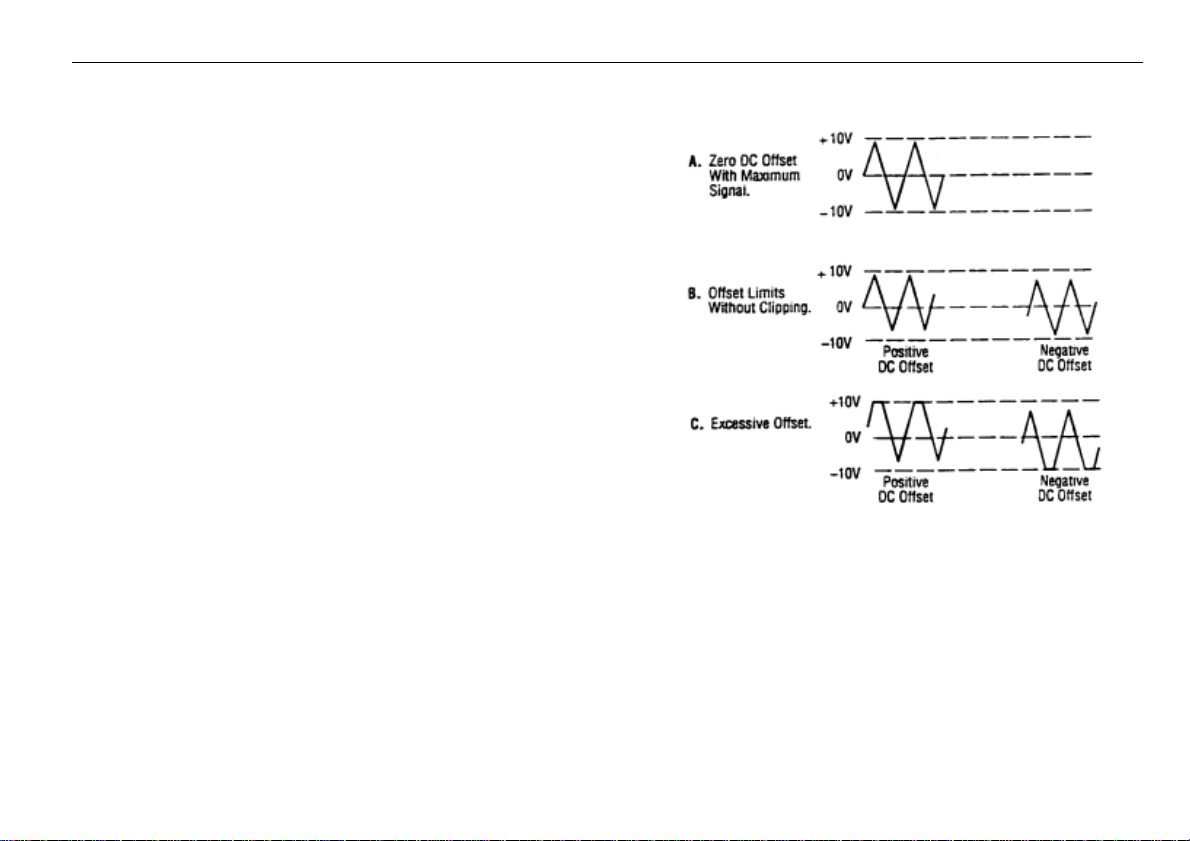

7. A superimposed DC component can be added to the output signal

by engaging the DC OFFSET switch (12) to enable operation of

the DC OFFSET control (5). Rotation of this control adds a

positive or negative DC component to the output signal. The DC

component introduced is independent of the OUTPUT LEVEL

control and can be varied by ±10 volts open circuited or ±5 volts

into 50Ω. The DC Offset does not affect the TTL/CMOS output

jack. The effect of DC OFFSET is shown in Fig. 3.

CONSIDERATIONS

1. l. Counterclockwise rotation of the COARSE frequency control

decreases the output frequency to approximately one-tenth of the

maximum for the range selected (10:1). For example, if the 50K

range is selected and the COARSE frequency control is set to

full counterclockwise, the output frequency is approximately

5kHz.

2. It is advisable to set the FINE frequency control to the

approximate center of its rotation before setting the COARSE

frequency control. This assures that the FINE control will not

reach its limit while trying to finalize the frequency setting.

3. The FINE frequency control provides approximately ±5%

frequency deviation from the COARSE control setting. This

provides vernier adjustment to easily set the frequency to a

precise value.

4. . When the 5Hz range is selected, the gate time is 10 seconds and

the display is updated once every 10 seconds. The result of a

frequency change will not be displayed until 10 seconds later.

Adjust the frequency in progressively smaller steps, waiting for

the display to update until the desired frequency is obtained.

5. When outputting square waves or when using the TTL output,

terminate the cable into 50Ω to minimize ringing. Also, keep

cables as short as possible.

Figure 3. Use of DC OFFSET Control

6. Remember that the output signal swing of the

generator is limited to ±10 volts open circuited or ±5

volts into 50Ω, and applies to the combined peak-to-

peak signal and DC offset. Clipping occurs slightly

above these levels. Fig. 3 illustrates the various

operating conditions encountered when using the DC

offset. If the desired output signal is large or if a large

DC offset is required, an oscilloscope should be used

to make sure that the desired signal is obtained without

undesirable clipping.

12

OPERATING INSTRUCTIONS

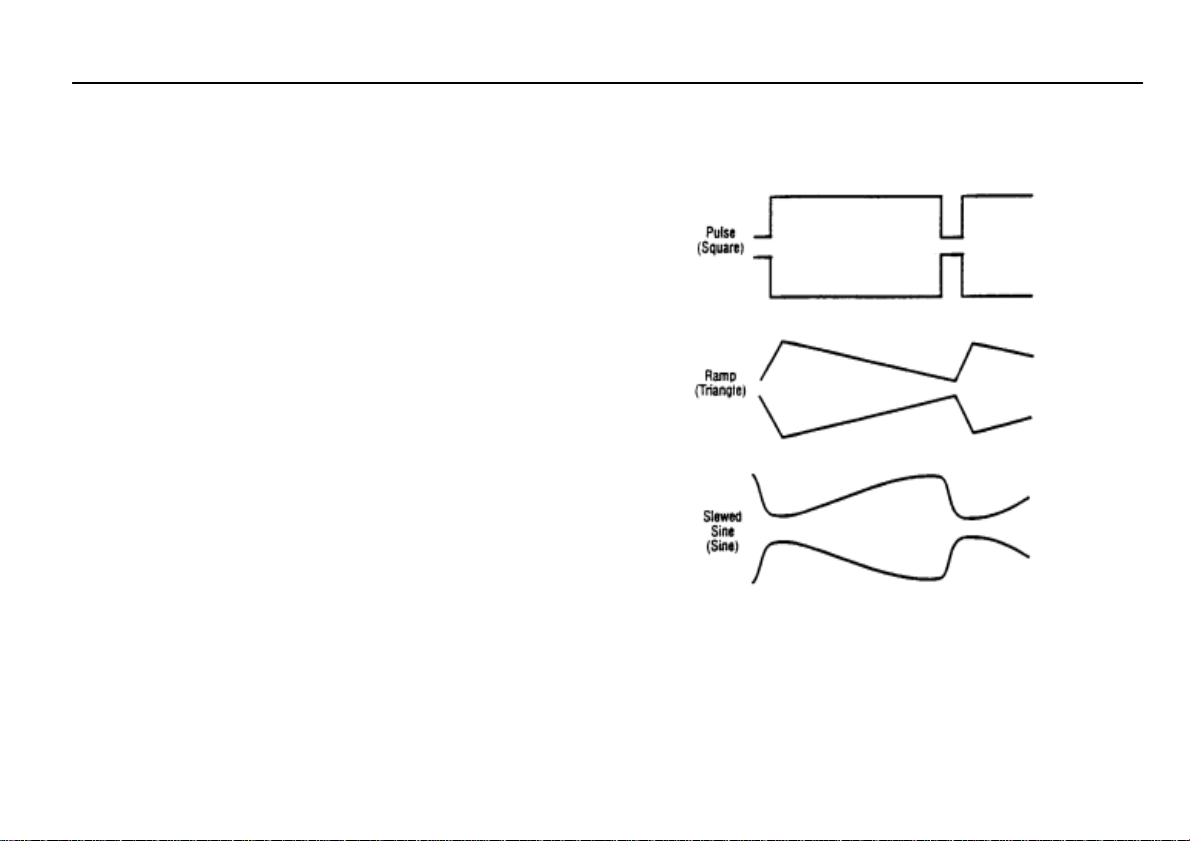

DUTY CYCLE CONTROL

The DUTY CYCLE control can be used to alter the

symmetry of the output waveform, to produce

waveshapes such as those shown in Fig. 4. For a

square wave, symmetry variation amounts to changing

the duty cycle (ratio of "high" to "low" time),

effectively converting the instrument into a pulse

generator. For a triangle wave, the result is a ramp, and

with a sine wave, a distorted waveshape called a

slewed sine is produced. The Model 4011A provides

for symmetry variation from 15% to 85%.

1. Select the waveform desired either SINE,

SQUARE or TRIANGLE.

2. Engage the DUTY CYCLE switch (14) and adjust

the DUTY CYCLE control (10) for the desired

waveshape. Clockwise rotation from center results

in an increase in square wave duty cycle, and

changes the sine and triangle waves as shown in

the top waveform of each pair of Fig. 4. Counter-

clockwise rotation results in the bottom waveform

in each pair.

3. Varying the duty cycle setting results in a slight

change in frequency. Adjust the COARSE and

FINE frequency controls as required.

Figure 4. Effects of Symmetry

Variation.

Loading...

Loading...