Page 1

3

2

1,5m

C

1,5m

1,5m

m

m

1,5m

m

m

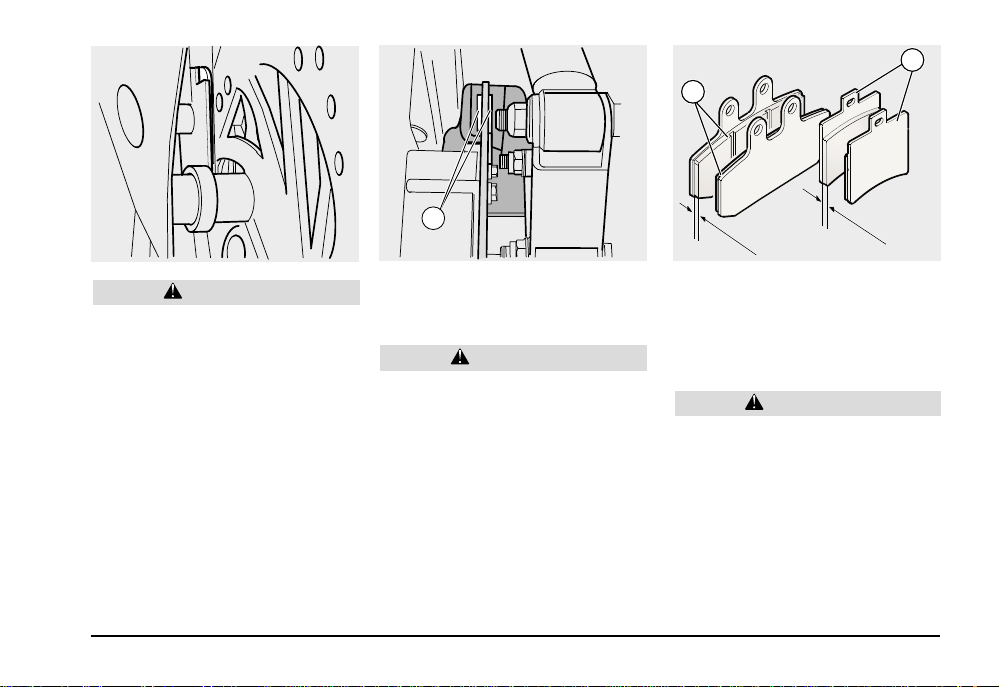

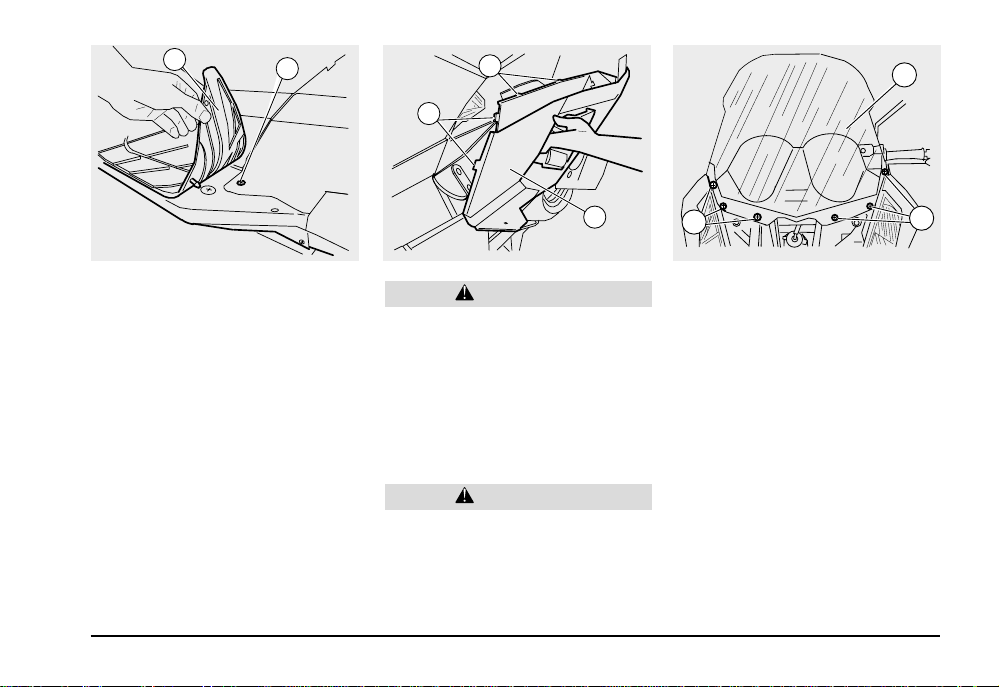

WARNING

Check the wear of the brake pads especially before every trip.

To carry on a quick check of the brake pad

wear:

♦ Position the vehicle on the central stand.

♦ Carry on a visual check between the brake

disk and the pads, proceeding:

FRONT BRAKE CALLIPER

– On the front, part from below, for both cal-

lipers.

REAR BRAKE CALLIPER

– On the rear part, from below, for both pads

(C).

WARNING

The excessive wear of the friction material would cause the contacts of the pad

metal support with the disk, with consequent metallic noise and production of

sparks from the calliper; braking efficiency, safety and soundness of the disk

would be compromised.

♦ If the thickness of the friction material (even

if of one pad only) has reduced to about

1.5 mm, have both pads replaced.

– Front pads (2).

– Rear pads (3).

WARNING

Have the pads replaced by your aprilia

Official Dealer.

use and maintenance

Atlantic 500

49

Page 2

CHECKING THE FRONT AND REAR

SUSPENSIONS

Carefully read page 39 (MAINTENANCE).

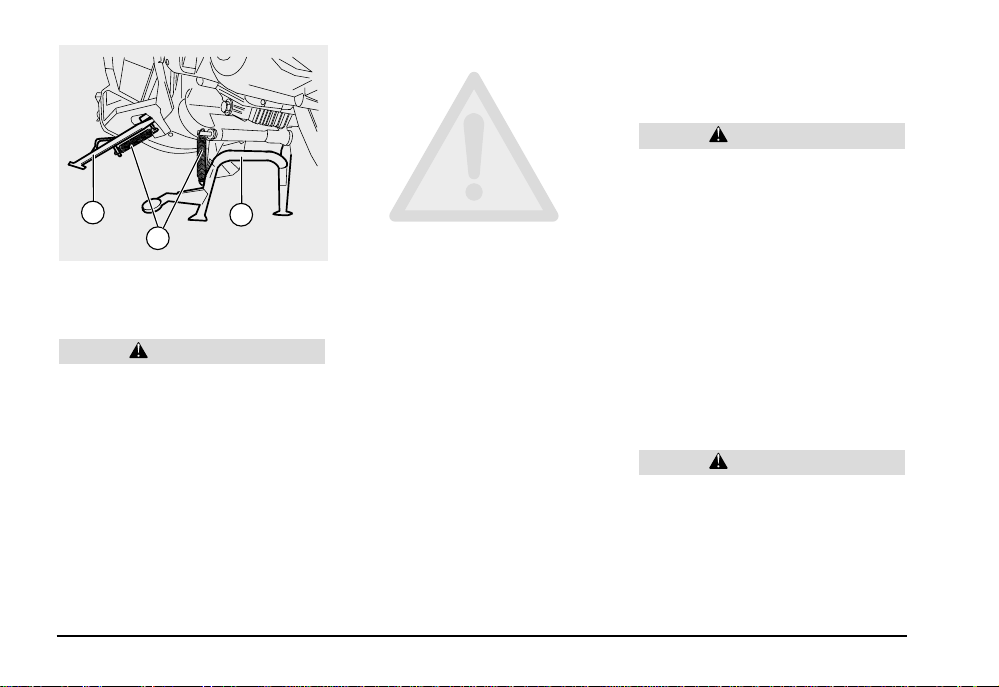

4

4

5

CHECKING THE STAND

Carefully read page 40 (MAINTENANCE).

FOR THE SIDE STAND ONLY

WARNING

Danger of fall or overturning

When straightening the vehicle, from the

parking position to the driving position,

the stand goes automatically up.

IMPORTANT The following information

refers to one stand only, but it is valid for

both.

use and maintenance Atlantic 500

50

The stand (4) must rotate without hindrances.

Carry on the following checks:

♦ The springs (5) must not be damaged,

worn, rusty or weakened.

♦ The stand must rotate without hindrances;

if necessary, grease the joint (see page 74

TABLE OF LUBRICANTS).

CHECKING THE SWITCHES

The vehicle is provided with two switches:

- Stoplight switch on the rear brake control

lever (combined)

- Stoplight switch on the front brake control

lever.

If you need assistance or technical advice,

contact your aprilia Official Dealer, who can

ensure you an accurate and prompt service.

To replace the front suspension oil con-

CAUTION

tact your aprilia Official Dealer, who can

ensure you an accurate and prompt service.

Have the front suspension oil changed every

30000 km (18750 miles) or every 4 years.

Carry on the following checks after the first

1000 km (625 miles) and successively after

6000 km (3750 miles):

♦ With pulled front brake lever, push the fork

repeatedly downwards. The stroke must be

smooth and there must not be any trace of

oil on the rods.

♦ Make sure that all components are fas-

tened and that the front and rear suspension joints work correctly.

CAUTION

Should you notice irregularities in the

operation or if the help of skilled personnel should be necessary, contact your

aprilia Official Dealer.

Page 3

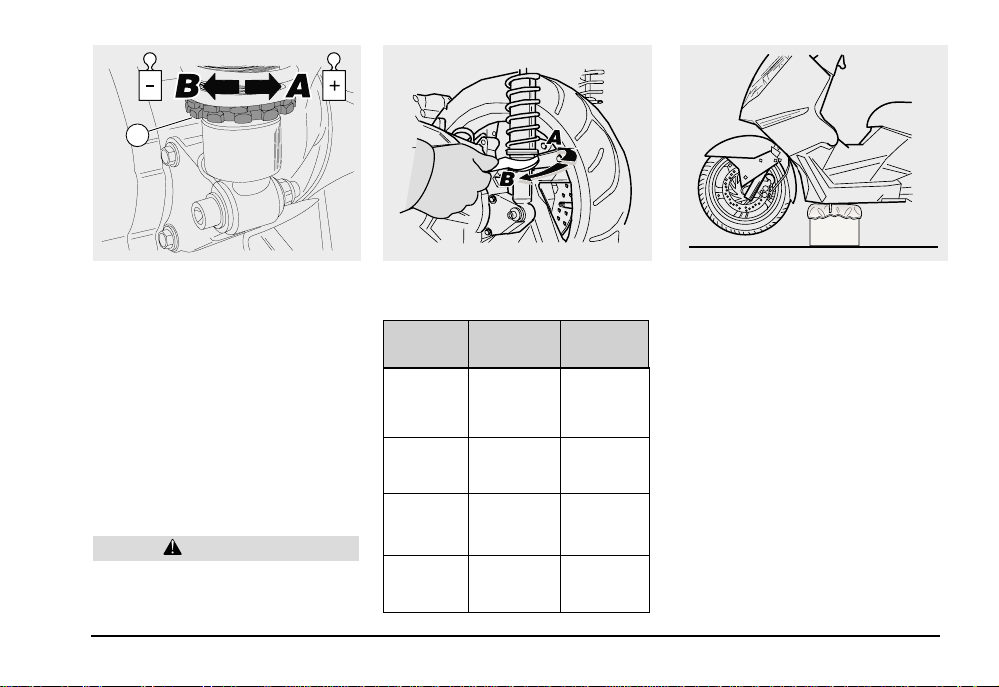

1

ADJUSTING THE REAR SUSPENSION

The rear suspension consists of a pair of

double-action shock absorbers (braking with

compressed/extended shock absorber) fastened to the engine by means of silentblocks.

The standard adjustment, set by the manufacturer, is suitable for a driver weighing

about 70 kg. In case of different weights or

needs, adjust the ring nut (1) by means of

the appropriate spanner provided in the tool

kit, thus setting the ideal drive conditions (see

table).

CAUTION

Set both shock absorbers on the same

position.

ADJUSTMENT OF THE REAR SUSPENSION SPRING PRELOAD

Adjusting

ring nut

Function

Attitude

Suggested

kind of

road

Notes

Rotation

(arrow A)

Spring

preload

increase

The vehicle

is more rigid

Smooth or

normal roads

Drive with

passenger

Rotation

(arrow B)

Spring

preload

decrease

The vehicle

is less rigid

Uneven

roads

Drive

without

passenger

CHECKING THE STEERING

Carefully read page 40 (MAINTENANCE).

It is necessary to check the steering slack

occasionally.

To carry on the check:

♦ Position the vehicle on the central stand.

IMPORTANT Provide for a support with

height and rest surface suitable to support

the vehicle safely.

♦ Place the support under the vehicle and a

spongy cloth between them, so that the

front wheel can move freely and the vehicle cannot fall down.

use and maintenance

Atlantic 500

51

Page 4

1

Make sure that the vehicle is stable.

♦ Shake the fork in the riding direction.

CAUTION

If you shake the fork excessively, the

stand will move, thus producing an incorrect slack. Repeat the previous operation

more than once.

♦ If the slack is considerable, contact your

aprilia Official Dealer, who will restore the

optimal operating conditions.

use and maintenance Atlantic 500

52

CAUTION

STEERING SHOCK ABSORBER

Carefully read page 40 (MAINTENANCE).

In case of full load trips (driver + passenger

+ luggage), it is possible to adjust the steering shock absorber.

To adjust the steering shock absorber:

♦ If you rotate the ring nut (1) clockwise, the

shock absorber becomes more rigid.

CAUTION

If you tighten the ring nut, the shock absorber becomes more rigid and consequently the effort to be made to rotate the

handlebar increases, thus reducing the

manoeuvrability.

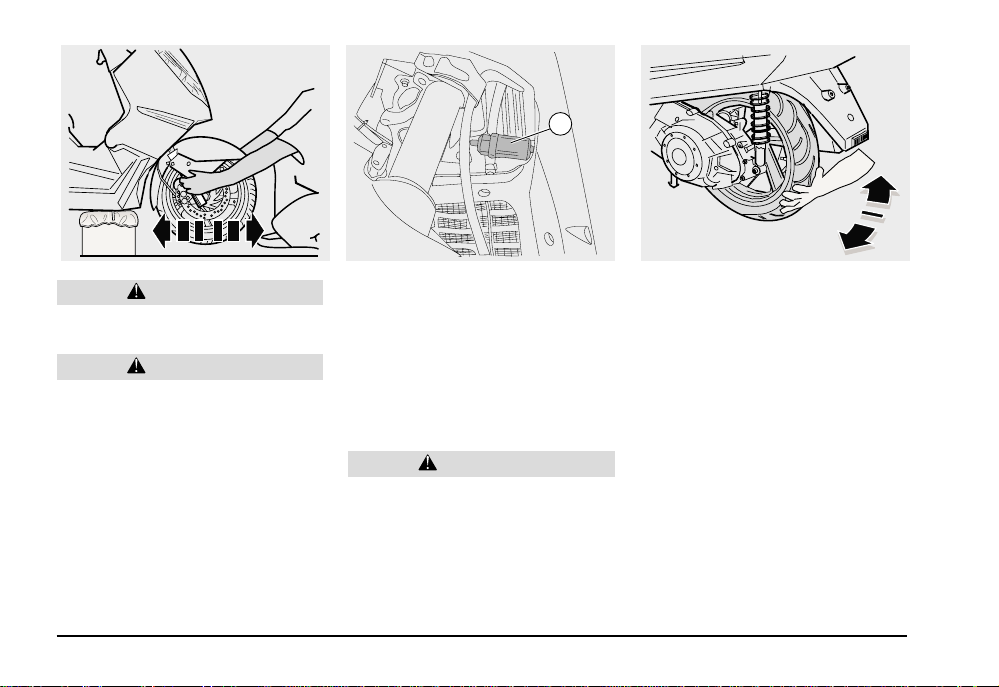

CHECKING THE ENGINE FULCRUM

AXIS

Carefully read page 40 (MAINTENANCE).

Periodically check the slack between the

engine pin bushes.

To carry on the check:

♦ Position the vehicle on the central stand.

♦ Shake the wheel transversally with respect

to the riding direction.

♦ If you notice some slack, contact your

aprilia Official Dealer, who will restore the

optimal operating conditions.

Page 5

1

2

3

2

3

REMOVING THE RIGHT AND LEFT

INSPECTION COVERS

Carefully read page 40 (MAINTENANCE).

♦ Position the vehicle on the central stand.

♦ Remove the right or left mat (1), by lifting it

with your hands.

♦ Unscrew and remove the screw (2).

4

CAUTION

Proceed with the utmost care.

Do not damage the tangs (3) and/or the

corresponding seats.

Handle the plastic and painted components with care; do not scrape or damage them.

♦ By means of a screwdriver, lift the lower

part of the inspection cover (4) with force,

until it comes out of its seat.

CAUTION

Upon reassembly, fit the tangs correctly

in their seats.

1

1

REMOVING THE FAIRING

Carefully read page 40 (MAINTENANCE).

♦ Position the vehicle on the central stand.

♦ Remove the front cover, see page 54 (RE-

MOVING THE FRONT COVER).

♦ Loosen and remove the six screws (1) fas-

tening the fairing to the vehicle.

♦ Remove the fairing (2).

use and maintenance

Atlantic 500

53

Page 6

2

1

Handle the plastic and painted components with care; do not scrape or damage them.

♦ Remove the rear-view mirror (2) by pulling

it upwards.

♦ Take the cover (1).

1

ABS

1

CAUTION

REMOVING THE REAR-VIEW

MIRRORS

Carefully read page 40 (MAINTENANCE).

The following information refers to one rearview mirror only, but it is valid for both.

♦ Position the vehicle on the central stand.

IMPORTANT Group the components of

the left and right rear-view mirrors separately.

♦ Remove the cover (1).

CAUTION

Hold the rear-view mirror (2) in order to

prevent it from falling down accidentally.

use and maintenance Atlantic 500

54

REMOVING THE FRONT COVER

Carefully read page 40 (MAINTENANCE).

♦ Position the vehicle on the central stand.

♦ Unscrew and remove the two screws (1).

CAUTION

Proceed with care.

Do not damage the tangs and/or the corresponding seats.

Handle the plastic and painted components with care; do not scrape or damage them.

♦ Unscrew and remove the two screws (2).

CAUTION

Upon disassembly, prevent the tang clips

from falling down.

Page 7

3

2

♦ Slightly open the front cover wings (see

arrow A) in order to disengage the tangs

from the fairing.

♦ Slightly lift the lower part of the cover, see

arrow B.

♦ Remove the front cover (3) by pulling it with

care.

CAUTION

Upon reassembly, fit the tangs correctly

in their seats by means of their clips.

4

3

1

2

ADJUSTING THE ACCELERATOR

CONTROL

Carefully read page 40 (MAINTENANCE).

The idle stroke of the accelerator grip must

be 2 – 3 mm, measured on the edge of the

grip itself.

5

If this is not the case, proceed as follows:

♦ Position the vehicle on the central stand.

♦ Remove the protection element (1).

♦ Loosen the lock nut (2).

♦ Turn the adjuster (3) so as to reset the pre-

scribed value.

♦ After the adjustment, tighten the lock nut

(2) and check the idle stroke again.

♦ Mount the protection element (1) again.

♦ The cable (4) acts on the gas opening.

♦ The cable (5) acts on the gas closing.

WARNING

After the adjustment, make sure that the

handlebar rotation does not change the

engine idling rpm and that the accelerator grip, after being released, comes back

smoothly and automatically to its original position.

use and maintenance

Atlantic 500

55

Page 8

2

1

SPARK PLUG

Carefully read page 40 (MAINTENANCE).

Check the spark plug every 6000 km (3750

miles) and replace it every 12000 km (7500

miles).

Periodically remove the spark plug and clean

it, removing carbon deposits; if necessary,

change it.

To reach the spark plug:

♦ Remove the left inspection cover, see page

53 (REMOVING THE LEFT AND RIGHT

INSPECTION COVERS).

use and maintenance Atlantic 500

56

0,7-0,8 mm0,7-0,8 mm

To remove and clean it:

WARNING

Before carrying on the following operations, let the engine and the exhaust silencer cool down until they reach room

temperature, in order to avoid burns.

♦ Move the coolant pipe (1) in order to reach

the spark plug more easily.

♦ Remove the high voltage cable cap (2) from

the spark plug.

♦

Remove the dirt from the base of the spark

plug, then unscrew it with the spanner you

find in the tool kit and extract it from its seat,

taking care that neither dust nor other substances enter the cylinder.

♦ Make sure that there are no carbon depos-

its or corrosion marks on the electrode and

on the central porcelain part; if necessary,

clean them with the special cleaners for

spark plugs, with an iron wire and/or a

metal brush.

♦ Energetically blow some air in order to pre-

vent the removed residues from getting into

the engine. If the spark plug has crackings

on the insulating material, corroded electrodes or excessive deposits, it must be

replaced.

♦ Check the gap between the electrodes with

a thickness gauge. The gap must be 0.7 –

0.8 mm; if necessary, adjust it, carefully

bending the earth electrode.

♦ Make sure that the washer is in good con-

ditions. With mounted washer, screw the

spark plug manually so as to avoid damaging the thread.

♦ Tighten the spark plug with the spanner you

will find in the tool kit, giving it half a turn to

compress the washer.

CAUTION

Spark plug driving torque:

12 ÷ 14 Nm (1.2 ÷ 1.4 kgm)

The spark plug must be well tightened,

otherwise the engine may overheat and

be seriously damaged.

Use the recommended types of spark

plug only, see page 70 (TECHNICAL

DAT A) in order to avoid compromising the

engine performance and life.

♦ Position the spark plug cap suitably , so that

it does not come off due to the engine vibrations.

♦ Mount the left inspection cover again, see

page 53 (REMOVING THE LEFT AND

RIGHT INSPECTION COVERS).

Page 9

BATTERY

Carefully read page 40 (MAINTENANCE).

Check the electrolyte level and the tightening of the terminals after the first 1000 km

(625 miles) and then every 6000 km (3750

miles).

WARNING

Danger of fire.

Keep fuel and other flammable substances away from the electric components.

The battery electrolyte is toxic and caustic and if it gets in contact with the skin,

it can cause burns, since it contains sulphuric acid. Wear protection clothes, a

face mask and/or goggles in case of maintenance operations.

In case of contact with the skin, rinse with

plenty of water.

In case of contact with the eyes, rinse with

plenty of water for fifteen minutes, then

consult an oculist immediately.

If the electrolyte is accidentally swallowed, drink a lot of water or milk, then

continue drinking milk of magnesia or

vegetable oil and consult a doctor immediately.

The battery produces explosive gases;

keep it away from flames, sparks, cigarettes and any other heat source.

During the recharging or the use, make

sure that the room is properly ventilated

and avoid inhaling the gases released

during the recharging.

KEEP OUT OF REACH OF CHILDREN

Do not incline the vehicle too much, in

order to avoid dangerous leaks of the

battery fluid.

CAUTION

Never invert the connection of the battery cables.

Connect and disconnect the battery with

the ignition switch in position “

erwise some components may be dam-

aged.

Connect first the positive cable (+) and

then the negative cable (-).

Disconnect following the reverse order.

The battery fluid is corrosive.

Do not pour o spill it, especially on the

plastic parts.

In case of installation of a “MAINTENANCE-FREE” battery, to recharge it use

a specific battery charger (with constant

voltage/amperage or constant voltage).

The use of a conventional battery charger

may damage the battery.

” oth-

I

D

A

Z

P

U

S

H

LONG INACTIVITY OF THE

BATTERY

Should the vehicle remain unused for more

than fifteen days, it would be necessary to

recharge the battery, in order to avoid its

sulphation, see page 59 (RECHARGING

THE BATTER Y):

♦ Remove the battery, see page 58 (RE-

MOVING THE BA TTERY) and keep it in a

cool and dry place.

Check the charge periodically (about once a

month), during the winter or when the vehicle remains unused, in order to prevent the

deterioration of the battery.

♦ Recharge it completely with a normal

charge, see page 59 (RECHARGING THE

BATTERY).

If the battery remains on the vehicle, disconnect the cables from the terminals.

use and maintenance

Atlantic 500

57

Page 10

3

4

2

1

REMOVING THE BATTERY

COVER

Carefully read page 57 (BATTERY).

IMPORTANT Position the vehicle on firm

and flat ground.

♦ Make sure that the ignition switch is in po-

♦ Raise the saddle, see page 23 (UNLOCK-

♦ T ake the fitted carpet out of the helmet com-

♦ Unscrew and remove the two screws (1).

♦ Remove the battery cover from below (2),

♦ Disconnect the electric connector (4) of the

♦ Remove the battery cover (2).

58

”.

sition “

ING/LOCKING THE SADDLE).

partment.

paying attention to the upper tangs (3).

crash helmet compartment lighting.

use and maintenance Atlantic 500

5

6

CHECKING AND CLEANING

THE TERMINALS

♦ Remove the battery cover, see beside (RE-

MOVING THE BATTERY COVER).

♦ Make sure that the cable terminals (5) and

the battery terminals (6) are:

- in good conditions (and not corroded or

covered with deposits);

- covered with neutral grease or Vaseline oil.

If necessary:

♦ Disconnect first the negative cable (-) and

then the positive (+) cable.

♦ Brush with a wire brush to remove any sign

of corrosion.

♦ Reconnect first the positive cable (+) and

then the negative cable (-).

♦ Cover the terminals with neutral grease or

Vaseline oil.

7

REMOVING THE BATTERY

♦ Remove the battery cover, see beside (RE-

MOVING THE BATTERY COVER).

♦ Remove the battery breather pipe (7).

♦ Remove the battery (8) from its seat,

slightly rotating it rightwards (see the arrow).

♦ Disconnect first the negative cable (-) and

then the positive (+) cable.

♦

Definitely remove the battery from its seat and

put it on a flat surface, in a cool and dry place.

8

WARNING

Once the battery has been removed, it

must be stored in a safe place and kept

away from children.

♦

Mount the battery cover again, see beside

(REMOVING THE BATTERY COVER).

CAUTION

Handle with care because the electrolyte

may flow out of the battery after removing

the breather pipe.

Page 11

CHECKING THE ELECTROL YTE

LEVEL

To check the electrolyte level:

♦ Remove the battery cover, see page 58

(REMOVING THE BATTERY COVER).

♦ Make sure that the fluid level is included

between the two MIN and MAX notches

stamped on the battery side.

Otherwise:

♦ Remove the element plugs.

CAUTION

Top up with distilled water only. Do not

exceed the MAX mark, since the electrolyte level increases during the recharge.

♦ Top up by adding distilled water.

RECHARGING THE BATTERY

♦ Remove the battery , see page 58 (REMOV-

ING THE BATTERY).

♦ Remove the element plugs.

♦ Check the electrolyte level, see beside

(CHECKING THE ELECTROLYTE

LEVEL).

♦ Connect the battery with a battery charger.

♦ A recharge with an amperage equal to 1/

10th of the battery capacity is recommended.

♦ After the recharge operation, check the

electrolyte level again and if necessary top

up with distilled water.

♦ Mount the element plugs again.

CAUTION

Reassemble the battery only 5-10 minutes

after disconnecting the battery charger,

since the battery continues to produce

gas for a short lapse of time.

7

8

INSTALLING THE BATTERY

♦ Remove the battery cover, see page 58

(REMOVING THE BATTERY COVER).

♦ Fit the battery in its seat.

CAUTION

Always connect the battery breather pipe,

to prevent the sulphuric acid vapours

from corroding the electric installation,

painted parts, rubber elements or gaskets

when they exit the breather pipe.

♦ Connect first the positive cable (+) and then

the negative cable (-).

♦ Cover the terminals with neutral grease or

Vaseline oil.

♦ Connect the battery breather pipe (1).

♦ Mount the battery cover again, see page

58 (REMOVING THE BATTER Y COVER).

use and maintenance

Atlantic 500

59

Page 12

4

2

3

5

6

9

REPLACING THE FUSES

Carefully read page 40 (MAINTENANCE).

CAUTION

Do not repair defective fuses.

Never use fuses different from the prescribed ones: the electric system may be

damaged or a fire may be produced, in

case of short circuit.

IMPORTANT When a fuse is frequently

damaged, there may be a short circuit or an

overload. In this case, contact your aprilia

Official Dealer.

If an electric component does not work or

works irregularly or if the engine does not

start, it is necessary to check the fuses.

Check 3A and 15A fuses first and then 30 A

fuses.

use and maintenance Atlantic 500

60

1

To carry on the check:

♦ Remove the battery cover, see page 58

(REMOVING THE BATTER Y COVER), or

the front cover, see page 54 (REMOVING

THE FRONT COVER).

♦ Extract the fuses one by one and make

sure that the filament (1) is not broken.

♦ Before replacing the fuse, try to find out

the cause of the problem, if possible.

♦ Replace the fuse, if it is damaged, with a

new one having the same amperage.

IMPORTANT If you use a spare fuse, fit

an identical one in the suitable seat.

♦ Mount the battery cover again, see page

58 (REMOVING THE BATTERY COVER)

or put back the front cover, see page 54

(REMOVING THE FRONT COVER).

8

7

ARRANGEMENT OF THE SECONDARY FUSES (FRONT COVER)

– 15A fuse (2)

From the voltage regulator to: injection,

stoplight/starting logic (seat A in the wiring

diagram).

– 15 A fuse (3)

From the ignition switch to: engine kill logic,

stoplights (seat B in the wiring diagram)

– 15 A fuse (4)

From the ignition switch to: lights, horn,

dashboard, fan relay, power supply for car

radio set (seat C in the wiring diagram).

– 15A fuse (5)

From the primary fuse to the outlet in the

crash helmet compartment.

– 3A fuse (6)

From the voltage regulator to the permanent power supply of the ECU central unit

(seat E in the wiring diagram).

– 15A fuse (7)

Spare fuse.

– 3A fuse (8)

Spare fuse.

– Free fuse (9)

Page 13

10

11

12

1

ARRANGEMENT OF THE PRIMARY

FUSES (BATTERY COMPARTMENT)

– 30A fuse (10)

From the battery to: ignition switch, fuse

(2), helmet compartment light, cooling fan,

dashboard permanent power supply.

– 30A fuse (11)

From the battery to: voltage regulator, fuse

(3), fuse (5).

– 30A fuse (12)

Spare fuse.

VERTICAL ADJUSTMENT OF

THE HEADLIGHT BEAM

To quickly check the correct direction of the

headlight beam, place the vehicle at ten

metres from a vertical wall, making sure that

the ground is flat.

Turn on the low beam, sit on the vehicle and

make sure that the beam projected on the

wall is slightly under the horizontal line of the

headlight (about 9/10th of the total height).

To adjust the headlight beam:

♦ Act on the suitable knob (1) positioned on

the front of the vehicle. By turning it

CLOCKWISE, the headlight beam is set

upwards. By turning it ANTICLOCKWISE,

the headlight beam is set downwards.

use and maintenance

Atlantic 500

61

Page 14

HORIZONTAL ADJUSTMENT OF

THE HEADLIGHT BEAM

♦ Remove the front inner shield, see page

54 (REMOVING THE FRONT INNER

SHIELD).

To adjust the headlight beam:

♦ Act on the appropriate knob (as shown

above) positioned on the front of the vehicle. By turning it CLOCKWISE, the headlight beam moves rightwards (with respect

to the riding direction). By turning it ANTICLOCKWISE, the headlight beam moves

leftwards (with respect to the riding direction).

BULBS

Carefully read page 40 (MAINTENANCE).

WARNING

Danger of fire.

The electric components must be kept

away from fuel and other flammable substances.

CAUTION

Before replacing a bulb, move the ignition switch to position “

few minutes until the bulb cools down.

When changing the bulb, wear clean

gloves or use a clean and dry cloth.

Do not leave fingerprints on the bulb,

since they may cause overheating and

breakage.

If you touch the bulb with bare hands,

remove any fingerprint with alcohol to

avoid its damaging.

DO NOT FORCE THE ELECTRIC CABLES.

” and wait a

IMPORTANT Before replacing a bulb,

check the fuses, see page 60 (REPLACING

THE FUSES).

2

1

REPLACING THE BULBS OF THE

FRONT DIRECTION INDICATORS

Carefully read beside (BULBS).

To replace the bulbs:

♦ Remove the front cover, see page 54 (RE-

MOVING THE FRONT COVER).

CAUTION

Proceed with care.

Do not damage the tangs and/or their

seats.

use and maintenance Atlantic 500

62

Page 15

1

3

T o replace the bulb of the LEFT direction indicator:

♦ Acting on the front of the vehicle, rotate

the support (1) with the bulb (2) clockwise

and extract both from their seat.

♦ Slightly press the bulb (2) and rotate it an-

ticlockwise.

♦ Extract the bulb from its seat.

IMPORTANT Introduce the bulb into the

bulb socket by making the two elements coincide with the respective guides on the bulb

socket.

♦ Correctly mount a bulb of the same kind.

♦

Upon reassembly, carry on the same operations in reverse order.

To replace the bulb of the RIGHT direction

indicator:

♦ Extract the secondary fuse box (3) from its

seat in order to have more space to carry

on the dismounting operations.

♦ Then carry on the same operations de-

scribed for the left direction indicator.

2

3

REPLACING THE HEADLIGHT

BULBS

Carefully read page 61 (BULBS).

The headlight houses the following bulbs:

- Two high beam bulbs (1).

- One low beam bulb (2).

- One parking light bulb (3).

To replace the bulb:

♦ Remove the front cover, see page 54 (RE-

MOVING THE FRONT COVER).

5

LOW BEAM BULBS

CAUTION

While extracting the bulb electric connector, do not pull the electric cables.

♦ Grasp the bulb electric connector (4), pull

it and disconnect it from the bulb (5).

♦ Rotate the bulb socket (6) anticlockwise

and extract it from the parabola seat.

♦ Remove the bulb (5).

Upon reassembly:

IMPORTANT Fit the bulb (5) in the pa-

rabola seat by making the three elements

on the bulb coincide with the respective

guides (7) on the parabola seat.

♦ Place the bulb socket (6) into the parabola

seat and turn it clockwise.

♦ Connect the bulb electric connector (4).

use and maintenance

Atlantic 500

63

Page 16

2

9

1

3

3

8

HIGH BEAM BULBS

♦ Rotate the bulb socket/bulb (8) anticlock-

wise and extract it from the parabola seat.

CAUTION

To extract the bulb socket/bulb from the

seat, try to avoid damaging the two tangs

(9).

♦ Remove the bulb (9).

♦ Replace it with a new one of the same kind.

Upon reassembly, carry on the same operations in reverse order.

use and maintenance Atlantic 500

64

PARKING LIGHTS

CAUTION

While extracting the bulb socket, do not

pull the electric cables.

♦ Acting on the front of the vehicle, grasp the

bulb socket (1), pull it and extract it from

its seat.

♦ Extract the parking light bulb (2) and re-

place it with a new one of the same kind.

4

4

REPLACING THE REAR LIGHT

BULBS

Carefully read page 61 (BULBS).

The rear light houses the following bulbs:

- Two parking light/stoplight bulbs (3).

- Two rear direction indicator bulbs (4).

To change them:

♦ Raise the saddle, see page 23 (UNLOCK-

ING/LOCKING THE SADDLE).

IMPORTANT The following information

refers to one indicator only, but it is valid for

both.

♦ Remove the knob (5) fastening the rear

lighting group to the vehicle.

Loading...

Loading...