Page 1

Manual | EN

C6025

Industrial PC

3/26/2021 | Version: 1.5

Page 2

Page 3

Table of contents

Table of contents

1 Notes on the documentation ....................................................................................................................5

2 For your safety...........................................................................................................................................6

2.1 Description of safety symbols............................................................................................................6

2.2 Intended use......................................................................................................................................6

2.3 Fundamental safety instructions........................................................................................................7

2.4 Operator's obligation to exercise diligence ........................................................................................7

3 Product overview.......................................................................................................................................8

3.1 Structure ............................................................................................................................................9

3.2 Interface description ........................................................................................................................10

3.2.1 Power supply ................................................................................................................... 10

3.2.2 Ethernet RJ45.................................................................................................................. 11

3.2.3 USB ................................................................................................................................. 12

3.2.4 DisplayPort ...................................................................................................................... 13

3.3 Status LEDs.....................................................................................................................................14

3.3.1 UPS-OCT LED................................................................................................................. 14

3.3.2 PWR LED ........................................................................................................................ 15

3.3.3 HDD LED ......................................................................................................................... 15

3.3.4 TC LED ............................................................................................................................ 15

3.4 Name plate ......................................................................................................................................16

4 Commissioning........................................................................................................................................17

4.1 Transport and unpacking.................................................................................................................17

4.2 Installation in the control cabinet .....................................................................................................18

4.2.1 Mounting options ............................................................................................................. 19

4.2.2 Dimensions ...................................................................................................................... 20

4.2.3 Installation in the control cabinet ..................................................................................... 22

4.3 Connecting the Industrial PC...........................................................................................................24

4.3.1 Grounding of the Industrial PC ........................................................................................ 25

4.3.2 Connecting cables and power supply .............................................................................. 26

4.4 Switching the Industrial PC on and off.............................................................................................27

5 Beckhoff Device Manager.......................................................................................................................28

6 Decommissioning....................................................................................................................................31

6.1 Disconnecting the power supply and cables ...................................................................................31

6.2 Disassembly and disposal ...............................................................................................................32

7 Maintenance.............................................................................................................................................34

7.1 Cleaning ..........................................................................................................................................34

7.2 Maintenance ....................................................................................................................................35

7.2.1 Replacing the battery....................................................................................................... 37

7.2.2 Replacing the storage media ........................................................................................... 38

8 Troubleshooting ......................................................................................................................................39

9 Technical data..........................................................................................................................................40

10 Appendix ..................................................................................................................................................41

10.1 Service and support.........................................................................................................................41

C6025 3Version: 1.5

Page 4

Table of contents

10.2 Approvals.........................................................................................................................................42

C60254 Version: 1.5

Page 5

Notes on the documentation

1 Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

The following instructions and explanations must be followed during installation and commissioning of the

components. The qualified personnel must ensure that the application of the described products meets all

safety requirements, including all applicable laws, specifications, regulations and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development. For that reason the documentation is not in every case checked for consistency with

performance data, standards or other characteristics. In the event that it contains technical or editorial errors,

we retain the right to make alterations at any time and without warning. No claims for the modification of

products that have already been supplied may be made on the basis of the data, diagrams, and descriptions

in this documentation. All illustrations shown are only examples. The configurations depicted may deviate

from the standard.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCAT P®, Safety over EtherCAT®, TwinSAFE®, XFC® and XTS®

are registered and licensed brands of Beckhoff Automation GmbH. Other designations used in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of

the owners.

Patents

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, DE102004044764, DE102007017835 with the corresponding applications

and registrations in various other countries. The TwinCAT Technology is covered, including but not limited to

the following patent applications and patents: EP0851348, US6167425 with corresponding applications or

registrations in various other countries.

Copyright

© Beckhoff Automation GmbH & Co. KG. Publication of this document on websites other than ours is

prohibited. Offenders will be held liable for the payment of damages. All rights reserved in the event of the

grant of a patent, utility model or design.

Delivery state

All the components are supplied in particular hardware and software configurations appropriate for the

application. Changes to the hardware or software configuration are permitted, provided they are within the

specified limits for power consumption and power dissipation (please refer to the respective data sheet).

Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH & Co. KG apply.

C6025 5Version: 1.5

Page 6

For your safety

2 For your safety

The Safety chapter first explains the safety symbols used in the documentation and their meanings. They

contain fundamental safety instructions that are essential for the avoidance of personal injuries and damage

to property.

Exclusion of liability

Beckhoff shall not be liable in the event of non-compliance with this documentation and thus the use of the

devices outside the documented operating conditions.

2.1 Description of safety symbols

The following safety symbols are used in these operating instructions. In order to avoid personal injuries and

damage to property, read and follow the safety and warning notices.

Warning of personal injuries:

DANGER

Disregarding the safety notice will lead to death or serious injuries.

WARNING

Disregarding the safety notice may lead to death or serious injuries.

CAUTION

Disregarding the safety notice may lead to minor injuries.

Warning of damage to property:

NOTE

Disregarding the notice may lead to damage to property.

2.2 Intended use

The Industrial PC is designed for space-saving control cabinet installation and for use as a control system in

machine construction and plant engineering for automation, visualization and communication.

The Industrial PC has been developed for an IP20 working environment. It is protected against the

penetration of fingers and solid foreign bodies of 12.5 mm or larger in size. It is not protected against water.

Operation of the devices in wet and dusty environments is not permitted.

The specified limits for technical data must be adhered to.

The Industrial PC can be used within the documented operating conditions.

Improper use

Do not use the Industrial PC outside the documented operating conditions.

C60256 Version: 1.5

Page 7

For your safety

2.3 Fundamental safety instructions

The following safety instructions must be observed when handling the Industrial PC.

Application conditions

• Do not use the Industrial PC under extreme environmental conditions. Keep the ventilation slots clear.

• Never use the Industrial PC in potentially explosive atmospheres.

• Do not carry out any work on the Industrial PC when it is live. Always switch off the supply voltage for

the device before mounting it, replacing device components or rectifying malfunctions. This does not

apply to the replacement of hard disks in a RAID configuration.

• Never plug or unplug connectors during thunderstorms. There is a risk of electric shock.

• Ensure that the device has a protective and functional earth connection.

• Observe hot surfaces when using the device. There is a risk of burns.

Damage to property, loss of data and impairment of functions

• If you change the hardware and software configurations, you must keep within the specified limits of

power consumption and power dissipation (please refer to the respective data sheet).

• Ensure that only trained specialists with a control and automation technology background, operate the

Industrial PC. Use by unauthorized persons can lead to damage to property and loss of data.

• Protect the power supply cable with a fuse with a max. rating of 16A. The fuse serves to protect the

supply line in the event of a short circuit.

• In case of fire, extinguish the Industrial PC with powder or nitrogen.

2.4 Operator's obligation to exercise diligence

The operator must ensure that

• the products are used only for their intended purpose (see Chapter 2.2 Intended use [}6]).

• the products are only operated in sound condition and in working order.

• the products are operated only by suitably qualified and authorized personnel.

• the personnel is instructed regularly about relevant occupational safety and environmental protection

aspects, and is familiar with the operating instructions and in particular the safety instructions contained

herein.

• the operating instructions are in good condition and complete, and always available for reference at the

location where the products are used.

C6025 7Version: 1.5

Page 8

Product overview

3 Product overview

The C6025 Industrial PC is part of the series of ultra-compact Industrial PCs for space-saving control cabinet

installation. It is a high-performance device with comparatively low energy consumption. It combines the

compactness and fanless design of the C601x devices with the high performance of the C603x devices.

Thanks to the available processors, the Industrial PC can be used for the following applications, among

others:

• demanding control applications taking into account green IT

• complicated HMI applications

• short cycle times

• high-volume data handling

• diverse automation and visualization tasks

• wide range of IoT tasks with data preprocessing

• other PC applications

The basic configuration of the C6025 includes the following aspects:

• M.2-SSD

• Graphic adapter integrated in the Intel® processor, 1 DisplayPort connection

• on-board Ethernet adapter with 3 x 100/1000BASE-T connection

• 4x USB 3.0

• 1 slot accessible for M.2 SSD

C60258 Version: 1.5

Page 9

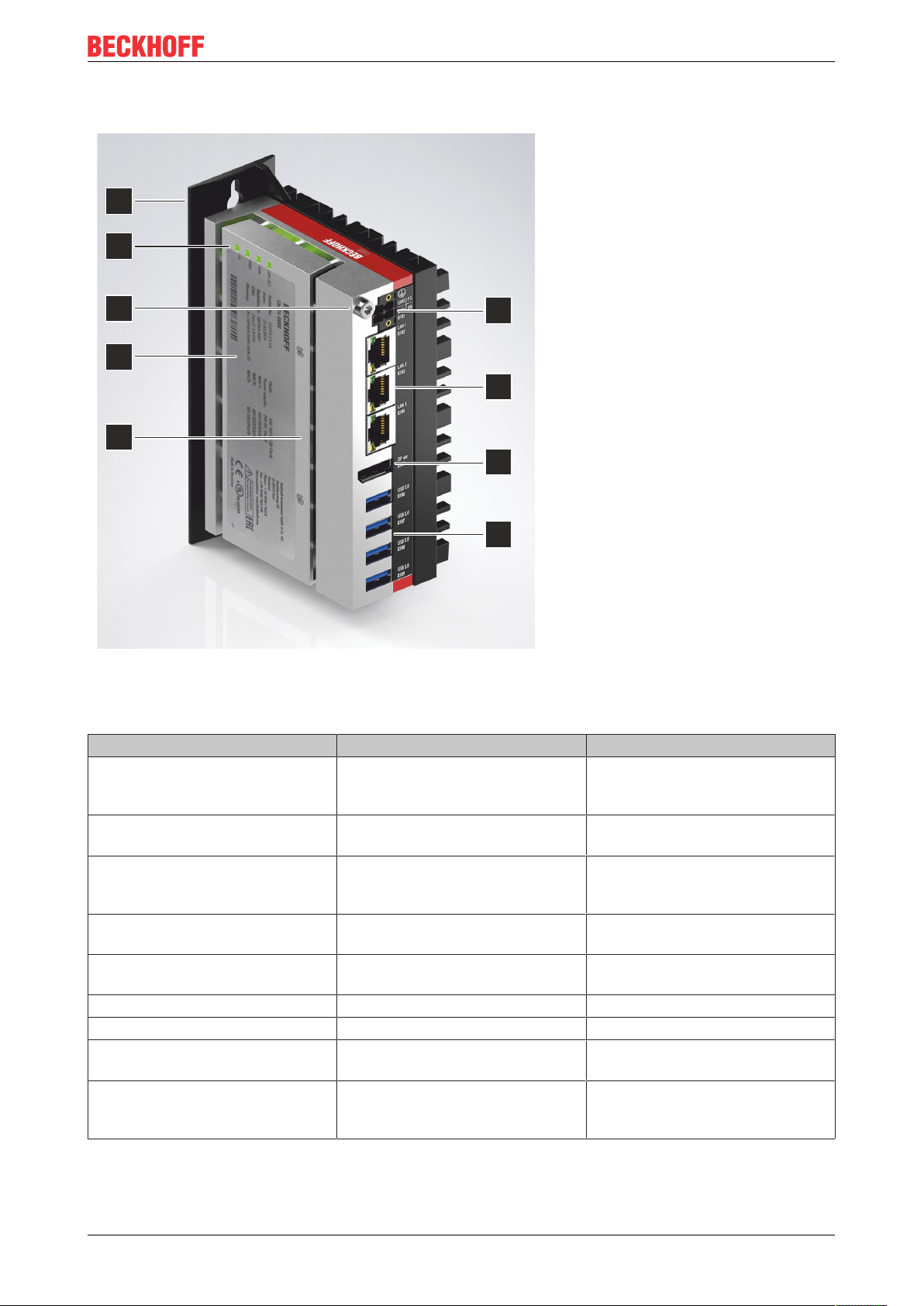

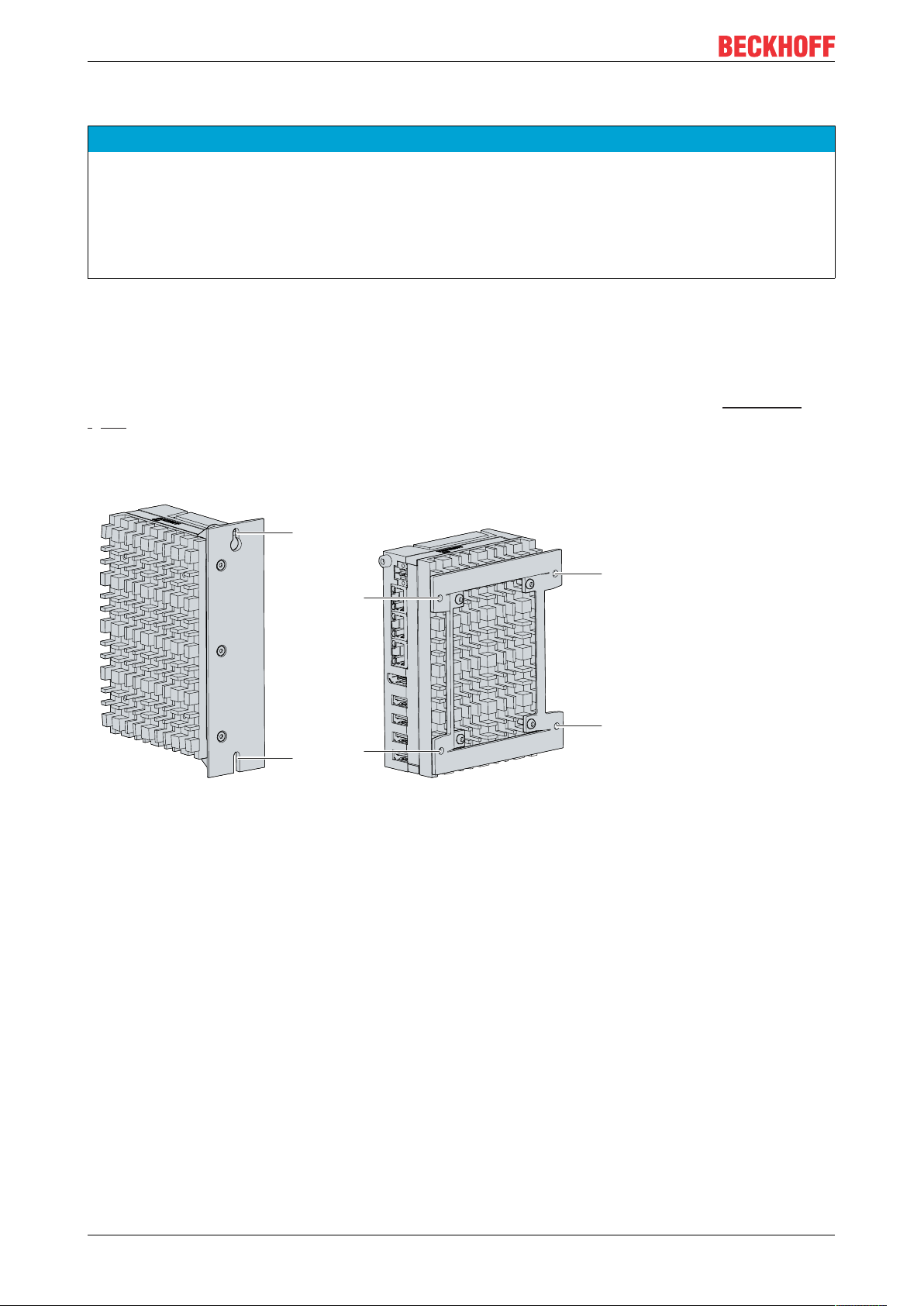

3.1 Structure

1

2

3

4

5

6

7

8

9

Product overview

Fig.1: C6025_Structure – basic configuration

Table1: Key - C6025 structure

No. Component Description

1 Mounting plate Plate for mounting the Industrial

PC over the narrow sides in the

control cabinet

2 Status LEDs Status display for UPS-OCT,

3 Protective conductor connectionPELow-resistance protective earthing

4 Name plate Information on the equipment of

5 Side cover Access to battery and storage

6 USB interfaces (X106-X109) Connection of peripheral devices

7 DisplayPort (X105) Transmission of the video signal

8 Ethernet interfaces RJ45 (X102 -

X104)

9 Power supply (X101) Connection of the power supply

power, hard disk, TwinCAT

and functional earthing of the

Industrial PC

the Industrial PC

medium

Connection of the Industrial PC to

a 100/1000BASE-T network

and external wiring of the Industrial

PC

C6025 9Version: 1.5

Page 10

Product overview

X101

1

2

3

4

3.2 Interface description

The basic version of the C6025 has the following interfaces:

• Power supply (X101)

• Ethernet RJ45 (X102-X104)

• DisplayPort (X105)

• USB (X106-X109)

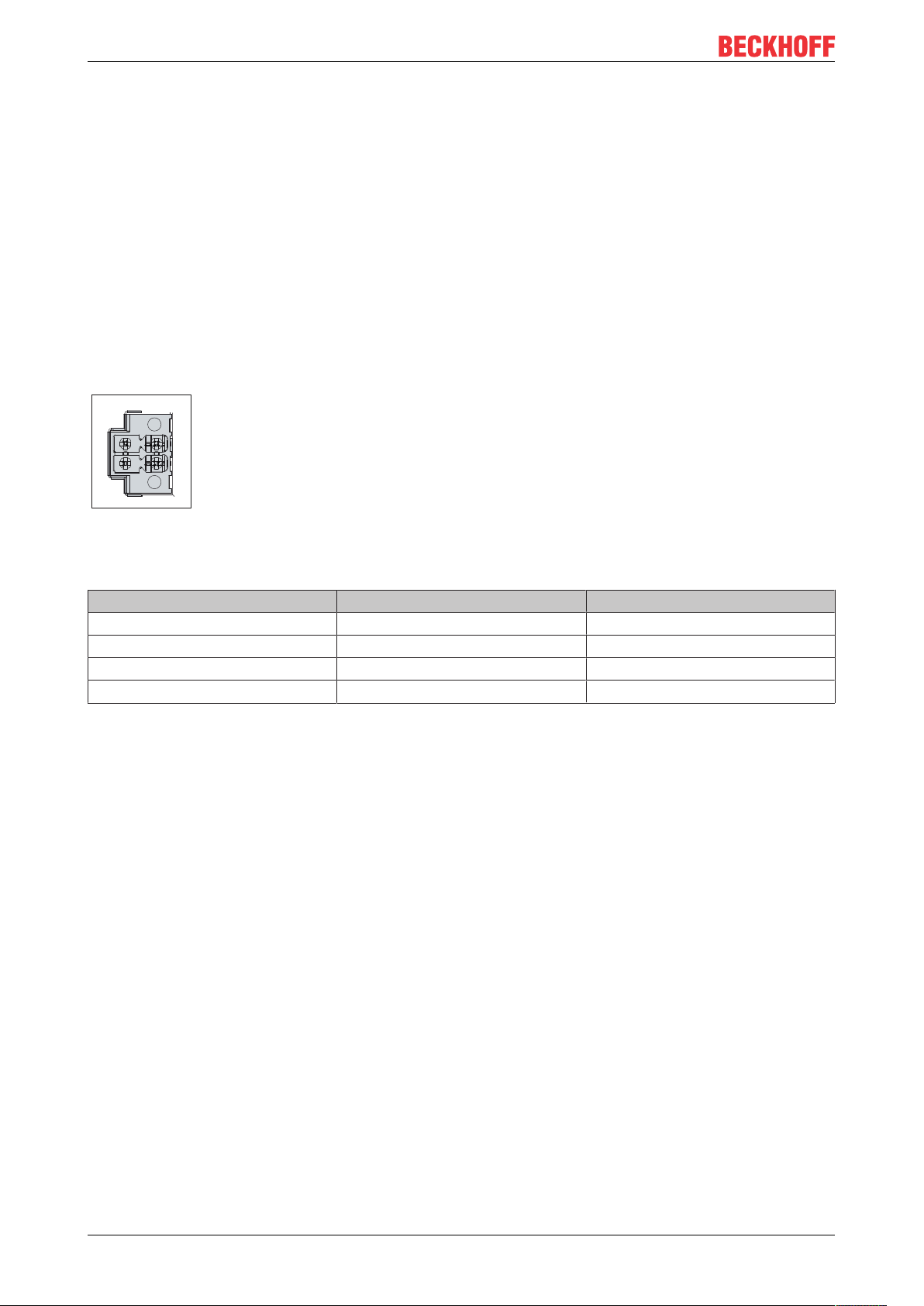

3.2.1 Power supply

The Industrial PC is supplied with a rated voltage of 24V. The 2x2-pin power socket (X101) is used for

connection to the power supply and the external wiring of the Industrial PC. The main supply voltage is

applied between PIN 3 (0V) and PIN 4 (24V) of the socket.

Fig.2: C6025_Power socket pin numbering

Table2: Power socket pin assignment

Pin Signal Description

1 ON PC_ON input

2 P-S Power status output

3 GND 0 V

4 24 V Power supply

The plug for the power supply is specified for 8A and can accommodate cable cross-sections of up to

1.5mm2. The plug is included in the delivery. If you need a replacement connector, please contact your

Beckhoff service team, quoting the order identifier C9900-P943 (see Chapter 10.1 Service and support).

C602510 Version: 1.5

Page 11

Product overview

1

8

1

1

8

8

LAN 1

LAN 2

LAN 3

X102

X103

X104

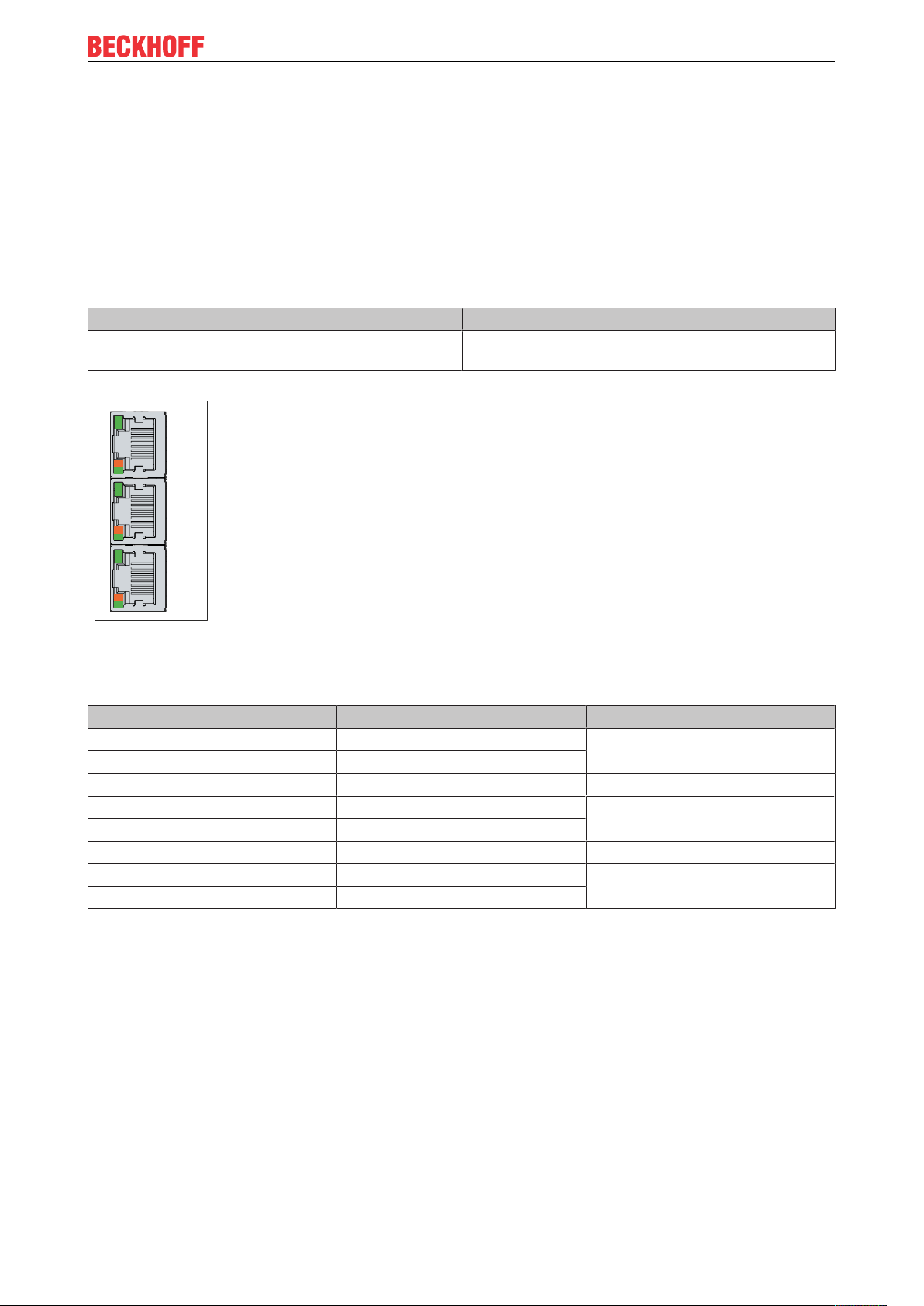

3.2.2 Ethernet RJ45

The C6025 has three Gigabit LAN ports (X102-X104). The Ethernet standards 100Base-T and 1000Base-T

enable connection of corresponding network components with data rates of 100/1000 Mbit/s. The required

speed is selected automatically.

The RJ45 connection technology with twisted-pair cables is used. The maximum length of the cable

connection is 100 m.

The controllers are used as follows, based on the device generations:

Table3: Controller classification based on device generations

Generation Controller

C6025-0000 Intel® i219 (PHY) for LAN1 and Intel® i210 (MAC/

PHY) for LAN2 and LAN3

Fig.3: C6025_Ethernet interface pin numbering

Table4: Ethernet interface pin assignment

Pin Signal Description

1 T2 + Pair 2

2 T2 -

3 T3 + Pair 3

4 T1 + Pair 1

5 T1 -

6 T3 - Pair 3

7 T4 + Pair 4

8 T4 -

The LEDs of the LAN interfaces indicate the activity and the speed of the data transfer (Mbit/s). The LED on

the left indicates whether the interface is connected to a network. If this is the case, the LED lights up green.

The LED flashes when data transfer is in progress.

The LED on the right indicates the speed of the data transfer. If the speed is 100 Mbit/s the LED is orange, at

1000 Mbit/s it is green.

C6025 11Version: 1.5

Page 12

Product overview

1 2 3

4

4

321

1 2 3

4

4

321

X106

X107

X108

X109

56789

56789

56789

56789

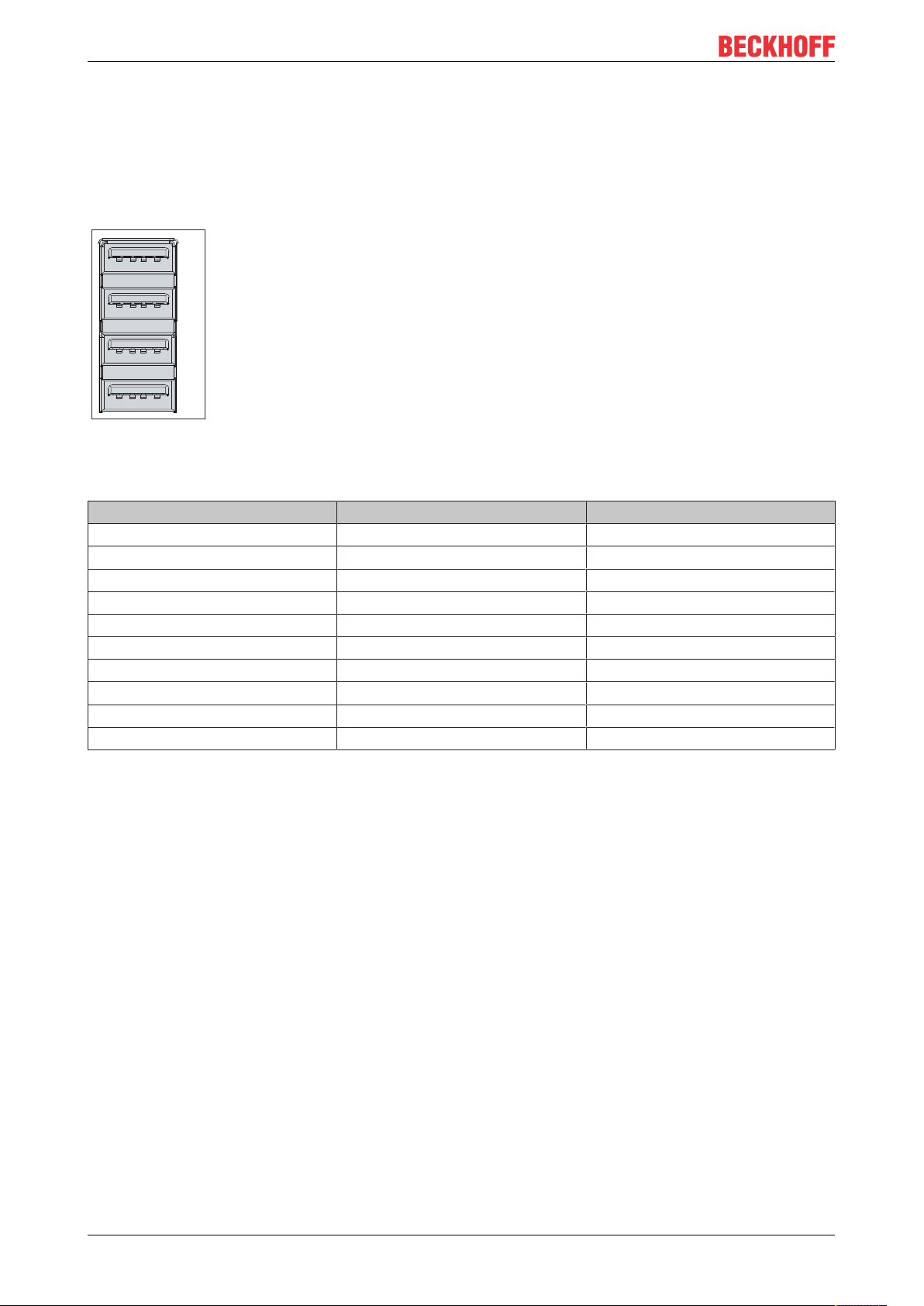

3.2.3 USB

The Industrial PC has four USB 3.0 interfaces (X106-X109). They are used to connect peripheral devices

with USB interfaces.

In contrast to the specification, the channels only supply current up to 500 mA. Devices with their own power

supply must be used for higher power demands. The USB interfaces are electronically protected.

Fig.4: C6025_USB interface pin numbering

Table5: USB interface pin assignment

Pin Connection Typical assignment

Shell Shield Drain Wire

1 VBUS Red

2 D - White

3 D + Green

4 GND Black

5 StdA_SSRX - Blue

6 StdA_SSRX + Yellow

7 GND_DRAIN N/A

8 StdA_SSTX - Purple

9 StdA_SSTX + Orange

C602512 Version: 1.5

Page 13

Product overview

1

2

19

20

X105

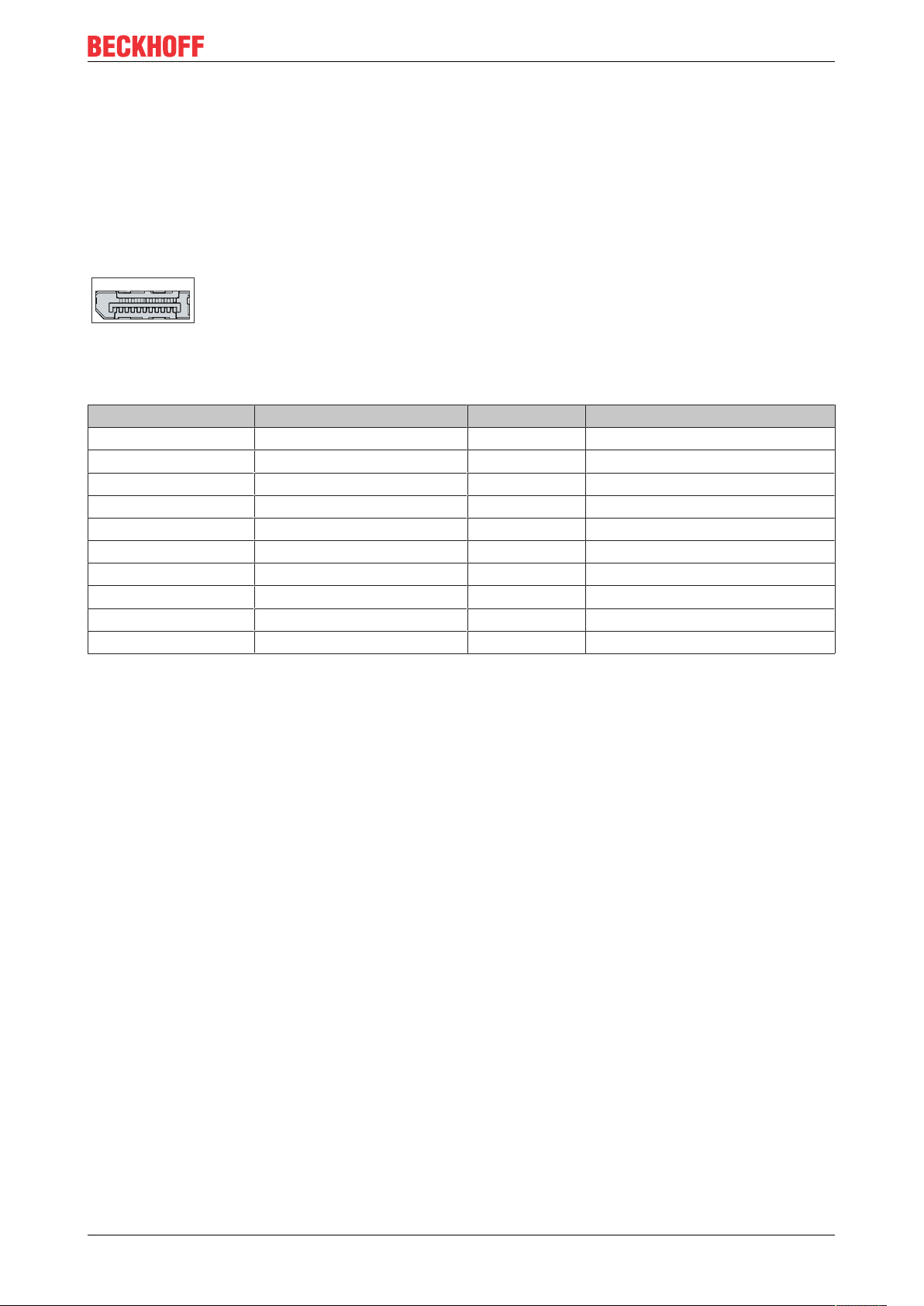

3.2.4 DisplayPort

The Industrial PC has a DisplayPort (X105) that enables connection of devices with DisplayPort. It facilitates

transfer of image signals.

In addition, DVI signals can be transferred via an adapter. Please order it from your Beckhoff sales team,

quoting order identifier C9900-Z468 adapter cable DisplayPort to DVI, 40 cm.

DisplayPort signals are led out via the interface by default. With the use of a level shifter cable the board

switches the DisplayPort specification automatically to HDMI signals.

Fig.5: C6025_DisplayPort pin numbering

Table6: Pin assignment of DisplayPort

Pin Connection Pin Connection

1 LVDS lane 0 + 2 Ground

3 LVDS lane 0 - 4 LVDS lane 1 +

5 Ground 6 LVDS lane 1 -

7 LVDS lane 2 + 8 Ground

9 LVDS lane 2 - 10 LVDS lane 3 +

11 Ground 12 LVDS lane 3 -

13 Config 1 14 Config 2

15 AUX channel + 16 Ground

17 AUX channel - 18 Hot-plug detection

19 Power supply: Ground 20 Power supply: 3.3 V/500 mA

C6025 13Version: 1.5

Page 14

Product overview

PWR

TC

HDD

UPS-OCT

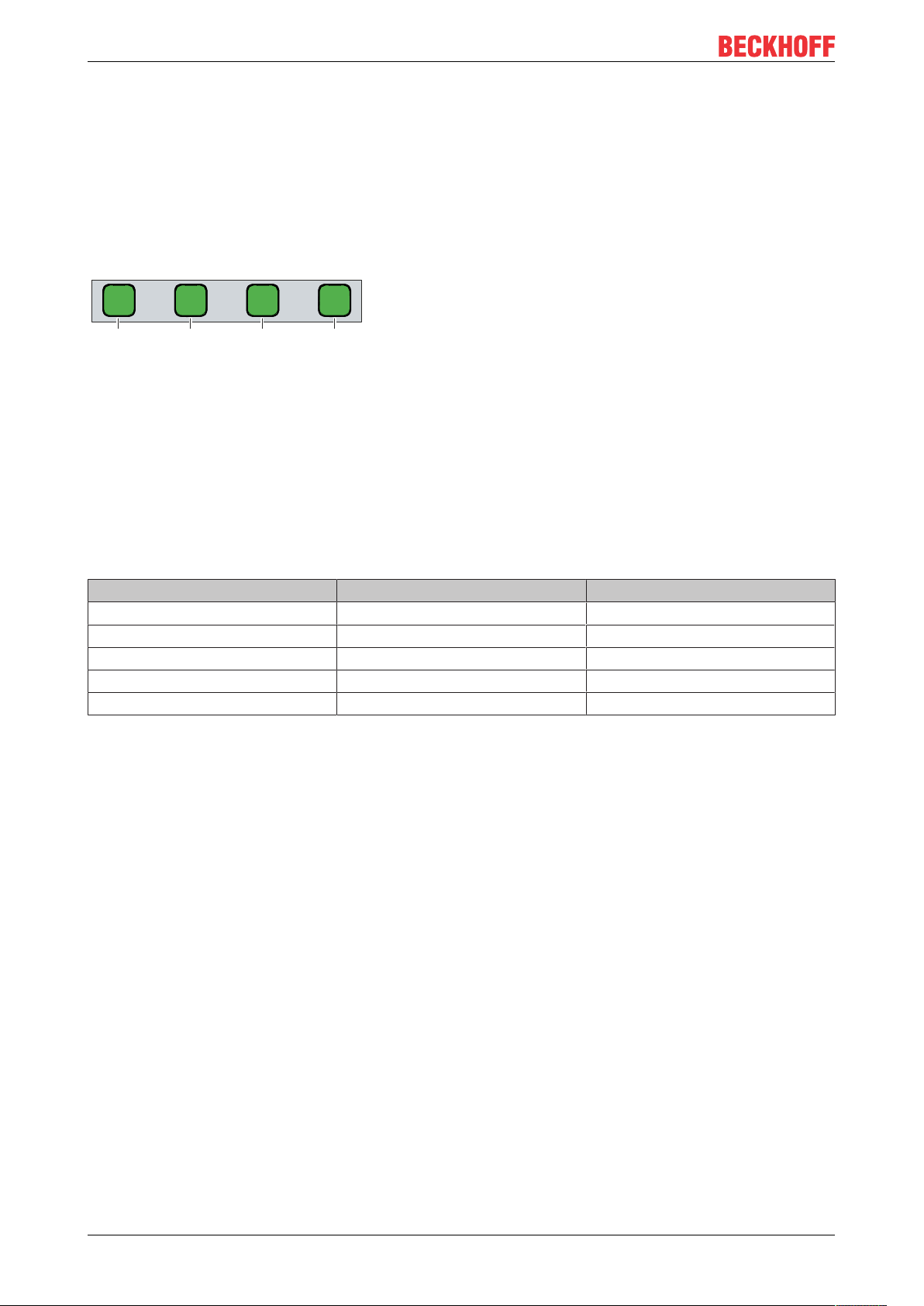

3.3 Status LEDs

The Industrial PC has four status LEDs: UPS-OCT, PWR, HDD, TC. They provide information on the

following aspects:

• the transmission quality of the UPS-OCT signals

• the status of the power controller

• the hard disk activity

• the TwinCAT status

Fig.6: Status LEDs

3.3.1 UPS-OCT LED

The UPS-OCT LED indicates the transmission quality of the UPS-OCT signals. UPS stands for the

uninterruptible power supply. One-cable technology (OCT) enables the communication between PC and

UPS to be transmitted together with the power supply, so that only one cable is required.

The colors and flashing intervals have the following meanings:

Table7: Meaning of the UPS-OCT LED

Color Flashing interval Meaning

None Steadily lit No UPS-OCT connected

Blue Flashing Bootloader active

Yellow Flashing Moderate signal quality

Green Flashing Good signal quality

Red Flashing Poor signal quality

C602514 Version: 1.5

Page 15

Product overview

3.3.2 PWR LED

The PWR (power) LED indicates the status of the power controller. The colors and flashing intervals have

the following meanings:

Table8: Meaning of the PWR LED

Color Flashing interval Meaning

None Steadily lit PC is off

White Steadily lit VCC power fail

Magenta Steadily lit S UPS active (if existent)

Yellow Steadily lit Windows shut down, supply

voltage still present

Green Steadily lit Normal operation

Red Steadily lit Reset/power fail

Green/yellow Flashing Bootloader running without error

Red/yellow Flashing Bootloader is starting (start

sequence is being run through)

Magenta Flashing (0.5s) S UPS capacitance test (if S UPS

exists)

Red/magenta Flashing Checksum error during the I2C

transmission in the bootloader

Cyan Flashing (2s) contact Beckhoff Service

3.3.3 HDD LED

The HDD LED indicates the activity of the storage medium. The colors and flashing intervals have the

following meanings:

Table9: Meaning of the HDD LED

Color Flashing interval Meaning

Red Flashing Activity (access to storage

medium)

3.3.4 TC LED

The TC LED indicates the TwinCAT status. The colors and flashing intervals have the following meanings:

Table10: Meaning of the TC LED

Color Flashing interval Meaning

Green Steadily lit TwinCAT Run Mode

Blue Steadily lit TwinCAT Config Mode

Red Steadily lit TwinCAT Stop

- - TwinCAT not started

C6025 15Version: 1.5

Page 16

Product overview

3.4 Name plate

The name plate provides information on the equipment fitted to the Industrial PC.

Table11: Key - C6025 name plate

No. Description

1 Manufacturer, including address

2 Model: The last four digits indicate the device

generation.

3 Serial number (BTN)

4 UPS-OCT LED

5 Date of manufacture

6 Power LED

7 Mainboard

8 CPU

9 Hard disk LED

10 Main memory

11 TwinCAT LED

12 Hot surface warning

13 CE conformity, EAC conformity

14 MAC addresses of the Ethernet interfaces (X102-

X104)

15 Power supply unit: 24 V

16 Storage medium

NEC class 2

DC,

C602516 Version: 1.5

Page 17

Commissioning

4 Commissioning

To be able to use the Industrial PC, you must first commission it. The first step is to transport the device to is

operating location and unpack it. This is followed by installing the device in the control cabinet, connecting

the cables and the power supply and finally switching on the Industrial PC.

4.1 Transport and unpacking

Note the specified transport and storage conditions (see Chapter 9, Technical data [}40]).

Despite the robust design of the unit, the components are sensitive to strong vibrations and impacts.

Transporting a control cabinet with a built-in PC can result in excessive impact on the Industrial PC. During

transport the device must therefore be protected from excessive mechanical stress. Appropriate packaging

of the Industrial PC, in particular the original packaging, can improve the vibration resistance during

transport.

NOTE

Hardware damage due to condensation

Unfavorable weather conditions during transport can cause damage to the device.

• Protect the device against moisture (condensation) during transport in cold weather or in case of extreme temperature fluctuations.

• Do not put the device into operation until it has slowly adjusted to the room temperature.

• Should condensation occur, wait for about 12 hours before switching the device on.

Unpacking

Proceed as follows to unpack the unit:

1. Remove packaging.

2. Keep the packaging for possible future transport.

3. Check your delivery for completeness by comparing it with your order.

4. Check the contents for visible shipping damage.

5. In case of discrepancies between the package contents and the order, or in case of transport damage,

please inform Beckhoff Service (see Chapter 10.1 Service and support [}41]).

C6025 17Version: 1.5

Page 18

Commissioning

3

1 2

4.2 Installation in the control cabinet

The C6025 Industrial PC is designed for installation in control cabinets in machine and plant technology.

Please observe the environmental conditions prescribed for the operation (see Chapter 9 Technical data

[}40]).

Using different mounting plates, you can align the cable entry based on the application requirements.

Figure 8 shows the three available mounting plates: the standard mounting plate 1, the optional mounting

plate 2 and the optional mounting plate 3 with DIN rail adapter. The three mounting plates are mounted on

the device as follows:

• Mounting plate 1: at the rear of the Industrial PC with three Torx TX10 screws and a tightening torque

of approx. 0.5 Nm

• Mounting plate 2: on the right-hand side wall of the Industrial PC with four Torx TX10 screws and a

tightening torque of approx. 0.5 Nm

• Mounting plate 3: at the rear of the Industrial PC with two Torx TX10 screws and a tightening torque of

approx. 0.5 Nm

Mounting plate 2 offers two mounting options (see Chapter 4.2.1 Mounting options [}19]).

Fig.7: C6025 _Mounting plates

By default, the Industrial PC is delivered with the standard mounting plate 1 already mounted as shown in

Fig. 8. Alternatively, you can select one of the ordering options listed below.

The following ordering options are available to you:

Table12: Mounting plate ordering options

Order designation Execution

C9900-M682 Mounting plate for C602x on the side wall, instead of

the standard mounting plate

C9900-M683 Mounting plate for side mounting of the C602x, single

part, not mounted

C9900-M684 Mounting plate with DIN rail adapter for C602x,

instead of the standard mounting plate

C9900-M685 Mounting plate with DIN rail adapter for C602x, single

part, not mounted

C602518 Version: 1.5

Page 19

Commissioning

A B

4.2.1 Mounting options

NOTE

Incorrect installation

Mounting the device in a way that deviates from the documentation can impair its functionality.

• Mount the device only according to the orientations shown in the documents.

The three different mounting plates enable you to align the Industrial PC according to the desired cable

routing in the control cabinet. In the case of mounting plates 1 and 3, you can only install the device in the

control cabinet via the rear side (see Fig. 9).

In the case of mounting plate 2, there are two different mounting options for the device. Figure 10 shows the

possible mounting options:

• Connections point to the right (A)

• Connections point to the left (B)

Fig.8: Mounting options for mounting plate 2

C6025 19Version: 1.5

Page 20

Commissioning

91

1

4

5

1

2

7

1

3

7

20

40

47,1

4

,

2

4

,

5

1

2

7

52,5

2,5

100

9

0

90

4,2

82

4.2.2 Dimensions

The dimensions of the Industrial PC and the mounting plates are used to prepare the control cabinet and to

mount the device correctly in the control cabinet.

All dimensions are in mm.

Fig. 11 gives an example of the dimensions using the mounting option via the rear of the device with

mounting plate 1.

Fig.9: C6025 _Mounting plate narrow side

Fig. 12 shows the dimensions using the mounting option with the connections pointing to the right with

mounting plate 2 as an example.

Fig.10: C6025 _Mounting plate side panel

Fig. 13 illustrates the dimensions using the mounting options via the rear of the device with mounting plate 3

with DIN rail adapter as an example.

C602520 Version: 1.5

Page 21

1

2

7

47

4

2

,

2

99

6

8

7

,

8

1

2

,

6

3

0

Fig.11: C6025 _Mounting plate DIN rail adapter

Commissioning

C6025 21Version: 1.5

Page 22

Commissioning

4.2.3 Installation in the control cabinet

NOTE

Extreme environmental conditions

Extreme environmental conditions can cause damage to the device.

• Avoid extreme environmental conditions.

• Protect the device against dust, moisture and heat.

• Do not block the ventilation slits of the device.

When installing in the control cabinet, make sure that there is 5 cm free space above and below the device

and 2 cm on the side of the device that is accessible for air circulation and for opening the PC.

Mounting via mounting plates

In order to mount the Industrial PC with mounting plate 1 or 2 in the control cabinet, it must be furnished with

the holes for the fastening screws according to the dimensions of the PC (see Chapter 4.2.2 Dimensions

[}20]). You need M4 screws for mounting.

After you have drilled the holes for the fastening screws in the control cabinet, you can mount the Industrial

PC in the control cabinet with mounting plates 1 or 2.

Fig.12: C6025 _Mounting plates for control cabinet installation

To install the Industrial PC in the control cabinet, follow the steps below:

1. Place the fastening screws in the drill holes in the rear panel of the control cabinet.

2. Hang the PC onto the screws at the marked points on the mounting plate (see Fig.14).

3. Tighten the fastening screws.

ð You have successfully installed the Industrial PC in the control cabinet.

Mounting via DIN rail adapter

If you want to install the Industrial PC in the control cabinet via the DIN rail adapter, no preparation of the

control cabinet is necessary. All you need to do is attach the device to the DIN rail using the adapter. To do

this, follow the steps shown in Fig. 15:

C602522 Version: 1.5

Page 23

Commissioning

A B

C

Fig.13: C6025_DIN rail adapter for control cabinet installation

1. Hook the lower side of the adapter into the DIN rail (A).

2. Push the device upwards so that the spring contacts of the adapter are pressed in (B).

3. Keep the device pressed upwards and also hook the upper side of the adapter into the DIN rail (C).

ð You have successfully installed the Industrial PC on the DIN rail.

Fig.14: C6025_DIN rail adapter mounted

C6025 23Version: 1.5

Page 24

Commissioning

L1

L2

L3

N

PE

230 V

24 V

~

_

Grounding busbar

4.3 Connecting the Industrial PC

CAUTION

Risk of electric shock

Dangerous touch voltages can lead to electric shock. To avoid electric shock, observe the following:

• Never connect or disconnect the device cables during a thunderstorm.

• Provide protective earthing for handling the device.

To prepare the Industrial PC for operation, it must be connected. The first step is to ground the device. Then

you can connect the cables and the power supply.

An external power supply unit is required to supply 24VDC (-15%/+20%) for operating the device.

Wire the Industrial PC in the control cabinet in accordance with the EN 60204-1:2006 standard on Protective

Extra Low Voltage (PELV) so that one side of the circuit or a point on the power source of this circuit is

connected to the protective conductor system.

Set "PE" and "0 V" (24 V power supply) to the same potential (connected in the control cabinet).

Connected devices that have their own power supply must have the same potential for "PE" and "GND" as

the Industrial PC system (no potential difference).

Fig.15: C6025 _Wiring example

C602524 Version: 1.5

Page 25

Commissioning

4.3.1 Grounding of the Industrial PC

Potential differences are minimized and electrical currents are diverted to the ground through grounding or

potential equalization of electronic devices. This is to prevent dangerous touch voltages and electromagnetic

interference.

The protective conductor connection PE is located on the housing of the Industrial PC (see also Chapter 3.1

Structure [}9]), which ensures both the protective earthing of the PC and the functional earthing. Therefore,

use cables with a cross-section of at least 4 mm2 for the connection of the protective conductor.

Protective earth

By connecting the PE protective conductor connection to the central grounding point of the control cabinet

panel in which the PC is installed, you establish low-resistance protective earthing of the Industrial PC and

thus avoid dangerous touch voltages.

EMC

NOTE

Hardware damage due to electromagnetic interference

Using the Industrial PC without functional earthing can lead to hardware damage due to electromagnetic interference.

• Only use the device with functional earthing.

Electromagnetic compatibility (EMC) refers to the Industrial PC's ability not to interfere with other devices

and equipment through electromagnetic interference, and not to be disturbed by electrical or electromagnetic

effects.

For this purpose, the Industrial PC must comply with certain protection requirements. The Industrial PC has

EMC interference immunity according to EN 61000-6-2. The EMC interference emission of the device meets

the requirements of EN 61000-6-4.

The EMC of the device is improved by functional earthing. You also establish the functional earthing by

connecting the PE protective conductor connection to the central grounding point of the control cabinet panel

in which the PC is installed.

C6025 25Version: 1.5

Page 26

Commissioning

4.3.2 Connecting cables and power supply

NOTE

Incorrect connection procedure

Incorrect procedure when connecting the cables and the power supply can cause hardware damage.

• Follow the documented procedure for connecting the cables and the power supply.

• Always connect the cables first and only then switch on the power supply.

• Please read the documentation for the external devices prior to connecting them.

Connecting cables

The connections are located in the front of the Industrial PC and are documented in Chapter 3.1 Structure

[}9].

Make sure that you first ground the PC (see Chapter 4.3.1 Grounding of the Industrial PC [}25]) and then

plug in all data transfer cables.

Connecting the power supply

Cables with a maximum cable cross-section of 1.5mm2 must be used for connecting the power supply. To

achieve the lowest possible voltage drop on the supply cable, we recommend connecting the maximum

possible cross-section. In the case of longer distances between the voltage source and the PC, take into

account the voltage drop in relation to the cable cross-section and voltage fluctuations in your supply

voltage, so that is secured that the voltage doesn´t fall under 22 V at the power supply.

Proceed as follows to connect the 24 VDC power supply unit:

1. Check the correct voltage of your external power supply.

2. Install the power cable.

3. Plug the power cable into the four-pin voltage connector of the Industrial PC.

4. Fasten the power cable to the power plug of the Industrial PC.

5. Connect the PC to your external 24 V power supply.

6. Switch on the 24V power supply.

C602526 Version: 1.5

Page 27

Commissioning

4.4 Switching the Industrial PC on and off

The Industrial PC does not have its own mains switch. Instead, the wiring for starting up and shutting down

the PC is connected via input PC_ON. You can connect a switch to the PC_ON input and use it as a

standard power switch. This allows you to position the switch as desired and make it easily accessible.

The Power Status signal indicates whether the PC is switched on or off. Read this signal to find out when

you can switch off the main supply voltage.

First switching on and driver installation

NOTE

Public networks

Connecting the PC to public networks without additional protective measures can compromise the safety of

the device.

• Protect the PC before connecting it to public networks.

The Industrial PC is started when the system is switched on or when the power supply is connected.

When you switch on the Industrial PC for the first time, the pre-installed operating system (optional) will be

started. For any additional hardware you have connected, you have to install the drivers yourself afterwards.

In addition, the Beckhoff Device Manager starts automatically. The Device Manager is a software from

Beckhoff that supports you in configuring the PC.

If you have ordered the PC without an operating system, you must install this and the driver software for the

additional hardware you have connected and for the devices in the PC yourself. Please follow the

instructions in the documentation for the operating system and the additional devices.

Switching off the Industrial PC

NOTE

Data loss due to running software

Switching off the Industrial PC before ending the running software and shutting down the device can lead to

data loss.

• Quit the running software and shut down the device before switching it off.

When the system is switched off or disconnected from its own power supply, the Industrial PC is also

switched off.

If 24 V are applied to the PC_ON input, the PC shuts down properly. The PC_ON signal is inverted, i.e. the

PC shuts down if the 24 V connection is live.

Once the PC has shut down, the Power Status output is switched from 24 V to 0 V. This output can be used,

for example, to switch a contactor that disconnects the entire system from the power supply. The maximum

load for the Power Status output is 0.5 A and a suitable fuse should be provided.

You can assign different access rights to all users in the operating system and in the application software.

Since there is a risk of data loss if the Industrial PC is switched off incorrectly, assign the rights advisedly. A

user who is not allowed to terminate the software should not be allowed to switch off the Industrial PC.

C6025 27Version: 1.5

Page 28

Beckhoff Device Manager

5 Beckhoff Device Manager

The Beckhoff Device Manager enables detailed system diagnostics with uniform secure access to the

existing hardware and software components. System data is recorded, analyzed and evaluated during

operation. The data helps to detect deviations at an early stage and prevent PC downtime.

The Beckhoff Device Manager always starts automatically after the Industrial PC has been booted. You also

have the option of manually restarting a previously closed Beckhoff Device Manager at any time.

The Industrial PC is delivered with predefined access data as standard:

• User name: Administrator

• Password: 1

You also have the option of using the Beckhoff Device Manager to configure the Industrial PC remotely via a

web browser. More detailed information is available in the Beckhoff Device Manager manual.

First start Beckhoff Device Manager

When your Industrial PC is booted for the first time, the Beckhoff Device Manager also starts automatically

for the first time. The Security Wizard opens. This tells you that you should reset the default password set by

Beckhoff. Proceed as follows:

1. Click Next on the Security Wizard start page.

ð This will take you to the Change Passwords page:

Fig.16: Beckhoff Device Manager - Change passwords

2. Enter the access data of the Device Manager on delivery.

3. Choose a secure new password. Instructions for choosing a secure password are given below.

4. Confirm the changes by clicking on the tick in the red box on the right.

5. Exit the Security Wizard to switch to the Device Manager home page:

C602528 Version: 1.5

Page 29

Beckhoff Device Manager

Fig.17: Beckhoff Device Manager home page

Navigate forward in the menu and configure the Industrial PC. Note that modifications only become active

once they have been confirmed. It may be necessary to restart the Industrial PC.

Starting the Beckhoff Device Manager manually

To start the Beckhoff Device Manager manually, proceed as follows:

1. Open a web browser on the host PC.

2. Enter the IP address or the host name of the Industrial PC in the web browser to start the Beckhoff

Device Manager.

• Example with IP address: https://169.254.136.237/config

• Example with host name: https://CP-2C1D7E/config

The Beckhoff Device Manager starts. The Security Wizard appears.

Secure passwords

Strong passwords are an important prerequisite for a secure system.

Beckhoff supplies the device images with standard user names and standard passwords for the operating

system. It is imperative that you change these.

Controllers are delivered without password in the UEFI/BIOS. Beckhoff recommends assigning a password

here as well.

Please note the following:

• Passwords should be unique for each user and service.

• Only change passwords after an incident in which passwords have become known without

authorization.

• Train the device users in the use of passwords.

A secure password has the following characteristics:

• Password complexity: The password should contain capital and lower-case letters, numbers,

punctuation marks and special characters.

• Password length: The password should be at least 10 characters long.

You can generate the password in different ways. An example is shown in the following table:

C6025 29Version: 1.5

Page 30

Beckhoff Device Manager

Table13: Password generation

Procedure Example

Start with one or two sentences. Complex passwords are more secure

Remove the spaces. Complexpasswordsaremoresecure

Abbreviate words or remove all vowels. Cmplxpsswrdsrmrscr

Insert numbers and special characters to extend the

password.

The following passwords are not secure:

• Words from a dictionary

• Words written backwards, common spelling mistakes, and abbreviations

• Repetitive sequences, e.g. 123456789 or abcdefgh

• Personal information, e.g. birthdays, ID numbers, telephone numbers

Cmplxpsswrdsrmrscr#529954#

C602530 Version: 1.5

Page 31

Decommissioning

6 Decommissioning

NOTE

Hardware damage due to power supply

A connected power supply can cause damage to the Industrial PC during disassembly.

• Disconnect the power supply from the device before starting to disassemble it.

When taking the Industrial PC out of operation, you must first disconnect the power supply and cables. You

can then remove the device from the control cabinet.

If you do not want to continue using the Industrial PC, Chapter 6.2 Disassembly and disposal [}32] provides

information on the correct disposal of the device.

6.1 Disconnecting the power supply and cables

CAUTION

Risk of electric shock

Disconnecting the Industrial PC during a thunderstorm can lead to electric shock.

• Never disconnect the cables of the Industrial PC during a thunderstorm.

Before you remove the Industrial PC from the control cabinet, you must follow the following steps:

1. Shut down the Industrial PC.

2. Disconnect the Industrial PC from the power supply (see below).

3. Disconnect the data transfer cables between the Industrial PC and the connected devices (see below).

Disconnect the power supply

Proceed as follows to disconnect the power supply:

1. Disconnect the PC from your external 24 V power supply.

2. Unscrew the four-pin power plug and pull it out of the PC.

3. Disassemble the power cable if the four-pin plug is to remain with the PC.

Disconnecting cables

To disconnect the cables from the Industrial PC, proceed as follows:

1. Make a note of the wiring configuration, if you wish to restore it with another device.

2. Disconnect all data transfer cables from the Industrial PC.

3. Finally, disconnect the grounding strap.

C6025 31Version: 1.5

Page 32

Decommissioning

6.2 Disassembly and disposal

Before you can remove the Industrial PC from the control cabinet, you must first disconnect the power supply

and the cables (see Chapter 6.1 Disconnecting the power supply and cables [}31]).

Disassembly via mounting plates

To remove the Industrial PC with the corresponding mounting plate 1 or 2 from the control cabinet, proceed

as follows:

1. Loosen the fastening screws just enough so that they remain attached to the control cabinet.

2. Lift the PC until the fastening screws slide into the keyholes (see Fig. 20).

3. Remove the PC from the control cabinet.

ð You have successfully disassembled the PC.

Fig.18: C6025 _Position of the fastening screws

Disassembly via DIN rail adapter

To remove the Industrial PC from the control cabinet via mounting plate 3 with the DIN rail adapter, follow

the steps below, which are shown in Fig. 21:

1. Push the PC upwards to press in the spring contacts on the DIN rail adapter (A).

2. Unhook the upper side of the adapter from the DIN rail (B).

3. Also unhook the lower side of the adapter from the DIN rail.

ð You have successfully removed the Industrial PC from the control cabinet.

C602532 Version: 1.5

Page 33

Decommissioning

A B

Fig.19: C6025_Dismantling the DIN rail adapter

Disposal of the Industrial PC

Be sure to observe the national electronic scrap regulations when disposing of the Industrial PC.

In order to dispose of the device, it must be removed and fully dismantled. Dispose of the components in the

following way:

• Send plastic parts (polycarbonate, polyamide (PA6.6)) for plastics recycling.

• Take metal parts to the metal recycling collection point.

• Electronic parts such as fans and circuit boards must be disposed of in accordance with national

electronic scrap regulations.

C6025 33Version: 1.5

Page 34

Maintenance

7 Maintenance

CAUTION

Risk of electric shock

Working on the Industrial PC while it is live can lead to electric shock.

• Turn off the supply voltage before cleaning the device or replacing device components. This does not

apply to the replacement of hard disks in a RAID configuration.

Maintenance measures increase the efficiency of the device by ensuring long-term functionality. Cleaning

and maintenance of certain device components and the replacement of other device components contribute

to this.

Repair

Only the manufacturer may repair the device. If a repair should be necessary, contact Beckhoff Service (see

Chapter 10.1 Service and support).

7.1 Cleaning

NOTE

Unsuitable cleaning agents

The use of unsuitable cleaning agents can damage the device.

• Only clean the Industrial PC as specified.

It is essential to observe the following aspects when cleaning the Industrial PC:

• Make sure that no dust gets into the PC.

• Always keep the ventilation slots clear.

• Only use a vacuum cleaner to clean the PC. The Industrial PC does not have to be switched off for

this.

• Never use compressed air to clean the PC.

C602534 Version: 1.5

Page 35

Maintenance

7.2 Maintenance

NOTE

Use of incorrect spare parts

The use of spare parts not ordered from Beckhoff Service can lead to unsafe and faulty operation.

• Only use spare parts that you have ordered from Beckhoff Service.

Beckhoff Industrial PCs are manufactured from components of the highest quality and robustness. They are

selected and tested for best interoperability, long-term availability and reliable function under the specified

environmental conditions.

Nevertheless, some components of the Industrial PC may be subject to a limited service life if they are

operated under certain conditions, such as more demanding ambient conditions during operation or during

storage, or if they are out of service for long periods of storage.

Beckhoff therefore recommends replacing some of the Industrial PC components after the time after which

predictions of the remaining service life of such components can no longer be reliably calculated.

These are the following components:

• Battery

• Storage medium

The following table provides recommendations for regular replacement of PC components:

Table14: Replacement recommendations for PC components

Component Recommendation for replacement intervals

(years)

UPS battery pack 5 years

2.5 inch hard disk 5 years or after 20,000 operating hours at more than

40 °C or after 30,000 operating hours at less than 40

°C

3.5 inch hard disk 5 years, irrespective of the operating hours

Fan 7 years

Compact Flash, CFast or SSD 10 years

Motherboard battery 5 years

Beckhoff is excluded from liability in the event of possible damage occurring during maintenance work.

Before working on the device, you should have established ESD protection to prevent damage to the device

through electrostatic discharge.

ESD protection

NOTE

Electrostatic discharge

Handling the Industrial PC without ESD protection can lead to functional impairment and destruction of the

device.

• Provide an ESD protected working environment for handling the device.

When working on electronic devices, there is a risk of damage due to ESD (electrostatic discharge), which

can impair the function or destroy the device.

Protect the Industrial PC and create an ESD-protected working environment in which any electrostatic

charges are discharged to the ground in a controlled manner and charging is prevented.

The best way to create an ESD-protected working environment is to set up ESD protection zones. The

following measures serve this purpose:

• ESD-compliant floors with sufficient conductivity to the reference potential PE;

C6025 35Version: 1.5

Page 36

Maintenance

1

2

• ESD-compatible, dissipative clothing such as shoes and safety shoes, protective gloves, protective

clothing over normal clothing;

• ESD-compatible work surfaces such as tables and shelves;

• Wrist grounding strap, especially for sedentary activities;

• grounded and electrostatically dissipating equipment and operating materials (e.g. tools) within the

ESD protection zone.

If it is not possible to create an ESD protection zone, you can still protect the device against ESD damage.

The following means can be used for this purpose:

• Wrist grounding strap

• Conductive mats connected to the ground potential for temporary storage of components

• ESD-compliant, conductive tool

Access to exchangeable device components

You can access the device components to be replaced via the cover on the left-hand side. You gain access

to the battery and the storage medium. To do this, remove the two Torx TX6 screws and take off the cover

(see Fig. 22).

Fig.20: C6025 _Access to battery and storage media

You now have access to the battery (1) and storage medium (2) (see Fig. 23).

Fig.21: C6025 _Battery and storage media

C602536 Version: 1.5

Page 37

Maintenance

+

-

+

-

+

+

7.2.1 Replacing the battery

NOTE

Incorrect battery type

Inserting the wrong type of battery can damage the device.

• Only replace the battery with a replacement battery from Beckhoff Service.

• When replacing the battery, make sure that the polarity is correct.

NOTE

Battery damage

Incorrect handling of the motherboard battery can damage it.

• Do not recharge the battery.

• Do not throw the battery on the fire.

• Do not open the battery.

• Protect the battery against direct sunlight and moisture.

NOTE

Motherboard failure

Scratches on the motherboard may cause the motherboard to fail.

• Be very careful with the battery replacement lever and be sure to avoid scratching the motherboard.

The Industrial PC does not contain a lithium-ion battery. The motherboard battery is a CR2032 lithium-metal

cell. It is used to supply power to the clock integrated on the motherboard. If the battery is depleted or

missing, the date and time are displayed incorrectly.

Replacement batteries should only be obtained from Beckhoff Service (see Chapter 10.1 Service and

support).

Table15: Technical data of the battery.

Battery type Electrical properties (at 20°C) Dimensions

Nominal voltage Nominal capac-

ity

CR2032 3.0 V 225 mAh 20.0mm 3.20mm 3.1g

Chapter 7.2 Maintenance [}35] shows how to access the battery.

To change the battery, proceed as follows:

1. Place a lever made of non-electrically conductive material on the negative pole of the battery holder

below the battery.

2. Lift the battery side out of the holder.

ð The battery is now in an inclined position (see Fig. 24).

Diameter Height Weight

Fig.22: C6025 _Battery change

3. Remove the battery completely from the battery holder.

4. Insert the new battery with the correct polarity back into the inclined position on the positive pole of the

battery holder. The correct polarity is shown in the figure.

5. Push the protruding side of the battery into the battery holder (see Fig. 24).

ð You have successfully replaced the battery.

C6025 37Version: 1.5

Page 38

Maintenance

A B

C

To dispose of the battery, remove it, tape off the poles and put it in the battery disposal.

7.2.2 Replacing the storage media

New storage media should only be obtained from Beckhoff Service (see Chapter 10.1 Service and support).

The C6025 contains one M.2 SSD.

Data transfer before replacement

If you want to exchange the SSD as recommended by Beckhoff, you must copy the data from the old to the

new SSD. You can use the Beckhoff Service Tool (BST) for this purpose. The BST is a graphical backup and

restore program for Industrial PCs with a Windows operating system. You can create an image of your

operating system and use it to back up the operating system. You can then restore the images created in

this way. You will receive the BST on a BST stick. For more information on the function of the BST, please

refer to the corresponding documentation.

If your SSD is defective and no backup copy of the data is available, Beckhoff Service will provide you with a

fresh Windows image. In this case the applications must be reinstalled.

Replacing the storage media

Chapter 7.2 Maintenance [}35] shows how to access the storage media.

To change the storage media, follow the steps shown in Fig. 25:

1. Remove the Torx TX10 fastening screw and the SW5 bolt of the storage medium you want to remove

(section A).

ð The storage medium automatically places itself in an inclined position (section B).

2. Pull the storage medium out of the slot in the inclined position (section C).

Fig.23: C6025 _Replace storage media

3. Insert the new storage medium into the slot in the same inclined position.

4. Push down the protruding side of the storage medium.

5. Replace the bolt and the fastening screw and tighten them with a tightening torque of approx. 0.3 Nm.

ð You have successfully replaced the storage medium.

The old storage media must be disposed of in accordance with the national electronic waste regulations.

C602538 Version: 1.5

Page 39

8 Troubleshooting

Table16: Troubleshooting

Fault Cause Measures

Nothing happens after the

Industrial PC has been switched on

The Industrial PC does not boot

fully

Missing power supply of the

Industrial PC

Other cause

Setup settings are incorrect

Check the power supply cable

Call Beckhoff Service

Check the setup settings

Troubleshooting

Computer boots, software starts,

but control does not operate

correctly

Other cause

Cause of the fault is either in the

software or in parts of the plant

outside the Industrial PC

Call Beckhoff Service

Call the machine and software

manufacturer

C6025 39Version: 1.5

Page 40

Technical data

9 Technical data

Table17: Technical data

Product designation C6025

Dimensions (W x H x D) 82 x 127 x 50 mm, without mounting plate

Weight approx.800g without mounting plate

approx.900g with mounting plate

Supply voltage 20.4-30 V

Power consumption max. 60 W with basic configuration

Protection class IP20

Vibration resistance (sinusoidal vibration) EN 60068-2-6: 10 to 58 Hz: 0.035mm

58 to 500 Hz: 0.5 G (approx. 5 m/s2)

Shock resistance (shock) EN 60068-2-27: 5 G (approx. 50 m/s2), duration:

30ms

EMC interference immunity conforms to EN 61000-6-2

EMC interference emission conforms to EN 61000-6-4

Permissible ambient temperature 0°C to +50°C (operation)

-25°C to +65°C (transport/ storage)

Permissible air humidity Maximum 95%, no condensation

Transport and storage The same values for air humidity and shock

resistance are to be observed during transport and

storage as in operation. The shock resistance during

transport can be improved by means of suitably

packing the Industrial PC.

(24 VDC power supply unit, NEC class 2)

DC

C602540 Version: 1.5

Page 41

Appendix

10 Appendix

10.1 Service and support

Beckhoff and their partners around the world offer comprehensive service and support, making available fast

and competent assistance with all questions related to Beckhoff products and system solutions.

Beckhoff Service

The Beckhoff Service Centre supports you in all matters of after-sales service:

• on-site service

• repair service

• spare parts service

• hotline service

Hotline: + 49 (0) 5246/963-460

Fax: + 49 (0) 5246/963-479

E-mail: service@beckhoff.com

If servicing is required, please quote the serial number of your Industrial PC, which can be found on the

name plate.

Beckhoff Support

Support offers you comprehensive technical assistance, helping you not only with the application of

individual Beckhoff products, but also with other, wide-ranging services:

• World-wide support

• design, programming and commissioning of complex automation systems

• extensive training program for Beckhoff system components

Hotline: + 49 (0) 5246/963-157

Fax: + 49 (0) 5246/963-9157

E-mail: support@beckhoff.com

Headquarters

Beckhoff Automation GmbH & Co. KG

Hülshorstweg 20

33415 Verl

Germany

Phone: + 49 (0) 5246/963-0

Fax: + 49 (0) 5246/963-198

E-mail: info@beckhoff.de

The addresses of the worldwide Beckhoff branches and agencies can be found on our website at http://

www.beckhoff.com/.

You will also find further documentation for Beckhoff components there.

C6025 41Version: 1.5

Page 42

Appendix

10.2 Approvals

The following table shows the certifications of the Industrial PC based on the device generation:

Table18: C6025 certifications

Device generation Certifications

C6025-0000 CE, EAC, UL

FCC approvals for the United States of America

FCC: Federal Communications Commission Radio Frequency Interference Statement

This device was tested and complies with the limits for a digital device of class A, according part 15 of the

FCC regulations. These limits are designed to provide adequate protection against adverse interference, if

the device is used in a commercial environment. This device generates, uses and may emit radio frequency

energy and may cause adverse interference with radio communications, if it is not installed and used in

accordance with the operating instructions. If this device is used in a residential area it is likely to cause

adverse interference, in which case the user must take appropriate countermeasures in order to eliminate

the interference at his own expense.

FCC approvals for Canada

FCC: Canadian Notice

This device does not exceed the class A limits for radiation, as specified by the Radio Interference

Regulations of the Canadian Department of Communications.

C602542 Version: 1.5

Page 43

List of figures

List of figures

Fig. 1 C6025_Structure – basic configuration........................................................................................ 9

Fig. 2 C6025_Power socket pin numbering........................................................................................... 10

Fig. 3 C6025_Ethernet interface pin numbering .................................................................................... 11

Fig. 4 C6025_USB interface pin numbering .......................................................................................... 12

Fig. 5 C6025_DisplayPort pin numbering .............................................................................................. 13

Fig. 6 Status LEDs................................................................................................................................. 14

Fig. 7 C6025 _Mounting plates.............................................................................................................. 18

Fig. 8 Mounting options for mounting plate 2......................................................................................... 19

Fig. 9 C6025 _Mounting plate narrow side ............................................................................................ 20

Fig. 10 C6025 _Mounting plate side panel .............................................................................................. 20

Fig. 11 C6025 _Mounting plate DIN rail adapter ..................................................................................... 21

Fig. 12 C6025 _Mounting plates for control cabinet installation .............................................................. 22

Fig. 13 C6025_DIN rail adapter for control cabinet installation ............................................................... 23

Fig. 14 C6025_DIN rail adapter mounted ................................................................................................ 23

Fig. 15 C6025 _Wiring example .............................................................................................................. 24

Fig. 16 Beckhoff Device Manager - Change passwords.......................................................................... 28

Fig. 17 Beckhoff Device Manager home page......................................................................................... 29

Fig. 18 C6025 _Position of the fastening screws..................................................................................... 32

Fig. 19 C6025_Dismantling the DIN rail adapter ..................................................................................... 33

Fig. 20 C6025 _Access to battery and storage media............................................................................. 36

Fig. 21 C6025 _Battery and storage media ............................................................................................. 36

Fig. 22 C6025 _Battery change ............................................................................................................... 37

Fig. 23 C6025 _Replace storage media .................................................................................................. 38

C6025 43Version: 1.5

Page 44

List of tables

List of tables

Table 1 Key - C6025 structure.................................................................................................................. 9

Table 2 Power socket pin assignment ...................................................................................................... 10

Table 3 Controller classification based on device generations................................................................. 11

Table 4 Ethernet interface pin assignment ............................................................................................... 11

Table 5 USB interface pin assignment ..................................................................................................... 12

Table 6 Pin assignment of DisplayPort..................................................................................................... 13

Table 7 Meaning of the UPS-OCT LED.................................................................................................... 14

Table 8 Meaning of the PWR LED............................................................................................................ 15

Table 9 Meaning of the HDD LED ............................................................................................................ 15

Table 10 Meaning of the TC LED ............................................................................................................... 15

Table 11 Key - C6025 name plate .............................................................................................................. 16

Table 12 Mounting plate ordering options .................................................................................................. 18

Table 13 Password generation ................................................................................................................... 30

Table 14 Replacement recommendations for PC components .................................................................. 35

Table 15 Technical data of the battery. ...................................................................................................... 37

Table 16 Troubleshooting ........................................................................................................................... 39

Table 17 Technical data ............................................................................................................................. 40

Table 18 C6025 certifications ..................................................................................................................... 42

C602544 Version: 1.5

Page 45

Page 46

More Information:

www.beckhoff.com/C6025/

Beckhoff Automation GmbH & Co. KG

Hülshorstweg 20

33415 Verl

Germany

Phone: +49 5246 9630

info@beckhoff.com

www.beckhoff.com

Loading...

Loading...